MAYTAG

Commercial Dryer - 30 lb. PC2, MC2 & MN2, 50, 75 and 100 lb.

Installation/Operator’s Manual

WARNING: For your safety the information in this manual must be

followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or death.

Do not store or use gasoline or other flammable vapor

and liquids in the vicinity of this or any other

appliance.

WHAT DO YOU DO IF YOU SMELL GAS

* Do not try to light any appliance.

* Do not touch any electrical switch; do not use any phone in your

building.

* Clear the room, building or area of all occupants.

* Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

* If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Retain These Instructions In A Safe Place

For Future Reference

011998MAYTAG/tf

ADC Part No. 113033

Retain This Manual In A Safe Place For Future Reference

This product embodies advanced concepts in engineering, design, and safety. If this product is properly

maintained, it will provide many years of safe, efficient, and trouble-free operation.

ONLY properly licensed technicians should service this equipment

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation/operator's

manual included with the dryer.

WARNING: UNDER NO CIRCUMSTANCES should the door switch or the heat circuit devices

ever be disabled.

WARNING: The dryer must never be operated with any of the back guards, outer tops, or

service panels removed. PERSONAL INJURY or FIRE COULD RESULT.

We have tried to make this manual as complete as possible and hope you will find it useful. Manufacturer

reserves the right to make changes from time to time, without notice or obligation, in prices, specifications, colors,

and material, and to change or discontinue models.

Important

For your convenience, log the following information:

DATE OF PURCHASE

DISTRIBUTORS NAME

Serial Number(s)

__________

MODEL NO.

F or replacement parts, contact the distributor fi-om which the dryer was purchased or contact:

MAYTAG

403 West Fourth St North

Newton, Iowa 50208

(515) 792-7000

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER

SMELLS GAS MUST BE POSTED IN A PROMINENT LOCATION. THE

INSTRUCTIONS TO BE POSTED SHALL BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

IMPORTANT

YOU MUST DISCONNECT and LOCKOUT THE ELECTRIC

SUPPLY and THE GAS SUPPLY or THE STEAM SUPPLY BEFORE ANY

COVERS or GUARDS ARE REMOVED FROM THE MACHINE TO

ALLOW ACCESS FOR CLEANING, ADJUSTING, INSTALLATION, or

TESTING OF ANY EQUIPMENT per OSHA (Occupational Safety and Health

Administration) STANDARDS.

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING

THE CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND

DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

CAUTION

DRYER(S) SHOULD NEVER BE LEFT UNATTENDED WHILE IN

OPERATION.

WARNING

CHILDREN SHOULD NOT BE ALLOWED TO PLAY ON OR IN

THE DRYER(S).

CHILDREN SHOULD BE SUPERVISED IF NEAR DRYER(S) IN

OPERATION.

WARNING

The dryer must never be operated with any of the back guards, outer tops,

or service panels removed. PERSONAL INJURY or FIRE COULD

RESULT.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

DO NOT DRY MOP HEADS IN THE DRYER.

DO NOT USE DRYER IN THE PRESENCE OF DRY CLEANING FUMES.

IMPORTANT

PLEASE OBSERVE ALL SAFETY PRECAUTIONS displayed on the

equipment and/or specified in the installation/operator's manual included with

the dryer.

Dryer(s) must not be installed or stored in an area where it will be exposed to

water and/or weather.

The wiring diagram for the dryer is located in the front electrical control box area

of the dryer. In addition, there is also one enclosed in the last page of this booklet.

j

Table of Contents

SECTION I

IMPORTANT INFORMATION..........................................................................................................................2

A. RECEIVINGandHANDLING.......................................................................................................................2

B. SAFETY PRECAUTIONS........................................................................................................................... 2

SECTION II

SPECIFICATIONS..............................................................................................................................................4

SECTION III

INSTALLATION PROCEDURES......................................................................................................................5

A. UNPACKING/SETTINGUP.........................................................................................................................5

B. LOCATION OF THE DRYER..................................................................................................................... 6

C. DRYER ENCLOSURE REQUIREMENTS................................................................................................. 7

D. FRESH AIR SUPPLY...................................................................................................................................7

E. EXHAUST REQUIREMENTS.....................................................................................................................8

F. ELECTRICAL INFORMATION..................................................................................................................9

G. GAS INFORMATION................................................................................................................................11

H. PREPARATION FOR OPERATION......................................................................................................... 14

