Page 1

NIA AG

Series Twelve

POWER VENT

GAS WATER HEATER

USER'SGUIDE

For Your Safety

AN ODORANTISADDEDTO THEGASUSEDBYTHISWATERHEATER Model Numbers

HN41240P

WARNING: If the information in these instructions are not fol- HN51240P

lowed exactly, a fire or explosion may result, causing property HP41240P

damage, personaliniury or death. HP51240P

HN41250P

-Do not store or use gasoline or other flammable vapors and liq- HN51250P

uidsinthe vicinity of this or any other appliance. HP41250P

-WHAT TO DOIFYOUSMELLGAS HP51250P

HN41250VZ

• Do not try to light any appliance. HN51250VZ

• Do not touch any electrical switch; do not use any phone in HN41275PZ

yourbuilding. HN51275PZ

• Immediately call your gas supplier from a neighbor's phone. HP41275PZ

Follow the gassupplier'sinstructions. HP51275PZ

• If you cannot reachyour gassupplier,call the fire department.

-Installation and servicemustbe performed bya qualified installer, FORPOTABLEWATER

serviceagencyor the gassupplier. HEATING ONLY

&WARNING NOT SUITABLEFOR

Improper installation, adjustment, alteration, service or mainte- SPACEHEATING

nance can cause DEATH, SERIOUSBODILY INJURY,OR PROPERTY

DAMAGE, Refer to this manual for assistanceor consult the local

gas utility for further information. NOT FOR USE IN

MANUFACTURED

AWARNING 1 (MOBILE) HOMES

Flammable vapors may be drawn by air currents from other

areas of the structure to this appliance.

Caution:

AWARNING I Read and Follow All

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE I Safety Rules and

COVERAND THEN THIS ENTIREMANUAL BEFOREINSTALLING Operating Instructions

OR OPERATING THIS WATER HEATER, Before First Use of

Save this Manual for Future Reference. This Product.

Page 2

Safety Instructions

AWARNING AWARNING

Improl_er installation, adjustment, alteration, service At the time of manufacture this water heater was pro-

or maintenance can cause DEATH, SERIOUS BODILY vided with a combination temperature-pressures relief

INJURY,OR PROPERTYDAMAGE. Refer to this manu- valve certified by a nationally recognized testing labo-

al for assistance consult your local gas utility or call ratory that maintains periodic inspection of production

Maytag Customer Service at %800-788-8899 for an of listed equipment or materials, as meeting the

authorized servicer for further information, requirements for Relief Valves and Automatic Gas

Shutoff Devices for Hot Water Supply Systems, and

the latest edition of ANSI Z21.22 and the code require-

ments of ASME. If replaced, the valve must meet the

•,WARNING requirements of local codes, but not less than a combi-

WATER HEATERS EQUIPPED FOR ONE TYPE GAS nation temperature and pressure relief valve certified

ONLY: This water heater is equipped for one type as meeting the requirements for Relief Valves and

gas only. Check the model rating plate near the gas I Automatic Gas Shutoff Devices for Hot Water Supply

control valve for the correctgas. DO NOT USE THIS Systems, ANSI Z21.22 by a nationally recognized test-

WATER HEATER WITH ANY GAS OTHER THAN THE ing laboratory that maintains periodic inspection of

ONE SHOWN ON THE MODEL RATING PLATE.Failure production of listed equipment or materials.

to use the correct gas can cause problems which can I The valve must be marked with a maximum sat pres-

result in DEATH, SERIOUS BODILY INJURY, OR PROP- sure not to exceed the marked hydrostatic working

ERTY DAMAGE. If you have any questions or doubts pressure of the water heater (150 Ibs./sq. in.) and a

consult your gas supplier or local utility, discharge capacity not less than the water heater

input rate as shown on the model rating plate.

(Electric beaters - watts divided by 1000 x 3415 equal

BTU/Hr. rate.)

AWARNING Your local jurisdictional authority, while mandating the

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ- use of a temperature-pressure relief valve complying

UIDS (VAPORS)ARE LIKELYTO BEPRESENTOR STORED with ANSI Z21.22 and ASME, may require a valve model

different from the one furnished with the water heater.

(GARAGES, STORAGE, AND UTILITY AREAS, ETC):

Flammable liquids (such as gasoline, solvents, propane Compliance with such local requirements must be sat-

(LP) or butane, etc.), all of which emit flammable isfied by the installer or end user of the water heater

vapors, may be improperly stored or used in such with a locally prescribed temperature-pressure relief

areas. The gas water heater ignitor or main burner can valve installed in the designated opening in the water

ignite suchvapors. The resulting flashback and fire can heater in place of the factory furnished valve.

causedeath or serious burns to anyone in the area, as Forsafe operation of the water heater, the relief valve

must not be removed from it's designated opening or

well as property damage.

If installation in such areas is your only option, then plugged.

the installation must be accomplished in a way that The temperature-pressure relief valve must be

the ignitor and main burner flame are elevatedfrom installed directly into the fitting of the water heater

the floor at least 18 inches. While this may reduce the designated for the relief valve. Position the valve

chances of flammable vapors from a floor spill being downward and provide tubing so that any discharge

ignited, gasoline and other flammable substances will exit only within 6 inches above, or at any distance

should never be stored or used in the same room or below the structural floor. Becertain that no contact is

area containing a gas water heater or other open made with any live electrical part. The discharge open-

flame or sparkproducing appliance, ing must not be blocked or reduced in size under any

NOTE: Flammable vapors may be drawn by air currents circumstances. Excessivelength, over 30 feet, or use of

from other areas of the structure to the appliance, more than four elbows can cause restriction and

reduce the discharge capacity of the valve.

No valve or other obstruction is to be placed between

the relief valve and the tank. Do not connect tubing

AWARNING

directly to discharge drain unlessa 6" air gap is provid-

IIf this water heat_ in beauty shops, ed. To prevent bodily injury, hazard to life, or property

]barber shops, cleaning establishments, or self-ser- damage, the relief valve must be allowed to discharge

Jvice laundries with dry cleaning equipment, it is water in quantities should circumstances demand. If

imperative that the water heater or water heaters the discharge pipe is not connected to a drain or other

be installed so that combustion and ventilation air suitable means, the water flow may cause property

be taken from outside these areas. Refer to the damage.

"Locating The New Water Heater" section of this The Discharge Pipe:

manual and also the latest edition of the National • Must not be smaller in size than the outlet pipe size

Fuel Gas Code, ANSI Z223.1, also referred to as NFPA of the valve, or have any reducing couplings or

54 for specifics provided concerning air required, other restrictions.

• Must not be plugged or blocked.

• Must be of material listed for hot water distribution,

AWARNING * Must be installed so as to allow complete drainage

of both the temperature-pressure relief valve, and

A fire can start if combustible materials such as the discharge pipe.

clothing, cleaning materials, or flammable liquids * Must terminate at an adequate drain.

are paced aga nst or next to the water heater. * Must not have any valve between the relief valve

and tank.

2

Page 3

Safety Instructions

_WARNING AWARNING

A gas water heater cannot operate properly without This water heater must not be installed directly on

the correct amount of air for combustion. Do not carpeting. Carpeting must be protected by a metal

install in a confined area such a closet, unless you or wood panel beneath the appliance extending

provide air as shown in the "Locating The New beyond the full width and depth of the appliance by

Water Heater" section. Never obstruct the flow of at least 3 inches (76.2mm) in any direction, or if the

ventilation air. If you have any doubts or questions appliance is installed in an alcove or closet, the

at all, call your gas company. Failure to provide the entire floor must be covered by the panel. Failure to

proper amount of combustion air can result in a fire heed th swarning may resu t in a f re hazard.

or explosion and can cause DEATH, SERIOUS BODILY

INJURY,OR PROPERTY DAMAGE,

AWARNING

The power vent water heater requires its own (sepa-

rate)venting system. It cannot be connected to an

•,WARNING existing vent pipe or chimney. It must be terminated I

HOTTER WATER CAN SCALD: Water heaters are to the outdoors. Failure to properly install the vent-

intended to produce hot water, Water heated to a ing system can result in asphyxiation, a fire or explo-

sion and can cause DEATH, SERIOUS BODILY INJURY

temperature which will satisfy clothes washing, dish

washing, and other sanitizing needs can scald and OR PROPERTYDAMAGE.

permanently injure you upon contact. Some people

are more likely to be permanently injured by hot

water than others. These include the elderly, children,

the infirm, or physically/mentally handicapped. If AWARNING

anyone using hot water m your home fits into one of

these. ¢_roupsor if there is a local code or state law No vent damper installation is compatible with this

power vented water heater design. No vent damper,

requiring a certain temperature water at the hot whether it is operated thermally or otherwise is to

water tap, then you must take special precautions. In be installed on this power vented water heater. AI-

addition to using the lowest possible temperature teration of any part of the factory-furnished vent as-

setting that satisfies your hot water needs, a means sembly could result in improper operation due to re-

such as a mixing valve, should be used at the hot striction of flue gases, spillage of flue gases and ma

water taps use(] by these people or at the water cause carbon monoxide poisoning.

heater. Mixing valves are available at plumbing sup-

ply or hardware stores. Follow manufacturers instruc-

tions for installation of the valves. Before changing

the factory setting on the thermostat, read the AWARNING

"Temperature Regulation" section in this manual.

The appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of the gas system at

test pressures in excess of ½ pound per square inch

•,WARNING (3.5kPa).

Soot build-up indicates a problem that requires cot- The appliance must be isolated from the gas sup-

rection before further use. Turn "OFF" gas to water ply piping system by closing its individual manual

heater and leave "OFF" until repairs are made, shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal or [

because failure to correct the cause of the sooting lessthan ½ pound per square inch (3.5kPa). I

can result in a fire or explosion causing DEATH, SERI-

OUS BODILYINJURY,OR PROPERTYDAMAGE.

AWARNING

AWARNING Chemical vapor corrosion of the flue and vent sys-

tem may occur if air for combustion contains certain

BEFORE LIGHTING [PROPANE (L.P.) GAS WATER chemical vapors. Spray can propellants, cleaning sol-

HEATERS]: Propane (L.P.) gas is heavier than air. I vents, refrigerator and air conditioner refrigerants,

Should there be a leak in the system, the gas will set- swimming pool chemicals, calcium and sodium chlo-

tie near the ground. Basements, crawl spaces, skirted ride, waxes, bleach, and process chemicals are typi-

areas under manufactured (mobile) homes (even cal compounds which are potentially corrosive.

when ventilated), closets and areas below ground

level will serve as pockets for the accumulation of

this gas. Before attempting to operate the water i

heater or turning on a nearby electrical light switch, J AWARNING J

be absolutely sure there is no accumulatecl gas in the

area. Search for odor of gas by sniffing at ground I Obstructed or deteriorated vent systems may pre-

Ilevel in the vicinity of the appliance. If odor is detect- I sent a serious health risk or asphyxiation.

ed, follow steps indicated at "For Your Safety" on the i

cover page of this manual then leave the premises, i 3 Safety Instructions continued on page 4.

Page 4

Safety Instructions

_WARNING 1 _,WARNING

Minimum clearances between the water heater and|" Vent termination" must not be within 4 feet of any

combustible or noncombustible construction are 0" at/ items such as gas meters, gas valves or other gas reg-

the sides and rear, 6" at the front, and 0" from the/ u atin_l equipment.

vent pipe. Clearance from the top of the jacket is 14"

on most models. Note that a lesserdimension may be

allowed on some models. Refer to the label on the I

water heater adjacent to tile gas control valve for all _ CAUTION

clearances, I WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomp ished in such a

manner that if the tank or any connections should I

leak, the flow of water will not cause damage to

AWARNING the structure. For this reason, it is not advisable to

Flood damage to a water heater may not be readily install the water heater in at attic or upper floor,

visible or immediately detectible. However, over a When such locations cannot be avoided, a suitable

period of time a flooded water heater will create drain pan should be installed under the water

dangerous conditions which can cause DEATH, SERI- heater. Drain pans are available at your local hard-

OUS BODILY INJURY, OR PROPERTY DAMAGE.

ware store. Such a drain pan must be not greater I

Contact the Maytag dealer from whom the appli- than 1½ inches deep, have a minimum length and I

ance was purchased or call Maytag Customer Service width of at least 2 inches greater than the water

at 1-800-788-8899 for an authorized servicer to heater dimensions and must be piped to an ade-

replace a flooded water heater. Do not attempt to quate drain. The pan must not restrict combustion

repair the unit! It must be replaced! air flow. Under no circumstances is the manufactur-

er or Maytag to be held liable for any water dam-

age in connection with this water heater.

AWARNING

HYDROGEN GAS: Hydrogen gas can be produced in

a hot water system that has not been used for a

long period of time (generally two weeks or more).

Hydrogen gas is extremely flammable and explosive.

To prevent the possibility of injury under these con-

ditlons, we recommend the hot water faucet be

opened for several minutes at the kitchen sink

before any electrical appliances which are connected

to the hot water system are used (such as a dish-

washer or washing machine). If hydrogen gas is pre-

sent, there will probably be an unusual sound simi-

lar to air escaping through the pipe as the hot water

faucet is opened. There must be no smoking or open

flame near the faucet at the time it is open.

AWARNING I

INSULATING JACKETS: When installing an external I

water heater insulation jacket on a gas water heater:

• DO NOT cover the temperature-pressure relief valve.

• DO NOT put insulation over any part of the top of

the gaswater heater.

• DO NOT put insulation over the gas control valve or

gas control valve/burner cover, or any access areas

to the burner.

• DO NOT let insulation around the gas water heater

to get within 8 inches of the floor (air must get to

the burner).

• DO NOT cover or remove operating instructions,

and safety related warning labels and materials

affixed to the water heater.

Failure to heed this will result in the possibility of

fire or explosion.

4

Page 5

Table of Contents

Customer Information ........................................................................................................................6

_rc_cdeuctr_epeci_'_ti_ss_.eec_.ec_._____7

Accessories ........................................................................................................................................................................ .7

Basic Tools ...................................................................................................................................................................... .7

Instructions for Installation ..................................................................................................8-2s

Removing the Old Water Heater ...................................................................................................................................... 8

Typical Installation. .............................................................................................................................................................. .9

Locating the New Water Heater ................................................................................................................................. 10, 11

Combustion Air and Ventilation .................................................................................................................................... 11

Venting Clearances ....................................................................................................................................................... 11, 12

Combustion Air and Ventilation for Appfiances in Unconfined Spaces ............................................................................ 12

Combustion Air and Ventilation for Appliances in Confined Spaces ............................................................................ 13

Water Piping .................................................................................................................................................................... 14

Temperature-Pressure Relief Valve .................................................................................................................................. 15

Filling the Water Heater ................................................................................................................................................... 16

Wiring ...................................................................................................................................................................... 16, 17

Venting ..................................................................................................................................................................... 18-26

Gas Piping ............................................................................................................................................................. .26, 27

Installation Checklist ...................................................................................................................................................... 28

Instructions for Operation ....................................................................................................... 29-32

Operating ............................................................................................................................................................... .2%31

Temperature Regulation ................................................................................................................................................ 32

Service and Maintenance ............................................................................................... 33-35

Venting System Inspection. .............................................................................................................................................. 33

Oiling Instructions ............................................................................................................................................................ 33

Burner Inspection ........................................................................................................................................................... .33

Burner Cleaning. ........................................................................................................................................................... .33

L.P. Gas Control Valve and Burner Assembly Replacement Information .......................................................................... 34

Draining ........................................................................................................................................................................ 34

Temperature-Pressure Relief Valve Operation ................................................................................................................. 35

Drain Valve Washer Replacement ................................................................................................................................. .35

Housekeeping ................................................................................................................................................................ 35

Service ......................................................................................................................................................................... .35

Troubleshooting ....................................................................................................................................... 36-43

Start Up Conditions ....................................................................................................................................................... 36

Condensation .............................................................................................................................................................. 36

Smoke/Odor ................................................................................................................................................................. .36

Thermal Expansion ..................................................................................................................................................... 36

Strange Sounds ........................................................................................................................................................... 36

Operational Conditions ............................................................................................................................................. 37, 38

Smelly Water ............................................................................................................................................................. 37

"Air" in Hot Water Faucets ....................................................................................................................................... 37

High Temperature Shut Off System ........................................................................................................................... .37

Venting Manual Reset Switch ....................................................................................................................................... 37

Not Enough Hot Water .............................................................................................................................................. 38

Water is too Hot .......................................................................................................................................................... 38

Leakage Checkpoints ................................................................................................................................................. .39

Thermostat and Gas Supply Check ......................................................................................................................... .40

Electrical System Check ...................................................................................................................................... A1-43

Repair Parts List ......................................................................................................................... 44-52

Warranty ...........................................................................................................................................................56

5

Page 6

Customer Information

Thank Youfor purchasing a Maytag water heater, the first few pages, READ THE ENTIRE MANUAL

BEFORE ATTEMPTING TO INSTALL OR OPER-

Properly installed and maintained, it should give you years of ATE THE WATER HEATER.

trouble flee service. It is strongly suggested that thls new water • The instaUation must conform with the instructions in this

heater be professionally installed, contact Maytag Customer

Service (1-800-788-8899) for recommended installers, manual; gas company rules; and Local Codes, or in the

absence of Local Codes, with the latest edition of the

Abbreviations Found In This Instruction Manual National Fuel Gas code, ANSI Z223.1, also referred to as

CSA - Canadian Standards Association NPPA 54. This publication is available from your local

NFPA - National Fire Protection Association government or public fibrary or gas company or by writing

ANSI - American National Standards Institute NFPA, Batterymarch Park, Quincy, MA 02269.

