Page 1

Technical InformationGas Cooktop

AKS3040* CGC2430AD* JGC6430AD* MGC5430BD* MGC6430BD*

• Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

• Refer to Service Manual 16022158 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions.

CAUTION

!

All safety information must be followed as provided in Service Manual 16022158.

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

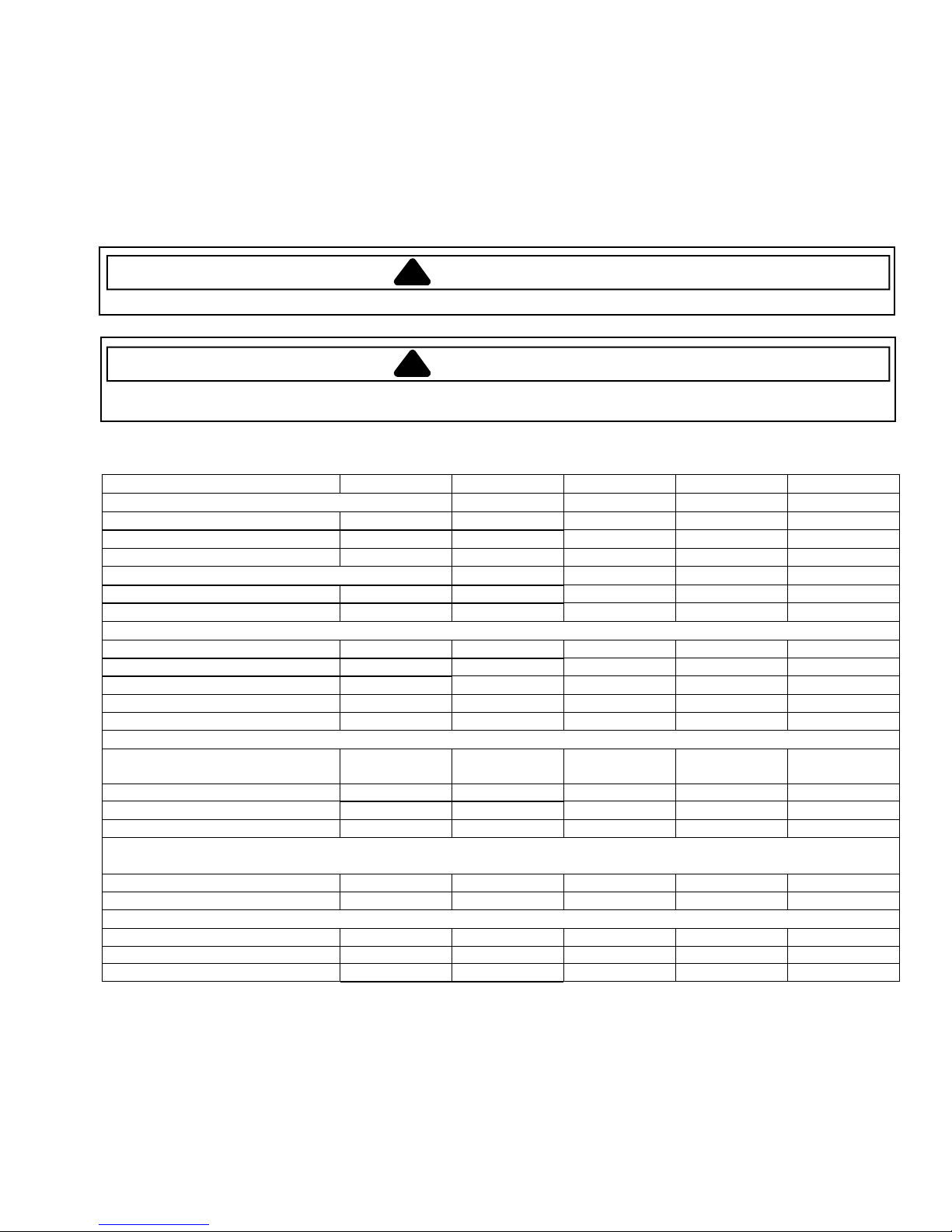

Model AKS3040* CGC2430AD* JGC6430AD* MGC5430BD* MGC6430BD*

Power Source

Voltage rating 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC

Amperage rating 10 Amp 10 Amp 10 Amp 10 Amp 10 Amp

Frequency 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

Water Column Pressure

Natural 4 in. W.C.P. 4 in. W.C.P. 4 in. W.C.P. 4 in. W.C.P. 5 in. W.C.P.

LP/Propane 10 in. W.C.P. 10 in. W.C.P. 10 in. W.C.P. 10 in. W .C.P. 10 in. W.C.P.

