Page 1

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

Jet Clean II

Stainless Steel

Dishwashers

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Maytag

MDB8750AW

MDB9750AW

Jenn-Air

JDB1060AW

JDB1100AW

JDB2100AW

JDB2150AWP

16022783

January 2004

Page 2

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however , that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts,

testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBLITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.AMANA.COM ............................................... 1-800-843-0304

WWW.JENNAIR.COM ............................................ 1-800-536-6247

WWW.MAYTAG.COM............................................. 1-800-688-9900

CAIR Center in Canada.......................................... 1-800-688-2002

Amana Canada Product .......................................... 1-866-587-2002

WARNING

Recognize Safety Symbols, Words, and Labels

DANGER

!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

!

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16022783 Rev . 0 ©2004 Maytag Appliances Company

Page 3

Table of Contents

Important Information

Important Notices for Consumers and Servicers.... 2

Recognize Safety Symbols, Words, and Labels ... 2

Important Safety Information

General Information...............................................4

Related Publications.............................................4

General Precautions and Warnings.......................4

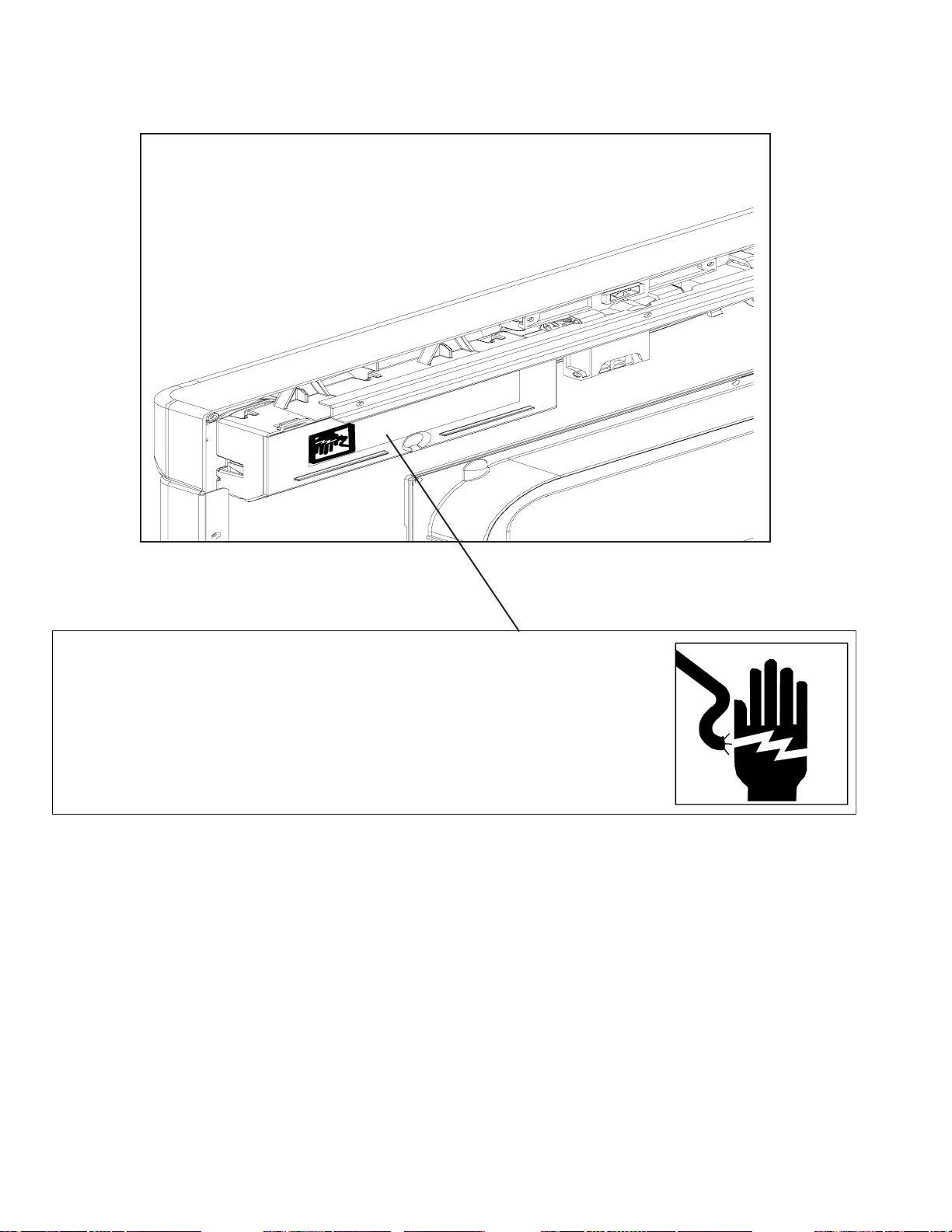

Product Warning Labels

Junction Box Warning...........................................5

Support Panel Warning.........................................5

Control Cover Warning ..........................................6

Electrical Equipment & Testing

Electrical T est Equipment .....................................7

Appliance T est Meter ............................................7

Continuity T esting .................................................7

Digital T est Meter..................................................7

Volt age Checks ..............................................8

Motor T est Cord ....................................................8

Grounding Polarity ................................................8

Electrical Tests

Water V alve ..........................................................9

Detergent / Rinse Aid Disp Wax Mtr Check ..........9

Cycles & Options

Cycles ................................................................10

Options............................................................... 11

Display ............................................................... 12

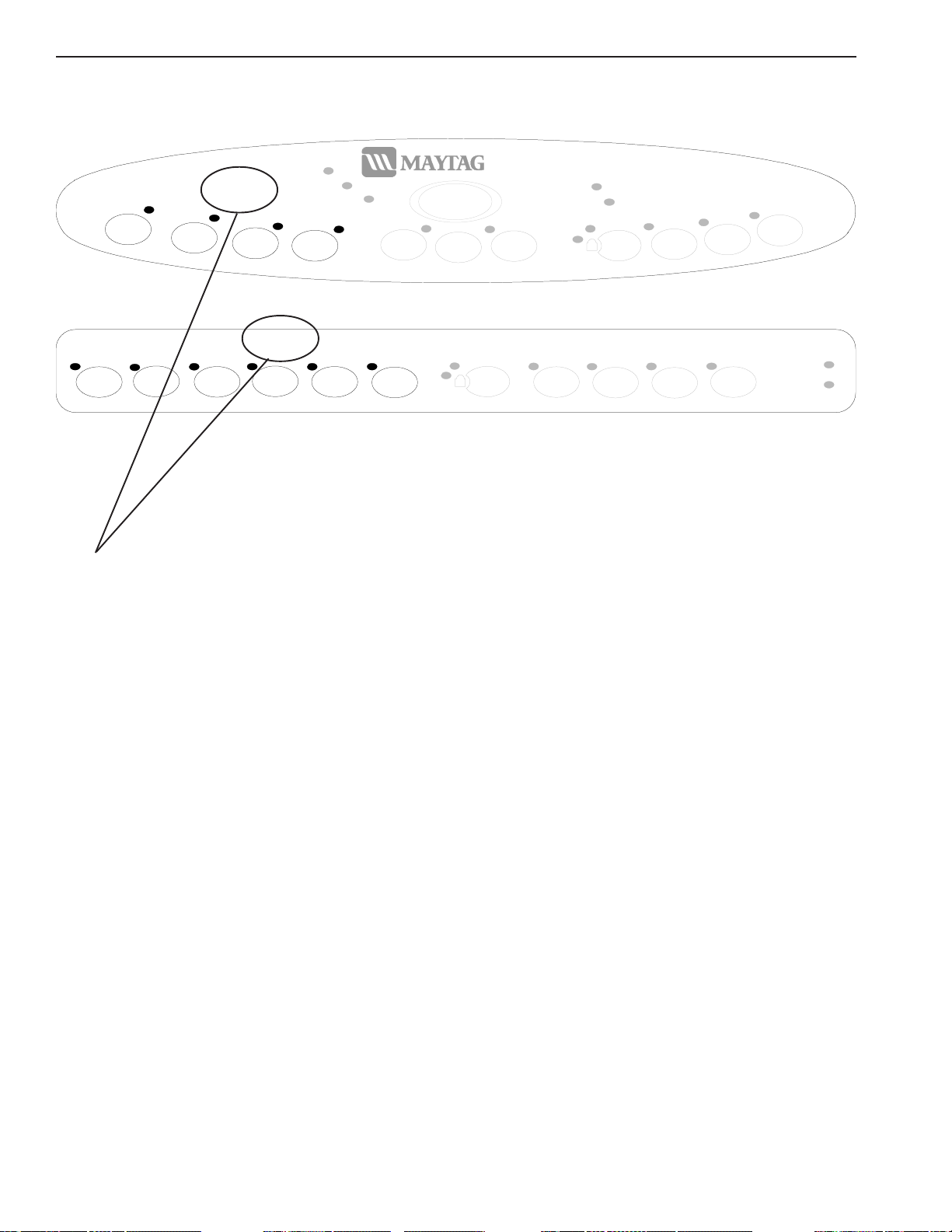

Control Style by Model........................................ 13

Troubleshooting

Will Not Fill......................................................... 15

Overflows ............................................................15

Poor Water Circulation........................................ 15

Poor Washability ................................................ 16

Will Not Drain ..................................................... 16

Continues to Drain ..............................................16

Poor Drying ........................................................ 16

Water Leaks .......................................................17

Noise ..................................................................17

Will Not Start or Program.................................... 17

Will Not Fill......................................................... 17

Will Not Wash .................................................... 18

Will Not Drain ..................................................... 18

Will Not Dry ........................................................18

Manual Function T est ......................................... 18

Field Service T est ............................................... 18

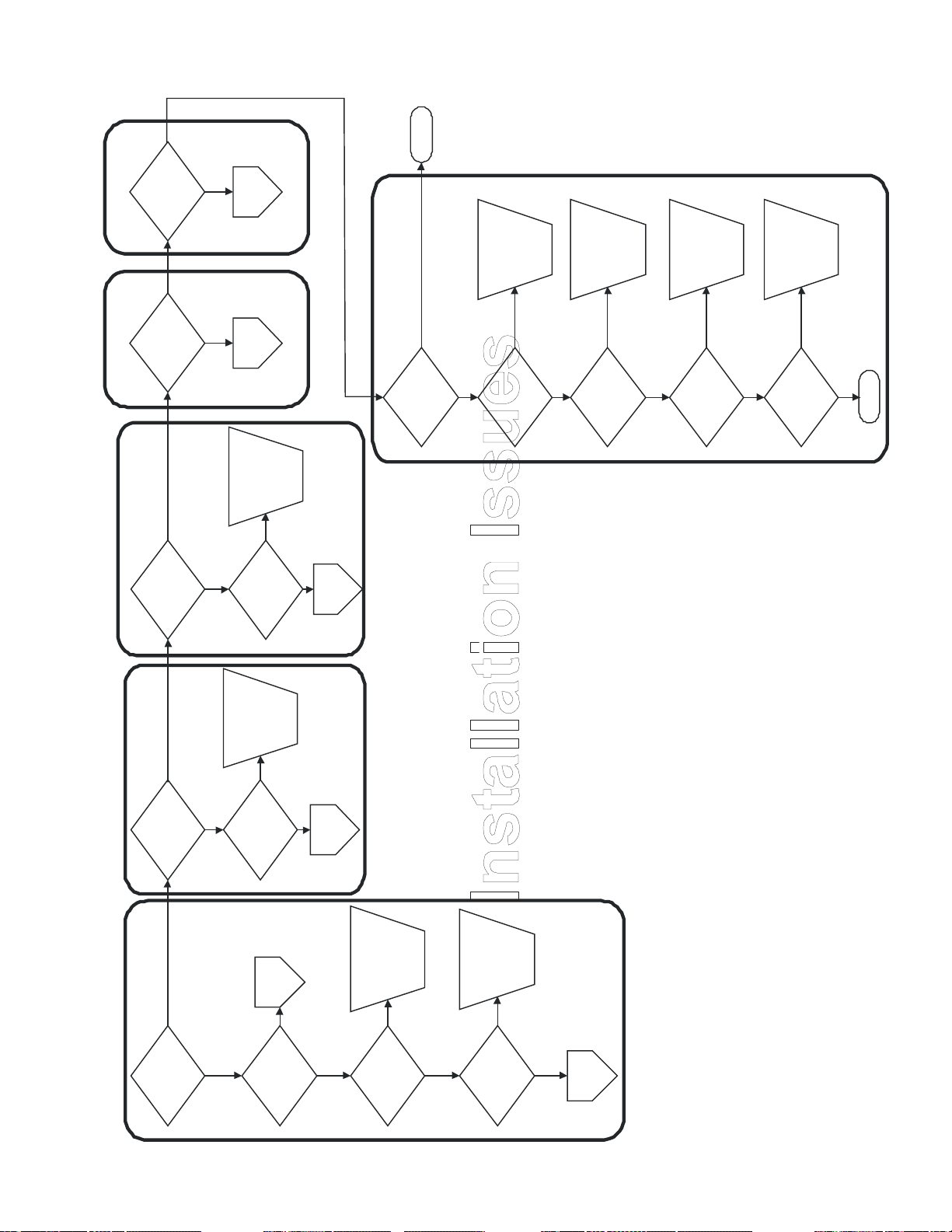

Troubleshooting Flow Chart

Installation Issues............................................... 19

Leak Issues Page 1 ............................................20

Leak Issues Page 2 ............................................21

No Function Operation Issues Page 1.................22

No Function Operation Issues Page 2.................23

Wash Performance / S taining Issues Page 1 ......24

Wash Performance / S taining Issues Page 2 ......25

Dry Performance Page 1..................................... 26

Dry Performance Page 2..................................... 27

Noise Issues Page 1...........................................28

Noise Issues Page 2...........................................29

Service and Disassembly Procedures

Front Support and T oe Panel Removal ................ 30

Inner Door Panel Removal ................................... 31

Detergent / Rinse Aid Disp..................................31

Wax Motor Detergent / Rinse Aid Disp................ 32

Vent....................................................................32

Wire Cover ..........................................................32

Door Latch & Switch Holder Assembly................ 3 3

PC Boar d............................................................ 3 4

T echnical Sheet ..................................................34

Control Panel ......................................................34

Door Latch Strike................................................ 34

Door Gasket ....................................................... 35

Outer Door.......................................................... 35

Door Hinge And Support ..................................... 36

Door Spring......................................................... 36

Door Spring And Component Replacement..........37

Over Pressure Filter ............................................37

T op W ash Arm.................................................... 3 7

Manifold ..............................................................38

Docking Station ..................................................38

Lower Wash Arm ................................................ 38

Float ...................................................................39

Heating Element .................................................40

Thermostats ....................................................... 41

Water V alve ........................................................ 41

Air Water Inlet and V ent......................................42

Upper Rack Removal ..........................................43

Tub Wheels ........................................................ 43

Turbidity Sensor..................................................43

Drain Pump ........................................................ 44

Wash Motor Assembly ....................................... 45

Appendix A

Installation Instructions ....................................... A-2

©2004 Maytag Appliances Company 16022783 Rev. 0 3

Page 4

Important Safety Information

WARNING

!

To avoid personal injury or death from improper

servicing, make sure you read and understand the

descriptions and meaning of various safety symbols,

words and labels used in this manual, before

attempting any procedures described in the manual.

Failure to understand and comply with safety

information may result in severe personal injury or

death.

General Information

This Service Manual describes the operation,

disassembly , troubleshooting, and repair of Maytag

