Page 1

Dishwasher — Technical Information

ADB3500AW*, MDBM755AW*, MDB7751AW*, MDB8751AW*,

MDB8951AW*

• Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

• Refer to Service Manual 16021814 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions

All safety information must be followed as provided in Service Manual 16021814.

CAUTION

!

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

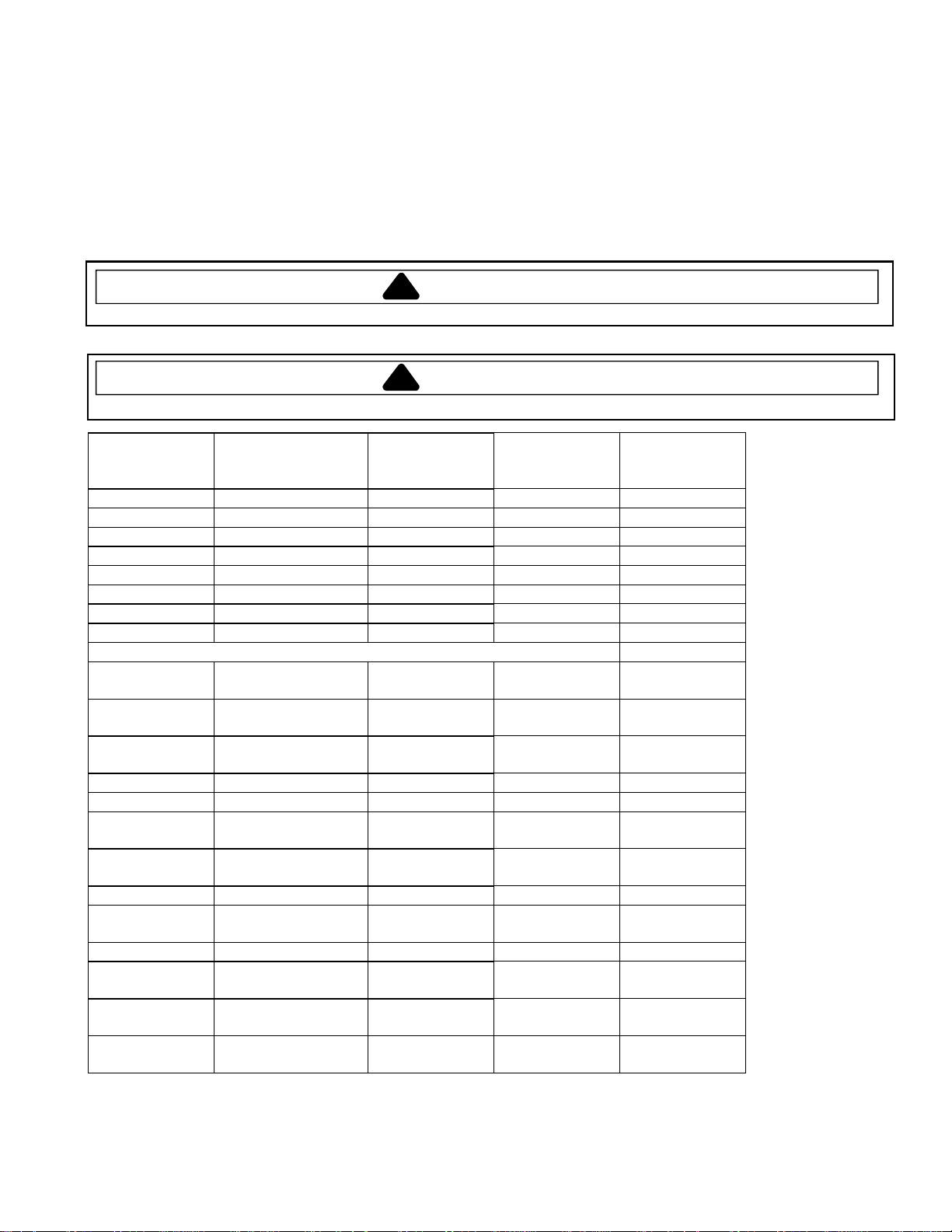

Benefits ADB3500AW* MDBM755AW*

MDB7751AW*

Wash cycles 5 4 6 5

Heavy Wash X X X X

Normal Wash X X X X

Quick Wash X

Light Wash X X X

Insta Wash X X

Auto Clean X X

Rinse Only X X X X

Features

Sound package

High Temp

Wash

Electronic

Controls

Sanitizer X X X

Sensor clean X X X X

Water Filtration

Delay Start

Energy Star X X X X

Hard Food

Disposer

Child lockout X X X X

Touch Pad

Controls

Silverware

Location

Low rinse aid

indicator

