Page 1

Customer Service

TM

Washer

Washer

Service Manual

Service Manual

16010061

Compiled From

16008373, 16010199,

Page 2

SAFETY PRECAUTIONS

This manual is to be used only by a Maytag Authorized Service Technician familiar with and

knowledgeable of proper safety and servicing procedures and possessing high quality testing

equipment associated with microwaves, gas, and electrical appliance repair.

All individuals who attempt repairs by improper means or adjustment subject themselves and

others to the risk of serious or fatal injury.

USE ONLY GENUINE MAYTAG APPROVED FACTORY REPLACEMENT COMPONENTS.

16008373-01 SAFETY PRECAUTIONS

© 1998 Maytag Corporation

Page 3

INTRODUCTION

Each model will be covered separately in a section pertaining only to its control system

and internal components. Because the basic structure for all washers is the same, they

will be covered generally without regard to model.

Model(s) covered in this manual:

MAH3000

For additional information on material covered in this manual, including safety issues,

contact:

Maytag Appliances Sales Company

240 Edwards Street, S.E.

Cleveland, TN 37311

Phone: 423.472.3333

FAX: 423.478.6722

16008373-01 INTRODUCTION

© 1998 Maytag Corporation

i

Page 4

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

SECTION 1. GENERAL INFORMATIONSECTION 1. GENERAL INFORMATION

SECTION 1. GENERAL INFORMATION

SECTION 1. GENERAL INFORMATIONSECTION 1. GENERAL INFORMATION

PRE-INSTALLATION REQUIREMENTS............................................................................................................ 1 - 1

UNCRATING....................................................................................................................................................................... 1 - 1

INSTALLATION.................................................................................................................................................................. 1 - 2

GROUNDING POLARITY CHECKS ...................................................................................................................... 1-4

SPECIFICATIONS............................................................................................................................................................. 1-4

WASHER CONTROLS................................................................................................................................................... 1 - 5

INPUT DEFINITIONS..................................................................................................................................................... 1 - 6

OUTPUT DEFINITIONS............................................................................................................................................... 1 - 8

CYCLE SEQUENCE DEFINITIONS................................................................................................................... 1-10

MISCELLANEOUS....................................................................................................................................................... 1-11

Door Latch Switch Monitoring.................................................................................................................... 1-11

Door Lock/Spin Control................................................................................................................................... 1-11

Redistribution ......................................................................................................................................................... 1-11

Push-To-Start Relay Operation .................................................................................................................... 1-12

CYCLE REVIEW............................................................................................................................................................. 1-13

GENERAL COMPONENT EXPLODED VIEW ............................................................................................ 1-14

......................................................................................................................................................................................................................................................................................................................

...........................................................................................................................................................

......................................................................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................

..............................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................

......................................................................................................

............................................................................................................................................................................................................

ii

i

ii

iiii

ii

iiii

1-11-1

1-1

1-11-1

SECTION 2. ELECTRICAL COMPONENTS & TESTINGSECTION 2. ELECTRICAL COMPONENTS & TESTING

SECTION 2. ELECTRICAL COMPONENTS & TESTING

SECTION 2. ELECTRICAL COMPONENTS & TESTINGSECTION 2. ELECTRICAL COMPONENTS & TESTING

ELECTRICAL TEST EQUIPMENT ........................................................................................................................ 2 - 1

ELECTRICAL TESTS ..................................................................................................................................................... 2-2

Grounded Components..................................................................................................................................... 2-2

Voltage Checks ......................................................................................................................................................... 2-2

Water Valve Test....................................................................................................................................................... 2-2

Wax Motor Check/Door Lock Mechanism............................................................................................ 2-2

Timer & Console Switches ............................................................................................................................... 2-3

Timer Input Charts.................................................................................................................................................. 2-3

Machine Control....................................................................................................................................................... 2-5

DRIVE MOTOR ................................................................................................................................................................... 2-7

MOTOR CONTROL BOARD ...................................................................................................................................... 2-7

Motor & Motor Control Test............................................................................................................................ 2-8

Motor Phase Test .................................................................................................................................................... 2-8

Motor Windings Check ....................................................................................................................................... 2-9

Tachometer Circuit Diagnostics ................................................................................................ .............2-10

UNBALANCE CONTROL SYSTEM .................................................................................................................. 2-11

Tub Displacement Switch............................................................................................................................... 2-12

Strut Displacement Switch ............................................................................................................................ 2 -1 2

Inertial Unbalance Switch ............................................................................................................................... 2-13

Cabinet Vibration Sensor ............................................................................................................................... 2-13

Cabinet Vibration Absorber ......................................................................................................................... 2-13

....................................................................................................................................

..................................................................

....................................................................................................................................

2-12-1

2-1

2-12-1

16008373-01

© 1998 Maytag Corporation

CONTENTS

iiii

ii

iiii

Page 5

SECTION 3. TROUBLESHOOTINGSECTION 3. TROUBLESHOOTING

SECTION 3. TROUBLESHOOTING

SECTION 3. TROUBLESHOOTINGSECTION 3. TROUBLESHOOTING

................................................................................................................................................................................................................................

................................................................................................................

................................................................................................................................................................................................................................

3-13-1

3-1

3-13-1

DIAGNOSTIC FLOW CHARTS....................................................................................................3-4

Fills and Will Not Tumble................................................................................................................................... 3-4

Washer Overfills....................................................................................................................................................... 3-5

Washer Will Not Spin ........................................................................................................................................... 3-6

Machine Stalls During Spin............................................................................................................................... 3-8

Maximum Spin Speed Is Not Reached ................................................................................................... 3-9

Wash Cycle Takes Longer Than Normal .............................................................................................. 3-10

Suds Coming Out Of Door............................................................................................................................. 3 - 10

Washer Will Not Start ........................................................................................................................................ 3-11

Motor Phase Test ................................................................................................................................................. 3-12

TIMER TEMPLATE OVERLAY ............................................................................................................................. 3- 13

MISCELLANEOUS INFORMATION.................................................................................................................. 3-14

SECTION 4. CONSOLESECTION 4. CONSOLE

SECTION 4. CONSOLE

SECTION 4. CONSOLESECTION 4. CONSOLE

........................................................................................................................................................................................................................................................................................

............................................................................................................................................

........................................................................................................................................................................................................................................................................................

4-14-1

4-1

4-14-1

REMOVAL............................................................................................................................................................................. 4-1

VERTICAL SWITCHES.................................................................................................................................................. 4-2

HORIZONTAL SWITCHES.......................................................................................................................................... 4-2

TIMER REMOVAL/REPLACEMENT.................................................................................................................... 4-3

SECTION 5. CABINET ASSEMBLYSECTION 5. CABINET ASSEMBLY

SECTION 5. CABINET ASSEMBLY

SECTION 5. CABINET ASSEMBLYSECTION 5. CABINET ASSEMBLY

..................................................................................................................................................................................................................................

.................................................................................................................

..................................................................................................................................................................................................................................

5-15-1

5-1

5-15-1

DOOR ASSEMBLY & HINGES ................................................................................................................................. 5-1

Cabinet Vibration Absorber ............................................................................................................................ 5-2

Door Latch Hoop ..................................................................................................................................................... 5-2

FRONT PANEL................................................................................................................................................................... 5-2

TOP COVER......................................................................................................................................................................... 5-3

DOOR LOCK MECHANISM ....................................................................................................................................... 5-3

FRONT SHROUD ASSEMBLY................................................................................................................................. 5-4

CABINET ASSEMBLY W/REAR ACCESS PANEL...................................................................................... 5-5

SECTION 6. WATER CARRYING COMPONENTSSECTION 6. WATER CARRYING COMPONENTS

SECTION 6. WATER CARRYING COMPONENTS

SECTION 6. WATER CARRYING COMPONENTSSECTION 6. WATER CARRYING COMPONENTS

................................................................................................................................................................

................................................................................

................................................................................................................................................................

6-16-1

6-1

6-16-1

WATER VALVE................................................................................................................................................................... 6 -1

WATER LEVEL PRESSURE SWITCH.................................................................................................................. 6-2

AIR DOME HOSE.............................................................................................................................................................. 6-2

DISPENSER ASSEMBLY............................................................................................................................................. 6-3

FRONT WATER FLUME INJECTOR..................................................................................................................... 6-4

PUMP ASSEMBLY.......................................................................................................................................................... 6-4

Pump Accessory ..................................................................................................................................................... 6-5

DRAIN HOSE....................................................................................................................................................................... 6-6

SECTION 7. OUTER TUB & SPINNER ASSEMBLYSECTION 7. OUTER TUB & SPINNER ASSEMBLY

SECTION 7. OUTER TUB & SPINNER ASSEMBLY

SECTION 7. OUTER TUB & SPINNER ASSEMBLYSECTION 7. OUTER TUB & SPINNER ASSEMBLY

........................................................................................................................................................

............................................................................

........................................................................................................................................................

7-17-1

7-1

7-17-1

BAFFLES................................................................................................................................................................................ 7 - 1

DOOR BOOT........................................................................................................................................................................ 7 -1

OUTER TUB COVER...................................................................................................................................................... 7-2

SPIN BASKET ASSEMBLY W/BALANCE RING .......................................................................................... 7-3

DRIVE PULLEY.................................................................................................................................................................. 7-4

SPINNER TUB SUPPORT........................................................................................................................................... 7-5

16008373-01

©1997 Maytag Corporation

CONTENTS

iiiiii

iii

iiiiii

Page 6

SEAL SYSTEM .................................................................................................................................................................. 7-6

OUTER TUB ASSEMBLY............................................................................................................................................ 7-7

BEARINGS............................................................................................................................................................................ 7-7

COUNTER WEIGHTS.................................................................................................................................................... 7-7

STRUT ASSEMBLY........................................................................................................................................................ 7-8

Strut Displacement Switch ............................................................................................................................... 7-8

INERTIAL UNBALANCE SWITCH......................................................................................................................... 7-8

TUB DISPLACEMENT SWITCH............................................................................................................................. 7-9

SECTION 8. MOTOR DRIVE SYSTEMSECTION 8. MOTOR DRIVE SYSTEM

SECTION 8. MOTOR DRIVE SYSTEM

SECTION 8. MOTOR DRIVE SYSTEMSECTION 8. MOTOR DRIVE SYSTEM

................................................................................................................................................................................................................

