Page 1

06786-04/12/22

Installer Manual

VENTILATION SYSTEMS

Model Numbers

HRV-150

HRV-210

ERV-150

ERV-210

VB0066

Page 2

2

Table of Contents

1.0 SERVICE ............................................................................................4

1.1 3-D Drawing ................................................................................4

1.2 Parts Ordering Chart....................................................................5

1.3 Technical Support ........................................................................5

2.0 SIZING ................................................................................................6

3.0 UNIT TYPE & DEFROST SETTING VS GEOGRAPHICAL LOCATION ..7

4.0 TECHNICAL DATA................................................................................8

4.1 Air Distribution (Normal Operation)..............................................8

4.2 Air Distribution (Defrost Mode) ....................................................8

4.3 Performance Charts................................................................9-10

4.4 Dimensions ................................................................................11

4.5 Controls and Furnace Link Option ............................................11

4.6 Specifications ............................................................................11

5.0 TYPICAL INSTALLATIONS ..................................................................12

5.1 Fully Ducted System ..................................................................12

5.2 Exhaust Ducted System

(Source Point Ventilation)

..................12

5.3 Simplified

(Volume Ventilation)

..................................................12

6.0 INSTALLATION....................................................................................13

6.1 Adsjusting the Damper Rod (for ERVs installed in warm regions) ........13

6.2 Locating and Mounting the Unit ................................................13

6.3 Planning of the Ductwork ..........................................................14

6.4 Calculating the Duct Size......................................................14-15

6.4.1 Example of Calculation ....................................................14

6.4.2 Example of a Design for a Fully Ducted System ............15

6.5 Installing the Ductwork and Registers ..................................15-17

6.5.1 Fully Ducted System........................................................15

6.5.2 Exhaust Ducted System (Source Point Ventilation) ........16

6.5.3 Simplified Installation (Volume Ventilation) ......................17

6.6 Connecting Duct to the Unit ......................................................18

6.7 Installing the Exterior Hoods ......................................................19

6.8 Connecting the Drain ................................................................19

7.0 CONTROL DEVICES ..........................................................................20

7.1 Main Controls ............................................................................20

7.2 Optional Control ........................................................................20

7.3 Other Features ..........................................................................21

7.4 Main and Optional Controls Available for your Unit ..................21

7.5 Special Cold Weather TBI Mode for ERVs................................21

Page 3

3

Table of Contents (cont’d)

About this Manual

8.0 INSTALLATION OF THE CONTROLS ..................................................22

8.1 Dimensions and Specifications ................................................22

8.2 Installation of the Main Control ..........................................22-23

8.3 Electrical Connection to Optional Controls ..............................24

8.4 Electrical Connection to the Furnace ......................................24

9.0 WIRING DIAGRAM ............................................................................25

10.0 AIR FLOW BALANCING................................................................26-27

11.0 OVERALL VERIFICATION ..................................................................28

11.1 Main Controls ..........................................................................28

11.2 Optional Control ......................................................................28

12.0 MAINTENANCE / INSTRUCTIONS FOR USER....................................29

13.0 TROUBLESHOOTING ....................................................................30-31

14.0 WARRANTY ......................................................................................32

15.0 REFERENCES....................................................................................32

This manual uses the following symbols to emphasize particular information:

NOTE: Indicates supplementary information needed to fully complete an instruction.

CAUTION

Denotes an instruction which, if not followed, may severely damage the unit and/or its

components.

WARNING

010

!

Identifies an instruction which, if not followed, might cause serious personal injuries including

possibility of death.

Page 4

4

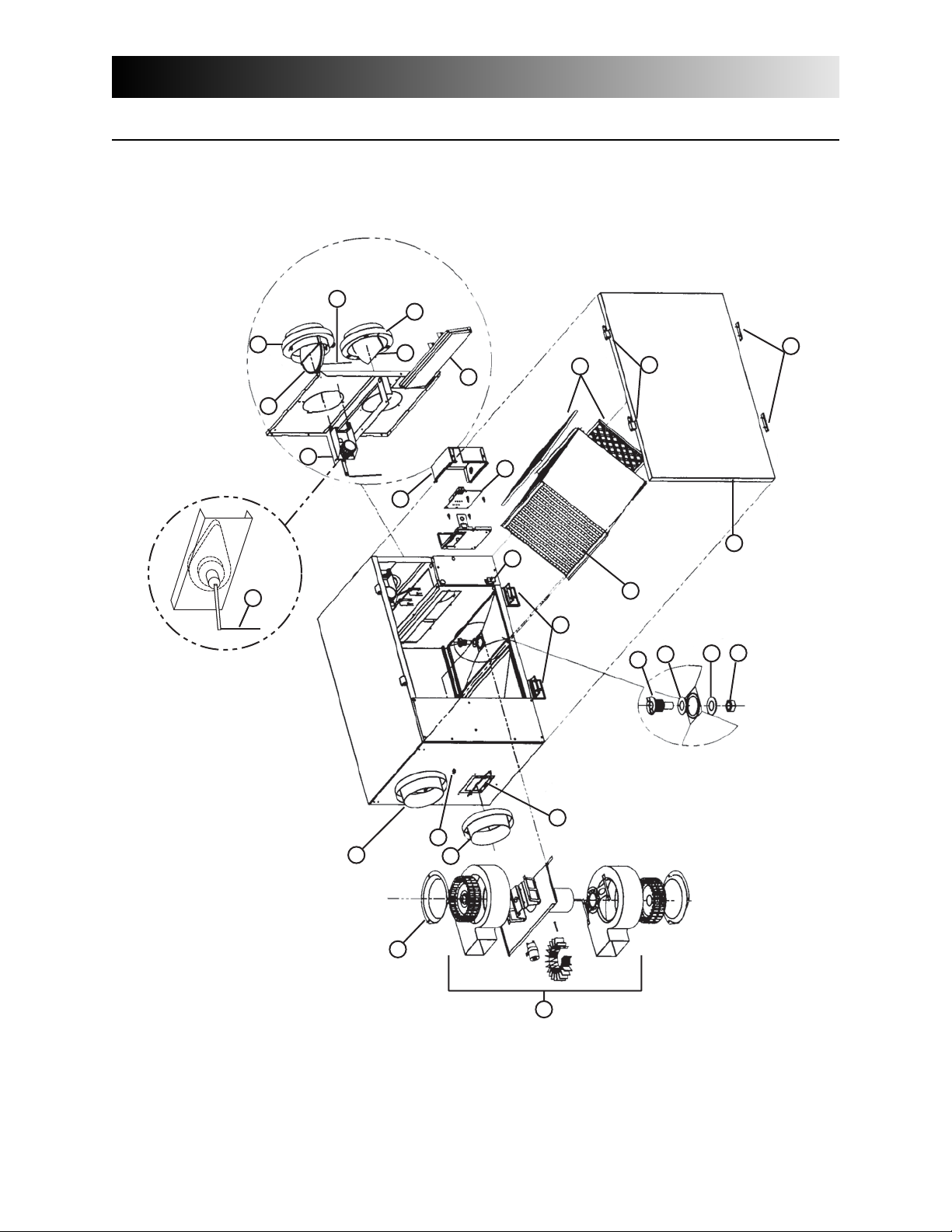

1.1 3-D DRAWING

1.0 Service

DAMPER ASSEMBLY (REAR VIEW)