I. PREOPERATIONAL TESTS.....................................................................................................................14

SECTION IV

100 lb. INSTALLATION INFORMATION..................................................................................................... 16

A. LOCATION OF THE DRYER................................................................................................................... 16

B. FRESH AIR SUPPLY.................................................................................................................................18

C. EXHAUST REQUIREMENTS.................................................................................................................. 19

SECTION V

OPERATING INSTRUCTIONS (30, 50, 75 & 100 lb. Models)......................................................................21

A. MECHANICAL COIN METER CONTROLS (non-computer)

B. MECHANICAL TIMER CONTROLS (non-computer).............................................................................22

C. OPLCOMPUTERMODELS (non-computer).............................................................................................23

................................................................

21

SECTION VI

MAINTENANCE.............................................................................................................................................. 25

A. CLEANING................................................................................................................................................ 25

B. ADJUSTMENTS.........................................................................................................................................26

C. LUBRICATION..........................................................................................................................................26

SECTION VII

PROCEDURE FOR FUNCTIONAL CHECK OF REPLACEMENT COMPONENTS

..................................

27

SECTION I

IMPORTANT INFORMATION

A. RECEIVING and HANDLING

The dryer is shipped in either a protective polyethylene cover and protective comers or is enclosed in a

cardboard carton as a means of protection in transit. Upon delivery, the shipping carton and wooden skid

should be visually inspected for shipping damage. If carton or wooden skid is damaged, inspect further.

Dryers Damaged in Shipment:

1. ALL dryers should be inspected upon receipt and before they are signed for.

2. If there is suspected damage or actual damage, the tmcker's receipt should be so noted.

3. If the dryer is damaged beyond repair, it should be refused. Those dryers which were not damaged in a

damaged shipment should be accepted, but the number received and the number refused must be noted on

the receipt.

4. If you determine that the dryer was damaged after the trucker has left your location, you should call the

delivering carrier's freight terminal immediately and file a claim. The freight company considers this

concealed damage. This type of freight claim is very difficult to get paid and becomes extremely difficult

when more than a day or two passes after the freight was delivered.

5. If you need further assistance in handling the situation, please contact the distributor.

IMPORTANT; THE DRYERSfTOl/Xi) RETRANSPORTED AND HANDLED IN AN

UPRIGHT POSITION AT ALL TIMES.

B. SAFETY PRECAUTIONS

1. DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

2. Purchaser/user should consult the local gas supplier for proper instructions to be followed in the event the

user smells gas. The instructions should be posted in a prominent location.

3. Dryer must be exhausted to the outdoors.

4. Although this commercial dryer is a very versatile machine, there are some articles that, due to fabric

composition or cleaning method, should not be dried in it.

WARNING: Dry only water-washed fabrics. DOiVOJdryarticlesspottedorwashedindry

cleaning solvents, a combustible detergent, or "ALL PURPOSE" cleaners.

FIRE OR EXPLOSION COULD RESULT.

WARNING: DO NOT dry rags or articles coated with gasoline, kerosene, paint, wax, oil, or grease.

FIRE OR EXPLOSION COULD RESULT.

WARNING: DO NOT dry mop heads. Contamination by wax or flammable solvents will create

a fire hazard.

WARNING: DO NOT use heat for drying articles that contain plastic, foam, sponge rubber, or

similarly textured mbber-like materials. Drying in a heated tumbler may damage plastics

or rubber and also may be a fire hazard.

5. A program should be established for the inspection and cleaning of lint in the heating unit area, exhaust

duct work, and inside the dryer. The frequency of inspection and cleaning can best be determined from

experience at each location.

WARNING: The collection of lint in the burner area and exhaust duct work can create a

potential fire hazard.

6. For personal safety, the dryer must be electrically grounded in accordance with local codes and/or the

National Electric Code ANSI/NFPA NO. 70-LATEST EDITION.

NOTE: Failure to do so will VOID THE WARRANTY.

9. UNDER NO CIRCUMSTANCES should the dryer door switch or heat safety devices ever be disabled.

WARNING: PERSONAL INJURY or FIRE COULD RESULT.

