Page 1

MAYTAG

Series Twelve PC

INTELLIGENT ELECTRIC

a

WATER HEATER

USER'S GUIDE

EPFICIENCY

RATING

CERTIFIED

ama

GAMA certification applies to all residential

electric water heaters with capacities of 20 to

120 Gallons. Input rating of 12 Kw or less at a

voltage no greater than 250 V.

Model Numbers

HE21250PC

HE21282PC

FOR POTABLE WATER

HEATING ONLY

NOT SUITABLE FOR

SPACE HEATING

A WARNING

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE

COVER AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING OR

OPERATING THIS WATER HEATER.

Save this Manual for Future Reference.

___________________________________

Caution:

Read and Follow All

Safety Rules and

Operating Instructions

Before First Use of

This Product.

Page 2

Safety Instructions

AWARNING

Improper installation, adjustment, alteration, service

or maintenance can cause DEATH, SERIOUS BODILY

INJURY, OR PROPERTY DAMAGE. Refer to this manu

al for assistance consuit your local utility or call

Maytag Customer Service at 1-800-788-8899 for an

authorized servicer for further information.

AWARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater,

make sure the electrical supply to the water heater

is turned "OFF". Failure to do this could result in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE.

AWARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a

temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald

and permanently injure you upon contact. Some

eople are more likely to be permanently injured by

ot water than others. These include the elderly,

K

children, the infirm, or physically/mentally handi

capped. If anyone using hot water in your home fits

into one of these groups or if there is a local code or

state law requiring a certain temperature water at

the hot water tap, then you must take special pre

cautions. In addition to using the lowest possible

temperature setting that satisfies your hot water

needs, a means sucn as a mixing valve, should be

used at the hot water taps used by these people or

at the water heater. Mixing valves are available at

plumbing supply or hardware stores. Follow manu

facturers instructions for installation of the valves.

Before changing the factory setting on the thermo

stat, read the "Temperature Regulation" section in

this manual.

AWARNING

INSULATING JACKETS: When installing an external

water heater insulation jacket on an electric water

heater:

•DO NOT cover the temperature-pressure relief

valve.

• DO NOT put insulation over the access covers or

any access areas.

• DO NOT cover or remove operating instructions,

and safety related warning labels and materials

affixed to the water heater.

AWARNING

Do not use this appliance if any part of it has been

under water. An electrical short or malfunction could

occur. The water heater should be replaced.

AWARNING

At the time of manufacture this water heater was pro

vided with a combination temperature-pressures relief

valve certified by a nationally recognizeci testing labora

tory that maintains periodic inspection of production of

listed equipment or materials, as meeting the require

ments for Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems, and the latest

edition of ANSI Z21.22 and the code requirements of

ASME. If replaced, the valve must meet the require

ments of local codes, but not less than a combination

temperature and pressure relief valve certified as meet

ing the requirements for Relief Valves and Automatic

Gas Shutoff Devices for Hot Water Supply Systems, ANSI

Z21.22 by a nationally recognized testing laboratory

that maintains periodic inspection of production of list

ed equipment or materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostatic working pressure

of the water heater (150 Ibs./sq. in.) and a discharge

capacity not less than the water heater input rate as

shown on the model rating plate. (Electric heaters watts divided by 1000 x 3415 equal BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the

use of a temperature-pressure relief valve complying

with ANSI Z21.22 and ASME, may require a valve model

different from the one furnished with the water heater.

Compliance with such local requirements must be satis

fied by the installer or end user of the water heater with

a locally prescribed temperature-pressure relief valve

installed in the designated opening in the water heater

in place of the factory furnished valve.

For safe operation of the water heater, the relief valve

must not be removed from it's designated opening or

plugged.

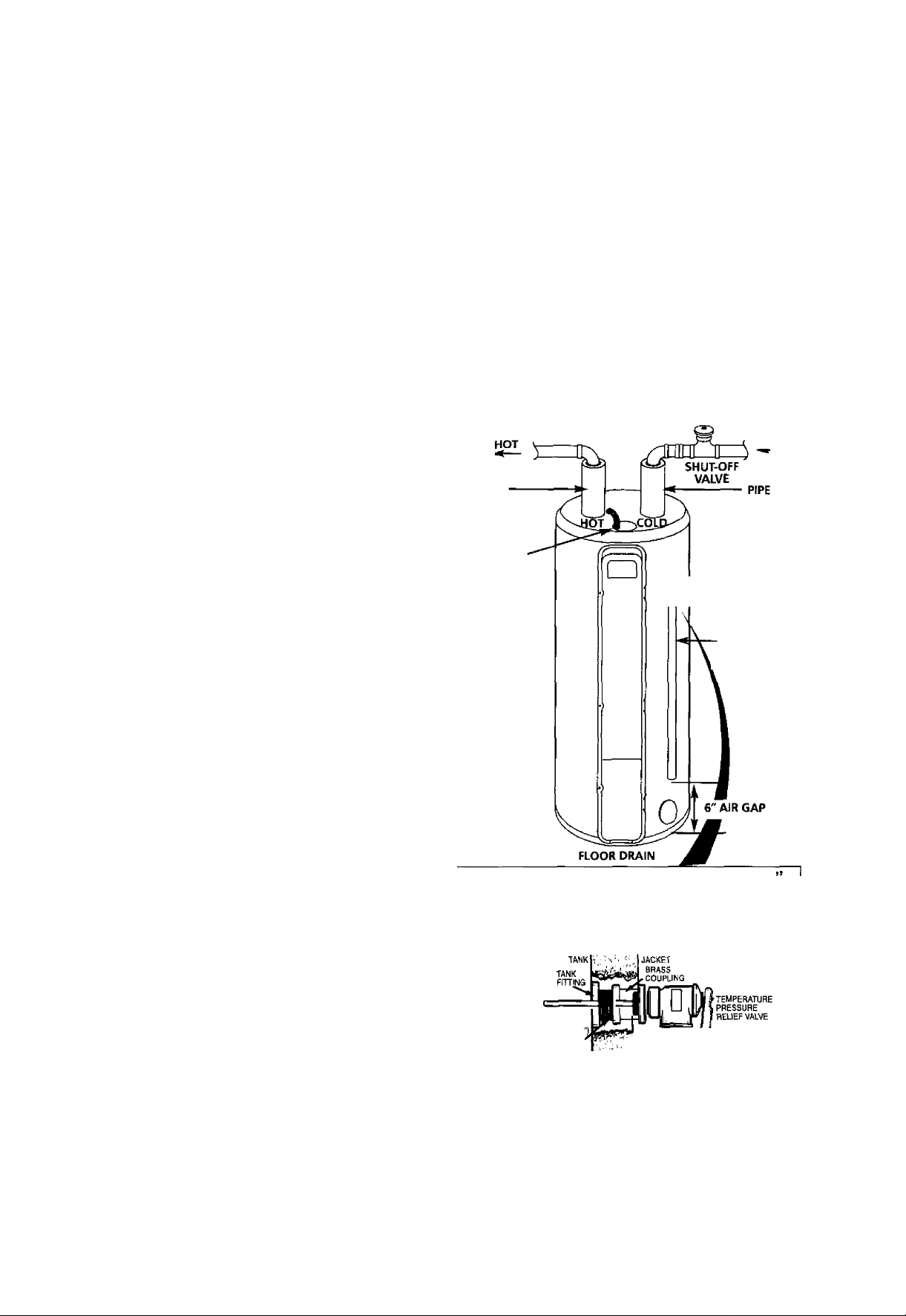

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designated

for the relief valve. Position the valve downward and

provide tubing so that any discharge will exit only with

in 6 inches above, or at any distance below the struc

tural floor. Be certain that no contact is made with any

live electrical part. The discharge opening must not be

blocked or reduced in size under any circumstances.

Excessive length, over 30 feet, or use of more than four

elbows can cause restriction and reduce the discharge

capacity of the valve.

No valve or other obstruction is to be placed between

the relief valve and the tank. Do not connect tubing

directly to discharge drain unless a 6" air gap is provid

ed. To prevent bodily injury, hazard to life, or property

damage, the relief valve must be allowed to discharge

water in quantities should circumstances demand. If the

discharge pipe is not connected to a drain or other suit

able means, the water flow may cause property damме.

The Discharge Pipe;

• Must not be smaller in size than the outlet pipe size of

the valve, or have any reducing couplings or other

restrictions.

• Must not be plugged or blocked.

• Must be of material listed for hot water distribution.

• Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the

discharge pipe.

• Must terminate at an adequate drain.

• Must not have any valve between the relief valve and

tank.

Page 3

Safety Instructions (cont'd)

▲ WARNING

WATER HEATERS EQUIPPED FOR ONE VOLTAGE

ONLY; This water heater is equipped for one type

voltage only. Check the rating plate near the bot

tom access panel for the correct voltage. DO NOT

use this water heater with any voltage other than

the one shown on the model rating plate. Failure to

use the correct voltage can cause problems which

can result in DEATH, SERIOUS BODILY INJURY. OR

PROPERTY DAMAGE. If you have any questions or

doubts consuit your eiectric company.

▲ CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomplished in such a

manner that if the tank or any connections should

leak, the flow of water wilt not cause damage to the

structure. For this reason, it is not advisabie to instaii

the water heater in an attic or upper floor. When

such locations cannot be avoided, a suitable drain

pan shouid be instalied under the water heater.

Drain pans are available at your local hardware

store. Such a drain pan must have a minimum diam

eter of at least 1% inches greater than the water

heater diameter and must be piped to an adequate

drain. Under no circumstances is the manufacturer to

be held liable for any water damage in connection

with this water heater.