After reading this manual you have any questions or do not

A WARNING understand any portion of the instructions, call Maytag

This gas-fired water heater is design certified by Customer Service at 1-800-788-8899 for an authorized

CSA INTERNATIONAL under American National servicer.

Standard/CSA Standard for Gas Water Heaters ANS

Z21.10.1 • CSA 4.1 (latest edition). The installation Carefiflly plan the place where you are going to put the

must conform with this manual, Local Codes and water heater. Correct combustion, vent action, and vent

with the latest edition of the National Fuel Gas pipe installation are very important in preventing death

Code, ANSI Z223.1. from possible carbon monoxide poisoning and fires.

This publication is available from your local govern-

ment or public library, gas company, or by writing Examine the location to ensure the water heater complies

NFPA, Batterymarch Park, Quincy, MA 02269. with the "Locating the New Water Heater" section in this

manual

• Read the "Safety Instructions" section, pages 2, 3 and 4 of

For California installation this water heater must be braced,

this manual first and then the entire manual carefillly. If anchored, or strapped to avoid £alfingor moving during an

you don't follow the safety rules, the water heater will not

earthquake. See instructions for correct installation proce-

operate properly. It could cause DEATH, SERIOUS

dures. Instructions may be obtained from your local dealer,

BODILY INJURY AND/OR PROPERTY DAMAGE. wholesaler, public utilities or California Office of the State

This manual contains instructions for the installation, Architect, 400 P Street, Sacramento, CA 95814,

operation, and maintenance of the gas-fired water heater. Massachusetts Code requires this water heater to be

It also contains warnings through out the manual that you installed in accordance with Massachusetts 248-CMR 2.00:

must read and be aware o£ All warnings and all instruc- State Plumbing Code and 248-CMR 5.00.

tions ate essential to the proper operation of the water Compiles with SCAQ_MD rule #1121 and districts having

heater and your safety. Since we cannot put everything on equivalent NOx requirements.

Product Specifications

Model HN41240P HP41240P HN41250P HP41250P IHN41250VZ HN41275PZ I HP41275PZ

l I

•HN51240P *HP51240P *HN51250P *HP51250P *HN51250VZ *HNS1275PZ *HPS1275PZ

Tank Capacity

In Gallons 40 40 50 50 50 75 75

Type of Gas Natural Propane Natural Propane Natural NaturM Propane

B.T.U. rate 40,000 40,000 40,000 40,000 52,500 75,000 70,000

Recovery Rate

In Gals Per Hr.

@90*FRise 46.0 46.0 46.0 46.0 57.0 77.0 72.0

Vent Pipe 3" ** 3" ** 3" ** 3" ** 3" *** 3" *** 3" ***

Diameter 20" 20" 22" 22" 22" 26%" 26Vf"

Height To

Top of Blower 71%" 71%" 71%" 71%" 68V_" 71%" 71Vf'

• High altitude models have a B.T.UJRecovery Rate 10% less than shown.

•*Limited usage ofT' vent pipe - see pages 19 through 26.

•**Limited usage of 4" vent pipe - see pages 19 through 26.

6

Page 7

Accessoriesand ToolsNeeded

Accessories

To simplify the installation Maytag has available the installa-

tion parts shown below. You may or may not need all of these

accessories depending on your type of installation. Call

Maytag Customer Service at 1-800-788-8899 for an autho-

rized installer.

DRAINPANSAVAILABLEIN 22" DIAMETER

(PARTNUMBER66001011)FORWATER

HEATERSHAVINGA DIAMETER20_ORLESS,

24' DIAMETER(PARTNUMBER66001105) FOR

EXPANSIONTANKSFORTHERMALEXPANSION WATERHEATERSHAVINGA DIAMETER22"

CONDITIONSAVAILABLEIN 2 GALLON(PART OR LESSAND AVAILABLEIN 28" DIAMETER

NUMBER66001013) AND 5 GALLON(PART (PARTNUMBER66001012)FORWATER

NUMBER66001014) CAPACITY HEATERSHAVINGA DIAMETER26" ORLESS

Tools

You may or may not need all of these tools, depending on your ADDITIONAL TOOLS NEEDED

type of installation. These tools can be purchased at your local WHEN SWEAT SOLDERING

hardware store.

• Tubing Cutters or Hacksaw

• Propane Torch

• Pipe Wrenches (2) 14" • Soft Solder

• Screwdriver • Solder Flux

• TinSnips _ I _ .EmeryCIoth

• 6 Foot Tape of Folding Rule • Wire Brushes

• Garden Hose

• Drill

• Pipe dope or Teflon Tape GARDENHOSE

HACKSAW

PPE6 FOOTTAPE WRENCH _

ROLLOF TEFLONTAPE 314"WIREBRUSH

(USEONLYON WATER

CONNECTIONS)

1/2" WIREBRUSH

_ _ PROPANETORCHSLOTHEADSCREWDRIVER

TIN SNIPS

PHILLIPSSCREWDRIVER ROLLOF LEADFREE

SOFTSOLDER

PIPEDOPE(SQUEEZETUBE) ROLLOFEMERY

(USEFORWATERAND _ _qw_ CLOTH SOLDERFLUX TUBINGCUTFER

GASCONNECTIONS) _ _

7

Page 8

Instructions for Installation

Removing the Old Water Heater

Turn "OFF" the supply to the water heater. ('_ Disconnect the vent pipe from the draft hood where they

gas

connect to the water heater. In most installations the vent

] pipe can be rifted offafter any screw or other attached

if the main gas hoe'sh_gas_'WARNING ap#iances is used, ]| devices are removed. Dispose of the draft hood. The new

alsoshut"off" the gasat each appliance.Leaveallgasappli-/ water heater has the draft hood which must be used for

ancesshut"off" untilthe water heaterinstallationiscomplete. J proper operation.

a. If you have copper piping to the water

heater, the two copper water pipes can

o

I four inches away from where they con-

nect to the water heater. This will

_'_- avoid cutting offthe pipes too short.

@__ Additional cuts can be made later if

necessary. Disconnect the temperature-

pressure relief valve drain fine. When

QTurn "OFF" the water to the water _ the water heater is drained, disconnect

the hose from the drain valve. Close

heater. Some installations

require

that

{_ the drain valve. The water heater is

the water be turned off to the entire

house. @ _ readyn°WcompletelYtobe removed.disc°nnectedand

,

make the

Check again to sure gas sup-

ply is "OFF" to the water heater. Then I _ B_a Q b. If you have galvanized pipe to the water

disconnect the gas supply connection _L_) heater, loosen the two galvanized pipes

from the gas control valve, with a pipe wrench at the union in each

t fine. Also disconnect the piping

t remaining to the water heater. These

Attach pieces should be saved since they may

hosea to the wa[3erheater drain

valve and put the other end in a floor

drain or outdoors. Open the water _ _-" _ be needed when reconnecting the new

water heater. Disconnect the tempera-

heater drain valve. Open a nearby hot ture-pressure relief valve drain line.

water faucet which will relieve pressure When the water heater is drained, dis-

in the water heater and speed draining, connect the hose from the drain valve,

Close the drain valve. The water heater

__ ._ is now completely disconnected and

ready to be removed.

_,WARNING ACAUTION

Thewater passingoutof thedrainvalvemaybeextremelyhot, Mineralbuildupor sedimentmay haveaccumulatedinthe old

Toavoidbeingscalded,makesureall connectionsare tightand water heater.Thiscausesthe waterheaterto be muchheavier

thatthe waterflow isdirectedawayfromanyperson, thannormalandthisresidue,ifspilledout, couldcausestaining.

8

Page 9

Instructions for Installation (cont'd)

Typical Installation

VENT TO

OUTDOORS

VacuumReliefrequired

some codes

codes)

COLD WATER INLET

HOT WATER OUTLE1

t

TEMPERATURE-

PRESSURE

TEMPERED

WATER OUTLET MIXING ( S (Do not cap or plug)

VALVE SL _LY PROVIDE A 6_AIR GAP

BETWEEN THE END OF

THEDISCHARGEPIPE

i AND DRAIN

7' POWER CORD

(Factory supplied) O

This appliance has been design certified as complying with American National Standard/CSA Standard for water heaters and is

considered anitable for:

Water (Potable) Heating: A11models are "considered suitable for water (potab]e) heating."

AWARNING AWARNING J

When the system requires water at temperatures This water heater shall not be connected to any heat-

higher than required for other uses, the hot water ing systems or component(s) previously used with a I

system may require a means such as a mixing valve non-potable water heating appliance. I

to be installed to temper the water at certain

points of use. Somepeople are more likely to be AWARNING

permanently injuredby hot water than others;

these include the elderly, children, the infirm, or Toxic chemicals such as used for treatment of boil- I

the physically/mentally handicapped. Before ers or non-potable water heating appliances shall I

immersing yourself or anyone else in hot water, be never be introduced into a potable water space

sure to check the water temperature. WARNING: heating system.

