Page 1

INSTALLATION INSTRUCTIONS

IMPORTANT:

Sa

IMPOR

À

.

30" (76.2 CM) DOUBLE OVEN DUAL FUEL RANGES

INSTRUCTIONS POUR L’INSTALLATION DES CUISINIÈRES

À BI-COMBUSTIBLE ET FOUR DOUBLE DE 30" (76,2 CM)

Table of Contents Table des matières

RANGE SAFETY .............................................................................2

INSTALLATION REQUIREMENTS .................................................4

Tools and Parts .............................................................................4

Location Requirements ................................................................4

Electrical Requirements - U.S.A. Only .........................................6

Electrical Requirements - Canada Only .......................................7

Gas Supply Requirements ...........................................................7

INSTALLATION INSTRUCTIONS ...................................................9

Unpack Range..............................................................................9

Adjust Leveling Legs ....................................................................9

Install Anti-Tip Bracket .................................................................9

Make Gas Connection ...............................................................10

Verify Anti-Tip Bracket Is Installed and Engaged ......................11

Level Range ................................................................................11

Electronic Ignition System .........................................................11

Complete Installation .................................................................12

Remove Oven Door(s) ................................................................13

GAS CONVERSIONS ....................................................................14

Propane Gas Conversion ...........................................................14

Natural Gas Conversion .............................................................16

Moving the Range ......................................................................17

SÉCURITÉ DE LA CUISINIÈRE ...................................................19

EXIGENCES D’INSTALLATION ...................................................20

Outils et composants .................................................................20

Exigences d’emplacement .........................................................21

Spécifications de l’alimentation en gaz .....................................23

INSTRUCTIONS D’INSTALLATION .............................................24

Déballage de la cuisinière ..........................................................24

Réglage des pieds de nivellement .............................................24

Installation de la bride antibasculement ....................................25

Raccordement au gaz ................................................................24

Vérifier que la bride antibasculement est

bien installée et engagée ...........................................................26

Réglage de l’aplomb de la cuisinière .........................................27

Système d’allumage électronique..............................................27

Achever l’installation ..................................................................28

Enlever la/les porte(s) du four ....................................................29

CONVERSIONS DE GAZ ..............................................................30

Conversion pour l’alimentation au gaz propane ........................30

Conversion pour l’alimentation au gaz naturel ..........................32

Déplacement de la cuisinière .....................................................34

ve for local electrical inspector's use.

conserver pour consultation par l'inspecteur local des installations électriques

W11241780A

TANT :

Page 2

RANGE SAFETY

WARNING: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

– Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch.

•

Do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

– Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

IMPORTANT: Do not install a ventilation system that blows air downward toward this gas cooking appliance. This type of

ventilation system may cause ignition and combustion problems with this gas cooking appliance resulting in personal injury or

unintended operation.

2

Page 3

4

In the State of Massachusetts, the following installation instructions apply:

Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

Acceptable Shut-off Devices: Gas Cocks and Ball Valves installed for use shall be listed.

A flexible gas connector, when used,must not exceed 4 feet (121.9 cm).

Range Foot

Anti-Tip

Bracket

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

To verify the anti-tip bracket is installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

3

Page 4

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

■ Tape measure

■ Phillips screwdriver

®

■ T20

Torx®† screwdriver

■ Flat-blade screwdriver

■ 1/8" (3.2 mm) flat-blade

screwdriver

■ Level

■ Hand or electric drill

■ Wrench or pliers

■ Pipe wrench

■ 15/16" (2.4 cm)

■ 3/8" (1 cm) nut driver

■ Marker or pencil

■ Pipe-joint compound

resistant to propane gas

■ Noncorrosive leak-

detection solution

For propane/Natural Gas

Conversions

■ 1/2" (1.3 cm) combination

wrench

■ 9/32" (7.0 mm) nut driver

■ Masking tape

combination wrench

■ 1/8" (3.2 mm) drill bit

Parts Supplied

Check that all parts are included.

■ Propane/Natural Gas Conversion Kit (located on back of

range near lower side)

■ Burner grates

■ Burner caps

■ Oven racks

■ #12 x 1

■ Anti-tip bracket (taped inside upper oven with literature

5

⁄8" (4.1 cm) screws (for mounting anti-tip bracket) (2)

package)

Anti-tip bracket must be securely mounted to the back wall

or floor. Thickness of flooring may require longer screws to

anchor bracket to subfloor. Longer screws are available from

your local hardware store.

Location Requirements

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct flow of combustion and ventilation air.

■ It is the installer’s responsibility to comply with installation

clearances specified on the model/serial/rating plate. The

model/serial/rating plate is located behind the control panel

and may be rotated up from behind the control panel for

viewing from the front of the range.

■ The range should be located for convenient use in the

kitchen.

■ Recessed installations must provide complete enclosure of

the sides and rear of the range.

■ All openings in the wall or floor where range is to be installed

must be sealed.

■ Do not seal the range to the side cabinets.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see “Install Anti-Tip Bracket”

section.

■ Grounded electrical supply is required. See the appropriate

“Electrical Requirements” section.

■ Proper gas supply connection must be available. See “Gas

Supply Requirements” section.

■ Contact a qualified floor covering installer to check that the

floor covering can withstand at least 200°F (93°C).

■ Use an insulated pad or 1/4" (6.3 mm) plywood under range

if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with

your builder or cabinet supplier to make sure that the materials

used will not discolor, delaminate or sustain other damage. This

oven has been designed in accordance with the requirements

of UL and CSA International and complies with the maximum

allowable wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part 280). When such

standard is not applicable, use the Standard for Manufactured

Home Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this range must conform with the

current standards CAN/CSA-A240-latest edition, or with local

codes.

Mobile home installations require:

■ When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as it conforms to the

standards listed above.

■ Four-wire power supply cord or cable must be used in a

mobile home installation.

†®TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC.

4

Page 5

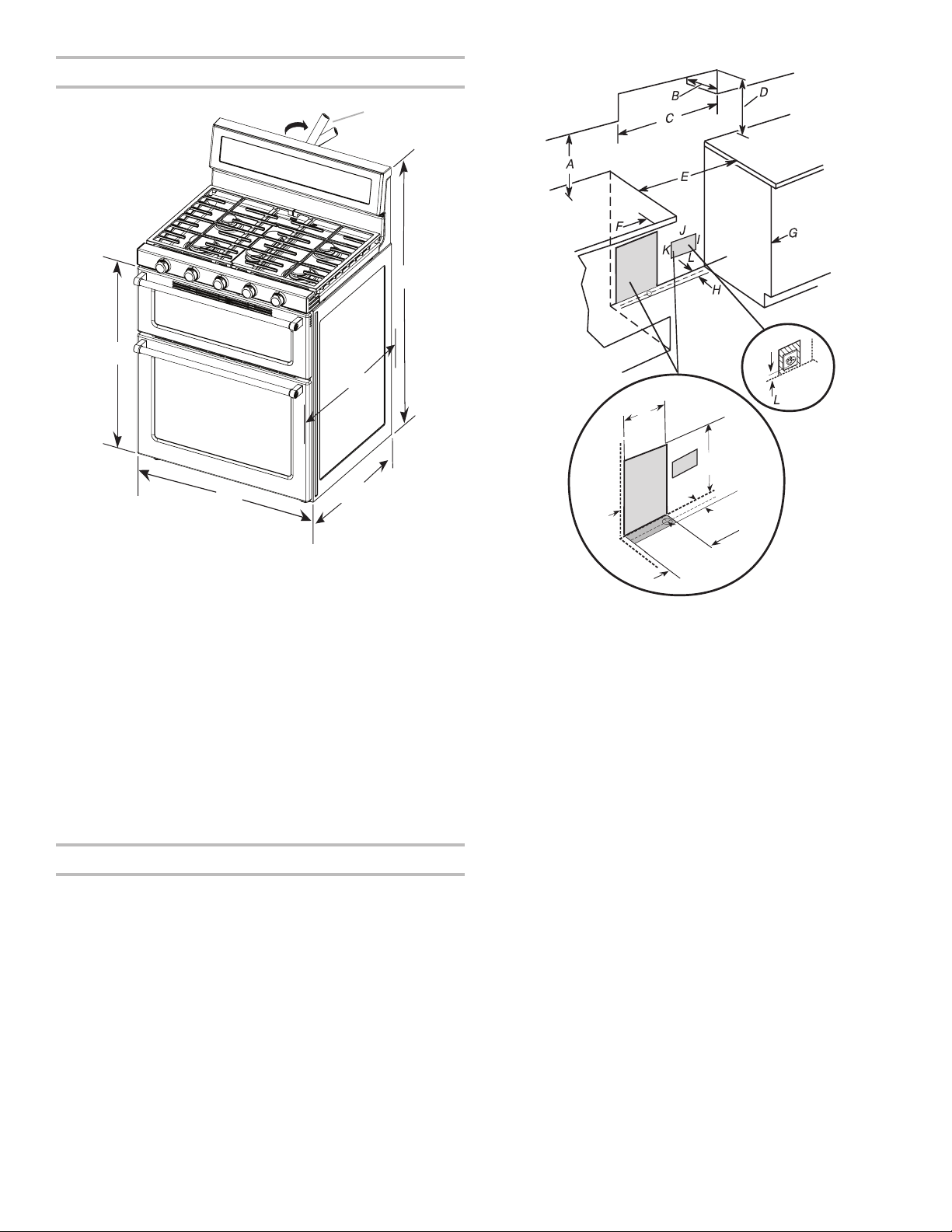

Product Dimensions

*

B*

A**

C*

D

8½ "

(21.6 cm )

14"

***

(35.6 cm )

E***

A. 35³⁄4" ± ¹⁄8" (90.8 ± 0.3 cm)

cooktop height (minimum) with

leveling legs screwed all the way

in

B. Model/serial/rating plates

(located behind the control

panel)*

F

C. 473⁄8" ± ¹⁄8" (120.3 ± 0.3 cm)

overall height (minimum) with

leveling legs screwed all the way

in**

D. 28¹⁄2" ± ¹⁄4" (72.4 ± 0.6 cm) depth

with handle

E. 26¹⁄8" ± ¹⁄8" (66.4 ± 0.3 cm)***

F. 29¹5⁄16" ± ¹⁄16" (76.0 ± 0.2 cm)

width

* Model/serial/rating plates may be rotated up from behind the

control panel for viewing from the front of the range.

**Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

***Excludes handle. Dimension given is from wall to front of

oven door and will vary based on electrical outlet receptacle

installation.

Cabinet Dimensions

Cabinet opening dimensions shown are for 25” (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and 36”

(91.4 cm) countertop height.

IMPORTANT: If installing a range hood or microwave hood

combination above the cooking surface, follow the range hood

or microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

Range may be installed with zero clearance to combustible

construction at the rear and on the sides below the cooktop.

1½"

(3.8 cm )

A. 18" (45.7 cm) upper cabinet to countertop

B. 13" (33.0 cm) upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to the top of the cooktop, see NOTE.

E. in U.S.A.: 30" (76.2 cm) min. opening width

in Canada: 31" (78.7 cm) min. opening width

F. 3" (7.6 cm) min. clearance from both sides of the range to the

side wall or other combustible material.

G. Cabinet door or hinges should not extend into the cutout.

H. 3" (7.6 cm) distance from wall

I. 1¹⁄2" (3.8 cm) min. from right side cabinet

J. 8" (20.3 cm) width

K. 7" (17.8 cm) min. from floor

L. 2" (5.1 cm) min. from floor

1¼"*

(3.1 cm )

8½" (21.6 cm)**

gas line location

2¼" (5.7 cm )

* Drill on centerline 1¼" (3.1 cm) from rear wall for gas supply

line.

**Gas lines must be installed within the shaded area to ensure

proper alignment of this oven with cabinets.

***Recessed electrical plugs must be installed within the shaded

area to ensure proper alignment of this oven with cabinets.

NOTE: 24” (61.0 cm) minimum when bottom of wood or metal

cabinet is covered by not less than ¹⁄4” (6.3 mm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015” (0.4 mm) stainless steel, 0.024” (0.6 mm) aluminum or

0.020” (0.5 mm) copper.

30” (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal cabinet.

5

Page 6

Electrical Requirements - U.S.A. Only

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/

NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

■ This range is manufactured with a 4-wire power supply cord

rated at 240 V, 40 A, rated at 194°F (90°C) and investigated

for use with this range.

Range Rating* Specified Rating of Power

Supply Cord Kit and

Circuit Protection

120/240 Volts120/208 VoltsAmpsTemp Rating

8.8 - 16.5 kW

16.6 - 22.5 kW

*The NEC calculated load is less than the total connected

load listed on the model/serial rating plate.

■ When a 4-wire, single phase 240 V, 60 Hz., AC only electrical

supply is available, a 40 A minimum circuit protection is

required on 30" (76.2 cm) ranges, fused on both sides of the

line.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a UL or CSA International

Certified Power Cord intended to be plugged into a standard

14-50R wall receptacle. Be sure the wall receptacle is within

reach of range’s final location.

7.8 - 12.5 kW

12.6 - 18.5 kW

40 or 5050194°F (90°C)

194°F (90°C)

Electrical Connection

Check local codes and consult gas supplier. Check

existing electrical supply and gas supply. See “Gas Supply

Requirements” sections.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

■ Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial/rating plate.

The model/serial/rating plate is located on the right vertical

surface of the oven door frame. Refer to the illustrations

in the “Product Dimensions” section of the “Location

Requirements” section.

■ Do not use an extension cord.

■ The wiring diagram is located on the back of the range or in

a clear plastic bag.

6

Page 7

Electrical Requirements - Canada Only

Gas Supply Requirements

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

Be sure that the electrical connection and wire size are adequate

and in conformance with the CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

■ Check with a qualified electrical installer if you are not sure

the range is properly grounded.

Range Rating* Specified Rating of Power

Supply Cord Kit and

Circuit Protection

120/240 Volts120/208 VoltsAmpsTemp Rating

8.8 - 16.5 kW

16.6 - 22.5 kW

7.8 - 12.5 kW

12.6 - 18.5 kW

40 or 5050194°F (90°C)

194°F (90°C)

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 — latest edition — or CAN/CGA B149 —

latest edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer’s instructions.

Type of Gas

*The NEC calculated load is less than the total connected load

listed on the model/serial/rating plate.

■ When a 4-wire, single phase 250 V, 60 Hz., AC only electrical

supply is available, a 40 A minimum circuit protection is

required on 30" (76.2 cm) ranges, fused on both sides of the

line.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a UL or CSA International

Certified Power Cord intended to be plugged into a standard

14-50R wall receptacle. Be sure the wall receptacle is within

reach of range’s final location.

■ Do not use an extension cord.

■ The wiring diagram is located on the back of the range or in

a clear plastic bag.

Natural Gas:

■ This range is factory set for use with Natural gas. See “Gas

Conversions” section. The model/serial/rating plate located

behind the control panel has information on the types of gas

that can be used. If the types of gas listed do not include the

type of gas available, check with the local gas supplier.

Propane Gas Conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial/rating plate for use with a different

gas without consulting the serving gas supplier. See “Gas

Conversions” section.

7

Page 8

Gas Supply Line

A

C

Gas Pressure Regulator

■ Provide a gas supply line of 3/4" (1.9 cm) rigid pipe to the

range location. A smaller size pipe on longer runs may

result in insufficient gas supply. With propane gas, piping or

tubing size can be 1/2" (1.3 cm) minimum. Usually, propane

gas suppliers determine the size and materials used in the

system.

NOTE: Pipe-joint compounds that resist the action of

propane gas must be used. Do not use TEFLON®† tape.

Flexible metal appliance connector:

■ If local codes permit, a new CSA design-certified, 4 to 5

ft (122 to 152.4 cm) long, 1/2" (1.3 cm) or 3/4" (1.9 cm)

I.D. (inside diameter), flexible metal appliance connector

may be used for connecting range to the gas supply line.

■ A 1/2" (1.3 cm) male pipe thread is needed for

connection to the female pipe threads of the inlet to the

appliance pressure regulator.

■ Do not kink or damage the flexible metal tubing when

moving the range.

■ Must include a shutoff valve:

Install a manual gas line shutoff valve in an easily accessible

location. Do not block access to shutoff valve. The valve is

for turning on or shutting off gas to the range.

B

A. Gas supply line

B. Shutoff valve “open” position

C. To range

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows for

proper operation:

Natural Gas:

Minimum pressure: 5" (12.7 cm) WCP

Maximum pressure: 14" (35.5 cm) WCP

Propane Gas:

Minimum pressure: 11" (27.9 cm) WCP

Maximum pressure: 14" (35.5 cm) WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

Burner Input Requirements

Input ratings shown on the model/serial/rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at

a rate of 4% for each 1,000 ft (304.8 m) above sea level (not

applicable for Canada).

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1”(2.5 cm) water column pressure above the manifold pressure

shown on the model/serial rating plate.

Line pressure testing above ½ psi (3.5 kPa) gauge 14"

(35.5 cm) WCP

The range and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of ½ psi (3.5 kPa).

Line pressure testing at ½ psi (3.5 kPa) gauge 14" (35.5 cm)

WCP or lower

The range must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal

to or less than ½ psi (3.5 kPa).

†®TEFLON is a registered trademark of Chemours.

8

Page 9

INSTALLATION INSTRUCTIONS

Unpack Range

WARNING

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and film from the range.

Keep cardboard bottom under range.

2. Remove oven racks and parts package from inside oven.

3. To place range on its back, take 4 cardboard corners from

the carton. Stack one cardboard corner on top of another.

Repeat with the other 2 corners. Place them lengthwise on

the floor behind the range to support the range when it is laid

on its back.

4. Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Pull cardboard bottom firmly to remove.

6. Use an adjustable wrench to loosen the leveling legs.

7. Place cardboard or hardboard in front of range. Using 2

or more people, stand range back up onto cardboard or

hardboard.

Adjust Leveling Legs

1. If range height adjustment is necessary, use a wrench or

pliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the

range supported on 2 legs after the range has been placed

back to a standing position.

