Maytag LSG7806ABQ, LSG7806ABE, LSG7806ABM, LSE7806ADM, LSE7806ADE Installation Guide

LEAVE THESE INSTRUCTIONS WITH THE OWNER

iMPORTANT TO iNSTALLER

REMOVE THE DOOR FROIVl ALL DISCARDED

APPLIANCES SUCH AS DRYERS AND

COMBINATION WASHER/DRYERS TO AVOID

THE DANGER OF A CHILD SUFFOCATING

SHOULD HE/SHE CRAWL INSIDE AND THE

DOOR BE SHUT.

THE APPLIANCE MUST NOT BE INSTALLED

OR STORED IN AN AREA WHERE IT WILL BE

EXPOSED TO WATER AND/OR WEATHER.

U.S. MODELS

PLEASE READ THE FOLLOWING INSTRUC-

TIONS CAREFULLY BEFORE STARTING TO

INSTALL THE DRYER. FOR GAS DRYERS,

THE INSTALLATION MUST CONFORM WITH

THE NATIONAL FUEL GAS CODE ANSI

Z223.1, LATEST REVISION. ANY QUESTIONS

CONCERNING THIS SHOULD BE REFERRED

TO THE LOCAL GAS UTILITY.

CANADIAN MODELS

PLEASE READ THE FOLLOWING INSTRUC-

TIONS CAREFULLY BEFORE STARTING TO

INSTALL THE DRYER. FOR GAS DRYER

INSTALLATION, REFER TO STANDARD

CAN/CGA B149 (.1 OR .2) INSTALLATION

CODE. ANY QUESTIONS SHOULD BE

REFERRED TO THE LOCAL GAS UTILITY.

This folder contains information of interest to the

owner. After the appliance has been properly

instafled, LEAVE THESE INSTRUCTIONS

WITH THE OWNER.

SERVICE CALLS PERFORMED

AS A RESULT OF POOR

INSTALLATION ARE THE

RESPONSIBILITY OF THE

INSTALLER.

printed in U,S,A, 6 3717020

iMPORTANT TO OWNER

Retain these instructions for future reference.

This new Maytag appliance is designed to serve

you dependably for many years. However, it

cannot do so unless provided with sufficient

electrical power, suitable exhausting and if a gas

model, adequate gas supply. We urge you to

read this carefully to make sure all requirements

are met.

Operating instructions, safety precautions and

your warranty are in the accessory package with

each appliance. Read the operating instructions

carefully.

NOTE: A wiring diagram for the dryer is located

on the inside of the dryer access panel. A wiring

diagram for the washer is located on the inside

of the washer cabinet.

To remove carton, cut around bottom of carton

on or below dotted line. Cut down each corner

of carton (vertically) and "peel" carton away from

stacked washer/dryer. Fold carton material for

removal. Check the unit for shipping damage.

Untape and open washer lid. Remove installa-

tion accessory package, fill hoses and close lid.

Leave tub block in place until installation is

complete. Be sure to remove tub block after

installation is complete and before use!

Using the carton corner posts stacked in pairs,

lay the washer on the posts on the left side.

Remove the crate base wires from the carton

base. Use pliers or screwdriver to pry wires from

wood. (Do not kick the shipping base off the

washer.)