8. This dryer is not to be used in the presence of dry cleaning solvents or fumes.

9. Remove articles fi'om the dryer as soon as the drying cycle has been completed.

10. READ and FOLLOW ALL CAUTION and DIRECTION LABELS ATTACHED TO THE DRYER.

SECTION II

SPECIFICATIONS

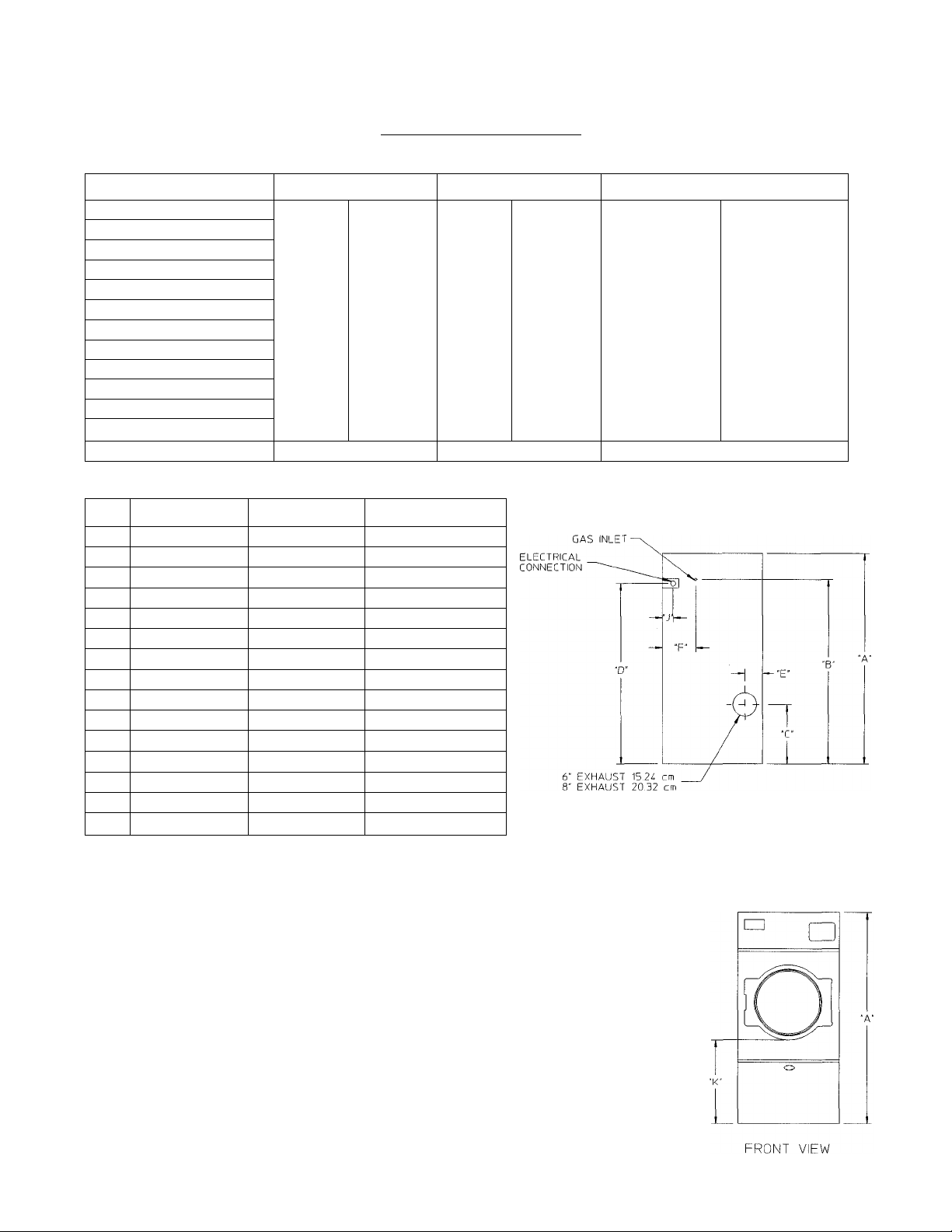

30 LB 50 LB 75 LB

Maximum Capacity (Dry I\feight)

Tumblff Diameter 30" 76.2 c 32-3/4"

Tumbler Depdi

Motor (Horsepowa-) 1/2

Door Opening

Dryers ftr 2W4& Contains

Dryers ftr 45748' Tmck 30/32 30/32

Air Flow

Approx. (unoated) 500# 211kg 565# 256 kg

Approx. Shipping I\feight

Gas Heat Input

Gas Inlet 1/2"

\foltage / Amperage

* A ininimum of 3/4" pipe must be supplied to each diyer.

