Page 1

Series Twelve

POWER VENT

GAS WATER HEATER

USER’S GUIDE

FOR POT ABLE WATER HEATING ONLY

NOT SUITABLE FOR SPACE HEATING

NOT FOR USE IN

MANUFACTURED (MOBILE) HOMES

Model Numbers

HVN41240P HVP41240P

HVN41250P HVP41250P

HVN41250V HVP41250V

C3 Technology® Gas Water Heaters meet

the new ANSI Z21.10.1 st andard that deals

with the accidental or unintended ignition

of flammable vapors, such as those

emitted by gasoline.

For Y our Safety

AN ODORANT IS ADDED TO THE GAS USED BY THIS

WA TER HEA TER.

• Safety Instructions

• Installation

• Operation

• Care and Maintenance

• Troubleshooting

• Parts List

PRINTED IN THE U.S.A. 0906 PART NO. 185378-001

www.maytagwaterheaters.com

1

Page 2

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very

important that the meaning of each safety message is understood by you and others who install, use or service this water heater.

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message and

how to avoid the risk of injury.

IMPORTANT DEFINITIONS

• Maytag Customer Service Center: The Maytag Customer Service Center has the ability equivalent to a licensed tradesman in the fields of

plumbing, air supply, venting and gas supply, including a thorough understanding of the requirements of the National Fuel Gas Code as it relates

to the installation of gas fired water heaters. The Service Center also has a thorough understanding of this instruction manual, and is able to

perform repairs strictly in accordance with the service guidelines provided by the manufacturer .

• Gas Supplier: The Natural Gas or Propane Utility or service who supplies gas for utilization by the gas burning

appliances within this application. The gas supplier typically has responsibility for the inspection and code approval of

gas piping up to and including the Natural Gas meter or Propane storage tank of a building. Many gas suppliers also

offer service and inspection of appliances within the building.

2

Page 3

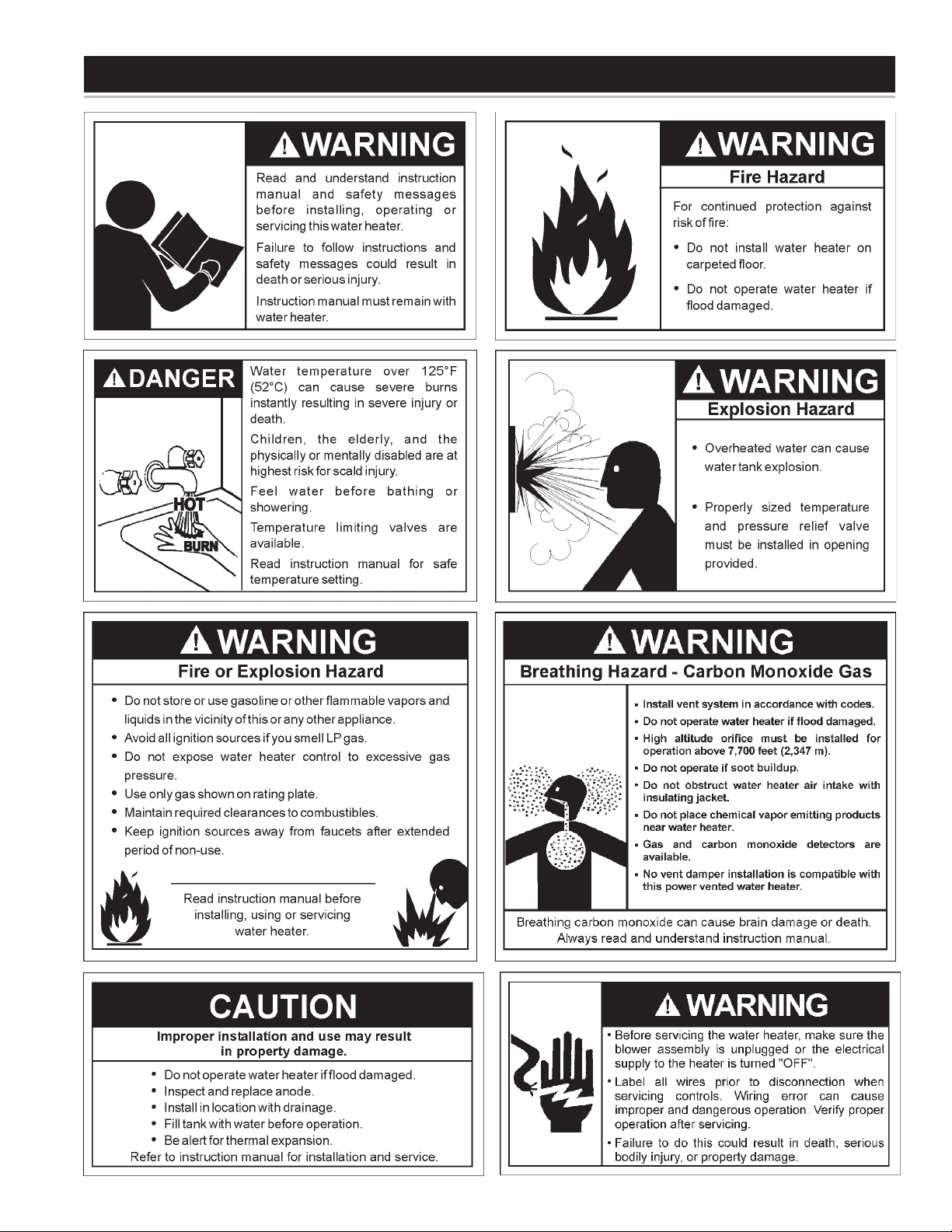

SAFETY PRECAUTIONS

3

Page 4

TABLE OF CONTENTS

SAFE INST ALLA TION, USE AND SERVICE.................................................................................................................................... 2

SAFETY PRECAUTIONS ................................................................................................................................................................. 3

TABLE OF CONTENTS .................................................................................................................................................................... 4

CUSTOMER RESPONSIBILITIES................................................................................................................................................... 5

PRODUCT SPECIFICA TIONS......................................................................................................................................................... 5

MATERIALS AND BASIC TOOLS NEEDED .................................................................................................................................... 6

TYPICAL INSTALLATION.............................................................................................................................................................. 7-8

INST ALLA TION INSTRUCTIONS .............................................................................................................................................. 9-22

Removing the Old Water Heater ............................................................................................................................................. 9

Facts to Consider About the Location .............................................................................................................................10-11

Insulation Blankets................................................................................................................................................................. 11

Combustion Air and Ventilation for Appliances Located in Unconfined Spaces ............................................................. 11

Combustion Air and Ventilation for Appliances Located in Confined Spaces ............................................................11-12

Water Piping ...................................................................................................................................................................... 13-14

Temperature-Pressure Relief Valve .....................................................................................................................................14

Gas Piping ............................................................................................................................................................................... 15

Sediment Traps ......................................................................................................................................................................16

Fil lin g the Wat er H eat er ......................................................................................................................................................... 16

Blower Assembly Installation ................................................................................................................................................ 16

Vent Connections to Blower Assembly................................................................................................................................. 17

Venting and Installation ................................................................................................................................................... 17-18

Condensation ......................................................................................................................................................................... 18

Maximum Vent Lengths..........................................................................................................................................................18

Venting ..................................................................................................................................................................................... 19

Vent Terminal Installation ................................................................................................................................................ 19-20

Vertical Vent Through Roof.....................................................................................................................................................20

Vertical Vent Restrictions .......................................................................................................................................................20

Vent Pipe Preparation ...................................................................................................................................................... 21-22

OPERA TING INSTRUCTIONS................................................................................................................................................. 23-24

Lighting and Operating Label ...............................................................................................................................................23

Temperature Regulation ........................................................................................................................................................ 24

FOR YOUR INFORMATION............................................................................................................................................................25

Start Up Conditions ...............................................................................................................................

Operational Conditions .......................................................................................................................................................... 25

SERVICE AND ADJUSTMENT ................................................................................................................................................. 26-27

Venting System Inspection ....................................................................................................................................................26

Burner Operation and Inspection ......................................................................................................................................... 26

Burner Cleaning .....................................................................................................................................................................26

Housekeeping ........................................................................................................................................................................ 26

Anode Rod Inspection ............................................................................................................................................................ 27

Temperature-Pressure Relief Valve Operation ................................................................................................................... 27

Draining ................................................................................................................................................................................... 27

Drain Valve Washer Replacement ........................................................................................................................................27

Service .....................................................................................................................................................................................27

LEAKAGE CHECKPOINTS ............................................................................................................................................................ 28

TROUBLESHOOTING GUIDELINES ...................................................................................................................................... 29-30

P ARTS ORDER LIST...................................................................................................................................................................... 31

WARRANTY..................................................................................................................................................................................... 32

.................................25

4

Page 5

CUSTOMER RESPONSIBILITIES

Thank Yo u for purchasing a Maytag water heater . Properly installed

and maintained, it should give you years of trouble free service. It is

strongly suggested that this new water heater be professionally

installed, contact Maytag Customer Service (1-800-788-8899) for

recommended installers.

Abbreviations Found In This Instruction Manual:

• CSA - Canadian Standards Association

• ANSI - American National Standards Institute

• NFP A - National Fire Protection Association

• ASME - American Society of Mechanical Engineers

• GAMA - Gas Appliance Manufacturer’s Association

• UL - Underwriters Laboratories Inc.

This gas-fired water heater is listed by Underwriters Laboratories Inc.

under American National S tandard/CSA Standard for Gas W ater Heaters

ANSI Z21.10.1 • CSA 4.1 (current edition).

PREPARING FOR THE INSTALLATION

1. Read the “Safety Precautions” section, page 3 of this manual first

and then the entire manual carefully. If you don’t follow the safety

rules, the water heater will not operate properly. It could cause

DEA TH, SERIOUS BODILY INJUR Y AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, operation, and

maintenance of the gas-fired water heater. It also contains warnings

throughout the manual that you must read and be aware of. All

warnings and all instructions are essential to the proper operation

of the water heater and your safety . Since we cannot put everything

on the first few pages, READ THE ENTIRE MANUAL BEFORE

A TTEMPTING TO INST ALL OR OPERATE THE W ATER HEA TER.

2. The installation must conform with these instructions and the local

code authority having jurisdiction. In the absence of local codes,

installations shall comply with the National Fuel Gas Code ANSI Z223.1/

NFPA 54 and the National Electrical Code, NFP A 70. These publications

are available from The National Fire Protection Association, 1

Batterymarch Park, Quincy , MA 02269.

3. The water heater when installed must be grounded in accordance

with the local codes, or in the absence of local codes,the National

Electrical Code NFPA 70.

