Maytag

Gemini™

Range

Service Manual

16010107

Issued 10/00

GENERAL SAFETY PRECAUTIONS

Information contained in this manual is intended for use by a qualified service technician. All

tests and repairs should be performed by a qualified service technician equipped with proper

tools and measuring devices. All component replacements should be made by a qualified

service technician using only factory approved replacement parts.

Improper assembly or adjustment may occur if service or repair is attempted by persons

other than qualified service technicians or if parts other than approved replacement parts are

used. Improper assembly or adjustment can create hazardous conditions.

There can be a risk of injury or electrical shock while performing services or repairs. Injury or

electrical shock can be serious or even fatal. Consequently, extreme caution should be taken

when performing voltage checks on individual components of a product. PLEASE NOTE:

Except as necessary to perform a particular step in servicing a product, the electrical power

supply should ALWAYS be disconnected when servicing a product.

Further, this appliance MUST be properly grounded. Never plug in or direct-wire an

appliance unless it is properly grounded and in accordance with all local and national codes.

See installation instructions that accompany the product for grounding this appliance.

USE ONLY GENUINE MAYTAG APPROVED FACTORY REPLACEMENT COMPONENTS.

IMPORTANT SAFETY NOTICE

THE INFORMATION INCLUDED IN THIS SERVICE

MANUAL IS INTENDED FOR THE USE OF

QUALIFIED SERVICE PERSONNNEL ONLY. ANY

ATTEMPT TO SERVICE THE APPLIANCE COULD

RESULT IN PERSONAL INJURY AND PROPERTY

DAMAGE.

DISCONNECT ELECTRICAL SUPPLY

BEFORE SERVICING.

IMPORTANT

ALL GROUNDING DEVICES MUST BE

RECONNECTED AND PROPERLY FASTENED.

GROUND PATH SPECIFICATIONS

GROUND PATH RESISTANCE: 0.1 Ω MAX.

INSULATION RESISTANCE: 250k Ω MIN.

ELECTRICAL CONNECTIONS

This range must be connected to a power source

that has the correct, voltage and frequency as

required by the rating plate. The rating plate can

be found on the back left side of control panel on

a lift up pivot bracket.

Wiring must be in accordance with local codes

and the National Electrical Code (NEC).

©2000 Maytag Appliances Sales Company

INTRODUCTION

The manual is printed in a loose format and is divided into sections relating to a general

group of components and/or service procedures. Each section is further subdivided to

describe a particular component or service procedure.

The subdividing of the subject matter, plus the loose leaf form, will facilitate the updating of

the manual as new revised components are added or new models are introduced.

Each page of the manual will be identified in the lower, left and right-hand corners, and as

new or revised pages are published, the manual can easily be updated by following the filing

instructions on the cover letter of the supplement.

This service manual is a valuable tool and care should be taken to keep it up-to-date by

promptly and proper filing of subsequent pages as they are used.

MODELS COVERED IN THIS MANUAL:

MER6770AAW

MER6770AAB

MER6770AAC

16010107 Introduction

i

©2000 Maytag Appliances Sales Company

16010107 Introduction

ii

©2000 Maytag Appliances Sales Company

CONTENTS

INTRODUCTION .................................................................................................................................i

CONTENTS .......................................................................................................................................iii

SECTION 1. GENERAL INFORMATION ......................................................................................1-1

SECTION 2. ELECTRICAL COMPONENTS & TESTING ............................................................2-1

SECTION 3. COMPONENT ACCESS ...........................................................................................3-1

EXPLODED VIEW .........................................................................................................................3-1

MAIN TOP.....................................................................................................................................3-2

ELEMENTS ...................................................................................................................................3-2

Ceran Element ........................................................................................................................3-2

Bake Element ..........................................................................................................................3-3

Broil Element ..........................................................................................................................3-3

Oven Sensor ...........................................................................................................................3-3

Oven Cavity Components (Electric) .....................................................................................3-4

Convect Fan Motor and Blade (Electric) ..............................................................................3-5

ELECTRONIC CLOCK AND OVEN CONTROL...........................................................................3-6

INFINITE SWITCH (Current Sensing).........................................................................................3-6

Signal Lights ...........................................................................................................................3-7

"Hot Surface" Light .................................................................................................................3-7

Oven Light Replacement .......................................................................................................3-7

HI-LIMIT THERMOSTAT ..............................................................................................................3-8

OVEN DOOR(S) ...........................................................................................................................3-8

UPPER DOOR...............................................................................................................................3-9

LOWER DOOR............................................................................................................................3-10

Lower Latch Assembly .........................................................................................................3-10

LOWER LATCH ASSEMBLY......................................................................................................3-11

Oven Door Hinge ..................................................................................................................3-11

LEVELING LEGS .........................................................................................................................3-12

CONVENIENCE OUTLET (Canadian Models Only) ................................................................3-12

SPECIFICATIONS .......................................................................................................................3-12

OVEN RACKS.............................................................................................................................3-12

RACK POSITIONS......................................................................................................................3-13

HALF RACK ACCESSORY ........................................................................................................3-13

SECTION 4. ELECTRICAL .............................................................................................................4-1

TOASTING CIRCUIT (Upper Oven Only) ...................................................................................4-1

OVEN CIRCUITS...........................................................................................................................4-1

SURFACE ELEMENTS - CERAN .................................................................................................4-2

DUEL ELEMENT ...........................................................................................................................4-2

PROBE, SENSOR / BOTH OVENS..............................................................................................4-2

HOT SURFACE LIGHTS ...............................................................................................................4-3

SURFACE INICATOR LIGHTS ......................................................................................................4-3

TRANSFORMER, STEPDOWN (12V) .........................................................................................4-4

16010107 Contents

iii

©2000 Maytag Appliances Sales Company

SURFACE ELEMENT SWITCH ....................................................................................................4-4

DUAL ELEMENT SWITCH...........................................................................................................4-4

ELECTRICAL CONNECTIONS/VOLTAGE...................................................................................4-5

SECTION 5. TROUBLESHOOTING..............................................................................................5-1

GEMINI DOUBLE OVEN CONTROLS .........................................................................................5-1

FAULT CODES..............................................................................................................................5-2

RELAY BOARD.............................................................................................................................5-3

TROUBLESHOOTING GUIDE ......................................................................................................5-4

PARTS LIST ..................................................................................................................................5-6

FAULT IDENTIFICATIONS SUMMARY ......................................................................................5-7

SECTION 6. WIRING DIAGRAMS ................................................................................................6-1

16010107 Contents

iv

SECTION 1. GENERAL INFORMATION

Bake: There will be two separate bake keys,

one for each oven. When the upper oven is

chosen there will be a rapid preheat

activated which turns both elements on. If

the lower oven is selected the elements will

cycle at the normal rate. The normal rates

for the bake functions in both ovens are: 6

seconds for the broil element, followed by 54

seconds for the bake element.

Broil: There will be two separate broil keys,

one for each oven. The HI broil function

controls the broil element at 100%, the LO

broil is controlled at 80% on time of a 60

second duty cycle. HI broil will be

maintained to reach a maximum

temperature of 550ºF, LO boil will be

maintained at a maximum of 450ºF.

Toasting: Available in upper oven only.

Toasting has a maximum allowable time of

10 minutes and maximum temperature of

550ºF. Toasting is only available when the

lower oven is not in use. If chosen during

lower oven operation the display will scroll

an information message regarding use.

Keep Warm: The keep warm function

controls only the bake element and is

available in the upper oven only. Allowable

temperature range is 145 to 190ºF.

