Page 1

ABS Laundry

Samsung Dryer

Model DV316LG

Maytag Technical Institute 2006 ABS-L2006-002

Page 2

Notes:

Page 3

CLOTHES DRYER

Model : DV316LG

Basic Model :

Model code : DV316LGW/XAA

Manual

SERVICE

CLOTHES DRYER

THE FEATURE OF PRODUCT

1. Energy Saving

2. Time Saving

3. Super Size Capacity

4. Fuzzy Algorithm

5. Easy Reversible Door

Page 4

-This Service Manual is a property of Samsung

Electronics Co., Ltd.

Any unauthorized use of Manual can be punished

under applicable International and/or domestic

law.

Samsung Electronics Co.,Ltd.

416, Maetan-3Dong, Yeongtong-Gu, Suwon City,

Gyeonggi-Do, Korea, 443-742

Printed in Korea

P/N : DC

URL : http://itself.sec.samsung.co.kr/

Page 5

CONTENTS

1. Precautions

1-1. Safety Precautions ............................................................................................................................1-1

1-2. Precautions upon Installation ............................................................................................................1-2

2. PRODUCT SPECIFICATIONS

2-1. THE FEATURE OF PRODUCT .........................................................................................................2-1

2-2. SPECIFICATIONS OF PRODUCTSPECIFICATIONS OF PRODUCT ....................................................................................................2-2

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT .................................................................2-3

2-4. OPTION SPECIFICATIONSSPECIFICATIONS ..............................................................................................................2-4

3. OPERATING INSTRUCTIONS AND INTALLATION

3-1. Each Key and Display .......................................................................................................................3-1

3-2. FUNCTION OF CONTROL KEYS .....................................................................................................3-2

3-3. MAIN FUNCTIONS ...........................................................................................................................3-6

3-4 SPECIAL FUNCTIONS ......................................................................................................................3-8

4. ALIGNMENT AND ADJUSTMENTS

4-1. GENERAL ERROR FUNCTION ........................................................................................................4-1

4-2. TEST MODE .....................................................................................................................................4-2

5. ASSEMBLY AND DISASSEMBLY

5-1. TOOLS FOR DISASSEMBLY AND ASSEMBLY ...............................................................................5-1

5-2. DISASSEMBLY .................................................................................................................................5-2

5-3. ASSEMBLY .......................................................................................................................................5-5

6. TROUBLE SHOOTING

6-1. TROUBLE DIAGNOSIS ....................................................................................................................6-1

6-2. PROBLEM CHECKING AND METHOD OF PCB .............................................................................6-3

6-3 Control Panel .....................................................................................................................................6-4

6-4 Driving Unit .........................................................................................................................................6-5

7. EXPLODED VIEWS AND PARTS LIST

7-1. ASSY-COVER TOP ...........................................................................................................................7-1

7-2. ASSY-TUB OUTER(SPIN BASKET) .................................................................................................7-2

7-3. ASSY-CASE OUTER .........................................................................................................................7-3

7-4. BOLT/SCREW PARTS LIST .............................................................................................................7-4

Page 6

CONTENTS

8. ELECTRICAL PARTS LIST .....................................................................................................................8-1

9. BLOCK DIAGRAM ..................................................................................................................................9-1

10. WIRING DIAGRAM .............................................................................................................................10-1

11. PCB DIAGRAM ....................................................................................................................................11-1

12. SCHEMATIC-DIAGRAMS .................................................................................................................12-1

13. CIRCUIT DESCRIPTIONS ..................................................................................................................13-1

14. REFERENCE INFORMATION

14-1. MODEL NAME ..............................................................................................................................14-1

14-2. TERMINOLOGY ............................................................................................................................14-2

14-3. FABRIC CARE CHART .................................................................................................................14-3

14-4. ELECTRICAL WARNINGS ...........................................................................................................14-4

14-5. Q & A .............................................................................................................................................14-5

Page 7

41#Suhfdxwlrqv

4041#Fdxwlrq#iru#vdihw|#gxulqj#vhuylflqj

1. Do not allow the customer to repair the product.

The person may be injured or the product life may be shortened..

2. Execute A/S after unplugging the power supply unit.

Be careful of the electric shocks.

3. Do not plug several plugs in the same outlet.

It may cause a fire due to overheat.

4. Check for damage, pressing or burning of the power plug or outlet.

Replace it promptly if it has a problem.(It may cause the electric shocks or fire)

5. Do not clean the main body with water.

It may cause electric shocks and fire and shorten the product life)

6. The wiring of the harness shall be free from moisture and tightened during serving.

It shall not be deviated by certain impact.

7. Remove any dust or filth on the housing section,wiring section,connection section during servicing.

Protect from possible cause of fire such as the tracking,shortage etc.

8. Check for any marks of moisture on the electrical parts, harness section etc.

Replace the parts or remove the moisture..

9. Check the assembly status of the parts after servicing.

Maintain the status before servicing..

10. Pull out the power cord by holding the plug.

Be careful of electric shocks and when the cord is damaged.

11. Unplug the power plug from the outlet when the dryer is not used.

Be careful of electric shocks and fire due to the strike of lightning.

12. Do not use or store sprays or flammable materials(including gasoline,alcohol etc.)

around the dryer.

Be careful of explosions or fire due to electric sparks.

13. Do not put bowls of water or wet laundry on the dryer.

If water has penetrated into the dryer, this may cause electric shocks or fire.

14. Do not install the dryer where it will be exposed to bad weather.

It may cause electric shocks and fire and shorten the product life.

1-1

Page 8

15. Do not push the control buttons with an awl,pin, or sharp materials.

It may cause electric shocks and damage.

16. Check the wash machine is leveled horizontally and installed properly on the floor.

The vibration may shorten the product life..

4051#Lpsruwdqw#Vdihw|#Lqirupdwlrq

To avoid risk of fire, electric shock, serious injury, or death when using your dryer, follow these basic precautions:

1. Read all instructions before using dryer.

2. Install dryer according to Installation Instructions. Refer to the Grounding Instructions in the

Installation Instructions for proper grounding of the dryer.

3. Do not dry articles that have been cleaned in, washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, or other flammable or explosive substances. Vapors could ignite or explode.

4. Do not use dryer to dry clothes which have traces of any flammable substance, such as vegetable oil,

cooking oil, machine oil, flammable chemicals, thinner, etc., or anything containing wax or chemicals,

such as mops and cleaning cloths. Flammable substances may cause fabric to catch fire by itself.

5. Do not store or use gasoline or other flammable vapors and liquids near this or any other appliance.

6. Do not allow children to play on or in dryer. Close supervision of children is necessary when dryer is

used near children, a safety rule for all appliances.

7. Before dryer is removed from service or discarded, remove doors to drying compartment.

8. Do not reach into dryer if cylinder is revolving.

9. Do not install or store dryer where it will be exposed to water and/or weather.

10. Do not tamper with dryer controls.

11. Do not repair or replace any part of dryer or attempt any service, unless specifically recommended in

user-maintenance instructions or in published user-repair instructions that you understand and have

skills to carry out, if you are a consumer.

12. To reduce risk of electric shock or fire, do not use extension cords or adapters to connect dryer to

electrical power source.

13. Use the dryer only for its intended purpose, drying clothes.

14. Always disconnect dryer from electrical supply before attempting any service. Disconnect power cord by

grasping the plug, not the cord.

15. Do not use heat to dry articles containing foam rubber or similarly textured rubberlike materials.

1-2

Page 9

16. Always clean the lint filter after every load. A layer of lint in the filter reduces drying efficiency and pro

longs drying time.

17. Use only fabric softeners or products to eliminate static that are appropriate for automatic dryers.

18. Keep your dryer in good condition. Bumping or dropping dryer can damage safety features. If damage

occurs, have dryer checked by qualified service technician.

19. Replace worn power cords and/or loose plugs.

20. Do not tumble fiberglass curtains and draperies unless the label says it can be done. If they are dried, wipe

out the cylinder with a damp cloth to remove particles of fiberglass.

21. Always read and follow manufacturers instructions on packages of laundry aids. Heed all warnings or

precautions. To reduce risk of poisoning or chemical burns, keep products away from children at all times,

preferably, in a locked cabinet.

22. Never operate dryer with guards and/or panels removed.

23. Do not operate dryer with missing or broken parts.

24. Do not bypass safety devices.

25. Keep area around the exhaust opening and adjacent surrounding areas free from accumulation of

lint, dust, and dirt.

26. Interior of dryer and exhaust duct should be cleaned periodically by qualified service personnel.

27. Dryer will not operate with loading door open. DO NOT bypass door safety switch by permitting dryer to

operate with door open. Dryer will stop tumbling when door is opened. Do not use dryer if it does not stop

tumbling when door is opened or starts tumbling without pressing or turning the START mechanism.

Remove the dryer from use and call the service person.

28. Remove laundry immediately after the dryer stops.

29. ALWAYS follow the fabric care instructions supplied by the garment manufacturer.

1-3

Page 10

Hohfwulfdo#Vhuylfh#Lqirupdwlrq

Electrical Dryers

- 240 VAC, 60 Hz, 30 Amps,

3-wire or 4-wire installations

Gas Dryers

- 120 VAC, 60 Hz, 15 Amps, 3wire installations

About Ground Wires

In the event of an electrical short circuit, a

ZDUQLQJ

To reduce the risk of fire, electric shock, serious injury or death, all wiring and grounding must conform with the latest edition of

the National Electric Code, or the Canadian

Electrical Code, and such local regulations as

might apply. It is the customers responsibility to have the wiring and fuses checked by a

qualified electrician to make sure your home

has adequate electrical power to operate the

dryer.

ZDUQLQJ

To avoid risk of personal injury or death due

to electrical shock:

- Observe all local codes and ordinances.

- Disconnect electrical power to unit

before servicing.

- Ground appliance properly.

- Check with a qualified electrician if you

are not sure this appliance is properly

grounded.

- DO NOT ground to gas line.

- DO NOT ground to cold water pipe if

pipe is interrupted by plastic, nonmetallic

gas kets, or other insulating

(nonconducting) materials.

- DO NOT modify plug on power cord.

If plug does not fit electrical outlet, have

proper outlet installed by qualified elec

trician.

- DO NOT have a fuse in the neutral or

ground circuit. A fuse in the neutral or

ground circuit could result in an electrical

shock.

- DO NOT use an extension cord with

this appliance.

- DO NOT use an adapter plug with

this appliance.

- DO NOT pinch powe cord.

1-4

ZDUQLQJ

To reduce the risk of fire and exposure to

combustion gases, the dryer MUST be exhausted to the outdoors.

DO NOT exhaust dryer air into a window well,

gas vent, chimney or enclosed, unventilated

area, such as an attic, wall, ceiling, crawl

space under a building or concealed space of

a building.

Page 11

Jdv#Gu|hu#Srzhu#Vxsso|

This equipment MUST be grounded. In the

event of an electrical short circuit, grounding

reduces the risk of electric shock by providing

an escape wire for the electrical current. This

unit is equipped with a cord having a grounding wire with a grounding plug. The plug must

be plugged into an outlet that is properly

installed and grounded.

connection to the main power panel.

Xqjurxqghg-The round hole connection is not

connected to a ground and/or the main power

panel.

Jdv#Frqqhfwlrq#Lqirupdwlrq

Consult a qualified electrician or servicer if

grounding instructions are not completely understood, or if doubt exists as to whether the

equipment is properly grounded.

Do not use an extension cord. If the product power cord is too short, have a qualified

electrician install a three slot receptacle.

This unit should be plugged into a separate 60

hertz circuit with the electrical rating as shown

on the serial plate.

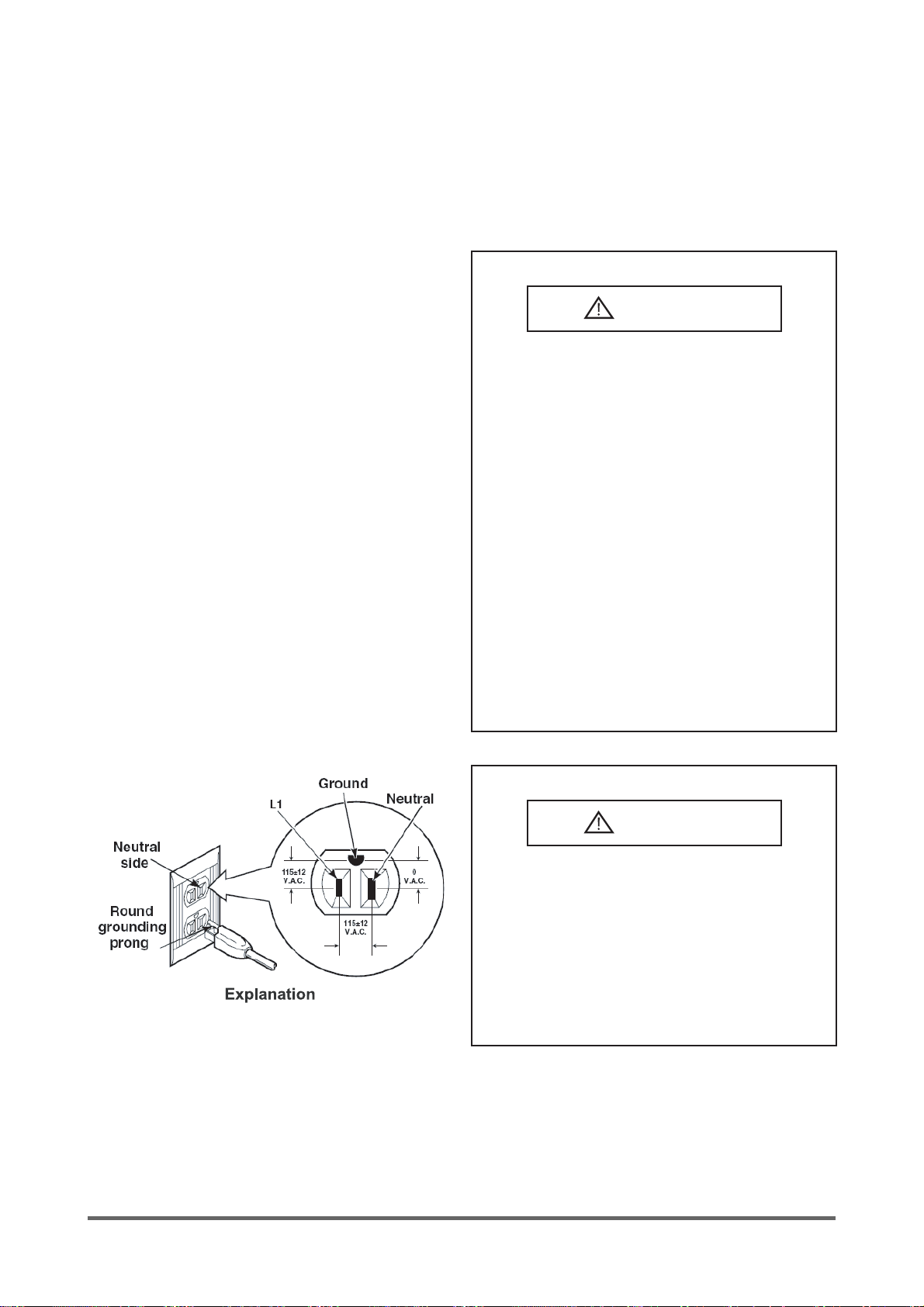

Surshu#Jurxqglqj#dqg#Srodul}dwlrq#iru#453#

YrowvZdoo#Rxwohwv

For the safety of our customers and the service technician ALL gas dryers have a three!!

prong power cord and MUST be connected to

a properly polarized and grounded wall outlet.

