Page 1

Service

Base manual covers general infomation.

Refer to individual T echnical Sheet for

information on specific models.

Jetclean II™

Dishwashers

This manual includes, but is not limited to

the following:

JDB4000AW

MDB5600AW

MDB6600AW

MDB7600AW

MDB8600AW

MDB9600AW

MDBF550AW

MDBF750AW

MDBH950AW

MDBH970AW

MDBL540AW

MDBL740AW

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

16021814

Revison 0

August 2002

Page 2

Important Information

G

!

N

!

!

!

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however ,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE

APPROPRIA TE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

Important Notices for Consumers and Servicers

WARNIN

T o avoid risk of serious injury or death, rep airs should not be attempted by unauthorized persons, dangerous

conditions (such as exposure to electrical shock) may result.

CAUTIO

Maytag will not be responsible for any injury or property damage from improper service procedures. If performing

service on your own product, assume responsibility for any personal injury or property damage which may result.

T o locate an authorized servicer , please consult your telephone book or the dealer from whom you purchased this

product. For further assistance please contact:

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.AMANA.COM........................................................................... 1-800-843-0304

WWW.JENNAIR.COM......................................................................... 1-800-536-6247

WWW.MAYTAG.COM ......................................................................... 1-800-688-9900

CAIR Center in Canada ...................................................................... 1-800-688-2002

Amana Canada Product ...................................................................... 1-866-587-2002