Clean: Only one oven is permitted to be

cleaned at a time. Both ovens will lock

during clean cycle. The clean cycle controls

both the broil and the bake element, the broil

element is on 100% for the first 40 minutes

of the cycle followed by the bake element on

100% for the duration of the cycle. The bake

element is cycled once the clean

temperature of 865º is reached.

Motorized Door Lock: A 3 RPM motor is

used on the door lock assemblies, with each

assembly having a locked and unlocked

switch. The motor will only run when a

clean cycle is chosen and the door actuated

switch is in the closed position.

16010107 Section 1. General Information

©2000 Maytag Appliances Sales Company

1-1

16010107 Section 1. General Information

©2000 Maytag Appliances Sales Company

1-2

©2000 Maytag Appliances Sales Company

SECTION 2. ELECTRICAL COMPONENTS & TESTING

ELECTRICAL TEST EQUIPMENT

The equipment required to service Maytag

products depends largely upon the condition

you encounter. Locating a malfunction will

often require the use of electrical testing

equipment such as:

Analog Test Meter

can be used to check for

open or closed circuits,

measure resistance, AC

and DC volts, and tem-

perature.

Description Part Number

Analog Test Meter 20000005

Digital Watt/Amp/Volt/Ohm/

Temperature Meter

Clamp-On Ammeter 20000002

AC Voltage Sensor 20000081

20000019

Clamp-On Ammeter

can be used to detect

shorts. Overloads on the

circuit breaker

or fuse can be

traced to either

the dryer or circuit

breaker by checking the dryer

current draw.

AC Voltage Sensor

Digital Watt/Amp/Volt/Ohm/Temperature

Meter

Measures power (wattage), AC/DC volts, AC/

DC amps, temperature (C & F) OHMS resistance, continuity and capacitance. Features

large LCD display w/backlight and analog

proper safety precautions can

be observed. The tip of the sensor

will glow bright red, if voltage is between 110-600 volts AC.

can be used to alert you

if AC voltage is present so

bar graph to show tendencies. Includes: AC

power adaptor for measuring wattage and

meter leads.

16010107 Section 2. Electrical Components & Testing

2-1

©2000 Maytag Appliances Sales Company

16010107 Section 2. Electrical Components & Testing

2-2

©2000 Maytag Appliances Sales Company

SECTION 3. COMPONENT ACCESS

EXPLODED VIEW

16010107 Section 3. Component Description

3-1

©2000 Maytag Appliances Sales Company

As a general rule, the appliance should

ALWAYS be disconnected from power

source before servicing appliance or

replacing component parts. Failure to

disconnect the power increases the

likelihood that a servicing error or mistake

will result in serious or fatal injuries.

MAIN TOP

To Raise Ceran Cooktop

2. Remove the two screws securing the

main top to the frame.

3. Lift up slightly and slide the main top

forward to access the wire harness.

Disconnect the harness.

4. Lift the top off and lay aside securely with

under side up.

5. Remove the screws securing element to

main top.

When cool open the door and remove the

two screws securing the cook top to the

frame. Once the screws are removed raise

cook top and slide forward slightly. With the

cook top forward disconnect the wire

harness and remove the cooktop.

ELEMENTS

Ceran Element Cooktop

Cooking areas are identified by patterns in

the Ceran surface. The elements consist of

coil(s) contained in the element housing.

Power to the element (240 volts) is provided

and controlled by an infinite switch. Each

heating element is equipped with a

temperature limiter, which prevents heat

surges and ensures that the heating

elements will not overheat. The element and

temperature limiter is available as a

complete unit or individual parts.

6. Disconnect wiring to element and

replace element.

7. Reverse procedure to reinstall.

To Remove Glass Top Assembly

1. Disconnect the appliance from power

source before servicing.

2. Remove two (2) screws securing glass

top to frame. The screws are located in

the front left and right corners with the

door open.

3. Grasp front edge of cooktop and slide out

slightly. With the top moved forward

disconnect the wiring harness.

4. Lift the top off the unit and lay aside

securely.

5. Reverse the procedure to reinstall.

When a cooking area is turned ON, the coil

element under the cook top will heat up and

glow. The element will cycle on and off to

maintain the heat setting. When the element

cycles on, it is normal to see a red glow

through the smooth top.

Note: It is normal for the element to cycle

when set on the high setting.

To Remove Element:

1. Disconnect the appliance from power

source before servicing.

16010107 Section 3. Component Description

Ceran Element

• Left front and right rear element wattage:

208/240 volts @ 900/1200 watts.

Approximately 48Ω.

• Left rear element wattage: 208/240 volts

@ 1580/2200 watts. Approximately 27Ω.

• Dual element wattage: 208/240 volts @

1580/2200 watts. Approximately 27Ω for

the outer element. 208/240 volts @ 580/

750 watts. Approximately 73Ω for the

inner element.

3-2

©2000 Maytag Appliances Sales Company

Bake Element

To Access Broil Element:

Element Wattage: 208/240 volts @ 2250/3000

watts. Approximately 19Ω

The bake function controls the Bake and

Broil heating elements. During a Bake cycle,

the Broil element will be on 6 seconds of a

60-second duty cycle, and then the Bake

element will be on the remaining 54

seconds. The Bake and Broil elements will

be staged with the exception of the rapid

preheat. In the rapid preheat, available when

the upper oven is used alone, the bake and

broil elements will be on at 100% until

temperature is reached. Once temperature

is reached, the elements will cycle as

outlined above.

Note: The Bake element will be the first

element to turn on at the beginning of any

conventional bake cycle.

To Access Bake Element:

1. Disconnect the appliance from power

source before servicing.

2. Remove lift off door for more

accessibility.

1. Disconnect the appliance from power

source before servicing.

2. Remove lift off door for more

accessibility.

3. Remove broil support brackets (2) and

remove screws securing broil element to

back oven.

4. Gently pull element through cavity wall

until terminals can be accessed.

5. Disconnect wiring.

6. Remove/Replace element as necessary.

7. Reverse procedure to reinstall.

Oven Sensor

The oven sensor is located inside the oven

cavity, attached to the rear wall of the cavity.

As the oven temperature increases, the

resistance of the oven sensor increases. The

resistance is measured by the electronic

control to determine the oven temperature.

3. Remove four (4) screws securing bake

element to back of oven cavity.

4. Gently pull element through cavity wall

until terminals can be accessed.

5. Disconnect wiring.

6. Remove/replace element as necessary.

7. Reverse procedure to reinstall.

Broil Element

To Access Oven Sensor:

1. Disconnect the appliance from power

source before servicing.

2. Open oven door and remove two (2)

screws securing sensor to oven cavity.

Gently pull through cavity wall.

3. Disconnect the oven sensor at the

connector blocks and remove/replace as

necessary.

4. Reattach the connector blocks and

reassemble.

The broil function controls only the broil

element. The bake element is inactive

during a broil cycle. During a broil cycle, the

control will monitor the oven temperature

and cycle the broil element on and off to

obtain the selected temperature.