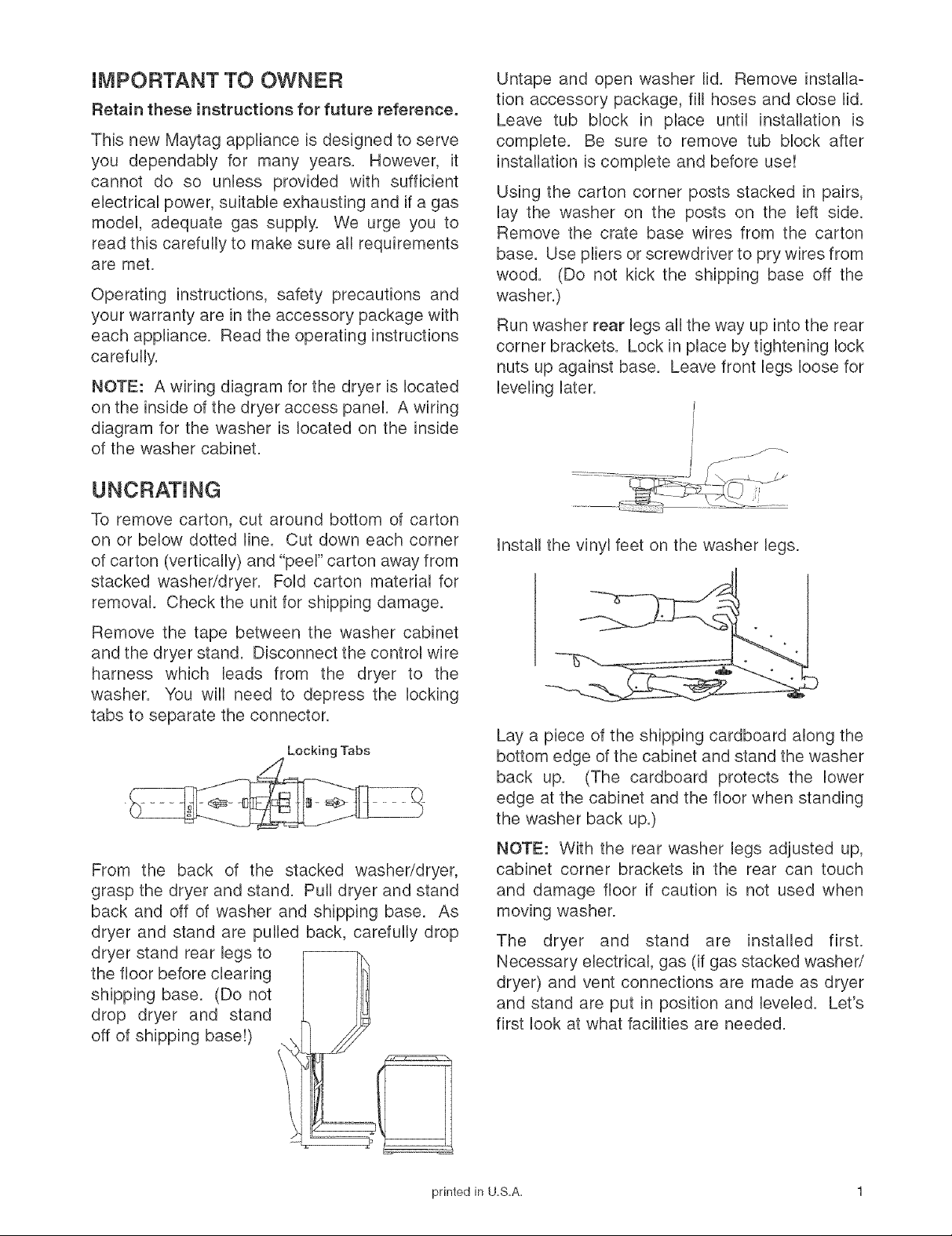

Run washer rear legs all the way up into the rear

corner brackets. Lock in place by tightening lock

nuts up against base. Leave front legs loose for

leveling later.

Install the vinyl feet on the washer legs.

Remove the tape between the washer cabinet

and the dryer stand. Disconnect the control wire

harness which leads from the dryer to the

washer. You will need to depress the locking

tabs to separate the connector.

Locking Tabs

From the back of the stacked washer/dryer,

grasp the dryer and stand. Pull dryer and stand

back and off of washer and shipping base. As

dryer and stand are pulled back, carefully drop

dryer stand rear legs to _,

the floor before clearing

shipping base. (Do not

drop dryer and stand

off of shipping base!)

9

Lay a piece of the shipping cardboard along the

bottom edge of the cabinet and stand the washer

back up. (The cardboard protects the lower

edge at the cabinet and the floor when standing

the washer back up.)

NOTE: With the rear washer legs adjusted up,

cabinet corner brackets in the rear can touch

and damage floor if caution is not used when

moving washer.

The dryer and stand are installed first.

Necessary electrical, gas (if gas stacked washer/

dryer) and vent connections are made as dryer

and stand are put in position and leveled. Let's

first look at what facilities are needed.

printed in U,S,A,

PREJNSTALLATJON CONSiDERATiONS

Location: The stacked washer/dryer is approved

for zero clearance installation on the sides and

the back (depending on venting used). The Ioca=

tion selected must take into consideration the

dimensions of the unit and convenience for cus=

tomer use and access in case service should be

needed. The floor must be capable of supporting

the weight of the unit (approximately 310 Ibs.)

enough to prevent excessive vibration in spin

cycles. A floor which is adequate for the

standard washer is sufficient for the stacked

washer/dryer.

