Page 1

240EdwardsStreet,SE

C]eve[and,Tennessee37311

Tei:423-472-3333

Fax:423-478-6710

STACKED WASHER- DRYER

INSTALLATION INSTRUCTIONS

IMPORTANT TO INSTALLER

REMOVE THE DOOR FROM ALL DISCARDED APPLIANCES SUCH AS DRYERS

AND COMBINATION WASHER/DRYERS TO AVOID THE DANGER OF A CHILD

SUFFOCATING SHOULD HE/SHE CRAWL INSIDE AND THE DOOR BE SHUT.

TIIE DRYER MUST NOT BE INSTALLED OR STORED IN AN AREA WHERE IT

WILL BE EXPOSED TO WATER ANI)/OR WEATHER.

US MODELS

PLEASE READ THE FOLLOWING 1FNSTRUCTIONS CAREI_q.ILLY BEFORE

STARTING TO INSTALL THE DRYER. FOR GAS DRYERS, THE INSTALLATION

MUST CONFORM WITH THE NATIONAL FUEL GAS CODE ANSI Z223.1, LAT-

EST REVISION. ANY QUESTIONS CONCERNING THIS SHOULD BE REFERRED

TO THE LOCAL GAS UTILITY.

MA'_IAG A_mlral 7t _,Je_N-_ 4V_ C._f

Page 2

C_s_omerSe_i_0 __

240EdwardsStreet,SE

Cleveland,Tennessee3731;

Te!:423-472-3333

Fax:423-478-6710

IMPORTANT TO OWNER

Retain these instructions for future reference.

This new Maytag appliance is designed to serve you dependably for many years. However,

it cannot do so unless provided with sufficient electrica! power, suitable exhausting and if a

gas model, adequate gas supply. We urge you to read this carefully to make sure all

requirements are met.

Operating instructions, safety precautions and your warranty are in the accessory package

with each appliance. Read the operating instructions carefully.

NOTE: A wiring diagram for the dryer is located on the inside of the dryer access panel. A

wiring diagram for the washer is located on the inside of the washer front panel.

LrNCRATING

To remove carton, cut around bottom of carton on or below dotted line. Cut down each

corner of carton (vertically) and "peel" carton away from stacked washer/dryer. Fold carton

material for removal. Check the unit for shipping damage.

The control cable for the washer is taped to the rear of the dryer stand at the bottom.

Remove tape from control cable and temporarily place end of control cable in dryer vent.

From the back of the Stacked Washer/Dryer, grasp the dryer and stand, Pull dryer and stand

back and off of washer and shipping base. As dryer and stand are pulled back, carefully drop

dryer stand rear legs to the floor before clearing shipping base. (Do not drop dryer and stand

off of shipping base!).

_] M,\'_rAG Admiral71 =_=mJENN-A;_ "_la_ic C,,_ef

Page 3

2a8EdwardsStreet.SE

Cleveland,Tennessee37311

Tel:423472-3333

Fax:423-478-6710

\

Untape and open washer lid. Remove installation accessory package, fill hoses and drain

hose and close lid. Leave tub block in place until installation is complete. Be sure to remove

tub block after installation is complete and before use.!

Using the carton corner posts stacked in pairs, lay the washer on the posts on the left side.

Remove the crate base wires from the carton base. Use pliers or screwdriver to pry wires

from wood. (Do not kick the shipping base off of the washer).

Run the washer rear legs all the way up into the rear corner brackets and lock in place by

tightening lock nuts. Leave the front legs loose for leveling in a following step.

Install vinyl feet on the washer legs.

With the washer laying down, check belt tension and motor track freedom. Lay a piece of

the shipping cardboard along the bottom edge of the cabinet and stand the washer back up.

(The cardboard protects the lower edge at the cabinet and the floor when standing the washer

back up).

NOTE: With the rear washer legs adjusted up, cabinet corner brackets in the rear can touch

and damage floor if caution is not used when moving washer

The dryer and stand are installed first. Necessary electrical, gas, (if gas stacked

washer!dryer) and vent connections are made as dryer and stand are put in position and lev-

eled. Let's first look at what facilities are needed.

.'¢V_£AG Admirai 7! _'nn_._N.._ _Magic C,het

Page 4

_ustomer..... o i ,,Jl :_1"_jl,,,_ml,

4TA_,,i.,ir"_

2aOEdwardsS_e:. SE

Cleveland,Tennessee37311

Tei:423-_72-3332

Fax:_23-_78-87i0

PREINSTALLATION CONSIDERATIONS

Location: The stacked washer/dryer is approved for zero clearance installation on the sides

and the back (depending on venting used). The location selected must take into consideration

the dimensions of the unit and convenience for customer use and access in case service should

be needed. The floor must be capable at supporting the weight of the unit (approximately

340 pounds) plus water (approximately 130 pounds) and be stable enough to prevent exces-

sive vibration in spin cycles. A floor which is adequate for the standard washer is sufficient

for the stacked washer/dryer.

The following specifications and drawings show dimensions and locations of fill valve, ter-

minal block (electric dryer) gas inlet (gas dryer) and drain outlet.

STACKED WASHER AND DRYER

Basic Dimensions 27 1/2" W x 27 1/2" D x 73" H (rain). See drawings for complete

dimensions. Uncrated Weight: Approximately 340 pounds.

KEY FACTS - WASHER

Capacity: Standard (16 gallons)

Water Usage: (full cycle) - 36 (30 Imp.) gal: 136 liters - large

30 (25 Imp.) gal: 114 liters - medium

24 (20 Imp.) gal: 91 liters - small

Motor: !/2 H.P, rated; 115 volt; 60 Hz; reversible; thermoprotected against overload;

automatic reset. Model LDE7804 available in 220-240 volt; to Hz.

Power: 0.1 - 0.17 kwh depending on cycle.

Hose Lengths: Inlet 5 feet (1.52 m); drain 4 feet (t.22 m).

Installation Requirements: Hot and cold water connections with water pressure within 30-

120 p.s.i. (2.11-8.44 kg/cm) range; 120F to 140F hot water; a drain; a t20 volt, 60Hz

electrical outlet properly grounded and protected by a 15 amp fuse.

Uncrated Weight: Approximately 340 pounds.

