Page 1

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

UpDraft Electric

Cooktops

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

AKT3040*

AKT3650*

CEC1430AA*

CEC1536AA*

JEC7430AA*

JEC8430AD*

JEC8536AD*

JEC8730AD*

JEC9530AD*

JEC9536AD*

MEC4430BD*

MEC5430BD*

MEC5536BA*

16022159

Revision 0

May 2003

Page 2

!

!

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however , that during

its lifetime a product may require service. Products should be serviced only by a qualified service technician who is

familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBLITY TO REVIEW ALL

APPROPRIATE SER VICE INFORMATION BEFORE BEGINNING REP AIRS.

WARNING

T o avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

T o locate an authorized servicer , please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.AMANA.COM ................................................ 1-800-843-0304

WWW.JENNAIR.COM ............................................. 1-800-536-6247

WWW.MAYTAG.COM ............................................. 1-800-688-9900

CAIR Center in Canada ........................................... 1-800-688-2002

Amana Canada Product ........................................... 1-866-587-2002

Recognize Safety Symbols, Words, and Labels

DANGER

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16022159 Rev. 0 ©2003 Maytag Appliances Company

Page 3

Table of Contents

Important Information .................................................. 2

Safety Information

Safety Procedures ................................................. 4

Safety Practices for Servicer.................................. 5

Before Installing ..................................................... 5

Receiving Cooktop ................................................. 5

Unpacking.............................................................. 5

Electrical Requirements ......................................... 5

Electrical Connection ............................................. 5

General Information

Model Identification Rating Label and

Ordering Replacement Parts............................... 6

Cooking Nomenclature ........................................... 6

Model Identification ................................................ 7

Service ................................................................... 7

Parts and Accessories........................................... 7

Extended Service Plan ........................................... 7

Troubleshooting Procedures ....................................... 8

Component Testing Information

Power Supply......................................................... 9

Internal Wiring ........................................................ 9

Indicator Light ........................................................ 9

Warming Element (Infinite Switch) ......................... 9

Surface Elements (Infinite Switch).......................... 9

Surface Elements (Dual Infinite Switch)................ 10

Control ................................................................. 11

Temperature Sensor............................................. 11

Ribbon Elements- Power Disconnected ............... 11

Ribbon Elements-Power Connected ..................... 11

Cooling Fan.......................................................... 11

High Limit Switch ................................................. 11

Disassembly Procedures

Disassembly Procedures for Models Listed

AKT3040F/E/S

AKT3650F/E/S ................................................. 12

Main Top Removal................................................ 12

Indicator Light Replacement................................. 1 2

Element Replacement.......................................... 12

Infinite Switch Replacement ................................. 1 2

Disassembly Procedures for Models Listed

CEC1536AAB/W/Q/C

CEC1430AAB/W/Q/C

JEC7430AAB/W

MEC4430BDB/W/Q.......................................... 12

Main Top Removal................................................ 12

Element Replacement.......................................... 12

Infinte Switch Replacement.................................. 12

Indicator Light Replacement................................. 1 2

Receptacle Replacement ..................................... 12

Disassembly Procedures for Models Listed

JEC8430ADB/W/F/N/S

JEC8536ADB/W/F/N/S

MEC5430BDB/W/S

MEC5536BAB/W/S .......................................... 13

Main Top Removal................................................ 13

Element Replacement.......................................... 13

Infinite Switch Replacement ................................. 1 3

Indicator Light Replacement................................. 1 3

Disassembly Procedures for Models Listed

JEC9530ADB/F/S

JEC9536ADB/F/S............................................. 13

Main Top Removal................................................ 13

Element Replacement.......................................... 13

Sensor Replacement............................................ 14

Limiter Replacement ............................................ 14

Infinite Replacement............................................. 14

Electronic Infinite Replacement............................ 14

Hi-Limit Switch Replacement ............................... 14

Indicator Light Replacement................................. 1 4

Cooling Fan Replacement .................................... 14

Appendix A

Installation Instructions ..........................A–1 — A–6

©2003 Maytag Appliances Company 16022159 Rev. 0 3

Page 4

Safety Information

!

As with all appliances, there are certain rules to follow

for safe operation. Verify everyone who operates the

cooktop is familiar with the operations and with these

precautions.

Use appliance only for its intended purpose as

described. Pay close attention to the safety sections of

this manual.

Recognize the safety section by looking for the symbol

or the word safety .

Recognize this symbol as a safety precaution.

!

WARNING

General

1. The cooktop must be installed and/or repaired by an

authorized installer or servicer .

2. Never use the cooktop for warming or heating the

room.

3. Do not store items on the cooktop. Items stored on

the cooktop can become too hot and melt.

4. Wear proper apparel. Loose fitting or hanging

garments should never be worn while using

cooktop.

5. Do not repair or replace any part of the cooktop

yourself unless it is recommended in this manual.

6. Flammable materials should not be stored near

cooktop.

7. Use only dry potholders. Moist or damp potholders

on hot surfaces may result in burns from steam. Do

not let a potholder touch an element. Do not use a

towel or a bulky cloth as a potholder.

!

WARNING

Surface Cooking

1. Use the proper pan size. Select utensils with flat

bottoms large enough to cover the element.

Undersized utensils will expose the element to direct

contact with clothing.

