Maytag LDG8506AAE, LDG9606AAE, LDG9606AAM, LDG9606ABE, LDG9316AAE Installation Instructions

...

24(3EdwarasStreet,SE

Cleveland,Tennessee37311

Tel:423477__3333

Fax:423478-6710

If at all possible, USE A MINIMUM OF 4 INCH DIAMETER RIGID ALUMINUM OR

RIGID GALVANIZED STEEL DUCT. Do not use smaller duct. If flexible metal must be

used, use the type with a stiff sheet metal wall. Do not use flexible duct with a thin foil wail.

Serious blockage can result if flexible metal duct is bent too sharp. Never instail any type of •

flexible duct in walls, ceilings, or other concealed spaces.

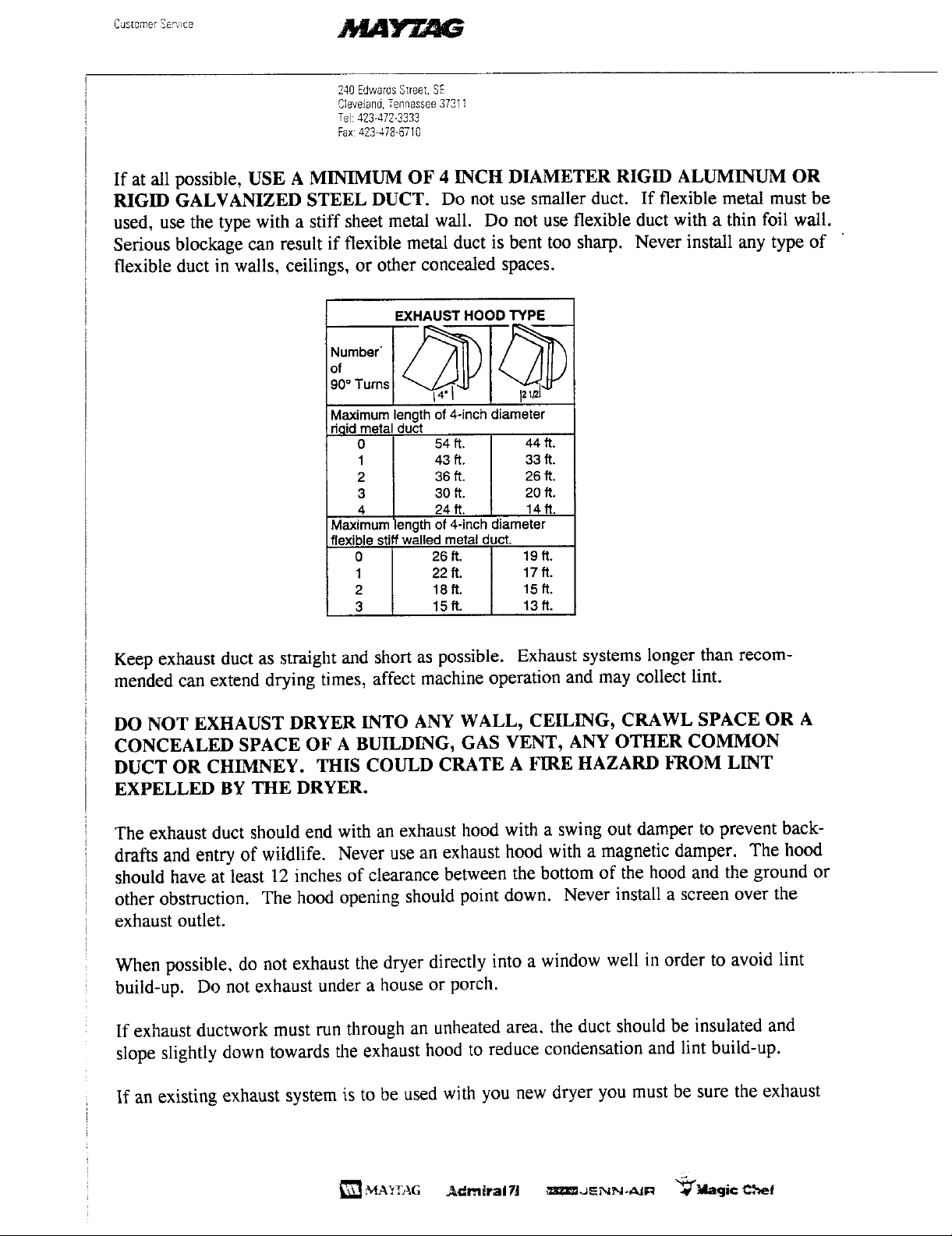

EXHAUST HOOD TYPE

of

90° Turns 12lt2

Maximum lengthof4-inch diameter

riqidmetal duct

0 54 ft. 44 ft.