4. If after reading this manual you have any questions or do not understand

any portion of the instructions, call the local gas utility or Maytag Customer

Service at 1-800-788-8899 for an authorized servicer.

5. Carefully plan the place where you are going to put the water heater.

Correct combustion, vent action, and vent pipe installation are very

important in preventing death from possible carbon monoxide

poisoning and fires.

Examine the location to ensure the water heater complies with the

“Facts to Consider About the Location” section in this manual.

6. For California installation this water heater must be braced, anchored,

or strapped to avoid falling or moving during an earthquake. See

instructions for correct installation procedures. Instructions may be

obtained from California Office of the St ate Architect, 400 P S treet,

Sacramento, CA 95814.

7. Massachusetts Code requires this water heater to be installed in

accordance with Massachusetts 248-CMR 2.00: State Plumbing Code

and 248-CMR 5.00. For more information see next page.

8. Complies with SCAQMD rule #1121 and districts having equivalent

NOx requirements.

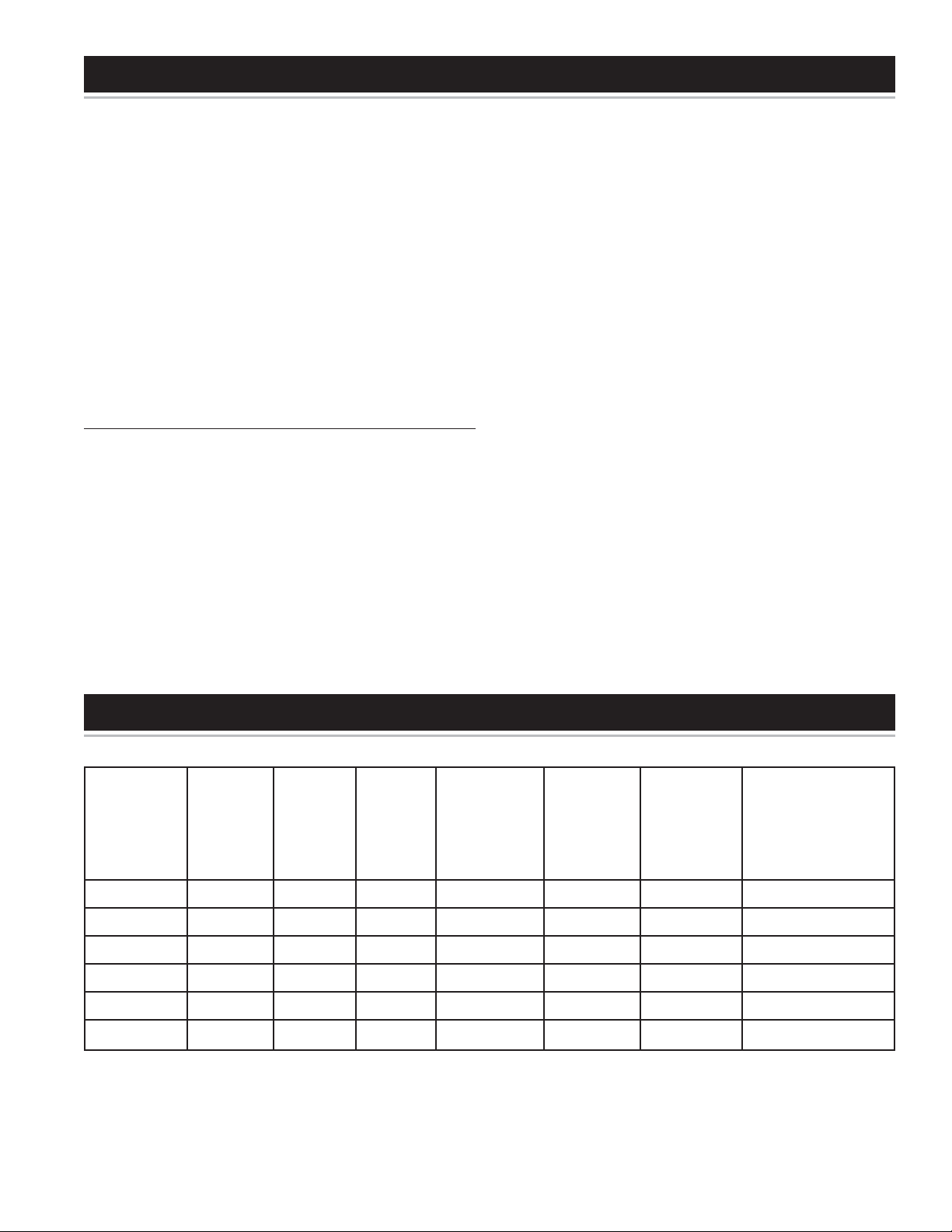

PRODUCT SPECIFICATIONS

TANK RECOVERY MINIMUM

CAP ACITY INPUT RATE GALS. VENT PIPE DIAMETER DIMENSIONS IN

MODEL IN GALS. TYPE OF RA TE PER HOUR INCHES INCHES INCHES (mm) HEIGHT

NUMBER (LTRS) GAS (Btu/hr) @ 90°F RISE (mm) (mm) TO JACKET TOP

HVN41240P 40 (151) NATURAL 40,000 44 2 (51) 20 1/2 (521) 55 (1,397)

HVN41250P 50 (189) NATURAL 40,000 44 2 (51) 22 (559) 56 3/4 (1,441)

HVN41250V 50 (189) NATURAL 50,000 53 2 (51) 22 (559) 56 3/4 (1,441)

HVP41240P 40 (151) PROPANE 40,000 44 2 (51) 20 1/2 (521) 55 (1,397)

HVP41250P 50 (189) PROPANE 40,000 44 2 (51) 22 (559) 56 3/4 (1,441)

HVP41250V 50 (189) PROP ANE 50,000 53 2 (51) 22 (559) 56 3/4 (1,441)

5

Page 6

INST ALLA TION REQUIREMENTS FOR THE COMMONWEAL TH OF MASSACHUSETTS

For all side wall terminated, horizontally vented power vent, direct vent, and power direct vent gas fueled water heaters

installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or

operated by the Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet above finished

grade in the area of the venting, including but not limited to decks and porches, the following requirements shall be satisfied:

INST ALLA TION OF CARBON MONOXIDE DETECTORS At the time of installation of the side wall horizontal vented gas fueled

equipment, the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and

battery back-up is installed on the floor level where the gas equipment is to be installed. In addition, the installing plumber or

gasfitter shall observe that a battery operated or hard wired carbon monoxide detector with an alarm is installed on each

additional level of the dwelling, building or structure served by the sidewall horizontal vented gas fueled equipment. It shall

be the responsibility of the property owner to secure the services of qualified licensed professionals for the installation of

hard wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired

carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner shall

have a period of thirty (30) days to comply with the above requirements provided that during said thirty (30) day period, a

battery operated carbon monoxide detector with an alarm shall be installed.

APPROVED CARBON MONOXIDE DETECTORS Each carbon monoxide detector as required in accordance with the above

provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed and CSA certified.

SIGNAGE A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating

appliance or equipment. The sign shall read, in print size no less than one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS.”

INSPECTION The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the

installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR 5.08(2)(a) 1 through 4.

EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most current edition of NFPA 54

as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the

dwelling, building, or structure used in whole or in part for residential purposes.

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED When the manufacturer of Product

Approved side wall horizontally vented gas equipment provides a venting system design or venting system components with

the equipment, the instructions provided by the manufacturer for installation of the equipment and the venting system shall

include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED When the manufacturer of a

Product Approved side wall horizontally vented gas fueled equipment does not provide the p art s for venting the flue gases, but

identifies “special venting systems,” the following requirements shall be satisfied by the manufacturer:

1. The referenced “special venting system” instructions shall be included with the appliance or equipment installation

instructions; and

2. The “special venting systems” shall be Product Approved by the Board, and the instructions for that system shall include

a parts list and detailed installation instructions.

A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting

instructions, all parts lists for venting instructions, and/or all venting design instructions shall remain with the appliance or

equipment at the completion of the installation.

6

Page 7

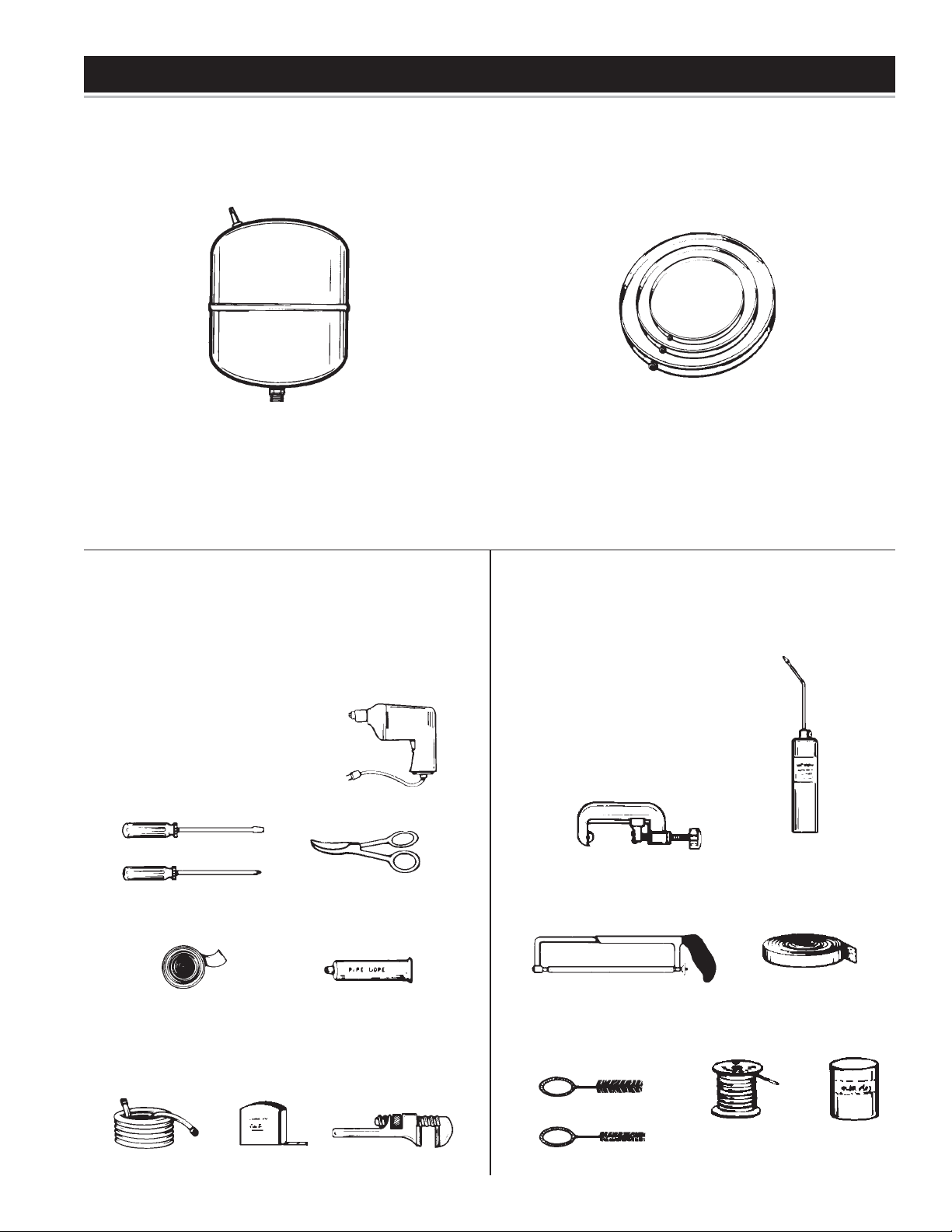

MATERIALS AND BASIC TOOLS NEEDED

Accessories

T o simplify the installation Maytag has available the installation parts shown below . Y ou may or may not need all of these accessories depending on

your type of installation. Call Maytag Customer Service at 1-800-788-8899 for an authorized inst aller.

