Page 1

Maytag

MAYTJiC

Washer

Service Manual

16010358

(16009485)

Issued 5/99

Revised 6/01

Page 2

SAFETY PRECAUTIONS

This manual, as well as the information contained in it, is to be used only by a Maytag

Authorized Service Technician. They should be familiar with and knowledgeable of

proper safety and servicing procedures and possessing high quality testing equipment

associated with microwaves, gas, and electrical appliance repair.

All individuals who attempt repairs by improper means or adjustment subject them

selves and others to the risk of serious or fatal injury.

USE ONLY GENUINE MAYTAG APPROVED FACTORY REPLACEMENT COMPONENTS.

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO AVOID

POSSIBLE EXPOSURE TO EXCESSIVE DANGER AND ELECTRICAL SHOCK:

‘'1

1. Disconnect electrical supply before servicing machine.

2. If electricity is required for a test:

(A) First, disconnect electrical supply;

(B) Second, make any connections or adjustments required for the test;

(C) Third, connect electrical supply;

(D) Fourth, perform the test. If service is required, disconnect electrical

supply before servicing machine.

3. Please use caution when servicing the machine with the front panel

removed because there is danger of injury due to potential contact

with spinning transmission.

4. Please use caution when servicing the machine with the front panel

removed because there is danger of injury due to contact with a

potential "pinch point” between the turned up edge of the transmission

cover and the tub support flange.

Page 3

INTRODUCTION

The information presented in this manual is printed in a loose format and is divided into

sections relating to a general group of components and/or service procedures. Each

section is further subdivided to describe a particular component or service procedure.

Anything of a unique nature concerning these models has been detailed and labeled as

such in the manual.

The subdividing of the subject matter, plus the loose leaf form will facilitate the updating

of the manual as new or revised components are added or new models are introduced.

Each page of the manual will be identified in the lower right-hand corner, and as new or

revised pages are published, the manual can easily be updated by following the file

instructions on the cover letter of the supplement.

The service manual is a valuable tool and care should be taken to keep it up to date by

prompt and proper filing of subsequent pages as they are issued.

Model(s) covered in this service manual:

M

Brand M=Maytag

MAV4057 MAV7200

MAV4500 MAV7000

MAV5000 MAV7057

MAV5057 MAV7600

MAV6000 MAV7700

MAV6057 MAV8000

MAV6200 MAV8057

MAV6257 MAV8500

MAV6300 MAV8600

AV

Product

AV=Automatic

Vertical Washer

5000

Model No.

MAV9600

Production

Code

w w

Color

Q=Bisque

W=White

16010280

(16009485-02)

Voltage

W=120VAC/60 Hz-U.S.

Introduction

©2000 Maytag Appliances Sales Company

Page 4

For additional information on material covered in this manual, including safety issues,

contact:

Maytag Appliances Sales Company -

Customer Service

240 Edwards Street, S.E.

Cleveland, TIM 37311

Phone: 423.472.3333

FAX: 423.478.6722

* V

16010280

(16009485-02)

Introduction

©2000 Maytag Appliances Sales Company

Page 5

INTRODUCTION.................................................................................................Mi

CONTENTS...................................................................................................... iii-vl

SECTION 1. GENERAL INFORMATION

PRE-INSTALLATION REQUIREMENT....................................................................................1-1

ELECTRICAL REQUIREMENTS.............................................................................................1-1

GROUNDING INSTRUCTIONS................................................................................................1-2

UNCRATING INSTRUCTIONS............................................................................................... 1-2

INSTALLATION PROCEDURE................................................................................................ 1-3

FINAL INSTALLATION CHECK LIST.......................................................................................1-5

UNIQUE INSTALLATIONS.......................................................................................................1-5

SPECIFICATIONS....................................................................................................................1-7

CYCLE CHARTS......................................................................................................................1-9

SPECIAL TOOLS....................................................................................................................1-12

..........................................................

1-1

SECTION 2. OUTLINE OF MECHANICAL OPERATION................................2-1

GENERAL INFORMATION......................................................................................................2-1

CLUTCH ASSEMBLY.............................................................................................................. 2-1

DRIVE PULLEY AND CAMS................................................................................................ ..2-3

SECTION 3. EXPLODED VIEW OF COMPONENTS

SECTION 4. CABINET ASSEMBLY COMPONENTS

CONTROL PANEL ASSEMBLY

VERTICAL SWITCHES.............................................................................................................4-2

TIMER REMOVAL

AUTOMATIC TEMPERATURE CONTROL BOARD

TOP COVER ASSEMBLY.........................................................................................................4-3

STANDARD LID ASSEMBLY................................................................................................... 4-4

30 DAY DETERGENT DISPENSER.........................................................................................4-5

DETERGENT DISPENSING.....................................................................................................4-6

CLEANING THE DISPENSER..................................................................................................4-7

FRONT PANEL.........................................................................................................................4-7

REAR ACCESS PANEL........................................................................................................... 4-8

CABINET BODY ASSEMBLY................................................................................................. 4-9

BASE ASSEMBLY....................................................................................................................4-9

STABILIZER ASSEMBLY................................................................................................ .....4-11

TOP COVER TO CABINET HINGE........................................................................................4-12

....................................................................................................................4-2

....

..........................................................................................4-1

................................................................

......................................

.....................................

3-1

4-1

4-3

SECTION 5. WATER - RELATED COMPONENTS.........................................5-1

WATER MIXING VALVE.......................................................................................................... 5-1

WATER INLET FLUME.............................................................................................................5-2

AIR BELL.................................................................................................................................. 5-2

HOSES..................................................................................................................................... 5-2

16010280

(16009485-02)

©2000 Maytag Appliances Sales Company

Contents

III

Page 6

TUB TOP.................................................................................................................................. 5-3

AGITTVrOR..............................................................................................................................5-3

INNER TUB.............................................................................................................................. 5-4

OUTER TUB ASSEMBLY........................................................................................................5-4

PUMP ASSEMBLY..................................................................................................................5-5

WATER VALVE INJECTION SYSTEM....................................................................................5-7

STAINLESS STEEL SPINNER ASSEMLY..............................................................................5-9

SECTION 6. SUSPENSION SYSTEM.............................................................6-1

SUSPENSION HOUSING........................................................................................................6-2

TUB BRACES..........................................................................................................................6-2

SUSPENSION SPRINGS......................................................................................................... 6-2

SECTION 7. TRANSMISSION AND RELATED..............................................7-1

SEAL NUT ASSEMBLY...........................................................................................................7-2

UPPER BEARING AND SEAL HOUSING...............................................................................7-2

TUB SEAL................................................................................................................................7-3

TUB SEAL REPLACEMENT....................................................................................................7-3

UPPER SPIN BEARING..........................................................................................................7-4

DRIVE PULLEY AND CAMS...................................................................................................7-4

BRAKE AND SNUBBER ASSEMBLY..................................................................................... 7-7

TRANSMISSION ASSEMBLY COMPLETE (Non-Repairable)................................................7-9

TRANSMISSION HOUSING ASSEMBLY..............................................................................7-10

LOWER BEARING ASSEMBLY............................................................................................ 7-10

DIAGNOSING TRANSMISSION PROBLEMS

TORQUE TESTING...............................................................................................................7-12

TRANSMISSION REMOVAL................................................................................................. 7-14

......................................................................

7-12

SECTION 8. ELECTRICAL COMPONENTS & TESTING

..............................

8-1

ELECTRICAL TEST EQUIPMENT.......................................................................................... 8-1

ELECTRICAL TEST.................................................................................................................8-2

TIMER......................................................................................................................................8-2

TIMER SEQUENCE CHART................................................................................................... 8-3

AUTOMATIC TEMPERATURE CONTROL BOARD

...............................................................

8-4

ANALOG TEMPERATURE CONTROL BOARD DIAGNOSTIC TABLE..................................8-6

MICROPROCESSOR TEMPERATURE CONTROL BOARD

MICROPROCESSOR TEMPERATURE CONTROL BOARD DIAGNOSTICS

.................................................

.......................

8-6

8-7

TIMER LINE SWITCH INPUT................................................................................................ 8-8

TEMPERATURE CONTROL BOARD TEST PROCEDURE {MAV8000 & MAV8057).............8-8

WATER VALVE........................................................................................................................8-8

MOTOR....................................................................................................................................8-9

MOTOR SWITCH.................................................................................................................... 8-9

MOTOR CIRCUIT TESTING.................................................................................................

8-11

MOTOR MOUNTING.............................................................................................................8-13

WATER LEVEL SWITCH.......................................................................................................8-14

SELECTOR SWITCHES........................................................................................................8-16

16010280

(16009485-02)

©2000 Maytag Appliances Sales Company

Contents

IV

Page 7

OPTION SWITCH...................................................................................................................8-16

WATER TEMPERATURE.......................................................................................................8-17

LID SWITCH...........................................................................................................................8-17

SECTION 9. TROUBLESHOOTING.................................................................9-1

DIAGNOSTIC FLOW CHARTS................................................................................................9-1

SECTION 10. ELECTRICAL SCHEMATICS................................................. 10-1

SCHEMATIC MAV4057,4500................................................................................................10-2

SCHEMATIC MAV5000..........................................................................................................10-3

SCHEMATIC MAV5057..........................................................................................................10-4

SCHEMATIC MAV6000..........................................................................................................10-5

SCHEMATIC MAV6057..........................................................................................................10-6

SCHEMATIC MAV7000..........................................................................................................10-7

SCHEMATIC MAV7057..........................................................................................................10-8

SCHEMATIC MAV8000..........................................................................................................10-9

SCHEMATIC MAV8057........................................................................................................10-10

SCHEMATIC MAV8500....................................................................................................... 10-11

SCHEMATIC MAV6200....................................................................................................... 10-12

SCHEMATIC MAV6257........................................................................................................10-13

SCHEMATIC MAV6300........................................................................................................10-14

SCHEMATIC MAV7200, MAV7600......................................................................................10-15

SCHEMATIC MAV770..........................................................................................................10-16

SCHEMATIC MAV8600........................................................................................................10-17

SCHEMATIC MAV9600........................................................................................................10-18

w

16010280

(16009485-02)

©2000 Maytag Appliances Sales Company

Contents

Page 8

NOTES

16010280

(16009485-02)

©2000 Maytag Appliances Sales Company

Contents

VI

Page 9

SECTION 1. GENERAL INFORMATION

WASHER PRE-IIMSTALLATION

REQUIREMENTS

NOTE: Proper installation is the responsi

bility of the purchaser.

Checkpoints for proper installation:

• Properly grounded electrical outlet is

required. Use 15 amp fuse or compa

rable circuit breaker for electrical

service.

• Standpipe Drain System must be able to

accept IVa" O.D. drain hose. In cases

where an air tight connection is re

quired, an anti-siphoning valve, part

number 12001586, should be placed in

the drain hose to prevent siphoning

from the washer or facility during

agitation. Standpipe height of 36" is

recommended.

NOTE: if drain standpipe is in excess of

5 feet above floor level, install pump

accessory kit, part number 12001587.

Do not store or operate washer in tem

peratures below freezing. This can cause

damage to the pump, hoses and other

components. (See page 1-5 for long term

storage.)

Water pressure of 20 -120 RS.I. is required

to fill the washer in the appropriate time

frame. Pressures of less than 20 RS.I. may

cause an extended or exceptionally long

fill time. Refer to the troubleshooting sec

tion for more information regarding a so

lution for slow fill situations.

Best performance is obtained with the

washer installed on a solid floor. Wood

floor constructions may need to be rein

forced to minimize vibration from unbal

anced load situations. Carpets and soft

tile surfaces are also contributing factors

in vibration and/or movement during the

spin cycle. Never install washer on plat

form or weak support structure.

W

• These units are not equipped with a

siphon break, and the drain hose must

be elevated to a minimum height of 36".

For installations with short standpipes,

the drain hose must be supported by

clipping the drain hose into the clip on

the back of the washer. Then a coupler

and additional hose length is added to

the existing drain hose.

• Hot and Cold water faucets should be

within four (4) feet of the back of the

washer. This allows for quick access for

immediate shut off of the water.

Water heater should be set to deliver a

minimum of 120° (49°C) hot water to

the washer.

16009485-01

©1999 Maytag Appliances Sales Company

ELECTRICAL REQUIREMENTS

1. Provide an individual 120 volt, 60 HZ,

branch circuit with ground for the washer.

This circuit must be rated for 15 amperes

or more.

2. Protect the washer's electrical circuit with

a 15 ampere time delay fuse or circuit

breaker.

3. Install in accordance with National

Electrical Code and all local codes

and ordinances.

Section 1. General Information

1-1

Page 10

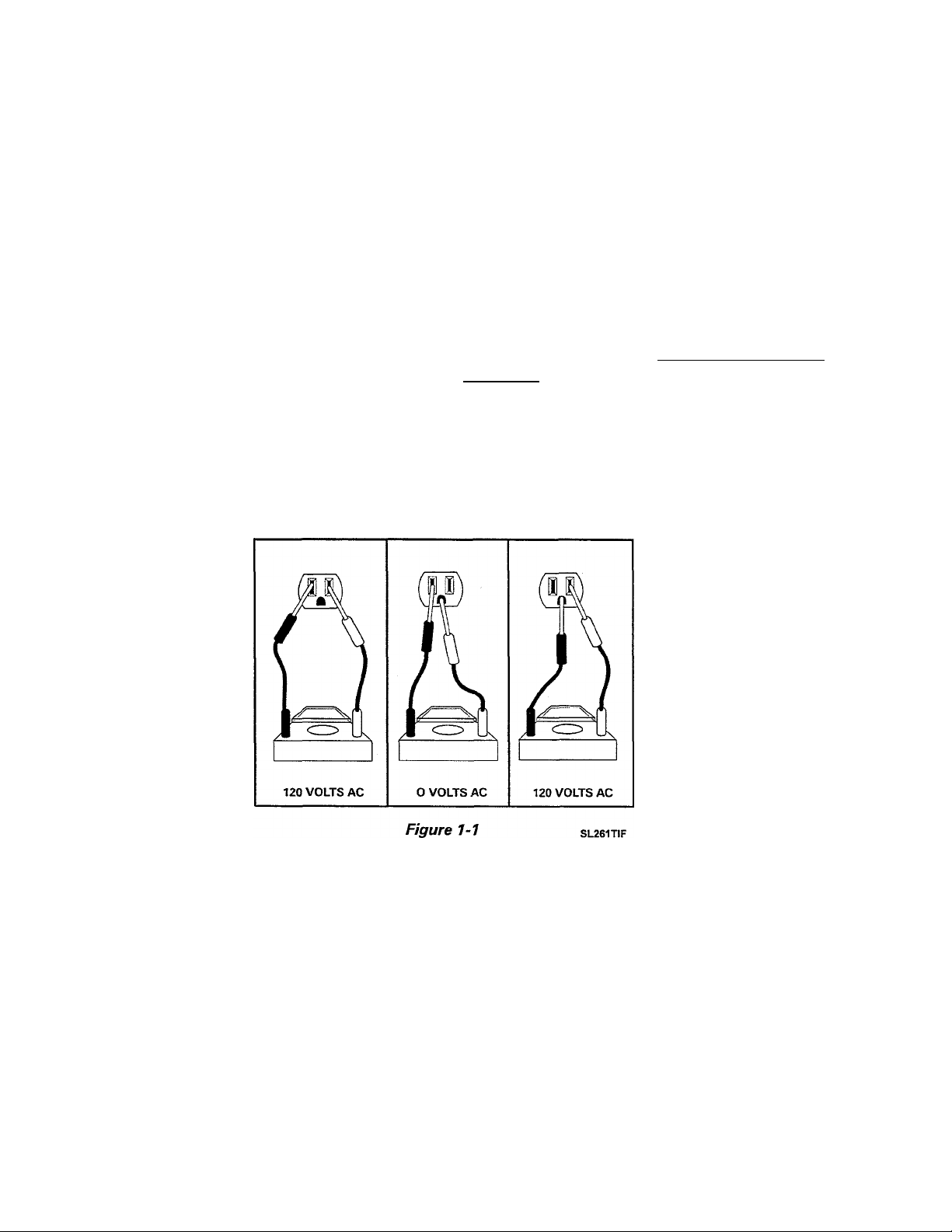

GROUNDING INSTRUCTIONS

The washer must be grounded. In the event

of a malfunction or breakdown, grounding will

reduce the risk of electrical shock by provid

ing a path of least resistance for electrical

current.