NOTE: To place range back up into a standing position, put

a sheet of cardboard or hardboard in front of range. Using 2

or more people, stand range back up onto the cardboard or

hardboard.

2. Adjust the leveling legs to the correct height. Leveling legs

can be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of 3/16" (5.0 mm) is needed to engage the anti-tip

bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

3. When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final location, check that the

anti tip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

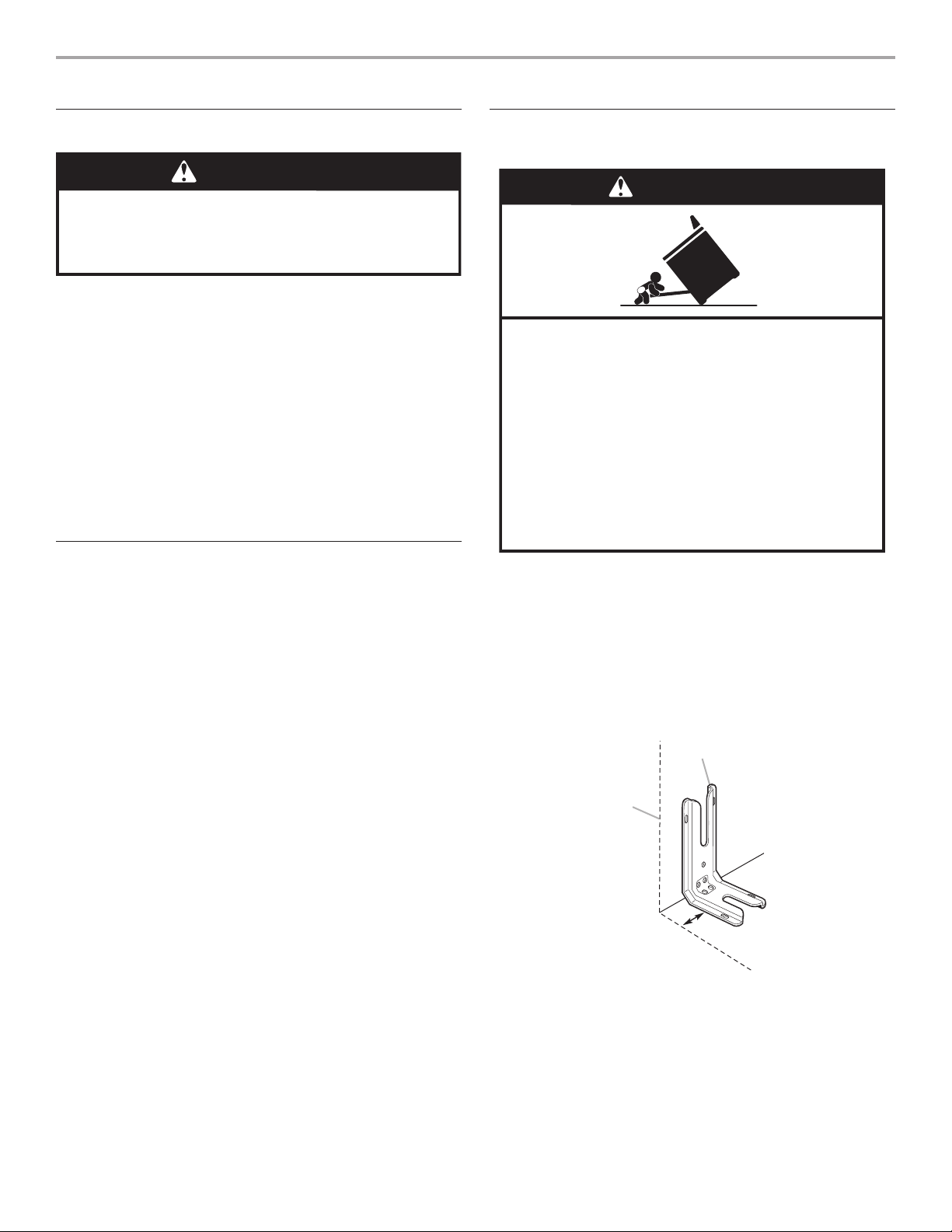

Install Anti-Tip Bracket

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Remove the anti-tip bracket that is taped inside the upper

oven with the package containing literature.

2. Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor, you can use the wall

mounting method.

3. Determine and mark edge of range in the cutout space. The

mounting bracket can be installed on either the left side or

right side of the cutout. Position mounting bracket in cutout

so that right (or left) edge of the bracket is 15/16" (2.4 cm)

from the marked edge of the range, as shown.

A

B

C

A. Anti-tip bracket

B. Mark edge of range

C. 15/16" (2.4 cm)

9

Page 10

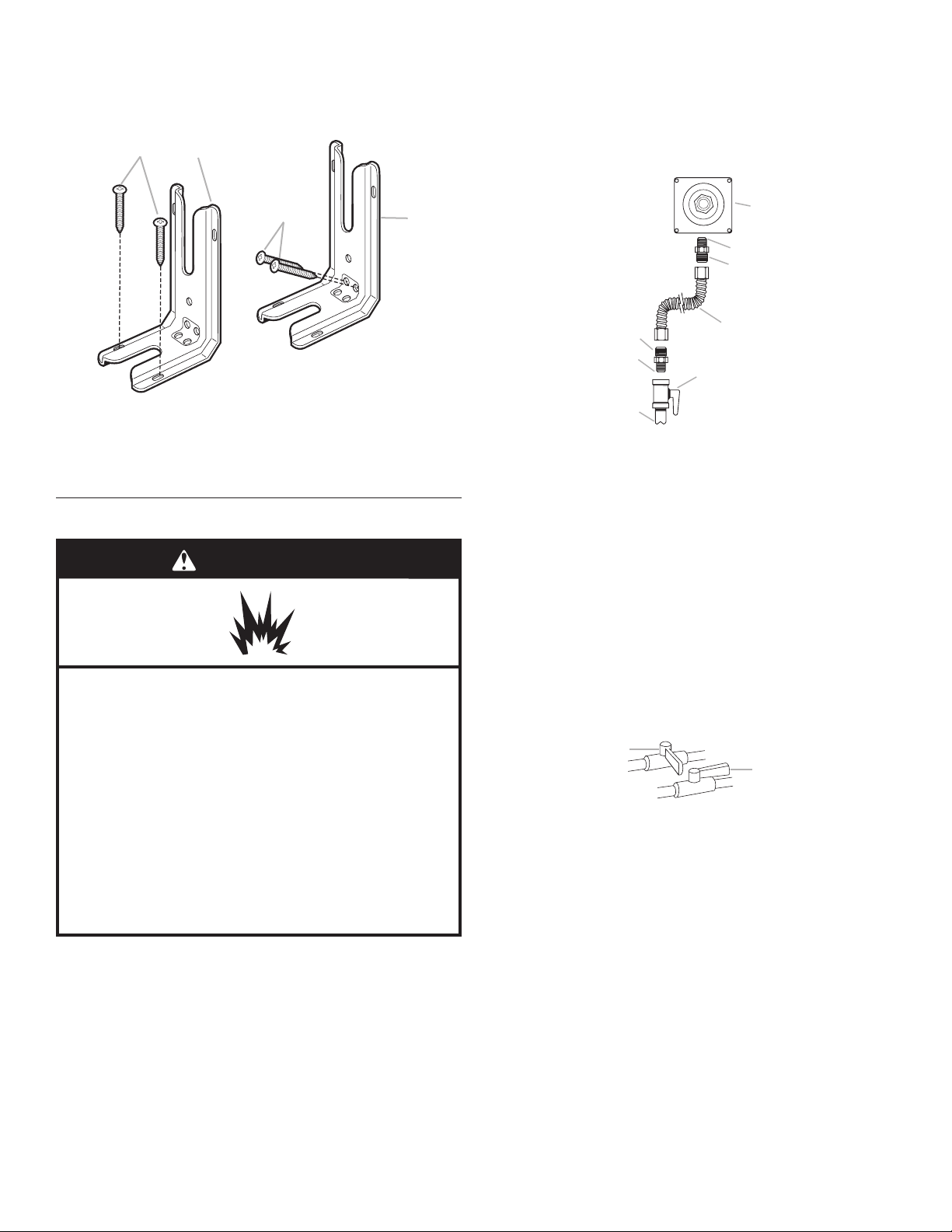

4. Drill two 1/8" (3.0 mm) holes that correspond to the bracket

A

A

holes of the determined mounting method. See the following

illustrations.

Floor Mounting Wall Mounting

B

3. Use a 15/16" (2.4 cm) combination wrench and an adjustable

wrench to attach the flexible connector to the adapters.

IMPORTANT: All connections must be wrench-tightened. Do

not make connections to the gas regulator too tight. Making

the connections too tight may crack the regulator and cause

a gas leak. Do not allow the regulator to turn when tightening

fittings.

A

A. #12 x 15⁄8" screws (4.1 cm)

B. Anti-tip bracket

5. Using the two #12 x 1

A. #12 x 15⁄8" screws (4.1 cm)

B. Anti-tip bracket

5

8

⁄

" (4.1 cm) Phillips-head screws

provided, mount anti-tip bracket to the wall or floor.