EXP ANSION TANKS FOR THERMAL EXPANSION CONDITIONS

AV AILABLE IN 2 GALLONS (7.6 LITERS), Part No. 66001013 AND 5

GALLONS (18.9 LITERS), Part No. 66001014 CAPACITY.

T ools

You may or may not need all these tools, depending on your type of

installation. These tools can be purchased at your local hardware store.

• Pipe Wrenches (2) 14” (356 mm)

• Screwdriver

• Tin Snips

• 6’ (1.82 m) Tape or Folding Ruler

• Garden Hose

• Drill

• Pipe Dope or Teflon Tape

DRILL

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

TIN SNIPS

DRAIN PANS A V AILABLE IN 22” (559 mm) DIAMETER (P ART NO.

66001011) FOR WA TER HEA TERS HAVING A DIAMETER 20” (508

mm) OR LESS, 24” (610mm) DIAMETER (PART NO. 66001 105) FOR

WA TER HEA TERS HAVING A DIAMETER 22” (559 mm) OR LESS AND

28” (711 mm) DIAMETER (P ART NO. 66001012) FOR WA TER HEA TERS

HA VING A DIAMETER 26” (660 mm) OR LESS.

Additional Tools Needed

When Sweat Soldering

• Tubing Cutters or Hacksaw

• Propane Torch

• Soft Solder

• Solder Flux

• Emery Cloth

• Wire Brushes

PROPAN E

TUBING CUTTER

TORCH

ROLL OF TEFLON

TAPE (USE ONL Y ON

WA TER HEA TER

CONNECTIONS)

GARDEN HOSE

6 FOOT TA PE

PIPE DOPE

(SQUEEZE TUBE)

USE FOR WA TER AND GAS

CONNECTIONS

PIPE WRENCH

3/4” (19 mm) WIRE BRUSH

1/2” (13 mm) WIRE BRUSH

7

HACKSAW

ROLL OF

EMERY CLOTH

ROLL OF LEAD-FREE

SOFT SOLDER

SOLDER

FLUX

Page 8

TYPICAL INSTALLATION

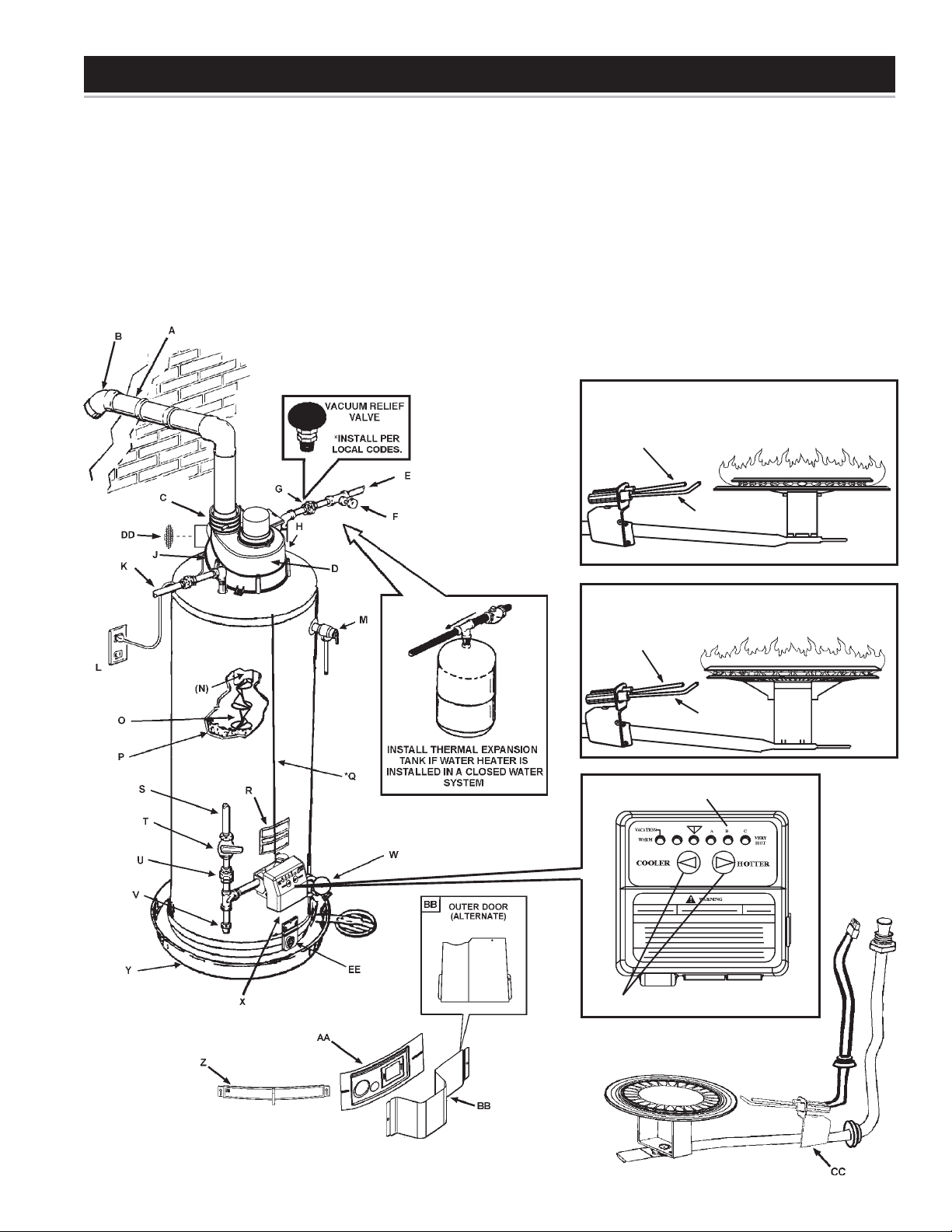

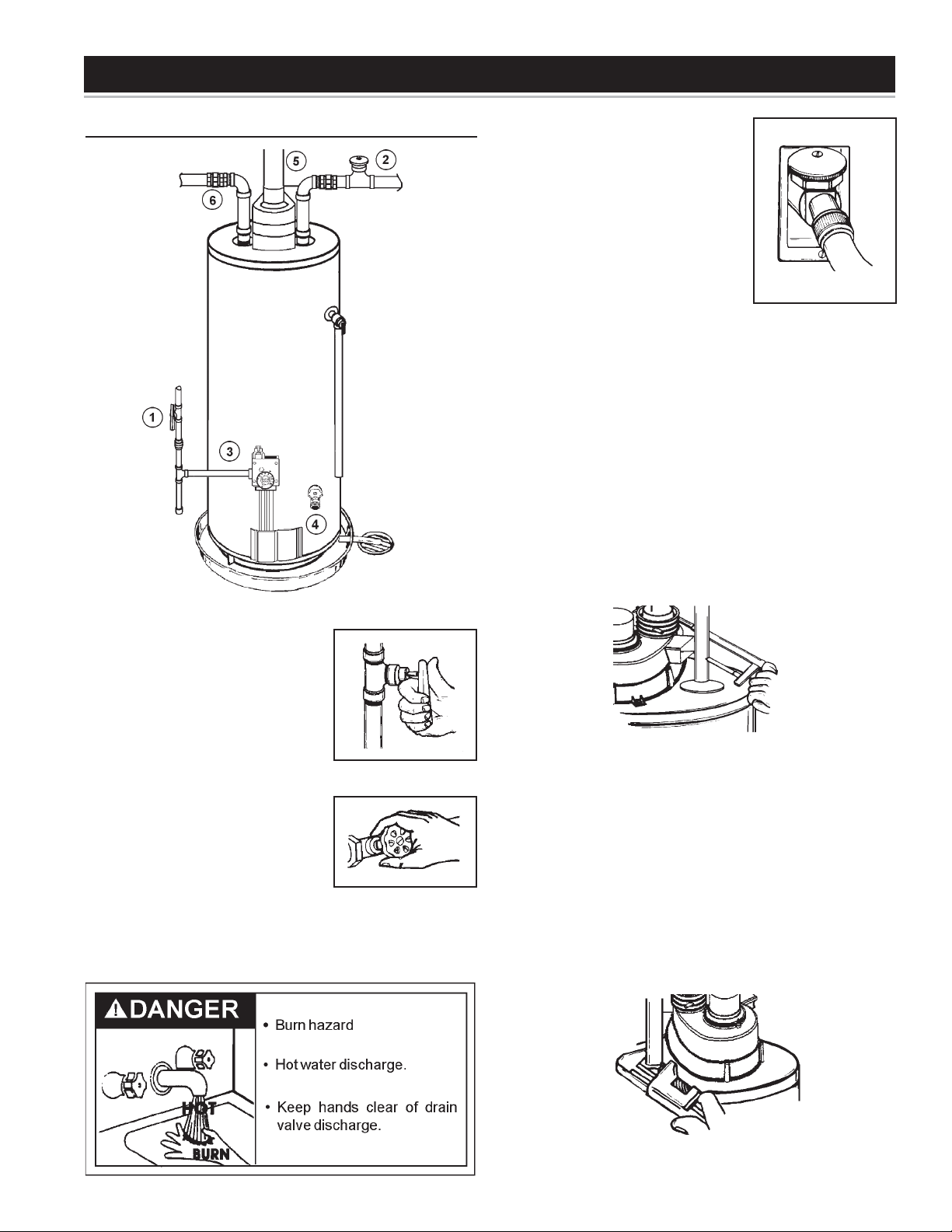

GET TO KNOW YOUR WATER HEATER - GAS MODELS

A V ent Pipe–Exhaust

B Vent Terminal

C Vent Adapter-Rubber Boot

D Blower Assembly

E Cold Water Inlet

F Inlet Water Shut-off Valve

G Union

H Inlet Dip Tube

J Anode**

* ALL PIPING MATERIALS TO BE SUPPLIED BY CUSTOMERS.