Sofsound III™

X X X X

X X X X

100% Filtered wash

water

2,4 or 6 Hour Delay

Start

X X X X

10 7 12 13

In door

X

QuietSeries™

Micro-Fine Plus

2,4 or 6 Hour

Delay Start

Compartment

WARNING

200

Filtration

Wash

MDB8751AW* MDB8951AW*

QuietSeries™

300

Micro-Fine Plus

Filtration

1-9 Hour Delay

Start

Wash

Compartment

QuietSeries™

400

Micro-Fine Plus

Filtration

1-9 Hour Delay

Start

Wash

Compartment

July 2005 1 16026394

©2005 Maytag Services

Page 2

Component Specifications

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

Specifications Value

Power Source

Voltage AC 120 VAC

Amperage (Single Unit) 15 A

Frequency 60 Hz

Motor horsepower

1/3

Height−overall

Weight

Dimensions

33 ½” to 35 ¼”

71

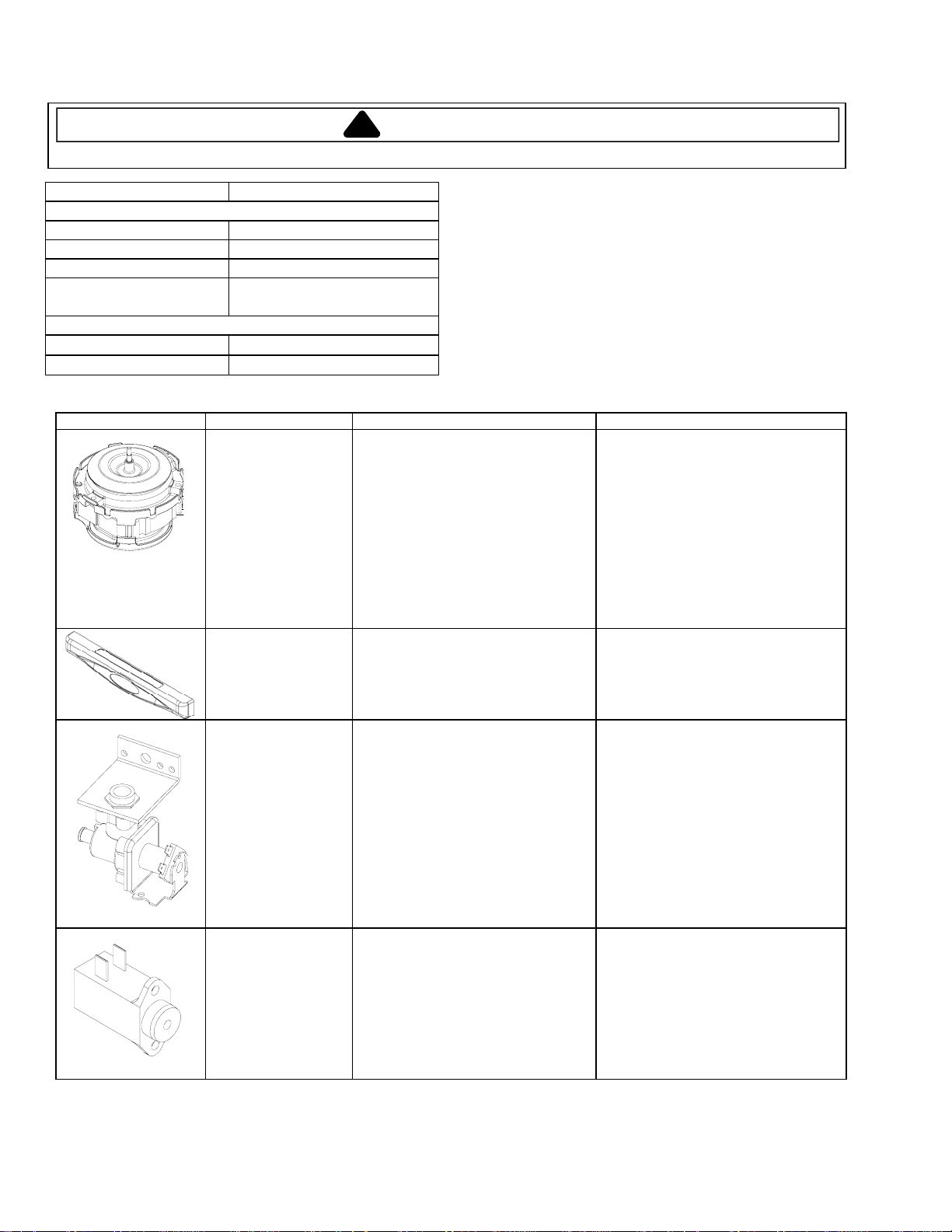

Illustration Component Test Procedure Results

Dishwasher Motor

CCW rotation only

viewed from shaft

end.