2. Never leave surface units unattended. Boilovers can

cause smoking and may ignite.

3. To reduce risk of burns, ignition of flammable

materials or spillage due to unintentional contact,

utensil handles must be turned inward and not

extend over adjacent surface.

4. Only certain types of glass, glass/ceramic, ceramic,

earthware, or other glazed utensils are suitable for

cooktop use. Unsuitable utensils may break due to

the sudden temperature change.

5. Clean cooktop with caution. To avoid steam burns,

do not use a wet sponge or cloth to wipe up spills on

a hot cooking area.

6. Do not place aluminum foil or foods packaged in

aluminum foil directly on element.

Safety Procedures

!

WARNING

To avoid risk of electrical shock, property damage,

personal injury or death; verify wiring is correct, if

components were replaced. V erify proper and

complete operation of unit after servicing.

Due to the nature of cooking, fires can occur as a

result of overcooking or excessive grease. Although a

fire is unlikely , if one occurs proceed as follows:

Surface Element Fires

1. Do not turn on the vent hood. The fan can spread

the flames.

2. If it is safe to do so, turn the surface element to

OFF. Turn off main electrical supply.

3. Smother the fire with nonflammable lid or use a

Class “ABC” or “BC” fire extinguisher. Do not use

water on a grease fire.

Installation and service must be performed by an

authorized installer, service agency or gas supplier.

4 16022159 Rev. 0 ©2003 Maytag Appliances Company

Page 5

Safety Information

Safety Practices for Servicer

Safe and satisfactory operation of electric cooktops

depends upon its design and proper installation.

However, there is one more area of safety to be

considered:

Before Installing

Installing the electric cooktop in compliance with local

electrical building codes results in proper operation and

consumer satisfaction with the cooktop.

Receiving Cooktop

• Inspect cooktop thoroughly at time of delivery.

• Immediately report any visible damage to carrier.

• Damage not discovered until after accepting delivery

can still be claimed by using a concealed damage

report form, available from the carrier’s agent.

All shipments, i.e., complete cooktop or parts, are

shipped at the buyer’s risk. Maytag responsibility ends

when the consignment is accepted by the carrier in

“good order.” Mayt ag supports damage claims by

supplying invoices, bills of loading and other

documentation as needed. Providing this assistance,

however , does not imply any responsibility for settling

claims.

• Do not deduct claims for loss or damage from the

invoice and do not withhold payment pending

adjustment of claims.

• Do not return any units or parts for credit without

written consent.

Unpacking

• Open the carton and slide cooktop out.

• Remove all literature packed with the cooktop and

place cooktop onto a protective flat surface.

• Avoid countertop damage by NOT sliding cooktop

across the countertop.

!

CAUTION

Do not store items of interest to children in cabinets

above cooktop. Children may climb on cooktop to

reach these items and become seriously injured.

Electrical Requirements

220-volt, 60 Hertz, individual circuit which is properly

grounded, polarized and protected by a circuit breaker

or fuse.

The neutral of this unit is grounded to the frame through

the solid copper grounding wire. If local conditions do

not permit grounding of the neutral, untwist or

disconnect the solid copper wire and connect the soild

copper wire to ground in accordance with local codes.

Connect the white neutral to the service neutral.

Electrical Connection

All wire connections must be in accordance with local

codes. Use National Electrical Code, ANSI/NFPA No.

70-Latest Edition in the absence of local codes.

A three-wire, single phase, 120/240 VAC 60 Hz, electric

system (properly circuit protected to meet local Codes of

NFPA No. 70) must be provided. The chart below

recommends the minimum circuit protector and wire

size if the appliance is the only unit on the circuit. If

smaller sizes of wire is used, the efficiency will be

reduced and a fire hazard may be created. It is

advisable that the elctrical wiring and hookup be

completed by a certified electrian.