_AG Admiral 7| "JmmnlJENN-AJi:t "_lc!lgiC C,"l_|

Page 5

_x igOUllqj

24GEdwardsStreet,SE

Cleve!and,Tennessee373!;

Tei:423472-3333

Fax:423-47g-67t0

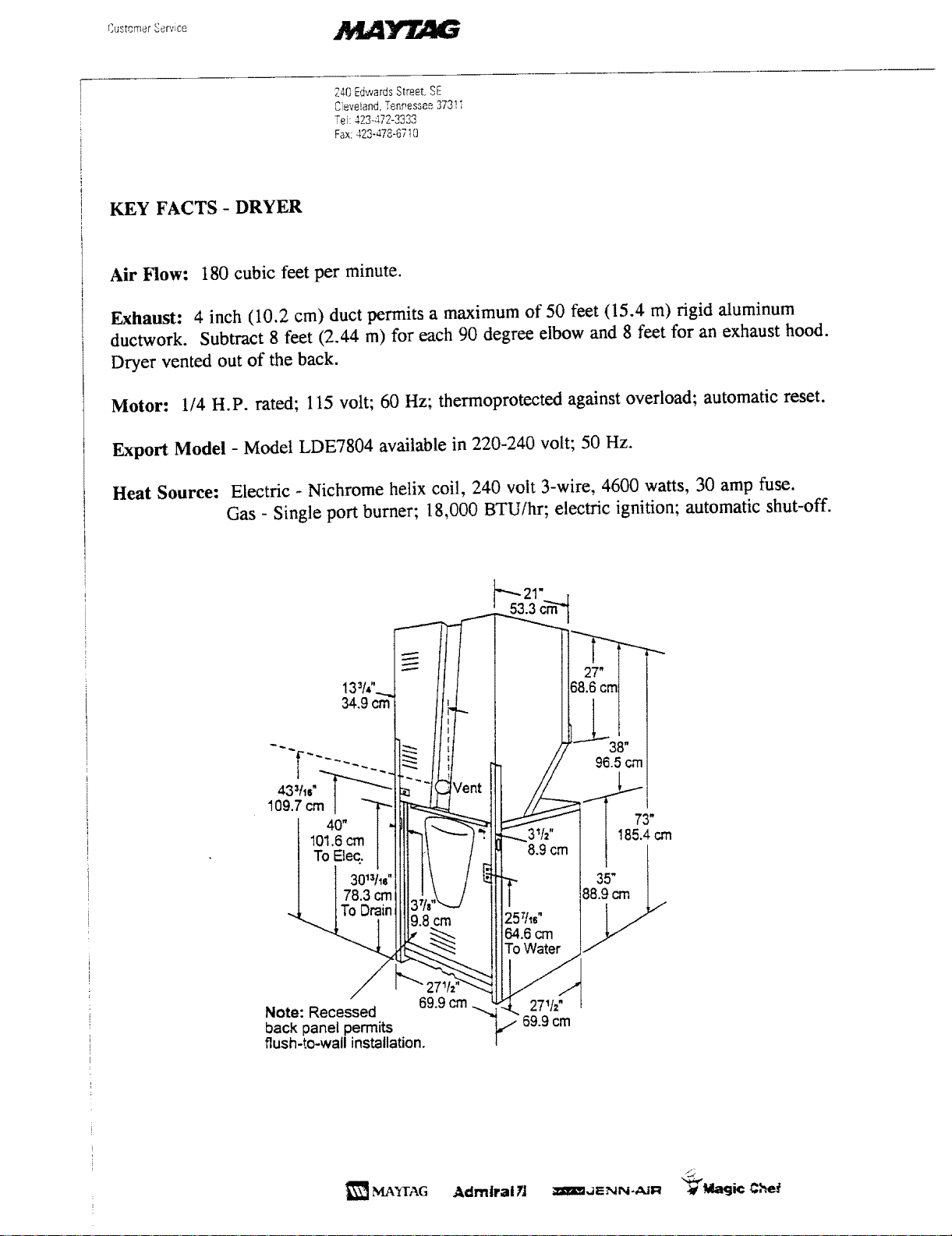

KEY FACTS - DRYER

Air Flow: 180 cubic feet per minute.

Exhaust: 4 inch (t0.2 cm) duct permits a maximum of 50 feet (15.4 m) rigid aluminum

ductwork. Subtract 8 feet (2.44 m) for each 90 degree elbow and 8 feet for an exhaust hood.

Dryer vented out of the back.

Motor: !/4 H.P. rated; 115 volt; 60 Hz; thermoprotected against overload; automatic reset.

Export Model - Model LDE7804 available in 220-240 volt; 50 Hz.

Heat Source: ELectric - Nichrome helix coil, 240 volt 3-wire, 4600 watts, 30 amp fuse.

Gas - Single port burner; 18,000 BTU/hr; electric ignition; automatic shut-off.

13_

34.9

96.5 cm

73"

185.4cm

Note: Recessed 69.9cm 27_I£

back panel permits 69.9cm

flush-to-wall installation.

MAYrA6 .&dm|rai tJ m.J_N-,_Jg _ _tacjm ¢,',_'