The washer is equipped with a power supply

cord which has a grounding conductor and

three-prong grounding plug. For proper

grounding, the three-prong grounding plug

must be plugged into an appropriate three-

prong grounded receptacle or outlet (see the

following figure). The receptacle must be

properly installed and grounded in accor

dance with the National Electrical Code and

all local codes and ordinances.

WARNING: Improper connection of the

grounding conductor or the three-prong

grounding plug of the power supply cord may

result in an electrical shock hazard. If there is

any doubt as to whether the washer is prop

erly grounded, have the installation checked

by a qualified electrician.

DO NOT MODIFY THE PLUG PROVIDED

WITH THE WASHER - If the plug will not fit

the outlet, have a proper outlet installed by a

qualified technician.

WARNING: For your

safety and to protect

the test equipment, be

sure that the wall out

let is properly polar

ized and grounded.

UNCRATING INSTRUCTIONS

NOTE: The following steps must be per

formed in the correct order to ease uncrating.

1. Remove the carton by cutting only marked

areas of the carton. CAUTION: Hoses are

connected to the washer.

2. Lift the carton and top cap assembly up

and clear of the washer. Carefully remove

any packaging materials from the outside

of the washer.

16009485-01

©1999 Maytag Appliances Sales Company

NOTE: Retain the corner posts for later use.

3. Remove tape and raise the washer lid; re

move the items shipped in the spin bas

ket. Save the literature for future refer

ence. Close lid and tape.

4. Position three (3) corner posts on the floor

near the rear base of the washer. Place

the remaining corner post on the floor

approximately two feet away. Carefully

lay the washer on its back, on top of the

corner posts.

Section 1. General Information

1-2

Page 11

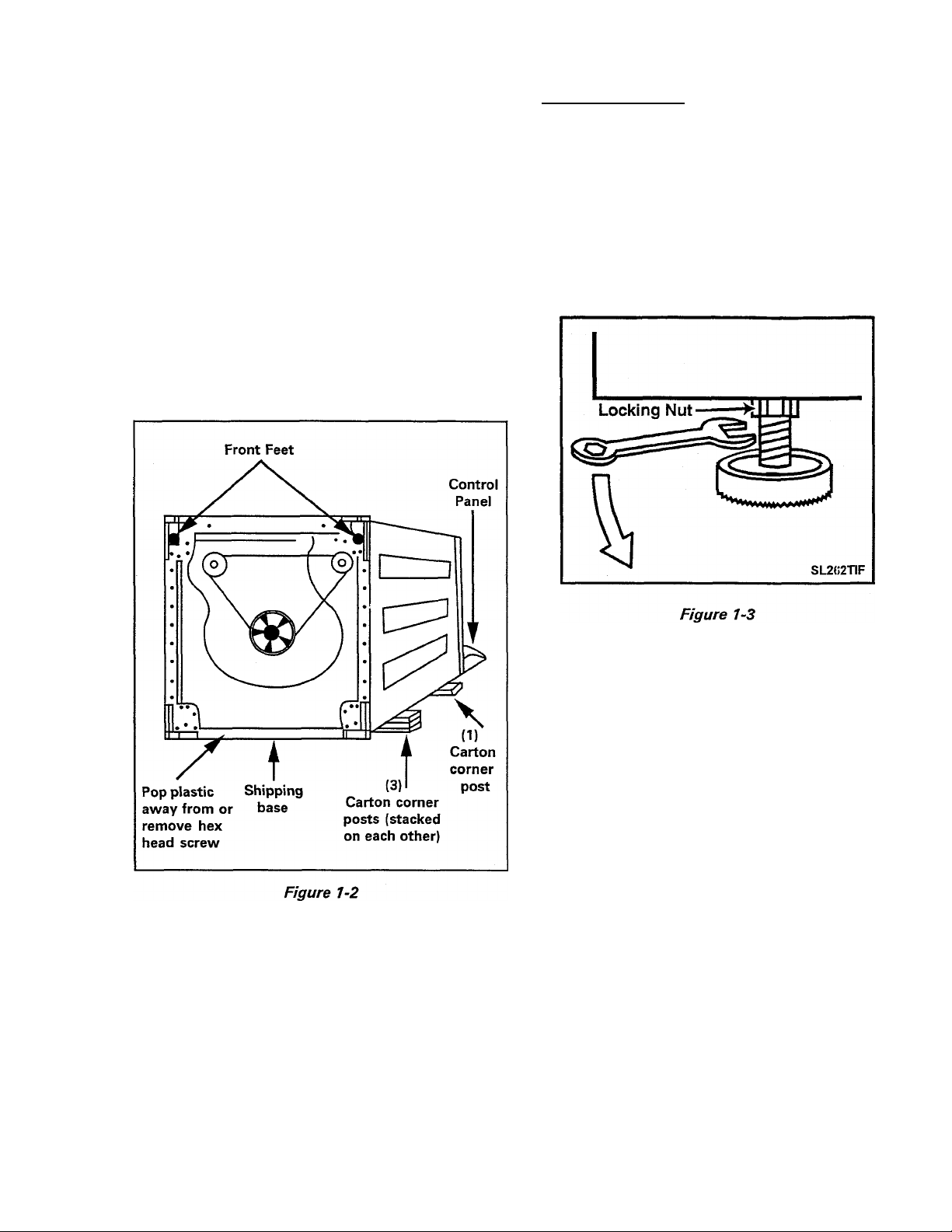

DO NOT LOWER OR RAISE THE WASHER

BY THE CONTROL PANEL

5. Remove the crate bottom from the washer.

Pop the plastic loose from the screw lo

cated between the back feet, or remove the

screw entirely with a screwdriver

(Figure

1-2). Pull the plastic base away from the

back feet. Grasping the plastic base on the

sides, pull down and toward you to release

the front feet from the slots and remove

the base. Discard the base (it can be re

cycled). RETURN THE WASHER TO THE

UPRIGHT POSITION.

Proceed as follows:

1. Place the washer as close to its final oper

ating location as possible.

2. Make sure rear feet move up and down

freely.

3. Place washer in final location.

INSTALLATION PROCEDURE

NOTE: Proper installation is the respon

sibility of the purchaser.

Service calls performed as a result of im

proper setup, adjustment and connection

are the responsibility of the installer.

4.

When the machine is in place, screw front

feet out of base against the floor until the

machine is level across the top front of

the washer.

5.

While holding foot still, turn the adjust

ing locknut clockwise until the nut is tight

ened firmly against base (Figure 1-3).

6.

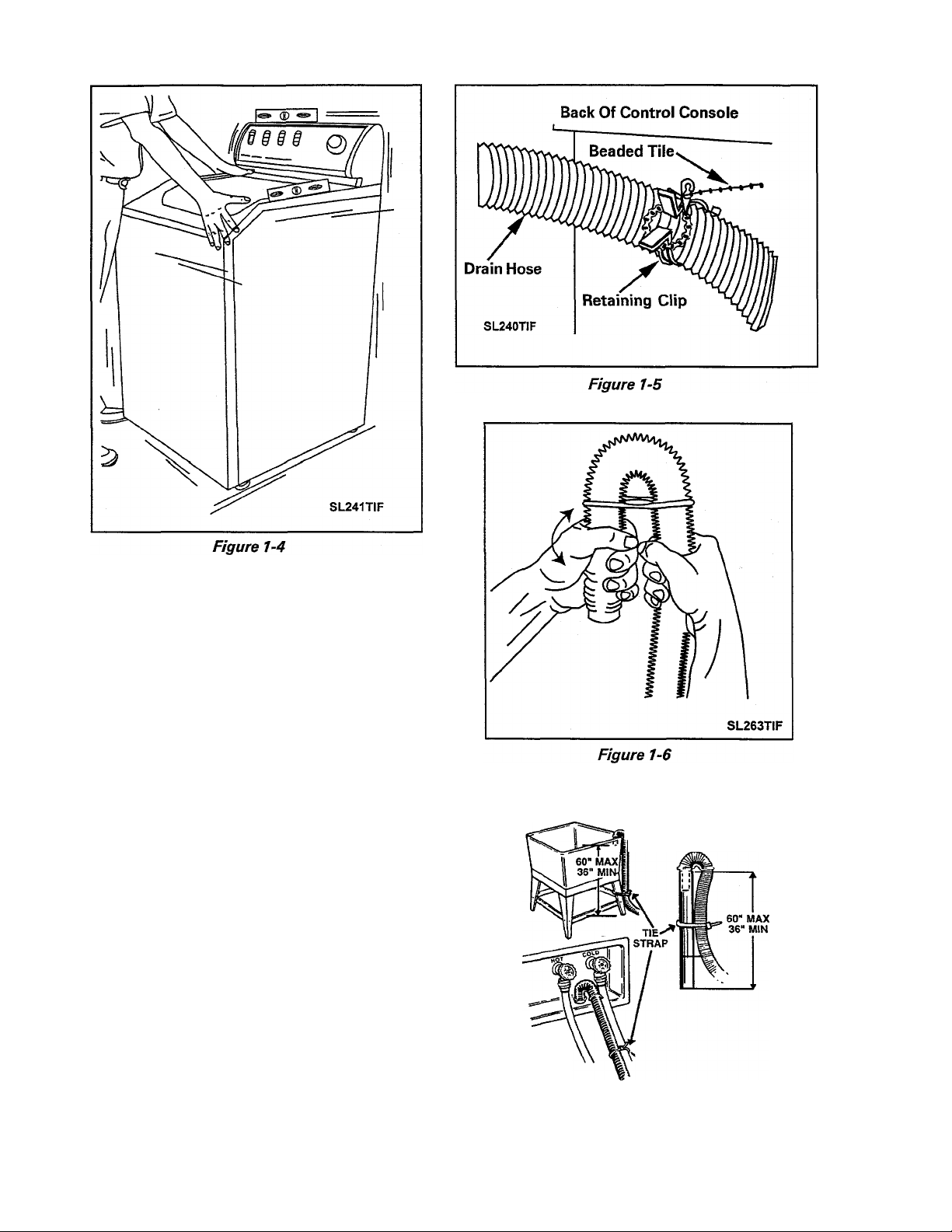

Tilt machine forward until rear of cabi

net is approximately 4 inches off the floor.

Lower the machine back to the floor on

the rear feet. This operation causes the

rear stabilizing feet to conform to the con

tour of the floor and seat them solidly.

Push washer with hands on opposite

corners to check stability (Figure 1-4).

16009485-01

©1999 Maytag Appliances Sales Company

Section 1. General Information

1-3

Page 12

7. If the standpipe is less than 36" high, pull

the drain hose up vertically and snap the

hose into the retaining clip positioned on

the upper, rear cabinet wall (Figure 1-5).

8. Install gooseneck end of drain hose into

drain standpipe. Be sure the connection

is not airtight between the drain hose and

the standpipe. Standpipe must be at least

36" high. If the hose is twisted after it has

been placed into the standpipe, adjust the

end of the hose to remove the twist. To

remove the twist, turn the short end of

the hose while holding the base of the

hose stationary (Figure 1-6).

9. The drain hose should fit loosely in the

standpipe to prevent siphoning. (An anti

siphon valve and associated parts are

available from your dealer, part number

12001586.)

SERVICE

UNIT

LAUNDRY

TUB

STANDPIPE

NOTE: Be sure the drain hose is not

twisted or kinked.

16009485-01

©1999 Maytag Appliances Sales Company

SL297TIF

Figure 1-7

Section 1. General Information 1-4

Page 13

10. Secure the drain hose to the standpipe

or drain facility with the cable strap pro

vided. This will ensure the drain hose will

not fall out of the drain facility

(Figure 1-7).

SIDE VIEW OF WASHER

11. Connect inlet hoses to water supply us

ing screen washers at faucet connections,

with the domed plastic screen facing the

faucet (Figure 1-8). Tighten hose con

nections by hand until snug. Then, turn

another 2/3 of a turn with the pliers.

At Faucet Connection

0=^333

At Water Valve Connection

SL2S5T1F

Figure 1-8

12. With hoses attached to both the faucets

and the water valve, turn on the water and

check for leaks. Note the H and C desig

nations on the water vaive bracket for the

Hot and Cold hoses.

Tub

Water Level

Figure 1-9

FINAL INSTALLATION CHECK LIST

1. Have all installation requirements

been observed?

2. Have locknuts on front feet been

tightened?

3. Are there any kinks in the hoses?

4. Are any water leaks evident?

UNIQUE INSTALLATIONS

13. Plug the power cord into an outlet.

14. Start the washer in a spin cycle per oper

ating instructions to center basket.

15. Start the washer in a wash cycle per oper

ating instructions. Allow water to fill in

machine until it reaches the level of the

bottom row of holes in the wash basket.

Then, stop the washer by pushing on timer

knob.

16. If the water is not level with the bottom

row of holes all around the basket (Figure

1-9), readjust the leveling feet as required

to level. Remove the water by selecting a

spin cycle.

16009485-01

©1999 Maytag Appliances Sales Company

Painted/Sloped Basement Floors - Apply non

slip discs, part number 211692, to the floor di

rectly under the rubber feet of the washer.

Carpeted Floors - Apply carpet installation

discs, part number 204986.

Weak Floors - Install rear legs with plastic

grommets, part number 12001577, to be

inserted into base frame to substitute for

the self adjusting legs.

Cold Storage or installations - Installation in

any location subject to freezing temperatures

is not recommended. If the washer must be

installed in such a location, it should be thor

oughly drained after each use as follows:

Section 1. General Information

1-5

Page 14

• Turn off hot and cold water faucets.