16010107 Section 3. Component Description

3-3

©2000 Maytag Appliances Sales Company

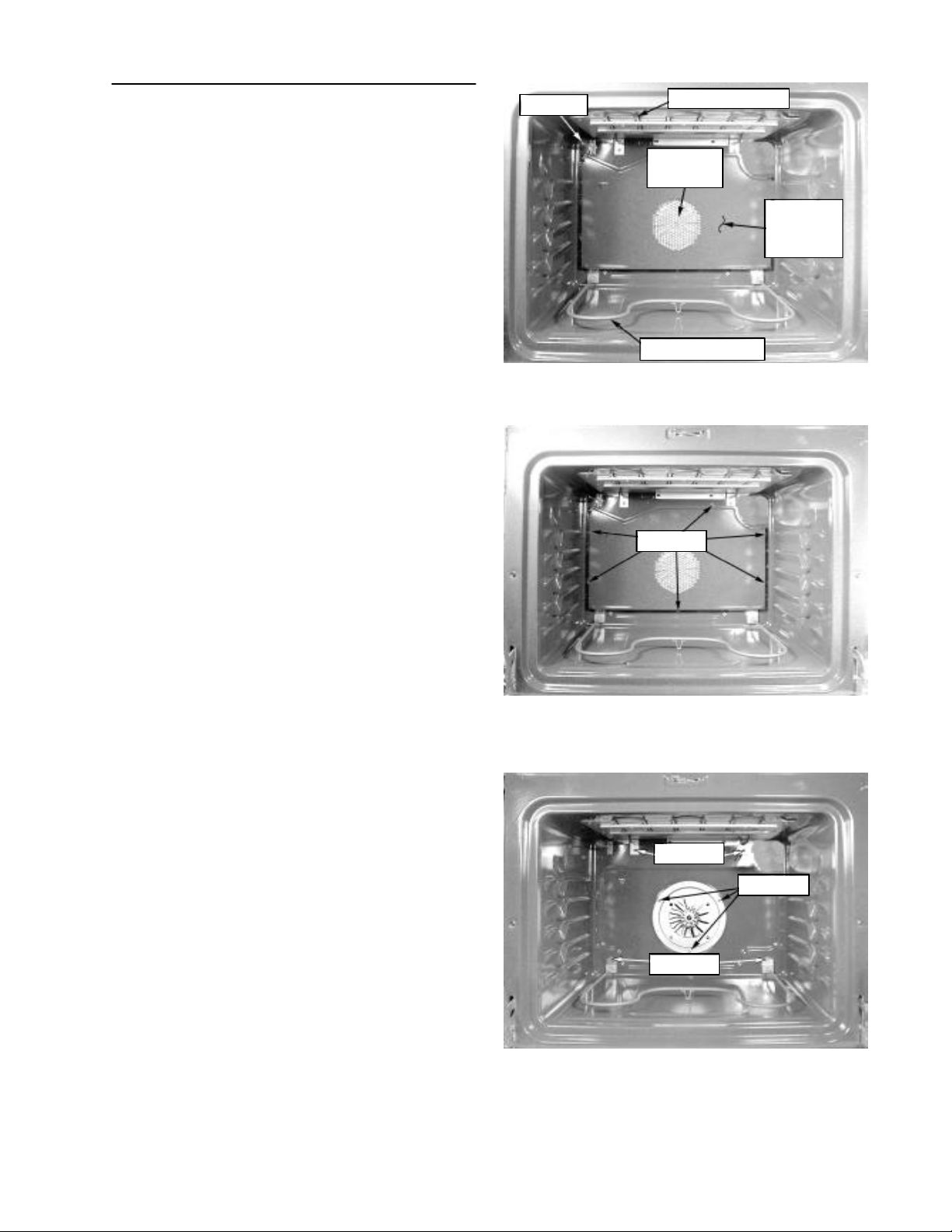

Oven Cavity Components (Electric)

Open or remove the oven door. The

following components are accessible:

Sensor

Broil Element

Convect

Fan

• Racks

• Oven Sensor

• Broil Element

• Convect Fan Cover

• Bake Element

Convection Fan (Electric)

Remove six screws (as shown) from the

perimeter of the convection fan cover. This

will loosen the cover, but it cannot be

removed easily without positioning it to

clear the rack guides. Care should be used

when moving parts and tools around inside

the oven cavity to avoid marring or chipping

the procelain surfaces.

Convect

Fan

Cover

Bake Element

Screws

Three screws (shown) secure the convection

fan mounting plate, remove these, to allow

access to the motor and connectors.

16010107 Section 3. Component Description

Screws

Screws

Screws

Also shown here are the screws that secure the

bake and broil elements.

3-4

©2000 Maytag Appliances Sales Company

Convect Fan Motor and Blade (Electric)

Motor Connectors

Motor

After the convect fan mounting plate is

removed, motor connectors, motor, motor

mount and insulation is accessible. Motor

connectors are also exposed by removing

the back panel (see range back removal).

The convect fan blade is attached to the

motor’s “D” shaft using a hex set screw.

The fan blade must be loosened and taken off

the motor shaft before the motor can be

removed. The motor mounting screws are

found on the front side of the convect fan

assembly. When reassembling, be sure to

reinstall the small piece of insulation under the

motor mount. The insulation provides sound

dampening and prevents heat loss. When

reinstalling the convect fan blade, be sure that

the blade has adequate clearance at all points

around the mounting plate. The blade should

“stand off” approximately 1/8” with very little

apparent warping.

Motor Mount

Insulation

Mounting Screws

16010107 Section 3. Component Description

Hex Head Set Screw

Note: When reinstalling the convect assembly, be sure to

check that no loose insulation is visible in the fan area

or anywhere in the oven cavity.

3-5

©2000 Maytag Appliances Sales Company

ELECTRONIC CLOCK AND OVEN

CONTROL

To Gain Access To Electronic Oven Control

1. Disconnect the

appliance from

power source

before servicing.

removes voltage from the heating element.

Control is attained by regulating the ratio of

the time between the opening and closing of

the contacts. This is usually referred to as

input percentage and is controlled by a cam,

which can provide virtually any infinitely

adjustable performance. This performance

is assured when the switch is subjected to

elevated ambient temperatures through

automatic temperature compensation.

2. Remove two screws

securing backguard

panel to the end caps.

3. Remove two (2) screws securing

backguard panel to backguard housing.

(Screws located between control panel

and main top).

4. Lift backguard panel up, tilt forward, and

lay panel on protected surface of main

top for servicing.

5. Remove two (2) screws securing controlmounting plate to backguard.

6. Remove four (4) screws securing control

to control mounting plate.

7. Disconnect wiring and remove/replace

control.

The infinite switch stems are color coded for

identification. The silver colored stem

controls the left front and right rear element,

the silver colored stem with a red dot

controls the left rear, and the brass colored

stem controls the right front element.

Amperage is rated at 3-15.5A range +/- 10%.

Note: When replacing the infinite switch,

the switch must be matched to the element.

To Access Control:

1. Disconnect the appliance from power

source before servicing.

2. Remove control knobs.

3. Remove two screws from backguard

panel securing panel to housing.

8. Reverse procedure to replace.

4. Remove two screws securing backguard

panel to end cap.

INFINITE SWITCH (Current Sensing)

5. Lift backguard panel up, tilt forward, and

lay panel on protected surface on main

This unit is equipped with controls that

top for servicing.

provide an infinite choice of settings from

LOW to HIGH. The control can be set on any

of the numbered settings. To operate, push

in and turn control knob to the desired

6. Remove two (2) mounting screws

securing infinite switch to backguard

panel.

setting.

7. Disconnect wiring and remove/replace

Note: The infinite switch is a current

control.

sensing switch.