1 43 ft. 33 ft.

2 36 ft. 26 ft.

3 30 ft. 20 ft.

4 24ft. 14ft.

Maximum )ength of 4-inch diameter

flexible stiff walled metal duct.

0 26ft. 19ft.

1 22 ft. 17 ft.

2 18ft. 15ft.

3 15ft. 13ft.

Keep exhaust duct as straight and short as possible. Exhaust systems longer than recom-

mended can extend drying times, affect machine operation and may collect lint.

DO NOT EXHAUST DRYER INTO ANY WALL, CEILING, CRAWL SPACE OR A

CONCEALED SPACE OF A BUILDING, GAS VENT, ANY OTHER COMMON

DUCT OR CHIMNEY. THIS COULD CRATE A FIRE HAZARD FROM LINT

EXPELLED BY THE DRYER.

The exhaust duct should end with an exhaust hood with a swing out damper to prevent back-

drafts and entry of wildlife. Never use an exhaust hood with a magnetic damper. The hood

should have at least 12 inches of clearance between the bottom of the hood and the ground or

other obstruction. The hood opening should point down. Never install a screen over the

exhaust outlet.

When possible, do not exhaust the dryer directly into a window well in order to avoid lint

build-up. Do not exhaust under a house or porch.

If exhaust ductwork must run through an unheated area. the duct should be insulated and

slope slightly down towards the exhaust hood to reduce condensation and lint build-up.

If an existing exhaust system is to be used with you new dryer you must be sure the exhaust

,_TAG Admiral 71 _._E_N-A_ _'_lagic Chef

.i

Sdstemer e_'r '°_ ,ilt_llll__

240EdwarusStreet,SE

Cleveland,Tennessee37311

Tel:422-472-,1333

Fax:423-478-67!0

system meets all local codes and exhaust requirements.

- That plastic flexible duct is not used.

- To completely inspect and clean all lint accumulation from the interior of the duct.

- The duct is not kinked or crushed.

- The exhaust hood damper opens and closes freely.

The back pressure in any exhaust system must not exceed 0.58 inches of water column. This

can be measured with a manometer at the point where the exhaust duct connects to the dryer.

A no heat setting should be used.

Inspect and clean the interior of the exhaust system at least once a year. Disconnect electric

service prior to cleaning. Check gas line on gas dryers anytime the dryer is moved. Fre-

quently check to be sure the exhaust hood damper opens and closes freely.

NONEXHAUSTED INSTALLATIONS

NOTE: In Canada, all dryers must be exhausted to the outside.

If the dryer is not exhausted to the outside, an exhaust deflector should be installed along

with a dacron mesh lint bag (see Accessories). Maintain a 6" clearance between the back of

the control panel and the wall. Although the lint screen and lint bag will retain most of the

lint, a certain amount will be expelled into the laundry area.

WARNING: IF THE DRYER IS NOT EXHAUSTED TO THE OUTSIDE, SOME FINE

LINT WILL BE EXPELLED INTO THE LAUNDRY AREA. AN ACCUMULATION OF

DUST OR LINT IN ANY AREA OF THE HOME CREATES A FIRE HAZARD. ANY

LINT ACCUMULATIONS MUST BE CLEANED OR VACUUMED FREQUENTLY.

GAS REQUIREMENTS

Use only Natural or LP gases.

THE INSTALLATION MUST CONFORM WITH LOCAL CODES, OR IN THE

ABSENCE OF LOCAL CODES, WITH THE NATIONAL FUEL GAS CODE

ANSI/Z223.1, LATEST REVISION (FOR THE UNITED STATES), OR WITH THE

CAN/CGA-B149 INSTALLATION CODES (FOR CANADA).

MA_ FAG Admiral 71 _ENN-_I_ _'Magi¢ _l_ef

240EdwardsStreet,SE

Cleveland,Tennessee3731;

Tel:423-4723333

Fax:423-478-6710

Read this before you start......

TOOLS needed for Installation

z_.-___ _ • Cuffing Knife

_ _ • Pipe Wrench

- '_ "_-"-". " Nut Driver

_..\ '_'%J

_)_',_!t • Duct Tape

ITEMS PROVIDED

• TeflonTape or Pipe Joint

Compound

.Leve,

• Screw Driver (Standard)

• Crescent Wrench

._, ,I._) Io')N ""-_"

. , . O r,;_ X.