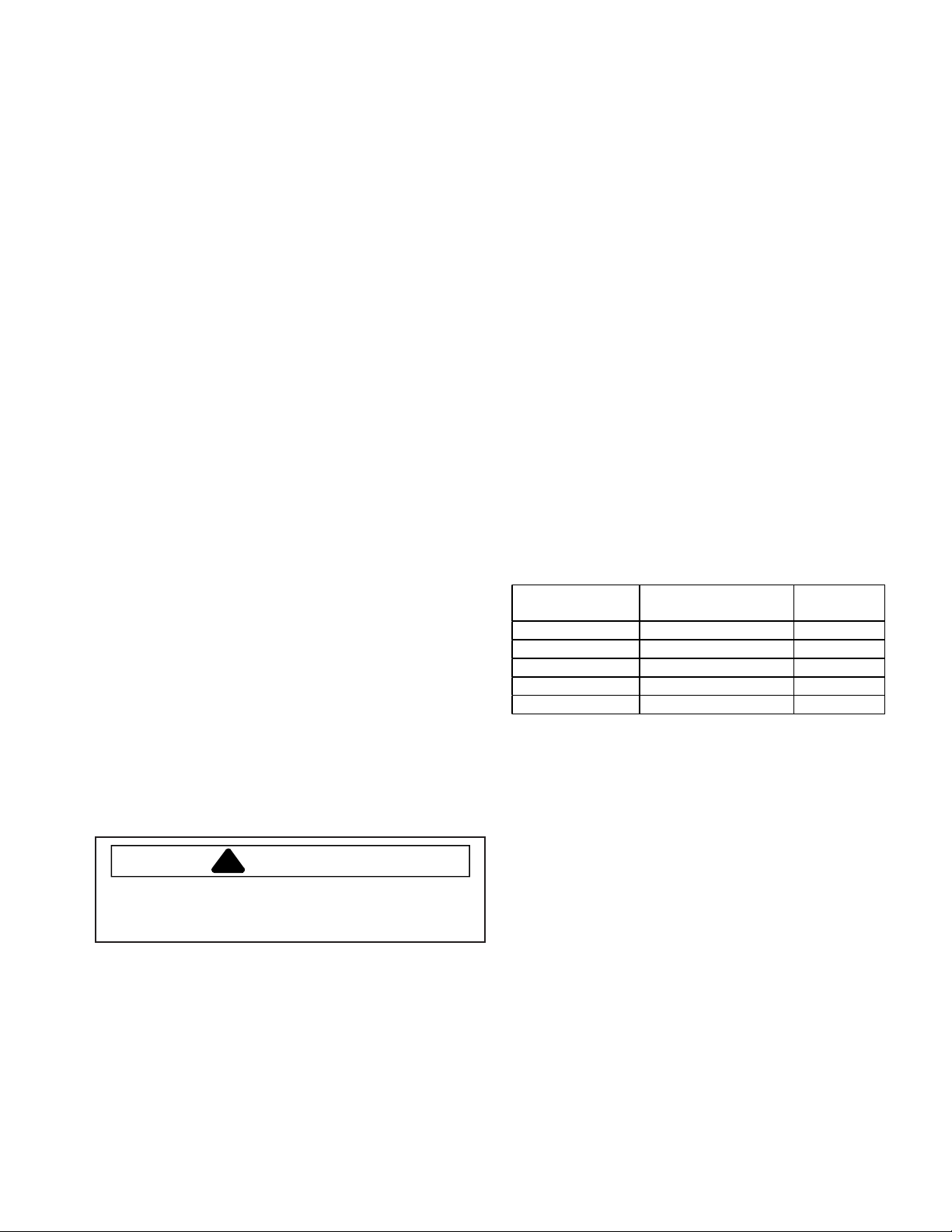

K.W. Rating

on Serial Plate

0–4.9 20 12

5.0 – 6.9 30 10

7.0 – 9.9 40 8

10.0 – 11.9 50 8

12.0 – 14.9 60 6

NOTE: The consumer is responsible for replacing any

wall receptacle with a grounded and polarized

outlet. A qualified electrician should check any

receptacle the customer doubts is properly

grounded. The wiring diagram is located on the

bottom of the cooktop.

Circuit Protection

in Amperes

Wire Size

(AWG)

©2003 Maytag Appliances Company 16022159 Rev . 0 5

Page 6

General Information

This manual provides basic instructions and suggestions

for handling, installing and servicing electric cooktops.

The directions, information, and warnings in this manual

are developed from experience with, and careful testing

of the product. If the unit is installed according to this

manual, it will operate properly and will require minimal

servicing. A unit in proper operating order ensures the

consumer all the benefits provided by clean, modern

Model Identification Rating Label and

Ordering Replacement Parts

Model numbers are recorded on the rating label. Rating

label is located on the bottom of the burner box. Before

ordering parts, write down the correct model and serial

number from rating label. This avoids incorrect

shipments and delays. Please refer to parts reference

material when ordering replacement parts.

cooking.

This manual contains information needed by authorized

service technicians to install and service electric

cooktops. There may be, however, some parts which

need further explanation. Refer to individual technical

sheets or the toll-free technical support line to answer

questions from authorized service technicians.

Cooking Nomenclature

MEC5536BAW

A AlmondonAlmond

Brand

AAmana

C Magic Chief

DDixieNarco

G Graffer & Sattler

HHardwick

J Jenn-Air

MMaytag

N Norge

U Universal

YCrosley

Fuel

B Butane

D DualFuel

E/J Electric

GGas

L Liquid Propane

MMicrowave

P Standing Pilot

XNoFuel

W Warming Drawer

Product Type

A Accessory/Cartridge

C Cooktop/Countertop

D Downdraft Cooktop&

Warming Drawer

E Eyelevel Range

GGrill

L Range (20")

M Range (36")

PDropIn

R Range, Free-Standing (30")

S Slide-In (30")

T Range Hood

VORT

WWallOven

Y RV Range

ZRVTop

Feature Content

1000-3999 Brands

4000-6999 Maytag / Amana

7000-9999 Jenn-Air

BBlack

C Brushed Chrome

FFrostWhite

H TraditionalW hite

L TraditionalAlmond

N Natural Bisque

P Prostyle

Q Monochromatic Bisque

S Stainless

T Tradition Bisque

WWhiteonWhite

F Sandstone

G Jade Green

MPlum

N TetonGray

R Gray Granite

ULapis

Listing

AUL/AGA

C CSA/CGA/CUL

DDualListed

G 220-240 V / 50-60 Hz

M Military Model

P PSB Approved

(Singapore)

X Export 120 V / 60 Hz

Production Code

This identifies which

version of production the

unit is.