** LOCATED UNDER THE BLOWER ASSEMBLY.

K Hot Water Outlet

L Outlet Receptacle (115 VAC)

M Temperature-Pressure Relief Valve

N Flue

O Flue Baffle Assembly**

P Insulation

Q Control Harness

R Rating Plate

S Gas Supply

T Manual Gas Shut-off Valve

U Ground Joint Union

NATURAL HOT SURF ACE IGNITER & MAIN BURNER

SURFACE

IGNITOR

PROPANE HOT SURF ACE IGNITER & MAIN BURNER

SURFACE

IGNITOR

V Drip Leg (Sediment Trap)

W Drain Valve

X Gas Valve-Thermostat

Y Drain Pan

Z Air Intake Screen - Base Pan

AA Inner Door

BB Outer Door

CC HSI Burner Assembly

DD Air Intake Screen -

Blower Assembly

EE FV Sensor Assembly

HOT

SENSOR

HOT

*CAUTION: 115 VAC IN CONTROL HARNESS

AND INSIDE OUTER DOOR

GAS MODELS

WITH HOT SURF ACE IGNITION

& 2", 3" OR 4" PVC VENT CAPABILITY

SENSOR

TEMPERATURE INDICA TORS

TEMPERATURE ADJUSTMENT BUTTONS

FIGURE 1.

8

Page 9

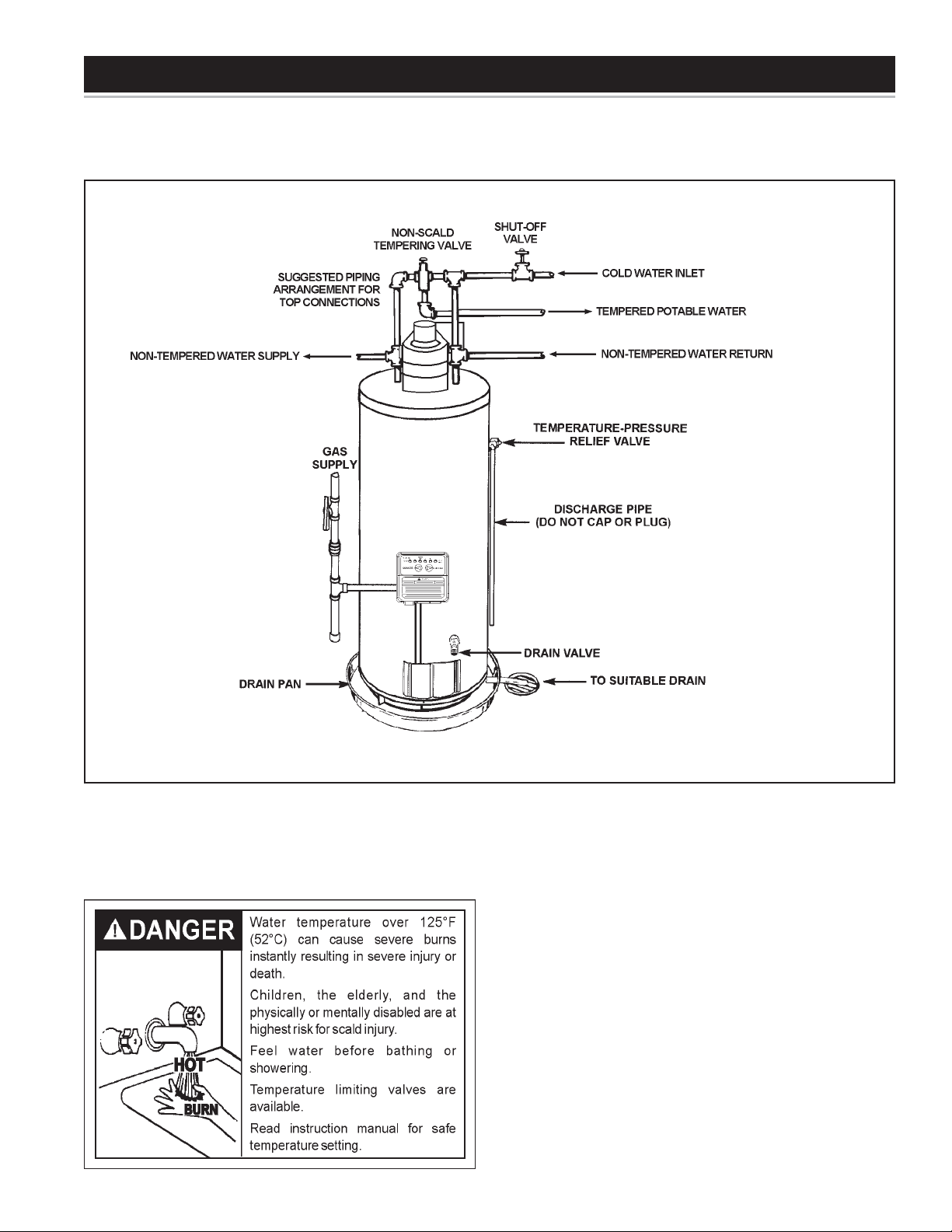

TYPICAL INSTALLATION

MIXING VALVE USAGE

FIGURE 2.

HOTTER WA TER CAN SCALD:

Water heaters are intended to produce hot water. Water heated to a

temperature which will satisfy space heating, clothes washing, dish

washing, and other sanitizing needs can scald and permanently injure

you upon contact. Some people are more likely to be permanently injured

by hot water than others. These include the elderly , children, the infirm, or

physically/mentally handicapped. If anyone using hot water in your home

fits into one of these groups or if there is a local code or state law

requiring a certain temperature water at the hot water tap, then you must

take special precautions. In addition to using the lowest possible temperature

setting that satisfies your hot water needs, a means such as a *Mixing

V alve, shall be used at the hot water taps used by these people or at the

water heater. Mixing valves are available at plumbing supply or hardware

stores. Consult Maytag Customer Service (1-800-788-8899). Follow

mixing valve manufacturer’s instructions for installation of the valves.

Before changing the factory setting on the thermostat, read the

“T emperature Regulation” section in this manual, see Figure 26.

9

Page 10

INSTALLATION INSTRUCTIONS

Removing the Old Water Heater

4. Att ach a hose to the water heater drain

valve and put the other end in a floor

drain or outdoors. Open the water

heater drain valve. Open a nearby hot

water faucet which will relieve

pressure in the water heater and speed

draining. The water passing out of the

drain valve may be extremely hot. T o

avoid being scalded, make sure all

connections are tight and that the water

flow is directed away from any person,

see Figures 3 and 6.

5. Disconnect the vent pipe from the blower assembly where it connects

to the water heater. In most inst allations the vent pipe can be lifted off

after any screw or other attached devices are removed. Make sure

existing vent complies with maximum and minimum vent lengths on

page 18.

6. If you have copper piping to the water heater, the two copper water

pipes can be cut with a hacksaw approximately four inches away

from where they connect to the water heater, see Figure 7. This will

avoid cutting off pipes too short. Additional cuts can be made later if

necessary. Disconnect the temperature-pressure relief valve drain

line. When the water heater is drained, disconnect the hose from the

drain valve. Close the drain valve. The water heater is now completely

disconnected and ready to be removed.

FIGURE 6.

FIGURE 3.

1. Turn “OFF” the gas supply to the water

heater.

If the main gas line Shut-off valve

serving all gas appliances is used, also

shut “OFF” the gas at each appliance.

Leave all gas appliances shut “OFF”

until the water heater installation is

completed, see Figures 3 and 4.

2. Turn “OFF” the water supply to the

water heater at the water shut off

valve or water meter. Some

installations require that the water be

turned off to the entire house, see

Figures 3 and 5.

3. Check again to make sure the gas supply is “OFF” to the water

heater. Then disconnect the gas supply connection from the gas

control valve.

FIGURE 4.

FIGURE 5.

FIGURE 7.

If you have galvanized pipes to the water heater, loosen the two

galvanized pipes with a pipe wrench at the union in each line. Also

disconnect the piping remaining to the water heater, see Figure 8.

These pieces should be saved since they may be needed when

reconnecting the new water heater. Disconnect the temperaturepressure relief valve drain line. When the water heater is drained,

disconnect the hose from the drain valve. Close the drain valve.

The water heater is now completely disconnected and ready to be

removed. Mineral buildup or sediment may have accumulated in the

old water heater. This causes the water heater to be much heavier

than normal and this residue, if spilled out, could cause staining.

10

FIGURE 8.