Page 4

Table of Contents

Safety Instructions.................................................................................................................................................................2^3

Table of Contents.......................................................................................................................................................................4

Customer Information............................................................................................................................................................... s

Product Specifications............................................................................................................................................................... 5

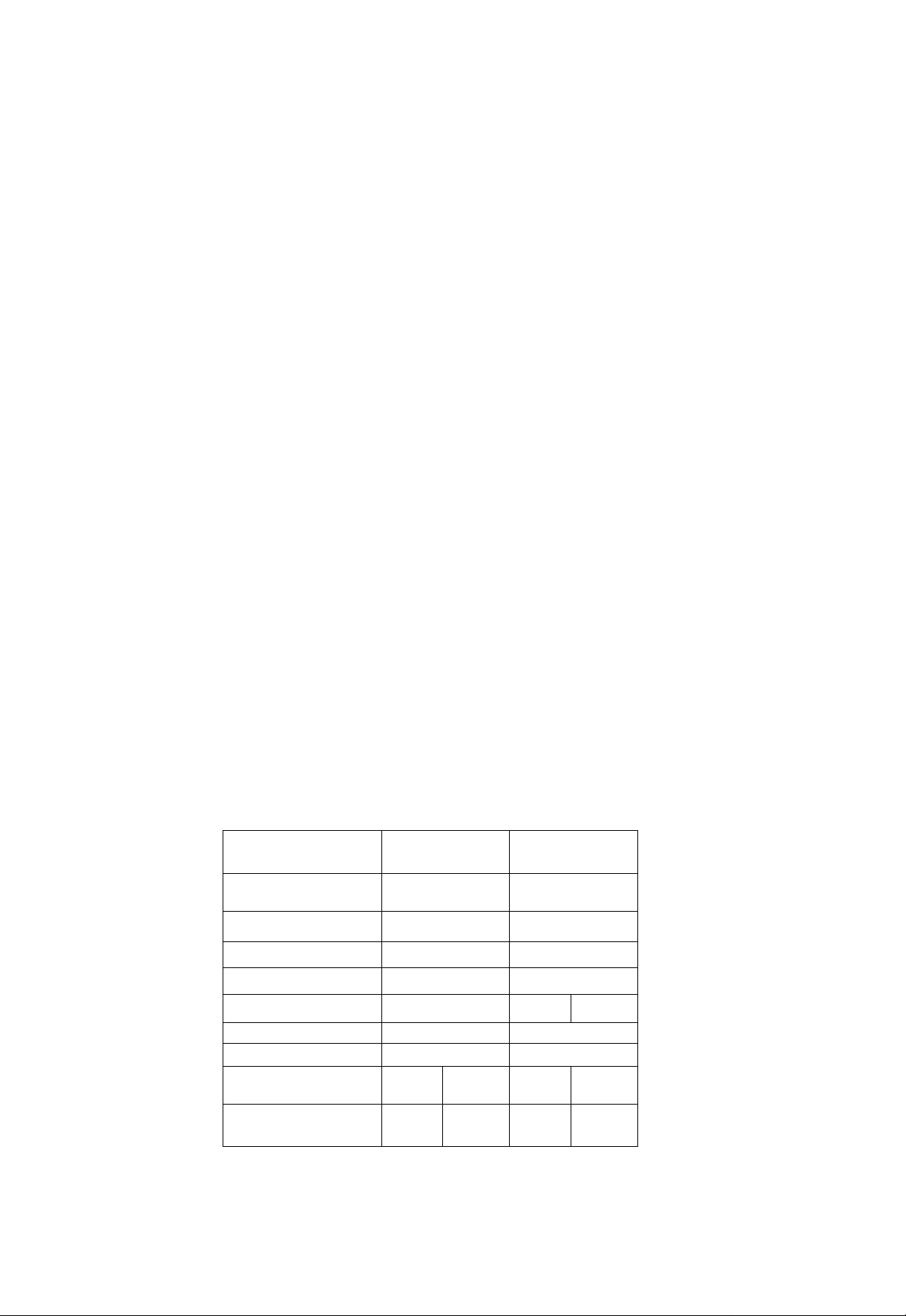

Accessories and Tools Needed....................................................................................................................................................6

Accessories............................................................................................................................................................................6

Tools.................................................................................................................................................................................... 6

Instructions for Installation................................................................................................................................................... 7-22

Removing the Old Water Heater....................................................................................................................................... ..7

Locating the New Water Heater............................................................................................................................................8

Typical Installation................................................................................................................................................................8

The Convertible Lower Element...........................................................................................................................................9

Water Piping........................................................................................................................................................................10

Temperature-Pressure Rehef Valve.................................................................................................................................... 11

Filling the Water Heater......................................................................................................................................................12

Converting the Lower Element......................................................................................................................................12-14

Wiring Diagram................................................................................................................................................................. 15

Wiring..................................................................................................................................................................................16

Selecting Thermostat Location........................................................................................................................................... 17

Routing Wire Harness to Location.................................................................................................................................17

Thermostat Removal................................................................................................................................................. 17,18

Remote Thermostat Wiring at Water Heater............................................................................................................ 18-20

Remote Thermostat Installation and Wiring.............................................................................................................20,21

Installation Checklist......................................................................................................................................................... 22

Instructions for Operation...................................................................................................................................................23-26

Temperature Regulation......................................................................................................................................................23

Temperature Conditions......................................................................................................................................................23

Programming the Thermostat........................................................................................................................................ 23-26

Service and Maintenance................................................................................................................................................... 27-31

Temperature-Pressure Relief Valve Operation................................................................................................................... 27

Draining...............................................................................................................................................................................27

Element Cleaning and Replacement...............................................................................................................................28'30

Drain Valve Washer Replacement......................................................................................................................................31

Service................................................................................................................................................................................ 31

Troubleshooting.................................................................................................................................................................. 32-35

Start Up Conditions.............................................................................................................................................................32

Thermal Expansion.........................................................................................................................................................32

Strange Sounds............................................................................................................................................................. 32

Operational Conditions.................................................................................................................................................. 32,33

Smelly Water..................................................................................................................................................................32

Air in Hot Water Faucets................................................................................................................................................32

Rumbling Noise..............................................................................................................................................................32

High Temperature Shut Off System......................................................................................................................... 32,33

Not Enough Hot Water...................................................................................................................................................33

Water is Too Hot............................................................................................................................................................ 33

Thermostat Diagnostics.................................................................................................................................................. 34

Leakage Checkpoints..................................................................................................................................................... 35

Repair Parts List.................................................................................................................................................................37-39

Warranty.................................................................................................................................................................................. 40

4

Page 5

Customer Information

Thank You for purchasing a Maytag water heater.

Properly installed and maintained, it should give you years of

trouble free service. It is strongly suggested that this new

water heater be professionally installed., call Maytag Customer

Service at 1-800-788-8899 for recommended installers.

Abbreviations Found In This Instruction Manual

U.L.- Underwriters Laboratories, 333 Pfingsten Rd.,

Northbrook, IL 60062

National Electrical Code-This publication is available from

your local government or public library or electric company or

by writing to U.L. above.

ANSI-American National Standards Institute

• Read the “Safety Instructions” section, pages 2 and 3 of this

manual first and then the entire manual carefully. If you

don’t follow the safety rules, the water heater wiU not oper

ate properly. It could cause DEATH, SERIOUS BODILY

INJURY AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, oper

ation, and maintenance of this electric water heater. It also

contains warnings throughout the manual that you must

read and be aware of. All warnings and all instructions are

essential to the proper operation of the water heater and

your safety. Since we cannot put everything on the first few

pages, READ THIS ENTIRE MANUAL BEFORE

ATTEMPTING TO INSTALL OR OPERATE THE

WATER HEATER.

The installation must conform with the instructions in this

manual; electric company rules; and Local Codes, or in the

absence of Local Codes, with the latest edition of the

National Electrical Code. This publication is available from

your local government or public library or electric company

or by writing Underwriters Laboratories, 333 Pfingsten

Road, Northbrook, IL 60062.

If after reading this manual you have any questions or do

not understand any portion of the instructions, call Maytag

Customer Service at 1-800-788-8899 for an authorized

servicer.

Carefully plan the place where you are going to put the

water heater. Correct electrical wiring and connections are

very important in preventing death from possible electrical

shock and fires.

Examine the location to ensure the water heater complies

with the “Locating the New Water Heater” section.

For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during an

earthquake. See instructions for correct installation proce

dures. Instructions may be obtained from the California

office of the State Architect, 400 P Street, Sacramento, CA

95814.

Massachusetts Code requires this water heater to be

installed in accordance with Massachusetts 248-CMR 2.00:

State Plumbing Code and 248-CMR 5.00.

Product Specifications

Model HE21250PC HE21282PC

Tank Capacity

In Gallons

Element Upp„

at 240 Volt Lower

Recovery Rate Upper

@ 90°F Rise Lower 17.3 1 25 17.3 25

Diameter 22" 26.25"

Height 58.5" 62"

Maximum Fuse or

Circuit Breaker Size 20

Minimum

Wire Size (Gauge)*

*Wiring size based on standard 60°C copper wire. If distance from

fuse box to water heater is more than 90 feet, refer to your local

electrical code.

3800 1 5500 3800 1 5500

12

50 80

3800 3800

17.3

30 20

10 12

5

17.3

30

10

Page 6

Accessories and Tools Needed

Accessories

To simplify the installation Maytag has available the installa

tion parts shown below. You may or may not need all of these

accessories depending on your type of installation. Call

Maytag Customer Service at 1-800-788-8899 for an autho

rized installer.