• Disconnect both water inlet hoses at the

faucets. Lower them to the floor.

• With the service cord connected to the

electrical outlet, rotate the timer to the

normal start or fill position and pull timer

knob to start washer. Turn water tempera

ture selector switch to warm.

• When water stops draining from the hoses,

disconnect service cord.

• Lower the drain hose to the floor and al

low it to drain into a floor drain or shallow

pan.

In below-freezing temperatures, ice may form

in the "fill" flume and the pump. Raise the room

temperature and allow time for the ice to melt

before using the washer.

16009485-01

©1999 Maytag Appliances Sales Company

Section 1. General Information

1-6

Page 15

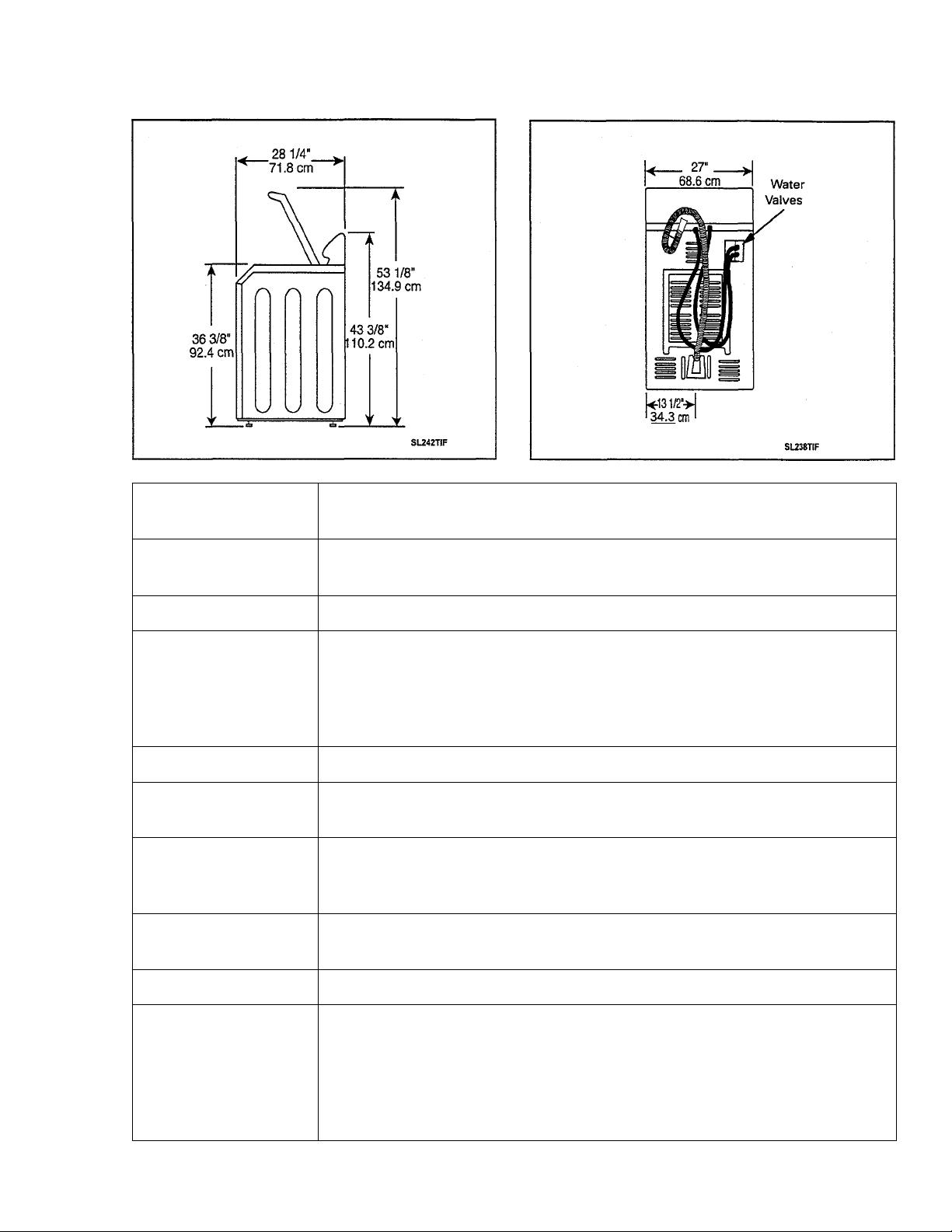

SPECIFICATIONS - WASHER

CAPACITY

ELECTRICAL

MOTOR

POWER USAGE

TRANSMISSION

WATER USAGE

HOSE LENGTHS

DIMENSIONS

3.2 Cubic Feet

120 Volts, 60 Hz; Requires 15 amp circuit breaker or fused electrical supply.

Power cord must be connected to a properly grounded and polarized outlet

1/2 H.P., reversible, 2 Speed, 115 volt, 60 cycle A.C.

Motor Input: During Agitation* -480 Watts Max. (Fast) 370 Watts Max.

(Slow)

During Pump Out* - 760 Watts (Fast) 510 Watts Max. (Slow)

Spin - 460 Watts (Fast) 340 Watts (Slow)

[‘Wattage readings taken with no clothes in spinner.]

Rack and pinion type, incorporating reduction gears

Water pressure should be 20 - 120 P.S.l. (1.06-8.44 kg/cm) at inlet hose

connection. (SEE PAGE 1-8 FOR MORE DETAILS)

Four foot inlet hoses with inlet washers attached to water valve.

Drain hose attached to pump and will accommodate 36" high drain stand

pipe.

Cabinet Dimensions: 27" (68.58cm)W x 27 (68.58cm)D x 43 3/8" (110.2cm)H

Vi#’

WEIGHT (Approx.)

FINISH

16009485-01

Uncartoned 160 lb. (72.6 kg.) Approx. Crated 185 lb. (84 kg.) Approx.

Top Cover - Porcelain

Lid - Porcelain

Outer Tub - constructed entirely of polypropylene

Spin Basket - polypropylene

Cabinet - baked enamel

Base and other finished parts - baked primer

©1999 Maytag Appliances Sales Company

Section 1. General Information

1-7

Page 16

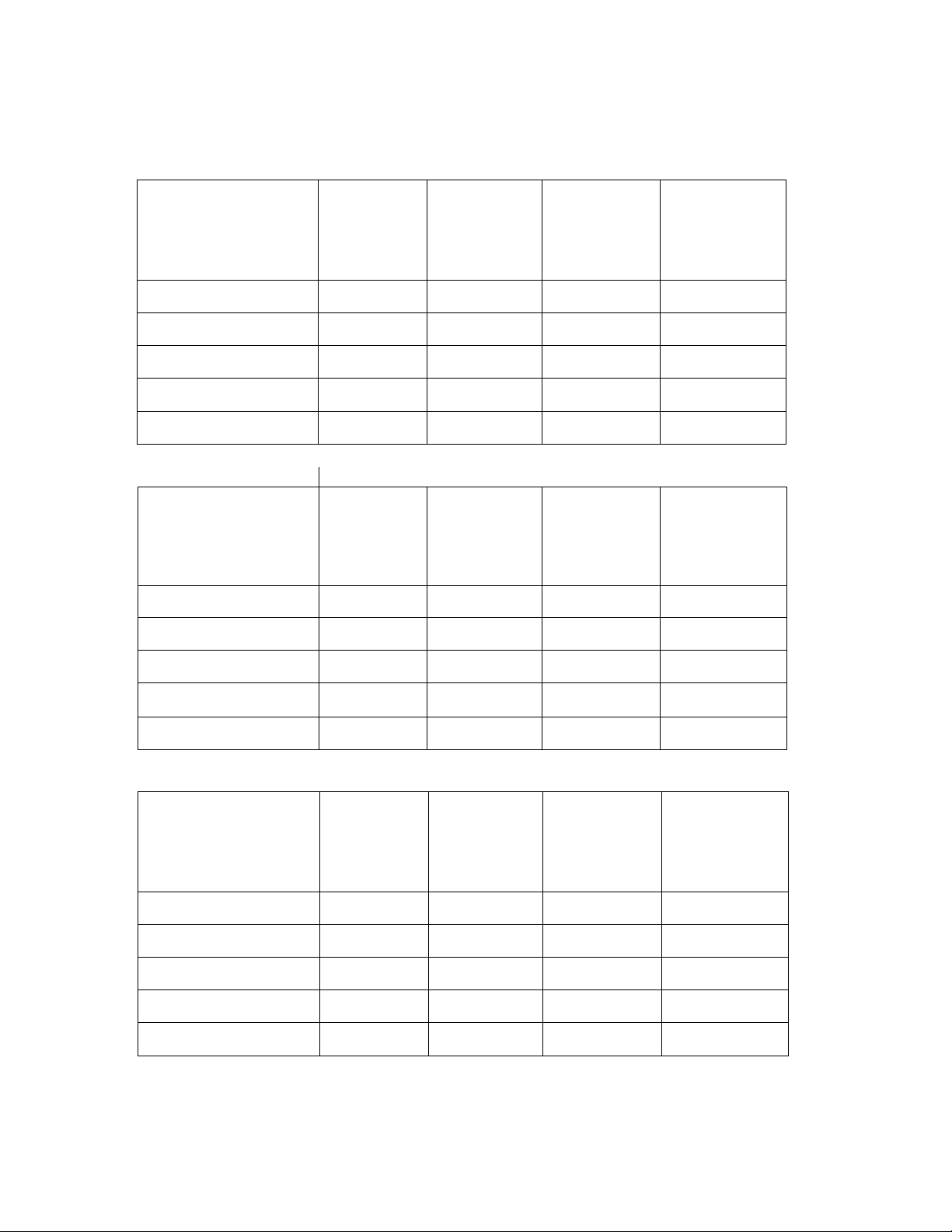

Setting

Mini

Medium

High

Super 23.3

^Allowable variations are plus or minus 1/2 inch.

Gallons

10.5

14.1

19.5

AGITATOR SPEED

*Depth

Inches

6"

8 1/2“ 5“

11" 7“

13 1/2“ 9 1/4"

Perforations

*Basket

3 1/2“

Regular Cycle 88 Oscillations per minute

Slow (Delicate) Cycle 57 Oscillations per minute 155 Degree Arc

155 Degree Arc

SPIN SPEED

Regular Cycle

Slow (Fine Wash) Cycle 410 R.RM.

TABLE 1-1. AMPERAGE CHART

WATER

CYCLE

Agitate-Regular Full Tub 10.4

Agitate-Slow Full Tub

Agitate-Regular

Spin-Regular

Spin-Slow DryTub

Pump Out-Regular

Pump Out-Slow Full Tub

LEVEL

DryTub 7.5

DryTub 10.2

Full Tub

620 R.RM.

♦AMPS

7.6

7.6

10.8

8.0

TABLE 1-3. WATTAGE CHART

♦WATTAGE

CYCLE

Agitate-Regular

Full Tub 610-640/670 (MAX.)

Agitate-Slow

Full Tub

Agitate-Regular

DryTub 460^70/480 (MAX.)

RANGE

370-400/420 (MAX.)

COMPONENTS

Timer Motor

Mixing Valve

Cold Solenoid

/Vof Solenoid

Drive Motor

16009485-01

TABLE 1-2. RESISTANCE CHART

♦RESISTANCE

(OHMS)

2360

500-1000

853

867

High Speed

Low Speed

Start 3.1

* These values can vary slightly.

1.3

2.3

©1999 Maytag Appliances Sales Company

Agitate-Slow

DryTub 350-360/370 (MAX.)

Pump Out-Regular

Pump Out-Slow

Spin-Regular

Full Tub

Spin-Slow

Full Tub 340

* These will vary with washer load and line voltage.

Section 1. General Information

760

510

460

1-8

Page 17

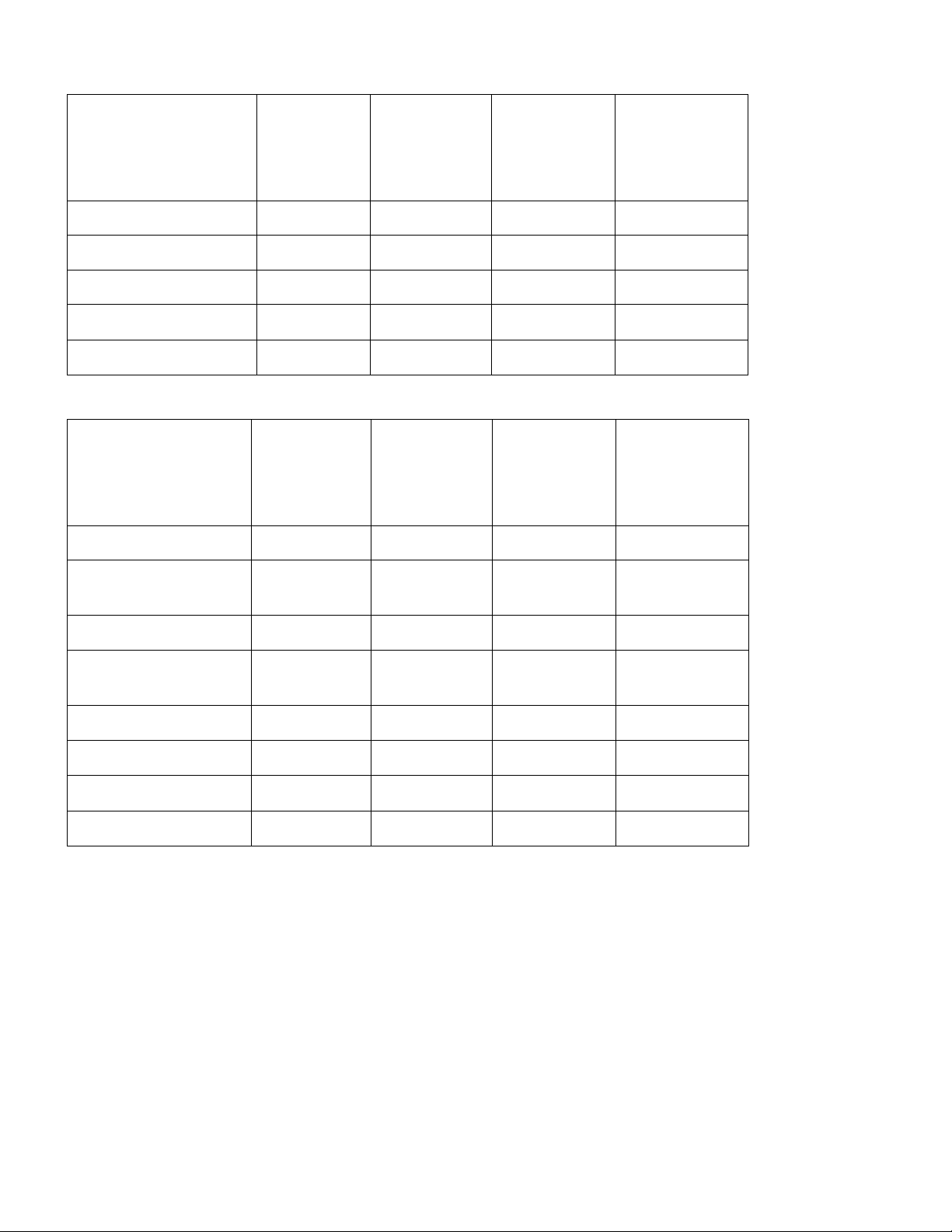

CYCLE CHARTS

COLORS

Function

Agitate

Agitate

Spin

Agitate

Spin w/Spray

SUPERWASH COLOF

Function

Agitate

Agitate Slow

Speed (Min.)