........................................................................................................

................................................................................................................................................................................................................

8-18-1

8-1

8-18-1

DRIVE BELT ......................................................................................................................................................................... 8 -1

DRIVE MOTOR ................................................................................................................................................................... 8 - 1

MACHINE CONTROL.................................................................................................................................................... 8-2

MOTOR CONTROL ......................................................................................................................................................... 8-3

SECTION 9. ELECTRICAL SCHEMATICSSECTION 9. ELECTRICAL SCHEMATICS

SECTION 9. ELECTRICAL SCHEMATICS

SECTION 9. ELECTRICAL SCHEMATICSSECTION 9. ELECTRICAL SCHEMATICS

....................................................................................................................................................................................................

..................................................................................................

....................................................................................................................................................................................................

9-19-1

9-1

9-19-1

Schematic Prior to Series 17 .......................................................................................................................... 9 - 1

Timer Chart Prior to Series 17 ....................................................................................................................... 9-2

Schematic Series 17.............................................................................................................................................. 9-3

Timer Chart Series 17 .......................................................................................................................................... 9-4

Schematic Series 18.............................................................................................................................................. 9-5

Timer Chart Series 18 .......................................................................................................................................... 9-6

Schematic Series 19.............................................................................................................................................. 9-7

16008373-01

© 1998 Maytag Corporation

CONTENTS

iviv

iv

iviv

Page 7

SECTION 1. GENERAL INFORMATION

PRE-INSTALLATION

REQUIREMENTS

NOTE: Proper installation is the responsibil-

ity of the purchaser .

Checkpoints for proper installation:

• Properly grounded electrical outlet is re-

quired. Use 15 amp fuse or compatible

circuit breaker for electrical service.

• Standpipe Drain System must accept 1½"

O.D. drain hose. Standpipe height of 36"

is recommended.

NOTE: If drain standpipe is in excess of 5 feet

above floor level, install pump accessory kit,

part number 22002136.

• This unit is not equipped with a siphon

break, and the drain hose must be elevated

to a minimum height of 24". A 36" high

standpipe is recommended. For all installations the drain hose must be supported

by the drain hose strap on the back of the

washer.

• Hot and Cold water faucets must be within

four (4) feet of the back of the washer . This

allows quick access for immediate water

shut off.

• Water heater should be set to deliver a

minimum of 120ºF (49º C) hot water to the

washer.

• Do not store or operate washer in tem-

peratures below freezing. This can cause

damage to the pump, hoses and other

components.

cause an extended fill time. Refer to the

troubleshooting section for more information regarding a solution for slow fill

situations.

• Best performance is obtained with the

washer installed on a solid floor. Wood

floor constructions may need to be reinforced to minimize vibration from unbalanced load situations. Carpets and soft

tile surfaces are also contributing factors

to vibration and/or movement during the

spin cycle. Never install washer on a plat-

form or weak support structure.

UNCRATING INSTRUCTIONS

NOTE: The following steps must be per-

formed in the correct order to ease uncrating.

1. Remove the carton by cutting only in

marked areas of the carton. CAUTION:

Hoses are connected to the washer.

2. Carefully remove any packaging materials from the outside of the washer.

IMPORTANT: DO NOT cut the red straps

securing the power cord and inlet hoses

at this time. They will be removed later

during installation.

3. Remove the accessory package from inside the tub.

4. Remove the crate bottom from the washer

by removing crate bottom wire clips.

• Water pressure of 20 - 120 P.S.I. is required

to fill the washer in the appropriate time

frame. Pressures of less than 20 P.S.I. may

16008373-01 SECTION 1. GENERAL INFORMATION

© 1998 Maytag Corporation

1-1

Page 8

INSTALLATION

1. Two separate red shipping straps are used

to secure the machine for shipping purposes and to secure the power cord with

the water inlet hoses. Remove the straps

in the following sequence:

A . Locate the metal buckles securing the red

straps which extend through slots in the

rear wall of the cabinet. The buckles are

positioned in the center of the red straps.

Carefully cut the red straps, and remove

the metal buckles. NOTE: Cut the straps

as close to the buckles as possible. Discard the buckles.

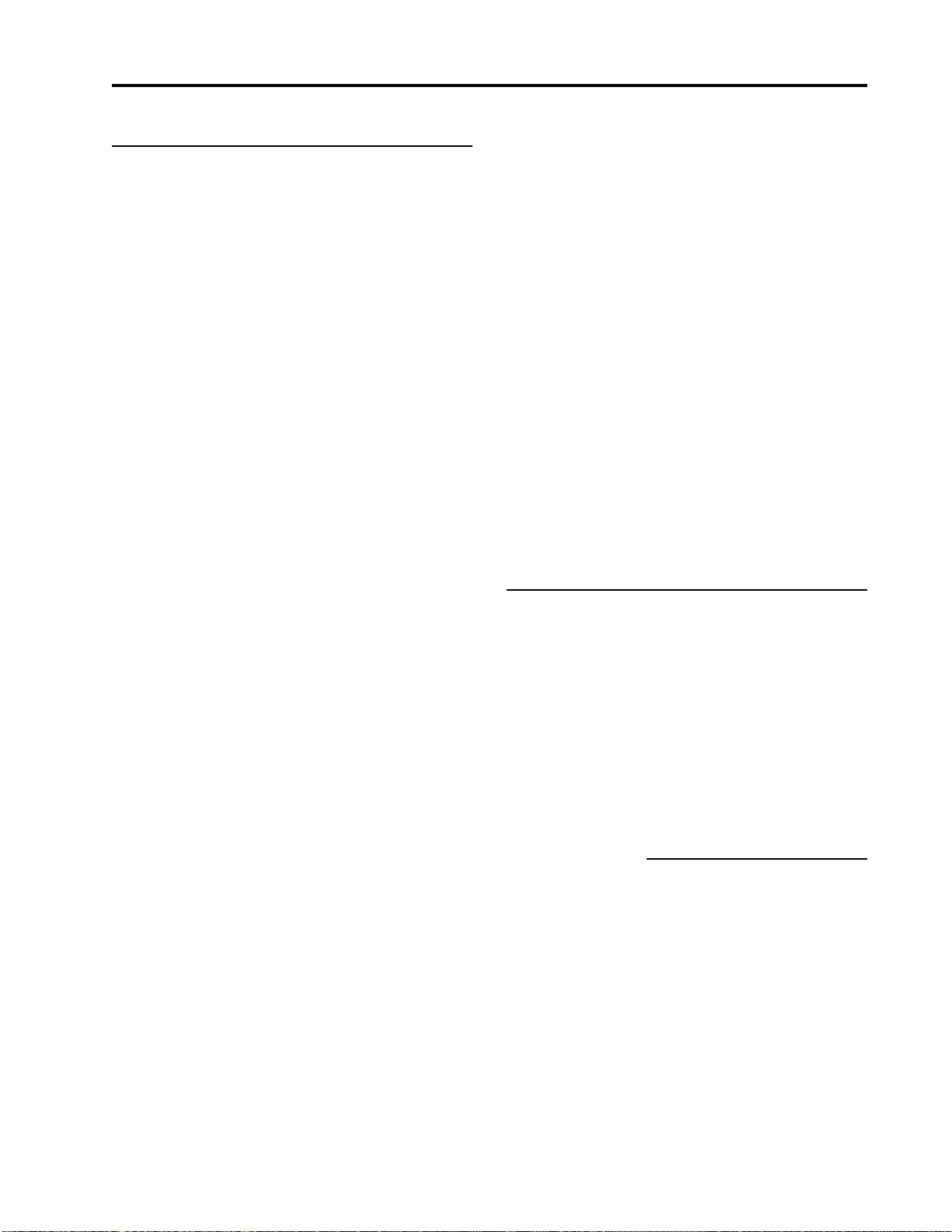

Figure 1-2

3. Locate the two (2) ½" hex head shipping

bolts extending up through the bottom of

the base (Figure 1-4). The shipping bolts

are near the center of the base toward the

front of the washer. Remove both bolts,

freeing the tub and suspension. Do not

be alarmed should the tub assembly shift

when the last bolt is removed. Some shifting of the tub is normal.

Figure 1-1

Figure 1-3

B. Grasp each loose strap individually and

pull the strap to remove it from the cabinet. Discard the strap (Figure 1-2).

2. Tip washer slightly forward. Loosen rear

leveling leg lock nuts. Tip washer back

slightly to loosen front leveling leg lock

nuts (Figure 1-3).