DRAIN PANS AVAIUBLE IN 22" DIAMETER

(PART NUMBER 66001011) FOR WATER

HEATERS HAVING A DIAMETER 20" OR LESS,

EXMNSION TANKS FOR THERMAL EXPANSION

CONDITIONS AVAILABLE IN 2 GALLON (PART

NUMBER 66001013) AND 5 GALLON (PART

NUMBER 66001014) CAPACITY

24" DIAMETER (PART NUMBER 66001105) FOR

WATER HEATERS HAVING A DIAMETER 22" OR

LESS AND AVAILABLE IN 28" DIAMETER (PART

NUMBER 66001012} FOR WATER HEATERS

HAVING A DIAMETER 26.25" OR LESS

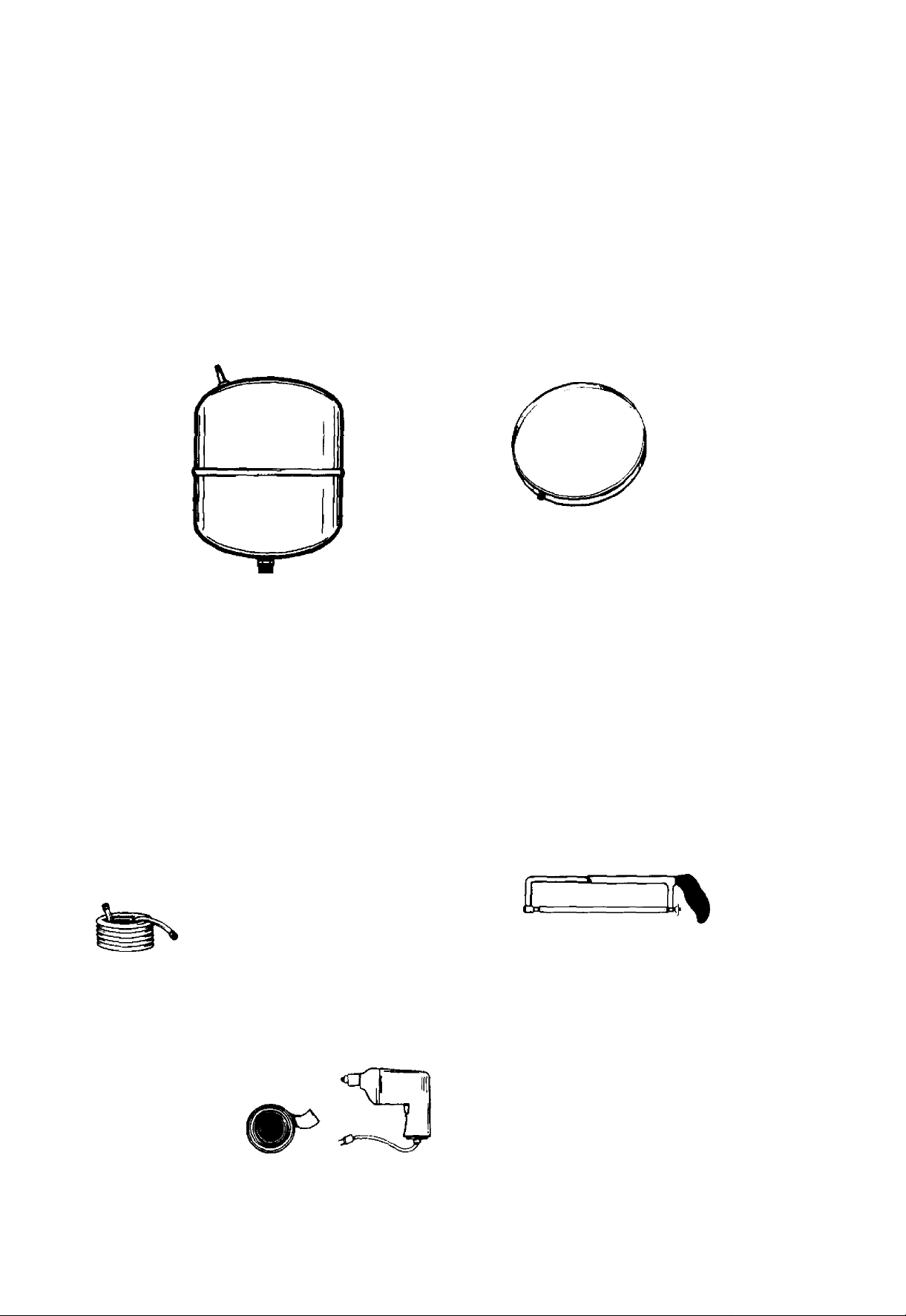

Tools

You may or may not need all of these tools, depending on your

type of installation. These tools can be purchased at your local

Maytag store.

• Pipe Wrenches (2) 14"

• Screwdriver

• 6 Foot Tape of Folding Rule

• Garden Hose

• Drill

• Pipe dope or Teflon Tape

GARDEN HOSE

SLOT-HEAD SCREW DRIVER

PHILLIPS SCREWDRIVER

PIPE DOPE

(SQUEEZE TUBE)

6 FOOT TAPE

ROLL OF TEFLON TAPE

(Use only on water connec

tions)

PIPE

WRENCH

DRILL

ADDITIONAL TOOLS NEEDED WHEN SWEAT SOLDERING

• Tubing Cutters or Hacksaw

• Propane Torch

• Soft Solder

• Solder Flux

• Emery Cloth

• Wire Brushes

HACKSAW

3/4" WIRE BRUSH

1/2" WIRE BRUSH

ROLL OF LEAD FREE

SOFT SOLDER

a

ROLL OF EMERY

CLOTH

SOLDER FLUX TUBING CUTTER

\

A

PROPANE TORCH

Page 7

Installation Instructions

Removing the Old Water Heater

^^Turn “OFF" electrical supply to the water heater. a.

Turn “OFF” the water supply to the

©

water heater at the water shutofif valve

or water meter.

Attach a hose to the water heater drain

valve and put the other end in a floor

drain or outdoors. Open the water

heater drain valve. Open a nearby hot

water faucet which will relieve pressure

in the water heater and speed draining.

If you have copper piping to the water heater, the two

copper water pipes can be cut with a hacksaw approxi

mately four inches away from where they connect to

the water heater. This will avoid cutting off the pipes

too short. Additional cuts can be made later if neces

sary. Disconnect the temperature-pressure relief valve

drain line. When the water heater is drained, discon

nect the hose from the drain valve. Close the drain

valve. The water heater is now completely disconnect

ed and ready to be removed.

b. If you have galvanized pipe to the water

©

heater, loosen the two galvanized pipes

with a pipe wrench at the union in each

line. Also disconnect the piping remain

ing to the water heater. These pieces

should be saved since they may be needed

when reconnecting the new water heater.

Disconnect the temperature-pressure

relief valve drain line. When the water

heater is drained, disconnect the hose

from the drain valve. Close the drain

valve. The water heater is now completely

disconnected and ready to be removed.

AWARNING

The water passing out of the drain

valve may be extremely hot. To

avoid being scalded, make sure all

connections are tight and that the

water flow is directed away from

any person.

Check again to make sure the electrical supply is turned

“OFF” to the water heater. Then disconnect the electri

cal supply connection from the water heater junction

box.

A CAUTION

Mineral buildup or sediment may have accumulated

in the old water heater. This causes the water

heater to be much heavier than normal and this

residue, if spilled out, could cause staining.

Page 8

Instructions for Installation (cont'd)

Locating The New Water Heater

You should carefully choose an indoor location for the new

water heater, because the placement is a very important con

sideration for the safety of the occupants in the building and

for the most economical use of the appliance. This water

heater is not intended for outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed.

1. The location selected should be indoors as close to and as

centralized with the water piping system as possible. This

water heater, as well as all water heaters, will eventually

leak. Do not install without adequate drainage provisions

where water flow will cause damage.

A CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomplished in such a

manner that if the tank or any connections should

leak, the flow of water will not cause damage to the

structure. For this reason, it is not advisable to install

the water heater in an attic or upper floor. When

such locations cannot be avoided, a suitable drain

pan should be installed under the water heater.

Drain pans are available at your local hardware

store. Such a drain pan must have a minimum diam

eter of at least IV« inches greater than the water

heater diameter and must be piped to an adequate

drain. Under no circumstances is the manufacturer or

Maytag to be held liable for any water damage in

connection with this water heater.

A CAUTION

INSTALLATION IN RESIDENTIAL GARAGES: The water

heater must be located and/or protected so it is not

subject to physical damage by a moving vehicle.

2. The location selection must provide adequate clearances for

servicing and proper operation of the water heater.