This information was written for those who do

not understand grounding and polarization

of a wall outlet. A 120 VAC wall outlet must

always be wired as shown below.

ZDUQLQJ

To avoid death, personal injury or property

damage, from fire or explosion, information

in this manual must be followed exactly.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

ZKDW#WR#GR#LI#\RX#VPHOO#JDV

- Do not try to light any appliance.

- Do not touch any electrical switch; do not

use any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas suppli

er’s instructions.

- If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

Srodul}dwlrq-This means that the larger slot

must be neutral and the small slot must be hot

(live).

Plvsrodul}hg-The outlet is miswired so that the

larger slot is hot (live) and the smaller slot is

neutral.

Jurxqghg -This means the round hole connection is connected to ground through a

ZDUQLQJ

To reduce the risk of fire and exposure to

combustion gases, the dryer MUST be exhausted to the outdoors.

DO NOT exhaust dryer air into a window well,

gas vent, chimney or enclosed, unventilated

area, such as an attic, wall, ceiling, crawl

space under a building or concealed space of

a building.

1-5

Page 12

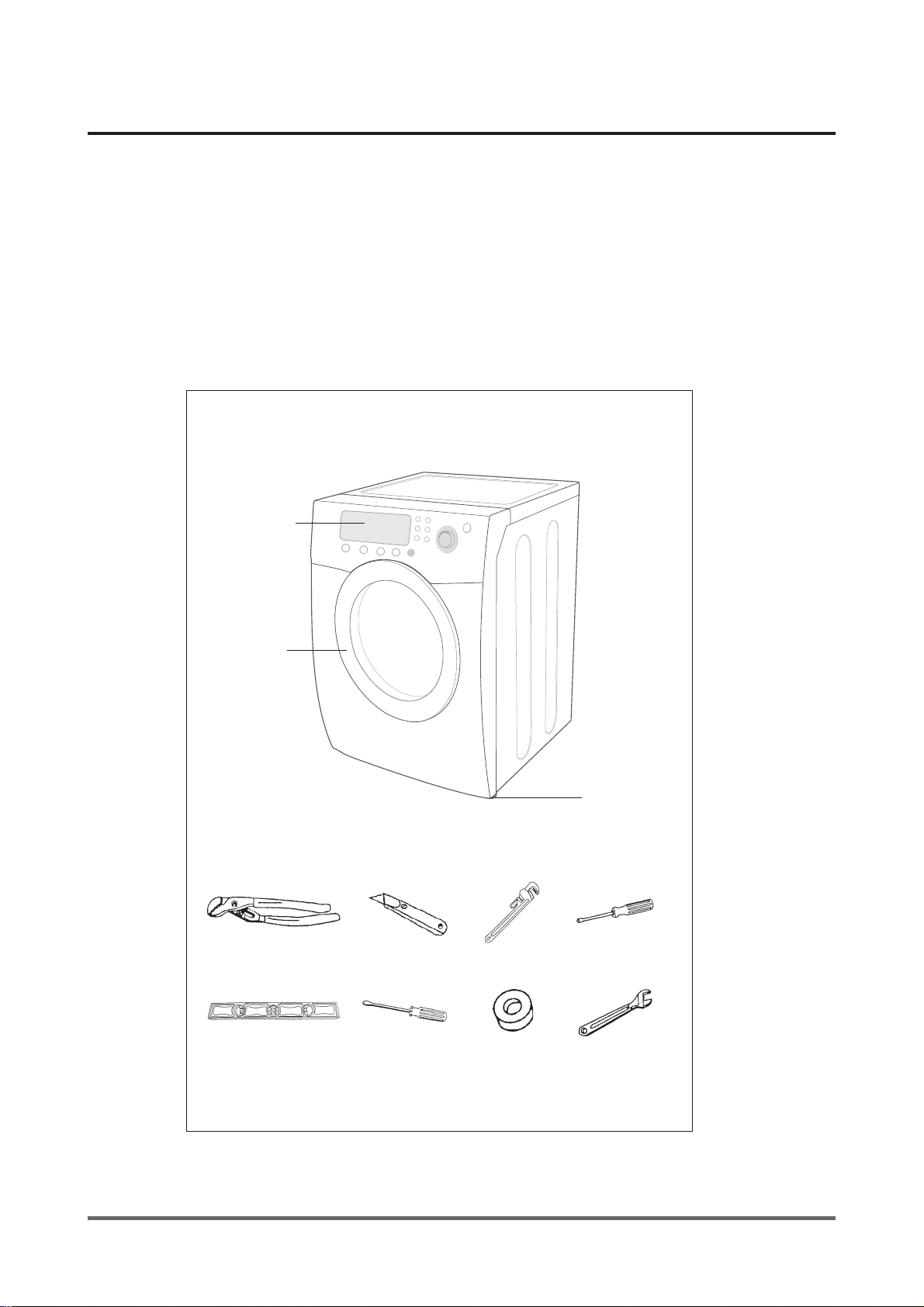

4061#Suhfdxwlrqv#xsrq#Lqvwdoodwlrq

Tools needed for installation

Proper installation is the owner’s responsibility.

HOWEVER, SERVICE CALLS PERFORMED AS A RESULT OF POOR SET-UP, ADJUSTMENT, AND CONNECTION ARE THE

RESPONSIBILITY OF THE INSTALLER.

Make sure you have everything necessary for proper installation.

1. GROUNDED ELECTRICAL OUTLET is required. See Electrical Requirements.

2. POWER CORD for electric dryers (except Canada).

3. GAS LINES (if a gas dryer) must meet national and local codes.

4. EXHAUST SYSTEM – must be rigid metal or fl exible stiffwalled metal exhaust ducting.

See Exhaust Requirements.

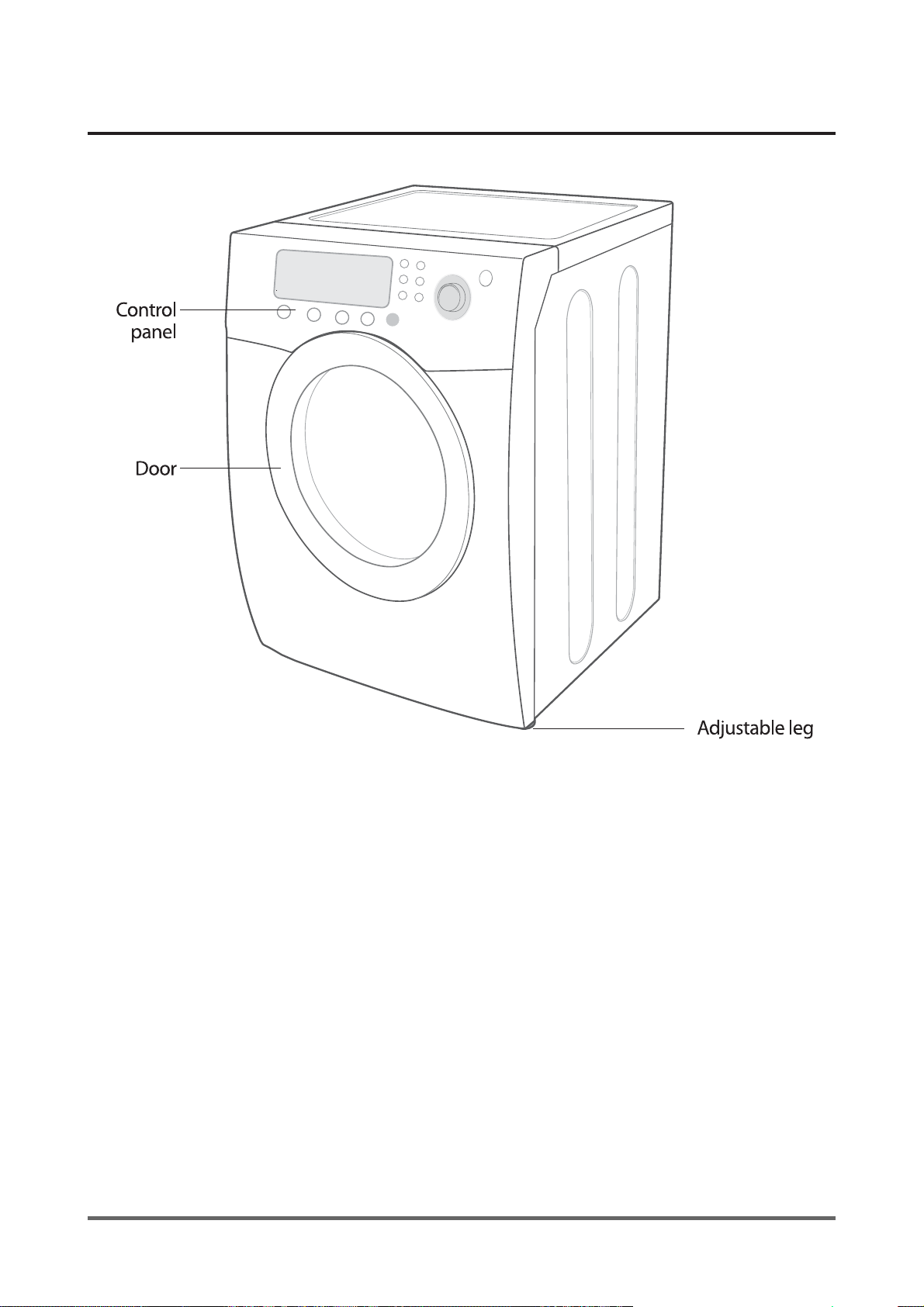

Control

panel

Door

Pliers Cutting knife Pipe wrench

Level Screwdriver

(standard)

Adjustable

(gas only)

Duct tape Crescent

Adjustable leg

Nut drivers

spanner

1-6

Page 13

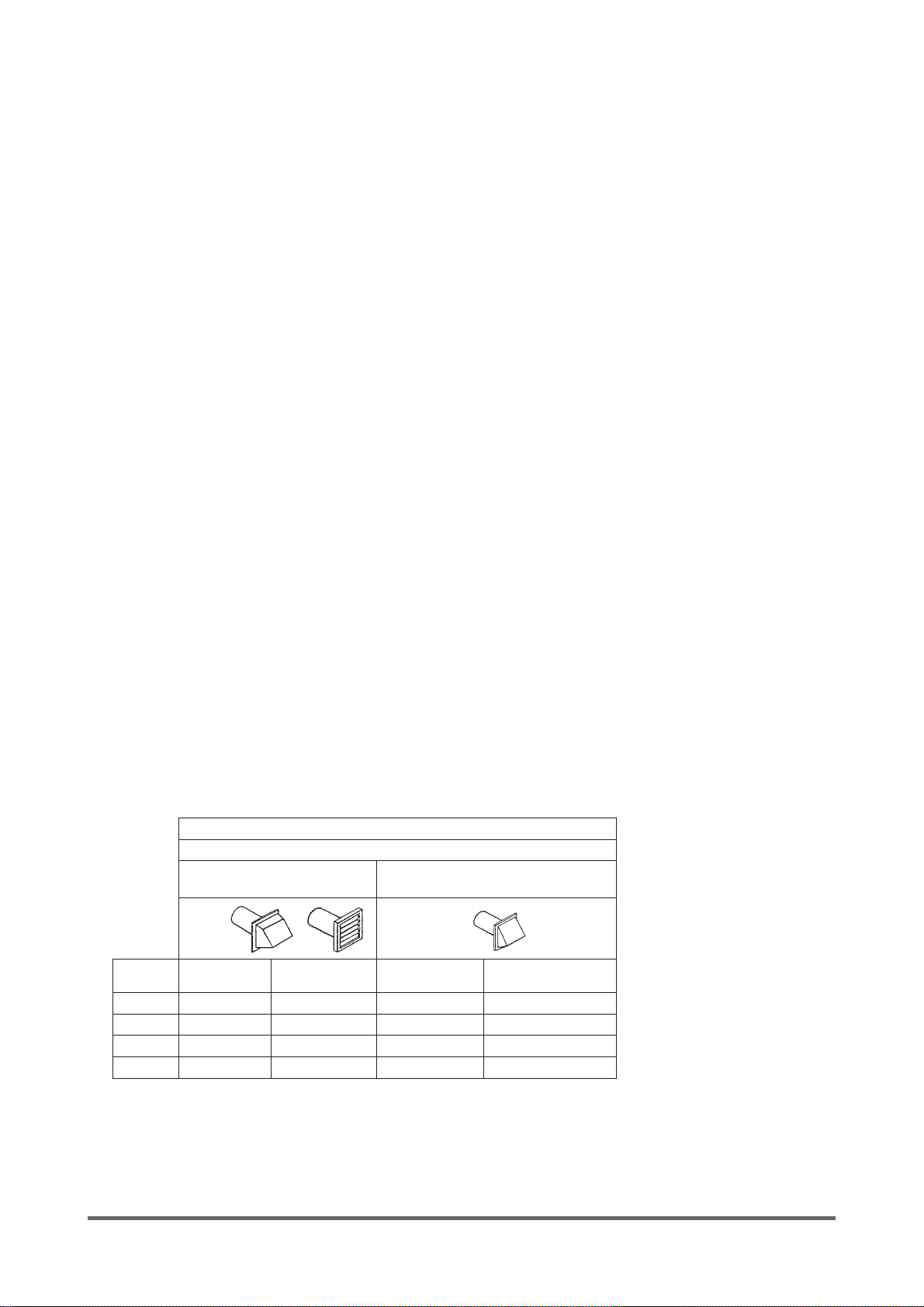

DUCTING REQUIREMENTS

• Use a 4-inch (10.2 cm) diameter rigid aluminum or rigid galvanized steel duct.

