Page 1

Page 2

Read this before you start…

TOOLS needed for installation:

• Cutting knife

• Channel lock

• Nut driver

•Level

• Crescent wrench

Proper installation is the responsibility of the purchaser.

SERVICE CALLS PERFORMED AS A RESULT OF POOR INSTALLATION ARE THE

RESPONSIBILITY OF THE INSTALLER.

Make sure you have everything necessary for proper installation.

1

3

2

4

GROUNDED ELECTRICAL OUTLETS are required. See Electrical Requirements.

1

STANDPIPE DRAIN SYSTEM must be able to accept 1-1/2 inch O.D.drain hose.

2

Standpipe height of 36 inches is recommended. The drain must permit 23 gallon per

minute flow to evacuate the washer.

NOTE: If the standpipe height is less than 3 feet or greater than 5 feet, refer to the

“DRAIN FACILITY” section to determine if special provisions are needed.

HOT AND COLD WATER FAUCETS must be within 4 feet of the back of the washer.

3

NOTE: For installations requiring longer hose length, it is recommended to purchase a

double male 3/4” NH coupling and Maytag hose #33-7046 or equivalent.

WATER HEATER set to deliver 140°F (60°C) hot water to the washer.

4

PROTECTION FROM WEATHER: Do not store or operate washer below 60°F (15°C).

5

PARTS supplied for installation:

Cable tie to secure drain hose to standpipe, inlet hose or laundry tub

2 washers and 2 screens for water hoses

Page 3

REQUIREMENTS

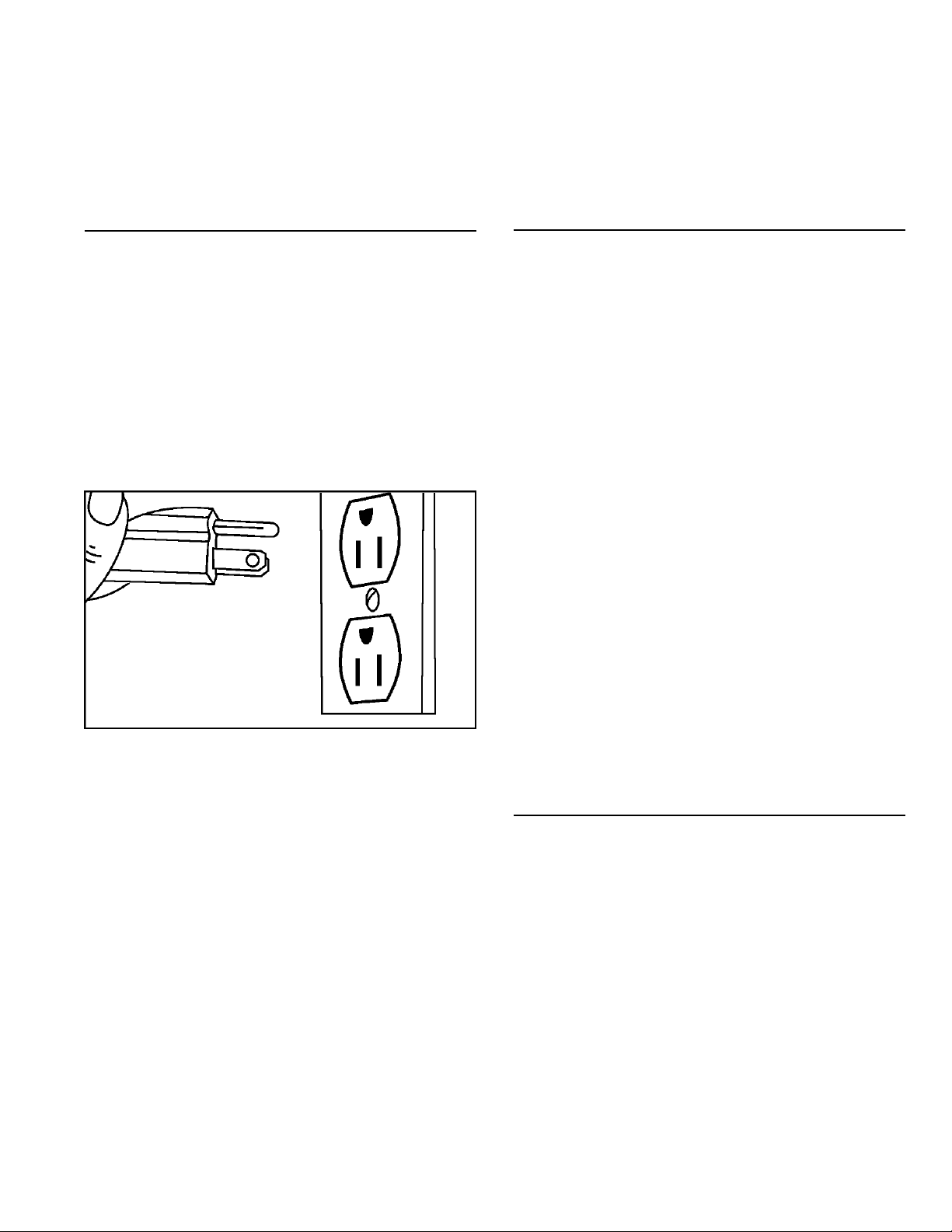

ELECTRICAL

120 Volt 60 Hz 15 AMP Fuse

Individual branch circuit serving only the

washer is recommended.

The washer is equipped with a power cord.

NEVER USE AN EXTENSION CORD.

GROUNDING

ELECTRICAL GROUND IS REQUIRED ON

THIS APPLIANCE.

Appliance is equipped with a power cord

having a 3-prong grounding plug for use in a

properly installed and grounded outlet.

Additional Ground Procedure:

If a separate ground is required by local

codes a grounding kit (Part No. 12001875)

containing accessory ground wire, clamp,

ground screw and washer can be

purchased. Contact your authorized

Maytag dealer for further assistance.

Follow ALL grounding requirements and

codes.

A proper external ground MUST be

determined prior to wire hookup. Consult

local building officials and a qualified

electrician if in doubt.

EXPORT MODELS – 50 HZ AND 60 HZ

A washer must be used on the voltage and

frequency it was designed for. It should be

operated on an individual branch circuit and

fused by no less than a 15 amp fuse or circuit

breaker for 120 volt units or 10 amp fuse or

circuit breaker on 220–240 volt units. Export

models may require the addition of a plug on

the power cord. It is the responsibility of the

installer to assure that this has been done

properly. Check the data plate to be sure of

voltage and line frequency requirements.

EXPORT–specific grounding instructions must

be determined due to variation of electrical

services.

WATER

Water pressure of 30 to 120 p.s.i.is required to

correctly fill the washer to the proper levels.

Pressures of less than 30 p.s.i. may cause a

failure to the water valve. The valve might not

shut off completely.

TO AVOID THE POSSIBILITY OF WATER

DAMAGE,SHOULD A HOSE LEAK,

ALWAYS HAVE FAUCETS ACCESSIBLE

AND TURN OFF FAUCETS WHEN WASHER

IS NOT IN USE.

Page 4

CABINET DIMENSIONS

DRAIN FACILITY

Recommended height of standpipe is 36”.

The standpipe must be large enough to accept

a 1-1/2 inch outside diameter drain hose.

Without the 36” high elevation, water may

run out of the washer prematurely. A

possible sign that the drain hose has not been

elevated to proper height is if the washer fills

and drains at the same time.

The drain hose is attached at the factory.

A drain that wil l per mi t 23 gall ons pe r mi nu t e

f l ow is required to evacuate the wa s h e r. T h e

standpipe should have a 1-1/2 inch minimu m

i n t e rnal diameter to prevent siphoning.

Tight connections between the drain hose and

the drain (standpipe, etc.) are not recommende d

since they violate most plumbing codes. I n

most cases where a tight connection is

demanded, an antisiphon va l ve should be

placed in the drain hose to prevent water from

siphon ing from t he was her or facil ity dur i n g

a g i t a t i o n . If required, an antisiphon va l ve

( Pa r t No. 12001586) is ava i l a ble from yo u r

dealer or store.