Color

Crescent Cooktops

6 16022159 Rev. 0 ©2003 Maytag Appliances Company

Page 7

General Information

Model Identification

Complete registration card and promptly return. If

registration card is missing:

• For Amana product call 1-800-843-0304 or visit the

Web Site at www.amana.com

• For Maytag product call 1-800-688-9900 or visit the

Web Site at www .mayt ag.com

• For Jenn-Air product call 1-800-536-6247 or visit the

Web Site at www.jennair.com

• For product inCanada call 1-800-688-2002 or visit the

Web Sites at www.amana.com or www.maytag.com or

www.jennair.com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an

authorized servicer:

• For Amana product call 1-800-628-5782 or visit the

Web Site at www.amana.com

• For Maytag/Jenn-Air product call 1-800-462-9824 or

visit the Web Site at www.maytag.com or

www.jennair.com

• For product inCanada call 1-800-688-2002 or visit the

Web Sites at www.amana.com or www.maytag.com or

www.jennair.com

Warranty service must be performed by an authorized

servicer. We also recommend contacting an authorized

servicer, if service is required af ter warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. To order accessories for your product call:

• For Amana product call 1-877-232-6771 or visit the

Web Site at www.amana.com

• For Maytag/Jenn-Air product call 1-800-462-9824 or

visit the Web Site at www.maytag.com or

www.jennair.com

• For product inCanada call 1-800-688-2002 or visit the

Web Sites at www.amana.com or www.maytag.com or

www.jennair.com

Extended Service Plan

We offer long-term service protection for this new oven.

• Asure™ Extended Service Plan is specially designed

to supplement Amana’ s strong warranty. This plan

covers parts, labor, and travel charges.

Call 1-866-232-6244 for information.

• Dependability Plus

specially designed to supplement Maytag’s and

Jenn-Air’s strong warranty. This plan covers parts,

labor, and travel charges.

Call 1-800-925-2020 for information.

SM

Extended Service Plan is

©2003 Maytag Appliances Company 16022159 Rev . 0 7

Page 8

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to cooktop before servicing, unless

testing requires power.

Problems Solutions

Switch burns out immediately after

installation.

Element fails to heat; indicator light

glows.

Element too hot; no control of heat at

any setting.

Element too hot on HI setting only. Failed limit switch.

Erratic operation of surface elements. Loose or broken wiring.

Improper wiring installation Hot Wired to Neutral terminal.

Warranty is VOID.(SEE Installation Instructions.)

NOTE:

1. Element is burned out.

2. Failed limit switch.

3. Failed infinite switch.

Failed infinite switch or limit has welded contacts.

Possible damage to glass.

Indicator light remains on when control

is turned OFF or does not light when

control is turned ON.

Element making a humming noise. Caused by a 60 Hz AC current passing through element winding.

Runaway surface control. 1. Failed infinite switch.

Poor performance when unit is

installed.

Broken glass. Check for runaway surface control, faulty limit switch that could

Glass−ceramic heater is wavy or

uneven.

Red spots or lines visible through

glass−ceramic heater panel.

Performance of surface element is

poor.

Infinite switch or hot light switch failed:

NOTE:

Normal occurrence does not affect performance.

2. Improperly wired.

1. Knobs on surface controls indicating incorrect setting. (knob set

2. Improper wiring or switch installation.

have caused glass to break.

Manufacturing process gives glass−ceramic heater panel a slight

wave across surface.

This IS NOT a defect.

Glass−ceramic heater panels are slightly opaque. Element may

transfer a glow through a panel. This IS NOT a defect in the unit

and has no effect on performance.

1. See test procedures.

2. Make sure pans are flat on bottom.

In case where light does not light, could be failed indicator

light. Possible inductance voltage, separate indicator light

wires running parallel with power supply wires.

to HI control is actually set on LO.)

8 16022159 Rev. 0 ©2003 Maytag Appliances Company

Page 9

Component Testing Procedures

!

To avoid electrical shock, personal injury, or death: disconnect power supply before servicing, unless testing

requires it.

Power Supply

If no part of the cooktop operates or only part of it

operates, the cause may be a problem in the power

supply.

1. Verify supply circuit breakers or fuses are not tripped.

Check rating.

2. Disconnect power source. Check terminals at

terminal block for tightness.

3. Verify cooktop service wires are properly connected.

Be sure wires are in good condition. Check for proper

voltage with a voltmeter.

Internal Wiring

1. Disconnect power from cooktop.

2. Place one ohmmeter lead at the terminal block.

Place the other lead at the line terminal of the

non−functioning part. Meter should indicate

continuity.

Use the appropriate wiring diagram to repeat this

procedure from the output of the control to the next point

until each wire section is checked. Often a visual check

of the wiring will determine where a wiring fault is.

Indicator Light

1. If the surface unit operates normally but the indicator

lights do not glow, check for voltage at the indicator

light terminals.

2. If voltage is present at the indicator terminals and the

indicator does not glow, replace the indicator light.

3. If no voltage is present at the terminals, check for

loose connections or broken wiring.

Warming Element (Infinite Switch)

Power Connection

1. See schematic diagrams for assistance in testing

voltages in and out of control.

2. Connect a voltmeter to the element or the terminals

H1 and H2 of the surface warming control.