8. Reverse procedure to replace.

The infinite switch is a rotary switch, which

controls the power dissipated by a heating

element. A heater-bimetal opens and closes

the cycling contacts, which applies and

16010107 Section 3. Component Description

3-6

©2000 Maytag Appliances Sales Company

Signal Lights

Oven Light Replacement

Range is equipped with two signal lights to

indicate when a surface element is on. The

light will remain on until the element is

turned off. After a cooking operation, be

sure element and signal light is off.

The signal lights are located on the

backguard panel and may be accessed from

the backside of the panel when removed.

The red indicator lens pop in and out, and

the light slides into a lock position. Reverse

the procedure to remove.

“Hot Surface ” Light

The Gemini Range is equipped with a Hot

Surface Light. This red light will turn on to

indicate that the cooking area is hot and will

remain on until the area has cooled.

The switch is located in the front center of

the burner box, and may be accessed by

removing the main top.

To Access Hot Surface Light:

The oven light used on the Gemini is a 12

volt 10 Watt Halogen bulb. The light

automatically comes on when the door is

opened or activation may occur via the light

pad when the door is closed. The light will

not operate during a clean cycle. The oven

light will automatically come on one minute

before the end of a clock controlled cooking

operation.

To Replace Oven Light Bulb:

1. Disconnect power to the range.

2. Open oven door and locate oven light.

3. Remove the lens cover to gain access to

bulb.

4. Carefully remove the old bulb by pulling

straight out of ceramic base.

NOTE: To avoid damaging the bulb and

decreasing the life of the bulb, do not touch

the bulb with bare hands or fingers. Hold

with a cloth or paper towel.

1. Disconnect the appliance from power

source before servicing.

2. Open oven door and remove the screws

securing the main top to the frame.

3. Slide the top forward and disconnect the

wire harness.

4. Lift the top off and lay on a protected

surface with under side up.

5. Release the tabs securing the switch to

the top. Once the tabs are released the

switch can be removed.

6. Reverse procedure to replace.

5. Push new bulb prongs straight into small

holes of ceramic base.

6. Replace bulb cover by snapping into

place.

7. Reconnect power to range and reset

clock.

Bulb specifications

G4 Type Halogen Bi-Pin 10 w -12V

16010107 Section 3. Component Description

3-7

©2000 Maytag Appliances Sales Company

HI-LIMIT THERMOSTAT

CAUTIONS:

The HI-Limit Thermostat is mounted to

range main back. The purpose of this

thermostat is to break line voltage to oven

control in case of a runaway temperature.

Range may be removed from cabinetry for

rear serviceability.

Contacts normally closed

Close Temperature - 250 ± 11ºF

Open Temperature - 300 ± 8ºF

• Do not attempt to open or close door

or operate oven until door is properly

replaced.

• Hinge arms are spring mounted and

will slam shut if accidentally hit.

Never place hand or fingers between

the hinges and the front oven frame.

You could be injured if hinge snaps

back.

Both the upper and lower oven doors are

removable.

To Remove Lift-Off Door:

Open door to stop position. In stop position

door is open approximately 4”. Grasp door

as illustrated. Lift up evenly until door clears

the hinge arms.

Thermostat Replacement

1. Disconnect the appliance from power

source before servicing.

2. Slide unit out of installation.

3. Remove screws securing main back

shield and remove shield.

4. Remove two (2) screws securing

thermostat to range main back.

5. Disconnect wiring.

6. Replace in reverse order.

OVEN DOOR(S)

Do not place excessive weight on an open

oven door or stand on an opened door as, in

some cases, it could cause the range to tip

over, breakage of the door, or serious injury.

DO NOT USE DOOR HANDLE TO LIFT

DOOR.

To Replace:

1. Grasp door at each side.

2. Align slots in the door with the hinge

arms on the range.

3. Slide the door down onto the hinge

arms until the door is completely

16010107 Section 3. Component Description

3-8

©2000 Maytag Appliances Sales Company

seated on the hinges. Push down on

the top corners of the door to

completely seat door on hinges. Door

should not appear crooked.

NOTE: The oven door on a new range

may feel “spongy” when it is closed.

This is normal and will decrease with

use.

5. Slide the doorframe and glass off liner

from the bottom.

6. Remove four (4) screws securing the

door handle to the door liner. (Two on

the sides and two in front).

7. Remove two (2) screws securing door

baffle to liner.

To Disassemble Door:

1. Open door to the stop position and lift

door off hinges. Remove door and lay

on protected surface, liner side up.

2. Remove three (3) screws securing the

doorframe to the liner at the bottom.

3. Remove two (2) side screws securing

doorframe to door liner.

4. Remove four (4) screws securing the

door trim at the top.

UPPER DOOR

8. Remove four (4) screws securing door

baffle to window pack. Remove baffle.

9. Remove insulation wrap.

10. Remove four (4) screws securing window

pack to liner. Window pack comes out as

an assembly.

11. Door gasket can be replaced without

door being disassembled by pulling

gasket out of bottom insert of door. The

gasket is secured with clips inserted into

door liner.

16010107 Section 3. Component Description

3-9

©2000 Maytag Appliances Sales Company

LOWER DOOR

To Replace Lock Assembly

1. Disconnect the appliance from power

source before servicing.

2. Open oven door or remove for

convenience.

3. Remove main top and slide forward.

Disconnect wire harness. (See Top

Removal).

4. Lift top off and lay aside securely.

5. Remove two (2) screws securing lock

assembly to oven frame in front.

6. Disconnect wiring.

16010107 Section 3. Component Description

7. Remove two (2) screws securing lock

assembly to frame.

8. Slide assembly out.

9. Reverse procedure to reinstall.

Lower Latch Assembly

1. Disconnect the appliance from power

source before servicing.

2. Remove main top assembly as described

previously and lay aside securely.

3-10

©2000 Maytag Appliances Sales Company

3. Remove main top and slide forward.

Disconnect wire harness. (See Top

Removal).

Note: Make sure the insulation is back in

place when finished. Failure to do so will

result in hot spots and poor baking

complaints.

LOWER LATCH ASSEMBLY

1. Disconnect the appliance from power

source before servicing.

2. Remove main top as outlined

in main top removal.

3. Remove the screws

securing the side

panel at the top and

back of frame.

4. Remove the screws

securing the rear

panel to frame. Remove rear panel.

5. Slide side panel away from the frame at

rear and lift out of the slots in front.

Remove side panel.

6. Release the bands, securing the

insulation wrap, at the bottom.

5. Reattach band to the bottom of frame.

6. Reconnect wiring to the lock switches.

7. Reinstall the side panel.

8. Reinstall the rear panel.

9. Reinstall the main top.

Oven Door Hinge

The unit will have to be pulled away from the

cabinetry to remove/replace door hinges.

To Access/Replace Oven Door Hinges:

1. Disconnect the appliance from power

source before servicing.

2. Remove main top assembly as described

previously and lay aside securely.

7. Slide the insulation wrap back.

Note: This will aid in guiding the latch

assembly in and out.

8. Disconnect the wiring from the lock

switches at the rear.

9. Slide the latch assembly out from the

rear.

To reinstall:

1. Slide latch assembly in from the rear.

2. Guide assembly to front using the side

access.

3. Make sure the screw holes of the

assembly line up with the screw holes in

the frame.

3. Remove oven door assembly as

previously described and lay aside

securely.

4. Remove the screws securing side panel

at the top and back of frame.

5. Remove the screws securing the rear

panel to frame.

6. Slide the side panel away from the frame

at rear and lift out of the slots in the

front. Remove panel.

7. Remove two (2) screws securing hinge to

front frame flange.