Fast

Slow

Fast

Slow

Fast

IS

Speed

Fast

Heavy

Option

Selected

Normal Light

Option

Selected

(Min.) (Min.)

9

9

6

6

9

Heavy

Option

Selected

(Min.)

18 12 9

0

3 0

9 9

6

6 6

9

Normal

Option

Selected

(Min.)

0

Option

Selected

6

9

Light

Option

Selected

(Min.)

0

Spin Fast

Agitate

Spin w/Spray Fast

Slow

6

6

9

6

6

9

WHITES

Heavy

Option Option

Selected Selected

Function

Agitate

Agitate Slow

Spin w/Spray Fast

Agitate Fast 6 6 6

Spin

Speed (Min.)

Fast

Fast

12 6

9

6 6

9

Normal Light

Option

Selected

(Min.) (Min.)

9 9

9

6

6

9

0

6

9

16009485-01

©1999 Maytag Appliances Sales Company

Section 1. General Information

1-9

Page 18

SUPERWASH WHITES

Heavy

Option

Selected

Function

Agitate

Speed

Fast

(Min.)

Agitate Slow 0

Spin w/Spray Fast 6

Agitate Fast 6

Spin

Fast

DELICATES

Heavy

Option

Selected

Function Speed

Agitate

Slow

(Min.)

21

9

0

Normal

Option

Selected

(Min.)

15

0 0

6 6

6 6

9

Normal

Option

Selected

(Min.)

3 0

Light

Option

Selected

(Min.)

9

9

Light

Option

Selected

(Min.)

Soak

Not

Applicable

Agitate Slow

Soak Not

Applicable

Agitate Slow

Spin w/Spray Slow

Agitate Slow

Spin

Slow

0

0

0

0

0

0

0

3 0

3 3

3 3

3 3

6

3 3

6 6

6

16009485-01

©1999 Maytag Appliances Sales Company

Section 1. General Information

1-10

Page 19

SUPERWASH DELICATES

Heavy

Option

Selected

Function

Agitate

Speed

Fast

(Min.)

Not

Soak

Agitate

Applicable 0

Slow

Not

Soak

Agitate

Applicable

Slow

Spin w/Spray Slow 0

Agitate Slow 0

Spin

Slow

Normal

Option

Selected

(Min.)

0

0 3

0 3

0

0

Light

Option

Selected

(Min.)

3

0

3 0

3

3

3 3

6 6

3 3

6 6

16009485-01

©1999 Maytag Appliances Sales Company

Section 1. General Information

1-11

Page 20

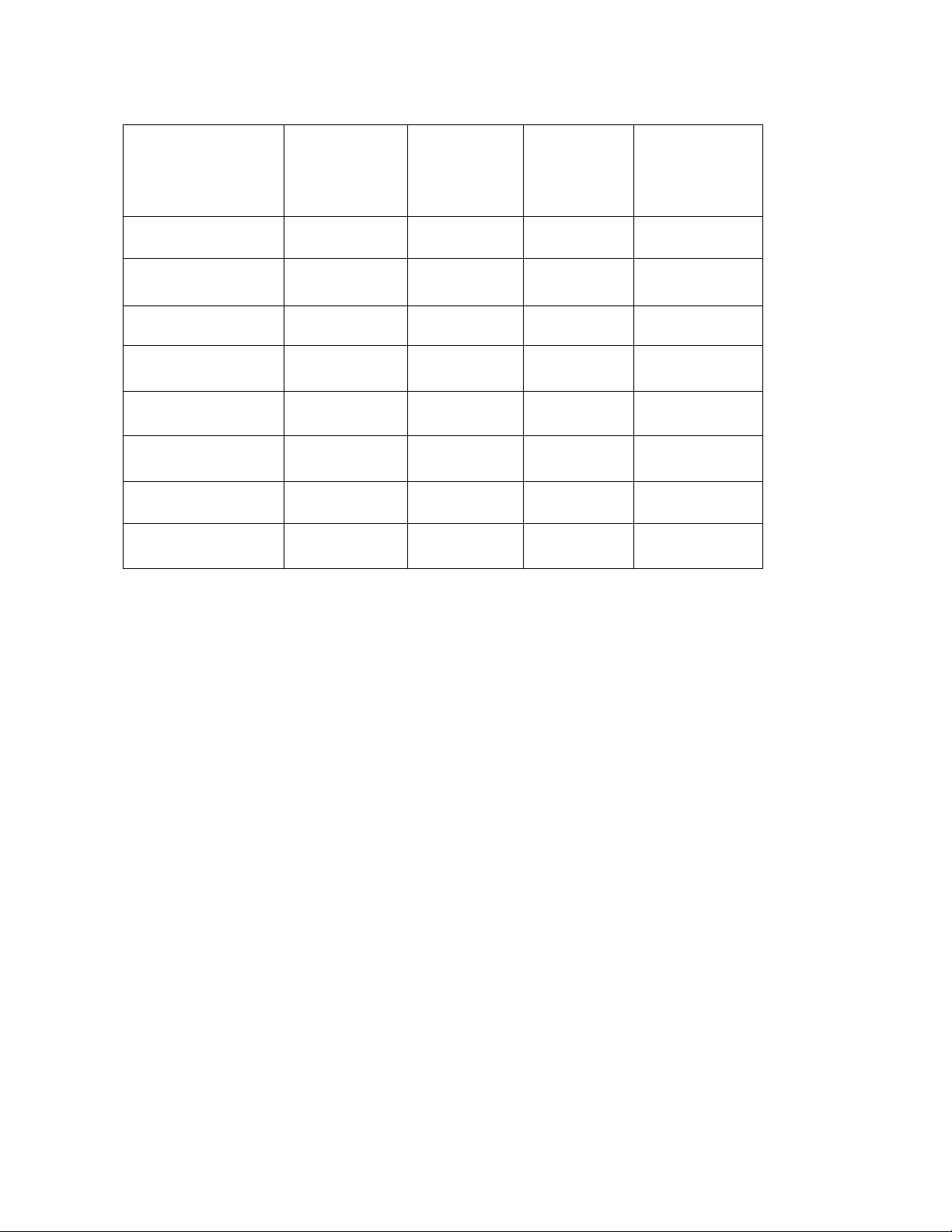

SPECIAL TOOLS

All special tools are manufactured by Robinaire with the exception of the 35-2442 Brake

Removal Tool and 35-2968 Spanner Wrench - Basket Hub. These tools are privately manu

factured for and stocked by Customer Service.

NOTE: The tools listed below can be ordered from any authorized Customer Service parts

distributor.

Brake Removal Tool, Part Number LA-2004

Spanner Wrench-Basket Hub, Part Number 35-2968

Spring Tool, Part Number 22002922

Seal Removal Tool, Part Number 2000021

16009485-01

©1999 Maytag Appliances Sales Company

Section 1. General Information 1-12

Page 21

SECTION 2. OUTLINE OF MECHANICAL OPERATION

GENERAL INFORMATION

NOTE: The rotation directions, stated in this

outiine, view the component from its ouiiev end.

The washer utilizes a reversible type motor

which turns clockwise during the agitate

cycle and counterclockwise during the spin

cycle.

A single belt is used to transmit power from

the motor pulley to the drive and pump pul

leys.

CLUTCH ASSEMBLY

The transmission drive pulley, which drives the

transmission drive shaft and hub assembly,

and the pump pulley which drives the pump

impeller, are in operation whenever the mo

tor is running.

The transmission assembly converts the

power from the motor to either drive the agi

tator or spin the basket. The direction the

clutch assembly rotates determines which

action takes place.

Washer-Thrust Hub

Figure 2-1

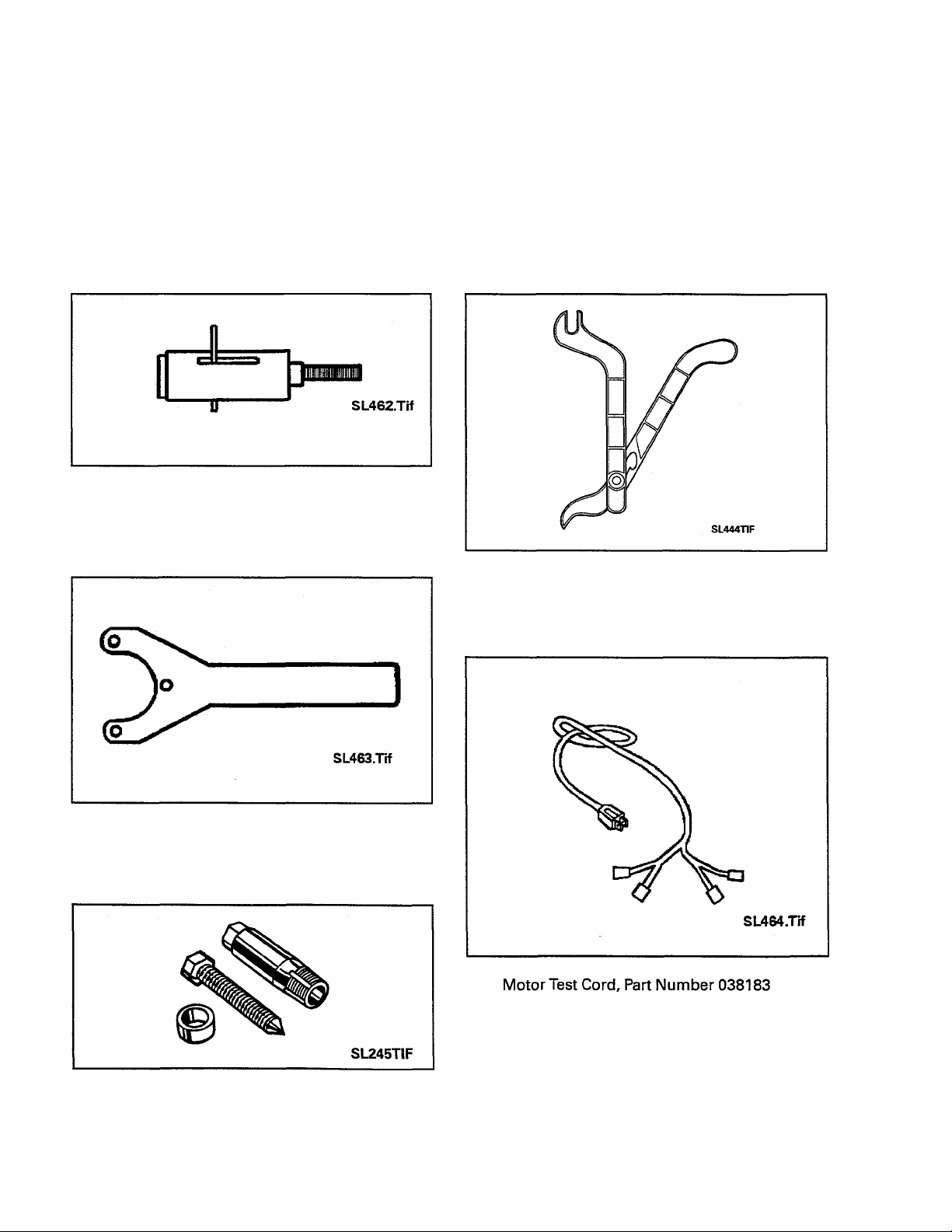

CLUTCH ASSEMBLY

The clutch assembly (Figure 2-1) consists of

the drive shaft and hub assembly, clutch

spring, and input pinion with gear lock assem

bly. The gear lock mechanism is part of the

input pinion. The drive shaft serves only as a

bearing surface for the drive pinion to revolve

on. No direct drive is imparted from the shaft

directly to the pinion. The inside diameter of

the clutch spring is designed so that when the

drive shaft is driven in a clockwise direction.

16009485-01

©1999 Maytag Appliances Sales Company

the clutch spring tightens on the two hubs and

becomes a positive link between them. When

the drive shaft hub runs counterclockwise, the

clutch spring relaxes in an override situation.

While in override, or relaxed position, the

clutch spring still maintains a drive link be

tween the two hubs. The override tension, or

torque, is used to drive the spin basket. The

gear lock mechanism consists of two "wings"

that project out from the input pinion.

Section 2. Operation

2-1

Page 22

Transmission

' Housing

Assembly

Lower Bearing

And Housing —

Assembly

Oil Seal ■

Suspension

Housing

Brake Spring

Retainer

Retaining

Ring

Drive Tube

Splines

Drive Shaft

Splines

Thrust Bearing

Washer (Curved)

Outer Edge

Turned Up

I

I

I Drive Pulley

I Assembly

Lower Cam ■

I

Spacer

Washer (thin)

~ Upper Race

)>^Washer (thick)

Lower Race

Washer (thin)

Thrust

Brake Rotor

And Lining

Assembly

Brake

Stator

Figure 2-2

Retaining

Ring

-Thrust

Washer

■Dust Cap

16009485-01

©1999 Maytag Appliances Sales Company

Section 2. Operation

2-2

Page 23

When the drive pinion rotates in a clockwise

direction, the gear lock mechanism exerts no

force on the input pinion. When the input pin

ion starts to revolve counterclockwise the

"wings" drop into dents in the lower housing

preventing the pinion from turning.