Page 11

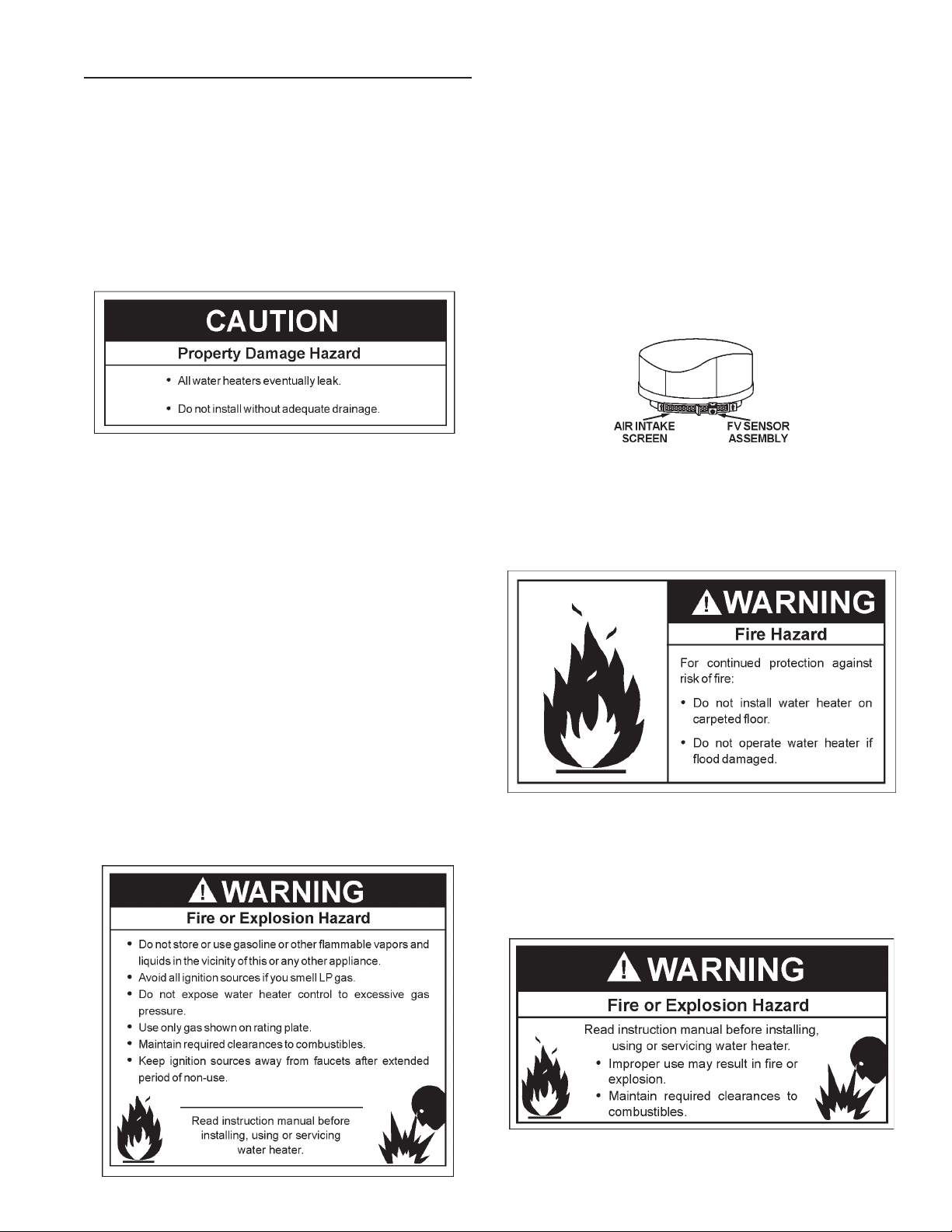

FACTS TO CONSIDER ABOUT THE LOCA TION

Carefully choose an indoor location for the new water heater, because

the placement is a very important consideration for the safety of the

occupants in the building and for the most economical use of the appliance.

This water heater is not for use in manufactured (mobile) homes

or outdoor installation.

Whether replacing an old water heater or putting the water heater in a

new location, the following critical points must be observed:

1. Select a location indoors as close as practical to the vent terminal or

location to which the water heater vent piping is going to be connected,

and as centralized with the water piping system as possible.

2. Selected location must provide adequate clearances for servicing

and proper operation of the water heater.

Installation of the water heater must be accomplished in such a manner

that if the tank or any connections should leak, the flow will not cause

damage to the structure. For this reason, it is not advisable to install the

water heater in an attic or upper floor. When such locations cannot be

avoided, a suitable drain pan should be installed under the water heater.

Drain pans are available at your local hardware store. Such a drain pan

must have a minimum length and width of at least 2" (5.1 cm) greater than

the water heater dimensions and must be piped to an adequate drain.

The pan must not restrict combustion air flow.

INSTALLA TIONS IN AREAS WHERE FLAMMABLE LIQUIDS (VAPORS)

ARE LIKELY TO BE PRESENT OR STORED (GARAGES, STORAGE AND

UTILITY AREAS, ETC.): Flammable liquids (such as gasoline, solvents ,

propane (LP or butane, etc.) and other substances (such as adhesives,

etc.) emit flammable vapors which can be ignited by a gas water

heater’s hot surface igniter or main burner. The resulting flashback

and fire can cause death or serious burns to anyone in the area. This

water heater is equipped with a FV sensor for detecting the presence

of flammable vapors, see Figure 9. When the sensor detects those

vapors, the unit will shut down and not operate. Should this happen,

please refer to the troubleshooting guide on pages 33-34. Even though

this water heater is a flammable vapors ignition resistant water heater

and is designed to reduce the chances of flammable vapors being

ignited, gasoline and other flammable substances should never be

stored or used in the same vicinity or area containing a gas water

heater or other open flame or spark producing appliance.

FIGURE 9.

Also, the water heater must be located and/or protected so it is not

subject to physical damage by a moving vehicle.

Water heater life depends upon water quality , water pressure and the

environment in which the water heater is installed. Water heaters are

sometimes installed in locations where leakage may result in property

damage, even with the use of a drain pan piped to a drain. However,

unanticipated damage can be reduced or prevented by a leak detector or

water shut-off device used in conjunction with a piped drain pan. These

devices are available from some plumbing supply wholesalers and

retailers, and detect and react to leakage in various ways:

• Sensors mounted in the drain pan that trigger an alarm or turn off the

incoming water to the water heater when leakage is detected.

• Sensors mounted in the drain pan that turn off the water supply to the

entire home when water is detected in the drain pan.

• Water supply shut-off devices that activate based on the water

pressure differential between the cold water and hot water pipes

connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater while at

the same time shutting off its water supply .

This water heater must not be installed directly on carpeting. Carpeting

must be protected by metal or wood panel beneath the appliance

extending beyond the full width and depth of the appliance by at least

3" (7.6 cm) in any direction, or if the appliance is installed in an alcove

or closet, the entire floor must be covered by the panel. Failure to heed

this warning may result in a fire hazard.

Minimum clearances between the water heater and combustible

construction are 0 inch at the sides and rear, 5" (12.7 cm) from the front

11

Page 12

and 12" (30.5 cm) from the top. (Standard clearance.) If clearances

stated on the heater differ from standard clearances, install water heater

according to clearances stated on the heater.

flammable in many cases, will also react to form corrosive hydrochloric

acid when exposed to the combustion products of the water heater .

The results can be hazardous, and also cause product failure.

Adequate clearance for servicing this appliance should be considered

before installation, such as changing the anodes, etc.

A minimum clearance of 5" (12.7 cm) must be allowed for access to

replaceable parts such as the thermostats, drain valve and relief valve.

When installing the heater, consideration must be given to proper location.

Location selected should be as close to the wall as practicable and as

centralized with the water piping system as possible.

FIGURE 10.

INSULA TION BLANKETS

Insulation blankets are available to the general public for external use

on gas water heaters but are not necessary with Maytag products.

The purpose of an insulation blanket is to reduce the standby heat loss

encountered with storage tank heaters. Your Maytag water heater

meets or exceeds the National Appliance Energy Conservation Act

standards with respect to insulation and standby loss requirements,

making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this heater, you

should follow these instructions (For identification of components

mentioned below, see Figure 1). Failure to follow these instructions

can restrict the air flow required for proper combustion, potentially

resulting in fire, asphyxiation, serious personal injury or death.

A gas water heater cannot operate properly without the correct amount

of air for combustion. Do not install in a confined area such as a closet,

unless you provide air as shown in the “Facts to Consider About the

Location” section. Never obstruct the flow of ventilation air. If you

have any doubts or questions at all, call your gas supplier. Failure to

provide the proper amount of combustion air can result in a fire or

explosion and cause death, serious bodily injury , or property damage.

FIGURE 11.

If this water heater will be used in beauty shops, barber shops, cleaning

establishments, or self-service laundries with dry cleaning equipment,

it is imperative that the water heater or water heaters be installed so

that combustion and ventilation air be taken from outside these areas.

Propellants of aerosol sprays and volatile compounds, (cleaners,

chlorine based chemicals, refrigerants, etc.) in addition to being highly

Do not apply insulation to the top of the water heater, as this will

•

interfere with safe operation of the blower assembly.

Do not cover the outer door, thermostat or temperature & pressure

•

relief valve.

Do not allow insulation to come within 2" (5.1 cm) of the floor to

•

prevent blockage of combustion air flow to the burner.

•

Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

Do obtain new warning and instruction labels from Maytag

•

for placement on the blanket directly over the existing labels.

Do inspect the insulation blanket frequently to make certain it

•

does not sag, thereby obstructing combustion air flow.

COMBUSTION AIR AND VENTILATION FOR

APPLIANCES LOCATED IN UNCONFINED SP ACES

UNCONFINED SPACE is space whose volume is not less than

50 cubic feet per 1,000 Btu per hour (4.8 cubic meters per kW) of the

aggregate input rating of all appliances installed in that space. Rooms

communicating directly with the space in which the appliances are

installed, through openings not furnished with doors, are considered a

part of the unconfined space.

In unconfined spaces in buildings, infiltration may be adequate to provide

air for combustion, ventilation and dilution of flue gases. However, in

buildings of tight construction (for example, weather stripping, heavily

insulated, caulked, vapor barrier, etc.), additional air may need to be

provided using the methods described in “Combustion Air and V entilation

for Appliances Located in Confined S paces.”

COMBUSTION AIR AND VENTILATION FOR

APPLIANCES LOCATED IN CONFINED SP ACES

CONFINED SPACE is a sp ace whose volume is less than 50 cubic feet

per 1,000 Btu per hour (4.8 cubic meters per kW) of the aggregate

input rating of all appliances installed in that space.

12

Page 13

Chemical vapor corrosion of the flue, blower assembly and vent system

may occur if air for combustion contains certain chemical vapors.

Spray can propellant s, cleaning solvents, refrigerator and air conditioner

refrigerants, swimming pool chemicals, calcium and sodium chloride,

waxes, bleach and process chemicals are typical compounds which

are potentially corrosive.

A. ALL AIR FROM INSIDE BUILDINGS: (See Figure 1 1 and 12)

The confined space shall be provided with two permanent openings

communicating directly with an additional room(s) of sufficient volume

so that the combined volume of all spaces meets the criteria for an

unconfined space. The total input of all gas utilization equipment installed

in the combined space shall be considered in making this determination.

Each opening shall have a minimum free area of one square inch per

1,000 Btu per hour (22 cm

equipment in the confined space, but not less than 100 square inches

(645 cm

2

). One opening shall commence within 12 inches

2

/kW) of the total input rating of all gas utilization

(31 cm) of the top and one commencing within 12 inches (31 cm) of the

bottom of the enclosures.

2. When communicating with the outdoors through vertical ducts, each

opening shall have a minimum free area of 1 square inch per 4,000

Btu per hour (5.5 cm

2

/kW) of total input rating of all equipment in the

enclosure, see Figure 14.

3. When communicating with the outdoors through horizontal ducts,

each opening shall have a minimum free area of 1 square inch per

2,000 Btu per hour (1 1 cm

2

/kW)) of total input rating of all equipment

in the enclosure, see Figure 15.

FIGURE 14.

FIGURE 12.