8. Complete hinge assembly may be

removed.

9. Reverse procedure to reinstall.

4. Reinsert the screws.

16010107 Section 3. Component Description

3-11

©2000 Maytag Appliances Sales Company

OVEN DOOR HINGE

Note: The door hinges are colored coded

for ease in installation. The upper spring

hook is gold and the lower spring hook is

white.

The convenience outlet circuit breaker may

trip if the small appliance plugged into it

exceeds 10 amps. To reset the circuit

breaker, press the switch located on the

lower edge of the backguard. (See figure

below).

LEVELING LEGS

Some floors are not level. For proper

baking, your range must be level.

Leveling legs are located on each corner of

the base of the range.

Place a level horizontally on an oven rack

and check front-to-back and side-to-side.

Level by turning the legs.

SPECIFICATIONS

Overall Dimensions:

Height (in./cm) 46

Width (in./cm) 29

Depth Excluding Handle (in./cm) 26

3

/4/118.7

7

/8/76

1

/8/66

Weight (lbs./kg.) 225/102

Total Connected Load (kw @ 24V/208V)

10.4/7.8

OVEN RACKS

CAUTIONS:

• Do not attempt to change the rack

position when the oven is hot.

CONVENIENCE OUTLET

(Canadian Models Only)

The convenience outlet is located on the

lower left side of the backguard. It is useful

for small appliances such as waffle irons.

When using the outlet be sure the appliance

cord does not rest on or near the surface

element. If the surface element is turned on,

the cord and outlet wil be damaged.

16010107 Section 3. Component Description

All racks are designed with a lock-stop edge.

Upper Oven

• Is equipped with one rack and rack

position.

• When pulling the

upper oven rack out

to remove or check

food, grasp the top

edge of the rack.

3-12

©2000 Maytag Appliances Sales Company

Lower Oven

• Is equipped with two RollerGlide™ racks.

To remove oven racks:

• Pull rack straight out until it stops at the

lock-stop position; lift up on the front of

the rack and pull out.

• For lower oven racks, pull both the rack

glide and rack base out together.

To replace oven racks:

• Place rack on the rack support in the

oven; tilt the front end up slightly; slide

rack back until it clears the lockstop

position; lower front and slide back into

the oven.

RACK POSITIONS

Multiple Rack Cooking:

Two Rack: Use rack position 2 and 4, or 1

and 4.

HALF RACK ACCESSORY

A half rack, to increase oven capacity, is

available as an accessory. It fits in the left,

upper portion of the oven and provides

space for a vegetable dish when a large

roaster is on the lower rack. Contact your

Maytag dealer for the "HALFRACK"

Accessory Kit or call 1-800-688-8408.

Rack 4: Use for two-rack baking.

Rack 3: Use for most baked goods on a

cookie sheet or jelly roll pan, layer

cakes, fruit pies, or frozen

convenience foods, and for most

broiling.

Rack 2: Use for roasting small cuts of meat,

casseroles, baking loaves of bread,

bundt cakes or custard pies, and

two-rack baking.

Rack 1: Use for roasting large cuts of meat

and poultry, frozen pies, dessert

souffles or angel food cake, and

two-rack baking.

16010107 Section 3. Component Description

3-13

©2000 Maytag Appliances Sales Company

NOTES

16010107 Section 3. Component Description

3-14

SECTION 4. ELECTRICAL

TOASTING CIRCUIT (Upper Oven Only)

T o Access Bake Element: Upper Oven Only

1. Disconnect power from unit before

servicing.

2. Remove door for more accessibility.

3. Remove 2 screws securing bake element

to back of oven cavity.

4. Gently pull element through cavity wall

until terminals can be accessed. Use

Caution: Space is limited.

5. Disconnect wiring.

6. Remove/replace element as necessary.

7. Reverse procedure to reinstall.

OVEN CIRCUITS

T o Access Broil Element:

1. Disconnect power from unit before

servicing.

2. Remove door for more accessibility.

3. Remove broil support brackets (2), and

remove 2 screws securing broil element

to back of oven.

4. Gently pull element through cavity wall

until terminals can be accessed.

Use Caution: Space is limited.

5. Disconnect wiring.

6. Remove/Replace element as necessary.

7. Reverse procedure to reinstall.

16010107 Section 4. Electrical

©2000 Maytag Appliances Sales Company

4-1

SURFACE ELEMENTS - CERAN

Verify there is proper voltage applied to the

oven (the range may have blown a fuse or

circuit breaker). A quick check is to see if the

other elements heat. If not, check the

voltage at the electrical outlet and check to

see that the power cord is wired correctly.

To Check Surface Element:

ELECTRICAL RA TINGS: 240V AC 2200W TOT AL

750W INNER RING

1450 OUTER RING

COLD RESIST ANCE: 74.6 Ohms (INNER)±5

38.6 Ohms (OUTER)±5

LIMITER TYPE:

ELECTRICAL RA TINGS OF LIMITER CONT ACTS

LIMITER CIRCUIT 10 AMP AT 250 V AC

LIMITER CIRCUIT 7.0 AMPA T 380 V AC

HOT LIGHT CIRUCIT 1.0 AMP A T 380 V AC

1. Disconnect unit from power source

2. Remove main top by removing screws

securing top to burner box and lay aside

securely.

3. Visually check the element for evidence

of damage or shorting. Then check the

element for continuity with an ohmmeter

connected to the element terminals.

With ohmmeter set at RX1, resistance

will normally be below 28 ohms, large

and 48 ohms, small. If the element

shows no continuity or extremely high

resistance, it should be replaced.

4. With power to the unit disconnected, set

the control switch for this element on the

high setting. With a voltmeter set on 250

or 300 volt scale, re-apply power and

check for voltage at the surface element

terminal block, then check the surface

element.

Each heating element is equipped with a

temperature limiter which prevents heat

surges and ensures that the heating

elements will not overheat.

DUEL ELEMENT

The cooking surface is equipped with a dual

element located in the right front position.

To operate, push in on the controlknob and

turn to the left to control the large element,

or push in and turn to the right to control the

small element.

PROBE, SENSOR / BOTH OVENS

Oven Sensor

The oven sensor is located inside the oven

cavity, attached to the rear wall of the cavity.

As the oven temperature increases, the

resistance of the oven sensor increases. The

resistance is measured by the electronic

control to determine the oven temperature.

The "Hot Surface" light will come on

indicating when ceran surface is 150ºF ±

50ºF. The Hi-Limit which shuts burner off at

1050ºF ± 60ºF.

16010107 Section 4. Electrical

©2000 Maytag Appliances Sales Company

4-2

T o check oven sensor:

1. Access sensor wires as outlined under

sensor removal.

2. Set meter to RX1000 Scale.

3. Check for the following:

TEMPERATURE RESISTANCE

100 Degrees F 1143 Ohm s

200 Degrees F 1350 Ohms

300 Degrees F 1553 Ohms

350 Degrees F 1654 Ohms

400 Degrees F 1753 Ohm s

500 Degrees F 1949 Ohms

600 Degrees F 2142 Ohm s

700 Degrees F 2331 Ohm s

800 Degrees F 2516 Ohm s

900 Degrees F 2697 Ohm s

1000 Degrees F 2874 Ohms

HOT SURF ACE LIGHTS

Each element has a HOT SURFACE indicator

light. A light will be illuminated when the

matching cooking area is hot. It will remain

on, even after the control is turned off, until

the area has cooled. They are located at the

front center of the cooktop.