Page 6

240EdwardsStreet,SE

C!eveland,Tenressee37311

TeJ:423-472-3333

Fax:422-478-67!0

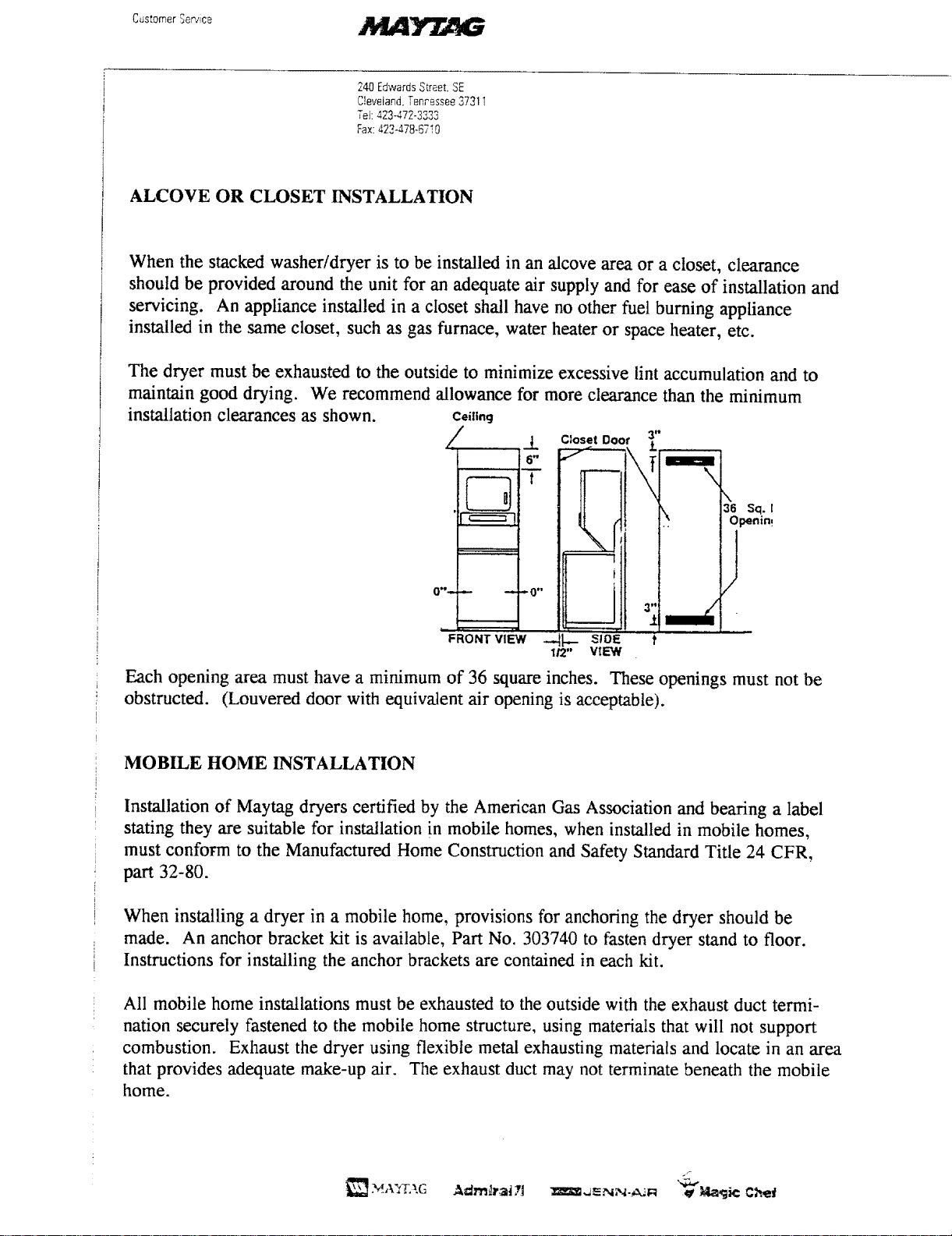

ALCOVE OR CLOSET INSTALLATION

When the stacked washer/dryer is to be installed in an alcove area or a closet, clearance

should be provided around the unit for an adequate air supply and for ease of installation and

servicing. An appliance installed in a closet shall have no other fuel burning appliance

installed in the same closet, such as gas furnace, water heater or space heater, etc.

The dryer must be exhausted to the outside to minimize excessive lint accumulation and to

maintain good drying. We recommend allowance for more clearance than the minimum

installation clearances as shown.

\

36 Sq. I

Openin_

J

Each opening area must have a minimum of 36 square inches. These openings must not be

obstructed. (Louvered door with equivalent air opening is acceptable).

MOBILE HOME INSTALLATION

Installation of Maytag dryers certified by the American Gas Association and bearing a label

stating they are suitable for installation in mobile homes, when installed in mobile homes,

must conform to the Manufactured Home Construction and Safety Standard Title 24 CFR,

part 32-80.

When installing a dryer in a mobile home, provisions for anchoring the dryer should be

made. An anchor bracket kit is available, Part No, 303740 to fasten dryer stand to floor.

Instructions for installing the anchor brackets are contained in each kit.

All mobile home installations must be exhausted to the outside with the exhaust duct termi-

nation securely fastened to the mobile home structure, using materials that will not support

combustion. Exhaust the dryer using flexible metal exhausting materials and locate in an area

that provides adequate make-up air. The exhaust duct may not terminate beneath the mobile

home.

:S

Page 7

240EdwardsStreet,SE

C[eveland,Tennes.-_ee.!7311

Tel:422-472-33._

Fax:423-478-57_0

MAKE - UP AIR

For proper operation of the dryer unit, it is important to make sure the location has adequate

make-up air. This is especially important in any confined area such as a bathroom or closet.

There must be at least two 36 inch square unobstructed openings for intake air. This can be a

louvered door or other equivalent opening.

On gas dryer units in particular, adequate clearance as noted on the dryer minimum clearance

label should be maintained to insure enough air for combustion and proper operation of the

dryer. The area where located must not obstruct the flow of combustion or ventilating air.

When installing a Maytag Stacked Washer/Dryer the following minimum clearances to com-

bustible surfaces must be maintained; clearance to wall and sides, 0 inches, top, 6 inches,

front 1/2 inch to washer, rear 0 inches with an outside exhaust, 4 inches with an inside

exhaust (not recommended). See Exhausting Section and Installation Accessories for exhaust

kits.

SERVICE ACCESS

Location should allow access to the foot at the unit for washer and dryer service. Access

must be available to two screws at the top front corners of the dryer front panel (on the top).

Page 8

240EdwardsS:raet,S£

Cleveland,Tensessee37_11

TeI:423-472-$333

Fax:423-478-67"3

EXHAUSTING

The free air flow rate is approximately 180 cubic feet per minute. The vent system carries

lint and moisture away and to the outside. The length of the venting and the number of

elbows affect the air flow rate and the efficiency of the exhaust system.

DO NOT EXHAUST DRYER INTO ANY WALL, CEILING, CRAWL SPACE OR A

CONCEALED SPACE OF A BUILDING, VENT CONNECTION, GAS VENT OR

CHIMNEY. THIS COULD CREATE A FIRE HAZARD FROM LINT EXPELLED BY

THE DRYER. FOR THE SAME I_ASON, WE RECOMMEND ONLY METAL

EXHAUST DUCT TO MINIMIZE RESTPdCTED AIR FLOW AND RELIABLY INSURE

THE CONTAINMENT OF EXHAUST AIR, HEAT AND LINT. NEVER INSTALL A

SCREEN OVER EXHAUST OUTLET. NEVER USE PLASTIC OR OTHER COMBUS-

TIBLE DUCTWORK. AT LEAST ONCE A YEAR, INSPECT AND CLEAN INTE_OR

OF DUCTWORK. FREQUENTLY CHECK AND CLEAN VENT HOOD TO ASSURE

PROPER OPERATION.