Recognize Safety Symbols, Words, and Labels

DANGER

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

2 16021814 Rev . 0 ©2002 Maytag Appliance Sales Company

Page 3

Table of Contents

Important Information

Important Notices for Consumers and Servicers.... 2

Recognize Safety Symbols, Words, and Labels ... 2

Section 1. Important Safety Information

General Information...............................................1-4

Related Publications.............................................1-4

General Precautions and Warnings.......................1-4

Product Warning Labels

Junction Box Warning...........................................1-5

Support Panel Warning.........................................1-5

Control Cover Warning ..........................................1-6

Section 2. Electrical Equipment & Testing

Electrical T est Equipment .....................................2-7

Appliance T est Meter ............................................2-7

Continuity T esting .................................................2-7

Digital Test Meter..................................................2-7

Voltage Checks..............................................2-8

Motor T est Cord ....................................................2-8

Grounding Polarity ................................................2-8

Electrical Tests

Water V alve ..........................................................2-9

Detergent / Rinse Aid Disp W ax Mtr Check ..........2-9

V ent W ax Motor Check.......................................2-10

Section 3. Cycles & Options

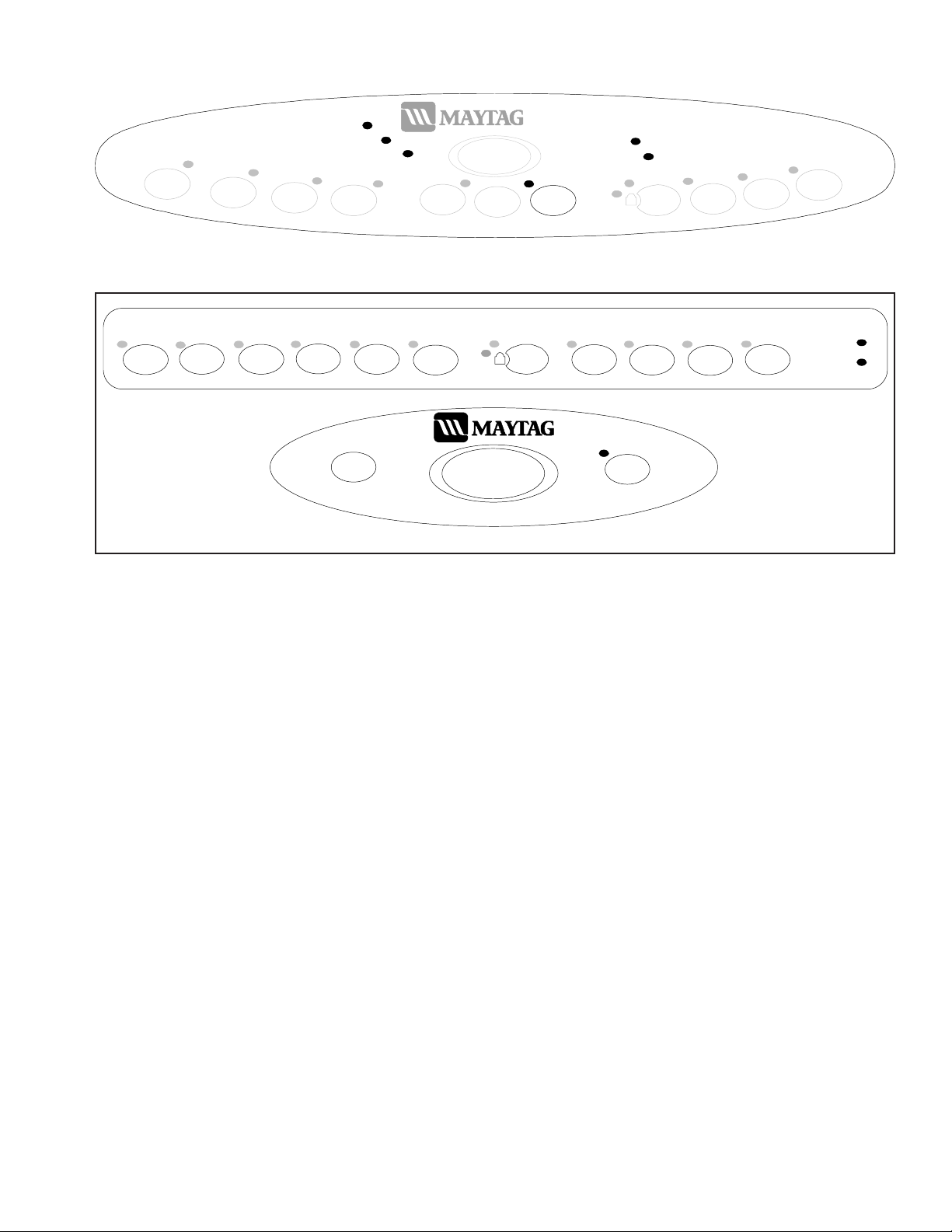

Cycles ................................................................ 3-11

Options............................................................... 3-12

Display ............................................................... 3-13

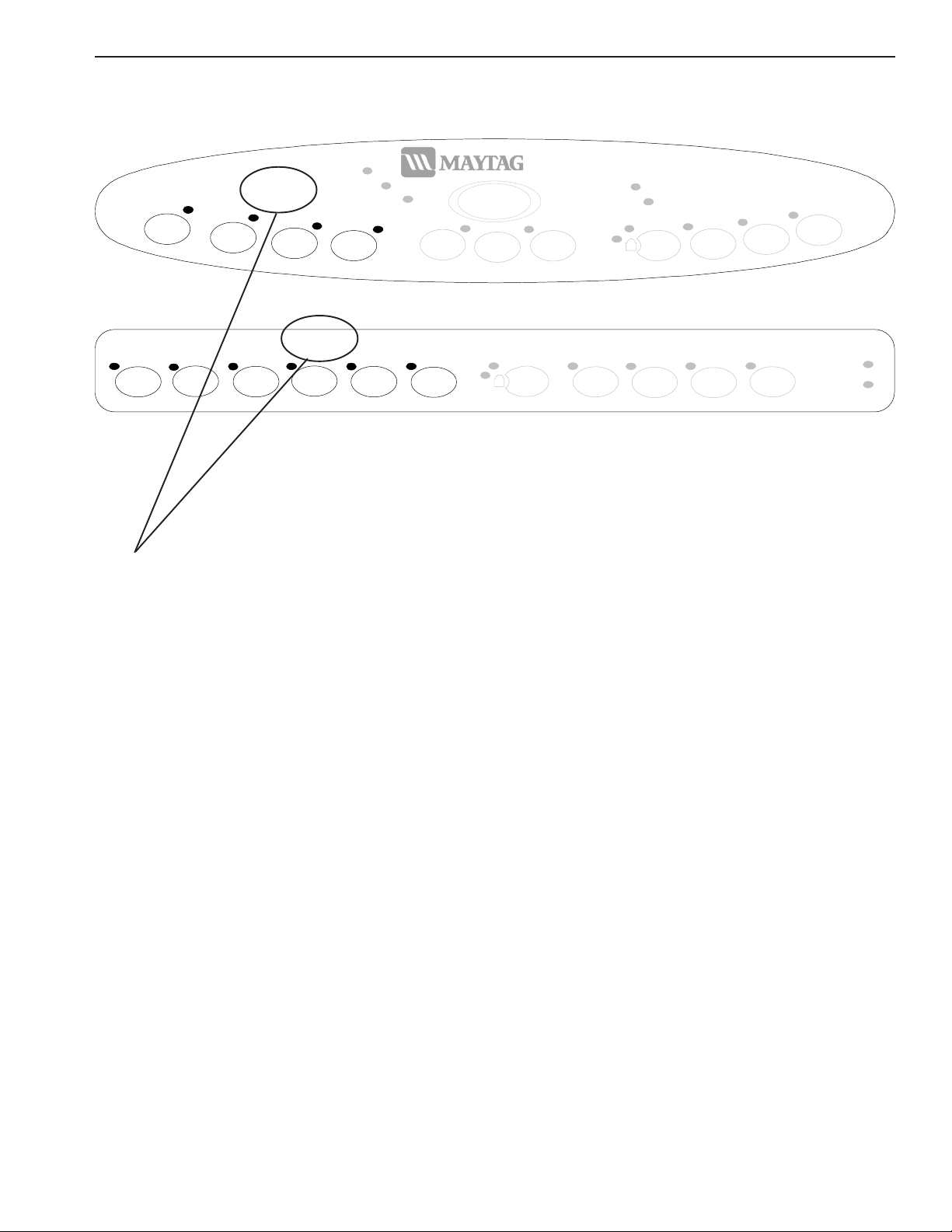

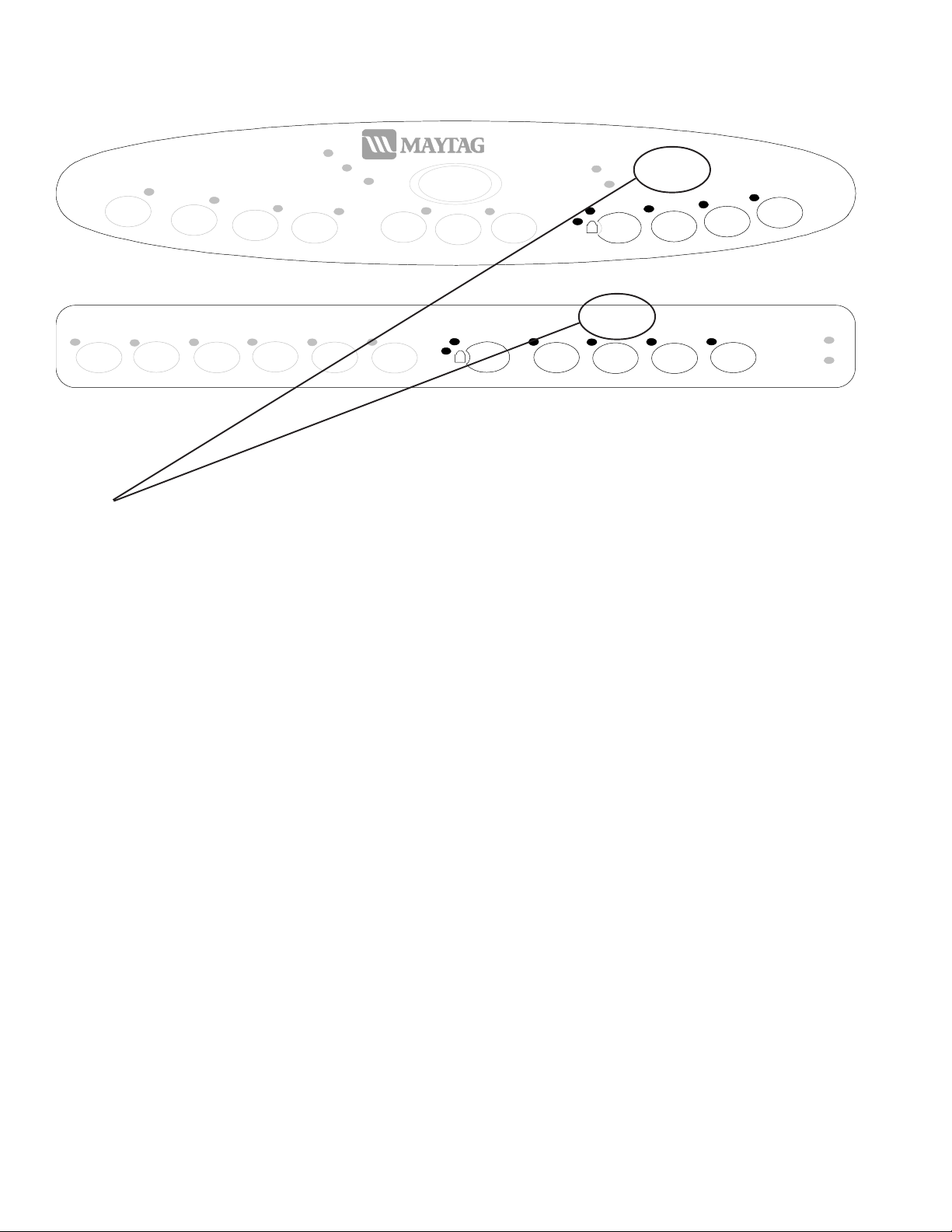

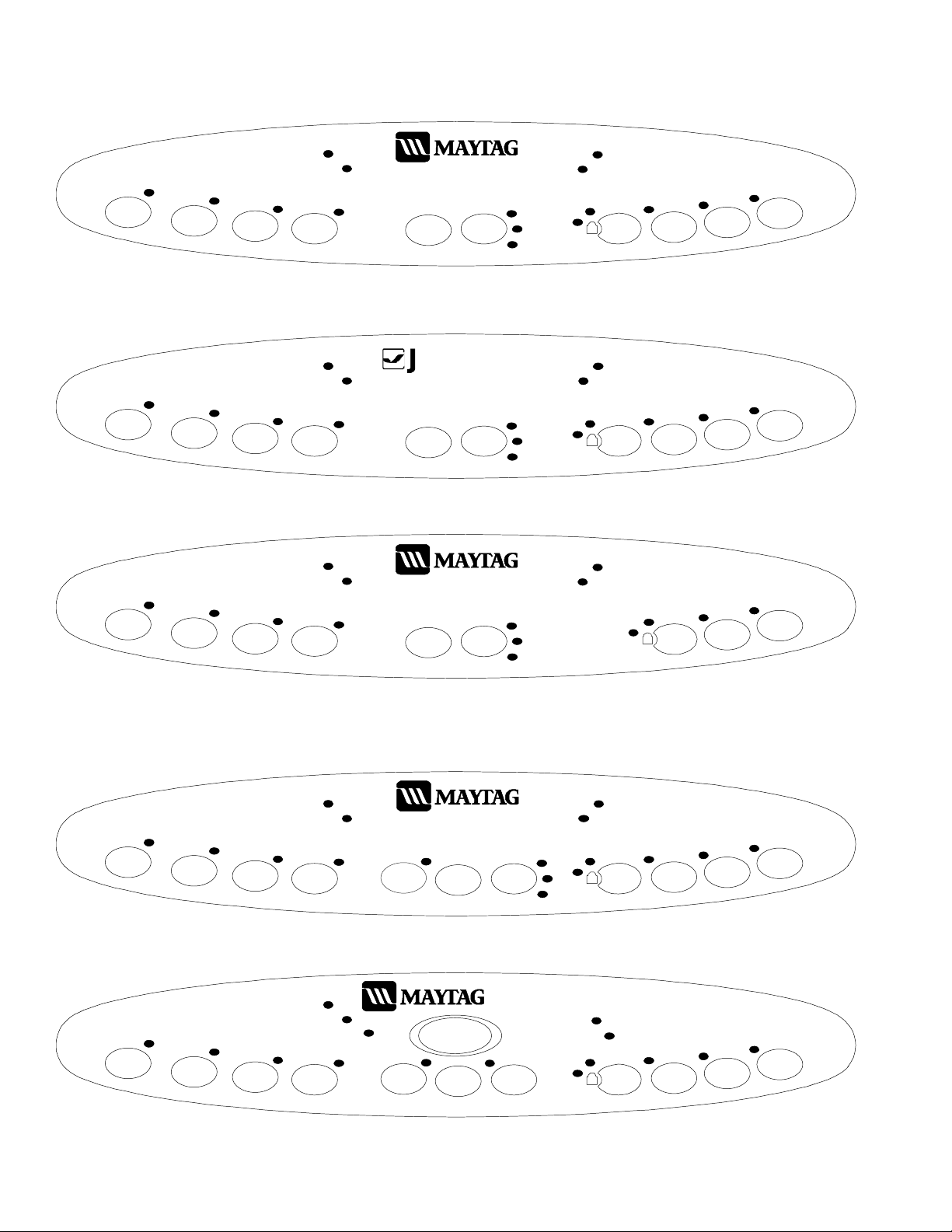

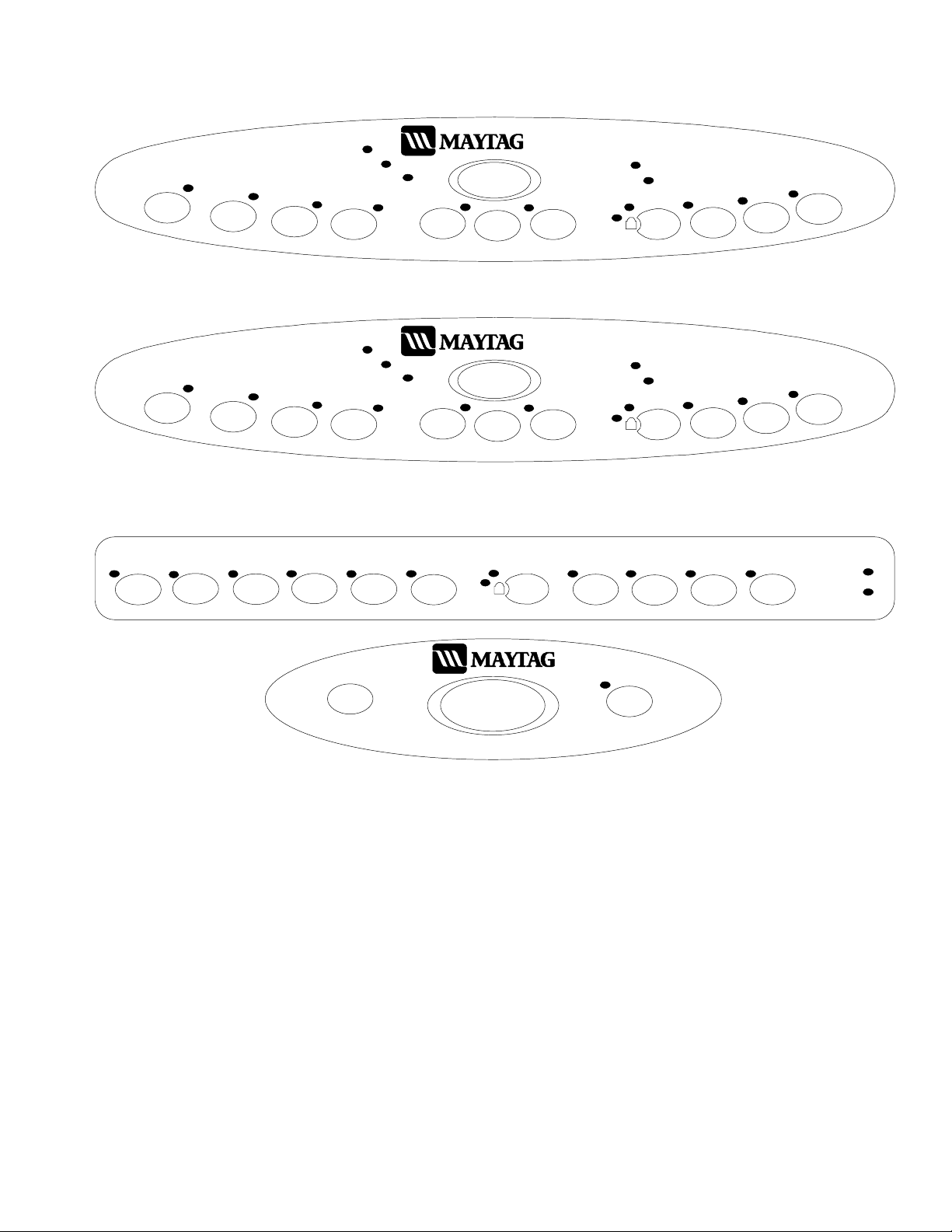

Control Style by Model........................................ 3-14

Control Style by Model........................................ 3-15

Section 4. Trouble Shooting

Will Not Fill......................................................... 4-16

Overflows ............................................................ 4-16

Poor Water Circulation........................................ 4-16

Poor Washability ................................................ 4-17

Will Not Drain ..................................................... 4-17

Continues to Drain .............................................. 4-17

Poor Drying ........................................................ 4-17

Water Leaks ....................................................... 4-18

Noise .................................................................. 4-18

Will Not St art or Program....................................4-18

Will Not Fill.........................................................4-18

Will Not Wash ....................................................4-19

Will Not Drain ..................................................... 4-19

Will Not Dry ........................................................4-19

Manual Function T est ......................................... 4-19

Field Service Test ...............................................4-19

Section 5. Service and Disassembly Procedures

Front Support and T oe Panel Removal ................ 5-20

Inner Door Panel Removal...................................5-21

Detergent / Rinse Aid Disp..................................5-21

Wax Motor Detergent / Rinse Aid Disp................5-22

Vent.................................................................... 5-22

Wire Cover .......................................................... 5-22

Door Latch & Switch Holder Assembly................ 5-23

PC Board............................................................ 5-24

Technical Sheet .................................................. 5-24

Control Panel...................................................... 5-24

Door Latch Strike................................................ 5-24

Door Gasket .......................................................5-25

Outer Door.......................................................... 5-25

Door Hinge And Support .....................................5-26

Door Spring......................................................... 5-26

Door Spring And Component Replacement..........5-27

Over Pressure Filter ............................................ 5-27

T op W ash Ar m ....................................................5-27

Manifold ..............................................................5-28

Docking S tation .................................................. 5-28

Lower Wash Arm ................................................ 5-28

Float ...................................................................5-29

Heating Element ................................................. 5-30

Thermostats ....................................................... 5-31

Water V alve ........................................................5-31

Air Water Inlet ....................................................5-32

Upper Rack Removal .......................................... 5-33

Tub Wheels ........................................................5-33

Turbidity Sensor.................................................. 5-33

Drain Pump ........................................................ 5-34

Wash Motor Assembly ....................................... 5-34

Appendix A

Installation Instructions ....................................... A-2

Appendix B

Jenn-Air User’s Guide ......................................... B-2

Appendix C

MDB-3 User’s Guide........................................... B-2

Appendix D

MDB-4 User’s Guide........................................... D-2

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 3

Page 4

Important Safety Information

WARNING

!

To avoid personal injury or death from improper

servicing, make sure you read and understand the

descriptions and meaning of various safety symbols,

words and labels used in this manual, before

attempting any procedures described in the manual.

Failure to understand and comply with safety

information may result in severe personal injury or

death.

General Information

This Service Manual describes the operation,

disassembly , troubleshooting, and repair of Maytag

Dishwashers. It is intended for use by authorized

servicer’s who troubleshoot and repair these units.

NOTE: It is assumed that users of this manual are

familiar with the use of tools and equipment used

to troubleshoot and repair electrical, and

mechanical systems; and understand the

terminology used to describe and discuss them.

®

Related Publications

This is a base service manual, covering a range of

similar models. It is intended to be used in conjunction

with the Parts Manual and Technical Sheet covering

specific model being serviced.

General Precautions and Warnings

• Dispose of discarded appliance and shipping or

packing material properly .

• Do not allow children to play in or on dishwasher .

• Do not abuse, sit, stand or play on door or racks of a

dishwasher.

• Use only detergents and rinse agents recommended for

use in a dishwasher.

• S tore dishwasher detergent and rinse agents out of the

reach of children.

• If the dishwasher drains into a food disposer , make

sure disposer is completely empty before running

dishwasher.

• Repairs should be done by a qualified technician.

• Do not tamper with controls.

• Do not touch the heating element during or immediately

after use.

• Load sharp knives with the handles up to reduce the

risk of cut-type injuries or damaging seal.

1-4 16021814 Rev . 0 ©2002 Maytag Appliance Sales Company

To avoid risk of personal injury or death due to

electrical shock:

• Grounding wires and wires colored like grounding

wires are NOT to be used as current carrying

conductors.

• Standard accepted color coding for ground wires

is green or green with a yellow stripe.

• Grounding wires should not be removed from

individual components while servicing, unless

component is to be removed and replaced.

• Replace all removed grounding wires before

completing service.

To avoid death, severe personal injury, fire or

electrical shock when using dishwasher observe

the following:

• Observe all local codes and ordinances.

• Disconnect electrical power to dishwasher before

servicing.

• Connect dishwasher to a grounded metal,

permanent wiring system.

• DO NOT ground to gas line.

• DO NOT ground to cold water pipe if pipe is

interrupted by plastic, non-metallic gaskets, or

other insulating (non-conducting) materials.

• Check with a qualified electrician if you are not

sure this appliance is properly grounded.

• This dishwasher is designed to operate on

regular house current (120 V , 60 Hz). Use a

circuit equipped with a 15 ampere fuse or circuit

breaker. Use a 20 ampere fuse if dishwasher is

connected with a food waste disposer.

• Under certain conditions, hydrogen gas may be

produced in a hot water system that has not

been used for 2 weeks or more. HYDROGEN

GAS IS EXPLOSIVE. If hot water system has

not been used for such a period, before using

dishwasher, turn on all hot water faucets and let

water flow from each for several minutes. This will

release any accumulated hydrogen gas.

HYDROGEN GAS IS FLAMMABLE. Do not

smoke or use an open flame during this time.

• Do not store or use combustible materials,

gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

• Do not wash plastic items unless marked

"dishwasher safe" or the equivalent. If not

marked, check with manufacturer for

recommendations. Items that are not dishwasher

safe may melt and create a potential fire hazard.

• To avoid entrapment and/or suffocation, remove

door or door latch mechanism from any

dishwasher that is discarded or not in use.

WARNING

!

WARNING

!

Page 5

Important Safety Information

:

e

s

.

s

PRECAUCIÓN

Desconecte la

energía eléctrica

antes de darie

servicio.

ATENCIÓN:

Solamente use

conductores de

cobre.Use cables d

suministro adecuado

para 75° (167°F).

CAUTION:

Disconnect electrical power

before servicing.

ATTENTION:

Use copper conductors only.

Use supply wires suitable for 75°C (167°F).

ATTENTION:

Débrancher de

l'alimentation électrique avant tout dépannage

ATTENTION:

Utiliser des conducteurs en

cuivre uniquement. Utiliser des fils

d'alimentationpouvant supporter une

température de 75°C (167°F).

GROUNDING: This unit must

be grounded in accordance with local

and/or national electric codes.

WARNING: The heating

element, drainpump, harness clip,

dispenser mount, and water valve are

intentionallynot grounded and may

present a risk of electrical shock only

during servicing. Discharge motor

capacitior before servicing. Failureto

follow these instructions can result in

death, seriousinjury,fire,or electrical

shock.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 1-5

MISE Á LA TERRE:

doit être relié à la terre conformément aux

codesélectriques locaux et/ou nationaux.

AVERTISSEMENT:

la pompe de vidange, l'attache du hamais, la

monture de distributeur et l'électrovanne ne

sont pas reliés à la terre intentionnellement et

peuvent présenterdes risques d'électrocution

uniquement en cas d'interventionde service

aprés-vente.Déchargerle condensateur

avanttoute intervention. Le non-respect de

ces consignes peut entrainer la mort, des

blessures graves, l'incendie ou l'électrocution.

Cetappareil

La résistance,

CONEXIÓN A TIERRA: Esta

unidad debe estar conectada a tierrade

acuerdo con los códigos eléctricos locales y

nacionales.

ADVERTENCIA: El elementocalentador,

la bomba de drenado,el sujetador del arnés,

el montaje del surtidory la válvula de

agua están sin conectara tierra

intencionalmente podrían presentar un riesgo

de descargas eléctricas cuando se les da

servicio solamente. El no seguir estas

instruccionespodría causarla muerte, lesione

graves, incendios o descargas eléctricas.

