Page 1

COMMERCIAL HE DRYER iNSTALLATiON iNSTRUCTiONS

(original instructions)

Electric

iNSTRUCTiONSD'INSTALLATIOND'UN SECHE-LINGEHECOMMERCIAL

(traduction des instructionsd'origine)

Eiectrique

INSTRUCCIONES DE INSTALACION- SECADORA HE COMERCIAL

(traducci6n de las instruccionesoriginales)

El_ctrica

ISTRUZIONID'INSTALLAZIONE- ASCIUGATRICEHE COMMERCIALE

(traduzione delie istruzionioriginali)

Elettrica

MDE25PD

W10379554A

www.maytagcommerciallaundry.com

Page 2

TABLEOF CONTENTS

DRYER SAFETY ............................................................................ 3

DRYER DISPOSAL ...................................................................... 3

INSTALLATION REQUIREMENTS .............................................. 4

Tools and Parts .......................................................................... 4

Location Requirements .............................................................. 4

Electrical Requirements ............................................................ 5

Venting Requirements .............................................................. 6

TABLEDESMATIERES

SECURITE DU SECHE=MNGE ................................................ 16

ELIMINATION DU SECHE-MNGE .......................................... 16

EXIGENCES D'INSTALLATION ................................................ 17

Outillage et pi_ces .................................................................... 17

Exigences d'emplacement ...................................................... 17

Specifications electriques ....................................................... 18

E×igences concernant revacuation .......................................... 19

INSTALLATION INSTRUCTIONS - ELECTRIC DRYER .......... 7

Install Leveling Legs.................................................................... 7

Electrical Connection .................................................................. 8

Connect Vent .............................................................................. 8

Complete Installation ................................................................ 8

MAINTENANCE INSTRUCTIONS ............................................. 8

REVERSING THE DOOR SWING ............................................. 9

ELECTRONIC CONTROL SETUP .......................................... 11

WARRANTY .............................................................................. 15

INSTRUCTIONS D'INSTALLATION - SECHE=LINGE

ELECTRIQUE ............................................................................ 21

Installation des pieds de nivetlement ........................................ 21

Raccordement electrique ........................................................ 21

Raccordement du conduit d'evacuation ................................ 21

Achever I'instatlation ................................................................ 22

INSTRUCTIONS D'ENTRETIEN ............................................... 22

INVERSION DU SENS D'OUVERTURE DE LA PORTE ......... 23

REGLAGE DE LA CARTE

DE CIRCUITS ELECTRONIQUES .......................................... 25

GARANTIE ................................................................................ 29

P

INDICE

SEGURIDAD DE LA SECADORA ............................................ 30

ELIMINACl6N DE LA SECADORA .......................................... 30

REQUISITOS DE INSTALAClON ............................................ 31

Piezas y herramientas .......................................................... 31

Requisitos de ubicaci6n ........................................................ 31

Requisitos electricos ............................................................ 32

Requisitos de ventilaci6n .................................................... 33

INDICE

SlCUREZZA DELL'ASCIUGATR_CE ........................................ 43

SMALTIMENTO DELL'ASCIUGATRICE .................................... 43

REQUISITI D'INSTALLAZIONE ................................................ 44

Attrezzi e componenti .............................................................. 44

Requisiti per ilposizionamento .............................................. 44

Requisiti elettrici ...................................................................... 45

Requisiti di scarico .................................................................. 46

INSTRUCCIONES DE INSTALACION -

SECADORA ELI=CTRICA ........................................................ 34

Instalaci6n de las paras niveladoras .................................... 34

Conexi6n electrica ................................................................ 35

Cone×i6n del conducto de escape ...................................... 35

Complete la instalaci6n ........................................................ 35

INSTRUCCIONES DE MANTENIMIENTO ............................. 35

COMO INVERTIR EL SENTIDO DE APERTURA

DE LA PUERTA ....................................................................... 36

PROGRAMACI6N DEL CONTROL ELECTRONICO ............ 38

GARANTIA ................................................................................ 42

ISTRUZIONI D'INSTALLAZIONE - ASCIUGATRICE

ELETTRICA ............................................................................ 47

Installazione dei piedini di regolazione .................................... 47

Connessione elettrica .............................................................. 48

Connessione delto scarico ...................................................... 48

Comptetamento dell'instaltazione ............................................ 48

ISTRUZlONI PER LA MANUTENZIONE ................................. 48

INVERS_ONE DELLA ROTAZIONE DI APERTURA ............... 49

CONFIGURAZIONE DEI CONTROLLI ELETTRONICI .......... 51

GARANZIA .................................................................................. 55

Page 3

DRYERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manua{ and on your appliance. Always read and obey a{{ safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

AI{ safety messages wi{{ fo{{ow the safety a{ert symbo{ and either the word "DANGER" or "WARN{NG."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

AHsafety messages will tell you what the potential hazard is, te{I you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

FOR YOUR SAFETY

1. DO NOT USE OR STORE PETROL OR OTHER FLAMMABLE MATERIALS IN THIS APPLIANCE OR NEAR THIS APPLIANCE.

2. DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE.

DRYERDISPOSAL

This appliance is marked according to the European directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE).

By ensuring this product is disposed of correctly, you will help avoid potential negative consequences for the environment and

human health, which could otherwise be caused by inappropriate waste handling of this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance may not be treated

as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical and

electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your local city office, your

household waste disposal service or the shop where you purchased the product.

Model Nomenclature

MDE Maytag Dryer- Electric

##(e.g. 25) Model Type number

PN Electronic Control - Non-Pay

PD Electronic Control - Coin Drop enabled

3

Page 4

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed:

m 200 mm (8") or 250 mm m 8 mm (5/16") socket

(10") Pipe wrench wrench

m 200 mm (8") or 250 mm m Utility knife

(10") Adjustable wrench m Vent clamps

m Flat-blade screwdriver m Sealing compound gun

m Phillips screwdriver and sealing compound (for

m Adjustable wrench that installing new exhaust vent)

opens to 25 mm (1") or m Pliers

hex-head socket wrench m Stiff-bladed putty knife

m Level

Parts supplied:

Remove parts bag from dryer drum. Check that all parts were

included.

[] Foot boot (4) [] PN models: Card reader

[] Dryer foot (4) bezel, card reader wire

[] PD models: Cam for

harness, hardware

service door lock

NOTE: The circuit diagram for this dryer is located inside the

lower front panel, within the Tech Sheets.

Technical

Specifications:

220-240 v, 50 Hz. AC

Clothes Capacity:

9 kg max.

4575W

Total mass: 68 kg max.

NOISE: Sound Pressure Level, Lpa: 58 dBA (uncertainty,

Kpa: +/-10 dBA).

If installed in a closet with a door, the minimum unobstructed air

opening in the top and bottom is required. Louvered doors

with equivalent air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

IMPORTANT: Observe all governing codes and ordinances.

[] Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

[] Do not install on carpet.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. This

dryer must not be installed behind a lockable door, a sliding door,

or a door with a hinge on the opposite side to that of the dryer.

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

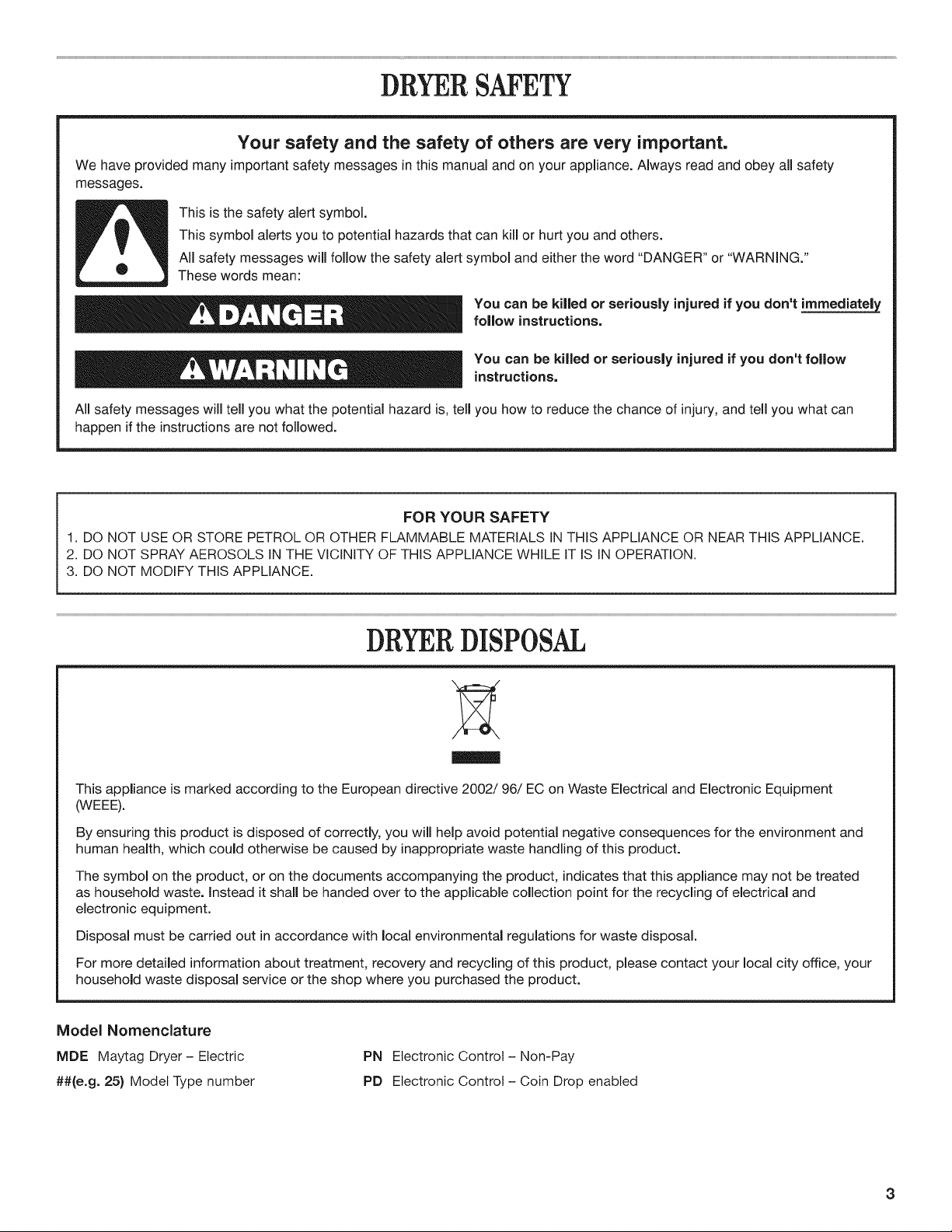

Minimum Installation Clearances

o o

381 mm

Os")

I I

Ornrn _ Ornrn

356 mm

C14'') max

Closet

door

J

(:1

! .... ]

'' _ Omm

CO") _ CO")

_1 ]_2s mm11")

Recessed front view

Additional clearances may be required for wall, door, and floor moldings or if

external exhaust elbow is used.

Closet side view

L

(48 in._)

Front

view

(24in._)

76 mm (3")

+

closet

door

0

76 mm (3")

*Opening is the minimum

for a closet door. Louvered

doors with equivalent air

openings are acceptable.

(0")

Page 5

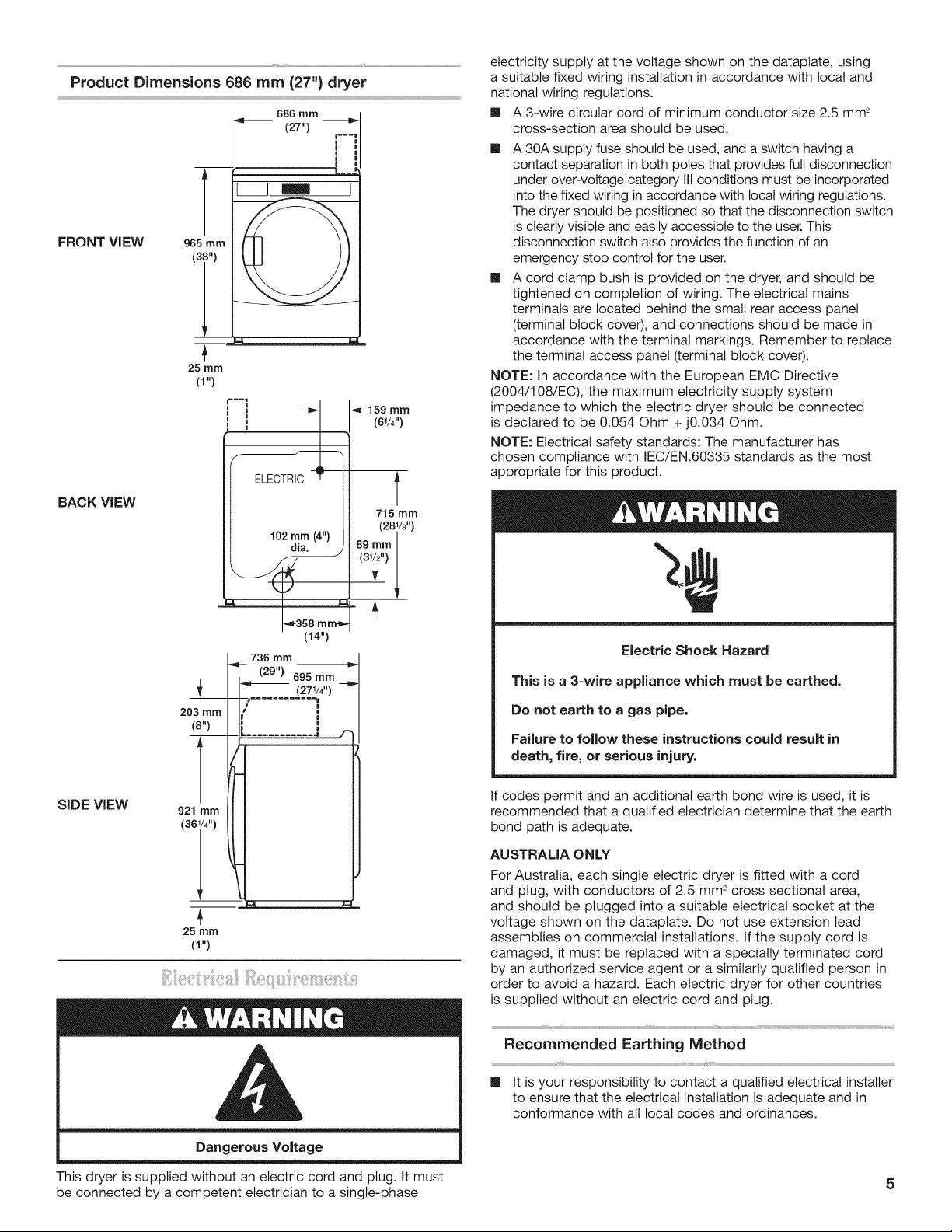

Product Dimensions 686 mm (27"} dryer

686 mm

(27")

r_

[Z2][ I

FRONT VIEW 965 mm

(3i")