Dishwashers. It is intended for use by authorized

servicer’s who troubleshoot and repair these units.

NOTE: It is assumed that users of this manual are

familiar with the use of tools and equipment used

to troubleshoot and repair electrical, and

mechanical systems; and understand the

terminology used to describe and discuss them.

®

Related Publications

This is a base service manual, covering a range of

similar models. It is intended to be used in conjunction

with the Parts Manual and Technical Sheet covering

specific model being serviced.

General Precautions and Warnings

• Dispose of discarded appliance and shipping or

packing material properly .

• Do not allow children to play in or on dishwasher.

• Do not abuse, sit, stand or play on door or racks of a

dishwasher.

• Use only detergents and rinse agents recommended for

use in a dishwasher.

• Store dishwasher detergent and rinse agents out of the

reach of children.

• If the dishwasher drains into a food disposer, make

sure disposer is completely empty before running

dishwasher.

• Repairs should be done by a qualified technician.

• Do not tamper with controls.

• Do not touch the heating element during or immediately

after use.

• Load sharp knives with the handles up to reduce the

risk of cut-type injuries or damaging seal.

4 16022783 Rev. 0 ©2004 Maytag Appliances Company

To avoid risk of personal injury or death due to

electrical shock:

• Grounding wires and wires colored like grounding

wires are NOT to be used as current carrying

conductors.

• Standard accepted color coding for ground wires

is green or green with a yellow stripe.

• Grounding wires should not be removed from

individual components while servicing, unless

component is to be removed and replaced.

• Replace all removed grounding wires before

completing service.

To avoid death, severe personal injury, fire or

electrical shock when using dishwasher observe

the following:

• Observe all local codes and ordinances.

• Disconnect electrical power to dishwasher before

servicing.

• Connect dishwasher to a grounded metal,

permanent wiring system.

• DO NOT ground to gas line.

• DO NOT ground to cold water pipe if pipe is

interrupted by plastic, non-metallic gaskets, or

other insulating (non-conducting) materials.

• Check with a qualified electrician if you are not

sure this appliance is properly grounded.

• This dishwasher is designed to operate on

regular house current (120 V , 60 Hz). Use a

circuit equipped with a 15 ampere fuse or circuit

breaker. Use a 20 ampere fuse if dishwasher is

connected with a food waste disposer.

• Under certain conditions, hydrogen gas may be

produced in a hot water system that has not

been used for 2 weeks or more. HYDROGEN

GAS IS EXPLOSIVE. If hot water system has

not been used for such a period, before using

dishwasher, turn on all hot water faucet s and let

water flow from each for several minutes. This will

release any accumulated hydrogen gas.

HYDROGEN GAS IS FLAMMABLE. Do not

smoke or use an open flame during this time.

• Do not store or use combustible materials,

gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

• Do not wash plastic items unless marked

"dishwasher safe" or the equivalent. If not

marked, check with manufacturer for

recommendations. Items that are not dishwasher

safe may melt and create a potential fire hazard.

• To avoid entrapment and/or suffocation, remove

door or door latch mechanism from any

dishwasher that is discarded or not in use.

WARNING

!

WARNING

!

Page 5

Important Safety Information

PRECAUCIÓN:

Desconecte la

energía eléctrica

antes de darie

servicio.

ATENCIÓN:

Solamente use

conductores de

cobre. Use cables de

suministro adecuados

para 75° (167°F).

CAUTION:

Disconnect electr ical powe r

before servicing.

ATTENTION:

Use copper conductors only.

Use supply wires suitable for 75°C ( 167°F).

ATTENTION:

Débrancher de

l'alimentation électrique avant tout dépannage.

ATTENTION:

Utiliser des co nducteurs en

cuivre uniquement. Utiliser des fils

d'alimentatio n pouv an t su pporter une

température de 75°C (167°F).

GROUNDING: This unit must

be grounded in accordance with local

and/or national electric codes.

WARNING: The heating

element, drain pump, harness clip,

dispenser mount, and water valve are

intentionally not grounded an d may

present a risk of electrical shock on ly

during servicing. Discharge motor

capacitior before servicing. Failure to

follow these instructions can result in

death, serious injury, fire, or electrical

shock.

MISE Á LA TERRE:

doit être re lié à la terre conformément aux

codes élec triques locaux et/ou nationaux.

AVERTISSEMENT: La résistance,

la pompe de vidange, l'atta ch e du hamais, l a

mont ur e de distributeur et l'éle ct r o v a nn e ne

sont pas reliés à la terre intentionnellement et

peuvent présenter des risques d'électrocution

uniquement en cas d'intervention de service

aprés-vente. Décharger le condensateur

avant toute intervention. Le non-respect de

ces consignes peut entrainer la mort, des

blessures graves, l'incendie ou l'électrocution.

Cet appareil

CONEXI ÓN A TIERRA:

unidad debe estar conectada a tierra de

acuerdo con los códigos eléctricos locales y

nacionales.

ADVERTENCIA: El elemento calentador,

la bomba de drenado, el sujetador del arnés,

el montaje del surtidor y la válvula de

agua están sin conectar a tierra

intencionalmente podrían presentar un riesgo

de desca r gas e léc t ric as cu ando se les da

servicio s olame nte. El no seguir estas

instrucciones podría causar la muerte, lesiones

graves, incendios o descargas eléctricas.

Esta

©2004 Maytag Appliances Company 16022783 Rev. 0 5

Page 6

Important Safety Information

l

e

c

t

r

o

n

i

q

e

u

c

e

e

e

s

s

s

c

t

o

d

n

e

s

l

i

g

a

c

n

t

r

e

ó

s

n

i

c

o

e

t

s

r

u

t

á

c

c

i

o

l

n

t

p

e

a

o

s

l

d

l

r

t

í

a

i

m

n

e

s

u

n

t

s

i

l

c

o

n

n

e

c

t

e

d

.

p

e

u

c

t

o

e

m

n

m

t

r

c

a

a

o

n

î

n

n

d

e

s

e

r

t

A

a

p

l

a

m

V

e

m

u

m

E

p

v

o

R

e

e

o

r

n

d

n

t

T

,

t

r

t

d

í

I

s

r

S

e

p

e

c

o

s

e

s

a

S

u

t

r

u

s

e

e

m

b

E

s

n

t

r

l

e

D

s

é

s

b

u

r

s

r

a

e

t

n

s

e

c

n

g

h

s

r

e

i

a

o

o

r

v

n

i

a

e

n

v

u

s

s

a

n

,

e

q

n

e

l

'

s

u

i

t

n

c

e

f

t

o

o

c

o

e

s

l

i

n

u

s

'

a

n

e

t

g

e

p

l

'

d

c

a

r

p

t

a

i

i

p

e

e

n

a

e

v

p

t

r

o

e

l

e

e

a

a

d

u

s

r

i

v

r

l

e

,

e

e

l

e

n

s

'

i

n

i

n

q

n

e

l

c

é

e

d

c

u

o

t

l

c

r

s

e

e

i

e

é

g

o

n

t

o

c

n

b

í

n

p

e

s

i

t

d

t

r

r

a

.

o

c

e

a

o

i

d

t

n

L

o

w

n

a

c

t

a

d

s

é

c

r

u

e

e

e

b

h

l

t

r

s

c

o

s

a

i

r

o

a

é

o

b

c

d

d

a

m

.

e

n

e

o

n

e

e

n

L

.

n

f

n

c

m

a

n

d

e

-

r

é

e

s

p

e

d

c

e

t

n

d

s

a

c

t

o

e

n

u

t

r

r

o

l

e

l

e

r

e

s

t

a

s

d

e

i

e

n

e

l

s

r

c

g

o

i

z

n

e

t

r

d

o

a

c

a

l

s

h

o

o

w

c

e

k

r

.

i

s

d

i

s

o

h

e

e

d

r

e

c

r

e

s

é

r

a

e

c

n

a

g

s

.

r

o

t

r

a

o

í

s

l

u

L

e

g

n

a

n

e

l

e

t

a

l

s

e

r

a

c

i

s

s

v

e

n

l

o

i

e

é

e

r

c

c

n

c

v

d

i

n

o

l

t

é

t

n

i

e

c

r

e

n

r

c

g

o

a

i

r

i

g

c

t

o

.

l

t

h

a

r

m

í

i

.

E

a

c

,

.

