Page 1

Maytag

111990"

Automatic

Dryers

Service

Manual

16000132

Issued

1990

Revised

2/98

Page 2

Page 3

Contents

SECTION 1. ELECTRICAL TEST EQUIPMENT "

1-1

APPLIANCE TEST METER

1-1

CLAMP-ON AMMETER

'.

. . . . . . . . . . . . . . . . . . . . . . .

..

1-3

MOTOR TEST CORD 1-4

VOLTAGE CHECKS 1-5

TEMPERATURE READINGS RANGE (50°F.

to

300°F.) 1-6

SECTION 2. ELECTRICAL - MECHANICAL TROUBLESHOOTING

2-1

WILL NOT RUN

2-1

WILL NOT DRY ' 2-2

WILL NOT SHUT OFF

,...............................

2-2

MISCELLANEOUS

,...................................

2-6

MICROPROCESSOR

BOARD

CONTROL MODELS 2-7

DRYER (MICROPROCESSOR BOARD CONTROL)

2-11

FAULT CODE 2-15

SECTION 3. SERVICE PROCEDURES

3-1

ACCESS

TO

CONTROL PANEL COMPONENTS

3-1

CONTROL PANEL ASSEMBLY COMPONENTS

3-1

MICROPROCESSOR

BOARD

CONTROL 3-10

FRONT PANEL AND COMPONENTS 3-13

TUMBLER AND RELATED COMPONENTS 3-17

THERMOSTATS 3-24

BLOWER

3··27

DRIVE MOTOR

AND

IDLER ASSEMBLY

,........................

3-28

HEATING ELEMENT

AND

RELATED COMPONENTS -- ELECTRIC MODELS

3-31

GAS VALVE AND RELATED COMPONENTS 3-34

CABINET AND TOP COVER

3-41

SECTION 4. PRE-INSTALLATION CONSIDERATIONS

4-1

LOCATING DRYER

4-1

EXHAUSTING 4-2

ADJUSTING

MAIN

BURNER 4-6

ELECTRICAL REQUIREMENTS 4-8

ELECTRICAL CONNECTIONS 4-10

A!?DITIONAL INFORMATION 4-12

PERSONAL SAFETY PRECAUTIONS

'.'

. .

..

4-12

SECTION 5. GENERAL INFORMATION

5-1

HEAT SOURCE

5-1

MODEL CHART 5-2

SCHEMATICS 5-3

ED/GD401 1090 Contents

Page 4

ED/GD401 1090

Contents

ii

Page 5

INTRODUCTION

This service manual is

intended

to assist

youindiagnosing

conditions

which

may

develop. Electrical

component

testingisfor

the

most part,

made

with

an

appliance

test

meter

and consists of checking

for

open

or

closed circuits. Mechanical checks

are

made

through

sight

and sound,

along

with

the

use of a clamp-on ammeter.

This

manualisdesigned

for

the

technician

whoisfamiliar

with

the

operation

and

construction

of

May

tag

products.

Information

containedinthis

manualisintended

for

use

byaqualified

service

technician,

familiar

with

proper

and

safe

procedures

to

be

followed

when

repairing

an

electrical

appliance.

All

tests

and

repairs

should

be

performed

byaqualified

service

technician

equipped

with

proper

tools

and

measuring

devices.

All

component

replacements

should

be

made

byaqualified

service

technician,

using

only

MA

yeOR

replacement

parts.

Improper

assembly

or

adjustment

may

occurifservice

or

repairisattempted

by

persons

other

than

qualified

service

technicians

orifparts

other

than

MA

yeOR

replacement

parts

are

used.

Improper

assembly

or

adjustment

can

cause

haz-

ardous

conditions.

There can

be

riskofinjury

or

electrical

shock

while

performing

services

or

repairs.

Injury

or

electrical

shock

can

be

serious

or

even

fatal.

The

first

and

most

important

stepofany

service

call istoaccurately

determine

what

the

complaint

is. This is best

accomplished

by

questioning

the

customer,

finding

out what

the

prodUct isorisn't

doing

and why

they

feel a

problem

exists.

Section 1 covers Electrical Test Equipment. This sections also

covers

general use

of

the

equipment;

an

Appliance

Test Meter, Clamp-On

Ammeter

and

Motor

Test

Cord.

Section 2

covers

Electrical-Mechanical

Troubleshooting

and a

listofpossible

com-

plaints. Find

the

complaint

which

you

feel best matches that

provided

by

the

cus-

tomer

and

turntothe

appropriate

page(s). You

will

find a

listofpossible

electrical

and mechanical

problems

for

the

complaint,

which

have been listedinthere

order

\

of:

1.

Easeinchecking.

2.

Probability.

ED/GD401 1090 INTRODUCTION Iii

Page 6

Systematically

eliminating

these

possibilities

will

allow

youtofind

and

correct

the

problem.

Section 3

covers

Service

Procedures.

This

section

will

provide

information

on

locationofcomponents,

disassembly

and/or

reassembly

procedures,

the

purpos,e

and/or

functionofthe

part

andinsome

instances

specific

checkstobe

made.

Section 4

covers

Pre-Installation

Considerations.

This

provides

information

on

location

and

exhaustingofdryer,

main

burner

adjustment,

electrical

requirements

and

connections.

Section 5

covers

General

Information.

This

section

covers

brief

specifications,

cycle

descriptions

and

schematics.

\

....

ED/GD401 1090

INTRODUCTION iv

Page 7

SECTION 1. ELECTRICAL TEST EQUIPMENT

The

equipment

required

to

service

May

tag

products

depends

largely

upon

the

condition

encountered.

Locating

a

malfunction

will

often

require

the

use

of

electrical

testing

equipment

such as:

•

Appliance

Test

Meter

•

Clamp-on

Ammeter

•

Motor

Test

Cord

APPLIANCE TEST METER

Probably

the

easiest

meansoftesting

electrical

components

is

~'continuity

testing"

with an

Appliance

Test

Meter.

Continuity

is a

complete

or

continuous

path

from

one

point

in an

electrical

circuittoanother

point.

The

obvious

advantagesofbeing

able

to

check electrical

components

and

cir-

cuits

without

power

applied

is one

of

the

featuresofthe

ohmmeter.

Multiple

ranges

allow

accurate

determination

of

resistancesofboth

single

components

and

entire

circuit

paths. Resistance is

measuredin"ohms".

An

Appliance

Test

Meter

is a

multi-

purpose

tester

combining

an AC-DC

voltage

tester

withamulti-range

ohmmeter.

\

SF

2

APPLIANCE

TEST

METER

SET METER FOR USE

AS

FOLLOWS:

1.

Calibrate

meter

by

touching

test

probes

together

and

turning

adjusting

dial

until

meter

reads

"0"

on

the

ohm

scale. Recheck

cali-

bration

whenever

adjusting

dial

for

ohms

settingsischanged. (Replace

battery

if

adjustment

will

not

bring

meter

reading

to

"0".)

2.

Select

the

scale

most

easily

read

and place test

probes

on respective

terminals.

When checking a switch,

the

reading

would

normally

be

either

open

or

closed. A

reading

of

70 on

the

R x 10 scale

would

for

example

be 700

ohms

resistance.

ED/GD401 1090

SECTION1.ELECTRICAL TEST EQUIPMENT 1-1

Page 8

~f~

~.,~"]