301b. 13.6 kg 501b.

30" 76.2 37-1/2" 95.3 cm

373 kw

21-1/2" 54.61 cm 21-1/2" 54.61 cm 21-1/2

12/28 12/28 10/20 10/20 10/20 10/20

600 cfin 17 onm 600 cfin 17 cmm 1100 cfin 31.15 cmm

550#

90,000 btuh

234 kg

22,680 kcal/hr

127 cm

115 volts / 15 amps 115 volts / 12 amps 115v / 13a 208v / 7a 230v / 6.5a / 15 amp

3/4

24/26

625#

150,000btuh 37,800 kcal/hr 200,000 blub

1/2" 1.27 cm

22.7 kg

83.2 cm

560 kw 1 .746 kw

24/26 24/24 24/24

284 kg

751b. 34 kg

37"

36"

690#

750#

3/4** 1.91 cm

94 cm

91.4 cm

54.61 cm

313 kg

340 kg

50,400 kcal/hr

DIM

A 72*

B 63

C 20-1/4

D 62-1/2

E 6

F 11-1/2

G 31-3/8 79.69 cm 34-1/4

H 41-7/8

I

J 7-1/2

K

L

M N

0

30 LB

182.88 cm

160.02 cm

51.44 cm

158.75 cm 50-3/4 128.9 cm

15.24 cm 6

29.21 cm 13 32.0 cm

106.36 cm

19.05 cm

“ -

-

~

-

50 LB

72

63-1/2 161.29 cm 20-1/4 51.44 cm

49 124.4 cm

43-7/8 111.4 cm

182.9 cm 75-1/8 190.82 cm

15.24 cm

87.0 cm 38-1/4 97.15 cm

-

~

-

-

75 LB

18-1/4 46.35 cm

8 20.3 cm

48-1/2

31-13/16 80.8 cm

14 35.56 cm

5 12.7 cm

10 25.4 cm

7 17.78 cm

-

-

123.2 cm

-

REAR VIEW

TOP VIEW

MAN3729

SECTION III

INSTALLATION PROCEDURES

Installation should be performed by competent technicians in accordance with local and state codes. In the

absence of these codes, the installation must conform to applicable AMERICAN NATIONAL STANDARDS:

ANSI.Z223.1-LATEST EDITION (National Fuel Gas Code)

and/or

ANSI/NFPA NO. 70-LATEST EDITION (National Electric Code)

A. UNPACKING/SETTING UP

Remove shipping carton, or polyethylene cover and protective shipping comers from dryer.

NOTE: The access keys for the control (service) door, and lint door are shipped in the dryer and

should be removed and put in a safe place. Y et made accessible, because some will be

needed throughout various phases in the installation of the unit. Non-coin dryers are equipped

with dummy locks in both the lint and the control doors. These locks can be turned with a

screw driver or other similar tool.

The dryer can be moved to its final location while still attached to the skid or with the skid removed.

To unskid the dryer, locate and remove the four (4) bolts securing the base of the dryer to the wooden skid.

Two (2) are located at the rear of the base, and two (2) are located in the lint chamber bottom. Once the

bolts are removed, slide the dryer off the skid.

NOTE: 100 lb. ONLY: Once the bolts are off, remove the eight (8) nuts and bolts holding the skid

together and take the skid apart. The dryer can now be removed from the skid.

