Page 1

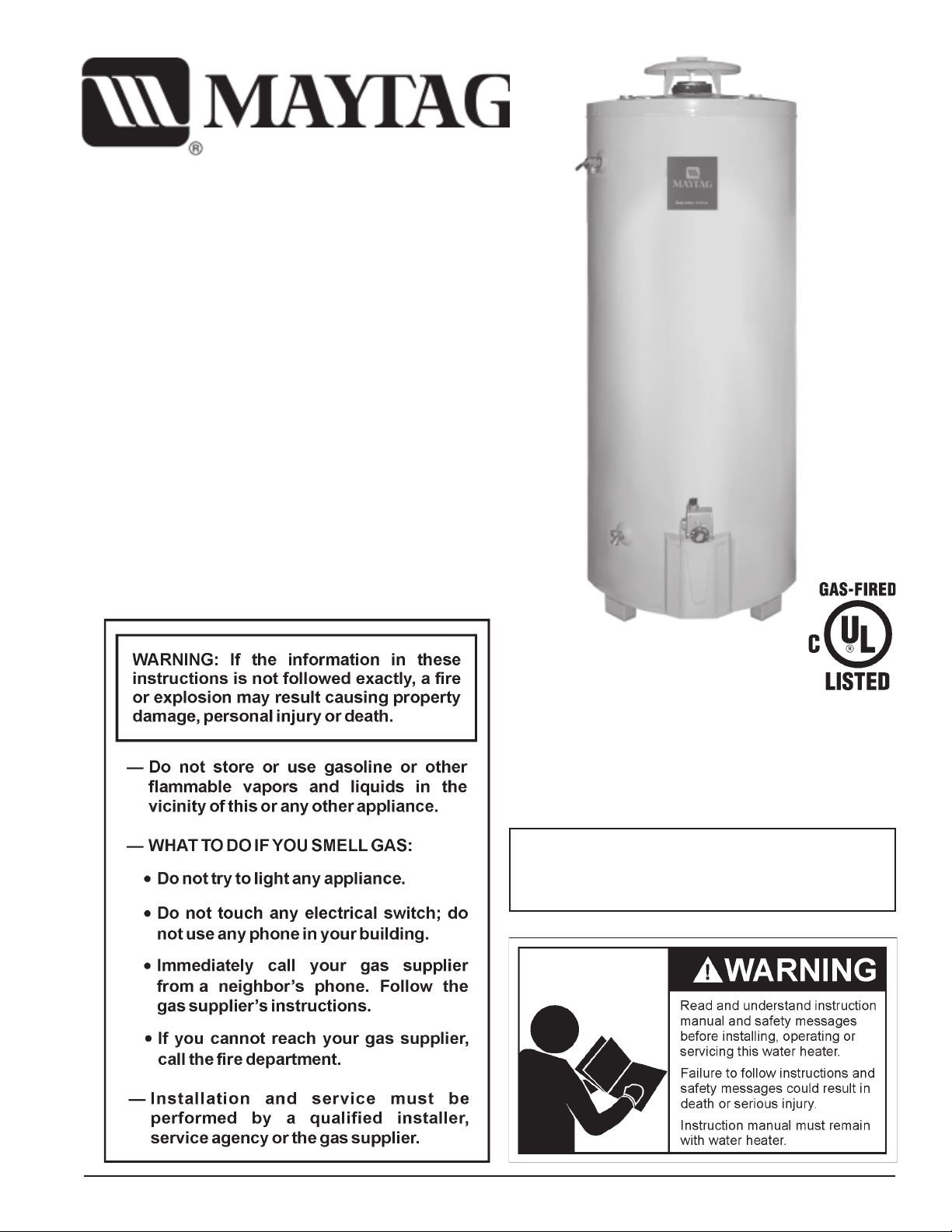

Series Nine

GAS WATER HEATER

USER’S GUIDE

FOR POTABLE WATER HEATING ONLY

NOT SUITABLE FOR SPACE HEATING

NOT FOR USE IN

MANUFACTURED (MOBILE) HOMES

Model Number

HXN4975S HXP4975S

For Your Safety

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

PRINTED 0107 197671-001

www.maytagwaterheaters.com

1

Page 2

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important

that the meaning of each safety message is understood by you and others who install, use or service this water heater.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently

DANGER

WARNING

CAUTION

hazardous situation which, if not avoided,

could result in death or injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in death or injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result

in minor or moderate injury.

CAUTION used without the safety alert

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message and

how to avoid the risk of injury.

symbol indicates a potentially hazardous

situation which, if not avoided, could result

in property damage.

IMPORTANT DEFINITIONS

• Maytag Customer Service Center: The Maytag Customer Service Center has the equivalent to a licensed tradesman in the fields

of plumbing, air supply, venting and gas supply, including a thorough understanding of the requirements of the Natural Gas and

Propane Installation Code as it relates to the installation of gas fired water heaters. The Service Center also has a thorough

understanding of this instruction manual, and is able to perform repairs strictly in accordance with the service guidelines provided

by the manufacturer.

• Gas Supplier: The natural gas or propane utility or service which supplies gas for utilization by the gas burning appliances within

this application. The gas supplier typically has responsibility for the inspection and code approval of gas piping up to and including

the natural gas meter or propane storage tank of a building. Many gas suppliers also offer service and inspection of appliances

within the building.

2

Page 3

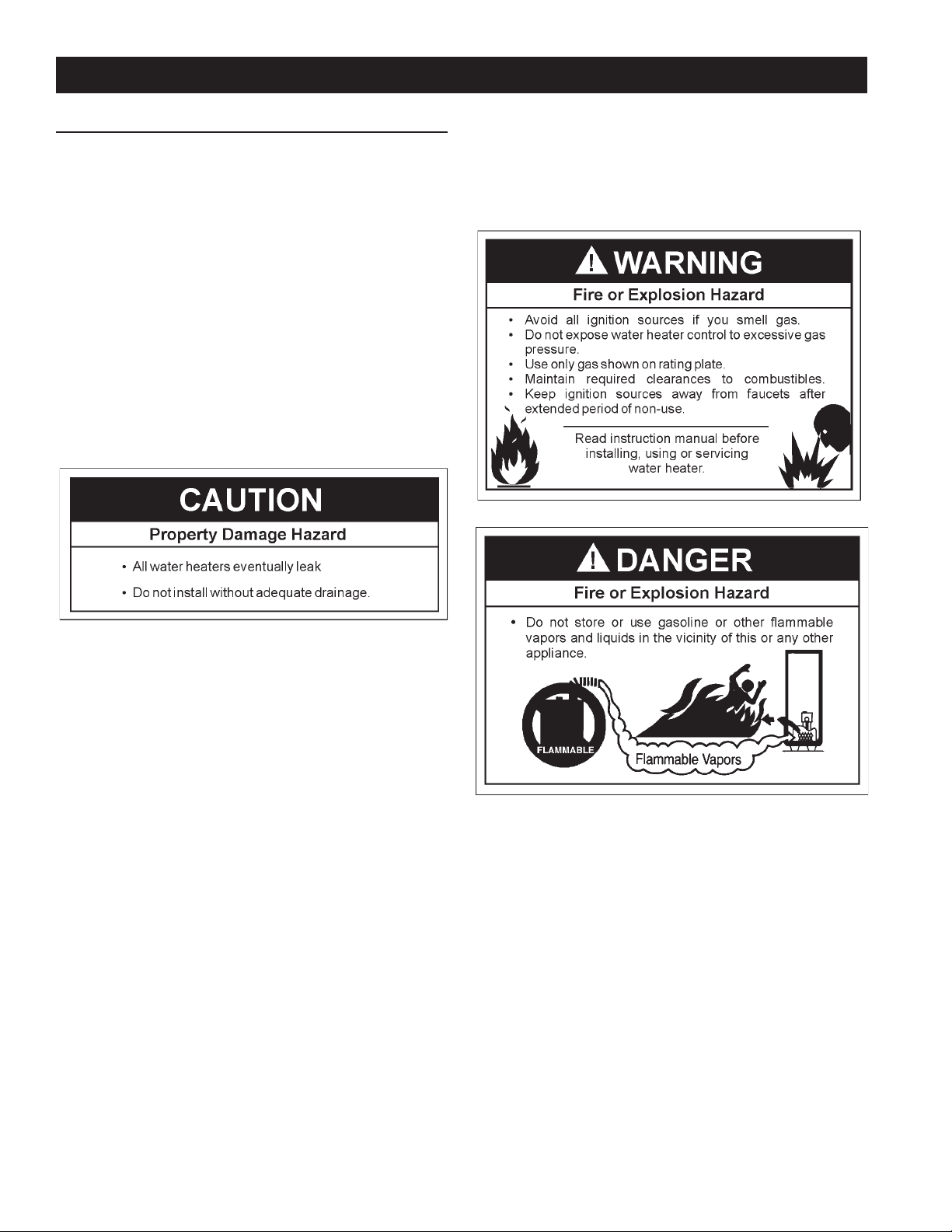

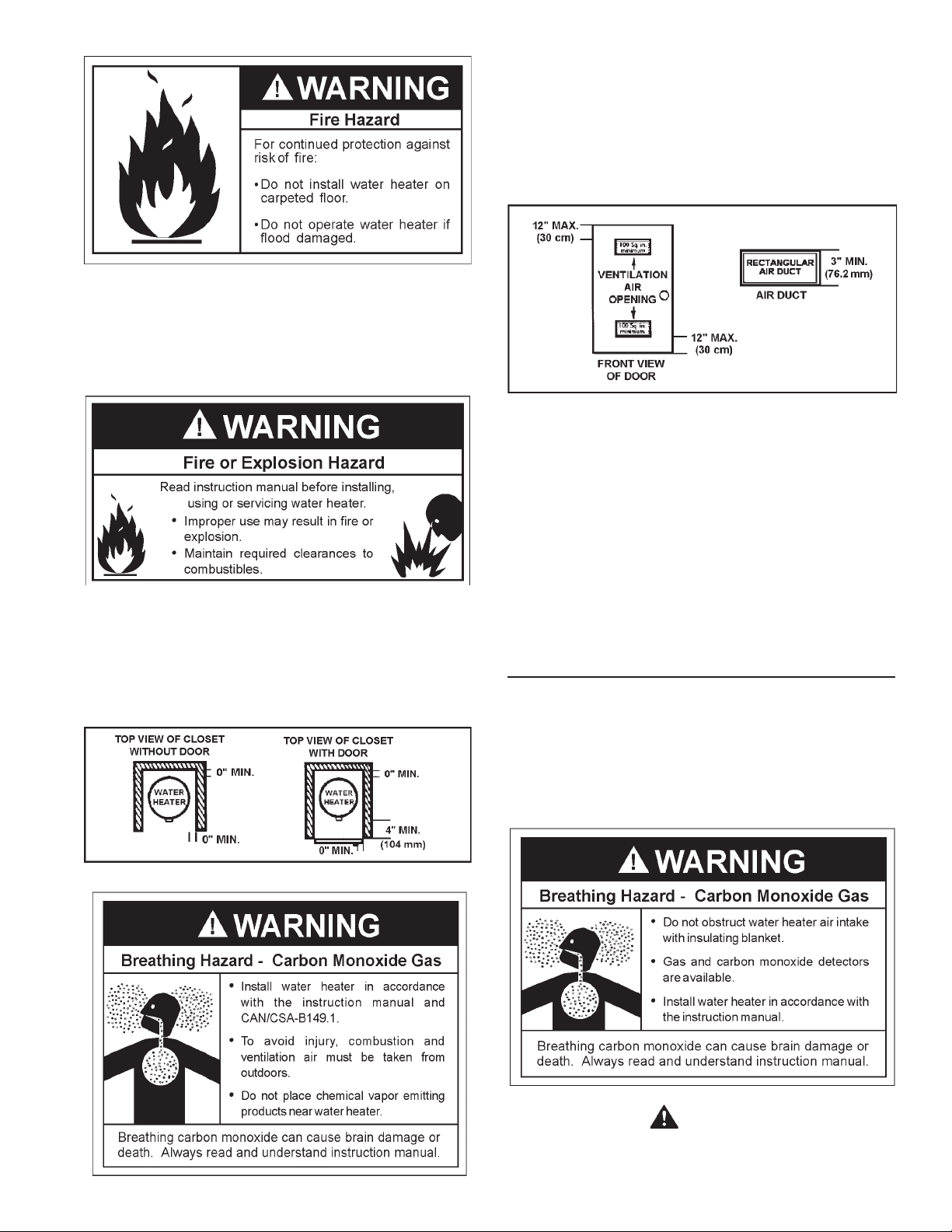

SAFETY PRECAUTIONS

3

Page 4

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE ................................................................................................ 2

SAFETY PRECAUTIONS ............................................................................................................................. 3

TABLE OF CONTENTS ................................................................................................................................ 4

CUSTOMER RESPONSIBILITIES................................................................................................................ 5

PRODUCT SPECIFICATIONS...................................................................................................................... 5

ACCESSORIES AND TOOLS NEEDED....................................................................................................... 6

Accessories ............................................................................................................................................................ 6

Tools ....................................................................................................................................................................... 6

PREPARATIONS FOR INSTALLATION........................................................................................................ 7

Removing the Old Water Heater ............................................................................................................................. 7

TYPICAL INSTALLATION .......................................................................................................................... 8,9

Get to Know Your Water Heater .............................................................................................................................. 8

Mixing Valve Usage ................................................................................................................................................ 9

LOCATING AND INSTALLING THE NEW HEATER............................................................................... 10-18

Facts to Consider About the Location .............................................................................................................. 10,11

Insulation Blankets........................................................................................................................................... 11,12

Combustion Air and Ventilation for Appliances

Located in Unconfined Spaces ............................................................................................................................. 12

Combustion Air and Ventilation for Appliances

Located in Confined Spaces ............................................................................................................................ 12,13