HOTTER WATER INCREASES THE RISK OF SCALD

INJURY. (Also see "Temperature Regulation" sec-

tion) Mixing valves are available at plumbing sup- NOTE: To protect against untimely corrosion of hot and cold

ply or hardware stores. Follow manufacturers water fittings, it is strongly recommended that di-electric

instructions for installation of these valves, unions or couplings be installed on this water heater when

connected to copper pipe.

9

Page 10

Instructions for Installation (cont'd)

Locating the New Water

Heater

Youshould carefiallychoose an indoor location for the new water A WARNING

heater, because the placement is a very important consideration

for the safetyof the occupants in the building and for the most DO not use an extension cord. If there is not a suit-

economical use of the appliance. Thiswaterheateris not foruse able receptacle and/or local codes prohibit use of a

in manufactured (mobile)homes oroutdoor installation, power cord, f e d wiring must be prov ded.

Whether replacing an old water heater or putting the water heater

in a new location, the following critical points must be observed. A CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

• The location selected should be indoors asclose as practical to the water heater must be accomplished in such a

the vent termination point, and ascentralized with the water manner that if the tank or any connections should

piping system as possible. The water heater, as all water leak, the flow of water will not cause damage to

heaters, will eventually leak. Do not install without adequate the structure. For this reason, it is not advisable to

drainage provisions where water flow will cause damage, install the water heater in an attic or upper floor.

When such locations cannot be avoided, a suitable

• 40,000 BTU/HRINPUTMODELS- If vented through an drain pan should be installed under the water

outside wall or through the roof, the 3" vent piping cannot heater. Drain pans are available at your local hard-

exceed a total of 115 feet (50 feet ifoptional 2"vent piping is ware store. Such a drain pan must be not greater

used), including vertical and horizontal runs with one 90° than 1½ inches deep, have a minimum length and

elbow.If more elbows are required, the venting distance must width of at least 2 inches greater than the water

be reduced 5 feet for every 90° elbow. See page 21 forvent heater dimensions and must be piped to an ade-

chart, quate drain. The pan must not restrict combustion

air flow. Under no circumstances is the manufactur-

• 52,500, 70,000 AND 75,000 BTU/HR INPUT MODELS-If er or Maytag to be held liable for any water dam-

vented through an outside wall or through the roof, the 3" vent age in connection with this water heater.

piping cannot exceed a total of 70 feet (110 feet if optional 4"

vent piping is used), including vertical and horizontal runs with

one 90° elbow. If more elbows are required, the venting distance • The location selection must provide adequate cleararlces for

must be reduced 5 feet for every 90°elbow. See page 21 for servicing and proper operation of the water heater.

vent chart.

• Vent piping cannot slope downward and horizontal runs AWARNING

require %"per five foot rise.All horizontal runs require ade- INSTALLATIONSIN AREAS WHERE FLAMMABLE LIQ-

quate support at 3 1/2foot intervals and verticalruns supported UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

at 5 foot intervals. STORED (GARAGES, STORAGE, AND UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

• The water heater requires its own (separate)venting system. It propane (LP) or butane, etc.), all of which emit

cannot be connected to an existing vent pipe or chimney. It flammable vapors, may be improperly stored or

must terminate to the outdoors. Whenever possible terminate used in such areas. The gas water heater ignitor or

the vent on the leeward sideof the building ifvented through main burner can ignite such vapors. The resulting

an outside wall. NOTE: Condensation maybe created, at flashback and fire can cause death or serious burns

times, as the combustion gases exit the vent cap and discol- to anyone in the area, as well as property damage.

orationofsurfacesinproximitytotheventcapmayoccur. If installation in such areas is your only option,

then the installation must be accomplished in a

way that the ignitor and main burner flame are ele-

vated from the floor at least 18 inches. While this

AWARNING may reduce the chances of flammable vapors from

The power vent water heater requires its own (sepa- a floor spill being ignited, gasoline and other

rate) venting system. It cannot be connected to an ex- flammable substances should never be stored or

isting vent pipe or chimney. It must be terminated to used in the same room or area containing agas

the outdoors. Failureto properly install the venting sys- water heater or other open flame or spark produc-

tem can result in asphyxiation, a fire or explosion and ing appliance.

cancause DEATH,SERIOUSBODILYINJURY,OR PROPER- NOTE:Flammable vapors may be drawn by air currents

TY DAMAGE. from other areasof the structure to the appliance.

AWARNING

• The water heater comes equipped with a 7 foot power cord Propellants of aerosol sprays and volatile com-

which can be used to connect to a 110/120 volt power pounds, (cleaners, chlorine based chemicals, refrig-

source if(l) local codes allow, and (2) there is a three prong erants, etc.) in addition to being highly flammable

receptacle available. This unit must have a grounded out- in many cases, will also change to corrosive

let to operate, hydrochloric acid when exposed to the combustion

products of the water heater. The results can be

hazardous, and also cause product failure,

10

Page 11

Instructions for Installation (cont'd)

Locating the New Water Combustion Air and Ventilation

Heater (cont'd) When determining the installation location for a power vent

water heater, snow accumulation and drifting should be con-

AWARNING sidered in areas where applicable.

This water heater must not be installed directly on

carpeting. Carpeting must be protected by a metal VENTING CLEARANCES

or wood panel beneath the appliance extending

beyond the full width and depth of the appliance • 0" clearancefor 3" (andopfionzl 2" and4") PVC, ABS or

by at least 3 inches (76.2mm) in any direction, or if CPVC Schedule40vent piping from combustiblesurfaces.

the appliance is installed in an alcove or closet, the

entire floor must be covered by the panel. Failure • 12" minimum from the ground,9" ceilingoverhangs.

to heed this warning may result in a fire hazard. Figure 2.

• The Power Vent outlet terminal shall terminate at least 36"

above any forced air inlet into the building located within 10

A WARNING feet. Figure 3a.

Minimum clearances between the water heater and

combustible or noncombustible construction are 0" • The Power Vent outlet terminal shall terminate atleast 4 feet

at the sides and rear, 6" at the front, and O" from below, 4 feet horizontally from or 1foot above any door, window

the vent pipe. Clearance from the top of the jacket or gravity air inlet into the building. Figure 3a.

is 14" on most models. Note that a lesser dimension

may be allowed on some models. Refer to the label • 18" minimum from other natural draft (gravity) direct vent,

on the water heater adjacent to the gas control power vent or power direct vent appliance inlet and/or outlet

valve for all clearances, vent(s) when directly aboveor 135°to either side of center

line. Figure 3b.

_ • 24" minimum from any appfiance inlet and/or outlet vents"

VENTILATION

/ A,. ,J u = , ,i/i _ = _M,N. • 18° minimum in all directions from any obstruction that may

/ OPENINGS_JI 0" MIN.

TOP VIEW , I

[ _ I OF CLOSET TOPVIEW 0 HIN. interfere. Figure 3c.

|_'_.,_ | _NIT_OLE DOOR OF CLOSET

/ 1_2"H_X, WITH DOOR

__ • The location selection must provide clearances for servicing

FRONTVIEW _ _"IN

OFDOOR . and proper operation of the water heater. Figure 4.

Figure 1 / A,_OUCT * Vent termination must not be within 4 feet of any items such]

as gas meters, gas valves orother gas regulating equipment.

A WARNING • The venting system must be installed in a manner which

allows inspection oftlie installation of the venting pipes and

A gas water heater cannot operate properly with- joints as well as periodic inspection after installation as

out the correct amount of air for combustion. Do

not install in a confined area such a closet, unless required byANSI Standards.

you provide air as shown in the "Facts to Consider

About the Location" section. Never obstruct the

flow of ventilation air, If you have any doubts or , AWARNING

questions at all, call your gas company. Failure to

provide the proper amount of combustion air can Vent termination must not be within 4 feet of any

items suchas gas meters, gas valves or other gas reg-

result in a fire or explosion and can cause DEATH, u ating equ pment.SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE.

AWARNING

AWARNING Failure to have required clearances between water

heater and combustible material will result in a fire

If this water heater will be used in beauty shops, hazard.

barber shops, cleaning establishments, or self-ser-

vice aundr es w th dry clean ng equ pment, it s

imperative that the water heater or water heaters

be installed so that combustion and ventilation air

be taken from outside these areas. Refer to the

"Facts to Consider About the Location" section of

this manual and also the latest edition of the

National Fuel Gas Code, ANSI Z223.1, also referred

to as NFPA 54 for specifics provided concerning air

required.

11

Page 12

Instructions for Installation (cont'd)

Mustmaintain

adequateservice /- .......... "--..

andmaintenance // ",

any9"min.overhangfrOm accessibility._ _: ",,,

otF,oe

12"rnin. Fgure 4 ' Rankleof degrees

I I "" ,/ availablefor vent

""_............."" pipe installation.I

i Venting Through Roof- ClearancesI I • 0" clearance for 3" (or optional 2" and 4") PVC, ABS, or

Figure 2 , _ CPVC Schedule 40 piping from combustible surfaces.

m

inches above the roof surface. Figure 5.

