Page 1

A

m

INSTALLATION INSTRUCTIONS

COMMERCIAL FRONT-LOAD WASHER

INSTRUCTIONS D'INSTALLATION

LAVE-LINGE COMMERCIAL À CHARGEMENT FRONTAL

Table of Contents/Table des matières................................. 2

Las Instrucciones de instalación en español e italiano están disponibles en www.maytagcommerciallaundry.com

Le istruzioni per l'installazione in spagnolo e in italiano sono disponibili su www

Model/Modèle

MAH22PDAGW0 & MAH22PNAGW0

.maytagcommerciallaundry.com

W10299730

www.maytagcommerciallaundry.co

Page 2

TABLE OF CONTENTS

TABLE DES MATIERES

WASHER SAFETY ..........................................................................2

WASHER DISPOSAL......................................................................3

INSTALLATION REQUIREMENTS ................................................4

Tools and Parts ............................................................................4

Options.........................................................................................4

Location Requirements................................................................4

Drain System................................................................................5

Electrical Requirements ...............................................................6

INSTALLATION INSTRUCTIONS ..................................................6

Remove Transport System ..........................................................6

Power Cord Installation................................................................7

Connect the Inlet Hoses...............................................................7

Route the Drain Hose...................................................................8

Secure the Drain Hose.................................................................8

Level the Washer..........................................................................8

Payment System Set-up..............................................................9

Installing Pad Strips .....................................................................9

Complete Installation ...................................................................9

USER & SET-UP INSTRUCTIONS ................................................9

General Information......................................................................9

Control Set-up Procedures........................................................10

Set-up Codes.............................................................................10

Washer Diagnostic Mode...........................................................13

WASHER CARE ............................................................................15

Cleaning Your Washer ...............................................................15

Water Inlet Hoses.......................................................................16

ASSISTANCE OR SERVICE.........................................................16

Accessories................................................................................16

WARRANTY ..................................................................................17

SECURITE DU LAVE-LINGE........................................................18

MISE AU REBUT DU LAVE-LINGE .............................................19

EXIGENCES D'INSTALLATION...................................................19

Outillage et pièces......................................................................19

Options .......................................................................................20

Exigences d'emplacement.........................................................20

Système de vidange...................................................................21

Spécifications électriques

INSTRUCTIONS D'INSTALLATION.............................................22

Dépose du système de transport.....

Installation du cordon d'alimentation

Raccordement des tuyaux d'arrivée d'eau................................23

Acheminement du tuyau de vidange .........................................24

Immobilisation du tuyau de vidange ..........................................24

Réglage de l'aplomb du lave-linge ............................................24

Réglage du système de paiement .............................................25

Installation des bandes de protection........................................25

Achever l'installation ..................................................................25

INSTRUCTIONS D'UTILISATION ET D'INSTALLATION ...........26

Informations générales...............................................................26

Procédures de réglage des systèmes de

Codes de paramétrage ..............................................................27

Mode de diagnostic du lave-linge..............................................30

ENTRETIEN DU LAVE-LINGE .....................................................32

Nettoyage du lave-linge .............................................................32

Tuyaux d'arrivée d'eau...............................................................33

ASSISTANCE OU SERVICE.........................................................33

Accessoires ................................................................................33

GARANTIE.....................................................................................34

..........................................................21

..........................................22

.........................................22

commande...............26

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

2

Page 3

WARNING:

To reduce the risk of re, electric shock, or injury to persons when using the washer, follow basic precautions,

including the following:

IMPORTANT SAFETY INSTRUCTIONS

■ Read all instructions before using the washer.

■ Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

petrol, dry-cleaning solvents, other ammable or

explosive substances as they give off vapours that

could ignite or explode.

■ Do not add petrol, dry-cleaning solvents, or other

ammable, or explosive substances to the wash

water. These substances give off vapours that could

ignite or explode.

■ Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for such a period, before using the washing

machine, turn on all hot water taps and let the water

ow from each for several minutes. This will release

any accumulated hydrogen gas. As the gas is

ammable, do not smoke or use an open ame during

this time.

■ Do not allow children to play on or in the washer.

Close supervision of children is necessary when the

washer is used near children.

SAVE THESE INSTRUCTIONS

■ The appliance is not intended for use by young children or

inrm persons without supervision.

■ Before the washer is removed from service or discarded,

remove the door or lid.

■ Do not reach into the washer if the drum, tub or agitator is

moving.

■ Do not install or store the washer where it will be exposed to

the weather.

■ Do not tamper with controls.

■ Do not repair or replace any part of the washer or attempt

any servicing unless specically recommended in this Use

and Care Guide or in published user-repair instructions that

you understand and have the skills to carry out.

■ See Installation Instructions for earthing requirements.

■ If the supply cord is damaged, it must be replaced by the

manufacturer or its service agent or a similarly qualied

person in order to avoid a hazard.

WASHER DISPOSAL

3

Page 4

INSTALLATION REQUIREMENTS

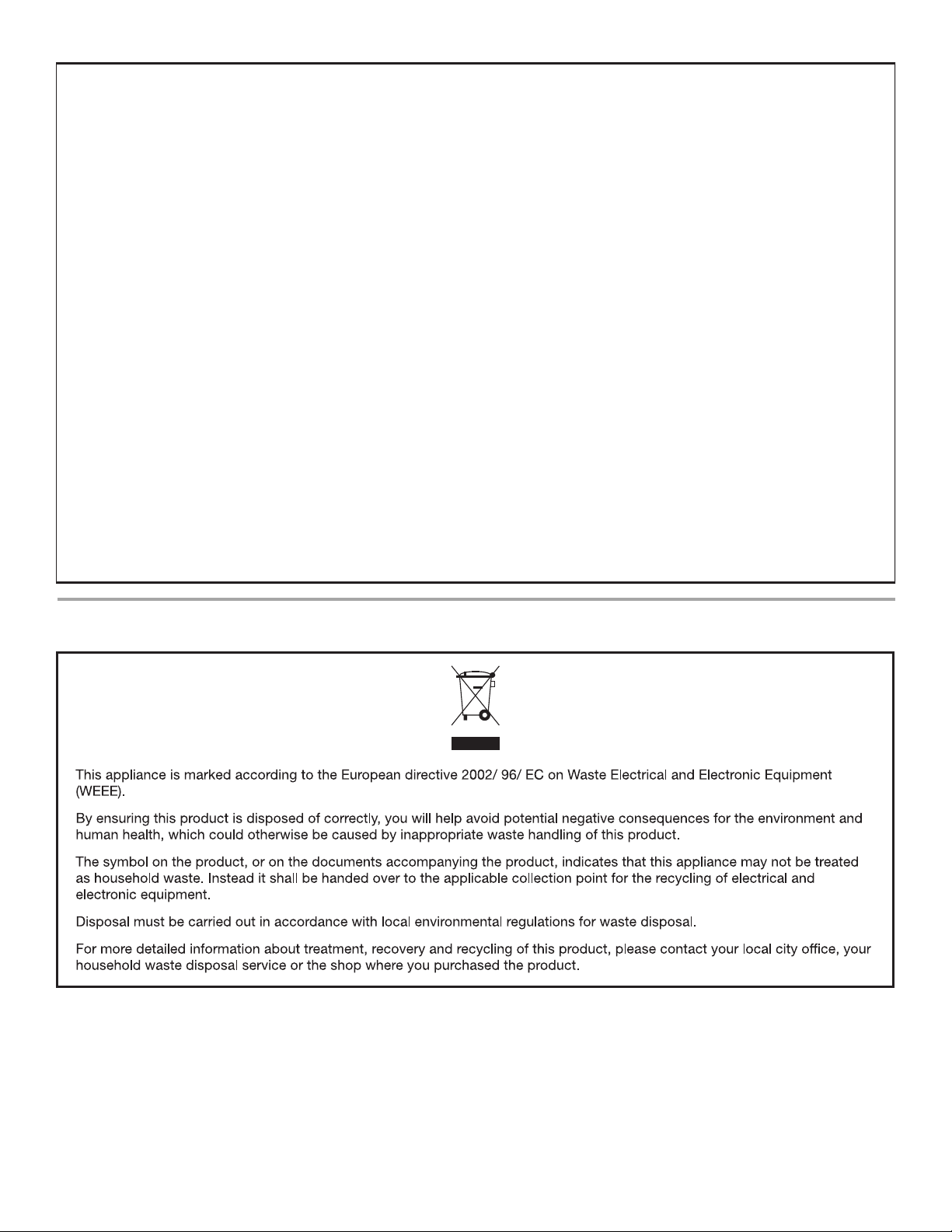

Tools and Parts

Gather the required tools and parts before starting installation.

The parts supplied are in the washer drum.

Tools needed for connecting the water inlet hoses

■ Pliers (that open to

39.5 mm [1

9

/16"])

Tools needed for installation

■ Open end wrenches

1

/2" and 9/16"

■ To rx

®†

T-20 Security

screwdriver

■ ¼" nut driver

Parts supplied

A BC

■ Flashlight (optional)

■ Level

■ Wood block

■ Ruler or measuring tape

D

If You Ha v e You Will N eed to Bu y

Overhead sewer Standard 76 L (20 gal. ), 762 mm (30") tall

d

rain tub or utility sink and sump pump

(available from local plumbing suppliers)

Floor drain Siphon break, Part Number 285834;

additional drain

hose,

Part Number 8318155; and connector

ki

t, Part Number 285835

Drain hose

too short

Water taps beyond

reach of fill hoses

1.2 m (4 ft.) drain hose extension kit,

Part Number 285863

2 longer water fill hoses:

1.8 m (6 ft.) Part Number 76314

3.0 m (10 ft.) Part Number 350008

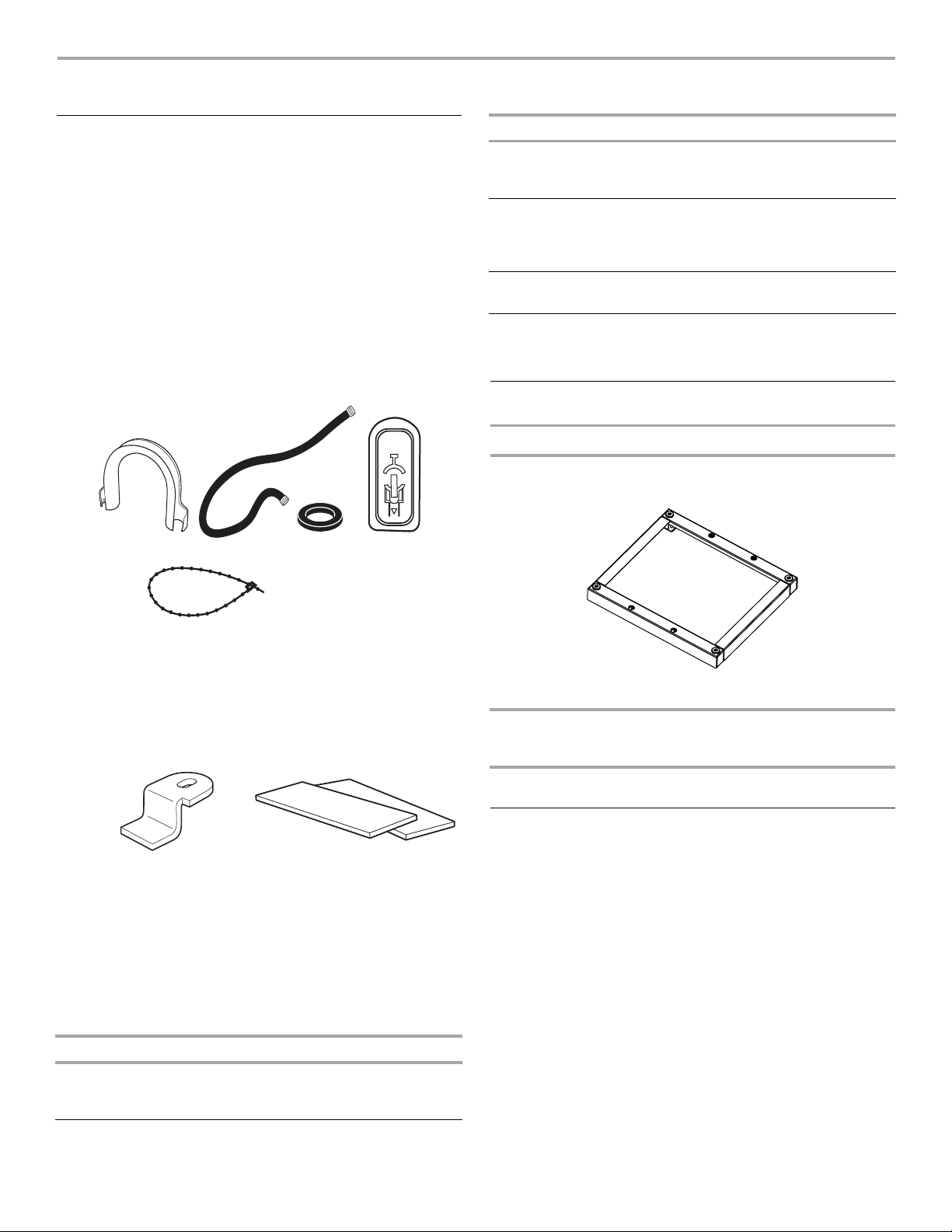

Options

Pedestal

You have the option of purchasing pedestals separately for this

washer. The pedestal will add to the total height of the washer.

E

A. U-shaped hose form

B. Water inlet hoses (2)

C. Inlet hose washers (4)

D. Transit bolt hole plug (4)

E. Beaded tie strap

Parts supplied for PD Models:

Service door lock cam Foam pads

Parts supplied for PD Models:

■ Coin sensor white

■ Coin sensor black

Alternate Parts

Your installation may require additional parts. If you are interested

in purchasing one of the items listed here contact your authorized

Maytag distributor.

If You Have You Will Need to Buy

Laundry tub or

dpipe taller

stan

than 2.4 m (96")

†

® TORX is a registered trademark of Acument Intellectual Properties, LLC.

Sump pump system (if not already

ava

ilable)

Optional pedestal

Pedestal

Height

Approximate

height

Color Model

Number

with washer

7

(73 mm) 2

/8" (1207 mm) 47.5" White WHP0400VW

Location Requirements

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer “walk.”

Your washer can be installed under a custom counter, or in a

ba

sement, laundry room, or recessed area. See “Drain System.”

Companion appliance location req

considered. Proper installation is your responsibility.

You will need

■ A water heater set to deliver 60°C (140°F) water to the

washer.

■ An earthed electrical outlet located within 1.8 m (6 ft.) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

■ Hot and cold water taps located within 1.2 m (4 ft.)

of the hot and cold water fill valves, and water pressure

of 137.9-689.6 kPa (20-100 psi).

■ A level floor with a maximum slope of 25 mm (1") under entire

washer. Installing the washer on soft floor surfaces, such as

carpets or surfaces with foam backing, is not recommended.

uirements should also be

4

Page 5

■ A sturdy and solid floor to support the washer with a total

weight (water and load) of 180 kg (400 lbs).

Do not operate your washer in temperatures below 0°C (32°F).

Some water can r

emain in the washer and can cause damage

in low temperatures.

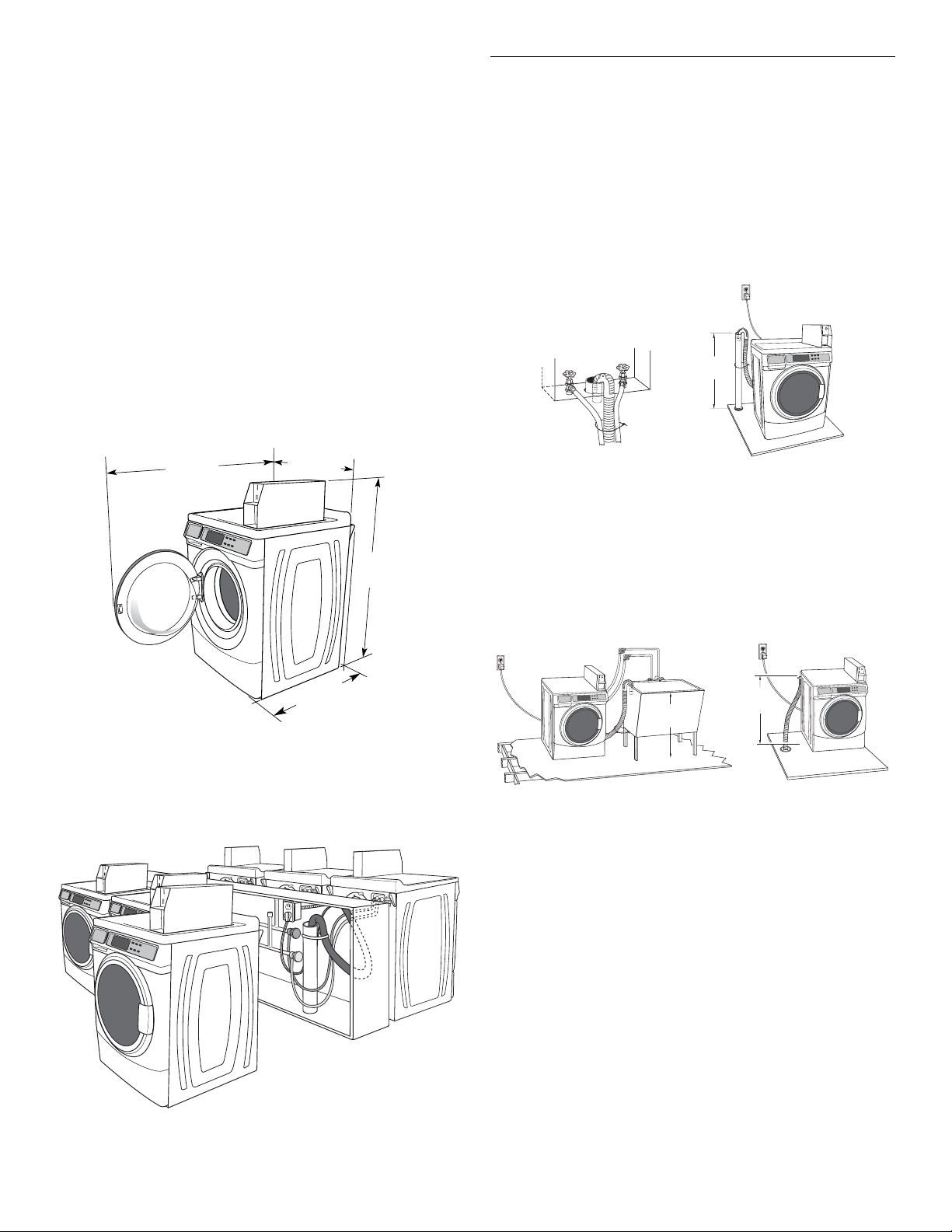

Installation clearances

■ The location must be large enough to allow the washer door

to be fully opened.

■ Additional spacing should be considered for ease of

installation and servicing. The door opens more than 90°

and it is not reversible.

■ Additional clearances might be required for wall, door, and

floor moldings.

■ Additional spacing of 25 mm (1") on all sides of the washer

is recommended to reduce noise transfer.

■ Companion appliance spacing should also be considered.

■ When installed, the mains plug should be accessible for

washer disconnection from the mains supply.

Drain System

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system. Select the drain hose installation method you need.

See “Tools and Parts.”

Standpipe drain system - wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe of

50 mm (2"). The minimum carry-away capacity can be no less

than 64 L (17 gal.) per minute.

The top of the standpipe must be at least 762 mm (30") high and

er than 2.4 m (96") from the bottom of the washer.

no high

762 mm

(30" min.)

Washer Dimensions

1282 mm

1

(50

/

")

2

Door is not reversible.

686 mm

(27")

732 mm

13

(28

/

")

16

1134 mm

5

(44

/

")

8

A floor drain should be provided under the bulkhead.

Prefabricated bulkheads with electrical outlets, water

inlet lines, and drain facilities should be used only where

local codes permit.

A

B

Laundry tub drain system (view C)

The laundry tub needs a minimum 76 L (20 gal.) capacity. The top

of the laundry tub must be at least 762 mm (30") above the floor.

Floor drain system (view D)

The floor drain system requires a siphon break that may be

purchased separately. See “Tools and Parts.”

The siphon break must be a minimum of 710 mm (28") from the

bottom of the washer

. Additional hoses might be needed.

710 mm

762 mm

(30" min.)

(28" min.)