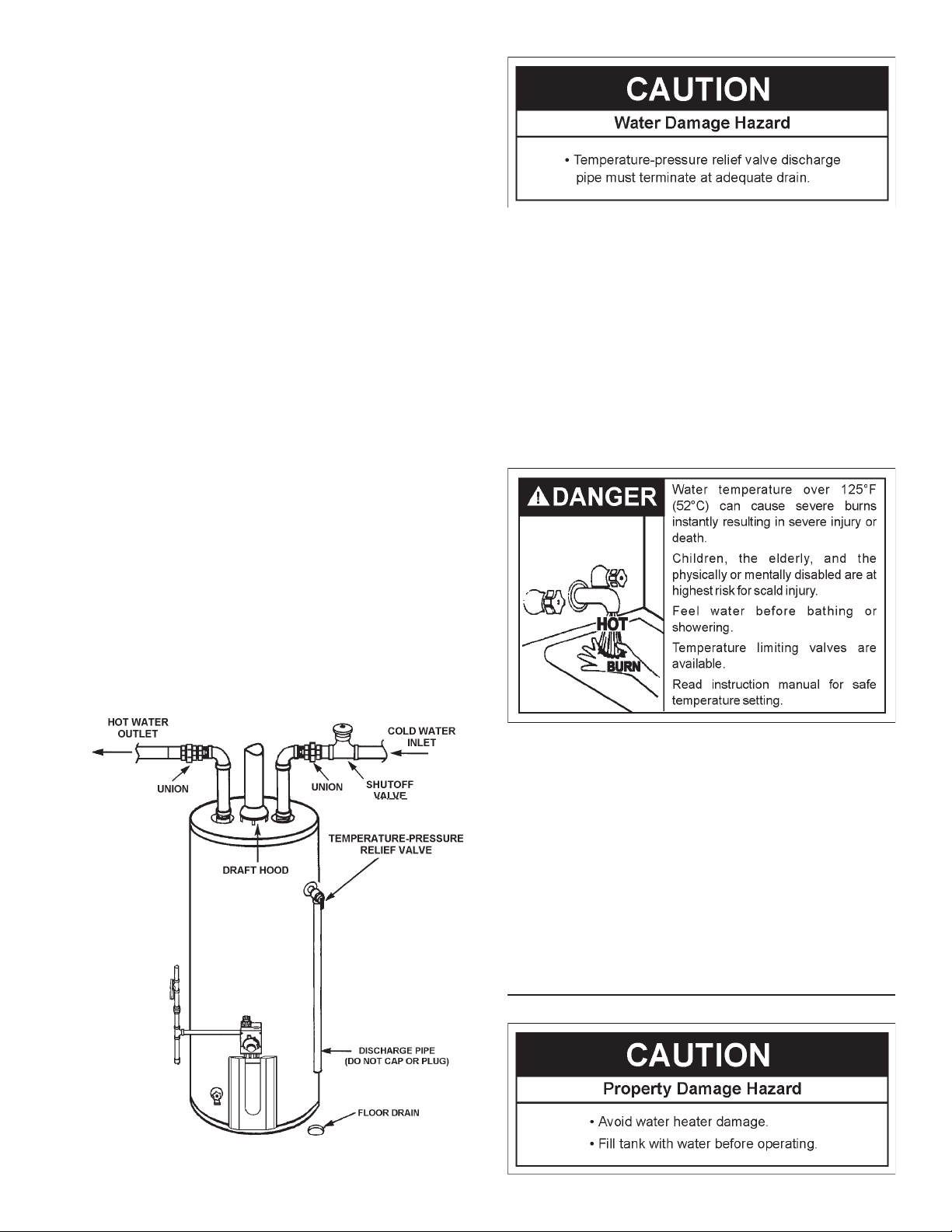

Water Piping .................................................................................................................................................... 13,14

Temperature Pressure Relief Valve ................................................................................................................. 14,15

Filling the Water Heater ................................................................................................................................... 15,16

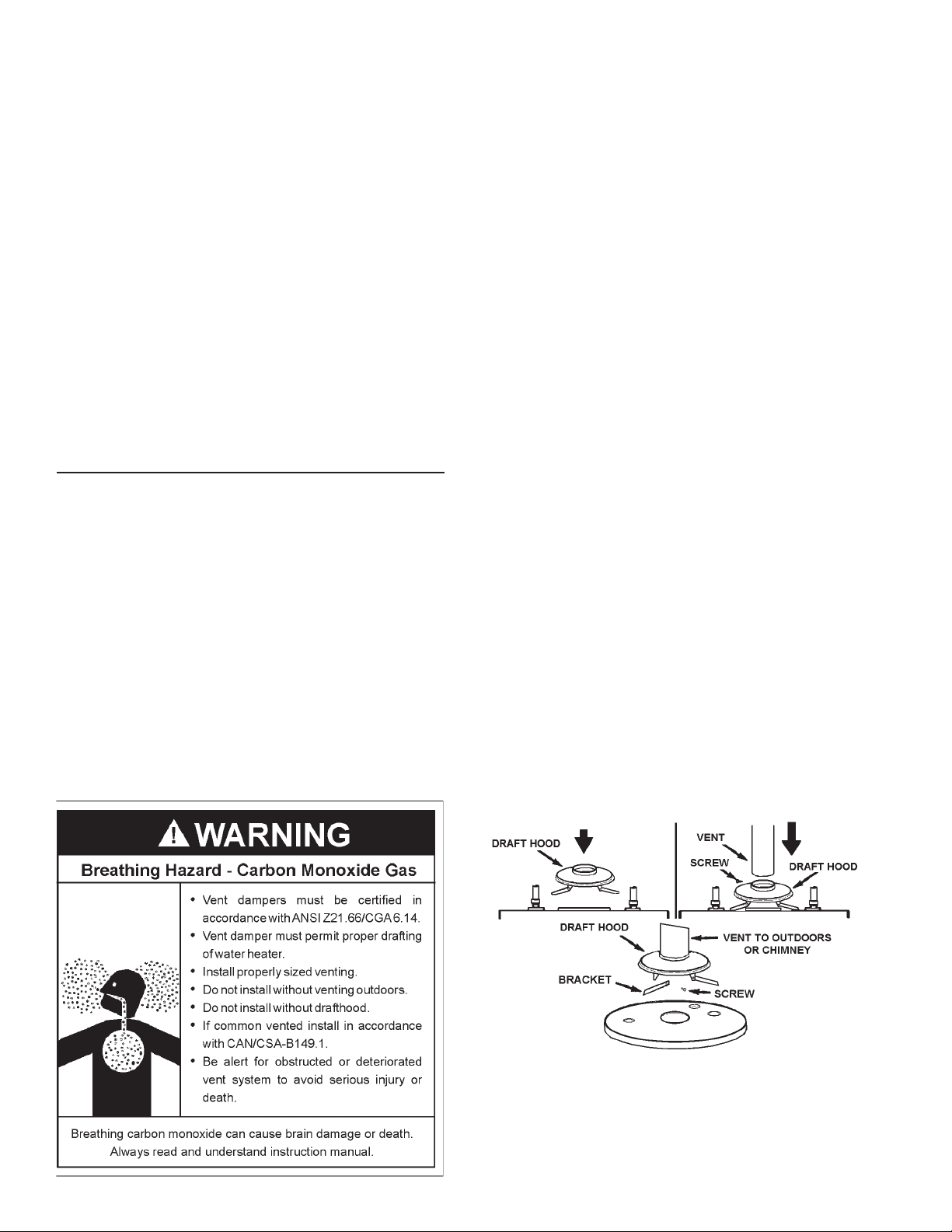

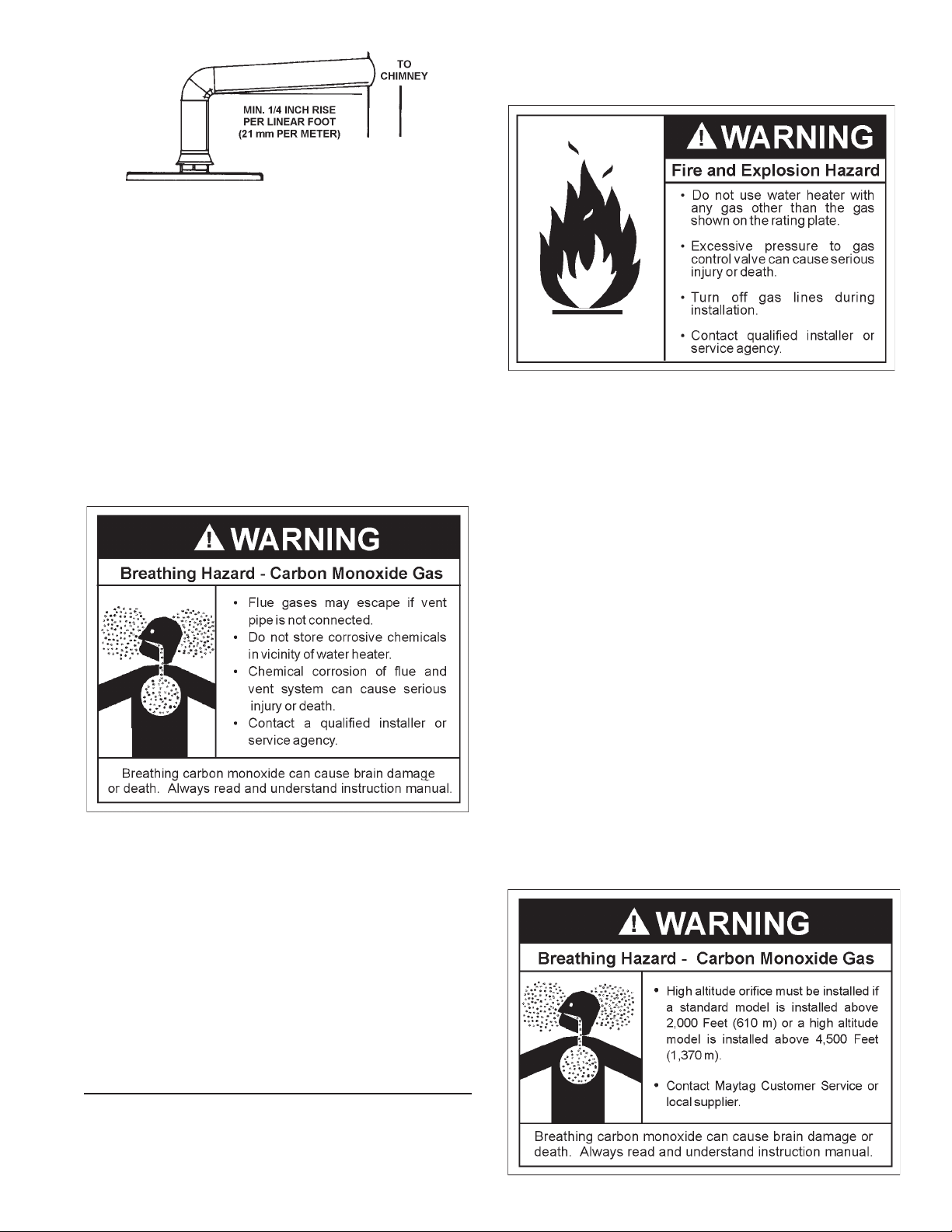

Venting............................................................................................................................................................. 16,17

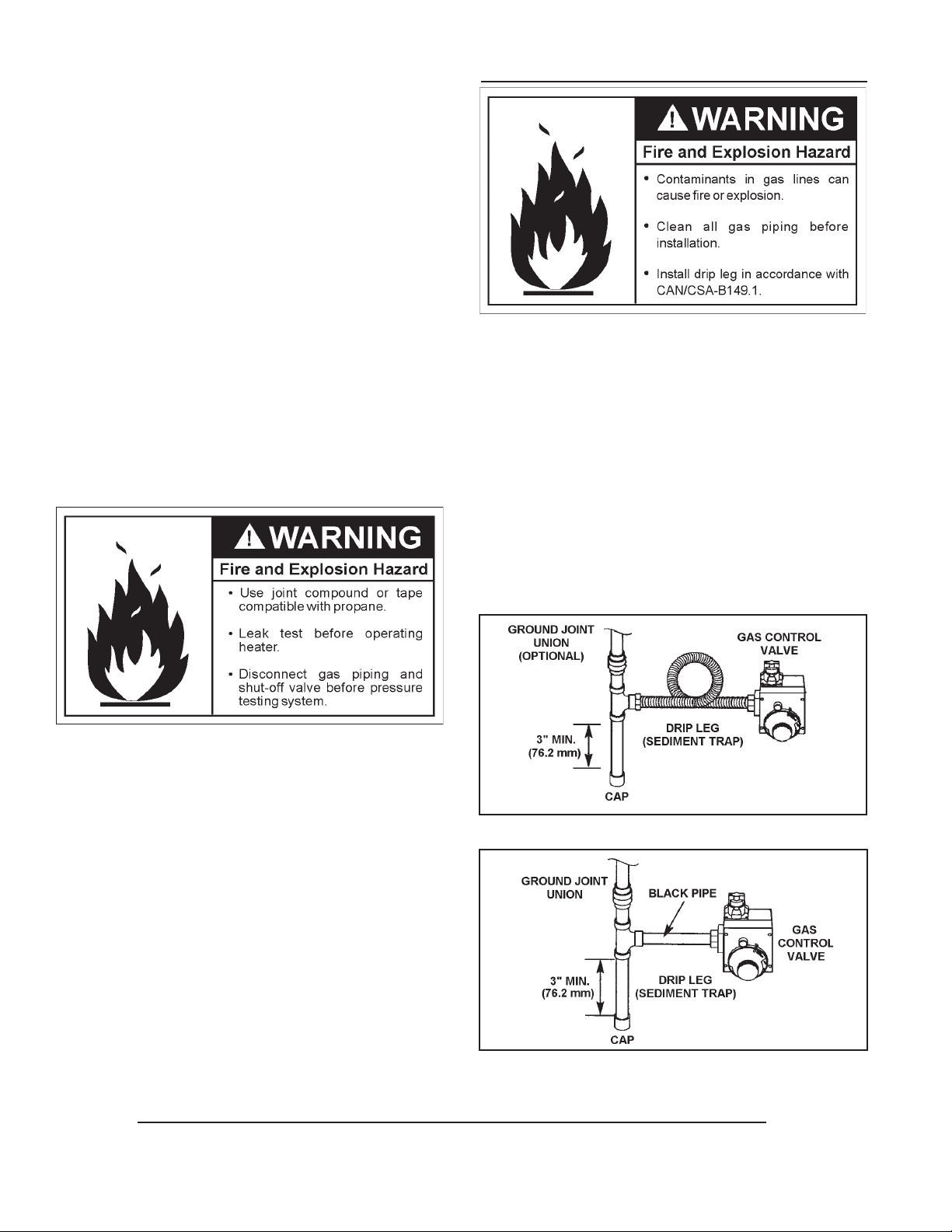

Gas Piping ....................................................................................................................................................... 17,18