"- • The location selection must provide clearances for servicing

and proper operation of the water heater. Figure 4.

• The venting system must be installed in a manner which

allows inspection of the installation of the venting pipes and

IFLESSTHAN joints as well asperiodic inspection after installation as

48" _ k_L-.,_,-_.,,_ required by AN SI Standards.

w,.REE./ '°°"EE'ELL

TP-EOR_ERVENTI FigUF" 3¢_IIiUmin" __,_ FO_NC_DALR_LET _'r' _:_

POWERVENTTERMINAL_ _-

- " -- '\ - _NATURALDRAFT(GRAVITY)

O,RE VENT.POWERVE.T.CombustionAir and Ventilation

ORPOWERO,RE VE T for AppliancesLocatedin_-=- APPLIANCEINLETAND/OR

\_ -- OUTLETVENT(S), Confined Spaces

IFigure 3111 Unconfined Space is a space whose volume is not less than

50 cubic feet per 1,000 Btu per hour of the aggregate input

rating of all appliances installed in that space. Rooms com-

municating directly with the space in which the appliances are

ventterminal 18"to wallorother

obstructionsthatmay installed, through openings not furnished with doors, are

interfere with venting.

considered a part of the unconfined space

I_ 18"rnin._

In unconfined spaces in buildings, infiltration may be ade-

quate to provide air for combustion, ventilation and dilution

_ /_ ventterminal of flue gases. However, in buildings of tight construction (for

1 example, weather stripping, heavily insulated, caulked, vaporFigure3Cj m" .

cornerofbuildina barrier, etc.), additional air may need to be provided using the

methods described in Combustion Air and Ventilation for

Appliances Located in Confined Spaces, b.

12

Page 13

Instructions for Installation (cont'd)

Combustion Air and Ventilation 1.Whendirectlycommunicatingwiththeoutdoors,each

for

opening shall have a minimum free area of 1 square inch

Locatedin per 4,000 BTU per hour of total input rating of all equip

Confined Spaces(cont'd) merit in the enclosure. (See Figure 7.)

Confined Space is a space whose volume is less than 50 cubic 2. When communicating with the outdoors through vertical

feet per 1,000 Btu per hour of the aggregate input rating of all ducts, each opening shall have a minimum free area of 1

appliances installed in that space, square inch per 4,000 BTU per hour of total input rating of

a. ALL AIR FROM INSIDE BUILDINGS: all equipment in the enclosure. (See Figure 8.)

(See Page 11 Figure 1, and Figure 6 below) (each endofattic)

The confined space shall be provided with two permanent

openings communicating directly with an additional

room(s) of sufficient volume so that the combined volume

, VENT TO

of all spaces meets the criteria for an unconfined space.

The total input of all gas utilization equipment installed in

the combined space shall be considered in making this

r 3

determination. Each

opening shall have a minimum free [ Figure 8 ]

area of one square inch per 1,000 BTU per hour of the

total input rating of all gas utilization equipment in the 3. When communicating with the outdoors through horizon-

confined space, but not less than 100 square inches. One tal ducts, each opening shall have a minimum free area of 1

opening shall commence within 12 inches of the top and square inch per 2,000 BTU per hour of total input rating of

one commencing within 12 inches of the bottom of the all equipment in the enclosure. (See Figure 9.)

enclosure.

_ ROOF

VENT THROUGH j

_ ROOF

m

i 1 o oooRsI I

OPENINGS WATER Figure 9

- HEATER

[igu,e ] "H

4. When ducts are used, they shall be of the same cross-sec-

tional area as the free area of the openings to which they

connect. The minimum short side dimension of rectangular

b. ALL AIR FROM OUTDOORS: (see Figures 7-9) air ducts shall not be less than 3 inches. (See Figure 9.)

The confined space shall be provided with two permanent 5. Louvers and Grilles: In calculating free area, consideration

openings, one commencing within 12 inches of the top shall be given to the blocking effect of louvers, grilles or

and one commencing within 12 inches from the bottom of screens protecting openings. Screens used shall not be

the enclosure. The openings shall communicate directly, or smaller than 1/4inch mesh. If the free area through a design

by ducts, with the outdoors or spaces (crawl or attic) that

of louver or grille is known, it should be used in calculating

freely communicate with the outdoors, the size opening required to provide the free area specified.

If the design and free area is not known, it maybe assumed

(eachendofattic) that wood louvers will be 20-25 percent free area and metal

louvers and grilles will have 60-75 percent free area.

Louvers and grilles shall be fixed in the open position or

interlocked with the equipment so that they are opened

automatically during equipment operation.

6. Special Conditions Created byMechanical Exhausting or

Fireplaces: Operation of exhaust fans, ventilation systems,

E

clothes dryers or fireplaces may create conditions requiring

Figure I special attention to avoid unsatisfactory operation of

7

VENTiLATiONLOUVERS installed gas utilization equipment.

13

Page 14

Instructions for Installation (cont'd)

Water Piping

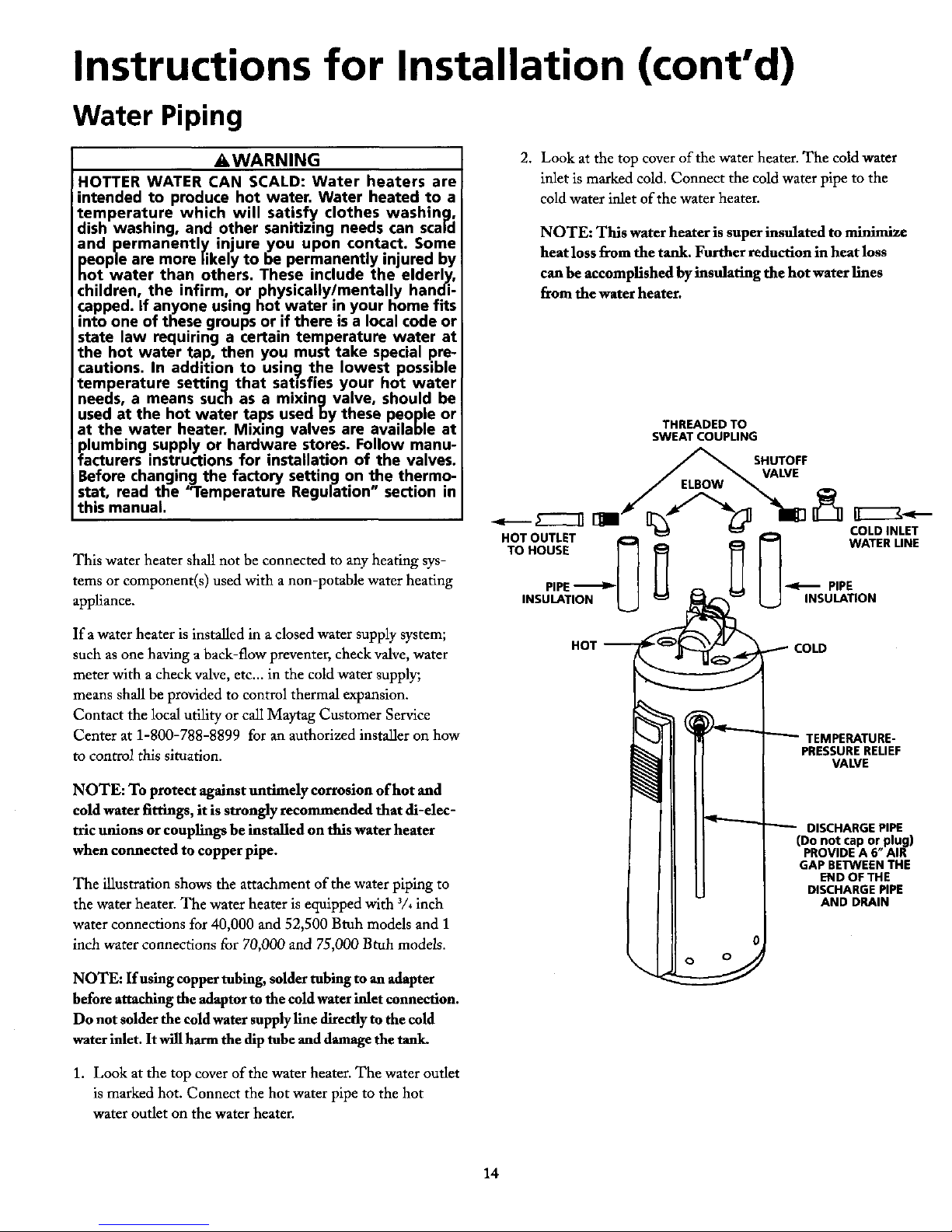

A,WARNING 2. Look at the top cover of the water heater. The cold water

HOTTER WATER CAN SCALD: Water heaters are inlet is marked cold. Connect the cold water pipe to the

intended to produce hot water. Water heated to a coldwater inlet of the water heater.

temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald NOTE: This water heater is super insulated to minimize

and permanently injure you upon contact. Some

people are more likely to be permanently injured by heat loss from the tank. Further reduction in heat loss

hot water than others. These include the elderly, can be accomplished by insulating the hot water llnes

children, the infirm, or physically/mentally handi- from the water heater.

capped. If anyone using hot water in your home fits

into one of these groups or if there is a local code or

state law requiring a certain temperature water at

the hot water tap, then you must take special pre-

cautions. In addition to using the lowest possible

temperature settingthat satisfies your hot water

needs, a means such as a mixing valve, should be

used at the hot water taps used by these people or

at the water heater, Mixing valves are available at THREADEDTO

SWEAT COUPLING

plumbing supply or hardware stores. Follow manu-

tacturers instructions for installation of the valves. _ SHUTOFF

Before changing the factory setting on the thermo- /[ E_._]3 _

stat, read the '_remperature Regulation" section in

this manual. • _ [1 I I1 _,-_

COLD INLET

HOT OUTLET _ _ _ _1 WATER LINE

This water heater shall not be connected to any heating sys- TOHOUSE [ [

tems or component(s) used with a non-potable water heating PIPE _ U II PIPE

appliance. INSULATION INSULATION

If a water heater is installed in a closed water supply system;

such as one having a back-flow preventer, check valve, water HOT _-_ COLD

meter with a check valve, etc.., in the cold water supply;

means shall be provided to control thermal expansion,

Contact the local utility or call Maytag Customer Service _ _ _ TEMPERATURE-

Center at 1-800-788-8899 for an authorized installer on how

to control this situation. PRESSURERELIEF

VALVE

NOTE: To protect against untimely corrosion of hot and

cold water fittings, it is strongly recommended that di-elec-

tric unions or couplings be installed on this water heater _ _ DISCHARGEPIPE

(Donot caporplug)

when connected to copper pipe. PROVIDEA 6" AIR

GAPBETWEENTHE

ENDOFTHE

The illustration shows the attachment of the water piping to ] DISCHARGEPIPE

the water heater. The water heater is equipped with 3/, inch ANDDRAIN

water connections for 40,000 and 52,500 Btuh models and 1

inch water connections for 70,000 and 75,000 Btuh models.

o O

NOTE: If using copper robing, solder tubing to an adapter

before attaching the adaptor to the cold water inlet connection.

Do not solder the cold water supply llne directly to the cold

water inlet. It will harm the dip tube and damage the tank.

1. Look at the top cover of the water heater. The water outlet

is marked hot. Connect the hot water pipe to the hot

water outlet on the water heater.

14

Page 15

Instructions for Installation (cont'd)

Temperature-Pressure Relief Valve

I _WARNING AWARNING

At the time of manuf_er heater was provid- The temperature-pressure relief valve must be manu-

ed with a combination temperature-pressuresrelief valve ally operated at least once a year. Caution should be

certified by a nationally recognizedtesting laboratory that taken to ensure that (1) no one is in front of or

maintains periodic inspection of production of listed around the outlet of the temperature-pressure relief

equipment or materials, as meeting the requirementsfor valve discharge line, and (2) the water manually dis-

Relief Valves and Automatic Gas Shutoff Devicesfor Hot charged will not cause any bodily injury or property

Water Supply Systems, and the latest edition of ANSI damage because the water may be extremely hot.

Z21.22 and the code requirements of ASME. If replaced, If after manually operating the valve, it fails to corn-

the valve must meet the requirementsof localcodes,but pletely reset and continues to release water, immedi-

not less than a combination temperature and pressure ately close the cold water inlet to the water heater,

relief valve certified as meeting the requirements for follow the draining instructions, and replace the

Relief Valves and Automatic Gas Shutoff Devicesfor Hot temperature-pressure relief valve with a new one.

Water Supply Systems,ANSIZ21.22 by a nationallyrecog-

nized testing laboratorythat maintainsperiodicinspection

of productionof listed equipmentor materials.

The valve must be marked with a maximum set pressure

not to exceedthe marked hydrostaticworking pressureof

the water heater (150 Ibs./sq.in.) and a dischargecapacity "_'_ _g_

not lessthan the water heater input rate asshownon the HOT

model rating plate. (Electric heaters - watts divided by I _¢=ll c°l-D

1000 x 3415 equal RTU/Hr.rate.)

Your local jurisdictional authority, while mandating the

useof a temperature-pressurerelief valve complyingwith _ -_ jTEMPERATURE-

ANSIZ21.22 and ASME,may requirea valve model differ- ",_, --_J_/ PRESSURERELIEF

ent from the one furnishedwith the water heater. _- _,_'_J VALVE

Compliancewith suchlocal requirements mustbe satisfied

by the installer or end user of the water heater with a _ _\ [ / DISCHARGEPIPE

locally prescribed temperature-pressure relief valve _ _ (Donotcaporplug)

installedin the designated opening in the water heater in _ S " PROVIDEA 6"AIR

_ --

placeof the factoryfurnishedvalve. __ GAPBE'IV4EENTHE

END OF THE

For safe operation of the water heater, the relief valve DISCHARGEPIPE

must not be removed from it's designated opening or ANDDRAIN

plugged.

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designated for I

the relief valve. Positionthe valvedownward and provide

tubing sothat any dischargewill exit only within 6 inches

above, or at any distancebelow the structural floor. Be

certain that no contact is made with any live electrical

part. The discharge opening must not be blocked or

reducedin sizeunderany circumstances.Excessivelength,

over 30 feet, or useof more than four elbows cancause

restrictionand reducethe dischargecapacityof the valve.

No valve or other obstructionisto be placedbetween the

reliefvalve andthe tank. Do not connecttubing directly to RELIEF VALVE OPENING

dischargedrain unlessa 6 air gap isprovided.To prevent

bodilyinjury, hazard to life, or propertydamage,the relief "THISWATERHEATERISAPPROVEDWITHACOMBINATIONTEMPERATURE-

PRESSURERELIEFVALVE. FOR SAFEOPERATIONOFTHE WATERHEATER,

valve must be allowed to dischargewater in quantities THE RELIEFVALVE(S)MUST NOT BEREMOVED FROM ITS DESIGNATED

should circumstances demand. If the discharge pipe is not POINTOFINSTALLATIONORPLUGGED."

connectedto a drain or other suitable means, the water YOURLOCALJURISDICTIONALAUTHORITY,WHILEMANDATINGTHEUSE

flow may causepropertydamage. OF A TEMPERATURE-PRESSURERELIEFVALVECOMPLYING WITH ANSI

The DischargePipe: z21.22 AND ASME,MAY REQUIREA VALVEMODELDIFFERENTFROMTHE

Must not be smaller in size than the outlet pipe sizeof ONEFURNISHEDWITHTHEWATERHEATER,

the valve, or have any reducing couplings or other COMPLIANCEWITHSUCHLOCALREQUIREMENTSMUSTBESATISFIEDBY

restrictions. THE INSTALLEROR ENDUSEROFTHE WATERHEATERWITH A LOCALLY

Must not be pluggedor blocked. DESIGNATEDPRESCRIBEDOPENINGTEMPERATURE-PRESSUREINTHEWATERHEATER.RELIEFVALVE INSTALLEDINTHE

Must beof material listed for hot water distribution. SEEMANUALHEADING- "TEMPERATURE-PRESSURERELIEFVALVES"FOR

Must be installed so as _o allow complete drainage of INSTALLATIONANDMAINTENANCEOFRELIEFVALVE,DISCHARGELINE

both the temperature-pressurerelief valve, andthe dis- ANDOTHERSAFETYPRECAUTONS.

chargepipe.

Mustterminate atan adequate drain.

Must not have any valve between the relief valve and

tank.

15

Page 16

Instructions for Installation (cont'd)

Filling the Water Heater

I A CAUTION If you are not familiar with electric codes and practices, or if

Never use this water heater unless it is completely you have any doubt in your ability to connect the wiring to

filled with water. Toprevent damage to the tank, this water heater, obtain the service of a competent electrician

the tank must be filledwith water. Water must flow or contact your local electric utility.

from the hot water faucet before turning "ON" gas

to the water heater.

AWARNING

To fill the water heater withwater: WATER HEATERS EQUIPPED FOR ONE TYPE VOLT-

. Close the water heater drain valve by turning the handle to AGE ONLY: This water heater is equipped for

the right (clockwise). The drain valve is on the lower front 1101120 volts only. DO NOT USE THIS WATER

ofthe water heater. HEATER WITH ANY VOLTAGE OTHER THAN THE

ONE SHOWN ABOVE. Failure to use the correct volt-

• Open the cold water supplyvalve to the waterheater, age can cause problems which can result in DEATH,

NOTE: The cold water supply valve must he left open SERIOUS BODILY INJURY OR PROPERTY DAMAGE. If

when the water heateris in use. you have nay questions or doubts consult your

• To insure complete tilting of the tank, allow air to exit by electric company.

opening the nearest hot water faucet. Allow water to run

until a constant flow is obtained. This will let air out of the A CAUTION

water heater and the piping. If wiring from the fuse box or circuit breaker box was

• Check all newwaterpiping for leaks.Repairasneeded, aluminum for the old water heater, replace it with

copper wire, If you wish to reuse the existing alu-

minum wire, have the connection at the water heater

i_11 It

wiring madebyatom.tentelmrician.Contacta

local elec-

trical contractor and/or the local electric utility.

