Maytag CHG9800BAE, CRG9830CAE, CRG9830CAM, CHG9830BAB, CHG9830BAE Installation Instructions

...Page 1

INSTALLER: LEA VE THESE INSTRUCTIONS WITH THE APPLIANCE.

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE.

The manual is intended to assist in the initial installation and adjustments of the range.

GAS INSTALLATION MANUAL

SEALED TOP BURNERS

30" WIDE SELF-CLEAN

FREE-STANDING AND SLIDE-IN RANGES

INDEX

I. INSTALLATION ............................................................................ 2-5

A. Service- Parts Information ................................................................... 2

B. Codes- Electric,Gas,MobileHome,RecreationalVehicles.......................................... 2

C. ClearanceDimensions ....................................................................... 2

D. Locatingthe Range ......................................................................... 2

E.Anti-Tip DeviceInstallationInstructions.......................................................... 3

Step 1- Locatingthe Bracket.................................................................. 3

Step 2 - Anti-Tip Bracket Installation ............................................................ 3

Step 3 - Range Installation .................................................................... 3

F, Connecting The Range ....................................................................... 4

1.Electrical Supply Connection ................................................................ 4

2. Gas Supply Connection .................................................................... 4

G. Checking Manifold Gas Pressure ............................................................... 5

H,Checking Pressure of HousePiping System ...................................................... 5

II. RANGE ADJUSTMENTS ..................................................................... 6-7

A. Top Section- Electric Ignition ................................................................. 6

B. Oven Adjustments .......................................................................... 6

1.Electric Ignition - BakeBurner with Electric Glow Bar ............................................. 6

2. Air Shutter - Oven Burner ................................................................... 6

3. Waist-Hi Broiler Burner ..................................................................... 7

C. Clean cycle ............ : ................................................................... 7

I11.GAS CONVERSION ........................................................................ 8-10

A. General ................................................................................... 8

B. Regulator Conversion ........................................................................ 8

C. Orifice Conversion .......................................................................... 9

D.Top BurnerWarm Adjustment ................................................................ 10

E. Oven Burner Air ShutterAdjustment ........................................................... t0

IV. INSTALLATION DRAWINGS ................................................................ 11-12

YOUR RANGE MAY NOT BE EQUIPPED WITH SOME OF THE FEATURES REFERRED TO IN I

THIS MANUAL.

8107P311-60

(5/92)

I

Page 2

INSTALLATION

SECTION I

A. SERVICE - PARTS INFORMATION

WHEN YOUR RANGE REQUIRES SERVICE OR RE- In Canada the range must be installed in accordance

PLACEMENT PARTS, CONTACT YOUR DEALER withthecurrentCSA StandardC22,1- CanadianElec-

OR AUTHORIZED SERVICE AGENCY. PLEASE tricalCodePart 1 and SectionZ240.4.1 - Installation

GIVE THE COMPLETE MODEL AND SERIAL NUM- Requirements for Gas Burning Appliancesin Mobile

BERS OFTHE RANGEWHICH ISLOCATEDON THE Homes(CSA StandardCAN/CSA- Z240MH).

RANGE MODEL NUMBER PLATE. NOTE: THE

RANGE MODEL NUMBER PLATE I$ LOCATED ON RECREATIONAL VEHICLES

THE LOWER FRONT FRAME OF THE RANGE. Theinstallationofa rangedesignedforrecreationalve-

B. CODES hiclesmustconformwith stateorothercodesor, inthe

These units must be installed to conform with all local tional Vehicles, ANSI A119.2-1982.

codes rulesandregulationsincluding municipal,provin-

cialandstatebuildingcodes, aswellas Ioca(utilityregu- In Canada the range must be installedin accordance

lations. Ranges approved for Canada will have the Ca- with Section C22,2 No. 148/CAN/CSA - Z240.6.2 -

nadian Gas Association (CGA) approval seal on the ElectricalRequirementsforR.V.'s(CSAStandardCAN/

model number plate. Ranges approved for Canada CSA-Z240RVSeries)andSectionZ240.4.2-1nstaila-

have been tested to insure compliance with CGA1.1. tion Requirementsfor Propane Appliances and Equip-

ELECTRIC SUPPLY des).

The range must be installed in accordance with Local C. CLEARANCE DIMENSIONS

and National Electric Code (NEC) ANSI/NFPA No. (Seebackpage for installation drawings).

70-1987.

In Canada the range must be installed in accordance againstavertical combustible wall,andthesides below

withthe currentCSA Standard C22.1 - CanadianElec- thecooking surfaceagainstcombustiblebasecabinets..:-

tricalCode Part 1. Slide-inrangesmust be installedinaccordancewithfig- _-_.