25 mm

(I ")

BACK VIEW

i02 mm(4")

dia.

electricity supply at the voltage shown on the dataplate, using

a suitable fixed wiring installation in accordance with local and

national wiring regulations.

[] A 3-wire circular cord of minimum conductor size 2.5 mm2

cross-section area should be used.

1

o

p

[] A 30A supply fuse should be used, and a switch having a

contact separation in both poles that provides full disconnection

under over-voltage category III conditions must be incorporated

into the fixed wiring in accordance with local wiring regulations.

The dryer should be positioned so that the disconnection switch

is clearly visible and easily accessible to the user. This

disconnection switch also provides the function of an

emergency stop control for the user.

[] A cord clamp bush is provided on the dryer, and should be

tightened on completion of wiring. The electrical mains

terminals are located behind the small rear access panel

(terminal block cover), and connections should be made in

accordance with the terminal markings. Remember to replace

the terminal access panel (terminal block cover).

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electricity supply system

impedance to which the electric dryer should be connected

is declared to be 0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN.60335 standards as the most

appropriate for this product.

t

715 mm

SIDE VIEW

203 mm

(8")

921 mm

(36i4")

25 mm

(I ")

_-358 mm_.

(i4")

736 mm

,4- 29" _'_

, ( ) 695 mm

B m

-÷

Electric Shock Hazard

This is a 3-wire appliance which must be earthed.

Do not earth to a gas pipe.

Failure to follow these instructions could result in

death, fire, or serious injury.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

AUSTRALIA ONLY

For Australia, each single electric dryer is fitted with a cord

and plug, with conductors of 2.5 mm2 cross sectional area,

and should be plugged into a suitable electrical socket at the

voltage shown on the dataplate. Do not use extension bead

assemblies on commercial installations. If the supply cord is

damaged, it must be replaced with a specially terminated cord

by an authorized service agent or a similarly qualified person in

order to avoid a hazard. Each electric dryer for other countries

is supplied without an electric cord and plug.

Recommended Earthing Method

Dangerous Voltage

This dryer is supplied without an electric cord and plug. It must

be connected by a competent electrician to a single-phase

[] It is your responsibility to contact a qualified electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

5

Page 6

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

[] Following these venting requirements will minimise ducting

air noise.

[] Adequate ventilation has to be provided to avoid the backflow

of gases into the room from appliances burning other fuels,

including open fires (i.e. available airflow into the room should

match airflow out from the room).

[] Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

[] Do not use an exhaust hood with a magnetic latch.

[] Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

[] Only a 102 mm (4") heavy metal exhaust vent and clamps

may be used.

f ,oavymeta, ,02mm

(4")

[] Use clamps to seat all joints. Vent must not be connected

or secured with screws or other fastening devices which

extend into the interior of the vent and catch lint. Do not use

duct tape.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal

vent to avoid sagging and kinking that will result in reduced

airflow and poor performance.

The total length of flexible metal vent should not exceed 2.4 m

(73/4ft.).

An exhaust hood should cap the vent to keep rodents and

insects from entering the building.

Exhaust hood must be at least 305 mm (12") from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, bushes, or snow).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

Plan installation to use the fewest number of elbows and turns.

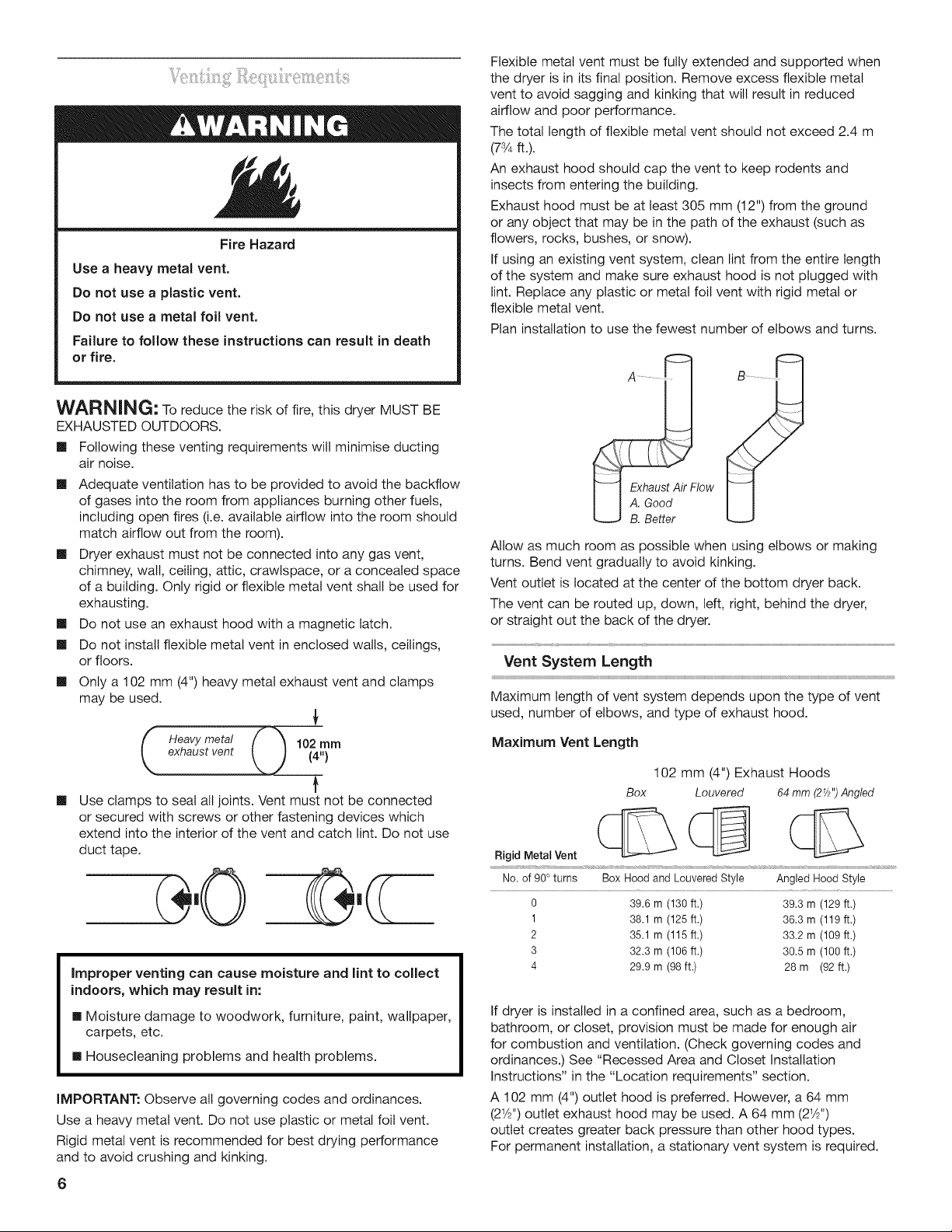

A ...........

OW

I I A ood

U B.Better

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the center of the bottom dryer back.

The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

Vent System Length

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Maximum Vent Length

102 mm (4") Exhaust Hoods

Box Louvered 64 mm (2_//) Angled

Rigid MetaIVent _ _

G,@_

improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

IMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended for best drying performance

and to avoid crushing and kinking.

6

No. of 90° turns Box Hood and Louvered Style Angled Hood Style

9 39.6 m (138 ft.) 39.3 m (129 ft.)

1 38.1 m (125 ft.) 36.3 m (119 ft.)

2 35.1 m (115 ft.) 33.2 m (199 ft.)

3 32.3 m (186 ft.) 38.5 m (180 ft.)

4 29.9 m (98 ft.) 28 m (92 ft.)

If dryer is installed in a confined area, such as a bedroom,

bathroom, or closet, provision must be made for enough air

for combustion and ventilation. (Check governing codes and

ordinances.) See "Recessed Area and Closet Installation

Instructions" in the "Location requirements" section.

A 102 mm (4") outlet hood is preferred. However, a 64 mm

(21/_'') outlet exhaust hood may be used. A 64 mm (2W')

outlet creates greater back pressure than other hood types.

For permanent installation, a stationary vent system is required.

Page 7

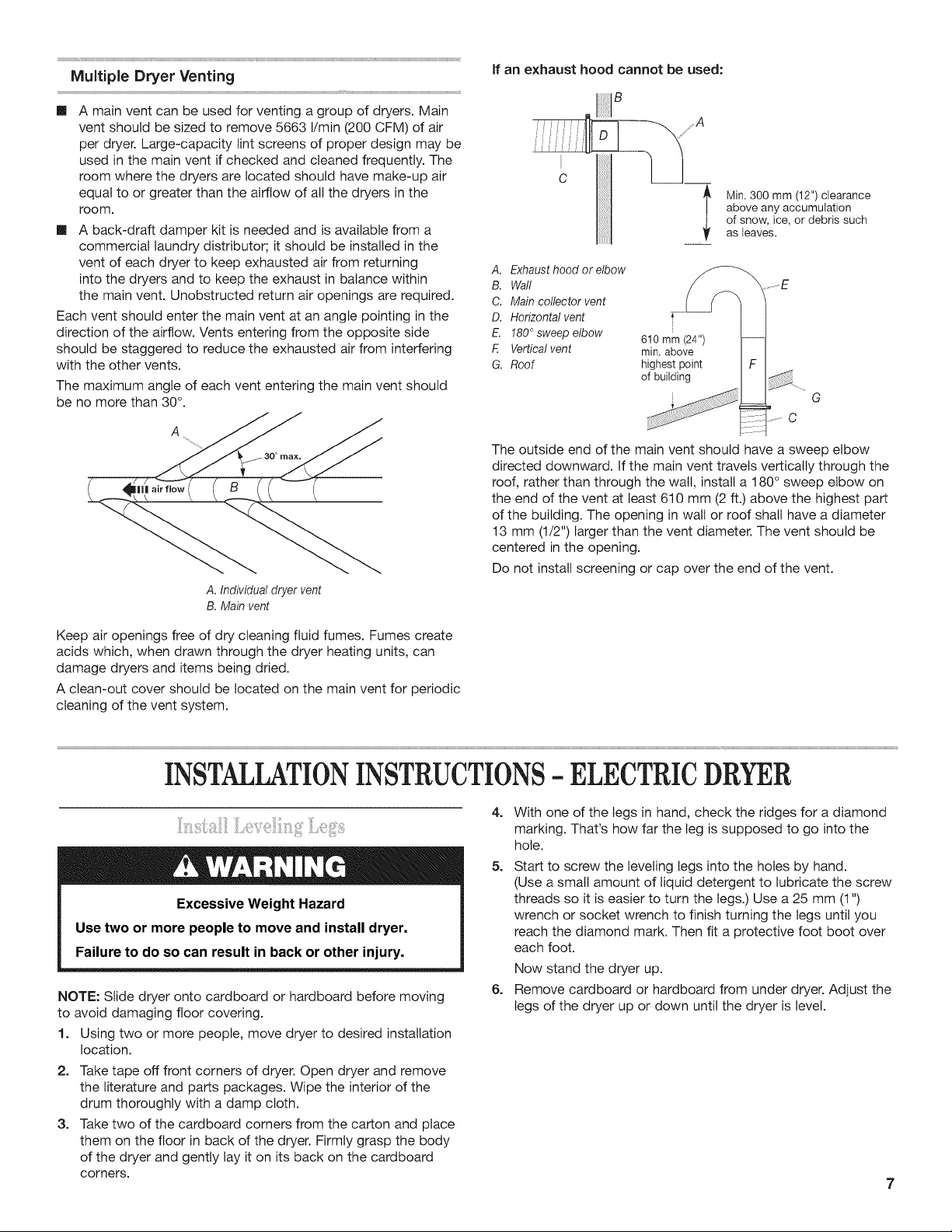

Multiple Dryer Venting If an exhaust hood cannot be used:

[] A main vent can be used for venting a group of dryers. Main

vent should be sized to remove 5663 I/min (200 CFM) of air

per dryer. Large-capacity lint screens of proper design may be

used in the main vent if checked and cleaned frequently. The

room where the dryers are located should have make-up air

equal to or greater than the airflow of all the dryers in the

room.