USEWITH POWER CORD

The water heater comes equipped with a 7 foot power cord USE WITHOUT POWER CORD

which can be used to connect to a 110/120 volt power source if,

(1) local codes allow, and (2) there is a three prong grounded If power cord cannot be used, then follow these wiring

receptacle available. This unit must have a grounded outlet to instructions.

operate.

7'MAXIMUM 1. Provide a way to easily shut off the electric power when

CORDLENGTH

(Factorysuppliedl working on the water heater. This could be with a circuit

breaker or fuse block in the entrance box or a separate dis-

connect switch.

2. Install and connect a circuit direcdy from the main fuse or

circuit breaker box. This circuit must he the right size and

have its own fuse or circuit breaker.

WIRE CONDUIT

NUTS

You must provide allwiring, (1) to a receptacle or, (2) between the

water heater and junction box when the power cord is not used.

AWARNING GRoGNREEsN

Do not use an extension cord. If there is not a suit-

able receptacle and/or local codes prohibit use of a

power cord, f e d w r ng must be prov ded.

You must provide all wiring of the proper size outside of the C

water heater. You must obey local codes and electric company

requirements when you install this wiring.

16

Page 17

Instructions for Installation (cont'd)

Wiring (cont'd)

USE WITHOUT POWER CORD (cont'd)

3. A standard 1/2"conduit opening has been made in the grounded. A green ground screw has been provided on the

water heater junction box for the conduit connection, water heater's junction box. Connect ground wire to this

location. For complete grounding details and all allowable

4. Use wire nuts and connect the power supply wiring to the exceptions, refer to the latest edition of the National

wires inside the water heater's junction box. Electrical Code.

5. The water heater must be electrically "grounded" by the 6. Replace the wiring junction cover using the screw

installer. The unit will not operate unless it is properly provided.

WIRING DIAGRAM

ON/OFFSWITCH

@

z

HILIMITSWITCH

_ I_IESSURESWrrCH @

O_:IFF

ACAUTION

Label all wires prior to disconnection when servic-

ing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

serv cing.

17

Page 18

Instructions for Installation (cont'd)

Venting

=t WARNING _,WARNING

To insure proper venting of this gas-fired water Chemical vapor corrosion of the flue and vent sys-

heater, the correct vent pipe diameter must be uti- tern may occur if air for combustion contains certain

lized. Do not install other gas appliances on the chemical vapors. Spray can propellants, cleaning sol-

same vent with this water heater as this will vents, refrigerator and air conditioner refrigerants,

adversely affect the operation of the water heater, swimming pool chemicals, calcium and sodium chlo-

ride, waxes, bleach, and process chemicals are typi-

cal compounds which are potentially corrosive.

The combustion and ventilation air flow must not be obstructed.

i .w.....

The power vent water heater requires its own (sepa-

rate)venting system. It cannot be connected to an

existing vent pipe or chimney. It must be terminated

to the outdoors. Failure to properly install the vent-

ing system can result in asphyxiation, afire or explo- |f-_l STRAPPING

sion and can cause DEATH, SERIOUS BODILY INJUR_

OR PROPERTY DAMAGE.

I I

_WARNING ayp_-

Obstructed or deteriorated vent systems m Horlzont_l runs mustbe securelysupportedat 3_/2foot intervals

sent a serious health risk or asphyxiation, and vertical runs supported at 5 foot interva/s.

AWARNING I VENTING THROUGH AN OUTSIDE WALL

The vent

pipe from the water heater must slope 75 GALLON 70,000 AND 75,000 BTU/HR, 50 GALLON

I

upward ¼ inch per f ve linear feet for any hor zon-

tal run. 52,500 BTU/HR MODELS ONLY(See rating plate for BTU/HR rating)

3" PVC, ABS or CPVC Schedule 40 vent piping:

All vent gases must be completely vented to the outdoors of the

structure (dwelling), • A 3" PVC Schedule 40-45 °vent cap with wire screen is

supplied with the water heater.

.__ • A 3" PVC, ABS or CPVC Schedule 40-90 ° street ell; used

-" I[_ toconnecttheventpipetothewaterheaterwhenthevent

pipe is to be turned horizontally directly off the blower (sup-

MIN,RISE¼"

PERFIVEFEET plied locally).

• 3" PVC, ABS or CPVC Schedule 40 pipe (must be sup-

I 1 pEed local/y).

3-Pvc,ABSORO,vc

I , AWARNING SCHEDULE40" 90*/."T"]

[ I

Failure to have required clearances between water STREETELBOW ( _J

heater and combustible material will result in a fire _ 3"PVC,ABSORCPVC

hazard. SCHEDULE40PiPE VENTCAP

WITHSCREEN

=t WARNING I

Be sure vent pipe is properly connected to prevent / I

l escape Of danc_erous flue gases which could cause

I deadly asphyxiation.

18

Page 19

Instructions for Installation (cont'd)

75 GALLON 70,000 AND 75,000 BTU/HR, 50 GALLON * The water heater requires its own (separate) venting system.

52,500 BTU/HR MODELS ONLY

• 4" and 3" PVC, ABS or CPVC Schedule 40 piping and rit-

e The water heater requires its own (separate) venting system, tings are acceptable materials for the vent system on all 75

gallon 70,000 and 75,000 BTU/HR and 50 gallon 52,500

• 3" PVC, ABS or CPVC Schedule 40 piping and fittings are BTU/HR models.

acceptable materials for the vent system on all 75 gallon

70,000 and 75,000 BTU/HR and 50 gallon 52,500 • It cannot be connected to existing vent piping or chimney.

BTU/FIR models.

• It must terminate horizontally to the outdoors.

• It cannot be connected to existing vent piping or chimney.

• It mustterminate horizontally to the outdoors. ALL 40 AND 50 GALLON 40,000 BTU/HR MODELS

ONLY

75 GALLON 70,000 AND 75,000 BTU/HR, 50 GALLON

52,500 BTU/HR MODELS ONLY -- OPTIONAL 4" VENT 3" PVC, ABS or CPVC Schedule 40 vent piping:

PIPING

• A 3" PVC Schedule 40-45 °vent cap with wire screen is

4" PVC, ABS or CPVC Schedule 40 vent piping: supplied with the water heater.

• A wire screen to fit a 4" PVC, ABS or CPVC Schedule 40- • A 3" PVC, ABS or CPVC Schedule 40-90* street ell; used

45°vent cap is supplied with the water heater, to connect the vent pipe to the water heater when the vent

pipe is to be turned horizontally directly offthe blower (sup-

• A 4" PVC, ABS or CPVC Schedule 40-45 °vent cap pried locally).

(must be supplied locally).

• 3" PVC, ABS or CPVC Schedule 40 pipe (must be sup-

• A 3" PVC, ABS or CPVC Schedule 40 pipe, minimum plied locally).

length of 3" (must be supplied locally), to make vent con-

nection at the blower outlet.

3" PVC,ABSORCPVC

SCHEDULE L--J"_ I_

• A 4" to 3" PVC, ABS or CPVC Schedule 40 reducer (must 40 90° ELBOW[e.LJ l I

be supplied locally). 3" PVC,ABSORCPVC

SCHEDULE40 PIPE VENTCAP

• A 4" PVC, ABS or CPVC Schedule 40-90 ° street ell; used _ WiTHSCREEN

to connect the vent pipe to the reducer when the vent pipe is

/-AtY

to be turned horizontally offthe blower (supplied locally). [ [

• 4" PVC, ABS or CPVC Schedule 40 pipe (must be sup-

plied locally). • The water heater requires its own (separate) venting

system.

4"PVC,ABSORCPVC

4" PVC,ABSORCPVC SCHEDULE40 PIPE • 3" PVC, ABS or CPVC Schedule 40 piping and fittings

SCHEDULE4090°_1_

t ,, I I _ are acceptable materials for the vent system on all 40 and

STREETELBOW

L_7

50 gallon 40,000 BTU/HR models.

4"VENTCAP

_4 _TO3" PVC,ABSOR WITHSCREEN

CPVCREDUCER • It cannot be connected to existing vent piping or

[_ 3" PVC,ABSORCPVCSCHEDULE40 chimney.

PIPE(MINIMUMLENGTH3")

• It must terminate horizontally to the outdoors.

19

Page 20

Instructions for Installation (cont'd)

Venting (cont'd)

VENTING THROUGH AN OUTSIDE WALL (cont'd) VENTING SYSTEM EXAMPLE INSTALLATIONS FOR ALL

MODELS

ALL 40 AND S0 GALLON 40,000 BTU/HR MODELS

OPTIONAL 2" VENT PIPING The vent piping cannot under any circumstances be run

downhill.