16008373-01 SECTION 1. GENERAL INFORMATION 1-2

© 1998 Maytag Corporation

Page 9

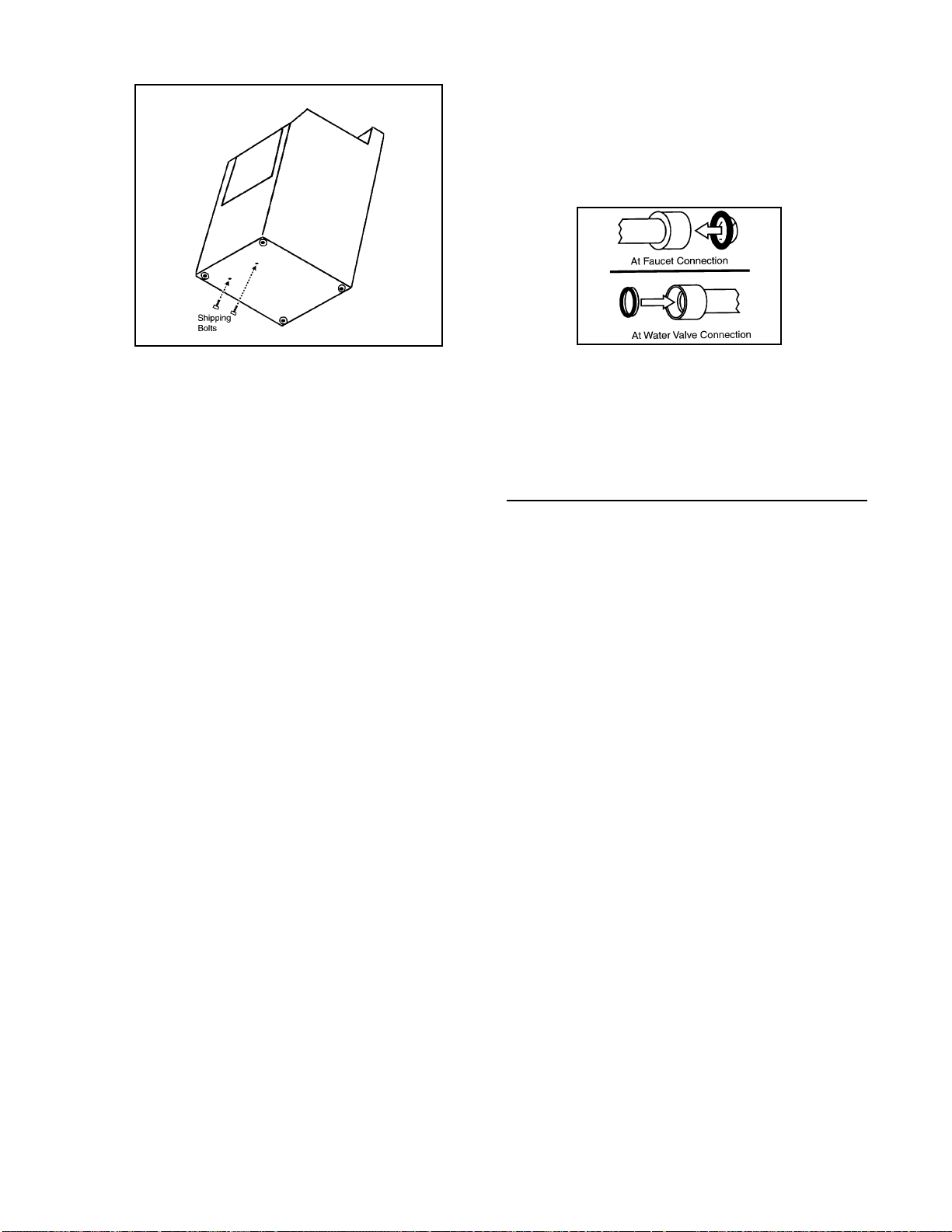

Turn on the water and check for leaks (Figure

1-5). Note the H and C designations on the

water valve bracket for the Hot and Cold

hoses.

Figure 1-4

4. Slide the washer into position and check

the levelness and stability of the washer.

If necessary, slide the washer out of position to either raise or lower the leveling

leg as required to level and stabilize the

washer securely on all four legs. Slide the

washer back into position to confirm levelness to the floor. When the washer is

level, tighten the locking nuts up against

the base of the washer. This will secure

the leveling legs in place.

5. Install the rubber feet, found in the installation package, on all four (4) legs (Figure

1-3).

6. Pull the drain hose vertically to the drain

strap . Then route the drain hose through

the drain hose strap on the back of the

washer and snap into the plastic hook of

the strap.

7. Install gooseneck end of drain hose into

drain standpipe. Be sure the connection

is not airtight between the drain hose and

standpipe. Standpipe must be at least 24"

high. 36" height is recommended.

8. Connect inlet hoses to water supply using screen washers (found in the installation package) at faucet connections, with

the domed screen facing the faucet. Attach hoses to the faucets and the water

valve.

Figure 1-5

NOTE: Accessory inlet hoses are available in

various lengths, up to 10 feet.

GROUNDING POLARITY CHECKS

The receptacle used for all Maytag products

operating on 120 Volts AC must be properly

grounded and polarized.

The power cord should be equipped with a

three (3) PRONG POLARIZED GROUNDING

PLUG FOR PROTECTION AGAINST SHOCK

HAZARD and should be plugged directly into

a properly grounded and polarized receptacle.

CAUTION: Do not cut or remove the grounding prong from this plug.

It is the responsibility of the person installing

the appliance to ensure it is adequately

grounded and polarized at the point of installation. Local conditions and requirements

should be taken into consideration. In cases

where only a two (2) prong receptacle is available, it is the personal responsibility of the

customer to have it replaced with a properly

grounded and polarized three (3) prong receptacle (Figure 1-6).

16008373-01 SECTION 1. GENERAL INFORMATION

© 1998 Maytag Corporation

1-3

Page 10

Plug power cord into a properly grounded 120

volt AC-approved electrical service. This

must be protected by a dedicated 15 amp fuse

or circuit breaker.

All grounding and wiring should be performed

in accordance with national and local codes.

USE OF ADAPTERS IS NOT RECOMMENDED.

Figure 1-6

SPECIFICATIONS

CAPACITY 3.1 Cubic Feet

CAPACITY 3.1 Cubic Feet

ELECTRICAL 120 volt s, 60 Hz; Requi r es 15 am p circ uit b r eaker or fus ed el ect ri cal

ELECTRICAL 120 volt s, 60 Hz; Requi r es 15 am p circ uit b r eaker or fus ed el ect ri cal

supply. Power cord must be connected to a properly grounded and

supply. Power cord must be connected to a properly grounded and

pol arized o utlet .

pol arized o utlet .

MOTOR Switched Reluctance Motor controlled by a microprocessor motor

MOTOR Switched Reluctance Motor controlled by a microprocessor motor

control board. Motor pulley ratio (motor to spinner RPM) 14 to 1.

control board. Motor pulley ratio (motor to spinner RPM) 14 to 1.

POWER U SAGE Motor Input : During Wash Tumble - 150 Watts

POWER U SAGE Motor Input : During Wash Tumble - 150 Watts

(Wattage readings taken with no clothes in spinner.)

(Wattage readings taken with no clothes in spinner.)

TU MBL ER SPEED Wash Tumble 47-51 RPM

TU MBL ER SPEED Wash Tumble 47-51 RPM

Rin se Tu m ble 47-5 1 RPM

Rin se Tu m ble 47-5 1 RPM

High Speed Spin 800 RPM (± 50 RPM based upon optim um

High Speed Spin 800 RPM (± 50 RPM based upon optim um

WATER USAGE Water pressure should be 20-120 p.s.i. (1.06-8.4 4 kg/cm ) at inlet hose

WATER USAGE Water pressure should be 20-120 p.s.i. (1.06-8.4 4 kg/cm ) at inlet hose

connection. Total water usage is approximately 25 gallons; varies w ith

connection. Total water usage is approximately 25 gallons; varies w ith

cl othe s lo ad. W ater fill in th e spi n b asket w it h no clo thes, m easured

cl othe s lo ad. W ater fill in th e spi n b asket w it h no clo thes, m easured

near the rear seam of the spin basket.

near the rear seam of the spin basket.

WASH LEVEL 3-4 inches

WASH LEVEL 3-4 inches

RINS E LEVEL 4-5 inc hes

RINS E LEVEL 4-5 inc hes

HOSE LENGTHS Four-foot inlet hoses with inlet washers and attaches to water valve.

HOSE LENGTHS Four-foot inlet hoses with inlet washers and attaches to water valve.

DIMENSIONS Cab ine t di mens io ns: 27" (68.58c m) W x 27 ½ ” (69.85 cm ) D x 36"

DIMENSIONS Cab ine t di mens io ns: 27" (68.58c m) W x 27 ½ ” (69.85 cm ) D x 36"

WEIGHT (Approx.) Un car to ned 190lb . (86 kg.) Ap p ro x .

WEIGHT (Approx.) Un car to ned 190lb . (86 kg.) Ap p ro x .

S CREW & BO LT T ORQ UES Bolt, Counter Weight 7in. lbs. (± 3in.lbs)

S CREW & BO LT T ORQ UES Bolt, Counter Weight 7in. lbs. (± 3in.lbs)

Drain hose attaches to pump and will accomm odate 36" dr ain stand

Drain hose attaches to pump and will accomm odate 36" dr ain stand

pipe.

pipe.

(91. 44cm )H.

(91. 44cm )H.

Crat ed 200lb . (91 kg) . Ap p ro x .

Crat ed 200lb . (91 kg) . Ap p ro x .

Bolt, Spin Pulley 30in. lbs (± 3in. lbs)

Bolt, Spin Pulley 30in. lbs (± 3in. lbs)

Bolt, Belt Adjuster 90in. lbs (± 10in. lbs)

Bolt, Belt Adjuster 90in. lbs (± 10in. lbs)

Screw, Front Baffle 25in. lbs (± 3in. lbs)

Screw, Front Baffle 25in. lbs (± 3in. lbs)

Screw, Rear Baffle 18.5in. lbs (± 3in. lbs)

Screw, Rear Baffle 18.5in. lbs (± 3in. lbs)

Clam p, Ho ses 15+ in. lb s

Clam p, Ho ses 15+ in. lb s

Nuts, Spinner Support 18in. lbs (± 3in. lbs)

Nuts, Spinner Support 18in. lbs (± 3in. lbs)

Nuts, Suspension Struts 7in. lbs (± 3in. lbs)

Nuts, Suspension Struts 7in. lbs (± 3in. lbs)

Du ring Rinse Tu m ble - 17 5 Watt s

Du ring Rinse Tu m ble - 17 5 Watt s

To p Spin - 80 0 Wa tt s

To p Spin - 80 0 Wa tt s

spin performance.)

spin performance.)

16008373-01 SECTION 1. GENERAL INFORMATION 1-4

© 1998 Maytag Corporation

Page 11

WASHER CONTROLS

The control system in the Neptune horizontal axis washer generally consists of a timer and

microprocessor-based machine control. These receive input signals and send output signals to

other equipment in the washer, including the motor and motor control, user input switches,

user indicator lights, the door latch and lock assembly, water valves, drain pump, unbalance

switches, dispenser actuator wax motors, a pressure switch, and a tub light.

The machine control has direct control of these items:

- Motor speed and direction, through signals to the motor control.

- Door lock wax motor.

- Hot and cold water valves, with an input signal from the timer and pressure switch.

- Timer motor.

- On Light.