Refer to the drain height drawing to determine

if special provisions must be taken for the drain

hose and pump:

A Between the floor and 3 feet, the routing of

the drain hose is critical. Be sure that at

least some portion of the hose reaches a

height of 3 feet before running to the drain.

B Between 3 feet and 5 feet is the recom-

mended drain height.

C For drain heights greater than 5 feet, a

high-volume pump (Part No. 12001587)

may improve draining performance, especially if the unit provides a customized

cycle with a slow spin speed (refer to the

User’s Guide).

If the drain hose needs to be extended to

reach the drain facility, an accessory kit must

be obtained (Part No.12001585). If a highvolume pump is purchased, the extension kit is

included. Contact your authorized Maytag

dealer for further assistance.

FLOORING

For best performance, the washer must be

installed on a solidly constructed floor. Wood

floors may need to be reinforced to minimize

vibration and/or unbalanced load situations.

Carpeting and soft tile surfaces are also

contributing factors in vibration and/or

tendency for a washer to move slightly during

spin cycle. Never install washer on a platform

or weak supported structure.

If installing on carpeting, be sure there is

adequate clearance between carpet and

moving parts beneath the washer.

LOCATION CONSIDERATIONS

It is recommended the washer never be

installed in areas where water may freeze,

since the washer will always maintain some

water in the water valve, pump and hose

areas. This can cause damage to belts, pump,

hoses and other components. Operating

temperature should be above 60°F.

COLD WEATHER STORAGE

The following precautions should be taken if a

washer is to be stored where it would be

subject to freezing conditions.

1. Turn off the water supply, and remove the

inlet hoses.

2. Select a fill cycle and energize the water

valve by selecting a warm water setting.

A few seconds of fill is sufficient.

3. Disconnect from electrical supply.

4. Lower the drain hose to floor level and tip

the washer on its back to allow water to

drain from the pump and drain hose.

5. Return washer to upright position.

6. 30 day detergent dispenser should be

completely emptied (on models so

equipped).

Page 5

Remove parts and literature from inside of wash

er

antisiphon kit must be used.

Start here…

Step 1

• Remove the carton by cutting only marked

areas of the carton. CAUTION: Hoses are

connected to the washer.

NOTE: If the washer is moved without the

carton in place, be sure to keep sharp edges

from damaging the washer cabinet or

attached hoses.

• Lift the carton up and clear of the washer.

Carefully remove any packaging materials

from the outside of the washer. NOTE:

Retain the corner posts for later use.

• Untape and raise the washer lid. R e m ove the

s t y r o foam tub bl o ck, remove the items shipped

in the spin basket, then replace the tub bl o ck .

S ave the l i t e rature f or f ut u re r efe r e n c e. C l o s e

and tape lid.

Step 4

Run water through faucets to remove particles

that might clog the water hoses. Determine

which of the faucets is hot and place an

identifying mark on it.

Step 2

With the tub bl o ck in place and the lid taped

shut, lay corner posts on the floor, as show n .

Use one cor ne r p ost to s upp ort the top, and

three posts for the bottom. Gently tip th e

washer on its ba ck, layi ng it ac ro s s the co rn e r

p o s t s.

Front Feet

Backguard

Pop plastic

away from or

remove hex

head screw

Shipping

Base

Carton corner

posts (stacked

on each other)

Corner

Post

Step 3

Pop the plastic shipping base away from the

metal baseframe, or remove the hex head

screw at the rear. Pull plastic base away from

rear feet, and pull downward to disengage

from front feet. Recycle or discard the plastic

base. Return washer to upright position.

Step 5

Water hoses are attached to the washer and

labeled as “Hot” and “Cold.” Push the screens

and washers (located in the parts package)

into the remaining ends of the hoses. Attach

the “Hot” and “Cold” hoses to the corresponding faucets. Tighten by hand until snug and

then an additional 2/3 turn with pliers. Turn on

faucets to check for leaks at the faucet and

machine. Tighten if necessary. Fill hoses

should have slack in them when attached to

faucets.