L1

P1

L2

H1

H2

WARNING

3. Turn control to LOW setting and allow it to cycle

approximately two minutes. Time the OFF and ON

cycle of the control and compare to the following

table based on a 60 second cycle.

SETTING APPROXIMATE SECONDS

TIME ON OFF

LOW 4 56

421 39

HIGH Constant 0

4. Replace the control if it is not cycling properly.

Calibration is not possible.

Resistance / Continuity

A malfunction in the internal switching may fuse the

cycling contacts. This causes the heating element to

operate at full power, at all control settings, while cycling

on element limiter.

1. Disconnect power from cooktop.

2. See “Disassembly Procedure“ to access switch.

3. Connect voltmeter test lead to H1 and H2 terminals.

4. Connect appliance to power source.

5. Set control to any setting. Meter should indicate

120 VAC volts. After allotted ON cycle, contacts

should cycle open and indicate 0 VAC.

Dial Position

Contacts OFF LO-MED HI

L1 – P O X X

L1 – H1 O X X

L1 – H2 O X – C X

H1–H2 X E X

O−Open X−Closed C−Cycles

E−Indicates resistance across internal

heater

Surface Elements (Infinite Switch)

Power Connection

1. See schematic diagrams for assistance in testing

voltages in and out of control.

2. Connect a voltmeter to the element or the terminals

H1 and H2 of the surface control.

3. Turn control to LOW setting and allow it to cycle

approximately two minutes. Time the OFF and ON

cycle of the control and compare these to the

following table.

©2003 Maytag Appliances Company 16022159 Rev. 0

9

Page 10

Component Testing Procedures

!

To avoid electrical shock, personal injury, or death: disconnect power supply before servicing, unless testing

requires it.

SETTING APPROXIMATE SECONDS

TIME ON OFF

LOW 3 20

MED 5 7

HIGH Constant 0

4. Replace the control if it is not cycling properly.

Calibration is not possible.

The surface units and controls offer infinite heat settings.

Controls must be pushed down before turning. All

surface controls are marked on the control panel for their

respective heating element. Infinite switch contacts

L1 - H1 and L2 - H2 provide power to the surface

elements.

Resistance / Continuity

A malfunction in the internal switching may fuse the

cycling contacts. This causes the heating element to

operate at full power, at all control settings, while cycling

on element limiter.

Check continuity on infinite switch contacts by using the

following steps.

1. Turn off power to cooktop.

2. See “Disassembly Procedure“ to access switch.

3. Remove all control panel knobs. Remove control

panel assembly.

4. Remove switch mounting bracket screws. Lift bracket

upward. The location of the switch terminals is shown

below.

TOP

PL1

L2

WARNING

Contacts OFF LO-MED HI

L1 – L2 O E X

L1 – P O X X

L1 – H1 O X X

L1 – H2 O X – C X

H1–H2 X E X

O−Open X−Closed C−Cycles

E−Indicates resistance across internal

heater

7. If any contacts fail continuity test, replace infinite

switch.

NOTE: During actual surface element operation,

contacts L2 - H2 will cycle to maintain the

correct heat setting. Contacts L1 - P provide

power to the surface element indicator light.

If the infinite switch contacts are good and the element

does not heat, check for voltage at the heating element

terminal plug block. A voltage of 240 V should be

indicated. If no voltage is indicated, check for a broken

wire or loose connection.

Dial Position

P1

L1

L2

Infinite Switch Schematic

H1

H2

Surface Element (Dual Infinite Switch)

The surface units and controls offer infinite heat settings.

Controls must be pushed down before turning. All

surface controls are marked on the control panel for their

H1

Infinite Switch Contacts

5. Remove wiring from switch.

6. Set ohmmeter on R x 1K scale. Check for continuity

according to the following chart.

H2

respective heating unit. Indicator ON light uses contacts

2 – 5, which must be closed before contacts 2 – 3 when

using the small burner. Also contacts 2 – 5 and 3 – 4

must be closed before contacts 2 – 3, when using the

small and large burner. Infinite switch contacts 2 - 3 and

3 - 4 provide power to the surface elements.

Check continuity on infinite switch contacts by using the

following steps.

1. Turn off power to cooktop.

2. See “Disassembly Procedures” to access switch.

10

16022159 Rev. 0

©2003 Maytag Appliances Company

Page 11

Component Testing Procedures

!

WARNING

To avoid electrical shock, personal injury, or death: disconnect power supply before servicing, unless testing

requires it.

4

N

5

TOP

16

Ribbon Elements−Power Disconnected

Small Element Continuity Test

1. Disconnect power from cooktop. Connect ohmmeter

leads to element terminals.

2. Meter should indicate continuity.

2

3

Large Element Continuity Test

1. Disconnect power from cooktop. Connect ohmmeter

leads to element terminals.

3. Remove wiring from switch.

2. Meter should indicate continuity.

4. If any contacts fail continuity test, replace infinite

switch.

L2

5

1

N

4

6

LOAD 2

LOAD1

Ribbon Elements−Power Connected

Performance Test

1. Set meter to measure at least 250 VAC. Connect

meter leads to element tabs.

2. Connect cooktop to power source.

3. Test element with no load (no pan on burner), turn

corresponding surface control to HI. Voltage should

indicate 240 VAC power supply voltage.