GAS SUPPLY ure 10C, For complete informationin regard to the in-

Installationofthis rangemustconformwithlocalcodes aneestocombustiblewallaboveth_cookingtopseethe

or,intheabsenceoflocalcodes,withtheNationalFuel installationdrawings (back pages) and/or the Model

Gas Code,ANSI Z223.1-1988. NumberPlateontherange.ForSAFETYCONSIDERA-

In Canadathe range must be installed in accordance TIONS do not install a rangein any combustible cabi-

with the current CGA Standard CAN/CGA-B 149 - In- hettywhich isnot inaccordwiththe installationdrawings

stallationCodes forGas BurningAppliances andEquip- and the clearance given on the range Model Number

ment and/orlocal codes. Plate.

Checkthe rangemodel number plateto seeifthe range CAUTION: DO NOT LIFT OR MOVE RANGE BY

isapprovedforinstallation in mobile homesand/orrec- DOORHANDLES, OR BACKGUARD.

reationalvehicles. If approvedthe following items are D. LOCATING THE RANGE

applicable. Donotset rangeoverholesinthefloororotherlocations

MOBILEHOMES the wall behind the range and in the floor under the

Theinstallationof arange designed for mobilehome in- tion or ventilation air is notobstructed,

stallation must conform with the Manufactured Home

Constructionand Safety Standard, Title 24 CFR, Part Be certain all packing materials are removed from the

3280 (formerlythe Federal Standard for Mobile Home rangebeforeoperating topreventfireor smokedamage

Constructionand Safety, Title 24 HUD, Part 280) or,

when suchstandard is not applicable, the Standard for NOTE:A range should NOT be installed directly over

Manufactured Home Installations 1982 (Manufactured kitchen carpeting unless an insulatingpad or 1/4-inch

Home Sites, Communities and Set-Ups), ANSI thick pieceof plywood isplacedbetweenthe rangeand

A225.1-1984, or with local codes, carpet.

absenceof suchcodes,withtheStandardfor Recrea-

mentinR.V.'s(CSA StandardCAN/CSA- Z240RVSo-

Allfree-standing ranges can beinstalled with the back

stallationof wall cabinetsabovethe rangeand clear-

where itmay besubjecttostrongdrafts.Anyopeningin

rangeshould be sealed. Makesure the flowofcombus-

shouldthe packing material ignite.

"'CO_ES OFTHE STANDARDLtST_.OABOVEMAY BE OBTAINED FROM: "*'COPIES OF THE STANDARDLISTED ABOVE MAYBE OBTALNEDFROM:

NATIONAL FIRE PROTECTION ASSOCIATION AMSRJCANGAS ASSOCJAT_ON

Satterymarch Park 1515 Wilson Boulevard

Quincy, Massachusetts 02259 ArlingtOn,V_rgmia 222(39

-2-

Page 3

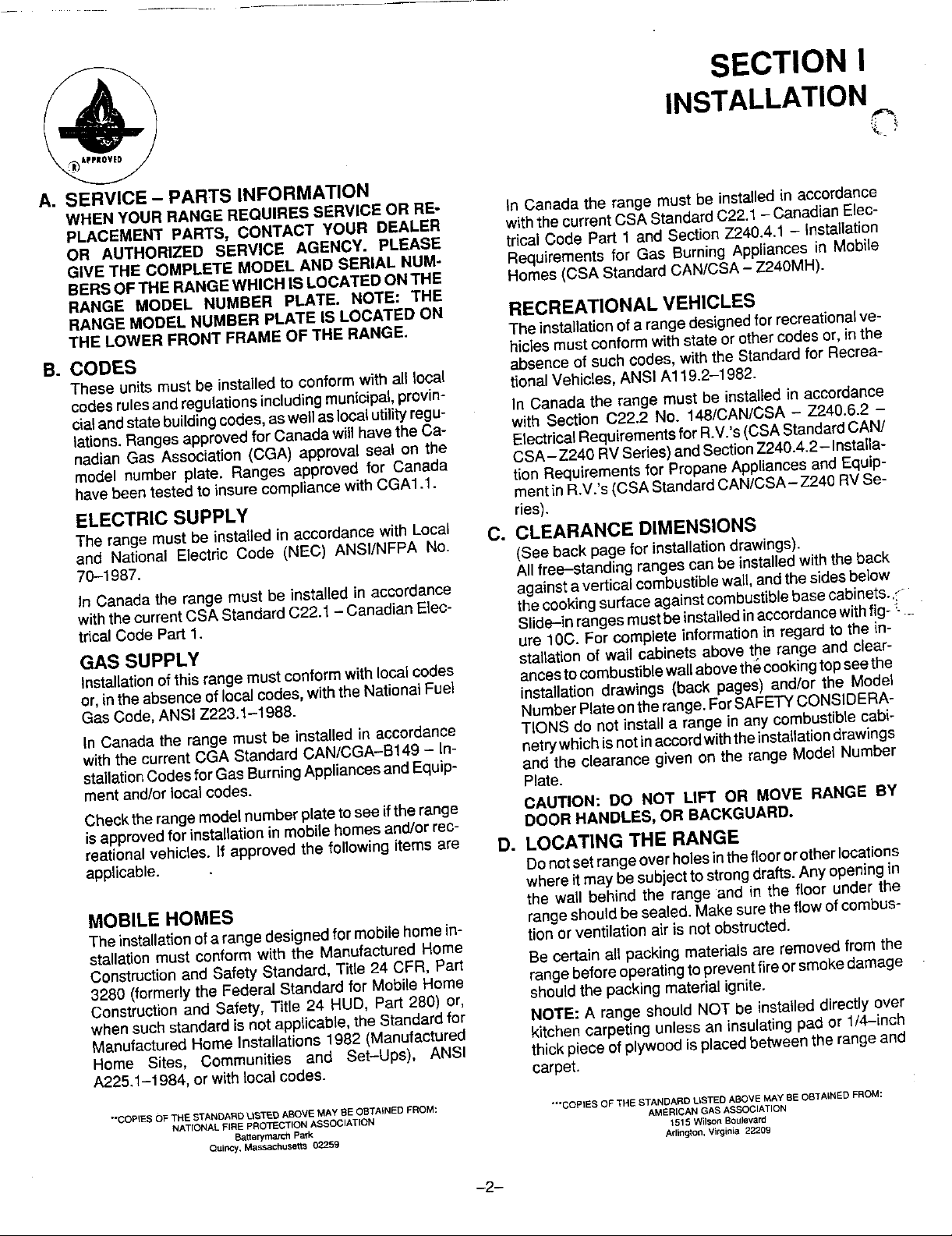

E. ANTI-TIP DEVICE INSTALLATION

INSTRUCTIONS

NOTE:A riskof rangetipoverexistifthe applianceis STEP 3 - Range Installation

r. notinstalled in accordancewith the installation instruc-

tions provided.The proper use of this device minimizes A. Completethe installationof the range perthe instal-

theriskof TIP--OVER.Inusingthis devicethe consumer lationinstructions providedwith the product.

must stillobservethesafetyprecautionsasstatedinthe B. Aligntherangeto its designatedlocationandslide it

USE and CARE MANUAL and avoid using the oven back into position. Note: A minimum clearance of

doorand/or lower drawer as a step stool. 1/4" is required between the rangeand the leveling

Installation instructions are providedfor wood and co- ure 2.

ment in either floor or wall. Any other type of construc-

tion may require special installation techniques as C. For SAFETY CONSIDERATIONS as welt as opti-

deemednecessaryto provideadequatefasteningofthe mumperformanceadjustthe rangesothat itislevel.

ANTI-TIP bracket to the floor orwall. This may be checked by placing a spirit level or a

STEP 1 - Locating The Bracket the range and rotate the leveling feet as required.

A. Mark the floor or wall where eitherthe right or left D. To check the range for proper installation of the

"EDGE" of the 30" opening is to be located, anti-tip bracket: Use a flashlight and look under-

B. Place the BRACKET SIDE, see figure 1, at the rear leveling legs is engaged in the bracket slot.

marked "EDGE" and against theback wall.

C. Use the bracket as a template and mark the re- structions provided with the range.

quired holes, as shown in figure 1, for the type of

construction you will be using.

footthat will engagethe ANTI-TIP bracket,seefig-

largepanof wateron thecooktop orthe oven rack.If

anadjustmentisrequiredpullthe range forward,tip

neaththe bottom of the rangeto see that one ofthe

E. Proceed with the remainder of the installation in-

STEP 2 - Anti-Tip Bracket Installation _"*-_

A. Wood Construction: ..... '

1. Floor:Locatethecenterofthetwo holesidenti- _ "_ _ _"

pilot holeinthe centerofeach hole(anailorawl

may be used if a drill is not available). Secure

the ANTI-TIP bracket to the floor with the two

screws provided. Proceedto STEP 3. '=_

2. Wall: Locate the center of the two holes identi- FIGURE1

fled in figure I as "WALL-PLATE". Ddll an an-

gled 1/8"pilot hole in thecenterof each holeas

Showninfigure2.(Anailorawl maybeusedifa

drill is not available). Secure the ANTI-TIP

bracket tothewa}lwiththe twoscrewsprovided

as shown in figure 2. Proceed to STEP 3.