• Do not use a smaller duct.

• Ducts larger than 4 inches (10.2 cm) in diameter can result in increased lint accumulation.

Lint accumulation should be cleaned regularly.

• If a fl exible metal duct must be used, use the type with a stiff sheet metal wall. Do not use a fl exible

duct with a thin foil wall. Serious blockage can result if the fl exible metal duct is bent too sharply.

• Never install any type of fl exible duct in walls, ceilings, or other concealed spaces.

• Keep exhaust duct as straight and short as possible.

• Secure joints with duct tape. Do not use screws.

• DO NOT EXHAUST DRYER INTO ANY WALL, CEILING, CRAWL SPACE, OR CONCEALED SPACE OF A

BUILDING, GAS VENT, OR ANY OTHER COMMON DUCT OR CHIMNEY.

THIS COULD CREATE A FIRE HAZARD FROM LINT EXPELLED BY THE DRYER.

• Plastic fl exible duct can kink, sag, be punctured, reduce airfl ow, extend drying times, and affect dryer

operation.

• Exhaust systems longer than recommended can extend drying times, affect machine operation, and may collect lint.

• The exhaust duct should end with an exhaust hood with a swing-out damper to prevent back drafts

and entry of wildlife. Never use an exhaust hood with a magnetic damper.

• The hood should have at least 12 inches (30.5 cm) of clearance between the bottom of the hood and

the ground or other obstruction. The hood opening should point down.

• Never install a screen over the exhaust outlet.

• To avoid lint buildup, do not exhaust the dryer directly into a window well. Do not exhaust under a

house or porch.

• If exhaust ductwork must run through an unheated area, the duct should be insulated and slope

slightly down towards the exhaust hood to reduce condensation and lint buildup.

• Inspect and clean the interior of the exhaust system at least once a year. Unplug the power cord

before cleaning.

• Check frequently to be sure the exhaust hood damper opens and closes freely.

ELECTRIC AND GAS DRYER

Weather Hood Type

Recommended Use only for short-run installation

4” (10 .16 cm) 2.5” (6.35 cm)

No. of 90°

elbows

0 24.4 m (80 ft.) 12.4 m (41 ft.) 22.6 m (74 ft.) 10.1 m (33 ft.)

1 20.7 m (68 ft.) 11.2 m (37 ft.) 18.9 m(62 ft.) 8.8 m (29 ft.)

2 17.4 m (57 ft.) 10.1 m (33 ft.) 15.5 m(51 ft.) 7.6 m (25 ft.)

3 14.3m (47 ft.) 9.0 m (29 ft.) 12.5 m(41 ft.) 6.5 m (21 ft.)

* Do not use non-metallic fl exible duct.

Rigid Metallic Flexible* Rigid Metallic Flexible*

1-7

Page 14

If new dryer is installed into an existing exhaust system you must make sure:

• The exhaust system meets all local, state, and national codes.

• That fl exible plastic duct is not used.

• Inspect and clean all lint buildup from inside the existing duct.

• The duct is not kinked or crushed.

• The exhaust hood damper opens and closes freely.

The static pressure in any exhaust system must not exceed 0.83 inches of water column, or be less than 0.

This can be measured with the dryer running with a manometer at the point where the exhaust duct connects

to the dryer. A no-heat setting should be used. The dryer tumbler shoul

REMOVE THE DOOR FROM ALL DISCARDED APPLIANCES TO AVOID THE DANGER OF A CHILD

SUFFOCATING.

LOCATION CONSIDERATIONS

The dryer should be located where there is enough space in front for loading the dryer, and enough space

behind for the exhaust system. This dryer is factory-ready for rear exhaust. To exhaust out the bottom or the

left, use the accessory exhaust kit. Instructions are included with the kit. It’s important to make sure the room

has enough fresh air. The dryer must be located where there is no air-fl ow obstruction.

On gas dryers, adequate clearance as noted on the data plate must be maintained to ensure adequate air for

combustion and proper dryer operation.

THE DRYER MUST NOT BE INSTALLED OR STORED IN AN AREA WHERE IT WILL BE EXPOSED TO

WATER AND/OR WEATHER. THE DRYER AREA IS TO BE KEPT CLEAR OF COMBUSTIBLE MATERIALS,

GASOLINE, AND OTHER FLAMMABLE VAPORS AND LIQUIDS. A DRYER PRODUCES COMBUSTIBLE

LINT. THE AREA AROUND THE DRYER SHOULD BE KEPT LINT-FREE.

ALCOVE OR CLOSET INSTALLATION

WARNING – The dryer must be exhausted to the outside to reduce the risk of fi re when

installed in an alcove or closet.

• No other fuel-burning appliance should be installed in the same closet as the dryer.

• WARNING: To reduce the risk of fi re, this dryer MUST BE EXHAUSTED TO THE OUTDOORS.

See EXHAUST INFORMATION section.

• Minimum clearances between the dryer and adjacent walls or other surfaces are: 2” in front,

17” on top, 1” on either side, and 2.375” in the back.

• Closet front must have two unobstructed air openings for a combined minimum total area of

72 in² with 3” minimum clearance on the top and bottom. A louvered door with equivalent space

clearance is acceptable.

1-8

Page 15

MOBILE HOME INSTALLATION

The installation of the dryer in mobile homes must conform to the Manufactured Home Construction and

Safety Standard Title 24 CFR, Part 32-80 {formerly the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD (Part 280), 1975} for the United States) or CSA Standards Z240 (for Canada).

When installing a dryer in a mobile home, provisions for anchoring the dryer to the fl oor must be made.

Locate in an area that has adequate fresh air.

A minimum of 72 in² (183 cm² ) of unobstructed space is required.

All mobile home installations must be exhausted to the outside with the exhaust duct termination securely

fastened to the mobile home structure, using materials that will not support combustion.

The exhaust duct may not terminate underneath the mobile home.

See Exhausting section for more information.

EXHAUSTING

Exhausting the dryer to the outside will prevent large amounts of lint and moisture from being blown

into the room.

In the United States:

• All dryers must be exhausted to the outside.

• Only rigid or fl exible metal duct should be used for exhausting.

In Canada:

• All dryers must be exhausted to the outside.

Outside the U.S. and Canada:

• Refer to local codes.

WARNING –The dryer must be exhausted to the outside to reduce the risk of fi re when installed

n an alcove or closet.

NEVER USE PLASTIC OR NON-METAL FLEXIBLE DUCT.

If your existing ductwork is plastic, non-metal, or combustible, replace it with metal.

Use only metal exhaust duct that is non-fl ammable to ensure containment of

exhaust air, heat, and lint.

1-9

Page 16

GAS REQUIREMENTS

Use only natural or LP (liquid propane) gases.

THE INSTALLATION MUST CONFORM WITH LOCAL CODES, OR IN THE ABSENCE OF LOCAL

CODES, WITH THE NATIONAL FUEL GAS CODE ANSI/Z223.1, LATEST REVISION (FOR THE UNITED

STATES), OR WITH THE CAN/CGA-B149 INSTALLATION CODES (FOR CANADA).

Gas dryers are equipped with a burner vent for use with natural gas. If you plan to use your dryer with LP

(liquid propane) gas, it must be converted for safe and proper performance by a qualifi ed service technician.

A 1/2” (1.27 cm) gas supply line is recommended and must be reduced to connect to the 3/8” (1 cm) gas line

on your dryer. The National Fuel Gas Code requires that an accessible, approved manual gas shut-off valve

be installed within 6’ of your dryer.

Gas dryers installed in residential garages must be raised 18 inches (46 cm) above the fl oor.

Additionally, a 1/8” (0.3 cm) N.P.T. (National Pipe Thread) plugged tapping, accessible for test gauge

connection, must be installed immediately upstream of your dryer’s gas supply connection.

Your dryer must be disconnected from the gas supply pipe system during any pressure testing of the

system.

DO NOT reuse old fl exible metal gas lines. Flexible gas lines must be design certifi ed by the American Gas

Association (CGA in Canada).

NOTE: • Any pipe joint compound used must be resistant to the action of any liquefi ed petroleum gas.

• As a courtesy, most local gas utilities will inspect a gas appliance installation.

GAS IGNITION – Your dryer uses an automatic ignition system to ignite the burner.

There is no constant burning pilot.

COMMONWEALTH OF MASSACHUSETTS INSTALLATION INSTRUCTIONS

Your dryer must be installed by a licensed plumber or gas fi tter. A “T” handle manual gas valve must be

installed in the gas supply line to your dryer. If a fl exible gas connector is used to install your dryer, the

connector must have a maximum length of 3’ (36”).

WARNING – Gas leaks may occur in your system, creating a dangerous situation.

Gas leaks may not be detected by smell alone.

Gas suppliers recommend you purchase and install a UL-approved gas detector.

Install and use in accordance with manufacturer’s instructions.

1-10

Page 17

ELECTRICAL REQUIREMENTS

NOTE: Wiring diagram is located on plate below the control panel.

WARNING –

• Improper connection of the equipment grounding conductor can result in a risk of electric shock. Check

with a qualifi ed electrician or serviceman if you are in doubt as to whether your dryer is properly

grounded. Do not modify the plug provided with your dryer – if it doesn’t fi t the outlet, have a proper

outlet installed by a qualifi ed electrician.

• To prevent unnecessary risk of fi re, electrical shock, or personal injury, all wiring and grounding must be

done in accordance with local codes, or in the absence of local codes, with the National Electrical Code,

ANSI/NFPA No. 70-Latest Revision (for the U.S.) or the Canadian Electrical Code CSA C22.1 – Latest

Revisions and local codes and ordinances. It is your responsibility to provide adequate electrical services

for your dryer.

• All gas installations must be done in accordance with the national Fuel Code ANSI/Z2231 – Lastest

Revision (for the U.S.) or CAN/CGA – B149 Installation Codes – Latest Revision (for Canada) and local

codes and ordinances.

GROUNDING

This dryer must be grounded. In the event of malfunction or breakdown, the ground will reduce the risk of

electrical shock by providing a path of least resistance for electrical current.

GAS MODELS

Your dryer has a cord with an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided with your dryer – if it doesn’t fi t the outlet, have a proper outlet installed

by a qualifi ed electrician.

NEVER CONNECT GROUND WIRE TO PLASTIC PLUMBING LINES, GAS LINES, OR HOT WATER

PIPES.

ELECTRIC MODELS

Your dryer has a cord with an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

If a power cord is not used and the electric dryer is to be permanently wired, the dryer must be connected

to a permanent grounded metal wiring system, or an equipment grounding conductor must be run with

the circuit conductors and connected to the equipment grounding terminal.

1-11

Page 18

ELECTRICAL CONNE CTIONS

Before operating or testing, follow all grounding instructions in the Grounding section.

An individual branch (or separate) circuit serving only your dryer is recommended. DO NOT USE AN

EXTENSION CORD.

GAS MODELS – U.S. and Canada

A 120 volt, 60 Hz AC approved electrical service, with a 15-ampere fuse or circuit breaker is required.

ELECTRIC MODELS – U.S. Only

Most U.S. dryers require a 120/240 volt, 60 Hz AC approved electrical service. Some require 120/208

volt, 60 Hz approved electrical service. The electric service requirements can be found on the data label

located behind the door. A 30-ampere fuse or circuit breaker on both sides of the line is required.

• If a power cord is used, the cord should be plugged into a 30-ampere receptacle.

• The power cord is NOT provided with U.S. electric model dryers.

IMPORTANT:

When local codes allow, the dryer electrical supply may be connected by means of a new power supply

cord kit, marked for use with a dryer, that is U.L. listed and rated at a minimum of120/240 volts, 30ampere with three No. 10 copper wire conductors terminated with closed loop terminals, open-end spade

lugs with turned up ends, or with tinned leads.

1. size of the conductors and the type of cord.

2. 3/4” (1.9 cm) UL-listed strain relief

• Do not reuse a power supply cord from an old dryer. The power cord electric supply wiring must be

retained at the dryer cabinet with a suitable UL-listed strain relief.

• Grounding through the neutral conductor is prohibited for (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding

through the neutral conductor. (Use 4-prong plug for 4 wire receptacle, NEMA type 14-30R.)

ELECTRIC MODELS – Canada Only

• A 120/240 volt, 60 Hz AC approved electrical service fused through a 30-ampere fuse or circuit breaker

on both sides of the line is required.

• All Canadian models are shipped with the power cord attached. The power cord should be plugged into

a 30-ampere receptacle.

NOTE: It is not permissible to convert a dryer in Canada to 208 volts.

REPLACEMENT PARTS AND ACCESSORIES

If your dryer requires replacement parts or accessories, contact the dealer from whom you purchased your

dryer or a SAMSUNG customer care center at 1-800-SAMSUNG (726-7864).

1-12

Page 19

INSTALLATION

Parts and literature are packaged inside your dryer drum. To install:

1. Move your dryer to an appropriate location for installation. Consider installing the dryer and washer side-by-side, to allow access to

gas, electrical, and exhaust connections.

Lay two of the carton cushion-tops on the fl oor. Tip your dryer on its side so it will lay across both cushion-tops.

2. Set your dryer back in an upright position.

3. Review the Exhausting section before installing the exhaust system. Install the ductwork from your dryer to the exhaust hood. The

crimped end of the duct sections must point away from your dryer.

DO NOT use sheet metal screws when assembling ducting. These joints should be taped.

use plastic fl exible exhaust material.

Never

Tip for tight installations: install a section of exhaust system to your dryer before putting it in place.

Use duct tape to secure this section to your dryer, but do not cover louvers in dryer cabinet.