A clothes dryer produces combustible lint and the area around the clothes dryer should be

kept free of lint. DO NOT STORE FLAMAVlABLE LIQUIDS OR MATERIALS NEAR

A DRYER.

It is recommended that a dryer be exhausted to the outside using 4" rigid or flexible metal

ducting.

When located in a bedroom, bathroom or closet, the dryer must be exhausted to the outside.

The stacked washer/dryer can only be exhausted out the back. A 4" vent should be installed

to accept the exhaust from the dryer.

To permit sufficient air circulation under the exhaust hood, there should be no less than a 12"

clearance between the bottom of the exhaust hood and the ground. When possible the

exhaust hood should not exhaust directly into a window well. DO NOT terminate exhaust

under a building.

NOTE: Where the exhaust hood is to be installed through masonry, a special masonry saw is

necessary to cut the hole.

Install the exhaust hood and secure with screws to the outside wall and seal with caulking

compound.

Page 9

2_0EdwardsStreet SE

Cieveiand.Tennessee57311

Tel:-:23-472-L333

Fax:423-478-6710

DIRECT EXHAUST

An exhaust hood positioned to line up with the dryer exhaust pipe can be installed directly

through an outside wall. This would be the shortest and most direct exhaust method.

To exhaust up, route standard 4" diameter ducting up the recess and in the cabinet back using

the furnished retaining strap an screws to get nearly flush to walt installation. To exhaust to

the side or down, install the furnished 4" long duct with four "S" clips to the inner dryer

exhaust, then use standard 4" ducting. This will position the dryer about 4 1/2" away from

the wall. Flush to wall side exhausting may be done by going above the dryer before going

sideways.

When exhausting down, wallboard can be removed from the wail to get the dryer closer to

the wall by placing the exhaust pipe between the studs. Check local codes for required

exhaust clearances.

Install ductwork from the dryer to exhaust hood. All joints must be made so exhaust end of

one pipe is inside the intake end of the next pipe. On flexible metal ductwork, all joints

should be secured with a 304630 clamp. DO NOT use sheet metal screws when assembling

rigid ducting. Joints should taped.

FLEXIBLE DUCTWORK LIMITATIONS

Flexible metal ductwork should not exceed 34' of straight 4" ducting. The exhaust hood is

equivalent to 8' of duct and each 90 degree bend is equivalent to 8'. As an example if an

exhaust hood is used and two 90 degree bends, the maximum straight run would be 10'.

NOTE: If the radius of a bend with 4" duct is 12" or greater, the bend can be considered a

straight run. No more than three 90 degree bends should be used in any run with an exhaust

hood.

If flexible metal exhaust ducting is used, cut a short piece (about 3") off the male end of a 4"

diameter metal duct pipe. The short extension can be secured to the dryer exhaust with the

clips and the flexible metal duct can be clamped to the short extension.

.,3

Page 10

240EdwardsStreet,SE

C;eve!and,Tennessee373tl

Te_:422-472-3333

Fax:423-478-67t0

RIGID DUCTWORK LIMITATIONS

Rigid metal ductwork should not exceed 50' of straight 4" duct. Each 90 degree elbow and

the exhaust hood should be considered equivalent to 8' of straight ductwork.

For example, if an exhaust hood and two 90 degree elbows are used, the maximum straight

duct allowed would be 26'. Not more than three 90 degree elbows should be used in any

rigid ductwork run with an exhaust hood. Four feet of straight duct should be allowed

between 90 degree elbows

Page 11

240EdwardsStreet,SE

Cleveland,7e"nessee37311

Tel:423-472-$333

Fax:423-478-,3710

ELECTRICAL REQUIREMENTS

OBSERVE ALL NATIONAL ELECTRICAL CODES, LOCAL CODES

AND

ORDINANCES

ELECTRICAL SERVICE - 120 VOLTS, 60 HZ ONLY

WASHER-GAS DRYER

A 120 volt, 60 Hz, 15 ampere fused eIectrical supply is required. An individual branch (or

separate) circuit serving only this appliance is recommended. DO NOT USE AN EXTEN-

SION CORD unless it meets all requirements as outlined for grounding, polarizing (3-wire)

and capacity. Wire size should be at least No. 14.

BEFORE OPERATING OR TESTING, follow grounding instructions in Grounding Sec-

tion.

GROUNDING - 120 VOLTS, 60 HZ

IMPORTANT SAFETY PRECAUTIONS

WARNING - To prevent unnecessary risk of fire, electrical shock or personal injury, all

wiring and grounding must be done in accordance with the National Electrical Code

ANSI/NFPA, No.70, Latest Revision and local codes and ordinances. It is the personal

responsibility and obligation of the appliance owner to provide adequate electrical service for

this appliance.

ELECTRICAL GROUND IS REQUIRED ON THIS APPLIANCE

MA'_.rAG Admiral tt _n'n_JENN-ZJ_ "_gie Cbet

Page 12

240EdwarusStree[,SE

Ueve]and,Tennessee37311

feF:_23-472-3333

Fax:423-_78-67_0

GROUNDING INSTRUCTIONS

i

F

This appliance must be grounded. In the event of malfunction or breakdown, grounding will

reduce the risk of electric shock by providing a path of least resistance for electric current.

This appliance is equipped with a cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into an appropriate outlet that is properly

grounded in accordance with all local codes and ordinances.

DANGER - Improper connection of the equipment-grounding conductor can result in a risk

of electric shock. Check with a qualified electrician or serviceman if you are in doubt as to

whether the appliance is properly grounded.