CD

5

Page 6

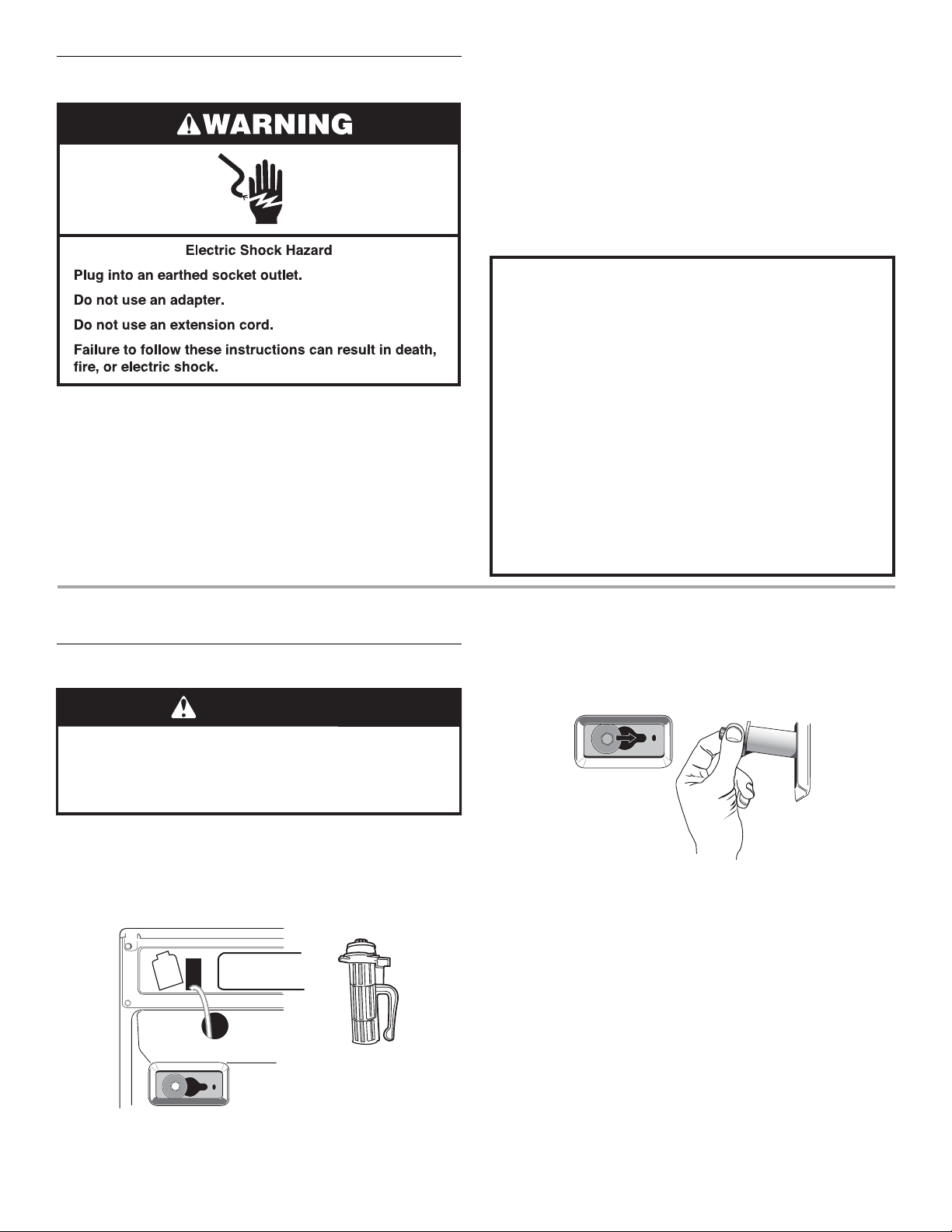

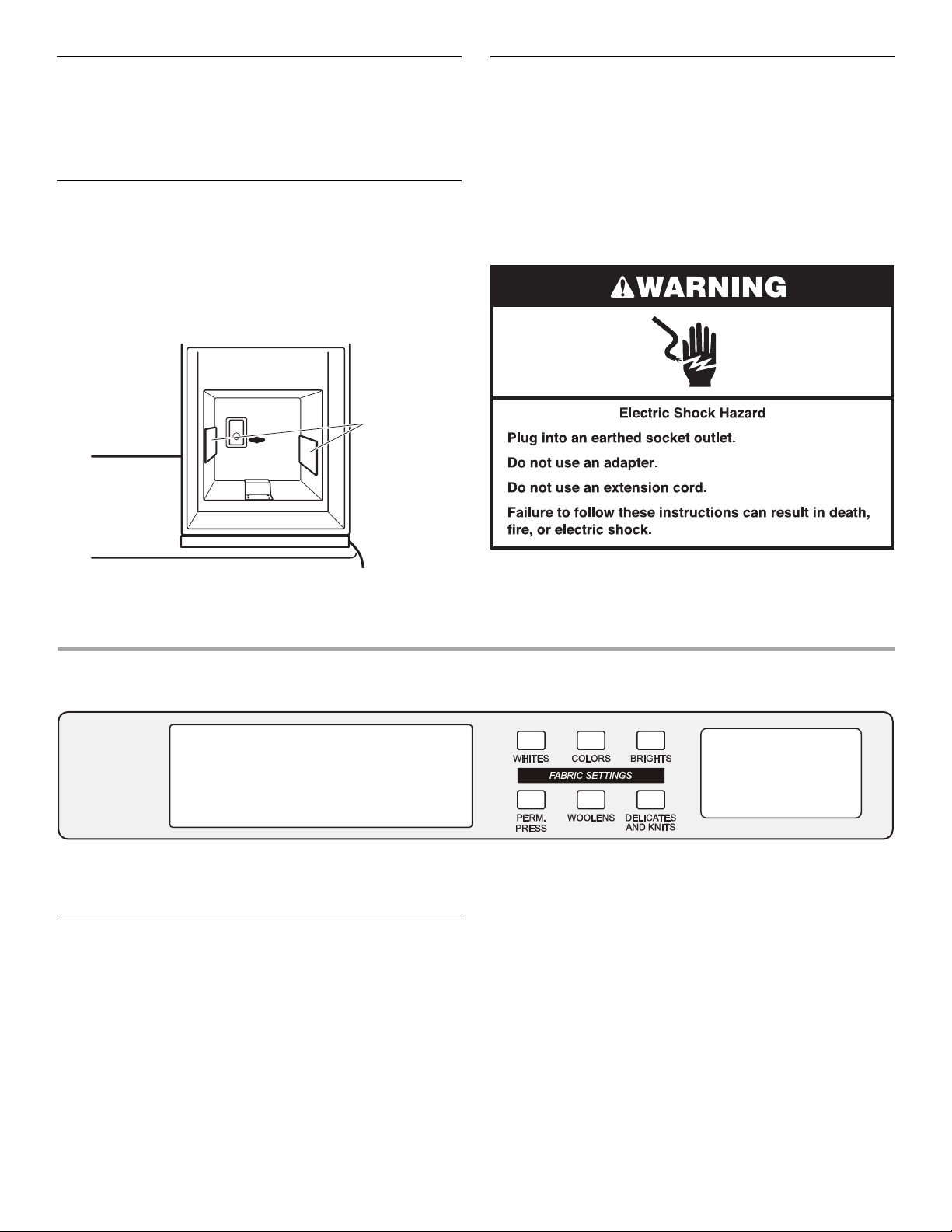

Electrical Requirements

■ A 220-240V, 50 Hz., fused electrical supply is required. A

time-delay 10-16A fuse or circuit breaker is recommended.

■ This washer is equipped with a power supply cord having an

earthed plug.

■ To minimize possible shock hazard, the cord must be

plugged into an earthed socket outlet, earthed in accordance

with local codes and ordinances. If a mating outlet is not

available, it is the personal responsibility and obligation of the

customer to have the properly earthed outlet installed by a

qualified electrician.

■ If codes permit and a separate earth wire is used, it is

recommended that a qualified electrician determine that the

earth path is adequate.

■ If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent, or a qualified person to avoid

a hazard.

■ Do not earth to a gas pipe.

■ Check with a qualified electrician if you are not sure the

washer is properly earthed.

■ Do not have a fuse in the neutral or earth circuit.

EARTHING INSTRUCTIONS

This washer must be earthed. In the event of a malfunction

or breakdown, earthing will reduce the risk of electric

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-earthing conductor and an earthing plug. The

plug must be plugged into an appropriate outlet that is

properly installed and earthed in accordance with all local

codes and ordinances.

WARNING:

earthing conductor can result in a risk of electric shock.

Check with a qualied electrician or serviceman if you are in

doubt as to whether the appliance is properly earthed.

Do not modify the plug provided with the appliance – if it

will not t the outlet, have a proper outlet installed by a

qualied electrician.

Improper connection of the equipment-

INSTALLATION INSTRUCTIONS

Remove Transport System

WARNING

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

IMPORTANT: Position the washer so that the rear of the washer

is within approximately 900 mm (3 ft.) of its final location.

There are 4 shipping bolts in the rear panel of the washer that

support the suspension system during transportation. These

bolts also retain the power cord inside the washer until the bolts

are removed.

2. Usin

3. Onc

4. Once all 4 bolts are removed, discard the bolts and spacers.

5. Close the bolt holes with the 4 transport bolt hole plugs. NOTE: If the washer is to be transported at a later date, call your

product distributor or installer. To avoid suspension and structural

damage, your washer must be properly set up for relocation by a

trained professional.

g a 1/2" wrench, loosen each of the bolts.

e the bolt is loose, move it to the center of the hole and

completely pull out the bolt, including the plastic spacer

covering the bolt.

Then push the power cord plug into the opening on the right

side of the rear panel and pull the power cord through the

opening on the left side of the rear panel and close holes with

the attached cap. Do not pull plug end of power cord through

the right side hole.

1. Keep the washer in the upright position while removing the

shipping bolts.

6

Page 7

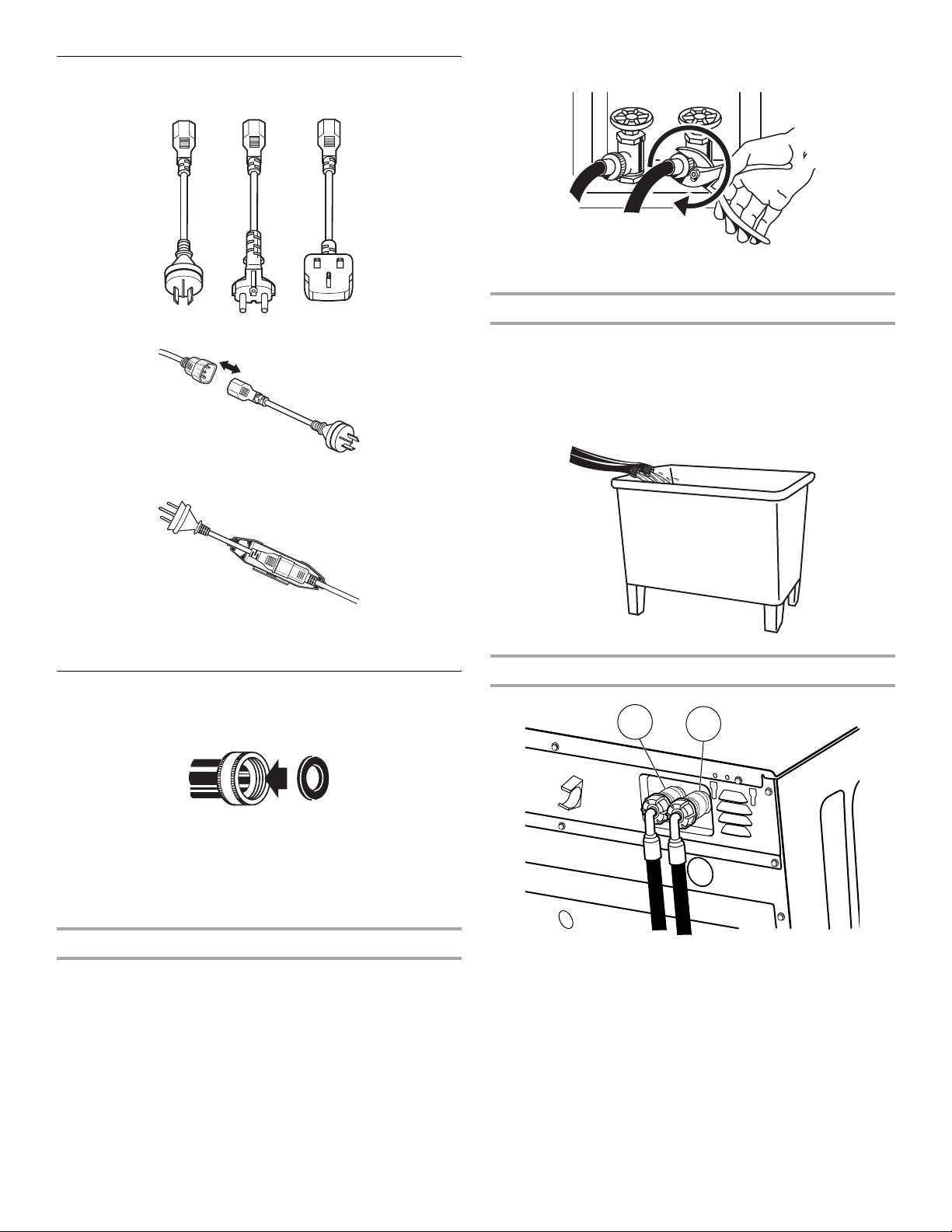

Power Cord Installation

1. Select the plug that fits with the electric receptacle.

2. Assemble the plug into the end of the power cord.

3. Secure the power cord by seating the connection on the cord

lock.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the tap.