Sediment Traps .................................................................................................................................................... 18

OPERATING INSTRUCTIONS ............................................................................................................... 19-21

Lighting & Operating Label .............................................................................................................................. 19,20

Temperature Regulation ....................................................................................................................................... 21

SERVICE AND MAINTENANCE ............................................................................................................. 22-24

Tank (Sediment) Cleaning .................................................................................................................................... 22

Vent System Inspection ........................................................................................................................................ 22

Burner Inspection.................................................................................................................................................. 22

Burner Cleaning .................................................................................................................................................... 22

Housekeeping....................................................................................................................................................... 23

Anode Rod Inspection .......................................................................................................................................... 23

Temperature-Pressure Relief Valve Operation ...................................................................................................... 23

Draining ........................................................................................................................................................... 23,24

Drain Valve Washer Replacement ........................................................................................................................ 24

Service.................................................................................................................................................................. 24

TROUBLESHOOTING ............................................................................................................................ 24-26

Start Up Conditions.......................................................................................................................................... 24,25

Draft Hood Operation ................................................................................................................................... 24

Condensation .......................................................................................................................................... 24,25

Smoke / Odor ............................................................................................................................................... 25

Thermal Expansion ...................................................................................................................................... 25

Strange Sounds ........................................................................................................................................... 25

Operational Conditions .................................................................................................................................... 25,26

Smelly Water ............................................................................................................................................... 25

“AIR” In Hot Water Faucets.......................................................................................................................... 25

High Temperature Shut Off System ........................................................................................................ 25,26

Leakage Checkpoints ........................................................................................................................................... 26

TROUBLESHOOTING GUIDE ................................................................................................................... 27

REPAIR PARTS LIST.................................................................................................................................. 28

NOTES .................................................................................................................................................................. 29-31

WARRANTY................................................................................................................................................ 32

4

Page 5

CUSTOMER RESPONSIBILITIES

Thank You for purchasing a Maytag water heater. Properly

installed and maintained, it should give you years of trouble free

service. It is strongly suggested that this new water heater be

professionally installed, contact Maytag Customer Service (1-

800-788-8899) for recommended installers.

Abbreviations Found In This Instruction Manual:

• EPACT - Energy Policy A ct

• UL - Underwriters Laboratories Inc.

• CAN - Canada

• CSA - Canadian Standards Association

• NFPA - National Fire Protection Association

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• GAMA - Gas Appliance Manufacturer’s Association

This gas-fired water heater is design certified by Underwriters

Laboratories Inc. under American National Standard/CSA

Standard for Gas Water Heaters ANSI Z21.3 • CSA 4.3 (current

edition). The installation must conform with CAN/CSA-B149.1,

installation code and/or Local Installation Codes.

• Read the “Safety Precautions” section, page 3 of this manual

first and then the entire manual carefully. If you don’t follow

the safety rules, the water heater will not operate properly. It

could cause DEATH, SERIOUS BODILY INJURY AND/OR

PROPERTY DAMAGE.

This manual contains instructions for the installation, operation,

and maintenance of the gas-fired water heater. It also contains

warnings through out the manual that you must read and be

aware of. All warnings and all instructions are essential to the

proper operation of the water heater and your safety. Since

we cannot put everything on the first few pages, READ THE

ENTIRE MANUAL BEFORE ATTEMPTING TO INSTALL OR

OPERATE THE WATER HEATER.

• The installation must conform with these instructions and the

local code authority having jurisdiction. In the absence of

local codes, installations shall comply with the Natural Gas

and Propane Installation Code CAN/CSA-B149.1. This

publication is available from the Canadian Standards

Association, 5060 Spectrum Way, Suite 100 Mississauga,

Ontario, Canada L4W 5N6.

• If after reading this manual you have any questions or do not

understand any portion of the instructions, call Maytag

Customer Service at 1-800-788-8899 for an authorized

servicer.

• Carefully plan the place where you are going to put the water

heater. Correct combustion, vent action, and vent pipe

installation are very important in preventing death from

possible carbon monoxide poisoning and fires, see

Figures 9 through 14.

Examine the location to ensure the water heater complies

with the Locating and Installing the New Heater section in this

manual.

PRODUCT SPECIFICATIONS

TANK RECOVERY MINIMUM DIMENSIONS

CAPACITY TYPE RATE GALS. VENT PIPE DIAMETER IN INCHES (mm)

IN GALS OF BTU PER HOUR INCHES INCHES HEIGHT TOP OF

MODEL NUMBER (LTRS) GAS RATE @ 90°F RISE (mm) (mm) DRAFT HOOD

HXN4975S 75 (284) NATURAL 75,100 81.0 4" (102) 26 3/8" (670) 61 1/8" (1,553)

HXP4975S 75 (284) PROPANE 75,100 81.0 4" (102) 26 3/8" (670) 61 1/8" (1,553)

5

Page 6

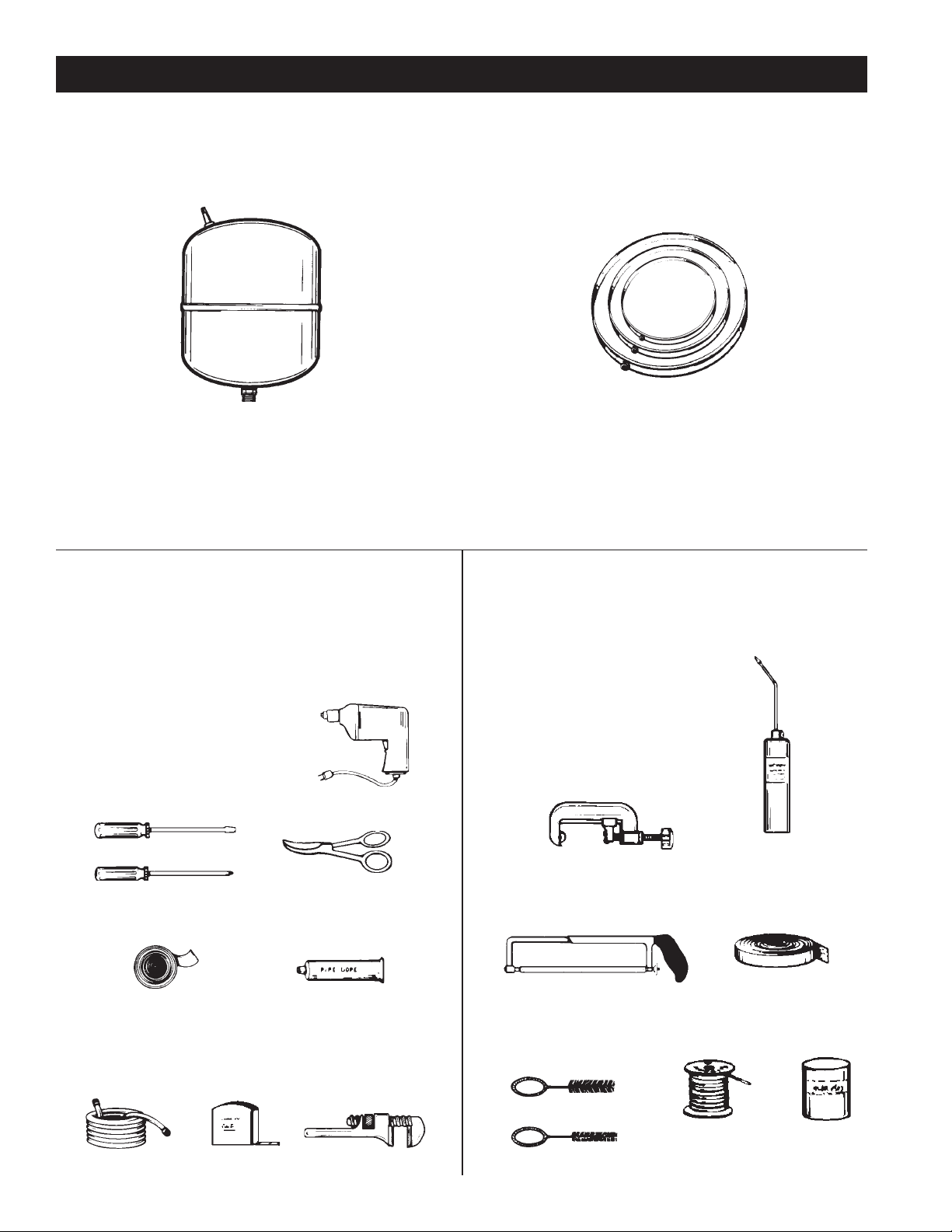

ACCESSORIES AND TOOLS NEEDED

Accessories

To simplify the installation Maytag has available the installation parts shown below. You may or may not need all of these accessories

depending on your type of installation. Call Maytag Customer Service at 1-800-788-8899 for an authorized installer.

EXPANSION TANKS FOR THERMAL EXPANSION CONDITIONS

AVAILABLE IN 2 GALLONS (7.6 LITERS), Part No. 66001013 AND 5

GALLONS (18.9 LITERS), Part No. 66001014 CAPACITY.

Tools

You may or may not need all these tools, depending on your

type of installation. These tools can be purchased at your local

hardware store.

• Pipe Wrenches (2) 14” (356 mm)

• Screwdriver

• Tin Snips

• 6’ (1.82 m) Tape or Folding Ruler

• Garden Hose

• Drill

• Pipe Dope or Teflon Tape

DRILL

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

TIN SNIPS

DRAIN PANS AVAILABLE IN 22” (559 mm) DIAMETER (PART NO.

66001011) FOR WATER HEATERS HAVING A DIAMETER 20” (508

mm) OR LESS, 24” (610mm) DIAMETER (PART NO. 66001105) FOR

WATER HEATERS HAVING A DIAMETER 22” (559 mm) OR LESS

AND 28” (711 mm) DIAMETER (PART NO. 66001012) FOR WATER

HEATERS HAVING A DIAMETER 26” (660 mm) OR LESS.

Additional Tools Needed

When Sweat Soldering

• Tubing Cutters or Hacksaw

• Propane Tank

• Soft Solder

• Solder Flux

• Emery Cloth

• Wire Brushes

PROPANE

TUBING CUTTER

TORCH

ROLL OF TEFLON

TAPE (USE ONLY ON

WATER HEATER

CONNECTIONS)

GARDEN HOSE

6 FOOT TAPE

PIPE DOPE

(SQUEEZE TUBE)

USE FOR WATER AND GAS

CONNECTIONS

PIPE WRENCH

3/4” (19 mm) WIRE BRUSH

1/2” (13 mm) WIRE BRUSH

6

HACKSAW

EMERY CLOTH

ROLL OF LEAD-FREE

SOFT SOLDER

ROLL OF

SOLDER

FLUX

Page 7

PREPARATIONS FOR INSTALLATION

Removing the Old Water Heater

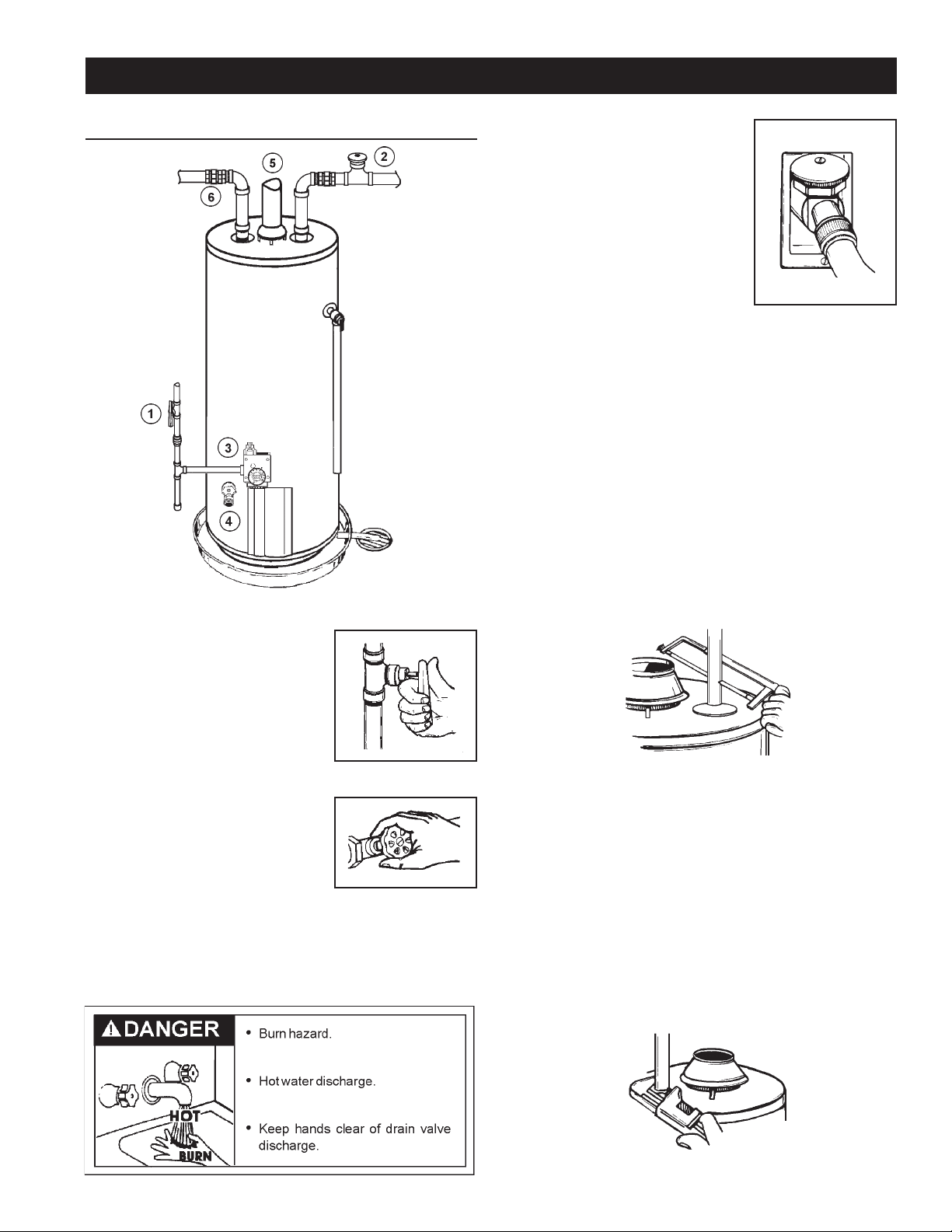

FIGURE 1.