21

22

23

24

21

25

20

3

15

13

16

14

11

10

9

12

19

17

6

18

8

7

2

1

4

3

5

VL0018

Page 5

5

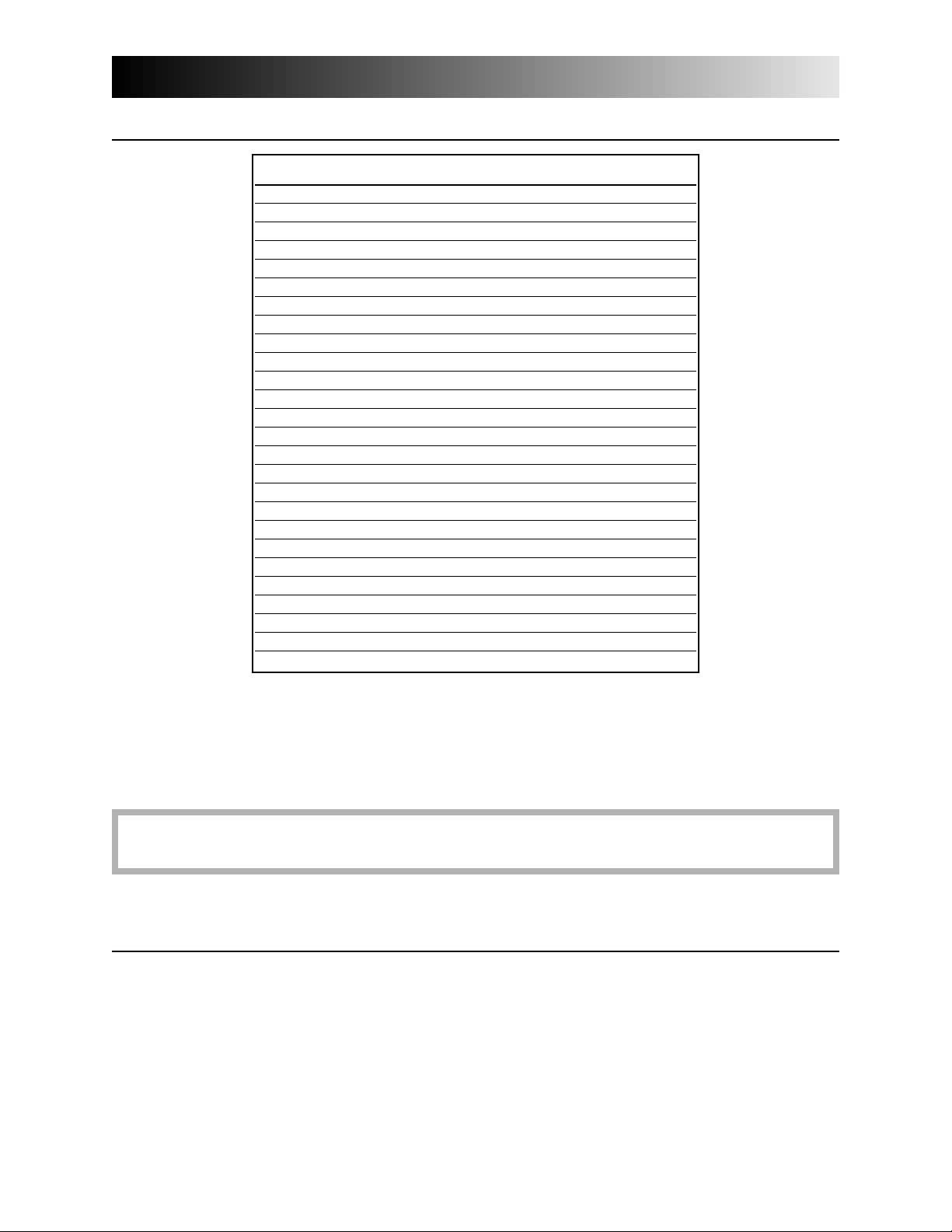

tel: 1-866-2MAYTAG

No Description

150 150 210 210

HRV ERV HRV ERV

1 Double collar port #2 00866 00866 00866 00866

2 Wing nut #10-32 00874 00874 00874 00874

3 Balancing double collar port 02256 02256 02256 02256

4 Inlet ring 12913 12913 12913 12913

5 Motor assembly 13504 13555 13556 13506

6 Electronic board V99 13507 13507 13507 13507

7 Square balancing damper 12645 12645 12645 12645

8 Door latches (latch) 00886 00886 00886 00886

9 Drain connector 02418 02418 02418 02418

10 Drain gasket 0.625”DI 02419 02419 02419 02419

11 Washer 5/8” ID x 1” OD 03117 03117 03117 03117

12 Nut 5/8-18 02420 02420 02420 02420

13 Recovery core 03132 03136 03133 03137

14 Door assembly 15770 15770 15770 15770

15 Door latches (keeper) 00887 00887 00887 00887

16 Hinge assembly 00672 00672 00672 00672

17 Filter 03096 03096 03097 03097

18 Switch E69 10A 01825 01825 01825 01825

19 Damper assembly #2 12643 12643 12649 12649

20 Plastic balancing damper 02253 02253 02253 02253

21 Damper rod 12620 12620 12620 12620

22 Double collar port #5 02021 02021 02021 02021

23 Damper #1 12459 12459 12459 12459

24 Damper actuator assembly 03124 03124 03124 03124

25 Electronic box cover 13046 13046 13046 13046

26* Thermistor kit 12895 12895 12895 12895

1.2 PARTS ORDERING CHART

1.0 Service (cont’d)

1.3 Technical Support (for assistance)

For assistance, call on week days, 8:00 AM to 4:30 PM (Cental Standard Time).

Technical Support Department

Please take note that parts not listed are not available; those parts require assembly knowledge that only

manufacturer can guarantee.

TO ORDER PARTS: Contact your local distributor

* Item 26 not shown.

Page 6

6

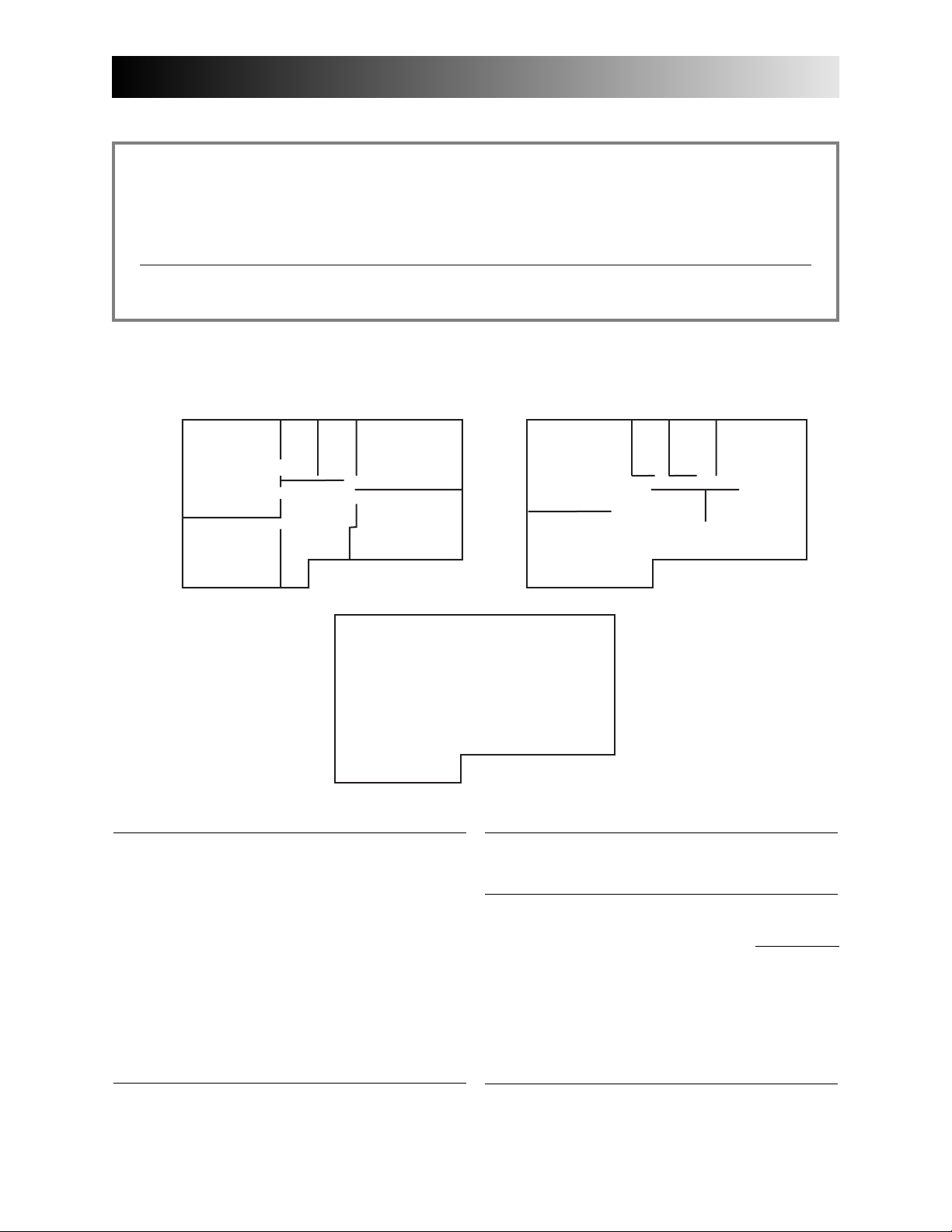

2.0 Sizing

These are the two most common methods used to evaluate the ventilation needs of a house:

CSA F326 and Canadian Building Code:

• High speed: 10 cfm per room

20 cfm for the master bedroom and the basement

• Low speed: 40-60% of high speed

ASHRAE Standard 62-2001:

• 0.35 air change per hour

Refer to ventilation code of your area to determine which method to use.

Example:

1320 ft

2

1320 ft

2

CSA F326

Kitchen (10 cfm)

Dining room (10

cfm)

Living room (10

cfm)

Family room (10

cfm)

Master bedroom (20

cfm)

Bedroom #1 (10

cfm)

Bedroom #2 (10

cfm)

Bedroom #3 (10

cfm)

Bathroom #1 (10

cfm)

Bathroom #2 (10

cfm)

Bathroom #3 (10

cfm)

Laundry room (10

cfm)

Basement (20 cfm)

Total 150

cfm

(high speed)

ASHRAE Standard 62-2001

Volume of basement 10560 ft

3

Volume of main floor 10560 ft

3

Volume of second floor 10560 ft

3

Total volume 31680 ft

3

x .35/h

11090 ft

3

/h

÷ 60 (min/h)

Total 185 cfm

(high speed)