Page 6

Important Safety Information

p

e

u

t

c

o

e

m

n

t

m

r

a

a

î

n

c

n

e

o

d

r

n

e

s

la

p

t

e

m

A

a

m

u

o

V

v

m

e

r

E

t

,

e

n

R

t

d

n

e

p

t

r

e

s

T

s

o

I

s

d

S

o

t

b

u

e

l

r

S

r

e

í

s

s

c

t

s

p

s

a

E

e

o

M

e

u

u

n

u

r

r

s

s

s

m

e

E

i

s

a

e

o

t

a

r

N

n

n

e

n

g

l

n

a

T

e

à

e

r

r

s

c

a

m

:

g

i

v

m

o

e

e

u

A

D

i

z

o

n

r

s

a

e

D

é

i

u

a

,

r

d

n

n

c

l

t

V

b

o

s

t

'

i

e

r

e

i

n

,

E

a

t

q

v

l

n

o

u

f

F

o

c

e

e

R

d

o

s

s

c

e

i

a

n

T

h

o

s

i

d

i

o

l

l

u

d

E

e

e

'

a

l

'

e

i

n

r

a

r

s

e

e

N

a

l

t

p

p

e

p

o

s

p

i

p

p

C

v

o

e

a

t

o

u

u

a

m

a

é

g

w

r

l

r

I

n

e

r

e

fo

s

'

a

A

t

e

p

i

i

é

v

t

r

o

l

l

l

l

d

l

e

:

W

o

i

n

d

o

e

e

s

h

e

w

c

s

D

u

a

é

d

,

A

t

d

s

b

tr

e

e

s

t

e

o

i

n

R

s

i

s

t

o

r

a

h

s

c

c

in

c

a

i

t

e

c

c

N

o

n

s

o

u

e

t

o

q

d

c

t

n

I

n

e

n

u

e

n

i

N

r

é

h

o

d

e

v

n

e

b

é

i

n

e

n

i

G

c

e

e

.

c

o

t

n

c

s

r

a

t

r

t

.

s

:

e

e

L

u

a

t

t

e

n

e

r

o

l

io

d

c

c

a

d

h

t

l

a

d

D

n

.

e

n

i

o

e

.

é

s

o

e

i

s

n

L

C

.

c

n

n

e

s

c

e

a

L

s

n

c

a

o

-

e

o

r

p

n

e

r

c

a

n

g

c

a

e

a

r

r

í

o

s

e

s

g

g

n

m

c

c

p

n

í

a

e

a

i

t

t

c

e

a

c

n

o

a

o

r

s

t

m

n

c

e

e

t

e

r

l

t

s

l

e

p

a

s

a

d

é

l

s

e

d

u

c

é

o

n

o

e

e

l

c

w

d

d

n

n

n

t

t

r

t

e

e

s

c

i

n

i

r

e

c

e

a

c

i

r

d

é

o

r

e

a

c

g

t

e

s

d

a

b

a

l

n

í

e

.

s

e

r

e

t

a

u

c

E

.

f

l

e

c

r

.

r

o

a

l

o

t

o

s

t

h

s

r

l

L

n

n

r

o

m

o

d

s

,

o

e

e

n

e

s

r

s

i

g

s

v

i

q

a

n

e

s

e

i

u

y

c

l

a

r

e

r

c

a

e

i

o

g

v

i

e

r

p

s

u

i

o

e

u

c

.

e

m

a

s

i

i

c

r

n

E

s

t

e

g

l

a

i

t

i

n

s

c

i

n

o

j

.

r

u

t

a

E

o

e

r

n

a

y

s

l

c

s

e

t

t

,

i

c

r

o

i

v

d

f

i

n

t

e

r

s

r

l

e

l

e

t

o

e

,

r

n

l

a

c

u

e

f

o

o

c

i

c

t

r

c

t

e

n

c

i

c

r

r

t

r

e

o

o

ó

o

l

e

e

n

n

n

l

l

c

e

t

i

e

p

r

c

c

tr

s

o

o

t

o

i

c

l

r

d

i

e

i

c

r

a

s

s

í

l

a

a

e

t

l

n

s

á

h

e

p

o

r

o

g

w

c

i

k

z

e

.

e

r

d

i

a

s

t

d

a

i

s

l

c

l

t

o

i

m

n

n

e

e

s

c

u

t

e

n

d

t

i

.

l

WARNING:

Disconnect power before servicing. Electronic control is energized at all times until

power is disconnected. Capacitors on control may remain active after electrical power is disconnected.

Failure to follow these instructions can result in death, serious injury, fire, or electrical shock.

ADVERTENCIA:

Desconecte la energí antes de darle servicio. El control electrónico está

energizado todo el tiempo hasta que se desconecta la energía. Los capacitores del control podrían

permanecer activos después de desconectar la energía eléctrica. El no seguir estas instrucciones

podrí causar la muerte, lesiones graves, incendios o descargas eléctricas.

AVERTISSEMENT:

Débrancher avant toute intervention. La commande électronique est

constamment sous tension à moins que l'appareil ne soit débranché. Les condensateurs de la

commande peuvent rester sous tension une fois l'appareil débranché. Le non-respect de ces consignes

peut entraîner la mort, des blessures graves, l'incendie ou l' électrocution.

1-6 16021814 Rev . 0 ©2002 Maytag Appliance Sales Company

Page 7

Section 2. Electrical Equipment & Testing

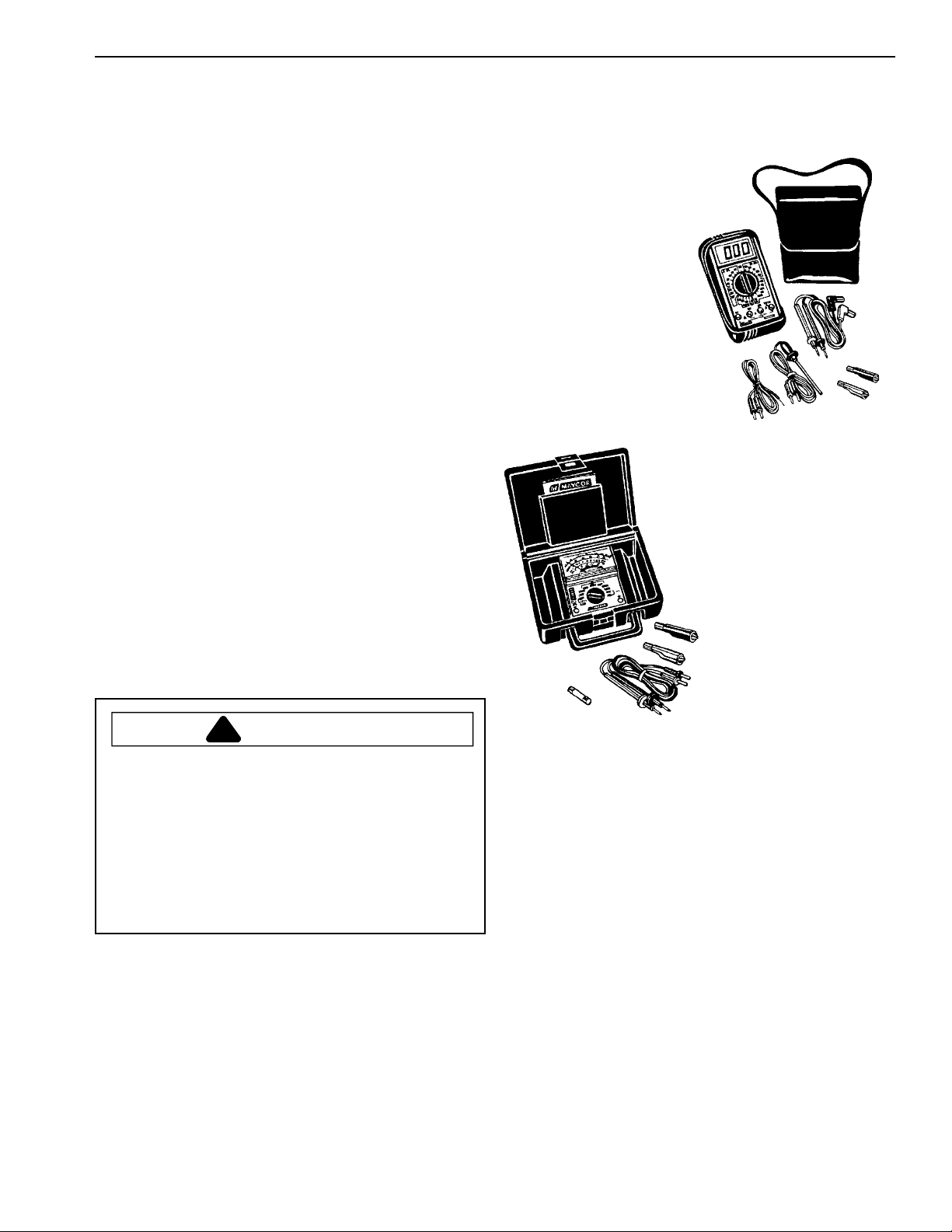

Electrical T est Equipment

The equipment required to service these models depends

largely upon the condition encountered. Locating a

malfunction will often require the use of electrical testing

equipment such as:

Appliance T est Meter

Clamp-On Ammeter

Motor T est Cord

Appliance T est Meter

An Appliance Test Meter is a multi-purpose tester

combining an AC/DC volt age tester with a multi-range

ohmmeter.

The easiest means of testing electrical components is

"Continuity Testing" with an appliance meter . Continuity

is a complete or continuous path from one point in an

electrical circuit to another.

Digital Test Meter

can be used to check for open

or closed circuits, measure

resistance, AC and DC volts,

and temperature.

Analog T est Meter

can be used to check for

open or closed circuits,

measure resistance, AC and

DC volts, and temperature.

The obvious advantages of being able to check electrical

components and circuits without power applied is one of

the features of the Ohmmeter. Multiple ranges allow

accurate determination of resistances of both single

components and entire circuit paths. Resistance is

measured in "Ohms."

WARNING

!

T o avoid risk of personal injury or death due to

electrical shock:

Always be sure the power has been disconnected

before making resistance measurements. Failure to

do so will also result in damage to your meter!

Internal batteries provide all the power needed to

make resistance checks. They should be checked

at least once a year and replaced as needed.

Continuity T esting: is a process of eliminating electrical

components involved in a given function of the appliance,

until the inoperative part is found. By reviewing the list of

possible electrical problems under a given condition, and

then performing appropriate continuity checks of the parts

involved, you should be able to locate the electrical

component which is inoperative.

NOTE: When checking components or circuit paths for

continuity , external wiring should be disconnected to

eliminate false readings through external paths. Isolate

what you want to test.

©2002 Maytag Appliance Sales Company 16021814 Rev. 0 2-7

Page 8

ELECTRICAL EQUIPMENT & TESTING

VOLTAGE CHECKS

Generally , these checks will consist of taking readings

at the wall receptacle in order to determine the

availability of voltage to the product. V oltage checks on

individual components of a product are not

recommended due to the possibility of electrical shock.

Component part testing is best accomplished through

continuity checks with an Appliance Test Meter.

NOTE:

indicated range may cause permanent damage to the

meter. T o prevent damage, first select highest range and

then lower the range for readings which fall within the

lower scale.

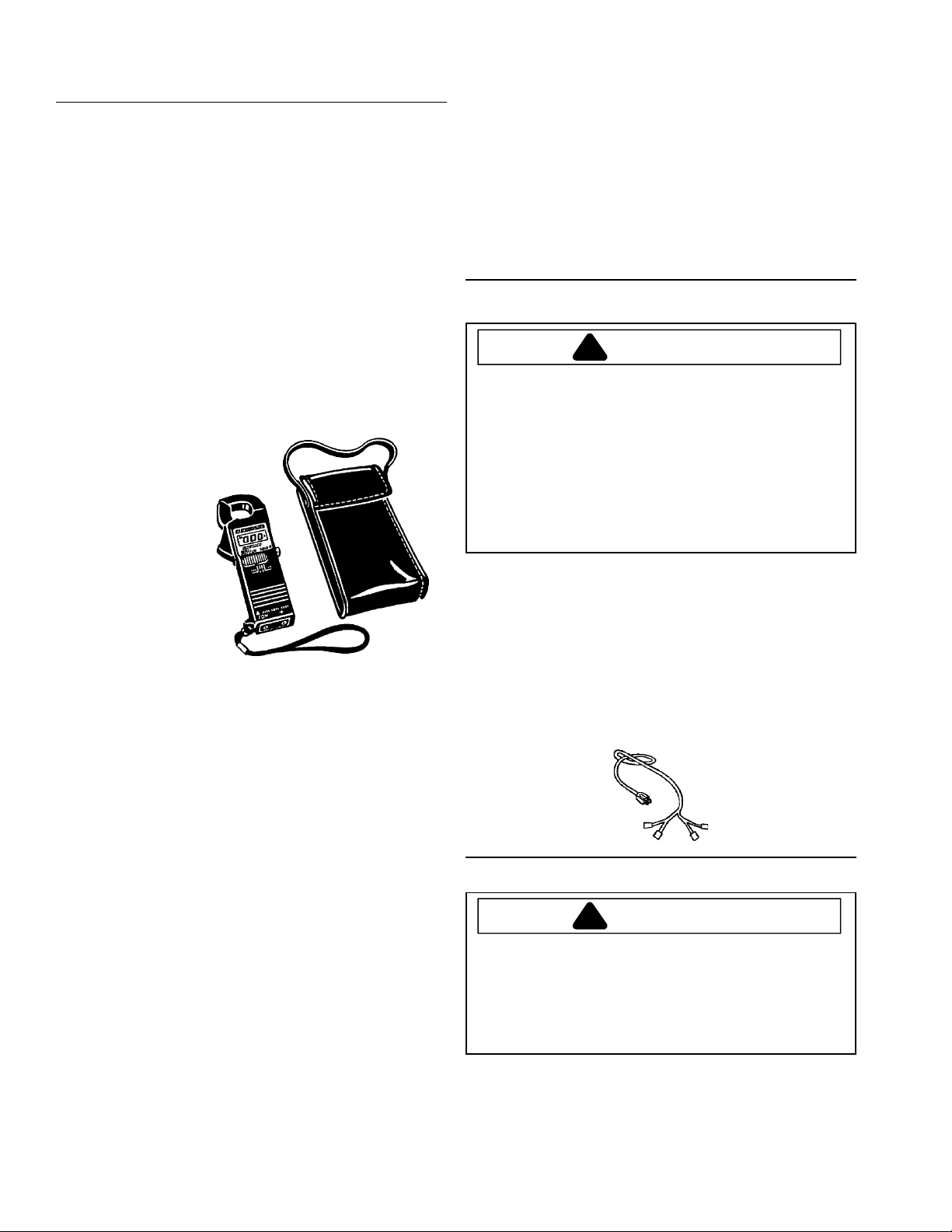

Clamp-On Ammeter

can be used to detect shorts.

Overloads on the circuit breaker

or fuse can be traced

to either the appliance

or circuit breaker by

checking the current

draw.

Each circuit in an appliance has a "Normal" current

draw, which is an indication of the performance of that

circuit. Current draw levels of less than or more than

normal give clues to possible malfunctions. The clampon ammeter measures these circuits without breaking

the circuit by measuring the strength of the magnetic

field developed around each conductor. Current is read

by separating the conductors and clamping the jaws of

the ammeter around each conductor on which current is

read. Low amperage readings indicate problems, such

as damaged heating elements, etc. High amperage

readings indicate the unit being tested is operating under

an increased mechanical or electrical load.

NOTE: Overloads on a circuit breaker or fuse can be

traced to the product being tested or the circuit breaker

(or fuse) by checking the products current draw . If the

amperage reading is less than the breaker reading, the

breaker or fuse box is at fault.

Use of the meter on voltage higher than the

Use of Ammeter on dishwasher:

1. Motor Current - the reading can be taken at the

leads on the motor start relay or at the male connector.