In general, the timer dial is rotated to a desired setting, selects the cycles options using the

option switches, and starts the washer. The machine control reads the inputs from the timer,

option switches and pressure switch then send output signals to the motor control and other

components based upon those inputs. When the machine control has completed its set of

instructions for the specific timer setting, it energizes the timer motor output to advance the

timer to the next increment, reads a new set of input signals from the timer, and acts upon

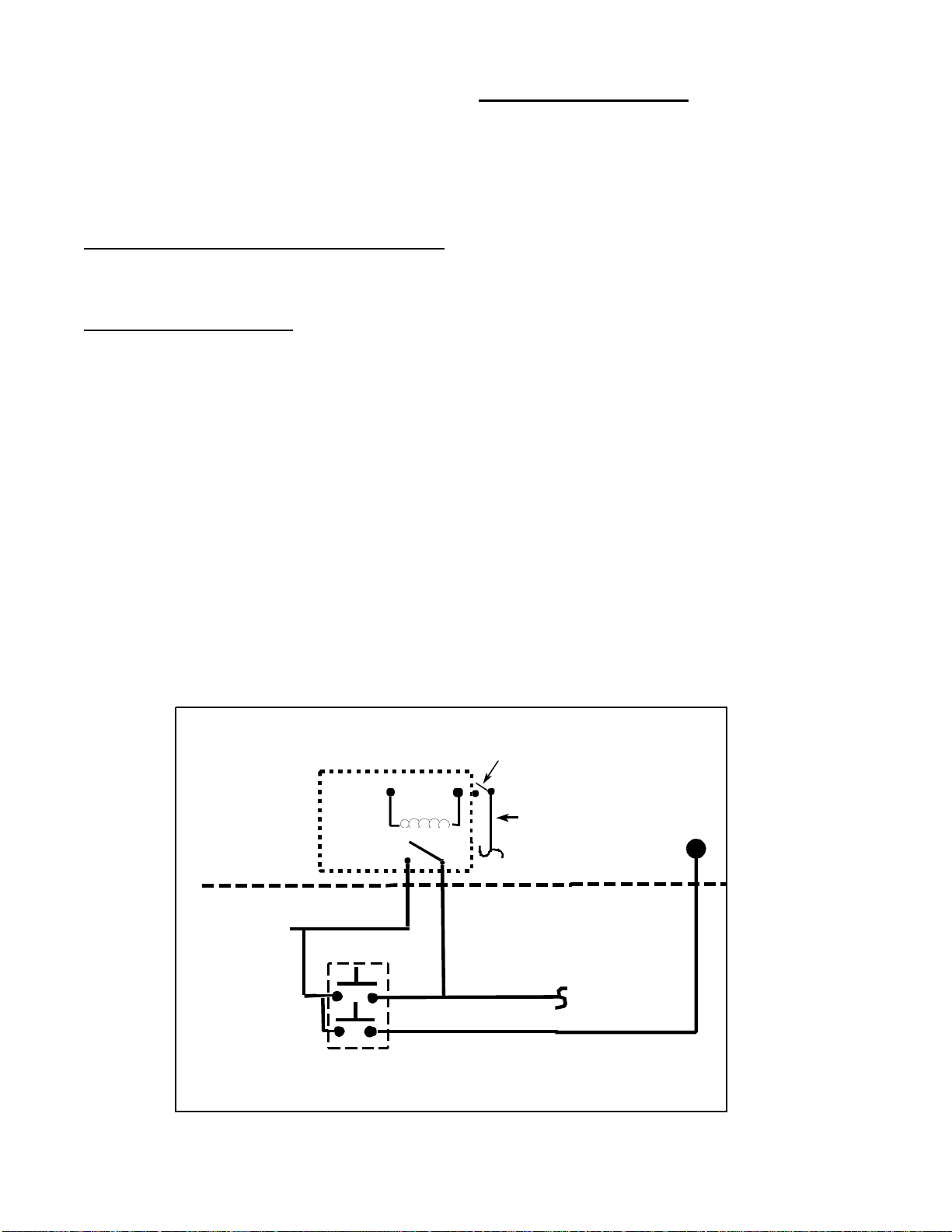

them. This continues until the cycle is complete. (See Figure 1-7 & 1-8 for a generic representa-

tion of the Neptune washer control system.)

Prior To Series 17

Figure 1-7

16008373-01 SECTION 1. GENERAL INFORMATION

© 1998 Maytag Corporation

1-5

Page 12

Figure 1-8

INPUT DEFINITIONS

DOOR LOCK SWITCH INPUT

When input is present, this is indication the

washer door is locked. The machine controller will not command the spinner to spin faster

than 50 rpm when the input is not present

prior to spin.

END-OF-CYCLE SIGNAL INPUT

The End-of-Cycle Signal Input is energized

through a user input switch on the control

panel. When this is energized and the cycle

has finished, the machine control will sound

the End-of-Cycle signal (See End-Of-Cycle Sig-

nal Output).

FABRIC SELECTION INPUTS

The Fabric Selection Inputs are energized

through a user input switch on the control

panel. The machine control reads these inputs to determine which cycles should be run

when the washer is started.

MAX EXTRACT INPUT

The Max Extract Input is energized through a

user input switch on the control panel. When

input is energized, the machine control will

modify the final spin profile to the max extract profile.

Series 17 & Later

NOTE: If the user selects the Hand Washables

fabric selection, all spins will follow the Max

Extract profile regardless of whether the user

selects the Max Extract option.

OUT-OF-BALANCE INPUT

The Out-of-Balance Input Signal is provided

by three normally-closed switches wired in

sequence. If any of these switches opens due

to an out-of-balance condition, the signal will

be momentarily lost (See Unbalance Control

System).

PRESSURE SWITCH INPUT

The input signal from the Pressure Switch

serves two purposes. It supplies power for

the water valves and provides an indication

to the machine control as to whether the commanded water level has been reached.

When the timer advances into a cycle sequence that calls for water, power is supplied

through the timer to either the wash or rinse

level contacts on the pressure switch. When

the water level in the tub is below the full level

for that setting, the pressure switch circuit is

closed, supplying power for the water valves

to the machine control. When the water level

switch is satisfied, the pressure switch circuit

is opened and power for the water valves is

no longer passed to the machine control. The

16008373-01 SECTION 1. GENERAL INFORMATION 1-6

© 1998 Maytag Corporation

Page 13

machine control interprets this loss of power

as an indication that the water level has

reached the full level.

When the washer is at the "full" level and the

timer is set in a Prewash Tumble, Main Wash

Tumble, Light Wash Tumble, or Rinse Tumble

increment, the machine control will begin the

sequence timing defined for each cycle and

fabric selection setting (See Cycle Sequence

Definitions).

During the drain and spin increments after the

main wash, first rinse, second rinse, and extra rinse increments, the wash side circuit in

the pressure switch is closed. When the water level drains below the wash full level, the

circuit will close and energize the pressure

switch input. The machine control interprets

this signal (not to energize the water valve

outputs) to measure how quickly the washer

is draining. If the machine control commands

a spin speed above 51 rpm before the pressure switch input is energized, it will drop the

speed to 0 rpm and hold there until the pressure switch input is energized. An additional

delay equal to the length of time elapsed will

occur before the pressure switch input is energized. If four minutes elapse without the

pressure switch input being energized, the

machine control will energize the timer motor output to advance the timer into the next

increment and continue with the cycle.

TACH INPUT

The tach input is a feedback signal from the

motor control. It provides eight pulses per

revolution of the switched reluctance motor.

The motor runs at 14 times the speed of the

spinner (14:1 belt ratio). The tach input is used

for monitoring speed and out-of-balance detection (See Tachometer Circuit Diagnostics).

If the machine control commands a motor

speed and direction but does not sense a tach

input signal within five seconds, it will disengage the line relay to stop the washer. This

generally indicates a locked rotor or a malfunction in the motor control.

If the machine control senses a tach input signal when it is not commanding the motor to

run, it will disengage the line relay to stop the

washer.

If the machine control commands a coast

down from final spin speed but is still receiving a tach input signal after two minutes, it

will disengage the line relay to stop the washer.

TEMPERATURE SENSOR INPUT

A thermistor is located in the water valve to

monitor the blended incoming water temperature. The machine control uses this input signal to regulate the water temperature with the

warm or cold wash or warm rinse temperature selections (See Water Valve Outputs).

START/STOP INPUT

The start/stop input is energized by the momentary Push-to-Start/Stop Switch. If this input is energized when a cycle is in progress,

the machine control will disengage the line

TIMER INPUTS

The Timer Input signals are energized through

the cams in the timer. The timer operates with

a 30 second drive cycle and a 5.8 second advance time (See Timer Input Charts).

relay, both water valve output signals, the door

lock wax motor signal, the timer motor output signal, and the on-light output signal. If

this input is energized when a cycle is not in

progress, the machine control will energize

the line relay and begin the cycle sequence as

defined by the timer and user input switches

(See Push-To-Start/Line Relay Operation).

16008373-01 SECTION 1. GENERAL INFORMATION

© 1998 Maytag Corporation

WATER TEMPERATURE INPUTS

The Water Temperature inputs are two separate signals defined by a user input switch on

the control panel. The machine control interprets these signals to determine what the water temperature should be for each fill (See

W ater Valve Outputs).

1-7

Page 14

OUTPUT DEFINITIONS

DOOR LOCKED LIGHT OUTPUT

NOTE: This section applies only to washers

between Series 10 and 16. The "Door Locked"

lights on washers from Series 17 and after are

controlled by a "Door Locked" light switch.

END-OF-CYCLE SIGNAL OUTPUT

The End-Of-Cycle Signal Output is an internal signal on the machine control between the

microprocessor and annunciator. The end-ofcycle signal sounds when a wash cycle is finished and the End-Of-Cycle Input is energized.

The end-of-cycle signal sounds as six pulses

in a 0.35 seconds on, 0.15 seconds off pattern

(See Timer Input Charts).

The Door Locked Light Output signal powers

a 1/3 watt neon indicator lamp on the control

panel. This output is first energized when the

Door Lock Wax Motor Output is energized. At

the end of the cycle, it remains energized for

50 seconds after the Door Lock Switch Input

shuts down. This delay allows the wax motor

to fully retract and unlock the door.