B. ALL AIR FROM OUTDOORS: (See Figures 13, 14 and 15)

The confined space shall be provided with two permanent openings,

one commencing within 12 inches (31 cm) of the top and one

commencing within 12 inches (31 cm) from the bottom of the enclosure.

The openings shall communicate directly , or by ducts, with the outdoors

or spaces (crawl or attic) that freely communicate with the outdoors.

1. When directly communicating with the outdoors, each opening shall

have a minimum free area of 1 square inch per 4,000 Btu per hour

2

(5.5 cm

/kW) of total input rating of all equipment in the enclosure,

see Figure 13.

4. When ducts are used, they shall be of the same cross-sectional

area as the free area of the openings to which they connect. The

minimum short side dimension of rectangular air ducts shall not be

less than 3 inches (7.6 cm), see Figure 15.

FIGURE 15.

5. Louvers and Grilles: In calculating free area, consideration shall be

given to the blocking effect of louvers, grilles or screens protecting

openings. Screens used shall not be smaller than 1/4 inch

(6.4 mm) mesh. If the free area through a design of louver or grille

is known, it should be used in calculating the size opening required

to provide the free area specified. If the design and free area is not

known, it may be assumed that wood louvers will be 20-25 percent

free area and metal louvers and grilles will have 60-75 percent free

area. Louvers and grilles shall be fixed in the open position or

interlocked with the equipment so that they are opened automatically

during equipment operation.

FIGURE 13.

6. Special Conditions Created by Mechanical Exhausting or Fireplaces:

operation of exhaust fans, ventilation systems, clothes dryers or

fireplaces may create conditions requiring special attention to avoid

unsatisfactory operation of installed gas utilization equipment.

13

Page 14

WATER PIPING

HOTTER WA TER CAN SCALD:

Water heaters are intended to produce hot water . W ater heated to a

temperature which will satisfy space heating, clothes washing, dish

washing, cleaning and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likely to be permanently

injured by hot water than others. These include the elderly, children, the

infirm, or physically/mentally handicapped. If anyone using hot water in

your home fits into one of these groups or if there is a local code or state

law requiring a certain temperature water at the hot water tap, then you

must take special precautions. In addition to using the lowest possible

temperature setting that satisfies your hot water needs, a means such

as a *mixing valve, shall be used at the hot water taps used by these

people or at the water heater, see Figure 2. V alves for reducing point of

use temperature by mixing cold and hot water are also available:

The water within the water heater tank expands as it is heated and

increases the pressure of the water system. If the relieving point of the

water heater’s temperature-pressure relief valve is reached, the valve

will relieve the excess pressure. The temperature-pressure relief

valve is not intended for the constant relief of thermal

expansion. This is an unacceptable condition and must be corrected.

It is recommended that any devices installed which could create a closed

system have a by-pass and/or the system have an expansion tank to

relieve the pressure built by thermal expansion in the water system.

Consult Maytag Customer Service at 1-800-788-8899 for an

authorized installer on how to control this situation.

NOTE: To protect against untimely corrosion of hot and cold

water fittings, it is strongly recommended that di-electric unions

or couplings be installed on this water heater when connected

to copper pipe.

Consult Maytag Customer Service (1-800-788-8899). Follow

manufacturer’s instructions for installation of the valves. Before changing

the factory setting on the thermostat, read the “T emperature Regulation”

section in this manual.

This water heater shall not be connected to any heating system or

component or used as a non-potable water heating appliance.

All piping components connected to this unit shall be suitable for use

with potable water.

T oxic chemicals, such as those used for boiler treatment shall not be

introduced into this system.

When the system requires water at temperatures higher than required

for domestic water purposes, a tempering valve must be installed. Please

refer to Figure 2 for suggested piping arrangement.

Water supply systems may, because of such events as high line

pressure, frequent cut-offs, the effects of water hammer among others,

have installed devices such as pressure reducing valves, check valves,

back flow preventers, etc. to control these types of problems. When

these devices are not equipped with an internal by-pass, and no other

measures are taken, the devices cause the water system to be closed.

As water is heated, it expands (thermal expansion) and closed systems

do not allow for the expansion of heated water.

FIGURE 16.

14

Page 15

Figure 16 shows the typical attachment of the water piping to the water

heater. The water heater is equipped with 3/4 inch NPT water

connections.

NOTE: If using copper tubing, solder tubing to an adapter before

attaching the adapter to the cold water inlet connection. Do not

solder the cold water supply line directly to the cold water inlet.

It will harm the dip tube and damage the tank.

T & P Valve and Pipe Insulation (if supplied)

Remove insulation for T & P valve and pipe connections from carton.

FIGURE 17.

Fit pipe insulation over the incoming cold water line and the hot water

line. Make sure that the insulation is against the top cover of the heater.

Fit T & P valve insulation over valve. Make sure that the insulation does

not interfere with the lever of the T & P valve.

The valve must be marked with a maximum set pressure not to exceed

the marked hydrostatic working pressure of the water heater

(150 psi = 1,035 kPa) and a discharge capacity not less than the water

heater input rate as shown on the model rating plate.

For safe operation of the water heater, the relief valve must not be

removed from its designated opening nor plugged.

The temperature-pressure relief valve must be installed directly into the

fitting of the water heater designed for the relief valve. Position the

valve downward and provide tubing so that any discharge will exit only

within 6 inches (15.2 cm) above, or at any distance below the structural

floor. Be certain that no contact is made with any live electrical part. The

discharge opening must not be blocked or reduced in size under any

circumstances. Excessive length, over 30 feet (9.14 m), or use of more

than four elbows can cause restriction and reduce the discharge

capacity of the valve, see Figures 16 or 20.

No valve or other obstruction is to be placed between the relief valve

and the tank. Do not connect tubing directly to discharge drain unless a

6" (15.2 cm) air gap is provided. T o prevent bodily injury , hazard to life,

or property damage, the relief valve must be allowed to discharge water

in quantities should circumstances demand. If the discharge pipe is not

connected to a drain or other suitable means, the water flow may cause

property damage.

Secure all insulation using tape.

TEMPERA TURE-PRESSURE RELIEF VALVE

This heater is provided with a properly certified combination

temperature - pressure relief valve by the manufacturer.

The valve is certified by a nationally recognized testing laboratory that

maintains periodic inspection of production of listed equipment of

materials as meeting the requirements for Relief V alves and Automatic

Gas Shut-off Devices for Hot Water Supply Systems, ANSI Z21.22 • CSA

4.4, and the code requirements of ASME.

If replaced, the valve must meet the requirements of local codes, but not

less than a combination temperature and pressure relief valve certified

as indicated in the above paragraph.

The Discharge Pipe:

•Shall not be smaller in size than the outlet pipe size of the valve, or

have any reducing couplings or other restrictions.

•Shall not be plugged or blocked.

•Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both the

temperature-pressure relief valve, and the discharge pipe.

•Shall terminate at an adequate drain.

•Shall not have any valve between the relief valve and tank.

The temperature-pressure relief valve must be manually operated at least

once a year. Caution should be taken to ensure that (1) no one is in front

of or around the outlet of the temperature-pressure relief valve discharge

line, and (2) the water manually discharged will not cause any bodily

injury or property damage because the water may be extremely hot.

If after manually operating the valve, it fails to completely reset and

continues to release water, immediately close the cold water inlet to the

water heater, follow the draining instructions, and replace the

temperature-pressure relief valve with a new one.

15

Page 16

GAS PIPING

Make sure the gas supplied is the same type listed on the model rating

plate. The inlet gas pressure must not exceed 14 inch water column (3.5

kPa) for natural and propane gas (L.P .). The minimum inlet gas pressure

shown on the rating plate is that which will permit firing at rated input.

All gas piping must comply with local codes and ordinances or with the

National Fuel Gas Code (ANSI Z223.1/ NFP A-54) whichever applies. Copper

and brass tubing and fittings (except tin lined copper tubing) shall not be used.

If the gas control valve is subjected to pressures exceeding 1/2 psi

(3.5 kPa), the damage to the gas control valve could result in a fire or

explosion from leaking gas.

If the main gas line Shut-off serving all gas appliances is used, also

turn “off” the gas at each appliance. Leave all gas appliances shut

“off” until the water heater installation is complete.

A gas line of sufficient size must be run to the water heater. Consult

the current edition of National Fuel Gas Code ANSI Z223.1/NFP A 54 and

your gas supplier concerning pipe size.

There must be:

• A readily accessible manual shut off valve in the gas supply line

serving the water heater, and

• A drip leg (sediment trap) ahead of the gas control valve to help

prevent dirt and foreign materials from entering the gas control valve.

• A flexible gas connector or a ground joint union between the shut off

valve and control valve to permit servicing of the unit.

When installed at elevations above 7,700 feet (2,347 m), input rating

should be reduced at the rate of 4 percent for each 1,000 feet (

above sea level which requires replacement of the burner orifice in

accordance with National Fuel Gas Code ANSI Z223.1/NFP A 54. Contact

your local gas supplier for further information.

Failure to replace the standard orifice with a high altitude orifice when

installed at elevations above 7,700 feet (2,347 m) could result in

improper and inefficient operation of the appliance, producing carbon

monoxide gas in excess of safe limits. This could result in serious

injury or death. Contact your gas supplier for any specific changes

which may be required in your area.

Use pipe joint compound or teflon tape marked as being resistant to the

action of petroleum [Propane (L.P.)] gases.

The appliance and its gas connection must be leak tested before placing

the appliance in operation.

The appliance and its individual Shut-off valve shall be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 pound per square inch

(3.5 kPa). It shall be isolated from the gas supply piping system by

closing its individual manual Shut-off valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

1/2 pound per square inch (3.5 kPa).

Connecting the gas piping to the gas control valve of the water heater can be

accomplished by either of the two methods shown in Figures 18 and 19.

305 m)

Be sure to check all the gas piping for leaks before lighting the water

heater. Use a soapy water solution, not a match or open flame. Rinse

off soapy solution and wipe dry.

Water heaters covered in this manual have been tested and approved

for installation at elevations up to 7,700 feet (2,347 m) above sea level.

FIGURE 18. GAS PIPING WITH

FLEXIBLE CONNECTOR.

FIGURE 19. GAS PIPING WITH ALL

BLACK IRON PIPE TO GAS CONTROL.

16

Page 17

SEDIMENT TRAPS

Never use this water heater unless it is completely full of water. To

prevent damage to the tank, the tank must be filled with water. Water

must flow from the hot water faucet before turning “ON” gas to the

water heater.

To fill the water heater with water:

1. Close the water heater drain valve by turning the handle to the right

(clockwise). The drain valve is on the lower front of the water

heater.

2. Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open when

the water heater is in use.

3. T o insure complete filling of the tank, allow air to exit by opening the

nearest hot water faucet. Allow water to run until a constant flow

is obtained. This will let air out of the water heater and the piping.

4. Check all water piping and connections for leaks. Repair as needed.

BLOWER ASSEMBL Y INSTALLA TION

Contaminants in the gas lines may cause improper operation of the gas

control valve that may result in fire or explosion. Before attaching the

gas line be sure that all gas pipe is clean on the inside. T o trap any dirt

or foreign material in the gas supply line, a drip leg (sometimes called a

sediment trap) must be incorporated in the piping. The drip leg must be

readily accessible. Install in accordance with the “Gas Piping” section.

Refer to the current edition of the National Fuel Gas Code,

ANSI Z223.1/NFP A 54.

A sediment trap shall be installed as close to the inlet of the water

heater as practical at the time of water heater installation. The sediment

trap shall be either a tee fitting with a capped nipple in the bottom outlet

or other device recognized as an effective sediment trap. If a tee fitting

is used, it shall be installed in conformance with one of the methods of

installation shown in Figures 18 and 19 on page 15.

SEQUENCE OF INST ALLATION

1. This power vented water heater comes with the blower assembly installed.

2 After the unit is set in place, make sure the blower assembly is still

mounted securely and the air intake screen of the blower assembly

is installed in the dilution air opening. Also make sure the drain port

of the rubber boot vent adapter is capped off. Lastly, make sure

there is no damage to the blower.

3. Make sure there is no packing material in the discharge of the

blower or the intake of the dilution air restrictor, see Figure 21.

4. Make sure that the plastic tubing is still attached from the air pressure

switch to the port on the blower housing. Make sure the plastic

tubing is not folded anywhere between the pressure switch and

the blower housing.

5. Make sure the ON/OFF switch is in the OFF position and that the

outer harness is connected from the blower control box to the

connector on the bottom side of the gas valve.

6. If the outer harness is not factory installed, make sure the ON/

OFF switch is in the OFF position and then connect the harness

from the blower control box to the connector on the bottom side

of the gas valve.

FIGURE 20.

FILLING THE WATER HEA TER

7. Do not plug in power cord until vent system is completely installed.

This power vent heater operates on 110-120 Vac, therefore a

grounded outlet must be within reach of the six (6) foot (1.8 m)

flexible power cord supplied with the unit (see Figure 1). The power

cord supplied may be used only where local codes permit. If local

codes do not permit the use of a flexible power supply cord:

a.) Make sure the unit is unplugged from wall outlet. Remove screws

and open panel on front of control box.

b.) Cut the flexible power cord, leaving enough to be able to make

connections and remove the strain relief fitting from box.

c.) Install suitable conduit fitting in side of enclosure and then follow

(d.) and (e.) below.

d.) Splice field wiring into existing wiring using code authorized method

(wire nuts, etc.).

e.) Be certain that neutral and live connections are not reversed when

making these connections.

f.) Close panel on the side of control box, make sure that access panel

is secured shut.

17

Page 18

VENT CONNECTIONS TO BLOWER ASSEMBLY

VENTING AND INSTALLA TION

Figure 15 shows the optimal placement of the 2" to 3" or 3" to 4" reducer;

however, the vent can be reduced at any point in the vent system as long

as the maximum vent length is not exceeded.

FIGURE 21.

Plan the layout of the vent system from the vent termination to the

water heater considering all of the 90° and 45° elbows plus the

number of feet of pipe that would be needed to install the total vent

system. The water heater must be vented to the outdoors as

described in these instructions. DO NOT connect this water heater

to an existing vent or chimney. It must be vented separately from

all other appliances. Nonmetallic vent may be used if it has “Heat

Deflection T emperature” (HDT@66 psi) or 455 kPa of at least 157°F

or 69°C. Typical nonmetallic vent materials meeting this requirement

are: PVC (Schedule 40, ASTM D-1785), Coex Cellular Core

(Schedule 40, ASTM F-441), CPVC (Schedule 40, ASTM D-2846),

ABS (Schedule 40, ASTM D-2661). The fittings, other than the

supplied Vent Termination should be equivalent to the following:

PVC (Schedule 40, DWV , ASTM D-2665), CPVC (Schedule 40, DWV ,

ASTM F-438), ABS (Schedule 40 DWV , ASTM D-2661).

The cement used should be as recommended by the vent pipe

manufacturer. See the instructions on pages 21 and 22 for the proper

method of cutting and cementing the PVC pipe and fittings.

18

Page 19

The unit may be vented horizontally through a wall or vertically through

the roof. Pipe runs must be adequately supported along both vertical

and horizontal runs as follows:

• For Schedule 40, 2" PVC, ABS, Coex Cellular Core vent pipe: Every

3 feet (0.9 m).

• For Schedule 40, 3" PVC, ABS, Coex Cellular Core vent pipe: Every

3.5 feet (1.1 m).

• For Schedule 40, 4" PVC, ABS, Coex Cellular Core vent pipe: Every

4 feet (1.2 m).

• For Schedule 40, 2" CPVC vent pipe: Every 5 feet (1.5 m).

• For Schedule 40, 3" CPVC vent pipe: Every 6 feet (1.8 m).

• For Schedule 40, 4" CPVC vent pipe: Every 6.5 feet (2.0 m).

It is imperative that the first hanger (or support) be located on the

horizontal run immediately adjacent to the first 90-degree elbow from

the vertical rise. Support method used should isolate the vent pipe

from the floor joists or other structural members to prevent the

transmission of noise and vibration. Do not support, pin, or otherwise

secure the venting system in a way that restricts the normal thermal

expansion and contraction of the chosen venting material.

CONDENSATION

Condensate formation does not occur in all installations of power vented

water heaters, but should be protected against on installations where

it can form in the venting system. Condensation in the venting system

of power vented water heaters is dependent upon installation conditions

including, but not limited to ambient temperature and humidity of

installation location, ambient temperature and humidity of venting space,

vent discharge and slope, and product usage. In certain conditions,

installations in unconditioned space or having long horizontal or vertical

vent runs may accumulate condensate. In these conditions, the vent

pipe should be sloped downward away from the blower assembly

1/4" (6.4 mm) per five feet (1.5 m) of pipe but not more than 1 1/2"

(3.8 cm) in the total vent length. If the vent piping is vented level or

sloped upwards away from the blower assembly , then adequate means

for draining and disposing of the condensate needs to be made by the

installer (if condensate is detected). If you have condensate, then a

3/8" drain hose can be connected to the built-in drain port of the rubber

boot on the blower assembly. For your convenience, the rubber boot

is supplied with a removable cap on the built-in drain port. Prior to

operating the water heater, make sure the removable cap is installed

on the drain port (if a drain hose is not needed).

MAXIMUM VENT LENGTHS

40,000 BTU Units:

If the water heater is being installed as a replacement for an existing

power vented heater in pre-existing venting, a thorough inspection of

the existing venting system must be performed prior to any installation

work. Verify that the correct material as detailed above has been

used, and that the minimum or maximum vent lengths and terminal

location as detailed in this manual have been met. Carefully inspect the

entire venting system for any signs of cracks or fractures, particularly

at the joints between elbows and other fittings and the straight runs of

vent pipe. Check the system for signs of sagging or other stresses in

the joints as a result of misalignment of any components in the system.

If any of these conditions are found, they must be corrected in

accordance with the venting instructions in this manual before

completing the installation and putting the water heater into service.

Except where instructed in this manual, the mixing of 2", 3" and 4" vent pipe

is NOT ALLOWED. If 2" pipe is to be used, then a 2" to 3" bell reducer is

recommended. Figure 21 shows the recommended location for the bell

reducer. If the bell reducer is located at the rubber boot on the blower

assembly, then a short section of 3" vent pipe needs to be inst alled in the

rubber boot for proper connection of the 2" to 3" bell reducer. That length can

be the minimum length required for the connection.

If 4" pipe is to be used, then a 3" to 4" bell reducer is recommended.

Figure 21 shows the recommended location for the bell reducer. If the

bell reducer is located at the rubber boot on the blower assembly, then

a short section of 3" vent pipe needs to be installed in the rubber boot

for proper connection of the 3" to 4" bell reducer. That length can be

the minimum length required for the connection.

For 2" Venting, the maximum equivalent feet of pipe allowed

is 40 feet (12.2 m). This does not include the supplied vent termination

for the water heater. For the 2" venting, one 90° elbow is approximately

equal to 5 feet (1.5 m). One 45° elbow is approximately equal to 2.5

feet (0.8 m). It is recommended that at least 2 feet (0.6 m) of spacing

be used in between all 45° elbows and all 90°elbows.

For 3" Venting, the maximum equivalent feet of pipe allowed

is 120 feet (36.6 m). This does not include the Vent T ermination (supplied

locally) for the water heater. For the 3" venting, one 90° elbow is

approximately equal to 5 feet (1.5 m). One 45° elbow is approximately

equal to 2.5 feet (0.8 m). It is recommended that at least 2 feet (0.6 m)

of spacing be used in between all 45° elbows and all 90°elbows.

For 4" Venting, the maximum equivalent feet of pipe allowed

is 160 feet (48.8 m). This does not include the Vent T ermination (supplied

locally) for the water heater. For the 4" venting, one 90° elbow is

approximately equal to 8 feet (2.4 m). One 45° elbow is approximately

equal to 4 feet (1.2 m). It is recommended that at least 2 feet (0.6 m) of

spacing be used in between all 45° elbows and all 90°elbows.

50,000 BTU Units:

For 2" Venting, the maximum equivalent feet of pipe allowed

is 40 feet (12.2 m). This does not include the supplied Vent T ermination

for the water heater. For the 2" venting, one 90° elbow is approximately

equal to 5 feet (1.5 m). One 45° elbow is approximately equal to 2.5

feet (0.8 m). It is recommended that at least 2 feet (0.6 m) of spacing

be used in between all 45° elbows and all 90°elbows.

The water heaters covered by this manual are supplied with a 2" Schedule

40 PVC 22.5° Vent Terminal. If you decide to vent with 3" or 4" pipe, a

Schedule 40 DWV 45° Vent T erminal must be used. For your convenience,

we have included a screen for both 3" and 4" Vent Terminals.

The vent piping should be connected to the blower with a rubber

adapter and secured with hose clamps. The adapter and clamps are

provided with the heater.

Even though the flue gas temperature leaving the blower is between 140°F

(69°C) and 175°F (79°C), some installations will have water vapor condense

in the vent piping. If this occurs, then adequate means of draining and disposing

of the condensate needs to be made by the installer.