Make Gas Connection

WARNING

B

B

C

D

H

G

E

F

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter [must have

1/2"(1.3 cm) male pipe thread]

D. Flexible connector

E. Manual gas shutoff valve

F. 1/2" (1.3 cm) or 3/4" (1.90 cm)

gas pipe

G. Use pipe-joint compound.

H. Adapter

4. Gas supply pipe must be located within clearance area as

shown in the “Cabinet Dimensions” illustration in “Location

Requirements” section.

5. Plug in range to a grounded outlet. See the appropriate

“Electrical Requirements” section.

6. Slide range into place so that the rear range foot is inserted

into the slot of the anti-tip bracket.

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Typical flexible connection

1. Apply pipe-joint compound made for use with propane gas

to the smaller thread ends of the flexible connector adapters

(see B and G in the following illustration).

2. Attach one adapter to the gas pressure regulator and

the other adapter to the gas shutoff valve. Tighten both

adapters, being certain not to move or turn the gas pressure

regulator.

Complete Connection

1. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A

B

A. Closed valve

B. Open valve

2. Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles appear, a

leak is indicated. Correct any leak found.

3. Remove cooktop burner caps and grates from parts

package. Align recess in burner caps with pins in burner

base. Burner caps should be level when properly positioned.

If burner caps are not properly positioned, surface burners

will not light. Place burner grates over burners and caps.

10

Page 11

Verify Anti-Tip Bracket Is Installed and

Engaged

1. Place the outside of your foot against the bottom front of the

oven door to keep the unit from moving, and grasp the lower

right- or left-hand side of the control panel as shown.

NOTE: If your countertop is mounted with a backsplash, it

may be necessary to grasp the range higher than is shown in

the illustration.

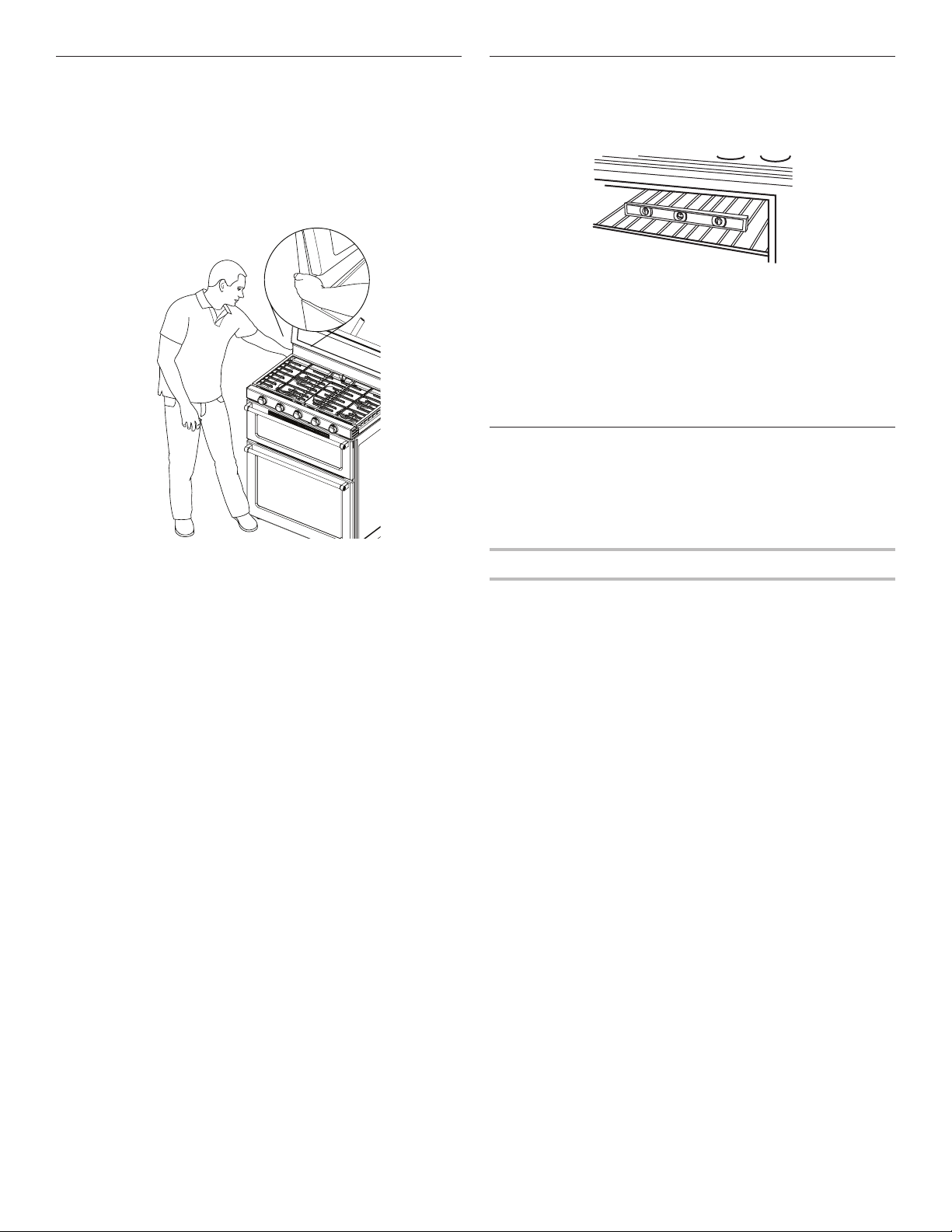

Level Range

1. Place rack in oven.

2. Place level on rack and check levelness of range, first side to

side; then front to back.

3. If range is not level, pull range forward until rear leveling leg

is removed from the anti-tip bracket.

4. Use wrench to adjust leveling legs up or down until range is

level. Push range back into position.

5. Check that rear leveling leg is engaged in anti-tip bracket.

Check that the flexible conduit or power supply cord are not

bent.

NOTE: Range must be level for satisfactory baking performance.

Electronic Ignition System

Initial Lighting and Gas Flame Adjustments

Cooktop burners use pilotless igniters in place of standing pilots.

When the cooktop control knob is turned to the “LITE” position,

the system creates a spark to light the burner. This sparking

continues, as long as the control knob is turned to “LITE.

2. Slowly attempt to tilt the range forward.

If you encounter immediate resistance, the range foot is

engaged in the anti-tip bracket.

3. If the rear of the range lifts more than 1/2" (1.3 cm) off the

floor without resistance, stop tilting the range and lower it

gently back to the floor. The range foot is not engaged in the

anti-tip bracket.

IMPORTANT: If there is a snapping or popping sound when

lifting the range, the range may not be fully engaged in the

bracket. Check to see if there are obstructions keeping the range

from sliding to the wall or keeping the range foot from sliding

into the bracket. Verify that the bracket is held securely in place

by the mounting screws.

4. Slide the range forward, and verify that the anti-tip bracket is

securely attached to the floor or wall.

5. Slide range back so the rear range foot is inserted into the

slot of the anti-tip bracket.

IMPORTANT: If the back of the range is more than 2" (5.1 cm)

from the mounting wall, the rear range foot may not engage

the bracket. Slide the range forward and determine if there

is an obstruction between the range and the mounting wall.

Changes to the gas supply must be performed by a qualified

service technician. If you need assistance or service, refer to

the “Warranty” section of the User Instructions for contact

information.

6. Repeat steps 1 and 2 to ensure that the range foot is

engaged in the anti-tip bracket.

If the rear of the range lifts more than 1/2" (1.3 cm) off

the floor without resistance, the anti-tip bracket may not

be installed correctly. Do not operate the range without

anti-tip bracket installed and engaged. Please reference

the “Warranty” section of the User Instructions to contact

service.

Check Operation of Cooktop Burners

Standard Surface Burners

Push in and turn each control knob to the “LITE” position.

The flame should light within 4 seconds. The first time a burner

is lit it may take longer than 4 seconds to light because of air in

the gas line.

If Burners Do Not Light Properly:

■ Turn cooktop control knob to the “OFF” position.

■ Check that the range is plugged in and the circuit breaker

has not tripped or the household fuse has not blown.

■ Check that the gas shutoff valve is set to the “open” position.

■ Check that burner caps are properly positioned on burner

bases.

Repeat start-up. If a burner does not light at this point, turn the

control knobs to “Off” and contact your dealer or authorized

service company for assistance.

Tap Touch Surface Burners (On Some Models)

Tap the “On” pad for the cooktop control.

Tap the “+” or “-” pads to adjust the cooktop burner flame

height. The flame should light within 4 seconds. The first time a

burner is lit, it may take longer than 4 seconds to light because

of air in the gas line.

11

Page 12

If Burners Do Not Light Properly:

■ Tap the “Off” pad for the cooktop control.

■ Check that the range is plugged in and the circuit breaker

has not tripped or the household fuse has not blown.

■ Check that the gas shutoff valve is set to the “open” position.

■ Check that burner caps are properly positioned on burner

bases.

Repeat start-up. If a burner does not light at this point, tap the

“Off” pad for the cooktop control and contact your dealer or

authorized service company for assistance.

Adjust Flame Height

Adjust the height of top burner flames. The cooktop “low” burner

flame should be a steady blue flame approximately

3/8" (9.5 mm) high.