[] A back-draft damper kit is needed and is available from a

commercial laundry distributor; it should be installed in the

vent of each dryer to keep exhausted air from returning

into the dryers and to keep the exhaust in balance within

the main vent. Unobstructed return air openings are required.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

A. Exhaust hood or elbow

B. Wall

C. Main collector vent

D. Horizontal vent

E. 180° sweep elbow

E Vertical vent

G. Roof

610 mm(24")

min. above

highestpoint

of building

be no more than 30°.

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the wall, install a 180 ° sweep elbow on

the end of the vent at least 610 mm (2 ft.) above the highest part

of the building. The opening in watt or roof shall have a diameter

13 mm (1/2") larger than the vent diameter. The vent should be

centered in the opening.

Do not install screening or cap over the end of the vent.

A. Individual dryer vent

B. Main vent

Min. 300 mm (12") clearance

above any accumulation

of snow, ice, or debris such

as leaves.

G

C

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

INSTALLATIONINSTRUCTIONS-ELECTRICDRYER

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

NOTE: Slide dryer onto cardboard or hardboard before moving

to avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

3. Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body

of the dryer and gently lay it on its back on the cardboard

corners.

4. With one of the legs in hand, check the ridges for a diamond

marking. That's how far the leg is supposed to go into the

hole.

5. Start to screw the leveling legs into the holes by hand.

(Use a small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 25 mm (1")

wrench or socket wrench to finish turning the legs until you

reach the diamond mark. Then fit a protective foot boot over

each foot.

Now stand the dryer up.

6. Remove cardboard or hardboard from under dryer. Adjust the

legs of the dryer up or down until the dryer is level.

7

Page 8

Electric Shock Hazard

This is a 3-wire dryer which must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

This dryer is supplied without an electric cord and plug;

it must be connected by a competent electrician.

In Australia, each single electric dryer is fitted with a cord

and plug. See "Electrical Requirements."

1. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 102 mm (4") clamp.

2. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

1. With dryer in final position place level on top of the dryer,

first side to side, then front to back. If the dryer is not level,

adjust the legs of the dryer up or down until the dryer is level.

2. Switch on power supply.

3. Check dryer operation:

Press the selection button for a full cycle and let the dryer run

for at least five minutes. Dryer will stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate.

When door is open, dryer stops, but timer continues to run.

To restart dryer, close door and press a cycle button.

4. Start the dryer and allow it to complete a full cycle to make

sure it is working properly.

MAINTENANCEINSTRUCTIONS

Maintenance instructions:

[] Clean lint screen after each cycle.

[] Removing accumulated lint (disconnect dryer from electricity

supply before starting this task):

• From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

• From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

If dryer does not operate, check the following:

[] Electric supply is connected.

[] Circuit breaker is not tripped or fuse is not blown.

[] Door is closed. Listen closely to hear door switch(es) activate.

[] Selected cycle button has been pressed firmly and display

shows cycle time.

If you need assistance:

Contact your authorized Maytag _'_Commercial Laundry distributor

or visit: www.MaytagCommerciatLaundry.com. When you call,

you will need the dryer model number and serial number.

Both numbers can be found on the serial-rating plate located

on your appliance.

Page 9

REVERSINGTHEDOORSWING

Door swing can be changed from a right-side opening to left-side

opening, if desired.

Place a towel or soft cloth on top of the dryer or work space

to avoid damaging the surface.

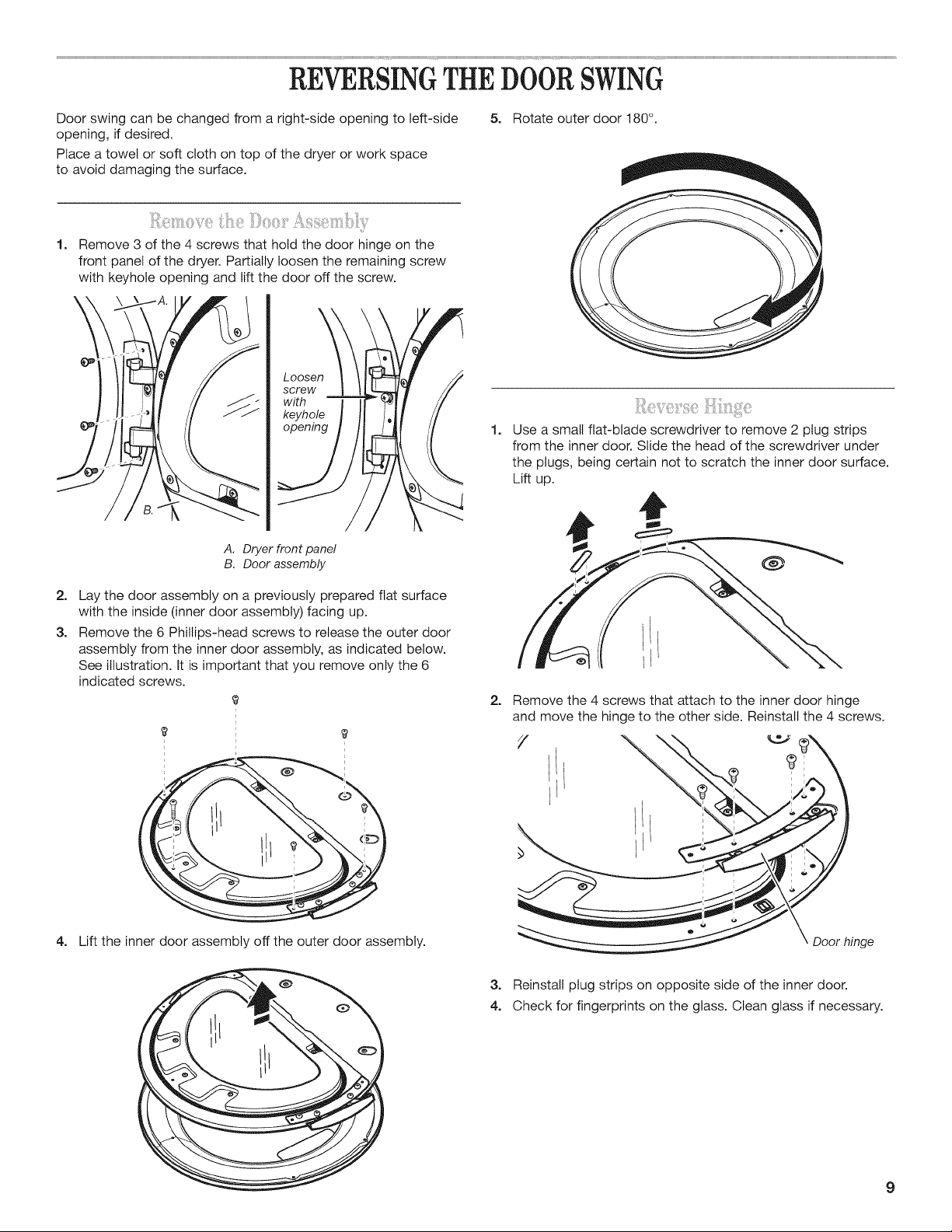

Remove 3 of the 4 screws that hold the door hinge on the

front panel of the dryer. Partially loosen the remaining screw

with keyhole opening and lift the door off the screw.

\

Loosen

screw

with

keyhole

opening

A. Dryer front panel

B. Door assembly

5. Rotate outer door 180 °.

(J

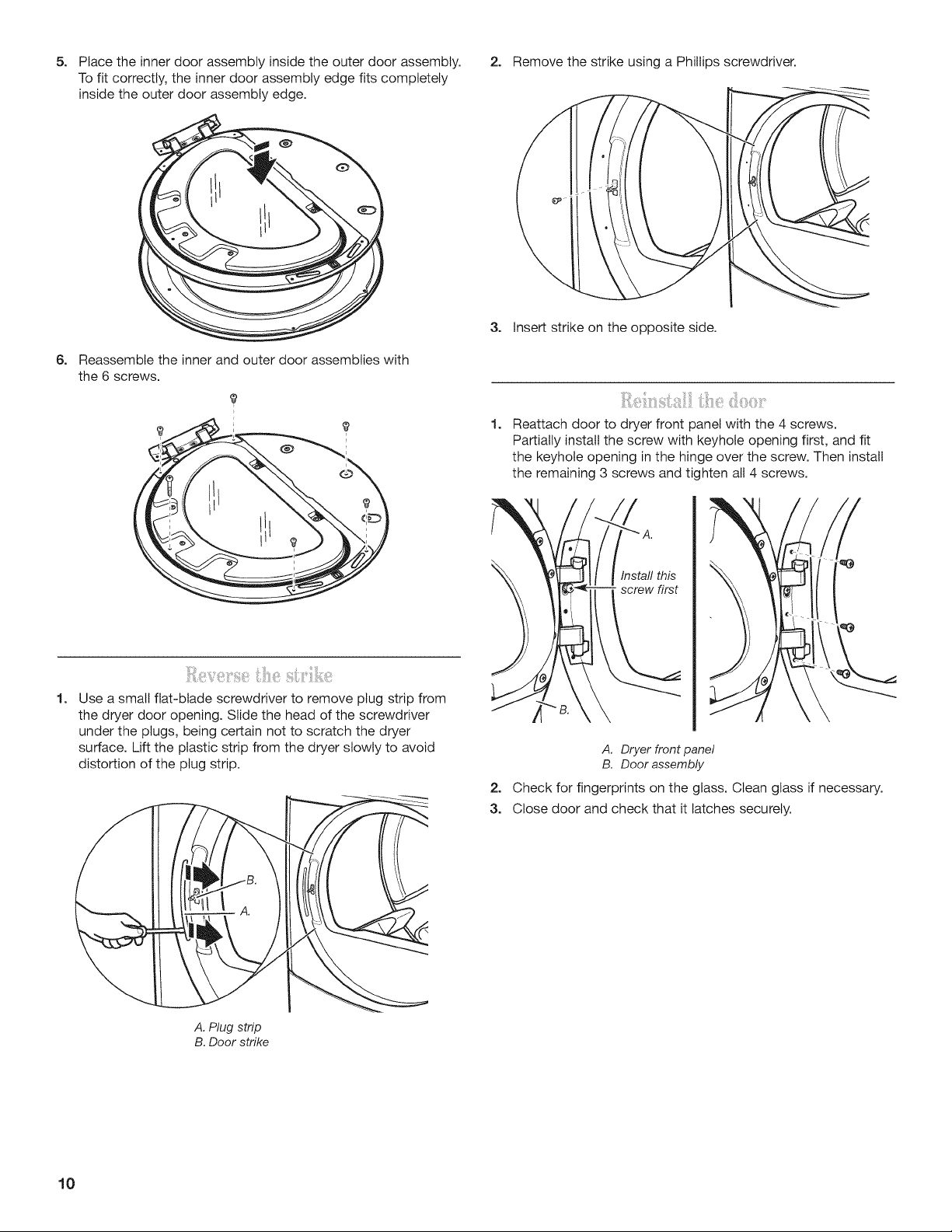

Use a small flat-blade screwdriver to remove 2 plug strips

from the inner door. Slide the head of the screwdriver under

the plugs, being certain not to scratch the inner door surface.

Lift up.

2_

Lay the door assembly on a previously prepared flat surface

with the inside (inner door assembly) facing up.

3.

Remove the 6 Phillips-head screws to release the outer door

assembly from the inner door assembly, as indicated below.

See illustration. It is important that you remove only the 6

indicated screws.

4. Lift the inner door assembly off the outer door assembly.

2_

Remove the 4 screws that attach to the inner door hinge

and move the hinge to the other side. Reinstall the 4 screws.