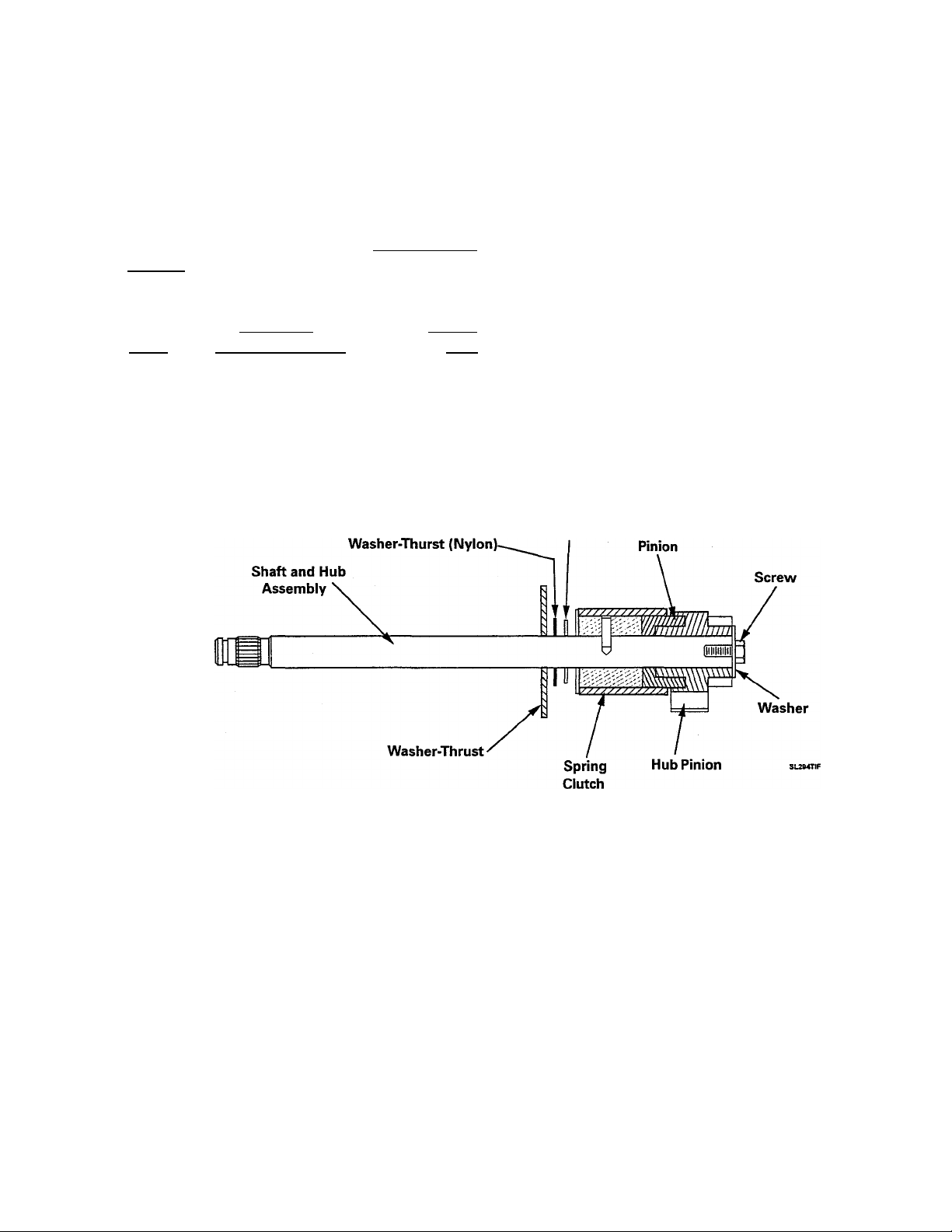

DRIVE PULLEY AND CAMS

OPERATION: AGITATION

When the drive pulley rotates CLOCKWISE,

the upper and lower cams are designed to nest

together which allows the drive pulley to re

main in position on the drive shaft. The brake

remains engaged and the drive pulley will turn

the lower cam and drive the shaft to cause

the transmission to agitate.

The drive pulley and cam is located below

the brake assembly on the drive shaft

(Figure 2-2).

All models are equipped with a plastic drive

pulley which has the upper cam molded

onto the bottom of the hub. The purpose of

the pulley and cam arrangement is to drive

the clutch assembly during the agitate and

spin cycle, and to disengage the brake

assembly during the spin cycle.

The drive pulley slips over the drive shaft and

rests against a series of washers, a thrust

bearing, and a large washer type spacer. The

spacer locates against the bottom of the

brake rotor and lining assembly (See the

illustration on page 7-6).

The lower cam slips over the end of the drive

shaft where splines formed in the cam en

gage with mating splines on the drive shaft

end. This imparts a direct drive from the cam

to the drive shaft.

A shoulder molded on the bottom of the

pulley hub engages “dogs" formed on the

sides of the lower cam, and will drive it and

the drive shaft in either direction.

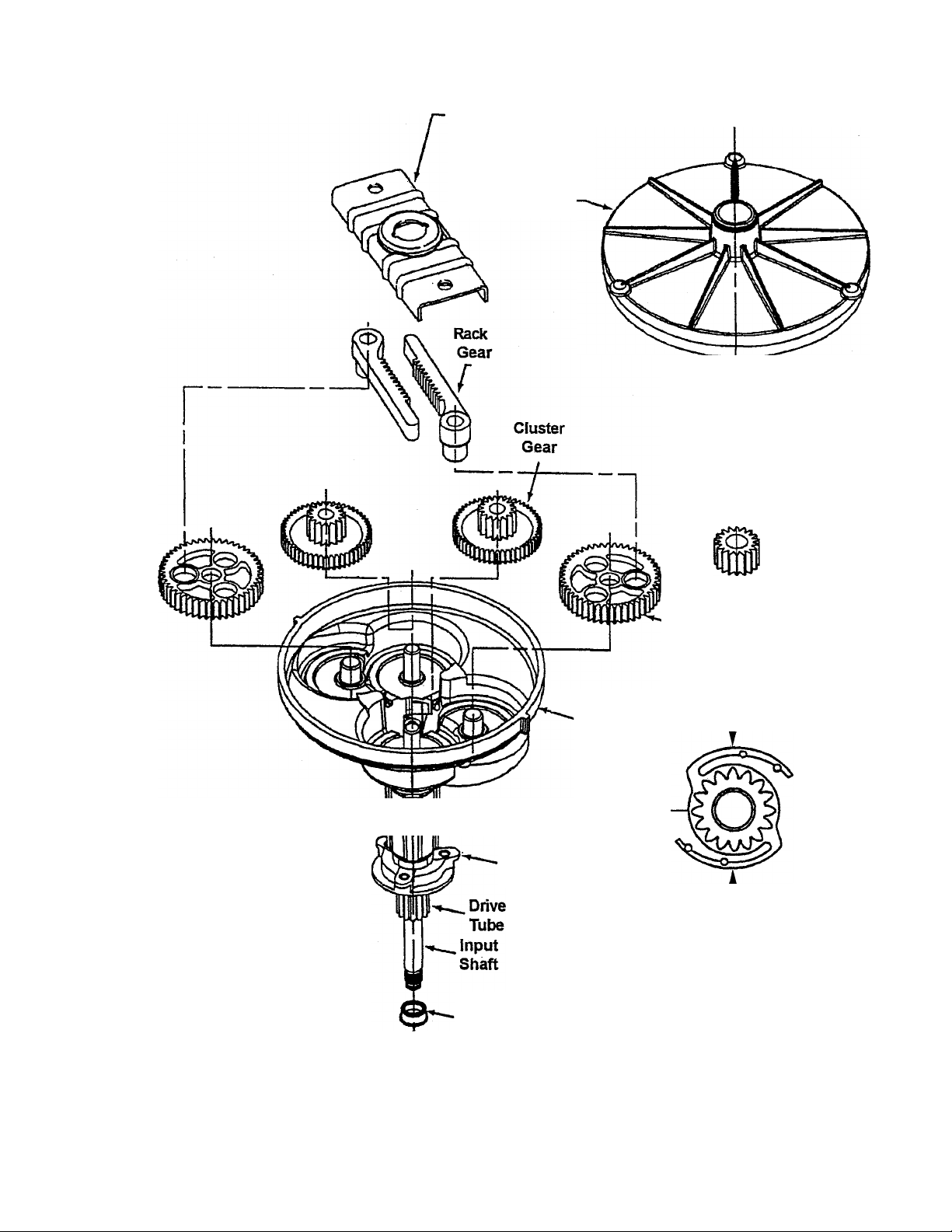

The agitation is due to the clockwise (agitate)

rotation of the drive shaft and the hub assem

bly as it is transmitted to the input pinion by

the clutch spring. The input pinion meshes

with the dual cluster gears which, in turn mesh

with the dual crank gears (Figure 2-3). The

circular motion of the dual crank gears are con

verted to the oscillating action of the agitator

shaft by the dual rack gears. The rack gears

have a stud that drops into the crank gears.

These rack gears are contained by a rack car

rier. Any tendency of the transmission to turn,

or "creep," is prevented by the engaged brake

assembly located on the under side of the

suspension housing.

OPERATION: SPIN

When the drive pulley rotates COUNTER

CLOCKWISE, the upper cam and pulley ride

up the lower cam approximately 3/16 of an

inch before the driving shoulders on the pul

ley hub engage the "dogs" on the lower cam.

This causes the top of the pulley hub to push

against the spacer which compresses the

brake spring and lifts the brake rotor and lin

ing assembly off the brake stator. The brake

is disengaged and the pulley will turn the lower

cam and drive shaft to cause the transmission

to spin.

A washer and retaining ring secure the pul

ley and cam on the drive shaft. A plastic dust

cap snaps to the underside of the pulley to

keep the cam surfaces clean.

16009485-01

©1999 Maytag Appliances Sales Company

A nylon cam, along with a special drive pul

ley, provides a cam action which raises the

drive pulley during the counterclockwise

(spin) rotation of the motor (Figure 2-2). As

the drive pulley hub moves up, it compresses

a brake spring and lifts the brake rotor and

lining assembly, disengaging it from the sta

tor. The transmission is now free to spin.

Section 2. Operation

2-3

Page 24

The counterclockwise rotation of the drive

shaft and hub assembly causes the clutch

spring to relax into an override position. The

clutch spring still exerts a driving force to the

input pinion even when it is in the override

position. As this driving force of torque starts

to turn the input pinion in a counterclockwise

direction, it causes the "wings" of the gear lock

mechanism to drop into dents on the lower

housing. This prevents the input pinion from

revolving in the counterclockwise direction.

Therefore, the torque being delivered by the

clutch spring is exerted against the transmis

sion housing, causing the entire assembly to

rotate. The washer basket is mounted to the

basket drive hub which is secured to the trans

mission cover assembly, and revolves as part

of the transmission. In this direction, the

pump assembly will drain the water out of the

unit.

16009485-01

©1999 Maytag Appliances Sales Company

Section 2. Operation 2-4

Page 25

Rack Gear

Carrier

Transmission

Cover

Agitator

"shaft

r

Output

^ Pinion

Lower

Seal

Bearing

Housing

Transmission

Housing

Input Pinion

Crank

Gear

—Wings

16009485-01

Figure 2-3

©1999 Maytag Appliances Sales Company

Section 2. Operation 2-5

Page 26

16009485-01

©1999 Maytag Appliances Sales Company

Section 2. Operation 2-6

Page 27

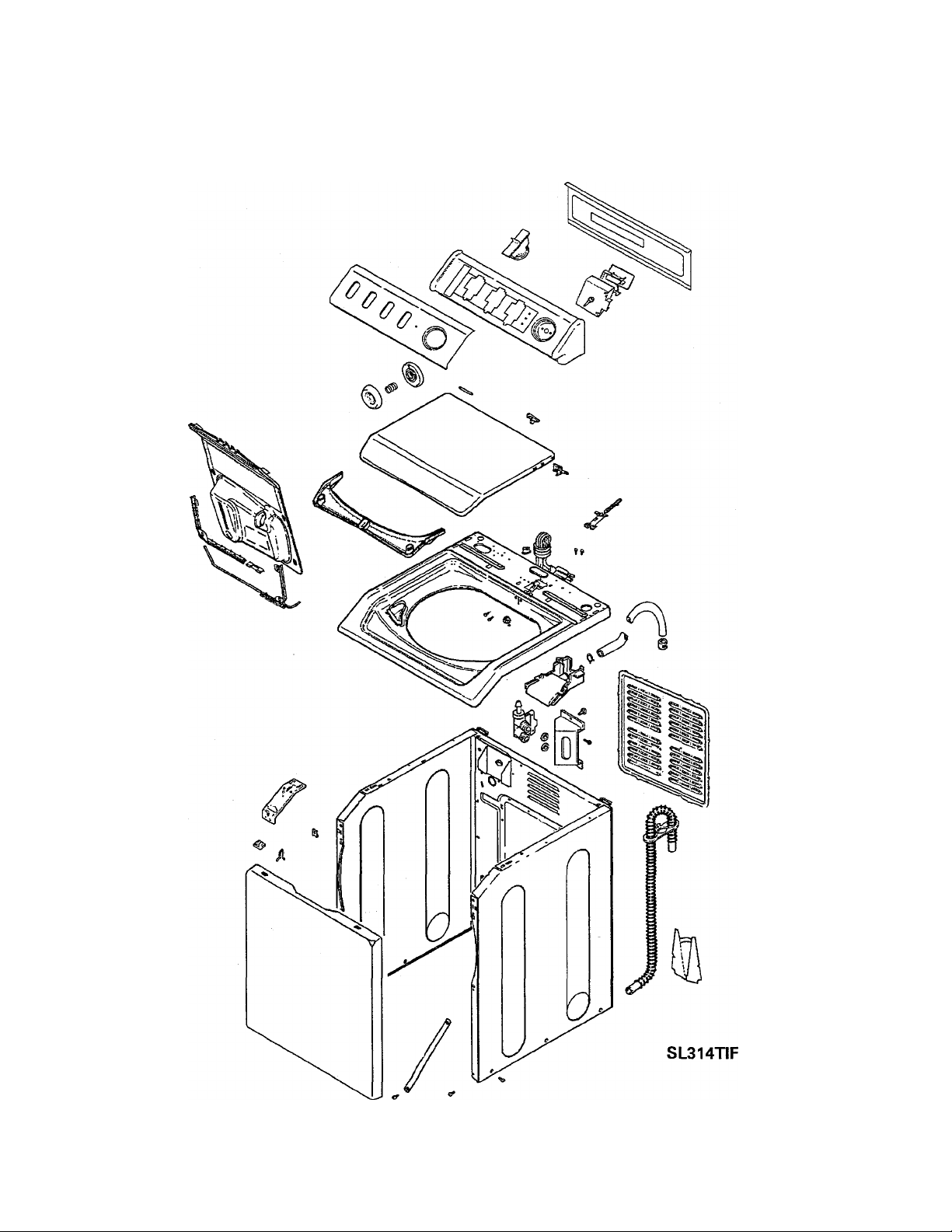

SECTION 3. EXPLODED VIEW OF COMPONENTS

16009485-01

Section 3. Exploded View Of Components 3-1

©1999 Maytag Appliances Sales Company

Page 28

:y

16009485-01

SL315TIF

Section 3. Exploded View Of Components 3-2

©1999 Maytag Appliances Sales Company

Page 29

SECTION 4. CABINET ASSEMBLY COMPONENTS

A

WARNING

Warning - Always shut

off electrical power to the

washer before beginning

any service repair proce

dures.