VACUUM RELIEF REQUIRED BY SOME CODES

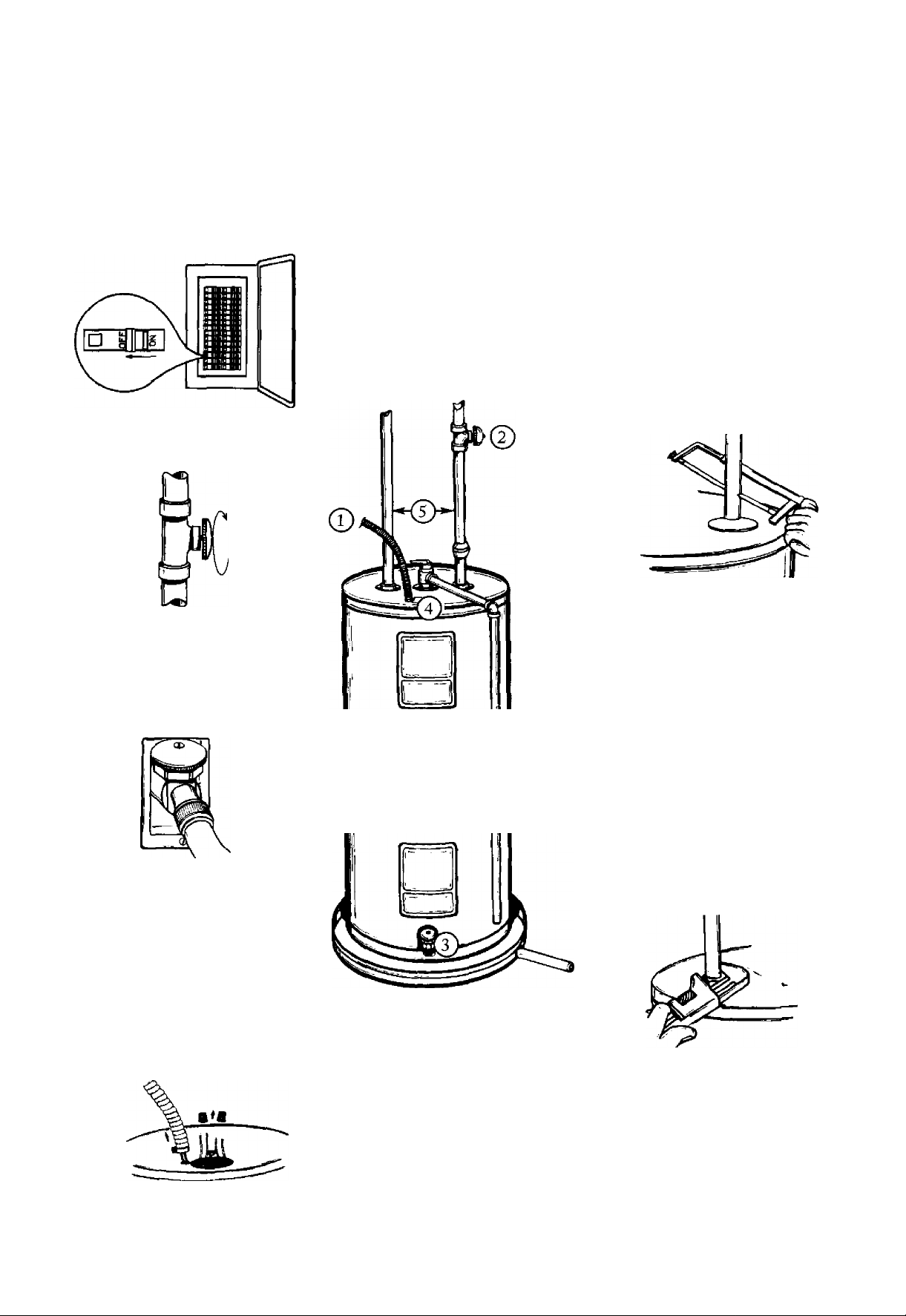

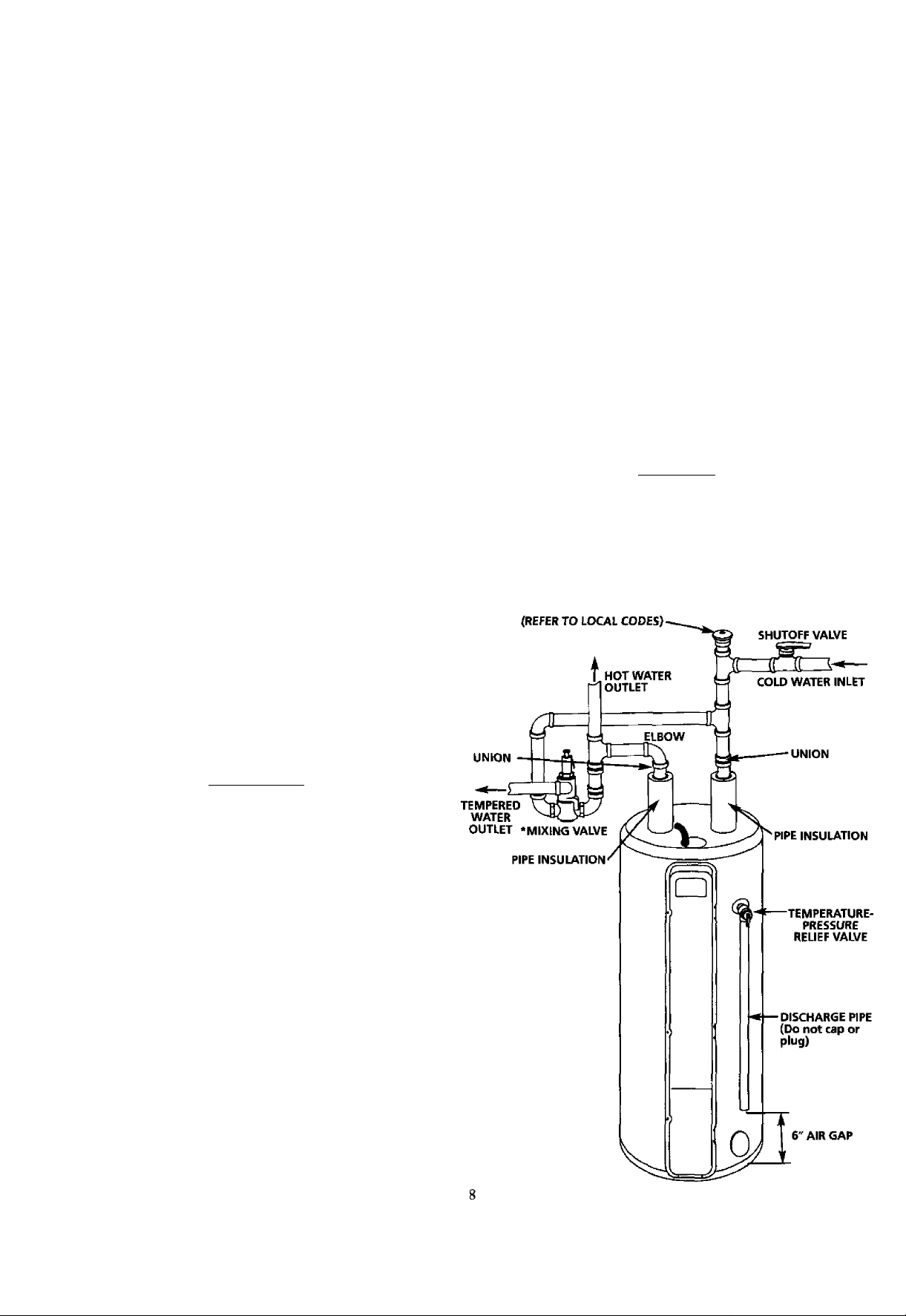

Typical Installation

CHECK ALL CONNECTIONS FOR LEAKS.

CONSULT THE LOCAL UTILITY COMPANY TO EXAM

INE INSTALLATION FOR PROPRIETY AND SAFETY.

^ A WARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a

temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald

and permanently injure you upon contact. Some

people are more likely to be permanently injured by

not water than others. These include the elderly,

children, the infirm, or physically/mentally handi

capped. If anyone using not water in your home fits

into one of these groups or if there is a local code or

state law requiring a certain temperature water at

the hot water tap, then you must take special pre

cautions. In addition to using the lowest possible

temperature setting that satisfies your hot water

needs, a means sucri as a mixing valve, should be

used at the hot water taps used by these people or

at the water heater. Mixing valves are available at

plumbing supply or hardware stores. Follow manu

facturers instructions for installation of the valves.

Before changing the factory setting on the thermo

stat, read the "Temperature Regulation" section in

this manual.

Page 9

Instructions for Installation (cont'd)

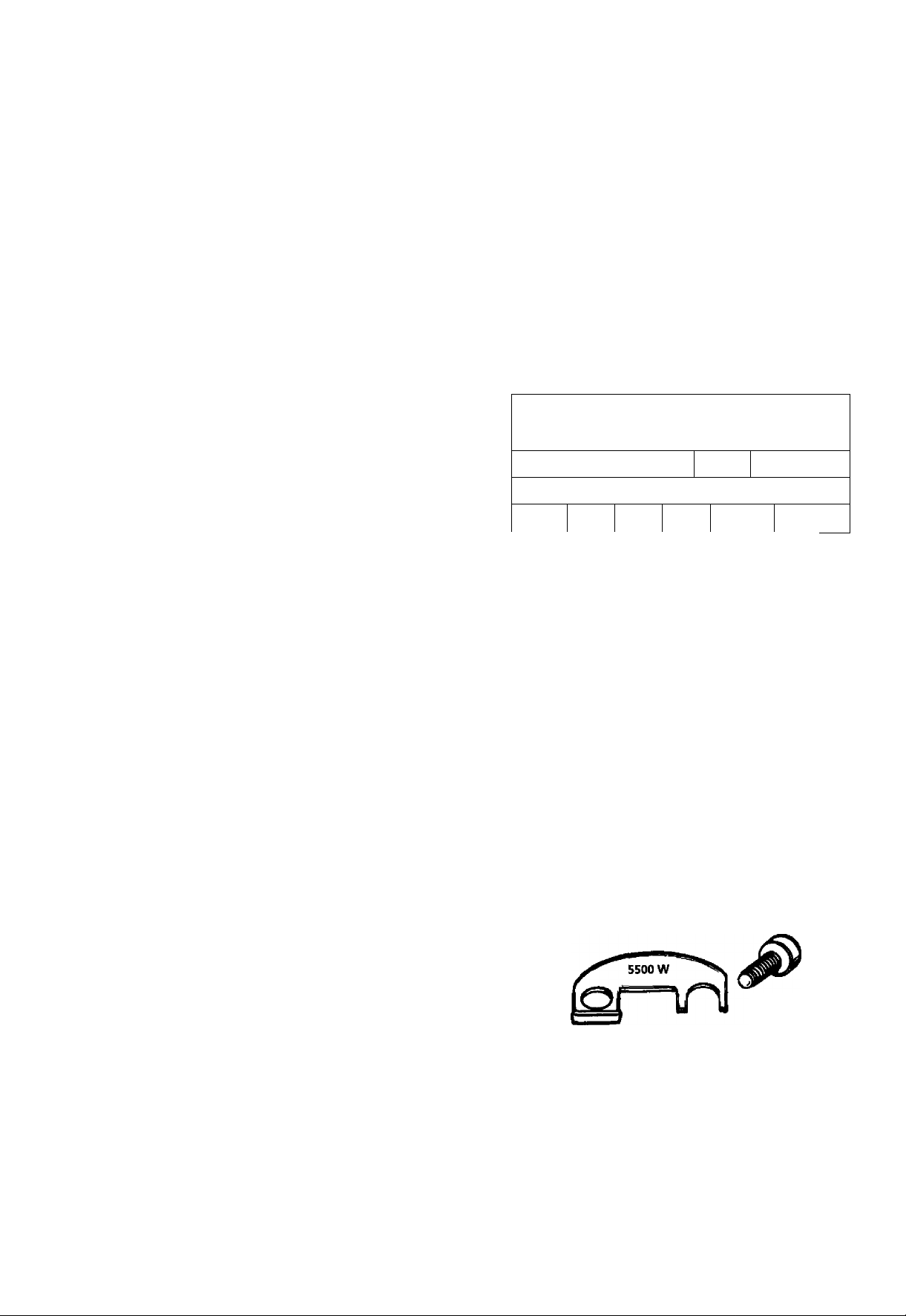

The Convertible Lower

Element

The Upper Element, is a conventional 3800 ■watt element

which only operates at its rated wattage on 240 volts.

(See rating plate on water heater).

The Lower Element of the water heater can be converted

from operation at 3800 watts to 5500 watts on a 240 volt

system.

Read and follow water heater warnings and instructions. If

after reading these instructions in this manual, if you do not

understand any portion, call Maytag Customer Service at

1-800-788-8899 for an authorized servicer.

AWARNING

Before making the conversion to 5500 watts, check

the (1) power supply...must be 240 volts. (2)

wiring...10 gauge AWG @ Type TW, 60°C or equiva

lent, and (3) Circuit breakers or fusing...capable of

30 amp loading. Also, the installation must conform

with this manual, local codes and electric utility

rules. Failure to comply can result in DEATH, SERI

OUS BODILY INJURY, OR PROPERTY DAMAGE.