Door hinge

3. Reinstall plug strips on opposite side of the inner door.

4. Check for fingerprints on the glass. Clean glass if necessary.

9

Page 10

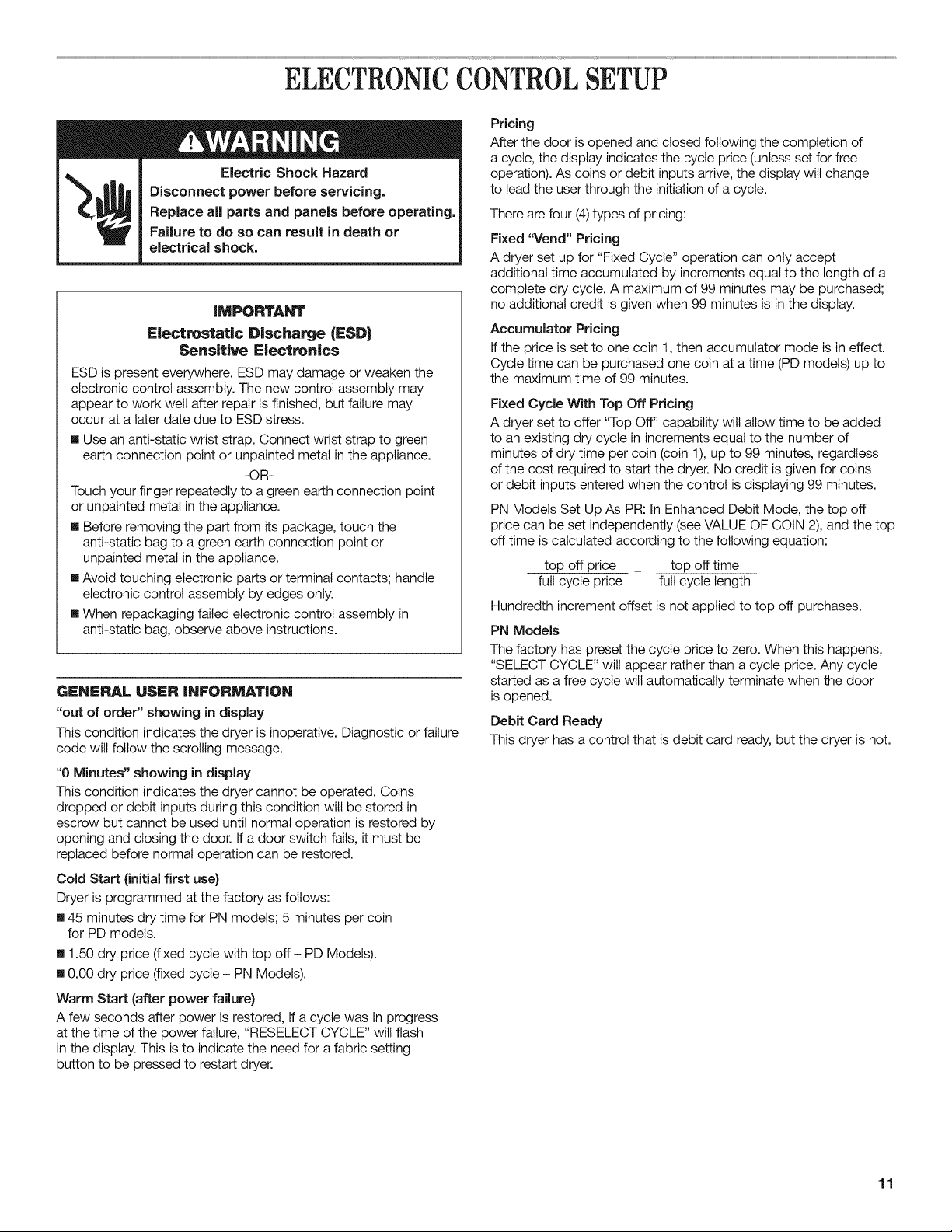

5. Place the inner door assembly inside the outer door assembly.

To fit correctly, the inner door assembly edge fits completely

inside the outer door assembly edge.

6.

Reassemble the inner and outer door assemblies with

the 6 screws.

2. Remove the strike using a Phillips screwdriver.

3. Insert strike on the opposite side.

1.

Reattach door to dryer front panel with the 4 screws.

Partially install the screw with keyhole opening first, and fit

the keyhole opening in the hinge over the screw. Then install

the remaining 3 screws and tighten all 4 screws.

1.

Use a small flat-blade screwdriver to remove plug strip from

the dryer door opening. Slide the head of the screwdriver

under the plugs, being certain not to scratch the dryer

surface. Lift the plastic strip from the dryer slowly to avoid

distortion of the plug strip.

Instafl this

screw first

A. Dryerfront panel

B. Door assembly

2.

Check for fingerprints on the glass. Clean glass if necessary.

3.

Close door and check that it latches securely.

10

A. Plug strip

B. Door strike

Page 11

ELECTRONICCONTROL SETUP

Electric Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

iMPORTANT

Electrostatic Discharge (_:SD)

Sensitive Electronics

ESD is present everywhere. ESD may damage or weaken the

electronic control assembly. The new control assembly may

appear to work well after repair is finished, but failure may

occur at a later date due to ESD stress.

[] Use an anti-static wrist strap. Connect wrist strap to green

earth connection point or unpainted metal in the appliance.

-OR-

Touch your finger repeatedly to a green earth connection point

or unpainted metal in the appliance.

[] Before removing the part from its package, touch the

anti-static bag to a green earth connection point or

unpainted metal in the appliance.

[] Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

[] When repackaging failed electronic control assembly in

anti-static bag, observe above instructions.

GENERAL USER iNFORMATION

"out of order" showing in display

This condition indicates the dryer is inoperative. Diagnostic or failure

code will follow the scrolling message.

"0 Minutes" showing in display

This condition indicates the dryer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in

escrow but cannot be used until normal operation is restored by

opening and closing the door. If a door switch fails, it must be

replaced before normal operation can be restored.

Cold Start (initial first use)

Dryer is programmed at the factory as follows:

[] 45 minutes dry time for PN models; 5 minutes per coin

for PD models.

[] 1.50 dry price (fixed cycle with top off - PD Models).

[] 0.00 dry price (fixed cycle - PN Models).

Warm Start (after power failure)

A few seconds after power is restored, if a cycle was in progress

at the time of the power failure, "RESELECT CYCLE" will flash

in the display. This isto indicate the need for a fabric setting

button to be pressed to restart dryer.

Pricing

After the door is opened and closed following the completion of

a cycle, the display indicates the cycle price (unless set for free

operation). As coins or debit inputs arrive, the display will change

to lead the user through the initiation of a cycle.

There are four (4)types of pricing:

Fixed "Vend" Pricing

A dryer set up for "Fixed Cycle" operation can only accept

additional time accumulated by increments equal to the length of a

complete dry cycle. A maximum of 99 minutes may be purchased;

no additional credit is given when 99 minutes is inthe display.

Accumulator Pricing

If the price is set to one coin 1,then accumulator mode is in effect.

Cycle time can be purchased one coin at a time (PD models) up to

the maximum time of 99 minutes.

Fixed Cycle With Top Off Pricing

A dryer set to offer "Top Off" capability will allow time to be added

to an existing dry cycle in increments equal to the number of

minutes of dry time per coin (coin 1), up to 99 minutes, regardless

of the cost required to start the dryer. No credit is given for coins

or debit inputs entered when the control is displaying 99 minutes.

PN Models Set Up As PR: In Enhanced Debit Mode, the top off

price can be set independently (seeVALUE OF COIN 2), and the top

off time is calculated according to the following equation:

top off price = top off time

full cycle price full cycle length

Hundredth increment offset is not applied to top off purchases.

PH Models

The factory has preset the cycle price to zero. When this happens,

"SELECT CYCLE" wilt appear rather than a cycle price. Any cycle

started as a free cycle will automatically terminate when the door

is opened.

Debit Card Ready

This dryer has a control that is debit card ready, but the dryer is not.

11

Page 12

CONTROLSE_UPPROCEDURES

IMPORTANT: Read all instructions before operating.

The fabric setting buttons along with the digital display are used

to set up the dryer controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related code

values available for use in programming the dryer.

Now to use the buttons to program the controls

1. The WHITES AND COLORS button is used to adjust the

values associated with set-up codes. Pressing the button will

increment the value by one (1). Rapid adjustment is possible

by holding down the button.

2. The PERM. PRESS button advances the display through the set-

up codes. Pressing the button will advance the display to the next

available set-up code. Holding down the button will automatically

advance through the set-up codes at a rate of one (1)per second.

3. The DELICATES button is used to select or deselect options.

Start Operating Set-Up

mPD Models: Insert service door key,turn, and lift to remove

access door.

mPN Models: Remove the AA1 jumper from the control board (see

procedure below) or use the Service Access Code below. Once the

debit card reader is installed (according to the reader manufacturer's

instructions), the set-up mode can be entered by inserting a manual

set-up card (supplied by the reader manufacturer) into the card slot.

Ifmanual set-up card is not available, manual set-up mode cannot

be entered. However, diagnostic mode can be entered by removing

connector AA1 on the circuit board.

IMPORTANT: The console must not be opened unless power is

first removed from the dryer. To access connector AA1 :

-> Unplug dryer or disconnect power.

-> Open console, disconnect plug on AA1, close console.

-> Plug in dryer or reconnect power.

mPN Models Equipped with Programming Switch: Insert access

panel key and turn counterclockwise.

mPN Models with Gen. 2 Debit Card Reader: Once a Gen. 2 debit

card reader is installed (according to the reader manufacturer's

instructions), the set-up mode can only be entered by inserting

a manual set-up card (supplied by the reader manufacturer)

into the card slot.

If manual set-up card is not available, only diagnostic mode

can be entered.

mAlternate method of entering Set-up Mode by entering Service

Access Code: This code can be entered to access set-up mode

without removing the console on dryers just removed from the

carton, or not yet programmed. The Service Access Code only

functions on dryers set up for 0 vend price without any Special

Pricing setup, and the Coin/Debit Option must be set to "J._d'.

Ifthe dryer is not in failure mode, the door must be opened to

proceed. Using only the three bottom buttons (numbered 1,2,

and 3 from left to right):

1. Press 2 for longer than 2 seconds but less than 10 seconds.

2. Press 1 & 3 simultaneously for 2 seconds. Display shows S 3.

3. Press 1 & 2 simultaneously. Display shows S 4.

4. Press 2 & 3 simultaneously. Display shows S 5.

5. Press 2.

6. Wait at least 2 seconds, but not more than 15 seconds;

then press insuccession 3, 2, 1,3.

The dryer is now in the set-up mode.

Before proceeding, it is worth noting that, despite attthe options

available, an owner can simply choose to uncrate a new commercial

dryer, hook it up, plug it in, and have a dryer that operates. NOTE:

PD models require a payment system or OPL kit to be installed prior

to operation.

mPD dryers are pre-set at the factory for fixed cycle price with top off.

mPN dryers are pre-set for fixed cycle operation, and they can be

run without payment.

12

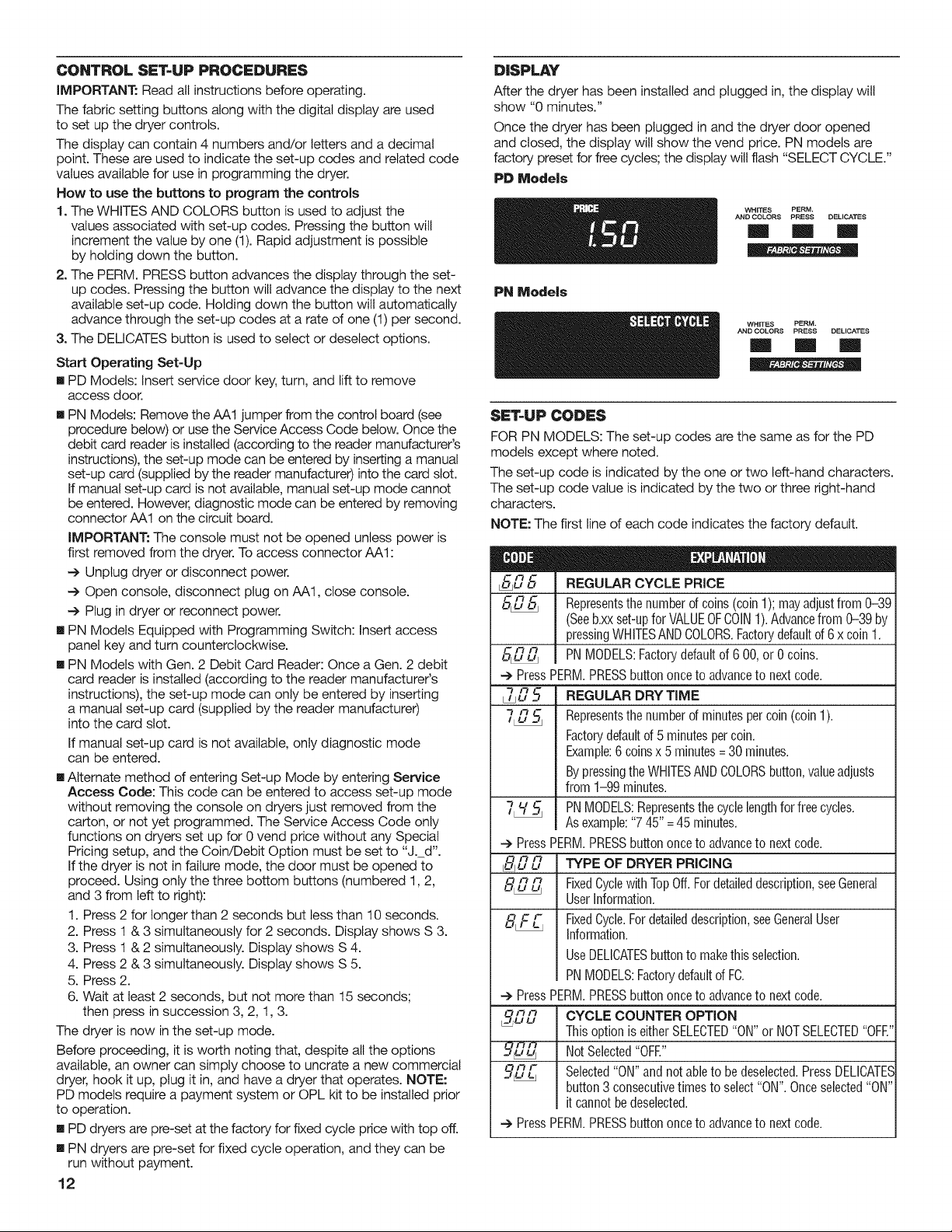

DISPLAY

After the dryer has been installed and plugged in,the dispiay will

show "0 minutes."