B. Cement or Concrete Construction:

1. Suitable screws for concrete construction can

be obtained at the hardware store. Drill the re-

quired size hole forthe hardware obtained into

theconcrete atthe centerofthe holes identified

in figure 1 as "FLOOR--CEMENT". Secure the

ANTI-TIP bracket to the floor. Proceed to

STEP 3. FIGURE2

-3-

Page 4

connecttherangeto the maingas supply mustbe

_- CLEAN,free of metalshavings, rust, dirt and liq-

uids(oil or water). Dirt,etc. in the supplylinescan

--_ I1_-- work its into the manifold and in turn

-" cause failure of the gas valves or controls and ,. :

clog burners andor pilot orifices.

way range #,-,.,,

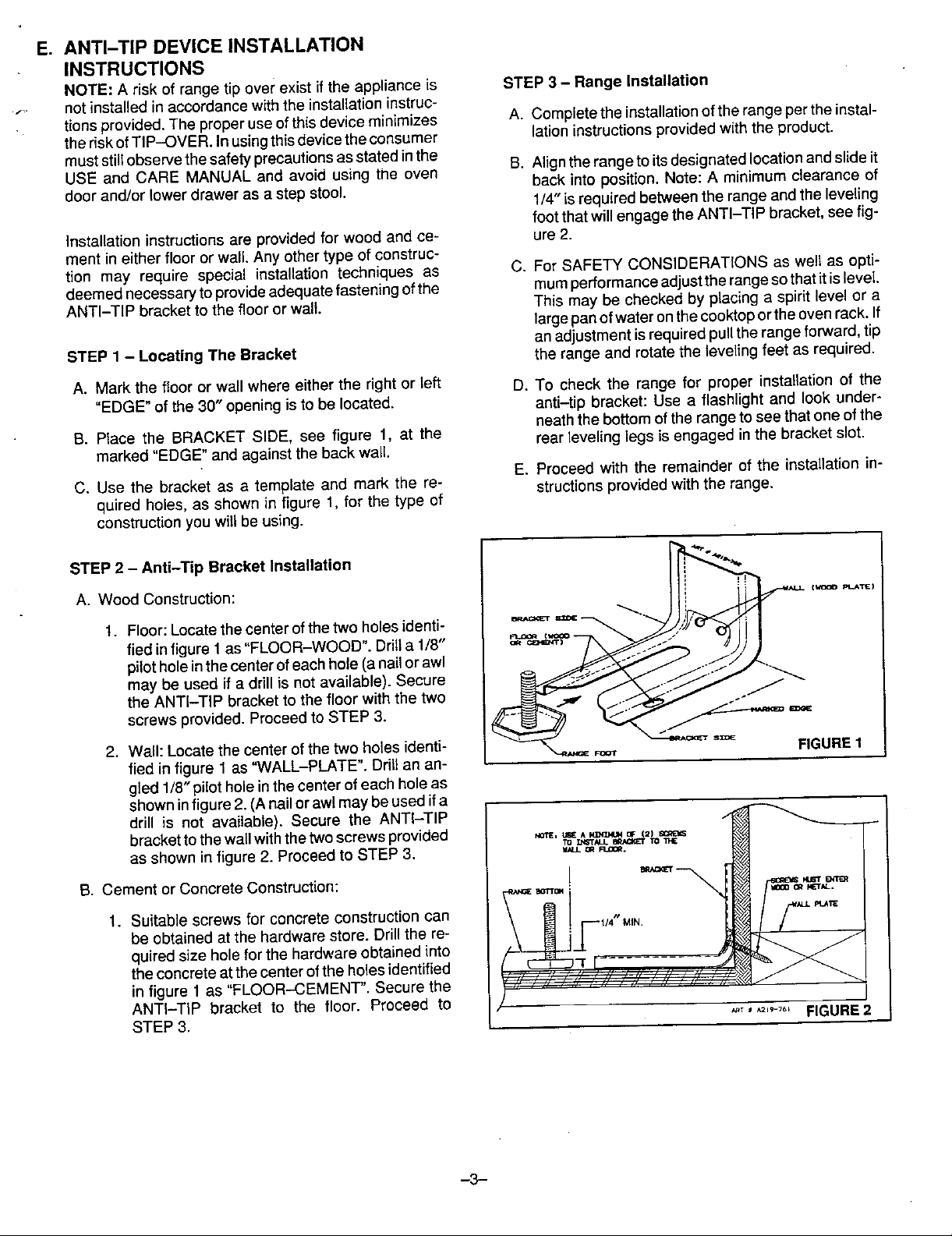

._._ b. The house pipingand/or rangeconnectorusedto

FIGURE3

NOTE: THE MAINTOP DOES NOTLIFT UP.

c. Turn off allpilotsand maingasvalve of other gas

appliances.

d. Turn off main gas valve at meter.