M

M

WKV*

FACTORY EQUIPPED WTm

. WATTE WAm WATTS A.C. ONLT lP*l»TMUDAt,_

OPtlCWAL WATTMaE

WATTS WATTS WATTS IF OONWRTED

NOTE: Whether or not the element conversion is made the

model rating plate must be marked. Using a hard point ink

pen, check the appropriate block within the model rating

plate, vriiich is located adjacent to the lower access panel.

ELECTRIC WATER HEATER

Tm HUTER Mr

----

----

^

Maytag a Trademark of Maytag Corporation and

Is used under License to State Industries, Inc.

w^

(©

IWMAIIII yqtTt CMKKWHWg HWHWWa

mCTORY BOUPfED

CHECK

----------------------

INSTALLED

----------------------------------------

hMXHUH HVMOVTAHO

WARNINO

SEE CONVERSION

INSTRUCTION

ECO

150

Page 10

Instructions for Installation (cont'd)

Water Piping

A WARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a

temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald

and permanently injure you upon contact. Some

eople are more likely to be permanently injured by

ot water than others. These include the elderly,

R

children, the infirm, or physically/mentally handi

capped. If anyone using not water in your home fits

into one of these groups or if there is a local code or

state law requiring a certain temperature water at

the hot water tap, then you must take special pre

cautions. In addition to using the lowest possible

temperature setting that satisfies your hot water

needs, a means sucri as a mixing valve, should be

used at the hot water taps used by these people or

at the water heater. Mixing valves are available at

plumbing supply or hardware stores. Follow manu

facturers instructions for installation of the valves.

Before changing the factory setting on the thermo

stat, read the "Temperature Regulation" section in

this manuai.

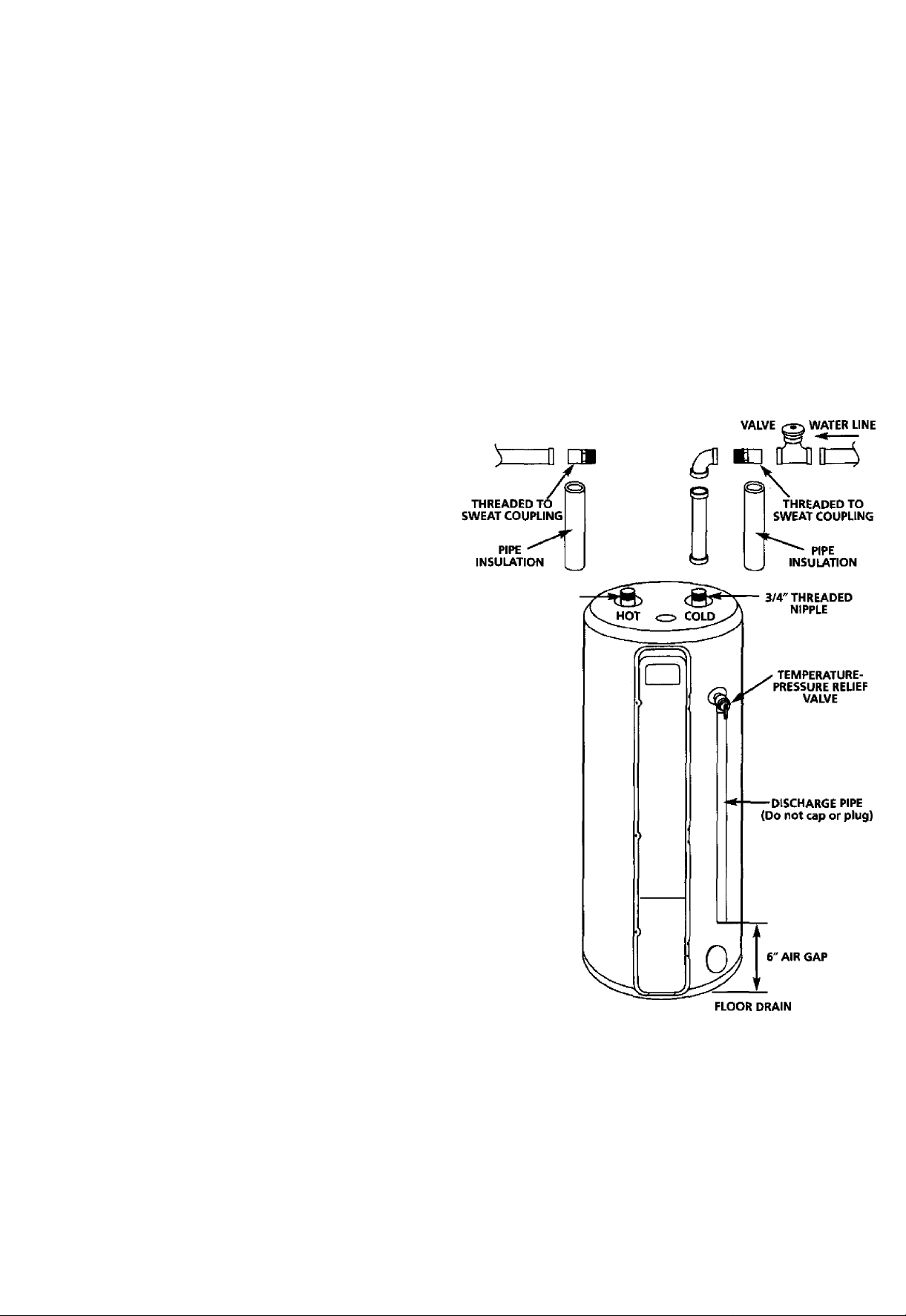

The illustration shows the attachment of the water piping to

the water heater. The water heater is equipped with ^/4 inch

water connections.

NOTE: Your water heater is super insulated to minimize

heat loss from the tank. Further reduction in heat loss can

be accomplished by insulating the hot water lines from the

water heater.

HOT OUTLET TO

HOUSE

-----

3/4" THREADED

NIPPLE

SHUT-OFF COLD INLET

If a water heater is installed in a closed water supply system;

such as one having a back-flow preventer, check valve, water

meter with a check valve, etc. in the cold water supply;

means shall be provided to control thermal expansion.

Contact the local utility or call Maytag Customer Service at

1-800-788-8899 for an authorized servicer on how to con

trol this situation.

NOTE: If using copper tubing, solder tubing to an adapter

before attaching the adaptor to the cold water inlet connec

tion. Do not solder the cold water supply line direcdy to the

cold water inlet. It will harm the dip tube and damage the

tank.

1. Look at the top cover of the water heater. The water outlet

is marked hot. Connect the hot water pipe to the hot water

outlet of the water heater.

2. Look at the top cover of the water heater. The cold water

inlet is marked cold. Connect the cold water pipe to the

cold water inlet of the water heater.

10

Page 11

Instructions for Installation (cont'd)

Temperature-Pressure Relief Valve

AWARNING

At the time of manufacture this water heater was provid

ed with a combination temperature-pressures relief valve

certified by a nationally recognized testing laboratory that

maintains periodic inspection of production of listed

equipment or materials, as meeting the requirements for

Relief Valves and Automatic Gas Shutoff Devices for Hot

Water Supply Systems, and the latest edition of ANSI

Z21.22 and the code requirements of ASME. If replaced,

the valve must meet the requirements of local codes, but

not less than a combination temperature and pressure

relief valve certified as meeting the requirements for

Relief Valves and Automatic Gas Shutoff Devices for Hot

Water Supply Systems, ANSI Z21.22 by a nationally recog

nized testing laboratory that maintains periodic inspection

of production of listed equipment or materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostatic working pressure of

the water heater (150 Ibs./sq. in.} and a discharge capacity

not less than the water heater input rate as shown on the

model rating plate. (Electric heaters - watts divided by

1000 X 3415 equal BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the

use of a temperature-pressure relief valve complying with

ANSI Z21.22 and ASME, may require a valve model differ

ent from the one furnished with the water heater.

Compliance with such local requirements must be satisfied

by the installer or end user of the water heater with a

locally prescribed temperature-pressure relief valve

installed in the designated opening in the water heater in

place of the factory furnished valve.

For safe operation of the water heater, the relief valve

must not be removed from it's designated opening or

plugged.

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designated for

the relief valve. Position the valve downward and provide

tubing so that any discharge will exit only within 6 inches

above, or at any distance below the structural floor. Be

certain that no contact is made with any live electrical

part. The discharge opening must not be blocked or

reduced in size under any circumstances. Excessive length,

over 30 feet, or use of more than four elbows can cause

restriction and reduce the discharge capacity of the valve.

No valve or other obstruction is to be placed between the

relief valve and the tank. Do not connect tubing directly to

discharge drain unless a 6” air gap is provided. To prevent

bodily Injury, hazard to life, or property damage, the relief

valve must be allowed to discharge water in quantities

should circumstances demand. If the discharge pipe is not

connected to a drain or other suitable means, the water

flow may cause property damage.

The Discharge Pipe:

• Must not be smaller in size than the outlet pipe size of

the valve, or have any reducing couplings or other

restrictions.

• Must not be plugged or blocked.

• Must be of material listed for hot water distribution.

• Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the dis

charge pipe.

• Must terminate at an adequate drain.

• Must not have any valve between the relief valve and

tank.

AWARNING

The temperature-pressure relief valve must be manu

ally operated at least once a year. Caution should be

taken to ensure that (1) no one is in front of or

around the outlet of the temperature-pressure relief

valve discharge line, and (2) the water manually dis

charged will not cause any bodily injury or property

damage because the water may be extremely hot.

If after manually operating the valve, it fails to com

pletely reset and continues to release water, immedi

ately close the cold water inlet to the water heater,

follow the draining instructions, and replace the

temperature-pressure relief valve with a new one.

PiPE

INSULATION

CONOUIT

^ ^^TEMPERATURE-

^ RELIEF VALVE

WARNING “RELIEF VALVE OPENING

This water heater is provided with a combination Tempefalure-PresSLire Relief Valve listed as complying with

the standard for Reliet Valves and Automatic Gas Shutoff Devices for Hot l/Vater Supply Systems, ANS .22

and the code rei^irements of ASME.

Your local jurisdictionai authority, while mandating the use ot a Temperature-Pressure Relief Valve complying

with ANS Z21-22 and ASME, may require a valve model different from the one furnished with the water twater

Compliance with such local requirements must be satisfied by the installer or end user

a locally prescribed Temperature-Pressure Relief Valve ir^stalled in the designated opening in the water

T&p relief

VALVE PROBE

MUST EXTEND

INTO TANK

• If a short shank (less than 2‘j temperature-pressure relief valve Is to be installed

(as stwFiTr). a rMpplo and coupting rrtusl be used.