1/3HP

120V/60hz, 3.2 amps,

3250 RPM

Main Wattage, 285

watts

Start Wattage, 1115

watts

Control Panel See Component Specifications/

Measure resistance from

ST5 (Motor Common – blue) to ST8

(Motor Main - yellow) .........................

See Component Specifications/Motor

Connections for details.

Membrane Readings for

troubleshooting/pin-out instructions.

3 to 4 Ω

Water valve

120V/60hz, 7 watts

1.13 ± .10 gpm at 20120 psi

Vent wax motor

120V with 1/4"

actuation stroke

within 90 seconds

Measure resistance from

J6 Pin 4 Aqua (Float switch) to ST4

Black (Common) ...............................

Measure resistance from J6 Pin 1

Purple (Vent) to ST4 Black (Common)

...........................................................

1.1 k Ω

(This value assumes the float switch is

closed).

1.2 k Ω

16026394 2 July 2005

©2005 Maytag Services

Page 3

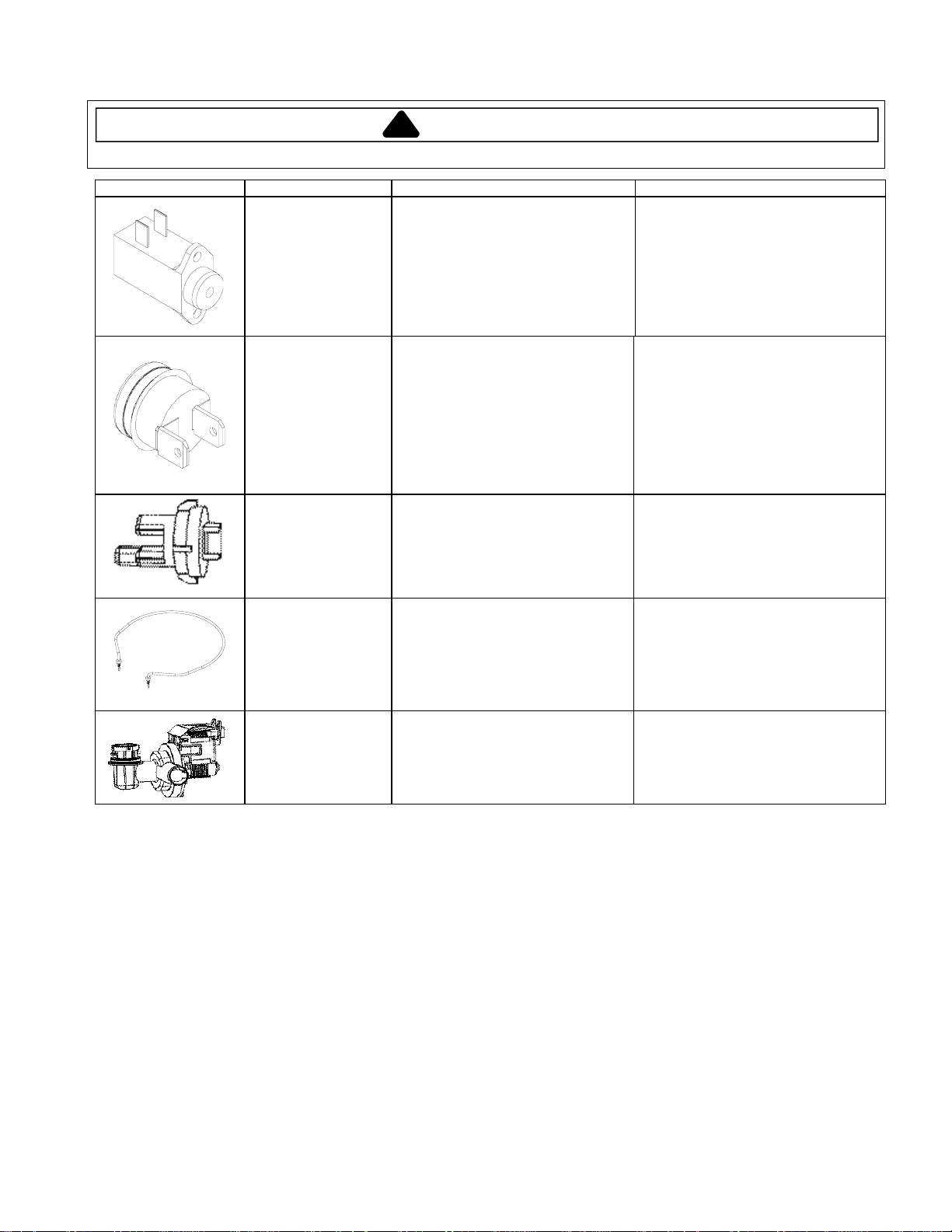

Component Specifications

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

Illustration Component Test Procedure Results

Dispenser wax motor

120V with 1/4"

actuation stroke

within 90 seconds

Limit Thermostat

Measure resistance from J6 Pin 3

Tan (Dispenser) to ST4 Black

(Common) .........................................

Close on Temperature drop @ 149°F

± 7°F (Temp) .......................................

Open on Temperature drop @ 164°F

± 4°F (Temp) .......................................

2 k Ω

0 Ω = Closed

Infinite Ω = Open

Sensor/Thermistor

10KΩ ± 3% at 77°F and 2.4 k Ω ±

6.5% at 140°F

J5 pin 1 - Orange (Temp) to J5 Pin 4 -

Red (Neutral) .......................................

Heater/Heating

Element

120v/60hz, 650 watts

± 5% in air, 830 watts

± 5% in 90°F water

Drain Motor

120v/60hz

45 watts

Measure resistance from ST1

Red/Black (Heater) to ST11 White

(Common) ...........................................

Measure resistance from

ST6 Gray (Drain) to ST4 Black

(Common) ...........................................

Infinite Ω = Open

0 Ω = Closed

16 Ω

(This value assumes the high limit

thermostat is closed).

25 Ω

July 2005 3 16026394

©2005 Maytag Services

Page 4

Component Readings/Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