SURF ACE INDICA TOR LIGHTS

There is an indicator light by each pair of

control knobs. When one or both of the

surface control knobs is turned on, the light

will turn on. The light will turn off when the

surface element(s) is turned off.

16010107 Section 4. Electrical

©2000 Maytag Appliances Sales Company

4-3

TRANSFORMER, STEPDOWN (12V)

Electrical Ratings:

Input Voltage: 120 Volts

Operating Frequency 60 Hz

Output Voltage: 7-12 VAC

SURF ACE ELEMENT SWITCH

at 10W Load 11.6 ± .2 VAC

at 20W Load 11.1 ± .3 VAC

DUAL ELEMENT SWITCH

16010107 Section 4. Electrical

©2000 Maytag Appliances Sales Company

4-4

ELECTRICAL CONNECTIONS/VOL T AGE

Range Amperage:

The total range wattage is stamped on

model plate in kilowatts, (kilowatt = 1,000

watts) to determine amperage for fuse or

circuit breaker:

• Check incoming voltage at range main

terminal block (pigtail) see illustration.

With range connected to electricity by

means of an approved range connector

(pigtail) voltmeter reading between L1 and

L2 should be approximately 240 VAC.

Voltmeter reading between terminal

NEUTRAL and terminal LINE 1 should be

approximately 120 VAC. Voltmeter reading

between NEUTRAL and LINE 2 should be

approximately 120 VAC. Center terminal of

main terminal block is netural. Range frame

is connected to neutral at this point by a

ground strap and screw.

• Divide voltage into total wattage.

Example: 10. K.W. (stamped on model

plate) X 1,000 = 10,000 watts. Voltage (at

terminal block) is 240 VAC. 10,000 ÷ 240

= 41.6 (AMPS). This indicates a fuse or

circuit breaker with a rating of slightly

over 41 AMPS would be needed.

The range is connected to an outlet through

an approved range connector (pigtail)

fastened securely to the terminal block with

proper strain relief at the range and a three

or four pronged plug at the opposite end.

NOTE: For cord (pigtail) replacement, only

a power supply cord kit rated at 240 volts

minimum, 40 amperes, with closed loop

terminals and marked for use with ranges

shall be used.

REMEMBER: MOBILE HOMES AND SOME

LOCAL CODES DO NOT PERMIT

GROUNDING THROUGH NEUTRAL.

HENCE, 4-WIRE SERVICE MUST BE

PROVIDED FOR SUCH INSTALLATIONS.

ALL OTHERS PERMIT 3-WIRE SER VICE, USE

COPPER WIRE ONL Y. AFTER

INSTALLATION, ENSURE TIGHTNESS OF

ALL ELECTRICAL CONNECTIONS AND

REPLACE ALL COVERS.

16010107 Section 4. Electrical

©2000 Maytag Appliances Sales Company

4-5

NOTES

16010107 Section 4. Electrical

©2000 Maytag Appliances Sales Company

4-6

SECTION 5. TROUBLESHOOTING

.

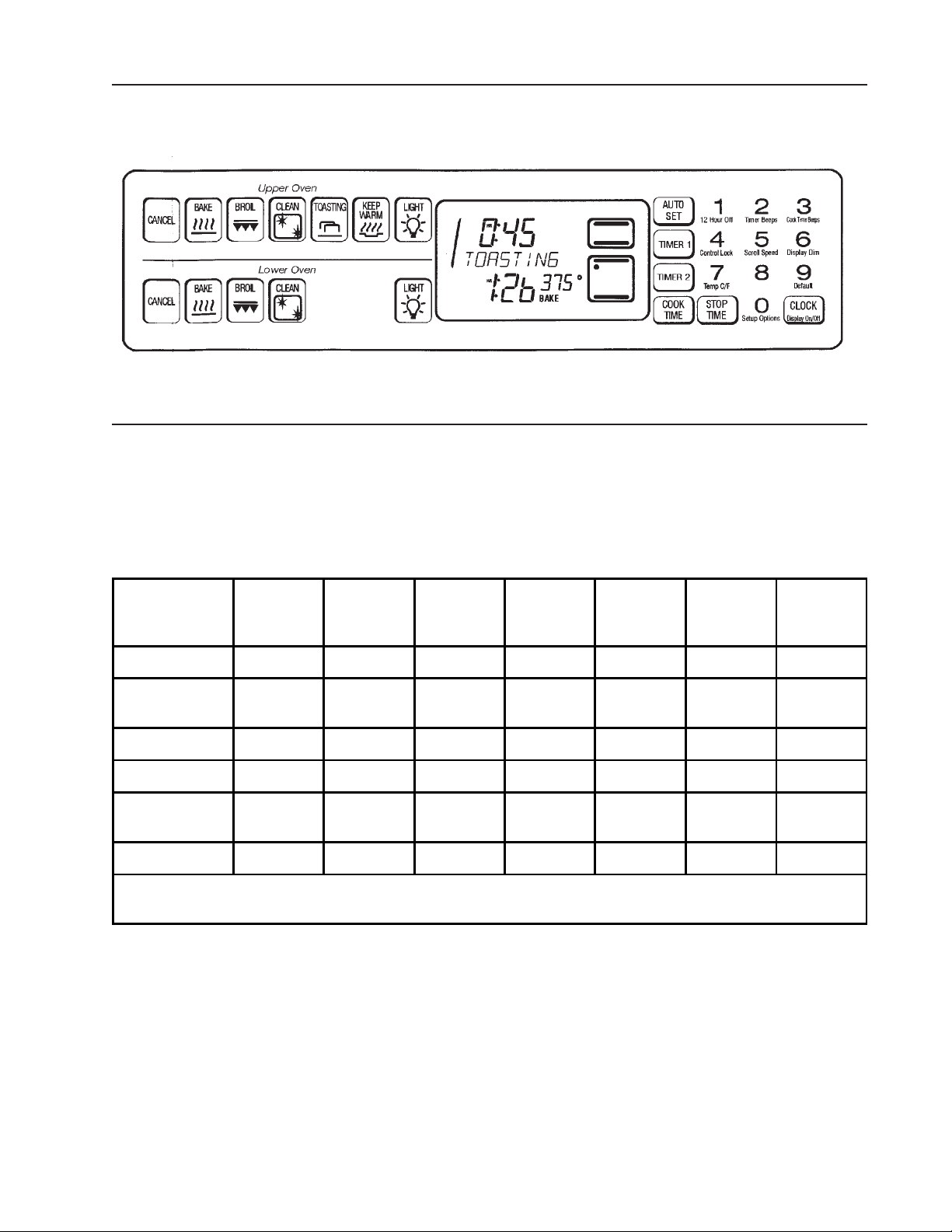

GEMINI DOUBLE OVEN CONROLS

The control is activated via a membrane switch which contains the function pads and 10 key

digi-pad. Data can be entered either by choosing the function and entering a value or by

choosing the function and using the Auto Set pad. Values for the Auto Set pad are listed

below.

COOKING

FUNCTION

Bake 350/1 75 375/1 90 400/20 5 425/2 15 450/ 230 475/245 325/160

Broil

Convect* 325/160 350/175 375/190 400/205 425/215 450/230 475/245

CleanTime 3:00Hrs. 4:00Hrs. 2:00Hrs.

Toasting * * 4:00 Min. 4:10 Min. 4:2 0 Min. 4:30 Min. 4:4 0 Min . 4:50 Min.

Keep Warm 170/75

* Ifequipped.