Electric Dryer Only _ Gas Dryer Only

Proper installation is the responsibility of the purchaser.

SERVICE CALLS PERFORMED AS A RESULT OF POOR INSTALLATION ARE

THE RESPONSIBILITY OF THE INSTALLER.

Make sure you have everything necessary for proper installation.

1. GROUNDED ELECTRICAL OUTLET is required. See Electrical Requirements.

2. GAS LINES (if a gas dryer) must meet National and Local codes.

3. EXHAUST SYSTEM must be rigid metal or flexible stiff walled metal exhaust ducting.

See Exhaust Requirements.

[] ,_,bxYrAG Admiral _J IJENN-_ _aq¢ C_

C,_0merSe_,i_e A_dl_f]_ll _

240EdwardsStreet,SE

Cieveiand.Tennessee3731:

Tei:423-472-3333

Fax:423-478-67!0

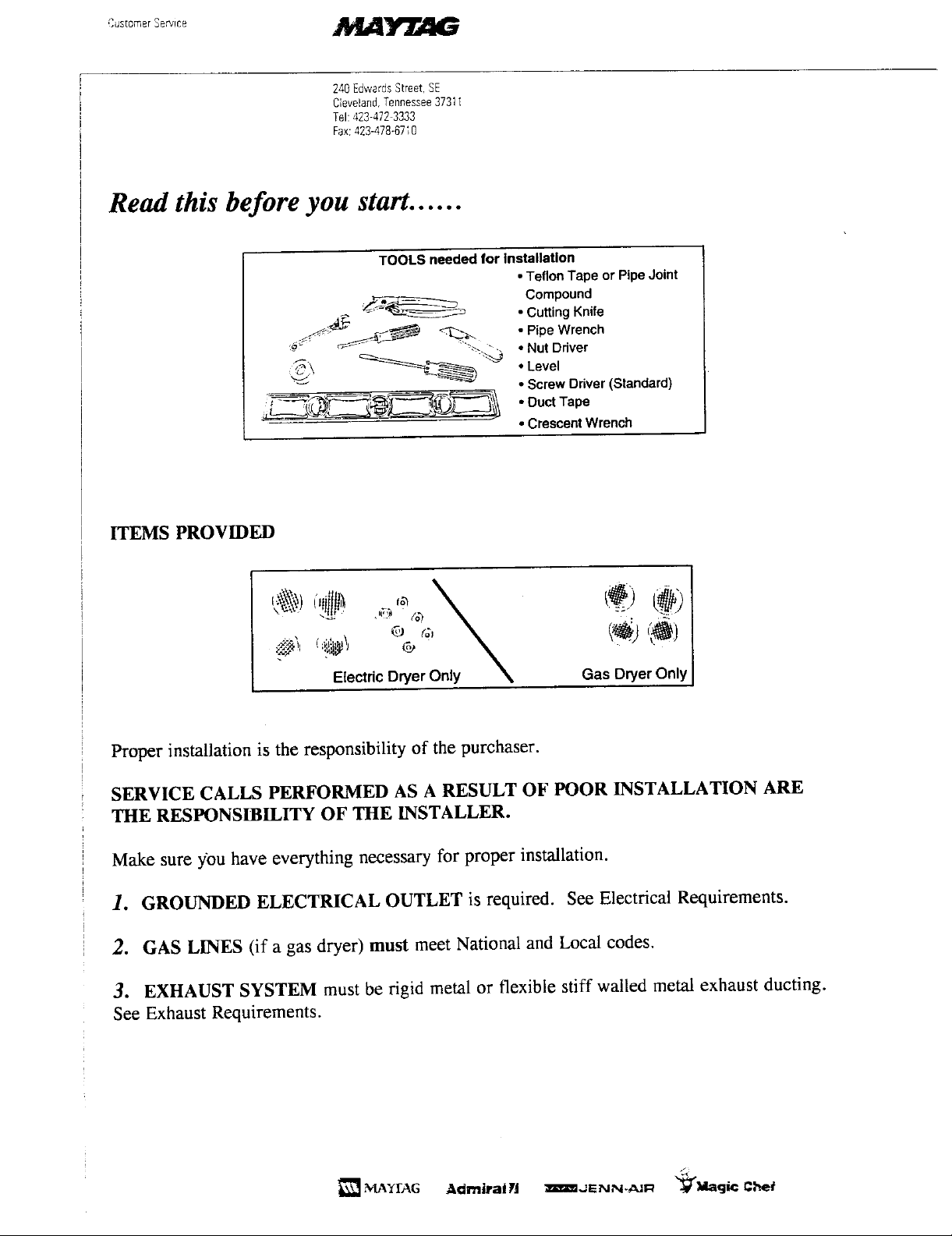

EXHAUSTING

Exhausting the dryer to the outside is recommended to prevent large amounts of moisture and "

lint being blown into the room. When located in a confined area such as a bedroom, bath-

room, or closet, the dryer must be exhausted outside.