Damage to the inlet hoses can result.

Clear water lines

■ Run water through both taps and inlet hoses, into a laundry

tub, drainpipe, or bucket, to get rid of particles in the water

lines that might clog the inlet valve screens.

■ Check the temperature of the water to make sure that the hot

water hose is connected to the hot water tap and that the

cold water hose is connected to the cold water tap.

4. Place the cord lock cover and push until it snaps.

ke sure the power cord connection is seated on the cord

5. Ma

lock and that the cord lock clamps correctly.

Connect the Inlet Hoses

Insert new flat washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

A B

A. Coupling

B. Washer

■ Use the new inlet hoses supplied with washer. Do not re-use

old inlet hoses.

Connect the inlet hoses to the water taps

Make sure the washer drum is empty.

1. Attach a hose

by hand until it is seated on the washer.

2. Atta

ch a hose to the cold water tap. Screw on coupling

by hand until it is seated on the washer.

to the hot water tap. Screw on coupling

Connect the inlet hoses to the check valves on washer

H

H. Hot water inlet

C. Cold water inlet

1. Attach the hot water hose to the check valve on washer’s hot

(H) water inlet valve. Screw on coupling by hand until it is

seated on the check valve.

2. Atta

3. Usin

ch the cold water hose to the check valve on washer’s

cold (C) water inlet valve. Screw on coupling by hand until it is

seated on the check valve.

g pliers, tighten the couplings with an additional two-

thirds turn.

NOTE:

Do not overtighten. Damage to the coupling can

result.

C

7

Page 8

4. Turn on the water taps completely and check for leaks. NOTE: Replace inlet hoses after 5 years of use to reduce the

risk of hose failure. Record hose installation or replacement

dates on the hoses for future reference.

Periodically inspect and replace hos

wear, or leaks are found.

es if bulges, kinks, cuts,

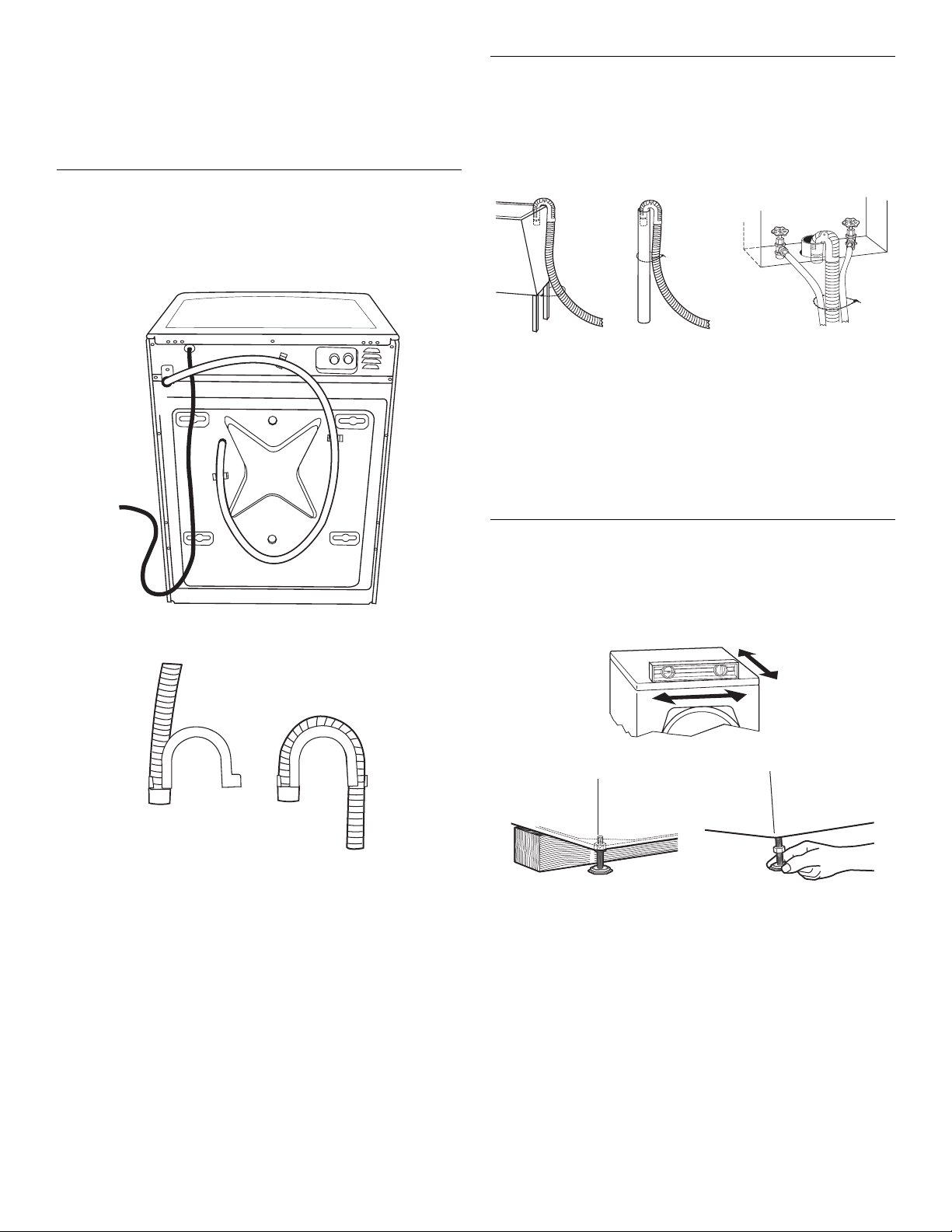

Route the Drain Hose

Proper routing of the drain hose protects your floor from damage

due to water leakage. Read and follow these instructions.

Remove drain hose from the washer

Gently pull the corrugated drain hose from the shipping clips.

Secure the Drain Hose

1. Drape the power cord over the washer top.

2. Move the washer to its final location.

3. Plac

4. Secur

5. If the washer taps and the drain standpipe are recessed, put

NOTES:

■ Do not force excess drain hose back into the rear of the

■ To avoid siphoning, do not seal the drain hose into the

e the drain hose in the laundry tub or standpipe as

shown. See illustrations A and B.

e the drain hose using the supplied beaded tie strap.

A BC

the hooked end of the drain hose in the standpipe as shown.

See illustration C.

washer.

standpipe.

Laundry tub drain or standpipe drain

Connect the drain hose form to the

A B

A. Snap either end of the drain hose form to the drain hose

at the point where the corrugation begins.

B. Bend drain hose over drain hos

To keep drain water from going back into the washer:

■ Do not straighten the drain hose, do not force excess drain

hose into standpipe. Hose should be secure, but loose

enough to provide a gap for air.

■ Do not lay excess hose on the bottom of the laundry tub.

corrugated drain hose.

e form and snap into place.

Floor drain

You may need additional parts. See Floor drain under “Tools and

Parts.”

Level the Washer

Properly leveling your washer avoids excessive noise and

vibration.

1. Check the levelness of the washer by placing a level on the

top edge of the washer, first side to side, then front to back.

If the washer is against a wall, move the washer out slightly

before tipping back. If the washer is not level, first prop the

front with a wood block and adjust the feet as necessary;

then prop the back and adjust feet as necessary. Repeat this

step until washer is level.

2. Ma

ke sure all four feet are stable and resting on the floor.

Check that the washer is level (use a level).

er the washer is level, use a 9/16" open-end wrench to turn

3. Aft

the nuts on the feet tightly against the washer cabinet.

IMPORTANT: All four fe

not tight against the washer cabinet, the washer may vibrate.

4. The

5. Slid

6. Conf

washer should not move front to back, side to side, or

diagonally when pushed on its top edges.

e the washer to its final location.

irm the levelness of the washer.

et must be tightened. If the nuts are

8

Page 9

Payment System Set-up

PD Model Washer is coin payment ready and allows the

connection of two different sizes of coins. Inside the drum are

two coin-sensor harnesses. To set-up the washer for coin

payment, acquire a coin drop mechanism. Connect the white and

black coin sensors to the coin slot 1 and 2, respectively.

Installing Pad Strips

NOTE: For PD Models only.

1. T

ake the 2 foam pad strips from bag.

2. Remove the tape fr

3. Install the pads on the

vault, leaving about 6 mm (1/4") to 13 mm (1/2") of space

near the front edge of the vault to allow room for the coin box

to lock into position.

om the back of the adhesive pads.

left and right inside walls of the coin

A

Complete Installation

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended earthing

method. See “Electrical Requirements.”

eck that all parts are now installed. If there is an extra part,

2. Ch

go back through the steps to see which step was skipped.

heck that you have all of your tools.

3. C

spose of/recycle all packaging materials.

4. Di

5. Check that the water taps are on.

6. Che

ck for leaks around taps and inlet hoses.

A. Foam pad strips

USER & SET-UP INSTRUCTIONS

1. Door must be closed before cycle selection is made.

2. Press fabric setting key pad for the wash cycle desired. After

the cycle is started, the time will display and count down.