2. Heating Element Current - The reading can be

taken using either lead to the element.

Motor Test Cord

DANGER

!

T o avoid risk of personal injury or death due to

electrical shock:

• Disconnect electrical power to dishwasher before

servicing.

• Always plug test cord into a properly grounded

receptacle.

• Always make connection to components before

plugging test cord into receptacle.

A motor test cord may be used to electrically check

operation of the various electrical components without

removing them from the unit. Testing in this manner

merely determines whether or not the part will function

independently of other electrical components. In order to

make accurate tests, proper connection of the motor test

cord is important. With the aid of the drawings under

Drive Motor Test, installation of the motor test cord may

be done quickly and accurately .

Grounding and Polarity

DANGER

!

T o avoid risk of personal injury or death due to

electrical shock:

• Do not cut or remove the grounding prong from any

plug.

The receptacle used for all Maytag products operating on

120 V AC must be properly grounded and polarized.

The power cord used on the appliances should be

equipped with a three (3) prong polarized grounding plug

2-8 16021814 Rev . 0 ©2002 Maytag Appliance Sales Company

Page 9

Electrical Equipment & Testing

for protection against shock hazard and should be

plugged directly into a properly grounded and polarized

receptacle.

It is the responsibility of the person installing the

appliance to assure it is adequately grounded and

polarized at the point of installation, taking into

consideration local conditions and requirements. In

cases where only a two (2) prong receptacle is available,

it is the personal responsibility of the consumer to have it

replaced with a properly grounded three (3) prong

receptacle. All grounding and wiring should be done in

accordance with National, State, and Local codes.

NOT USE AN ADAPTER PLUG WITH THIS

APPLIANCE.

DO

ELECTRICAL TESTS

WARNING

!

T o avoid risk of personal injury or death due to

electrical shock:

Wax Motor Check

Detergent / Rinse Aid Dispenser

A single Wax Motor is used to activate both the release of

the Detergent Cup Cover and the rinse aid from the

reservoir.

T o check the operation of the W ax Motor, removal from

the Dispenser Retainer or Inner Door is not necessary .

First, snap the Detergent Cup Door shut. Then, connect

a Power Test Cord across the two terminals of the Wa x

Motor. Plug the Power Test Cord into a 120 VAC

receptacle. The plunger in the center of the Wax Motor

should "push out" and actuate the Dispenser in

approximately 45-60 seconds. Remove voltage to the

Wax Motor and allow the plunger to retract into the Wax

Motor. Apply voltage to the W ax Motor again and observe

for proper lifting of the rinse aid plunger .

• Disconnect electrical power to dishwasher before

servicing.

• Always plug test cord into a properly grounded

receptacle.

• Always make connection to components before

plugging test cord into receptacle.

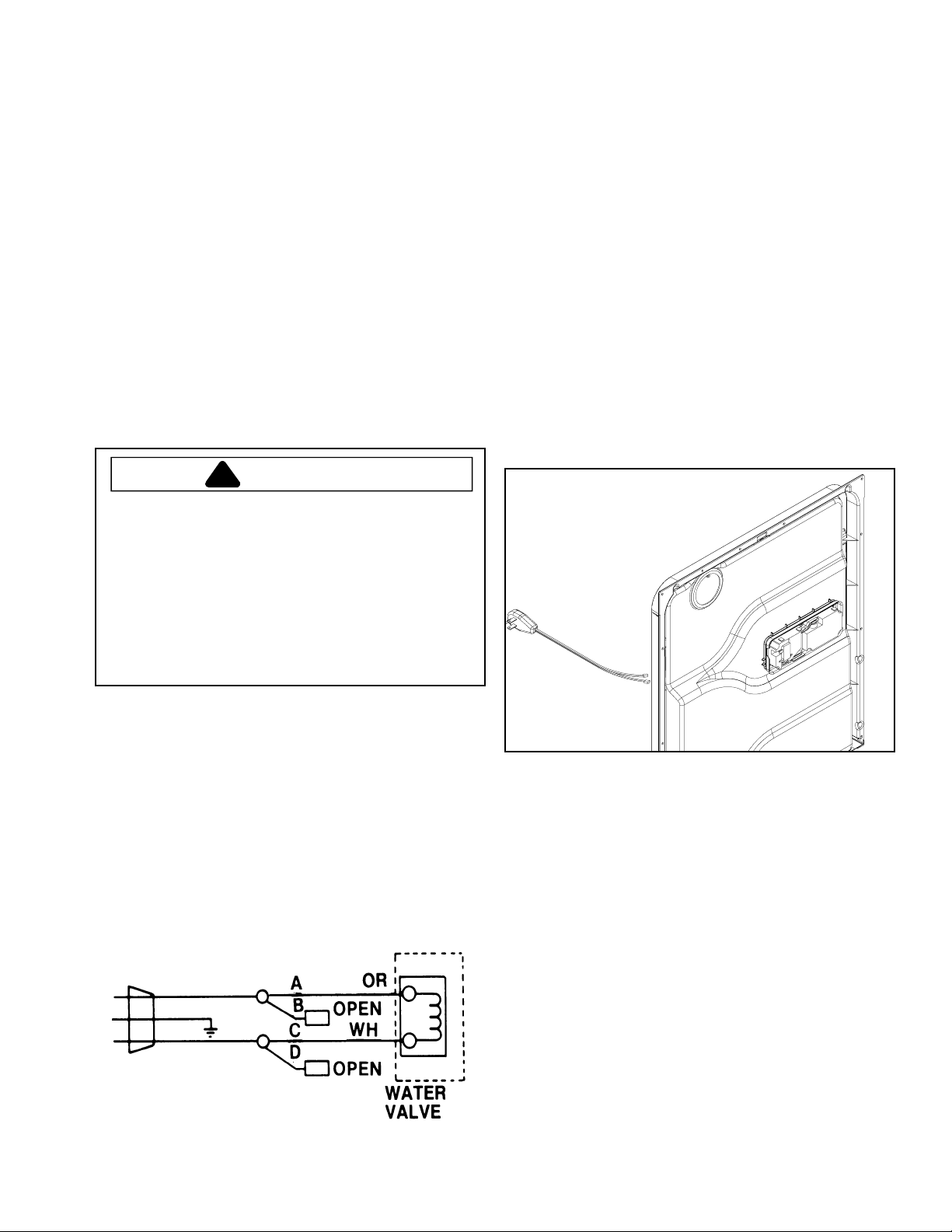

WATER VALVE TEST

The Water V alve may be checked without removing it from

the Dishwasher.

T o check the W ater V alve for operation, hook up the test

cord as follows:

©2002 Maytag Appliance Sales Company 16021814 Rev. 0 2-9

Page 10

Electrical Equipment & Testing

Wax Motor Check- Vent

A single continuous duty wax motor is used to operate

the vent.

WARNING

!

T o avoid risk of personal injury or death due to

electrical shock:

• Disconnect electrical power to dishwasher before

servicing.

• Always plug test cord into a properly grounded

receptacle.

• Always make connection to components before

plugging test cord into receptacle.

Connect a Power Test Cord across the two terminals of

the Wax Motor . Plug the Power Test Cord into a 120 V AC

receptacle. The punger should extend (push out) and

force the Vent Flap tight against the vent opening in

approximately 45-60 seconds. When power is removed

from the Wax Motor , the plunger should retract along with

the Vent Flap, opening the vent.

2-10 16021814 Rev . 0 ©2002 Maytag Appliance Sales Company

Page 11

Section 3. Cycles & Options

Qu ietSeries300

Cancel

DELAY

1-9

Heating Delay

Sanitized

3

Heated

Dry

Options

Sanitize

Tough

Scrub

Extra

Rinse

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

Washing

Rinse

Only

Drying

Clean

Auto

Clean

START/

Covers all other models

Auto

Clean

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

Rinse

Only

Quick

Wash

Heated

3 Sanitize

Dry

Options

Extra

Rinse

Tough

Scrub

Plus

160°

Wash

Clean

Sanitized

MDB9600 Only

See User's Guide for specific operation.

Cycle Description

Auto Clean Designed to auto select the number of fills and length of wash time based on soil level

of the dish load. Water usage ranges from 3 to 8 gallons.

Heavy Wash Designed to provide a longer cycle for washing items with heavy

food soils. Water usage is 8 gallons.

Normal Wash Designed to wash loads containing dishes with normal amounts of food soils.

Water usage ranges from 3 to 6 gallons.

Light Wash Designed to wash loads containing dishes that are lightly soiled. Water usage is 5

gallons.

Quick Wash Designed for light food soils. The cycle ends with a rinse and does not include drying.

Water usage is 4 gallons.

Rinse Only Rinses dishes being held until the dishwasher is full, and another

cycle is selected. This cycle helps reduce the potential for development of odors.

Water usage is 2 gallons.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 3-11

Page 12

Cycles & Options

Qu ietSeries300

Cancel

DELAY

1-9

Heating Delay

Sanitized

3

Heated

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

Washing

Rinse

Only

Drying

Clean

Auto

Clean

START/

Covers all other models

Auto

Clean

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

Rinse

Only

Quick

Wash

Heated

3 Sanitize

Dry

Options

Extra

Rinse

MDB9600 Only

See User's Guide for specific operation.

Option Description

T ough Scrub™ This option adds fills, heat and/or wash time to the

Tough Scrub Plus™ wash cycle.

Dry

Options

Sanitize

Tough

Scrub

Plus

Tough

Scrub

160°

Wash

Extra

Rinse

Clean

Sanitized

Sanitize This option monitors cycles for sanitization.

Extra Rinse This option adds an extra rinse to the cycle which helps in hard water situations.

160° Wash This option raises temperature in the final rinse to 160° F.

Heated Dry This option improves drying results by turning the heating element on and off during

the dry portion of the cycle.

Delay Delays the start of the dishwasher based on user input.

Control Lock Lock's the control touch pads from unwanted usage. This option does not lock the

door.

3-12 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Page 13

Cycles & Options

Auto

Clean

Heavy

Wash

Heavy

Wash

Normal

Wash

Cycles

Wash

Normal

Wash

Light

Cycles

Light

Wash

Washing

Rinse

Only

START/

Cancel

Drying

Rinse

Only

Clean

Auto

Clean

START/

Covers all other models

Quick

Wash

QuietSeries 300

Qu ietSeries300

Cancel

Heated

3

Dry

DELAY

1-9

Heating Delay

Sanitized

Sanitize

DELAY

Heated

3

Dry

Options

Extra

Rinse

1-9

Options

Sanitize

Tough

Scrub

Plus

Tough

Scrub

160°

Wash

Extra

Rinse

Sanitized

Clean

MDB9600 Only

Display Description

Clean The "Clean" light illuminates at the end of the cycle and remains on until the door has

been open continuously for 30 seconds.

Drying The "Drying" light illuminates until the cycle is complete.

Washing The "Wash" light illuminates through all the rinse and wash portions of the cycle.

Heating Delay The "Heating Delay" light illuminates when the cycle is being extended to heat the

water.

Clean/Sanitized These two lights illuminate from the end of cycle until the next cycle is selected,

or the door has been open continuously for 30 seconds.

Delay The "Delay" light will illuminate whenever a delay count down is in progress, or until

the "Delay" pad is pressed again.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 3-13

Page 14

Cycles & Options

Heavy

Wash

Heavy

Wash

Normal

Wash

Normal

Wash

Cycles

Light

Wash

Cycles

Light

Wash

Cycles

Washing

Rinse

Only

Washing

Rinse

Only

Washing

Drying

Drying

Drying

Qu ietSeries100

START/

Cancel

DELAY

2-4-6

MDB5600

ENN-AIR

START/

Cancel

Qu ietSer ies100

DELAY

JDB4000

2-4-6

Sanitized

Clean

2

4

6

2

4

6

3

Sanitized

Clean

3

Sanitized

Clean

Heated

Dry

Heated

Dry

Options

Sanitize

Options

Sanitize

Options

Tough

Scrub

Tough

Scrub

Extra

Rinse

Extra

Rinse

Heavy

Wash

Heavy

Wash

Heavy

Wash

Normal

Wash

Normal

Wash

Normal

Wash

Light

Wash

Cycles

Light

Wash

Cycles

Light

Wash

Rinse

Only

Washing

Rinse

Only

Washing

Rinse

Only

Drying

Drying

Clean

START/

Cancel

DELAY

2-4-6

MDBH950

MDBF550

QuietSeries 200

Auto

Clean

START/

Cancel

MDB6600

Auto

Clean

START/

Cancel

2

4

6

Sanitized

Clean

DELAY

2-4-6

2

4

3

6

Qu ietSeries300

Heating Delay

Sanitized

DELAY

1-9

3

Heated

Dry

Heated

Dry

Heated

3

Dry

Options

Sanitize

Options

Sanitize

Sanitize

Tough

Scrub

Tough

Scrub

Extra

Rinse

Extra

Rinse

Extra

Rinse

MDB7600

MDB8600

3-14 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Page 15

Cycles & Options

Auto

Clean

Heavy

Wash

Heavy

Wash

Heavy

Wash

Normal

Wash

Normal

Wash

Cycles

Cycles

Normal

Wash

Light

Wash

Light

Wash

Cycles

Light

Wash

Washing

Rinse

Only

Washing

Rinse

Only

Drying

Drying

Rinse

Only

Clean

Clean

Auto

Clean

Auto

Clean

Quick

Wash

START/

Cancel

MDBH970

START/

Cancel

MDBF750

Heated

3

Qu ietSeries200

Heating Delay

Sanitized

DELAY

1-9

Qu ietSeries200

Heating Delay

Sanitized

DELAY

1-9

Dry

Sanitize

Heated

3

Dry

Heated

3

Dry

Options

Extra

Rinse

Options

Sanitize

Options

Sanitize

Tough

Scrub

Plus

Tough

Scrub

Plus

Tough

Scrub

160°

Wash

Extra

Rinse

Extra

Rinse

Clean

Sanitized

START/

Cancel

QuietSeries 300

MDB9600

DELAY

1-9

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 3-15

Page 16

Section 4. Electrical-Mechanical

!

!

Troubleshooting

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

CAUTION

Units covered in this manual are polarized. Reversing polarity of a unit or any of its components will cause

damage. To avoid reversing polarity, any wires disconnected or removed during service must be reconnected to the

same location. T o ensure wires are reconnected to the proper location, tag or otherwise mark the wires before

disconnecting or removing.

Will Not Fill

Water Access Valve

Check to determine if the valve is turned on and water is

available to the Dishwasher . Check water pressure.

Circuit Breaker/Fuse

Check for tripped breaker or blown fuse. Reset or replace

as necessary .

Door Latch

Check door switches for continuity . With door switches

engaged, no continuity , replace switch.

Float

Check float position. If in the up position, check for

obstruction or disengagement from the Float Switch Arm.

Float Switch

If the float is in the down position, check the switch for

continuity . If no continuity, replace the Float Switch.