A Manual Func ti on Test may be st arted by pressing the key

5 times fol l ow ed by the key within8 seconds.

The LED will 3 times indicating manual test mode is

Normal W ash Flash

active. Specific ke y pads will turn on or off a component a s fo ll o w s:

Hi Temp Wash Wash Mot or Hi Temp Wash

Heated Dry Heating Element Heated Dry

Cycles Select / Normal

First Press No Action Heavy Wash

Second Press Dispenser Normal Wash

Third Press Drain Pump Light Wash / China Cryst al

The test will cancel 120 seconds after the last keypad is pr essed. The display

(if available) will show ‘99’ until the remaining timeout period is less than 99

seconds. At this point it will countdown until the mode times out, is cancelled,

or another key is pressed. To cancel test, press the keypad.

To check control LED’s and components, enter . If control

fails to perform sequence as described, and a fault is detected, determine

failure as described in the . If a load component failure has

been diagnosed, proceed to the . To check individual

load com p o ne nts for proper operation, enter . Follow

test procedure as described. Repair or replace component as neede d.

: The or may be detected during

Note High Current Low Current Motor Error

a wash cyc l e selected by a consu mer. If this happe ns, the control will go i n t o a

30 second auto restart mode and shut down if the unit is not able to restart the

motor.

Manual Func tion Test

Start

KEY Function LED

Delay Water Inlet Valve Delay

, Field Servic e Test

Diagnostic Tips

Field Service Test

Manual Function Te st

Manual Function Test

Heated Dry

Start / Cancel

Membrane Readings

(All Models)

Heavy Wash

Normal Wash

Light Wash / China Crystal / Gentle Wash

Quick

Rinse Only

Auto Clean / Sensor Clea n

Heated Dry

Sanitize

Hi Te mp Wash

*

*

*

*

*

*

/

Connector

J1

J1

J1

J1

J1

J1

J1

J1

Measu r e Between

Pin 9 - Pin 5

Pin 9 - Pin 6

Pin 9 - Pin 7

Pin 9 - Pin 8

Pin 10 - Pin 5

Pin 11 - Pin 5

Pin 11 - Pin 6

Pin 11 - Pin 8

(Front Only Controls)

Cycle Select

Start / Cancel

Delay

T ough Scrub Plus / Su per Scrub / Power Sc ru b

T ough Scrub / Extra Wash / Hi Temp

Insta Wash

Model ID Jumper

An unpressed switch will read as an open circuit.