Step 6

Unhook the hose retainer and drain hose from

the back of the cabinet and place the drain

hose in the drain facility (standpipe, laundry

tub, etc). A small amount of water may still be

in the drain hose from factory testing. The

height of the drain facility is important. Refer

to the “DRAIN FACILITY” section to determine

if special provisions are needed. NOTE: Do

not remove the hose retainer from the drain

hose. If the hose is twisted after it has been

placed in the drain, adjust the end of the hose

to remove the twist. To remove the twist, turn

the short end of the hose while holding the

base of the hose stationary.

NOTE: If you must make an airtight seal, an

Page 6

b. With the tub block in place, retape the lid. After

ins

● Improper connection of

the equipment-gr o u n d i n g

conductor can result in a

risk of electrical shock .

C h e ck with a qualified

e l e c t rician or serv i c e m a n

if you are in doubt as to

whether the appliance is

p r o p e rly gr o u n d e d .

Step 7

To prevent accidental dislodging, secure the

drain hose to the standpipe, inlet hose, or

laundry tub with the tie strap provided in the

parts package.

● Do not modify the plug provided with the

appliance – if it will not fit the outlet, have a

proper outlet installed by a qualified electri c i a n .

I M P O RTANT SAFETY PR ECAU T I O N S

● To prevent unnecessary risk of fire, electrical

shock or personal injury, all wiring and

grounding must be done in accordance with

the National Electrical Code ANSI/NFPA, No.

70-Latest Revision (for U.S.) or the Canadian

Electrical code CSA C22.1-Latest Revision

(for Canada) and local codes and ordinances.

It is the personal responsibility and obligation

of the appliance owner to provide adequate

electrical services for this appliance.

Step 8

If separate ground is required by local

codes:

An accessor y gr o und ing kit (Pa rt No. 1 2 0 0 1 8 7 5 )

containing accessory ground wire, clamp,

ground screw and washer can be purchased

separately, Connect ground wire to back of

unit with the cabinet ground screw and washer.

Secure the other end of ground wire with

clamp to grounded COLD metal water pipe.

NEVER CONNECT GROUND WIRE TO

PLASTIC PLUMBING LINES, GAS LINES, OR

HOT WATER PIPES.

Step 9

Plug the power cord into a properly grounded

electrical outlet.

Consult local building officials and a qualified

electrician if in doubt.

Step 10

The washer is equipped with self-stabilizing

rear legs. The front legs are threaded and can

be adjusted to level the washer.

Place the washer in its final operating location.

Tilt the machine forward until the rear of the

machine is approximately 4 inches off the floor.

Allow the unit to gently drop onto the rear feet.

This causes the rear feet to conform to the

floor and seat solidly.

Step 11

With hands on opposite corners, rock the

washer to check for stability.

With a level, check the washer and make the

n e c e s s a ry ad just m ent s to the front leveling legs.

N OT E :Self-st abilizing rear leg s level th e rear of

the machine side-to-side. T h ey do not prov i d e

f r o n t - t o - b a ck leve l i n g .

Page 7

llation is completed, be sure to remove tub block.

■

■

■

■

■

■

■

■

■

Step 12

Once the machine is level, tighten both front

leveling leg locking nuts with a wrench. Once

again, reset the rear stabilizer as described in

Step 10. On models equipped with a felt

sound deflector under the front of the machine,

the felt should be tucked under the machine.

Step 14

Check the operation by using the check list

provided.

Step 13

Remove tape from the lid. Open the lid to

remove the styrofoam tub block. Remove any

remaining shipping materials.

Remove the protective film from the fascia.

CHECK LIST

Tub block, parts package and instructions have been removed from the tub.

Washer has been properly grounded and plugged into a polarized electrical outlet.

Water has been turned on. Check for leaks at faucets and water valve connections.

Drain hose is properly located into drain facility and is not twisted or kinked.

Washer has been leveled with legs firmly on the floor. The front leveling legs’locking nuts

have been tightened.

Fill washer, checking for the correct water temperature.

After the washer has filled, let the washer agitate.

Spin the water out.

Demonstrate washer usage to consumer. Be sure to leave these instructions and the

User’s Guide with the owner.

Loading...

Loading...