F. CONNECTING THE RANGE e. Beforeconnecting range, applypipethread corn-

1, ELECTRICAL SUPPLY CONNECTION: pound approved for LPG to all threads.

The range requires 120 volts, 60 cycle alternating

current from an outlet capable of supplying 15 am- f. Connect range to gas supply at regulator using

peres, rigid pipe or adaptors supplied with flexible con-

nector. See rating platefor type of gas range has

been manufacturedfor. Gas conversion kits are

available.

g. Turnonmaingasvalveat meter,andrelightpilots

atother gas appliances.

h. Apply soap suds to the gas connection at range ----

plug. and check for leakage. Check for leakage at all __

gasconnections and fittings in the range.

CAUTION: NEVER CHECK FOR LEAKS WITH

A FLAME.

i. Connect electric supply cord to wall receptacle

120 volt, 60 cycle alternating current, at 15 am-

peres.

j. Adjust burner air shutter to the widest opening

2. GAS SUPPLY CONNECTION: that willnot cause theflame toliftor blow off the

ATRAINEDSERVICEMAN MUSTMAKETHEGAS

INSTALLATION. NOTE: Correctlyadjusted sealed burners will

a. AGAS CUTOFFVALVE SHOULD BEPUT INAN blow off without a pot over the burner. These

ACCESSIBLE LOCATION IN THE SUPPLY could be adjustedwith a pot in place.

LINEAHEAD OF THE RANGE, FORTURNING

isto beconnectedtOhouse pipingwithflexible or _ _)_@1

CONNECTOR NUTS MUST NOT BE CON-

NECTED DIRECTLY TO PIPE THREADS. THE

semi-rigid metal connectors for gas appliances, /._4 d_._._Q _ _

CONNECTOR MUST BE INSTALLED WITH FLEXIBLESUPPLYLINE PRESCribE

ADAPTORS PROVIDED WITH THE CONNEC- _Ut-ATO"=II'

burnerwhencold.

OFF VALVE

T-OFF

ToR nG0,E, '

Regulator&Connection

-4-

Page 5

G. CHECKING MANIFOLD GAS PRESSURE

sure, remove right rear burner assembly by placing

burner wrench (part no. 8002P026-60, available from

your dealer orauthorizedservice agency*) oversurface

Ifitshouldbenecessarytocheckthemanifoldgaspres- _ORFICE HOO_j/_

burner assembly with ignitor positioned inside gap in

wrench ring(figure5A).This prevents ignitorfrom being

crushedwhenwrenchtightensonburner assembly.Ro- '_'_"

late burner assembly approximately one--eighth turn

counter-clockwise and lift from main top (figure 5B).

Connect manometer (water gauge) or other pressure _ ",._" _H

device to the top burner right rear orifice hood, using a ........x.._._._ _..<_'x_rubber hose with inside diameter of approximately 1/4"

inch,holdtubingdown tightover orifice hood. Turnburn-

er valve on. For an accurate pressure check have at

leasttwo (2)other top burners burning. Be surethe gas

supply (inlet) pressure is at least one inch (1") above

specified range manifold pressure. The gas supply

pressureshouldneverbeover 14 inches water column.

When properly adjusted for Natural Gas the water coF

FIGURE5B

umn pressure is 4", for LP Gas the water column pres-

sure is 10". Replace burner assembly in main top and

rotate approximately onc cighth turn clockwise using

burnerwrench untilburnerlockeinto positionwith ignitor

facing rearward. H, CHECKING PRESSURE OF HOUSE PIPING

SYSTEM

COUNTER-CLOCKNISE be disconnected fromthe gas supply piping system

t.OOSEN during any pressure testing of that system at test

1. The appliance and its individual shutoff valve must

pressuresinexcessof 1/2Ibs./sq.in.(3.5kPa) (13.8

I_NITOe_'OS_'rION 2. Theappliance must be isolatedfrom thegassupply

ZNSZOEWRENCHGAP pipingsystem by dosing its individual manualshutoff

valve during any pressure testing of the gassupply

piping system at test pressures equalto or lessthan

CLOCKWISE 1/2Ibs./sq. in, (3.5 kPa) (13.8 in. water column).

TO TIGHTEN ._._

.... ___ in. water column).

19-812

FIGURE5A

*If burner wrench is not available locally, contact Maycor Parts and Service, 240 Edward Street, Cleveland, TN 37311,

(61_72-3500).

-5-

Page 6

SECTION II

RANGE ADJUSTMENTS

A. TOP SECTION - ELECTRIC IGNITION

To operate, push and turn top burner knob to the LITE er flame wilt go "out" in 20 to 30 seconds after the

position. The top burner will light. To turn OFF spark af- ignitor goes "OFF". To maintain any given oven

ter the top burner has ignited: temperature this cycle will continue as long as the

dial (or display) is at the given temperature.