A pressed switch wi l l read as 10 k .

* On select mo dels

*

*

*

*

Connector

J1

J1

J1

*

J1

J1

J1

J1

Measu r e Between

Pin 9 - Pin 5

Pin 10 - Pin 6

Pin 10 - Pin 7

Pin 10 - Pin 8

Pin 11 - Pin 7

Pin 12 - Pin 5

Pin 12 - Pin 7

A Field Service Test may be started by pressing the key 6 times

followed by the key within 8 seconds. This test must be performed with

clean water to insure proper sensor performance.

“88” will appear in the di splay (if available*) and the follo wing sequence of

events will occur:

SECONDS

The time for the Thermistor chec k / Turbidy Sensor che ck & calibration may

vary slight ly.

The Field Service Test will not repeat. The LED will during

the test mo de. All I nd i cator lights (except ) will illum inate. If the

dishwasher door is opened during the test, the test sequence will pause, and

resume when the door is closed. To cancel test, press the

keypad.

The cont r ol has been designed to test the Sensor Memory and Motor. During

the F ield Servi ce Test, i f a fault has been detected, the test will abort any time

after the m ot or current has been checked and 2 or more LED ' s wil l begin to

Flash Memory / Software Check

start ed. The LED and one of t he following:

* On select models

Insta Wash

Tough Scrub Plus / Super Scrub / Power Scrub

160° Wash

Tough Scrub / Extr a Wash / Hi Temp

Model ID Jumper

Start / Ca nc el

Delay

Start

106

5

120

180

120

4

. A will occur immediately after the test is

(Delay / Delay 2 hr)

*

*

(Top Only Controls)

Insta Wash

Tough Scrub Plus / Super Scrub

160° Option

Tough Scrub / Extr a Wash / Hi Temp

Model ID Jumper

Start Cancel

Delay

*

Field Serv i c e Test

FUNCTIONS / ACTIVE LOADS

Vent Wax Motor / Water Valve

Thermistor check / Turbidity Sensor check &

calibration - no loads active.

Wash Motor / Vent Wax Motor / Dispenser

Wax Motor

Wash Motor / Heater / Vent Wax Motor

Drain Pump

Water Valve

Heavy Wash

Turbidity Sensor Hi Temp Wash

Thermistor Heavy Wash

Motor Normal Wash

- high current - LED

Motor Light Wash

- low current - LED

Memory Failure Heated Dry

- failure - LED

- failur e - LED

- LED

Heated Dry

Heavy Wash Flash

the

,,

Start / Cancel

Membrane Readings

(Front & Top Controls)

J1

J1

J1

J1

J1

J3

J3

J1

J1

J1

J1

J1

J1

J1

Measur e B et w e e n

Pin 10 - Pin 6

Pin 10 - Pin 7

Pin 10 - Pin 8

Pin 11 - Pin 7

Pin 12 - Pin 8

Pin 9 - Pin 5

Pin 9 - Pin 6

Measur e B et w e e n

Pin 10 - Pin 6

Pin 10 - Pin 7

Pin 10 - Pin 8

Pin 11 - Pin 7

Pin 12 - Pin 6

Pin 13 - Pin 12

Pin 13 - Pin 14

Connector

*

*

*

*

Connector

*

*

Load Readings

Heater¹

Wash Motor

Drain Motor

Dispenser Wax Motor

Water Valve²

Thermistor

Notes:

1. This value as su mes the high limit th er m ostat is closed.

2. This value as sumes the float swi tch is cl osed.

3. Results are approximated values.

ST5 (Motor Common ) - ST8 (Motor Main)

16026394 4 July 2005

©2005 Maytag Services

Measure Betw een

ST1 (Heater) - ST11 (Dlb Neutral)

ST6 (Drain) - ST4 (Dlb Line)

J6 Pin 3 (Di sp ) - ST4 (Dlb Lin e)

J6 Pin 4 (Inlt) - ST4 (Dl b Li ne)

J5 Pin 1 (Temp) - J5 Pin 4 (Neutral)

Result

16

3 to 4

25

2k

1.1k

See Comp on ent Info

Page 5

Electrical Diagnostics

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

*** A resistor in the control board wired in parallel will result in an approximate reading of 4.0 k ohms

with connector J5 plugged in.