NEVER USE PLASTIC, NONMETAL OR COMBUSTIBLE DUCTWORK

If your existing ductwork is plastic, nonmetal or combustible, replace it with metal. Use

only metal exhaust duct that will not support combustion to insure the containment of exhaust

air, heat and lint.

Plastic exhaust material can kink, sag, collapse, be easily punctured, reduce airflow, cause

lint build-up, extend drying times, and effect dryer operation.

I'*-_ 26 3/4"_ ,o 281/2" 72.39 cm =

!_ 67'95 cm 71 m_

L_ cm

.... _ _"

1 314"

,o,21cm om

LI °0.3°,,,,,,

-4 _- 33/," 9.5cm _4"1016cml_34.12crn-,

WARNING- The

dryer must be

exhausted to the

outside to reduce

the risk of fire,

CustomerSe_i_ __

240£dwardsStreet,SE

Cleveland,Tennessee3731i

Tel:423-472-3333

Fax:423-,:t786710

NOTE: DRYER DOOR REVERSAL INSTRUCTIONS ARE IN USERS GUIDE.

IMPORTANT TO INSTALLER

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY BEFORE

STARTING TO INSTALL THE DRYER.

REMOVE THE DOOR FROM ALL DISCARDED APPLIANCES SUCH AS DRYERS

TO AVOID THE DANGER OF A CHILD SUFFOCATING.

LOCATION CONSIDERATIONS

The dryer should be located to permit 18" in front for removal of the front panel for access,

and sufficient room behind the dryer for the exhaust system.

This dryer is factory-ready for rear exhaust. To exhaust out the bottom or left side use the

accessory exhaust kit (see Accessories). Instructionsare included with the kit.

It is important to make sure the room has adequate make-up air.

On gas dryers, adequate clearance as noted on the data plate must be maintained to insure

adequate air for combustion and proper operation of the dryer. The area where the dryer is

located must not obstruct the flow of combustion or ventilating air.

THE DRYER MUST NOT BE INSTALLED OR STORED IN AN AREA WHERE IT

WILL BE EXPOSED TO WATER AND/OR WEATHER. THE DRYER AREA IS TO BE

KEPT CLEAR AND FREE FROM COMBUSTIBLE MATERIALS, GASOLINE AND

OTHER FLAMMABLE VAPORS AND LIQUIDS. A DRYER PRODUCES COMBUS-

TIBLE LINT. THE AREA AROUND THE DRYER SHOULD BE KEPT FREE OF LINT.