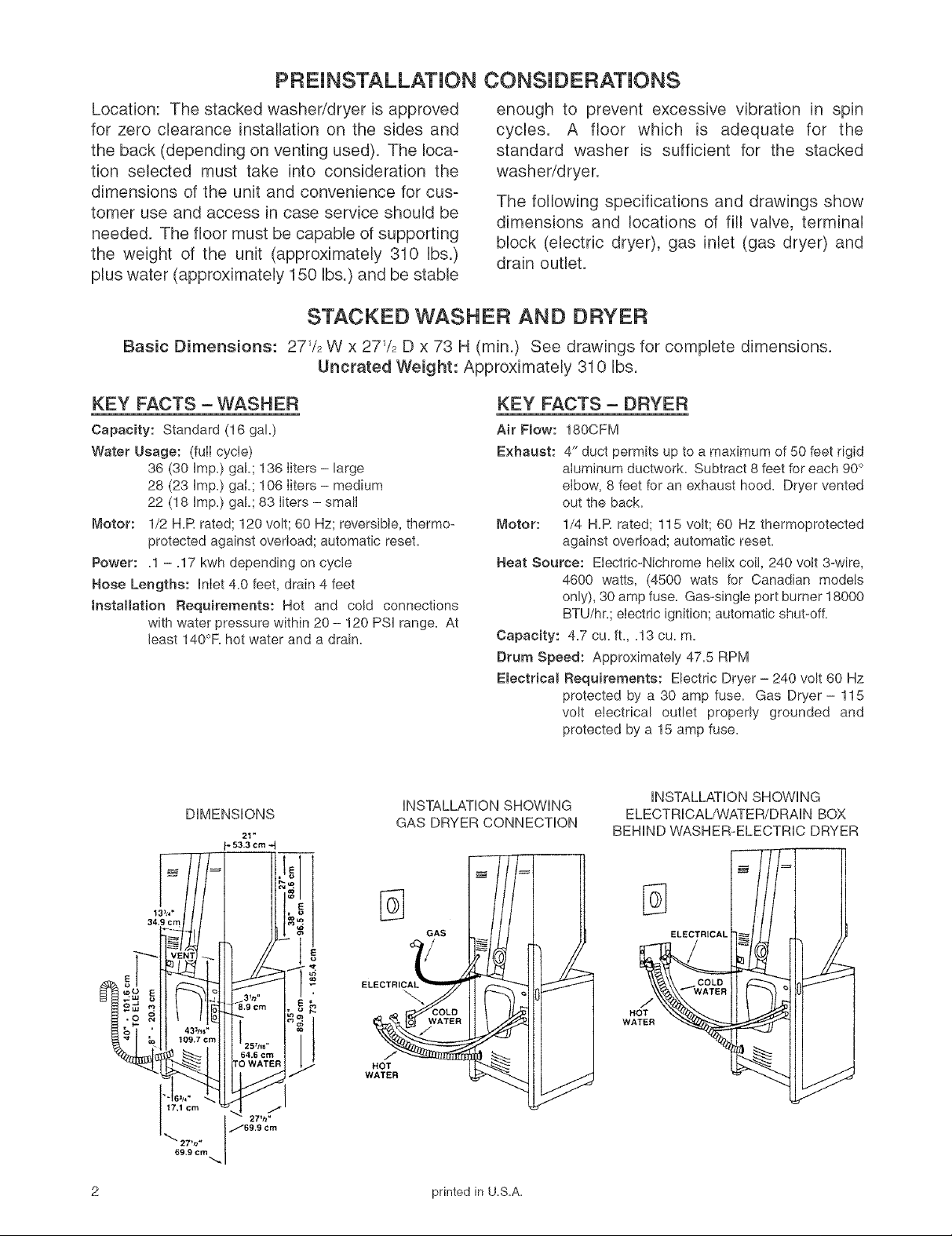

The following specifications and drawings show

dimensions and locations of fill valve, terminal

block (electric dryer), gas inlet (gas dryer) and

drain outlet.

plus water (approximately 150 Ibs.) and be stable

STACKED WASHER AND DRYER

Basic Dimensions: 271/2W x 271/2 D x 73 H (min.) See drawings for complete dimensions.