4. Element should glow after a few seconds. If it does

not glow check element resistance or continuity to

high limit/ hot light assembly.

L1

GROUND

2

SCHEMATIC

3

5. While element is heating, observe voltage and

If the infinite switch contacts are good and the element

does not heat, check for voltage at the heating element

terminal plug block. A voltage of 240 V should be

indicated. If no voltage is indicated, check for a broken

wire or loose connection.

element. Voltage should indicate 240 VAC power

supply voltage.

6. After a delay of approximately six minute

(±30 seconds), the high limit switch will open its

contacts and turn power off to the element. Observe

two complete cycles prior to setting surface control to

Dial Position

OFF position.

Contacts OFF Small Large

3-4 OFF OFF ON

2-3 OFF Cycle Cycle

2 - 5 OFF ON ON

Control

1. Verify power is applied to the input on the control.

2. Verify power is present at the output on the control.

3. If power is not present at input or output of the

control, replace control.

Temperature Sensor

Sensor resistance can be checked by disconnecting the

sensor leads from the control and connecting an

ohmmeter to the sensor. A resistance reading of

approximately 1100 ohms should be indicated at

ambient room temperature (75

If a resistance of 0 ohms or infinite ohms is indicated.

Replace the temperature sensor.

°

F).

Cooling Fan

Fan motor may come on at anytime to cool components.

1. Turn off power to unit.

2. See “Disassembly Procedures” to access motor.

3. Disconnect terminals to cooling fan.

4. Attach meter leads to terminals on the motor.

5. A resistance of ohms should be indicated

approximately 667 ohms, but may vary with each

motor tested. This test is to check the motor winding

for an open or shorted winding. If zero or infinite

ohms is indicated, the motor windings has failed and

the motor must be replaced.

High Limit Switch

1. Turn off power to unit.

2. See “Disassembly Procedures” to access switch.

3. Disconnect wires from switch terminal connections.

4. Attach meter leads to terminals on the switch. At

ambient room temperature (70

°

F), continuity should

be indicated.

©2003 Maytag Appliances Company 16022159 Rev. 0

11

Page 12

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to cooktop before servicing, unless

testing requires power.

Disassembly Procedures for Models Listed

• AKT3040F/E/S

• AKT3650F/E/S

Main Top Removal

1. Disconnect power to cooktop.

2. Remove cooktop from cutout and place on a

protected surface.

3. Remove control knobs from infinite switches.

NOTE: To remove knob(s), slide a rag under the knob

and pull upward.

4. Remove screws securing cooktop frame to burner

box frame.

5. Remove main top.

6. Reverse procedure to reassemble, verifying that

cooktop frame is properly aligned.

Disassembly Procedures for Models Listed

• CEC1536AAB/W/Q/C

• CEC1430AAB/W/Q/C

• JEC7430AAB/W

• MEC4430BDB/W/Q

Main Top Removal

1. Disconnect power to cooktop.

2. Remove elements, drip bowls, and knobs.

NOTE: To remove knob(s), slide a rag under the knob

and pull upward.

3. Remove screws securing main top to burner box.

4. Remove main top.

5. Reverse procedure to reassemble, verifying that

cooktop frame is properly aligned.

Element Replacement

Indicator Light Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing control mounting bracket to

burner box frame.

3. Disconnect and label wiring from indicator light.

4. Remove bolt and nut securing indicator light, if so

equipped.

5. Replace indicator light.

6. Replace indicator light and reverse procedure to

reinstall.

1. Disconnect power to cooktop.

2. Lift element and remove from receptacle.

3. Insert replacement element into receptacle.

Infinite Switch Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing infinite switch to main top

and remove switch.

3. Disconnect and label wiring to infinite switch.

4. Replace infinite switch and reverse procedure to

reinstall.

Element Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing element mounting bracket

to burner box frame.

3. Disconnect and label wiring to failed element.

4. Remove screws securing failed element from

element mounting bracket and replace element.

NOTE: Mark screw location on element to reassemble

correctly.

5. Replace element and reverse procedure to reinstall.

Infinite Switch Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing control mounting bracket to

burner box frame.

3. Replace control assembly .

4. Replace infinite switch and reverse procedure to

reinstall.

12 16022159 Rev . 0 ©2003 Maytag Appliances Company

Indicator Light Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Slide indicator light receptacle to the side to release

from lens.

3. Transfer wires from failed light to replacement light.

4. Reverse procedure to reinstall new indicator light.

Receptacle Replacement

1. Disconnect power to cooktop.

2. Remove screw securing receptacle to main top.

3. Replace receptacle and reverse procedure to

reinstall.

Page 13

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to cooktop before servicing, unless

testing requires power.

Disassembly Procedures for Models Listed

• JEC8430ADB/W/F/N/S

• JEC8536ADB/W/F/N/S

• MEC5430BDB/W/S

• MEC5536BAB/W/S

Main Top Removal

1. Disconnect power to cooktop.

2. Remove knobs from valve stems.

NOTE: To remove knob(s), slide a rag under the knob

and pull upward.

3. Remove cooktop from installation position and place

face down on protected surface.

4. Remove screws securing main top to burner box

bottom.

5. Remove screws securing control panel box and

conduit mounting plate to burner box assembly .