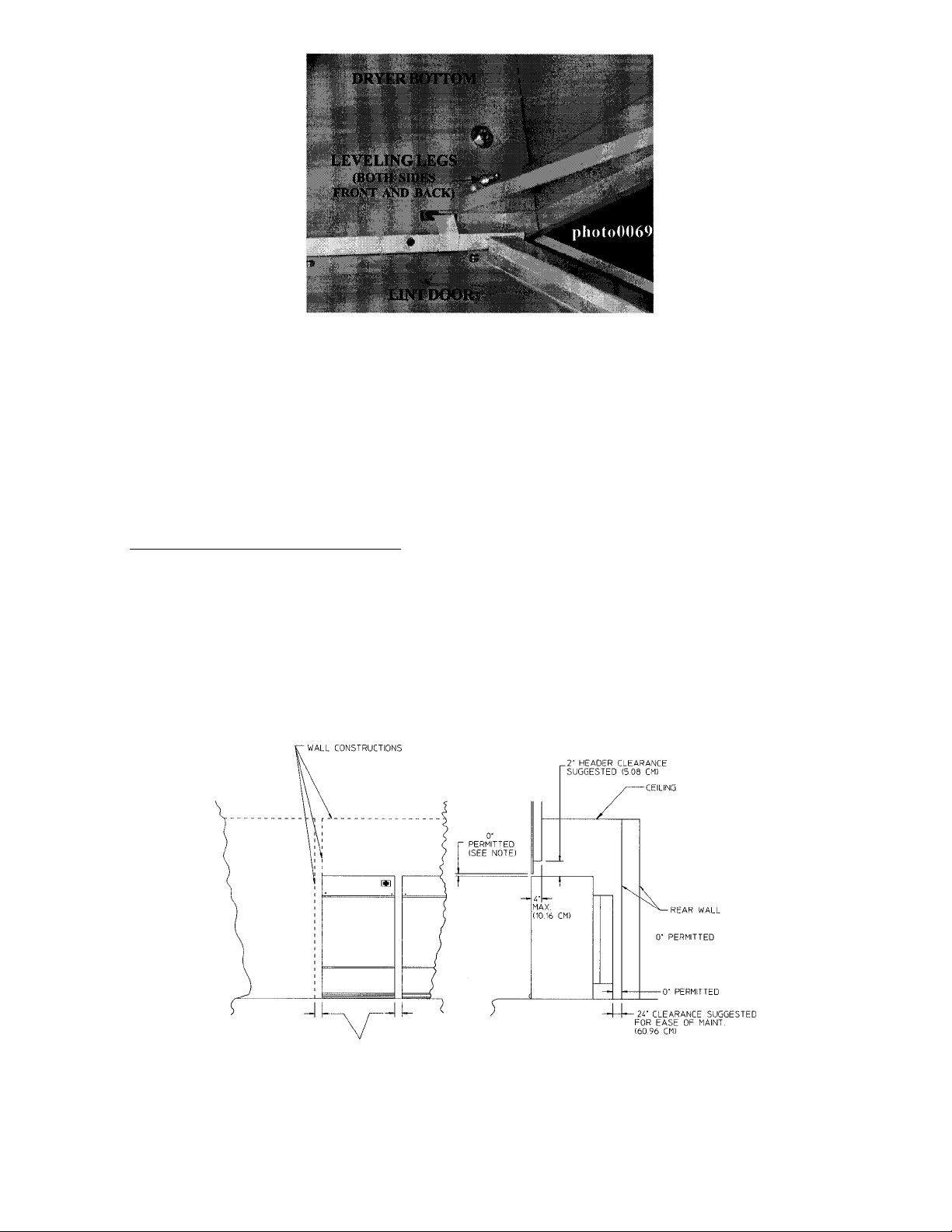

With the skid removed, to make it easier to slide the dryer into its final position, slightly lower all leveling legs

so that the dryer will slide on the legs instead of the base frame. The dryer is equipped with four (4) leveling

legs, one at each comer of the drying base. Two (2) are located at the rear of the dryer base and two (2) are

located in the lint chamber.

NOTE: 100 lb. ONLY: This unit does not have leveling legs. To level the dryer, place 4-inch square

metal shims or other suitable material under the base pads.

The tumblers of the 30, 50, and 75 lb. model dryers are supported during shipping by a wooden block.

Remove the block before starting the dryer.

The lint coops of the 30, 50, 75, and 100 lb. model dryers are supported during shipping by a bracket.

Remove this bracket before starting the dryer.

100 ib. Model ONLY - The V-belts are disconnected from the tumbler drive motor for shipping.

Reconnect the belts before starting the dryer.

B. LOCATION OF THE DRYER

Before installing the dryer, be sure the location conforms to local codes and ordinances.

The dryer must be installed on a sound, level floor capable of supporting its weight. It is recommended that

carpeting be removed from the floor area on which the dryer is to rest.

It is recommended that the rear of the dryer be positioned about two (2) feet away from the nearest

obstruction (i.e., wall) for ease of installation, maintenance and service.

NEAREST COMBUSTIBLE

0" PERMITTED i1"-2" SUGGESTED FOR EASE OF MAINT )

(2.52-5,08 CM)

BONNET EXTENDS UP 1 3/2' ABOVE DRYER ON ALL MODELS

INSTALLATION DRYER CLEARANCE TO ADJACENT WALL STRUCTURES.

MAN3727

Loading...

Loading...