** Toasting has a max im um allow abletime of 10 m inutes, available inupper ovenonly.

1ST

PRESS

ºF / ºC

HI

550/290

2ND

PRESS

LO

450/2 30

3RD

PRESS

4TH

PRESS

5TH

PRESS

6TH

PRESS

7TH

PRESS

5:00 Min

10:00

16010107 Section 5. Troubleshooting

©2000 Maytag Appliances Sales Company

5-1

FAUL T CODES

Fault Codes, Displayed in Upper Time Digits:

There are three major fault codes that will be

displayed in the time digits of the upper

clock display to the left of the colon. Minor

fault codes are displayed in the time digits to

the right of the display colon, these are used

to direct the technician to more specific

locations for diagnosis. Major fault codes

are as follows:

F1: Temperature runaway. Membrane

switch shorted. Alarm is continuous, if

cancel key is pressed alarm will stop, if fault

still present alarm will repeat. If membrane

switch is disconnected the alarm will only

sound for 30 seconds and stop.

Correction: Test membrane switch and oven

sensor, if OK, replace control.

F3: Open or shorted sensor. The cancel key

resets the control and stops the alarm. If

fault is still present it will reactivate the

alarm when a cook mode is chosen.

Correction: Check sensor and wiring for

shorted or open circuit.

Oven Temperature Adjust: Bake

temperature can be adjusted by pressing

Bake in either upper or lower oven, entering

a temperature of 550ºF, then hold bake key

for 3 seconds. Auto set is used to adjust the

temperature either + / - 35ºF in 5º F

increments

(+ / - 21ºC, in 3ºC increments).

Control Lockout: The control can be Locked

Out by pressing Setup and then 4. When

locked "Control Locked" will be displayed and

scroll twice. Press Auto Set to toggle

between Locked and Unlocked. The control

locktout will not lock out the timer, clock,

setup options or oven light.

Test Mode: Accessed by holding Cancel and

Broil keys down for 3 seconds within 5

minutes of power up. The test mode cannot

be accessed if the oven temperature is above

400ºF. When test mode is activated all digits

will display "-". To exit the test mode press

Cancel or auto exit occurs 16 seconds after

last key pressed.

KEY PRESSED

RELA Y or ACTION

ACTIVATED

F9: Door lock error. Check the status of the

door lock switches. Unlocked and locked

switches must be in sequence, unlocked

closed during normal operation and locked

open. The opposite is true during a clean or

locked state.

Timer Functions: The timer operates

independently of all other functions. There

are two timer functions. Timer 1 and Timer

2. The countdown time in the upper VFD

can be toggled by pressing the clock and

timer 1 keys.

Off/Cancel: Will cancel any oven operation

by pressing the appropriate cancel key for

the respective oven. Cancel will not effect

the timer or clock functions.

*Convection Fan Relay: If equipped, the

convection fan relay will activate the convect

fan motor when the oven door is closed. In

a convect mode the relay will shut off the

convect fan when the door is opened.

Upper Bake Upper Bake Element

Lower Bake Lower Bake Element

Upper Broil Upper Broil Element

Lower Broil Lower Broil Element

Convecti on Bake* Conv ecti on fan*

Upper Oven Light Upper Oven Light

Lower Oven Light Lower Oven Light

Upper Clean M otorized Do or Lock, Upper

LowerClean MotorizedDoorLock,Lower

Stop Time Beeper

Cook Time Display error codes

Clock Display all time digits

16010107 Section 5. Troubleshooting

©2000 Maytag Appliances Sales Company

5-2

Engineering Mode: Used to view the actual

oven temperature for both ovens at all times,

even when an oven function is active. This

mode will also display the current fault code

for 5 seconds in the time digits. Enter the

engineering mode by pressing the Bake Key

Dual Line Break Relay: Canadian Models

Only. Relay wil be a 17 amp, 240 VAC

minimum contact rating. There will also be

a 5.6 Ohm resistor and a connection to the

normally open contact on Canadian models

to allow for "Hi-Pot" testing at the factory.

of either oven, enter a bake temperature of

100ºF, then hold Bake down for 3 seconds

within 30 seconds of initial Bake press. The

50/60 Hertz Option: Control automatically

senses cycle rate of supply line.

mode can be exited by pressing Cancel.

Demo Mode: The control can be placed in a

Oven Light: Oven light key toggles the oven

light on and off. Oven light is deactivated

during a clean cycle.

sales demo mode by pressing Bake and

Cancel keys for 3 seconds. The demo mode

can be exited by pressing any key. This

mode will activate the display as if the unit is

operating without energizing the heating

elements.

RELA Y BOARD

Relay Board: The relay board will be equipped to operate the following outputs. Some

shown can be optional. The Double Line Break (DLB) is located remotely, off board from the

main control.

RELAY OUTPUTS

Lower Broil - 3600 Watts 240

Lower Bake - 2585 Watts 240

Convect* 120 0

Upper Broil - 2200 Watts 240 9

Upper Bake - 1800 Watts 240 9

Upper Oven Light 12

Lower Oven Light 12

Upper Door Lock 120

Lower Door Lock 120 0

Upper Double LineBreak 240

Lower Double Line Break 240

SURF ACE ELEMENT VALUES VOLTS

VOLTAGE

(Volts AC)

C

UR

(A

WA

1

0

Left Front/Right Rear 240 1

Left Rear 240 2

Right Front/Dual 240 750 inner

16010107 Section 5. Troubleshooting

©2000 Maytag Appliances Sales Company

5-3

TROUBLESHOOTING GUIDE

Check these points if . . .

• Check to be sure plug is securely inserted into receptacle.

Part or all of the

appliance does

not work.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Surface or oven

elements fail to

operate or heat

food.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Glass-Ceramic

surface shows

wear.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Baking results are

not what you

expected.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Baking results

differ from

previous oven.

• Check or re-set circuit breaker. Check or replace fuse.

• Check power supply.

• Check if surface and/or oven controls have been properly set.

• Check if oven door is unlocked after a self-clean cycle.

• Check if oven is set for a delayed cook or clean program.

NOTE: On Canadian models, the glass-ceramic cooking surface will not

operate during a self-clean cycle.

• Check to be sure plug is securely inserted into receptacle.

• Check or re-set circuit breaker. Check or replace fuse.

• Check power supply.

• Check if surface and/or oven controls have been properly set.

• Check if oven is set for a delayed oven operation.

• Upper oven may be in a toasting operation. Lower oven will operate when the

toasting operation is completed.

1. Tiny screatches or abrasions.

• Check to make sure cooktop and pan bottom are clean. Do not slide glass

or metal pans across top. Make sure pan bottom is not rough. Use the

recommended cleaning agents.

2. Metal marks.

• Do not slide metal pans across top. If metal marks appear, clean when cool

with Cooktop Cleaning Creme.

3. Brown streaks and specks.

• Spills not removed promptly. Wiping with soiled cloth or sponge. Pan

bottom not clean.

4. Areas with a metallic sheen.

• Mineral deposits from water and food.

5. Pitting or flaking.

• Sugary boilovers that were not removed promptly.

• Check the oven temperature selected. Make sure oven is preheated when

recipe or directions recommended preheat.

• Check rack positions.

• Use correct pan. Dark pans produce dark browning. Shiny pans produce

light browning. See "Cooking Made Simple" booklet for more information on

bakeware.

• Check the use of foil in the oven. Never use foil to cover an entire oven rack.

Place a small piece of foil on the rack below the pan to catch spillovers.