A

B

A. Low flame

B. High flame

To adjust standard burners:

The flame can be adjusted using the adjustment screw in the

center of the valve stem. The valve stem is located directly

underneath the control knob.

If the “low” flame needs to be adjusted:

1. Light 1 burner and turn to lowest setting.

2. Remove the control knob.

Hold the knob stem in the low position using a pair of pliers.

Use 1/8" (3.0 mm) flat-blade screwdriver to turn the screw

located in the center of the control knob stem until the flame

is the proper size.

Complete Installation

1. Check that all parts are now installed. If there is an extra

part, go back through the steps to see which step was

skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check that the range is level. See the “Level Range” section.

5. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, see

the “Range Care” section of the Use and Care Guide or User

Instructions.

6. Read “Range Use” in the Use and Care Guide or the User

Instructions.

7. Turn on surface burners and oven. See the Use and Care

Guide or the User Instructions for specific instruction on

range operation.

If Range Does Not Operate, Check the Following:

■ Household fuse is intact and tight, or circuit breaker has not

tripped.

■ Range is plugged into a properly grounded outlet.

■ Electrical supply is connected.

■ See “Troubleshooting” or “Problem Solver” in the Use and

Care Guide or the User Instructions.

If You Need Assistance or Service:

Please reference the “Warranty” section of the Use and Care

Guide or the User Instructions.

3. Replace the control knob.

4. Test the flame by turning the control from “LO” to “HI,”

checking the flame at each setting.

5. Repeat above steps for each burner.

12

Page 13

Remove Oven Door(s)

A

■ The range is designed to not need the oven doors removed

for standard usage and cleaning, however, they can be

removed if necessary.

■ Do not lift or move the range by the door handle(s).

■ Prepare a surface where you will place the door(s). This

surface should be flat and covered with a soft blanket, or use

the corner posts from the packaging material.

A. Oven door hinge in the

locked position

Use two hands to remove and replace

the oven door(s). It may be necessary to

gently shift door from side to side.

B

B. Oven door hinge in the

unlocked position

Partially close the door to engage the

door latch locks. The door will stop at

this point.

A

A. Slot in the oven frame for the

door hinge lock

■ To replace the oven door(s), locate the slots in the oven

cavity for the hinge locks and repeat the steps above in

reverse order. Make sure the door closes properly and there

is no interference from the door latch. If necessary, remove

the door and repeat the steps above. If power is connected

to the range, open and close the door to make sure the oven

light comes on and goes off appropriately.

■ Follow the installation instructions found in the bag

containing the literature.

13

Page 14

GAS CONVERSIONS

A

C

A

Gas conversions from Natural gas to propane gas or from

propane gas to Natural gas must be done by a qualified installer.

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Propane Gas Conversion

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shutoff valve to the closed position.

B

A. Gas supply line

B. Shutoff valve (closed position)

C. To range

2. Unplug range or disconnect power.

To Convert Gas Pressure Regulator

1. Locate gas pressure regulator at the rear of the range.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

14

Page 15

2. Unscrew the regulator cap, and then remove the plastic

A

C

cover.

B

4. Apply masking tape to the end of a 9/32" (7.0 mm) nut driver

to help hold the Natural gas orifice spud in the nut driver

while changing it. Press nut driver down onto the Natural gas

orifice spud and remove by turning it counterclockwise and

lifting out. Set the Natural gas orifice spud aside.

A

A. Natural gas orifice spud

A. Plastic cover

B. Regulator cap

3. Flip the regulator pin over, and then replace the plastic cover.

B

A

A. Natural gas position

B. Propane gas position

C. Plastic cover

4. Screw the regulator cap securely back into place. Do not

overtighten.

To Convert Surface Burners

1. If the burner grates are installed, remove them.

2. Remove the burner caps.

3. Using a Phillips or T20® Torx® screwdriver, remove the burner

base.

Use the following chart for correct propane gas orifice spud for

each burner. Refer to the model/serial/rating plate behind the

control panel for proper sizing of propane gas orifice spuds for

each burner location.

Propane Gas Orifice Spud Chart

Burner Rating Color Number

4,000 BTU

7,000 BTU

9,100 BTU

14,000 BTU

5. Replace the Natural gas orifice spud with the correct

propane gas orifice spud. See the “Propane Gas Orifice

Spud Chart”.

6. Replace burner base and hand tighten the screws.

7. Replace burner cap.

8. Repeat steps 1 through 7 for the remaining burners.

9. Place Natural gas orifice spuds in plastic parts bag for future

use and keep with literature package.

10. Replace burner grates.

11. Complete installation. See “Make Gas Connection” and

Electronic Ignition System” sections.

Checking for proper cooktop burner flame is very important.

The small inner cone should have a very distinct blue flame

1/4" to 1/2" (0.64 to 1.3 cm) long. The outer cone is not as

distinct as the inner cone. Propane gas flames have a slightly

yellow tip.

IMPORTANT: You may have to adjust the low setting for

each cooktop burner.

Blue

Black

Green

Red

64L

81L

97L

114L

A

C

B

D

A. Burner cap

B. Gas tube opening

C. Burner base screws

D. Burner base

†®TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC.

15

Page 16

WARNING

A

C

A

A

C

Natural Gas Conversion

2. Unscrew the regulator cap and remove the plastic cover.

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shutoff valve to the closed position.

B

A. Gas supply line

B. Shutoff valve (closed position)

C. To range

2. Unplug range or disconnect power.

To Convert Gas Pressure Regulator

1. Locate gas pressure regulator at the rear of the range.

B

A. Plastic cover

B. Regulator cap

3. Flip the regulator cap over and replace the plastic cover.

B

A

A. Propane gas position

B. Natural gas position

C. Plastic cover

4. Screw the regulator cap securely back into place. Do not

overtighten.

To Convert Surface Burners

1. If the burner grates are installed, remove them.

2. Remove the burner caps.

3. Using a Phillips or T20® Torx® screwdriver, remove the burner

base.

A

C

B

D

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

A. Burner cap

B. Gas tube opening

C. Burner base screws

D. Burner base

16

Page 17

4. Apply masking tape to the end of a 9/32" (7.0 mm) nut driver

to help hold the propane gas orifice spud in the nut driver

while changing it. Press nut driver down onto the propane

gas orifice spud and remove by turning it counterclockwise

and lifting out. Set the propane gas orifice spud aside.

A

Moving the Range

WARNING

A. Propane gas orifice spud

Use the following chart for correct Natural gas orifice spud for

each burner. Refer to the model/serial rating plate behind the

control panel for proper sizing of Natural orifice spuds for each

burner location.

Natural Gas Orifice Spud Chart

Burner Rating Color Number

5,000 BTU

7,300 BTU

9,200 BTU

10,000 BTU

15,000 BTU

16,000 BTU

5. Replace the propane gas orifice spud with correct Natural

gas orifice spud. See the “Natural Gas Orifice Spud Chart.”

6. Replace burner base and hand tighten the screws.

7. Replace burner cap.

8. Repeat steps 1 through 7 for the remaining burners.

9. Place propane gas orifice spuds in plastic parts bag for

future use and keep with literature package.

10. Replace burner grates.

11. Complete installation. See “Make Gas Connection” and

“Electronic Ignition System” sections.

Checking for proper cooktop burner flame is very important.

The small inner cone should have a very distinct blue flame

1/4" (6.35 mm) to 1/2" (1.3 cm) long. The outer cone is not

as distinct as the inner cone. Natural gas flames do not have

yellow tips.

IMPORTANT: You may have to adjust the low setting for

each cooktop burner.

Green

Yellow

Orange

Transparent

White

Black

107N

125N

142N

149N

180N

195N

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

When moving range, slide range onto cardboard or hardboard to

avoid damaging the floor covering.

If removing the range is necessary for cleaning or maintenance:

For Power Supply Cord-Connected Ranges:

1. Slide range forward.

2. Turn manual shutoff valve to the closed position.

3. Unplug the power supply cord.

4. Disconnect the gas supply tubing.

5. Complete cleaning or maintenance.

6. Reconnect the gas supply tubing.

7. Open the manual shutoff valve in the gas supply line.

8. Plug in power supply cord.

9. Slide range back so rear range foot is under anti-tip bracket.

10. Refer to the “Verify Anti-Tip Bracket Is Installed and

Engaged” section to verify engagement.

11. Check that range is level.

17

Page 18

NOTE

18

Page 19

SÉCURITÉ DE LA CUISINIÈRE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERTISSEMENT : Si les renseignements dans ces instructions ne sont pas

exactement observés, un incendie ou une explosion peut survenir, causant des

dommages au produit, des blessures ou un décès.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

– Ne pas entreposer ni utiliser de l’essence ou d’autres vapeurs ou liquides inflammables

à proximité de cet appareil ou de tout autre appareil électroménager.

– QUE FAIRE DANS LE CAS D’UNE ODEUR DE GAZ :

Ne pas tenter d’allumer un appareil.

•

Ne pas toucher à un commutateur électrique.

•

Ne pas utiliser le téléphone se trouvant sur les lieux.

•

Appeler immédiatement le fournisseur de gaz à partir du téléphone d'un voisin. Suivre

•

ses instructions.