E

l

a

a

.

s

E

e

s

l

y

L

e

l

c

.

o

t

r

r

n

r

i

e

o

s

o

o

m

u

c

n

s

s

a

i

e

c

a

p

i

i

g

n

c

n

a

u

o

j

u

c

a

i

n

r

i

c

t

t

y

t

o

r

i

,

o

v

r

f

e

e

l

i

r

i

s

e

s

a

,

f

t

o

e

r

r

e

e

l

l

e

e

c

c

t

t

r

r

i

i

c

a

l

p

a

M

a

e

e

s

n

r

n

o

u

i

o

n

à

:

m

D

s

i

o

n

e

u

é

s

d

h

a

c

s

o

t

n

a

n

e

t

i

o

n

s

a

c

c

i

t

o

r

r

E

e

l

g

s

a

A

c

i

N

z

e

m

D

a

r

T

u

d

V

F

a

o

e

E

a

c

r

t

t

t

R

o

i

i

l

e

u

v

d

,

r

o

T

p

o

e

l

s

e

E

o

d

e

t

w

o

N

l

e

e

t

f

s

C

i

W

o

r

e

p

l

i

m

I

l

A

s

o

A

p

w

d

R

:

o

i

D

s

t

N

i

h

s

c

e

o

I

N

s

n

e

n

G

e

i

n

:

c

t

t

r

e

u

d

c

.

C

a

p

WARNING: Disconnect power before servicing. Electronic control is energized at all times until

power is disconnected. Capacitors on control may remain active after electrical power is disconnected.

Failure to follow these instructions can result in death, serious injury, fire, or electrical shock.

ADVERTENCIA: Desconecte la energí antes de darle servicio. El control electrónico está

energizado todo el tiempo hasta que se desconecta la energía. Los capacitores del control podrían

permanecer activos después de desconectar la energía eléctrica. El no seguir estas instrucciones

podrí causar la muerte, lesiones graves, incendios o descargas eléctricas.

AVERTISSEMENT: Débrancher avant toute intervention. La commande électronique est

constamment sous tension à moins que l'appareil ne soit débranché. Les condensateurs de la

commande peuvent rester sous tension une fois l'appareil débranché. Le non-respect de ces consignes

peut entraîner la mort, des blessures graves, l'incendie ou l' électrocution.

6 16022783 Rev. 0 ©2004 Maytag Appliances Company

Page 7

Electrical Equipment & Testing

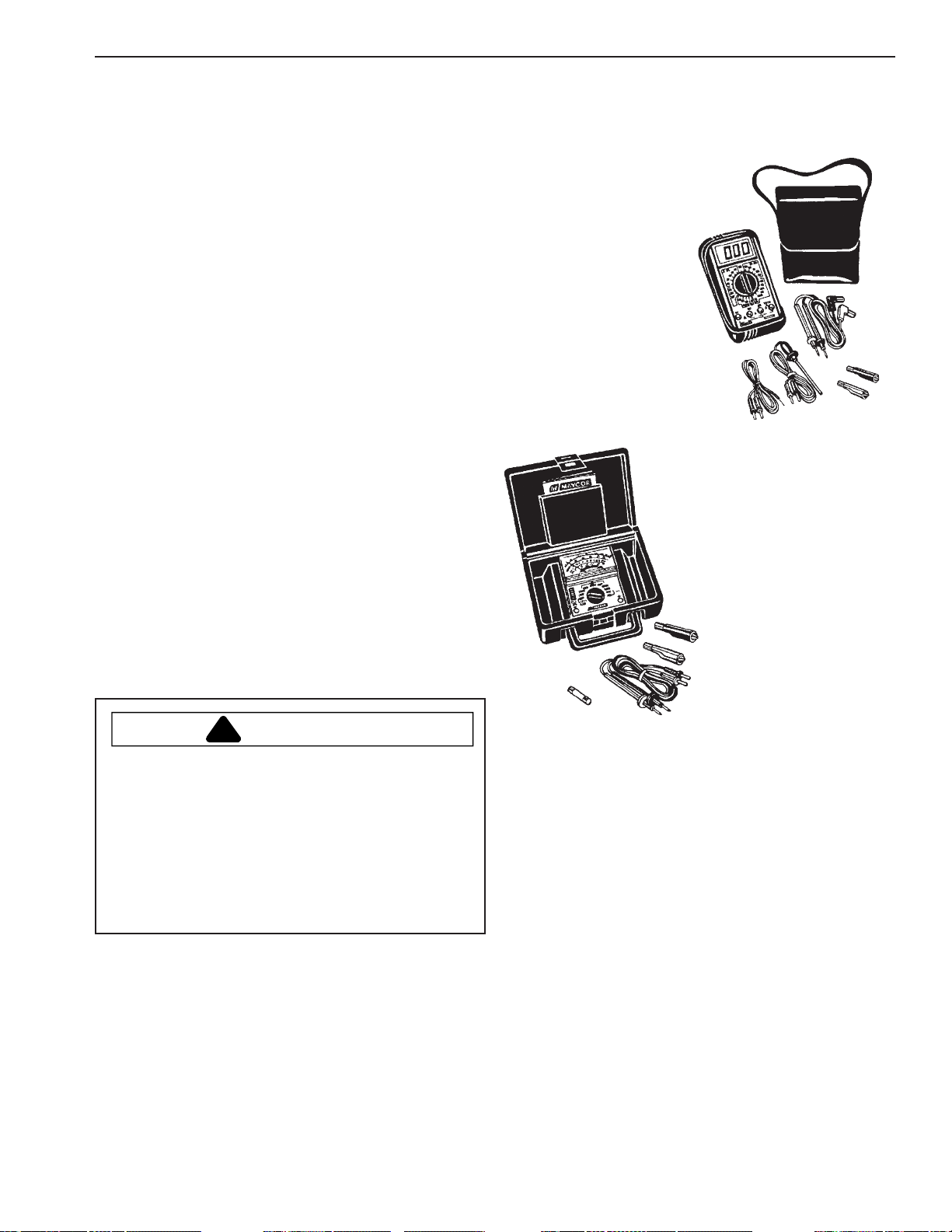

Electrical T est Equipment

The equipment required to service these models depends

largely upon the condition encountered. Locating a

malfunction will often require the use of electrical testing

equipment such as:

Appliance T est Meter

Clamp-On Ammeter

Motor T est Cord

Appliance T est Meter

An Appliance Test Meter is a multi-purpose tester

combining an AC/DC volt age tester with a multi-range

ohmmeter.

The easiest means of testing electrical components is

"Continuity Testing" with an appliance meter. Continuity

is a complete or continuous path from one point in an

electrical circuit to another.

Digital Test Meter

can be used to check for open

or closed circuits, measure

resistance, AC and DC volts,

and temperature.

Analog T est Meter

can be used to check for

open or closed circuits,

measure resistance, AC and

DC volts, and temperature.

The obvious advantages of being able to check electrical

components and circuits without power applied is one of

the features of the Ohmmeter. Multiple ranges allow

accurate determination of resistances of both single

components and entire circuit paths. Resistance is

measured in "Ohms."

WARNING

!

T o avoid risk of personal injury or death due to

electrical shock:

Always be sure the power has been disconnected

before making resistance measurements. Failure to

do so will also result in damage to your meter!

Internal batteries provide all the power needed to

make resistance checks. They should be checked

at least once a year and replaced as needed.

Continuity T esting: is a process of eliminating electrical

components involved in a given function of the appliance,

until the inoperative part is found. By reviewing the list of

possible electrical problems under a given condition, and

then performing appropriate continuity checks of the parts

involved, you should be able to locate the electrical

component which is inoperative.

NOTE: When checking components or circuit paths for

continuity , external wiring should be disconnected to

eliminate false readings through external paths. Isolate

what you want to test.

©2004 Maytag Appliances Company 16022783 Rev . 0 7

Page 8

ELECTRICAL EQUIPMENT & TESTING

VOLTAGE CHECKS

Generally , these checks will consist of taking readings

at the wall receptacle in order to determine the

availability of voltage to the product. V oltage checks on

individual components of a product are not

recommended due to the possibility of electrical shock.

Component part testing is best accomplished through

continuity checks with an Appliance Test Meter.

NOTE:

indicated range may cause permanent damage to the

meter. T o prevent damage, first select highest range and

then lower the range for readings which fall within the

lower scale.

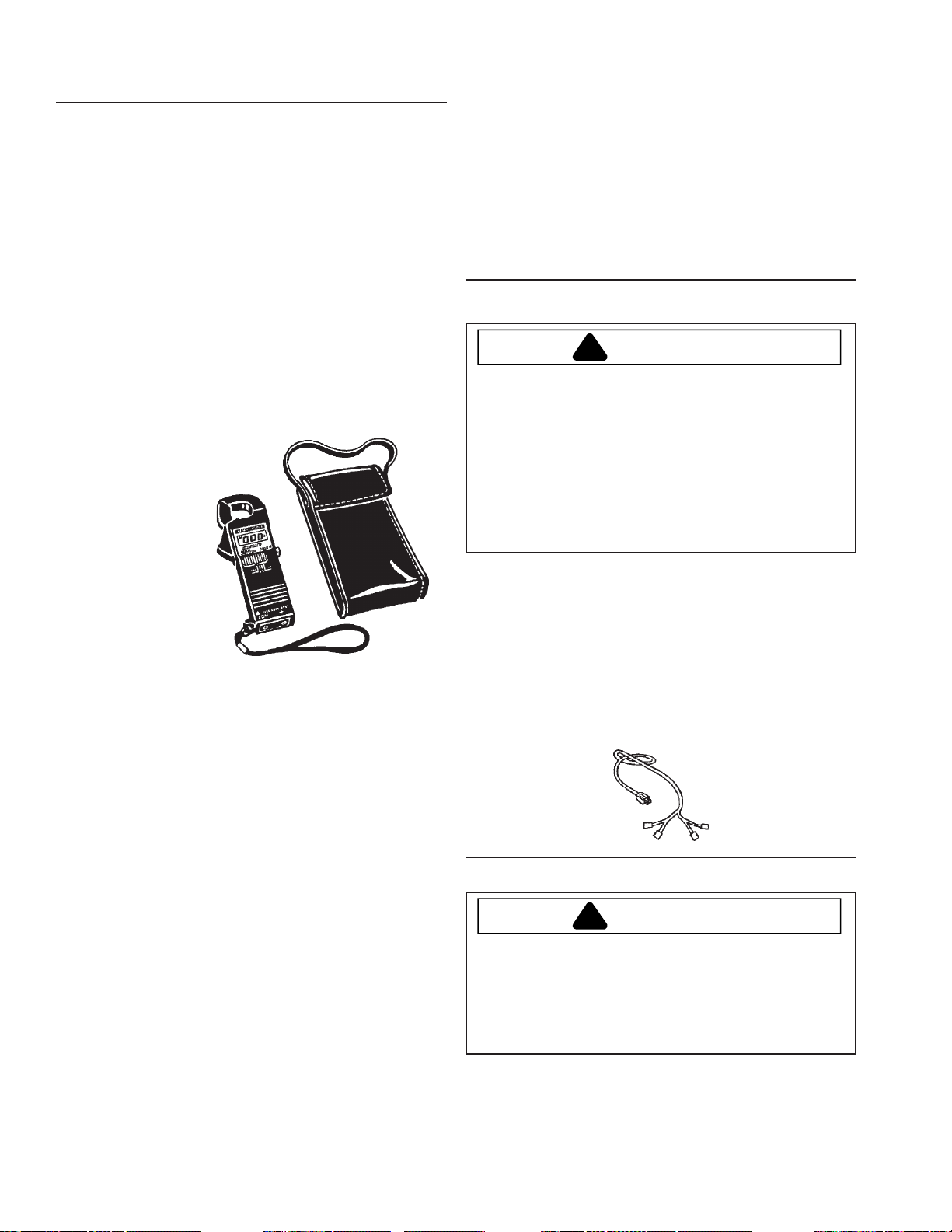

Clamp-On Ammeter

can be used to detect shorts.

Overloads on the circuit breaker

or fuse can be traced

to either the appliance

or circuit breaker by

checking the current

draw.

Each circuit in an appliance has a "Normal" current

draw, which is an indication of the performance of that

circuit. Current draw levels of less than or more than

normal give clues to possible malfunctions. The clampon ammeter measures these circuits without breaking

the circuit by measuring the strength of the magnetic

field developed around each conductor. Current is read

by separating the conductors and clamping the jaws of

the ammeter around each conductor on which current is

read. Low amperage readings indicate problems, such

as damaged heating elements, etc. High amperage

readings indicate the unit being tested is operating under

an increased mechanical or electrical load.