Q

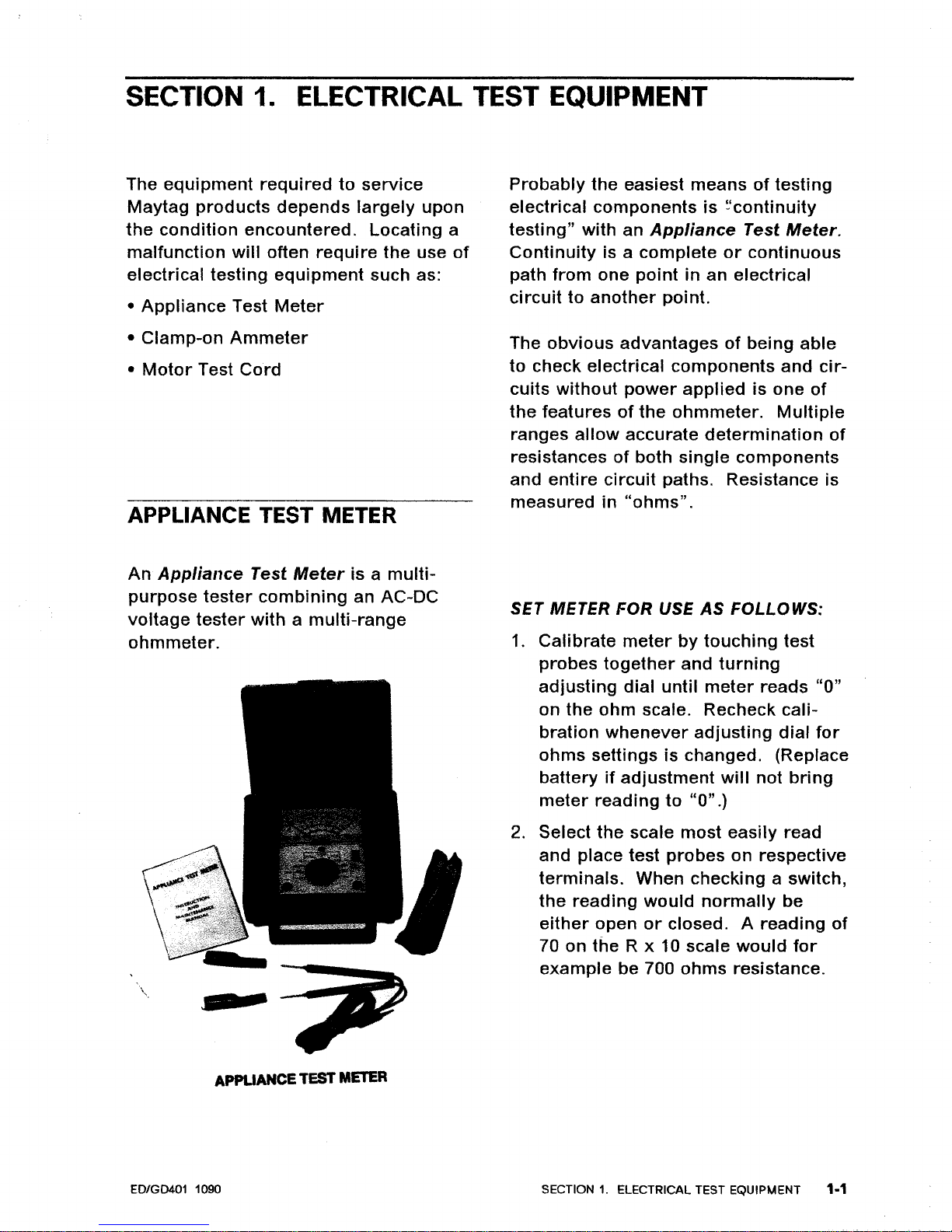

CAUTION

---------------,

Always

be

sure

the

power

has been

disconnected

before

making

resist-

ance

measurements.

Failuretodo

so

will

resultindamagetoyour

meter! Internal

batteries

provide

all

the

power

needed to make resist-

ance checks. They

should

be

checked at least once a

year

and

replaced as needed.

For

the

most

part, we

will

only

be

con-

cerned

with

continuity.

Is

there

a path

or

not? References

are

made

between

a

"closed"

(continuity)

reading

and an

"open"

(no

continuity)

reading.

One

note,

when

you

get an

"open"

reading,

tryahigher

resistance

range

(setting).

A

very

high

resistance

appea~s

as an

"open"

on

the

lower

ranges.

For

best

accuracy

alw~ys

"re-zero"

meter

when

changing

ranges

and/or

the

physical

positionofthe

meter.

Continuity

testing,

as

related

to an elec-

\

tricarcomponent,

is

the

checkofa

part

for

an

"open"

or

"closed"

circuit.

Electrical

components

fall into

two

general

categories.

1.

Loads-

Devices

that

use

or

consume

electricity:

Examples

ED/GD401 1090

would

include

drive

motor,

heating

elements, lamps,

timer

and

solenoid

coils.

2.

Switches

- Devices

that

control

the

supplyofelectricity

to the load

or

loads

in a

circuit.

Examples

include

door

switches,

timer

contacts,

selector

switch and

relay

contacts.

Continuity

testof"load"

devices

will

show

varying

levelsofresistance

from

very

low

for

some

transformer

and

motor

windingstovery

high

for

some

timer

motors

and

components

on elec-

tronic

control

boards.

Usually

it is

more

importanttoknowifthere

is a

path

for

current

.flow

throughadevice

(continuity)

thantoknow

the

exact

resistance (ohms)

of

the

device.

Continuity

testsofswitches

will

show

virtually

no resistance, even

low

values

indicates

burned

or

dirty

contacts in a

switch.

Continuity

testingisa

processofelimi-

nating

those

electrical

components

involved

in a

given

functionofthe

appliance,

until

the

inoperative

part

is

found.

By

reviewing

the

listofpossible

electrical

problems

underagiven

con-

dition,

and

then

performing

appropriate

continuity

checks

on

the

parts

involved,

you

should

be

able

to locate

the

elec-

trical

component

whichisinoperative.

When checking

components

or

circuit

paths

for

continuity,

external

wiring

should

be

disconnectedtoeliminate

false

readings

through

external

paths.

Isolate what

you

wanttotest.

The

following

shows

typical

resistance

values

for

someofthe

components

found

on

May

tag

dryers.

Heating

Element

-- 10.23

ohms.

SECTION1.ELECTRICAL TEST EQUIPMENT 1-2

Page 9

Gas

Valve

Disconnect

radiant

sensor

and

igniter

wires.

Measure

across

igniter

wires

or

igniter

plug

from

valvetoget a

resist-

ance

valueof-- 425-450

ohms.

Measure

across

sensor

wires

to get a

resistance

of

-- 450-475

ohms.

Drive

Motor

Red

terminal

to

Gray

terminal

-- 1.5

ohms.

In

order

to

measure

the

individual

windings

the

red

and

gray

wires

will

havetobe

pulled

offofthe

start switch.

Run

winding

only

-- 2.25

ohms.

Start Winding

only

-- 3

ohms.

Glow

Bar

Igniter

Becauseofthe

make-upofthe

igniter,

the resistance

will

vary

overarather

wide

range. Values

from

180

ohms

to

400

ohms

would

be

typical

with

an

igniteratroom

temperature.

These

values

are

provided

so

that

you

may

have

an

ideaofthe

resistance

that

you

can see in

testing.

These resist-

ances

are

not

meanttobe used as the

exact

valuestodetermine

whether

a

t;omponent

should

be replaced. They

\

are

provided

so

that

you

may

have

an

ideaofthe

resistance

that

you

can see

in

testing

components.

EDIGD401 1090

CLAMP-ON

AMMETER

Each

circuitinan

appliance

has a

"normal"

current

draw

which

is an

indi-

cationofthe

performanceofthat

circuit.

Current

draw

levels, less

than

or

more

than

normal,

give

cluestomalfunctions.

The clamp-on

ammeter

measures

these

currents

without

breaking

the

circuit

by

measuring

the

strengthofthe

magnetic

field

developed

around

each

conductor.

Current

is read

by

separating

the

con-

ductors

and

clamping

the

jawsofthe

ammeter

around

each

conductor

on

which

currentisto

be read.

Low

amperage

readings

indicate

problems

such as

damaged

heating

elements,

etc.

High

amperage

readings

indicate

the

unit

being

tested is

operating

under

an

increased

mechanicalorelectrical

load.

SECTION1.ELECTRICAL TEST EQUIPMENT

1·3

Page 10

Note:

Overloads

onacircuit

breaker

or

fuse can be

tracedtothe

product

being

tested

or

the

circuit

breaker

(or

fuse) by

checking

the

product's

current

draw.Ifthe

amperage

reading

is less

than

the

breaker

reading,

the

breaker

or

fuse

box

is at fault.

USE

OF

AMMETER

ON

DRYER

There

are

two

currentsofconcern

to

us

in an

electric

dryer;

the

heating

element

current

and

the

drive

motor

current.

These

currents

can be meas-

ured

by useofa

"split

line

cord"

exten-

sion

for

the

dryer

cord

or

by

attaching

the

ammetertothe

respective

power

line

wiresatthe

dryer

terminal

block.

Current

measured

should

be

21

amps

on

the

heating

element

sideofthe

line,

24

amps

on

the

drive

motor

sideofthe

line

and4amps

on

the

center

or

neutral

line.

A

\".