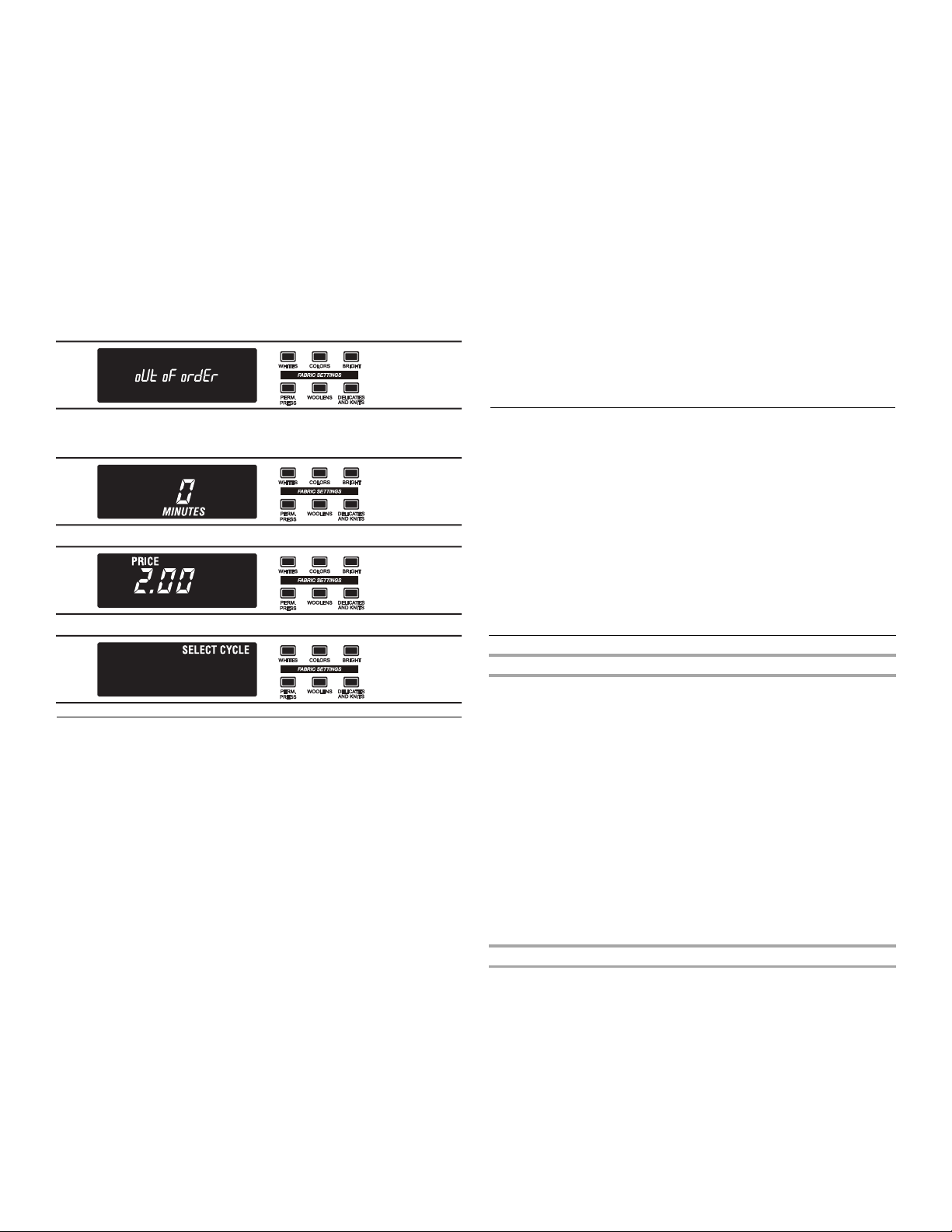

General Information

Scrolling ‘out of order’ showing in display, followed by a

failure code

This condition indicates the washer is inoperative.

“0 Minutes” showing in display

This condition indicates the washer cannot be operated. Coins

opped or debit inputs during this condition will be stored in

dr

escrow but cannot be used until normal operation is restored by

opening and closing the door. If a door switch fails, it must be

replaced before normal operation can be restored.

7. Plug into an earthed socket outlet.

8. To test and to clean your washer, measure 1/2 the detergent

manufacturer’s recommended amount for a medium-size

load. Pour the detergent into the detergent dispenser. Select

any cycle and allow the washer to complete one whole cycle.

Cold Start (initial first use)

Washer is programmed at the factory as follows:

■ 14-minute wash period

■ 3 rinses (extra rinse not enabled)

■ 7 x coin 1 wash price (PD models)

Warm Start (after power failure)

A few seconds after power is restored, if a cycle was in progress

the time of the power failure, “RESELECT CYCLE” will flash in

at

the display, indicating the need for a key press to restart washer.

Door Lock

The door will be locked when th

remain locked until the end of a cycle or approximately 2 minutes

after a power interruption.

e cycle starts. The door will

9

Page 10

Pricing

After the door is opened following the completion of a cycle, the

display indicates the cycle price (unless set for free operation). As

coins are dropped or debit inputs arrive, the display will change

to lead the user through the initiation of a cycle.

Free Cycles

This is established by setting the cycle price to zero. When this

ha

ppens, “SELECT CYCLE” will appear rather than a cycle price.

Display

After the washer has been installed

will show “0 MINUTES.” Once the washer has

and the washer door opened and closed, the display will show

the price. In washers set for free cycles, the display will flash

“SELECT CYCLE.”

and plugged in, the display

been plugged in

How to use the key pads to program controls

1. The PERMANENT PRESS key pad is used to adjust the

values associated with set-up codes. Pr

will change the value by incr

is possible by holding the key pad down.

2. The WOOLENS key

codes. Pressing this key pad will advance you to the next

available set-up code. Holding the key pad down will

automatically advance through the set-up codes at a rate

of 1 per second.

3. The

DELICATES & KNITS key pad is used to select or

deselect options.

pad advances you through the set-up

ements. Rapid adjustment

essing this key pad

Start Operating Set-up

NOTE: Prior operation, a payment system or an OPL kit must be

installed.

Before proceeding, it is worth noting that, despite all of the

options ava

commercial washer, hook it up, plug it in, and have a washer that

operates. Washers are preset at the factory for a 14-minute wash

period and 3 rinses (no extra rinse).

ilable, an owner can simply choose to un-crate a new

NOTE: Not displayed on washer as shown. Message scrolls

followed by the failure code.

Control Set-up Procedures

IMPORTANT: Read all instructions before operating.

■ PD Models: Insert access door key, turn, and lift to remove

access door.

■ PN Models: Remove connector AA1 on the circuit board.

Set-up procedures can be entered by

Code for PN washers without a key switch installed.

IMPORTANT: Unplug wa

opening the console. To access connector AA1:

Unplug

Open con

Plu

The washer is now in the set-up mod

key pads and the digital display are used to set up the controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related

code values available for use in programming the washer.

Once the washer has been programmed with a hand held

using Accu Trac, or a Gen. 2 card reader has been installed, the

washer will be put into dAS mode permanently, and dAS will be

displayed every time set-up mode is accessed.

washer or disconnect power.

g in washer or reconnect power.

sher or disconnect power before

sole, disconnect plug on AA1, close console.

using the Service Access

e. The lower fabric setting

device

Set-up Codes

■ The WOOLENS key pad will advance you from code to code.

■ The PERMANENT PRESS key pad will change the code

value.

■ The DELICATES & KNITS key pad will select or deselect

options.

FOR PN MODELS: The set-up codes are the same as for the

“PD” model except where noted.

The set-up code is indicated b

characters. The set-up code value is indicated by the two or

three right-hand characters.

CODE EXPLANATION

6 07 REGULAR CYCLE PRICE (Factory Default)

6 607

7 14 WASH LENGTH

7 14

Represents the number of coins (Coin 1) needed to

start the

VALUE OF COIN 1.) Advance from 0-39 by

pressing PERMANENT PRESS key pad. Factory

default of 7 x coin 1.

PN MODELS ONLY: Factory default for 0 coins.

00

With coin slide activation, this represents the

n

umber of push-in actuations of a coin slide to start

the washer.

6 01 setting would represent one coin slide

ac

NOTE:

meter case is necessary.

Press the WOOLENS key pad onc

next code.

This is the number of minutes for WASH. Washer

omes from the factory preset with 14 minutes.

c

Choose fr

PERMAN

Press the WOOLENS key pad once to advance

to next code.

washer; may adjust from 0-39. (See

tuation.

For coin slide activation, replacement of the

ENT PRESS key pad.

y the one or two left-hand

e to advance to

om 9-17 minutes by pressing the

10

Page 11

CODE EXPLANATION

8 00 ADDITIONAL RINSE OPTION

This option is either SELECTED “ON” or

NOT SELECTED “OFF.”

8800

Not Selected “OFF.”

Ar

Selected “ON.” Cannot be combined with the

Super Cycle

Press the DELICATES & KNITS key pad

rinse option.

this selection.

Press the WOOLENS key pad once to advance

to next code.

9 00 CYCLE COUNTER OPTION

This option is either SELECTED “ON” or

NOT SELECTED “OFF.”

9900

Not Selected “OFF.”

0C

Selected “ON” and not able to be deselected.

Press the DELICATES & KNITS key pad

3 consecutive times to select “ON.” Once selected

“ON” it cannot be deselected.

Press the WOOLENS key pad once to advance

to next code.

once for

CODE EXPLANATION

5. 00 TIME-OF-DAY CLOCK, MINUTES

5. 00

This is the TIME-OF-DAY CLOCK, minute setting;

sele

ct 0-59 minutes by pressing the PERMANENT

PRESS key

pad.

Press the WOOLENS key pad once to advance

to next code.

6. 00 TIME-OF-DAY CLOCK, HOURS

s the 24 hr. clock

ct 0-23 hours by pressing the PERMANENT

pad.

6. 00

NOTE: Use

This is the TIME-OF-DAY CLOCK, hour setting;

sele

PRESS key

Press the WOOLENS key pad once to advance

to next code.

7. 00 SPECIAL PRICE START HOUR

s the 24 hr. clock

pressing the PERMANENT PRESS key

7. 00

NOTE: Use

This is the start hour; 0-23 hours. Select START

HOUR by

pad.

Press the WOOLENS key pad once to advance

to next code.

1. 00 MONEY COUNTER OPTION

This option is either SELECTED “ON” or NOT

LECTED “OFF.”

SE

1.

00

Not Selected “OFF.”

1.

0C

Selected “ON.”

Press the DELICATES & KNITS key pad

3 consecutive times to select “ON” and

3 consecutive times to remove (Not Selected

“OFF”). Counter r

esets by going from “OFF” to

“ON.”

Press the WOOLENS key pad once to advance

to next code.

1.

Selected “ON” and not able to be deselected.

C0

To select “ON” and not able to be deselected,

first select “ON,” then within 2 seconds, press

the DELICATES & KNITS tw

ice, the PERMANENT

PRESS once, and exit the set-up mode.

2. 00 SPECIAL PRICING OPTION

This option is either SELECTED “ON” or NOT

LECTED “OFF.”

SE

2. 2.00 SPNot Selected “OFF”, and next available code will

be A.00.

Selected “ON.” Press the DELICATES & KNITS key

pad

once for this selection.

If SPECIAL PRICING OPTION is selected, ther

e is access to

codes “3.XX” through “9.XX.”

Press the WOOLENS key pad once to advance to

ne

xt code.

8. 00 SPECIAL PRICE STOP HOUR

NOTE: Uses the 24 hr. clock

8. 00

This is the stop hour; 0-23 hours. Select STOP

HOUR by

pressing the PERMANENT PRESS key

pad.

Press the WOOLENS key pad once to advance

to next code.

9. 10 SPECIAL PRICE DAY

9. 10 This represents the day of the week and whether

sp

ecial pricing is selected for that day. A number

followed by “0” indicates no selection that

particular day (9.10). A number followed by an “S”

indicates selected for that day (9.1S). To change

the value of “0” and “S,” use the “DELICATES &

KNITS” key pad.

Days of the week (1-7) are selected by pressing the

PERMAN

ENT PRESS key pad.

When exiting set-up code “9”, the display must

show

current day of week:

DISPLAY DAY OF WEEK CODE (selected)

10

20

30

40

50

60

70

Day 1=

Day 2=

Day 3=

Day 4=

Day 5=

Day 6=

Day 7=

Sunday

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

1S

2S

3S

4S

5S

6S

7S

Options to use if SPECIAL PRIC

3. 07 SPECIAL CYCLE PRICE

3. 3.07

Represents the number of coins (coin 1) needed to

start the

VALUE OF COIN 1.) Advance from 0-39 by

pr

Factory default of 7 x coin 1.

00

PN MODELS ONLY: Factory default of 0 coins.

Press the WOOLENS key pad once to advance

washer; may adjust from 0-39. (See

essing the PERMANENT PRESS key pad.

to next code.

ING is selected:

Press the WOOLENS key pad once to advance

to next code.

11

Page 12

CODE EXPLANATION

A. 00 VAULT VIEWING OPTION

This option is either SELECTED “ON” or NOT

LECTED “OFF.”

SE

A.A.00

b. 05 VALUE OF COIN 1

b. 05

C. 20 VALUE OF COIN 2

C.

C.

d. 00 COIN SLIDE OPTION

d. d.00

Not Selected “OFF.”