Surface Burner (BTU Nat. / LP)

Type of burner Sealed Sealed Sealed Sealed Sealed

Right front 12.5 K/10.5 K 12.5 K/10.5 K 12.5 K/10.5 K 12.5 K/10.5 K 12.5 K/10.5 K

Right rear 9.2 K / 9.1 K 9.2 K / 9.1 K 9.2 K / 9.1 K 9.2 K / 9.1 K 9.2 K / 9.1 K

Left front 9.2 K / 9.1 K 9.2 K / 9.1 K 9.2 K / 9.1 K 9.2 K / 9.1 K 9.2 K / 9.1 K

Leftrear 5K/4K 9.2K/9.1K 5K/4K 5K/4K 5K/4K

Features

Grate sytle One-piece

continuous

Grates material Cast Heavy steel Heavy cast Cast Cast

Cooktop surface Porc/steel Porc/steel Temp glass Porc/steel Porc/steel

Electronicignition XXXXX

Product cutout dimensions

in. (cm)

Width 28.5 (72.4) 28.5 (72.4) 28.5 (72.4) 28.5 (72.4) 28.5 (72.4)

Depth 19.9 (50.6) 19.9 (50.6) 19.9 (50.6) 19.9 (50.6) 19.9 (50.6)

Nat / LP Orifice Spuds

12.5 K / 10.5 K 1.85 / 0.97 1.85 / 0.97 1.85 / 0.97 1.85 / 0.97 1.85 / 0.97

9.2 K / 9.1 K 1.55 / 0.91 1.55 / 0.91 1.55 / 0.91 1.55 / 0.91 1.55 / 0.91

5 K / 4 K 1.10 / 0.64 1.55 / 0.91 1.10 / 0.64 1.10 / 0.64 1.10 / 0.64

WARNING

Square One-piece

continuous

One-piece

continuous

One-piece

continuous

March 2003 16022195 Rev. 01

Page 2

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

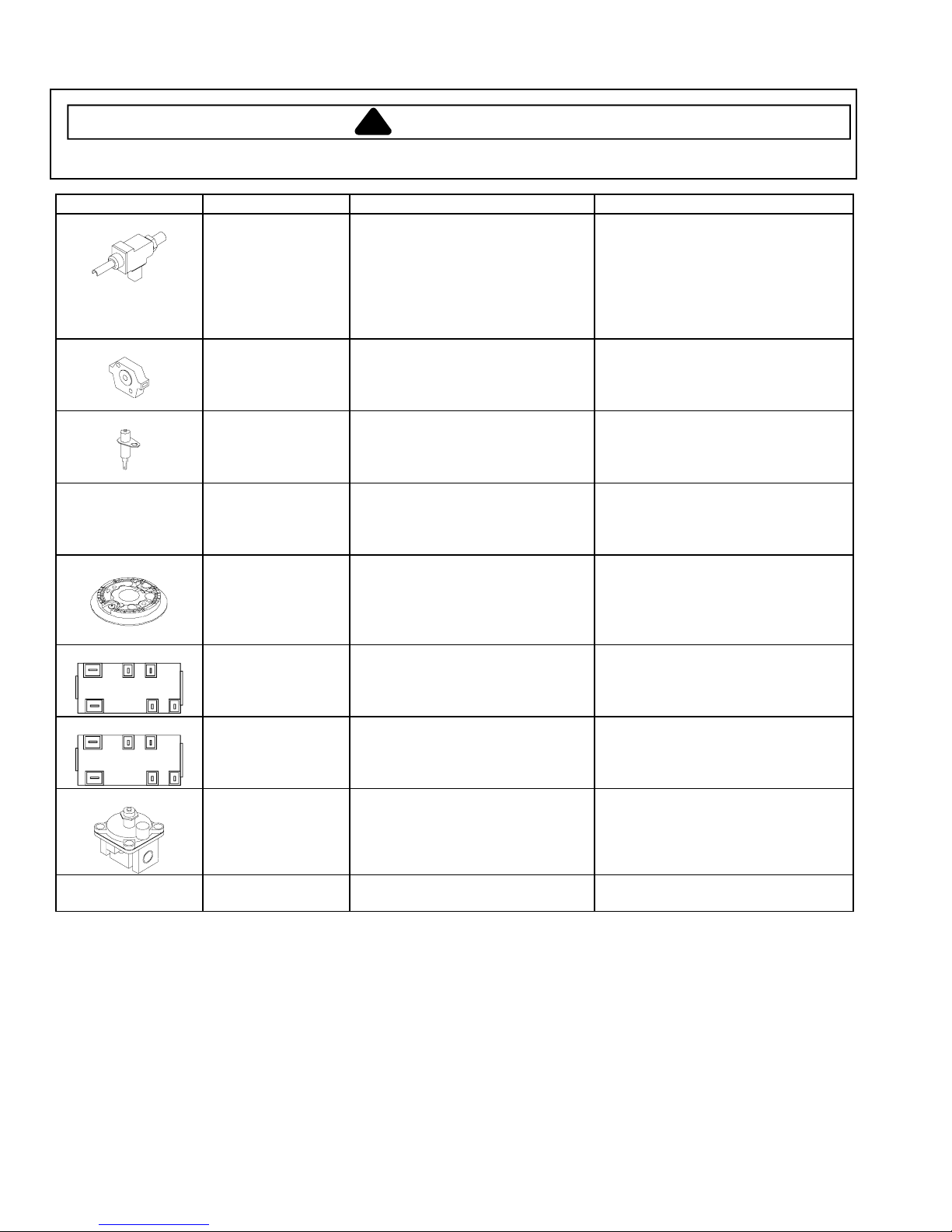

Illustration Component Test Procedure Results

270° valve

Verify gas is supplied.

To replace burner valve(s),

complete assembly must be

Orifice adjusted for

replaced (manifold and valves).

Natural or LP.

Adjust set screw for simmer

See conversion section.

control.

Spark 270° switch

Test for voltage at terminals.......

120 VAC

Disconnect wiring and check for

Spark ignition

continuity in LITE position...........

Test for resistance of spark lead

Continuity in LITE position.

Continuity

electrode

Test ignitor to chassis.................

No continuity from ignitor to

chassis.

Spark ignition

Test for resistance of spark lead

Continuity

electrode

Test ignitor to chassis.................

No continuity from ignitor to

chassis.

Top surface

burner

Verify gas is supplied..................

Check for obstructions in burner

ports.

Verify burner cap is positioned

correctly.

L

AB

B1N

A1

L

AB

B1N

A1

Spark module

4+0

Spark module

4+0

Pressure regulator Verify gas pressure (W.C.P.).

Test for voltage at terminals

L and N.......................................

Check polarity and ground..........

Test for voltage at terminals

L and N.......................................

Check polarity and ground..........

120 VAC

See wiring diagram

120 VAC

See wiring diagram

4" or 5" Natural, see specifications

10" LP/propane

If on LP service verify proper gas

supply conversion.

Power cord 3-wire Verify resistance of wires to