4. Review Electrical Requirements section.

BEFORE OPERATING OR TESTING, follow the grounding instructions in the Grounding section.

U.S. MODELS:

IMPORTANT – All U.S. models are produced for a 3-WIRE SYSTEM CONNECTION.

The dryer frame is grounded to the neutral conductor at the terminal block.

A 4-WIRE SYSTEM CONNECTION is required for new or remodeled construction, mobile homes,

or if local codes do not permit grounding through neutral. If the 4-wire system is used, the dryer frame cannot be grounded to the

neutral conductor at the terminal block. Refer to the following instructions for 3- and 4-WIRE SYSTEM CONNECTIONS.

Remove the terminal block cover plate.

Insert the power cord with a UL-listed strain relief through the hole provided in the cabinet near the terminal block.

NOTE: A strain relief must be used.

Do not loosen the nuts already installed on the terminal block. Be sure they are tight.

Use a 3/8” (1cm) deep well socket.

5. Review Gas Requirements section.

Remove the pipe thread protective cap.

Apply pipe joint compound or about 1 1/2 wraps of Tefl on tape over all threaded connections.

NOTE: Pipe joint compound must be resistant to the action of any liquefi ed petroleum gas.

Connect the gas supply to your dryer.

An additional fi tting is required to connect the 3/4” (1.9 cm) female thread end of a fl exible connector to the 3/8” (1 cm) male

threaded end on the dryer.

Securely tighten the gas line fi tting over threads.

Turn on the gas supply. Check all gas connections for leaks using a soap solution.

If bubbles appear, tighten the connections and recheck.

DO NOT use an open fl ame to check for gas leaks.

1-13

Page 20

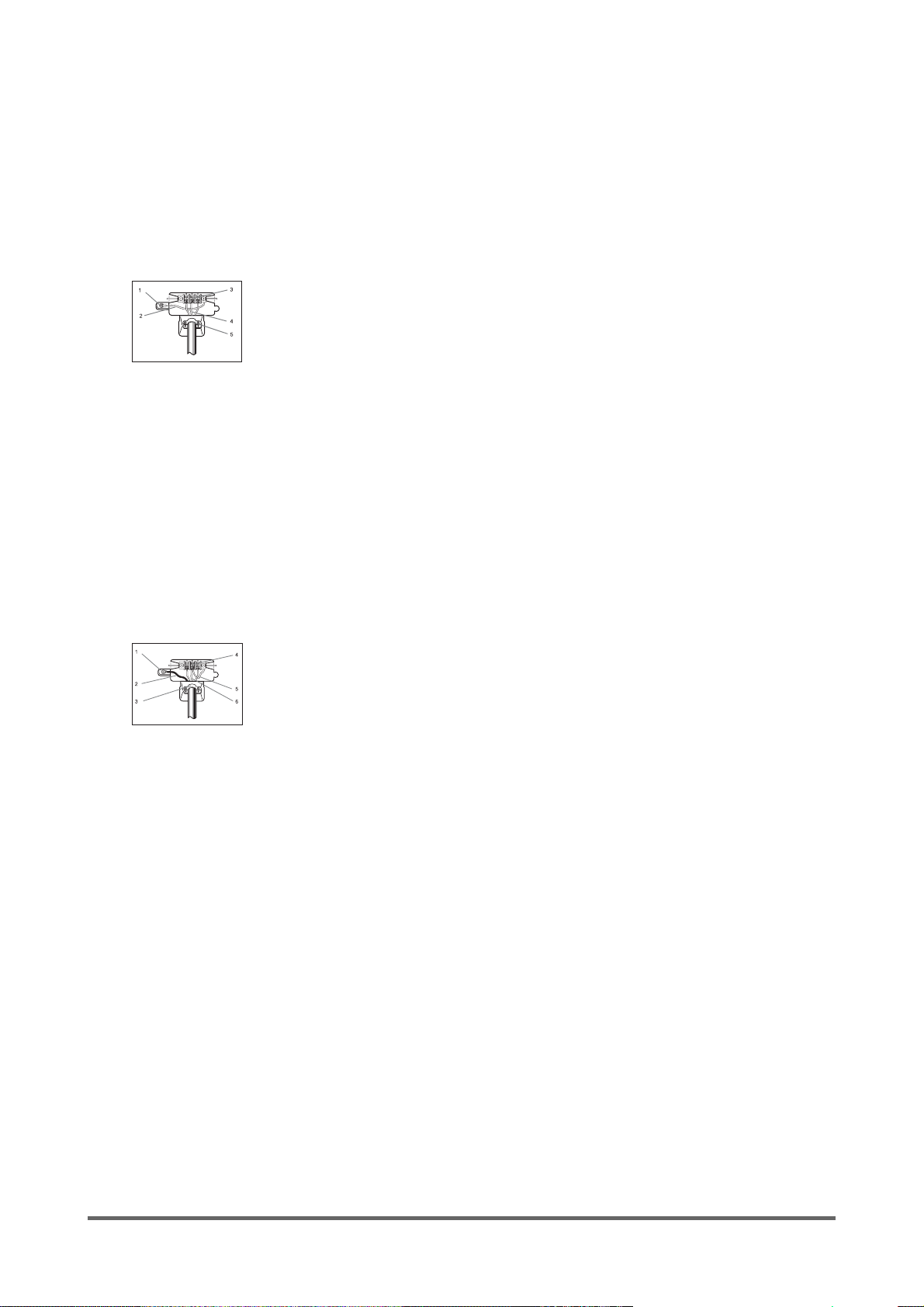

3-WIRE SYSTEM CONNECTIONS

1. Loosen or remove center terminal block screw.

2. Connect neutral wire (white or center wire) of the power cord to the center, silver-colored

terminal screw of the terminal block. Tighten screw.

3. Connect the other wires to outer terminal block screws. Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into your dryer’s rear panel slot.

Secure cover with hold-down screw.

• External ground connector

• Neutral grounding wire (green/yellow)

• Center silver-colored terminal block screw

• Neutral wire (white or center wire)

• 3/4” (1.9 cm) UL-listed strain relief

WARNING: If converting from a 4-wire electrical system to a 3-wire, the ground strap must be

reconnected to the terminal block support to ground the dryer frame to the neutral conductor.

4-WIRE SYSTEM CONNECTIONS

1. Remove center terminal block screw.

2. Connect ground wire (green or unwrapped) of power cord to external ground conductor screw.

3. Connect neutral wire (white or center wire) of power cord and appliance ground wire (green

with yellow stripes) under central screw of the terminal block.

4. Connect the other wires to outer terminal block screws. Tighten screws.

5. Tighten strain relief screws.

6. Insert tab of terminal block cover into your dryer’s rear panel slot.

Secure cover with hold-down screw.

• External ground connector

• Green or bare copper wire of power cord

• 3/4 in. (1.9 cm) UL-listed strain relief

• Center silver-colored terminal block screw

• Grounding wire (green/yellow)

• Neutral wire (white or center wire)

6. With a level, check your dryer and make necessary adjustments to the leveling legs.

7. At this time, make sure all gas connections (on gas models), exhaust and electrical connections are

complete. Plug in your dryer, and check operation by using the checklist below.

8. (GAS MODELS ONLY)

The burner may not ignite initially due to air in the gas line. Allowing your dryer to operate on a heat

setting will purge the line. If the gas does not ignite within 5 minutes, turn your dryer off and wait

5 minutes. Be sure the gas supply to your dryer has been turned on. In order to confi rm gas ignition,

check the exhaust for heat.

FINAL INSTALLATION CHECKLIST

□ Dryer is plugged into electrical outlet and properly grounded.

□ Exhaust ductwork is hooked up and joints taped.

□ Plastic fl exible duct is NOT used.

□ Use rigid or stiff-walled fl exible metal vent material.

□ Dryer is level with all legs fi rmly on the fl oor.

□ Gas models – gas is turned on with no gas leaks.

□ Start your dryer to confi rm that it runs, heats, and shuts of f.

1-14

Page 21

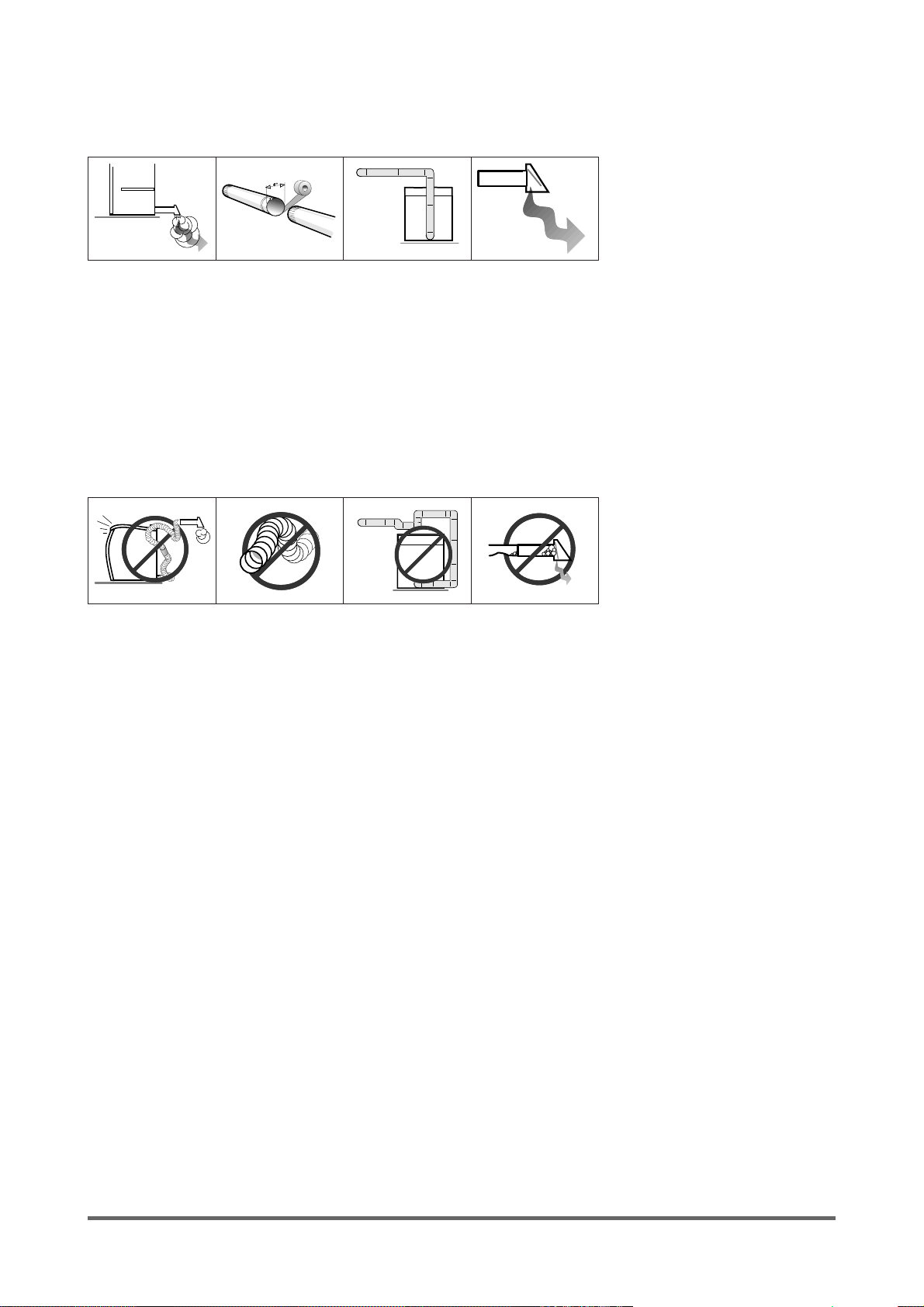

Dryer Exhaust Tips

WARNING: Plastic or non-metal fl exible duct presents a potential fi re hazard.

1. Let your dryer exhaust the air easily.

2. Use 4” diameter rigid metal duct.Tape all joints, including at the dryer.

Never use lint-trapping screws.

3. Keep ducts as straight as possible.

4. Clean all old ducts before installing your new dryer.

Be sure vent fl ap opens and closes freely.

Inspect and clean the exhaust system annually.

Don’t let a poor exhaust system slow drying by:

1. Restricting your dryer with a poor exhaust system.

2. Using a plastic, thin foil, or non-metal fl exible duct.

3. Using unnecessarily long duct runs with many elbows.

4. Allowing crushed or clogged ducts and vent.

1-15

Page 22

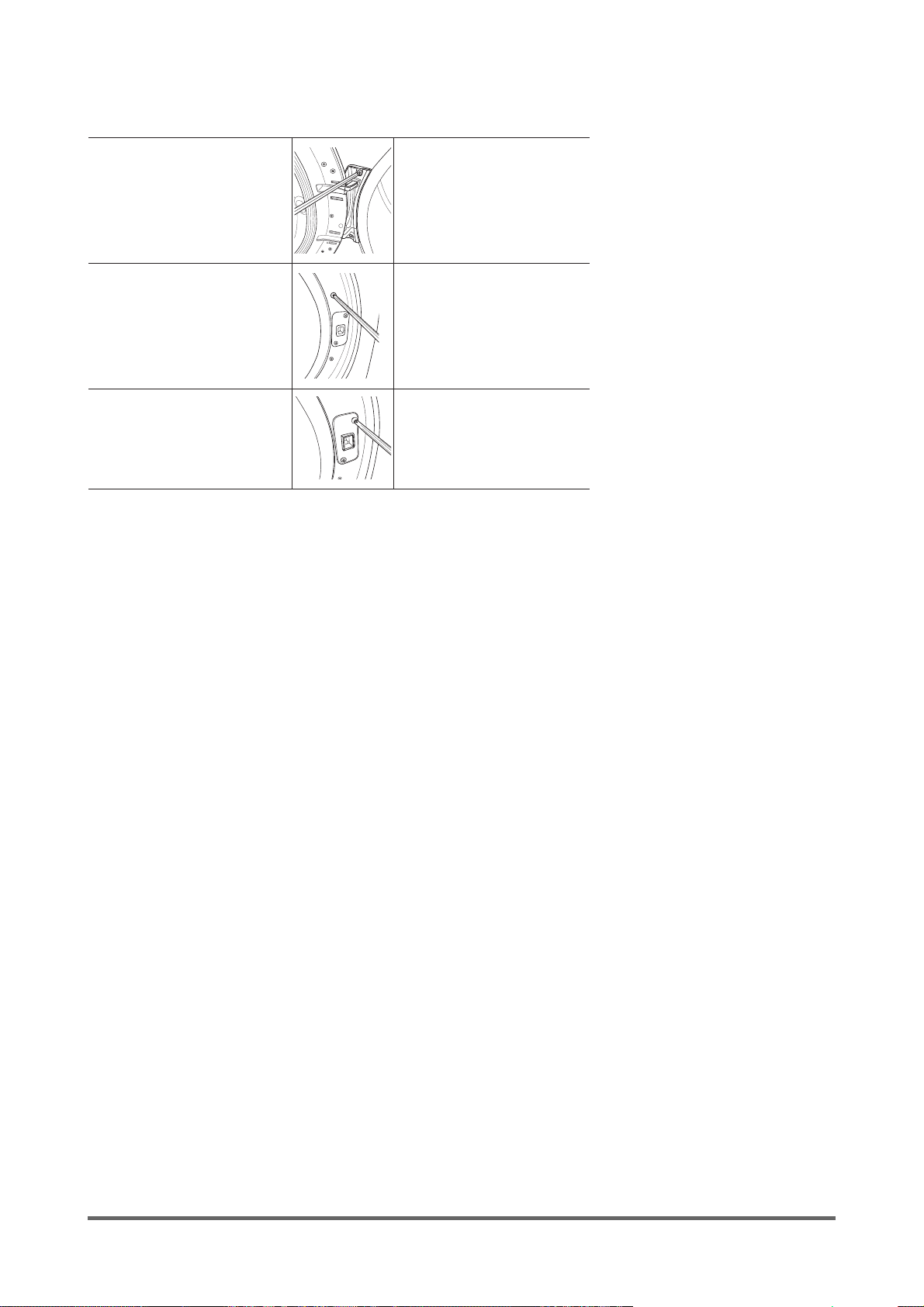

Door Reversal

1. Unplug power cord.

2. Remove two door hinge

screws.