** Nominalvalueforohmsof electrical resistance of component only. Thesevalueswillvary slightly

due to the additional resistance of the wire harness. Greater variation can occur if the component is

still warm from being energized during testing.

3

Perform the resistance checks on the component(s) in question at the locations shown on the chart.

* Select ModelsOnly.

2

(A white plastic latch must be inserted in the latch assembly for this test.)

> With one ohm meter lead connected to the white (neutral) power lead, you should have continuity at

stakelugs10&11.

> With one ohm meter lead connected to the black (line) power lead, you should have continuity at

stakelugs3&4,andpin#8onconnectorJ5.

To check continuity from ends of power leads to control board through door switches

1

Use the "Manual Function Test" as described on the electrical schematic sheet to

check components before

Pin#12345678 Pin#1234 StakeLug11109876 54321

OR RD RD AQ PU BK PU TN AQ

opening the door to perform continuity testing or replacing parts.

J5 J6

connector unplugged)***

2.4K* +/- 6.5% @ 140

10K* +/- 3% @77

o

F

o

F

*Vent WM

(1.2K**)

Resistance Check Points and Values

Thermistor (thru harness only with

Disp. WM

(2K**)

Circuit Board

mustbe closed)

WH WH

before performing any resistance or

Always

YL GY BU BK B K RD

continuity checks.

remove power to the unit

(High limitt'stat must

(14.5 - 16.5**)

be closed)

Heater

Wash Motor

(3 - 4**)

(25**)

Water V alve

(float switch

(1.1K**)

Drain Motor

BK

July 2005 5 16026394

©2005 Maytag Services

Page 6

Control Definition

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

Designed to provide a

longer cycle for

washing items with

heavy food soils.

water usage is 8

gallons.

Designed to wash

loads containing

dishes with normal

amounts of food

soils. Water usage

ranges from 3 to

6 gallons.

Designed for light

food soils. The

cycle ends with

a rinse and does

not include drying.

water usage is 4

gallons.

Rinses dishes being

held until the dishwasher

is full, and another cycle

is selected. This cycle

helps reduce the

potential for developing

odors. Water usage

is 2 gallons.

Light Wash- Designed to wash loads containing dishes that are lightly soiled Water usage is 5 gallons.

Insta Wash- Designed to wash loads containing dishes that are lightly soiled Water usage is 5 gallons.

Auto Clean- Designed to auto select the number of fills and length of wash times based on soil level of dish load.

Water usage ranges from 3 to 8 gallons.

Tough Scrub- This option adds fills, heat and/or wash time to the wash cycle.

16026394 6 July 2005

©2005 Maytag Services

Designed to auto

select the number

of fills and length

of wash times

based on soil

level of dish

load. Water

usage ranges

from 3 to 8

gallons.

WARNING

Delays the start of

the dishwasher

based on user

selection.

This option improves drying

results by turning the heating

element on and off during the

dry portion of the cycle.

This option monitors

cycles for sanitization.

This option raises

Temperature in the

Final rinse to 160

° F

Page 7

Control Definition/Motor Connectivity

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

120V/60hz, 3.2 amps, 3250 RPM

July 2005 7 16026394

©2005 Maytag Services

WARNING

Green

Yellow

Blue

(Common)

1/3HP

(Start)

(Ground)

(Main)

Wire harness

Connection plug

Page 8

Cycle Chart

A

/

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

1. All times are approximate.

2. Temperature checks force a maximum 20 minute heating delay to reach the desired temperature.

3. The cycle definition gives the minimum and maximum possible cycle lengths. Actual cycle length and executed cycle functions will vary based on the sensor input.

4. Fill length varies between different models.

Auto Clean/Sensor Clean

Sanitize Sanitize Light Wash

160° Option 160° Option

Temperature Options (Available on select models)

adds 5 minutes unheated circulation prior to rinse aid dispen se.

Notes

: If the option is available for a given cycle, it for ces a 140°F temp check at the end of the main wash for the , a 154 °F temp check prior to the rinse aid dispense in the final rinse, and

SENSOR CLEAN CYCLE

AUTO CLEAN CYCLE/

(128 Minutes - max)

(94 Minutes - min)

: If the is available for a given cycle, it forces a 160°F temp check prior to the rinseaid dispense in the final rinse.