• If a long shank (2" or longer} is to be installed, do not use the nipple and coupling.

"Install Temperature-Pressure protective equipment required by local codes, but not less than a combina

tion Temperature-Pressure Relief Valve certified as meeting the requirements for Relief Valves and

Automatic Gas Shutoff Devices for Mot-Water Supply Systems, MS Z21.22 by a nationally recognized test

ing laboratory that maintains periodic inspection of production of Hated equipment or materials. The valve

must be oriented, provided with tubing, or otherwise installed so that discharge carr exit only wHhir 6 inches

above, or at any distance below ti>e stiuctural floor, and cannot contact any live eledricaf part.''

For safe operatron of the water heater, the Relief Valve must not be removed or plugged.

See manual heading - Temperature-Pressure Relief Valve" lor installation and maintenance of Relief

Valve, discharge pipe and other safety precautions.

(IV.' X V.

èRASS

NIPPLE

TAP

SHANK

LENGTH

INSULATION

:

----

PRESSURE

DISCHARGE PIPE

(Do not cap or plug)

of the water heater with

11

COLD

Page 12

Instructions for Installation (cont'd)

Filling the Water Heater

To fill the water heater with water:

1. Close the water heater drain valve by turning the handle to

the right (clockwise). The drain valve is on the lower front

of the water heater.

2. Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open

when the water heater is in use.

3. To insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run

until a constant flow is obtained. This will let air out of the

water heater and the piping.

A CAUTION

Never use this water heater unless it is completely

full of water. To prevent damage to the tank and

heating element, the tank must be filled with

water. Water must flow from the hot water faucet

before turning "ON" power.

4. Check aU new water piping for leaks. Repair as needed.

Converting the Lower Element

AWARNING

Before making the conversion to 5500 watts, check

the (1) power supply...must be 240 volts, (2)

wiring...10 gauge AWG @ Type TW, 60°C or equiva

lent, and (3) Circuit breakers or fusing...capable of

30 amp loading. Also, the installation must conform

with this manual, local codes and electric utility

rules. Failure to comply can result in DEATH, SERI

OUS BODILY INJURY, OR PROPERTY DAMAGE.

. electric water heater ECO

wMvt MPtTiON yaosL % lUI 1

FACTORY EQUIPPED wim

ÆBt ¿SiSlr UWIUM

MootLiiUMwn ''isy cmotT anuLMiMBi

VOLTI CHKKIiOHM *iSSSSwSBSSSr

UAOAL

«BP IMTAIIED

150

warning

SEE CONVERSION

WATTS WATIB WATTS IFCONWITSD

<9 Mayiag is a Trademark of Maytag Corporation and

is used under Lioensa to State Industries, Inc.

M9TRUCD0N

These instructions only cover the conversion of the convert

ible element, read this entire manual before attempting to

install or operate the water heater. The water heater is factory

set to operate at 3800 watts. The lower element can be con

verted to operate at 5500 watts. Refer to “The Convertible

Lower Element” section.

The Upper Element is a conventional 3800 watt element

which only operates at its rated wattage on 240 volts, (See rat

ing plate on water heater).

The Lower Element of the water heater can be converted

from operation at 3800 watts to 5500 watts on a 240 volt sys

tem.

If after reading these instructions and this manual, if you do

not understand any portion, call Maytag Customer Service at

1-800-788-8899 for an authorized servicer.

NOTE: Whether or not the element conversion is made the

model rating plate must be marked. Using a hard point ink

pen, check the appropriate block vnthin the model rating

plate, which is located adjacent to the lower access panel.

Necessary element conversion parts are located in a small bag

contained within the large plastic manual envelope attached

to the side of the water heater.

CONVERSION PARTS

SCREW

BUSS BAR

12

Page 13

Instructions for Installation (cont'd)

Converting the Lower Element (cont'd)

1. Before beginning the conversion turn “OFF” electric

power supply to the water heater.

A WARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater,

make sure the electrical supply to the water heater

is turned "OFF". FAILURE TO DO THIS COULD

RESULT IN DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE.

2. The convertible element is located behind the lower access

panel of the water heater. Remove the screw securing the

access panel, and remove panel.

4. Remove the screws from terminal 2 of the element, and

move the looped end of the wire aside.

5. The buss bar is labeled 5500 W. Place the buss bar over ter

minals 2 and 3 with the 5500 W visible. Install the extra

screw provided into terminal 3.

3. Remove the flap of insulation to expose the opening.

6. The wire removed from terminal 2 has a looped end. It

must remain looped and now be placed (as shown) on top

of the buss bar, over the opening of terminal 2, and secured

using the remaining screw.

7. Tighten terminals 2 and 3 to ensure proper electrical con

nection.

AWARNING

Failure to tighten terminal screws can cause a fire

which can result in DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE.

13

Page 14

Instructions for Installation (cont'd)

Converting the Lower Element (cont'd)

8. Press the insulation back in place so that it completely cov

ers the thermlster and element.

9. Replace the access panel.

10. Complete wiring to the water heater, or if completed, turn

“ON” electric power to the water heater after filling the

tank with water.

A CAUTION

Never use this water heater unless it is completely

full of water. To prevent damage to the tank and

heating element, the tank must be filled with water.

Water must flow from the hot water faucet before

turning "ON" power.

14

Page 15

Instructions for Installation (cont'd)

Wiring Diagram

TO ELECTRIC

POWER supply

Page 16

Instructions for Installation (cont'd)

Wiring

A CAUTION

Never use this water heater unless it is completely

full of water. To prevent damage to the tank and

heating element, the tank must be filled with

water. Water must flow from the hot water faucet

before turning on power.

You must pro\ide all wiring of the proper size outside of the

water heater. You must obey local codes and electric company

requirements when you install this wiring.

If you are not familiar with electric codes and practices, or if

you have any doubt, even the slightest doubt, in your ability to

connect the wiring to this water heater, obtain the service of a

competent electrician. Call Maytag Customer Service at

1-800-788-8899 for an authorized servicer.

AWARNING

WATER HEATERS EQUIPPED FOR ONE VOLTAGE

ONLY; This water heater Is equipped for one type

voltage only. Check the rating plate near the bot

tom access panel for the correct voltage. DO NOT

use this water heater with any voltage other than

the one shown on the model rating plate. Failure to

use the correct voltage can cause oroblems which

can result in DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE, lif you have any questions or

doubts consult your electric company.

A CAUTION

If wiring from your fuse box or circuit breaker box

was aluminum for your old water heater, replace it

with copper wire. If you wish to reuse the existing

aluminum wire, have the connection at the water

heater made by a competent electrician. Call

Maytag Customer Service at 1-800-788-8899 for an

authorized servicer.

C. Flexible metal conduit or 3 metallic tubing shall be per

mitted for grounding if all the following conditions are

met:

1. The length in any ground return path does not exceed

6 feet.

2. The circuit conductors contained therein are protected

by overcurrent devices rated at 20 amperes or less.

3. The conduit or tubing is terminated in fittings

approved for grounding.

For complete grounding details and aU allowable exceptions,

refer to the latest edition of the National Electrical Code.

4. A standard Vz" conduit opening has been made in the water

heater junction box for the conduit connection.

5. A wiring diagram (See “Wiring Diagram” Section) has been

supplied showing the connections between the water heater

and the power supply. You can easily see the connection by

removing the junction box cover on top of the water heater.

Connect red to red, black to black, and the ground wire to

the green ground screw in the junction box of the water

heater.

6. Use wire nuts and connect the power supply wiring to the

wires inside the water heater’s junction box,

7. The water heater must be electrically “grounded” by the

installer. A green ground screw has been provided on the

water heater's junction box. Connect ground wire to this

location.

8. Replace the wiring junction cover using the screw provided.

1. Provide a way to easily shut off the electric power when

working on the water heater. This could be with a circuit

breaker or fuse block in the entrance box or a separate dis

connect switch.

2. Install and connect a circuit directly from the main fuse or

circuit breaker box. This circuit must be the right size and

have its own fuse or circuit breaker. Refer to the chart in

the “Product Specifications" section for the correct size

wire and fuse or circuit breaker.

3. If metal conduit is used for the grounding conductor:

A. The grounding electrode conductor shall be of copper,

aluminum, or copperclad aluminum. The material shall

be of one continuous length without a splice or joint.

B. Rigid metal conduit, intermediate metal conduit, or

electrical metallic tubing may be used for the grounding

means if conduit or tubing is terminated in fittings

approved for grounding.

16

Page 17

Instructions for Installation (cont'd)

Selecting Thermostat Location

1, The programmable thermostat control module is shipped

attached to the front of the water heater, located behind the

hinged cover panel.

If this thermostat location is acceptable to the homeowner,

proceed directly to the “Installation Checklist” on page 22 and

then to “Temperature Regulation" on page 23.

2. The thermostat control module can also be installed next to

the home’s heating or heating/cooling thermostat, or in

another convenient location remote from the water heater.

6. Probe for any obstruction in the partition. In a clear area drill

a 'A" hole through the wall at the selected location.

7. Through this hole in the wall, drop a light chain or short chain

attached to a strong cord. Snag the cord with a hooked wire

from the basement. (In a home with no basement, drop the

cord from ceding and snag it at the thermostat hole location.)

8.

Attach one end of the wiring harness to the cord. Pull the

cable through the hole in the wall so that 6 inches of cable

protrudes. Other end of cable is to be routed back to the junc

tion box on top of the water heater (Step 21). Before proceed

ing, turn “OFF” the electric power supply to the water heater.

©MAYTAG ' ' ’

3. The remote location should be about 5 feet above the floor

on any wall with good air circulation at average room tem

perature.

ROUTING WIRE HARNESS TO LOCATION

4. A wiring harness kit for up to 50 feet of wiring is available

(see Repair Parts list) from your Maytag Dealer.

5. Before drilling a hole in the wall at the selected location, take

up floor moulding (quarter round or other) and drill a small

guide hole for sighting. From the basement, drill a ’A" hole in

partition floor next to guide hole (in homes with no base

ment, drill a Vi" hole through ceiling above the partition).

AWARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater,

make sure the electrical supply to the water heater

is turned "OFF". Failure to do this could result in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE.