3. Lift the door and remove

from

dryer.

4. Remove two screws on the

opposite side of door hinge.

5. Remove two screws on holder

lever.

6. Place the door on the other

side and reattach it to dryer.

7. Reassemble holder lever.

8. Reassemble the screws in

the

remaining holes.

1-16

Page 23

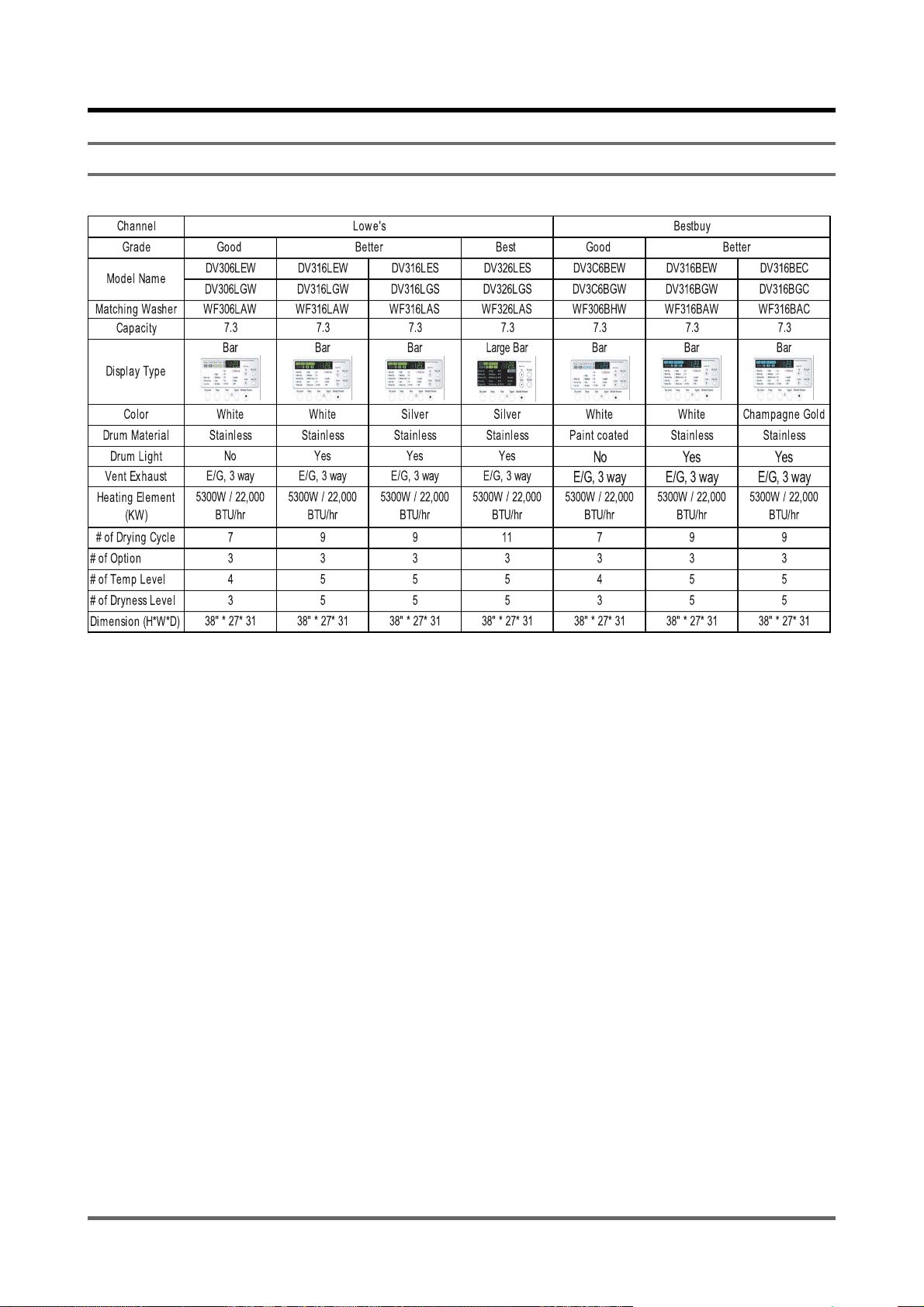

2. PRODUCT SPECIFICATIONS

2-1. THE FEATURE OF PRODUCT

2-1

Page 24

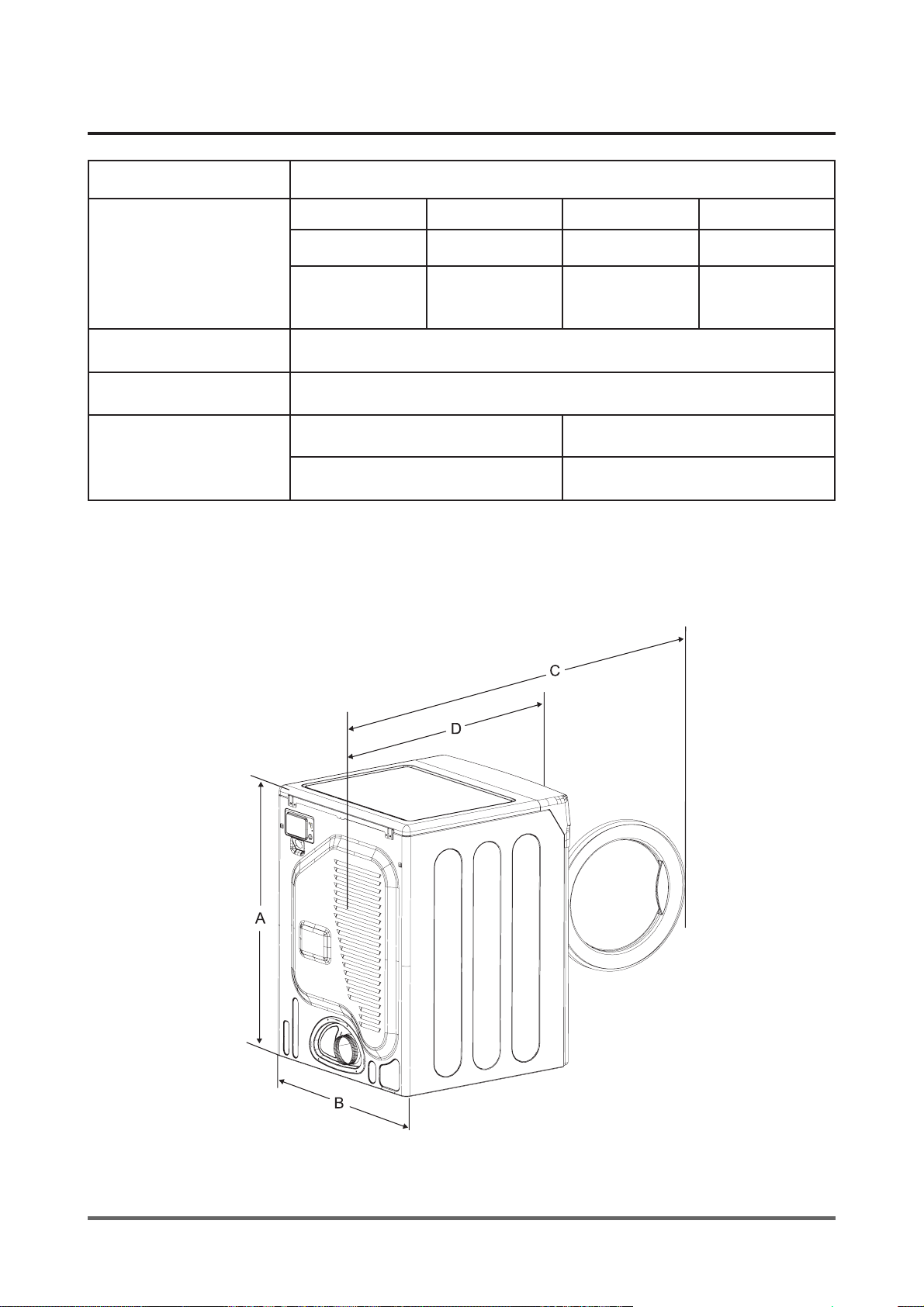

5051#VSHFLILFDWLRQV#RI#SURGXFW

ZDVK#W\SH

GLPHQVLRQ

ZHLJKW

KHDWHU#UDWLQJ

SRZHU#FRQVXPSWLRQ

FRONT LOADING TYPE

Div Inches (cm) Div Inches (cm)

A. Height 38”(96.5)

B. Width 27”(68.6) D. Depth 30.25” (77.0)

56.8kg

5300W

NO HEAT 268W

HEATING 5445W

C. Depth with

door open 90°

49”(124.5)

2-2

Page 25

5061#RYHUYLHZ#RI#WKH#GU\HU

2-3

Page 26

61#RSHUUDWLQJ#LQVWDOODWLRQV#DQG#LQVWDOODWLRQ

6041#RYHUYLHZ#RI#WKH#FRQWURO#SDQHO

1. Digital Graphic Display

The display window shows the estimated time remaining in the cycle after the Cycle Selector dial is

pressed. The estimated time remaining may fl uctuate as the cycle progresses.

The Drying light will illuminate and remain lit until the cycle is complete.

When your dryer is in the cool-down phase, the Cooling light will illuminate.

When your dryer is in the wrinkle prevent phase, the Wrinkle Prevent light will illuminate.

When the cycle is complete, “END” will appear in the display panel until the dryer door is opened or

Power key is pushed.

If your dryer is paused during a cycle, the indicator lights will blink until the Cycle Selector dial is

pressed.

2. Dry Level Selection Button

To select the dry level in the Normal, Heavy Duty, or other Sensor Dry cycles, press the Dry Level

button. An indicator light will illuminate next to the desired dryness level.

Press the button repeatedly to scroll through the settings. Larger or bulkier loads may require the

Very Dry (select models) or More Dry setting for complete dryness.

The Less Dry setting is best suited for lightweight fabrics or for leaving some moisture in the clothing

at the end of the cycle. Damp Dry (select models) is designed to partially dry items.

Use for items that lay fl at or hang to dry.

3. Temp Selection Button

To select the correct temperature for the load, press the Temp button. An indicator light will

illuminate next to the desired temperature. Press the button repeatedly to scroll through the

settings.

High – For sturdy cottons or those labeled Tumble Dry.

Medium – For permanent press, synthetics, lightweight cottons, or items labeled Tumble Dry Medium.

Medium Low – For lower heat than Medium to dry synthetic or washable knit fabrics.

Low – For heat sensitive items labeled Tumble Dry Low or Tumble Dry Warm.

Extra Low – Provides the lowest heated dry temperature possible.

4. Time Selection Button

When using Manual Dry cycles, time can be adjusted by pressing time selection button.

During the Sensory Dry cycle, the time light indicator is off because exact drying times are

determined by fl uctuating humidity levels.

3-1

Page 27

5. Signal Selection Button

When the cycle is complete, a chime will sound.

When the Wrinkle Prevent option is selected, the chime will sound intermittently.

Adjust the volume of the chime or turn it off by pressing the Signal button.

Press the button repeatedly to scroll through the choices.

6. Wrinkle Prevent Selection Button

Wrinkle Prevent provides approximately 90 minutes of intermittent tumbling in unheated air at the

end of the cycle to reduce wrinkling. Press the Wrinkle Prevent button to activate this feature.

The indicator light above the pad will illuminate when Wrinkle Prevent is selected.

Chasing lights appear in the display when the Wrinkle Prevent option is selected. The load is dry, and

can be removed at any time during the Wrinkle Prevent cycle.

7. Select Cycle Option

Adjust Time – Time can be added or subtracted from the automatically set times in the Manual

Dry cycles (Time Dry, Freshen Up, Delicates, Wrinkle Release, or Air Fluff cycles).

To add or subtract time from the cycle, press the Adjust Time arrow pad up or down until the desired

time is displayed.

My Cycle – Choose your favorite cycle including cycle, temp, dry level option, etc.

Rack Dry – Rack Dry is available at Time Dry cycle. Temperature will be set only to Extra Low.

8. Cycle Selector

To select a cycle, rotate the Cycle Selector dial to the desired cycle.

The indicator light by the cycle name will illuminate. The Normal, Heavy Duty, Towels, Perm Press and

Delicates cycles are Sensor Dry cycles.