NOTE: The washer will continue to tumble

at the end of cycle until this 50 second delay

is elapsed.

DOOR LOCK WAX MOTOR OUTPUT

The Door Lock Wax Motor Output signal powers a wax motor in the door lock assembly.

The wax motor extends to drive the door lock

system for the washer.

If the washer is started with the timer set in a

Prewash Tumble, Main Wash Tumble, or Light

Wash Tumble increment, the machine control

will wait for three minutes before energizing

the Door Lock Wax Motor Output. This delay

is not affected by water level. This output remains energized until the end of the cycle.

If the washer is started with the timer set in a

Prewash Drain, Bleach Dispense, Spin1, Rinse

Tumble, Spin2, or Spin3 increment, the machine control will energize this output immediately.

ON LIGHT OUTPUT

NOTE: This section applies only to washers

from Series 17 and after. The "Door Locked"

lights on washers between Series 10 and 16

are controlled by a cam on the timer.

The Door Locked Light Output signal powers

a 1/3 watt neon indicator lamp on the control

panel. This output is energized when the

washer is operating in a wash or spin cycle.

Note that the "On" light is not illuminated when

the timer is in a delay increment.

TIMER MOTOR OUTPUT

The machine control energizes the Timer

Motor Output to allow for variable-length

timer increments. If the washer is started with

the timer set in a Prewash Tumble, Main Wash

Tumble, Light Wash Tumble, or Rinse Tumble

increment, the machine control will not begin the cycle sequence timing until the water

level reaches the appropriate level. The Timer

Motor Output is disengaged during this time.

The machine control will stop the washer by

disengaging the line relay if the following occur: 1) The machine control energizes the

timer motor until it senses a timer change. 2)

The timer motor remains energized for five

minutes while the timer inputs change (See

Timer Input Charts).

The machine control will continuously energize the Door Lock Wax Motor Output during

the final (Spin 3) sequence until 30 seconds

before the washer begins to coast from the

final speed.

16008373-01 SECTION 1. GENERAL INFORMATION 1-8

© 1998 Maytag Corporation

Page 15

The machine control counts the number of

rinses during a normal wash cycle. In the first

and second Rinse Tumble increments, the

machine control will energize the Timer Motor Output as soon as the Pressure Switch Input is no longer energized, indicating that the

water has reached the full level. In the third

and fourth (if Extra Rinse is selected) Rinse

Tumble increments, the machine control will

energize the Timer Motor Output 30 seconds

after the Pressure Switch Input is no longer

asserted.

The machine control will energize the Timer

Motor Output when the timer is set into a

Spin1, Spin2, or Spin3 increment 30 seconds

before the end of the spin. It will remain energized until the timer inputs change.

TORQUE OUTPUT

The machine control commands motor speed

and direction through the Torque Output from

the machine control to the motor control.

This output is a pulse width modulated (PWM)

signal (See Section 2: Machine Control).

circuit opens and de-energizes the Pressure

Switch Input on the machine control, which

de-energizes the Water Valve Outputs.

The machine control will read the Water Temperature Sensor Input to determine the

blended water temperature passing through

the water valve. In a warm wash fill, the machine control will first energize both the hot

and cold Water Valve Outputs for five seconds

then de-energize the cold Water Valve Output

and monitor the water temperature. When

the Water Temperature Sensor Input passes

the warm threshold (approx. 20 K Ohms), the

machine control will re-energize the cold output for the remainder of the fill.

In a cold wash fill, the machine control will

first energize only the cold Water Valve Output for five seconds. It then energizes the hot

Water Valve Output and monitors the Water

Temperature Sensor Input until it passes the

cold threshold (approx. 44 K Ohms), when it

de-energizes the Hot Water Valve Output for

the remainder of the fill.

Vcc REFERENCE VOLTAGE OUTPUT

The Vcc Outputs are a reference voltage for

many of the signal outputs. On the machine

control, the Vcc outputs are 24 VDC referenced to the 120 VAC neutral line.

WATER VALVE OUTPUTS

The machine control determines whether the

hot or cold Water Valve Outputs should be energized during each timer increment, but it

only gates the power to the water valves, it

does not directly provide that power. When

the timer is in an increment calling for water,

power passes from the timer to the wash or

rinse level circuit in the pressure switch. When

the water level is below the full level, the pressure switch circuit is closed and the power

passes to the machine control. The machine

control gates the power to the hot and cold

Water Valve Outputs. When the pressure

switch senses that the full level is reached, the

If the user selects a warm rinse temperature,

the machine control will count the rinses and

allow a warm rinse fill only on the third and

fourth (if the user also selects the Extra Rinse

option) rinses. The first two rinses will be cold

only. The machine control does not regulate

water temperature during the rinses.

NOTE: If the user chooses the Easy Care/

Perm Press fabric selection, all rinse fills will

be cold regardless of whether the user also

selected the warm rinse temperature.

16008373-01 SECTION 1. GENERAL INFORMATION

© 1998 Maytag Corporation

1-9

Page 16

CYCLE SEQUENCE DEFINITIONS

NOTE: Refer to Section 2: Timer Input Charts

for information on the timing of each cycle

sequence.

BLEACH DISPENSE

In a Bleach Dispense increment, the machine

control will follow the same tumble pattern

and speed as in a Main Wash Tumble increment.

DELAY

During a Delay increment, the door Lock Wax

Motor Output, Door Locked Light Output (Series 17 and later only), Motor Torque Output,

"On" light (Series 10 to 16 only), and Water

Valve Outputs are de-energized. Note that the

Delay indicator is energized through a cam

on the timer.

EXTRA RINSE

When the user selects the Extra Rinse option,

the spin increment following the third rinse

will follow the Spin2 cycle sequence. The

Timer Motor Output will be energized 60 seconds prior to the end of the spin cycle sequence and will remain energized to advance

the timer through the "Off" increment into the

Rinse Tumble increment.

washers only) will de-energize and the Endof-Cycle Signal will sound if the user had selected the End-of-Cycle Signal option.

LIGHT WASH TUMBLE, MAIN WASH

TUMBLE, and RINSE TUMBLE

The machine control will tumble the washer

at the pattern and speed defined by the Fabric

Selection Inputs (See Cycle Review). Each

tumble will start only after the previous

tumble has completely stopped. The machine

control will reverse the tumble direction after

each pause. The machine control will continue to tumble the washer until the timer inputs change.

In a Light Wash Tumble or Main Wash Tumble

increment, the machine control will de-energize the line relay if the washer continues to

tumble for 29 minutes. This would only occur if the timer were to stall (See Section 1:

Timer Motor Output and Section 2: Timer

Input Chart).

PREWASH DRAIN

During a prewash drain increment, the washer

will tumble at the same speed and in the same

pattern as in the Prewash Tumble increment

for the fabric selection. The Door Lock Wax

Motor Output will be energized during this

increment (See Prewash Tumble).

If the Extra Rinse option is not selected, this

spin will follow the Spin3 cycle sequence and

the Timer Motor Output will be energized 30

seconds prior to the end of the final spin.

IDLE

The Idle increment follows the final spin increment in each cycle. If the Door Lock Switch

Input is energized when the timer advances

into the Idle increment at the end of the cycle,

the machine control will tumble the washer

until 50 seconds after the Door Lock Switch

input is no longer energized. This allows time

for the Door Lock Wax Motor to fully retract.

At this time, the Door Lock Light Output

(washers between Series 10 and 16 only) or

the "On" Light Output (Series 17 and later

16008373-01 SECTION 1. GENERAL INFORMATION 1-10

© 1998 Maytag Corporation

PREWASH TUMBLE

When the timer is set into a Prewash Tumble

increment, the machine control will tumble

at 51 rpm in the following tumble pattern:

Cycle Tumble-Pause Pattern

Cotton/Sturdy 6 sec. - 24 sec.

Easy Care/Perm Press 6 sec. - 24 sec.

Delicates 6 sec. - 24 sec.

Hand Washables 3 sec. - 27 sec.

Page 17

In a Prewash Tumble increment, the machine

control will de-energize the line relay if the

washer continues to tumble for 15 minutes.

This would only occur if the timer were to stall

(See Section 1: Timer Motor Output and Section 2: Timer Input Chart).

MISCELLANEOUS

Door Latch Switch Monitoring

At the end of a cycle, when the timer advances

into the Idle increment, the machine control

will keep the line relay energized until it loses

power when the door latch switch opens. This

guards against the switch contacts welding

closed. In this condition, the machine control will limit what additional cycles can be run

before the door is opened as follows:

Washers between Series 10 and 16

The machine control will allow the washer

to restart only if the user sets the timer

into a Rinse Tumble or Spin3 increment.

Washers from Series 17 and Later

The machine control will allow the washer

to restart in any setting. After that cycle

completes, the user must open the door

before the machine control will allow a

third cycle to start.

Door Lock/Spin Control

control will energize the timer motor output

until the timer inputs change so the washer

can proceed with the cycle.

At the end of spin sequence, if the door lock

switch input is de-energized before the washer

drops below 91 rpm, a hardware circuit on the

machine control will interrupt the torque output signal, which forces the motor control to

0 rpm, and energize the door lock wax motor

circuit to lock the door. This hardware circuit

will keep the door lock wax motor circuit energized until the door lock switch input signal

is energized.

Redistribution

The machine control commands a distribution profile speed ramp from 0 rpm to 85 rpm

at the beginning of each high speed (above

100 rpm) spin. When the washer reaches 85

rpm, the machine control monitors the Tach

Input to determine if the speed varies through

one revolution of the spinner basket. If it

senses a high enough variation in speed (suggesting an out-of-balance condition in the

clothing load), it will drop the spinner speed

to 0 rpm and force a short reverse tumble to

redistribute the clothing load before resuming the spin. If any of the out-of-balance

switches trip and open the out-of-balance input circuit at a speed below 500 rpm, the machine control will also drop the speed to 0 rpm

and force the reverse tumble to redistribute

the clothing load.