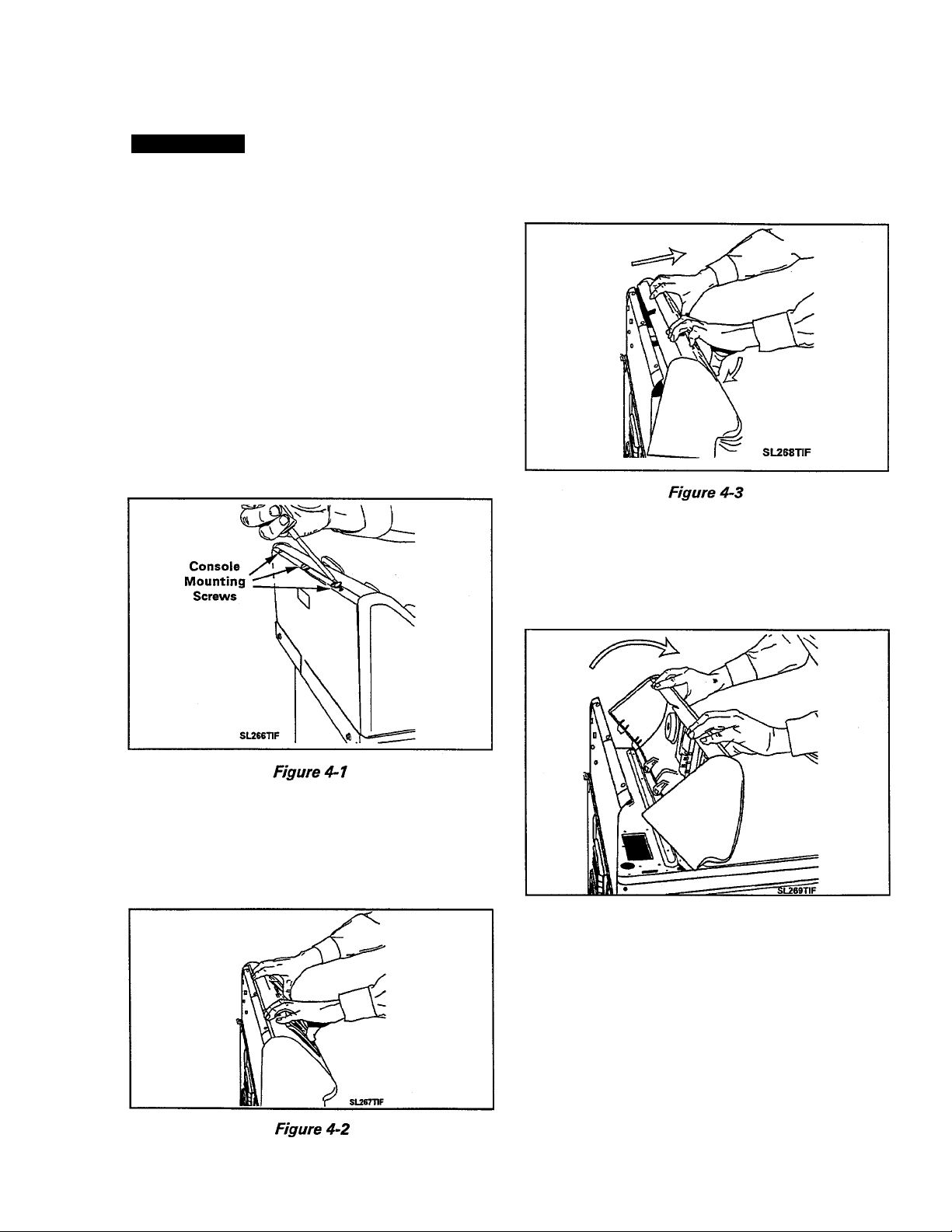

CONTROL PANEL ASSEMBLY REMOVAL

1. Disconnect power to the unit.

2, Remove the three screws securing the

console rear cover plate across the rear

top edge of the console (Figure 4-7).

5. Push the bottom of the console toward the

back panel to disengage the six locking

feet from the top cover (Figure 4-3).

6. Carefully lift and roil the console forward

onto the top cover. You now have access

to the console components and wiring

(Figure 4-4).

3. Lay a drop cloth across the top cover of

the washer.

4. Grasp the top of the console and gently

rock the top forward (Figure 4-2).

16009485-01

©1999 Maytag Appliances Sales Company

Figure 4-4

To Reinstall: Roll the console back into an

upright position, engaging the locking feet

into the slots in the top cover. Replace the

three screws to attach console back to rear

panel.

Section 4. Cabinet Assembly Components 4-1

Page 30

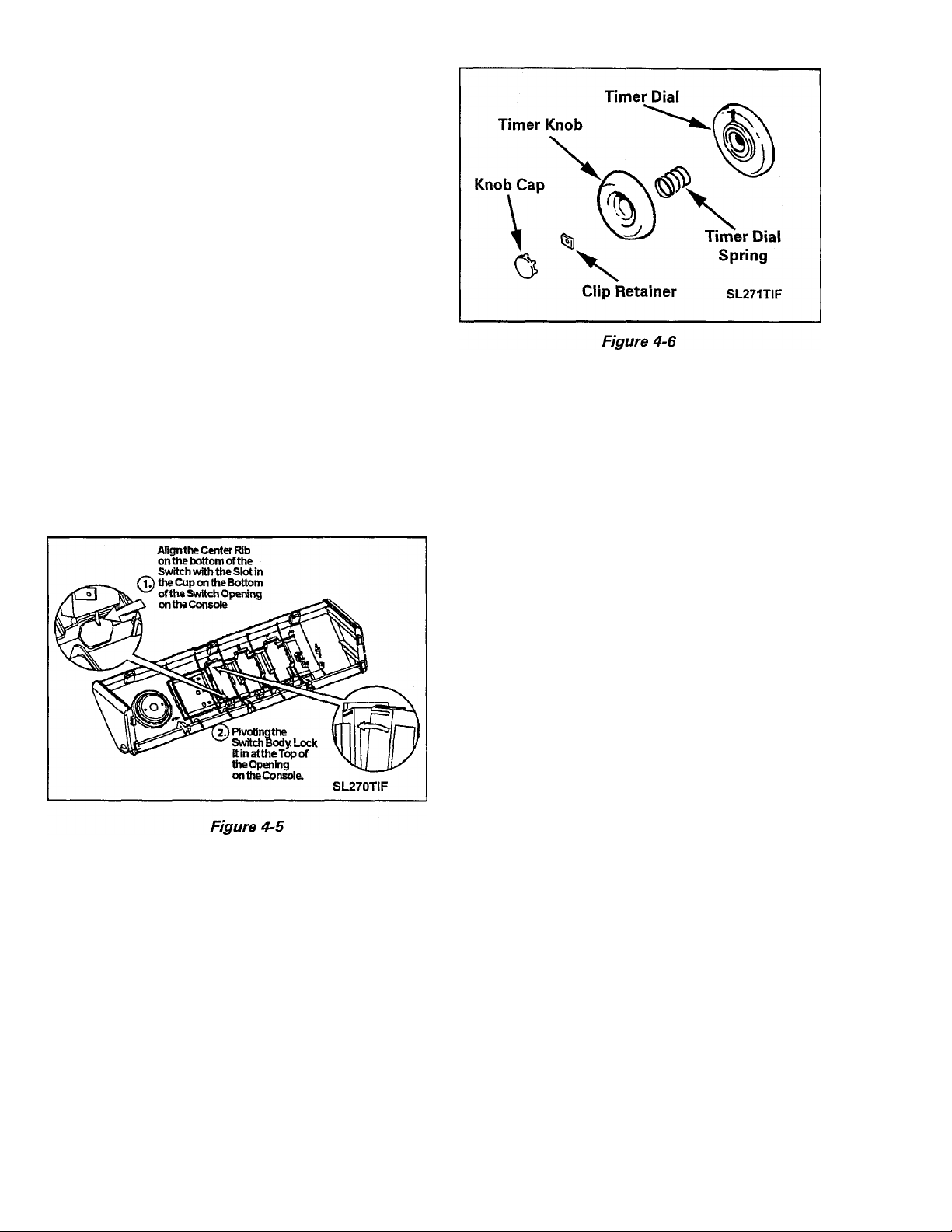

VERTICAL SWITCHES (Push Button)

REMOVAL

1. Depress the tab at the top of the switch

with a screwdriver to disengage the tab

from the console. Pivot the switch away

from the console to remove (Figure 4-5).

REPLACEMENT

1. Align the rib on the bottom of the switch

with the slot in the console. Pivot the

switch up into the console until the tab en

gages the console securely. Check that the

locating tabs on either side of the switch's

lower alignment rib are in position to prop

erly center and lock the switch into the

lower part of the switch opening.

3. Disengage the console assembly from the

top cover and roll forward (See Console

Removal).

4. Remove timer mounting screws under the

timer knob.

5. Lift the timer away from the console.

TIMER REMOVAL - All MAV Models Except

MAV8500

1. Disconnect power to the unit.

2. Carefully lift the timer knob cap from the

timer knob and pry the clip retainer from

the timer shaft. Lift the dial and knob off

the timer shaft by pulling away from the

face of the control console (Figure 4-6).

REPLACEMENT

1. Reverse steps 1 through 5.

TIMER REMOVAL - MAV8500 Models

1. Disconnect power to the unit.

2. Remove the knob cap.

3. Gently pry the locking pin up and lift the

timer knob off the dial skirt.

4. Lift the dial skirt off the timer shaft

(Figure 4-7).

16009485-01

Section 4. Cabinet Assembly Components 4_2

©1999 Maytag Appliances Sales Company

Page 31

AUTOMATIC TEMPERATURE CONTROL BOARD

REMOVAL

1. Disengage the console assembly from the

top cover and roll forward (See Console

Removal).

2. Remove wire harness from control board.

3. Squeeze the locking tabs together

(Figure 4-9).

4. Slide the control board and bracket away

from the timer motor to unhook the bracket

from the timer rear face plate. Mounting

hooks on the bracket engage with the edge

of the timer rear face plate.

FOR ALL MAV8500 MODELS

1. Remove board mounting screw, and

bracket mounting screw.

2. See Figure 4-8 for additional assistance.

16009485-01

©1999 Maytag Appliances Sales Company

Section 4. Cabinet Assembly Components 4-3

Page 32

TOP COVER ASSEMBLY

The top cover assembly consists of the top

cover, washer lid assembly, lid switch and

bracket, water inlet flume, bleach dispenser,

and the control panel assembly.

The assembly is mounted to the cabinet with

two (2) steel hinges which are attached to the

upper cabinet. These hinges engage into

hinge slots located in the back edge of the

cabinet which allows the top cover to be raised

for servicing.

Two (2) slots pierced into the front flange of

the top assembly align with two (2) locating

plastic shipping stops to center the top cover

to the cabinet. Two (2) spring clips engage

the top cover flange and secure the top as

sembly to the cabinet front.

NOTE: The locating pins and top dips are

mounted to the front pane! flange on all the

models (Figure 4-10).

Raising the top will allow access to:

3. Raise the top cover assembly and remove

the flume inlet hose from the water valve.

4. Lower the top and remove the control

panel rear shield.

5. Disconnect the pressure switch hose and

all necessary wiring. Feed the hose and

wiring through their respective top holes.

6. While pulling forward, slightly raise the top

cover assembly forward and remove.

• Flume and Inlet Hose

• Lid Switch Actuator

• Air Dome Hose Connection

• Water Inlet Valve Wiring

• Spin Basket Assembly

• Outer Tub Assembly

REMOVAL

1. Disconnect power to the unit.

2. To raise the top assembly, insert a thinbladed tool (such as a putty knife) between

the front panel and top assembly approxi

mately three (3) inches in from each cor

ner. While raising the top assembly, de

press each spring clip (Figure 4-10).

STANDARD LID ASSEMBLY

The washer and lid assembly consists of the

lid, mounting hinges, plastic lid switch cam

(switch actuator) and condensation seal with

bumpers. The assembly is secured to the top

panel by the two mounting hinges.

When the washer lid is lowered, the plastic lid

switch cam protrudes through a slot in the rear

of the top cover and depresses a plunger that

actuates the lid switch (Figure 4-11).

16009485-01

Section 4. Cabinet Assembly Components

©1999 Maytag Appliances Sales Company

4-4

Page 33

REMOVAL

1. Lift the washer lid.

2. Locate the left hinge and lift the locking

tab in the center of the hinge from the lo

cating hole in rear edge of the lid

(Figure 4-12).

3. Gently pry the hinge toward the center of

the lid. This will draw the pin of the hinge

out of the bushing in the top cover

(Figure 4-12).

4. With the left hinge removed, grasp the lid

and pull the lid away from the right hand

bushing in the top cover.

REPLACEMENT

1. Reverse steps 1 through 4.

30 DAY DETERGENT DISPENSER (Optional Accessory)

The Dosing Lid Assembly consists of the de

tergent reservoir, dispenser valve assembly,

cap and twist locks.

The reservoir stores liquid detergent and will

dispense the detergent directly into the spin

basket when the actuator is manually de

pressed. The detergent reservoir is secured

into the lid by four twist locks.

Removal of Reservoir

1. Turn each of the twist locks on the face of

the detergent reservoir 1/4 turn counter

clockwise (Figure 4-13).

2. Pull the bottom of the reservoir away from

the lid and unhook the top of the reservoir

from under the lip of the lid.

Removal of Valve Assembly

1. Locate the locking clip below the dispens

ing button (Figure 4-14).

2. Depress the dispensing button while slid

ing the retaining clip down. This will re

lease the plunger and dispensing button

and allow removal.

16009485-01 Section 4. Cabinet Assembly Components 4-5

©1999 Maytag Appliances Sales Company

Page 34

Figure 4-13

Warning: The spring in the valve assembly

is compressed and may fly out of the dis

penser. Depressing the plunger button

during dip removal will prevent this from

occurring.

Slide the left retainer toward the center of

the lid and remove from behind the lid

flange (Figure 4-15).

With the left retainer removed, grasp the

lid vertically and rotate the torsion rod in

a clockwise direction away from the right

hand plastic bushing in the top cover.

TORSION ROD ASSEMBLY

The torsion rod assembly acts as a counter

balance when liquid detergent is in the dis

penser. This allows for easier opening and

closing of the washer lid.

REMOVAL

1. Lift the washer lid and remove the deter

gent reservoir.

2. Remove the center support from the tor

sion rod by rolling the support toward you.

DETERGENT DISPENSING

Figure 4-16

1. After initially filling the reservoir of the dis

penser, lower the lid to fill the dispensing

chamber on the left side of the dispenser.

16009485-01

Section 4. Cabinet Assembly Components 4_0

©1999 Maytag Appliances Sales Company

Page 35

2. Position the cap of the detergent bottle be

ing used under the spout of the dispenser.

3. Press and hold the button and dispense liq

uid into the cup until the desired amount

has dispensed.

4. Slide the plastic indicator down the sight

window until even with the detergent

shown.

5. The next time the lid is lowered and raised,

the sight window will fill with liquid deter

gent. By depressing the button until the

level in the sight window is even with the

indicator, will provide uniform dispensing

of detergent brand being used.

NOTE: Empty dispenser completely before

refilling. Do not mix different detergents.

2. Remove the dispenser valve assembly and

rinse with warm water fSee Removal of

Valve Assembly Page 4-6).

3. Fill the dispenser with hot or warm water

and gently tilt the dispenser forward and

back to flush the water around inside the

dispenser.

4. Turn the dispenser vertically so the fill cap

is facing up and remove the cap. Pour the

contents out and repeat the process until

dispenser is flushed. NOTE:

Water will

flow out of the dispenser valve area.