Water Valve

Check Solenoid for continuity . No continuity , replace

Water V alve. Check Inlet Screen for restrictions. Clean

screen or replace Water V alve as necessary. (See section

5).

NOTE: Low water pressure can result in failure of the

Water V alve to close properly.

Float

Ensure that the Float isn't stuck in the down position.

Check for sediment buildup. Clean and/or replace as

necessary.

Float Switch Actuator Lever

Check the actuator lever on the bracket. It must be able

to move freely . Repair or replace as necessary . (See

section 5).

Float Switch

Check Float Switch for continuity with the Float in the up

position. If continuity is present and Float moves up and

down freely , replace Float Switch.

POOR WATER CIRCULATION

Water Level - Too Low

Normal water fill should be at level depicted by arrows.

Wiring/Electrical Connections

Check for loose or frayed wire terminal connections.

Check for broken wire within harness. Repair or replace

as necessary .

Overflows

Water Valve

Check that water continues to flow when electrical power

is turned off. If the water continues to flow without

electrical power, replace W ater V alve.

4-16 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Pump Assembly

Check assembly for obstructions or restricted movement

of parts. Repair and/or replace p arts as necessary.

Page 17

Electrical-Mechanical Troubleshooting

!

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Filters

Check for blockage of Strainer , Over Pressure Filter .

Repair as necessary .

Poor Washability

Spray Arms

Check all Spray Arms for blockage of water ports or

cracks. Check for proper rack loading to avoid interference

with Spray Arms during wash action. Check for proper

sealing, fastening, and movement of Spray Arms. Repair

as necessary.

Filters

Check for blockage of Strainer , Primary Filter , and Filter

Support. Repair as necessary .

Detergent Cup Cover

Check spring hinge operation of Detergent Cup Cover.

Repair as necessary .

Detergent Cup

Check operation of Detergent Cup Assembly , W ax Motor,

Actuator, Linkage, and Cover Latch. Rep air and/or replace

parts as necessary. Note: For testing of Wax Motor, see

Section 2.

Rinse Dispenser

Check level of rinse aid in reservoir. Check rinse aid

dispenser setting.

Wash Delivery System

Check manifold and Docking Station for good seal and no

leaks.

Will Not Drain

Pump Assembly

Check pump assembly for obstructions or restricted

parts. Repair or replace p arts as necessary.

Wiring/Electrical Connections

Check for loose or frayed wire terminal connections.

Check for broken wire within harness. Repair or replace

as necessary .

Continues To Drain

Control Board

Check Control Board for proper operation.

Poor Drying

Water Temperature

Check for low water temperature. T emperature should be

between 120 - 150 degrees Fahrenheit. If not, advise

consumer to adjust water heater setting. Encourage

consumer to purge water lines to the dishwasher area

prior to starting the dishwasher .

Cycle Options

Advise consumer use of options available on dishwasher

that improve drying. Options that improve drying are

Heated Dry , and 160° Wash.

Detergent

Check water hardness. Instruct consumer on detergent

usage, one teaspoon of detergent per grain of water

hardness.

Rinse Dispenser

Check level of rinse aid in reservoir. Check dispenser

setting under cap. Use "MAX" for hard water conditions.

Inadequate Drainage

Check Drain Pump for proper operation. Check the drain

pipe connections and repair as needed. If draining into the

garbage disposal, check for unprocessed food waste at

drain hose connection to disposer . Clean out as needed.

Drain Hose

Check drain hose for kink or restrictions. Reroute or

remove any restriction of drain hose as needed.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 4-17

Improper Rack Loading

Check how the consumer loads the dishes into the racks.

Improper loading of some types of dishes can trap water

which causes dishes not to dry.

Heating Element

Check load readings listed on Technical Sheet located

behind T oe Panel.

Page 18

Electrical Mechanical Troubleshooting

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Thermostat

Check mating surface of the High Limit Thermostat face

to surface of tub enclosure. Contact area must be flat.

Adjust the thermostat placement if necessary . See

T echnical Sheet, located behind Toe Panel for thermostat

data.

Noise

Banging

Check for loose Spray Arms. Check for dishes interfering

with Spray Arm rot ation. See loading information in the

User's Guide at the end of this manual.

Water Leaks

Installation

Check Dishwasher for proper leveling and squareness in

cabinet.

Door Alignment

Check proper alignment of Door Liner to Door Gasket.

Door Gasket

Check for torn or damaged Door Gasket. Repair or

replace as necessary .

Hoses

Check for loose hose clamps or hoses that leak. Tighten

hose clamps or replace hoses as needed.

Spray Arms / Manifold

Check for cracks and replace as necessary .

Detergent / Rinse Aid Dispenser Seal

Check Rinse Aid Dispenser Seal for proper positioning or

cracking. Reposition or replace as needed.

Water Valve

Check Water V alve body for damage and leaks. Replace if

necessary . Also, check plumbing connections to Water

V alve.

Wash Motor Assembly

Check for water leak between Pump Assembly and tub.

Hammering/Chattering

Check Water V alve for , noise, low voltage, or high valve

coil resistance. Replace W ater Valve if needed. Also,

check incoming water supply line for proper size and

pressure. Make sure the supply line is secured.

Grinding

Check for objects in Pump Assembly. If objects are

found, inspect Pump Assembly for damage. Repair as

needed.

Vibration

Check components for source of vibration. Adjust and/or

tighten as needed.

Will Not Start Or Program

Control Board

Check incoming voltage to Control Board.

Membrane Switch

Check for proper operation of Membrane Switch. See

membrane readings on the Technical Sheet located

behind toe panel.

NOTE: Make sure the pin connectors are making proper

contact with pins on the Control Board. If the

voltage is correct into the Control Board, and the

board will not activate, replace board.

Will Not Fill

Drain Pump Assembly

Check Pump Assembly Housing for cracks. Check Drain

Pump "O" ring for leaks.

4-18 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Water Valve

Check Water V alve circuit. See Technical Sheet for water

valve data located behind toe panel.

NOTE: Make sure the pin connectors are making proper

contact with pins on the Control Board.

Page 19

Electrical Mechanical Troubleshooting

!

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Will Not Wash

Wash Motor

Check Wash Motor circuit. See data listed on the

T echnical Sheet, located behind toe panel.

Will Not Drain

Drain Motor

Check Drain Motor circuit. See data listed on the

T echnical Sheet, located behind Toe Panel.

Will Not Dry

Vent Assembly

Check V ent Assembly for proper operation. Check W ax

Motor.

Heating Element

Check Heating Element circuit. See data listed on the

T echnical Sheet, located behind Toe Panel.

Manual Function Test

See T echnical Sheet, located behind T oe Panel.

Field Service T est

See T echnical Sheet, located behind T oe Panel.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 4-19

Page 20

Section 5. Service and Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

The following paragraphs describe how to disassemble

unit under test. Disassembly to some extent is required

to install unit, to perform troubleshooting procedures, and

to remove and replace failed components.

Component names used throughout disassembly

procedures are the same as those used in Parts

Manuals.

For quicker reassembly , disassemble unit under test only

to extent necessary to troubleshoot and repair . Unless

noted, reassembly is opposite of disassembly .

WARNING

!

T o avoid risk of personal injury or death due to

electrical shock, ground wires and wires colored like

ground wires are NOT to be used as current carrying

conductors. The standard accepted color coding for

ground wires is green or green with a yellow

stripe. Electrical components such as the water valve

and motor are grounded through an individual wire

attached to the electrical component. Ground wires

should not be removed from individual components

while servicing, unless the component is to be

removed and replaced. It is extremely important to

replace all removed ground wires before completing

service.