NOTE: Overloads on a circuit breaker or fuse can be

traced to the product being tested or the circuit breaker

(or fuse) by checking the products current draw . If the

amperage reading is less than the breaker reading, the

breaker or fuse box is at fault.

Use of the meter on voltage higher than the

Use of Ammeter on dishwasher:

1. Motor Current - the reading can be taken at the

leads on the motor start relay or at the male connector.

2. Heating Element Current - The reading can be

taken using either lead to the element.

Motor Test Cord

DANGER

!

T o avoid risk of personal injury or death due to

electrical shock:

• Disconnect electrical power to dishwasher before

servicing.

• Always plug test cord into a properly grounded

receptacle.

• Always make connection to components before

plugging test cord into receptacle.

A motor test cord may be used to electrically check

operation of the various electrical components without

removing them from the unit. Testing in this manner

merely determines whether or not the part will function

independently of other electrical components. In order to

make accurate tests, proper connection of the motor test

cord is important. With the aid of the drawings under

Drive Motor Test, installation of the motor test cord may

be done quickly and accurately .

Grounding and Polarity

DANGER

!

T o avoid risk of personal injury or death due to

electrical shock:

• Do not cut or remove the grounding prong from any

plug.

The receptacle used for all Maytag products operating on

120 V AC must be properly grounded and polarized.

The power cord used on the appliances should be

equipped with a three (3) prong polarized grounding plug

8 16022783 Rev. 0 ©2004 Maytag Appliances Company

Page 9

Electrical Equipment & Testing

for protection against shock hazard and should be

plugged directly into a properly grounded and polarized

receptacle.

It is the responsibility of the person installing the

appliance to assure it is adequately grounded and

polarized at the point of installation, taking into

consideration local conditions and requirements. In

cases where only a two (2) prong receptacle is available,

it is the personal responsibility of the consumer to have it

replaced with a properly grounded three (3) prong

receptacle. All grounding and wiring should be done in

accordance with National, State, and Local codes.

NOT USE AN ADAPTER PLUG WITH THIS

APPLIANCE.

DO

ELECTRICAL TESTS

WARNING

!

T o avoid risk of personal injury or death due to

electrical shock:

Wax Motor Check

Detergent / Rinse Aid Dispenser

A single Wax Motor is used to activate both the release of

the Detergent Cup Cover and the rinse aid from the

reservoir.

T o check the operation of the W ax Motor, removal from

the Dispenser Retainer or Inner Door is not necessary .

First, snap the Detergent Cup Door shut. Then, connect

a Power Test Cord across the two terminals of the Wax

Motor. Plug the Power Test Cord into a 120 VA C

receptacle. The plunger in the center of the Wax Motor

should "push out" and actuate the Dispenser in

approximately 45-60 seconds. Remove voltage to the

Wax Motor and allow the plunger to retract into the Wax

Motor. Apply voltage to the W ax Motor again and observe

for proper lifting of the rinse aid plunger .

• Disconnect electrical power to dishwasher before

servicing.

• Always plug test cord into a properly grounded

receptacle.

• Always make connection to components before

plugging test cord into receptacle.

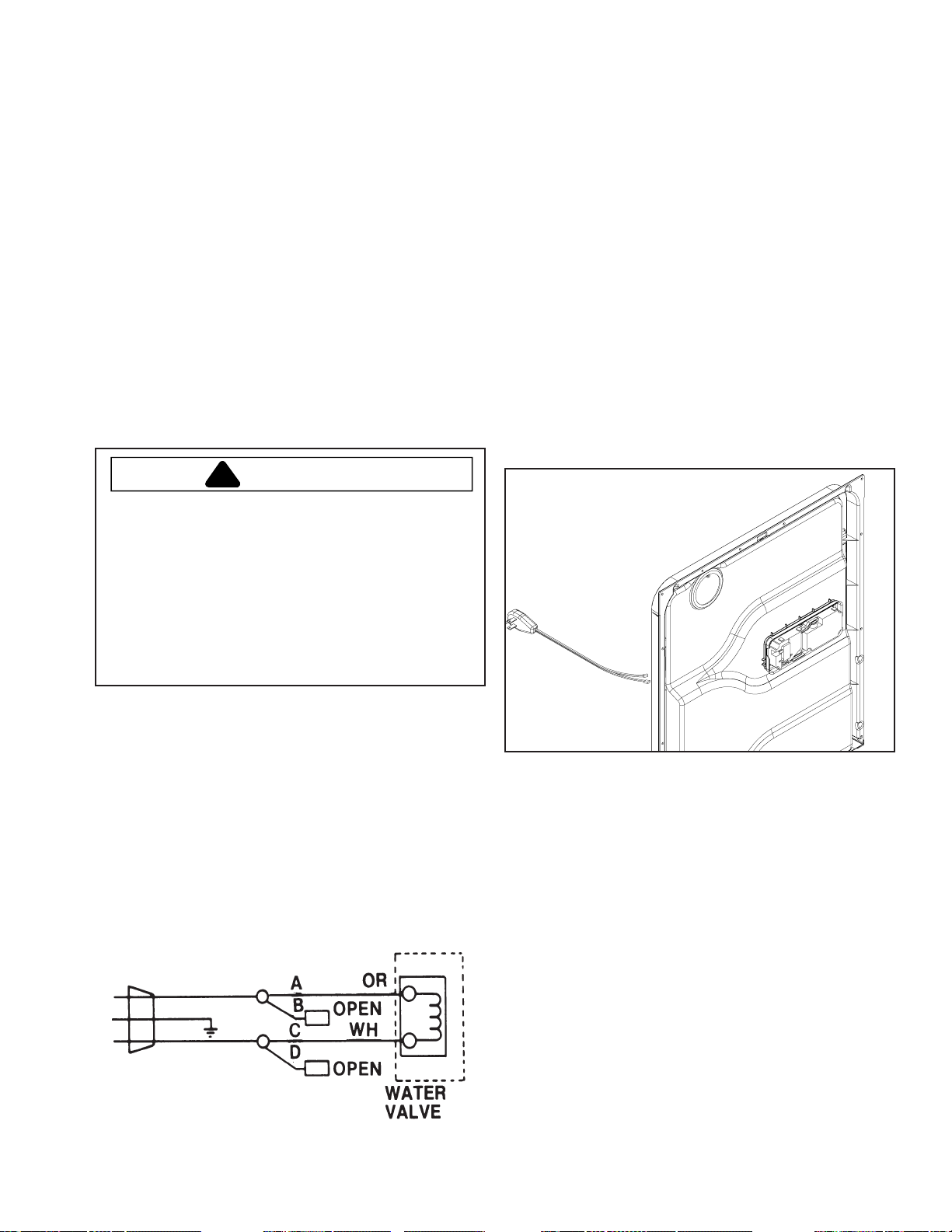

WATER VALVE TEST

The Water V alve may be checked without removing it from

the Dishwasher.

T o check the W ater V alve for operation, hook up the test

cord as follows:

©2004 Maytag Appliances Company 16022783 Rev . 0 9

Page 10

Cycles & Options

QuietSeries 300

Cancel

DELAY

1-9

Heatin g D e l ay

Sanitized

3

Heated

Dry

Options

Sanitize

Tough

Scrub

Extra

Rinse

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

Washing

Rinse

Only

Drying

Clean

Auto

Clean

START/

Covers all other models

Auto

Clean

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

Rinse

Only

Quick

Wash

3

Heated

Dry

Sanitize

Options

Extra

Rinse

Tough

Scrub

Plus

160°

Wash

Clean

Sanitized

MDB9750 Only

See User's Guide for specific operation.

Cycle Description

Auto Clean Designed to auto select the number of fills and length of wash time based on soil level

of the dish load. Water usage ranges from 3 to 8 gallons.

Heavy Wash Designed to provide a longer cycle for washing items with heavy

food soils. Water usage is 8 gallons.

Normal Wash Designed to wash loads containing dishes with normal amounts of food soils.

Water usage ranges from 3 to 6 gallons.

Light Wash Designed to wash loads containing dishes that are lightly soiled. Water usage is 5

gallons.

Quick Wash Designed for light food soils. The cycle ends with a rinse and does not include drying.

Water usage is 4 gallons.

Rinse Only Rinses dishes being held until the dishwasher is full, and another

cycle is selected. This cycle helps reduce the potential for development of odors.

Water usage is 2 gallons.

10 16022783 Rev . 0 ©2004 Maytag Appliances Company

Page 11

Cycles & Options

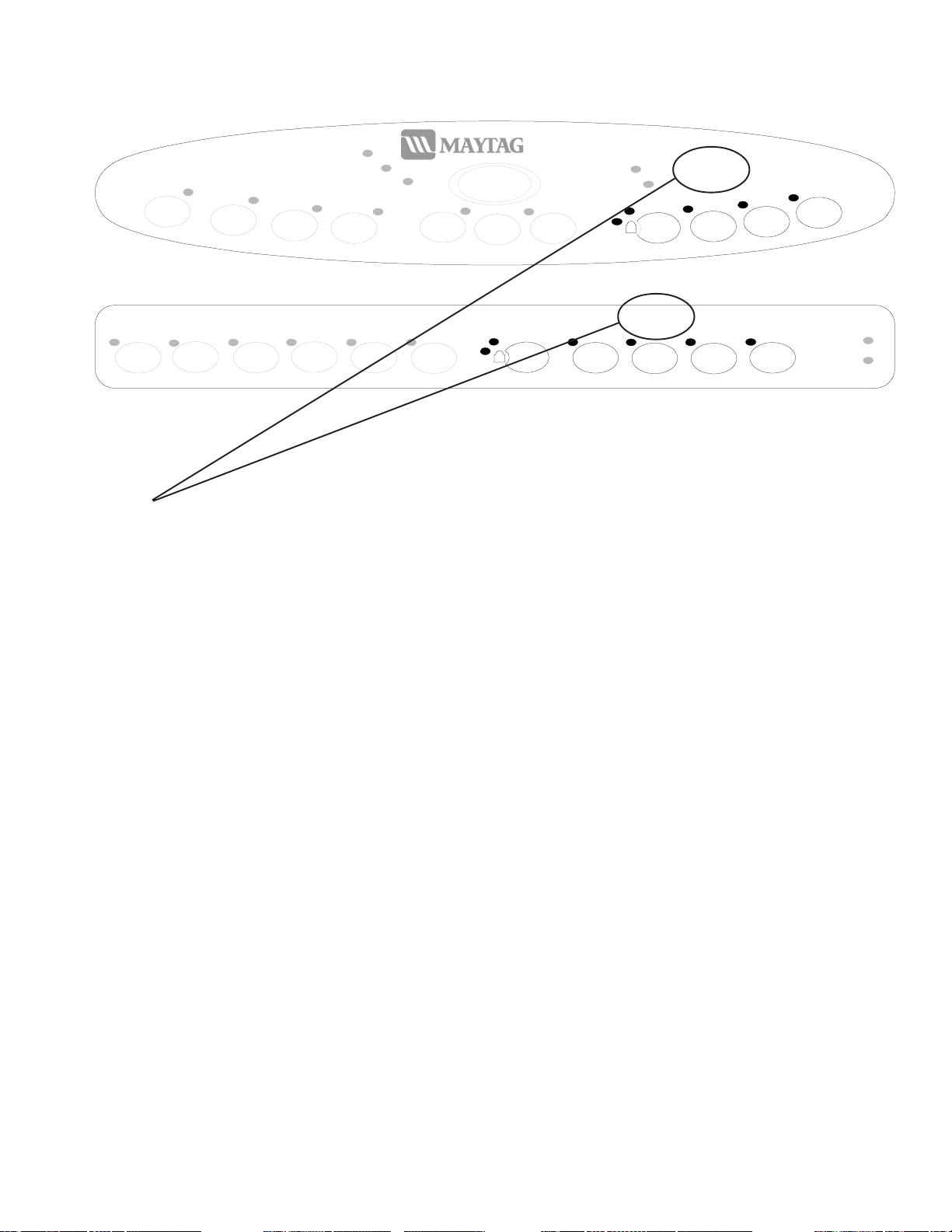

QuietSeries 300

Cancel

DELAY

1-9

Heatin g D e l ay

Sanitized

3

Heated

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

Washing

Rinse

Only

Drying

Clean

Auto

Clean

START/

Covers all other models

Auto

Clean

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

Rinse

Only

Quick

Wash

3

Heated

Dry

Sanitize

Options

Extra

Rinse

MDB9750 Only

See User's Guide for specific operation.