Do not modify the plug provided with the appliance. If it will not fit the outlet, have a

proper outlet installed by a qualified electrician

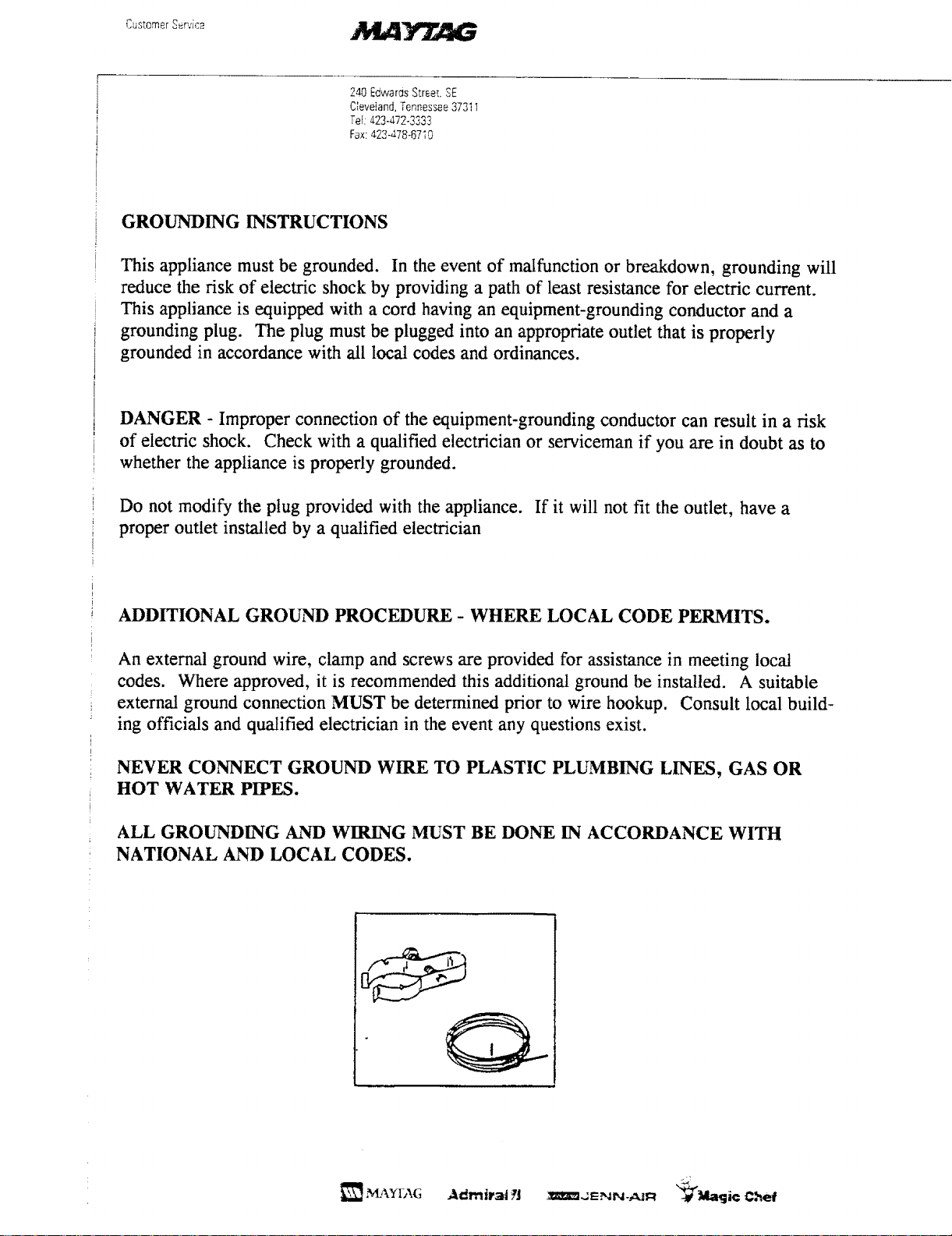

ADDITIONAL GROUND PROCEDURE - WHE_ LOCAL CODE PERMITS.

An external ground wire, clamp and screws are provided for assistance in meeting local

codes. Where approved, it is recommended this additional ground be installed. A suitable

external ground connection MUST be determined prior to wire hookup. Consult local build-

ing officials and qualified electrician in the event any questions exist.

NEVER CONNECT GROUND WIRE TO PLASTIC PLUMBING LINES, GAS OR

HOT WATER PIPES.

ALL GROUNDING AND WIRING MUST BE DONE IN ACCORDANCE WITH

NATIONAL AND LOCAL CODES.