Uncrated Weight: Approximately 31 0 Ibs.

KEY FACTS - WASHER

Capacity: Standard (16 gaL)

Water Usage: (full cycle)

36 (30 Imp.) gaL; 136 liters -large

28 (23 Imp.) gaL; 106 liters- medium

22 (18 Imp.) gaL; 83 liters -small

Motor: 1/2 H.R rated; 120 volt; 60 Hz; reversible, thermo-

protected against overload; automatic reset.

Power: .1 - .17 kwh depending on cycle

Hose Lengths: Inlet 4.0 feet, drain 4 feet

Installation Requirements: Hot and cold connections

with water pressure within 20 - 120 PSI range. At

least 140°R hot water and a drain.

KEY FACTS - DRYER

Air Fmow: 180CFM

Exhaust: 4" duct permits up to a maximum of 50 feet rigid

aluminum ductwork. Subtract 8 feet for each 90°

elbow, 8 feet for an exhaust hood. Dryer vented

out the back.

Motor: 1/4 H.R rated; 115 volt; 60 Hz thermoprotected

against overload; automatic reset.

Heat Source: Eiectric-Nichrome helix coil, 240 volt 3-wire,

4600 watts, (4500 wats for Canadian models

only), 30 amp fuse. Gas-single port burner 18000

BTU/hr.; electric ignition; automatic shut-off.

Capacity: 4.7 cu. ft, .13 cu. m.

Drum Speed: Approximately 47.5 RPM

Emectrical Requirements: Electric Dryer - 240 volt 60 Hz

protected by a 30 amp fuse. Gas Dryer - 115

volt electrical outlet properly grounded and

protected by a 15 amp fuse.

DiMENSiONS ELECTRICAL/WATER/DRAIN BOX

2_" BEHIND WASHER-ELECTRIC DRYER

I_ 53.3 crn q

I /69.9 cm

69,9 cm

2 printed in U.S.A.