When the machine control begins a spin increment, it will not command spin speed

above 51 rpm unless the door lock switch input is energized. At the start of a spin increment, the machine control will drop the speed

to 0 rpm then tumble until the switch is energized. At that point, it will restart the spin sequence. If the door lock switch is not energized after 2 minutes of tumbling, the machine

16008373-01 SECTION 1. GENERAL INFORMATION

© 1998 Maytag Corporation

1-11

Page 18

© 1998 Maytag Corporation

16008373-01 SECTION 1. GENERAL INFORMATION 1-12

The following rules determine the maximum

number of redistribution attempts that will be

allowed in each spin step before the machine

control skips the step and continues with the

spin profile (See Section 2: Unbalance Con-

trol System).

STOPPING THE WASHER

1. With the washer running, power is

supplied to the machine control and

washer from gray wire no. 26 through the

line relay.

2. When the user presses the push-to-start

button, a signal is sent to the machine control through red wire no. 28 telling the

washer to shut down.

3. The machine control opens the internal

logic switch which de-energizes the line

relay.

4. When the user releases the push-to-start

button, power is removed from the machine control and washer (Black wire no.

27).

STARTING THE WASHER

1. With the door closed, press the push-to

start switch.

2. The red no. 28 wire sends a signal to the

machine control to start running.

3. 120 VAC is supplied to the machine control board through black wire no. 27.

4. The machine control closes an internal

switch to energize the line relay.

5. When the push-to-start button is released,

power remains supplied to the machine

control and the washer from gray wire

no. 26 through the line relay.

Push-To-Start Relay Operation

PUSH TO START SWITCH

LINE

RELAY

MACHINE CONTROL BOARD

120 VAC POWER

FRO M MACH INE

CONT ROL BOARD

INTERN AL LOGI C

SWITCH

120 VAC LINE

(When door is

closed)

GY 26

BK 27

RD 28

120 VAC Line

To Timer &

Motor Co ntrol Board

NO

COM

Figure 1-8

Page 19

CYCLE REVIEW

Main Wash Time/Total Cycle Time - Minutes (See Notes).

N on-M ax

Extract Cotton/ Sturdy

Heavy W ash 23 .0 /4 9. 0 20 .0 /4 5.5 20/46.5 Not A pplicable

Normal Wash 17 .0 /4 3. 0 14 .0 /3 9.5 14.0 /4 0.5 No t A pplicable

Light/Quick

Wash

Fin al Sp in

(RPM /M i n )

Max Extract

Cycles Cotton/ Sturdy

Heavy W ash 23 .0 /4 6. 0 20 .0 /4 1.5 2 0 .0 /4 2. 0 20 .0 /4 3 .0

Normal Wash 17 .0 /4 0. 0 14 .0 /3 5.5 1 4 .0 /3 6. 0 14 .0 /3 7. 0

Light/Quick

Wash

Fin al Sp in

(RPM /M i n )

11 .0 /3 7.0 8.0/33.5 7.0/34 .5 Not A pplicable

800/3.5 60 0/3.0 500/4.5 No t A pplicable

11 .0 /3 4.0 8.0/29.5 8 .0 /3 0.0 8 .0 /3 1.0

800/4.0 60 0/3.5 500/5.0 500/5.0

Easy Care/

Perm Press Delicates

Easy Care/

Perm Press Delicates

Hand

Washables

Hand

Washables

Notes:

1. The main wash times listed include 2 minutes of bleach fill and tumble time.

2. The total cycle times are approximate and will vary based on water fill times, due to types of

clothing loads, available water pressure and the time for the door lock system to retract at

the end of the cycle.

3. The main wash time is affected significantly if the machine control detects an excessive

amount of suds. The washer will go into a suds reduction routine, consisting of a series of

additional rinse and partial drain cycles to reduce the suds present (See Troubleshooting &

Diagnosis - Clothes Wet at End of Spin).

Tumble Pattern - Number of seconds tumbling/Number of seconds of pause between tumbles.

Cotton/ Sturdy Easy Care/

Perm Press

7/3 5/ 3 6/2 4 3/27

De licates Hand W ashab les

16008373-01 SECTION 1. GENERAL INFORMATION

© 1998 Maytag Corporation

1-13

Page 20

GENERAL COMPONENT EXPLODED VIEW

16008373-01 SECTION 1. GENERAL INFORMATION 1-14

© 1998 Maytag Corporation

Page 21

SECTION 2. ELECTRICAL COMPONENTS & TESTINGSECTION 2. ELECTRICAL COMPONENTS & TESTING

SECTION 2. ELECTRICAL COMPONENTS & TESTING

SECTION 2. ELECTRICAL COMPONENTS & TESTINGSECTION 2. ELECTRICAL COMPONENTS & TESTING

ELECTRICAL TEST EQUIPMENTELECTRICAL TEST EQUIPMENT

ELECTRICAL TEST EQUIPMENT

ELECTRICAL TEST EQUIPMENTELECTRICAL TEST EQUIPMENT

The equipment required to service Maytag

products depends largely upon the conditions

you encounter. Locating a malfunction will

DescriptionDescription

Description

DescriptionDescription

Analog Test Meter 200 00005

Digital Test Meter 20001001

Clamp-On Ammeter 20000002

AC Voltage Sensor 20000081

Analog Test MeterAnalog Test Meter

Analog Test Meter

Analog Test MeterAnalog Test Meter

can be used to check

for open or closed

circuits, measure resistance, AC and DC volts,

and temperature.

often require the use of electrical testing

equipment such as:

Part NumberPart Number

Part Number

Part NumberPart Number

Clamp-On AmmeterClamp-On Ammeter

Clamp-On Ammeter

Clamp-On AmmeterClamp-On Ammeter

can be used to detect

shorts. Overloads on

the circuit

breaker or fuse

can be traced

to either the

washer or circuit

breaker by checking the washer

current draw.

AC Voltage SensorAC Voltage Sensor

Digital Test MeterDigital Test Meter

Digital Test Meter

Digital Test MeterDigital Test Meter

can be used to check for

open or closed circuits,

measure resistance,

AC and DC volts,

and temperature.

16008373-01 SECTION 2. ELECTRICAL COMPONENTS & TESTING

© 1998 Maytag Corporation

AC Voltage Sensor

AC Voltage SensorAC Voltage Sensor

can be used to alert you if

AC voltage is present so proper

safety precautions can be observed.

The tip of the sensor will glow

bright red if voltage is between

110-600 volts AC.

2-12-1

2-1

2-12-1

Page 22

ELECTRICAL TESTS

Water Valve Test

Warning - Always shut off

electrical power to the

unit before beginning any

service repair procedures.

Grounded Components

When performing service diagnostics, replacements and repairs, always check to determine whether all ground wires linking

panel and components are reattached if

removed.

Voltage Checks

Generally, these checks will consist of taking

readings at the wall receptacle to determine

the availability of voltage to the product. Voltage checks on individual components of a

product are not recommended due to the

possibility of electrical shock. Component part

testing is best accomplished through continuity checks with an Appliance Test Meter

(See Electrical Test Equipment).

NOTE: Use of the meter on voltage higher

than the indicated range may cause permanent damage to the meter. To prevent damage, first select the highest range and then

lower the range for readings which fall within

the lower scale.

Set up meter for use as follows:

1. Turn selector knob to desired meter function and appropriate range.

2. Plug black lead into socket marked black

(-).

Check the water valve for electrical continuity. This check should be made with the elec-

trical supply disconnected from the washer.

Remove the wire harness from the water valve

terminals and place the ohm meter probes on

the terminals of the water valve. The water

valve solenoid coil should have a resistance

between 500-1000 ohms. If no ohms are

shown on the display of the electrical test

meter, the solenoid coil has an open winding

and the valve should be replaced. The thermistor in the water valve changes in resistance

in direct relationship to water temperatures.

To monitor the performance of the thermistor,

run a partial hot water fill and check the ohm

resistance of the thermistor circuit. Then, run

a cold water fill and measure the resistance

again. There should be a notable difference

in the resistance readings. To check the ohm

resistance, pull the P2 wire harness connector off the machine control and locate the

P2(5) and P2(6) leads in the connector

(Figure 2-3).

Wax Motor Check - Door Lock

Mechanism

Check the wax motor for proper resistance.

This check should be made with the electrical

supply disconnected from the washer. Re-

move the wire harness from the wax motor

terminals and place the ohm meter probes on

the terminals of the wax motor. The wax motor should have a resistance of approximately

1900 ohms at room temperature. To check

wax motors through console, see section:

Machine Control page 2-5.

3. Plug red lead into socket marked red (+).

4. Place test leads into receptacle to determine voltage available.

16008373-01 SECTION 2. ELECTRICAL COMPONENTS & TESTING

© 1998 Maytag Corporation

2-2

Page 23

Timer & Console SwitchesTimer & Console Switches

Timer & Console Switches

Timer & Console SwitchesTimer & Console Switches

The timer is located in the control console on

the back. It is composed of a series of switches

driven by an electric timer motor. The timer

motor rotates a pinion gear which then rotates

internal cams. As the cams rotate, they lift

and drop various switch contacts which ride

on the cam. The internal switches provide

cycle sequence or step inputs to the machine

control to control the pump, dispenser wax

motors, delay light, ON light and timer motor .

The timer wire harness connector can be

pulled and the individual contacts for the various circuits can be checked with an ohm

meter. As illustrated, timer contact for the

drain pump is 14T

(Figure 2-1).(Figure 2-1).

(Figure 2-1).

(Figure 2-1).(Figure 2-1).

CC

C

TTTCC

TT

Figure 2-2Figure 2-2

Figure 2-2

Figure 2-2Figure 2-2

BB

B

BB

motor windings. The following chart can be

used for checking other components via the

timer wire harness connector.

Figure 2-1Figure 2-1

Figure 2-1

Figure 2-1Figure 2-1

Y ou can identify the wire for the drain circuit

(Figure 2-2)(Figure 2-2)

(Figure 2-2)

(Figure 2-2)(Figure 2-2)

by tracing down the side of the

connector to contact 14, and across to align

with column T.

Contact 8B in the connector is a direct contact to the neutral leg of the timer . When an

ohm meter probe is placed into the 14T connection and the other probe is placed into 8B,

an ohm reading of the complete drain circuit

can be performed. The drain circuit should

have a resistance of approximately 18 ohms.