4. Attach a hose to the water heater

drain valve and put the other end

in a floor drain or outdoors. Open

the water heater drain valve. Open

a nearby hot water faucet which

will relieve pressure in the water

heater and speed draining. The

water passing out of the drain

valve may be extremely hot. To

avoid being scalded, make sure all

connections are tight and that the

water flow is directed away from

any person, see Figures 1 and 4.

5. Disconnect the vent pipe from the draft hood where they

connect to the water heater. In most installations the vent

pipe can be lifted off after any screw or other attached devices

are removed. Dispose of the draft hood. The new water

heater has the draft hood which must be used for proper

operation.

6. If you have copper piping to the water heater, the two copper

water pipes can be cut with a hacksaw approximately four

inches away from where they connect to the water heater.

This will avoid cutting off pipes too short. Additional cuts can

be made later if necessary. Disconnect the temperaturepressure relief valve drain line. When the water heater is

drained, disconnect the hose from the drain valve. Close the

drain valve. The water heater is now completely disconnected

and ready to be removed, see Figure 5.

FIGURE 4.

1. Turn “OFF” the gas supply to the

water heater.

If the main gas line Shut-off valve

serving all gas appliances is used,

also shut “OFF” the gas at each

appliance. Leave all gas

appliances shut “OFF” until the

water heater installation is

completed, see Figures 1 and 2.

2. Turn “OFF” the water supply to the

water heater at the water shut-off

valve or water meter. Some

installations require that the water

be turned off to the entire house,

see Figures 1 and 3.

3. Check again to make sure the gas supply is “OFF” to the

water heater. Then disconnect the gas supply connection from

the gas control valve.

FIGURE 2.

FIGURE 3.

FIGURE 5.

If you have galvanized pipe to the water heater, loosen the

two galvanized pipes with a pipe wrench at the union in each

line. Also disconnect the piping remaining to the water

heater. These pieces should be saved since they may be

needed when reconnecting the new water heater.

Disconnect the temperature-pressure relief valve drain line.

When the water heater is drained, disconnect the hose from

the drain valve. Close the drain valve. The water heater is

now completely disconnected and ready to be removed.

Mineral buildup or sediment may have accumulated in the

old water heater. This causes the water heater to be much

heavier than normal and this residue, if spilled out, could

cause staining, see Figure 6.

FIGURE 6.

7

Page 8

TYPICAL INSTALLATION

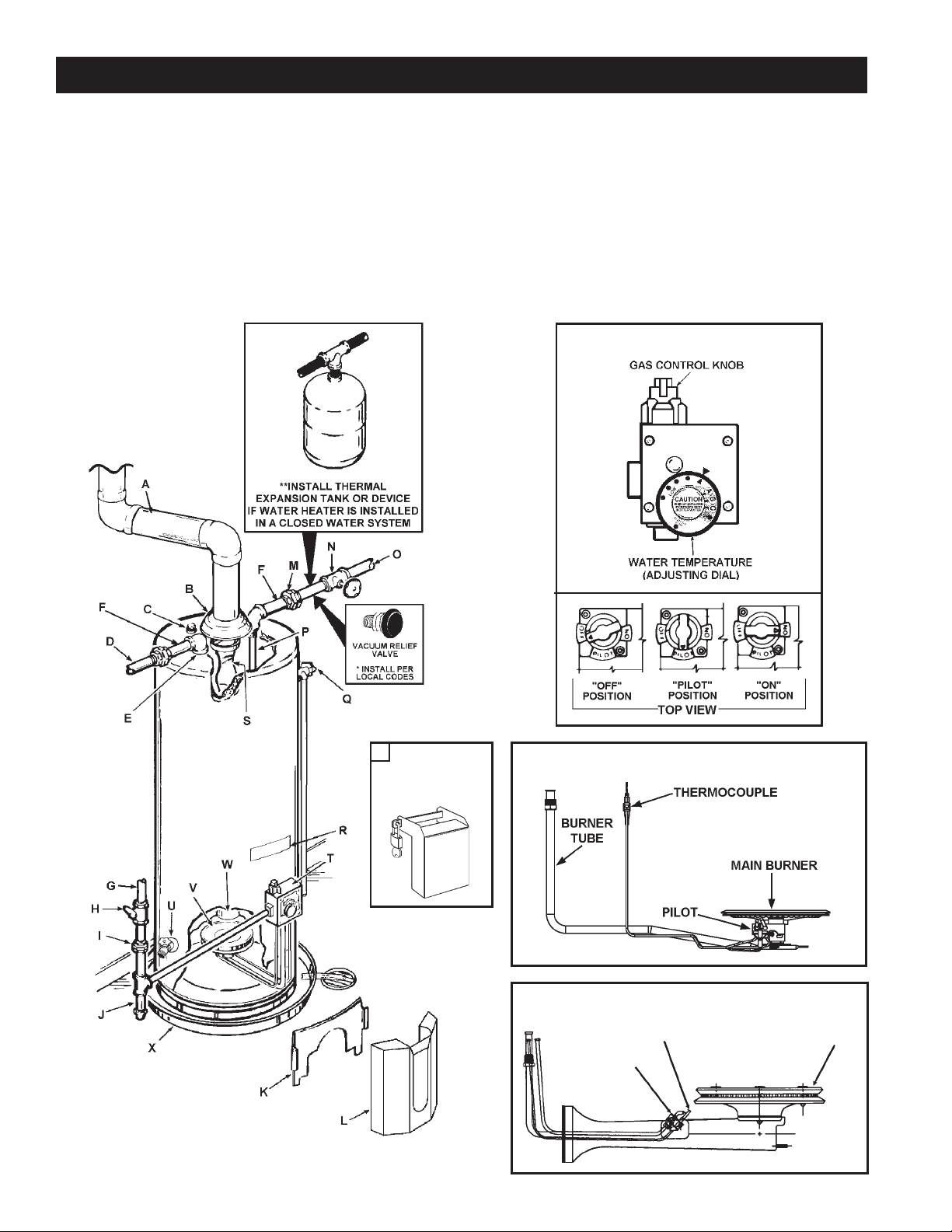

GET TO KNOW YOUR WATER HEATER - GAS MODELS

A Vent Pipe

B Draft Hood

C Anode

D Hot Water Outlet

E Outlet

F Water Connections

G Gas Supply

H Manual Gas Shut-off Valve

I Ground Joint Union

* INSTALL IN ACCORDANCE

WITH LOCAL CODES.

* DRIP LEG AS REQUIRED

BY LOCAL CODES.

TO VENT TERMINATION

ON ROOF

J Drip Leg (Sediment Trap)

K Inner Door

L Outer door

M Union

N Inlet Water Shut-off Valve

O Cold Water Inlet

P Inlet Dip Tube

Q Temperature-Pressure Relief Valve

R Rating Plate

S Flue Baffle(s)

T Thermostat

U Drain Valve

V Pilot and Main Burner

W Flue

X Drain Pan

Y Thermostat Shield (optional)

(T) THERMOSTAT

* ALL PIPING MATERIALS TO BE

SUPPLIED BY CUSTOMERS.

** CLOSED WATER SYSTEMS ARE THOSE WITH

BACK FLOW PREVENTION DEVICES INSTALLED

IN THE INLET WATER SERVICE LINE.

Y

THERMOSTAT

SHIELD

(OPTIONAL)

FIGURE 7.

8

(V) PILOT & MAIN BURNER - NATURAL GAS

(V) PILOT & MAIN BURNER - PROPANE GAS

MAIN

BURNER

PILOT

BURNER

THERMOCOUPLE

Page 9

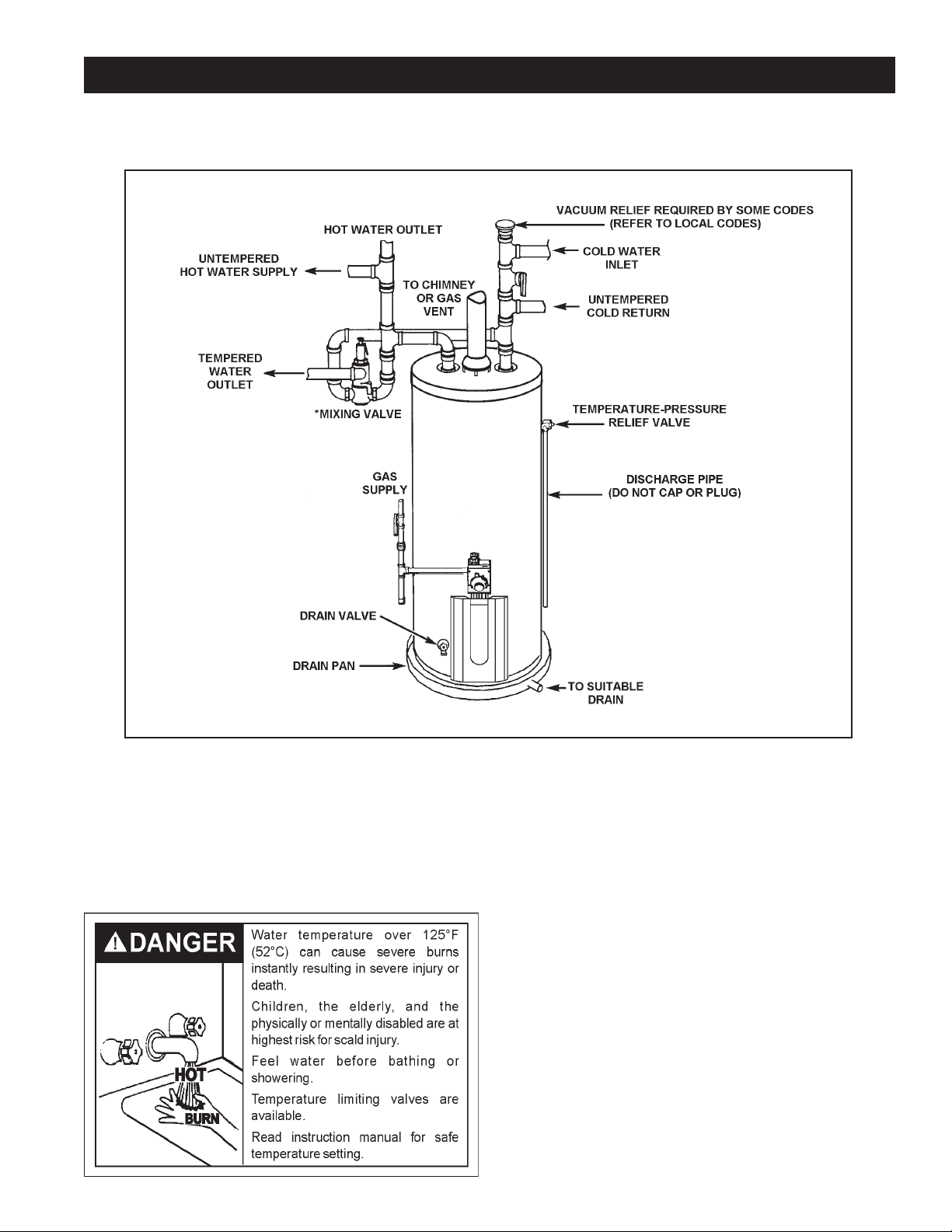

TYPICAL INSTALLATION

MIXING VALVE USAGE

FIGURE 8.

This appliance has been design certified as complying with

American National Standard/CSA Standard for water heaters and

is considered suitable for:

Water (Potable) Heating: All models are considered suitable

for water (potable) heating.

HOTTER WATER CAN SCALD:

Water heaters are intended to produce hot water. Water heated

to a temperature which will satisfy clothes washing, dish

washing, and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likely to be

permanently injured by hot water than others. These include

the elderly, children, the infirm, or physically/mentally

handicapped. If anyone using hot water in your home fits into

one of these groups or if there is a local code or province law

requiring a certain temperature water at the hot water tap, then

you must take special precautions. In addition to using the

lowest possible temperature setting that satisfies your hot water

needs, a means such as a *Mixing Valve, shall be used at the

hot water taps used by these people or at the water heater.

Mixing valves are available at plumbing supply or hardware

stores. See Figure 8. Valves for reducing point of use

temperature by mixing cold and hot water are also available.

Consult Maytag Customer Service (1-800-788-8899). Follow

mixing valve manufacturer’s instructions for installation of the

valves. Before changing the factory setting on the thermostat,

read the “Temperature Regulation” section in this manual, see

Figures 22 and 23 on page 21.

9

Page 10

LOCATING AND INSTALLING THE NEW WATER HEATER

Facts to Consider About the Location

Carefully choose an indoor location for the new water heater,

because the placement is a very important consideration for the

safety of the occupants in the building and for the most

economical use of the appliance. This water heater is not for

use in manufactured (mobile) homes or outdoor installation.

Whether replacing an old water heater or putting the water heater

in a new location, the following critical points must be observed:

• Select a location indoors as close as practical to the gas vent

or chimney to which the water heater vent is going to be

connected, and as centralized with the water piping system

as possible.

• Selected location must provide adequate clearances for

servicing and proper operation of the water heater.

• Water supply shut-off devices that activate based on the

water pressure differential between the cold water and hot

water pipes connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater

while at the same time shutting off its water supply.

Installation of the water heater must be accomplished in such a

manner that if the tank or any connections should leak, the flow

will not cause damage to the structure. For this reason, it is not

advisable to install the water heater in an attic or upper floor.

When such locations cannot be avoided, a suitable drain pan

should be installed under the water heater. Drain pans are

available at your local hardware store. Such a drain pan must

have a minimum length and width of at least 2 inches (51 mm)

greater than the water heater dimensions and must be piped to

an adequate drain. The pan must not restrict combustion air

flow.

Water heater life depends upon water quality, water pressure

and the environment in which the water heater is installed. Water

heaters are sometimes installed in locations where leakage may

result in property damage, even with the use of a drain pan piped

to a drain. However, unanticipated damage can be reduced or

prevented by a leak detector or water shut-off device used in

conjunction with a piped drain pan. These devices are available

from some plumbing supply wholesalers and retailers, and detect

and react to leakage in various ways:

• Sensors mounted in the drain pan that trigger an alarm or

turn off the incoming water to the water heater when leakage

is detected.