NOTE: Control panel box screws are located in front

center and conduit mounting plate screws are

located in rear left.

6. Remove main top.

NOTE: Make sure the pieces of insulation, located in

the front left and right rear corners, are put back

in place. Failure to do so could create

excessive cabinet temperatures.

7. Reverse procedure to reassemble, verifying that

cooktop frame is properly aligned.

Element Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing element clips to main top.

NOTE: Element clips are positioned at numbered

locations. If element clips are removed from

element, note the locations prior to removal.

3. Disconnect and label wiring to element.

4. Replace element and reverse procedure to reinstall.

5. Disconnect and label wiring to infinite switch.

6. Replace infinite switch and reverse procedure to

reinstall.

Indicator Light Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing mounting plate to main top.

3. Lift plate to gain access to indicator light.

4. Depress tabs securing indicator light to mounting

plate.

5. Disconnect and label wiring to indicator light.

6. Replace indicator light and reverse procedure to

reinstall.

Disassembly Procedures for Models Listed

• JEC9530ADB/F/S

• JEC9536ADB/F/S

Main Top Removal

1. Disconnect power to cooktop.

2. Remove knobs from valve stems.

NOTE: To remove knob(s), slide a rag under the knob

and pull upward.

3. Remove cooktop from installation position and place

face down on protected surface.

4. Remove screws securing main top to burner box

bottom.

5. Remove screws securing conduit mounting plate to

burner box assembly .

NOTE: Conduit mounting plate screws are located in

rear left corner.

6. Remove main top.

NOTE: Make sure the pieces of insulation, located in

the front left and right rear corners, are put back

in place. Failure to do so could create

excessive cabinet temperatures.

7. Reverse procedure to reassemble, verifying that

cooktop frame is properly aligned.

Infinite Switch Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing switch-mounting plate to

main top.

NOTE: An access panel is provided on the bottom of

the burner box for component diagnosis.

3. Lift plate to gain access to switch mounting screws.

4. Remove screws securing switch to mounting plate

and remove switch.

©2003 Maytag Appliances Company 16022159 Rev . 0 13

Element Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing element clips to main top.

NOTE: Element clips are positioned at numbered

locations. If element clips are removed from

element, note the locations prior to removal.

3. Disconnect and label wiring to element.

4. Replace element and reverse procedure to reinstall.

Page 14

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to cooktop before servicing, unless

testing requires power.

Sensor Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing element clips to main top.

3. Lower element and remove screws securing sensor

to element.

4. Disconnect wiring to sensor.

5. Replace sensor and reverse procedure to reinstall.

Limiter Replacement (Dual Element Only)

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing element clips to main top.

3. Lower element and remove screws securing limiter

to element.

4. Disconnect and label wiring to limiter.

5. Replace limiter and reverse procedure to reinstall.

Infinite Switch Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing mounting plate to main top.

Hi–Limit Switch Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing hi-limit switch to the

mounting plate and remove hi-limit switch.

3. Disconnect and label wiring to hi-limit switch.

4. Replace hi-limit switch and reverse procedure to

reinstall.

Indicator Light Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing mounting plate to main top.

3. Lift plate to access indicator light.

4. Depress tabs securing indicator light to mounting

plate.

5. Transfer wires from failed light to replacement light.

6. Reverse procedure to reinstall new indicator light.

Cooling Fan Replacement

1. Disconnect electricity to unit.

2. Remove knobs from valve stems.

NOTE: An access panel is provided on the under side

of the burner box for component diagnosis.

3. Lift plate to access switch mounting screws.

4. Remove screws securing switch to mounting plate.

5. Disconnect and label wiring to infinite switch.

6. Replace infinite switch and reverse procedure to

reinstall.

Electronic Infinite Switch Replacement

1. Remove main top, see "Main Top Removal"

procedure.

2. Remove screws securing mounting plate to main top.

NOTE: An access panel is provided on the under side

of the burner box for component diagnosis.

3. Lift plate to access switch mounting nut.

4. Remove nut securing switch to mounting plate.

5. Depress tabs securing switch from bottom side.

6. Disconnect and label wiring to infinite switch.

7. Replace infinite switch and reverse procedure to

reinstall.

NOTE: To remove knob(s), slide a rag under the knob

and pull upward.

3. Remove cooktop from installation position and place

face down on protected surface.

4. Remove screws securing bottom baffle to burner box

bottom.

5. Remove baffle to gain access to fan.

6. Remove screws securing cooling fan to burner box

bottom.

7. Disconnect and label wiring to cooling fan.

8. Replace cooling fan and reverse procedure to

reinstall.

14 16022159 Rev . 0 ©2003 Maytag Appliances Company

Page 15

Appendix A

©2003 Maytag Appliances Company 16022159 Rev. 0 A–1

Page 16

Installation Instructions

Installing Cabinetry Over Your Cooktop

A = 30" (76.2 cm) minimum clearance between the top of

the cooktop and the bottom of an unprotected wood or

metal cabinet.

A = 24" (60.96 cm) minimum when bottom of wood or

metal cabinet is protected by not less than 1/4" (0.635

cm). FLAME RETARDANT millboard covered with not

less than no. 28 MSG sheet steel, 0.015" (0.038 cm)

stainless steel, 0.024" (0.061 cm) aluminum or copper.