SC

Selected “ON.” Press the DELICATES & KNITS key

pad once for this selection. When selected, the

money and/or cycle counts will be viewable (if

counter option(s) is selected) when the coin box is

removed.

Press the WOOLENS key pad once to advance

to next code.

This represents the value of coin 1 in the quantity of

5% increments of the larger coin value. 5 x

5%=25%.

By pressing the PERMANENT PRESS key pad,

here is the option of 1-199 for the quantity of 5%

t

ncrements.

i

With coin slide activation, this represents the total

vend price.

Press the WOOLENS key pad once to advance

to next code.

This represents the value of coin 2 in the quantity of

20

5% increments of the larger coin value. 20 x

5%=100%.

By pressing the PERMANENT PRESS key pad,

here is the option of 1-199 for the quantity of 5%

t

i

ncrements.

05

PN MODELS: This represents the value of coin 2 in

CS

e quantity of 5% increments of the larger coin

th

value. Factory default = 5 x 5% of the larger coin

value.

Press the WOOLENS key pad once to advance

to next code.

This option is either SELECTED “ON” or NOT

LECTED “OFF.”

SE

Not Selected “OFF.” Used with coin drop or card

eaders.

r

Selected “ON.” Press the DELICATES & KNITS key

pad 3 consecutive times for this selection.

NOTE: This option needs to

the meter case has been changed to accept a

coind slide device.

When coin slide mode is selected “On”, set b.

al to value of vend price. Set set-up code 6

equ

(regular cycle price) and set-up code 3 (special

cycle price) to number of slide pushes. If washer is

set up as “CS” and a coin drop is installed, it will

not register coins.

Press the WOOLENS key pad once to advance

to next code.

be set to”00” unless

CODE EXPLANATION

E. 00 ADD COINS OPTION

This option is either SELECTED “ON” or NOT

SELECTED “OFF

display to show the number of coins (coin 1) to

enter, rather than the amount.

E. 00

F. 00 ENHANCED PRICING OPTION

F.

F.

F.

H. 01 SUPER CYCLE UPGRADE PRICE

H. 01

h. 01 SUPER CYCLE TYPE

h. 01

J. Cd COIN/DEBIT OPTION

J.

J.

J.

J.

Not Selected “OFF.”

AC

Selected “ON.” Press the DELICATES & KNITS key

pad 3 consecutive times for this selection.

Press the WOOLENS key pad once to advance

to next code.

Not Selected “OFF.”

00

Cycle-Based pricing enabled. This option allows

CP

onfiguration of different prices for cold, warm, and

c

hot water cycles.

Super Cycle pricing enabled. This option allows

Su

ustomers to upgrade cycles by depositing extra

c

money. Set-up codes “H.” and “h.” will be

displayed only when this option is enabled. Press

the DELICATES & KNITS key pad once for this

selection.

Press the WOOLENS key pad once to advance

to next code.

(Skipped unless super cycle pricing is enabled.)

This represents the number of coin 1 required

to upgrade a base cycle to a super cycle. Advance

fr

om 0-39 by pressing the PERMANENT PRESS

k

ey pad.

Press the WOOLENS key pad once to advance

to next code.

(Skipped unless Super Cycle pricing is enabled.)

This represents the super cycle upgrade option.

Cd

C_

_d

Ed

ess the PERMANENT PRESS key pad to step

Pr

through upgrade options 1-3 as follows:

01 - enhanced wash, extra 3 minutes of wash

tumble in

02 - extra rinse for all cycles.

03 - both 01 and 02.

Press the WOOLENS key pad once to advance

to next code.

Both coin & debit selected. Press the DELICATES &

key pad 3 consecutive times to change this

KNITS

section.

Coins selected, debit disabled. Press the

DELICA

times to change this selection.

Debit card selected, coins disabled. This is

the factory default for PN

DELICATES & KNITS key pad 3 consecutive

times to change this selection.

Enhanced Debit is self-selected when a Generation

2 car

option cannot be manually selected or deselected.

Press the WOOLENS key pad once to advance

to next code.

TES & KNITS key pad 3 consecutive

d reader is installed in the washer. The Ed

.” This option causes the customer

addition to the programmed wash time.

models. Press the

12

Page 13

CODE EXPLANATION

L. 00 PRICE SUPPRESSION OPTION

This option causes the customer display to show

“ADD” or

“AVAILABLE” rather than the amount of

money to add. (Used mainly in debit installations.)

L. 00

Not Selected “OFF.”

PS

Selected “ON.” Press the DELICATES & KNITS key

once for this selection.

pad

Press the WOOLENS key pad once to advance

to next code.

n. CE CLEAR ESCROW OPTION

When selected, money held in escrow for

30 minutes without further escrow or cycle

activity will be cleared.

n.n.00

Not Selected “OFF.”

CE

Selected “ON.” Press the DELICATES & KNITS key

pad once for this selection.

Press the WOOLENS key pad once to advance

to next code.

r. 800 TOP SPIN SPEED RPM

r. 800

This can be selected from the following spin

speeds: 600 rpm, 750 rpm, 800 rpm, 1000

(displa

ys as 999) rpm. Step between speeds by

pr

essing the PERMANENT PRESS key pad.

Factory pre-set for 800 rpm.

Press the WOOLENS key pad once to advance

to next code.

U. 00 PENNY INCREMENT OFFSET

U. 00 This option is not supported for European Models

and the

value must be set to 00.

Press the WOOLENS key pad once to advance

to next code.

A1. 00 PREWASH LENGTH

A1. 00

This is the number of minutes of PREWASH.

hoose 0 to disable the prewash or

C

2 and 7 minutes by pressing the PERMANENT

ESS key pad.

PR

Press the WOOLENS key pad once to advance

select between

to next code.

A2. 03 FINAL SPIN LENGTH

A2. 03

This is the number of minutes of final high speed

Choose from 3-8 minutes by pressing the

spin.

ERMANENT PRESS key pad.

P

Press the WOOLENS key pad once to advance

to next code.

If cycle counter (9 0C) is selected, the following is true:

1 00 Represents the number of

n HUNDREDS.

cycles i

2 00 Represents the number of

les in ONES.

cyc

1 02 = 200

25 = 25

2

TOTAL CYCLES = 225 cycles

This is “VIEW ONLY” and cannot be cleared.

ess the WOOLENS key pad once to advance to

Pr

next code.

If money counter (1.0C or 1.C0) is selected,

the following is

true:

3 00 Number of coins in

DREDS

HUN

3 01 = 400 x coin 1

4 00 Number of coins in ONES 4 68 = 272 x coin 1

5 00 Number of COINS. 5

75 = 3 x coin 1

Total = 675 x coin 1

END OF SET-UP PROCEDURES

EXIT FROM SET-UP MODE

■ PD Models: Reinstall access door.

■ PN Models:

Unplug washer or

Open

Pl

■ PN MODELS WITH PROGRAMMING SWITCH:

console, reinsert plug into AA1, close console.

ug in washer or reconnect power.

disconnect power.

Turn key clockwise and remove.

■ PN MODELS WITHOUT PROGRAMMING SWITCH:

Set-up mode can be exited by using procedures from.

Washer Diagnostic Mode

To enter the “Washer Diagnostic Mode,” first enter “Start

Operating Set-up.” Then press and hold the DELICATES AND

KNITS key pad for 1 second while in any of th

through six, anytime a diagnostic code is present, or while dAS

displays if operating with Maytag Data Acquisition set-up.

On entry to diagnostic mode the

entire display will flash, a

cycle in process is canceled, money in escrow is cleared, and

gnostic codes are cleared. If a diagnostic code persists,

dia

it must be corrected before th

e following cycle options

are permitted.

There are five possible ways to initiate cycle activity from

diagnostic

mode as follows:

1. Washer Cleanout cycle - With the entire display flashing, this

cycle is started by pressing the BRIGHT key pad.

Use the Washer Cleanout cycle once a month to keep the

side of your washer fresh and clean. This cycle uses a

in

higher water level. Use with liquid chlorine bleach to

thoroughly clean the inside of the washer. This cycle should

not be interrupted.

IMPORTANT: Do not place garments or

washer during the Washer Cleanout cycle. Use this cycle with

an empty wash drum.

2. Cycl

e Credit - With the entire display flashing, a cycle may be

credited by pressing the PERMANENT PRESS key pad (CC

will display). When the service mode is exited, “SELECT

CYCLE” will be displayed unless the end-of-cycle door

opening is required.

3. Manual Overview T

est - With the entire display flashing, this

cycle is started by pressing the WHITES key pad. This cycle

provides more typical full length fills, tumbles, drains, and

actuator dispenser movement, allowing for a more thorough

analysis of the washer operation, including pressure switch

behavior.

4. Quick

Spin Cycle - With the entire display flashing, this cycle

is started by pressing the COLORS key pad. This cycle

provides a method to quickly drain and spin (remove water

from the washer) if desired.

e set-up codes one

other items in the

13

Page 14

5. Quick Overview Test - With the entire display flashing, this

cycle is started by pressing the WOOLENS key pad. This

cycle provides a quick verification that the cold and hot water

valves, dispensers, and pump motor are working, as well as

actuator dispenser movement. It also includes door lock,

drain, and spin operations.

Pressing the DELICATES AND KNITS key pad will exit diagnostic

mode and cancel a diagnostic cycle in process.

DIAGNOSTIC CODES

If the set-up mode is entered and one of the following has

occurred, the appropriate diagnostic code will be in the display.

d5 Blocked coin 1 or coin drop control circuit failure (coin

d9 Low voltage detected for 8 seconds.

d13 Blocked coin 2 or coin drop control circuit failure

F20 Slow Fill. The washer will not detect water input for

F22 The door is not able to lock. Door lock error or

r

ecognition and price display disabled while blockage

persists). PN Models Only: Set-up mode J. should be

set to _d (or Ed if in free operation mode) to eliminate

coin related diagnostic codes.

(coin recognition and price display disabled

blockage persists).

4 min. Pressure switch failure or no water inlet. This

reported as d8 on d7.

code is

someone trying to start the washer, by pressing the

door switch with the finger. This code is reported as

d17 on Accu Trac.

while

WASHER HELP MODE

This mode is entered by pressing the PERMANENT PRESS key

pad while in special pricing option mode 2.XX (or while dAS

displays if operating with Maytag Data Acquisition set-up).

In help mode, other display symb

to reflect the state of various inputs a

Display Symbol Description

Wash Water sensed at wash level.

*

° (Circle above digit) Door closed.

DOOR LOCKED Door sensed locked.

COLD Cold water relay on.

HOT Hot water relay on.

OR Door unlock.

AVAILABLE Drain pump ON.

ols and elements are mapped

nd outputs as follows:

Low voltage present (below about

90 VAC).

(For different code consult service personnel)

14

Page 15

WASHER CARE

Cleaning Your Washer

Cleaning the Door Seal/Bellow

1. Open the washer door and remove any clothing or items from

the washer.

2. Inspect

3. If stained areas are found, wipe down these areas of the

IMPORTANT:

■ Wear rubber gloves when cleaning for prolonged periods.

■ Refer to the bleach manufacturer’s instructions for proper

the colored seal/bellow between the door opening

and the drum for stained areas. Pull back the seal/bellow to

inspect all areas under the seal/bellow and to check for

foreign objects.