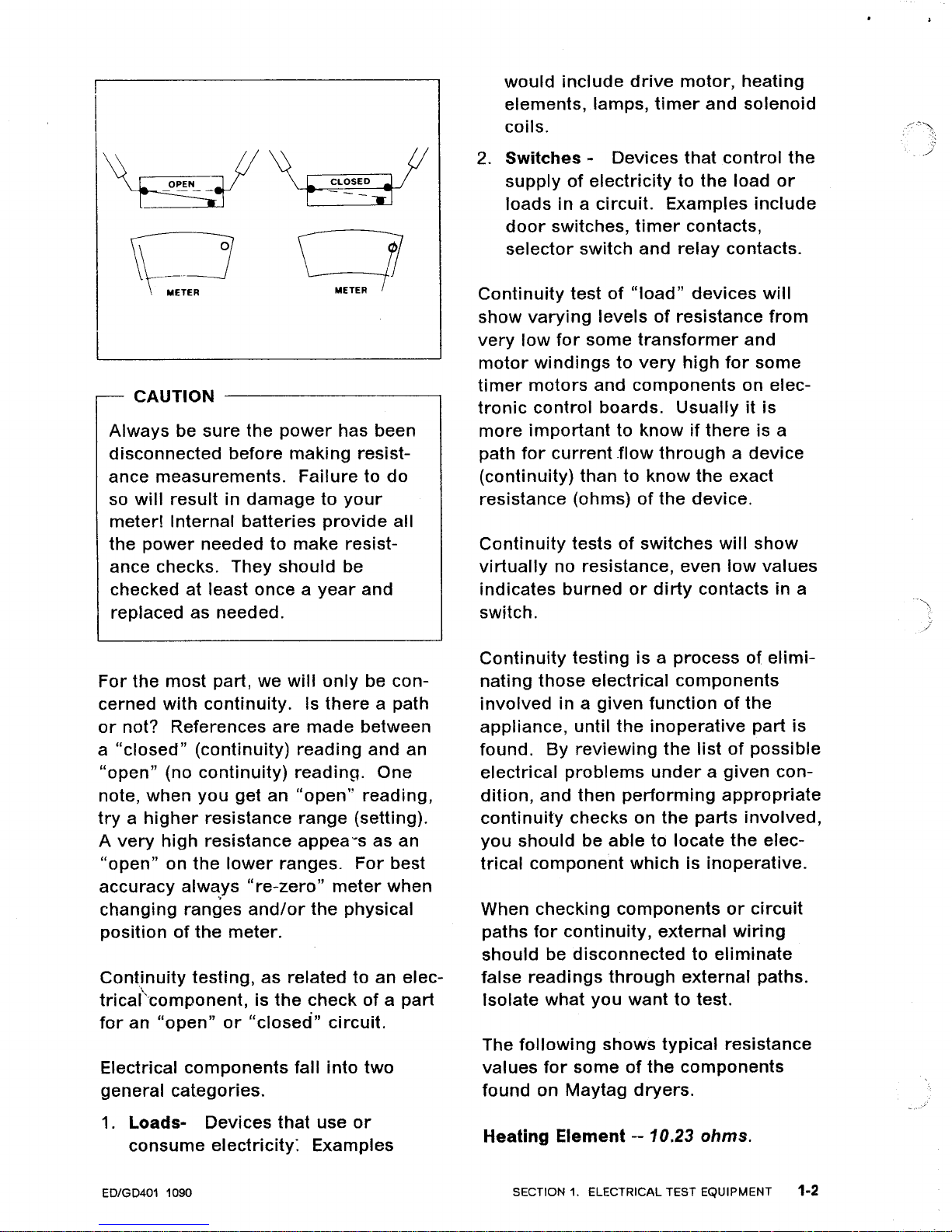

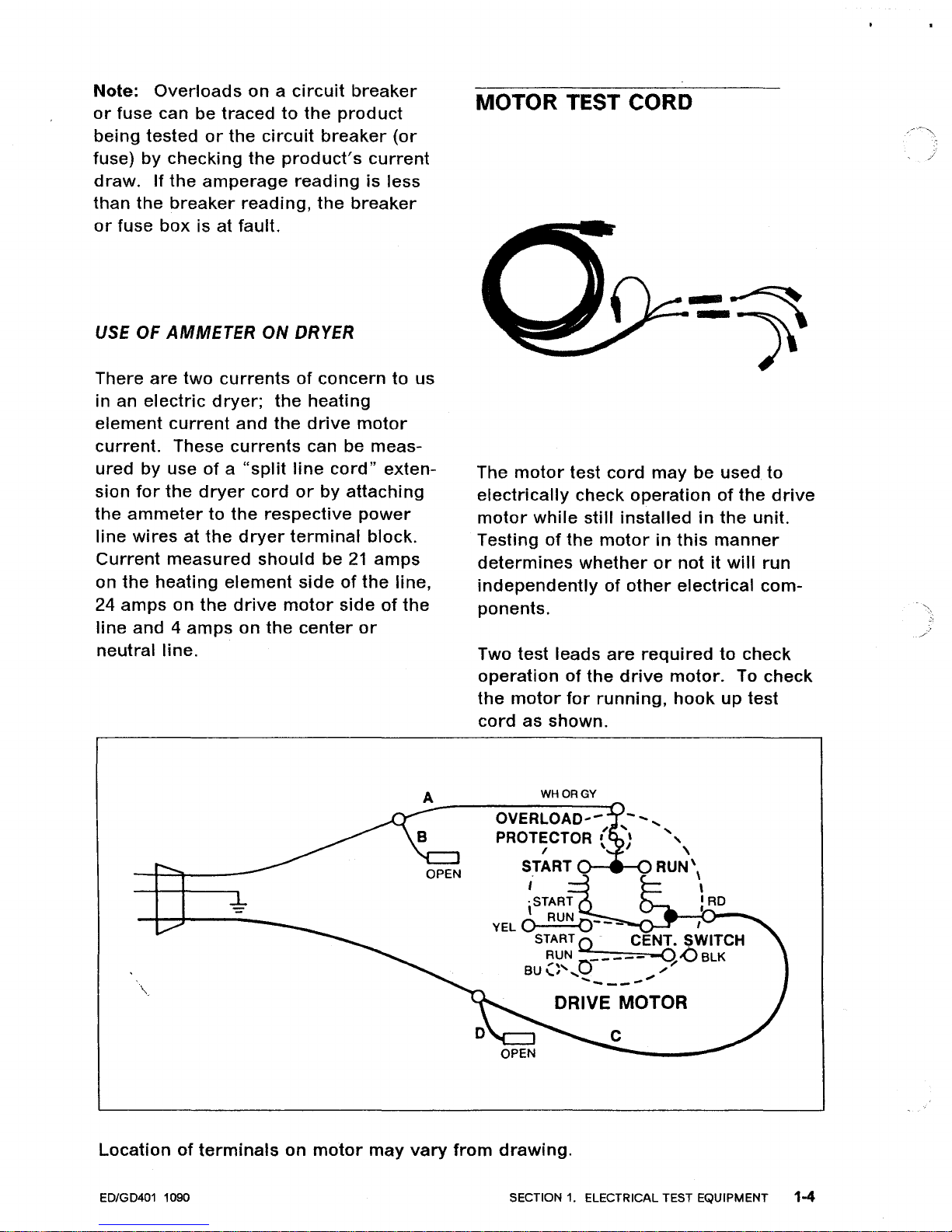

MOTOR TEST CORD

The

motor

test

cord

may

be used.

to

electrically

check

operationofthe

drive

motor

while

still

installedinthe

unit.

Testing

of

the

motorinthis

manner

determines

whether

or

notitwill

run

independently

of

other

electrical

com-

ponents.

Two test

leads

are

required

to

check

operationofthe

drive

motor.

To

check

the

motor

for

running,

hook

up

test

cord

as

shown.

WHORGY

OVERLOAD'-

,

PROTECTOR ( "

, \

START

RUN'

\

I \

,START

: AD

YEL

0 RUN

0---

I

START Q . CENT. SWITCH

~~N

0-----

-q-oBLK

BU

....

,',

...

/

..........

__

....

DRIVE MOTOR

Locationofterminals

on

motor

may

vary

from

drawing.

ED/GD401 1090 SECTION

1.

ELECTRICAL TEST EQUIPMENT 1-4

Page 11

CHECKING

HEAT

CONTACTS,

MOTOR

CENTRIFUGAL

SWITCH

1.

Disconnect

dryer

power

source.

2.