1. For ranges with SINGLE purpose valves, turn knob to

the right, clockwise to the HI setting, figure 6A. b. In case servicing should become necessary, a

2. For ranges with HI-SIM-WARM valves, turn knob, burner only. (See figures 3 and 4).

either direction to HI setting, figure 6B.

FIGURE 6A FIGURE 6B figure 7.

Single PurposeKnob Hi-Sim-Warm Knob

manual gas valve is supplied on the pressure

regulator to shut off the gas to the oven and broiler

c. The oven CANNOT be used during periods of

power outage. In case of power failure, turn the

2. AIR SHU'n'ER - OVEN BURNER

a. The approximate length of the flame on the oven

burner is 1/2 inch (distinct inner, blue flame). See

BURNER

3. There are separate ignition devices for each burner. BAFFLE_J-..._ "r_ "?_1/2"FLAME

These ignitors are turned "on" when any knob is _ _._.(,:,:/'<_" J-/- _C'",

setting. In case of an electrical power failure, the top

long as any of the top burner knobs are at the LITE ___

burners can still be used, To light a burner, hold a

turned to the LITE setting. The ignitors will "spark" as _ -- _ '---'

lighted kitchen match adjacent to the top burner to be

used and turn valve knob for the burner to LITE. USE

EXTREME CAUTION. The electric ignitor will not

come "on". It is necessary when using the top burners

during this type of emergency to light each burner to b. Oven burner flame can be checked as follows,

be used with a kitchen match as described above without burner baffle in place:

each and every time the burner or burners are to be

used. - Yellow flame on burner - open air shutter "2"

on figure 8.

B. OVEN ADJUSTMENTS - Distinctblueflamebutlifting-closeairshutter

1. ELECTRIC IGNITION - BAKE BURNER WITH "2" on figure 8.

ELECTRIC GLOW BAR

a. The bake burner is equipped with an electric con- c. The air shutter, figure 8, should be set approxF

trol system as well as an electric oven burner ig- mately 2/3 open for natural gas and full open on

niter. This control system requires NO adjust- LP gas.

ment. To operate, turn thermostat knob to any

temperature setting or to broil. Current will flow to

the ignitor. It will "glow" similar to a light bulb. (This

glow may be reflected into the oven through the LOCKSCREW

openings in the oven bottom). When the ignitor

hasreachedatemperature sufficienttoignitegas, AIR SHUTTER

the electrically controlled oven valve will open and /2

flame will appear at the oven burner. There is a ORIFtCEHOOO

time lapse from 30 to 45 seconds after the thermo- 1_..

stat is turned ON before flame appears at the

oven burner. When the oven has reached the dial

setting, the glowing ignitor will go OFF. The burn- FIGURE 8

--6-

FIGURE 7

\

Page 7

3, WAIST-HI BROILER BURNER

(See figure 9) The approximate length ofthe flame of the broil

a. The waist-hi broiler is equipped with its own burner is a distinct inner btue flame of 3/8 inch.

(separate) electric control system and electric Theouterflamewillextendoutwardasasheetof

broiler burner ignitor. To operate turn oven ther- flame adjacent to the burner baffle (flame

mostat knob to the BROIL setting. The system spreader) above the broil burner,figure 9.

functions the same as described under Bake

Burner. The airshutter, figure 8 should be setto full open

on both NaturalGas and on LPGas.

b, A manual gasshut-off valveissupplied,onregu- d. The waist-hi broiler CANNOT be used during

lator incase servicingshouldbecome necessary, periods of power outage. Incaseof power fail-

See figure 4. ure, turn thermostat tothe OFF position.

c. Theair shutter adjustmentsare thesameas illus- C. CLEAN CYCLE - SEE USE & CARE MAN-

trated in figure 8. UAL FOR SELF CLEAN INSTRUCTIONS.

WAIST HIGH

BROILER BURNER

FIGURE9

TypicalGas PipingSystem

YY<'

-7-

Page 8

SECTION III

GAS CONVERSION

A. GENERAL 1. Removethecap, pushdownandturncou te clock- "

All sealed burner ranges and cooktops are equipped wise. Turn the cap over and reinstall (figure 10).

with double coaxial (universal)orificesand with a con- NOTE: THE GASTYPE YOU ARE CONVERTING

vertible gas regulator. The unit model number plate TO MUST BE VISIBLEONTHE TOP OF THE IN-

states which gas it was adjusted for at thefactory. To STALLED REGULATORCAP.

convert the unit to either Naturalgas or LPgas will re-

quireadjustmentofthe surfaceburnerorifice hoods,ad- 2. Remove plasticdust cover from cap nut on top of

justment oftheoven orifice/airshutter and replacement regulator. Remove cap nut from regulator (plastic

and/or adjustment of the pressure regulator converter dust cover comes off with nut)."IMPORTANT" re-

cap. move plastic dust cover from cap nut and reinstall

on oppositeside of cap nut.