Option Description

T ough Scrub™ This option adds fills, heat and/or wash time to the

T ough Scrub Plus™ wash cycle.

Dry

Options

Sanitize

Tough

Scrub

Plus

Tough

Scrub

160°

Wash

Extra

Rinse

Clean

Sanitized

Sanitize This option monitors cycles for sanitization.

Extra Rinse This option adds an extra rinse to the cycle which helps in hard water situations.

160° Wash This option raises temperature in the final rinse to 160° F.

Heated Dry This option improves drying results by turning the heating element on and off during

the dry portion of the cycle.

Delay Delays the start of the dishwasher based on user input.

Control Lock Lock's the control touch pads from unwanted usage. This option does not lock the

door.

©2004 Maytag Appliances Company 16022783 Rev . 0 11

Page 12

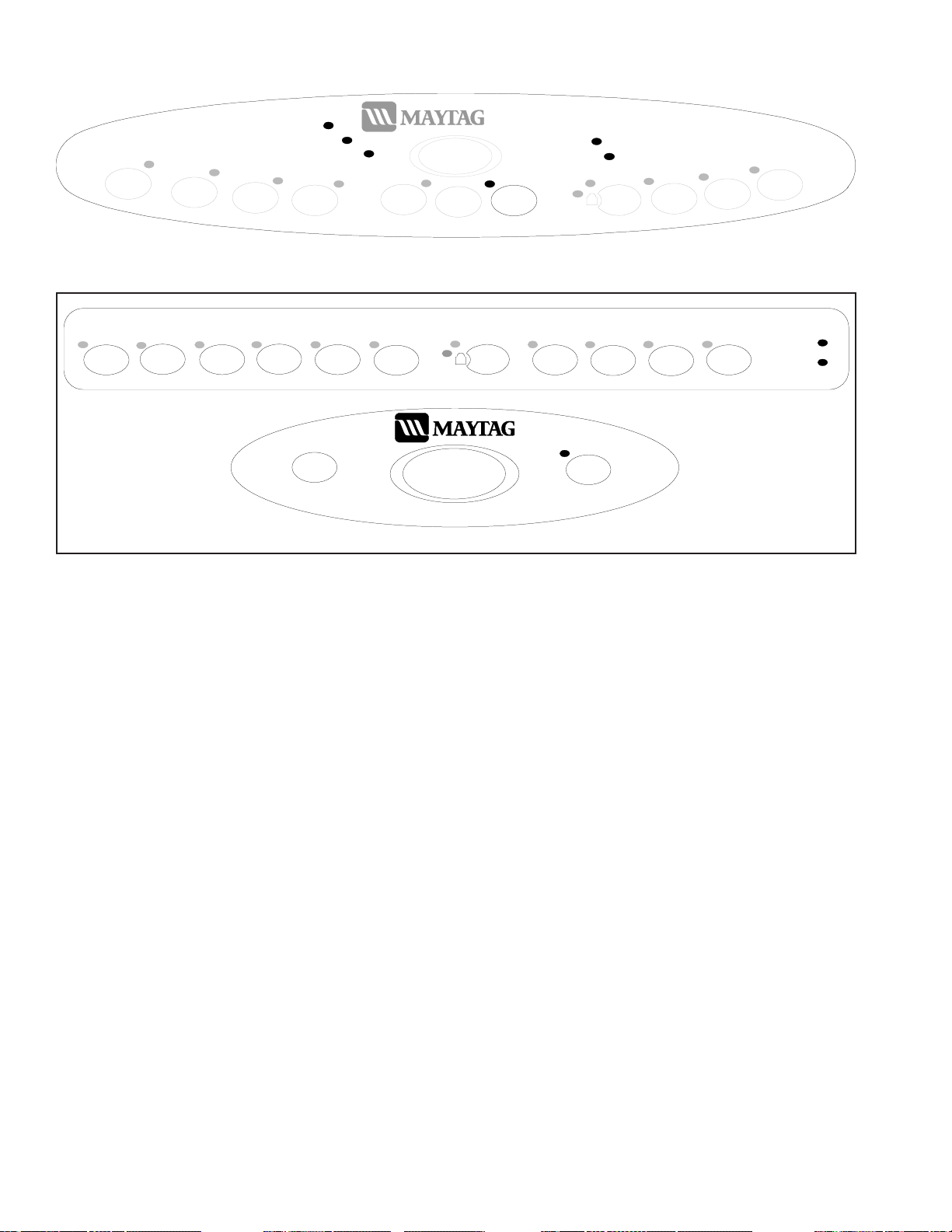

Cycles & Options

Auto

Clean

Heavy

Wash

Heavy

Wash

Normal

Wash

Cycles

Normal

Wash

Light

Wash

Cycles

Light

Wash

Washing

Rinse

Only

START/

Cancel

Drying

Rinse

Only

Clean

Auto

Clean

START/

Covers all other models

Quick

Wash

QuietSeries 300

QuietSeries 300

Cancel

Heated

3

Dry

DELAY

1-9

Heatin g D e l ay

Sanitized

Sanitize

DELAY

Heated

3

Dry

Options

Extra

Rinse

1-9

Options

Sanitize

Tough

Scrub

Plus

Tough

Scrub

160°

Wash

Extra

Rinse

Sanitized

Clean

MDB9750 Only

Display Description

Clean The "Clean" light illuminates at the end of the cycle and remains on until the door has

been open continuously for 30 seconds.

Drying The "Drying" light illuminates until the cycle is complete.

Washing The "Wash" light illuminates through all the rinse and wash portions of the cycle.

Heating Delay The "Heating Delay" light illuminates when the cycle is being extended to heat the

water.

Clean/Sanitized These two lights illuminate from the end of cycle until the next cycle is selected,

or the door has been open continuously for 30 seconds.

Delay The "Delay" light will illuminate whenever a delay count down is in progress, or until

the "Delay" pad is pressed again.

12 16022783 Rev . 0 ©2004 Maytag Appliances Company

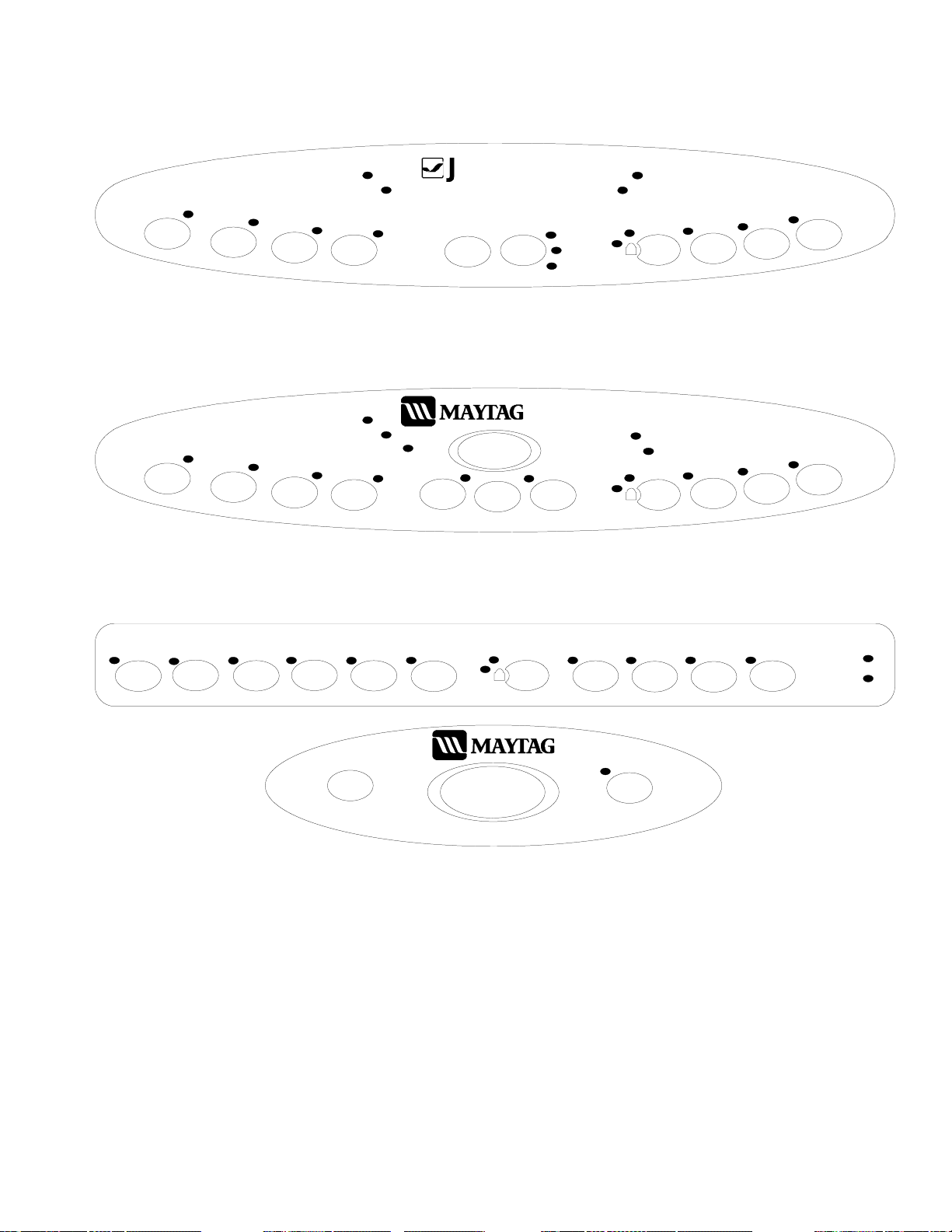

Page 13

Cycles & Options

Heavy

Wash

Heavy

Wash

Normal

Wash

Normal

Wash

Cycles

Light

Wash

Cycles

Light

Wash

Washing

Rinse

Only

Washing

Rinse

Only

Drying

Drying

Clean

ENN-AIR

START/

Cancel

JDB1060

Auto

Clean

START/

Cancel

MDB8750

2-4-6

2

4

6

DELAY

QuietSeries 200

Heatin g D e l ay

DELAY

1-9

Sanitized

Clean

Sanitized

3

3

Heated

Dry

Heated

Dry

Options

Sanitize

Options

Sanitize

Tough

Scrub

Tough

Scrub

Plus

Extra

Rinse

Extra

Rinse

Auto

Clean

Heavy

Wash

Normal

Wash

Cycles

Light

Wash

START/

Cancel

Rinse

Only

Quick

Wash

3

QuietSer ies 300

MDB9750

Heated

Dry

Sanitize

Options

Extra

Rinse

DELAY

1-9

Tough

Scrub

Plus

160°

Wash

Clean

Sanitized

©2004 Maytag Appliances Company 16022783 Rev . 0 13

Page 14

Electrical-Mechanical Troubleshooting

!

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

!

Units covered in this manual are polarized. Reversing polarity of a unit or any of its components will cause

damage. T o avoid reversing polarity , any wires disconnected or removed during service must be reconnected to the

same location. T o ensure wires are reconnected to the proper location, t ag or otherwise mark the wires before

disconnecting or removing.

Will Not Fill

Water Access Valve

Check to determine if the valve is turned on and water is

available to the Dishwasher. Check water pressure.

Circuit Breaker/Fuse

Check for tripped breaker or blown fuse. Reset or replace

as necessary .

Door Latch

Check door switches for continuity . With door switches

engaged, no continuity , replace switch.

Float

Check float position. If in the up position, check for

obstruction or disengagement from the Float Switch Arm.

WARNING

CAUTION

NOTE: Low water pressure can result in failure of the

Water V alve to close properly .