Once the dryer has been plugged in and the dryer door opened

and closed, the display wilt show the vend price. PN models are

factory preset for free cycles; the display will flash "SELECT CYCLE."

PD Models

AND COLORS PRESS DELICATES

WHITES PERM.

PN Models

AND COLORS PRESS DELICATES

WHITES PERM.

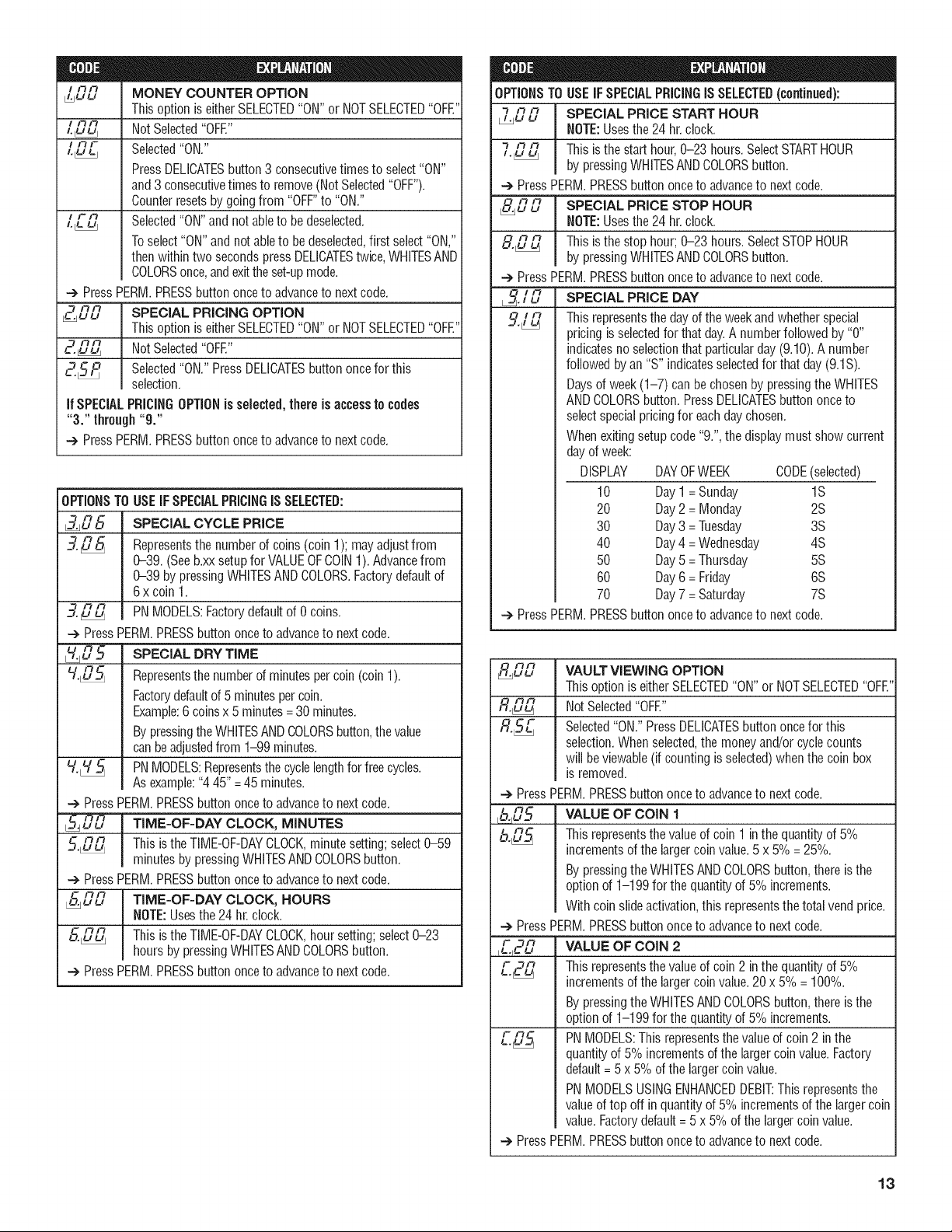

SET-UP CODES

FOR PN MODELS: The set-up codes are the same as for the PD

models except where noted.

The set-up code is indicated by the one or two left-hand characters.

The set-up code value is indicated by the two or three right-hand

characters.

NOTE: The first line of each code indicates the factory default.

REGULAR CYCLE PRICE

¢.Tn ¢.T

c1_ Representsthe numberofcoins(coin1); mayadjustfrom 0-39

(Seeb.xxset-upfor VALUEOFC01N1).Advancefrom 0-39 by

pressingWHITESANDCOLORS.Factorydefaultof 6x coin1.

c_J__ PNMODELS:Factorydefaultof 6 00, or 0 coins.

-> PressPERM.PRESSbuttononceto advanceto nextcode.

L_u S REGULAR DRY TIME

/ _ Representsthenumberof minutespercoin(coin 1).

Factorydefaultd 5 minutespercoin.

Example:6 coinsx 5 minutes= 30 minutes.

BypressingtheWHITESANDCOLORSbutton,valueadjusts

from 1-99 minutes.

_ PNMODELS:Representsthe cyclelengthforfreecycles.

Asexample:"745" =45 minutes.

-> PressPERM.PRESSbuttononceto advanceto nextcode.

L_U u TYPE OF DRYER PRICING

oc_ FixedCyclewith TopOff.Fordetaileddescription,seeGeneral

UserInformation.

J-_c _- FixedCycle.Fordetaileddescription,seeGeneralUser

Information.

UseDELICATESbuttonto makethisselection.

PNMODELS:FactorydefaultofFC.

-> PressPERM.PRESSbuttononceto advanceto nextcode.

_u u CYCLE COUNTER OPTION

This optionis eitherSELECTED"ON"or NOTSELECTED"OFE"

-_J-_L"""""_NotSelected"OFE"

_-7_ Selected"ON"andnot ableto bedeselected.PressDELICATES

button3 consecutivetimesto select "ON".Onceselected"ON"

it cannotbedeselected.

-> PressPERM.PRESSbuttononceto advanceto nextcode.

Page 13

_uu

MONEY COUNTER OPTION

This option iseitherSELECTED"ON"or NOTSELECTED"0rE"

i._ NotSelected"0rE"

I1"_11 -

i._ Selected"ON."

PressDELICATESbutton3 consecutivetimes to select"ON"

and3 consecutivetimes to remove(NotSelected"OFF").

Counterresetsbygoing from "OFF"to "ON."

I1--1"_1

i._ Selected"ON"and not ableto bedeselected.

Toselect"ON"and not ableto bedeselected,first select"ON,"

thenwithin two seconds pressDELICATEStwice,WHITESAND

COLORSonce,andexittheset-upmode.

•._ PressPERM.PRESSbutton onceto advanceto nextcode.

J__.uu SPECIAL PRICING OPTION

This option iseitherSELECTED"ON"or NOTSELECTED"OFE"

_aa

c. u_,L,,,,,,_,Not Selected"ORE"

"_co

_--.-L_ Selected"ON." PressDELICATESbuttononcefor this

selection.

ifSPECIALPRICINGOPTIONisselected, there is accessto codes

"3." through "g."

-->PressPERM.PRESSbutton onceto advanceto nextcode.

OPTIONSTO USEIFSPECIALPRICINGISSELECTED:

_nC

=_.u u SPECIAL CYCLE PRICE

=-7._ Representsthe numberof coins (coin 1); mayadjustfrom

0-39. (Seeb.xxsetupfor VALUEOFCOIN1).Advancefrom

0-39 by pressingWHITESANDCOLORS.Factorydefaultof

6x coin1.

J-Ed""""'_PNMODELS:Factorydefaultof 0 coins.

--->PressPERM.PRESSbuttononceto advanceto nextcode.

U

_.u S SPECIAL DRY TIME

%1._ Representsthe numberof minutespercoin(coin 1).

Factorydefaultof 5 minutespercoin.

Example:6 coinsx 5 minutes= 30 minutes.

BypressingtheWHITESANDCOLORSbutton,thevane

canbeadjustedfrom 1-99 minutes.

_1._ PNMODELS:Representsthecyclelengthfor free cycles.

Asexample:"4 45"=45 minutes.

-e PressPERM.PRESSbuttononceto advanceto nextcode.

L.-_nn

u u TIME-OF-DAY CLOCK, MINUTES

C FI FI

-_.J-_C"""""_This isthe TIME-OF-DAYCLOCK,minutesetting;select0-59

minutesbypressingWHITESANDCOLORSbutton.

-> PressPERM.PRESSbuttononceto advanceto nextcode.

LT FI FI

u u TIME-OF-DAY CLOCK, HOURS

NOTE:Usesthe 24 hr. clock.

c,.J-_C--------------_This isthe TIME-OF-DAYCLOCK,hour setting; select0-23

¢.Tm r_ 1

hoursby pressingWHITESANDCOLORSbutton.

-e PressPERM.PRESSbuttononceto advanceto nextcode.

OPTIONSTOUSEIFSPECIALPRICINGIS SELECTED(continued):

_u u SPECIAL PRICE START HOUR

NOTE:Usesthe 24 hr.clock.

/._ This isthe starthour,0-23 hours.SelectSTARTHOUR

by pressingWHITESANDCOLORSbutton.

--->PressPERM.PRESSbutton onceto advanceto nextcode.

cco_.uu SPECIAL PRICE STOP HOUR

NOTE:Usesthe 24 hr.clock.

o. A_,,,,_ This is the stop hour; 0-23 hours.SelectSTOPHOUR

by pressingWHITESANDCOLORSbutton.

--->PressPERM.PRESSbutton onceto advanceto nextcode.

I u SPECIAL PRICE DAY

n _n This representsthedayof the weekandwhether special

pricing isselectedfor that day.A numberfollowedby "0"

indicatesno selectionthatparticularday (9.10).A number

followedbyan "S" indicatesselectedfor that day(9.1S).

Daysofweek(1-7) canbechosenby pressingthe WHITES

ANDCOLORSbutton.PressDELICATESbuttononceto

selectspecialpricingfor eachdaychosen.

Whenexitingsetupcode"9.", the displaymust show current

dayofweek:

DISPLAY DAYOFWEEK CODE(selected)

10 Day1=Sunday 1S

20 Day2=Monday 2S

30 Day3=Tuesday 3S

40 Day4=Wednesday 4S

50 Day5=Thursday 5S

60 Day6=Friday 6S

70 Day7 = Saturday 7S

-> PressPERM.PRESSbutton onceto advanceto nextcode.

!]_.uu

'-iRa

-_CF

H.___

-e PressPERM.PRESSbuttononceto advanceto nextcode.

_L_jU__ VALUE OF COIN 1

_._ This representsthe valueof coin 1in the quantityof 5%

-) PressPERM.PRESSbuttononceto advanceto nextcode.

F "_n

,_.._cu VALUE OF COIN 2

F '3R

F FIC

c._ PNMODELS:This representsthevalueof coin 2in the

-->PressPERM.PRESSbuttononceto advanceto nextcode.

VAULT VIEWING OPTION

This optionis eitherSELECTED"ON"or NOTSELECTED"OFE"

NotSelected"OFE"

Selected"ON."PressDELICATESbutton oncefor this

selection.Whenselected,themoneyand/or cyclecounts

will beviewable(if counting is selected)whenthe coinbox

is removed.

incrementsofthe largercoinvalue.5 x 5% = 25%.

BypressingtheWHITESANDCOLORSbutton,thereis the

optionof 1-199 for the quantityof 5% increments.

With coin slideactivation,this representsthetotal vend price.

This representsthevalueof coin 2in the quantityof 5%

incrementsofthe largercoinvane. 20 x 5% = 100%.

BypressingtheWHITESANDCOLORSbutton,thereis the

optionof 1-199 for the quantityof 5% increments.

quantityof 5% incrementsofthe largercoinvalue.Factory

default= 5x 5% ofthe largercoin value.

PNMODELSUSINGENHANCEDDEBIT:This representsthe

vane oftop off in quantityof 5% incrementsof the largercoin

value.Factorydefault=5 x 5%of the largercoinvalue.