• Sensors mounted in the drain pan that turn off the water

supply to the entire home when water is detected in the drain

pan.

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQUIDS

(VAPORS) ARE LIKELY TO BE PRESENT OR STORED

(GARAGES, STORAGE AND UTILITY AREAS, ETC.):

Flammable liquids (such as gasoline, solvents, propane [LP or

butane, etc.] and other substances such as adhesives, etc.) emit

flammable vapors which can be ignited by a gas water heater’s

pilot light or main burner. The resulting flashback and fire can

cause death or serious burns to anyone in the area, as well as

property damage. If installation in such areas is your only option,

then the installation must be accomplished in a way that the pilot

flame and main burner flame are elevated from the floor at least

18 inches. While this may reduce the chances of flammable

vapors, from a floor spill being ignited, gasoline and other

flammable substances should never be stored or used in the

same room or area containing a gas water heater or other open

flame or spark producing appliance. NOTE: Flammable vapors

may be drawn by air currents from other areas of the structure to

the appliance.

Also, the water heater must be located and/or protected so it is

not subject to physical damage by a moving vehicle.

10

Page 11

This water heater must not be installed directly on carpeting.

Carpeting must be protected by metal or wood panel beneath

the appliance extending beyond the full width and depth of the

appliance by at least 3 inches (76.2 mm) in any direction, or if

the appliance is installed in an alcove or closet, the entire floor

must be covered by the panel. Failure to heed this warning may

result in a fire hazard.

A gas water heater cannot operate properly without the correct

amount of air for combustion. Do not install in a confined area

such as a closet, unless you provide air as shown in the Locating

and Installing the New Water Heater section. Never obstruct

the flow of ventilation air. If you have any doubts or questions at

all, call your gas supplier. Failure to provide the proper amount

of combustion air can result in a fire or explosion and cause

death, serious bodily injury, or property damage.

FIGURE 10.

If this water heater will be used in beauty shops, barber shops,

cleaning establishments, or self-service laundries with dry

cleaning equipment, it is imperative that the water heater or water

heaters be installed so that combustion and ventilation air be

taken from outside these areas.

Minimum clearances between the water heater and combustible

construction are 0 inch at the sides and rear, 4 inches (102 mm)

at the front, and 6 inches (153 mm) from the vent pipe. Clearance

from the top of the jacket is 12 inches

(305 mm) on most models. Note that a lesser dimension may

be allowed on some models, refer to the label attached adjacent

to the gas control valve on the water heater, see Figure 9.

FIGURE 9.

Propellants of aerosol sprays and volatile compounds, (cleaners,

chlorine based chemicals, refrigerants, etc.) in addition to being

highly flammable in many cases, will also change to corrosive

hydrochloric acid when exposed to the combustion products of

the water heater. The results can be hazardous, and also cause

product failure.

Insulation Blankets

Insulation blankets available to the general public for external

use on gas water heaters are not necessary with Maytag

products. The purpose of an insulation blanket is to reduce the

standby heat loss encountered with storage tank heaters. Your

Maytag water heater meets or exceeds the EPACT standards

with respect to insulation and standby loss requirements, making

an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions (See Figure 7 for

identification of components mentioned below). Failure to follow

11

WARNING

Page 12

these instructions can restrict the air flow required for proper

combustion, potentially resulting in fire, asphyxiation, serious

personal injury or death.

• Do not apply insulation to the top of the water heater, as this

will interfere with safe operation of the draft hood.

• Do not cover the outer door, thermostat or temperature &

pressure relief valve.

• Do not allow insulation to come within 2” (50.8 mm) of the

floor to prevent blockage of combustion air flow to the burner.

• Do not cover the instruction manual. Keep it on the side of

the water heater or nearby for future reference.

• Do obtain new warning and instruction labels from Maytag

for placement on the blanket directly over the existing labels.

commence within 12 inches (30 cm) of the top and one

commencing within 12 inches (30 cm) of the bottom of the

enclosures.

• Do inspect the insulation blanket frequently to make certain

it does not sag, thereby obstructing combustion air flow.

Combustion Air and Ventilation for

Appliances Located in Unconfined Spaces

UNCONFINED SPACE is space whose volume is not less than

50 cubic feet per 1,000 Btu per hour (4.8 m

aggregate input rating of all appliances installed in that space.

Rooms communicating directly with the space in which the

appliances are installed, through openings not furnished with

doors, are considered a part of the unconfined space.

In unconfined spaces in buildings, infiltration may be adequate

to provide air for combustion, ventilation and dilution of flue

gases. However, in buildings of tight construction (for example,

weather stripping, heavily insulated, caulked, vapor barrier, etc.),

additional air may need to be provided using the methods

described in Combustion Air and Ventilation for Appliances

Located in Confined Spaces.

3

per kW) of the

Combustion Air and Ventilation for

Appliances Located in Confined Spaces

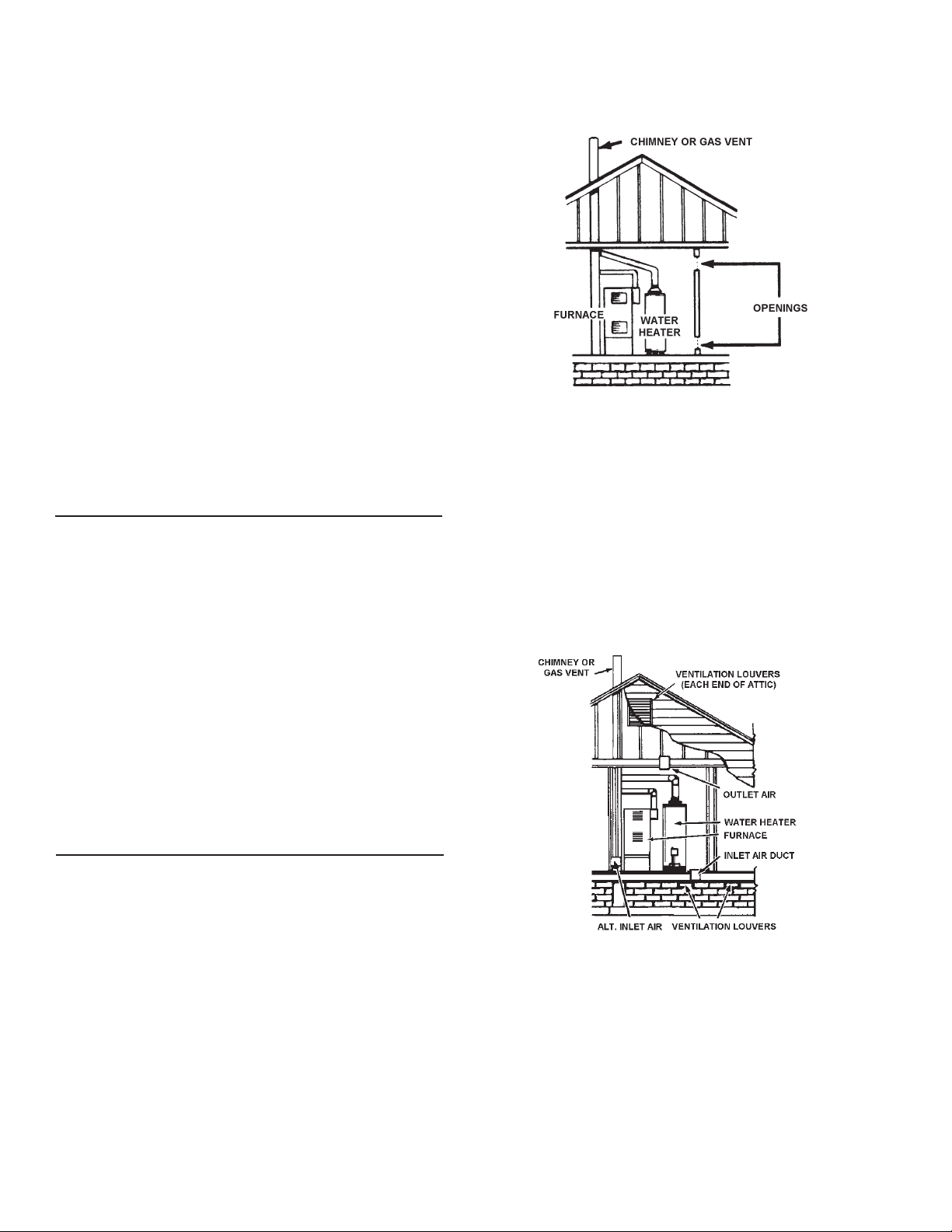

FIGURE 11.

B. ALL AIR FROM OUTDOORS: (See Figures 12, 13 and 14)

The confined space shall be provided with two permanent

openings, one commencing within 12 inches (30 cm) of the top

and one commencing within 12 inches (30 cm) from the bottom

of the enclosure. The openings shall communicate directly, or

by ducts, with the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

CONFINED SPACE is a space whose volume is less than

50 cubic feet per 1,000 Btu per hour (4.8 m

3

per kW) of the

aggregate input rating of all appliances installed in that space.

A. ALL AIR FROM INSIDE BUILDINGS:

(See Figures 10 and 11)

The confined space shall be provided with two permanent

openings communicating directly with an additional room(s)

of sufficient volume so that the combined volume of all spaces

meets the criteria for an unconfined space. The total input of

all gas utilization equipment installed in the combined space

shall be considered in making this determination. Each

opening shall have a minimum free area of one square inch

per 1,000 Btu per hour (22 cm

2

/kW) of the total input rating of

all gas utilization equipment in the confined space, but not

less than 100 square inches (645 cm

2

). One opening shall

FIGURE 12.

• When directly communicating with the outdoors, each opening

shall have a minimum free area of 1 square inch per 4,000 Btu per

hour (5.5 cm

2

/kW) of total input rating of all equipment in the

enclosure, see Figure 12.

• When communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of

1 square inch per 4,000 BTU per hour (5.5 cm

2

/kW) of total

input rating of all equipment in the enclosure, see

Figure 13.

12

Page 13

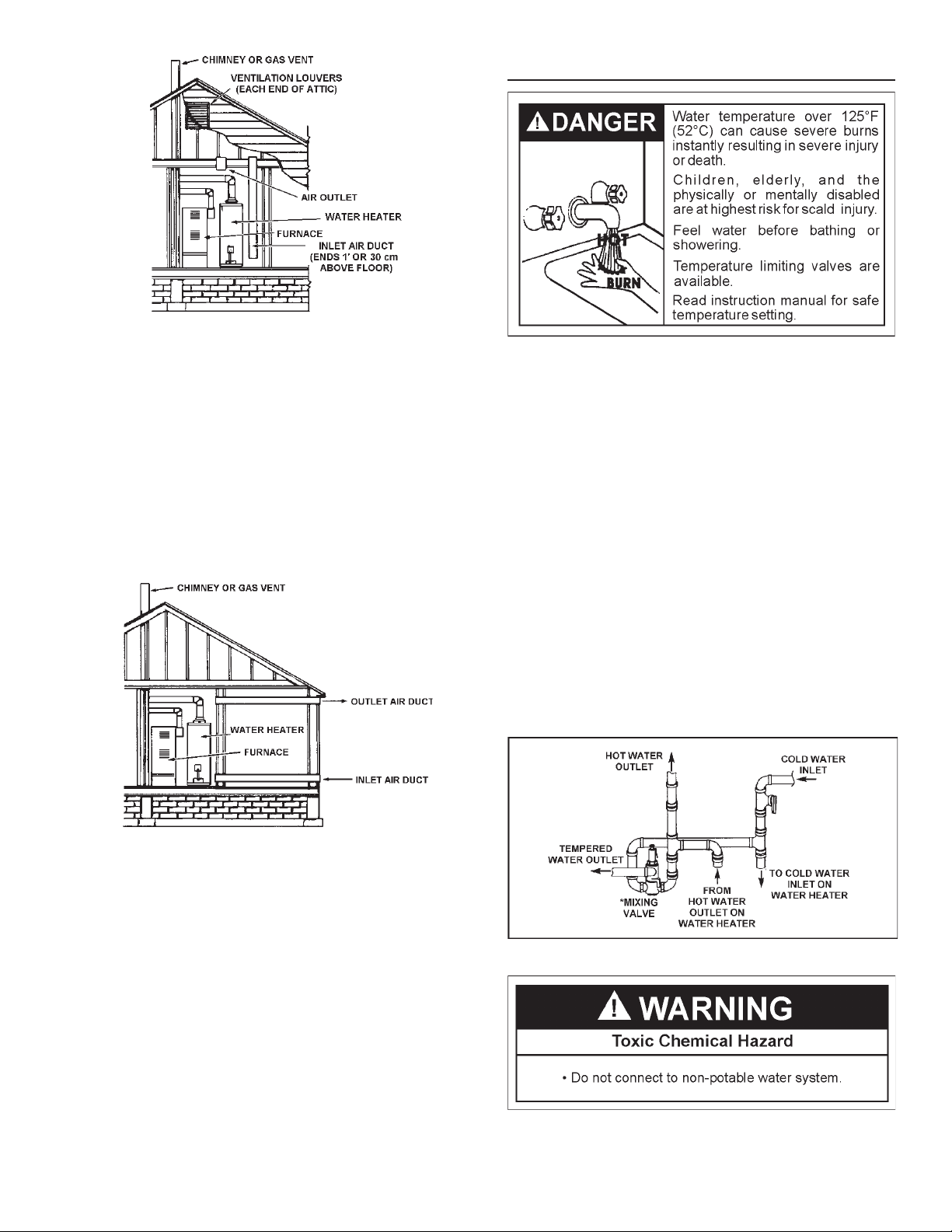

FIGURE 13.

• When communicating with the outdoors through horizontal

ducts, each opening shall have a minimum free area of 1

square inch per 2,000 BTU per hour (11 cm

2

/kW) of total

input rating of all equipment in the enclosure, see

Figure 14.

• When ducts are used, they shall be of the same crosssectional area as the free area of the openings to which they

connect. The minimum short side dimension of rectangular

air ducts shall not be less than 3 inches

(76.2 mm), see Figure 14.

Water Piping

HOTTER WATER CAN SCALD:

Water heaters are intended to produce hot water. Water

heated to a temperature which will satisfy clothes washing,

dish washing, cleaning and other sanitizing needs can scald

and permanently injure you upon contact. Some people are

more likely to be permanently injured by hot water than others.