[] _V;fAG Admira| ]| 8,.,;ENN-.a41:I _l_']llagic C,'_e|

Page 13

240EdwardsStreet.SE

CJeveiand,Tennessee37311

Tel:423-472-3333

Fax:423-478-5710

ELECTRIC DRYER UNITS

GROUNDING INSTRUCTIONS

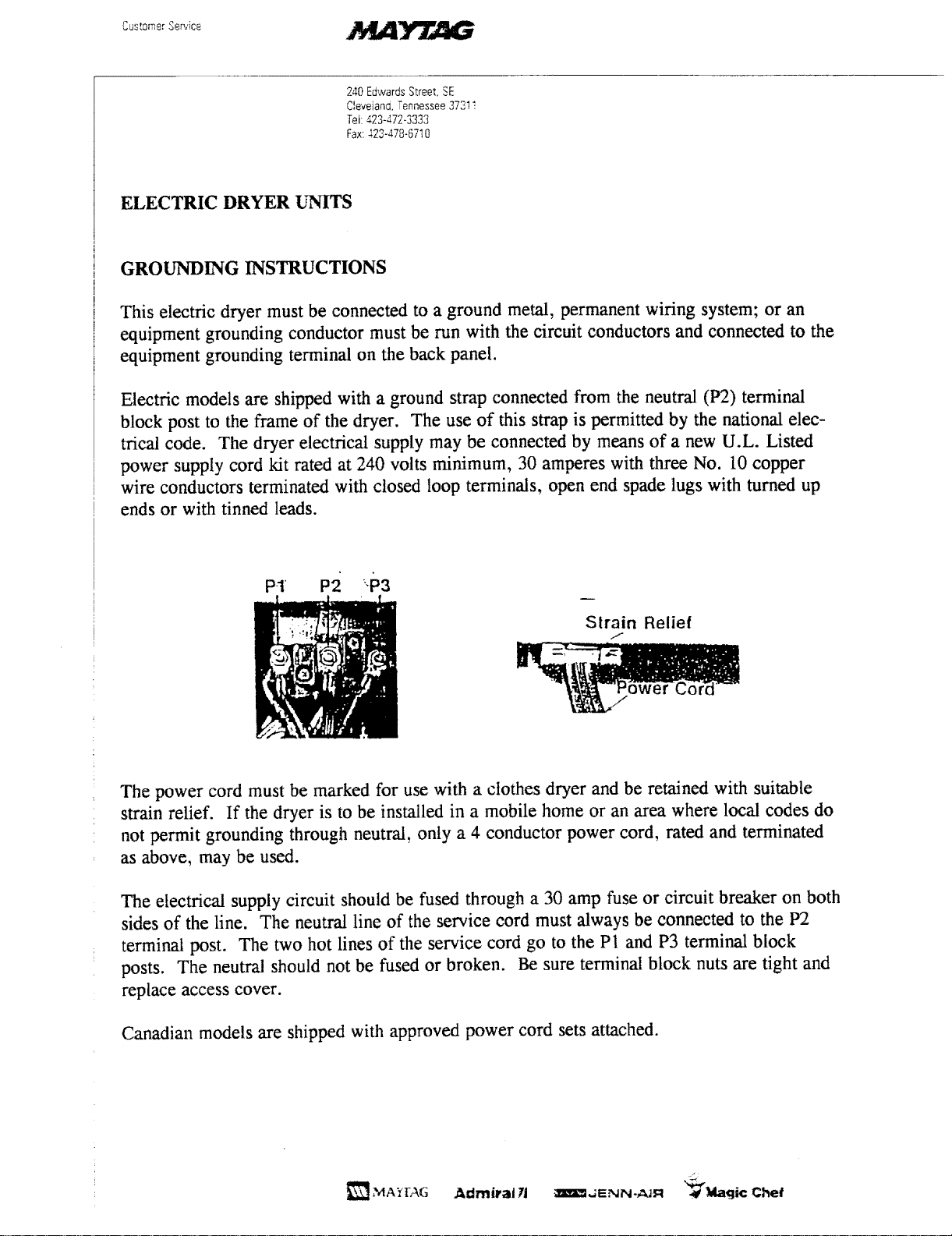

This electric dryer must be connected to a ground metal, permanent wiring system; or an

equipment grounding conductor must be run with the circuit conductors and connected to the

equipment grounding terminal on the back panel.

Electric models are shipped with a ground strap connected from the neutral (P2) terminal

block post to the frame of the dryer. The use of this strap is permitted by the national elec-

trical code. The dryer electrical supply may be connected by means of a new U.L. Listed

power supply cord kit rated at 240 volts minimum, 30 amperes with three No. 10 copper

wire conductors terminated with closed loop terminals, open end spade lugs with turned up

ends or with tinned leads.

Pt" P2 -P3

Strain Relief

f"

The power cord must be marked for use with a clothes dryer and be retained with suitable

strain relief. If the dryer is to be installed in a mobile home or an area where local codes do

not permit grounding through neutral, only a 4 conductor power cord, rated and terminated

as above, may be used.

The electrical supply circuit should be fused through a 30 amp fuse or circuit breaker on both

sides of the line. The neutral line of the service cord must always be connected to the P2

terminal post. The two hot lines of the service cord go to the PI and P3 terminal block

posts. The neutral should not be fused or broken. Be sure terminal block nuts are tight and

replace access cover.

Canadian models are shipped with approved power cord sets attached.

MA'fi_AG Admiral 71 =dE.._r,4-,._l _llagic Che!

Page 14

240EdwardsStreet,SE

Cleveiand,Tennessee37311

Tek423472-3333

Fax:423-478-8710

G.F.I.

If the electric dryer is protected by a GROUND FAULT INTERRUPTER, follow the pro-

cedure for a 4-wire hookup below.

4-WIRE RECEPTACLE

The frame of a 120/240 Volt machine must NOT be connected to neutral terminals. It

MUST be connected to the 4th wire (green of the power supply) or to the metallic covering

of a three-wire supply.

If a 4-wire receptacle of NEMA type is used, a matching UL Listed power supply cord (pig-

tail) must be used. This cord contains four NO. 10 copper conductors with spade or ring

terminals on the dryer end. The 4th (grounding) conductor must be identified by a green

cover and the neutral conductor by a white cover. The cord should have a suitable strain

relief and should be a minimum of 4 feet long. The poser supply cord and strain relief are

not provided with the dryer.

MA'_rAG Admtrai TI _l_,JeNN.,_m "-_'_'_lagic C_'_et

Page 15

240EdwardsStreet.SE

Cleveland,Tennessee37311

Tei:423-z72-3333

Fax:423-478-67"0

4-WIRE SYSTEM CONNECTIONS

1. Remove the terminal block cover.

2. Remove the ground strap from the ground screw and center (silver colored) terminal of

the terminal block.

3. Connect the neutral (white) wire of the power supply cord to the center (silver colored)

terminal of the terminal block. Connect the grounding (green) wire of the cord to the exter-

nal ground connector, sing the green screw.

4. connect the other two wires of the cord to the outer terminals of the terminal block.

5. Replace the terminal block cover.

208 VOLT OPERATION

A 306378 kit is used to convert the electric microprocessor stacked washer/dryer for 208 volt

operation. A new heater element label and instructions are included.

The elctrical mechanical stacked washer/dryer is not available for 208 volt operation.

MA*_£\G Admiral I1 _,_.,ad_ .¥ Jd.-aqic e_t

Page 16

240EdwardsStreet,SE

CIeveian&Te£_essBe;7311

1el: 423-472-,3333

Fax:423-478-6710

WATER SUPPLY AND DRAIN

WATER SUPPLY

The water supply to the washer unit should be capable of providing both adequate water

pressure and water temperature. The pressure should fall within the range of 30 pounds per

square inch to 120 pounds per square inch when the washer is filling. Note that this is flow

pressure and not static pressure. Low water pressure will result in slow fill and could result

in a water valve sticking open after a fill.

The temperature of the hot water as delivered to the washer should be 140 degrees F. The

temperature of the cold water as delivered to the washer should be 75 degrees F.

Warm water temperature is a result of the mix of the hot and cold water supplies. The final

temperature is dependent on both the pressure and the temperatures of the hot and cold sup-

plies. The desired temperature for warm is between 100 degrees F and 105 degrees F.

DRAIN FACILITIES

Because of the desirability of flush to the wall installation of the stacked washer/dryer, a

drain directly behind the unit is preferred to a drain located on either side.