Gain accesstomotor

and

remove

blue

and

black

leads

from

motor

switch.

3. Use

eitherofthe

following

test

methods

using

appropriate

caution.

A.

Live

test

-- USE

CAUTION

1.

Usingadouble

insulated

spade

con-

nector,

connect

blue

and

black

wires

removed

from

motor

switch.

2. Reconnect

dryer

to

power

and

set

for

heat cycle.

3. Start

dryer,ifheat is

produced,

replace

motor

switch

on

motor.

If

no heat,

continue

additional

circuit

checks.

B.

Continuity

Check

(Insulate

wires

removed

from

motor

sWitch.)

1.

Using

clip

adapters,

attach

meter

probestothe

blue

and

black

motor

switch

terminals.

2.

Arrange

probe

leads

away

from

any

moving

parts

and

set

meter

on

RX1

range.

3.

Reconnect

dryer

to

power

source

and

start

dryer,

continuity

on

meter

indicates

good

switch. No

conti-

nuity,

replace

motor

switch

or

motor.

4.

Open

door

to

stop

dryer.

When

\

motor

stops,

motor

switch

contacts

must

open,ifnot

replace

switch

or

motor.

ED/GD401 1090

VOLTAGE CHECKS

For

the

most part

these

checks

will

consistoftaking

readingsatthe

wall

receptacleinorder

to

delermine

the

availability

of

voltagetothe

product.

Voltage checks on

individual

compo-

nentsofa

product

are

not

recom-

mended

duetothe

possibility

of

electrical

shock.

Component

part

testing

is best

accomplished

through

continuity

checks

with

an

Appliance

Test

Meter.

Note:

Useofthe

meter

on

voltage

higher

than

the

indicated

range

may

cause

permanent

damagetothe

meter.

To

prevent

damage,

first

select

highest

range

for

readings

which

fall

within

the

lower

scale.

SET UP METER FOR USE

AS

FOLLOWS:

1.

Turn

selector

knobtodesired

meter

function

and

appropriate

range.

2.

Plug

black

lead

into

socket

marked

-

(negative).

3. Plug red

lead

into

socket

marked

+

(positive).

4.

Place test

leads

into

receptacle

in

order

to

determine

voltage

avail-

able.

SECTION1.ELECTRICAL TEST EQUIPMENT 1-5

Page 12

TEMPERATURE READINGS

RANGE

(50°F. to 300°F.)

Air

temperature

readings

can be taken

at

the

lint

filter

by

removing

the

filter

and

placing

the

accessory

temperature

probe

(Part NO. 38562)

directlyinthe

lint

filter

opening.

Cyclingofthe

ther-

mostats can

actually

be

observed

as

can the

temperatureofthe

exhausted

air.

SET UP METER FOR USE

AS

FOLLOWS:

1.

Turn

selector

knob

to TEMP.

2.

Insert

black

negative

leadoftemper-

ature

probe

into

socket

marked

-

(negative).

3.

Insert red

positive

leadoftemper-

ature

probe

into

socket

marked

+

(positive).

4.

To

calibrate

meter,

touch

black

plug

from

red

positive

leadtoblack

nega-

tive

lead

and

turn

calibration

dial

until

needle

aligns

with

CAL.

5.

Probeisreadytouse -- read

blue

scale

on

meter

face

marked

TEMP.

ED/GD401 1090

SECTION

1.

ELECTRICAL TEST EQUIPMENT 1-6

Page 13

SECTION

2.

ELECTRICAL - MECHANICAL

TROUBLESHOOTING

WILL NOT RUN

Dryer

won't

start

or

run.

•

All

wires

are

hooked

uptotheir

corre-

sponding

terminals.

•

Dryerisplugged

in.

•

Blown

fuseorcircuit

breaker.

•

Door

switch.

•

Push-to-start

switch.

•

Timer.

•

Drive

motor.

•

Thermal

fuse.

Drive

motor

runs--drum

won't

turn.

•

Belt

offorbroken.

•

Motor

pulley

loose

or

off.

•

Idler

tension

spring.

•

Idler

pulley.

Dryer

runsafew

minutes

and

then

stops

--Motor

overload

protector

opens.

•

Lint

build-up

around

drive

motor.

•

Low

voltage.

•

Blower

impeller

blocked.

e,

Drive

motor.

\\.

Dryer

blows

fuses

or

trips

circuit

breaker.

Electric

Models

• The

amperage

readings

areat240

volts.

One

line

will

be

24

amps

and

the

other

line

will

be

21

amps.

The

neutral

line

will

beat4

amps.

If

you

have

the

above

amperage

readings,

the

problemisnot

the

dryer.

Check

the

fuse

box,

circuit

breaker

or

house

wiring.

•

Shorted

heating

element.

•

Incorrect

wiring

orawire

shorting

to

ground.

•

Drive

motor.

Gas

Models

•

During

ignition

the

dryer

will

draw

7

amps.

With

the

burner

on,

the

dryer

will

draw

4.5

amps.

If

the

dryer

is

drawing

the

above

amperage

and

the

fuse

blows,

the

problemisnot

the

dryer.

Check

the

fuse

box,

circuit

breaker

or

house

wiring.

•

Igniter.

•

Incorrect

wiring

orawire

shorting

to

ground.

•

Drive

motor.

CAUTION

---------------------------,

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resist-

ance

readings.

ED/GD401 1090

SECTION2.ELECTRICAL - MECHANICAL TROUBLESHOOTING

2.,.1

Page 14

WILL NOT DRY

Dryer

won't

heat

(motor

runs).

ELECTRIC MODELS

•

Blown

fuseortripped

circuit

breaker.

• Open

heating

element.

•

Hi-limit

thermostat.

•

Regulating

thermostat.

•

Temperature

selector

switch.

• Timer.

• Cycle

selector

switch (where used).

•

Drive

motor

start

switch.

Improper

Drying--Clothes

Wrinkled

--

Harsh

-- Taking

too

long

•

Lint

filter

is clean.

• Restriction in exhaust.

• Exhaust

hood

door

stuck.

• Exhaust

too

long.

•

Poor

make-up

air.

•

Incorrect

drum

speed.

Adjust

motor

pulley

or

wrong

motor

pulley.

•

Blower

impeller

bound.

•

Be

sure

elementorgas

valve

cycles

on and off.

•

Shorted

heating

element-electric

dryers

only.

•

Customer

ove'tloading

dryer.

• Check

clothing

labels

for

fabric

content.

WILL NOT SHUT OFF

Time

Dry

Models

•

Timer

motor.

• Timer.

AUTO DRY MODELS

• Set

timer

for

time

dry.

Check

voltage

across

timer

motor.Iftimer

will

not

advance, replace

timer.

• When

valve

or

element

cycles off,

should

have

powertotimer

motor,

if

not,

proceed

with

next

check.

•

Dryer

cycling

on

hi-limit

thermostat.

Check

following.

•

Lint

filter

clean.

•

Restriction

in exhaust.

• Exhaust

hood

door

stuck.

• Exhaust

too

long.

•

Regulating

thermostat.

•

Customerisoverloading

dryer.

ELECTRONIC CONTROL MODELS

The

electronic

control

and

timer

are

usedtocomplete

the

drying

cycle

and

cool-down

period

for

these

dryer

models.

The

dryer

starts

out

with

the

drive

motor

running,

the

timer

motor

running,

the

heat

cycling

and

the

elec-

tronic

control

disabled.

As

the

timer

advancestoa

certain

pointinthe

cycle,

CAUTION

-------------------------,

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resist-

ance

readings.

ED/GD401 1090

SECTION

2.

ELECTRICAL - MECHANICAL TROUBLESHOOTING 2-2

Page 15

the

electronic

control

becomes

opera-

tional

as cam

number

two

opens. A

short

time

later,

the

timer

motorisde-

energized

when

cam

number

one

for

the

timer

motor

opens.

It is

during

this

stall

period

that

the

electronic

control

system uses

the

wet

clothes

falling

across

the

sensorinthe

drum

to

dis-

charge

the

capacitor

and

keep

the

dryer

running.

There

are

three

dryness

levels;

More

Dry,

Normal

Dry

and

Less Dry. These

dryness

levels

have been

accomplished

by

placing

resistors

on

the

electronic

control

(printed

circuit

board)

and

routing

the

bypass

wiring

accordingly.

The levelofresistanceinthe

circuit

,

determined

by

the

dryness

level

selected, affects

the

charge-up

rate

of

the

capacitor

and

accomplishes

the

desired

dryness

level.