1:46 max

1:36 min

FILL

WASH

PRE

8:00

DRAIN

2:20

Available Options:

Hi Temp Wash

Tough Scrub/

Tough Scrub Plus Tough Scrub

Extra Wash/Hi Temp

- This option has no effect on this cycle.

/Super Scrub/Power Scrub

- This option adds an additional 5 minutes of heated wash to the wash

1:46 max

- This option is the same as but the main wash temp check is boosted to 145°F.

HEATED

8:00

(133 Minutes - max)

WASH

2:20

(132 Minutes - min)

1:36 min

HEAVY WASH CYCLE

PRE

DRAIN

Tough Scrub Plus/Super Scrub/Power Scrub Tough Scrub

FILL

- This option is the same as but the main wash temp check is boosted to 145°F.

HEATED

SKIP?

1:46 max

1:36 min

FILL

DISP

DET

HEATED

WASH

25:00

CHECK

TEMP

140°F

DRAIN

2:00

1:46 max

1:36 min

FILL

HEATED

RINSE

10:00

PRE

1:46 max

1:36 min

FILL

HEATED

WASH

8:00

main and a 10 minute heated pre- r inse.

DISP

DET

HEATED

WASH

22:00

CHECK

TEMP

140°F

DRAIN

2:00

1:46 max

1:36 min

FILL

WARNING

Available Options:

Hi Temp Wash

Tough Scrub/Extra Wash/Hi Temp 5

- This optio n ov e r rides the sensor’s decision to sk i p cycle functions / modify temp checks and adds an additional minutes of heate d wash to the ma in wash.

NORMAL WASH CYCLE

(117 Minutes - max)

(97 Minutes - min)

- Overrides the sensor’s decision to modify the temp checks and skip a rinse.

1:46 max

1:36 min

FILL

HEATED

WASH

PRE

8:00

DRAIN

2:20

SKIP?

1:46 max

1:36 min

FILL

DISP

DET

HEATED

WASH

26:00

HEATED

WASH

SKIP?

2:00

SEE NOTE

CHECK

TEMP

TC 1

DRAIN

2:00

1:46 max

1:36 min

FILL

Available Options:

Hi Temp Wash

Tough Scrub/Extra Wash/Hi Temp

Tough Scrub Plus/Super Scrub/Power Scrub Tough Scrub

- This option is the same as but the main wash temp check is boosted to 145°F.

GENTLE WASH/QUICK WASH

CHINA/CRYSTAL CYCLE/

82 Minutes - Max

81 Minutes - Min

- This option boosts the final rinse temp check to 145°F.

- This optio n ad ds an 8 minute pre-wash and 5 minutes of heat ed wash to the main wash.

1:46 max

1:36 min

FILL

DISP

DET

HEATED

WASH

10:00

DRAIN

2:00

1:46 max

1:36 min

FILL

HEATED

RINSE

10:00

DRAIN

2:00

1:46 max

1:36 min

FILL

HEATED

RINSE

15:00

CHECK

TEMP

140°F

Available O p tions:

Only the option is available with the cycle.

LIGHT WASH CYCLE/

INSTA WASH CYCLE

Heated Dry Insta Wash

51 Minutes - Max

20

Minutes - Min

1:46 max

1:36 min

FILL

DISP

DET

HEATED

WASH

4:00

DRAIN

2:00

1:46 max

1:36 min

FILL

HEATED

RINSE

2:00

DRAIN

2:00

1:46 max

1:36 min

FILL

HEATED

RINSE

3:00

DRAIN

2:00

Available Options:

No options are available with the cycle.

RINSE ONLY CYCLE

9 Minutes

Rinse Only

1:46 max

1:36 min

FILL

RINSE

5:00

DRAIN

2:00

FILL

0:02

HEATER

3:00

DRY CYCLE

ON

HEATER

OFF

1:30

(Front Only Display Models)

SKIP?

DRAIN

2:00

1:46 max

1:36 min

HEATED

RINSE

10:00

PRE

FILL

DRAIN

2:00

RINSE

SKIP?

10:00

PRE

DRAIN

2:00

RINSE

DISP

AID

RINSE

5:00

FILL

0:02

(FrontTop

HEATER

1:00

ON

HEATER

OFF

1:30

HEATED

RINSE

10:00

PRE

DRAIN

2:00

1:46 max

1:36 min

FILL

HEATED

RINSE

20:00

CHECK

TEMP

145°F

RINSE

DISP

AID

RINSE

5:00

This represents the portion of a cycle that be

omitted. The determination of whether a segment

is skipped or not is made by input from the sensor.