Continuity

terminals.

16022195 Rev. 0 March 20032

Page 3

Converting from Natural Gas to L.P. Gas

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

Converting from Natural Gas to LP Gas

Converting the Burner Orifice Spuds

1. Remove the grates and burner caps.

2. Remove securing burner base to cooktop surface.

3. Remove the Natural Gas burner spud using a

9

/32" (7 mm) nut driver. Save spud to reconvert if

necessary in the future.

WARNING

3. Apply downward finger pressure at the disc edges to

place pin into the cap.

NAT

4. Place pressure regulator cap on pressure regulator

and tighten.

Low Flame Adjustment

Properly adjusted burner flames are clean and blue with

a distinct inner cone approximately ½ inch long.

1. Remove control knob from valve stem.

2. Carefully remove rubber grommet from cooktop.

3. Locate valve adjustment screw.

4. Insert a slender thin bladed screwdriver into knob

hole and engage blade with slot in adjusting screw.

5. Turnadjustingscrewclockwiseuntiltight(5–7in-lbs.

Max.). Do not over tighten.

6. Replace rubber grommet and control knob.

7. Repeat process for remaining burners.

Natural

LP

L.P.

4. Install the LP/Propane spud (included in literature

package).

NOTE: See Specifications Chart on first page for

location of components.

5. Tighten to a torque of orifice 15 to 20 inch-lbs.

6. Tighten burner base screws 25 to 30 inch-lbs.

7. Repeat steps 2 through 4 for each burner.

8. Replace burner caps and grates.

Converting Pressure Regulator for LP/Propane

1. Remove pressure regulator cap using a wrench.

2. Apply sideward finger pressure to remove pin from

cap.

Apply sideways

finger pressure

to remove pin

from cap

After adjusting the screw the burner should produce a

stable, steady blue flame of minimum size. The setting

should be checked by turning the knob from high to low

several times without extinguishing the flame.

This operation will automatically provide the proper flame

size at medium setting.

After conversion steps have been completed, check the

appearance of each burner flame at high and low

settings. If the flames appear too large or small, review

each step to verify it was completed correctly.

March 2003 16022195 Rev. 03

Page 4

Wiring Diagram and Schematic

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

WARNING

SCHEMATIC

TOP BURNER

TOP IGNITORS

SPARK

MODULE

N

L

IGNITION SWITCHES

WIRING DIAGRAM

TOP BURNER

IGNITION SWITCHES

BLK BLK

BLK

TAN

NL

SPARK

MODULE

TOP IGNITORS

TAN TAN TAN

8104P828-60

BLK

NEUTRAL

POWER

CORD

GROUND

LINE

16022195 Rev. 0 March 20034

Loading...

Loading...