• Check pan placement. Stagger pans when using two racks. Allow 1-2 inches

between pan and oven walls.

• Make sure the oven vent has not been blocked.

• Check to make sure range is level.

• Temperatures often vary between a new oven and an old one. As ovens age,

the oven temperature often "drifts" and may become hotter or cooler.

NOTE: It is not recommended to adjust the temperature if only one or two

recipes are in question.

16010107 Section 5. Troubleshooting

©2000 Maytag Appliances Sales Company

5-4

TROUBLESHOOTING GUIDE Continued...

Check these points if . . .

• Check if oven controls have been properly set.

Food is not

broiling

properly.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Oven smokes

excessively during

broiling.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Oven will not

self-clean.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

• Check oven rack positions.

• Broil element was not preheated.

• Aluminum foil was incorrectly used. Never line the broiler insert with foil.

• Oven door was closed during broiling. Leave the door open to the first stop

position (about 4 inches).

• Food too close to element.

• Broiler insert covered with aluminum foil.

• Trim excess fat from meat prior to broiling.

• A soiled broiler pan was used.

• Check if controls are set properly.

• Check to make sure the cycle is not set for a delayed start.

• Check if door is closed.

Oven did not

clean properly .

• Longer cleaning time may be needed.

• Excessive spillovers, especially sugary and/or acid foods, were not removed

prior to the self-clean cycle.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Oven Door will

not unlock after

self-clean cycle.

• Oven interior is still hot. Allow about one hour for the oven to cool after the

completion of a self-clean cycle. The door can be opened when the LOC

indicator word is not displayed.

• Both ovens will lock when either oven is cleaned.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Moisture

condensation

collects on oven

• This is normal when cooking food high in moisture.

• Excessive moisture was used when cleaning the window.

window.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

There is a strong

odor or light

smoke when oven

is turned on.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Steam comes

from vent area.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

• This is normal for a new range and will disappear after a few uses. Initiating a

clean cycle will "burn off" the smells more quickly.

• Turning on a ventilation fan will help remove the smoke and/or odor.

• Excessive food soils on the oven bottom. Use a self-clean cycle.

• When high moisture foods are cooked in the upper oven, steam may be

visable coming form the vent area. This is normal.

• This is called a fault code. If a fault code appears in the display and beeps

"F" plus a number

and the message.

sound, press the CANCEL pad. If the fault code and beeps continue,

disconnect power to the appliance. Wait a few minutes, then reconnect

power. If fault code and beeps still continue, disconnect power to the

appliance and call an authorized servicer.

• If the oven is heavily soiled, excessive flare-ups may result in a fault code

during a clean cycle. Press CANCEL pad and allow the oven to cool for one

hour, then reset the clean cycle. If the fault code and beeps still continue,

disconnect power to the appliance and call an authorized servicer.

16010107 Section 5. Troubleshooting

©2000 Maytag Appliances Sales Company

5-5

©2000 Maytag Appliances Sales Company

PARTS LIST

Main Top Assembly (Black) 74004515

Main Top Assembly (White) 74004516

Hinge, Oven Door (EURO) 74003968

Hinge, Oven Door Upper Gemini 74004523

Switch, Infinite 2600 7403P239-60

Switch, Dual Element 74002144

Element, Broil 3600W/6Pass 74003040

Element, Bake Upper Gemini 74004105

Element, Broil Upper Gemini 74004106

Element, Bake Lower Oven 74004107

REPLACEMENT PARTS

PART NAME PART NUMBER

Element, Ribbon 1200W 74001011

Element, Ribbon 2200W 74001012

Element, Ceran Dual 74004556

Lamp, Assembly Halogen 74004521

Transformer, Stepdown 12V 74004545

Probe, Sensor/Both Ovens 74003390

Clock, E-Trnc-Elc D/O M/T 74004542

Overlay, Clock Gemini White Maytag 74004544

Overlay, Clock Gemini Black Maytag 74004543

Latch, Door Lock Motor 3RPM Upper 74004528

Latch, Door Lock Motor 3RPM Lower 74004519

16010107 Section 5. Troubleshooting

5-6

©2000 Maytag Appliances Sales Company

FAULT IDENTIFICATION SUMMARY

Fault Suspect Failure Area Correction When Checked

F0-0 No Fault None Anytime

F1-1 Runaway Cook Upper Oven Check the sensor 1050-1100

ohms, wiring, control

Every 6 seconds that the

control sees the latch

unlocked.

F1-2 Runaway Cook Lower Oven Check the sensor 1050-1100

ohms, wiring, control

Every 6 seconds that the

control sees the latch

unlocked

F1-3 Runaway Clean Upper Oven Temperature above 650º F.

Check the sensor and

Every 6 seconds that the

control sees the latch locked

control

F1-4 Runaway Clean Lower Oven Temperature above 650º F.

Check the sensor and

Every 6 seconds that the

control sees the latch locked

control

F1-5 Cancel Keypad Upper Oven Replace Control Every 30 seconds

F1-6 Cancel Keypad Lower Oven Replace Control Every 30 seconds

F1-7 Keypad Disconnected Replace Control Every 30 seconds

F1-8 Keypad Shorted Replace Control Every 30 seconds

F1-9 Slave Replace Control Every 30 seconds

F1-A Latch Switch Upper Oven Check that upper latch

Every 30 seconds

switch is closed

F1-B Latch Switch Lower Oven Check that lower latch switch

Every 30 seconds

is closed

F1-C Door Open Upper Oven Check that door position

Every 30 seconds

switch is closed

F1-D Door Open Lower Oven Check that lower door

Every 30 seconds

position switch is closed

F1-E EEPROM Replace Control Every 6 seconds

F1-F Jumper Replace Control Every 30 seconds

F1-H EEPROM Read Error Replace Control Anytime

F1-L Sensor Wire Ohm sensor wire end to end

to ensure a closed path

Anytime at least one oven is

active

Continued...

16010107 Section 5. Troubleshooting

5-7

©2000 Maytag Appliances Sales Company

Fault Suspect Failure Area Correction When Checked

F3-1 Sensor Upper Oven Ohm Sensor (1050-1100

ohms) @ room temperature

F3-2 Sensor Lower Oven Ohm Sensor (1050 - 11

ohms) @ room temperature

F9-1 Latch Switch Upper OVen Check switches and wiring

to latch assembly

F9-2 Unlock Switch Upper Oven Check switches and wiring

to latch assembly

F9-3 Lock and Unlock Switch Upper

Oven

Check switches and wiring

to latch assembly

F9-4 Lock Switch Lower Oven Check switches and wiring

to latch assembly

F9-5 Unlock Switch Lower Oven Check switches and wiring

to latch

F9-6 Lock and Unlock Switch Lower

Oven

Check switches and wiring

to latch assembly

Every 6 seconds

Every 6 seconds

Every 60 seconds that the

control sees the door locked

Every 60 seconds that the

control sees the door locked

Every 30 seconds

Every 60 seconds that the

control sees the door locked

Every 60 seconds that the

control sees the door locked

Every 30 seconds

16010107 Section 5. Troubleshooting

5-8

©2000 Maytag Appliances Sales Company

SECTION 6. WIRING DIAGRAMS

16010107 Section 6. Wiring Diagrams

6-1

©2000 Maytag Appliances Sales Company

16010107 Section 6. Wiring Diagrams

6-2

Maytag Appliances Sales

Company

Customer Service

240 Edwards S treet, S.E.

Cleveland, Tennessee 3731 1

Loading...

Loading...