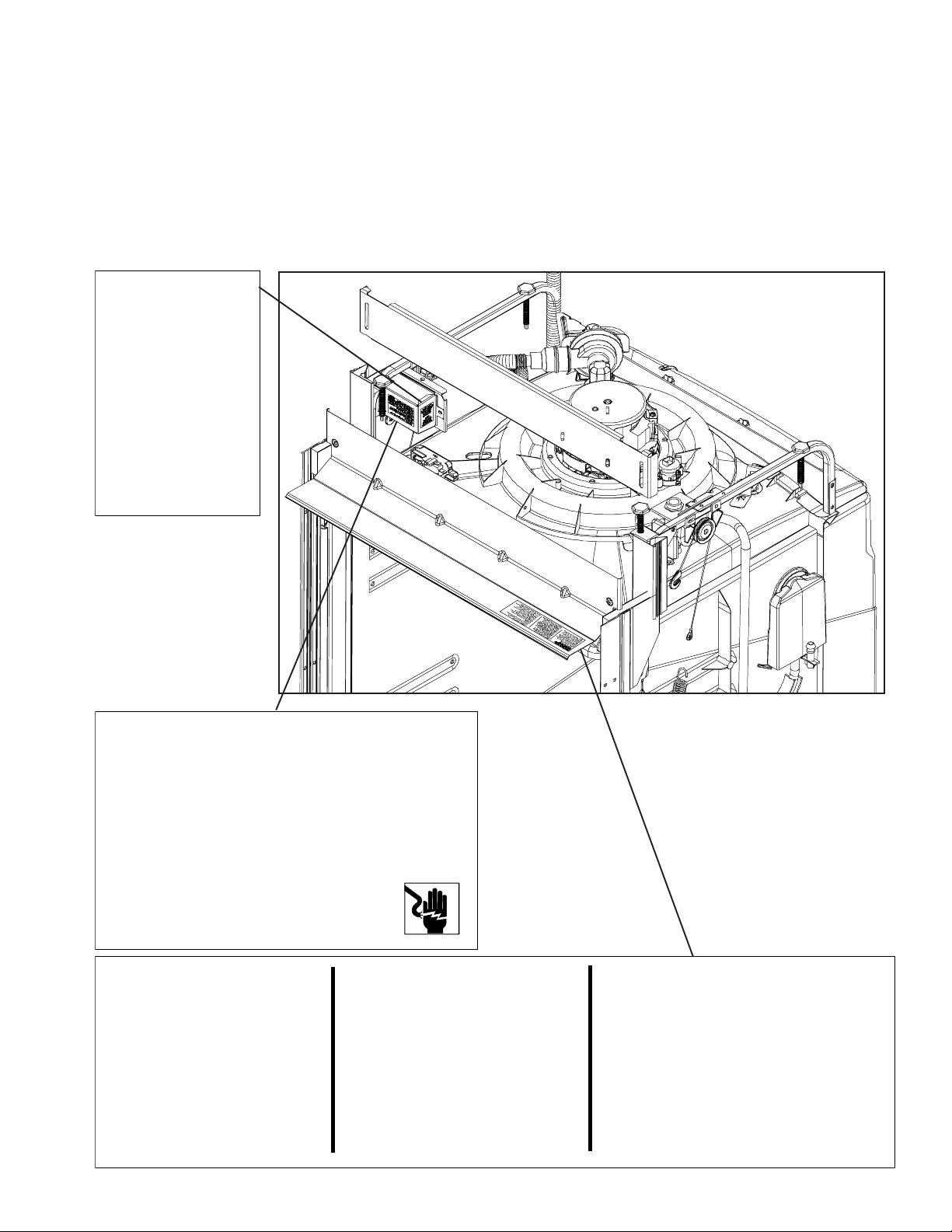

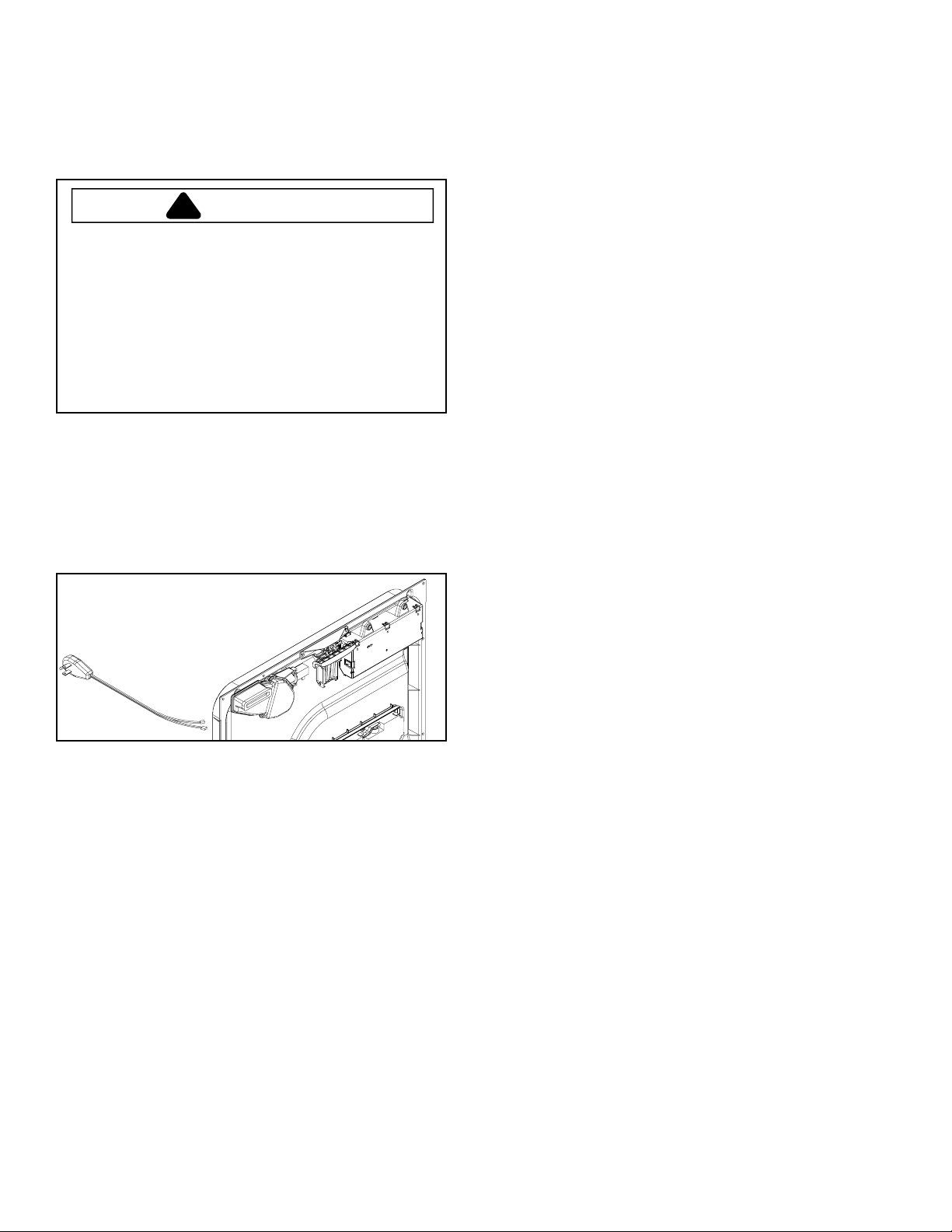

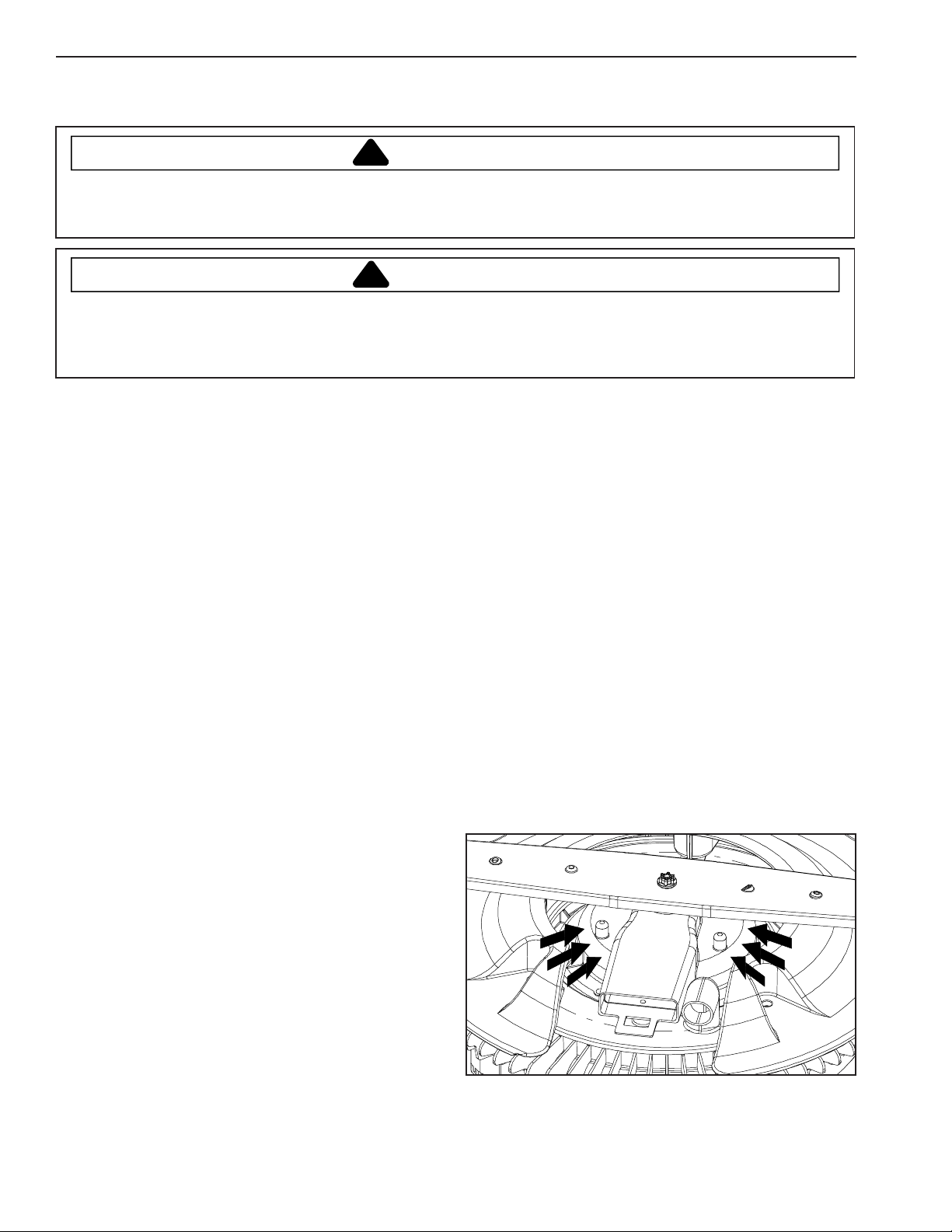

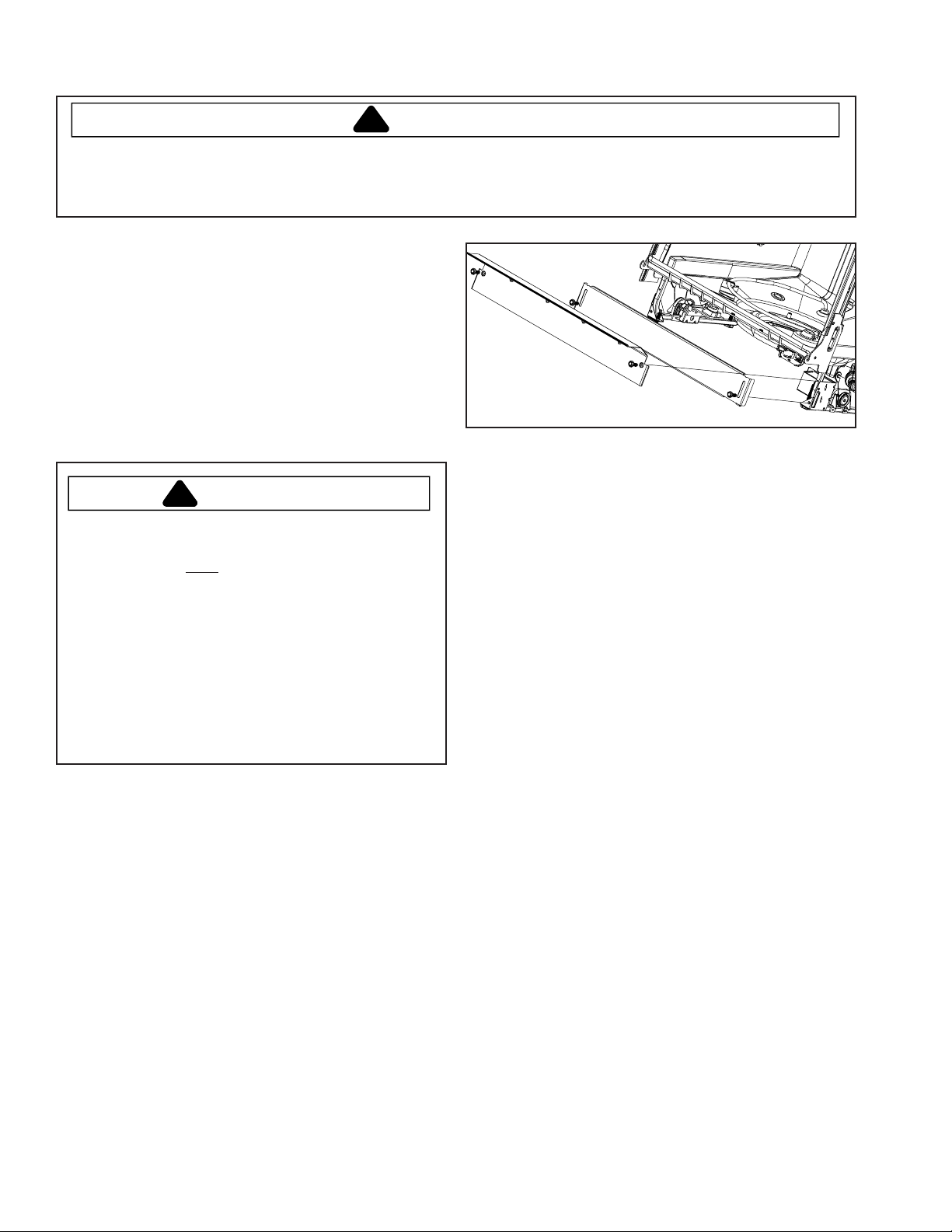

Front Support and Toe Panel Removal

Removal of Front Support and T oe Panel will allow access

to the Water Valve, Float Switch Assembly, Electrical

Junction Box, hoses, thermostats, St art Capacitor and

Motor/Pump Assembly.

Removal

1. Disconnect power to the machine.

2. The Front Support Panel is held by 2 screws, one

each side. Remove both screws.

3. The Toe Panel is held by 2 screws, one each side.

5-20 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Page 21

Service and Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

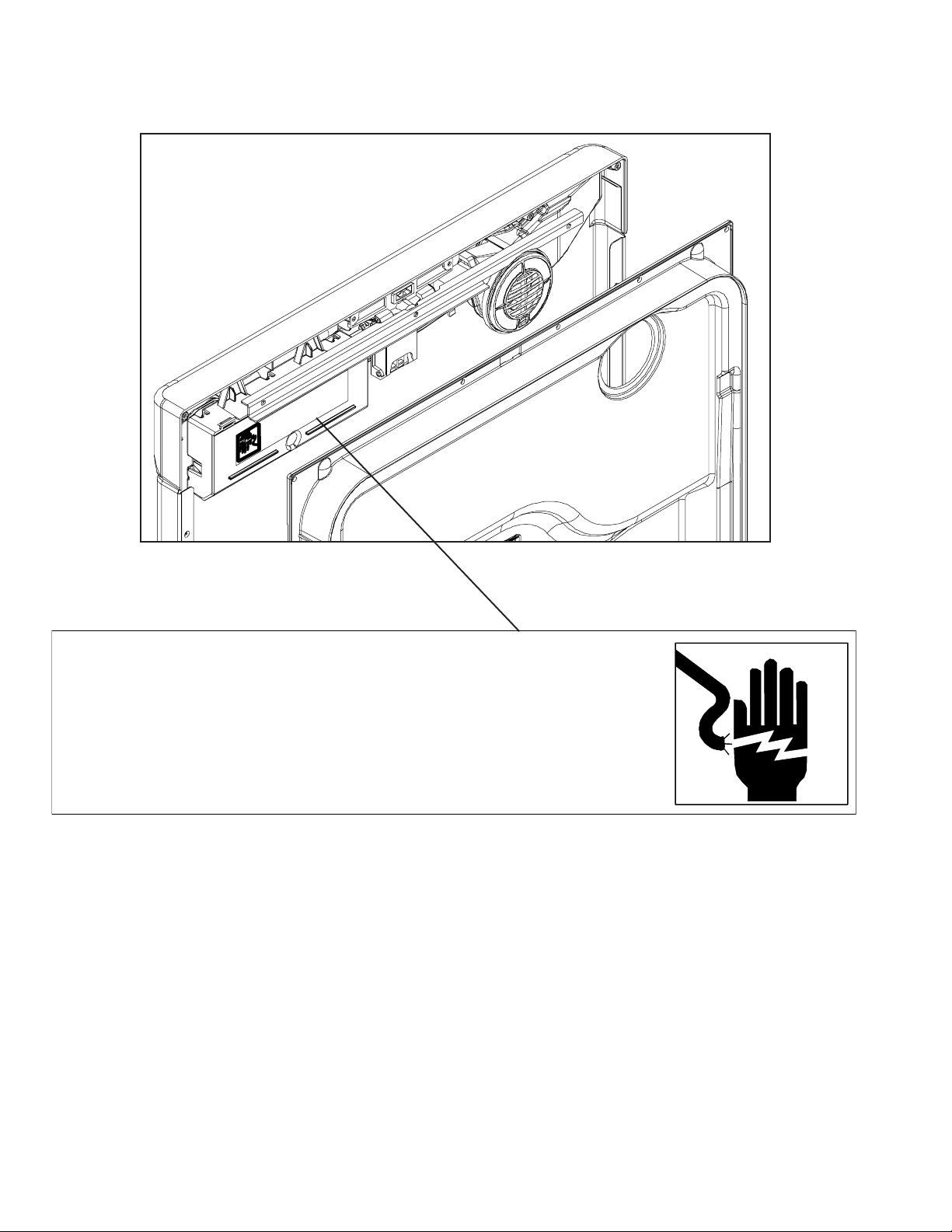

Inner Door Panel

Removal of the Inner Door Panel will allow access to the

Microprocessor Board, Door Switches, Detergent / Rinse

Aid Dispenser, and Vent Assembly.

Removal

1. Disconnect power to the machine.

2. Open the Dishwasher door.

3. Remove the 1 1 T orx™ screws along the sides and

top of the Inner Door Panel.

4. Separate the Inner Door Panel from the Outer Door .

5. Disconnect wires from the Vent and Dispenser W ax

Motors before pulling the Inner Door Panel away

from the Dishwasher.

IMPORTANT: When replacing Inner Door Panel, remove

Inner Door reinforcement, Bottom Seal and install on

new panel.

Detergent / Rinse Dispenser Mechanism

and Reservoir

Checking Operation

1. Disconnect power to the machine.

2. Remove the Inner Door Panel. (See paragraph Inner

Door Panel removal).

3. Snap the Detergent Door shut.

4. Gently lift the lever of the dispenser mechanism until

a click is herd. The Detergent Door releases. Release the lever.

5. Lift the lever again. Now the actuator will lift the Rinse

Aid Plunger.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 5-21

Page 22

Service and Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

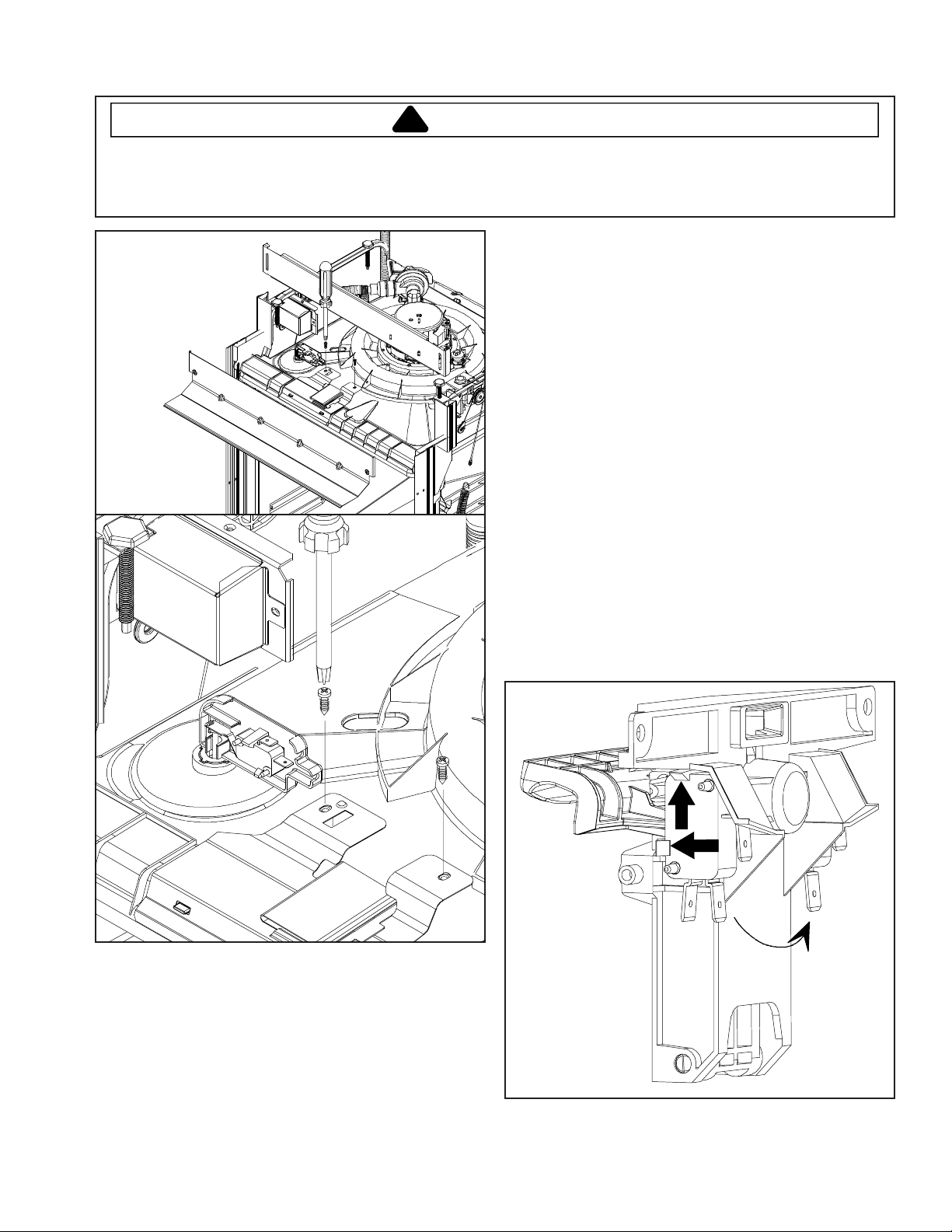

Wax Motor Detergent / Rinse Dispenser

Removal

1. Disconnect power to the machine.

2. Remove the Inner Door Panel. (See paragraph Inner

Door Panel removal).