Sensor Dry automatically senses the moisture in the load and shuts the dryer off when the selected

dryness level (very dry to damp dry) is reached.

Normal – Dry loads such as cotton, underwear, and linens use this cycle to get various levels of heat

for drying.

Heavy Duty – Use this cycle to get high heat for heavy fabrics such as jeans, corduroys, or work

clothes.

Towels – Dry loads such as bath towels.

Perm Press – Dry wrinkle-free cottons, synthetic fabrics, knits, and permanent press fabrics

automatically. The cycle minimizes wrinkling by providing a longer unheated cool-down

period at the end of the cycle.

Delicates – The Delicates cycle is designed to dry heat-sensitive items at a low drying temperature.

Freshen Up – This cycle removes odors and freshens garments.

Time Dry – Time Dry allows you to select the desired cycle time in minutes.

Turn the Cycle Selector dial to Time Dry, then press the Adjust Time up arrow to set the drying time.

Press the arrow repeatedly to scroll through the time settings.

Wrinkle Release – The Wrinkle Release cycle will release wrinkles from items that are clean, dry,

and only slightly wrinkled, such as clothes from a crowded closet, suitcase or items that have been

in the dryer too long after the cycle has ended. Wrinkle Release can be used with any temperature

selection.

Air Fluff – The Air Fluff cycle tumbles the load in room temperature air.

9. Start/Pause Selection Button

Press to pause and restart programs.

10. Power Button

Press once to turn your dryer on, press again to turn it off. If your dryer is left on for more than 10

minutes without any buttons being touched, the power automatically turns off.

3-2

Page 28

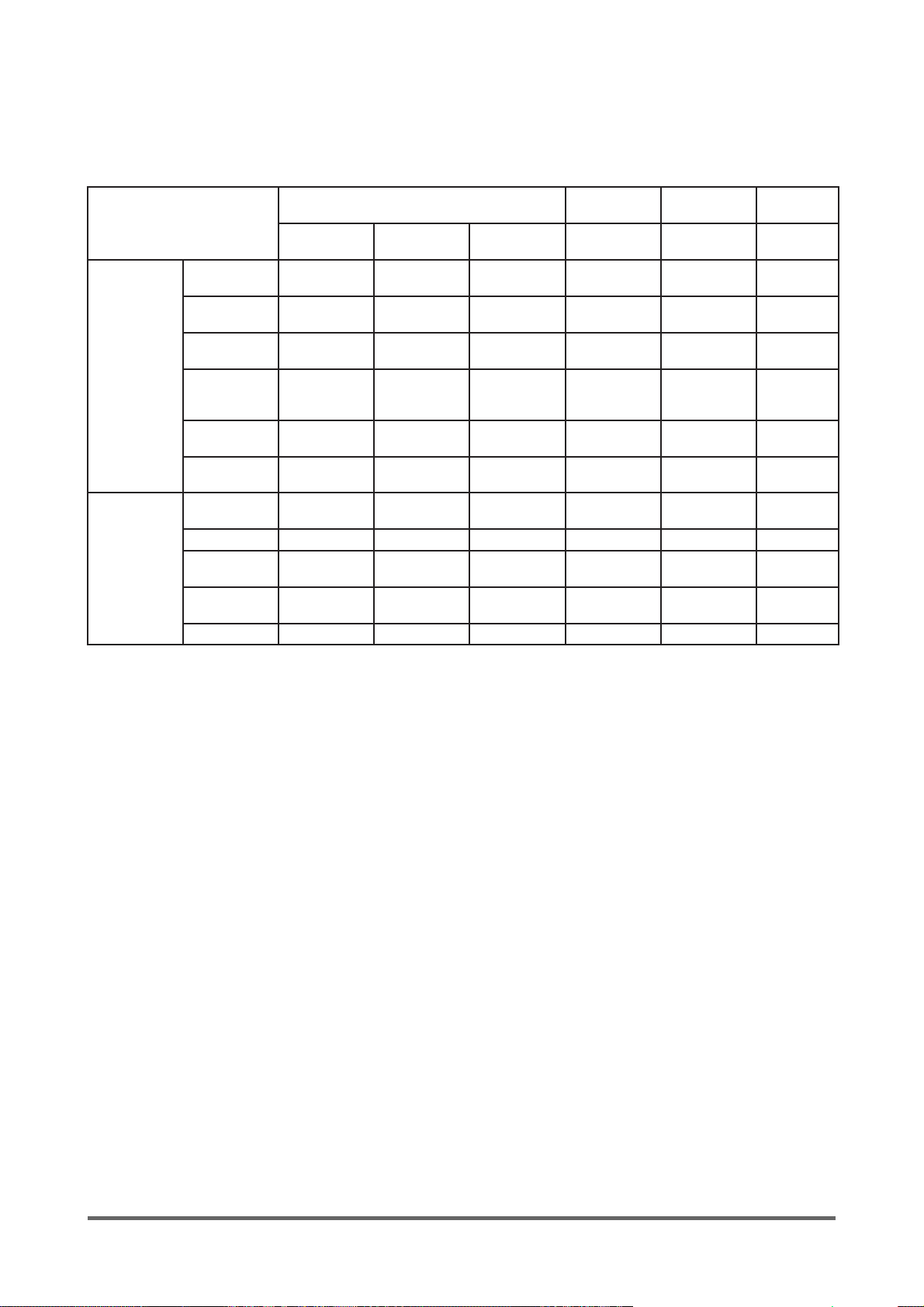

6051#F\FOH#FKDUW

Sensor

Dry

Manual

Dry

Default Drying Cooling

Cycle

Normal

Heavy

Duty

Towels

Perm Press

Delicates

Extra

Delicates

Freshen Up

Time Dry High - 40 min 35 min 5 min -

Wrinkle

Release

Air Fluff

Quick Dry High - 30 min 25 min 5 min -

Temp con-

trol

High

(Medium)

High (No

change)

High (Me-

dium)

Medium

Low

(No change)

Low (No

change)

Extra Low

(No change)

High (No

change)

Medium - 25 min 20 min 5 min -

- (No

change)

Sensor dry

level

Normal dry 44 min 39 min 5 min 90 min

Normal dry 60 min 55 min 5 min 90 min

Normal dry 52 min 47 min 5 min 90 min

Normal dry 34 min 24 min 10 min 90 min

Normal dry 29 min 24 min 5 min 90 min

Normal dry 29 min 24 min 5 min 90 min

- 30 min 25 min 5 min -

- 20 min - 20 min -

Time Time Time Time

Wrinkle

prevent

3-3

Page 29

6061#PDLQ#IXQFWLRQ

CHILD LOCK

A function to prevent children from playing with your dryer.

SETTING/RELEASING

If you want to set or release Child Lock, press both the Time and Signal buttons at the same time for 3

seconds.

How to Set:

1. It can be set while your dryer is running.

2. Once you set the Child Lock function, no button, except for the Power button,

can be controlled until you release the Child Lock function.

3. The Child Lock indicator will be lit.

Notice:

1. If the power is on again, the Child Lock function remains unchanged.

2. To release that function, follow the instructions above.

Notice:

When other buttons, except for the Power button, do not respond, check the Child Lock indicator.

MY CYCLE

Lets you activate your customized cycle that includes Dry Level, Temp, Time option, etc.

By pushing the My Cycle button, you activate the settings used during the previous My Cycle mode.

(Default : Normal Cycle)

If My Cycle mode is activated, My Cycle button will be lit.

You can select all options in My Cycle mode as follows.

1. Select cycle using Cycle Selector dial.

2. After cycle selection, set each option.

Note: At this time, the option will follow as per each cycle’s default option selection.

Then you can start My Cycle by pushing the Start/Pause button in My Cycle mode.

The cycle and options you select will be displayed next time you choose My Cycle.

3-4

Page 30

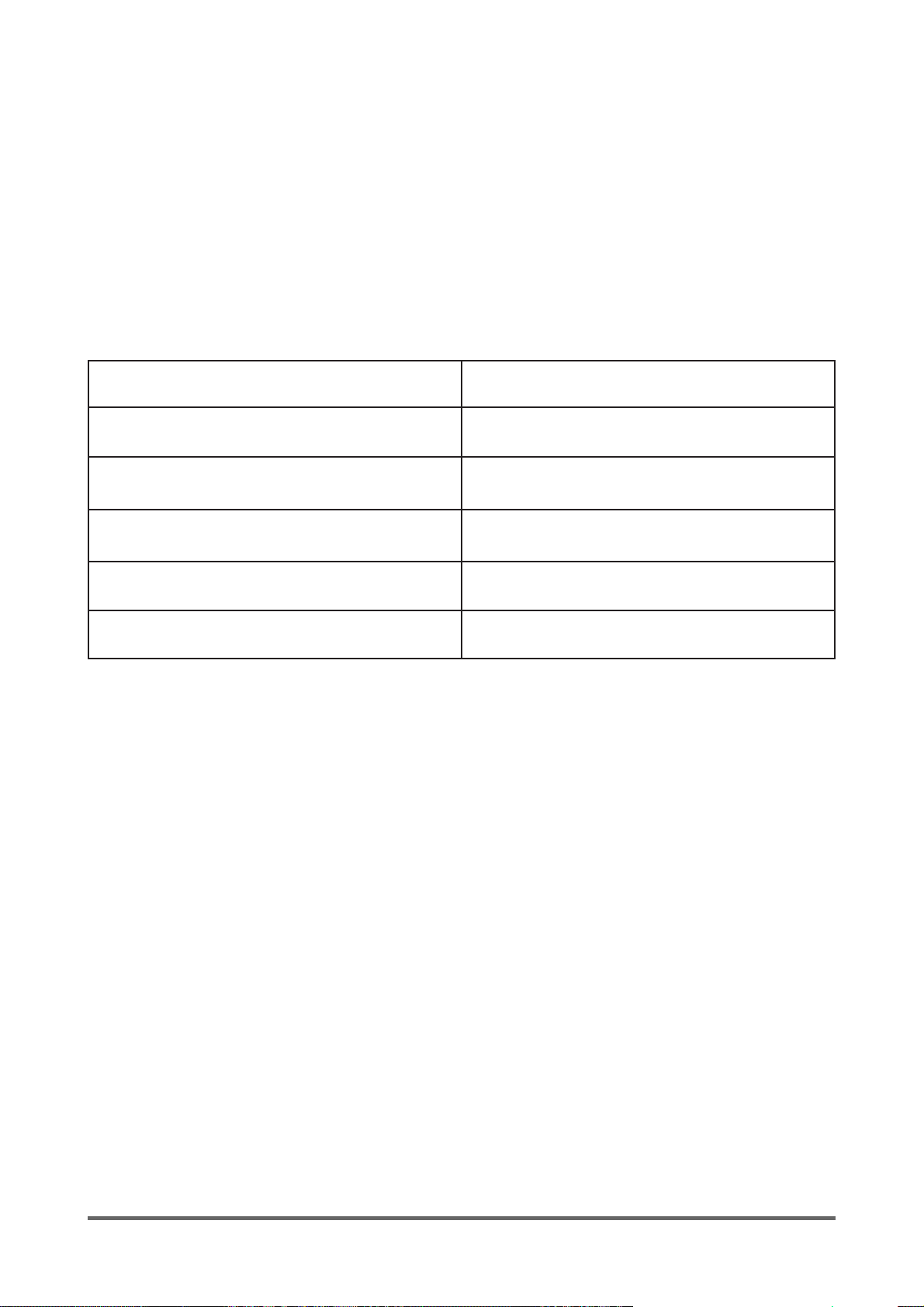

Rack Dry

INSTALLING THE DRYING RACK

1. Open dryer door.

2. Position drying rack in tumbler, placing the rear legs in the two recessed areas of the dryer’s

back wall.

3. Place the front lip of the drying rack on top of the lint fi lter.

4. Place items to be dried on the rack, leaving space between them so air can reach all surfaces.

5. Close dryer door.

6. Use the Time Dry cycle. Select time according to moisture and weight of the items. Start dryer.

It may be necessary to reset the timer if a longer drying time is needed.

SUGGESTED ITEMS SUGGESTED TEMP. SETTINGS

Washable sweaters (block to

shape and lay fl at on rack)

Stuffed toys (cotton or

polyester fi berfi lled)

Stuffed toys (foam or

rubber-fi lled)

Foam rubber pillows Air Fluff

Sneakers Fluff or Heat

WARNING – Drying foam rubber, plastic, or rubber on a heat setting may cause damage to the item

and lead to a fi re hazard.

Heat (Low/Extra Low)

Heat (Low/Extra Low)

Air Fluff

3-5

Page 31

Memo

3-12

Page 32

71#DOLJQPHQW#DQG#DGMXVWPHQWV

7041#Huuru#lwhpv#dqg#Gldjqrvwlf#Frghv

1. An occurrence of an Error will make a sound of error melody for 5sec and continuously show one of the

Error Displays from the following errors.

Display Description Trigger Action Taken

Check for:

- Clogged lint screen.

- Restricted vent system.

- Check Thermistor

resistance.

Check for:

- Clogged lint screen.

- Restricted vent system.

- Check Thermistor

resistance.

Check for:

- Close the door, and

run the dryer

- Loose or open wire

terminals in Door

Sense circuit.

Check for:

- Not using regular

power source

frequency

- Invalid power frequency sense circuit

Check for:

- Loose or open wire

terminals in Door

Sense circuit.

Check for:

- Restricted vent system.

- Check Thermistor

resistance.

Check for:

- Display PCB key

circuit short or not

Check for:

- Sensor bar Open

- using Adjust time Up

excessively

Check for

- PCB on EEprom

circuit

tS

tO

do Door Open

FE

dF Door Circuit Failure

hE Heater Error

bE Button Error

od Over Dry

Et EEprom Fail

Dryer Thermistor Short

Sensed

Dryer Thermistor Open

Sensed

Power source frequen-

cy Error

The Thermistor

resistance is

very low.

The Thermistor

resistance is

very high.