1320 ft

2

Second floor

Main floor

Basement

Master

Bedroom

Bedroom #1

Bathroom

#1

Bedroom

#2

Bathroom

#2

Bedroom

#3

Basement

VH0021A

Laundry

room

Bathroom

Living room

Family room

#3

Kitchen

Dining room

Page 7

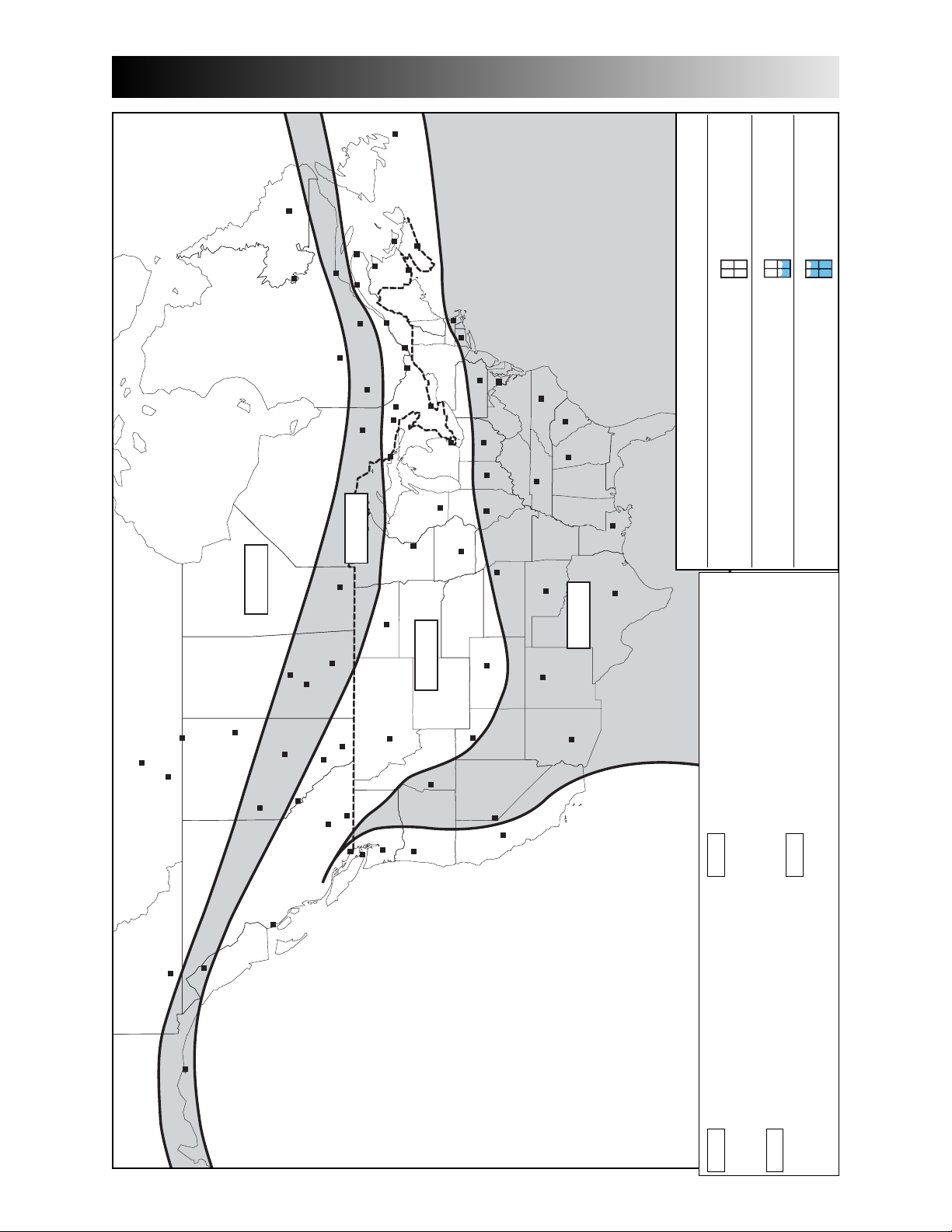

7

3.0

Unit Type and Defrost Setting vs Geographical Location

ZONE A

(HRVs only)

•

Set Extended Defrost according to section 8.2, point 10.

•

MODELS: HRV-150, HRV-210

ZONE B

(HRVs only)

•

Extended Defrost setting not required (factory defrost

strategy pre-set).

•

MODELS: HRV-150, HRV-210

ZONE C (HRV or ERV according to your client’s particular

problems)

see ZONE C SELECTION CHART beside

•

HRV MODELS: HRV-150, HRV-210.•ERV MODELS: ERV-150, ERV-210.

ZONE D ERVs recommended)

• ERV MODELS: ERV-150, ERV-210.

• ERVs: Set Defrost mode #1 according to section 6.1.

SYMPTOM SOLUTION

(condensation)

Indoor air quality problem ERV

and / or

Excess moisture problem ERV

and / or

Important excess moisture problem HRV

ZONE C SELECTION CHART

ST JOHN'S

GOOSE BAY

CHARLOTTETOWN

BATHURST

QUEBEC

HALIFAX

ST-JOHN

BOSTON

SEPT-ILES

LABRADOR CITY

GASPÉ

MATANE

YELLOWKNIFE

HAY RIVER

CHICOUTIMI

VAL-DOR

CHIBOUGAMAU

TIMMINS

ZONE B

WINNIPEG

MONTRÉAL

OTTAWA

NORTH BAY

TORONTO

SUDBURY

SAULT STE MARIE

ST. PAUL

DETROIT

MADISON

DES MOINES

HARTFORD

HARRISBURG

COLUMBUS

INDIANAPOLIS

SPRINGFIELD

RALEIGH

WASHINGTON

NASHVILLE

TOPEKA

COLUMBIA

ATLANTA

OKLAHOMA CITY

BATON ROUGE

AUSTIN

ZONE A

BISMARCK

ZONE D

REGINA

PRINCE ALBERT

SASKATOON

FORT SMITH

FORT MCMURRAY

GRANDE PRAIRIE

EDMONTON

JASPER

KAMLOOPS

CALGARY

LETHBRIDGE

PENTICTON

ZONE C

HELENA

BOISE

DENVER

SALT LAKE CITY

RENO

SANTA FE

PHOENIX

WHITEHORSE

ANCHORAGE

JUNEAU

Prince Rupert

VICTORIA

OLYMPIA

SALEM

SACRAMENTO

VN0002

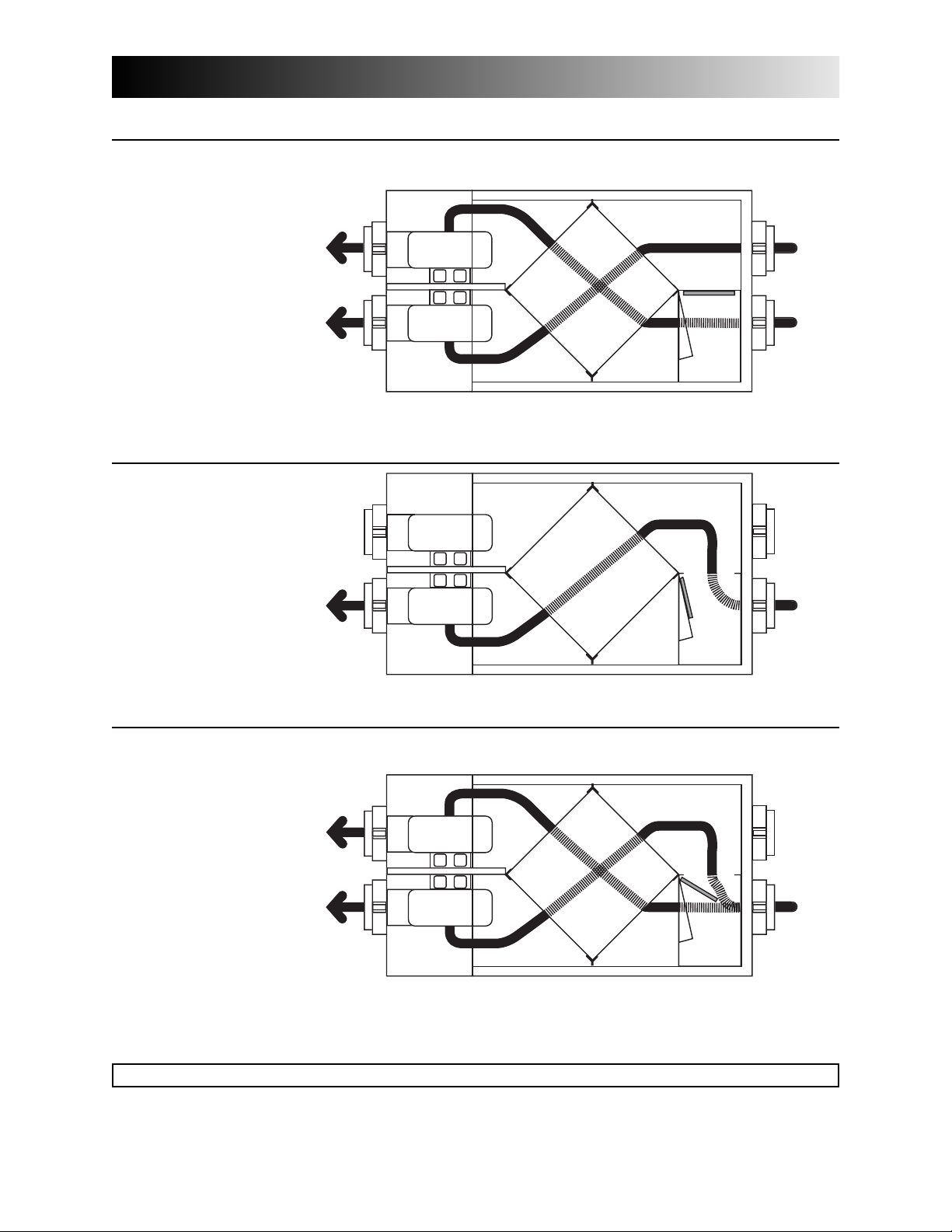

Page 8

8

Applicable to all model numbers.

Defrost Mode 1

Applicable to model numbers:

• HRV-150

• HRV-210

Defrost Mode 2

Applicable to model numbers:

• ERV-150

• ERV-210

4.1 AIR DISTRIBUTION (NORMAL OPERATION)

4.2 A

IR DISTRIBUTION (DEFROST MODE)

4.0 Technical Data

FRESH AIR

FROM

OUTSIDE

STALE AIR

FROM

BUILDING

STALE AIR

TO OUTSIDE

FRESH AIR

TO BUILDING

STALE AIR

FROM

BUILDING

STALE AIR

TO OUTSIDE

FRESH AIR TO

BUILDING

STALE AIR

FROM

BUILDING

FRESH AIR

TO BUILDING

For defrost cycles tables, refer to Section 9.0, Wiring Diagram.