3. Remove the 6 mounting screws securing the

Detergent Dispenser mounting bracket.

4. T o remove the W ax Motor , pry out of retainer.

NOTE: It is not necessary to remove Detergent

Dispenser before removing Wax Motor .

Vent

The Vent is located on the Inner Door Panel to allow

moisture to be vented outside of the Dishwasher during

the dry cycle.

Removal

1. Disconnect power to the machine.

2. Remove the Inner Door Panel. (See paragraph Inner

Door Panel removal).

3. Rotate V ent Cover counter clockwise 1/4 turn and lift

off.

Wire Cover

The Wire Cover retains the Wire Harness to the bottom of

the Tub. It is located on the bottom side of the Tub.

Removal

1. Disconnect power to the machine.

2. Remove Front Support and Toe Panel. (See paragraph

Front Support and T oe Panel removal).

3. Remove 2 screws securing Wire Cover to bottom of

Tub.

4. Feed Wire Harness out of bracket.

5-22 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Page 23

Service and Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Removal

1. Disconnect power to the machine.

2. Remove the Inner Door Panel. (See paragraph Inner

Door Panel removal).

3. Lift Door Latch Assembly out.

Switch Removal

1. Disconnect power to the machine.

2. Remove the Inner Door Panel. (See paragraph Inner

Door Panel removal).

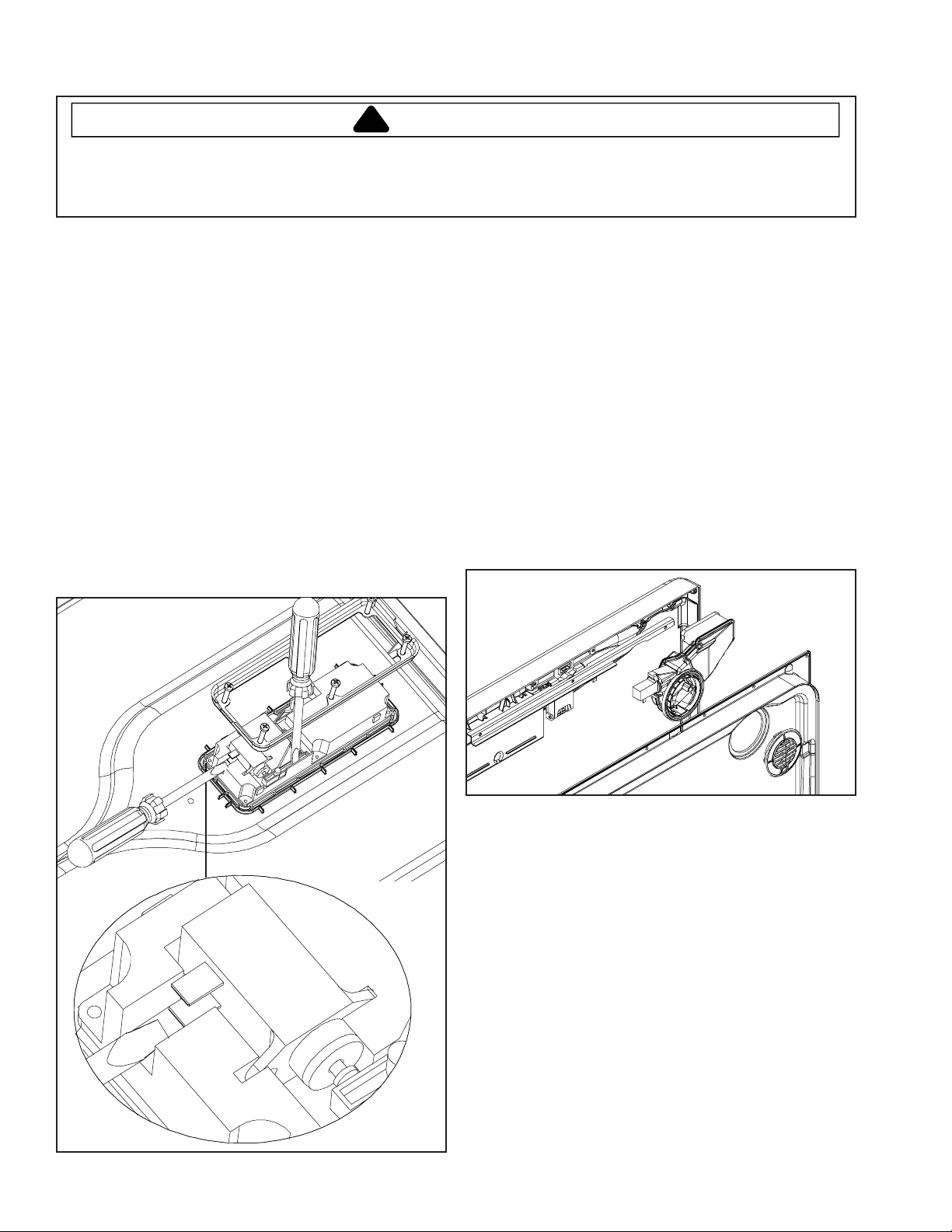

Door Latch & Switch Holder Assembly

Two Door Switches are used in the Latch Assembly. Both

switches are normally CLOSED and will open only when

engaged by the Door Latch mechanism. Each switch is

in series with respect to L1 and neutral line operations.

Failure of either or both switches will result in rendering

the Dishwasher inoperative.

3. Remove Door Latch and Switch Holder Assembly .

4. Depress locking tabs and lift switch from holder .

NOTE: Door Switches require no field adjustment.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 5-23

Page 24

Service and Disassembly Procedures

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

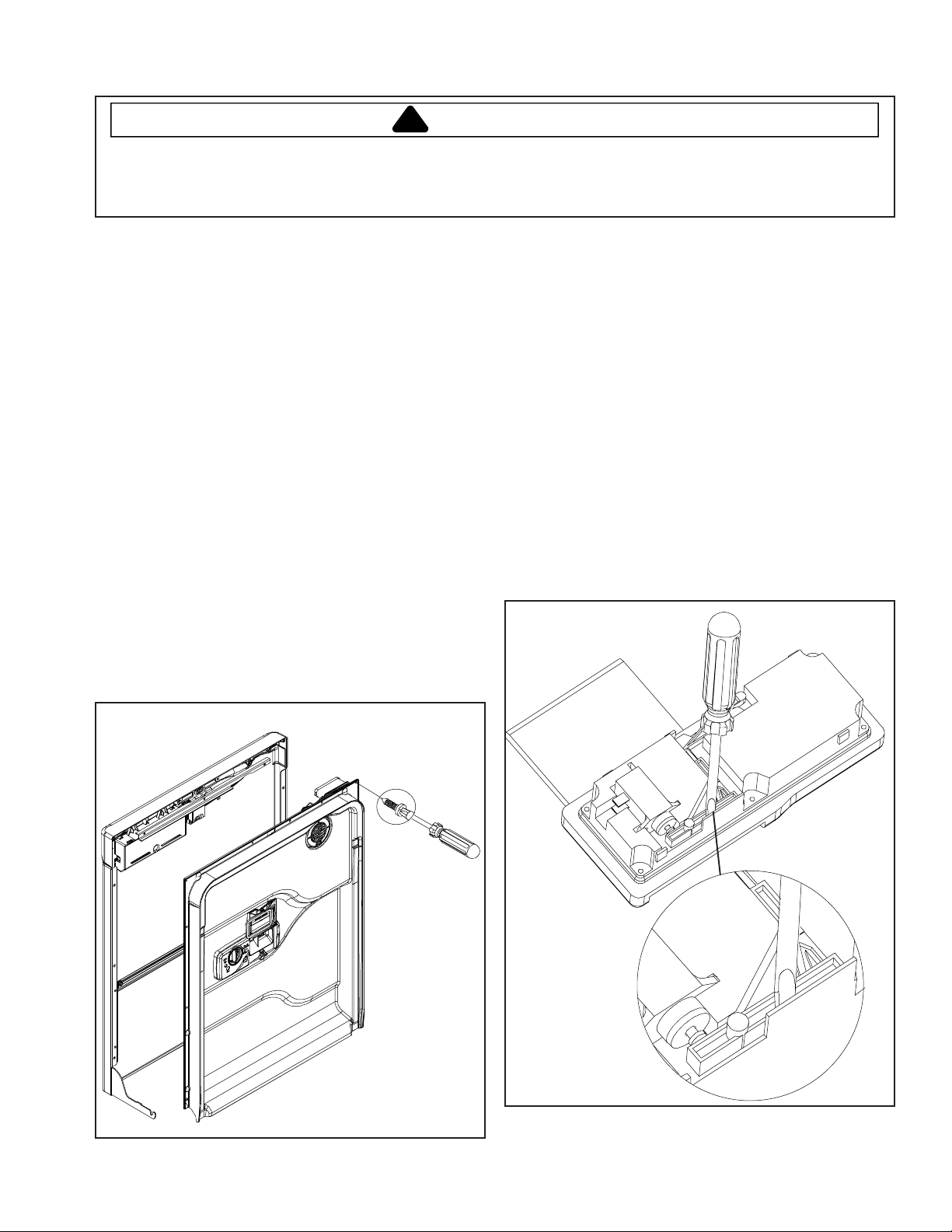

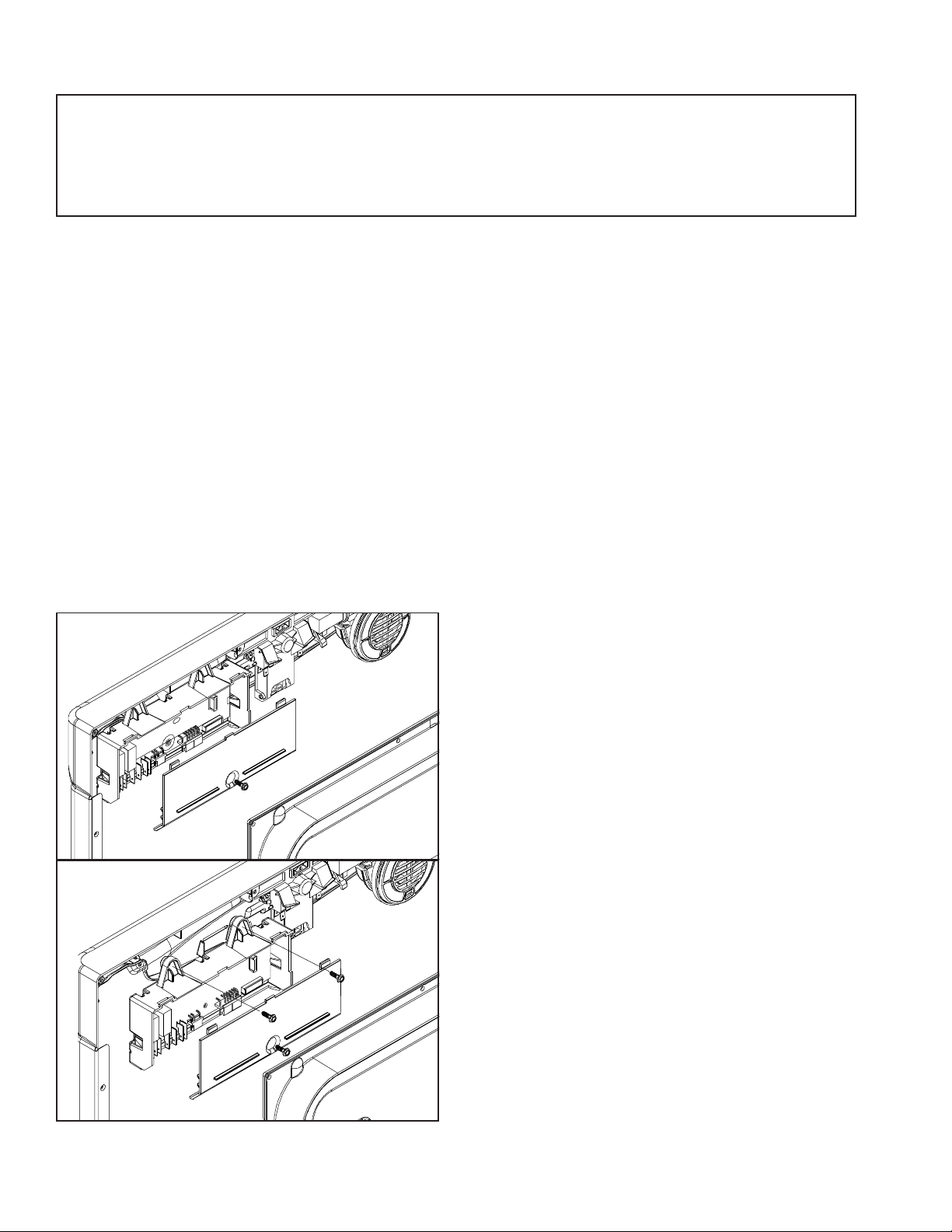

PC Board

Removal

1. Disconnect power to the machine.

2. Remove the Inner Door Panel. (See paragraph Inner

Door Panel removal).

3. T o access PC Board, remove 1/4" screw on PC

Board Housing Cover.

4. T o remove PC Board, loosen (2) 1/4" screws

securing PC Board Base to Control Panel.

5. Remove pin and ribbon connectors from PC Board.

6. Depress tabs on PC Board Housing to remove PC

Board.

Technical Sheet

The Dishwasher T echnical Sheet is located behind the

T oe Panel. The Schematic Diagram is unique to each

model and contains the following:

Timing Sequence Chart

Load Readings

Component Specifications

Manual Function T est

Field Service Test

Electrical Schematic

Control Panel

The Membrane/Facia on the Control Console is not

replaceable.