[] MA_TAG Admiral _l _u., ds=r,iN.,._d_ "_ t4acJ/c Chet

240EdwarDsStreet,SE

Cleveiane.Tennessee27317

TeL:423-472-3333

Fax:423-_78-_710

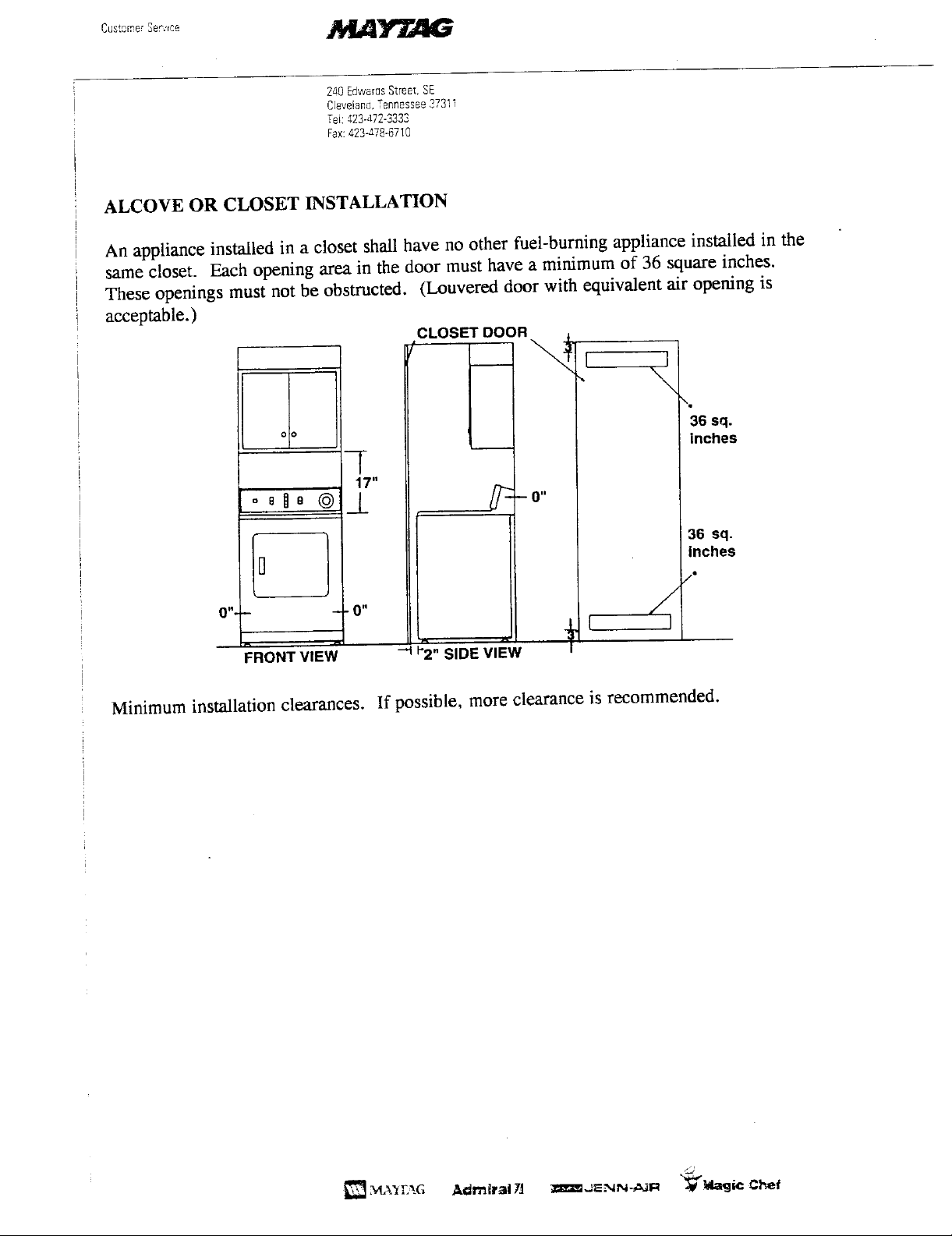

ALCOVE OR CLOSET INSTALLATION

An appliance installed in a closet shall have no other fuel-burning appliance installed in the

same closet. Each opening area in the door must have a minimum of 36 square inches.

These openings must not be obstructed. (Louvered door with equivalent air opening is

acceptable.)

CLOSET DOOR

36 sq.

inches

l

17"

2-

Inches

D 36sq.

0"-- -0" //

n rt n

FRONT VIEW -- P2" SIDE VIEW

i

, l

ze

Minimum installation clearances. If possible, more clearance is recommended.

240EdwarasStreet.SE

Cleveland,Tennessee37311

Tel:423-47Z-3333

Fax:a23-478-67,0

Gas dryers are equipped with a burner orifice for operation on NATURAL gas. If the dryer

is to be operated on LP (liquid propane) gas, it must be converted for safe and proper

performance and must be converted by a qualified service technician. Conversion kits

from NATURAL to LP, or LP to NATURAL are available through your local Maytag

dealer (see Accessories). If other conversions are required, check with the local gas utility

for specific information concerning conversion requirements.

a 1/2" gas supply line is recommended and must be reduced to connect to the 3/8" gas line

on the dryer.

Additionally, a 1/8" N.P.T. (National Pipe Thread) plugged tapping, accessible for test

gauge connection, must be installed immediately upstream of the gas supply connection to the

dryer.

HIGH PRESSURE TESTING

The dryer and its individual shutoff valve must be disconnected from the gas supply piping

system during any pressure testing of the system at test pressures in excess of 1/2 psig

(3.45kPa).

LOW PRESSURE TESTING

The dryer must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test pres-

sures equal to or less than 1/2 psig (3.45 kPa).

DO NOT re-use old flexible metal gas line. Flexible gas line must be design certified by

American Gas Association (CGA in Canada). NOTE: Any pipe joint compound used must

be resistant to the action of any liquifled petroleum gas.

NOTE: As a courtesy, most local gas utilities will inspect a gas appliance installation.

GAS IGNITION

This dryer uses an automatic ignition system to ignite the burner. There is no constant

burning pilot.

Loading...

Loading...