For 3" Venting, the maximum equivalent feet of pipe allowed

is 120 feet (36.6 m). This does not include the Vent T ermination (supplied

locally) for the water heater. For the 3" venting, one 90° elbow is

approximately equal to 5 feet (1.5 m). One 45° elbow is approximately

equal to 2.5 feet (0.8 m). It is recommended that at least 2 feet (0.6 m)

of spacing be used in between all 45° elbows and all 90°elbows.

For 4" Venting, the maximum equivalent feet of pipe allowed

is 160 feet (48.8 m). This does not include the Vent T ermination (supplied

locally) for the water heater. For the 4" venting, one 90° elbow is

approximately equal to 8 feet (2.4 m). One 45° elbow is approximately

equal to 4 feet (1.2 m). It is recommended that at least 2 feet (0.6 m) of

spacing be used in between all 45° elbows and all 90°elbows.

19

Page 20

VENTING

Vent pipes serving power vented appliances are classified by

building codes as “vent connectors”. Required clearances from

combustible materials must be provided in accordance with

information in this manual under FACTS TO CONSIDER ABOUT THE

LOCATION and VENT TERMINAL INST ALLA TIONS, and with the

National Fuel Gas Code and local codes.

VENT TERMINAL INST ALLATION

1. After the point of termination has been determined, use the cover

plate as a template to mark the hole for the vent pipe to insert

through the wall. BEWARE OF CONCEALED WIRING AND PIPING

INSIDE OF WALL.

2. If the Vent Terminal is being installed on the outside of a finished

wall, it may be easier to mark both the inside and outside wall.

Align the holes by drilling a hole through the center of the template

from the inside through to the outside. The template can now be

positioned on the outside wall using the drilled hole as a centering

point for the template.

3. A) MASONRY SIDE WALLS

Chisel an opening approximately one half inch larger than the

marked circle.

B) WOODEN SIDE WALLS

Drill a pilot hole approximately one quarter inch outside of the

marked circle. This pilot hole is used as a starting point for a

saws-all or sabre saw blade. Cut around the marked circle staying

approximately one quarter inch outside of the line. (This will allow

the vent pipe to easily slide through the opening. The resulting

gap will be covered up by the vent terminal cover plates.) Repeat

this step on inside wall if necessary.

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current edition of the

Fuel Gas Code, ANSI Z223.1/NFP A 54, 7.3.4e and 7.8a,b, as follows:

1. The exit terminals of a mechanical vent system shall be not less

than 7 feet (2.13 m) above grade when located adjacent to public

walkways, see Figure 23.

2. A venting system shall terminate at least 3 feet (91 cm) above any

forced air inlet located within 10 feet (3.1 m), see Figure 23.

3. The venting system shall terminate at least 4 feet (1.2 m) below, 4

feet (1.2 m) horizontally from or, 12 inches (30 cm) above any door ,

window or gravity air inlet into any building.

The manufacturer also recommends that the vent termination should not

be installed closer than 3 feet (91 cm) from an inside corner of an L

shaped structure and not be less than 12 inches (30 cm) above grade.

The vent shall terminate a minimum of 12 inches (30 cm) above expected

snowfall level to prevent blockage of vent termination, see Figure 23.

4. In cold climates, it is recommended that vent termination not be mounted

directly above or within 3 feet (91 cm) horizontally from an oil tank vent or

gas meter to avoid potential freeze-up from condensation, see Figure 23.

Plan the vent system layout so that proper clearances are maintained

from plumbing and wiring.

National

4. When the vent piping cannot pass through an outside wall at a

height greater than or equal to 12" above the ground (or above

snow accumulation level), then the installation can be modified as

shown below.

FIGURE 22.

20

Page 21

FIGURE 23.

This unit can vent through 2", 3" or 4" nonmetallic pipe and fittings.

The vent pipe installation can be started from either the blower discharge

or the termination wall. Keep in mind the total vent system (pipe and

elbows) when installing the vent system, see VENTING AND

INSTALLA TION AND MAXIMUM VENT LENGTHS, pages 17 - 18.

FIGURE 24.

The vent terminal should be kept as close as possible to the outside

wall, but you need to allow at least 1.5" (3.8 cm) of pipe past the wall,

for the wall flange and vent terminal to mount on the pipe.

Before the vent terminal is installed, caulk (not supplied) around the pipe

on the exterior wall and install the optional wall flange. The flange can be

held to the outside wall by placing some of the caulking on the back of the

flange. The wall flange is supplied for decorative purposes only and is

not a requirement for the vent termination (if not needed by the installer).

VERTICAL VENT RESTRICTIONS

1. Minimum of twelve 12" (30.5 cm) above the roof or twelve 12"

(30.5 cm) above the anticipated snow level. Provide proper support

for all pipe protruding through the roof.

VERTICAL VENT THROUGH ROOF

This unit is approved for venting through the roof with the type vent

terminal that is included with the unit. A proper flashing or “BOOT”

should be used to seal the pipe where it exits the roof.

The total vent system should not exceed that which is specified, see

VENTING AND INST ALLA TION, pages 17 - 18.

All of the pipe should be secured as per the instructions in the instructions

in the VENTING AND INST ALLA TION, pages 17 - 18.

FIGURE 25.

2. 4' (1.2 m) from or 1' (0.3 m) above any gable, dormer, or other roof

structure with access to interior of building (i.e.-vent, window etc.).

3. 3' (0.9 m) above any forced air inlet located within 10' (3.0 m).

21

Page 22

VENT PIPE PREP ARA TION

1. INITIAL PREP ARATION

A. Make sure the solvent cement you are planning to use is

designed for the specific application you are attempting.

B. Know the physical and chemical characteristics and limitations

of the PVC and CPVC piping materials that you are about to use.

C . Know the reputation of your manufacturer and their products.

D. Know your own qualifications or those of your contractor.

The solvent welding technique of joining PVC and CPVC pipe

is a specialized skill just as any other pipe fitting technique.

E . Closely supervise the installation and inspect the finished

job before start-up.

F. Contact the manufacturer, supplier , or competent consulting

agency if you have any questions about the application or

installation of PVC and CPVC pipe.

G. Take the time and effort to do a professional job. Shortcut s

will only cause you problems and delays in start-up. By far,

the majority of failures in PVC and CPVC systems are the

result of shortcuts and/or improper joining techniques.

2. SELECTION OF MATERIALS

• Cutting Device - Saw or Pipe Cutter

• Deburring T ool, Knife, File, or Beveling Machine (2" and above)

formamide (DMF) may be included to act as a retarding agent to extend

curing time. Select the proper cement; Schedule 40 cement should be

used for Schedule 40 pipe. Never use all-purpose cements, commercial

glues and adhesives or ABS cement to join PVC or CPVC pipe and fittings.

APPLICAT ORS

Select a suitable pure bristle type paint brush. Use a proper width

brush or roller to apply the primer and cement (see chart below).

Speedy application of cement is important due to its fast drying

characteristics. IMPORT ANT NOTE: A dauber type applicator should

only be used on pipe sizes 2" and below. For larger diameter pipe, a

brush or roller must be used.

RECOMMENDED BRUSH* SIZE FOR PRIMER

AND CEMENT APPLICA TIONS

Nominal Pipe Size Brush Width

(IPS) (INS.)

2 1-1/2

3 1-1/2 - 2-1/2

• Brush - Pure Bristle

• Rag - Cotton (Not Synthetic)

• Primer and Cleaner

• Solvent Cement - PVC for PVC Components and CPVC for CPVC

Components

• Containers - Metal or Glass to hold Primer and Cement. Select the

type of PVC or CPVC materials to be used on the basis of their

application with respect to chemical resistance, pressure rating,

temperature characteristics, etc.

• Insertion T ool - Helpful for larger diameter pipe and fittings 6 inches

(15.2 cm) and above.

PRIMER

It is recommended that T etrahydrofuran (THF) be used to prepare the

surfaces of pipe and fittings for solvent welding. Do not use water,

rags, gasoline or any other substitutes for cleaning PVC or CPVC

surfaces. A chemical cleaner such as MEK may be used.

CEMENT

The cement should be a bodied cement of approximately 500 to 1600

centipoise viscosity containing 10-20% (by weight) virgin PVC material

solvated with tetrahydrofuran (THF). Small quantities of dimethyl

*USE ONLY NATURAL BRISTLE

3. MAKING THE JOINT

A. Cutting

Pipe must be squarely cut to allow for the proper interfacing of the

pipe end and the fitting socket bottom. This can be accomplished

with a miter box saw or wheel type cutter. Wheel type cutters are

not generally recommended for larger diameters since they tend to

flare the corner of the pipe end. If this type of cutter is used, the

flare on the end must be completely removed.

NOTE: Power saws should be specifically designed to cut plastic pipe.

STEP A

22

Page 23

B. Deburring

Use a knife, plastic pipe deburring tool, or file to remove burrs from the end

of small diameter pipe. Be sure to remove all burrs from around the inside

as well as the outside of the pipe. A slight chamfer (bevel) of about 10°15° should be added to the end to permit easier insertion of the pipe into

the end of the fitting. Failure to chamfer the edge of the pipe may remove

cement from the fitting socket, causing the joint to leak.

STEP B

C. Test dry fit of the joint

T apered fitting sockets are designed so that an interfaced fit should

occur when the pipe is inserted about 1/3 to 2/3 of the way into the

socket. Occasionally, when pipe fitting dimensions are at the

tolerance extremes, it will be possible to fully insert dry pipe to the

bottom of the fitting socket. When this happens, a sufficient quantity

of cement must be applied to the joint to fill the gap between the pipe

and fitting. The gap must be filled to obtain a strong, leak-free joint.

D. Inspection, cleaning, priming

Visually inspect the inside of the pipe and fitting sockets and remove

all dirt, grease or moisture with a clean dry rag. If wiping fails to

clean the surfaces, a chemical cleaner must be used. Check for

possible damage such as splits or cracks and replace if necessary .

STEP E

F. Joint assembly

Working quickly , insert the pipe into the fitting socket bottom and

give the pipe or fitting a 1/4 turn to evenly distribute the cement. Do

not continue to rotate the pipe after it has hit the bottom of the fitting

socket. A good joint will have sufficient cement to make a bead all

the way around the outside of the fitting hub. The fitting will have a

tendency to slide back while the cement is still wet so hold the joint

together for about 15 seconds.

Depth-of-entry

Marking the depth of entry is a way to check if the pipe has reached

the bottom of the fitting socket in Step F. Measure the fitting depth

and mark this distance on the pipe O.D. You may want to add

several inches to the distance and make a second mark as the

primer and cement will most likely destroy your first one.