These include the elderly, children, the infirm, or physically/

mentally handicapped. If anyone using hot water in your home

fits into one of these groups or if there is a local code or

province law requiring a certain temperature water at the hot

water tap, then you must take special precautions. In addition

to using the lowest possible temperature setting that satisfies

your hot water needs, a means such as a *mixing valve, shall

be used at the hot water taps used by these people or at the

water heater. Mixing valves are available at plumbing supply

or hardware stores, see Figure 8 on page 9 and Figure 15

below. Valves for reducing point of use temperature by mixing

cold and hot water are also available. Consult Maytag

Customer Service (1-800-788-8899). Follow manufacturer’s

instructions for installation of the valves. Before changing

the factory setting on the thermostat, read the Temperature

Regulation section in this manual.

FIGURE 14.

• Louvers and Grilles: In calculating free area, consideration

shall be given to the blocking effect of louvers, grilles or

screens protecting openings. Screens used shall not be

smaller than 1/4 inch (6.4 mm) mesh. If the free area through

a design of louver or grille is known, it should be used in

calculating the size opening required to provide the free area

specified. If the design and free area is not known, it may be

assumed that wood louvers will be 20-25 percent free area

and metal louvers and grilles will have 60-75 percent free

area. Louvers and grilles shall be fixed in the open position

or interlocked with the equipment so that they are opened

automatically during equipment operation.

• Special Conditions Created by Mechanical Exhausting or

Fireplaces: operation of exhaust fans, ventilation systems,

clothes dryers or fireplaces may create conditions requiring

special attention to avoid unsatisfactory operation of installed

gas utilization equipment.

FIGURE 15.

This water heater shall not be connected to any heating systems

or component(s) used with a non-potable water heating

appliance.

13

Page 14

Toxic chemicals, such as those used for boiler treatment shall

not be introduced into this system.

Water supply systems may, because of such events as high

line pressure, frequent cut-offs, the effects of water hammer

among others, have installed devices such as pressure reducing

valves, check valves, back flow preventers, etc. to control these

types of problems. When these devices are not equipped with

an internal by-pass, and no other measures are taken, the

devices cause the water system to be closed. As water is heated,

it expands (thermal expansion) and closed systems do not allow

for the expansion of heated water.

The water within the water heater tank expands as it is heated

and increases the pressure of the water system. If the relieving

point of the water heater’s temperature-pressure relief valve is

reached, the valve will relieve the excess pressure. The

temperature-pressure relief valve is not intended for the

constant relief of thermal expansion. This is an unacceptable

condition and must be corrected. It is recommended that any

devices installed which could create a closed system have a

by-pass and/or the system have an expansion tank to relieve

the pressure built by thermal expansion in the water system.

Refer to the Thermal Expansion section under Troubleshooting

Guide or contact local plumbing authority or call Maytag

Customer Service at 1-800-788-8899 for an authorized

installer on how to control this situation.

can be accomplished by insulating the hot water lines

from the water heater.

NOTE: To protect against untimely corrosion of hot and cold

water fittings, it is strongly recommended that di-electric

unions or couplings be installed on this water heater when

connected to copper pipe.

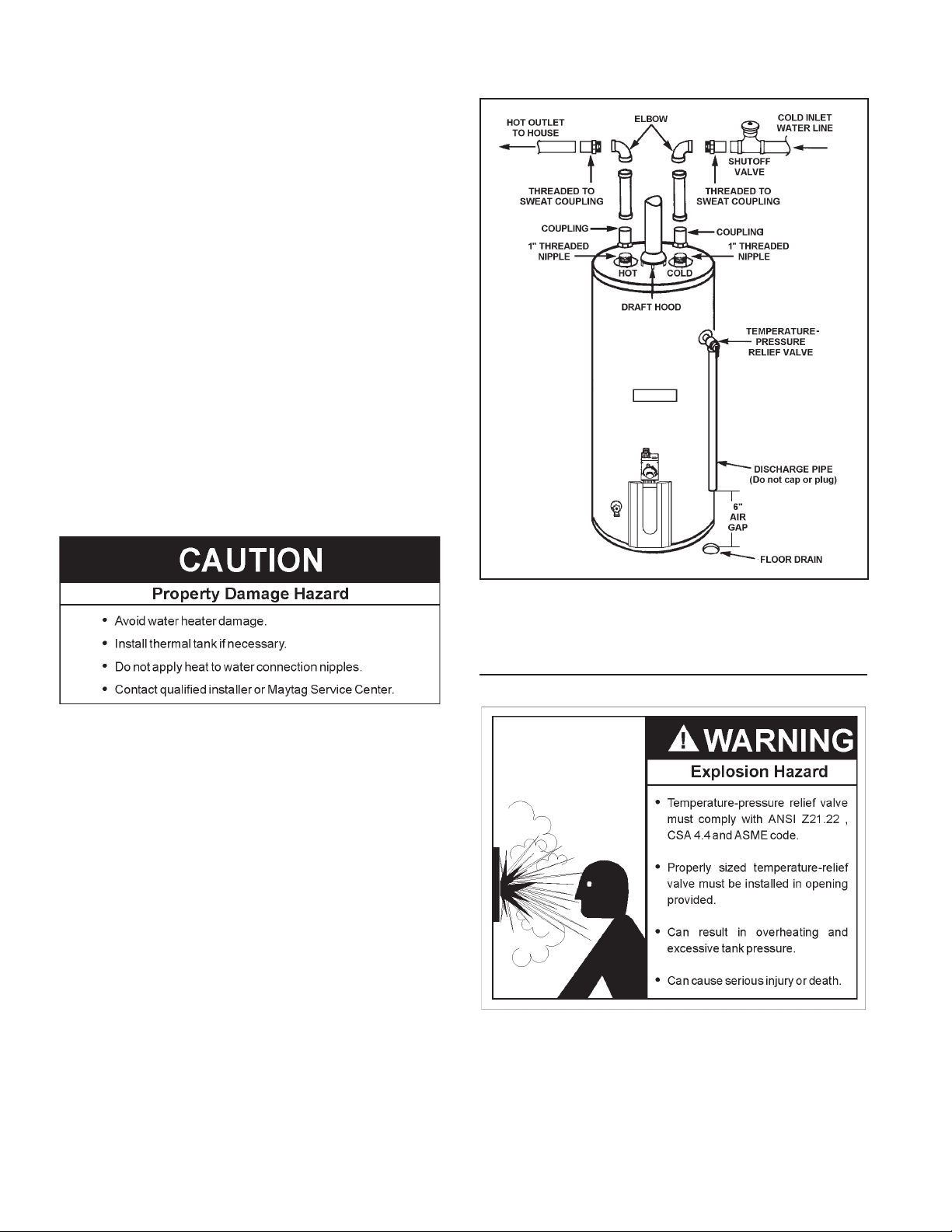

Figure 16 shows the typical attachment of the water piping to

the water heater. The water heater is equipped with 1” NPT

water connections for 75 gallon models.

NOTE: If using copper tubing, solder tubing to an adapter

before attaching the adapter to the water connections. Do

not solder the water lines directly to the water connections

on the tank. It will harm the dip tube and damage the tank.

• Look at the top cover of the water heater. The water outlet is

marked “HOT”. Put two or three turns of teflon tape around

the exposed end of the 1” NPT threaded nipple. Connect the

hot water pipe to the hot water outlet on the water heater.

• Look at the top of the water heater. The cold water inlet is

marked “COLD”. Put two or three turns of teflon tape around

the exposed end of the 1” NPT threaded nipple. Connect the

cold water pipe to the cold water inlet of the water heater.

NOTE: This water heater is super insulated to minimize

heat loss from the tank. Further reduction in heat loss

FIGURE 16.

Temperature-Pressure Relief Valve

This heater is provided with a properly certified combination

temperature - pressure relief valve by the manufacturer.

The valve is certified by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed

equipment of materials as meeting the requirements for Relief

Valves for Hot Water Supply Systems, ANSI Z21.22 • CSA 4.4

and the code requirements of ASME.

14

Page 15

If replaced, the valve must meet the requirements of local

codes, but not less than a combination temperature and

pressure relief valve certified as indicated in the above

paragraph.

The valve must be marked with a maximum set pressure not

to exceed the marked maximum working pressure of the water

heater (150 psi = 1,035 kPa) and a discharge capacity not

less than the water heater input rate as shown on the model

rating plate.

For safe operation of the water heater, the relief valve must not

be removed from its designated opening nor plugged.

The Discharge Pipe:

• Shall not be smaller in size than the outlet pipe size of the

valve, or have any reducing couplings or other restrictions.

• Shall not be plugged or blocked.

The temperature-pressure relief valve must be installed directly

into the fitting of the water heater designed for the relief valve.

Position the valve downward and provide tubing so that any

discharge will exit only within 6 inches (153 mm) above, or at

any distance below the structural floor. Be certain that no contact

is made with any live electrical part. The discharge opening

must not be blocked or reduced in size under any circumstances.

Excessive length, over 30 feet (9.14 m), or use of more than

four elbows can cause restriction and reduce the discharge

capacity of the valve, see Figure 17.

No valve or other obstruction is to be placed between the relief

valve and the tank. Do not connect tubing directly to discharge

drain unless a 6 inch air gap is provided. To prevent bodily

injury, hazard to life, or property damage, the relief valve must

be allowed to discharge water in quantities should circumstances

demand. If the discharge pipe is not connected to a drain or

other suitable means, the water flow may cause property

damage.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both

the temperature-pressure relief valve, and the discharge

pipe.

• Shall terminate at an adequate drain.

• Shall not have any valve between the relief valve and tank.

The temperature-pressure relief valve must be manually

operated at least once a year. Caution should be taken to ensure

that (1) no one is in front of or around the outlet of the

temperature-pressure relief valve discharge line, and (2) the

water manually discharged will not cause any bodily injury or

property damage because the water may be extremely hot.

FIGURE 17.

If after manually operating the valve, it fails to completely reset

and continues to release water, immediately close the cold

water inlet to the water heater, follow the draining instructions,

and replace the temperature-pressure relief valve with a new

one.

Filling the Water Heater

15

Page 16

Never use this water heater unless it is completely full of water.

To prevent damage to the tank, the tank must be filled with water.

Water must flow from the hot water faucet before turning “ON”

gas to the water heater.

To fill the water heater with water:

• Close the water heater drain valve by turning the handle to

the right (clockwise). The drain valve is on the lower front of

the water heater.

• Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open

when the water heater is in use.

• To insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run

until a constant flow is obtained. This will let air out of the

water heater and the piping.

To insure proper venting of this gas-fired water heater, the

correct vent pipe diameter must be utilized. Any additions

or deletions of other gas appliances on a common vent with

this water heater may adversely affect the operation of the

water heater. Consult your Maytag Service Center at

1-800-788-8899 or gas supplier if any such changes are

planned.

For proper venting in certain installations, a larger diameter vent

pipe may be necessary. Consult your Maytag Customer

Service Center at 1-800-788-8899 or gas supplier to aid you

in determining the proper venting for your water heater from

the vent tables in the current edition of CAN/CSA-B149.1

Installation Code.

Periodically check the venting system for signs of obstruction or

deterioration and replace if needed.

• Check all water piping and connections for leaks. Repair as

needed.

Venting

VENT DAMPERS - Any vent damper, whether it is operated

thermally or otherwise must be removed if its use inhibits proper

drafting of the water heater.

Thermally Operated Vent Dampers: This gas-fired water heater

has a thermal efficiency at or above 80% which may produce a

relatively low flue gas temperature. Such temperatures may

not be high enough to properly open thermally operated vent

dampers. This would cause spillage of the flue gases and may

cause carbon monoxide poisoning.

Vent dampers must bear evidence of certification as complying

with the current edition of the American National Standard

ANSI Z21.66/CGA 6.14, (covering electrically and mechanically

actuated vent dampers). Before installation of any vent damper,

consult your Maytag Customer Service Center at 1-800-7888899 or the local gas supplier for further information.

The combustion and ventilation air flow must not be obstructed.

The water heater with draft hood installed must be connected to

a chimney or listed vent pipe system, which terminates to the

outdoors. Never operate the water heater unless it is vented to

the outdoors and has adequate air supply to avoid risks of

improper operation, explosion or asphyxiation.

• For proper draft hood attachment, the draft hood legs may

be angled slightly inward.

• Place the draft hood legs in the receiving holes on the top of

the water heater. The legs will snap in the holes to give a

tight fit. Secure draft hood with the supplied brackets.

• Place the vent pipe over the draft hood. With the vent pipe in

position, drill a small hole through both the vent pipe and

draft hood. Secure them together with a sheet metal screw,

see Figure 18.

Obstructed or deteriorated vent systems may present serious

health risk or asphyxiation.

FIGURE 18.

The vent pipe from the water heater must be no less than the

diameter of the draft hood outlet on the water heater and must

slope upward at least 1/4 inch per linear foot (21 mm per meter),

see Figure 19.

16

Page 17

FIGURE 19.

All vent gases must be completely vented to the outdoors of the

structure (dwelling). Install only the draft hood provided with the

new water heater and no other draft hood.

Vent pipes must be secured at each joint with sheet metal

screws.

There must be a minimum of 6 inches (153 mm) clearance

between single wall vent pipe and any combustible material.

Fill and seal any clearance between single wall vent pipe and

combustible material with mortar mix, cement, or other

noncombustible substance. For other than single wall, follow

vent pipe manufacturer’s clearance specifications. To insure a

tight fit of the vent pipe in a brick chimney, seal around the vent

pipe with mortar mix cement.

1/2 pound per square inch (3.5kPa), the damage to the gas

control valve could result in a fire or explosion from leaking gas.

If the main gas line Shut-off serving all gas appliances is used,

also turn “OFF” the gas at each appliance. Leave all gas

appliances shut “OFF” until the water heater installation is

complete.

A gas line of sufficient size must be run to the water heater.

Consult the current edition of the CAN/CSA-B149.1, Installation

Code and/or your gas supplier concerning pipe size.

Failure to have required clearances between vent piping and

combustible material will result in a fire hazard.

Be sure vent pipe is properly connected to prevent escape of

dangerous flue gases which could cause deadly asphyxiation.

Chemical vapor corrosion of the flue and vent system may occur

if air for combustion contains certain chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air

conditioner refrigerants, swimming pool chemicals, calcium and

sodium chloride, waxes, bleach and process chemicals are

typical compounds which are potentially corrosive.