5. Reinstall the dispensing valve assembly

into the reservoir. While depressing the

button, replace the clip onto the valve

assembly.

6. Reinstall the reservoir into the lid and se

cure the twist locks.

Figure 4-17

CLEANING THE DISPENSER

Mixing different liquid detergents in the res

ervoir can cause the detergent to clump and

clog the dispenser outlet. In which case, clean

ing out the reservoir is necessary.

1. Remove the dispenser from the lid (See

Removal of Reservoir Page 4-6).

7. Close and open the lid.

8. Press the "PUSH" button (plunger) to re

lease any remaining water/detergent. Re

peat steps 7 & 8 until no more water can

be drained from the dispenser. It is nor

mal for a small amount of water to remain

in the dispenser after cleaning.

9. Refill the dispenser with liquid detergent.

The reservoir will hold 100 fluid ounces at

one time.

FRONT PANEL

The front panel is attached to the cabinet side

flanges via screws at the top and secured at

the bottom with base mounting clips. Locat

ing tabs on the front panel flanges position

the top cover for assembly (Figure 4-18).

The front panel provides mounting for the lo

cating tabs and top clips. A plastic support

brace is wedged in the center of the panel for

support.

16009485-01

©1999 Maytag Appliances Sales Company

Section 4. Cabinet Assembly Components 4-7

Page 36

Front panel removal will allow access to the:

Motor

Motor Mount

Motor Wiring

Motor Pivot Spring

Suspension Springs

Tub Brace

Pump

Remove the two 5/16" hex/cross head

screws securing the front panel to the up

per front corner braces of the cabinet.

(Figure 4-19 & 4-20)

Move top edge of front panel away from

4.

cabinet while lifting. This will disengage

the bottom of front panel from base clips.

REPLACEMENT

1. Reverse above steps.

REMOVAL

1. Disconnect power to the unit.

2. Insert a thin-bladed tool between the front

panel and the top cover assembly, approxi

mately three (3) inches in from each cor

ner. While lifting up on the top cover as

sembly, press the blade against the wire

clips, one side at a time to disengage them.

Lift the top cover up to a stationary

position.

16009485-01

©1999 Maytag Appliances Sales Company

Figure 4-19

REAR ACCESS PANEL

Removal of the access panel, gains access

to the rear inside components of the washer.

Panel removal will allow access to:

• Stabilizer Assembly

• Rear and Side Suspension Springs

• Tub Braces

REMOVAL

1. Remove the four screws surrounding

the access panel (Figure 4-20).

Section 4. Cabinet Assembly Components 4.3

Page 37

CABINET BODY ASSEMBLY

The cabinet provides mounting for the front

panel, rear access panel, top cover assembly,

water valve and the power cord.

9. Remove the eleven (11) screws that secure

the cabinet body to the perimeter of the

base.

10. Open the front of the cabinet body slightly

and push if off the rear of the base frame.

BASE ASSEMBLY

The base assembly, which serves as a support

for the entire wash unit, is constructed of

heavy gauge metal that has been flanged and

embossed for strength.

There is a spherical configuration on the lower

end of the brake/transmission/tub assembly.

This spherical shape rides on the raised dome

like area in the center of the base. The mount

ing is similar to a ball joint and allows the hous

ing to move freely in all directions

(Figure 4-21).

The cabinet is attached to the perimeter of the

base with eleven (11) screws.

REMOVAL

1. Disconnect power to the unit.

2. Remove the top cover (See TOP COVER

REMOVAL - Page 4-3).

3. Remove the front panel (See FRONT PANEL

REMOVAL - Page 4-8).

4. Remove the power cord.

5. Remove rear access panel and drain hose

cover.

6. Remove water valve and bracket.

7. Remove wiring clips and clamps from

inner cabinet rear.

The base assembly also provides mounting for

the pump assembly, motor and plate assem

bly, suspension springs, front panel clips, and

the stabilizer assembly.

The cabinet is secured to the base with screws

and positioned foam pads to prevent vibra

tion or noise transfer. The cabinet does not

support any of the wash unit's weight.

BASE REPLACEMENT

1. Disconnect power to the unit.

2. Tip unit back and remove the drive belt.

3. Remove the drain hose cover from the

cabinet rear and disconnect the discharge

hose from the pump outlet.

4. Remove the top cover (See TOP COVER

REMOVAL - Page 4-3).

8. Remove front cross braces and screws.

16009485-01

©1999 Maytag Appliances Sales Company

5. Remove the front panel (See FRONT

PANEL REMOVAL - Page 4-7).

Section 4. Cabinet Assembly Components 4-9

Page 38

6. Disconnect lower wiring from the cabinet

rear (water mixing valve, power cord, etc.)

and remove pressure switch hose from tub

air bell.

7. Remove the screws attaching the cabinet

to the base.

8. Remove lower screws on cross braces.

9. Push the front of the cabinet slightly back

and carefully push or pull it off the rear of

the base assembly.

11. Remove motor mounting screws, ground

wire and wiring clips from base. Lift the

motor and plate assembly from the base.

12. Remove the suspension springs (See

SPRING REMOVAL, Page 6-2 thru 6-3).

13. Remove the stabilizer assembly from

the base assembly, as detailed later in

this section.

14. Transfer the remaining hardware from

the defective base to the replacement.

10. Disconnect the pump hose from the tub

outlet and remove the pump assembly and

hose from the base.

16009485-01

©1999 Maytag Appliances Sales Company

15. Installation is a reversal of the above

procedure.

Section 4. Cabinet Assembly Components 4-10

Page 39

STABILIZER ASSEMBLY

The stabilizer assembly consists of the

stabilizer bar assembly, two (2) stabilizer

brackets, two (2) self stabilizing feet, and

two (2) foot pins. It is mounted on the top

rear of the base assembly.

The stabilizer assembly allows the base

assembly to rest solidly and firmly against

the floor, even if the floor is unlevel. The

solidity of the base to the floor keeps the

washer from rocking back and forth or

“walking" during

operation.

As the name implies, the stabilizer only

stabilizes the unit; it does not level it. Any

leveling that is required must be done

with the front adjusting (leveling) legs.

In rare cases where the floor is so uneven

that it is beyond the stabilizing limit of the

assembly (+ or - 5/8"), It may be neces

sary to remove the stabilizer assembly

and install two (2) rear adjustable feet.

Two (2) threaded holes have been pro

vided in the rear corners of the base for

this situation. A kit, part number

12001577 is available.

REMOVAL

1. Disconnect power to the unit.

2. Remove the access panel from the

cabinet rear.

3. Tip or lay washer down, either forward

or on the side. Remove the screws

from the underside of the base that

attaches the stabilizer assembly to the

rear of the base (Figure 4-21).

4. Remove the stabilizer assembly

through the rear access panel.

5. To disassemble the stabilizer assembly

after removal, drive the two (2) foot

pins out of the feet and brackets.

NOTE: in order for the stabilizer assem

bly to operate properly, a thin coating of

grease must be applied over the entire

length of the four (4) pin guides as well

as the foot holes in the bracket (Figure 4-

11).

16010280

(16009485-02)

SECTION 4. Cabinet Assembly Components

©2000 Maytag Appliances Sales Company

4-11

Page 40

TOP COVER TO CABINET HINGE

Some models will have a plastic hinge

assembly holding the main top to the

cabinet. (Figure 4-1)

Figure 4-1

The hinge assembly is removed from the

unit by lifting the main top about 2 inches

and sliding it forward. The hinge is then

removed by pushing up and out on the

lower tab and lifting the hinge up to

release it from the cabinet. (Figure 4-2)

Lift up and push out on hinge tab to

release hinge from cabinet

Figure 4-2

16010280

(16009485-02)

SECTION 4, Cabinet Assembly Components

©2000 Maytag Appliances Sales Company

4-12

Page 41

SECTION 5. WATER ■ RELATED COMPONENTS

A

WARNING

WATER MIXING VALVE

Warning - Always shut

off electrical power to

the washer before begin

ning any service repair

procedures.

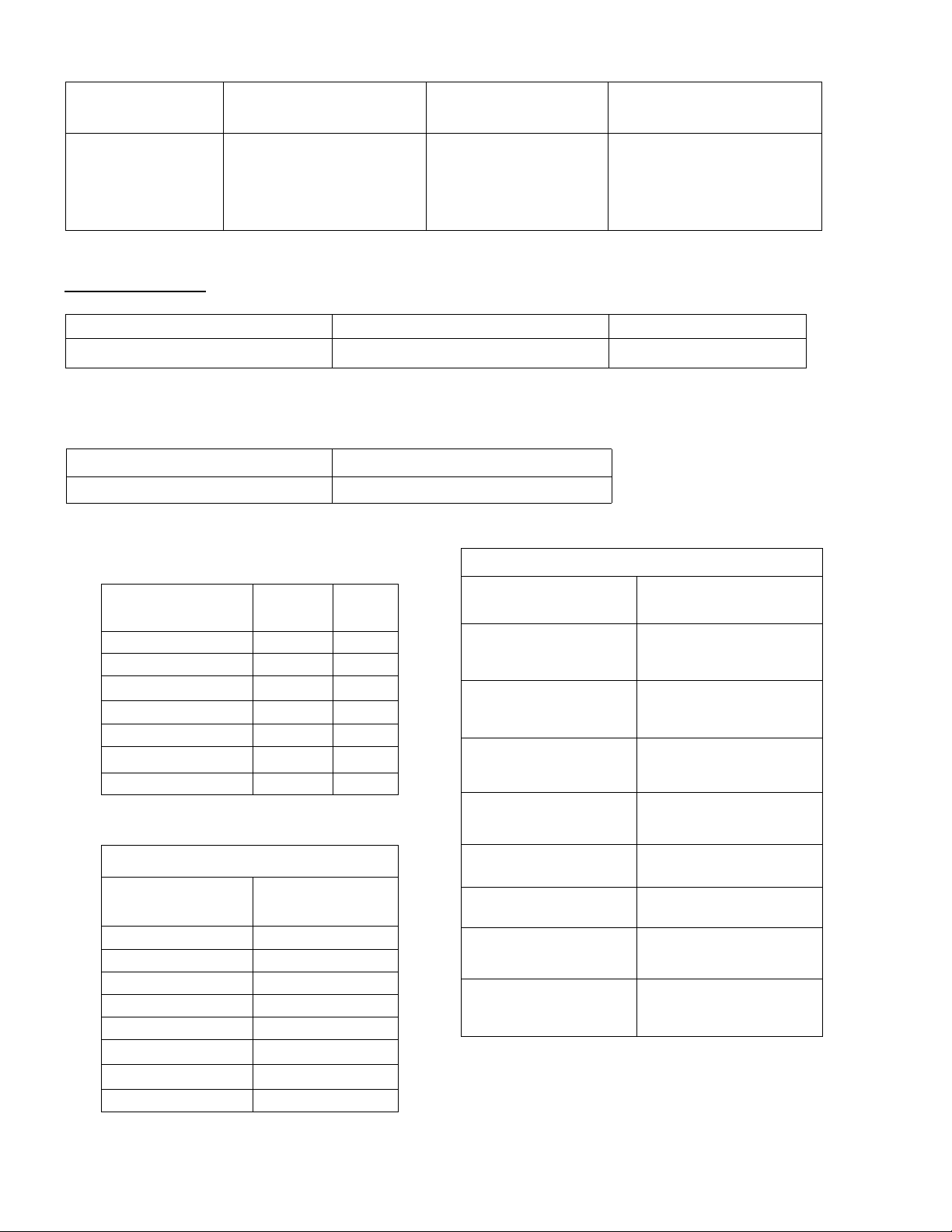

The water mixing valve is located inside the

left rear cabinet area, when viewing from the

front. It is secured by two (2) screws inserted

through the valve bracket and into the cabi

net. The hot and cold water supply inlet hoses

are attached to the nozzles of the water valve.

The mixing valve will allow hot or cold water,

or a mixture of the two as called for by the

27"

68.6 cm

Water

Valves

control circuitry, to enter the machine through

the inlet hose and inlet flume.

Usually, the temperature of the warm water

entering the machine will be about halfway

between the cold and hot water temperatures

delivered to the valve. This will occur when

the flow rate of both are equal.

Inlet Hoses

16009485-01

<■131/2">1

34.3" cm '

SL232TIF

SL238TIF

Figure 5-1

Section 5. Water Related Components 5-1

©1999 Maytag Appliances Sales Company

Page 42

WATER INLET FLUME

HOSES

The molded plastic water inlet flume consists

of an upper and lower section that has been

snap-locked together.

The flume is located on the rear underside of

the washer top assembly. The flume fits flush

with the top opening and is secured to the top

by one mounting screw, accessed through the

control console. An inlet hose from the wa

ter mixing valve connects to the flume nozzle.

Water Supply Inlet Hoses

Two (2) water inlet hoses attach from hot and

cold water supply lines to their respective

nozzles on the water mixing valve. They are

secured at both ends with threaded couplings.

Flume Inlet Hose

The flume inlet hose attaches the water mix

ing valve to the water inlet flume. It is secured

at both ends with spring type hose clamps.

Pressure Switch Hose

The pressure switch hose is made of soft plas

tic tubing and fits snugly over the water level

switch nipple at one end, and the air bell nipple

at the other. A clamp on the inner cabinet rear

positions the hose, and a pad prevents the

hose from contacting the back of the cabinet

during operation. The hose is installed with

its ends seated against the switch and air bell

bodies, and is secured at the tub ends with a

spring type hose clamp.

AIR BELL

A polypropylene air bell and nipple assembly

have been thermally welded to the lower, outer

tub, rear. One end of the pressure switch hose

connects to the air bell nipple and the other

end is attached to the water level switch.

As the water level rises in the tub, it com

presses the air in the air bell and the attached

hose. The compressed air inside the hose will

activate the pneumatically operated water

level switch when the selected water level has

been reached. When the air pressure is low

ered during the drain cycle, the switch will

reset.

N OTE ; When reinstalling the pressure switch

hose, make sure the system is free of air leaks

and water in the hose or an overflow condi

tion will occur.

Tub to Pump Hose

The tub to pump hose attaches from the drain

outlet on the tub to the pump inlet. It is se

cured at each end with a spring-type hose

clamp.

Drain Hose

The drain hose attaches the pump outlet to

the drain standpipe. It is secured to the pump

with a spring-type hose clamp.

16009485-01

©1999 Maytag Appliances Sales Company

Section 5. Water Related Components 5-2

Page 43

TUB TOP

The tub top is constructed of molded polypro

pylene. It is secured to the tub by eight (8)

tabs which have been formed around its up

per edge. These tabs snap over mating tab

locks which are molded around the upper

sides of the tub.

Overflow

Area

It is necessary to remove the tub top before

removing the inner tub. To remove the tub

top, push down on it while disengaging the

tabs from the tab locks on the tub.