A

A. Seal/Bellow

seal/bellow, using the procedure that follows.

a) Mix a dilute solution, using 177 mL (3/4 cup) of liquid

chlorine bleach, and 3.8 L (1 gal.) of warm tap water.

b) Wipe the seal/bellow area with the dilute solution,

using a damp cloth.

c) Let stand 5 minutes.

d) Wipe

down area thoroughly with a dry cloth and let the

washer interior air dry with door open.

use.

Washer Maintenance Procedure

This washer has a special cycle that uses higher water volumes in

combination with liquid chlorine bleach to thoroughly clean the

inside of the washer.

NOTES:

■ Read these instructions completely before beginning the

cleaning process.

■ If necessary, the cleaning cycle may be interrupted by

pressing the DELICATES AND KNITS button twice. However,

this will not immediately stop the cycle. The machine will

continue with several rinse and drain steps to ensure that all

remaining bleach is rinsed from the washer.

Begin procedure

1. Open the washer door and remove any clothing or items from

the washer.

2. Use liquid chlorine bleach:

Open the dispenser drawer and immediately

160 mL (

2

/3 cup) of liquid chlorine bleach to the bleach

compartment.

NOTE: Do not add any detergent to this cycle. Use of more

than 160 mL (

2

/3 cup) of bleach will cause product damage

over time.

3. Close the washer door and the dispenser drawer.

o start the Clean Washer cycle, first enter “Start Operating

4. T

Set-up.” Then press and hold DELICATES AND KNITS for

1 second. With the entire display flashing, press BRIGHTS.

NOTE: Th

e drum will rotate, then the door will unlock, lock

again, and then the cycle will continue.

■ The machine will not fill, but the drum will rotate while the

washer runs a short sensing cycle. This will take

approximately 3 minutes.

5. The cycle will determine whether clothing or other items are

in the washer.

a) b)If no items are detected in the washer, it will proceed to

ep 7.

St

If any items are detected in the washer, “rL” or “F-34” will

be displayed. Then the door will unlock.

■ Press DELICATES AND KNITS to cancel the failure

code. Then repeat steps 1, 3, and 4 to start the cycle

aga

in.

add

6. Once the cycle has begun, allow the cycle to complete.

ter the cycle is complete, leave the door open slightly,

7. Af

to allow for better ventilation and

drying of washer interior.

15

Page 16

Always do the following to maintain washer freshness

■ Use only detergent for automatic washer.

■ Leave the door slightly open after each cycle to allow for

better ventilation and drying of washer interior.

■ Clean the washer monthly using the Washer Maintenance

Procedure, 160 mL (

■ If the procedure does not sufficiently improve the machine

freshness, please evaluate your installation and usage

conditions for other causes.

2

/3 cup) of liquid chlorine bleach.

Cleaning the exterior

Cleaning the dispenser drawer

The dispenser drawer is removable for easy cleaning.

1. Unlock the

Remove the drawer.

2. Remove the

compartments).

3. W

ash the parts under running water.

NOTE: D

eplace the inserts and return the dispenser to the drawer.

4. R

dispenser drawer by pressing the Release Lever.

inserts (the siphon from the softener and bleach

o not wash components in the dishwasher.

Use a soft damp cloth or sponge to wipe up any spills.

Occasionally wipe the outside of your washer to keep it looking

new. Use mild soap and water. Do not use abrasive products.

ASSISTANCE OR SERVICE

Before calling for assistance or service, please check

“Troubleshooting.” It may save you the cost of a service call. If

you still need help, contact the dealer from whom you purchased

the appliance, or a Maytag designated service company.

When calling, please know the purchase date and the complete

model and serial number of your appliance. This information will

help us to better respond to your request.

Water Inlet Hoses

Replace inlet hoses after 5 years of use to reduce the risk of hose

failure. Periodically inspect and replace inlet hoses if bulges,

kinks, cuts, wear, or leaks are found.

When replacing your inlet hoses, record the date of replacement.

Accessories

Enhance your washer with these premium accessories.

For more high-quality items or to order, contact your authorized

Maytag distributor

Part

Number

8212638RP 1.8 m (6 ft) Nylon braided space-saving inlet

8212487RP 1.5 m (5 ft) Nylon braided inlet hose. (2-pack)

8212526 Washer drip tray, fits under all

31682 All purpose appliance cleaner

1903WH Laundry supply storage cart

.

Accessory

, 90° elbow, hypro-blue steel couplings.

hose

(2-pack)

16

Page 17

MAYTAG COMMERCIAL WASHER, DRYER, STACKED DRYER/DRYER,

COMMERCIAL STACK LAUNDRY, AND MULTI-LOAD COIN OPERATED

COMMERCIAL WASHERS AND DRYERS WARRANTY

LIMITED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the instructions

attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for factory specified parts or original

equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date is required to obtain service under this

warranty.

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to replace or repair

fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of God, improper

installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in accordance with

published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN. IMPLIED

WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE

SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES

AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE

DURATION OF IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR

PROVINCE TO PROVINCE.

If you need service, please contact your authorized Maytag Commercial Laundry distributor. To locate your authorized Maytag Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com. 9/07

Keep this book and your sales slip together for future reference. You must provide proof of purchase or installation date for in-warranty service.

Write down the following information about your major appliance

to better help you obtain assistance or service if you ever need it.

You will need to know your complete model number and serial

number. You can find this information on the model and serial

ITEMS MAYTAG WILL NOT PAY FOR

Dealer name____________________________________________________

Address ________________________________________________________

Phone number__________________________________________________

Model number __________________________________________________

number label located on the product.

Serial number __________________________________________________

Purchase date __________________________________________________

17

Page 18

SECURITE DU LAVE-LINGE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

IMPORTANTES INSTRUCTIONS DE SECURITE

AVERTISSEMENT :

lave-linge, il convient d'observer certaines précautions fondamentales, notamment :

An de réduire le risque d'incendie, de choc électrique ou de blessures lors de l'utilisation de ce

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

■ Lire toutes les instructions avant d'utiliser le lave-linge.

■ Ne pas laver des articles qui ont été précédemment

nettoyés, lavés, trempés ou tachés avec de l'essence,

un solvant pour nettoyage à sec ou d'autres

substances inammables ou explosives; ces

substances dégagent des vapeurs qui pourraient

s'enammer ou provoquer une explosion.

■ Ne pas ajouter d'essence, de solvant pour nettoyage à

sec ou d'autre substance inammable ou explosive à

l'eau de lavage; ces substances dégagent des vapeurs

qui pourraient s'enammer ou provoquer une explosion.

■ Dans certaines conditions, un circuit d'eau chaude qui

n'a pas été utilisé depuis 2 semaines ou plus peut

contenir de l'hydrogène. L'HYDROGENE EST UN GAZ

EXPLOSIF. Si le circuit d'eau chaude est resté inutilisé

pendant une telle période, ouvrir tous les robinets

d'eau chaude et laisser l'eau s'écouler pendant

plusieurs minutes avant d'utiliser le lave-linge. Ceci

permettra l'évacuation de toute accumulation

d'hydrogène. Le gaz est inammable : ne pas fumer

ou utiliser une amme nue durant cette période.

■ Ne pas laisser des enfants jouer sur le lave-linge ou à

l'intérieur de celui-ci. Une surveillance attentive des

enfants est nécessaire lorsque le lave-linge est utilisé

à proximité d'enfants.

CONSERVER CES INSTRUCTIONS

■ L'appareil ménager n'est pas conçu pour une utilisation sans

surveillance par de jeunes enfants ou des personnes

handicapées.

■ Retirer la porte ou le couvercle du lave-linge avant de le

retirer du service ou de le mettre au rebut.

■ Ne pas accéder à l'intérieur du lave-linge si le tambour, la

cuve ou l'agitateur est en mouvement.

■ Ne pas installer ou conserver le lave-linge en un endroit où il

sera exposé aux intempéries.

■ Ne pas effectuer d'intervention non autorisée sur les

commandes.

■ Ne pas réparer ou remplacer une quelconque pièce du

lave-linge ou effectuer une quelconque intervention

d'entretien qui ne serait pas expressément recommandée

dans le Guide d'utilisation et d'entretien ou dans des

instructions de réparation par l'utilisateur que vous

comprenez et que vous êtes capables d'exécuter.

■ Voir les instructions d'installation au sujet de la mise à la

terre de l'appareil.

■ Si le cordon d'alimentation est endommagé, il doit être

remplacé par le fabricant ou par son agent de service agréé,

ou par une autre personne qualiée, an d'éviter tout danger.

18

Page 19

MISE AU REBUT DU LAVE-LINGE

EXIGENCES D'INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant de commencer

l'installation. Les pièces fournies se trouvent dans le tambour du

lave-linge.

Outils nécessaires au raccordement des tuyaux d'arrivée

d'eau

■ Pince (ouverture jusqu'à

39,5 mm [1

9

/16"])

Outils nécessaires à l'installation

■ Clés plates de

■ Tournevis de sécurité

■ Tourne-écrou de

To rx

®†

T-20

Pièces fournies

1

/2" et 9/16"

1

/4"

■ Lampe de poche

(facultative)

■ Niveau

■ Cale en bois

■ Règle ou mètre ruban

Pièces fournies pour les modèles PD :

Came de verrouillage

de la porte de service

Bandes de

protection

Pièces fournies pour les modèles PD :

■ Détecteur de pièces blanc

■ Détecteur de pièces noir

Autres pièces

Il se peut que l'installation nécessite des pièces supplémentaires.

Pour acheter l'un des articles indiqués ici, contacter votre

concessionnaire Maytag agréé.

A BC

D

E

A. Bride de retenue pour tuyau de vidange (en forme de U)

B. Tuyaux d'arrivée d'eau (2)

C. Rondelles pour tuyau d'arrivée d'eau (4)

D. Bouchons d'obturation des boulons de trans

E. Courroie perlée

port (4)

Si vous avez Vous devrez acheter

Evier de buanderie

ou tuyau rigide de

Système de pompe de puisard (si non

déjà disponible)

rejet à l'égout plus

haut que 2,4 m

(96"

)

Egout surélevé Evier de vidange standard de 76 L

(20 gal.) de 762 mm (30") de hauteur ou

évier utilitair

e et pompe de puisard

(disponibles chez votre fournisseur local

d'articles de plomberie)

Egout au plancher Brise-siphon, pièce n° 285834; tuyau de

vidange additionnel, pièce n° 8318155; et

en

semble de connexion, pièce n° 285835

†

® TORX est une marque déposée de Acument Intellectual Properties, LLC.

19

Page 20

Si vous avez Vous devrez acheter

Tuyau de vidange

trop court

Robinets d'eau

hors d'atteinte des

tuyaux d'admission

Trousse de rallonge du tuyau de vidange

de 1,2 m (4 pi), pièce n° 285863

2 tuyaux d'admission d'

eau plus longs :

1,8 m (6 pi), pièce n° 76314

3 m (10 pi), pièce n° 350008

Options

Piédestal

Vous avez la possibilité d’acheter des piédestaux séparément

pour ce lave-linge. Le piédestal augmentera la taille totale du

lave-linge.

Ne pas faire fonctionner le lave-linge à des températur

es

inférieures à 0ºC (32ºF). Une certaine quantité d'eau peut

demeurer dans le lave-linge et causer des dommages à des

températures basses.

Dégagements de séparation à respecter

■ L'emplacement doit être assez grand pour permettre d'ouvrir

complètement la porte du lave-linge.