The washer unit is equipped with a built-in siphon break which allows for a variance in

height of the drain facility. The drain must be capable of accepting a flow rate of approxi-

mately 20 gallons per minute. An inside diameter of at least 1" - 1 l/2" is required.

The portion of the drain hose from the siphon break to the drain can be extended to a floor

drain. Consult the parts catalog for extra drain hose as needed.

The use of a laundry built-in wall box can greatly simplify installation of the unit.

_'_ MA'zrAG Admiral !| _OENN-AIR _,_'_giC ¢_|

Page 17

240EdwardsStreet,SE

Cleveiand,TennesseeZ7311

Tel:423-472-3333

Fax:423-478-6710

Models are available that incorporate water supply, water drain, 120 Volt AC and 240 Volt

AC connections. An example is shown.

O

©

O

\

If the faucets and!or drain is located to either side of the stacked washer/dryer, openings are

located in the dryer stand uprights to allow hoses and power cords to be passed through.

This is to allow installation against the back wall. (This is dependent on venting used.)

[] _'_-vfr,',.G Admiral YI m.JeNN-aJR "_Magic Chef

Page 18

240EdwardsStreet,SE

Creveianct,Tennessee37311

Tel:423-47"2-3333

Fax:423-478-6710

GAS CONNECTION

Gas operated dryers are equipped with a burner orifice for operation on NATURAL gas. If

the dryer is to be operated on LP gas, it must be converted correctly for safety and proper

performance. Conversion kits from NATURAL to LPG or LPG to NATURAL are available

through your local Maytag dealer. If other conversions are required, check with local gas

utility for specific information concerning conversion requirements. NOTE: The conver-

sion should always be performed by a qualified service technician.

A 1/2" gas supply line is recommended and must be reduced to connect to the 3/8" gas line

on the dryer.

NOTE: A 3/8" x 2" pipe nipple is included to adapt valve connection from a 3/8" female to

a 3/8" male I.P.S. connection.

Additionally, a 1/8" N.P.T. (National Pipe Thread) plugged tapping, accessible for test

gauge connection, must be installed immediately upstream of the gas supply connection to the

dryer. Refer to your local gas utility or plumbing contractor should you have questions on

the installation of the plugged tapping.

The dryer and its individual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of the system at test pressures in excess of 1/2 P.S.I.G.

The dryer must be isolated from the gas supply piping system by closing its individual

manual shut-off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 P.S.I.G.

Gas Line

Dryer

118"' NPT Plug

Gas Line

The gas supply should be connected to the dryer using pipe joint compound or a Teflon tape

on male thread connections. NOTE: Any pipe joint compound used must be resistant to the

action of any liquefied petroleum gas.

J

MA_£_G Admiral 11 _E_N-,._ "_Maqic Chef

Page 19

CustomerSe_ic_ _'__

240EGwardsStreet, SE

Cleveland,Tennessee3731;

Tel::t23-472-3333

Fax:_23-478-67t0

Turn on gas supply and open the shutoff at the gas valve. Check all gas connections for leaks

using a soap solution. If bubbles occur, tighten connections and recheck. DO NOT use an

open flame to check for gas leaks.

NOTE: As a courtesy, many local gas utilities will inspect a gas appliance installation.

Check with your utility to see if this service is provided in your area.

NOTE: The minimum permissible gas (natural or mixed) supply pressure for purposes in

input adjustment is 4.5 inches of water.

GAS IGNITION

This dryer uses an automatic ignition system to light the main burner when the dryer is

turned on.

If a 4-wire receptacle of NEMA type is used, a matching UL Listed power supply cord (pig-

tail) must be used. This cord contains four No. 10 copper conductors with spade or ring

terminals on the dryer end. The 4th (grounding) conductor must be identified by a green

cover and the neutral conductor by a white cover. The cord should have a suitable strain

relief, and should be a minimum of 4 feet long. The power supply cord and strain relief are

not provided with the dryer.

Page 20

240EdwardsStreet,SE

Cleveland.Tennessee37311

Te!:423-472-3333

Fax:423-478-6710

INSTALLATION

INSTALL DRYER UNIT AND STAND

The dryer and stand are installed first. With the connections prepared for exhausting, electric

power and gas (if gas stacked washer/dryer, see Gas Connection), the dryer and stand are

moved to the location.

NOTE: When moving the dryer and stand on an appliance hand truck, it is recommended

that the dryer and stand be Backed upside down. Protective padding should be used to avoid

damage to the cabinet finish.

Install the vinyl feet on the dryer stand legs. Note the rear legs are "washer" legs and use

the larger feet.

Install electric power cord (electric stacked washer/dryer). See Electrical Requirements sec-

tion.

The vent connection is lined up from underneath the dryer as the dryer and stand are moved

back into position when a straight-out-the-back vent is used. When venting down, up, or to

the side, an elbow or flat duct section is placed on to the dryer exhaust before the dryer is

slid into position.

Level the dryer and stand and lock leveling legs using leg lock nuts.

Connect gas line for gas units and check for leaks. Use a liquid soap solution or leak detec-

tor. DO NOT use a match or open flame !

With dryer "and stand in position, exhaust vent connected, unit leveled and gas line connected

(if gas unit), power cord set installed (if electric unit), plug power cord into electric outlet.

INSTALL WASHER UNIT

Install washer glide bars on rear of washer cabinet. The glide bars are in the installation

package found in the washer tub. Install with rounded edge down. The glide bars will

extend beyond the edge of the cabinet on each side when properly installed.

[] MA_ raft Admiral II _mII._ENN._il_ _Magic Chef

Page 21

240EdwardsStreet,SE

Cleveland,Tennessee37311

Tel:423-472-,3333

Fax:423-478-67;0

INSTALL FILL HOSES

Insert plain hose washers in 90 degree end of fill hoses and screen washers in straight end of

hoses. The screens should point outward.

The valve inlets are marked '_H" and "C" to denote the hot inlet (top) and cold inlet (lower).

Connect 90 degree ends of hoses to the valve. Connect lower hose first. Be sure that hose

connectors are not cross threaded on the valve. Tighten securely by hand plus 1/4 turn with

pliers. Do no overtighten as this can strip the threads on the valve.

Connect the straight ends of the hose to the corresponding supply faucets (hot and cold).