Float

Ensure that the Float isn't stuck in the down position.

Check for sediment buildup. Clean and/or replace as

necessary .

Float Switch Actuator Lever

Check the actuator lever on the bracket. It must be able

to move freely . Repair or replace as necessary . (See

section 5).

Float Switch

Check Float Switch for continuity with the Float in the up

position. If continuity is present and Float moves up and

down freely , replace Float Switch.

Float Switch

If the float is in the down position, check the switch for

continuity . If no continuity, replace the Float Switch.

Water Valve

Check Solenoid for continuity . No continuity , replace

Water V alve. Check Inlet Screen for restrictions. Clean

screen or replace Water V alve as necessary. (See section

5).

Wiring/Electrical Connections

Check for loose or frayed wire terminal connections.

Check for broken wire within harness. Repair or replace

as necessary .

Water Level - Too Low

Normal water fill should be at level depicted by arrows.

POOR WATER CIRCULATION

Overflows

Water Valve

Check that water continues to flow when electrical power

is turned off. If the water continues to flow without

electrical power, replace W ater V alve.

©2004 Maytag Appliances Company 16022783 Rev. 0 14

Pump Assembly

Check assembly for obstructions or restricted movement

of parts. Repair and/or replace part s as necessary .

Page 15

Electrical-Mechanical Troubleshooting

!

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Filters

Check for blockage of Strainer , Over Pressure Filter .

Repair as necessary .

Poor Washability

Spray Arms

Check all Spray Arms for blockage of water ports or

cracks. Check for proper rack loading to avoid interference

with Spray Arms during wash action. Check for proper

sealing, fastening, and movement of Spray Arms. Repair

as necessary .

Filters

Check for blockage of Strainer , Primary Filter , and Filter

Support. Repair as necessary .

WARNING

Pump Assembly

Check pump assembly for obstructions or restricted

parts. Repair or replace parts as necessary.

Wiring/Electrical Connections

Check for loose or frayed wire terminal connections.

Check for broken wire within harness. Repair or replace

as necessary .

Continues To Drain

Control Board

Check Control Board for proper operation.

Poor Drying

Detergent Cup Cover

Check spring hinge operation of Detergent Cup Cover.

Repair as necessary .

Detergent Cup

Check operation of Detergent Cup Assembly , W ax Motor ,

Actuator, Linkage, and Cover Latch. Repair and/or replace

parts as necessary. Note: For testing of Wax Motor, see

Section 2.

Rinse Dispenser

Check level of rinse aid in reservoir. Check rinse aid

dispenser setting.

Wash Delivery System

Check manifold and Docking Station for good seal and no

leaks.

Will Not Drain

Inadequate Drainage

Check Drain Pump for proper operation. Check the drain

pipe connections and repair as needed. If draining into the

garbage disposal, check for unprocessed food waste at

drain hose connection to disposer. Clean out as needed.

Drain Hose

Check drain hose for kink or restrictions. Reroute or

remove any restriction of drain hose as needed.

Water Temperature

Check for low water temperature. T emperature should be

between 120 - 150 degrees Fahrenheit. If not, advise

consumer to adjust water heater setting. Encourage

consumer to purge water lines to the dishwasher area

prior to starting the dishwasher.

Cycle Options

Advise consumer use of options available on dishwasher

that improve drying. Options that improve drying are

Heated Dry , and 160° Wash.

Detergent

Check water hardness. Instruct consumer on detergent

usage, one teaspoon of detergent per grain of water

hardness.

Rinse Dispenser

Check level of rinse aid in reservoir. Check dispenser

setting under cap. Use "MAX" for hard water conditions.

Improper Rack Loading

Check how the consumer loads the dishes into the racks.

Improper loading of some types of dishes can trap water

which causes dishes not to dry .

Heating Element

Check load readings listed on T echnical Sheet located

behind T oe Panel.

15 16022783 Rev. 0 ©2004 Maytag Appliances Company

Page 16

Electrical Mechanical Troubleshooting

!

T o avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Thermostat

Check mating surface of the High Limit Thermostat face

to surface of tub enclosure. Contact area must be flat.

Adjust the thermostat placement if necessary . See

T echnical Sheet, located behind Toe Panel for thermostat

data.

Water Leaks

Installation

Check Dishwasher for proper leveling and squareness in

cabinet.

Door Alignment

Check proper alignment of Door Liner to Door Gasket.

Door Gasket

Check for torn or damaged Door Gasket. Repair or

replace as necessary .

Hoses

Check for loose hose clamps or hoses that leak. Tighten

hose clamps or replace hoses as needed.

WARNING

Noise

Banging

Check for loose Spray Arms. Check for dishes interfering

with Spray Arm rotation. See loading information in the

User's Guide at the end of this manual.

Hammering/Chattering

Check Water V alve for , noise, low voltage, or high valve

coil resistance. Replace Water Valve if needed. Also,

check incoming water supply line for proper size and

pressure. Make sure the supply line is secured.

Grinding

Check for objects in Pump Assembly. If objects are

found, inspect Pump Assembly for damage. Rep air as

needed.

Vibration

Check components for source of vibration. Adjust and/or

tighten as needed.

Will Not Start Or Program

Spray Arms / Manifold

Check for cracks and replace as necessary .

Detergent / Rinse Aid Dispenser Seal

Check Rinse Aid Dispenser Seal for proper positioning or

cracking. Reposition or replace as needed.

Water Valve

Check Water V alve body for damage and leaks. Replace if

necessary. Also, check plumbing connections to Water

V alve.

Wash Motor Assembly

Check for water leak between Pump Assembly and tub.

Drain Pump Assembly

Check Pump Assembly Housing for cracks. Check Drain

Pump "O" ring for leaks.

Control Board

Check incoming voltage to Control Board.

Membrane Switch

Check for proper operation of Membrane Switch. See

membrane readings on the T echnical Sheet located

behind toe panel.

NOTE: Make sure the pin connectors are making proper

contact with pins on the Control Board. If the

voltage is correct into the Control Board, and the

board will not activate, replace board.

Will Not Fill

Water Valve

Check Water V alve circuit. See Technical Sheet for water

valve data located behind toe panel.

NOTE: Make sure the pin connectors are making proper

contact with pins on the Control Board.

©2004 Maytag Appliances Company 16022783 Rev. 0 16

Page 17

Electrical Mechanical Troubleshooting

!

T o avoid risk of electrical shock, personal injury , or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

WARNING

Will Not Wash

Wash Motor

Check Wash Motor circuit. See data listed on the

T echnical Sheet, located behind toe panel.

Will Not Drain

Drain Motor

Check Drain Motor circuit. See data listed on the

T echnical Sheet, located behind Toe Panel.

Will Not Dry

Vent Assembly

Check Vent Assembly for proper operation.

Heating Element

Check Heating Element circuit. See data listed on the

T echnical Sheet, located behind Toe Panel.

Manual Function Test

See T echnical Sheet, located behind T oe Panel.

Field Service T est

See T echnical Sheet, located behind T oe Panel.

17 16022783 Rev. 0 ©2004 Maytag Appliances Company

Page 18

Troubleshooting Flow Chart

No

Yes

Go to

Noise

Issues flow

chart

Complete

Noise Problem

No

Are there any leaks? Is it noisy?

Leak Problem

Drain Problem

Yes

properly?

Does it drain

Yes

Does it fill properly?

Starting Problem Fill Problem

Yes

pressed?

cancel key is

when the start/

Does the cycle start

Yes

No

No

No

chart

Go to Leak

Issues flow

drain

system

Repair or

reconfigure

No

and air break

Are the drain line

operating correctly?

on

Turn water

No

on to the unit?

Is the water turned

Fuction

Go to No

flow chart

Yes

Are any of the

indicator lights for

cycle and options

illuminated?

Yes

Fuction

Go to No

flow chart

Yes

Fuction

Go to No

flow chart

Verify wiring

No

correctly at

junction box

is connected

No

breaker panel or

Is the power turned

on to the unit at the

Yes

Appearance Problem

in the installation?

Does it look correct

power

and turn on

fuse box?

©2004 Maytag Appliances Company 16022783 Rev. 0

It is

unit

extremely

LEVEL the

important to

No

No

Is the unit level left

home

Correct

wiring issue

No

Yes

(minimum) at

junction box?

Is there 105VAC

Yes

to back?

to right and front

Yes

Go to No

Adjust to

touch floor

No

Do all 4 levelling

Fuction

flow chart

and

recheck

legs touch the floor?

levelness

Repair

cabinets

No

Yes

Are the cabinets

Yes

level and plumb?

strips

Install trim

No

side and top?

installed on each

Are the trim strips

Yes

Complete

18

Page 19

Troubleshooting Flow Chart

Check

below

manual

for leaks

operation

after each

Leaks

No

Top of the Door

Yes

top of the door?

Is there a leak at the

16022783 Rev. 0 ©2004 Maytag Appliances Company 19

Normal

Operation

Yes

No

Does it leak when

you open the door?

recheck

seal and

Adjust foam

Yes

No

eyelets?

Can you see foam

material in the vent

foam seal

Install new

No

Yes

panel?

vent and control

Is the rectangular

installed between

foam seal correctly

Complete

Page 20

Troubleshooting Flow Chart

Loosenclamp,push fillhose onand fullyreseatclam

p

Is the air/water inletfoam in place?Reseat/replacefoa

m

Removeandreinstall air/water inle

twith n

ew o-ringNoN

oNoYes

RepairconnectionN

oIs the leak comin

g

the rear behindthe main washmotor?Are the heater nutsfully seated/tighted?Is the heater itselfleaking?Is there a crack inthe tub

wall near thel

ower rear corners

?

YesYesYesYesYesNoNoNoNoCompleteIs the air

/water inletbezel present?InstallbezelN

oCompleteYes

Removeandreinstallheater nutsComplete

From Page 1

Replacethe heaterReplaceuni

t

clamp

Tighten the

No

Yes

clamp tight?

Is the drain hose

Yes

A

Is the drain pump to

No

drain hose leaking?

Repair

connection

Yes

From Page 1

B

leaking?

Is the incoming

water under the sink

©2004 Maytag Appliances Company 16022783 Rev. 0

No

Yes

Is the water valve

clamp fully seated?

Replace

the hose

Yes

No

end?

Is the fill hose

leaking at either

No

attached to

Is the other end of

the fill hose securely

Complete

Yes

going into the

Is the drain hose

plumbing leaking?

plumbing?

Yes

inlet?

Is water splashing

out of the air/water

No

Complete

leaking at the tub

Is the air/water inlet

Yes

connection?

from

20

Page 21

Troubleshooting Flow Chart

Cycle Selection

Problem

16022783 Rev. 0 ©2004 Maytag Appliances Company 21

Page 22

Troubleshooting Flow Chart

Is there 105VAC(minimum) to thejunction box?RepairinstallationproblemNo

r o

r

c

e

ssYes

o

Door or Latch Problem

Verify the door is onboth hinges, bothdoor springsare attachedcorrectly,and installationis correct

Is there a proble

mwith the rack?NoNoYesYesYesReplacerackNoNo

Rack Proble

m

A

djust tosameheightIs there a brokenpart?Orderreplace-ment partIs it hard to move inor out

?

e rac

k

lock int

o

ce?Replaceracka

djustersNoWill the rack slide allthe way in?Removeitem that isblockingrackYesNoYesIs food trapped inrack slides?RemovefoodNoIs rack

warpedcausing it to bindYesBend backif possibleor replaceAre bolts in tu

bwheels tight?TightenboltsYesNoYesYesSnapsnuggers torackAre snuggers atback of rack fullysnapped to rack?YesNo

Dispenserproble

m

re a proble

m

he dispenser?See "A" infl

ow chartWashPerformanceCompleteNoYe

s

FromPage

1

No

height?

Are both sides

adjusted to same

No

latch?

Is there a problem

with the door or door

A

Replace

Drain Problem

No

draining the unit?

Is there a problem

C

From

Page 1

No

Yes

Will the door clo se

drain pump

See Wash

Yes

Yes

and latch

completely?