As

the

clothes

get

dry,

the

capacitorisabletobuild

up a

chargetoa

point

where

the

neon

bulb

fires,

thus

triggering

the

gate on a

SCR. When

this

happens,acircuit

is

made

through

the

SCR,

energizing

the

coilinthe

relay. This

takes

onlyasplit

second

and

the

relay's

coilisthen

held

energized

through

a setofcontacts

in

the

relay.

Also,

when

the

coilinthe

relayisener-

gized,

the

timer

motorisactivated

through

another

setofcontactsinthe

relay. The

timer

advances

and

opens

cam

number

three

for

the

heater

and

the

dryer

beginsatimer

controlled

CAUTION

cool-down

period.

The

amountofcool-

down

time

will

depend

upon

the

cycle

selected:

Regular

- 6

minutes,

Permanent-Press

- 13

minutes

and

Permanent-Press

with

Press

Care

- 33

minutes.

NOTE:

These

times

are

approximate.

The

timer

then

advances

to

where

cam

number

1A opens,

de-

energizing

the

drive

motor

and

the

cycle

ends.

TROUBLESHOOTING

When

the

dryer

does

not

go

into

cool-

down

and

shut

off with

dry

clothes,

you

needtoknow

whether

you

have a

control

problem

orasensor

problem.

Troubleshooting

the

electronic

control

is

made

easierifwe

break

the

circuit

down

into

parts. We can

separate

the

two

parts

by

disconnecting

the

W-BU

wireinthe

control

panel at

the

plastic

coupler.

The

upper

part

contains

the

electronic

control

assembly

which

con-

sistsofthe

edgeboard

connector

assembly,

printed

circuit

board

assembly

and

relay. The

lower

part

consistsofthe

sensor

assembly

located

on

the

tumbler

front

bulkhead.

Separating

the

two

areas

by

pulling

the

wires

apartatthe

coupler

will

show

where

the

problemislocated.Ifthe

dryerisstarted

without

any

clothes

in

the

drum

and

shuts

offinabout

20

minutes

without

the

sensor

circuit

hooked

up,

then

the

sensor

must

be

keeping

the

dryer

from

shutting

off.

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resist-

ance

readings.

ED/GD401 1090 SECTION

2.

ELECTRICAL - MECHANICAL TROUBLESHOOTING

2-3

Page 16

NOTE:

This

amountoftimeisfor

Regular

Fabrics

onaLess

Dry

setting.

A

settingofNormal

Dry

or

More

Dry

will

add

more

time

before

the

dryer

shuts

off. If

the

dryer

does

not

shut

off,

then

the

problem

is in

the

electronic

control

assembly.

Sensor

Assembly

1.

Disconnect

power

supply.

2.

Remove

front

panel.

3.

Remove

wires

goingtothe

sensor

bars.

4.

Check

with

ohmmeter

to

make

sure

there

is NO

continuity

across

the

sensor

bars. If

you

have

continuity

across

the

sensor

bars

the

capacitor

cannot

buildacharge,itwill

contin-

ually

bleed

off.

CAUTION

Always

disconnect

power

supply

before

making

continuity

or

resistance

checks.

5.

Checktomake

sure

the

sensor

bar

(the

one

not

connected

to

cabinet

ground)isnot

shorted

to

cabinet

ground.Ifthis

sensor

bar

has

a

leakage

pathtocabinet

ground,

the

capacitor

cannot

buildacllarge

and

will

continually

bleed

off. Use

ohmmeter

to

~heck

from

sensor

bar

to

cabinet

ground.

Electronic

Control

Assembly

If

dryer

does

not

go

into

cool-down

and

shut

off

with

the

sensor

disconnected

the

problem

isinthe

electronic

control

assembly.

While

the

dryerisrunning,

observe

the

neon

bulb

on

the

electronic

control

(printed

circuit

board).

When

the

capacitor

reaches

approximately

72

volts,

the

neon

bulb

"fires"

(flashes),

the

SCR

conducts,

the

relay

coil

is

energized

and

the

contactsinthe

relay

close.

If

neon

bulb

"FIRES"

but

timer

does

not

advance

(timer

motorisnot

ener-

gized):

1.

Check

relay

coil

for

continuity

or

resistance.

A.

Disconnect

power

supply.

B.

Remove

BK

and

BR

wires

from

relay

(refertoelectrical

wiring

diagram).

C.

Attach

meter

leads

across

these

terminals

and

complete

check.

If

checking

resistance,

you

should

see

about

2200

ohmsofresistance.

No

continuity,

replace

relay.

2.

Check

continuity

across

contacts

O-BKtoRDinrelay.

When

closed,

this

setofcontacts

is usedtokeep

the

coil

energized.

A.

Disconnect

power

supply.

B.

Remove

wires

O-BK

and

RD

from

relay.

CAUTION

--------------------------,

Always

disconnect

po~er

supply

before

making

any

continuity

checks

or

resistance

readings.

ED/GD401 1090

SECTION2.ELECTRICAL - MECHANICAL TROUBLESHOOTING 2-4

Page 17

C.

Remove

BK

wire

from

buzzer.

D.

Attach

motor

test

cordtothe

BK

wire

(removed

from

buzzer)

and

to

the

O-BK

wire

(removed

from

relay).

E.

Plug

motor

test

cord

into

outlet

(coilinrelay

should

now

be

ener-

gized).

F.

Check

for

continuity

from

ter-

minal

RD on

relaytoterminal

O-BK

on relay. No

continuity,

replace

relay.

CAUTION SHOULD

BE

EXERCISED

WHENEVER WORKING AROUND

LIVE VOLTAGE.

3.

Check

continuity

across

contacts

W-BKtoRDinrelay. When

closed,

this

setofcontactsisusedtoener-

gize

the

timer

motor

by

bringing

the

neutral

sideofthe

power

supply

through

the

relay,tothe

timer

motor.

A.

Disconnect

power

supply.

B.

Remove

wires

W-BK,

O-BK

and

RD

from

relay.

C.

Remove

BK

wire

from

buzzer.

D.

Attach

motor

test

cord

to

the

BK

wire

(removed

from

buzzer)

and

to

the

O-BK

wire

(removed

from

relay).

E.

Plug

motor

test

cord

into

outlet

(coilinrelay

should

now

be

ener-

gized).

\"-

CAUTION

F.

Check

for

continuity

from

ter-

minal

RD on

relaytoterminal

W-BK

on relay. No

continuity,

replace

relay.

4.

Replace

electronic

control

(printed

circuit

board).

If

neon

bulb

does

not

"FIRE":

1.

Check

capacitor.

A.

Disconnect

power

supply.

B.

Remove

electronic

control

(printed

circuit

board).

C. Set

ohmmetertoan

ohm

scale,

such as Rx100.

D.

Place

meter

leads

into

openings

in

the

edgeboard

connector

where

capacitor

leads

terminate.

First,

make

sure

you

have

discharged

the

capacitor

by

shorting

the

leads. Use

a

pieceofinsulated

wire

with

the

ends

stripped.

E.

Needle

should

deflecttoone

side

and

then

slowly

drop

backtozero.

F.

Failuretodeflect

the

needle

would

indicate

an

open

capacitor.

Failureofthe

needletodrop

back

would

indicateashorted

capacitor.

Replace

edgeboard

connector

assembly.

2. Replace

electronic

control

(printed

circuit

board).

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resist-

ance

readings.

ED/GD401 1090 SECTION2.ELECTRICAL - MECHANICAL TROUBLESHOOTING 2-5

Page 18

MISCELLANEOUS

Dryer

noisy.

•

Thumping

sound.

Check

for

loose

drum

baffle.

•

Thumping

sound.

Rear

drum

roller(s)

worn

or

misaligned.

•

Thumping

sound.

Check

drum

for

rough

spots.

• Ticking

sound.

Loose

wire

hitting

cabinet

or

other

component.

• Ticking

sound.

Check

for

an

object

caught in

the

blower.

•

Scraping

sound.

Frontorrear

bulkhead felt seal

outofposition.

•

Scraping

sound.

Teflon

bearings

mountedtothe

front

bulkhead

worn.

• Popping

or

squealing

sound.

Check

for

a sticky

beltorfrayed

belt.

Buzzer

will

not

buzzatendofcycle.

(Auto

Dry

Models)

•

Be

sure

all

wires

are

connected

and

wired

correctly

on

the

timer,

buzzer

and

drive

motor.