This is the resistance reading of the pump

Description Connector Connector Ohms

Pump

Motor

Bleach Wax

Motor

Softener

Wax Motor

Timer

Motor

Timer Input ChartsTimer Input Charts

Timer Input Charts

Timer Input ChartsTimer Input Charts

14T 10B 18

2B 10B 950-1100

2T 10B 950-1100

10T 10B 5000

As stated previously, the machine control

board receives inputs from the timer monitor

where the timer is in the cycle. The machine

control board accomplishes this by routing

four circuits through the timer. Two of the circuits (1A & 1B) are supplied with 120 V AC and

the other two circuits (2A & 2B) are 24 VDC.

The voltages for the four circuits is shown on

the timer chart of the electrical schematic

enclosed in the washer console.

16008373-01 SECTION 2. ELECTRICAL COMPONENTS & TESTING

© 1998 Maytag Corporation

2-32-3

2-3

2-32-3

Page 24

Software in the machine control board specifically monitors the timer input circuits to

determine where the timer is in all the wash cycles and will rapidly advance the timer to

OPEN and break contacts in the timer. The timer is solely used as an off-board set of

relay switches. Note: The timer motor is hard wired to timer cams 10T and 10B in the

timer.

TIMER 1A

(120 VAC)

CYCLE SEQUENCE

PREWASH TUMBLE 0 1 1 0

PREWASH DRAIN 1 1 1 0

MAIN WASH TUMBLE 0 1 0 0

LIGHT WASH TUMBLE 1 1 0 0

BLEACH DISPENSE 1 0 1 0

RINSE TUMBLE 1 0 0 1

SPIN 1 0 0 1 0

SPIN 2 0 0 0 1

SPIN 3 0 1 0 1

EXTRA RINSE 1 1 0 1

DELAY 1 0 0 0

PK19/P7(8)

TIMER 1B

(120 VAC)

YL16/P7(7)

TIMER 2A

(24 VDC)

PU17/P3(3)

TIMER 2B

(24 VDC)

BU18/P3(5)

IDLE 0 0 0 0

Key: 0 = Input Signal Not Asserted 1= Input Signal Asserted

There are conditions under which the machine control will shut the cycle down if the

timer does not advance.

- During Extra Wash/Prewash: If the timer inputs do not change away from Prewash

Tumble for 15 minutes, the machine control will open the line relay.

- During Main Wash: If the timer inputs do not change for 29 minutes, the machine

control will open the line relay.

- During any increment when the machine control energizes the timer motor until it

sees the timer inputs change: If the timer inputs do not change for 5 minutes with the

timer motor continuously energized, the machine control will open the line relay.

These varying delays are to allow the washer to progress through several increments

where the timer inputs normally do not change. In these cases, the machine control

energizes the timer motor for 30 seconds, which is its advance time. It does not look for

a timer input change.

16008373-01 SECTION 2. ELECTRICAL COMPONENTS & TESTING

© 1998 Maytag Corporation

2-4

Page 25

Machine ControlMachine Control

Machine Control

Machine ControlMachine Control

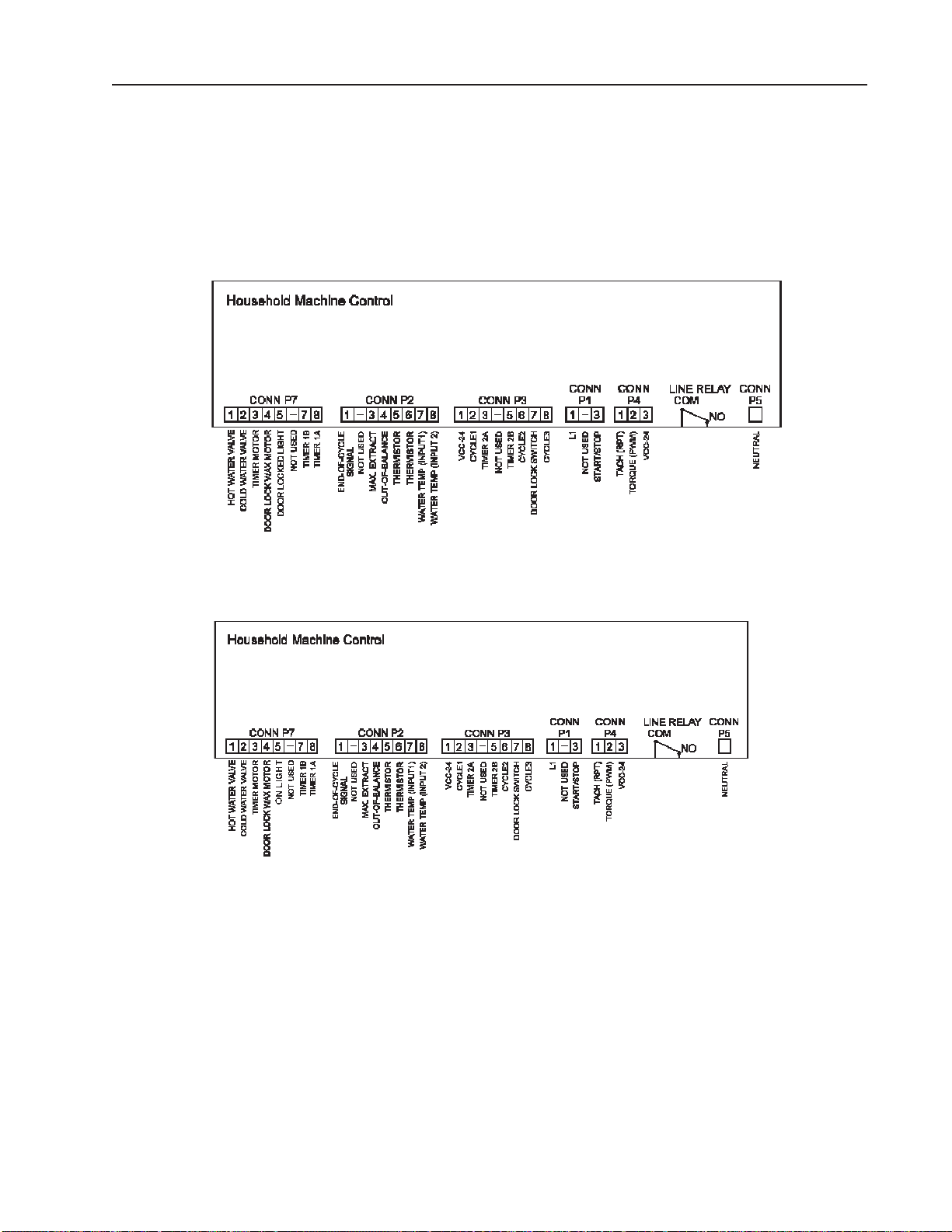

The machine control microprocessor board is located in the control console, mounted to the

rear panel. The board receives input from the timer , door latch and lock switches, and unbalance and selector switches on the console. It also communicates with the motor control board

to facilitate the various cycles and drive the motor for optimum perfor mance. Torque and

speed of the motor are monitored through the motor control board.

Prior to Series 17Prior to Series 17

Prior to Series 17

Prior to Series 17Prior to Series 17

Figure 2-3Figure 2-3

Figure 2-3

Figure 2-3Figure 2-3

Series 17 and AfterSeries 17 and After

Series 17 and After

Series 17 and AfterSeries 17 and After

Figure 2-3bFigure 2-3b

Figure 2-3b

Figure 2-3bFigure 2-3b

Both incoming and exiting voltage are monitored through the machine control board and the

surrounding circuitry . The following table lists the voltages for the various terminals on the

microprocessor board. If proper voltage is not present, check switches and wiring for any

loose connections or open circuits by disconnecting the power supply and performing continuity checks of individual circuits.

Line Relay Connector Comm (Gray wire), L1 output is Line Relay Connector Comm (BlackLine Relay Connector Comm (Gray wire), L1 output is Line Relay Connector Comm (Black

Line Relay Connector Comm (Gray wire), L1 output is Line Relay Connector Comm (Black

Line Relay Connector Comm (Gray wire), L1 output is Line Relay Connector Comm (BlackLine Relay Connector Comm (Gray wire), L1 output is Line Relay Connector Comm (Black

wire).wire).

wire).

wire).wire).

NOTE:NOTE:

NOTE:

NOTE:NOTE:

Connector P5 is Neutral input and L1 input is the Connector P5 is Neutral input and L1 input is the

Connector P5 is Neutral input and L1 input is the

Connector P5 is Neutral input and L1 input is the Connector P5 is Neutral input and L1 input is the

To check voltages from the board, turn timer dial to a wash cycle and press the start/off button.

This will activate the L1 relay board and apply power on the machine control.

16008373-01 SECTION 2. ELECTRICAL COMPONENTS & TESTING

© 1998 Maytag Corporation

2-52-5

2-5

2-52-5

Page 26

FUNCTION

MACHINE

CONTROL

BOARD

TERMINAL/WIRE

MACHINE

CONTROL

BOARD

TERMINAL/WIRE

VOLTAGEAPPROX.