À défaut de joindre votre fournisseur de gaz, appeler les pompiers.

•

– L’installation et l’entretien doivent être effectués par un installateur qualifié, une agence

de service ou le fournisseur de gaz.

AVERTISSEMENT : L’odorat ne permet pas toujours la détection d’une fuite de gaz.

Les distributeurs de gaz recommandent l’emploi d’un détecteur de gaz (homologation UL ou CSA).

Pour d'autres informations, contacter le fournisseur de gaz local.

En cas de détection d’une fuite de gaz, exécuter les instructions “Que faire dans le cas d’une odeur de gaz”.

IMPORTANT : Ne pas installer un système de ventilation avec évacuation de l'air vers le bas, qui évacuerait l'air vers cet

appareil de cuisson à gaz. Ce type de système de ventilation peut causer des problèmes d'allumage et de combustion avec cet

appareil de cuisson à gaz et entraîner des blessures corporelles ou le fonctionnement non désiré de cet appareil.

19

Page 20

4

Dans l’État du Massachusetts, les instructions d’installation suivantes sont applicables :

■ Les travaux d’installation et réparation doivent être exécutés par un plombier ou tuyauteur qualifié ou licencié, ou par le

personnel qualifié d’une entreprise licenciée par l’État du Massachusetts.

■ Remplacer par des dispositifs de fermeture acceptables : Les robinets de gaz et robinets à bille installés pour l'utilisation

devraient être indiqués.

■ Si un conduit de raccordement flexible est utilisé, sa longueur ne doit pas dépasser 4 pi (121,9 cm).

AVERTISSEMENT

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisinière, ce qui peut causer un

décès.

Fixer la bride antibasculement au plancher ou au mur, conformément aux instructions

d'installation.

Faire glisser de nouveau la cuisinière de façon à ce que le pied arrière de la cuisinière se

trouve dans la fente de la bride antibasculement.

Réengager la bride antibasculement si la cuisinière a été déplacée.

Ne pas faire fonctionner la cuisinière si la bride antibasculement n'est pas installée et engagée.

Le non-respect de ces instructions peut causer un décès ou des brûlures graves aux enfants et

aux adultes.

Pour vérifier que la bride antibasculement est bien installée et engagée :

Bride

antibasculement

• Faire glisser la cuisinière vers l'avant.

• Vérifier que la bride antibasculement est bien fixée au plancher ou au mur.

• Faire de nouveau glisser la cuisinière vers l'arrière de sorte que le pied de la cuisinière

Pied de la cuisinière

se trouve sous la bride antibasculement.

• Voir les instructions d'installation pour plus de détails.

EXIGENCES D’INSTALLATION

Outils et composants

Rassembler les outils et composants nécessaires avant

d’entreprendre l’installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outils nécessaires

■ Ruban à mesurer

■ Tournevis cruciforme

■ Foret T20

■ Tournevis à lame plate

■ Tournevis à lame plate de

®

Torx®†

1/8" (3,2 mm)

■ Niveau

■ Perceuse manuelle ou

électrique

■ Clé ou pince

■ Clé à tuyauterie

■ Clé mixte de 15/16" (2,4

cm)

■ Foret de 1/8" (3,2 mm)

■ Tourne-écrou de 3/8"

(1 cm)

■ Marqueur ou crayon

■ Composé d’étanchéité des

raccords filetés résistant

au gaz propane

■ Solution non-corrosive de

détection des fuites

Pour les conversions au gaz

propane/naturel

■ Clé mixte de 1/2" (1,3 cm)

■ Tourne-écrou de 9/32" (7,0

mm)

■ Ruban adhésif de

masquage

Pièces fournies

Vérifier que toutes les pièces sont présentes.

■ Ensemble de conversion au gaz propane/gaz naturel (situé à

l’arrière de la cuisinière en bas)

■ Grilles de brûleur

■ Chapeaux de brûleur

■ Grilles du four

■ Vis n° 12 de 1

5

⁄8" (4,1 cm) (pour le montage de la bride

antibasculement) (2)

■ Bride antibasculement (fixée par du ruban adhésif

à l’intérieur du four supérieur avec l’ensemble de

documentation)

La bride antibasculement doit être bien fixée à la cloison

arrière ou au plancher. La profondeur du plancher peut

nécessiter des vis plus longues pour l’ancrage de la bride

dans le sous-plancher. Des vis plus longues sont disponibles

auprès de votre quincaillerie locale.

†®TORX et T20 sont des marques déposées de Acument Intellectual Properties, LLC.

20

Page 21

Exigences d’emplacement

*

B*

IMPORTANT : Observer les dispositions de tous les codes et

règlements en vigueur. Ne pas obstruer le flux de combustion et

la ventilation.

■ C’est à l’installateur qu’incombe la responsabilité de

respecter les distances de séparation exigées, spécifiées

sur la plaque signalétique (numéros de série/modèle) de

l’appareil. La plaque signalétique est située derrière le tableau

de commande et peut être orientée vers le haut pour pouvoir

être consultée à partir de l’avant de la cuisinière.

■ La cuisinière doit être installée à un endroit pratique dans la

cuisine.

■ Dans le cas d’une cuisinière encastrée, l’enceinte doit

recouvrir complètement les côtés et l’arrière de la cuisinière.

■ Toutes les ouvertures dans le mur ou le plancher de

l’emplacement d’installation de la cuisinière doivent être

scellées.

■ Ne pas réaliser un scellement entre la cuisinière et les

placards latéraux.

■ Respecter les dimensions indiquées pour les ouvertures à

découper dans les placards. Ces dimensions constituent des

valeurs minimales de dégagement.

■ La bride antibasculement doit être installée. Pour l’installation

de la bride antibasculement expédiée avec la cuisinière, voir

la section “Installation de la bride antibasculement”.

■ Une source d’électricité avec liaison à la terre est nécessaire.

Voir la section “Spécifications électriques”.

■ Une source de gaz adéquate doit être disponible. Voir la

section “Spécifications de l’alimentation en gaz”.

■ Contacter un installateur de revêtement de sol qualifié, qui

pourra déterminer si le revêtement de sol peut résister à une

température d’au moins 200°F (93°C).

■ Dans le cas de l’installation de la cuisinière sur un revêtement

de moquette, placer sous la cuisinière une plaque d’appui

isolée, ou une plaque de contreplaqué de ¼” (0,64 cm).

IMPORTANT : Pour éviter d’endommager les placards, consulter

le constructeur de la maison ou le fabricant des placards pour

déterminer si les matériaux utilisés peuvent subir un changement

de couleur, une déstratification ou d’autres dommages. Ce four a

été conçu conformément aux exigences des normes UL et CSA

International et respecte les températures maximales permises

de 194°F (90°C) pour les placards en bois.

Résidence mobile – Spécifications additionnelles à respecter

lors de l’installation

L’installation de cette cuisinière doit être conforme aux

dispositions de la norme Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280 (anciennement

Federal Standard for Mobile Home Construction and Safety, Title

24, HUD Part 280). Lorsque cette norme n’est pas applicable,

l’installation doit satisfaire aux critères de la norme Standard for

Manufactured Home Installations, ANSI A225.1/NFPA 501A ou

aux dispositions des codes locaux.

Au Canada, l’installation de cette cuisinière doit satisfaire

aux stipulations de la version la plus récente de la norme

CAN/CSAA240 ou des codes locaux en vigueur.

Autres critères à respecter pour une installation en résidence

mobile

■ Dans le cas de l’installation de cette cuisinière dans une

résidence mobile, la cuisinière doit être fixée au plancher

durant tout déplacement du véhicule. Toute méthode de

fixation de la cuisinière est adéquate dans la mesure où elle

satisfait aux critères des normes mentionnées ci-dessus.

■ Pour une installation en résidence mobile, un câble ou cordon

d’alimentation à quatre fils doit être utilisé.

Dimensions du produit

C*

A**

D

F

A. Hauteur minimale de la table

de cuisson avec les pieds de

nivellement complètement vissés

: 35³⁄4" ± ¹⁄8" (90,8 ± 0,3 cm)**

B. Plaque signalétique (numéros

de modèle et de série) [située

derrière le panneau de

commande]*

C. Hauteur minimale d’ensemble

de la table de cuisson avec

les pieds de nivellement

complètement vissés :

47³⁄8" ± ¹⁄8" (120,3 ± 0,3 cm)**

D. 28¹⁄2” ± ¹⁄4" (72,4 ± 0,6 cm) de

profondeur avec poignée

E. 26¹⁄8" ± ¹⁄8" (66,4 ± 0,3 cm)***

F. 29¹5⁄16" ± ¹⁄16" (76,0 ± 0,2 cm) de

largeur

E***

* Les plaques signalétiques (numéros de série/modèle) peuvent

être orientées derrière le panneau de commande pour être

vues à l’avant de la cuisinière.

**La cuisinière peut être surélevée d’environ 1" (2,5 cm) en

réglant les pieds de nivellement.

***Hors poignée. Les dimensions données sont du mur à l’avant

de la porte du four et varient en fonction de l’installation de la

prise d’alimentation électrique.