There must be:

• A readily accessible manual shut off valve in the gas supply

line serving the water heater, and

• A drip leg (sediment trap) ahead of the gas control valve to

help prevent dirt and foreign materials from entering the gas

control valve.

• A flexible gas connector or a ground joint union between the

shut off valve and control valve to permit servicing of the

unit.

Be sure to check all the gas piping for leaks before lighting the

water heater. Use a soapy water solution, not a match or open

flame. Rinse off soapy solution and wipe dry.

The minimum inlet gas pressure shown on the rating plate is

that which will permit firing at the rated input.

Gas Piping

Make sure the gas supplied is the same type listed on the model

rating plate. The inlet gas pressure must not exceed

14 inch water column (2.6kPa) for natural and propane (L.P.)

gas. If the gas control valve is subjected to pressures exceeding

17

Page 18

Standard Models are for installation up to 2,000 feet (610 m)

above sea level.

High Altitude Models are for installation from 2,000 feet (610

m) to 4,500 feet (1,370 m) above sea level.

If a standard model is installed above 2,000 feet (610 m) or

high altitude model is installed above 4,500 feet (1,370 m), the

input rating should be reduced at the rate of 4 percent for each

1,000 feet (305 m) above sea level which requires replacement

of the burner orifice in accordance with National CAN/CSA B-

149.1. Contact Maytag Customer Service Center at 1-800-

788-8899 or your local gas supplier or call for further

information.

Failure to replace the standard orifice with a high altitude orifice

when installed at elevations above 2,000 feet (610 m) or above

4,500 feet (1,370 m) for high altitude model could result in

improper and inefficient operation of the appliance, producing

carbon monoxide gas in excess of safe limits, which could result

in serious injury or death. Contact Maytag Customer Service

at 1-800-788-8899 or your local gas supplier for any specific

changes which may be required in your area.

Sediment Traps

Contaminants in the gas lines may cause improper operation of

the gas control valve that may result in fire or explosion. Before

attaching the gas line be sure that all gas pipe is clean on the

inside. To trap any dirt or foreign material in the gas supply line,

a drip leg (sometimes called a sediment trap) must be

incorporated in the piping. The drip leg must be readily

accessible. Install in accordance with the Gas Piping section.

Refer to the current edition of CAN/CSA-B149.1 and/or Local

Installation Codes.

A sediment trap shall be installed as close to the inlet of the

water heater as practical at the time of water heater installation.

The sediment trap shall be either a tee fitting with a capped

nipple in the bottom outlet or other device recognized as an

effective sediment trap. If a tee fitting is used, it shall be installed

in conformance with one of the methods of installation, shown

in Figures 20 and 21.

Use pipe joint compound or teflon tape marked as being resistant

to the action of petroleum (Propane [L.P.]) gases.

The appliance and its gas connection must be leak tested before

placing the appliance in operation.

The appliance and its individual Shut-off valve shall be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/

2 pound per square inch (3.5kPa). It shall be isolated from the

gas supply piping system by closing its individual manual Shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 pound per

square inch (3.5kPa).

Connecting the gas piping to the gas control valve of the water

heater can be accomplished by either of the two methods, shown

in Figures 20 and 21.

FIGURE 20. GAS PIPING WITH FLEXIBLE CONNECTOR.

FIGURE 21. GAS PIPING WITH ALL

BLACK IRON PIPE TO GAS CONTROL.

18

Page 19

OPERATING INSTRUCTIONS

19

Page 20

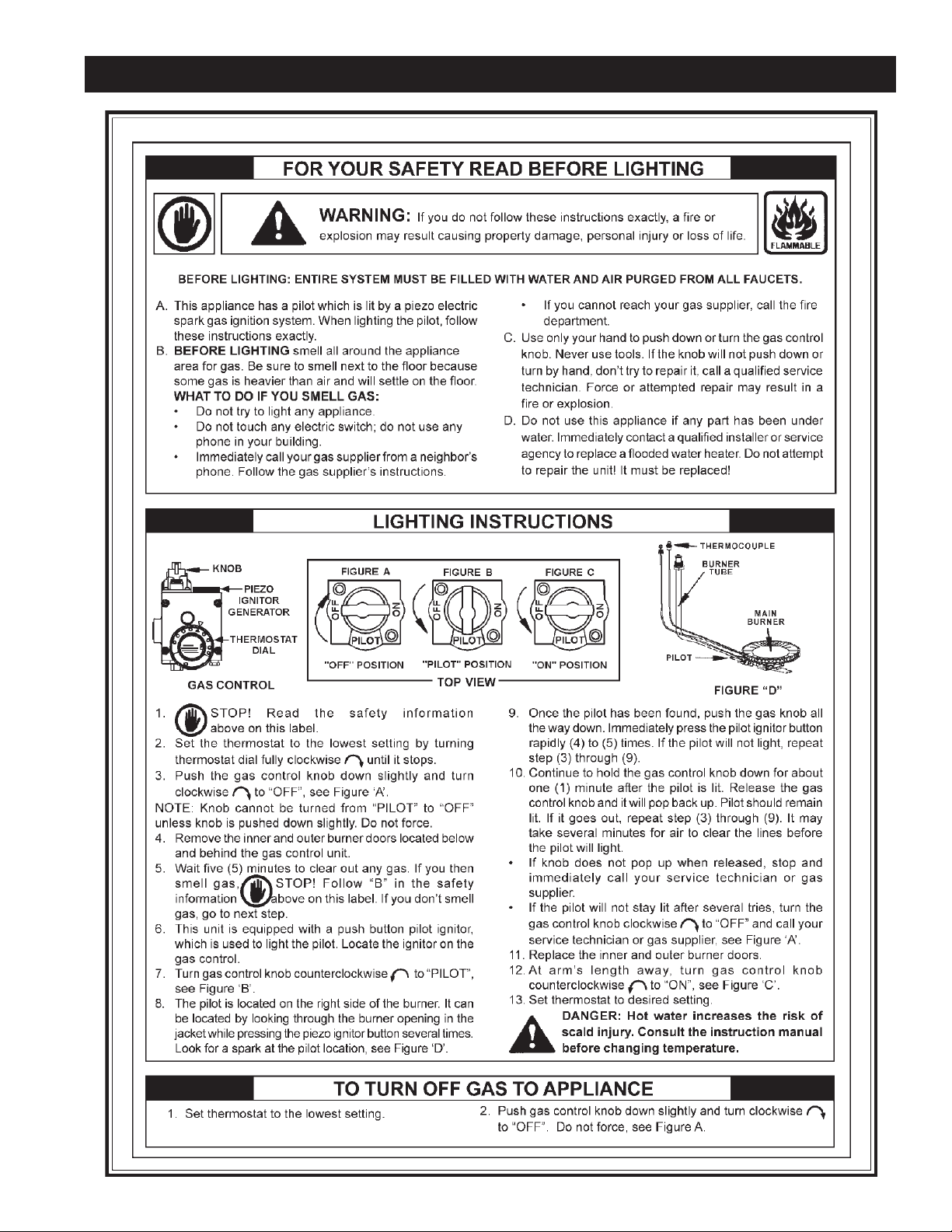

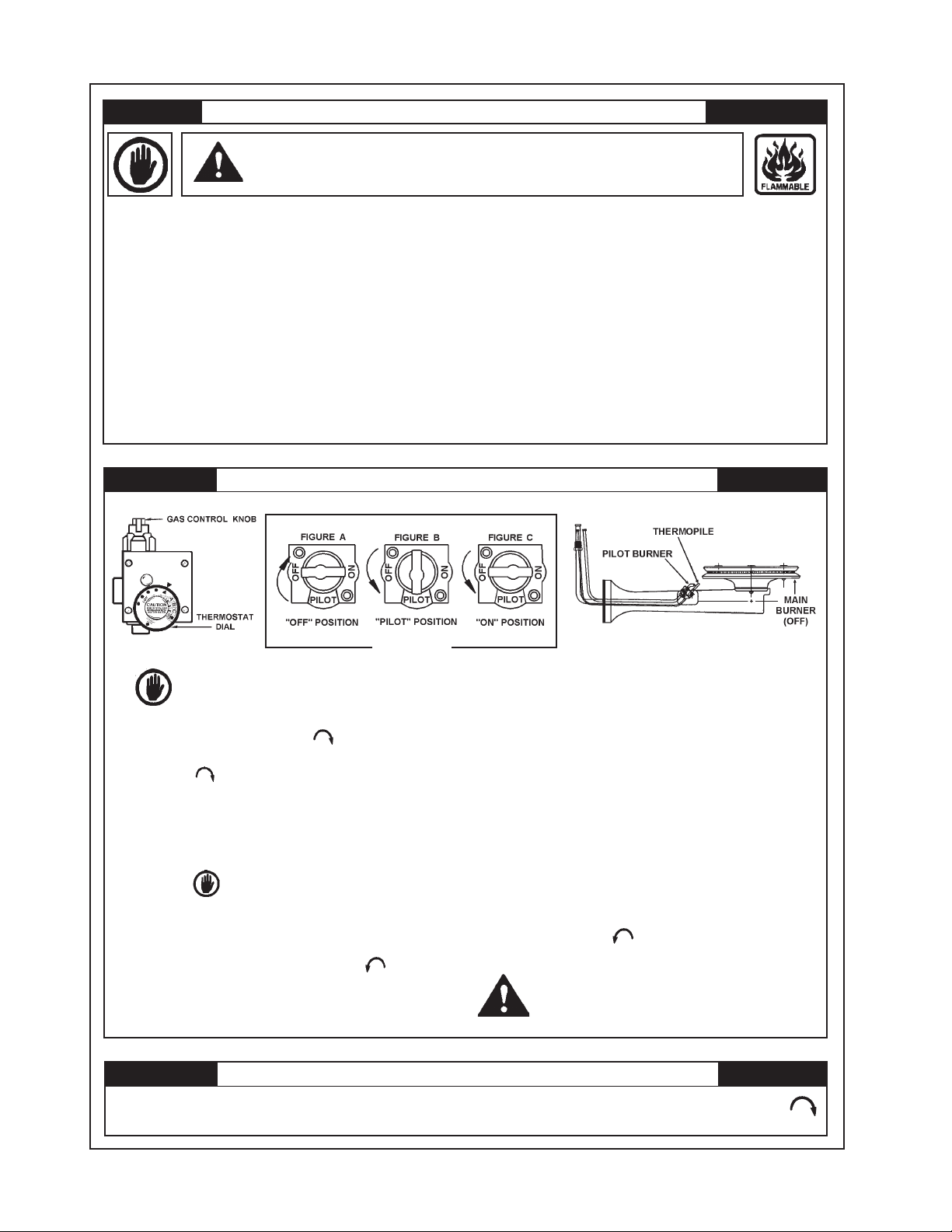

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

BEFORE LIGHTING: ENTIRE SYSTEM MUST BE FILLED WITH WATER AND AIR PURGED AT FAUCETS.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING: smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

LIGHTING INSTRUCTIONS

FIGURE 1.

1. STOP! Read the safety information above on

this label.

2. Set the thermostat to the lowest setting by turning

thermostat dial fully clockwise

3. Push the gas control knob down slightly and turn

clockwise

NOTE: Gas control knob CANNOT be turned from "PILOT"

to "OFF" unless it is pushed down slightly. Do not force.

4. Remove the inner and outer doors located below and

behind the gas control unit.

5. Wait five (5) minutes to clear out any gas. If you then

smell gas STOP! Follow "B" in the safety information

above on this label. If you do not smell gas, go to the

next step.

6. Find Pilot. Follow metal tube from the bottom , right of

the gas control to the pilot burner. (Figure D).

7. Turn gas control knob counterclockwise

(Figure B).

8. Push gas control knob down all the way and hold it down.

Immediately light the pilot with a match. Continue to hold

to "OFF" (Figure A).

until it stops.

TOP VIEW

to "PILOT"

• If you cannot reach your gas supplier, call the

fire department.

C. Use only your hand to push down or turn the gas control

knob. Never use tools. If the knob will not push down or

turn by hand, don’t try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

FIGURE D.

the gas control knob down for about one (1) minute

after the pilot is lit. Release the gas control knob and it

will pop back up. Pilot should remain lit. If it goes out,

repeat Steps 3 through 8. It may take several minutes for

air to clear the lines, before the pilot will light.

• If knob does not pop up when released, stop and

immediately call your service technician or gas

supplier.

• If the pilot will not stay lit after several tries, turn the

gas control knob to "OFF" (Figure A) andcall your

service technician or gas supplier.

9. Replace inner and outer burner doors.

10. At arm's length away, turn the gas control knob

counterclockwise

11. Set thermostat to desired setting (Figure 1).

CAUTION: Hotter water increases the risk of

scald injury. Consult the instruction manual

before changing temperature.

to on (Figure C).

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Push gas control knob down slightly and turn clockwise

to “OFF”. Do not force, see Figure A.

20

Page 21

Temperature Regulation

Short repeated heating cycles caused by small hot water uses

can cause temperatures at the point of use to exceed the

thermostat setting by up to 30°F (16.7°C). If you experience this

type of use you should consider using lower temperature settings

to reduce scald hazards.

HOTTER WATER CAN SCALD: Water heaters are intended to

produce hot water. Water heated to a temperature which will

satisfy clothes washing, dish washing, and other sanitizing needs

can scald and permanently injure you upon contact. Some people

are more likely to be permanently injured by hot water than

others. These include the elderly, children, the infirm, or

physically/mentally handicapped. If anyone using hot water in

your home fits into one of these groups or if there is a local code

or province law requiring a certain temperature water at the hot

water tap, then you must take special precautions. In addition to

using the lowest possible temperature setting that satisfies your

hot water needs, a means such as a mixing valve, shall be used

at the hot water taps used by these people or at the water heater.

Mixing valves are available at plumbing supply or hardware

stores, see Figure 8 on page 9 and Figure 15 on page 13.

Valves for reducing point of temperature by mixing cold and hot

water are also available. Consult Maytag Customer Service

(1-800-788-8899). Follow manufacturer’s instructions for

installation of the valves. Before changing the factory setting

on the thermostat, see Figures 22 and 23. Using the lowest hot

water temperature that meets your needs will also provide the

most energy efficient operation of the water heater.