Figure 5-3

Designed into the tub top is a drain groove,

an overflow area, and a bleach dispenser. In

case water should splash out of the basket

during machine operation, the drain groove

directs the water back into the tub. The over-

fiow area is located at the tub top rear and

will direct any overflow water away from the

drive motor. The bleach dispenser is func

tional only when used in conjunction with the

proper cabinet top assembly which is avail

able on designated models.

A foam seal has been installed in a groove on

the underside of the tub top. The seal pro

vides a water seal between the tub and the

tub top.

NOTE: When reinstalling the tub top, please

observe the following:

1. Make sure the foam seal is in place

on the underside of the tub top.

2. Align the tab (Position 7:30- looking down

on the tub top) having the larger opening

with its mating tab lock on the tub, and

lock it down around the tub. This seals

the top.

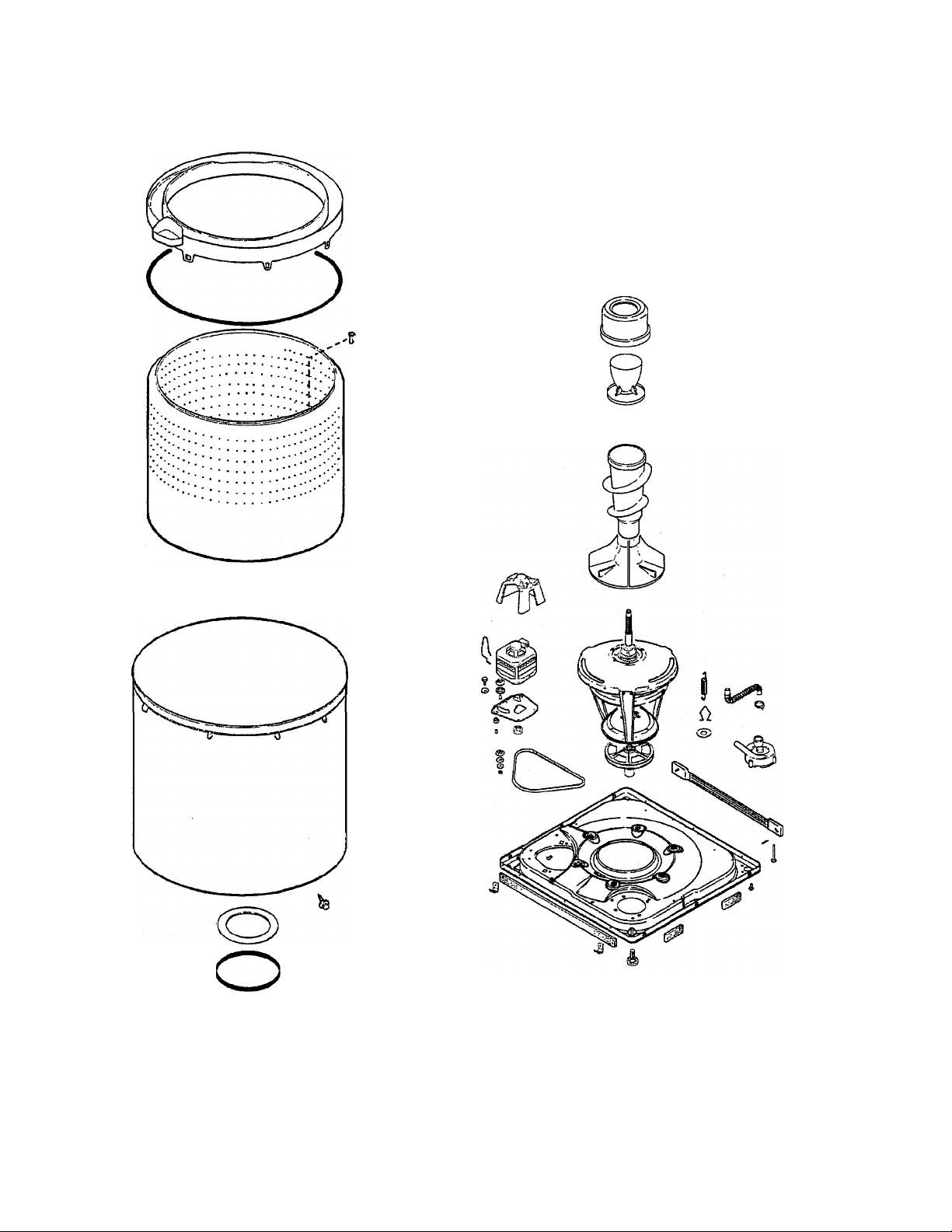

AGITATOR

The agitator is composed of an auger and a

base. The base is a four-vane design molded

from a polypropylene compound. It is tough

flexible material, highly resistant to breakage.

The agitator is mounted on the splined shaft

and secured with the agitator retaining screw

and washer. A fabric softener dispenser snaps

over the top of the agitator (Figure 5-5).

16009485-01

©1999 Maytag Appliances Sales Company

Section 5. Water Related Components 5-3

Page 44

REMOVAL

1. Disconnect power to the unit.

2. Raise the top assembly and lean it back.

3. Remove the tub top.

4. Remove the agitator.

5. Remove the mounting screws.

6. Lift the inner tub up over the center post

and out of the cabinet.

NOTE: When reinstalling the inner tub, be

sure to:

• Clean all connecting surfaces to ensure

proper sealing.

INNER TUB

The inner tub is perforated in a pattern de

signed to allow free flow of the wash and rinse

water for maximum efficiency in removing

sediment, soil deposits, and lint.

The inner tub is constructed entirely of

polypropylene and is secured to the basket

hub assembly with four (4) mounting screws.

A foam gasket is installed between the basket

and the basket hub assembly.

• Position the basket on the basket hub

assembly.

• Align the assembly and tighten all screws

securely.

OUTER TUB ASSEMBLY

The outer tub assembly is molded entirely of

polypropylene.

The outer tub assembly is mounted to the bear

ing and seal housing and to the tub support.

A foam gasket and a rubber seal are installed

between the tub bottom and the bearing and

seal housing.

16009485-01

©1999 Maytag Appliances Sales Company

Section 5. Water Related Components 5-4

Page 45

REMOVAL

NOTE: When reinstalling the tub assembly,

be sure to:

• Protect the air bell nipple.

• Clean all connecting surfaces to ensure

proper sealing.

• Position the gasket and seal on the bear

ing and seal housing.

• Tighten all screws securely.

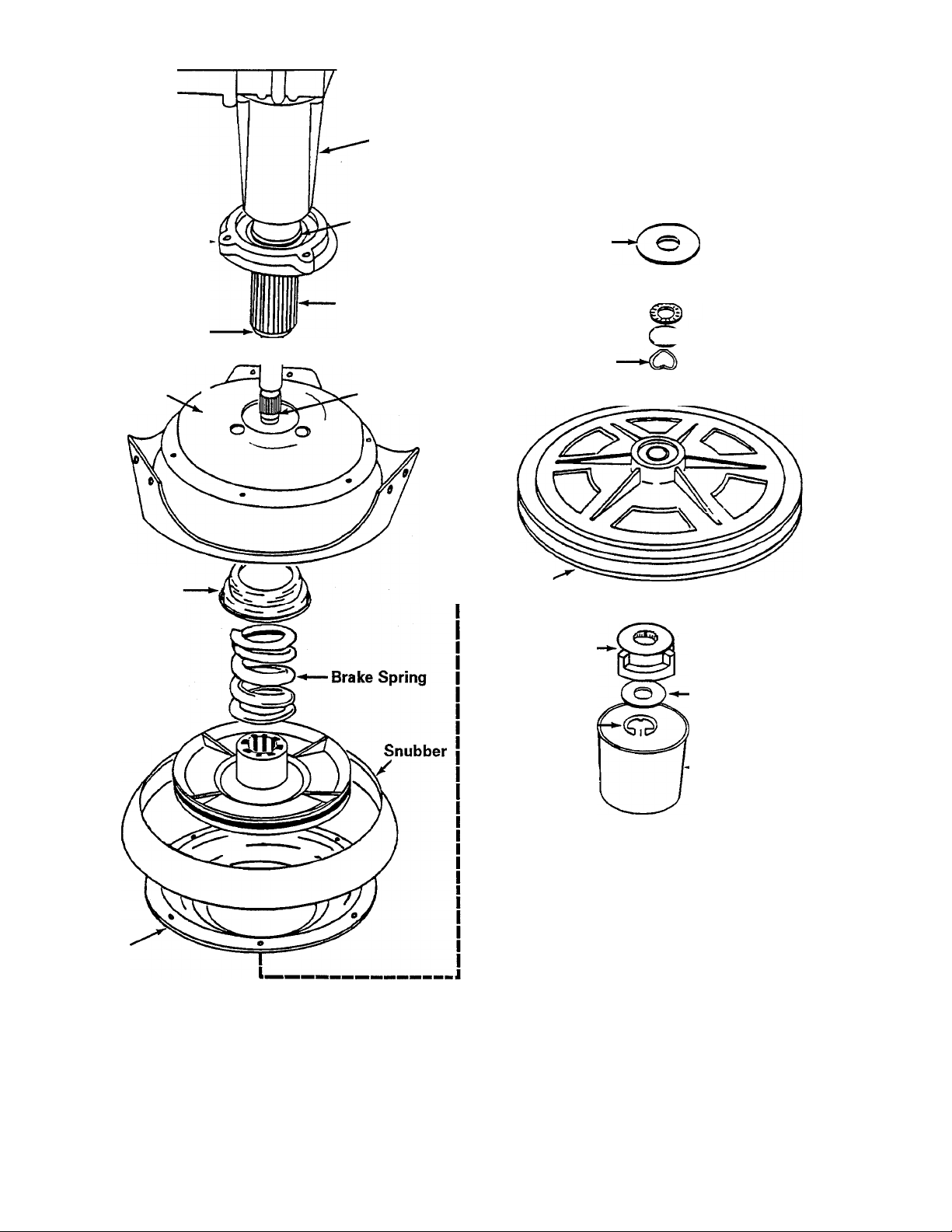

PUMP ASSEMBLY

Figure 5-7

1. Disconnect power to the unit.

2. Remove the inner tub.

3. Remove the front panel.

4. Disconnect the pump inlet hose from the

outer tub outlet.

5. Remove the screws located on each side

of the tub brace bolts which secure the

tub to the tub support.

6. Remove the mounting screws on the in

side of the tub which mount the tub to the

bearing and seal housing.

7. Disconnect air dome hose.

8. PROTECT THE AIR BELL NIPPLE and lift

the tub from the cabinet.

Pump

Housing

Impeller

Seal

Assembly

NOTE: The air bell nipple is fragile, handle

carefully.

16009485-01

©1999 Maytag Appliances Sales Company

Plate & Pulley

Assembly

Figure 5-8

Section 5. Water Related Components 5-5

Page 46

The pump assembly is located on the right

front corner of the washer base.

The pump pulley is engaged to the drive belt

at all times and will be operating in both mo

tor directions: Clockwise during agitation and

counterclockwise during spin. The pump is

designed so it will only discharge water from

the machine when it is running in the coun

terclockwise, or spin direction.

REMOVAL

1. Disconnect power to the unit.

2. Remove the front panel.

3. Remove the drain hose from the pump

outlet.

4. Disconnect the pump inlet hose.

5. Remove the three (3) screws which

mount the pump assembly to the base.

6. Slide the pump to the rear to disengage

the belt from the pulley.

REPLACEMENT

Place one hand through the pump opening

and lift belt. Set the pump pulley into the open

ing and place the belt on the pulley. While

holding tension on the belt to keep it on the

pulleys, install the mounting screws.

DISASSEMBLY

1. Remove the pump from the washer base.

2. Remove the four (4) screws that secure the

housing to the pump base, and lift off the

housing.

3. Remove the screw that secures the impel

ler.

4. Using two (2) screwdrivers, one on each

side of the impeller, carefully pry the im

peller off the spline shaft.

5. Work the seal mating ring and "O" ring up

and off the shaft.

NOTE: If this is done carefully, the belt will

remain on the motor and transmission drive

pulley, making installation easier.

16009485-01

©1999 Maytag Appliances Sales Company

Section 5. Water Related Components 5-6

Page 47

WATER VALVE INJECTION

SYSTEM

On some models the water valve is installed

at the top rear of the cabinet (Figure 5-1).

The following procedures are used to

remove the water valve.

Figure 5-1

To raise the top asssembly, insert a thin

bladed tool (such as a putty knife) between

the front panel and top assembly

approximately three inches in from each

corner. While lifting up on the top cover

assembly, press the blade against the wire

clips, one side at a time to disengage them.

Lift the top cover up to a stationary position.

(Figure 5-2)

Figure 5-2

With the top assembly up you will have

access to the water valve assembly.

(Figure 5-3)

Figure 5-3

16010280

(16009485-02)

SECTION 5. Water - Related Components

©2000 Maytag Appliances Sales Company

5-7

Page 48

The water valve is held to the cabinet by one

screw. (Figure 5-4)

Figure 5-4

Remove the screw and swing the bracket

and valve assembly to the right to release

the bracket from the cabinet. (Figure 5-5)

The fill hoses can be removed at this point.

Figure 5-7

Remove the wiring from the water valve.

(Figure 5-6)

Remove the screw and using a small flat

bladed screw driver, carefully pry up on the

plastic tab to release the water valve from

the bracket. (Figure 5-9)

Figure 5-5

Figure 5-6

BE SURE THE WATER IS TURNED OFF.

(Figure 5-7)

The water valve is held to the bracket by one

screw and a tab molded into the plastic part

of the bracket. (Figure 5-8)

Figure 5-8

Figure 5-9

16010280

(16009485-02)

SECTION 5. Water - Related Components

©2000 Maytag Appliances Sales Company

5-8

Page 49

Slide the metal part of the bracket out of the

slots in the plastic part of the bracket.

(Figure 5-10)

4. Remove the agitator

5. Remove the mounting screws.

6. Remove the upper insulating ring.

(Figure 5-11)

Figure 5-11

Figure 5-10

Installation of the water valve is the reverse

of the above procedure.

Stainless Steel

Spinner Assembly

The stainless steel spinner is composed of a

crimped stainless steel basket and a

polypropylene spinner top. There is a lower

insulating ring attached to the bottom of the

spinner and an upper insulating ring that fits

over the inner spinner bottom. These

insulating rings provide stability to the lower

spinner area. When replacing a spinner it is

recommended that the insulating rings be

replaced with the spinner assembly.

Lift the spinner up over the center post

and out of the cabinet

8.

Depress the six (6) tabs (Figure 5-12) that

hold the spinner top to the spinner and

remove the spinner top.

Depress the four (4) tabs that hold the

lower insulating ring to the bottom of the

spinner and remove. (Figure 5-12) These

four (4) tabs are not necessary for correct

machine operation. These tabs are used

to assist in the manufacturing process. If

one or more break during removal, the

part is still functional. (See Figures 5-13

thru 5-14)

Removal:

1. Disconnect the power to the unit.

2. Raise the top assembly and lean it back.

3. Remove the tub top.

16010280