VF0013

VF0020

VF0012

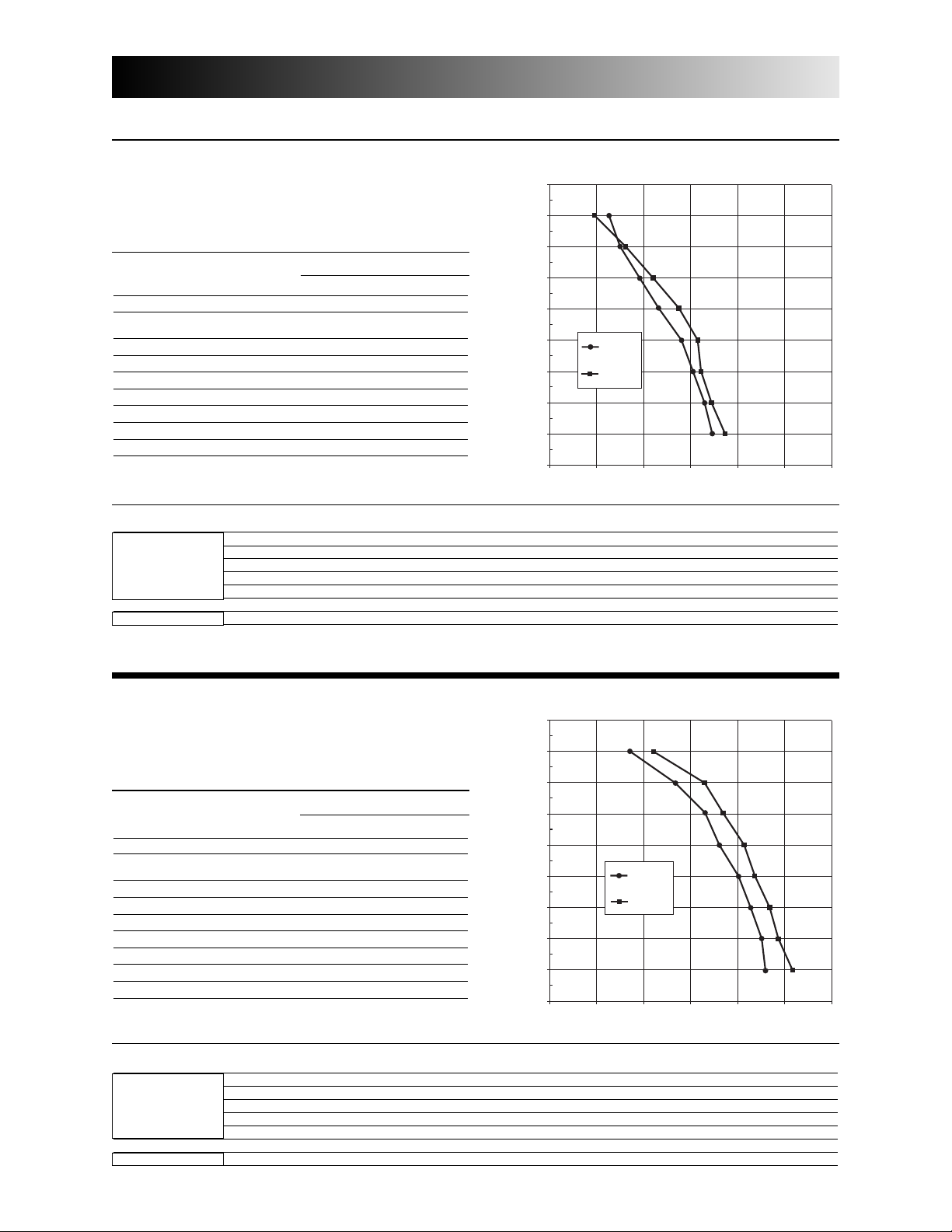

Page 9

9

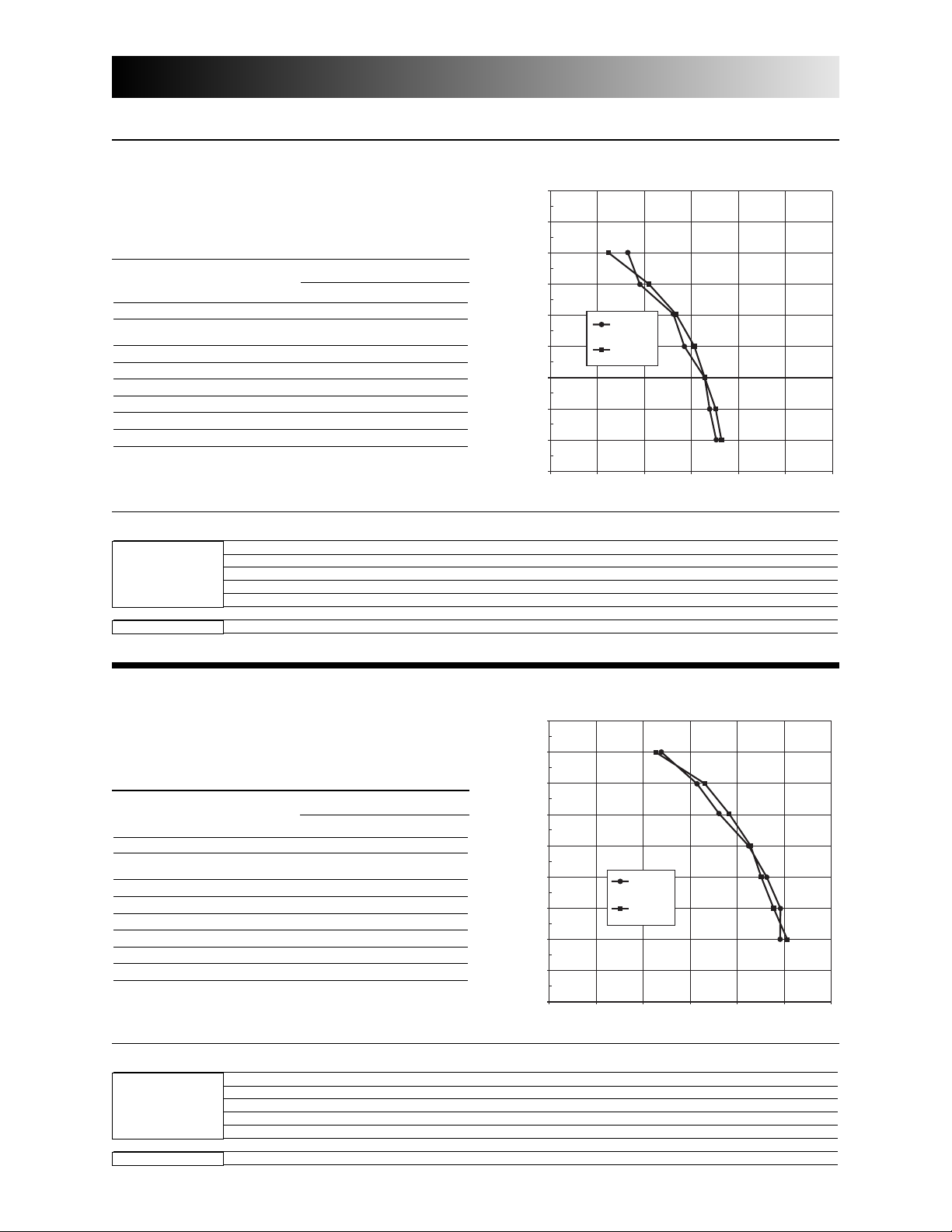

MODEL NUMBER: ERV-150

Electrical requirements: 120 volts, 1.3 Amps

Exhaust Air Transfer Ratio: 0.06

4.3 PERFORMANCE CHARTS

4.0 Technical Data (cont’d)

VENTILATION PERFORMANCE

External Static Net Supply Gross Air Flow

Pressure Air Flow Supply Exhaust

Pa in. w.g. l/s cfm l/s cfm l/s cfm

25 0.1 81 173 87 184 93 197

50 0.2 78 165 83 175 86 182

75 0.3 72 152 76 162 80 169

100 0.4 67 142 71 151 77 163

125 0.5 55 117 59 124 67 143

150 0.6 46 98 49 104 56 118

175 0.7 36 77 39 82 41 87

200 0.8 30 63 32 67 24 51

Note: Unit operating at maximum speed.

ENERGY PERFORMANCE

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F l/s cfm Watts % %

0 32 29 60 56 71 79 0.53

0 32 47 100 80 64 73 0.41

0 32 65 137 126 60 68 0.36

-15 5 31 65 64 56 81 0.41

Total Recovery Efficiency

35 95 28 59 52 45

HEATING

COOLING

ENERGY PERFORMANCE

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F l/s cfm Watts % %

0 32 52 110 93 69 76 0.45

0 32 74 157 130 64 71 0.38

0 32 96 203 193 60 68 0.30

-15 5 52 110 122 55 76 0.26

Total Recovery Efficiency

35 95 50 106 89 41

HEATING

COOLING

MODEL NUMBER: ERV-210

Electrical requirements: 120 volts, 1.9 Amps

Exhaust Air Transfer Ratio: 0.06

VENTILATION PERFORMANCE

External Static Net Supply Gross Air Flow

Pressure Air Flow Supply Exhaust

Pa in. w.g. l/s cfm l/s cfm l/s cfm

25 0.1 109 231 116 245 128 271

50 0.2 107 228 114 241 123 260

75 0.3 101 214 107 227 118 249

100 0.4 95 201 101 213 110 233

125 0.5 86 182 91 193 103 217

150 0.6 79 167 83 177 92 195

175 0.7 62 132 66 140 81 172

200 0.8 40 85 43 90 55 116

Note: Unit operating at maximum speed.

External Static Pressure - Pascals

(250 Pascals = 1” of water)

Gross Airflow - l/s (0.47 l/s = 1 cfm)

External Static Pressure - Pascals

(250 Pascals = 1” of water)

Gross Airflow - l/s (0.47 l/s = 1 cfm)

225

175

200

150

125

100

75

50

25

0

05025 100 12575

150

VG0042

Supply

(l/s)

Exhaust

(l/s)

Supply

(l/s)

Exhaust

(l/s)

225

200

175

150

125

100

75

50

25

VG0041

0

05025 100 12575

150

Page 10

ENERGY PERFORMANCE

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F l/s cfm Watts % %

0 32 51 109 92 70 77 -0.01

0 32 73 155 128 65 72 -0.02

0 32 102 215 191 62 70 -0.01

-25 -13 52 110 104 60 94 0.05

Total Recovery Efficiency

35 95 Not tested

ENERGY PERFORMANCE

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F l/s cfm Watts % %

0 32 30 64 54 75 83 -0.03

0 32 46 97 78 67 74 0.01

0 32 65 138 124 64 72 -0.02

-25 -13 26 55 62 67 89 0.05

Total Recovery Efficiency

35 95 Not tested

10

MODEL NUMBER: HRV-150

Electrical requirements: 120 volts, 1.3 Amps

Exhaust Air Transfer Ratio: 0.05

4.3 PERFORMANCE CHARTS (CONT’D)

4.0 Technical Data (cont’d)

VENTILATION PERFORMANCE

External Static Net Supply Gross Air Flow

Pressure Air Flow Supply Exhaust

Pa in. w.g. l/s cfm l/s cfm l/s cfm

25 0.1 84 177 88 186 90 190

50 0.2 80 169 84 178 86 182

75 0.3 77 163 81 171 81 171

100 0.4 69 146 72 153 76 161

125 0.5 61 130 65 137 66 139

150 0.6 46 98 49 103 52 110

175 0.7 38 81 40 85 31 67

Note: Unit operating at maximum speed.