* To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches beyond the bottom of the

cabinets.

A*

Important Installation Suggestions

1. Chamfer all exposed edges of decorative laminate to

prevent damage from chipping.

2. Radius corners of cutout and file to insure smooth

edges and prevent corner cracking.

3. Rough edges, inside corners which have not been

rounded and forced fits can contribute to cracking of

the countertop laminate.

4. Countertop must be supported within 3" (7.62 cm) of

cutout.

CAUTION!

Warranty is void on equipment installed other than as

recommended by manufacturer.

Electrical Wiring Information

The neutral of this unit is grounded to the frame through

the solid copper grounding wire. If used on new branchcircuit installations (1996 NEC), mobile homes,

recreational vehicles, or in an area where local codes

prohibit grounding through the neutral conductor, untwist

or disconnect the solid copper wire and connect the

ground wire to ground in accordance with local code.

Connect the white neutral to the service neutral. Connect

all wires to the branch circuit with approved connectors.

Use copper or aluminum wire. If aluminum wire is used,

use connectors recognized for joining aluminum to

copper.

Proper Electrical Supply

You must provide an adequate electrical supply system

as required for your cooktop. All wire connections must be

in accordance with local codes and properly insulated.

Check with local utility for governing electrical codes and

ordinances. In the absence of local electrical codes, the

National Electrical Code, NFPA No. 70, governing electric

range installations must be followed.

A copy of the National Electrical Code, NFPA No. 70, can

be obtained by writing to:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

A three-wire, single phase, A.C. 120/240 volt 60 cycle

electrical system (properly circuit protected to meet Local

Codes of NFPA No. 70) must be provided. Unit must be

properly grounded in accordance with local wiring code.

The chart below recommends the minimum circuit

protector and wire size if the appliance is the only unit on

the circuit. If smaller sizes of wire are used, the unit

efficiency will be reduced and a fire hazard may be

created. It is advisable that the electrical wiring and

hookup be accomplished by a competent electrician.

K.W. Rating

on Serial Plate

0 – 4.9 20 12

5.0 – 6.9 30 10

7.0 – 9.9 40 8

10.0 – 11.9 50 8

12.0 – 14.9 60 6

Circuit Protection

in Amperes

Wire Size

(AWG)

A–2 16022159 Rev. 0 ©2003 Maytag Appliances Company

Page 17

Installation Instructions

Junction Box Connection

Junction box is not supplied with cooktop. Junction box

must be U.L. or C.S.A. listed and meet NEC and Mobile

Home Manufactures Association Standards.

• Three-wire conductor junction box allowed for residental

usage in United States.

• Four-wire conductor junction box required in Canada

and for most mobile home installations, but can be

used for residental.

• Refer to local, municipal, and stae building codes.

NOTE: A power cord must not be used.

Red House

Wire

Black

House Wire

Red

Cooktop Wire

Black

Cooktop Wire

3 - Wire Electrical Installation

United Sates Only

Red House

Wire

Black

House Wire

Red

Cooktop Wire

White

House Wire

White

Cooktop Wire

Green

Cooktop Wire

Green

House Wire

White

House Wire

White

Cooktop Wire

Notice To Installer

Follow accompanying instruction carefully.

CAUTION!

Never use a metal blade to pry knob off. If knob cannot

be easily removed, tuck folds of a dish- towel under

knob skirt and pull upward with steady, even pressure.

Preparation Of Countertop

The cutout in the countertop into which the appliance is to

be installed should be prepared according to the cutout

dimensions given on page 1 of these instructions.

CAUTION!

Cutout dimensions are critical. Dimensions must be

measured and cut accurately to within + 1/16" (.16 cm)

to insure proper fit.

Installation Of Appliance

1. Remove the cooktop from the carton and place it

upside down over two soft pads making sure control

knobs do not interfere with any surface.

2. Provide cutout in countertop.

3. Place unit in the cutout.

4. Make electrical wire connection to unit. Consult local

codes for proper power hook-up.

5. Test to insure control knobs operate all elements

properly.

Refer to the following Installation Instructions for

detailed information on installing units.

• AKT3040* and AKT3640* – 8101P469

• CEC1430AA, CEC1536AA, JEC7430AA, and

MEC4430BD – 8101P480

• JEC8430AD, JEC8536AD – 8101P503

• JEC9530AD, JEC9536AD – 8101P495

• MEC5430BD and MEC5536BA – 8101P478

Black

Cooktop Wire

4 - Wire Electrical Installation

United States or Canada

©2003 Maytag Appliances Company 16022159 Rev. 0 A–3

Green

Cooktop Wire

Page 18

Installation Instructions

This is the first page of the Installation Instruction (see part number listed in the bottom

right corner for complete set of instructions.

A–4 16022159 Rev. 0 ©2003 Maytag Appliances Company

Page 19

Installation Instructions

This is the first page of the Installation Instruction (see part number listed in the bottom

right corner for complete set of instructions.

©2003 Maytag Appliances Company 16022159 Rev. 0 A–5

Page 20

Installation Instructions

This is the first page of the Installation Instruction (see part number listed in the bottom

right corner for complete set of instructions.

A–6 16022159 Rev. 0 ©2003 Maytag Appliances Company

Loading...

Loading...