13

Page 14

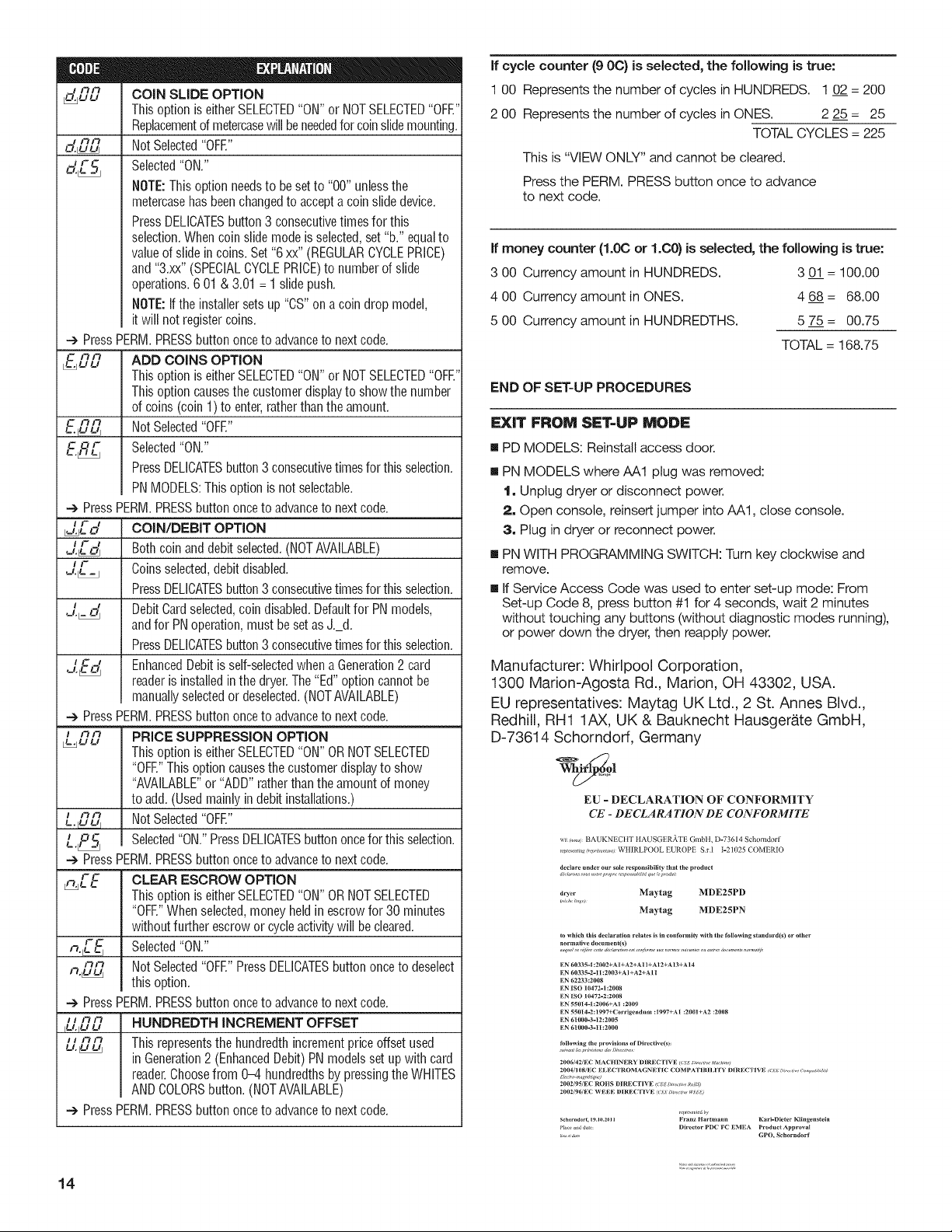

¢L_.UU COIN SLIDE OPTION

This option iseitherSELECTED"ON"or NOTSELECTED"0FE"

Replacementof metercasewill beneededforcoin slidemounting.

o.u_ NotSelected"OFE"

d._ Selected"ON."

NOTE:This option needsto besetto "00" unlessthe

metercasehas beenchangedto accepta coinslide device.

PressDELiCATESbutton3 consecutivetimes for this

selection.Whencoin slidemode isselected,set "b." equalto

valueof slide in coins.Set"6 xx" (REGULARCYCLEPRICE)

and"3.xx" (SPECIALCYCLEPRICE)to numberof slide

operations.6 01 & 3.01 =1 slidepush.

NOTE:ifthe installersetsup "CS" ona coin drop model,

itwill not registercoins.

-> PressPERM.PRESSbutton onceto advanceto nextcode.

Cnn

J_.uu ADD COINS OPTION

This option iseitherSELECTED"ON"or NOTSELECTED"0FE"

This optioncausesthe customerdisplayto showthe number

of coins (coin 1)to enter,ratherthanthe amount.

cnn

c._ Not Selected"OFE"

C'_l-

c._ Selected"ON."

PressDELiCATESbutton3consecutivetimesfor this selection.

PNMODELS:This optionis not selectable.

-> PressPERM.PRESSbutton onceto advanceto nextcode.

If" I

,__co COIN/DEBIT OPTION

II-- I

,a._ Bothcoin anddebitselected.(NOTAVAILABLE)

IF

u._ Coins selected,debitdisabled.

PressDELICATESbutton3 consecutivetimesfor this selection.

I t

,.J.-L=_o DebitCardselected,coin disabled.Defaultfor PN models,

andfor PNoperation,must besetas J._d.

PressDELICATESbutton3 consecutivetimesfor this selection.

IC t

,..i._ EnhancedDebitis self-selectedwhen aGeneration2 card

readeris installedinthe dryer.The"Ed" option cannotbe

manuallyselectedor deselected.(NOTAVAILABLE)

-> PressPERM.PRESSbutton onceto advanceto nextcode.

c_.juu PRICE SUPPRESSION OPTION

This option iseitherSELECTED"ON"ORNOTSELECTED

"0FE"This optioncausesthe customerdisplayto show

"AVAILABLE"or "ADD" ratherthan the amountof money

to add.(Usedmainly in debit installations.)

c._ Not Selected"OFE"

o c Selected"ON."PressDELICATESbuttononcefor this selection.

c._

-> PressPERM.PRESSbutton onceto advanceto nextcode.

_.c c CLF..ARESCROW OPTION

This option iseitherSELECTED"ON"ORNOTSELECTED

"OFE"Whenselected,moneyheldin escrowfor 30 minutes

withoutfurther escrow or cycleactivitywiii becleared.

r_t_2_ Selected"ON."

nn NotSelected"OFE"PressDELiCATESbuttononceto deselect

this option.

-> PressPERM.PRESSbutton onceto advanceto nextcode.

i i n n HUNDREDTH INCREMENT OFFSET

IU.tU U

u.u_ This representsthehundredthincrementpriceoffset used

in Generation2 (EnhancedDebit)PNmodels setup with card

reader.Choosefrom 0-4 hundredthsby pressingthe WHITES

ANDCOLORSbutton. (NOTAVAILABLE)

-> PressPERM.PRESSbutton onceto advanceto nextcode.

If cycle counter (90C) is selected, the following is true:

1 00 Represents the number of cycles in HUNDREDS. 102 = 200

2 00 Represents the number of cycles in ONES. 2 2,5= 25

TOTAL CYCLES = 225

This is "VIEW ONLY" and cannot be cleared.

Press the PERM. PRESS button once to advance

to next code.

If money counter (1.0C or 1.C0) isselected, the following is true:

3 00 Currency amount in HUNDREDS. 3 01 = 100.00

4 00 Currency amount in ONES. 4 68 = 68.00

5 00 Currency amount in HUNDREDTHS. 5 7,5= 00.75

TOTAL = 168.75

END OF SET-UP PROCEDURES

F.X|T FROM SET=UP MODI:

[] PD MODELS: Reinstall access door.

[] PN MODELS where AA1 plug was removed:

1. Unplug dryer or disconnect power.

2. Open console, reinsert jumper into AA1, close console.

3. Plug in dryer or reconnect power.

[] PN WITH PROGRAMMING SWITCH: Turn key clockwise and

remove.

[] If Service Access Code was used to enter set-up mode: From

Set-up Code 8, press button #1 for 4 seconds, wait 2 minutes

without touching any buttons (without diagnostic modes running),

or power down the dryer, then reapply power.

Manufacturer: Whirlpool Corporation,

1300 Marion-Agosta Rd., Marion, OH 43302, USA.

EU representatives: Maytag UK Ltd., 2 St. Annes Blvd.,

Redhill, RH1 lAX, UK & Bauknecht Hausgerb_te GmbH,

D-73614 Schorndorf, Germany

EU - DECLARATION OF CONFORMITY

_T- DECLARATION DE CONFORMITE

_ /,,o,.) BAUKNECIIT HAUSG[ RA,TE Gmb[l, D-73614 Schomdorf

_pr entix hq),¢_¢_a,d_WIIIRLPOOL EUROPE St] 1-21025 COMERIO

declare under our sole responsibility that tile pro_l*i

d_,,r Maytag MDE25PD

Maytag MDE25PN

to which lids declaration relates is in con formii7 with tile following stalldard(s) or other

normative document(s)

EN 60335-1:2002+A I+A2+A1 I+AI 2+A13+A 14

EN 60335-2-11:2003+A ]+A2+A I 1

EN 62233:2008

EN ISO 10472-1:2008

EN ISO 10472-2:2008

EN 55014-1:2006+AI :2009

EN 55014-2:1997+Corrigend_lm :1997+A [ :2001+A2:2008

EN 61000-3-12:2005

EN 61000-3-I 1:2000

following the provisions of Directive(s):

2006/42/EC MACHINERY I)ll/EC rIVE (_ _J_,,,i __,_.,,_

_;cllornflori;19.10.2011 Franz ttartmann Karl-Dieter Klini_ensteln

_U_ _,_a_: Director PI)(: FC EMEA Product Approval

_,,,_,,,a..... GPO, Schorndorf

14

Page 15

MAYTAG® COMMERCIAL WASHER, DRYER, STACKED DRYER/

DRYER,COMMERCIAL STACK LAUNDRY, AND MULTI-LOAD

COiN OPERATED COMMERCIAL WASHERS AND DRYERS

WARRANTY

LiMiTED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter "Maytag") will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

10. Repairs made by a Non-Whirlpool authorized Service Technician.

DiSCLAiMER OF iMPLiED WARRANTIES; LiMiTATiONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THiS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. iMPLiED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABiLiTY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LiMiTATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag ® Commercial Laundry distributor. To locate your authorized Maytag ®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

For written correspondence:

Maytag ® Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

1/11

15

Page 16

SECURITEDUSECHE.LINGE

Votre s_curit_ et celle des autres est tr_s importante.

Nous donnons de nombreux messages de s_curit6 importants dans ce manuel et sur votre appareil m6nager. Assurez-vous de

toujours {iretous {es messages de s_curit_ et de vous y conformer.

Voici {e symboie d'alerte de s(_curit&

Ce symboie d'a{erte de s6curit_ vous signa{e {es dangers potentie}s de d_c_s et de b{essures graves & vous

et a d'autres.

Tous {es messages de s_curit6 suivront le symbole d'alerte de s_curit6 et le mot "DANGER" ou

"AVERTiSSEMENT". Ces mots signifient :

Risque possible de d_c_s ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_ces ou de blessure grave si vous

ne suivez pas les instructions.

Tous {es messages de s_curite vous diront que{ est {e danger potentiel et vous disent comment r6duire {e risque de biessure et

ce qui peut se produire en cas de non-respect des instructions.

POUR VOTRE SECURITE

1. NE PAS UTILISER OU REMISER D'ESSENCE OU AUTRES MATE_RIAUXINFLAMMABLES DANS CET APPAREIL MC:NAGER

OU A PROXIMITE DE CELUI-CI.

2. NE PAS VAPORISER D'AC:ROSOLS _, PROXIMIT¢: DE CET APPAREIL MC:NAGER LORSQU'IL EST EN FONCTIONNEMENT.

3. NE PAS MODIFIER CET APPAREIL MC:NAGER.

ELIMINATIONDUSECHE-LINGE

Le marquage de I'appareil est conforme & la directive europeenne 2002/96/EC sur les equipements _lectroniques et

electriques, pour gestion des dechets.

En veiHant h I'elimination correcte de ce produit, vous eviterez d'eventuelles consequences nefastes pour I'environnement et la

sant6 humaine qui peuvent _tre associ_es au traitement inappropri_ de ce produit Iorsqu'il a _t_ mis au rebut.

Le symbole figurant sur le produit ou dans les documents qui accompagnent le produit indique que cet appareil ne dolt pas _tre

trait_ comme d6chet m_nager; on dolt plut6t le remettre & un centre de collecte sp_cialis_ pour le recyciage des _quipements

_lectriques et 61ectroniques.

L'elimination de ce produit apres raise au rebut dolt _tre effectuee conformement aux prescriptions de la reglementation locale

de protection de I'environnement.

Pour I'information d6taill_e concernant le traitement, le recyclage et la r_cup_ration de ce produit, contacter la municipalit_

{ocale, {e service d'6{imination des d6chets m_nagers, ou {e commergant qui a vendu {e produit.