MODEL NUMBER: HRV-210

Electrical requirements: 120 volts, 1.9 Amps

Exhaust Air Transfer Ratio: 0.042

VENTILATION PERFORMANCE

External Static Net Supply Gross Air Flow

Pressure Air Flow Supply Exhaust

Pa in. w.g. l/s cfm l/s cfm l/s cfm

50 0.2 120 253 124 264 126 268

75 0.3 118 250 123 262 119 251

100 0.4 111 235 116 245 114 241

125 0.5 102 216 106 224 107 226

150 0.6 87 185 91 193 96 204

175 0.7 75 160 78 167 81 172

200 0.8 57 120 59 124 57 121

Note: Unit operating at maximum speed.

External Static Pressure - Pascals

(250 Pascals = 1” of water)

Gross Airflow - l/s (0.47 l/s = 1 cfm)

225

175

200

150

125

100

75

50

25

0

05025 100 12575

150

VG0039

External Static Pressure - Pascals

(250 Pascals = 1” of water)

Gross Airflow - l/s (0.47 L/s = 1 cfm)

225

175

200

150

125

100

75

50

25

0

05025 100 12575

150

VG0040

HEATING

COOLING

HEATING

COOLING

Supply

(l/s)

Exhaust

(l/s)

Supply

(l/s)

Exhaust

(l/s)

Page 11

11

Model numbers:

• ERV-150

• HRV-150

Model numbers:

• ERV-210

• HRV-210

)

20" (508mm)

)

)

)

0

4.4 DIMENSIONS

4.0 Technical Data (cont’d)

)

20" (508mm)

0

)

)

)

0039

Main controls:

• Basic Wall Control

• Electronic Wall Control

Optional control:

• 20/40/60-minute push button

Link option:

• Furnace interlock (use with

forced air systems)

4.5 CONTROLS AND FURNACE LINK OPTION

4.6 SPECIFICATIONS

Model numbers

Weight

Port Diameter

Drain Diameter

ERV-150, HRV-150

65 lb (30 kg)

6” (152 mm)

1/2” (12 mm)

ERV-210, HRV-210

73 lb (33 kg)

6” (152 mm)

1/2” (12 mm)

Installation Chains, springs and hooks (provided with the unit).

Motor Speed High and low speeds factory set (optional increased low speed - BLUE wire).

Electrical supply 120 V, 60 Hz 120 V, 60 Hz

Power Consumption 150 Watts 225 Watts

VK004

VK

6" (152mm

6" (152mm

30-1/4" (768mm

30-1/4" (768mm

13-3/4" (349mm

50"

2.5" (63mm

19" (483mm

8m5

2.5" (63mm

Page 12

12

5.0 Typical Installation

(Primarily for homes with radiant hot water or

electric baseboard heating. See figure 1.)

Moist, stale air is exhausted from the high

humidity areas in the home, such as bathrooms,

kitchen and laundry room. Fresh air is supplied

to bedrooms and principal living areas.

The use of bathroom fans and a range hood is

suggested to better exhaust stale air.

Homes with more than one level require at least

one exhaust register at the highest level.

5.1 FULLY DUCTED SYSTEM

There are three (3) common installation methods.

4

figure 1

See 6.5.1

for details

5.2 EXHAUST DUCTED SYSTEM

(SOURCE POINT VENTILATION)

(For homes with forced air heating. See figure 2.)

Moist, stale air is exhausted from the high

humidity areas in the home, such as bathrooms,

kitchen and laundry room. Fresh air is supplied

to the cold air return or the supply duct of the

furnace.

The use of bathroom fans and a range hood is

suggested to better exhaust stale air.

Homes with more than one level require at least

one exhaust register at the highest level.

NOTE: For this type of installation, it is not

essential that the furnace blower runs

when the unit is in operation, but we

recommend it.

5

See 6.5.2

for details

figure 2

5.3 SIMPLIFIED

(VOLUME VENTILATION)

(For homes with forced air heating. See figure 3 or 4.)

Fresh air and exhaust air flow through the furnace ducts wich simplifies the installation.

The use of bathroom fans and a range hood is suggested to better exhaust stale air.

NOTE: For the installation type shown in figure 4, furnace blower should be running when the unit is

in operation.

7

figure 3

See 6.5.3

6

figure 4

See 6.5.3

OR

VH002

VH002

VH002

VH002

Page 13

13

6.0 Installation

6.1 ADJUSTING THE DAMPER ROD (FOR ERVS INSTALLED IN WARM REGIONS)

Refer to Section 4.2 and observe the difference in the damper

position at the right in diagrams Defrost Mode 1 and Defrost Mode 2:

for Defrost Mode 1 the damper is completely closed, whereas

for Defrost Mode 2 the damper is half closed. At the factory, all ERVs

are assembled for defrost Mode 2. Therefore, if your installation

is for an ERV in a warm region (zone D as defined in Section 3),

the rod must be moved to position 1 (see figure 5).

NOTE: Before attempting to change the position of the damper

rod, place the unit on a table for easy access and remove

the recovery core.

6.2 LOCATING AND MOUNTING THE UNIT

Choose an appropriate location for the unit:

• Within an area of the house where the temperature is above 10°C /

50°F (basement, attic, furnace room, laundry room, etc.).

• Away from living areas (dining room, living room, bedroom), if possible.

• So as to provide easy access to the interior cabinet and to

the control panel on the right hand side of the unit.

• Close to an exterior wall, so as to limit the length of the insulated

flexible duct to and from the unit.

• Close to a drain. If no drain is close by, use a pail to collect

run-off.

• Away from hot chimneys, electrical panel and other fire hazards.

• Allow for a power source (110 V standard outlet).

Hang the unit to ceiling joists with the 4 chains and

springs provided (see figures 6 and 7).

figure 6

figure 7

CAUTION

Make sure the unit is level.

CAUTION

This is a delicate operation: to avoid injury proceed carefully and use the appropriate tools.

O0015

O00 5

1

2

figure 5

INSPECT THE CONTENTS OF THE BOX

• Inspect the exterior of the unit for shipping damage. Ensure that there is no damage to the door, door

latches, door hinges, dampers, duct collars, cabinet, etc.

• Inspect the interior of the unit for damage. Ensure that the fan motor assembly, recovery core, insulation,

dampers, damper actuator and drain pan are all intact.

• If the unit was damaged during shipping, contact your local distributor. (Claim must be made within

24 hours after delivery.)

• Use checklist included with the unit to ensure that no parts are missing.

V

VD0064

VD0038

Page 14

14

6.0 Installation (cont’d)

a) Follow the instructions in Section 6.4 below to determine the appropriate duct diameters for your system.

b) Keep it simple. Plan for a minimum number of bends and joints. Keep the length of insulated duct to

a minimum.

c) Do not use wall cavities as ducts. Do not use branch lines smaller than 4” (102 mm) Ø.

d) Do not ventilate crawl spaces or cold rooms. Do not attempt to recover the exhaust air from a dryer or

a range hood. This would cause clogging of the recovery module. Use sheet metal for the kitchen

exhaust duct.

e) Be sure to plan for at least one exhaust register on the highest lived-in level of the house if it has

2 floors or more.

Use the table below to ensure that the ducts you intend to install will be carrying air flows at or

under the recommended values. Avoid installing ducts that will have to carry air flows near the

maximum values and never install a duct if its air flow exceeds the maximum value.

NOTE: Examples 6.4.1 and 6.4.2 use imperial measures.

The same calculation applies to metric measures.

6.4.1 Example of calculation:

Problem: My installation requires two exhaust registers (one for the kitchen, one for the bathroom).

I will connect these registers to a main duct which will connect to the unit (high speed performance

value of 140 cfm). What size of duct should I use for the main exhaust duct and for the two end

branches leading to the registers? (See figure 8.)

Solution: Simplified method.

(For a more detailed method of calculating duct size refer to the

ASHRAE or HRAI HANDBOOK).

Main duct:

Table above indicates a 6” Ø duct: recommended air flow: 120 cfm; maximum air flow:

180 cfm. The high speed air flow of 140 cfm is close enough to the recommended value (120) and

far enough away from the maximum value (180). Therefore a 6ӯ duct or larger is an appropriate

choice for the main exhaust duct.

End branches: Each end branch will have to transport an air flow of 70 cfm (140 divided by 2). Table

above indicates a 5ӯ duct: recommended air flow: 75 cfm; maximum air flow: 110 cfm. The high

speed air flow of 70 cfm is close enough to the recommended value (75) and far enough away

from the maximum value (110). Therefore a 5ӯ duct or larger is an appropriate choice for the

2 end branches

.

NOTE: A 4ӯ duct would have been too small because the maximum acceptable value for a 4ӯ

duct is 60 cfm.

6.3 PLANNING OF THE DUCTWORK

6.4 CALCULATING THE DUCT SIZE

end

branches

main branch

6”ø 140 cfm

5”ø

70 cfm

4”(102 mm) 40 cfm 19 l/s 68 m3/h 60 cfm 28 l/s 102 m3/h

5”(127 mm) 75 cfm 35 l/s 127 m3/h 110 cfm 52 l/s 187 m3/h

6”(152 mm) 120 cfm 57 l/s 204 m3/h 180 cfm 85 l/s 306 m3/h

7”(178 mm) 185 cfm 87 l/s 314 m3/h 270 cfm 127 l/s 459 m3/h

8”(203 mm) 260 cfm 123 l/s 442 m3/h 380 cfm 179 l/s 645 m3/h

Duct Recommended Maximum

Diameter Air Flow Air Flow

figure 8

140 cfm

VI0003

Page 15

15

6.0 Installation (cont’d)

6.4.2 Example of a design for a fully ducted system for a unit having a high

speed performance of 222 cfm

(See figure 9).

4” Ø

42 cfm

6” Ø

129 cfm

5” Ø

65 cfm

5” Ø

64 cfm

6” Ø

93 cfm

5”

6”

7”

7”

6”

6”

6”

4”

4”

4”

4”

7” Ø 222 cfm

7” Ø 222 cfm

4” Ø 42 cfm

6” Ø 84 cfm

6” Ø 96 cfm

6” Ø 138 cfm

6.5.1 Fully Ducted System (as illustrated in Section 5.1)

Stale air exhaust ductwork:

• Install registers in areas where contaminants are produced: kitchen, bathrooms,

laundry room, etc.