Dimensions du placard

Les dimensions de l’espace d’installation entre les placards

correspondent à une installation entre des placards de

25" (64 cm) avec plan de travail de 24" (61 cm) de profondeur et

36" (91,4 cm) de hauteur.

IMPORTANT : Si une hotte ou un ensemble hotte/four à microondes est installé au-dessus de la surface de cuisson, suivre les

instructions d’installation fournies avec la hotte ou l’ensemble

hotte/four à micro-ondes concernant les dimensions de

dégagement à respecter au-dessus de la surface de cuisson.

Il est possible d’installer la cuisinière de manière à ce qu’elle soit

en contact avec des matériaux de construction combustibles à

l’arrière et sur les côtés, en dessous de la table de cuisson.

21

Page 22

8½ "

(21.6 cm )

14"

***

(35.6 cm )

1½"

(3.8 cm )

A. 18" (45,7 cm) entre le placard supérieur et le plan de travail

B. Profondeur des placards supérieurs : 13" (33 cm)

C. Largeur de l’ouverture 30” (76,2 cm) min.

D. Pour la distance libre minimale vers la partie supérieure de la

table de cuisson, voir la REMARQUE.

E. Aux États-Unis : Largeur de l’ouverture 30" (76,2 cm) min.

Au Canada : Largeur de l’ouverture 31” (78,7 cm) min.

F. Dégagement de 3" (7,6 cm) min. entre les deux côtés de

la cuisinière et les parois latérales ou d’autres matériaux

combustibles.

G. La porte ou les charnières du placard ne doivent pas dépasser

à l’intérieur de l’ouverture.

H. Distance à partir du mur de 3" (7,6 cm)

I. 1¹⁄2" (3,8 cm) min. à partir du côté droit du placard

J. 8" (20,3 cm) de largeur

K. 7" (17,8 cm) min. du sol

L. 2" (5,1 cm) min. du sol

1¼"*

(3.1 cm )

8½" (21.6 cm)**

gas line location

2¼" (5.7 cm )

* Percer sur l’axe central à 1¼" (3,1 cm) du mur arrière pour la

canalisation de gaz.

**Les canalisations de gaz doivent être installées dans la zone

ombrée afin de garantir un alignement correct de ce four avec

les placards.

***Les prises électriques encastrées doivent être installées dans

la zone ombrée pour garantir un alignement correct de ce four

avec les placards.

REMARQUE : Distance minimale de séparation de 24" (61,0 cm)

lorsque le fond d’un placard de bois ou de métal est protégé

par une planche ignifugée d’au moins 1/4" (0,64 cm) recouverte

d’une feuille métallique d’épaisseur égale ou supérieure à : acier

calibre 28 MSG, acier inoxydable 0,015" (0,4 mm), aluminium

0,024" (0,6 mm), ou cuivre 0,020" (0,5 mm).

Distance minimale de séparation de 30" (76,2 cm) entre le

dessus de la table de cuisson et le fond d’un placard de bois ou

de métal non protégé.

AVERTISSEMENT

Risque de choc électrique

Relier la cuisinière à la terre.

Le non-respect de cette instruction peut causer

un décès, un incendie ou un choc électrique.

Vérifier que le raccordement à la source d’électricité et le calibre

des conducteurs sont adéquats et conformes aux prescriptions

de la plus récente édition de la norme CSA C22.1, partie 1 Code canadien de l’électricité, et de tout code ou règlement

local en vigueur.

On peut obtenir un exemplaire de la norme ci-dessus auprès de :

■ En cas de doute quant à la qualité de la liaison à la terre de

la cuisinière, consulter un électricien qualifié.

Spécifications électriques

pour la cuisinière*

120/240 volts 120/208 volts Ampères Temp. Rating

8,8 - 16,5 KW

16,6 - 22,5 KW

*La charge NEC calculée est inférieure à la charge totale

connectée indiquée sur la plaque signalétique.

■ Lorsqu’on dispose d’une alimentation électrique

monophasée à 4 conducteurs de 250 volts, 60 Hz, et CA

uniquement, une protection de circuit de 40 ampères

minimum est requise pour les cuisinières de 30” (76,2 cm);

dans chaque cas, la protection de circuit doit être protégée

par fusible aux deux extrémités de la ligne.

■ On recommande l’emploi d’un fusible temporisé ou d’un

disjoncteur.

■ Cette cuisinière est dotée d’un cordon d’alimentation

(homologation UL ou CSA International) destiné à être

branché sur une prise de courant murale standard 14-50R.

Veiller à ce que la prise de courant murale soit placée à

portée de la position de service finale de la cuisinière.

■ Ne pas utiliser de câble de rallonge.

■ Le schéma de câblage est situé à l’arrière de la cuisinière,

dans un sachet plastique.

Canadian Standards Association

178 Rexdale Blvd

Toronto, ON M9W 1R3 CANADA

Intensité nominale

spécifiée du cordon

d’alimentation et de la

protection du circuit

7,8 - 12,5 KW

40 ou 50 50194°F (90°C)

12,6 - 18,5 KW

194°F (90°C)

22

Page 23

Spécifications de l’alimentation en gaz

A

C

AVERTISSEMENT

Risque d’explosion

Utiliser une canalisation neuve d’arrivée de gaz pour

utilisation à l’extérieur approuvée par la CSA

International.

Installer un robinet d'arrêt.

Bien serrer chaque organe de connexion de la

canalisation de gaz.

En cas de connexion au gaz propane, demander à une

personne qualifiée de s’assurer que la pression de gaz

ne dépasse pas 36 cm (14 po) de la colonne d’eau.

Par personne qualifiée, on comprend :

le personnel autorisé de chauffage,

le personnel autorisé d’une compagnie de gaz, et

le personnel d’entretien autorisé.

Le non-respect de ces instructions peut causer un

décès, une explosion ou un incendie.

Observer toutes les prescriptions des codes et règlements en

vigueur.

IMPORTANT : L’installation doit satisfaire aux critères de tous

les codes et règlements locaux. En l’absence de code local,

l’installation doit satisfaire aux prescriptions de la plus récente

édition du code national en vigueur : National Fuel Gas Code

ANSI Z223.1 (American National Standard), ou CAN/CGA B149

(édition la plus récente).

IMPORTANT : Les tests de fuite de la cuisinière doivent être

effectués selon les instructions du fabricant.

Canalisation de gaz

■ Installer une canalisation de gaz rigide de 3/4" (1,9 cm)

jusqu’à l’emplacement d’installation de la cuisinière. L’emploi

d’une canalisation de plus petit diamètre ou plus longue

peut susciter une déficience du débit d’alimentation. Pour

l’alimentation au propane, le diamètre des canalisations doit

être de 1/2" (1,3 cm) ou plus. Usuellement le fournisseur

de gaz propane détermine les matériaux à utiliser et la

dimension appropriée.

REMARQUE : On doit utiliser un composé d’étanchéité de

tuyauterie résistant à l’action du gaz propane. Ne pas utiliser

de ruban TEFLON®†.

Raccord métallique flexible :

■ Si le code local le permet, on peut utiliser pour raccorder

la cuisinière à la canalisation de gaz un raccord

métallique flexible neuf (homologation CSA) de 4 à 5 pi

(122 à 152,4 cm) de longueur, de diamètre interne de

1/2" (1,3 cm) ou 3/4" (1,9 cm).

■ Un raccord avec filetage mâle de 1/2" (1,3 cm) est

nécessaire pour la connexion sur le raccord à filetage

femelle à l’entrée du détendeur de l’appareil.

■ Veiller à ne pas déformer/écraser/endommager le tube

métallique flexible lors d’un déplacement de la cuisinière.

■ Robinet d’arrêt nécessaire :

Installer un robinet d’arrêt manuelle à un emplacement facile

d’accès. Ne pas bloquer l’accès au robinet d’arrêt. Le

robinet permet d’alimenter et de couper l’alimentation en gaz

à la cuisinière.

B

Type de gaz

Gaz naturel :

■ Cette cuisinière a été configurée à l’usine pour l’alimentation

au gaz naturel. Voir la section “Conversions pour

changement de gaz”. La plaque signalétique située derrière

le module de commande contient des renseignements sur

les types de gaz qui peuvent être utilisés. Si le type de gaz

disponible n’est pas mentionné sur la plaque signalétique,

consulter le fournisseur de gaz local.

Conversion pour l’alimentation au propane :

L’opération de conversion doit être exécutée par un technicien

qualifié.

Consulter le fournisseur de gaz avant toute conversion

de l’appareil pour l’utilisation d’un type de gaz qui n’est

pas mentionné sur la plaque signalétique. Voir la section

“Conversions pour changement de gaz”.

Détendeur de gaz

Le détendeur fourni avec cette cuisinière doit être utilisé. Pour un

fonctionnement correct, la pression d’alimentation du détendeur

doit être comme suit :

Gaz naturel :

Pression minimum : 5" (12,7 cm) (colonne d’eau)

Pression maximum : 14" (35,5 cm) (colonne d’eau)

Propane Gas:

Pression minimum : 11" (27,9 cm) (colonne d’eau)

Pression maximum : 14" (35,5 cm) (colonne d’eau)

En cas d’incertitude quant à la pression d’alimentation à établir,

contacter le fournisseur de gaz local.