Nomenc{ature des mod_{es

MDE S_che-tinge Maytag electrique

##(p. ex. 25) Numero de type du module

PN Module de commande electronique sans paiement

PD Module de commande etectronique avec chute de piece active

16

Page 17

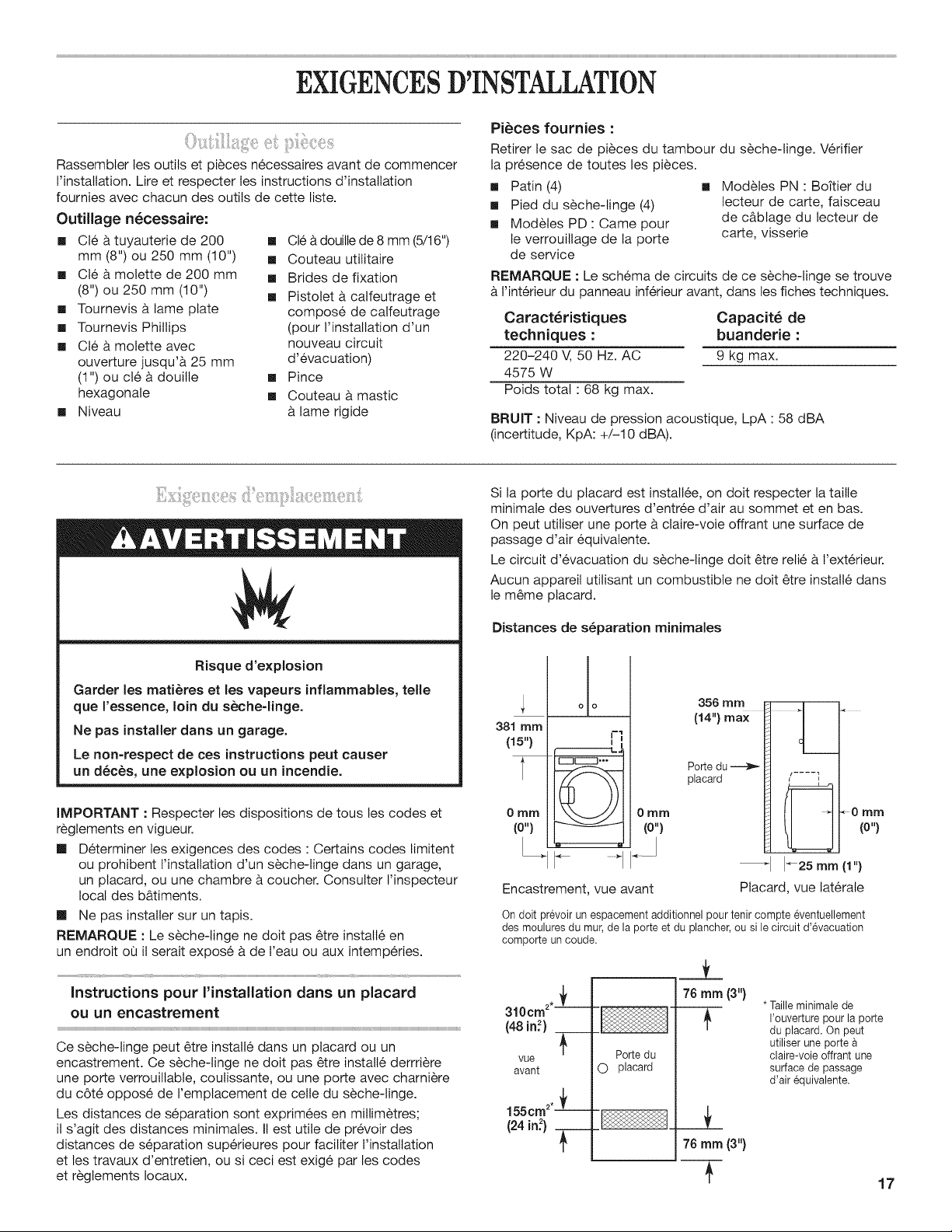

EXIGENCESD'INSTALLATION

Rassembter tes outils et pi_ces necessaires avant de commencer

I'instatlation. Life et respecter les instructions d'instattation

fournies avec chacun des outits de cette liste.

OutiHage n6cessaire:

m Cle & tuyauterie de 200 [] Cle hdouille de 8 mm (5/16")

mm (8") ou 250 mm (10") [] Couteau utilitaire

[] Cte h molette de 200 mm [] Brides de fixation

(8") ou 250 mm (10") [] Pistolet h calfeutrage et

[] Tournevis h lame plate compose de calfeutrage

[] Tournevis Phillips (pour I'instatlation d'un

[] Cle _ molette avec nouveau circuit

ouverture jusqu'_ 25 mm d'evacuation)

(1") ou cte _ douilte [] Pince

hexagonate [] Couteau _ mastic

[] Niveau h lame rigide

Pi_ces fournies :

Retirer le sac de pi_ces du tambour du s_che-linge. V6rifier

la presence de toutes les pi_ces.

[] Patin (4) []

[] Pied du s_che-linge (4)

[] ModUles PD : Came pour

le verrouiltage de la porte

ModUles PN : Bottler du

lecteur de carte, faisceau

de c&btage du lecteur de

carte, visserie

de service

REMARQUE : Le schema de circuits de ce seche-linge se trouve

h l'interieur du panneau inferieur avant, dans les fiches techniques.

Caract_ristiques

techniques :

220-240 V, 50 Hz. AC

Capacit_ de

buanderie :

9 kg max.

4575 W

Poids total : 68 kg max.

BRUIT : Niveau de pression acoustique, LpA " 58 dBA

(incertitude, KpA: +/-10 dBA).

Si la porte du placard est installee, on dolt respecter la tailte

minimale des ouvertures d'entree d'air au sommet et en bas.

On peut utiliser une porte h claire-vole offrant une surface de

passage d'air equivatente.

Le circuit d'evacuation du seche-linge dolt _tre retie h l'exterieur.

Aucun appareit utilisant un combustible ne dolt _tre instatte dans

le m_me placard.

Risque d'expiosion

Garder les mati_res et les vapeurs inf{ammabies, te{ie

que I'essence, loin du s(_che=linge.

Ne pas installer dans un garage.

Le non=respect de ces instructions peut causer

un d_c(_s, une e×plosion ou un }ncendie.

IMPORTANT : Respecter les dispositions de tousles codes et

r_glements en vigueur.

[] Determiner les exigences des codes : Certains codes limitent

ou prohibent l'instaltation d'un seche-linge dans un garage,

un placard, ou une chambre h coucher. Consulter I'inspecteur

local des b&timents.

[] Ne pas installer sur un tapis.

REMARQUE : Le seche-linge ne dolt pas _tre installe en

un endroit oQ il serait expose h de l'eau ou aux intemperies.

instructions pour I'installation dans un placard

ou un encastrement

Ce seche-linge peut 6tre installe dans un placard ou un

encastrement. Ce seche-tinge ne dolt pas _tre instatle derrri_re

une porte verrouillable, coulissante, ou une porte avec charni_re

du c6te oppose de I'emplacement de cetle du s_che-linge.

Les distances de separation sont exprimees en miltim_tres;

il s'agit des distances minimales. II est utile de prevoir des

distances de separation superieures pour facititer l'instatlation

et les travaux d'entretien, ou si ceci est exige par les codes

et r_glements Iocaux.

Distances de s6paration minimales

o o

381 mm

Os")

r--_riil...

{ I

0 mm _ 0 mm

356 mm

(14") max

Portedu

placard

d

cl

/ .... ]

:' _ Omm

(o") "-_ (o")

.........II......

Encastrement, vue avant

On dolt pr6voir un espacement additionnel pour tenir compte 6ventuellement

des moulures du mur, de la porte et du plancher, ou si le circuit d'6vacuation

comporte un coude.

76 mm (3")

(48in._)

vue

avant O

Portedu

placard

+

_l 1_2smm0")

Placard, vue laterale

* Taille minimale de

I'ouverture pour la porte

du placard. On peut

utiliser une porte

claire-vole offrant une

surface de passage

d'air _quivalente.

(24in._)

76 mm (3")

(0")

17

Page 18

Dimensions du produit = S_che-linge

de 686 mm (27")

686 mm

(27")

VUE AVANT

VUE ARRI#RE

965 mm

+

25 mm

(1")

CABLE

ELECTRIQUE

{ IIm_ I

715mm

102mm (4")

dia.

+

b358 mm_

04")

t

Tension Electrique Dangereuse

Ce s_che-linge est livr_ sans cordon d'atimentation etectrique et

sans prise. II doit _tre raccorde par un electricien competent _ une

source d'alimentation electrique monophasee, de tension telle

qu'indiquee sur la plaque signat_tique en utilisant un c&blage fixe

approprie, conformement aux r_gtements Iocaux et nationaux.

[] Un cordon circutaire & 3 ills avec des conducteurs d'au

moins 2,5 mm 2de section doit _tre utilis&

[] Un fusible de 30A dolt _tre utilise sur I'alimentation et un

sectionneur bipolaire sur tes deux lignes doit _tre incorpor_

dans le c&btage fixe pour assurer une deconnexion totate

en cas de survoltage de categorie I!1,conformement aux

r6glements Iocaux en mati_re de raccordement. Le seche-

linge doit _tre place de fa(_on _ ce que le sectionneur soit

clairement evident et facilement accessible pour I'utitisateur.

Ce sectionneur remplit egatement la fonction de commande

d'arr_t d'urgence pour I'utilisateur.

[] Une garniture de serre-fil pour le d'alimentation est foumie avec

le seche-linge et dolt _tre serr_e une fois le cgblage termin& Les

bomes de raccordement au secteur se trouvent derriere le petit

panneau d'acc_s arri6re (couvercle du bottler de connexion), et

les connexions doivent _tre r_atisees conformement au marquage

des bomes. Nepas oublier de remettre en placele panneau d'acc_s

du bottler de connexion (couvercle du bottler de connexion).

REMARQUE : Conformement _ ta directive europeenne

CEM (2004/108/EC), I'impedance maximate du syst_me

d'atimentation electrique auquel le seche-tinge electrique

doit _tre connecte est de 0,054 Ohm + j0,034 Ohm.

REMARQUE : Normes de securite electriques : Pour ce produit,

le fabricant a estime que la mise en conformite avec les normes

IEC/EN.60335 etait la plus appropriee.

203 mm

VUE LATleRALE _

921 mm

(36i4")

18

+

(8")

25 mm

(1")

736 mm

. (29) 695 mm

, 1

Risque de choc electrique

Cet appareil est un s_che-I{nge a 3 conducteurs

qui doit 6tre reli_ _ la terre.

Ne pas utiliser une tuyauterie de gaz pour le

raccordement & la terre.

Le non=respect de ces instructions peut causer

un d6c_s, un incendie ou des blessures graves.

Si les codes le permettent et si un conducteur supplementaire

de mise & la terre est utilise, il est recommande qu'un electricien

quatifie inspecte le parcours du fil de mise & la terre.

.4 _r

M_thode recommand_e pour la raise _ la terre

[] It incombe & t'utilisateur de contacter un electricien qualifie

afin de veitler & ce que I'instattation electrique soit realisee de

fagon adequate et en conformite avec les exigences de tous

les codes et r_glements Iocaux.

Page 19

Risque d'Jncendie

UtitJser un conduit d'_vacuation en m_tal Iourd.

Ne pas utiiiser un conduit d'_vacuation en plastique.

Ne pas utJliser un conduit d'_vacuation en feuJJle

de rn_tal.

Le non=respect de ces instructions peut causer

un d_c_s ou un Jncendie.

AVERTISSEMENT : Pour reduire le ri.sque d'incendie,

ce s_che-tinge DOlT IeVACUER L'AIR A L'EXTERIEUR.

[] Si l'on suit ces specifications d'evacuation, le bruit produit

par les conduits sera minimis&

[] Une a@ation adequate est necessaire pour eviter le retour des

gaz dans lapiece en provenance d'appareils menagers qui

utilisent d'autres carburants comme combustible, y compris

les feux ouverts (autrement dit le debit d'air entrant dans la

piece dolt _tre egal au debit qui en sort).

[] Le conduit d'evacuation du seche-linge ne dolt pas _tre

raccorde A une evacuation de gaz, une cheminee, un mur,

un plafond, un grenier, un vide sanitaire ou un vide de

construction. Seul un conduit d'evacuation metattique rigide

ou souple dolt _tre utilise pour le syst_me d'evacuation.

[] Ne pas utiliser un ctapet d'evacuation A fermeture

magnetique.

[] Ne pas installer le conduit m6tatlique flexible dans les cavites

fermees des murs, ptafonds ou ptanchers.

[] Utiliser uniquement un conduit d'evacuation en metal Iourd

de 102 mm (4") et des brides de serrage.

Conduit

d'evacuation en I }

metal lourd k, J

102mm

(4")

t

[]

Utiliser des brides de fixation pour sceller tousles joints.

Uevent ne dolt pas _tre connecte ou fixe avec des vis ou

autres dispositifs d'accrochage qui se prolongent & I'interieur

de I'event et peuvent retenir les peluches. Ne pas utitiser

de ruban adhesif en toite.

IMPORTANT : Respecter les dispositions de tousles codes

et r_glements en vigueur.

Utiliser un conduit d'evacuation en metat lourd. Ne pas utiliser

un conduit de plastique ou en feuille metatlique.

On recommande d'utiliser un conduit metallique rigide pour une

meilleure performance de sechage et pour r_duire les risques

d'ecrasement et de deformation.