• Buzzer.

•

Motor

centrifugal

switch

sticking

in

run

position.

Buzzer

stays

on

too

longorgoes

off

too

quickly.

(Auto

Dry

Models)

•

Lengthoftime

the

buzzer

stays on is

dependent

upon

the

timeittakes

the

motor

to

slow

down,

allowing

the

motor

switch to reset. The

normal

time

incrementisbetween 2

and

3

seconds.

Buzzer

will

not

buzz

during

Press

Care

Setting.

• With

dial

set on

auto

dry

permanent

press and

the

press

care

"on"

button

depressed,

the

buzzer

will

sound

at

the

endofthe

normal

14

minute

cool-

down.

After

this,

the

dryer

will

con-

tinuetotumble

clothes in cool

air

for

24

minutes.Ifbuzzer

does

not

sound,

proceed

on.

•

Buzzer

signal

on.

•

Miswired

press

care

switchortimer.

• Buzzer.

•

Timer.

Buzzer

will

not

periodically

buzz

during

permanent

press

cool

down.

• Timer.

CAUTION

---------------~---------,

Always

disconnect

power

supply

before

making

any

continuity

checksorresist-

ance

readings.

ED/GD401 1090

SECTION 2. ELECTRICAL -

MECHANICAL

TROUBLESHOOTING 2-6

Page 19

MICROPROCESSOR BOARD

CONTROL MODELS

The

microprocessor

board

receives

input

information

from

the

various

com-

ponents

involved

with

the

operation

of

the

dryer;

such as

the

dryness

sensor

and

the

thermistor.

It uses

this

infor-

mationtodetermine

the

necessary

control

for

the

completion

of

the

cycle.

One

of

the

waysitaccomplishes

this

is

through

the

useofcontrol

relays.

A

control

relay

(S.P.S.T.) is placedinthe

motor

circuit

for

both

the

gas

and

elec-

tric

dryer.

Another

relay

(S.P.S.T.) is

placed

in

the

heat

circuit

for

the

electric

dryer

only.

With

these

relays

the

microprocessor

board

is capable of

usingalow

voltage

circuittocontrol

a

high

voltage

circuit.

We can call

these

two

circuits

the

control

circuit

and

the

controlled

circuit.

NOTE: The

control

for

the

gas

dryer's

gas

valve

circuit

is

different

andiscovered

later.

The

control

circuit

for

the

drive

motor

consistsofthe

microprocessor

board

and

the

Motor

Relay's

coil. The

con-

trolled

circuit

for

the

drive

motor

con-

sists

of

the

Motor

Relay's

switch

contacts,

thermal

fuse

and

cut-off

drive

,

motor

and

door

switch. The

micro-

processor

board

starts

the

drive

motor

by

sending

24 VDCtothe

Motor

Relay's

coil. When

energized,

the

coil

creates a

magnetic

field

that

closes

the

CAUTION

switch

contactsinthe

relay

and

pro-

vides

a path

for

voltage

to

the

motor.

When

the

microprocessor

board

deter-

minesitneedstostop

the

motor,

it

removes

the

24 VDCtothe

relay's

coil.

The

switch

returnstoits

normally

open

position

and

the

path

for

voltagetothe

motorisopened.

The

control

circuit

and

controlled

circuit

for

the

heating

element

on

the

electric

dryer

operate

on

the

same

principle

as

the

motor

relay's

circuits.

When

the

microprocessor

board

wantstoener-

gize

the

heating

elementitsends

24

VDC to

the

coilinthe

Heater

Relay

and

a path

for

voltageiscompleted

through

the

switch contactstothe

heating

element.

When

the

24 VDC

are

removed

from

the

coil

the

switch

con-

tacts

open

and

the

path

for

voltage

to

the

heating

elementisopened.

TROUBLESHOOTING

When

trying

to

determine

what

is

causing

the

problem

(drive

motor

will

not

run

or

heating

element

will

not

come

on),

separate

the

two

circuits

to

isolate

the

problem

area. Start

with

the

control

circuit

(it hastofunction

before

the

controlled

circuit

will

work).

Deter-

mine

what is

involvedinthis

circuit

and

proceedtocheck

the

components.

If

these

components

are

foundtobe

func-

tioning

correctly,

focus

on

the

con-

trolled

circuit.

Determine

what

is

involved

and

proceedinchecking

the

components.

Always

disconnect

power

supply

before

making

any

continuity

checksorresist-

ance

readings.

ED/GD401 1090

SECTION

2.

ELECTRICAL -

MECHANICAL

TROUBLESHOOTING 2-7

Page 20

CONTROL

CIRCUIT

Drive

motor

will

not

run

(gas

and

elec-

tric):

1.

Disconnect

the

power

supply.

CAUTION

Always

disconnect

power

supply

before

making

continuity

or

resistance checks.

2.

Make

continuity

check

or

resistance

check on

Motor

Relay's

coil.

A.

Remove

wire

connectors

O-BK

and W-BU on

the

Motor

Relay.

B. Attach

meter

leads

across

termi-

nals

O-BK

and W-BU. You

should

see

about

470

ohmsofresistance

if

checking resistance.

C.

No

continuity,

replace

the

relay.

CAUTION:

Use

extreme

care

when

checking

voltage.

3.

Check

for

24 VDC

across

the coil on

the

Motor

Relay. To check

for

this

voltage

the

dryer

hastobe in a

program.

A. Place

meter

leads

across

wire

connectors

O-BK

and W-8U on

the

Motor

Relay (the

relay

has

two

sizes

of

terminals;

the

smaller

terminals

for

DC

and the

larger

terminals

for

AC).

\.

CAUTION

Note:

You

are

checking

DC

voltage,

set and use

meter

accordingly.

B. No voltage, suspect

the

micro-

processor,

transformer,

edgeboard

connector

AA

or

power

supply.

CONTROLLED

CIRCUIT

1.

Check

for

continuity

across

the

Motor

Relay's

switch

contacts

with

the

coil

energized.

A. Disconnect

power

supply.

B.

Remove

wire

connectors

R-BK

and

GY.

C. Attach

the

meter's

leads

across

terminals

R-BK

and

GY.

D. Connect

power

supply_

CAUTION SHOULD BE EXERCISED

WHENEVER WORKING AROUND

LIVE VOLTAGE.

E.

No

continuity

across

switch

con-

tacts

with

coil

energized,

replace

the

relay.

2.

Another

methodofchecking.

A.

Disconnect

the

power

supply.

B. Remove

and

connect

wires

R-BK

and

GY

together

(the

wires

connec-

tors

are

insulated,ajumper

will

have to be used).

_

......

,~

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resistance

readings.

ED/GD401 1090

SECTION2.ELECTRICAL - MECHANICAL TROUBLESHOOTING 2-8

Page 21

C.

Connect

power

supply.

D.

If

motor

runs,

the

switchinthe

relay

has failed,

replace

relay.

3.

Check

drive

motor.

Refer

to Elec-

trical

Test

Equipment

section

for

drive

motor

test.

,-

CAUTION

----------,

I

Always

disconnect

power

supply

before

making

continuity

or

resistance checks.

4.

Make

continuity

checks on

thermal

fuse

and

cut-off. No

continuity,

replace.

5.

Make

continuity

check on

door

switch

with

door

closed. No

conti-

nuity, replace.

CONTROL CIRCUIT

No

heat

(electric

dryer):

1.

Check

for

continuity

or

resistance

across

the coil on the

Heater

Relay.

A.

Disconnect

power

supply.

B. Place

meter

leads

across

YL

and

W-BU.

C.

Should

see

about

310

ohms

if

reading

resistance. No

continuity,

replace relay.

\ CAUTION

CAUTION:

Use

extreme

care

when

checking

voltage.

2.

Check 24

DC

voltage

to relay.

A. Place

meter

leads

across

wire

connectors

YL

and

W-BU.

NOTE: Checking DC

voltage,

set

and use

meter

accordingly.

B. Make

voltage

check. No

voltage,

suspect

microprocessor

board,

transformer,

edgeboard

connector

AA

or

power

supply.

CONTROLLED CIRCUIT

1.

Check

for

continuity

across

switch

contacts in

Heater

Relay.

A. Disconnect

power

supply.

B.

Remove

wire

connectors

BK

and

BK

from

relay.

C.

Place

meter

leads

across

termi-

nals

BK

and

BK

on relay.

D.

Connect

power

supply.