†®TEFLON est une marque déposée de Chemours.

A. Canalisation de gaz

B. Robinet d’arrêt manuel - position d’ouverture

C. Vers la cuisinière

23

Page 24

Débit thermique des brûleurs

Tests de pressurisation de la canalisation de gaz

Les débits thermiques indiqués sur la plaque signalétique

correspondent à une altitude d’utilisation inférieure à 2000 pi

(609,6 m).

Lorsque l’appareil est utilisé à une altitude supérieure à 2000 pi

(609,6 m), on doit réduire le débit thermique indiqué de 4 % pour

chaque tranche de 1000 pi (304,8 m) au-dessus du niveau de la

mer (pas applicable au Canada).

INSTRUCTIONS D’INSTALLATION

Déballage de la cuisinière

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installer la cuisinière.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

1. Ôter les matériaux d’emballage, le ruban adhésif et le film de

la cuisinière. Laisser la base de carton sous la cuisinière.

2. Retirer les grilles de four et le sachet de pièces de l’intérieur

du four.

3. Pour placer la cuisinière sur sa partie postérieure, sortir les

4 coins de protection du carton d’emballage. Empiler l’un

des coins sur un autre. Répéter avec les 2 autres coins. Les

disposer sur le plancher dans le sens de la longueur derrière

la cuisinière en guise de support lorsque la cuisinière est

placée sur sa partie postérieure.

4. À l’aide de deux personnes ou plus, saisir fermement la

cuisinière et la poser délicatement sur sa partie postérieure,

sur les coins de protection.

5. Tirer fermement sur la partie inférieure du carton pour le

retirer.

6. Utiliser une clé à molette pour desserrer les pieds de

nivellement.

7. Placer le carton ou le panneau de fibres dur devant la

cuisinière. À l’aide de deux personnes ou plus, relever la

cuisinière et la placer sur le carton ou sur le panneau de

fibres dur.

On doit tester le détendeur sous une pression supérieure d’au

moins 1” à la pression de la tubulure de distribution indiquée sur

la plaque signalétique.

Pressurisation à une pression supérieure à ½ lb/po² (3,5 kPa)

[14" (35,5 cm)] - colonne d’eau)

Lors de tout test de pressurisation de ce système à une pression

supérieure à ½ lb/po² (3,5 kPa), on doit déconnecter l’appareil et

son robinet d’arrêt individuel de la canalisation de gaz.

Pressurisation à une pression inférieure ou égale à ½ lb/po²

(3,5 kPa) [14"(35,5 cm) ] de colonne d’eau ou moins)

Lors de tout test de pressurisation de la canalisation de gaz à

une pression égale ou inférieure à ½ lb/po² (3,5 kPa), on doit

isoler l’appareil de la canalisation de gaz par fermeture de son

robinet d’arrêt manuel individuel.

Réglage des pieds de nivellement

1. Si un ajustement de la hauteur de la cuisinière est

nécessaire, utiliser une clé ou une pince pour desserrer les 4

pieds de nivellement.

Ceci doit être effectué alors que la cuisinière repose sur sa

partie postérieure ou qu’elle est soutenue par 2 pieds après

avoir été replacée en position verticale.

REMARQUE : Pour replacer la cuisinière en position

verticale, placer un carton ou un panneau de fibres dur

devant la cuisinière. À l’aide de deux personnes ou plus,

relever la cuisinière et la placer sur le carton ou le panneau

de fibres dur.

2. Ajuster les pieds de nivellement à la hauteur nécessaire. Les

pieds de nivellement peuvent être desserrés pour ajouter une

hauteur maximale de 1" (2,5 cm). Un minimum de 3/16" (5,0

mm) est nécessaire pour engager la bride antibasculement.

REMARQUE : Si un ajustement de la hauteur est effectué

alors que la cuisinière est debout, incliner la cuisinière vers

l’arrière pour ajuster les pieds avant, puis incliner la cuisinière

vers l’avant pour ajuster les pieds arrière.

3. Lorsque la cuisinière est à la hauteur souhaitée, vérifier

qu’il y a un espace suffisant sous la cuisinière pour loger la

bride antibasculement. Avant de faire glisser la cuisinière à

son emplacement final, vérifier qu’il sera possible de faire

glisser la bride antibasculement sous la cuisinière et sur le

pied de nivellement arrière avant l’installation de la bride

antibasculement.

24

Page 25

Installation de la bride antibasculement

A

AVERTISSEMENT

4. Percer deux trous de 1/8" (3,0 mm) qui correspondent aux

trous de la bride selon la méthode de montage déterminée.

Voir ci-dessous.

Montage au plancher Montage au mur

B

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la

cuisinière, ce qui peut causer un décès.

Fixer la bride antibasculement au plancher ou au mur,

conformément aux instructions d'installation.

Faire glisser de nouveau la cuisinière de façon à ce que

le pied arrière de la cuisinière se trouve dans la fente

de la bride antibasculement.

Réengager la bride antibasculement si la cuisinière a

été déplacée.

Ne pas faire fonctionner la cuisinière si la bride

antibasculement n'est pas installée et engagée.

Le non-respect de ces instructions peut causer un

décès ou des brûlures graves aux enfants et aux

adultes.

1. Retirer la bride antibasculement fixée dans le four supérieur

par du ruban adhésif avec le sachet de documentation.

2. Déterminer la méthode de montage à utiliser : au plancher ou

au mur.

Pour un plancher en pierre ou en briquetage, on peut utiliser

la méthode de montage au mur.

3. Déterminer et marquer l’emplacement du bord de la

cuisinière dans l’espace à découper. On peut installer la

bride de montage du côté gauche ou droit du découpage.

Positionner la bride de montage dans la zone découpée de

façon à ce que le bord droit (ou gauche) de la bride se trouve

à 15/16" (2,4 cm) de l’emplacement du bord de la cuisinière,

tel qu’illustré.

A

B

C

A

A. Vis n°12 x 15⁄8" (4,1 cm)

B. Bride antibasculement

5. À l’aide des deux vis à tête cruciforme n° 12 x 1

cm) fournies, visser la bride antibasculement au mur ou au

plancher.

A. Vis n°12 x 15⁄8" (4,1 cm)

B. Bride antibasculement

5

8

⁄

" (4,1

Raccordement au gaz

AVERTISSEMENT

Risque d'explosion

Utiliser une canalisation neuve d'arrivée de gaz

approuvée par la CSA International.

Installer un robinet d'arrêt.

Bien serrer chaque organe de connexion de la

canalisation de gaz.

En cas de connexion au gaz propane, demander à une

personne qualifiée de s'assurer que la pression de gaz

ne dépasse pas 36 cm (14 po) de la colonne d'eau.

Par personne qualifiée, on comprend :

le personnel autorisé de chauffage,

le personnel autorisé d'une compagnie de gaz, et

le personnel d'entretien autorisé.

Le non-respect de ces instructions peut causer

un décès, une explosion ou un incendie.

B

A. Bride antibasculement

B. Marquage de l’emplacement du

bord de la cuisinière

C. 15/16" (2,4 cm)

Raccordement typique par raccord flexible

1. Appliquer une pâte à joints spéciale pour tuyauterie propane

sur les extrémités du petit filetage des raccords d’adaptation

flexibles (voir B et G dans l’illustration suivante).

2. Fixer un raccord d’adaptation sur le détendeur et l’autre

raccord d’adaptation sur le robinet d’arrêt de la canalisation

de gaz. Serrer les deux raccords d’adaptation, en s’assurant

de ne pas déplacer ou tourner le détendeur.

25

Page 26

3. À l’aide d’une clé mixte de 15/16" (2.4 cm) et d’une

A

clé à mollette, visser le raccord flexible sur les raccords

d’adaptation.

IMPORTANT : Tous les raccords doivent être bien serrés à

l’aide d’une clé. Ne pas serrer excessivement la connexion

sur le détendeur. Un serrage excessif pourrait provoquer une

fissuration du détendeur et une fuite de gaz. Lors du serrage

des raccords, empêcher le détendeur de tourner.

B

C

Vérifier que la bride antibasculement est

bien installée et engagée

1. Placer l’extérieur du pied contre la partie inférieure avant de

la porte du four et saisir le côté inférieur droit ou gauche du

tableau de commande tel qu’indiqué.

REMARQUE : Si le plan de travail comporte un dosseret, il

faudra peut-être saisir la cuisinière plus haut que ce

qu’indique l’illustration.

H

D

G

E

F

A. Détendeur

B. Utiliser une pâte à joints.

C. Raccord d’adaptation [avec

filetage mâle de 1/2" (1.3 cm)]

D. Raccord flexible

E. Robinet d’arrêt manuel

F. Tuyau de gaz de 1/2"(1.3 cm)

ou 3/4" (1.90 cm)

G. Utiliser une pâte à joints.

H. Raccord d’adaptation

4. Le conduit d’alimentation en gaz doit être installé avec

un dégagement suffisant, tel qu’indiqué dans l’illustration

“Dimensions du placard” de la section “Exigences

d’emplacement”.

5. Brancher la cuisinière sur une prise électrique. Voir la section