• Install registers 6 to 12 inches (152 to 305 mm) from the ceiling on an interior wall OR

install them in the ceiling.

• Install the kitchen register at least 4 feet (1.2 m) from the range top.

• If possible, measure the velocity of the air flowing through the registers. If the velocity is higher than 400 ft/min. (122 m/min), then the register type is too small. Replace with a larger one.

Fresh air distribution ductwork:

• Install registers in bedrooms, dining room, living room and basement.

• Install registers either in the ceiling or high on the walls with air flow directed towards the

ceiling. (The cooler air will then cross the upper part of the room, and mix with room air

before descending to occupant level.)

• If a register must be floor installed, direct the air flow up the wall.

6.5 INSTALLING THE DUCTWORK AND REGISTERS

figure 9

6.4 CALCULATING THE DUCT SIZE (CONT’D)

WARNING

010

!

Never install a stale air exhaust register in a room where a combustion device is, such as a gas

furnace, a gas water heater or a fireplace.

VI0004

Page 16

6.5.2 Exhaust Ducted System (Source Point Ventilation) (as illustrated in Section 5.2)

Stale air exhaust ductwork: (same as for Fully Ducted System, described on page 15)

Fresh air distribution:

There are two methods for connecting the unit to the furnace:

Method 1: supply side connection

• Cut an opening into the furnace supply duct at least

18 inches (0.5 m) from the furnace.

• Connect this opening to the fresh air distribution port

of the HRV/ERV (use steel duct, see figure 10).

• Make sure that the HRV/ERV duct forms an elbow

inside the furnace ductwork.

• If desired, interlock (synchronize) the furnace blower

operation with the HRV/ERV operation.

(See Section 8.4).

Method 2: return side connection

• Cut an opening into the furnace return duct not less than

10 feet (3.1 m) from the furnace (A+B).

• Connect this opening to the fresh air distribution port of

the HRV/ERV (see figure 11).

NOTE: For Method 2, it is not essential that the furnace

blower runs when the HRV/ERV is in operation,

but we recommend it. If desired, synchronize the

furnace blower operation (see Section 8.4).

16

6.0 Installation (cont’d)

6.5 Installing the Ductwork and Registers (cont’d)

minimum

18” (0.5 m)

Steel duct with

backdraft damper

A+B= not less

than 10’ (3.1 m)

figure 10

figure 11

WARNING

010

!

When performing duct connection to the furnace, installation must be done in accordance with all

applicable codes and standards. Please refer to your local building code.

CAUTION

When performing connection to the furnace supply duct, this duct must be sized to support the

additional airflow produced by the HRV/ERV. Also, use a steel duct with a backdraft damper to prevent the risk of overheating the HRV/ERV.

VD0040

VD0041

A

B

Page 17

6.5.3 Simplified installation (Volume Ventilation) (as illustrated in Section 5.3)

There are two methods (figures 12 and 13) for connecting the unit to the furnace:

Method 1: return-supply Method 2: return-return

Stale air intake:

• Cut an opening into the furnace return duct (not less than 10 feet (3.1 m) from the

furnace (A+B)).

• Connect this opening to the stale air intake port on the HRV/ERV as shown .

Fresh air distribution: (same instructions as for Method 1 or Method 2, Section 6.5.2).

For method 2 (return-return) make sure there is a distance of at least 3 feet (0.9 m) between

the 2 connections to the furnace.

NOTE: For Method 1, it is not essential to synchronize the furnace blower operation

with the HRV/ERV operation, but we recommend it.

17

minimum 3’

(0.9 m)

figure 12

figure 13

CAUTION

If using Method 2, make sure the furnace blower operation is synchronized with the HRV/ERV

operation! See Section 8.4.

6.0 Installation (cont’d)

6.5 Installing the Ductwork and Registers (cont’d)

CAUTION

When performing connection to the furnace ducts (Method 1), these ducts must be sized to

support the additional airflow produced by the HRV/ERV. Also, the supply duct must be a steel

duct with a backdraft damper to prevent the risk of overheating HRV/ERV.

Steel duct with

backdraft damper

minimum

18” (0.5 m)

A+B= not less

than 10’ (3.1 m)

A+B= not less

than 10’ (3.1 m)

WARNING

010

!

When performing duct connection to the furnace, installation must be done in accordance with all

applicable codes and standards. Please refer to your local building code.

A

B

VD0042

A

B

VD0043

Page 18

18

6.0 Installation

(cont’d)

Insulated flexible duct

Use the following procedure for connecting the insulated flexible duct to the ports on the unit (exhaust to

outside and fresh air from outside).

a) Pull back the insulation to expose the flexible duct.

b) Connect the interior flexible duct to the port using a duct tie.

c) Carefully seal the connection with duct tape.

d) Pull the insulation over the joint and tuck it between the inner and outer rings of the double collar.

e) Pull the vapor barrier over the insulation and over the outer ring of the double collar.

f) Apply duct tape to the joint making an airtight seal

. Avoid compressing the insulation when you pull the

tape tightly around the joint. Compressed insulation loses its R value and causes water dripping due

to condensation on the exterior surface of the duct.

a) b) c) d), e) f)

Rigid duct:

Use duct tape to connect the rigid ducts to the ports.

Make sure that the 2 balancing dampers are left in a fully open position before

connecting the ducts to

these ports (fresh air distribution port and stale air exhaust port as shown on figure 14).

VJ0001

VJ0002

VJ0003

VJ0004

VJ0005

6.6 CONNECTING DUCTS TO THE UNIT

CAUTION

Make sure that the vapor barrier on the insulated ducts does not tear during installation to avoid

condensation within the duct.

CAUTION

Do not use screws to connect rigid ducts to the ports.

figure 14

VJ0009

Page 19

19

6.7 INSTALLING THE EXTERIOR HOODS

6.0 Installation (cont’d)

Choose an appropriate location for

installing the exterior hoods:

• a minimum distance of 6 feet (1.8 m)

between the hoods to avoid

cross-contamination

• a minimum distance of 18 inches (457 mm)

from the ground

Make sure the intake hood

is at least 6 feet

(1.8 m) away from any of the following:

• dryer exhaust, high efficiency furnace

vent, central vacuum vent

• gas meter exhaust, gas barbecue-grill

• any exhaust from a combustion source

• garbage bin and any other source of

contamination

Refer to figure 15 for connecting the insulated duct to the hoods. Place the “FRESH

AIR INTAKE” sticker, provided in the installation kit, on corresponding hood. An “AntiGust Intake Hood” should be installed in

regions where a lot of snow is expected to

fall.

CAUTION

All models require an exhaust hood with a backdraft damper. This damper closes when the unit is

off and prevents unwanted cold air from entering the house.

Exhaust

hood

Optional duct

location

Tape and duct tie

Caulking

Intake

hood

6ӯ

(152 mm)

18”

(457 mm)

18”

(457 mm)

6’

(1.8 m)

6’

(1.8 m)

18”

(457 mm)

figure 15

6.8 CONNECTING THE DRAIN

)

Attach the 2 plastic drain fittings

to the unit using the gaskets,

washers and nuts as shown.

Cut 2 sections of plastic tubing,

about 12” (305 mm) long and

attach them to each drain fitting.

1

2

Join the 2 short sections to the “T”

junction and main tube as

shown.

3

To drain

Tie-wrap

4

Make a water trap loop in the tube to prevent the unit from drawing

unpleasant odors from the drain source. Make sure this loop is

situated BELOW the “T” as shown. This will prevent water from

being drawn back up into the unit in case of negative pressure. Run

the tube to the floor drain or to an alternative drain pipe or pail. Be

sure there is a slight slope for the run-off.

VD0028

12"(305 mm

VO0003

VO0004

VO0005

VO0011

Page 20

20

Basic model

7.1 Main Controls

7.0

Control Devices

CO

O

AIR SUPPL

Y CONTRO

OFF

EXCHANGE

0

C

C

O

F

Electronic model

C

5

C

CO

O

AIR SUPPL

Y CONTRO

CO

OL

D

SS

CONTINUOUS

20 MI

N

.

ON

40 MIN.

M

OFF

C

O

M

MODELS Basic Electronic

OFF Position

XX

Intermittent exchange (TBI) 20 ON - 40 OFF

X

Low speed continuous exchange

XX

High speed continuous exchange

XX

Condensation control (Temperature scale)

XX

Mode indicator

XX

Air exchange indicator

X

Condensation/Pollutant control max speed indicator

X

Maintenance indicator with flashing intermittent

X

Sliding button

X

Push button

X

Switches

Modes

CAUTION

All models require a main control.

Detector

types

Indicators

20/40/60-MINUTE PUSH-BUTTON TIMER:

This remote illuminated switch is typically installed in bathrooms, kitchen and laundry room to provide

20, 40 or 60 minutes of high speed ventilation at the push of a button. The switch is supplied and mounted

on a white single gang wall plate.

7.2 OPTIONAL CONTROL

NDENSI0N CONTR

VC0027

S

U

M

M

E

R

-2

-

NDENSI0N CONTR

-

NDENSAION CONTR

MAXIMUM SPEE

VC0028

S

U

M

M

-

AIR EXCHANGE IN PROGRE

E

R

Page 21

21

7.0

Control Devices (cont’d)

7.4 MAIN AND OPTIONAL CONTROLS AVAILABLE FOR YOUR UNIT

MAIN CONTROLS OPTIONAL CONTROL

Model number BASIC ELECTRONIC 20/40/60-min. push-button timer Furnace Interlock

ERV-150 X X X Integrated

HRV-150 X X X Integrated

ERV-210 X X X Integrated

HRV-210 X X X Integrated

7.5 SPECIAL COLD WEATHER TBI MODE FOR ERVS

The enthalpic core installed in ERVs requires extra protection when the outside temperature drops below

-15°C (5°F).

A special operating mode called TBI (Time-Based Intermittent) is activated under these conditions.

Characteristics of cold weather TBI mode

• activated when the outside temperature drops below -15°C (5°F).

• 20/40 cycle (20 minutes LOW speed followed by 40 minutes OFF).

• usual control of air supply via the main wall control is suspended (except for the OFF position).

• optional control (20/40/60-minute push button) retain its temporary high speed activation capability.

• deactivated when the outside temperature warms up higher than -15°C (5°F).