CAUTION SHOULD

BE

EXERCISED

WHEN WORKING AROUND LIVE

VOLTAGE.

E.

Make

continuity

check. No

conti-

nuity, replace relay.

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resistance readings.

EDIG

D401

1090

SECTION

2.

ELECTRICAL - MECHANICAL TROUBLESHOOTING 2-9

Page 22

2.

Another

method

for

testingisto

bypass

the

Heater

Relay.

A.

Disconnect

power

supply.

B.

Remove

wire

connectors

BK

and

BK

(wire

connectors

are

insulated,

jumper

wire

will

havetobe used).

C. Connect

power

supply.

If

heating

elementisenergized,

relay

has failed,

replace

relay.

CAUTION

Always

disconnect

power

supply

before

making

continuity

or

resistance checks.

3. Check

for

continuity

across

160

0

Limit

Thermostat

(when cool). No

continUity, replace

thermostat.

4. Check

for

continuity

across

Hi-Limit

Thermostat. No

continuity,

replace

thermostat.

Note: When checking

continuity

or

resistance

always

isolate

what

you

wanttocheck.

5.

Check

for

continuity

or

resistance

across

the

Heater

(heating element).

Should

see

about

11

ohms

(240

volt

element),

about8ohms

(208

volt

element)

when

checking resistance.

No

continuity,

replace heating

element.

6. Check

continuity

across

centrifugal

$witch

on

motor

switch.

A. Remove

wire

connectors

BU

and

BK

from

motor

switch.

B. Attach

meter

leads

across

termi-

nals SU and

BK

on switch.

C.

Use

small

screwdriver

to

move

centrifugal

lever

on

the

drive

motor

to the

"run"

position.

D.

Check

for

continuity

across

ter-

minals

BU

and

BK, no

continuity,

replace

motor

switch.

HEAT

CIRCUIT

FOR THE

GAS

DRYER

No

heater

control

relay

is placed

in

series

with

the

gas

valve

on

the

gas

dryer.

The

control

for

this

circuit

is

done

on

the

microprocessor

board

itself. The L1

sideofthe

power

supply

is

routedtothe

microprocessor

board

through

edgeboard

connector

SB

(refer

to schematic). The

microprocessor

board

determines

when

the

gas

valve

should

be

energized

and

relays

L1

back

through

edgeboard

connector

BB

and

completes

the

circuit

for

the

gas

valve.

Will

not

heat

(gas

dryer):

CAUTION

-----------,

Always

disconnect

power

supply

before

making

continuity

or

resist-

ance checks.

1.

Check

continuity

across

1600Limit

Thermostat

(when cool). No

conti-

nuity,

replace.

CAUTION

-----------------------.,

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resistance

readings.

ED/GD401 1090 SECTION

2.

ELECTRICAL - MECHANICAL TROUBLESHOOTING 2·10

Page 23

2.

Check

continuity

across

Hi-Limit

Thermostat. No

continuity,

replace.

3.

Check

continuity

across

centrifugal

switch on

motor

switch.

A. Remove

wire

connectors

BU

and

BK

from

motor

switch.

B. Attach

meter

leads

across

BU

and

BK

terminals

on the switch.

C.

Use

small

screwdriver

to

move

the

centrifugal

lever

on

the

drive

motorto"run"

position.

D.

Check

for

continuity

across

BU

and

BK, no

continuity,

replace

motor

switch.

4.

Check

gas

valve.

Refer to section

covering

gas valve.

5. Check

for

the

L1

sideofthe

voltage

to the gas

valve.

The L1

side

is con-

trolled

by

the

microprocessor

board.

Wiringiscompleted

through

edgeboard

connector

B (pin 3 and

pin 1).

CAUTION:

Use

extreme

care

when

checking

voltage.

A.

Dryer

must

be in a

program

that

is

calling

for

heat.

B. Use

voltmeter

to

check

from

ter-

minal

BK

on 1600Limit

Thermostat

to cabinet

ground

(be

sure

polarity

is correct)

with

dryer

calling

for

heat.

C.

No

voltage

(120 VAC), suspect

microprocessor,

edgeboard

con-

\

nector

BB,

transformer

or

power

supply.

DRYER (MICROPROCESSOR

BOARD CONTROL)

A

microprocessor

board

provides

the

control

for

this

dryer.Itaccomplishes

this

control

with

several

components.

The

components

involved

are

the

trans-

former,

thermistor,

control

relays,

dryness

sensor

and

lint

filter

switch.

To

start

the

dryer

the

user

selects the

desired

program

by

pressing

the

indi-

cated pad on

the

menu. There

are

17

of

these pads

from

which

the

user

can

select the

programs

and

options

for

the

dryer.

Behind

the

pads

are

actuators

(push rods)

that

activate

switches

on

the

microprocessor

boardtoinitiate

the

program

and

options.

NOTE:

An

option

can be selected

only

after

a

program

has been selected.

No test

boardisavailabletocheck

microprocessors.

Therefore,

all

other

componentsinthis

section

should

be

checked first. If no

problemisfound,

replace

microprocessor.

TRANSFORMER

A

step-down

transformer,

consisting

of

a

primary

winding

and

three

secondary

windings,isused to

provide

the

neces-

sary

voltagestothe

microprocessor

board.

The

primary

sideofthe

trans-

former

receives

the

voltage

(120

volts

measure

across

L1 and Neutral). The

transformer

then

steps

this

voltage

down

through

the

secondary

windings

into the

voltages

neededtopower

the

CAUTION

-------------------------,

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resist-

ance

readings.

EDIGD401

1090

SECTION 2.

ELECTRICAL-MECHANICAL

TROUBLESHOOTING

2-11

Page 24

microprocessor

board

and

provide

the

voltages

that

the

microprocessor

board

usestocontrol

or

operate

the

various

functionsofthe

dryer.

The

output

volt-

ages on

the

secondary

side

are

20.7

VAC, 22.6 VAC and 3.8 VAC (this

winding

has a

center

tap

that

provides

1.9 VAC

when

measured

from

the

center

taptoeitherofthe

outside

leads).

VARISTOR

The

varistor

is a

semiconductor

device

(solid state) connected

across

the

primary

input

terminals

on

the

trans-

former.

Its

function

is to

protect

the

microprocessor

board

against

voltage

surgesorspikes. The resistanceofthe

varistor

decreases

as

the

voltage

across it increases. If

the

voltage

exceeds

the

"threshold"

of

the

varistor,

its resistance

will

decrease

rapidly

to

the

pointofprovidingashort

circuit

across

the

primary

terminals.

This

may

trip

circuit

breaker

or

open fuse

or

destroy

varistor.

If

varistor

is

damaged,

replace

transformer.

TROUBLESHOOTING

Because

the

transformer

provides

the

powertothe

microprocessor

board

it

should

be checked

firstifit

appears

the

microprocessor

board

or

anyofthe

componentsinits

circuitryisnot

func-

CAUTION

tioning

properly.

In checkingortrou-

bleshooting

the

transformeritis

important

to

remember

the

transformer

only

transforms

or

changes

the

voltage

to

different

values. It

does

not

rectify

the

voltagetoDC,

thatisdone

on

the

microprocessor

board.,

NOTE:

There

are

two

sizesofspade

terminals

used

on

the

transformer.

The

two

large

spade

term!nals

are

used

for

the

primary

winding

and

the

smaller

spade

terminals

are

used

for

the

secondary

windings.

NO

POWER

Primary

Side:

1.

Is

dryer

plugged

into

power

supply?

2.

Is

voltage

(120 VAC)

present

at

primary

side?

CAUTION:

Use

extreme

care

when

checking

voltage.

3.

Check

for

voltage

(120 VAC).

A. Attach

meter

leadstowire

con-

nectors

R-BK

and

W-BR.

B. Make

voltage

check,

should

see

120 VAC (voltage

value

may

vary),

if

not,

check

power

supply.

4.

Disconnect

power.

5.

Remove

wire

connectors

R-BK

and

W-BR

from

primary

sideoftrans-

former.

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resistance

readings.

ED/GD401 1090

SECTION2.ELECTRICAL - MECHANICAL TROUBLESHOOTING 2-12

Page 25

6.

Check

for

continuity

across

these

terminals.

No

continuity,

replace

transformer.Ifchecking

resistance

there

should

be

about

42

ohms

across

primary

leads.

Secondary

Side:

CAUTION

----------,

Always

disconnect

power

supply

before

making

continuity

or

resist-

ance checks.

1.