Running the

dryer with door

open

Invalid power

source

Frequency

Invalid state for more

than 256

milliseconds

Invalid heating Temp in

running the dryer

Invalid state

of key circuit short

for 75secs

Invalid Dry

time in

excess Dry time

Invalid state

of Eeprom

communication

4-1

Page 33

7051#WHVW#PRGH

4-2-1. Continuous Run Mode

Continuous Run Mode:

1. Press Signal + Dryness Level for 3 sec during Power On State (Normal User Mode) .

2. Once in Continuous Run Mode, 7-Segment will toggle display “cc” and the remaining time.

3. The previous cycle will restart during Continuous Run Mode until continuous run mode is

disabled.

4. During Continuous Run Mode, press Signal + Dryness Level for 3 seconds to return to normal

user mode. 7-segment will no long display “cc” and only display the remaining time.

4-2-2. Special Test Mode

Defi nition of Special Test Mode:

- Dryer must be on before Service Mode can be entered.

- Press Signal and Temp Keys for 3 seconds, or until 3 beeps are heard.

- The machine will now be in Service Mode.

- Upon entry into Service Mode, the Sensor Bar Touch Data will be shown (Default Special Test Mode).

How to Enter:

- To enter Special Test Mode press Signal and Temp Keys for 3 seconds for 3 seconds or until the control

beep.

(same for all Frontier models.)

4-2

Page 34

4-2-3. Sensor Bar Touch Data Mode

Defi nition of Sensor Bar Touch Data Mode:

-While in Power On pressing Signal and Temp Keys for 3 seconds

-This action will put the dryer into sensor bar touch data mode

- Dryer will display Sensor Bar data. This mode is default mode of entering service mode

How to Enter:

- While in Power off pressing Signal and Temp Keys for 3 seconds (same for all Frontier models.)

4-2-4. Cycle Count Mode

Defi nition of Cycle Count Mode:

- While in Service Mode pressing the Signal key will put the dryer into the cycle count mode

- Cycle number executed will display.

How to Enter:

- To enter Special Test Mode press While in Service Mode pressing the Signal key for 3 seconds or until

the control beep.

(same for all Frontier models.)

4-3

Page 35

4-2-5. Software Version Mode

Defi nition of Software Version Mode:

- While in Service Mode pressing the Temp key will put the dryer into the software version mode

How to Enter:

- To enter Special Test Mode press Temp Key until the control beep.

(same for all Frontier models.)

ex) In case of “U105”, U0 means major version “v1“ 05 means minor version “05”

4-2-6. System Check Mode

Special Test Mode:

- While in Power Off, pressing the Dryness Level + Power keys simultaneously will put the dryer into the

System Check mode

- “ t2 “ will display.

- System Check Mode Progress

t2 mode Function Performed Start/Pause Motor(CW) Relay On → Heater Relay On → Heater Relay Off →

Motor(CW) Relay Off (Circulation)

4-4

Page 36

81#DVVHPEO\#DQG#GLVDVVHPEO\

8041#WRROV#IRU#GLVDVVHPEO\#DQG#DVVHPEO\

NO. TOOL

1

2

3 Vice pliers

4 Other(Driver, Nipper, Long nose) General tools for the after service.

5 JIG for the Tub 1 (Disassemble and Assemble)

Box driver

Double-ended

spanner

10mm

13mm

19mm

10, 13,19mm

######

Heater (1)

Motor (1), Balance (5), 2 holes of each left and right of the

shock absorber 1 Pulley hole

Replaceable for the box driver.

Since the bolt runs idle when the box driver is used, use the

box driver 17mm.

Tool to protect the idle and abrasion of the bolt for the

box driver.

5-1

Page 37

5-2. DISASSEMBLY

Warning! To avoid risk of electrical shock, personal injury or death, disconnect the power to the washing machine.

Part Name

Top

Removal

Descriptive Picture

How To Do

1.Disconnect power supply to unit.

2.Remove 2 10mm screws from

dryer back.

3.Slide Top Cover towards the rear

and lift from unit.

Drum Baffl e

Removal

Console

Removal

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove four screws located at

the sound dampening seem.

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove two screws mounting

the Heater PCB Board.

4.Disconnect the black and white

connectors.

5.Remove four screws attaching

Console to dryer

6.Rotate Console down and

remove from dryer.

####

5-2

Page 38

Part Name

Front Panel

Removal

Front Bulk-

head

Removal

Descriptive Picture

How To Do

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove Console.

4.Remove four screws attaching

Front Panel to dryer.

5.Remove two screws in the door

area.

6.Pull Front Panel forward and

disconnect the Interior Light

harness.

7.Lift the Front Panel off the three

tabs across the bottom and

remove.

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove Console.

4.Remove Front Panel.

5.Remove screws retaining

Console Back Cover.

6. Disconnect Interior Light wiring

harness.

7.Disconnect Moisture Sensor

wiring harness.

8.Remove four Bulkhead retaining

screws.

9.Lift Bulkhead from Cabinet and

remove.

####

Moisture

Sensor

Removal

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove Console.

4.Remove Front Panel.

5.Disconnect Moisture Sensor wire

harness.

6.Remove sensor attachment

screw.

5-3

Page 39

Part Name

Drum Re-

moval

Descriptive Picture

How To Do

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove Console.

4.Remove Front Panel.

5.Remove Console Back Cover.

6.Remove Front Bulkhead.

7.Remove belt from Idler Pulley.

8.Grasp the Drum with one hand

and the belt with the other. Lift

the Drum and slide out the front.

Carefully spread the cabinet as

needed to gain additional

clearance.

Rear Roller

Removal

Motor/Blow-

er

Assembly

Removal

(1)

1.Disconnect power supply to unit.

2.Remove Rear Bulkhead.

3.Remove Roller Keeper and nut.

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove Console.

4.Remove Front Panel.

5.Remove Console Back Cover.

6.Remove Belt from Idler Pulley.

7.Remove Drum.

8.Remove the two screws securing

the Blower Intake Panel to the

Blower Housing. Remove Blower

Intake panel.

9.Removed the screw at the

bottom of the blower housing.

10.Remove the blower attachment

screw under the Thermistor.

11.Remove two screws attaching

the motor bracket to the base.

12.Disconnect the Motor wire

harness and the two wires to the

belt switch.

####

5-4

Page 40

Part Name

Motor/Blow-

er

Assembly

Removal

(2)

Rear Bulk-

head

Removal

Descriptive Picture

How To Do

13.Slide the Motor Blower.

Assembly toward the heater and

lift to disengage the tabs on the motor

from the slots in the base.

14.Remove the 14mm nut securing the blower

wheel to the shaft. The nut is a left hand

thread.

QRWH=#D#zuhqfk#fdq#eh#sodfhg#rq#erwk##

# # hqgv#ri#wkh#Prwru#Rxwsxw#Vkdiw1

15.Remove Blower Wheel.

16.Remove the three screws

securing the blower housing to

the motor bracket.

17.Remove the three screws

securing the blower housing to

the motor bracket .

18.Use a wide blade screwdriver to pop off the

motor retentionclamps.

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove Console.

4.Remove Front Panel.

5.Remove Console Back Cover.

6.Remove Belt from Idler Pulley.

7.Remove Drum.

8.Remove 7 screws from the back.

9.Lift the rear bulkhead off the right

and left side hangers.

Burner Re-

Heater As-

Removal

####

moval

sembly

1.Disconnect power supply to unit.

2.Shut off gas supply.

3.Disconnect gas line.

4.Remove two screws securing

burner to bracket.

QRWH=#Wkh#Ljqlwhu#Edu#lv#iudjloh1#Eh#

# # fduhixo#qrw#wr#gdpdjh#Ljqlwhu#zkhq##

# # uhprylqj#Exuqhu#Dvvhpeo|1

5.Remove the two screws attaching

the housing to the burner bracket.

The screws are recessed from view.

6.Slide Burner Assembly from dryer.

1.Disconnect power supply to unit.

2.Remove Top Cover.

3.Remove Console.

4.Remove Front Cover.

5.Remove Heater Assembly retaining screw.

6.Slide Heater Assembly out the front of dryer.

7.Remove the wiring terminals from the Heater

Assembly.

8.Reinstall by aligning the tabs on the back

bulkhead with the notches in the Heater As

sembly.

5-5

Page 41

5-3. REASSEMBLY

Reassembly procedures are in the reverse order of dissasembly procedures.

5-6

Page 42

91#WURXEOH#VKRRWLQJ

9041#WURXEOH#GLDJQRVLV

- As the micom dry machine is confi gured of the complicate structure, there might be the

service call.

Below information is prepared for exact trouble diagnosis and suitable repair guide.

Caution for the Repair and Replacement

Please follow below instruction for the trouble diagnosis and parts replacement.

1) As some electronic components are damaged by the charged static electricity from the resin

part of wash machine or the human body, prepare the human body earth or remove the potential differ

ence of the human body and wash machine by contacting the power supply plug when the work contact

ing to PCB is executed.

2) Since AC220~240V is applied to the triac T1 and T2 on P.C.B, the electric shock may occur by

touching and be careful that the strong and weak electricity are mixed.

3) As the P.C.B assembly is designed for no trouble, do not replace the P.C.B assembly by the

wrong diagnosis and follow the procedure of the trouble diagnosis when the micom is not op

erated normally.

6-1

Page 43

No Problem What T o Do

• All wires are hooked up to their corresponding terminals.

• Dryer is plugged in.

• Blown fuse or circuit breaker.

• Door switch functional...door closed. Check for error code 3 (See Table for code

Will Not Start or Run

1

2 Motor runs/ tumbler will not turn

Runs a few minutes and then

3

stops

Blows fuses or trips circuit

4

breaker

Blows fuses or trips circuit

5

breaker

(Gas Model)

6 Will not heat (motor runs)

Will Not Dry Gas Model

7

Poor Gas Ignition

8 The igniter does not glow

9 Igniter glows - No gas ignition

The gas is ignited but the fl ame

10

goes out

Improper drying

clothes wrinkled

11

Rough texture

long dry time

12 Noisy and/Or Vibration

defi nition).

• Start/Pause rotary selector dial functional.

• Control Board operational.

• Belt off or broken and Belt Cut-off Switch operates.

• Drive motor functional.

• Check motor winding resistance: 2.88ohms between pin #3 and 4, 3.5ohms

between pin #4 and 5.

• Belt off or broken/damaged.

• Idler tension spring too weak or stretched.

• Idler pulley jammed or stuck.

• Lint buildup around drive motor.

• Low voltage present.

• Blower impeller blocked in blower housing.

• Drive motor - start switch contacts stuck closed.

- Is the belt connected well?

- Is the winding of the motor continuous?

(Rotor winding, stator winding, generator)

- Is the motor protector normal?

• If above points are not found, the PCB assembly is out of order.

Replace it.

• During ignition the dryer will draw X amps. With the burner ON, the dryer will

draw X amps. If the dryer is drawing amperages above this, then the house

wiring, fuse box or circuit breaker is suspected to be at fault.

• Igniter harness loose and shorted to base.

• Incorrect wiring or wire shorted to ground.

• Drive motor winding shorting to ground.

Open heating element.

• Hi-Limit trips easily or is open.

• Regulating thermostat trips easily or is open.

• Membrane switch open.

• Check Thermistor.

When the dryer is operated on a heat setting, the igniter should be energized and

burner shall fi re within 45 seconds at 120 VAC. The failure of a component in this

system will usually be indicated by one of three symptoms:

If the igniter does not heat up, remove power and using an ohmmeter, check the

following:

• Open fl ame sensor

• Open igniter

• Shorted booster coil

• Open wiring

• Bad motor switch ( Neutral supply)

• No power from control ( L1 supply)

If the igniter heats up but the main burner fl ame is not ignited, remove power and

using an ohmmeter, check the following:

• Open secondary coil

• Open holding coil

• Open wire harness

• Stuck fl ame sensor (Stuck closed)

If a normal ignition takes place and after a short while the fl ame goes out, check

for the following:

• Radiant sensor contacts opening prematurely.

• Weak gas valve coil may open when stressed by higher Temps.

• Weak Hi-Limit

• Poor venting

• Bad drum seals

• Lint fi lter is not clean.

• Restriction in exhaust.

• Outside exhaust hood damper door stuck closed.

• Exhaust too long, too many elbows, fl ex ductwork installed.

• Poor intake air available for the dryer.

• Incorrect tumbler speed. Tumbler belt slipping.

• Blower impeller bound; check for foreign material in blower area.

• Customer overloading dryer.

• Check clothing labels for fabric content and cycle selected.

• Clothes too wet due to insuffi cient spin out by washer.

• Thumping Check for loose tumbler baffl e, rear tumbler roller(s) worn or

misaligned, out-of-round tumbler or high weld seam on tumbler.

• Ticking Check for loose wire harness or object caught in blower wheel area.

• Scraping Check for front or rear bulkhead felt seal out of position or worn

tumbler front bearings.

• Roaring Check for blower wheel rubbing on blower housing or bad motor

bearings.

• Popping or squealing sound. Check for a sticky or frayed belt.

6-2

Page 44

9051#SUREOHP#FKHFNLQJ#DQG#PHWKRG#RI#SFE

-If you plug in the power cord and turn Power S/W on, memorized data is displayed.

If any data is not displayed, check the followings.

90504#Wkh#Sduw#Ri#Srzhu#Vrxufh#

No Power ON

The Voltage Of

Betweenⓐand ⓑIs

As Big As 12V?

Yes

The Voltage Of

Betweenⓒand ⓓ Is

As Big As 12V?

Yes

The Voltage Of

Betweenⓔand ⓓ Is

As Big As 5V?

Yes

No

No

No

Exchange IC3(7805) And Check

Check The Trans

Check The Diode

(D11,D12,D16,D17,D18)

And Condenser(CE3)

The Condenser(CE5)

6-3

Page 45

905051#Uhvhw#Sduw

The Value Of Measurement

Result Of Between Micom 25

And Gnd Is 5V?

Yes

Check IC4

905061#Lqwhuuxsw#Sduw

Check The Curve

Output Of ⓐ ?

No

Check The Power Source

IC4

7533

CE7 1UF

Check D11,12,16,17,18

R40 100

25

Yes

Check The Micom

Number 67 ?

Yes

Check The Part Of

Oscillator

Check TR2,R35

6-4

Page 46

905071#Fkhfnlqj#Wkh#Sduw#Ri#Dq#Rvfloodwru

The Value Of Measurement

Result Of Between Micom 25

And Gnd Is 5V?