7.3 OTHER FEATURES

FURNACE INTERLOCK (for forced air heating system)

The furnace fan can be interlocked so that it will run simultaneously with the ERV or HRV to ensure proper

distribution of fresh air throughout the house (see table section 7.4, to see if it is available on your unit).

PERMANENT MEMORY

Our electronic controls have a default memory feature in the event of a power outage. Even the date of the

last service reminder is maintained as a convenience to the homeowner.

CONTROL UPGRADES

All controls can be used on any ERV, so a Basic control can be upgraded to the Electronic in the future

(see table in Section 7.4 below for control availability according to the units).

Page 22

22

8.0

Installation of the Controls

Voltage: 12 volts DC

Dimensions: 5” x 5” x 1 3/8”

(127 mm x 127 mm x 35 mm)

INSTRUCTIONS:

1- Determine the location of the control.

The wall control must be installed in a central location on the

main floor. Typical locations for these controls are kitchen, main hallways and family room.

2- Remove the button(s) and the cover plate of the control.

3- Install the wall control 60 inches (1.5 m) from the floor and

leave a free space of at least 2 inches (5 cm) to the right of

the control to allow user to slide out the control instructions.

Use the template provided in the control box to position the

wire hole and the screw holes. Use the screws and the plastic

anchors provided in the installation kit to secure the control.

(See figure 16.)

8.1 DIMENSIONS AND SPECIFICATIONS (MAIN CONTROLS)

8.2 INSTALLATION OF THE MAIN CONTROL

(

B

ASIC ANDELECTRONIC

)

FRONT VIEW

SIDE VIEW

ELECTRONIC

BASIC

CAUTION

Never install more than one main control per unit.

60" (1.5 m)

5

)

figure 16

VC0016

5" (127 mm)

5" (127 mm)

13/8"

(35 mm)

VC0026

2" (5 cm

" (1.

VD0025

Page 23

23

8.0

Installation of the Controls (cont’d)

4- Connect the wires to the main control.

(See figure 17.)

5- Make sure the instruction pull-out is in the

occupant’s language. If not, turn it to the other side.

(See figure 18.)

6- Reinstall the cover plate and the button(s).

7- Connect the wires to their corresponding position inside the

electrical compartment. Make sure the connections of the unit

and of the wall control correspond exactly. (See figure 19.)

8- Connect the optional control (if applicable) by referring to Section 8.3.

9- Do the appropriate connection to the furnace (if applicable) by referring to Section 8.4.

10- NOTE: If the unit is installed in a cold region (Zone A, as defined in Section 3.0), set up “extended

defrost” by removing jumper JU1F on the main circuit board inside the electrical compartment

(see Section 9.0).

11- Plug in the unit and do the “overall verification” of the system as described in Section 11.0.

Y

GB

VD0026

Y

8.2 INSTALLATION OF THE MAIN CONTROL (cont’d)

figure 17

figure 18

figure 19

VC0061

VE0072

Page 24

24

8.0

Installation of the Controls (con’d)

Standard furnace interlock wiring

8.3 ELECTRICAL CONNECTION TO OPTIONAL CONTROLS

0L

8.4 ELECTRICAL CONNECTION TO THE FURNACE

Alternate furnace interlock wiring

For a furnace connected to cooling system:

On some older thermostats, energizing the “R” and “G” terminals at the furnace has the effect of energizing

“Y” at the thermostat and thereby turning on the cooling system. If you identify this type of thermostat, you

must use the “alternate furnace interlock wiring”. An additional control relay will then have to be installed.

WARNING

010

!

Never connect a 120-volt AC circuit to the terminals of the furnace interlock (standard wiring). Only

use the low voltage class 2 circuit of the furnace blower control.

MAIN PC BOARD

9

8

7

6

5

OL

4

OC

3

I

2

1

J3

J1

1 4 7

2 5 8

3 6 9

REAR VIEW

VE0036A

PUSH-BUTTON SWITCHES

(5 switches maximum)

THERMOSTAT

Y

TERMINALS

HRV CONTROL CONNECTOR

J3

I OC OL Y R G BF F

TWO WIRES

COOLING SYSTEM

FOUR

WIRES

TWO WIRES

heating only

W

R

G

C

Y

FURNACE

24-VOLT

TERMINAL BLOCK

VE0010A

W R G

987654321

Unit Control Module

9-PIN AMP PLUG

J1

124

GRAY BROWN

COM

RELAY

COOLING SYSTEM

568

4 WIRES

2 WIRES

heating only

W

R

G

C

Y

FURNACE

24-VOLT

TERMINAL BLOCK

VE0009A

WRGY

R

Y

*FURNACE INTERLOCK RELAY, PART # 12658

THERMOSTAT

TERMINAL

wiring

nuts

GREEN

BLUE

2 WIRES

RED

NC NO

*FURNACE INTERLOCK

7

7

93

Page 25

25

9.0

Wiring Diagram

A1

M1

M2

K1

RELAY

K2

RELAY

K5

RELAY

FAN

MOTOR

DAMPER

MOTOR

NEUTRAL

MEDNCHIGH

LOW

J1 6

J1 3

J1 4

J1 9

K4

RELAY

J3 1

J3 2

FURNACE BLOWER INTERLOCK

CLASS 2 CIRCUIT ONLY

ELECTRONIC ASSEMBLY

S1

120V 60Hz

FROM MAIN

J1 2

J1 1

J1 8

VE0018A

Models: ERV-150, HRV-150,

ERV-210, HRV-210

NOTES

1- Controls available. See Section 8.0 (Low voltage only, 12VDC)

2- The factory set wiring for blower speed selection is high and low.

Medium speed can be selected instead of low speed. Disconnect the

RED wire from the motor RED tap and connect it to the motor BLUE tap.

3- If any of the original wire, as supplied, must be replaced, use the

same or equivalent wire.

4- Use the factory supplied protective tubing.

5- The field wiring must comply with applicable codes, ordonnances and

regulations.

6- The furnace fan circuit must be class 2 circuit only.

LINE VOLTAGE

LOW VOLTAGE AND

FIELD WIRE

COLOR CODE

BK BLACK NC NO CONNECTION

BL BLUE O ORANGE

BN BROWN R RED

G GREEN W WHITE

GY GREY Y YELLOW

DEFROST TIME

JUMPERS TABLE MODEL MODEL DEFROST/VENTILATION

TYPES MINUTES

23°F 5°F -17°F

JU1A JU1B JU1C JU1D JU1E JU1F JU1G -5°C -15°C -27°C

OUT OUT IN IN OUT IN OUT

HRV-150

6/32 6/32 6/20

HRV-210

OUT IN OUT IN OUT IN OUT

ERV-150

6/32 NOTE NOTE

ERV-210

NO NO NO NO NO

OUT

NO EXTENDED DEFROST

10/30 10/20 10/15

CHANGE CHANGE CHANGE CHANGE CHANGE CHANGE H RV ONLY

Connection

Logic

A B C D E F G

2

1

JU 1

. .

. .

. .

. .

. .

. .

. .

FUNCTION TABLE RELAY

MODE K1 K2 K4 K5

Intermittent 0 0 0 0

Exchange Low 1 0 1 1

Exchange High 1 1 1 1

Circulation Low 1 0 1 0

Circulation High 1 1 1 0

Defrost Cycle 1 1 1 0

Off 0 0 0 0

0 = Relay coil is de-energized

1 = Relay coil is energized

SPECIAL DEFROST CYCLE:

The mode is the same whichever the exchange

speed selected by the wall control.

6 min. defrost 34 min. OFF 20 min. exchange low speed

BELOW

-15°C - A change of air exchange speed on the wall control

(-5°F) during the special defrost cycle will reset the special

defrost cycle to the beginning (6 min. defrost).

- The override circuit will remain active during the

special defrost cycle. An override call will be answered.

- If the outside temperature revert above -15°C (5°F),

it is only during the last part of the cycle (20 min.

exchange) that the controller will stop the special

defrost cycle.

NOTE

WARNING

010

!

Risk of electrical shocks. Before performing any maintenance or servicing, always disconnect the

unit from its power source.

NOTES 1, 5

WALL CONTROL

WALL CONTROL

WALL CONTROL

WALL CONTROL

NOTE 5

OPTIONAL

OPTIONAL

NOTES 5, 6

FURNACE BLOWER

INTERLOCK

OVERRIDE SWITCH

OVERRIDE SWITCH

OVERRIDE LED

M1

NEUTRAL

GYOGBLR

X1

1

2

GYOGNCR

C1

BN

BN

LOW

MEDIUM

HIGH

FAN MOTOR

3

MOTOR

BL

BL

(NOTE 2)

M2

X2

DAMPER

BL

1

2

Y

W1

POINT

MAIN EARTHING

120V 60 Hz

NEMA-15P

5-15 PLUG

W

G

BK

LINE

NEUTRAL

BKGRYRBKY

NOTE 4

1

2

A1

DEFROST

TEMPERATURE

ABCDEFG

JU1

SENSOR

FF IOCOLYRGB

123

456789

J4

T1

-t°

R1

NO

Y

BL

R

9

7

J3

GY

O

6

4

12

3

BK

J1

W

SWITCH S1

DOOR INTERLOCK

COM

BK

ELECTRONIC ASSEMBLY

VE0037A

Page 26

26

WHAT YOU NEED TO BALANCE THE UNIT

• A magnehelic gauge capable of measuring 0 to

0.25 inch of water (0 to 62.5 Pa) and 2 plastic

tubes.

• Two ”Flow Measuring Stations” or two flow

collars (the size will vary depending on the duct

diameter).

PRELIMINARY STAGES TO BALANCE THE UNIT

• Seal all the unit ductwork with tape. Close all windows and doors.

• Turn off all exhaust devices such as range hood, dryer and bathroom fans.

• Make sure all filters are clean (if it is not the first time you balance the unit).

• Make sure the balancing dampers are fully open (F and G in figure 20).

Choose appropriate locations for the 2 flow collars (or flow measuring stations), according to figure 20:

• On the exhaust air duct (first measuring location, A)

• On the fresh air distribution duct (second measuring location, B

• At least 36” away from the unit; at least 12” before or after a 90° elbow; at least 12” away from a

register.