SKIP?

DRAIN

2:00

FILL

0:02

CYCLE

30:00

DRY

1:46 ma x

1:36 min

FILL

HEATED

RINSE

10:00

PRE

DRAIN

2:00

1:46 max

1:36 min

FILL

HEATED

RINSE

20:00

CHECK

TEMP

145°F

RINSE

DISP

AID

RINSE

5:00

DRAIN

2:00

FILL

0:02

CYCLE

30:00

DRY

1:46 ma x

1:36 min

FILL

HEATED

RINSE

20:00

TC 1: If sensor detects lighter soil, the temp check will be 128 ° F

TC 2: If sensor detects lighter soil, the temp check will be 140 ° F

If sensor detects heavier so il, the temp check will be 140 ° F

If sensor detects heavier soil, the temp check will be 145 ° F

SEENOTE

CHECK

TEMP

TC 2

RINSE

DISP

AID

RINSE

5:00

DRAIN

2:00

FILL

0:02

CYCLE

30:00

DRY

DRAIN

2:00

FILL

0:02

CYCLE

30:00

Notes: If is not selected, the heater will not be activated during the dry cycle.

3:00or1:00

ON

If is selected, the first two minutes of heating is changed to 2 minutes of unheated at the end of

t dry cycle.

he

Heated Dry

160° Option

HEATER

OFF

3:00

DRY

HEATER

1:00

ON

HEATER

OFF

3:00

HEATER

1:00

ON

HEATER

OFF

3:00

HEATER

1:00

ON

HEATER

OFF

3:00

HEATER

1:00

ON

HEATER

OFF

3:00

HEATER

1:00

ON

M

Y

OFF

7:00or9:00

Note: If is not selected, the heater will not be activated during the dry cycle.

HEATER

DRY CYCLE

TopOnly Display Models)

HEATER

HEATER

1:00

ON

Heated Dry

HEATER

OFF

1:30

HEATER

1:00

ON

HEATER

OFF

1:30

HEATER

1:00

ON

HEATER

OFF

1:30

HEATER

1:00

ON

HEATER

OFF

1:30

HEATER

1:00

ON

HEATER

OFF

1:30

HEATER

1:00

ON

HEATER

OFF

9:30

16026394 8 July 2005

©2005 Maytag Services

Page 9

Wiring Diagram

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to dishwasher before servicing.

GY

BK

LI

BK

BK

DOOR SWITCH

(LI)

BK

RD

BK

BK

BK

BU

GY

YL

WH

WH

AQ

TN

BK

BK

BK

BU YL

GY

WH

WH AQ

TN

RD

CIRCUIT BOARD

J6

PIN

1

WIRES NOT CONNECTED

WIRES CONNECTED

DOOR SWITCH

KEY

(N)

HEATER

BK

WASH MOTOR

NOT E : SO ME W IR ES HAVE

STRIPES. STRIPED WIRES ARE

LABELED WITH THE SOLID

COLOR FIRST AND THE STRIPE

COLOR SECOND.

RD

WH

RD

BK

OVERLOAD

MAIN

GROUND

START

(TUB SHIELD)

GR

WH

WH

N

GR

WH

WH

THERMOSTAT

BK

YLBU RD

GR

(TERMINAL

BOX)

GR

GR

WH

WH

YL

CAPACITOR

MOTOR

YL

RD

WH

WH

(HINGE)

GR

EXAMPLE: A RED WIRE WITH A

BLACK STRIPE WOULD BE

LABELED

RD

BK

WATER

VALVE

RD

MOTOR

DRAIN

BK

AQ

GY

BK

AQ

AQ

TN

SWITCH

FLOAT

DISPENSER

BK

BK

AQ AQUA

BK BLACK

BU BLUE

BR BROWN

GY GRAY

GN GREEN

OR ORANGE

PK PINK

PU PURPLE

RD RED

TN TAN

WH WHITE

YL YELLOW

COLOR CODE

TN

BK

BK

BK

OR

SENSOR & THERMISTOR

OR PU RDAQ

OR

BK

TN

BK

BK

PU

PU

AQ

BK

AQ

RD

RD

PU

OR

AQ

RD

OR

BK

PU

RDAQ

RD

OR

J5

PIN

1

BK

July 2005 9 16026394

©2005 Maytag Services

Loading...

Loading...