2" PVC, ABS or CPVC Schedule 40 vent piping:

• A wire screen to fit a 2" PVC, ABS orCPVC Schedule 40-

45 °vent cap is supplied with the water heater.

• A 2" PVC, ABS or CPVC Schedule 40-45 ° vent cap

(elbow) (must be supplied locally).

• A 3" PVC, ABS or CPVC Schedule 40 pipe, minimum

length of 3" (must be supplied locally), to make vent con-

nection at the blower outlet.

• A 3" to 2" PVC, ABS or CPVC Schedule 40 reducer (must (_

be supplied locally).

The vent piping may be installed as follows:

• A 2" PVC, ABS or CPVC Schedule 40-90* street ell; used

to connect the vent pipe to the reducer when the vent pipe is • Horizontal runs require a minimum %" rise per five feet.

to be turned horizontally off the blower (supplied locally).

3

• 2" PVC, ABS or CPVC Schedule 40 pipe (must be sup- ELBOW

2" PVC, ABS OR CPVC / [1 J PER FIVE FEET

2" PVC, ABS OR CPVC SCHEDULE 40 PIPE /

SCHEDULE 40,,,.--n {_

B0°E'BOWI JVENTC.

3" TO 2" PVC, ABS OR WITH SCREEN

CPVC REDUCER

3" PVC, ABS OR CPVC I I

[_] SCHEDULE 40 PIPE

(MINIMUM LENGTH 3")

ELBOW

t _ MIN. RISEYs"

PER FtVE FEET

• The water heater requires its own (separate) venting

system.

i

• 2" and 3" PVC, ABS or CPVC Schedule 40 piping and fit-

tings are acceptable materials for the vent system on all 40

and 50 gallon 40,000 BTU/HR models.

MIN. RJSE¼"

• It cannot be connected to existing vent piping or PERFIVEFEET

chimney.

• It must terminate horizontally to the outdoors.

NOTE: See pages 24 to 26 for vertical venting through a roof.

20

Page 21

Instructions for Installation (cont'd)

• The total vertical and horizontal vent run cannot exceed the

l_ ma_dmumlength with the number °f 90° elb°ws as specitled

_,__ in the tables below. If more elbows arerequired, the venting

E distance must be reduced 5 feet forevery 90° elbow:

MIN.RISEYs"

PERFIVEFEET

75 GALLON 70,000 AND 75,000 BTU/HR, 50 GALLON

52,500 BTU/HR MODELS ONLY

3" DIA.VENT NUMBER OF 90° DEG.

MAX. LENGTH (FT.) ELBOWS*

70 1

65 2

PERFiVEFEET 60 3

55 4

I 50 5

45 6

75 GALLON 70,000 AND 75,000 BTU/HR MODELS 75 GALLON70,000AND 75,000 BTU/HR,50GALLON52,500

AND 50 GALLON 52,500 BTU/HR MODELS BTU/HRMODELSONLY_OPTIONAL4" VENTPIPING

4" DIA.VENT NUMBER OF 90° DEG.

Seechartinnextcolumnformax.length. MAX. LENGTH (FT.) ELBOWS*

16"MIN. -'] 110 1

105 2

100 3

95 4

13Yf"MIlL _ l_,,_aiN MIN.RISE'/8" 90 5

/ _ --r_- PERFIVEFEET 85 6

I ALL 40 AND 50 GALLON 40,000 BTU/HR MODELS

ONLY.

3" DIA.VENT NUMBER OF 90° DEG.

MAX. LENGTH _F'I'.) ELBOWS*

40 and 50 GALLON 40,000 BTU/HR MODELS 115 1

110 2

105 3

Seechartinnextcolumnform_x. length. 100 4

4' MIN. _'_ 95 5

90 6

14"MIN MIN.RISE_-V' ALL 40 AND 50 GALLON 40,000 BTU/HR MODELS --

15½"MIII',Lt_ / PERFOOT OPTIONAL 2" VENT PIPING

2" DIA.VENT NUMBER OF 90 ° DEG.

_- 1 MAX. LENGTH (FT.) ELBOWS*

50 1

45 2

40 3

35 4

30 5

25 6

NOTE: Two 45° elbows are equivalent to one 90° elbow.

One 90°elbow eqtuds 5 feet of equivalent vent length.

21

Page 22

Instructions for Installation (cont'd)

Venting (cont'd)

VENTING THROUGH AN OUTSIDE WALL (cont'd) 75 GALLON 70,000 AND 75,000 BTU/HR,

50 GALLON 52,500 BTU/HR MODELS ONLY

i"_-'_95_ MAX" "L_ 3" DIA.VENT NUMBER OF 90° DEG.

l _ PERMIN,FIVEI_1_RISEFEETW" MAX. LENGTH(FT.)6055 ELBOWS*linside bldg.)21

20' / ONEELBOW 50 3

EXAMPLE) 45 4

40 5

35 6

3"VENTPiPE

40GALLON 75 GALLON70,000 AND 75,000BTU/HR,50 GALLON52,500

40,000BTU/HR

[ MODELEXAMPLE 8TU/HR MODELSONLY--OPTIONAL4" VENTPIPING

I

4" DIA.VENT NUMBER OF 90° DEG.

MAX. I_ENGTH(FT.) ELBOWS*0nside bldg.)

• Minimum vent length for all 40,000 BTU/HR input mod- 100 1

els is 4 feet and 16 inches for all other models.

95 2

90 3

VENTING THROUGH AN OUTSIDE WALL WITH LOW 85 4

GROUND CLEARANCE 80 5

75 6

• When the vent piping cannot pass through an outside wall

at a height greater than or equal to 12" above the ground

(or above snow accumulation level), then the installation ALL 40 AND 50 GALLON 40,000 BTU/HR MODELS

canbe modified asshown below, 3" DIA.VENT NUMBER OF 90° DEG.

MAX. LENGTH (FT.) ELBOWS*{inside bldg.)

105 1

100 2

95 3

//_ 90 4

85 5

I I 112"MIN.ABOVE ALL 40 AND 50 GALLON 40,000 BTU/HR MODELS --

R i

/_ I I GROUNDORSNOW

_ ACiUMULATIONLEVEL OPTIONAL 2" VENT PIPING

I-_ 2" DIA.VENT NUMBER OF 90° DEG.

MAX. LENGTH (FT.) ELBOWS*(inside bldg.)

40 1

35 2

30 3

25 4

20 5

15 6

• Refer to the tables in the next column for maximum vent

lengths for low ground clearance installations. All installa- NOTE: Two 45° elbows are equivalent to one 90"elbow.

r.ionsassume the use of two additional 90° elbows and the One 90"elbow equals 5 feet of equivalent vent length.

standard 45° vent cap with screen outside of the exterior wall.

22

Page 23

Instructions for Installation (cont'd)

CEMENTING PVC, ABS OR CPVC PIPEAND FITI'INGS cUTrlNG OPENING THROUGH AN OUTSIDE WALL

AND COLLARINSTALLATION

Read and observe all safety information printed on primer,

cleaner, and cement containers. After reading the manual and you have determined the loca-

tion of the opening in the wall, (using the drawing below), cut

1 P, r, * * ,p . .

_i DANGER a2/2 hole for 2 vent piping, 31/2" hole for 3 vent piping or

Primer, cleaner, and cements are extremely flammable, a 471" hole for 4" vent piping through an exterior wall.

They are harmful or fatal if swallowed. The vapors are

harmful. They may irritate eyes and skin andcan be NOTE: When determining location of the opening in the

absorbed through the skin. outside wall allow for the 1/8"rise per five feet that has taken

place in the horizontal run.

At,PRECAUTIONS

Always store primers, cleaner, and cements in cool, dry,

well ventilated places. Do not store them near heat, _ OFFLUE

sparks, or flames, Keep containers closed. Use them in 12-MIN.75GAL.

well ventilated areas. Wear impervious clothing while 12"MIN.SOGAL. MIN.RISE½"

1_" _(_.4Q&s0G_-. PERFIVEFEET

handling. Do not smoke, eat, or drink while handling, ao,oooBTU/HR

Washthoroughly after handling and before eating. Wear

eye protection when handling. If swallowed, drinkwater,

do not induce vomiting, and call a physician or poison

control center immediately. If inhaled, get fresh air and

seek medicalattention if il/feelings persist.In caseof eye

and skincontact, immediately flush with plenty of water

for 15 minutes and seek medical attention if irritation

)ersists.KEEPOUT OR REACHOFCHILDREN. 4oGAL.-60"

50GAL.-59'/2_

75GAL.-63¼"

All primers, cleaners, and cements must meet all local codes [

and applicable standards of the American Society For Testing [ ....

Materials Standards.

Before using primers, cleaners, and cements, stir or shake,

making sure contents are liquid. Do not use if found to be ._