Removal

1. Disconnect power to the machine.

2. Remove the Inner Door Panel. (See paragraph Inner

Door Panel removal).

3. Remove PC Board Housing Cover. (See p aragraph

PC Board removal).

4. Disconnect Membrane Switch from PC Board.

5. Remove PC Board Base.

6. Lift out Latch Assembly.

7. Remove 4 screws securing Control Panel to Outer

Door.

NOTE: Facia is susceptible to damage during

reinstallation.

DOOR LATCH STRIKE

The Door Latch serves as a mechanical actuator for Door

Switch operation and provides door tension for proper

door seal.

5-24 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Page 25

Service and Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Removal

1. Disconnect power to the machine.

2. Remove T orx™ screw securing S trike to T ub.

5. Check for proper Door Latch adjustment to ensure

proper door sealing.

Outer Door

Removal

1. Disconnect power to the machine.

2. Remove the Inner Door Panel. (See paragraph Inner

Door Panel removal).

3. Remove 2 screws securing PC Board Base to Inner

Door Panel.

4. Lift off Latch Assembly .

5. Lay Outer Door to it's fully open position.

6. Prop door open, by inserting an object into the 1/8"

dia. hole in hinge bracket.

DOOR GASKET

The Door Gasket provides a seal between the Door and

the Tub.

Removal

1. Open Door.

2. From either corner, pull gasket up and out of tub

recess.

Replacement

1. To ease installation, wet gasket with water.

2. St arting in the lower right corner , Gently work gasket

into the recess of Tub up the right side.

3. With other end, place gasket flush with the Tub in

lower left corner.

4. Gently work gasket in to the recess of the Tub, up the

left side, and across the top.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 5-25

Page 26

Service and Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

7. Remove 4 screws securing Control Panel to Outer

Door.

8. Remove 4 screws securing Outer Door to Door

Hinges. (2 each side).

9. Slide Outer Door off of Door Hinges.

Do not remove Door Prop until tension is relieved from

door spring.

WARNING

!

4. Disconnect Cable Link from Hinge. (See warning

above).

5. Lift Hinge out of Hinge Support.

6. Remove 2 attachment screws if replacing hinge

support.

Door Spring

The Door Springs provide a counter balance to the weight

Door Hinge and Support

Removal

1. Disconnect power to the machine.

2. Remove the Outer Door Panel. (See paragraph Outer

Door Panel removal).

3. Remove Dishwasher from cabinets.

5-26 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

of the door.

The Door Spring position is preset by model at the factory .

If possible note the position of the spring. This may be

determined by wear marks. Door Spring adjustment

Brackets are located on the lower right and left side of the

Dishwasher . Spring tension is achieved by positioning the

spring in the slots provided. The higher position increases

spring tension.

NOTE: Always point spring hooks toward the Dishwasher .

Page 27

Service and Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Door Spring and Component Replacement

NOTE: Always point spring hooks toward the Dishwasher .

1. Disconnect power to the machine.

2. Remove Dishwasher from cabinets.

3. Attach Door Cable Link to Door Hinge.

4. Attach Cable to Cable Link.

5. Route Cable under Cable Roller.

Over Pressure Filter

The purpose of the Over Pressure Filter is to filter

sediment missed by the lower filter rather than circulating

it back through the wash.

Removal

1. Spread locking t abs.

2. Rotate filter down and remove from manifold.

T op W ash Arm

6. Attach Cable to short hook of S pring.

7. Place large hook end of Spring into S pring Adjustment

Bracket in proper location.

NOTE: T o replace Cable Bracket, remove 2 Torx™

screws securing bracket to frame. See

procedure above for reassembly of Spring and

Cable.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 5-27

Removal

1. Spread locking t abs and remove Wash Arm Retainer .

Page 28

Service and Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Manifold

Water is supplied to the Top and Center Wash Arms

through this tube via the Pump Assembly . The Manifold

attaches to the Pump Assembly and runs vertically up the

rear and along the top of the Dishwasher Tub. The

Manifold is attached to the Tub with a clip.

Removal

1. Disconnect power to the machine.

2. Remove Racks, Stop s, and Rack Assemblies.

3. Spread Manifold Clip s located on the back and top of

Tub.

4. Tip top of Manifold towards door opening slightly .

Disengage the snap located on the bottom of the

Manifold, locking the Manifold to the Discharge

Housing .

5. Slide Manifold back and out of the Pump Assembly .

Docking Station

The purpose of the Docking S tation is to seal the water

flow to the upper rack Wash Arm.

Removal

1. Slide Upper Rack forward to gain access to Docking

Station.

2. Spread sides of Docking S tation and remove from

Manifold.

Lower Wash Arm

Water is supplied to the Lower W ash Arm via the Pump

Assembly.

Removal

1. Disconnect power to the machine.

2. Remove lower Rack Assembly .

3. Loosen Wash Arm Hub and Pivot.

4. Lift Wash Arm out of Dishwasher .

5-28 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Page 29

Service and Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

2. Perform continuity check of switch across terminals.

Closed- Actuator of switch depressed.

Open- Actuator of switch released.

Removal

1. Disconnect power to the machine.

2. Lift Float straight up from Float Guide.

3. Remove Front Support and T oe Panel. (See p aragraph

Front Support and T oe Panel removal).

4. Remove electrical connectors on switch.

Float

The Float Assembly controls the amount of water fill.

The Float Switch is wired in series with the Water

V alve. When the Float Switch OPENS, the electrical

circuit to the Water Valve is opened, causing the

Water V alve to shut of f.

5. Float Switch mounting screw is located behind Float

Switch mounting plate. Loosen 1/4" screw several

turns to remove entire assembly .

6. Spread locking tabs on Float Switch mounting plate

to remove switch.

A normal fill is when water makes contact with

heating element in bottom of dishwasher.

To Check Float Switch

1. Disconnect power to the machine.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 5-29

Page 30

Service and Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Heating Element

The purpose of the Heating Element is to provide heat

during the dry cycle and increase water temperature

during portions of the wash cycle when certain options are

selected.

The element is dual wattage. During wash cycles, it is

rated at 830 watts. During the dry portion of the cycle, it

is rated at 650 watts. Increased wattage is possible

because of water flowing across the element sheath.

To Check Heating Element

1. Disconnect power to the machine.

2. Remove Front Support and T oe Panel. (See p aragraph

Front Support and T oe Panel removal).

3. Locate element terminals, remove wires, perform

continuity check across terminals.

4. The resistance of the element should be

approximately 22 ohms. If OPEN, replace element.

5. Perform continuity check from each terminal to the

element sheath. NO continuity should be present. If

continuity is present, replace the element.

Removal

1. Disconnect power to the machine.

2. Remove Front Support and T oe Panel. (See p aragraph

Front Support and T oe Panel removal).

3. Locate element terminals and remove wires.

4. Remove mounting nuts securing Heating Element to

Tub.

NOTE: Before reinstalling Heating Element, examine

condition of O-ring seals that are located between

element leads and tub basin. Replace if needed.

Failure of seal will result in a water leak and

possible floor damage.

Wattage Checks

T o verify watt age of the element, take an amperage

reading at the blue wire of the Heating Element. Multiply

the amperage reading by voltage at the Dishwasher

(Amps x Volts = Watts).

Normal element amperage during the dry portion of the

cycle is 5.0 to 5.5 amps. When used during a wash

cycle, normal amperage is 7.0 to 7.5 amps.

5. Release Heating Element by tipping Heater Support

Brackets towards the Tub front corners and rotating

until bracket unlocks.

6. Lift element out of Tub.

5-30 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Page 31

Service and Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Thermostats

Two types of thermost ats are used in the Dishwasher . A

Thermistor and a Limit Thermostat.

The Thermistor is used to sense water temperature when

certain cycles or options are selected (Refer to Cycles &

Options section). The Thermistor is part of the sensor

mounted in the Tub.

The other thermostat is a Limit Thermostat and is used as

a protective device to sense overheating of the Heating

Element. It is located behind the Front Support and Toe

Panel. The limit is mounted to the tub bottom. This

thermostat has ¼" terminals and has a normally CLOSED

position.

NOTE: Refer to section labeled T echnical Data for

specifications on thermostat.

Removal

1. Disconnect power to the machine.

Water V alve

The valve is located behind the Support and T oe Panel,

mounted to the left side of the Tub Support. Inlet water

supply to the valve is directly below the valve.

NOTE: Turn off water supply to the Dishwasher before

servicing this component.

The valve is designed to operate at water pressures of 15 120 psi.

NOTE: Low water pressure will affect the ability of the

Water V alve to properly fill T ub in the required

amount of time.

Incoming water temperature should be a minimum of 120

degrees F . However , a higher water temperature will

enhance washing and drying results.

Removal

1. Disconnect power to the machine.

2. Remove Front Support and T oe Panel. (See p aragraph

Front Support and T oe Panel removal).

3. Press down on spring clip to release from Tub and

rotate till clip unlocks.

4. Remove wires from thermostat.

NOTE: When reinstalling, proper location and wiring of

thermostat(s) is critical.

2. Turn off water supply to the Dishwasher .

3. Remove Support and T oe Panels. (See paragraph

Front Support and T oe Panel removal).

4. Remove wires from Valve Solenoid.

5. Remove 2 1/4" screws securing Water V alve to W ater

Valve Bracket.

6. Disconnect injector hose at valve outlet.

©2002 Maytag Appliance Sales Company 16021814 Rev . 0 5-31

Page 32

Service and Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Checking V alve Operation

No Fill

1. Disconnect power to the machine.

2. Remove Support and T oe Panel. (See p aragraph Front

Support and T oe Panel removal).

3. Remove wires from Valve Solenoid.

4. Perform continuity check across terminals of

Solenoid. If NO continuity is present, replace Water

V alve.

Alternate T est: Use Motor T est Cord hooked directly to

the V alve Solenoid. Turn water supply on

and plug in test cord. If NO water is

present, replace Water V alve.

Overfill

If Water V alve allows water to flow without power to V alve

Solenoid, replace the Water V alve.

NOTE: The Water V alve is a non-repairable component.

The only servicing required is to clean the Inlet

Screen if needed.

Inlet Screen

Sediment on the Inlet Screen can hinder water flow

through the Water V alve.

Cleaning

1. Disconnect power to the machine.

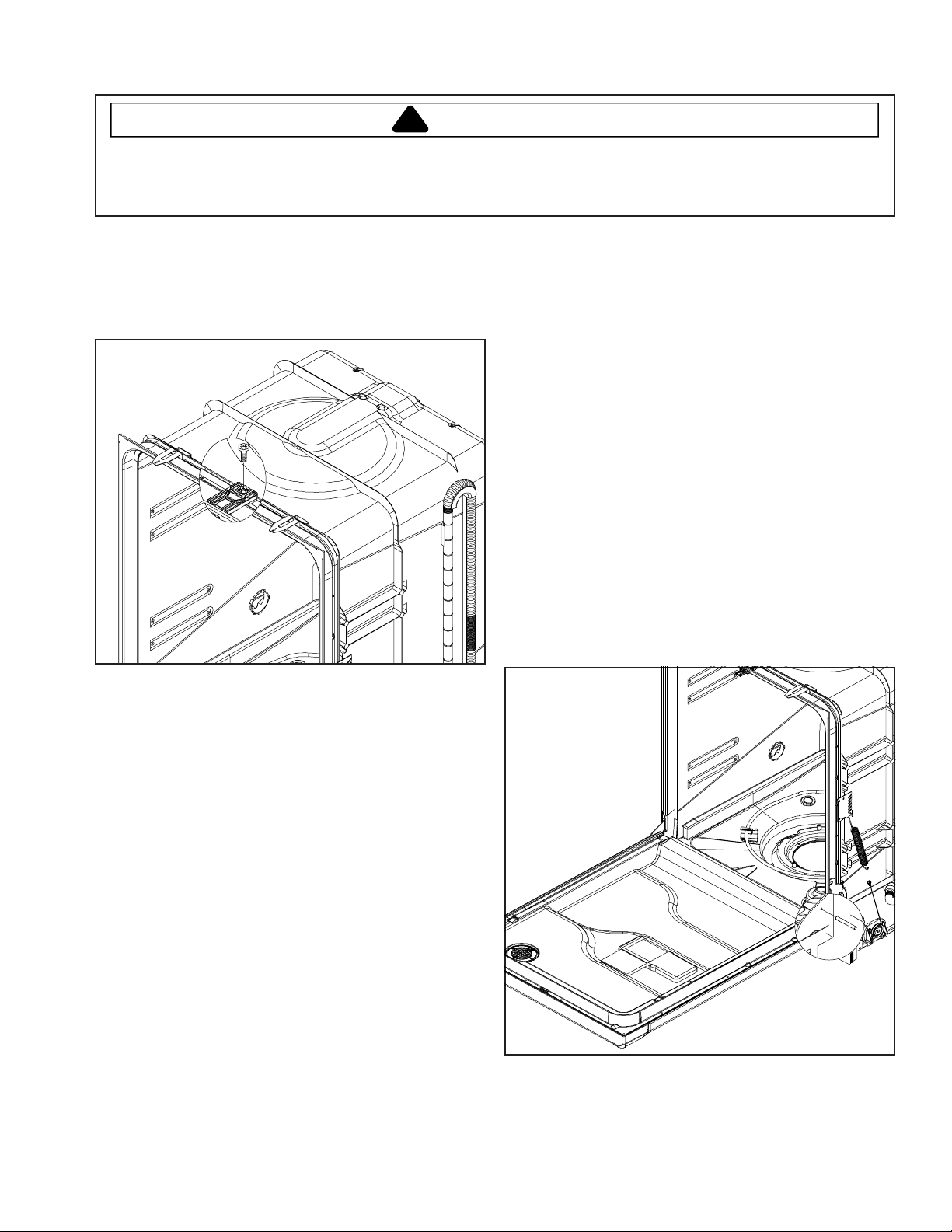

Air Water Inlet

The Air Water Inlet is located on the left side of the T ub,

and mounted to the exterior of T ub. Removal of the Air

Water Inlet requires the removal of the Dishwasher from

under the counter.

Removal

1. Disconnect power to the machine.

2. Remove the Air W ater Inlet Cover located on the left

inside wall of Tub. Pull cover straight out to remove.

3. Carefully pull back insulation from the left side of the

Tub.

4. Remove rubber hose from channel in Tub, or slip off of

fitting on inlet.

5. Grasp upper portion of the Air/Water Inlet. Pull and

rotate the Air/W ater Inlet clockwise to release it from

the Tub.

2. Remove Water V alve from the Dishwasher (See Water

Valve Removal).

3. Remove 4 screws securing valve body to Water Inlet

Mounting Bracket.

4. Clean screen.

NOTE:

5-32 16021814 Rev. 0 ©2002 Maytag Appliance Sales Company

Make sure to reattach the ground wire to the

mounting bracket.

Page 33

Service and Disassembly Procedures