iNSTALLATiON SHOWING

GAS DRYER CONNECTION

iNSTALLATiON SHOWING

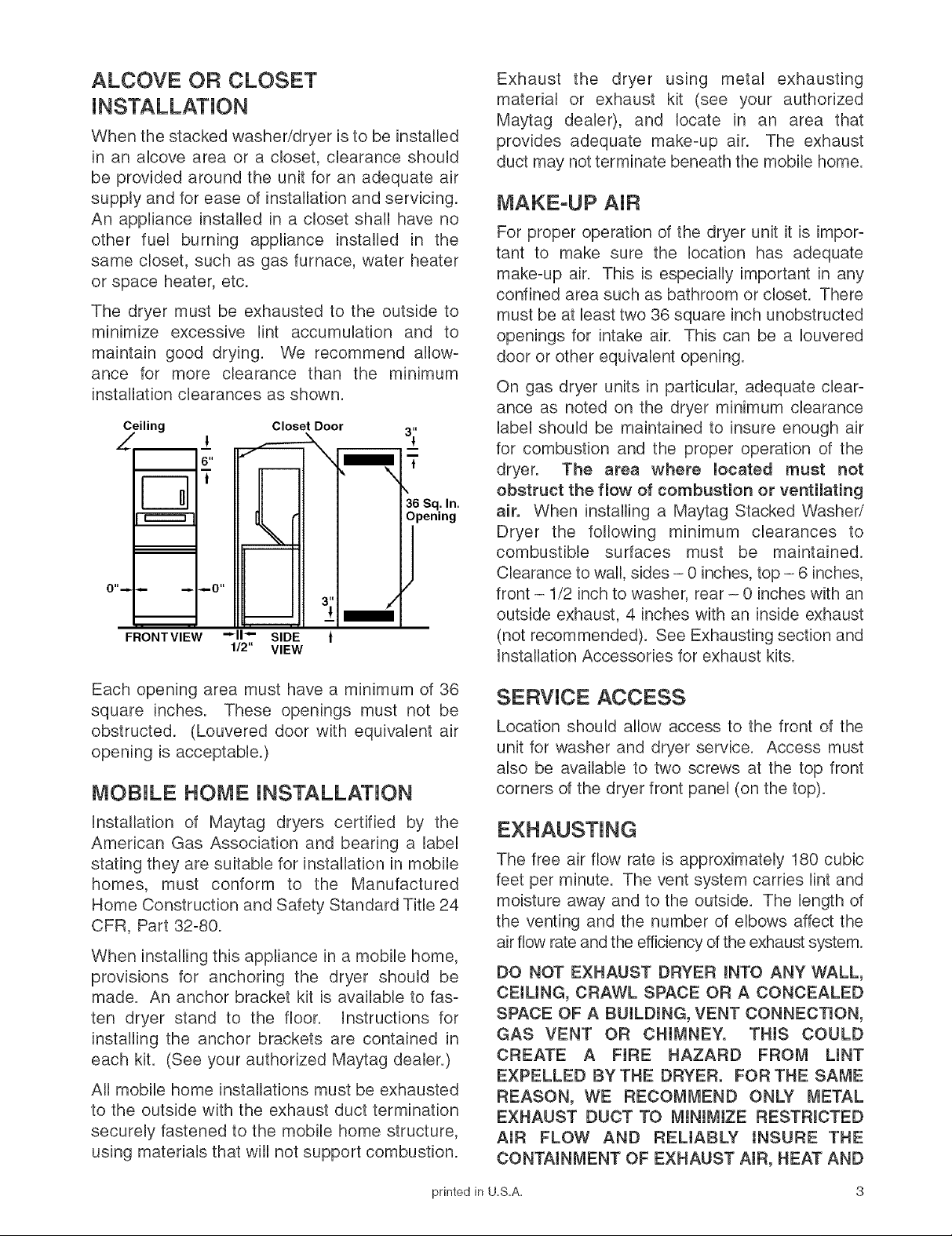

ALCOVE OR CLOSET

When the stacked washer/dryer is to be installed

in an alcove area or a closet, clearance should

be provided around the unit for an adequate air

supply and for ease of installation and servicing.

An appliance installed in a closet shall have no

other fuel burning appliance installed in the

same closet, such as gas furnace, water heater

or space heater, etc.

The dryer must be exhausted to the outside to

minimize excessive lint accumulation and to

maintain good drying. We recommend allow-

ance for more clearance than the minimum

installation clearances as shown.

Ceiling

! Sq: In.

0"-- -- _0"

FRONTVIEW

--II-- SIDE t

1/2" VIEW

penmg

Exhaust the dryer using metal exhausting

material or exhaust kit (see your authorized

Maytag dealer), and locate in an area that

provides adequate make-up air. The exhaust

duct may not terminate beneath the mobile home.

MAKE=UP AiR

For proper operation of the dryer unit it is impor-

tant to make sure the location has adequate

make=up air. This is especially important in any

confined area such as bathroom or closet. There

must be at least two 36 square inch unobstructed

openings for intake air. This can be a Iouvered

door or other equivalent opening.

On gas dryer units in particular, adequate clear-

ance as noted on the dryer minimum clearance

label should be maintained to insure enough air

for combustion and the proper operation of the

dryer. The area where located must not

obstruct the flow of combustion or ventilating

air. When installing a Maytag Stacked Washer/

Dryer the following minimum clearances to

combustible surfaces must be maintained.

Clearance to wall, sides - 0 inches, top - 6 inches,

front - 1/2 inch to washer, rear - 0 inches with an

outside exhaust, 4 inches with an inside exhaust

(not recommended). See Exhausting section and

Installation Accessories for exhaust kits.

Each opening area must have a minimum of 36

square inches. These openings must not be

obstructed. (Louvered door with equivalent air

opening is acceptable.)

MOBILE HOME iNSTALLATiON

Installation of Maytag dryers certified by the

American Gas Association and bearing a label

stating they are suitable for installation in mobile

homes, must conform to the Manufactured

Home Construction and Safety Standard Title 24

CFR, Part 32-80.

When installing this appliance in a mobile home,

provisions for anchoring the dryer should be

made. An anchor bracket kit is available to fas-

ten dryer stand to the floor. Instructions for

installing the anchor brackets are contained in

each kit. (See your authorized Maytag dealer.)

All mobile home installations must be exhausted

to the outside with the exhaust duct termination

securely fastened to the mobile home structure,

using materials that will not support combustion.

SERVICE ACCESS

Location should allow access to the front of the

unit for washer and dryer service. Access must

also be available to two screws at the top front

corners of the dryer front panel (on the top).