INSTALLATION OF FLOW COLLARS OR “FLOW MEASURING STATIONS”

• If you are using Flow Collars:

Insert the flow collars in the duct at each location. Make sure their arrows are pointing in the direction

of the airflow. Tape collars in place temporarily.

• If you are using “Flow Measuring Stations”:

Cut a 1” (25.4mm) diameter hole in the duct at each location. Insert the “Flow Measuring Stations”.

Make sure their arrows are pointing in the direction of the airflow. Tape the “Flow Measuring Stations”

in place temporarily.

10.0

Air Flow Balancing

Flow collar

Flow measuring station

Figure 20

L

O

W

H

W

HIG

H

LO

W

FLO

W

)

m

36

)

36

)

VP0012A

VP0005

VP0006

30m)4

1

(304mm

(914mm

914mm

Page 27

27

BALANCING PROCEDURE

1. Set the unit to high speed.

Make sure that the furnace blower is ON if the installation is in any way connected to the ductwork of

the cold air return. If not, leave furnace blower OFF. If the outside temperature is below 0°C / 32°F,

make sure the unit is not running in defrost while balancing. (By waiting 10 minutes after plugging the

unit in, you are assured that the unit is not in a defrost cycle.)

2. Place the magnehelic gauge on a level surface and adjust it to zero.

3. Connect tubing from gauge to flow collar (or “Flow Measuring Station”) in

exhaust air stream at location A. Be sure to connect the tubes to their appropriate

high/low

fittings. If the gauge drops below zero, reverse the tubing connections.

NOTE: It is suggested to start with the exhaust air flow reading because the

exhaust has typically more restriction than the fresh air, especially in

cases of fully ducted installations and exhaust ducted installation.

Place the magnehelic gauge upright and level. Record the readings.

4. Move tubing to FRESH air flow on the other side of the unit (location B) and

note readings.

Adjust the fresh air balancing damper F until the reading at B is approximately

the same as the reading at A. If the reading at B is less than the reading at A,

then go back and adjust the exhaust balancing damper

G to equal the fresh

air flow.

5. Secure both dampers in place with tape or with a fastening screw.

6. If you are using flow collars, remove them, reconnect the duct and seal with duct tape. If you are using

“Flow Measuring Stations”, remove them and seal the holes with duct tape. Write the required air flow

information on a label and stick it near the unit for future reference (date, maximum speed air flows,

your name, phone number and business address).

NOTES: Most flow collar kits provide a conversion chart located on the collar which enables you to convert

magnehelic gauge readings to equivalent cfm values.

The unit is considered balanced even if there is a difference of +/- 10 cfm (+/- 0.015 inch w.g.)

between the two air flow readings.

If you are only using one flow collar or one “Flow Measuring Station”, then, after completing the

first reading, transfer this measuring device to the other side of the unit and take the second reading.

VD0052

VD0069

10.0

Air Flow Balancing (cont’d)

L

O

W

H

IG

H

F

L

O

W

O

F G

LOW

HIGH

F

LOW

O

VP0003

VP0004

Page 28

28

BASIC

(6 different control scenarios to be tested)

11.1 MAIN CONTROLS

This procedure allows the installer to verify that all modes of operation are fully functional.

During the verification of a main control, make sure that all optional remote controls are inactive.

11.0

Overall Verification

Set the slider Set condensation control Results expected

switch to dial to fan speed

1 Off maximum counterclockwise motor off

2 Off maximum clockwise motor off

3 Min. maximum counterclockwise low speed

4 Min. maximum clockwise high speed

5 Max. maximum counterclockwise high speed

6 Max. maximum clockwise high speed

CO

O

AIR SUPPL

Y CONTRO

OFF

EXCHANGE

0

C

C

O

F

Set air supply Set condensation control

Results expected

control to dial to

Fan Exchange Max speed

speed indicator indicator

(A) (B)

1 Off maximum counterclockwise off off off

2 Off maximum clockwise off off off

3 Min. maximum counterclockwise low on off

4 Min. maximum clockwise high on on

5 Max. maximum counterclockwise high on off

6 Max. maximum clockwise high on on

7 Intermittent maximum counterclockwise

off 40 min off 40 min off

low 20 min on 20 min off

8 Intermittent maximum clockwise high on on

ELECTRONIC (8 different control scenarios to be tested)

C

5

C

CO

O

AIR SUPPL

Y CONTRO

CO

OL

D

SS

CONTINUOUS

20 MION40 MIN.

M

OFF

C

O

M

S

U

M

M

E

R

VC0028

B

A

11.2 OPTIONAL CONTROL

First, turn OFF the main control device (Basic or Electronic) before checking the remote optional control.

20/40/60-MINUTE PUSH-BUTTON TIMER:

Activate the push button. Within 2 seconds, push one time for 20 minutes, two times for

40 minutes or three times for a 60-minute activation.

Results expected:

1. Motor speed: high for 20, 40 or 60 minutes.

2. Indicator light goes “ON” and flashes every 5 seconds (one time to indicate a

20-minute operation, two times for a 40-minute, and three times for a 60-minute

operation).

3. Air exchange indicator light goes “ON” (Electronic wall control only).

NOTE: To stop activation, push one more time.

NDENSI0N CONTR

VC0027

NDENSI0N CONTR

NDENSAION CONTR

MAXIMUM SPEE

-2

-

-

S

U

M

M

E

R

-

AIR EXCHANGE IN PROGRE

VC0046

20 min.

40 min.

60 min.

Page 29

29

• Review with the user the steps required for the regular maintenance of her/his ventilation system.

These steps are described in details in the user manual:

• Warn the user of the necessity to rebalance the system following a major house renovation or following

the installation of any extra registers.

• Make sure the user understands how to use the main control as described in the user manual.

• If the unit being installed is an ERV, then make sure the user understands the characteristics of the special

cold weather TBI mode. The user should understand that his unit will not obey the settings on the main

wall control when the temperature drops below -15°C (5°F). See Section 7.5.

12.0

Maintenance / Instructions for User

FOUR TIMES A YEAR:

• Inspect the intake hood, and clean if needed.

• Clean the filters.

• Clean the interior of the cabinet and clean the door.

• Clean the condensation tray and inspect the drain tubing.

ONCE A YEAR:

• Clean the recovery core.

• Clean the blades of the blower wheels if needed.

CAUTION

Do not oil the motor. It is already permanently lubricated.

WARNING

010

!

Risk of electrical shocks. Before performing any maintenance or servicing, always disconnect the

unit from its power source.

Page 30

30

Problems Possible causes You should try this

1. Unit does not work. • The circuit board may

be defective.

• Unplug the unit. Disconnect the main control

and the optional(s) control(s) (if need be). Jump

B and G terminals. Plug the unit. If the motor

runs on high speed and the damper opens, the

circuit board is not defective.

2. The damper actuator • The 9-pin connector may • Unplug the unit and check to make sure all the

does not work. have a loose connection. crimp connections are secured. Check the damper

actuator connections as well.

• The damper actuator may • Feed 120 V directly to the damper actuator. If the

be defective. problem persists, replace the damper actuator.

• The circuit board may • Replace the circuit board if the problem is not

be defective. solved by the above.

3. The wall control does • TBI mode is activated. • If the outside temperature is below -15°C (5°F)

not work OR and the unit has an enthalpic recovery core

the indicators flashes (energy recovery core), then the TBI mode is

every 8 seconds. probably activated. (See Section 7.5.)

• The wires may be in • Ensure that the color coded wires have been

reverse position. connected to their appropriate places.

• Erratic operation of the • Unplug the unit. Wait 30 seconds. Plug it back in.

control every 8 seconds.

• The wires may be broken. • Inspect every wire and replace any that are damaged.

• There may be a short-circuit.• With the help of a multimeter, check for continuity.

• The wire in the wall OR • Remove the wall control and test it right beside

the wall control may the unit using another shorter wirer. If the wall

be defective. control works there, change the wire. If it does

not, change the wall control.

• The circuit board may • If the second wall control does not solve the

be defective. problem, then replace the circuit board.

Start-up troubleshooting:

NOTE: Inspect the unit before proceeding with these steps.

13.0

Troubleshooting

VE0082

B

G

Page 31

31

Problems Possible causes You should try this

4. The 20-minute push-button • The switch

or the 20/40/60-minute may be defective.

push-button timer does

not workOR its indicator

light does not stay on.

• Unplug the unit. Disconnect the main control

and the optional(s) control(s) (if need be). Jump

the OL and OC terminals. Plug the unit. If the

unit switches to high speed, replace the switch.

5. The defrost cycle • Ice deposits may be hindering • Remove the ice.

does not work the damper operation.

(the fresh air duct is

frozen OR the fresh air • The damper rod or the port • Inspect these parts and replace if necessary.

distributed is very cold damper itself may be broken.

OR the “AIR EXCHANGE”

light flashes). • The damper actuator • Plug in the unit and select “MIN” or “MAX”.

may be defective. Press the door switch and see if the port damper

opens. If it doesn’t open, feed 120V directly to

the damper actuator. If the port damper still does

not open, replace the damper actuator.

• The circuit board may • Unplug the unit. Unplug the defrost sensor wire

be defective. (see J4 on electrical diagrams, Section 9.0).

Plug the unit back in. Select “MIN” and make sure

the unit is adjusted for low speed operation (turn

all dehumidistats maximum counterclockwise).

Wait 3 minutes. The unit should switch to high

speed and the damper at the fresh air intake

port should close (defrost mode). If this does

not happen, then replace the circuit board.

• The thermistor may • If the defrost mode works well after having

be defective. disconnecting the thermistor wire (above test),

this means the thermistor is probably defective.

You should replace it.

13.0

Troubleshooting (cont’d)

VE0067

OL

OC

Page 32

14.0

Warranty

The standard warranty for the HRV or ERV unit is one year parts only. If this product was installed with a

matched MAYTAG system, it carries a 10-year parts only warranty.

15.0

References

D

D

• HVI, “Installation Manual for Heat Recovery Ventilators”, 1987 edition.

• ASHRAE 1984 Systems Handbook, chapter 11, “Air Distribution Design for Small Heating and

Cooling Systems”.

R 2000

LISTE

LISTE

Loading...

Loading...