Yes

Flow Chart

Performance

Yes

bottom?

front of tub or door

Is there food soil at

pla

Will th

adusters

wire

repla

harne

Repai

striker

replace

latch or

Repair or

Yes

striker broken?

Is the door latch or

drain cycle?

drain pump during

Is there 105VAC to

No

No

drain only cycle?

come on during a

Will the drain pump

replace

Repair or

door switch

No

No

correctly?

Do both door

switches work

No

Control

Replace

Yes

Yes

Is the carry over

©2004 Maytag Appliances Company 16022783 Rev. 0

N

Yes

Is there 105VAC

J5, pin 8 & ST-10?

(minimum) between

No

Yes

With the door switches

(minimum) between ST-

closed, is there 105VAC

Unclog

Yes

No

correct?

volume after the

cycle is complete

Is the drain pu mp

Yes

board?

3 & ST-11 on control

drain pump

clogged?

start after

If the unit won't

No

control

cancel key

then replace

multiple times

pressing the start/

Is the

with t

drain

valve

Level unit

No

Is the unit level?

Replace

Yes

Yes

Is the drain outl et

check valve stuck

No

open?

From

Page 1

system

Repair or

reconfigure

No

Yes

Wash

flow chart

and air break

Are the drain line

operating correctly?

B

See "A" in

Performance

22

Page 23

Troubleshooting Flow Chart

y spotting,

NoIs it only tall glassesOnlyloadshortYes

in the corners?items inthecorners

Incoming water tempmust be 120°For grater (at sink)

Spotting, Filming,Etching, & CornerIssues

Steps

Important 1st

No

Go to

Function

flow chart

No

Yes

the machine?

Are there staining

issues with parts of

Yes

No

Is the wash

performance good?

16022783 Rev. 0 ©2004 Maytag Appliances Company 23

Only Task

Technician

Yes

over time

will discolor

Accessories

binding or hitting

with

Use a

bleach

detergent

Yes

No

door?

Are there staining

issues with the tub or

No

Yes

wet?

Are the items getting

Are the wash arms

No

Are there items

blocking the wash

No

Can the wash arms

No

No

rack?

Yes

Are the

filming, or etching?

Glasses

arms?

rotate freely?

Sanitize Issues

getting clean?

What items are not

bottom

Tub or door

Yes

Sanitize

Issues

Tub/Door

Soil left on

Heavy

try heavy cycle

Normal operation

other

Dishes,

flatware, or

A

On Page 2

Page 24

Troubleshooting Flow Chart

ethin

g

th

e

door?

s

eplac

eheater or

rmostat

N

o

If the dispenser didnot open repairor replace

Is the carry overvolume correct?LevelunitNoYe

s

surface of

housin

g

" bel

ow to

p

of DHIs the drain pumpclogged?Complete

Pump & Valve Issues

Is the unit level?Is the drain outletcheck valve stuckopen?

ressurewithin tolerance?CorrectpressureNoIs the unit level?No

usin

g

ic D/WRefer t

o

FromPage

1

ent?U & C

rNoNo

Wash/Drai

n

YesNoYesYesYesNoYes

Refer to U & C forR/A & DetergentrecommendationsDeterminewaterhardness?Replac

ewatervalveUnclogdrainpumpLevelunitReplacevalveIs the floatlimiting thefill? Repairor replace floatNo

Water & Detergent

A

Isolated Redeposit/

Original Soil Issues

From

Page 1

B

©2004 Maytag Appliances Company 16022783 Rev. 0

Is the water p

No

Is the fill volume

water

Increase

Yes

Issues

Is the incoming water

No

Are any of the spray

No

Are items nested

together, touching

No

Is the redep

Yes

within tolerance?

120F

temp to

No

< 120F?

temperature (at sink)

nozzles clogged?

path?

other items, or

blocking the spray

everywhere?

wate

surface

discharge

2 Rack - 1/4

3 Rack - Top

Back

again

and try

Change

Yes

No

Have you changed

detergent recently?

Yes

Yes

spray

Unclog

nozzles

remove

seeds, &

from load?

large soils,

Be sure and

hard objects

Heavy/Random

load to

problem

eliminate

Rearrange

Yes

Yes

Remove

obstruction

No

blocking

dispenser

Is there som

Yes

No

R

Did the detergent

completely dissolve?

filter

Replace

Redeposit Issue

Yes

No

it torn?

Remove filter guard &

inspect filter mesh. Is

Clear

Yes

the

No

Yes

working?

Is the heater

port

sample

No

clogged?

Is the sample port

Are you

automat

filter

Install

flapper

No

present?

Is the filter flapper

Yes

deterg

ears

Insert

flapper

No

Yes

Yes

port opening?

Are all 4 flapper ears

inserted into the drain

24

Page 25

Troubleshooting Flow Chart

Instruct toloaddifferentl

y

wate

r

t 120F?Instruct toraise

watertemp forbetterperformanceIs the consumer onlyhaving problem

swith plastic or Teflonitems?Instruct thatthese itemswill not getdry in anymachineIs the consumer onlycomplaining aboutwater droplets onthe tub and innerdoor?Instruct thisis normaloperationandsuggestovernightdryin

g

IMPORTANT

Refer to U & C forR/A & Detergentrecommendationsbased on waterhardnes

s

Customer Instruct IssueCycleSelectionVentRinse AidLoadingWater TempOp NormalSee Page

2

wire

chart

This flow

checked

have been

assumes all

connections

16022783 Rev. 0 ©2004 Maytag Appliances Company 25

load

Instruct to

differently

No

Yes

and oriented

collecting water?

Are items spaced

properly to reduce

for better

Instruct to

Dry" option

use "Heated

performance

No

selected?

Dry" option

Was the "Heated

No

the racks?

cups located on

Are glasses and

slanted sections of

"Sanitize" or

"160 Degree"

Instruct to use

No

Yes

Was the sanitize

No

Yes

Is incoming

better

option (if

performance

available) for

Yes

option selected?

Instruct to

move items

Is anything blocking

Yes

temp at leas

vent

openings

away from

Yes

No

the control panel?

the vent openings in

Yes

No

Aid

Instruct to

use Rinse

No

Yes

used?

Is Rinse Aid being

Yes

No

Increase

Rinse Aid

created

too much

foam isn't

setting by 1

making sure

No

Yes

Is the Rinse Aid

setting on MAX?

Page 26

Troubleshooting Flow Chart

Repair orreplace asnecessar

y

gh limi

t

t bee

n

d?Verify it hasnot failed inthe openposition andis sitting on aflat surfaceYesYesYesNoNoNo

V

ent BezelVentHigh Limit Thermosta

t

operation o

f

ing element

verified?Run FieldService testand verifycorrectoperationHas the operation ofthe Turidity Sensorbeen verified?Has the voltagebeen checked to theunit?Less than115VAC cannegativelyaffect thedryingperformanceHas the operation ofthe Rinse AidDispenser beenverified?Run FieldService testand verifycorrectoperationRun FieldService testand verifycorrectoperationCompleteYesYesYesYesNoNoNoN

o

Functional IssueHeaterR

/ADispenserTurbiditySenso

rVoltag

e

and

reinstall

Remove

vent bezel

No

Yes

the inner door

installed flush?

Is the vent bezel on

©2004 Maytag Appliances Company 16022783 Rev. 0

been

the heat

Has the

No

Yes

bezel oriented

toward the bottom?

Is the slot in the vent

operation

Run Field

and verify

wax motor

Service test

been verified?

the vent wax motor

Has the operation of

Is the vent flapper

operating correctly?

checke

thermosta

Has the hi

From Page 1

26

Page 27

Troubleshooting Flow Chart

Instructcustomerandrearrangeite

m

r

Complet

e

H

owling/Surgin

g

YesComplete

Are there excessiveleaks at hubs ordistribution system?Are there objectsbetween chopperand chopper plate?

Is there anexcessive amount offoaming in unit?to use less RinseAid. See U&C forrecommendeddetergentamounts basedon

waterhardnessYesYesNoVerifyRinse Aidtank is notleakingRepair orreplaceIs the tub rear wallCheck allmanifoldhar

dwarefor correctoperationandplacementNobowed in?Verifynothing isprotrudingfrom backwall intoback of tubdocking ports out ofDisassemble,look for partsthat haverubbedtogether andrealign orreplaceNoYesN

o

Are the flappersfrom the unusedplace, missing, ordeformed?Repair or"WashChart" Fl

owreplaceYe

s

m

e 2

DDoes it sound likean intense grindingor buzzing?Look for hardo

bjects betweenchopper andchopper plate

.

Grinding/Buzzin

g

YesYesNoRemove itemsand instructcustomertoscrapehard o

bjects Does it sound like aringing noise incadence with thewash arm?This iscaused b

ywaterhitting apan and isnormal

Ringing

YesAre pump rotatingparts rubbingstationary parts?YesNoNoNoDisassemble,Togetherand realign or replacelook for partsrubbin

g

16022783 Rev. 0 ©2004 Maytag Appliances Company 27

Pump & Valve

See "Wash/Drain

Issues" portion of

Performance

Yes

Fro

Pag

No

Did the noise stop?

back?

going all the way

Are there objects

keeping rack from

No

From Page 2

C

hand

Add 2

water by

quarts of

Are the wash tubes/

No

Yes

followed by a fill?

Does it surge a few

times and then drain

No

noise?

howling/surging

Does it sound like a

Wash

During

A

No

Does the noise only

On Page 2

Yes

cycle?

portion of the

occur during the

wash

No

3 times during a cycle.

Control is going into the

can occur a maximum of

foam guard routine which

B

Thumping/

?

thumping or

clicking

Does it sound like a

steady

No

Modify

During Fill

fill

occur during the

Does the noise only

portion of the cycle?

Hissing

Yes

Yes

correctly?

manifolds docking

etc.

in too much air which

This occurs when the

low water, out of level,

main wash pump draws

can be caused by foam,

On Page 2

arm

items to

Relocate

avoid spray

Clicking

Yes

Yes

Is the spray arm

home

eliminate

reduce or

plumbing to

Yes

No

noise?

hissing

Does it sound like a

No

rack?

hitting items in the

able to

May be

eliminate

reduce or

Yes

Does it sound like a

objects

instruct

Remove

items and

customer to

scrape hard

Yes

No

Yes

Instruct custome

rack

replace

or load or

Adjust rack

Yes

No

hitting the rack?

Is the spray arm

by

plumbing

modifying

noise?

thumping

Thumping

No

racks

secure

items in

load and

Rearrange

Yes

each other?

Are items moving

around and hitting

water

Install a

hammer

suppressor

Complete

No

Are seals or

mechanical parts

rubbing together?

No

load to

Instruct

No

to eliminate

coming

block jets

rearrange

customer to

wash arm

from lower

Yes

No

Is the upper spray

arm hitting the tub?

parts

Adjust,

replace

realign, or

Yes

filter cover?

arm hitting the

Is the lower spray

heater element or

Yes

No

arm hitting

Is the lower spray

Single

Thump

No

racks?

fallen through the

something that has

cup lid

normal

detergent

This is the

operation

hitting the

door and is

Yes

during

No

final rinse?

Does it sound like a

single thump

Page 28

Troubleshooting Flow Chart

Removeo

bject

s

Replacewash arm

Yes

YesYesYesYe

s

o

On Page 1

1

Yes

Verifynothing i

swedgedbe

tweendrain pumpand floo

r

it sound like a noise?

ndingRemovehard o

bjectfrom drainpumpDoes the after water isfully drained?noise getlouderInstructcustomerthis isnormaloperationComplet

e

d like

a

ise

?

Does it sound like a noise?grinding

DoorBuzzingVibratingHummingGrindingLoudPoppingGrindin

g

YesYesYesYesYesYesYesYesYesNoNoNoNoNoNoNoYe

s

Opening/Closing

With the door fullyopen, is the front lipof the tub visible?Does the deco panelinterfere with thehinge in the l

owercorners?Is the door installedon the hingesproperly?Are the springs orcables rubbingagainst the cabinetor the machine?