Never allow small children to use a hot water tap, or to draw

their own bath water. Never leave a child or handicapped person

unattended in a bathtub or shower.

NOTE: A water temperature range of 120°F-140°F (49°C-60°C)

is recommended by most dishwasher manufacturers.

The thermostat of this water heater has been factory set at its

lowest position (PILOT LIGHTING). It is adjustable and must

be reset to the desired temperature setting to reduce the risk of

scald injury. The mark (

) indicative of approximately 120°F

(49°C) is preferred starting point. Some local codes or provinces

have a requirement for a lower setting.

Turn the water temperature dial clockwise ( ) to decrease

the temperature, or counterclockwise ( ) to increase the

temperature.

Should overheating occur or the gas supply fail to shut off, turn

off the manual gas control valve to the appliance.

FIGURE 22.

Temperature Time to Produce 2nd & 3rd

Settings Degree Burns on Adult Skin

VERY HOT= approx. 160°F (71°C)

C = approx. 150°F (66°C) About 1-1/2 seconds

B = approx. 140°F (60°C) Less than 5 seconds

A = approx. 130°F (54°C) About 30 seconds

= approx. 120°F (49°C) More than 5 minutes

LOW = approx. 80°F (27°C) - - - - - - - - - - - - - - - -

FIGURE 23.

About 1/2 second

21

Page 22

SERVICE AND MAINTENANCE

Tank (Sediment) Cleaning

Sediment build-up on the tank bottom may create varying amount

of noise, if left in the tank will cause permanent tank failure. In

some water areas, sediment can be removed by draining off

approximately one gallon of water each month.

Vent System Inspection

Burner Inspection

Flood damage to a water heater may not be readily visible or

immediately detectable. However, over a period of time a flooded

water heater will create dangerous conditions which can cause

DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAMAGE.

Contact the Maytag dealer from whom the appliance was

purchased or call Maytag Customer Service at

1-800-788-8899 for an authorized servicer to replace a

flooded water heater. Do not attempt to repair the unit! It

must be replaced!

At least once a year a visual inspection should be made of the

main burner and pilot burner, see Figure 24.

You should check for sooting. Soot is not normal and will impair

proper combustion.

Soot build-up indicates a problem that requires correction before

further use. Turn “OFF” gas to water heater and

leave off until repairs are made, because failure to correct the

cause of the sooting can result in a fire causing death, serious

injury, or property damage.

NATURAL

At least once a year a visual inspection should be made of the

venting system. You should look for:

• Obstructions which could cause improper venting. The

combustion and ventilation air flow must not be obstructed.

• Damage or deterioration which could cause improper venting

or leakage of combustion products.

• Rusted flakes around top of water heater.

Be sure the vent piping is properly connected to prevent escape

of dangerous flue gases which could cause deadly

asphyxiation.

Obstructions and deteriorated vent systems may present serious

health risk or asphyxiation.

Chemical vapor corrosion of the flue and vent system may occur

if air for combustion contains certain chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air

conditioner refrigerants, swimming pool chemicals, calcium and

sodium chloride, waxes, bleach and process chemicals are

typical compounds which are potentially corrosive.

If after inspection of the vent system you found sooting or

deterioration, something is wrong. Call Maytag Customer

Service at 1-800-788-8899 for an authorized servicer or your

local gas supplier to correct the problem and clean or

replace the flue and venting before resuming operation of

the water heater.

PROPANE

FIGURE 24.

Burner Cleaning

If inspection of the burner shows that cleaning is required, turn

the gas control knob clockwise ( ) to the “OFF” position,

depressing slightly.

NOTE: The knob cannot be turned from “PILOT” to “OFF”

unless knob is depressed slightly. DO NOT FORCE.

Loose deposits on or around the burner can be removed by

carefully using the hose of a vacuum cleaner inserted through

the access door of the water heater. If the burner needs to be

removed for additional cleaning, call Maytag Customer Service

at 1-800-788-8899 for an authorized servicer to remove and

clean the burner and correct the problem that required the

burner to be cleaned.

22

Page 23

Housekeeping

Vacuum around base of water heater for dust, dirt, and lint on a

regular basis.

When checking the temperature-pressure relief valve operation,

make sure that (1) no one is in front of or around the outlet of

the temperature-pressure relief valve discharge line, and (2) that

the water discharge will not cause any property damage, as the

water may be extremely hot, see Figure 25.

INSTALLED IN SUITABLE AREA: To insure sufficient ventilation

and combustion air supply, proper clearances from the water

heater must be maintained. See Facts to Consider About the

Location section. Combustible materials such as clothing,

cleaning materials, or flammable liquids, etc. must not be

placed against or adjacent to the water heater which can cause

a fire.

Anode Rod Inspection

The anode rod is used to protect the tank from corrosion. Most

hot water tanks are equipped with an anode rod. The submerged

rod sacrifices itself to protect the tank. Instead of corroding the

tank, water ions attack and eat away the anode rod. This does

not affect the water’s taste or color. The rod must be maintained

to keep the tank in operating condition.

FIGURE 25.

If after manually operating the valve, it fails to completely reset

and continues to release water, immediately close the cold

water inlet to the water heater, follow the draining instructions,

and replace the temperature-pressure relief valve with a new

one.

If the temperature-pressure relief valve on the appliance weeps

or discharges periodically, this may be due to thermal expansion.

You may have a check valve installed in the water line or a water

meter with a check valve. Consult Maytag Customer Service

at 1-800-788-8899 for further information. Do not plug the

temperature-pressure relief valve.

Draining

The water heater should be drained if being shut down during

freezing temperatures. Also periodic draining and cleaning of

sediment from the tank may be necessary.

Anode deterioration depends on water conductivity, not

necessarily water condition. A corroded or pitted anode rod

indicates high water conductivity and should be checked and/or

replaced more often than an anode rod that appears to be intact.

Replacement of a depleted anode rod can extend the life of

your water heater. Inspection should be conducted by a qualified

technician. At a minimum, the anode(s) should be checked

annually after the warranty period.

Temperature-Pressure Relief Valve Operation

The temperature-pressure relief valve must be manually

operated at least once a year.

• Turn the gas control knob to the “OFF” position.

• CLOSE the cold water inlet valve to the water heater.

23

Page 24

• OPEN a nearby hot water faucet and leave open to allow for

draining.

• Connect a hose to the drain valve and terminate to an

adequate drain.

• OPEN the water heater drain valve to allow for tank draining.

NOTE: If the water heater is going to be shut down and

drained for an extended period, the drain valve should

be left open with hose connected allowing water to

terminate to an adequate drain.

• CLOSE the drain valve.

• Screw the handle and cap assembly back into the drain

valve and retighten using a wrench. DO NOT OVER

TIGHTEN.

• Follow instructions in the Filling The Water Heater section.

• Check for leaks.

• Follow the lighting instructions in the Lighting section to restart

the water heater.

• Follow instructions in the Filling The Water heater section.

• Follow the lighting instructions in the Lighting section to restart

the water heater.

Drain Valve Washer Replacement

(for selected models with plastic drain valves)

(See Figure 26)

NOTE: For ordering replacement washers, refer to the

“Repair Parts List” section of this manual.

• Turn “OFF” gas supply to water heater.

• Follow “Draining” instructions.

• Turning counter clockwise ( ), remove the hex cap below

the screw handle.

• Remove the washer and put the new one in place.

TROUBLESHOOTING

Start Up Conditions

FIGURE 26.

Service

Before calling for repair service, read the Start Up Conditions

and Operational Conditions found in the Troubleshooting Guide

of this manual.

If a condition persists or you are uncertain about the operation

of the water heater, let the Maytag Customer Service Center

check it out.

Call the Maytag Customer Service at 1-800-788-8899 for an

authorized servicer.

• Large amounts of hot water are used in a short time and the

refill water in the tank is very cold.

Draft Hood Operation

Check draft hood operation by performing a worst case

depressurization of the building. With all doors and windows

closed, and with all air handling equipment and exhaust fans

operating, such as furnaces, clothes dryers, range hoods and

bathroom fans, a match flame should still be drawn into the draft

hood of the water heater with its burner firing. If the flame is not

drawn toward the draft hood, shut off the water heater and make

necessary air supply changes to correct.

Condensation

Whenever the water heater is filled with cold water, some

condensate will form while the burner is on. A water heater may

appear to be leaking when in fact the water is condensation.

This usually happens when:

• A new water heater is filled with cold water for the first time.

• Burning gas produces water vapor in water heaters,

particularly high efficiency models where flue temperatures

are lower.

Moisture from the products of combustion condense on the

cooler tank surfaces and form drops of water which may fall

onto the burner or other hot surfaces to produce a “sizzling” or

“frying” noise.

Excessive condensation can cause pilot outage due to water

running down the flue tube onto the main burner and putting out

the pilot.

Because of the suddenness and amount of water, condensation

water may be diagnosed as a “tank leak”. After the water in

the tank warms up (about 1-2 hours), the condition should

disappear.

Do not assume the water heater is leaking until there has been

enough time for the water in the tank to warm up.

An undersized water heater will cause more condensation. The

water heater must be sized properly to meet the family’s

demands for hot water including dishwashers, washing

machines and shower heads.

Excessive condensation may be noticed during the winter and

early spring months when incoming water temperatures are at

their lowest.

24

Page 25

Good venting is essential for a gas fired water heater to operate

properly as well as to carry away products of combustion and

water vapor.

Smoke / Odor

It is not uncommon to experience a small amount of smoke and

odor during the initial start-up. This is due to burning off of oil

from metal parts, and will disappear in a short while.

water conditions will cause a reaction between this rod and the

water. The most common complaint associated with the anode

rod is one of a “rotten egg smell”. This odor is derived

from hydrogen sulfide gas dissolved in the water. The smell is

the result of four factors which must all be present for the odor

to develop:

• a concentration of sulfate in the supply water.

• little or no dissolved oxygen in the water.

Thermal Expansion

Water supply system may, because of such events as high line

pressure, frequent cut-offs, the effects of water hammer among

others, have installed devices such as pressure reducing valves,

check valves, back flow preventers, etc., to control these types

of problems. When these devices are not equipped with an

internal by-pass, and no other measures are taken, the devices

cause the water system to be closed. As water is heated, it

expands (thermal expansion) and closed systems do not allow

for the expansion of heated water.

The water within the water heater tank expands as it is heated

and increases the pressure of the water system. If the relieving

point of water heater’s temperature-pressure relief valve is

reached, the valve will relieve the excess pressure. The

temperature-pressure relief valve is not intended for the

constant relief of thermal expansion. This is an unacceptable

condition and must be corrected.

• a sulfate reducing bacteria within the water heater. (This

harmless bacteria is non-toxic to humans.)

• an excess of active hydrogen in the tank. This is caused by

the corrosion protective action of the anode.

Smelly water may be eliminated or reduced in some water heater

models by replacing the anode(s) with one of less active material,

and then chlorinating the water heater tank and all hot water

lines. Contact Maytag Customer Service at

1-800-788-8899 for further information concerning an Anode

Replacement Kit and this Chlorination Treatment.

If the smelly water persists after the anode replacement and

chlorination treatment, we can only suggest that chlorination or

aeration of the water supply be considered to eliminate the water

problem.

Do not remove the anode leaving the tank unprotected. By

doing so, all warranty on the water heater tank is voided.

“AIR” In Hot Water Faucets

It is recommended that any devices installed which could create

a closed system have a by-pass and/or the system have an

expansion tank or device to relieve the pressure built by thermal

expansion in the water system. Thermal expansion tanks are

available for ordering through the Maytag Customer Service

Center (1-800-788-8899). Contact the local plumbing inspector,

water supplier and/or call Maytag Customer Service at

1-800-788-8899 for assistance in controlling these situations.

Strange Sounds

Possible noises due to expansion and contraction of some metal

parts during periods of heat-up and cool-down do not represent

harmful or dangerous conditions.

Condensation causes sizzling and popping within the burner

area during heating and cooling periods and should be

considered normal. See Condensation section.

Operational Conditions

Smelly Water

In each water heater there is installed at least one anode rod

(see parts section) for corrosion protection of the tank. Certain

HYDROGEN GAS: Hydrogen gas can be produced in a hot water

system that has not been used for a long period of time (generally

two weeks or more). Hydrogen gas is extremely flammable and

explosive. To prevent the possibility of injury under these

conditions, we recommend the hot water faucet, located farthest

away, be opened for several minutes before any electrical

appliances which are connected to the hot water system are

used (such as a dishwasher or washing machine). If hydrogen

gas is present, there will probably be an unusual sound similar

to air escaping through the pipe as the hot water faucet is

opened. There must be no smoking or open flame near the

faucet at the time it is open.

High Temperature Shut Off System

This water heater is equipped with an automatic gas Shut-off

system. This system works when high water temperatures

are present. The high temperature Shut-off is built into the

gas control valve. It is non-resettable. If the high temperature

Shut-off activates, the gas control valve must be replaced. Turn

25

Page 26

“OFF” the entire gas supply to the water heater. Call Maytag

Customer Service at 1-800-788-8899 for an authorized

servicer.

and drip onto the burner or run on the floor. This is common

at the time of start-up after installation and when incoming

water is cold.

Leakage Checkpoints

Read this manual first. Then before checking the water heater

make sure the gas supply has been turned “OFF”, and never

turn the gas “ON” before the tank is completely full of water.

Never use this water heater unless it is completely filled with

water. To prevent damage to the tank, the tank must be filled

with water. Water must flow from the hot water faucet before

turning “ON” gas to the water heater, see Figure 28.

A. Water at the draft hood is water vapor which has condensed

out of the combustion products. This is caused by a problem

in the vent. Call Maytag Customer Service at

1-800-788-8899 for an authorized servicer.

I. Water in the water heater bottom or on the floor may be from

condensation, loose connections, or the relief valve.

DO NOT replace the water heater until a full inspection of all

possible water sources is made and necessary corrective

steps taken.

Leakage from other appliances, water lines, or ground seepage

should also be checked.

* To check where threaded portion enters tank, insert cotton

swab between jacket opening and fitting. If cotton is wet, follow

“Draining” instructions in the Service and Maintenance

section and then remove fitting. Put pipe dope or teflon tape

on the threads and replace. Then follow Filling the Water

Heater instructions in the Locating and Installing the New

Water Heater section.

B. *Condensation may be seen on pipes in humid weather or

pipe connections may be leaking.