.MA'ffAG Adrnirai _J IJENN-AIR '_'_la{Ji¢ the|

Page 22

_0st0_erS_ice _A4'Y"/,4G

240EdwardsStreet,SE

Cleveland.Tennessee3731t

Tel:423-472-3333

Fax:423-478-67;0

INSTALL DRAIN HOSE

Secure drain hose to siphon break using the hose clamp provided in the parts package. The

siphon break can be turned right or left to meet the end of the drain hose. Place the goose-

neck into the standpipe (or position the gooseneck as if it were in the standpipe). Insert the

clamp over the hose and direct the straight end of the hose toward the siphon break outlet

with a very gradual bend. Push the drain hose over the siphon break outlet and if necessary

twist the hose to relieve any stress on the hose between the siphon break outlet and the

standpipe after the hose is inserted into the standpipe.

NOTE: It is very important when connecting the drain hose that it is properly installed to

minimize the chance of the hose becoming kinked when the washer is moved into position.

If it is necessary to extend the drain hose, attach one end of the extension hose to the siphon

break, and in the other end insert an accessory coupler, similar to the one shown below.

Push the drain hose (hose with short gooseneck) over the coupler until the extension hose and

drain hose join together in approximately the middle of the coupler. When the coupler is

properly used, hose clamps are not required.

€OUFUnl

DUIN HOSE

Ma_rAG Aamtrai _'| _.JENN-,_Ii:! _'_lagic Chef

Page 23

240EdwardsStreet,SE

Cleveland,Tennessee37311

Te_:423-472-3333

Fax:423-478-6710

If not previously done, remove shipping pads from washer top.

Move the washer into position in front of the dryer and stand. Use caution to avoid floor

damage because of the minimum height of the rear legs.

Tip forward enough for glides to clear the legs of the stand, and guide the glides into the slots

on the top of the stand legs.

Lower Washer Glide

Bar Down into slot.

Slide Washer Back

onto Stand

Before sliding washer back into position, connect fill hoses.

Be sure the gooseneck is fully inserted into the drain standpipe to prevent any chance of the

hose coming out of the standpipe from the force of the water being discharged.

Connect the. two control cables, one from the dryer and one from the washer, as shown.

.',4A'YI',._,GAdmirat 7| _JENN-.-,'k_R "_?AlacJi¢ C,._:_f

Page 24

240EdwardsStreet,SE

Cleveland.Tennessee3731

Tel:423-472-3333

Fax:422-478-6710

If the unit is a microprocessor stacked washer/dryer, connect the washer power cord to the

120 volt AC outlet.

Slide washer back into position. A peg on the back right corner of the washer wilt locate in a

socket on the fight leg of the dryer stand.

Adjust the washer front legs down against the floor to raise the washer front slightly. The

washer should be level side to side and just barely higher in the front than in the back (bubble

just touching in the level). Lock leveling leg in position using leg lock nuts.

Remove all instruction packages from washer tub and dryer drum before using units.

Remove tub block ring from washer tub opening.

ADDITIONAL INFOI/dVIATION

ODD CYCLE OPERATION

This Maytag stacked washer/dryer is manufactured for operation on 60 Hz approved electri-

cal service. It is not designed for use on 50 Hz AC electrical service and conversion of the

product from 60 to 50 cycle operation is not recommended. For additional information on 50

cycle products, write, MAYTAG INTERNATIONAL, 8700 Bryn Mawr Ave. Chicago, IL

60631. Or call 3t2-7t4-0100 (FAX 312-714-8180).

LUBRICATION

No routine lubrication is required to maintain the stacked washer/dryer. In the event some-

thing does need attention, contact an authorized Maytag dealer or servicer.

_'_!AG Admira|_l _,_r_nJENN._a, IR "_da_jk: Cb_t

Page 25

240EdwardsStreet,SE

C;eve{end,Tennessee37311

Tek422-472-33,g3

Fax:423-478-67:0

FINISH

All the cabinet and external finishes are protected against rust to keep product looking well

for many years. Cleaning and waxing will provide additional protection to these finishes.

The washer top has a porcelain finish. Since porcelain is "glass" bonded to metal, it is very

durable. Avoid damage from sharp blows of objects or tools used around and in the appli-

ance.

Clean the control panel with a soft damp cloth. Avoid abrasive cleaners that would scratch

the surface. A coat of household was will reduce the chance of scratches on the control panel

surface.

Caution: If "spilled" or used improperly, bleaches and other strong laundering chemicals can

permanently spot or stain finishes unless wiped up immediately. Aerosol pretreat products

can also damage finish on control panel. When using these products on garments placed in

the stacked washer/dryer, it is advisable to avoid control panel area with the overspray.

WATER DAMAGE FROM FLOODING

In the event the stacked washer/dryer is exposed to water from flooding, call you local May-

tag dealer before using. Always unplug the appliance and have a qualified technician inspect

the appliance before any attempt is made to operate the unit. Never wash product inside and

out with a garden hose or pressure cleaning equipment.

REPLACEMENT PARTS

If your unit requires replacement parts, contact the dealer from who you purchased your

appliance, or Maytag Customer Service. 240 Edwards St. SE, Cleveland, TN 37311 for

information on the nearest Maytag parts distributor.

Service manuals are available through your dealer or nearest parts distributor.

MAYfAG ._dm_rat n _JENN-_MI:; _lilaqic C_'lef

Page 26

A,tt4Y'TAG

240EdwardsStreet,SE

Cleve]an&Tennessee37311

Tel:423-472-3333

Fax:423-478-67;8

INSTALLATION ACCESSOR S

059129

059130

059131

059134

059143

304353

304630

306642

306205

Vent hood - 4" (10.16 cm) opening

Aluminum pipe - 4" x 24:(10.16 cm x 60.96 cm)

Aluminum elbow - 4" (10.16 cm)

Aluminum window plate - 15" x 20" (38.10 cm x 50.80 cm) - 4"

(10.16 cm) hole

Flexible vent kit - contains wide opening vent hood, wall plate, two

clamps and flexible aluminum vent duct

Flexible aluminum vent duct - 4" (10.16 cm) diameter 38" (81.28 cm)

length stretches to 8' (2.44 m)

Clamp for flexible aluminum duct.

Exhaust deflector kit - inside exhaust kit

Natural to LPG conversion it for gas valve

311353

Dacron lint bag

[] MAYrAG Admiral _1 =m_l,ast_l_l.Alla _._iagi¢ Cb,e_

Loading...

Loading...