THERMOSTAT REMOVAL

9. Holding fingers along the top and thumb on bottom, between

the thermostat and wall plate, gently remove thermostat from

the wall plate. The thermostat will be installed at the selected

remote location in Steps 32 and 33,

17

Page 18

Instructions for Installation (cont'd)

THERMOSTAT REMOVAL (cont'd)

10. Carefully disconnect wiring harness terminal connector

from back of riiennostat.

11. Remove the wall plate from the water heater by unscrewing

the two mounting screws. The wall plate will be installed at

the selected location in Steps 28 and 29.

PLATE

13. Press the end of the thermostat cable back into the insulating

bushing. No other connections will be made to this end of

the cable.

INSULATING

BUSHING

WIRING

HARNESS

14. Close and latch outer door.

REMOTE THERMOSTAT WIRING ATWATER HEATER

IS. Remove mounting screw and right junction box cover. Also

lift up and remove black plug on left junction box cover.

Discard plug.

12. Loosen each screw in the terminal connector and remove the

wire ends. The terminal connector will be installed at the

selected remote location in Step 31.

18

Page 19

Instructions for Installation (cont'd)

16. Find the loop of thermostat wiring cable (grey colored) inside

the junction box and pub it out.

17. Cut the thermostat wiring cable in half at the top of the loop.

19. Strip the thermostat cable outer insulation back 1'A inches.

Strip the ends '/4 inch on each of the six colored wires.

20. A second terminal connector is provided in a small bag eontained within the large plastic manual envelope attached to

the side of the water heater. Loosen each screw in the termi

nal connector. Insert the six colored wires of the thermostat

cable into the terminal connector and tighten each screw to

secure each wire. Be sure to arrange wires in exact color

sequence as shown.

IS. The wire side of the loop ridiich does not have the red tape

strip on it should be cut off or pressed into the junction box

out of the way.

UNUSED

THERMOSTAT

ACTIVE THERMOSTAT

CABLE HALF

CABLE HALF

A CAUTION

The six colored insulated wires must be installed in the terminal connector exactly as shown for the thermostat to operate correctly.

21. Locate the end of the remote thermostat cable routed to the

water heater in Step 8.

19

Page 20

Instructions for Installation (cont'd)

Selecting Thermostat Location (cont'd)

22. Guide the end of the remote thermostat cable through the

hole where the black plug was removed in the left junction

box cover.

23. Strip the end of the remote thermostat cable outer insulation

back VA inches. Strip the ends V4 inch on each of the six col

ored wires.

25. CarefUly press the terminal connector and connected wires

down into the water heater junction box,

26. A strain-relief bushing is also provided in the small bag that

contained the terminal connector. Open the bushing and

place it around the remote thermostat cable exiting the junc

tion box. Press the bushing into the hole in the left junction

box cover.

24. Loosen each screw in the terminal connector one at a time

and insert wire with the same color insularion into each

numbered slot. Tighten each screw securely making sure

both wires in each slot are tight.

27. Replace the right junction box cover using the screw provid

ed. This completes the remote thermostat wiring at the water

heater.

REMOTE THERMOSTAT INSTALUTION AND WIRING

28. Locate the 6 inches of remote thermostat cable protruding

through the wall opening (from Step 8). Using the wall plate

removed in Step 11, puU the cable through opening near cen

ter of wall plate.

20

Page 21

Instructions for Installation (cont'd)

29, Fasten wall plate loosely to the wall in position shown using

the three screws provided in the plastic bag. Wall anchors are

recommended for drywall installation. Place a level on top of

the wall plate, adjust until level, and then tighten screws to

secure wall plate.

30. Strip the remote thermostat cable outer insulation back I’A

inches. Strip the ends ’/4 inch on each of the six colored wires.

A CAUTION

The six colored insulated wires must be instailed in

the terminal connector exactly as shown for the

thermostat to operate correctly.

32. Carefidly plug the wired terminal connector to the mating

pins on the thermostat back. Connector will install in one

direction only as shown.

33. Place thermostat over wall plate, press firmly, and thermostat

win snap into place on the wall plate.

31. Using the terminal connector removed in Step 12, insert the

six colored insulated wires in the remote thermostat cable

into the numbered slots in the terminal connector and tight

en each screw to secure each wire. Be sure to arrange wires in

exact color sequence as shown.

34, Turn “ON” electric power to water heater.

35. Read Temperature Regulation Warning and Temperature

Settings, then proceed to Programming the Thermostat.

21

Page 22

Instructions for Installation (cont'd)

Installation Checklist

1. Whether or not the element conversion is made, the

model rating plate must be marked. Using a hard point

ink pen, check the appropriate block within the model rat

ing plate, which is located adjacent to the lower access

panel.

2. Is the fuse or circuit breaker size correct as shown in the

chart in the “Product Specifications” section?

3. Are the wires from the circuit breaker or fuse service to the

water heater’s junction box on the correct wire size (gauge)

as shown in the chart in the “Product Specifications” sec

tion?

HOT

CONDUIT

COLD

TEMPERATURE'

PRESSURE

RELIEF VALVE

4. Is the new temperature-pressure relief valve properly

installed, and piped to an adequate drain? See

“Temperature-Pressure Relief Valve” in the “Instructions

for Installation” section.

5. Is the water heater completely filled with water? See

“Filling the Water Heater” instructions in the

“Instructions for Installation” section.

6. Will a water leak damage anything? See “Locating the

New Water Heater” in the “Instructions for Installation"

section.

7. Are the cold and hot water lines connected to the water

heater correctly? See “Water Piping” instructions in the

“Instructions for Installation” section.

8. Is there adequate clearance for maintenance around the

water heater?

9. If the programmable thermostat has been moved to a

remote location, has the wiring been done correctly?

10. Do you need to call your electric company to check your

wiring?

FAC TORY E OLH PP6 0 WITH

UH NT n m m v м т лм

■'ВВ. ¿s »

WA TT* ммтта

ELECTRIC TOfTER HEATlR eoo

>i7S MSTAllH)

i

LLM AI.

CMCKtvIHM

VO LTS

Mum

СНЕШтНЕМ

MA XIMU M

-- -- ----- -- -- ----- -- -- -- --- -- -

________________

MO ONV CTtlD

\ wAmMO

SEECONVE RSK M

\ wemucnciN

DISCHARGE PIPE

(Do not cap or

plug)

WM —«III—яотс

WO fMM PMM UIIS

ISO

p.i.1,

22

<E> Maytag is alt'adamark ot Maytag Corporation and

la U3»d undar License to State Industries, Inc.

MODEL RATING PLATE

Page 23

Instructions for Operation

Temperature Regulation Programming the Thermostat

AWARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a

temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald

and permanently injure you upon contact. Some

eople are more likely to be permanently injured by

ot water than others. These include the elderly,

R

children, the infirm, or physically/mentally handi

capped. If anyone using hot water in your home fits

into one of these groups or if there is a local code

or state law requiring a certain temperature water

at the hot water tap, then you must take special

recautions. In addition to using the lowest possi

le temperature setting that satisfies your hot

E

water needs, a means such as a mixing valve,

should be used at the hot water taps used by these

people or at the water heater. Mixing valves are

available at plumbing supply or hardware stores.

Follow manufacturers instructions for installation of

the valves.

AWARNING

Never allow small children to use a hot water tap,

or to draw their own bath water. Never leave a

child or handicapped person unattended in a bath

tub or shower.

Before programming the settings on the thermostat, read

the "Temperature Regulation” section again.

This new programmable thermostat technology makes it pos

sible for you to enjoy all the benefits of hot water whenever

you need it and save the cost of heating water when you don’t

need it.

Simple and easy to use, the programmable control has three

basic modes of operation:

1. Manual mode - a set and forget operation.

2. Vacation mode - for those occasions when the residence

is unoccupied and there is no need for hot water.

3. Programmable mode - can be programmed for up to 24

hour a day, 7 days a week with 4 set periods a day.

Override is an optional setting that allows for temperature

adjustments during a given time period. This setting reverts

back to the previous mode of operation upon completion of

the designated override time period.

Option menu is a mode to change the factory setting for the

time clock (12 hr. clock or 24 hr. militaiy), temperature scale

(°F to °C), default heating setpoint, vacation setpoint and

maximum heating setpoint.

Temperature Conditions

VERY LOW — The thermostat minimum setback tempera

ture is 60°F.

HOT- A thermostat setting of 120°F will supply hot

water at the most economical temperatures.

VERYHOT- The thermostat maximum temperature is

160°F. It is recommended that the tempera

ture be set lower whenever possible.

NOTE: Water temperature range of 120°-140°F recom

mended by most dishwasher manufacturers.

DATE AND TIME SETTING:

Your new programmable control comes complete with a day of

the week and digital clock display. These settings are changed

using the day and time keys on the control pad. To adjust day

and/or time, depress the appropriate key button. The day of the

week scrolls left to right on the display as the “DAY” button is

depressed. The time setting can be adjusted by scrolling for

ward or backward using the + and - of the “TIME” button.

The clock is based on a 24-hour rolling display with AM and

PM appearing below the hour and minute characters.

CONSTANT TEMPERATURE DISPLAY:

The constant display screen shows the water temperature

“WATER TEMP” inside the tank. It is continually on dis

play until interrupted by a reprogram procedure, but reappears

after 20 seconds of inactivity.

MODE CHANCE

To change the mode-of-operation depress the “MODE” but

ton at the bottom of the control. The mode display will change

by scrolling from top to bottom with the Auto mode appearing

on the top of the column, followed by the Manual mode in the

middle and finally the Vacation mode at the bottom. Continue

to change between mode settings by depressing the “MODE”

button until the desired setting is displayed.

23

Page 24

Instructions for Operation (cont'd)

Programming the Thermostat (cont'd)

Normal Display

-TIME

BUTTON

MANUAI. MODE

The most basic operation of the Intelligent water heater ther

mostat is the Manual Mode. With this mode the thermostat is

set at a desired temperature and the water heater operates to

maintain that temperature. The Intelligent Maytag water heater

utilizes a special sensing device in the control system that allows

for temperature accuracy to be maintained at plus or minus 1°F.

VACATION MOOR

Vacation mode is used whenever the residency is unoccupied for

a considerable length of time (2-days or longer) and hot water is

not needed. By selecting the Vacation Mode the water heater

will maintain a reduced setting of 80 degrees untU a new opera

tion mode is selected.