The free air flow rate is approximately 180 cubic

feet per minute. The vent system carries lint and

moisture away and to the outside. The length of

the venting and the number of elbows affect the

air flow rate and the efficiency of the exhaust system.

DO NOT EXHAUST DRYER INTO ANY WALL,

CEIMNG, CRAWL SPACE OR A CONCEALED

SPACE OF A BUiLDiNG, VENT CONNECTION,

GAS VENT OR CHMNEY. THIS COULD

CREATE A FIRE HAZARD FROM UNT

EXPELLED BY THE DRYER. FOR THE SAME

REASON, WE RECOMMEND ONLY METAL

EXHAUST DUCT TO MiNIMiZE RESTRICTED

AIR FLOW AND RELIABLY toNSURE THE

CONTAINMENT OF EXHAUST AIRo HEAT AND

printed in U=S=A= 3

LINT. NEVER iNSTALL A SCREEN OVER

EXHAUST OUTLET. NEVER USE PLASTIC OR

OTHER COMBUSTIBLE DUCTWORK. AT

LEAST ONCE AYEAR, INSPECT AND CLEAN

iNTERIOR OF DUCTWORK. FREQUENTLY

CHECK AND CLEAN VENT HOODTO ASSURE

PROPER OPERATION.

A cbthes dryer produces combustibUe tint and

the area around the clothes dryer shouUd be kept

free of tint. DO NOT STORE FLAMMABLE

LIQUIDS OR MATERmALS NEAR A DRYER.

tt is recommended that the dryer be exhausted

to the outside using 4 inch rigid or flexible metaU

ducting.

When located in a bedroom, bathroom or cUoset,

the dryer must be exhausted to the outside.

The stacked washer/dryer can only be exhaust°

ed out the back. A 4 inch vent shouUd be

installed to accept the exhaust from the dryer.

To permit sufficient air circulation under the

exhaust hood, there shouUd be no less than a 12

inch cUearance between the bottom of the

exhaust hood and the ground. When possible

the exhaust hood shouUd not exhaust directly

into a window weft. DO NOT terminate exhaust

under a building.

NOTE: Where the exhaust hood is to be

installed through masonry, a special masonry

saw is necessary to cut the hole.

tnstall the exhaust hood and secure with screws

to the outside waft and seal with caulking compound.

DIRECT EXHAUST

An exhaust hood positioned to line up with the

dryer exhaust pipe can be installed directly

through an outside wall. This would be the

shortest and most direct exhaust method.

To exhaust up, route standard 4 inch diameter

ducting up the recess in the cabinet back using

the furnished retaining strap and screws to get

nearly flush to wall installation. To exhaust to the

side or down, install the furnished 4 inch long

duct with four"S" clips to the inner dryer exhaust,

then use standard 4 inch ducting. This will posi-

tion the dryer about 4ol/2 inches away from the

wall. Flush-to-wall side exhausting may be done

by going above the dryer before going sideways.

When exhausting down, wallboard can be

removed from the wall to get the dryer closer to

the wall by placing the exhaust pipe between

studs. Check toccata codes for required

exhaust cmearances.

Install ductwork from the dryer to exhaust hood.

All joints must be made so exhaust end of one

pipe is inside the intake end of next pipe. On

flexible metal ductwork, all joints should be

secured with a clamp. DO NOT use sheet metal

screws when assembling rigid ducting. Joints

should be taped.