Check

for

continuity

on

secondary

windings.

NOTE: The resistance

valuesofthe

secondary

windings

are

small and

may

not

be

detectable

unless

usingadigital

meter. These

are

approximate

values: Y-BK to

Y-BK 2 ohms, W-OR

to

W-OR 1

ohm

and

PK to PK 5 ohms.

2. Remove

wire

connectors

Y-BK and

Y-BK

from

secondary

winding.

3.

Check

for

continuity

across

termi-

nals on

this

secondary

winding.

No

continuity,

replace

transformer.

4.

Remove

wire

connectors

W-OR, BU

and W-OR

from

secondary

winding.

5.

Check

for

continuity

from

BU to both

W-OR

terminals.

No

continuity,

replace

transformer.

CAUTION

6.

Remove

wire

connectors

PK and PK

from

secondary

winding.

7.

Check

for

continuity

across

termi-

nals on

this

secondary

winding.

No

continuity,

replace

transformer.

Voltage

checks

on

the

secondary

windings.

CAUTION:

Use

extreme

care

when

checking

voltage.

1.

Attach

meter

leads

across

terminals

Y-BK and Y-BK on

secondary

winding.

Should

see 20.7 VAC, no

voltage

replace

transformer

if

primary

and

power

supply

check

okay.

2.

Disconnect

power

supply.

A. Remove

wire

connectors

W-OR,

BU

and

W-OR

from

secondary

winding.

B. Attach

meter

leads

across

termi-

nals W-OR and W-OR on

secondary

winding.

C.

Connect

power

supply.

Make

voltage

check.

Should

see 3.8 VAC

across

W-OR

and

W-OR (1.9 VAC

from

BUtoeitherofthe

W-OR

termi-

nals), no voltage, replace

trans-

formerifprimary

and

power

supply

check okay.

Always

disconnect

power

supply

before

making

any

continuity

checks

or

resistance

readings.

ED/GD401 1090

SECTION2.ELECTRICAL - MECHANICAL TROUBLESHOOTING 2-13

Page 26

3. Attach

meter

leads

across

terminals

PK

and

PK. Make

voltage

check.

Should

see 22.6 VAC, no

voltage,

replace

transformerifprimary

"and

power

supply

check okay.

Note: These

voltages

may

vary

slightly.

FAULT CODE

The

microprocessor

board

has

the

capabilitytodetect

certain

problems

associated

with

the

operationofthe

dryer.

When

the

microprocessor

board

detects

oneofthese

problemsitdis-

plays a

fault

code in

the

dryer's

display

window.

The fault

codeisdisplayed

as

a

letterFfollowed

byanumber

that

corresponds

to

the

problem.

The

microprocessor

board

makes

the

dryer

inoperative

for

all but oneofthe

fault

codes. Fault code F-9 is

the

exception,

it

does

not

appearinthe

display

(unless a certain

procedureisfollowed)

and

does

not

make

the

dryer

inopera-

tive.

FAULT CODES

F-1

•

Door

circuit-board

component

failure.

•

Dryer

inoperative.

• Can

appear

anytime.

• Replace

microprocessor

board.

F-2

•

Low

temperature

sensed (40°

below

zero).

•

Dryer

inoperative.

• Can

appear

after

the

first

1 1/2

minutesofa cycle

calling

for

heat.

• Open

in

thermistor

circuit.

• Room

temperature

(unlikely).

F-3

•

High

temperature

sensed (above

200°F.).

•

Dryer

inoperative.

• Can

occur

anytimeacycleiscalling

for

heat.

•

Check

venting.

•

Short

circuitinthermistor

circuit.

CAUTION

-------------------------,

Always

disconnect

power

supply

before

making

any

continuity

checksorresist-

ance

readings.

ED/GD401 1090 SECTION2.ELECTRICAL - MECHANICAL TROUBLESHOOTING 2-14

Page 27

F-4

•

Motor

transistor

on

board

failure.

•

Dryer

inoperative.

• Can

occur

only

on

start

up.

• Replace

microprocessor

board.

F-9

•

Low

voltage

(below

about

95

volts).

•

Dryer

will

operate

and

fault

code

is

not

displayed.

• Can

occur

anytime

but

will

only

show

up

and

be

cleared

on

request.

• To

check

for

F-9,

press

OFF pad

and

while

holding

OFF

pad,

press

the

PAUSE/RESUME

pad

and

hold

for

2

seconds.

This

sequence

will

show

all

display

segments

and

then

display

a

F-9

if

low

voltage

has

occurred

since

last check.

•

Check

electrical

circuit

that

dryer

is

on.

CLEARING THE FAULT

•

Disconnect

power

supply.

•

Correct

problem.

•

Restore

power.

CAUTION

------------------------,

Always

disconnect

power

supply

before

making

any

continuity

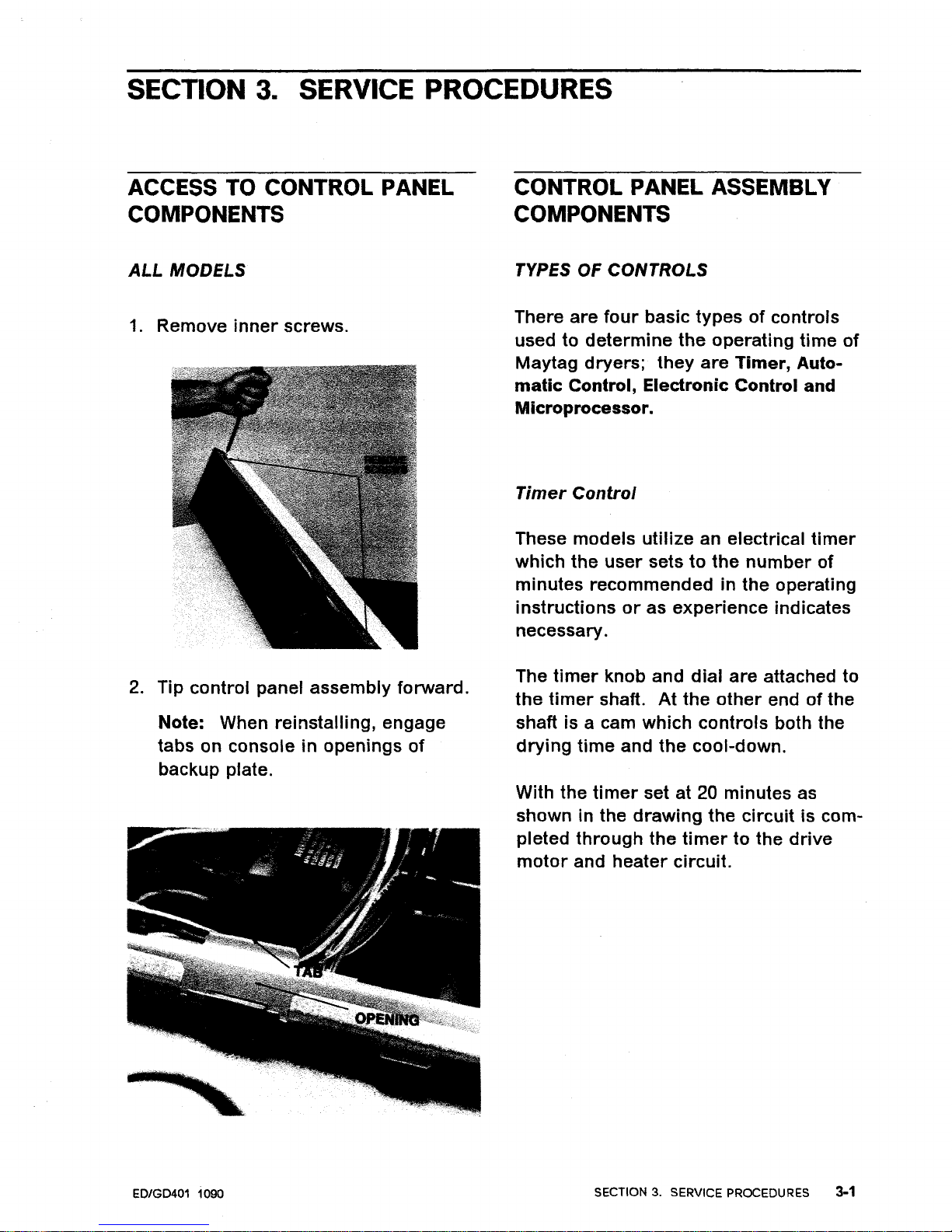

checks