PROGRAMMAR! F. MODE

The Auto mode selection permits the water heater to be pro

grammed for four periods a day, 24-hours a day and 7-days a

week. To begin programming, depress the “MODE” button

until the AUTO selection appears in the display. To activate

the Program Mode depress the “PROGRAM” button at the

top of panel. The programming mode should appear as the

next display.

The first period to program is Monday “Morn” - this period is

designated as “Mom”. By depressing the + or - of the “TIME”

button, the owner can choose the target time for the water to be

at a specific temperature. The heating elements will be activated

15 minutes before the target time to heat the water to the

desired temperature. For example, if 6:00 AM is the time the

occupant desires 130°F water for bathing, the time on the pro

grammed display would be set for 6:00 AM. The next selection

to program is the desired water temperature to have for morning

activities. In this example the temperature would be set to 130°F

by depressing either the up ( A ) arrow or the down ( ▼ ) arrow,

located next to the display panel, until the target temperature is

displayed.

Program Display

PROGRAM

BUTTON

The second period to program is Monday “Day” - the method

of setting the time and temperature are the same for all four

selected periods of the day. The second period designated

can be set to a reduced temperaUire (70°F or lower) due to the

lack of need for hot water, assuming no one is at home during

the day. If everyone leaves at 9:30 AM, this time can be entered

into the program and the heating elements would not activate

until the temperature in the tank dropped to 70°F.

The third period to program is Monday “Eve” ~ this period is

designated “Eve would usually begin when people arrive home

from their daily activities. The temperature for this period can

be adjusted to a normal hot water setting considering evening

demand like washing dishes or clothes. For example if 125°F is

the chosen temperature to have at 5:30 PM then these settings

would be entered into the program.

The fourth period to program is Monday “Nite” - this period

is designated “Nite” and is usually the beginning of decreased

hot water needs as the residents retire for the night. In the

example the temperature would be set for 70°F or lower with

the begin time set at 11:00 PM.

Program Copy - The first day of programming has now been

completed. If each succeeding day of the workweek requires the

same desired settings as those just programmed for Monday,

these settings can be copied to the remaining four days of the

week by depressing and holding the “PROGRAM” button for

several seconds. In this manner the first day’s settings are

repeated to аД four remaining weekdays.

Weekend programming - the weekend programming can be

set different than the weekday settings, if desired. Saturday and

Sunday can be separately programmed by advancing the pro

gram selection to the day marked “SA” and/or “SU”. The steps

described above for programming the four periods per day can

be repeated for the weekend only using different rimes and tem

peratures to provide desired water temperatures when needed on

the weekend.

“Day”

24

Page 25

Instructions for Operation (cont'd)

ERASE is the option that can delete all the settings that had

been programmed previously. While in the programmable

mode, depressing the “ERASE” button will delete a particular

time period that is on display. Depressing and holding the

“ERASE" button down for several seconds will erase all the set

tings for an entire week. This procedure should be adminis

tered careftillv. as erasing the entire week’s programmed set

tings will necessitate a complete reprogtamming procedure.

OVRRRÌDE is an option that can be used to temporarily

adjust water temperature for a specific length of time. If for

example there is a need for higher water temperatures during a

specific number of hours or days, the “OVERRIDE” button

can be depressed. The first screen to be displayed is the

HOURS and DAYS time menu and DESIRED

TEMPERATURE. The default time period is 3 hours. This

time can be adjusted upward or downward by using the + or - of

the “TIME” button. After holding the + “TIME” button

beyond 24 hours the hours and days designation vrili appear.

The OVERRIDE can be adjusted for both days as weU as

hours. The maximum number of days to OVERRIDE is 99.

Override Display

OPTIONAL SETTING CHANGES

There are five optional settings the owner can change in the

programmable control module. To advance to the Optional

Setting Mode, depress the “PROGRAM” and “MODE” but

tons simultaneously for four seconds. Four zeros should appear

in the upper left hand corner (0000) and a large number 1

should appear in the bottom right-hand corner. This indicates

the optional menu is on the type of time setting.

The first optional mode (1) setting involves the type of time

that will appear on the clock display. The default setting is the

normal twelve-hour clock. For military time depress either + or

- of the “TIME” button until the description 0001 appears in

the upper-left hand comer. To change back to normal time in

optional setting 1 depress either (+ or -) of the time buttons

until 0000 appears in the upper left-hand corner.

-OVERRIDE

BUTTON

After setting the time duration, the override temperature can

be adjusted by using the up ( A) arrow or the down ( ^ )

arrow, located next to the display panel, until the target tem

perature is displayed. For example, if guests arrive for the

weekend and warmer water temperatures are desired, the

occupant may adjust the temperature setting to 130°F for 2

days and 10 hours. This would control the target temperature

until the completion of the designated time and return the

thermostat to the program control that had been in operation

before the override was implemented.

The second optional mode (2) setting involves the temperature

scale. To change to the temperature setting option, depress the

up or down arrow button until the large number 2 appears in

the lower right hand corner. The default setting is in the

Fahrenheit scale. To change to Centigrade, depress either + or

' of the “TIME” button until the description 0001 appears in

the upper-left hand corner. To change back to the Fahrenheit

scale, repeat the procedure until 0000 appears in the upper-left

hand corner.

25

Page 26

Instructions for Operation (cont'd)

Programming the Thermostat (cont'd)

The third optional mode (3) setting involves the default tem

perature set point for the control. To be in this mode, depress

the up ( ▲) arrow or the down ( ^ ) arrow until a large number 3

appears in the lower right-hand corner. The default temperature

from the factory is 120°F. This wU appear in the upper-left

hand corner as 0120. To change the default setting, depress

either -t- or - of the “TIME” button until the desired default

temperature is displayed in the upper left-hand comer. The

range for set point temperature is 80°F to 160°F.

The fourth optional mode (4) setting involves the vacation tem

perature setting. This is factory set at 80°F or 0080 in the upper

left-hand corner. To change the vacation default setting, make

sure the optional mode is in the number (4) setting by depress

ing the up ( a) arrow or the down ( ^ ) arrow button until a

large number 4 is displayed in the lower right-hand corner. To

change the vacation temperature default setting, depress either +

or - of the “TIME” button until the desired vacation tempera

ture is achieved in the upper left-hand comer of the display.

The range for vacation default setting is 60°F to 120°F.

To return to regular operation of the program control, depress

the “PROGRAM” and “MODE” buttons simultaneously

again until the normal display appears. All the optional settings

that were revised will remain until they are once again reset by

using the above prescribed procedures.

SCALD WARNING is a flashing display warning any time

the temperature is adjusted above 120°F. It represents an indus

try warning that water temperatures above 120°F represent a

scald hazard when sldn surface is exposed for a small amount of

time. This is a warning and can not be removed from the screen

display.

“PWR" (POWER) BUTTON is a button at the right-hand

bottom of the panel which will activate or deactivate the display

panel. It will not turn oflFthe power to the water heater and

will not kill the power to the heating elements.

A WARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater,

make sure the electrical supply to the water heater

is turned "OFF". Failure to do this could result in

DEATH. SERIOUS BODILY INJURY. OR PROPERTY

DAMAGE.

The fifth optional mode (5) setting involves the masdmum tem

perature set point. To be this mode, depress the up ( A) arrow

or the down ( ▼ ) arrow while in optional setting sequence until

a large number 5 is displayed in the lower right-hand corner.

The default factory maximum set point is 160°F or 0160 in the

upper left-hand comer. To change this setting depress either +

or - of the “TIME” button until the desired maximum set point

is achieved in the upper left-hand comer. The range for maxi

mum set point is 100°F to 160°F.

EI ECTRICAL POWER OUTAGES will not effect the

Intelligent programming or control settings. The unit has a bat

tery backup that maintains the programmed settings until the

electrical power is restored. At the time power is restored the

program will again display the settings and information that had

been available before the loss of power.

DRY FIRE PREVENTION is a feature that has been pro

grammed into the Intelligent water heater. Should someone

install or service the water heater and forget to fill the tank, the

unit will sense a rapid heat cycle beyond normal expectations

and disable the energy. A message will be displayed on the

screen to add water, at which time the unit can be re-energized.

26

Page 27

Service and Maintenance

Temperature-Pressure Relief Draining

Valve Operation

The iemperature-pressure rehef valve must be manually oper

ated at least once a year.

A WARNING

The temperature-pressure relief valve must be

manually operated at least once a year. Caution

should be taken to ensure that (1) no one is in front

of or around the outlet of the temperature-pres

sure relief valve discharge line, and (2) the water

manually discharged will not cause any property

damage or bodily injury. The water may be

extremely hot.

If after manually operating the valve, it fails to

completely reset and continues to release water,

immediately dose the cold water inlet to the water

heater, follow the draining instructions, and

replace the temperature-pressure relief valve with

a new one.

The water heater should be drained if being shut down during

freezing temperatures. Also periodic draining and cleaning of

sediment from the tank may be necessary.

1. Before beginning turn “OFF” the electric power supply to

the water heater.

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater,

make sure the electrical supply to the water heater

is turned "OFF". Failure to do this could result in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE.

2. CLOSE the cold water inlet valve to the water heater.

3. OPEN a nearby hot water faucet and leave open to allow

for draining.

4. Connect a hose to the drain valve and terminate to an ade

quate drain or outdoors.

5. OPEN the water heater drain valve to allow for tank

draining.

NOTE: If the water heater is going to be shut down and

drained for an extended period, the drain valve should be

left open with hose connected allowing water to termi

nate to an adequate drain.

A WARNING

Failure to install and maintain a new properly listed tempera

ture-pressure relief valve wiU release the manufacturer from

any claim which might result from excessive temperature or

pressure.

AWARNING

If the temperature-pressure relief valve on the

appliance weeps or discharges periodically, this

may be due to thermal expansion. Your water

heater may have a check valve installed in the

water line or a water meter with a check valve. Call

Maytag Customer Service at 1-800-788-8899 for an

authorized servicer. Do not plug the temperature-

pressure relief valve.

6. Close the drain valve.

7. FoUow “Filling the Water Heater” instructions in the

“Instructions for Installation” section.

8. Turn “ON" power to the water heater.

A CAUTION

Never use this water heater unless it is completely