CompleteDoes the noise onlyoccur while movingthe in or out? rac

k

Moving Rack

YesYesYesYe

s

FromPage

1

This isdetergentcup lidhitting doorand isnormalReplaceinner doorA

djust orreplace asneccessaryInstall dooron hingesAdjust orreplacePlace cableback onpulleyComplet

e

Yes

flow chart

See "Rack

No Function

of

Problem" section

Does it occur one

NoNo

?

opening

No

wash?

time only after a

no

No

No

No

Yes

No

Are the cables off

No

the pulleys?

or closing door

Does the noise only

occur while

No

cycle?

portion of the

occur during the

drain

Does the noise only

adjust

Realign or

noise

pieces?

buzzing

Does it sound like a

between sheet metal

popping

Does it soun

Readjust

insulation

or reroute

drain hose

noise?

vibrating

Does it sound like a

humming

noise?

constant

Does it sound like a

gri

Does

During Drain

A

C

On Page

Yes

Rattling

Does it sound like a

No

noise like

pebbles being

thrown around?

rattling

D

station

replace

docking

Repair or

N

with docking?

Is there a problem

Yes

No

against

water

tub?

consistenlty

spraying

Does it sound like

an intensejet

No

blocked or

Is wash arm

hitting rack?

Yes

docking stations?

Is there a leak in the

No

hitting rack

slow, blocked, or

Are the wash arms

stopped or rotating

Replace

wash arm

No

Water

No

seam?

wash arm weld

Is there a leak in the

Spraying

replace

wash arm

Tighten or

replace

wash arm

Tighten or

No

stationary and

stuck between

at a wash arm hub?

Is there a large leak

Are there objects

No

Complete

Yes

wash arm hub?

rotating parts of the

No

seam?

wash arm weld

Is there a leak at the

Complete

No

at a wash arm hub?

Is there a large leak

fillers

or add

change

Instruct to

installation

During Wash

If motor is

stays level

touching floor

raise machine

making sure it

No

Yes

Humming

From

Page 1

B

noise?

humming

loud low frequency

Does it sound like a

Adjust

water valve

Yes

touching the tub?

Is the water valve

No

©2004 Maytag Appliances Company 16022783 Rev. 0

loop

correct

remains

Reroute

enusuring

drain hose

Yes

rubbed

replace

that have

realign or

together and

look for parts

Disassemble,

Yes

Repair

installation

Yes

& 2 foam pieces

installed correctly?

Are all 3 trim strips,

2 parts of kick plate,

Loud

No

wedged tightly

Is the drain hose

No

cabinet/wall?

between tub and

parts rubbing

Are pump rotating

No

stationary parts?

Is the door or other

part of the machine

No

cabinet?

forced against

Consistently

Yes

sound

too loud?

Is the overall

consistent

Yes

Yes

between the

cabinet/wall?

machine and the

Are there large gaps

No

No

Complete

seal or

normal

Replace

operation

instruct as

Yes

Squeaking

No

sound as

stop?

Does it sound like a

sqeaking

machine coasts to a

28

Page 29

Service and Disassembly Procedures

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

The following paragraphs describe how to disassemble

unit under test. Disassembly to some extent is required

to install unit, to perform troubleshooting procedures, and

to remove and replace failed components.

Component names used throughout disassembly

procedures are the same as those used in Parts

Manuals.

For quicker reassembly, disassemble unit under test only

to extent necessary to troubleshoot and repair. Unless

noted, reassembly is opposite of disassembly.

WARNING!

To avoid risk of personal injury or death due to

electrical shock, ground wires and wires colored like

ground wires are NOT to be used as current carrying

conductors. The standard accepted color coding for

ground wires is green or green with a yellow

stripe. Electrical components such as the water valve

and motor are grounded through an individual wire

attached to the electrical component. Ground wires

should not be removed from individual components

while servicing, unless the component is to be

removed and replaced. It is extremely important to

replace all removed ground wires before completing

service.

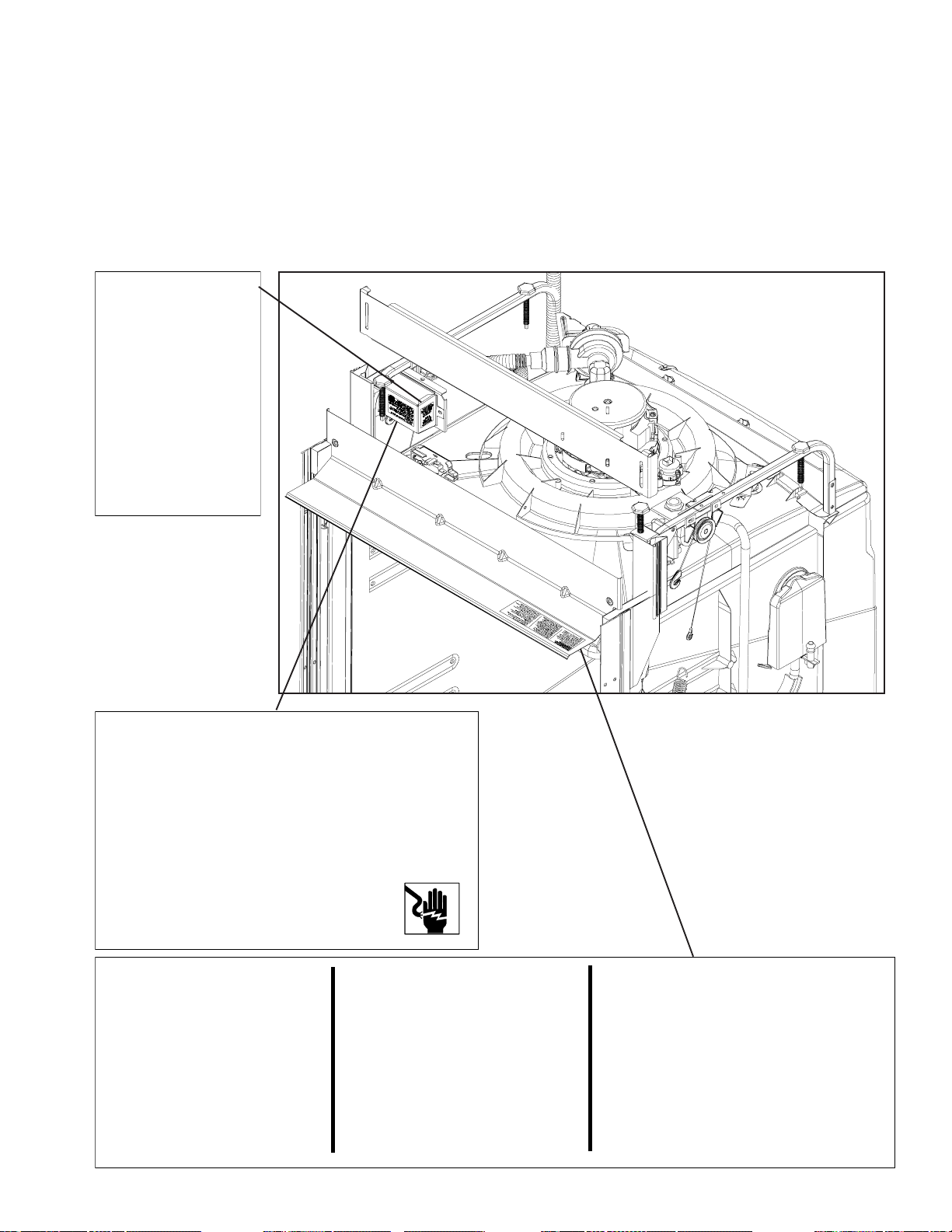

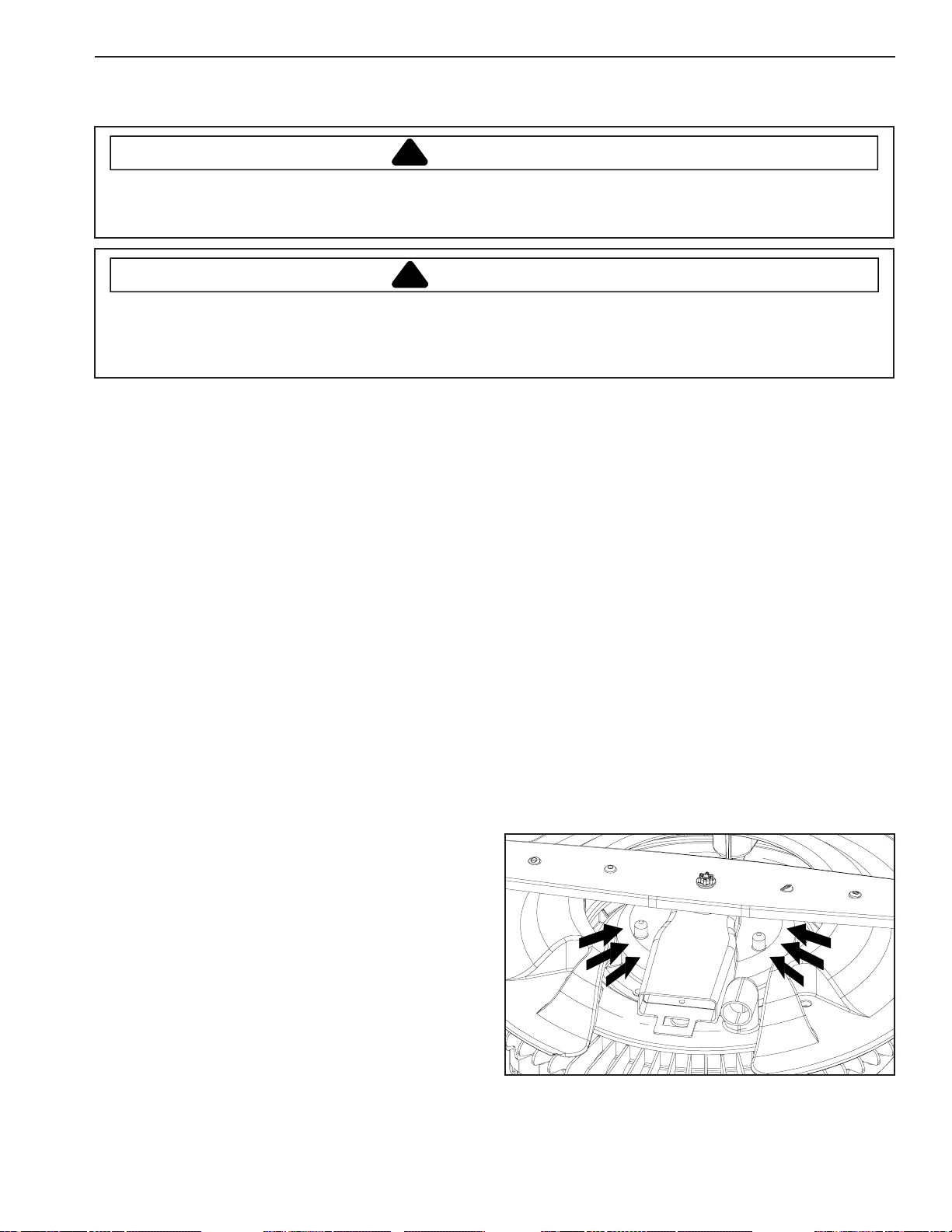

Front Support and Toe Panel Removal

Removal of Front Support and Toe Panel will allow access

to the Water Valve, Float Switch Assembly, Electrical

Junction Box, hoses, thermostats, Start Capacitor and

Motor/Pump Assembly.

Removal

1. Disconnect power to the machine.

2. The Front Support Panel is held by 2 screws, one

each side. Remove both screws.

3. The Toe Panel is held by 2 screws, one each side.

29 16022783 Rev. 0 ©2004 Maytag Appliances Company

Page 30

Service and Disassembly Procedures

! WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit and discharge

capacitor through a 10,000 ohm resistor before attempting to service, unless test procedures require power to be

connected. Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Inner Door Panel

Removal of the Inner Door Panel will allow access to the

Microprocessor Board, Door Switches, Detergent / Rinse

Aid Dispenser, and Vent Assembly.

Removal

1. Disconnect power to the machine.

2. Open the Dishwasher door.

3. Remove the 11 Torx™ screws along the sides and

top of the Inner Door Panel.

4. Separate the Inner Door Panel from the Outer Door.