B, REGULATOR CONVERSION Reinstall cap nut to regulator and replace dust

The unit regulator must be set to match the type gas cover. "CAUTION" be sure marking for the type of

supply used. If converting from natural gas to LP gas, gas to which regulatorhasjust been converted is

the regulator must be converted to regulate LP gas. If visible intop ofcap nut beforereplacingplastic dust

converting from LP gas to natural gas, the regulator cover. See figure 11.

must be converted to regulatenatural gas.

3. Remove cap and forcibly snap out plastic plunger

TO CONVERTTHE PRESSURE REGULATORFROM from bottom of cap. Turn plunger over and forcibly

ONE GAS TO ANOTHER, DO EITHER (1), (2) OR (3) snap back in original location (figure 12). NOTE:

BELOW:YOUR UNITWILLBE EQUIPPEDWITHONE PLUNGER MUST SNAP INTO POSITION; THE

OF THE THREE REGULATOR TYPES SHOWN BE- GAS TYPE YOU ARE CONVERTING TO MUST

LOW. BEVISIBLE ON LOWER SIDE OF PLUNGER.

nr

FIGURE10 FIGURE11 FIGURE12

.-8-

Page 9

C. ORIFICE CONVERSION ORFICEHOeO.- +

a. Place burnerwrench(part no. 8002P026-60,

availablefromyourdealerorauthorizedservice

"+_ agency*)oversurface burnerassemblywithig-

1. FROM NATURAL GAS TO LP GAS: _._/_/

nitorpositioned insidegapinwrenchring(figure

13A).This prevents ignitor from being crushed

whenwrenchtightensonburnerassembly.Ro-

tate burner assembly approximately one-

top(figure 13B).Usinga 1/2"deep--wellsocket,

tighten each burner orifice hood approximately

two complete turns clockwise TO THE

eighthturncounter-clockwise and liftfrommain _. __ _.,

bly in main top and rotate approximately one-

CLOSED POSITION. Replace burner assem- _

eighthturn clockwise using burner wrench until

burner locks into position with ignitor facing

rearward. FIGURE13B

b. On ranges, use the 1/2" open end wrench to 2. FROM LP GAS TO NATURAL GAS:

tighten the oven orifice hood (1-figure 18) ap- a. Place burner wrench (part no. 8002P026-60,

proximatelytwo complete turns clockwiseTO ava(labIefromyourdealerorauthorizedservice

THE CLOSED POSITION. See figure 14B. agency*) oversurfaceburnerassembly with ig-

nitorpositionedinsidegapinwrenchring (figure

13A).This preventsignitorfrom be{ngcrushed

c. Adjustburner air shutter to the widest opening whenwrench tightenson burner assembly. Ro-

tate burner assembly approximately one--

thatwiiJnot causetheflame to liftor blowoffthe eighthturn counter-clockwiseandIiftfrommain

burnerwhen cold. top(figure 13B).Usinga 1/2"deep-well socket,

NOTE; Correctly adjusted sealed burners will looseneach burner orificehood approximately

blow off without a pot over the burner. These two complete turns counter-clockwise. Re-

should be adjusted with a pot in place, place burner assembly in main top and rotate

approximatelyone eighthturnclockwise using

burner wrench until burner locks into position

with ignitor facing rearward.

LOOSEN b. On ranges, use the 1/2" open end wrench to

-CLOCKWISE

loosenthe oven orifice hood (1-figure 18) ap-

wise until the flames on the burner do not in-

_ _"-_----*_Z_-_-...__ .]. proximatelytwo completeturnscounter-clock-

IGNITORPQSlTION - crease in length.See figure 14A.

INSIDE WRENCH GAP

thatwill notcausethe flametoliftor blowoffthe

CLOCKWZSE burner when cold.

TOTIGHTEN ._._ NOTE: Correctly adjusted sealed burners will

blow off without a pot over the burner. These

___ c. Adjustburner airshutter to the widest opening

ZN-t4_JSE_ _ - I_MOV_L

9-8L2 should be adjusted with a pot in place.

FIGURE13A

HOOD HOOD

ORIFICE ORIFICE

FIGURE14A FIGURE14B

*If burner wrench is not available local)y, contact NATURALGAS LPGAS

Maycor Parts and Service, 240 Edward Street, SE'r'rING SETTING

Cleveland, TN 37311. (615-472-3500).