■ Prévoir davantage d'espace pour faciliter l'installation et

l'entretien. La porte s'ouvre à plus de 90° et n'est pas

réversible.

■ Un espace supplémentaire peut être requis pour les moulures

de porte et de plancher et pour les plinthes.

■ Un espace supplémentaire de 25 mm (1") de tous les côtés

du lave-linge est recommandé pour réduire le transfert du

bruit.

■ Il faut aussi prendre en compte l'espace requis entre les

appareils voisins.

■ Une fois installées, les prises principales doivent être

accessibles pour permettre de débrancher le lave-linge du

câblage principal.

Piédestal facultatif

Hauteur du

piédestal

Hauteur

approximative

Couleur Numéro

de modèle

avec lave-linge

73 mm (2

7

/8") 1207 mm (47,5") Blanc WHP0400VW

Exigences d'emplacement

Le choix d'un emplacement approprié pour le lave-linge en

améliore le rendement et réduit au minimum le bruit et le

“déplacement” possible du lave-linge.

Le lave-linge peut être installé sous

dans un sous-sol, une salle de buanderie, un encastrement.

Voir “Système de vidange”.

Il faut aussi prendre en compte les exigences d'emplacement

des appar

eils voisins. C'est à l'utilisateur qu'incombe la

responsabilité de réaliser une installation correcte.

Il vous faudra

■ Un chauffe-eau configuré pour fournir de l'eau à 60°C

(140°F) au lave-linge.

■ Une prise électrique reliée à la terre située à 1,8 m (6 pi)

maximum du cordon d'alimentation électrique fixé à l'arrière

du lave-linge. Voir “Spécifications électriques”.

■ Des robinets d'eau chaude et d'eau froide situés à

1,2 m (4 pi) maximum des robinets d

et d'eau froide et une pression d'eau de 137,9-689,6 kPa

(20-100 lb/po²).

■ Un plancher de niveau ayant une pente maximale de

25 mm (1") sous l'ensemble du lave-li

lave-linge sur des surfaces de sol souples, telles que tapis

ou surfaces avec sous-couche en mousse n'est pas

r

ecommandée.

■ Un plancher robuste et solide capable de soutenir le poids

total du lave-linge (eau et charge) de 180 kg (400 lb).

un comptoir personnalisé,

'admission d'eau chaude

nge. L'installation du

Dimensions du lave-linge

1282 mm

(50

La porte n'est pas réversible.

686 mm

1

/

")

2

(27")

732 mm

13

(28

/

16

")

1134 mm

5

(44

/

")

8

Un système de vidange au plancher doit être installé sous la

cloison. Des cloisons pré-fabriquées avec prises de courant,

canalisations d'arrivée d'eau et aménagements pour installation

de vidangeage ne doivent être installées que là où les codes

locaux l'autorisent.

20

Page 21

Système de vidange

Le lave-linge peut être installé en utilisant le système de rejet à

l'égout (au plancher ou mural), le système de vidange de l'évier

de buanderie ou le système de vidange au plancher. Sélectionner

la méthode d'installation du tuyau de vidange selon les besoins.

Voir “Outillage et pièces”.

Système de rejet à l'égout - mural ou au plancher (vues A et B)

Le système de rejet à l'égout nécessite un tuyau rigide d'un

diamètre minimum de 50 mm (2"). La capacité minimale

d'a

cheminement ne doit pas être inférieure à 64 L (17 gal.) par

minut

e.

Le sommet du tuyau rigide de rejet à l

762 mm (30") de hauteur et au maximum à 2,4 m (96" ) de la base

du lave-lin

ge.

A

Système de vidange avec évier de buanderie (vue C)

L'évier de buanderie doit avoir une capacité minimale de

76 L (20 gal.). La partie supérieure de l'évier

être à au moins 762 mm (30") au-dessus du plancher.

Système de vidange au plancher (vue D)

Le système de vidange au plancher nécessite un brise-siphon qui

peut être acheté séparément. Voir “Outillage et pièces”.

Le brise-siphon doit être au moins à 710 mm (28") de la base

du lave-linge. Des tuyau

x supplémentaires peuvent être requis.

762 mm

(30" min.)

'égout doit être au moins à

762 mm

(30" min.)

B

de buanderie doit

710 mm

(28" min.)

Spécifications électriques

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise reliée à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou un choc électrique.

■ Une alimentation électrique de 220-240V, 50 Hz, protégée par

un fusible est requise. On recommande d'utiliser un fusible

temporisé de 10 à 16 A ou un disjoncteur temporisé.

■ Ce lave-linge comporte un cordon d'alimentation électrique

pour liaison à la terre.

■ Pour minimiser les risques de choc électrique, on doit

brancher le cordon sur une prise de courant de configuration

correspondante reliée à la terre et installée conformément

aux codes et règlements locaux. Si une prise de courant de

configuration correspondante n'est pas disponible, le client a

la responsabilité et l'obligation de faire installer par un

électricien qualifié une prise de courant correctement reliée à

la terre.

■ Si les codes le permettent et si on utilise un conducteur

distinct de liaison à la terre, il est recommandé qu'un

électricien qualifié vérifie la qualité de la liaison à la terre.

■ Si le cordon d'alimentation est endommagé, il doit être

remplacé par le fabricant, son agent de service ou toute autre

personne qualifiée afin d'éviter tout danger.

■ Ne pas utiliser une tuyauterie de gaz pour le raccordement

à la terre.

■ En cas de doute quant à la qualité de la liaison à la terre

du lave-linge, consulter un électricien qualifié.

CD

21

Page 22

■ Ne pas installer un fusible dans le conducteur neutre ou le

conducteur de liaison à la terre.

INSTRUCTIONS DE LIAISON A LA TERRE

Ce lave-linge doit être relié à la terre. En cas d'anomalie de

fonctionnement ou de panne, la liaison à la terre réduira le

risque de choc électrique en offrant au courant électrique

un itinéraire d'évacuation de moindre résistance. Ce

lave-linge est alimenté par un cordon électrique comportant

un conducteur relié à la terre et une che de branchement

munie d'une broche de liaison à la terre. La che doit être

branchée sur une prise de courant appropriée qui est bien

installée et reliée à la terre conformément à tous les codes

et règlements locaux.

AVERTISSEMENT :

appareil au conducteur de liaison à la terre peut susciter un

risque de choc électrique. En cas de doute quant à la

qualité de la liaison à la terre de l'appareil, consulter un

électricien ou technicien d'entretien qualié.

Ne pas modier la che de branchement fournie avec

l'appareil – si la che ne correspond pas à la conguration

de la prise de courant, demander à un électricien qualié

d'installer une prise de courant convenable.

Le raccordement incorrect de cet

3. Une

4. Une fois que les 4 boulons ont été retirés, jeter les boulons et

5. Obtur

REMARQUE : Si le lave-linge doit être transporté à une date

ultérieure, appeler le distributeur ou l'installateur du produit. Pour

éviter des dommages concernant la suspension et la structure,

votre lave-linge doit être correctement monté pour réinstallation

ultérieure par un technicien certifié.

fois le boulon desserré, le déplacer au centre

du trou et retirer complètement le boulon, y compris

la cale d'espacement en plastique couvrant le boulon.

les cales d'espacement. Enfoncer ensuite la prise du cordon

d'alimentation dans l'ouverture située du côté droit du

panneau arrière et tirer le cordon d'alimentation à travers

l'ouverture située du côté gauche du panneau arrière, puis

boucher les trous à l'aide du capuchon fourni. Ne pas tirer

l'extrémité du côté prise du cordon d'alimentation par le trou

de droite.

er les trous des boulons avec les 4 bouchons

d'obturation des boulons de transport.

INSTRUCTIONS D'INSTALLATION

1. Sélectionner la prise qui correspond à la prise électrique

Dépose du système de transport

Installation du cordon d'alimentation

murale.

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installer le lave-linge.

Le non-respect de cette instruction peut causer une

blessure au dos ou d'autre blessure.

IMPORTANT : Positionner le lave-linge de sorte que l'arrière du

lave-linge soit à environ 900 mm (3 pi) de son emplacement final.

On trouve sur le panneau arrièr

d'expédition qui soutiennent le système de suspension durant le

transport. Ces boulons retiennent aussi le cordon d'alimentation

électrique à l'intérieur du lave-linge jusqu'à ce que les boulons

soient retirés.

e du lave-linge 4 boulons

2. Fixer la prise à l'extrémité du cordon d'alimentation.

3. Fixer le cordon d'alimentation en immobilisant le raccord sur

le dispositif de blocage du cordon.

1. Laisser le lave-linge en position verticale pendant que l'on ôte

les boulons d'expédition.

2. Au moye

n d'une clé de 1/2", desserrer chacun des boulons.

22

Page 23

4. Installer le couvercle du dispositif de blocage du cordon et

appuyer jusqu'à ce qu'il s'emboîte.

5. S'assur

er que le raccord du cordon d'alimentation est

immobilisé sur le dispositif de blocage du cordon et que le

serrage du dispositif de blocage est correct.

Raccordement des tuyaux d'arrivée d'eau

Insérer les rondelles plates neuves (fournies) dans chaque

extrémité des tuyaux d'arrivée d'eau. Insérer fermement les

rondelles dans les raccords.

A B

A. Raccord

B. Rondelle

■ Utiliser les nouveaux tuyaux d'arrivée d'eau fournis avec le

lave-linge. Ne pas réutiliser de tuyaux d'arrivée d'eau usagés.

Connecter les tuyaux d'arrivée d'eau aux robinets d'eau

S'assurer que le tambour du lave-linge est vide.

1. Fixer un tuyau

le raccord à la main pour qu'il comprime le joint.

2. Fixer un tuya

le raccord à la main pour qu'il comprime le joint.

3. A l'aide d'une pince, serrer les raccords en effectuant deux

tiers de tour supplémentaires.

au robinet d'eau chaude. Visser complètement

u au robinet d'eau froide. Visser complètement

■ Vérifier la température de l'eau pour s'assurer que le tuyau

d'eau chaude est connecté au robinet d'eau chaude et que

le tuyau d'eau froide est connecté au robinet d'eau froide.

Raccordement des tuyaux d'arrivée d'eau aux clapets anti-retour sur le lave-linge

H

C

REMARQUE : Ne pas serrer excessivement ou utiliser du ruban

adhésif ou un calfeutrant sur le robinet. Les tuyaux d'arrivée

d'eau risquent d'être endommagés.

Purger les canalisations d'eau

■ Laisser s'écouler l'eau des deux robinets et des tuyaux

d'arrivée d'eau dans un évier de buanderie, un tuyau rigide

de rejet à l'égout ou un seau, pour éliminer les particules se

trouvant dans les canalisations d'eau qui pourraient obstruer

les tamis de la valve d'arrivée d'eau.

H. Tuyau d'arrivée d'eau chaude

C. Tuyau d'arrivée d'eau froide

1. Fixer le tuyau d'eau chaude au clapet anti-retour du tuyau

d'arrivée d'eau chaude (H) du lave-linge. Visser

complètement le raccord à la main pour qu'il comprime le

clapet anti-retour.

2. Fixer le tu

d'arrivée d'eau froide (C) du lave-linge. Visser complètement

le raccord à la main pour qu'il comprime le clapet anti-retour.

3. A

l'aide d'une pince, serrer les raccords en effectuant deux

tiers de tour supplémentaires.