Yes

Check IC4

No

905081#Fkhfn#Wkh#Sduw#Ri#Ex}}hu

ⓐ Part Confirm DC12V ?

No

Check The Power Source

Check The Part Of Power Source

Yes

Exchange BUZZER1,

Check R5,R46

6-5

Page 47

Memo

6-6

Page 48

EEEExxxxppppllllooooddddeeeeddddVVVViiiieeeewwwwooooffffWWWWhhhhoooolllleeeePPPPaaaarrrrttttssss

- 4 -

Page 49

1. Exploded View of Duct, Heater, Motor

39

18

11

41

36

29

24

50

2

30

37

3

40

31

21

13

46

47

45

33

49

53

52

42

22

34

12

38

23

44

14

43

32

51

( GAS MODEL ONLY )

28

4

7

19

10

6

27

35

15

1

8

9

0

2

25

16

20

48

26

35

5

17

- 5 -

Page 50

1. Parts List of Duct, Heater, Motor

No. CODE NO. DESCRIPTION SPECIFICATION QTY

1 6021-001201 NUT-INCH LEFT TURN,3/8"-24,ZPC(YEL),MSWR10,INCH 1

2 DC31-00055A MOTOR-DRYER WINGS-PJT,120V 60Hz,60Hz,120V 1

3 DC61-01214A SPRING-PLATE WINGS-DRYER,SK-5,MOTOR 2

4 3405-001077 SWITCH-MICRO 125V,15A,180gf,2 1

5 DC61-01215A SPRING-TENSION WINGS-DRYER,HSWR,BELT CONTROL 1

6 DC61-01228A HOLDER-SHAFT WINGS-DRYER,NYLON#6,NTR,ROLLER 1

7 DC97-07509B ASSY-ROLLER MDE9700AYW,DRYER/MOTOR/IDLER 1

8 DC61-01241A GUIDE-DUCT FAN WINGS-DRYER,TB-54,NTR 1

9 DC63-00536A COVER-DUCT FAN WINGS-DRYER,TB-54,NTR 1

10 DC97-07895A ASSY-DUCT CONNECTOR MDE9700AYW,DRYER/ELECTRIC 1

11 DC47-00018A THERMOSTAT 60T11,250V,25A20~15030~150,25A,23.6,100M,260F-50F(HI-LIMIT) 1

12 DC99-00507A ASSY PIPE MDG9700AWW,GAS DRYER/ELBOW ASSY 1

13 DC62-00200A TUBE-BURNER WINGS-DRYER,PRESS(GAS UNIT),-,-,-,-,MAYTAG G/S 1

14 DC32-00008A SENSOR-RADIANT 10RS,GD-PJT,0~150,120,4.5,100,-,-,FRAME GAS 1

15 DC67-00180A FAN WINGS-DRYER,FRPP(15%) 1

16 DC47-00016A THERMOSTAT B-2,-,250V,25A,-20~150,-40~150,25A,16,100M,-,85/SAFETY 1

17 DC96-00882B ASSY-BRACKET IDLER MDE9700AYW,DRYER/IDLER 1

18 DC47-00019A HEATER-DRY GD-PJT,-,5300W,21A,240,10,D1.3,240V5300 1

19 6002-000213 SCREW-TAPPING TH,+,1,M4,L12,ZPC(YEL),SWRCH18 2

20 6002-000470 SCREW-TAPPING TH,+,1,M4,L10,ZPC,SCRCH18A 5

21 6009-001342 SCREW-SPECIAL TH,+,M5,L11,ZPC(YEL) 1

22 DC47-00022A HEATER-IGNITOR 120V4.5A 1

23 DC61-01232A BRACKET-BURNER SGCC(GI),1.4t 1

24 DC61-01224A DIE-HEATER WINGS-DRYER,SECC(EGI),NTR,T1.0 1

25 DC61-01240A BRACKET-THERMISTOR WINGS-DRYER,TB-54,GUIDE-DUCT FAN 1

26 DC61-01213A BRACKET-MOTOR WINGS-DRYER,HGI,T2.0 1

27 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 3

28 6002-000488 SCREW-TAPPING PH,+,2S,M3,L16,ZPC(YEL),SWRCH1 1

29 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 1

30 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 2

31 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 2

32 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 1 2

33 6002-001310 SCREW-TAPPING TH,+,2S,M3.5,L20,PASS 1

34 DC63-00623A ABSORBER-IGNITOR FELT,T2,W10,L10 1

- 6 -

Page 51

1. Parts List of Duct, Heater, Motor

No. CODE NO. DESCRIPTION SPECIFICATION QTY

35 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 2

36 DC67-00132A DUCT-HEATER(U) WINGS-DRYER,AL-COAT,T0.6,NTR,UPPER 1

37 DC67-00133A DUCT-HEATER(L) WINGS-DRYER,AL-COAT,T0.6,NTR,- 1

38 6002-001305 SCREW-TAPPING TH,+,2S,M5,L10,PASS 1

39 DC97-08891A ASSY-HEATER DUCT WINGS-DRYER,HEATER,5300W 1

40 6002-000239 SCREW-TAPPING TH,+,2S,M4,L8,ZPC(YEL),SM20C 7

41 6002-000239 SCREW-TAPPING TH,+,2S,M4,L8,ZPC(YEL),SM20C 4

42 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 3

43 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 2

44 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 1

45 6021-001130 NUT-CIRCULAR SPN-4,ID3.8,OD12,BLK,SK-5,H1.4,T0.3 1

46 6006-001172 SCREW-TAPPING WE,TH,+,M4,L12,ZPC(YEL) 3

47 DC62-00201A VALVE-GAS WINGS-DRYER,DIECASTING,-,-,-,MAYTAG GAS 1

48 DC32-00007A THERMISTOR N3S1-K41-S1,10K,10KOHM 25,-40~105,-,5,-,5,N3S1-K41-S1 1

49 DC47-00017A THERMOSTAT 60T21,250V,15A/25A,-20~150,-30~150,230F-50F(HI-LIMIT) 1

50 DC96-00887A

51 DC67-00136B DUCT-CONE(F) WINGS-DRYER,AL-COAT,T0.6,-,-,NTR,FRONT 1

52 DC67-00137B DUCT-CONE(B) WINGS-DRYER,AL-COAT,T0.6,-,-,NTR,BACK 1

53 DC97-07602B ASSY-DUCT CONE MDG9700AWW,GAS 1

ASSY-BRCKET

THERMOSTAT

MDE9700AYW,DRYER/ELECTRIC 1

- 7 -

Page 52

2. Exploded View of Front

16

17

9

8

10

1

20

12

13

15

5

11

6

14

19

18

4

3

2

11

10

7

- 8 -

Page 53

2. Parts List of Front

No. CODE NO. DESCRIPTION SPECIFICATION QTY

1 DC66-00395A LEVER-DOOR WINGS-DRYER,POM,NTR 1

2 DC97-07510A ASSY-HOLDER LEVER WINGS-DRYER,POM,NTR 1

3 DC97-10338A ASSY-COVER DOOR FRONTIER 1

4 DC61-01523A HOLDER-GLASS FRONTIER-DRYER,TB-54,GRAY 1

5 DC61-01532A HINGE-DOOR FRONTIER,ZNDC 1

6 DC61-01576A SUPPORT-HINGE FRONTIER,STS304,T1.2,HOLDER-GLASS 1

7 DC97-10350A ASSY-FRAME FRONT FRONTIER-DRYER,WHT 1

8 DC64-00828A DOOR-SWITCH GD-PJT,PA,T13.6,H38.5,W44.3,WHT,120V/15A SPE110F 1

9 6006-001172 SCREW-TAPPING WE,TH,+,M4,L12,ZPC(YEL) 3

10 6002-001006 SCREW-TAPPING TH,+,2S,M4,L12,PASS,STS430 4

11 6001-001773 SCREW-MACHINE TH,+,M5,L12 4

12 6002-000444 SCREW-TAPPING TH,2S,M4,L14,PASS,STS430 2

13 DC61-00891A GUIDE-HINGE HAUZEN(DOM),POM,WHT,HINGE 4

14 6002-000213 SCREW-TAPPING TH,+,1,M4,L12,ZPC(YEL),SWRCH18 8

15 6002-000444 SCREW-TAPPING TH,2S,M4,L14,PASS,STS430 9

16 DC72-00032B SPONGE-EPDM MDE9700AYW,EPDM,T3,W15,L345,BLK,FRAME-FRONT 4

17 DC61-01222A BRACKET-HINGE WINGS-DRYER,SECC(EGI),T1.6 2

18 DC64-00993A DOOR-GLASS WINGS-DRYER,GLASS,T5,TRP,G/SOURCING 1

19 DC62-00198B SEAL-DOOR WINGS-DRYER,SILICON,GRAY 1

- 9 -

Page 54

3. Exploded View of Drum

13

17

31

26

14

7

4

4

3

3

1

18

19

16

28

9

33

23

6

27

12

10

11

7

20

24

25

30

24

15

23

32

7

4

4

22

21

5

4

3

23

3

7

4

29

4

4

8

2

- 10 -

Page 55

3.PartsListofDrum

No. CODE NO. DESCRIPTION SPECIFICATION QTY

1 DC97-10355A ASSY-DRUM WRAPPER FRONTIER-DRYER,STAINLESS 1

2 DC66-00436A DRUM-LIFTER WINGS-DRYER,TI-42,GRAY 3

3 DC60-50145A NUT-HEX MSWR10,M10 4

4 DC60-60060A WASHER T2,ID12,OD24,YEL 8

5 DC66-00398A DRUM-BACK WINGS-DRYER,STS-301,T0.6,HAIRLINE#4 1

6 DC97-07521A ASSY-DUCT AIR MDE9700AYW,DRYER/ELECTRIC 1

7 DC97-07523A ASSY-ROLLER MDE9700AYW,DRYER/EPDM 2

8 6602-001314 BELT-TIMING GEAR 0724,RUBBER(GOODYEAR),T3*W8,-,L2337,BLACK 1

9 4713-001199 LAMP-INCANDESCENT 120V,83mA,10W,NTR,22x54mm 1

10 DC61-01231A PLATE-SENSOR WINGS-DRYER,STS-304,T0.8,TOUCH-SENSOR 2

11 DC61-01235A GUIDE-SENSOR WINGS-DRYER,TI-42,GRAY,TUOCH-SENSOR 1

12 DC63-00531A COVER-LAMP WINGS-DRYER,PC(LEXAN#141R),TRP 1

13 DC97-07526A ASSY-DUCT OUTLET MDE9700AYW,SRYER/ELECTRIC 1

14 DC61-01521A CASE-FILTER WINGS-DRYER,TI-42,GRAY,26*26 MESH INSERT 1

15 DC63-00675A COVER-FILTER(B) WINGS-DRYER,TI-42-,GRAY,BACK 1

16 6002-001204 SCREW-TAPPING TH,+,1,M4,L16,PASS,STS304 12

17 6006-001172 SCREW-TAPPING WE,TH,+,M4,L12,ZPC(YEL) 4

18 6002-001006 SCREW-TAPPING TH,+,2S,M4,L12,-,STS410 1

19 DC61-01220A GUIDE-LAMP WINGS-DRYER,TB-54,BLK,INTERIPOR LAMP 1

20 DC63-00538A COVER-FILTER(F) WINGS-DRYER,TI-42,GRAY,FRONT 1

21 DC61-01238A BRACKET-DRUM BACK(T) WINGS-DRYER,SECC(EGI),T1.0,TOP 1

22 DC61-01237A BRACKET-DRUM BACK(S) WINGS-DRYER,SECC(EGI),T1.0,SIDE 2

23 6002-000239 SCREW-TAPPING TH,+,2S,M4,L8,ZPC(YEL),SM20C 7

24 6002-001366 SCREW-TAPPING BH,+,2S,M4(P1.8),L16,PASS,STS304 3

25 6002-001320 SCREW-TAPPING TH,+,2S,M4,L8,PASS,STS304 1

26 6002-000231 SCREW-TAPPING TH,+,2S,M4,L12,ZPC(YEL),SM20C 3

27 6002-001320 SCREW-TAPPING TH,+,2S,M4,L8,PASS,STS304 1

28 DC47-00021A SOCKET-LAMP WINGS-DRYER,125V,0.6A,-,125V75W 1

29 DC97-10362A ASSY-S.DRUM FRONT FRONTIER-DRYER,EGI,WHT 1

30 DC97-08889A ASSY-GUIDE SENSOR WINGS-DRYER,PREMIUM 1

31 6046-000310 STAND OFF ID11.5,L2,NTR,NYLON66,DAWH-3NA 3

32 DC61-40081A HOLDER-WIRE DAWH-2NC,NYLON66,-,-,-,-,NTR(PI18.5) 1

33 DC97-07521C ASSY-DUCT AIR MDG9700AWW,DRYER/GAS 1

- 11 -

Page 56

4. Exploded View of Frame, Panel-Control

10

11

3

20

21

28

4

26

9

12

23

13

36

33

29

27

7

22

30

27

15

32

14

35

19

18

16

28

31

25

24

33

34

5

19

19

6

8

1

17

2

- 12 -

Page 57

4. Exploded View of Frame, Panel-Control

- 13 -

Page 58

4. Parts List of Frame, Panel-Control

No. Part Number DESCRIPTION SPECIFICATION

1 DC96-00763A ASSY-FLAT WIRE HARNESS GR-PJT,FLAT WIRE 1

2 DC96-00764A ASSY-M.WIRE HARNESS GR-PJT,HEATER USA 1

2-1 DC96-00765A ASSY-M.WIRE HARNESS GR-PJT,GAS USA 1

3 MFS-FTDT-00 ASSY PCB PARTS MDE27-00 DRYER 1

4 MFS-F12DL-S0 ASSY PCB PARTS MDP27-S0 DRYER 1

5 DC61-01233A GUIDE-EXHAUST WINGS-DRYER,SECC(EGI),T0.8 1

6 DC61-01226A BRACKET-LEG WINGS-DRYER,SECC(EGI),T1.6 4

7 DC97-08855A ASSY-COVER POWER WINGS-DRYER,SECC(EGI),T0.8,NTR 1

8 DC61-01212A LEG WINGS-PROJECT,FRPP 1

9 DC97-10358A ASSY-PANEL CONTROL FRONTIER-DRYER,GOOD 1