(When Activated)

TIMER

CONTACT

Permanent Press

(Fabric Switch)

Delicates

(Fabric Switch)

Hand Wash

(Fabric Switch)

Cotton/Sturdy

(Fabric Switch)

Signal ON/OFF

(Options Switch)

Extra Rinse

(Options Switch)

Max Extract

(Options Switch)

Push To Start

Switch

(When pressed)

Unbalance

Control

P5 (WH11) P3/2 (PK 37) 24 VDC Not Involved

P5 (WH11) P3/6 (OR 38) 24 VDC Not Involved

P5 (WH11) P3/8 (BR 39) 24 VDC Not Involved

P5 (WH 11)

P5 (WH 11)

P5 (WH 11)

P5 (WH 11) P2/1 (PU 21) 24 VDC - ON

P5 (WH 11) P7/8 (PK 19) 120 VAC 12B, 6B,8T

P5 (WH 11) P2/3 (YL 20) 24 VDC Not Involved

P5 (WH 11) P1/3 (RD 28) 120 VAC Not Involved

P5 (WH11) P2/4 (OR 40) 24 VDC Not Involved

P3/2 (PK 37)

P3/6 (OR 38)

P3/8 (BR 39)

0 VDC

0 VDC

0 VDC

0 VDC - OFF

Not Involved

Not Involved

Door Lock - Spin P3 (1) P3/7 (YL 36) 24 VDC Not Involved

Motor Control &

Machine Control

Hot Water Valve P5 (WH11) P7/1 (OR7) 120 VAC or

Cold Water Valve P5 (WH11) P7/2 (BU 9) 120 VAC or

Door Lock Wax

Motor

Bleach Wax

Motor

Softener Wax

Motor

Delay Light P5 (WH11) Not Involved 120 VAC 4T

On Light

(Series 17)

P5 (WH11) LINE RELAY COM

(BK 27 or BK1)

P5 (WH11) P7/4 (BR 14) 120 VAC Not Involved

P5 (WH11) Not Involved 120 VAC 2T

P5 (WH11) Not Involved 120 VAC 2B

P5 (WH11) P7/5 (RD 3) 120 VAC Not Involved

120 VAC Not Involved

Not Involved

500-1000 Ohms

Not Involved

500-1000 Ohms

16008373-01 SECTION 2. ELECTRICAL COMPONENTS & TESTING

© 1998 Maytag Corporation

2-6

Page 27

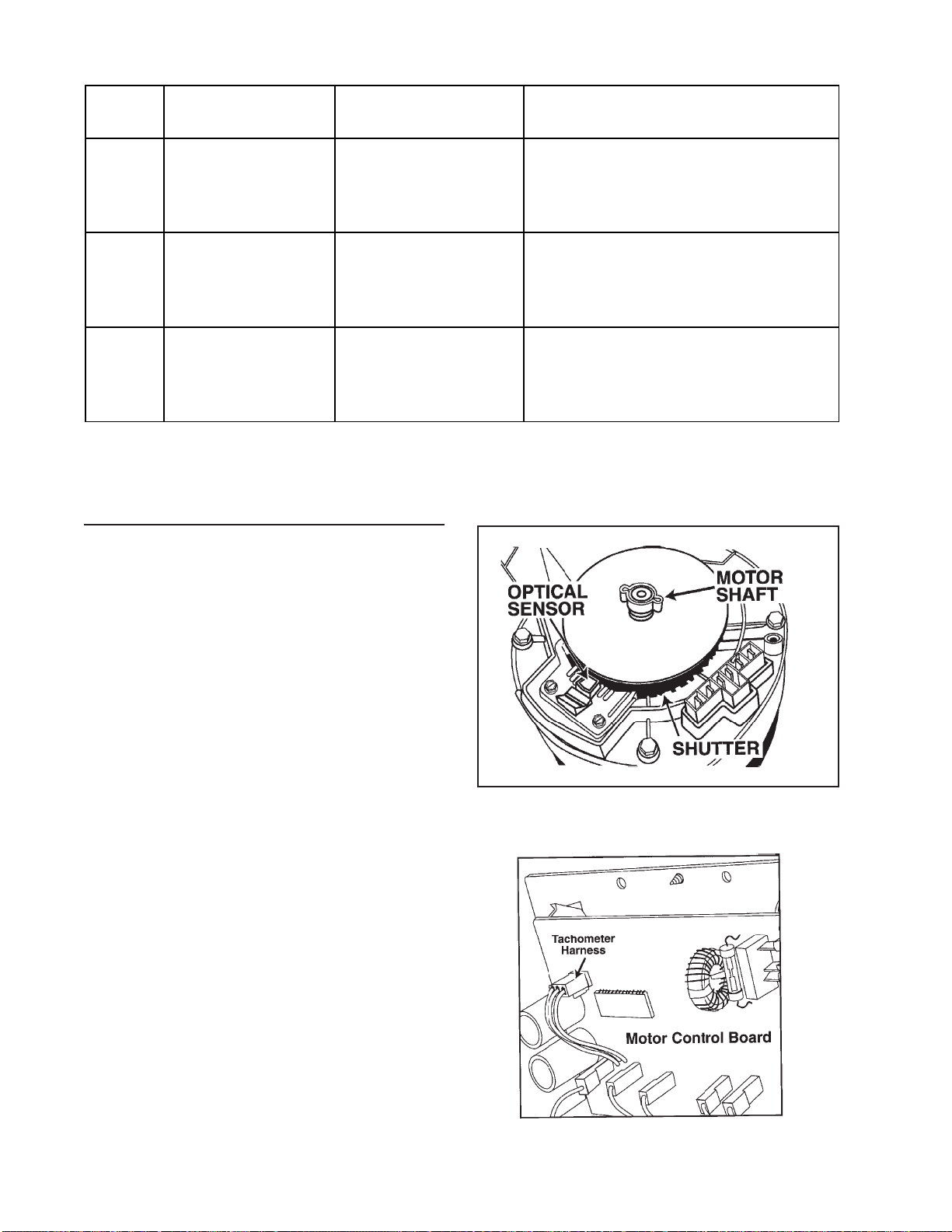

DRIVE MOTORDRIVE MOTOR

DRIVE MOTOR

DRIVE MOTORDRIVE MOTOR

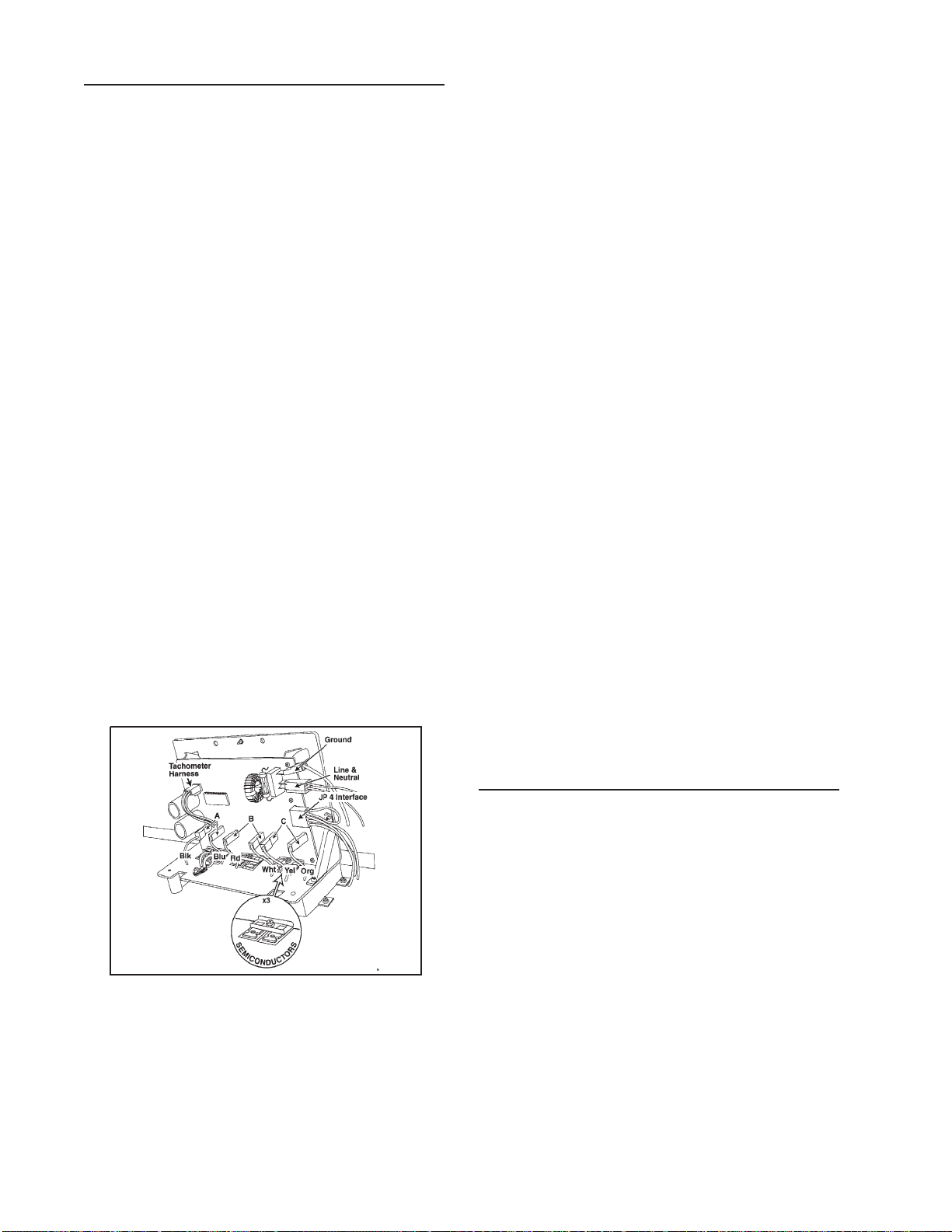

The drive motor is a switched reluctance type

motor. The basic operating principle of the

switched reluctance motor is direct magnetic

attraction between the stationary electromagnetic coils (stator) and a specially configured

rotor or armature

comprised of stacked plates or laminations

mounted on a center shaft. The shape of

these laminations are characteristic of the

switched reluctance motor. The rotor, when

viewed from the end of the rotor, has "teeth"

much like a gear . These "teeth", or pole pieces,

are pulled as the result of direct current power

through the stator coils.

(Figure 2-4)(Figure 2-4)

(Figure 2-4)

(Figure 2-4)(Figure 2-4)

. The rotor is

The following illustration shows the motor

terminals for each of the coils involved. The

letters with positive and negative symbols indicate the motor phase circuitry of the

terminals.

Motor Harness Connector

Figure 2-5Figure 2-5

Figure 2-5

Figure 2-5Figure 2-5

Figure 2-4Figure 2-4

Figure 2-4

Figure 2-4Figure 2-4

Multiple stator coils are positioned around the

rotor and are connected in three different

phased "sets" of paired coils.

Magnetic attraction causes the rotor poles to

turn toward the coils. The electronic motor

control board switches the magnetic field off

as the rotor pole piece approaches; then,