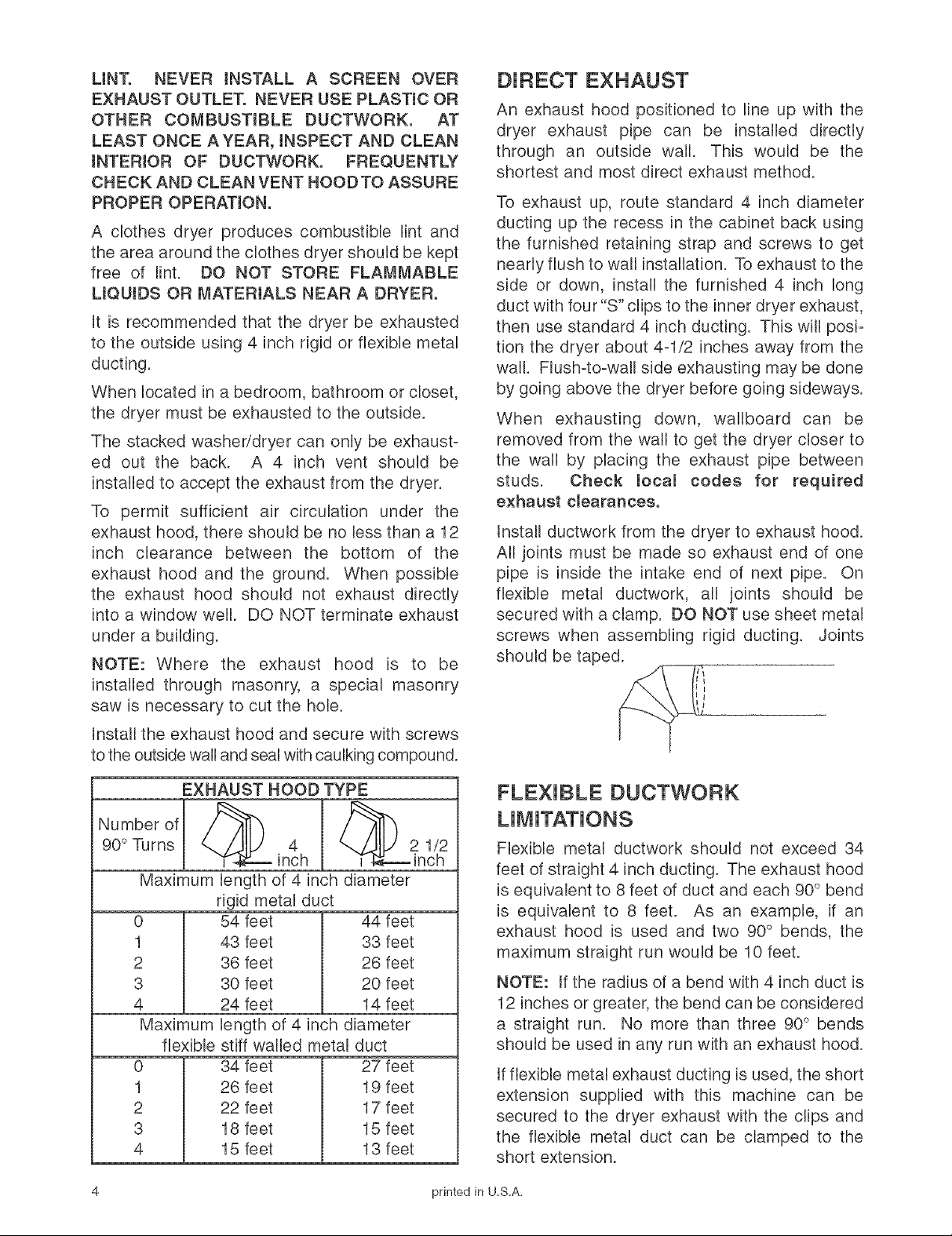

EXHAUST HOOD TYPE

90 ° Turns 4 1/2

Number of i_ _ 2

Maximum length of 4 inch diameter

rigid metal duct

0

1

2

3

4

Maximum

flexible

0

1

2

3

4

4 printed in U.S.A.

54 feet 44 feet

43 feet 33 feet

36 feet 26 feet

30 feet 20 feet

24 feet 14 feet

length of 4 inch diameter

stiff walled metal duct

34 feet

26 feet

22 feet

18 feet

15 feet

inch T_---inch

27 feet

19 feet

17 feet

15 feet

13 feet

FLEXIBLE DUCTWORK

Flexible metal ductwork should not exceed 34

feet of straight 4 inch ducting. The exhaust hood

is equivalent to 8 feet of duct and each 90 ° bend

is equivalent to 8 feet. As an example, if an

exhaust hood is used and two 90 ° bends, the

maximum straight run would be 10 feet.

NOTE: if the radius of a bend with 4 inch duct is

12 inches or greater, the bend can be considered

a straight run. No more than three 90° bends

should be used in any run with an exhaust hood.

tf flexible metal exhaust ducting is used, the short

extension supplied with this machine can be

secured to the dryer exhaust with the clips and

the flexible metal duct can be clamped to the

short extension.

Loading...

Loading...