-9--

Page 10

D. TOP BURNER "WARM" ADJUSTMENT E. OVEN BURNER AIR SHUTTER

Ifequipped witha single purpose valve (see figure 15) ADJUSTMENT

no adjustment is required. If equipped with HI, SIM, Theapproximate length of the distinct inner blue flame

WARM valves, the burner flame atthe WARM position of the oven burner is 1/2 inch (figure 17).Remove the,

should extendto the outer edge of the lipof the burner burnerbaffleto adjustthe burnerflame with the air shut-

cap. The WARM settingshould be such that a stable ter. Theair shutter (figure18)should be approximately

flame is maintainedonthe burnerwhenturningthe knob 2/3open for naturalgas andapproximatelyfull open on

from HIto WARM. If itshould be necessaryto increase LPgas. If the oven burner flame isyellow, open the air

or decrease the flame at the WARM setting, operate shutter until it is distinct and blue. If the oven burner

burner at HI position for approximately five minutes, flame isdistinctandblue but lifting,closethe air shutter

Turn knobtoWARM(seefigure 16).Removevalveban- until the lifting stops.

die and with a small screwdrivermake the desired ad-

justment by turning adjustment screw "A" (figure 16). , .

BURNER

A FIGURE 17

FIGURE 15 FIGURE 16 LOCK SCREW i

\

ORIFICE HOOD ,-/"2

RGURE18

i

AIR SHUTTER

-10-

Page 11

SECTION IV

INSTALLATION DRAWINGS

FREE STANDING RANGES

Range may be installed with zero inches clearance adjacent to (against) combustible construction at the rear and on the

sides below the cooktop.For clearence for wall cabinets above a free-standing conventional range cooktep see illustration

and dimensions given below. Wall cabinets can be installed above and adjacent to a range, with elevated oven as illustrated.

*NOTE: 30 inch dimension between cooking top and wall cabinet shown on illustration does not apply to ranges with an

elevated oven. The 30 inch dimension may be reduced to not less than 24 inches when the wall cabinets in a domestic home

are protected with fireproof materials in accordance with American National Standards - National Fuel Gas Code or in mo-

bile homes when they are protected with fireproof materials in accordance with the Manufactured Home Construction and

Safety Standard (see Section I (B) codes).

CAUTION: Some cabinets and building materials are not designed to withstand the heat produced bythe normal safe opera-

tion of a listed appliance. Discoloration or damage, such as delamination, may occur.

TABLE NO.1

DIMENSION A DIMENSIONB DIMENSIONC LOWERCABINET

WIDTH OF NO LESS THAN WIDTH DEPTH & CUTOUT

RANGESERIES NUMBER RANGES OF RANGES

30" Free Standing, Self Clean 30"** 30" 3"* Figure 19B

30" Slide-In, Self Clean 30.... 30" 3"* Figure 19C

FOR DIMENSIONS A, B & C - SEE TABLE NO. 1

FRONT VIEW DETAIL

FIGURE 19A

INSTALLATION ILLUSTRATION FREE STANDING RANGES

-11-

Page 12

,To,_"Y,_'o'_oP

(BOTH SIDES)

PROVIDE FOR IZO¥

HEl_Cr A,RF.A (xn'LET MUST BE

I I Ot,II'I.ET IN 'THaSGENERAL

24' _

t K

**, THIS AREA.

_SO 21t "_--GAS RIPE TO BE IN

CABINt'T _ _'_"

WRH LEVELIN_I LEGS _,-"" ART_A2_-657

COMPt.STELT IN,

FIGURE 19B

Gas Free-Standing Ranges

SERIES I WIDTH HEIGHT DEPTH WIDTH HEIGHT DEPTH WIDTH HE/GHT DEPTH WT. (LBS.)

Self Clean 22" ";2 1/2" 18" 13 1/2" 3 1/4" 15" 30" 36" 24" 215

_ENINS_

OVEN BROILER CUTOUT DIMENSIONS APPROX.

SHIPPING

=s" _ , . _NOTE

1NORMALC&BINET __ 7,- P.3___ USE THIS OIM,WHEN _ ON CABINET TOPS WITH

DEPTH TRIM STRIP _ NOT USED.

STRIPo.K.Os_s_..o . _oSECT.O.

_KIT. TO CLEAR TOP.

BE FLUSH.

_ GAS PlPg TO BE IN THIS AREA.

Ik'_ _ LEVELIMe LEeS r,*,,z,9.6_

FIGURE 19C

Gas Slide-In Ranges

OVEN BROILER CUTOUT DIMENSIONS APPROX.

SERIES WIDTH HEIGHT DEPTH WIDTH HEIGHT DEPTH WIDTH HEIGHT DEPTH WT.(LBS.)

SHIPPING

Self Clean 22" 12 1/2" 18" 13 1/2" 3 1/4' 15" 30" 36" • 210

-12-

Loading...

Loading...