Un conduit metallique flexible dolt @re totalement deploye et

soutenu torsque te s_che-linge est &sa position finale. Enlever

tout exc_s de conduit flexible pour eviter tout affaissementJ

deformation qui r_duira le debit d'air et le rendement du

seche-tinge.

La Iongueur totate du conduit metaltique flexible ne dolt pas

exceder 2,4 m (7,%pi).

Terminer le conduit d'evacuation par un clapet de decharge

pour eviter les rongeurs et insectes d'entrer dans le b&timent.

Le clapet de decharge dolt _tre situe & au moins 305 mm (12")

au-dessus du sot ou de tout autre objet susceptible de se trouver

sur le trajet de t'air humide rejete (par exempte, fleurs, roches,

arbustes, ou neige).

Lots de I'utitisation d'un circuit d'evacuation existant, nettoyer les

peluches sur toute la Iongueur du syst_me et veilter & ce que la

bouche de decharge ne soit pas obstruee par une accumulation

de peluches. Remplacer tout conduit de plastique ou de feuille

metaltique mince par un conduit metallique flexible ou rigide.

Planifier t'instaltation pour introduire le nombre minimal de coudes

et de changements de direction.

A

D#bitd'#vacuation J l

Si des coudes sont utilises ou des changements de direction

effectu_s, prevoir autant d'espace que possible. Plier le conduit

graduellement pour eviter de le deformer.

La bouche de sortie est situee & I'arri@e du seche-tinge, en

bas/au centre.

On peut acheminer le conduit d'evacuation par le haut, par te

bas, par la gauche, par la droite, derri@e le seche-tinge ou en

ligne droite depuis l'arri@e du seche-linge.

Longueur du circuit d'_vacuation

La longueur maximate du circuit d'evacuation depend du type de

conduit utilise, du nombre de coudes et du type de bouche de

decharge.

Une mauvaise _vacuation de I'aJr peut causer de

I'humidit_ et une accumulation de charpie _ I'int_rieur de

la maison, ce qui peut provoquer :

Ill Dommages par I'humidit_ aux boiseries, meubles, peinture,

papier-peint, tapis, etc.

m Problemes de nettoyage dans la maison et problemes

de sant&

Longueur maximale du conduit

Clapet de decharge de 102 mm (4")

Typebofte A persiennes Inclin#de64mm(2V_")

coo .t

metallique rigide

t t t

Nombre d'angles Clapets de type bofte et Clapet inclin_

9 39,6 m (130 pi.) 39,3 m (129 pi.)

1 38,1 m (125 pi.) 36,3 m (119 pi.)

2 35,1 m (115 pi.) 33,2 m (199 pi.)

3 32,3 m (106 pi.) 30,5 m (100 pi.)

4 29,9 m (98 pi.) 28 m (92 pi.)

19

Page 20

Si le s_che-linge est instatte dans un espace r6duit tel qu'une

chambre _ coucher, une salle de bain ou un placard, on dolt

prevoir une arrivee d'air en quantite suffisante pour lacombustion

et ta ventilation. (Consulter les codes et r_glements en vigueur.)

Voir "Instructions pour l'installation dans un placard ou dans

un encastrement" de la section "Exigences d'emptacement".

Uemptoi d'une bouche de decharge de 102 mm (4") est

pref6rabte. On peut cependant utiliser une bouche de 64 mm

(21/2").Une bouche de decharge de 64 mm (21/2'') peut causer

une plus forte retropression que les autres genres de bouches.

Pour une installation permanente, un syst_me d'evacuation

fixe est requis.

SJune bouche de d_charge ne peut 6tre utilis_e :

de toute accumulation de

neige, gtace ou debris

i 300 mm (121') min. au-dessus

comme des feuittes.

i_vacuation multiple du s_che-Jinge

[] Un conduit d'evacuation principal peut 6tre utilise pour un

groupe des seche-linge. Le conduit d'evacuation principal

devrait _tre d'un diam_tre suffisant pour evacuer 5663 I/min

(200 pi3/min) d'air par seche-linge. Des fittres _ peluches

de forte capacite et de conception adequate peuvent _tre

utitises dans le conduit principal d'evacuation s'ils sont

inspectes et nettoyes fr_quemment. La piece o_ se trouvent

les seche-linge devrait recevoir un apport d'air de debit egat

ou superieur au debit total (pP/min) de debit de tous

les seche-linge installes dans la piece.

[] Un ensemble antirefoulement est necessaire et est fourni

par un distributeur de buanderie commercial et devrait _tre

instatle dans le conduit d'evacuation de chaque seche-tinge

pour eviter Fair evacue de retourner dans les s_che-linge

et pour maintenir une pression equitibr_e dans le conduit

principal d'evacuation. Des orifices de passage d'air

de retour non obstrues sont requis.

Chaque conduit d'evacuation devrait penetrer dans leconduit

principal _ un angle pointant dans la direction du debit d'air.

Les conduits raccordes au conduit principal de part et d'autre

devraient _tre disposes en quinconce pour que I'air evacue

par un s_che-linge ne puisse perturber I'evacuation d'un autre

seche-tinge.

Uangle maximal entre le conduit connecte _ un s_che-tinge

et le conduit principal ne devrait pas depasser 30°.

A. Bouche de d_charge

ou coude de d_viation

B. Mur

C. Chemin_e principale

de mise a I'air Iibre

D. Conduit horizontal

E. Coude de d_viation

180°

F. Conduit vertical

G. Toit

t

610mm(2pi)

min.au-dessus

dupoint le

plus_lev_

dub_timent

G

C

Uextremite exterieure du conduit principal devrait 6tre munie d'un

coude de deviation dirige vers le bas. Si le conduit principal suit

une trajectoire verticate Atravers le toit, plut6t qu'A travers lemur,

installer un coude de deviation de 180° _ l'extr_mite du conduit et

depassant d'au moins 610 mm (2 pi) au-dessus de la partie la

plus elevee du bAtiment. Uouverture murate ou dans le toit dolt

avoir un diam_tre superieur de 13 mm (1/2") Acelui du conduit

d'evacuation. Le conduit d'evacuation devrait _tre centr_

dans I'ouverture.

Ne pas installer une grille ou un couvercle sur I'extr6mite

du conduit d'evacuation.

A

A. Conduit individuel d'_vacuation du s_che-Iinge

B. Conduit principal d'_vacuation

Faire en sorte que les vapeurs generees par les tiquides de

nettoyage A sec ne puissent pas atteindre les orifices d'entree

d'air; ces vapeurs creent des composes acides qui, Iorsqu'ils

sont attires vers les unites de chauffage des s_che-linge, peuvent

endommager les seche-linge et le linge en cours de sechage.

Une bouche de nettoyage devrait _tre instaltee dans le conduit

principal d'evacuation pour les nettoyages periodiques du

syst_me d'evacuation.

2O

Page 21

INSTRUCTIONSffINSTALLATION-SECHE.LINGEELECTRIQUE

Risque du poids excessif

Utiliser deux ou plus de personnes pour d_piacer et

installer le seche=linge.

Le non-respect de cette instruction peut causer

une biessure au dos ou d'autre biessure.

Risque de choc _lectrique

NOTE : Placer le seche-linge sur une feuitle de carton ou un

panneau de bois dur avant de la deplacer sur le ptancher, afin

d'eviter d'endommager le rev_tement du sol.

1. A l'aide de deux personnes ou plus, deptacer le seche-tinge

h I'emplacement d'instatlation desire.

2. Enlever le ruban adhesif dans les angles avant du seche-linge.

Ouvrir le s_che-linge; enlever les brochures et sachets de

pi6ces. Essuyer parfaitement la surface interne du tambour

avec un chiffon humide.

3. Prendre deux corni_res de carton de I'emballage et les placer

sur le plancher h l'arri_re du s_che-tinge. Saisir fermement le

seche-tinge et le placer doucement en appui sur le dos, sur

les corni_res de carton.

4. Prendre I'un des pieds et identifier la marque en losange dans

le filetage. Ce repere indique jusqu'oQ le pied dolt _tre visse

dans le trou.

5. Commencer h visser & la main les pieds avant dans les trous.

(Utiliser une petite quantite de detergent liquide pour lubrifier

la section fitetee, pour qu'it soit plus facile de tourner les

pieds). Utitiser une cle de 25 mm (1") ou une cle h douilte pour

visser les pieds jusqu'au repute. Placer ensuite un patin de

protection sur chaque pied.

Placer maintenant le seche-linge verticalement.

6. Retirer la feuitle de carton ou le panneau de bois dur place

sous le seche-linge. Regler les pieds du seche-linge vers

le haut ou vers le bas jusqu'h ce que le seche-tinge soit

d'aptomb.

Cet apparel{ est un s_che-linge h 3 conducteurs

qui dolt _tre re{i_ _ la terre.

Bien setter toutes {es conne×ions _{ectriques.

Le non-respect de ces instructions peut causer

un d_c_s, un incendie ou un choc _{ectrique.

Ce seche-tinge est livr6 sans cordon d'alimentation electrique

et sans prise; il dolt _tre raccorde par un electricien competent.

Voir "Specifications etectriques".

1. A I'aide d'une bride de fixation de 102 mm (4"), relier le

conduit d'evacuation h la bouche d'evacuation du s_che-

linge. Si on utilise le conduit d'evacuation existant, s'assurer

qu'il est propre. Le conduit d'evacuation du seche-tinge dolt

_tre fixe sur la bouche d'evacuation du seche-linge et dans

le clapet d'evacuation. S'assurer que le conduit d'evacuation

est fixe au clapet d'evacuation h I'aide d'une bride de

fixation de 102 mm (4").

2. Placer le s_che-linge _ I'emplacement final desire. Ne pas

ecraser ni deformer te conduit d'evacuation. V_rifier que

le seche-tinge est de niveau.

21

Page 22

1. Une fois le s_che-tinge &son emplacement final, placer

un niveau sur le sommet du seche-tinge, transversalement,

puis dans le sens avant arri@e. Si le seche-tinge n'est pas

d'aplomb, ajuster les pieds pour modifier la hauteur et etabtir

un bon aplomb du seche-linge.

2. Brancher le seche-tinge ou reconnecter la source de courant

etectrique.

INSTRUCTIONSD'ENTRETIEN

3. Contr61er le bon fonctionnement du seche-tinge :

Appuyer sur le bouton de selection pour un programme

complet et laisser le s_che-linge fonctionner pendant au

moins 5 minutes. Le s_che-linge s'arr_tera A I'expiration

de la periode ainsi determin6e.

REMARQUE : I1faut que la porte soit fermee pour que

le seche-tinge puisse fonctionner. Le s_che-linge s'arr_te

d_s I'ouverture de [a porte, mais laminuterie continue

de fonctionner. Pour remettre le seche-linge en marche,

fermer la porte et appuyer sur le bouton du programme.

4. Mettre le seche-tinge en marche; le laisser executer

un programme comptet pour verifier qu'il fonctionne

correctement.

Instructions d'entretien :

[] Nettoyer le filtre & peluches aprbs chaque utilisation.

[] Comment enlever les peluches accumutees : (deconnecter le

s_che-linge de I'atimentation etectrique avant d'effectuer cette

op@ation) :

• De I'int@ieur du sbche-tinge :

IIfaut retirer les peluches tousles 2 ans ou plus souvent,

selon l'utilisation du seche-linge. Le nettoyage dolt _tre

effectue par une personne qualifiee.

• Du conduit d'evacuation :

IIfaut retirer les peluches tous les 2 ans ou plus souvent,

selon I'utitisation du sbche-linge.

SJJes_che-linge ne fonctionne pas, vdrifier ce qui suit :

[] Le circuit d'alimentation electrique est bien connecte.

[] Les disjoncteurs ne sont pas ouverts et les fusibtes sont intacts.

[] La porte est fermee. (couter etroitement pour entendre

I'activation du contacteur(s) de la porte.

[] Le bouton du programme a ete enfonce fermement

et I'afficheur montre la duree de cycle.

Si vous avez besoin d'assistance :

Veuitlez communiquer avec votre distributeur d'ensembte

de buanderie commercat Maytag _'_autorise, ou visitez le site Web

www.MaytagCommercialLaundry.com. Lots de I'appel,

vous aurez besoin des num@os de module et de serie du

seche-linge. Les deux numeros sont indiques sur la plaque

signatetique de I'appareil.

22

Page 23

INVERSIONDUSENSD'OUVERTUREDE LAPORTE

Le sens d'ouverture de la porte peut _tre change du c6te droit

au c6te gauche, si desire.

Placer une serviette ou un chiffon doux sur le dessus du seche-

linge ou du plan de travail pour eviter d'endommager la surface.

1. Enlever 3 des 4 vis qui maintiennent ta charni_re de la porte

sur le panneau avant du seche-linge. Desserrer partiellement

la vis restante qui a une ouverture de trou de la serrure et

soutever la porte de lavis.

\

lavis

qui a une

ouverture

de trou

de la

serrure

A. Panneau avant du s_che-linge

B. Armature de la porte

5. Faire pivoter la partie exteme de 180°.

1.

Utitiser un petit tournevis & lame plate pour enlever 2 pitons