Page 1

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

This manual replaces RS2520001 Revision 0.

Electric

Wall Ovens

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

AOES3030*

AOCS3040*

16021875

Revision 0

November 2003

Page 2

Table of Contents

Important Information................................................ 4

Important Safety Information

All Appliances ..................................................... 5

Ovens ................................................................. 5

Self-Cleaning ...................................................... 5

In Case of Fire .................................................... 5

General Information

Oven Operation ................................................... 6

Cooking Guide .................................................... 6

Convection Broiling Rack ..................................... 7

Oven Rack Placement ......................................... 7

Spacesaver™ Convection Rack ............................ 7

Convection Pan Placement .................................. 7

Pan Placement ................................................... 7

Slow-Cook™ Roasting Rack ................................ 7

Removing Oven Door ........................................... 8

Replacing Oven Door ........................................... 8

Replacing Oven Light ........................................... 8

Titling Control Panel ............................................ 8

Care and Cleaning

Cleaning Oven Parts ............................................ 9

Component Testing Information ...............................10

Testing Procedures

Oven Door Switch ..............................................14

Oven High Limit/Fan Switch ...............................14

Oven Temperature Sensor ..................................14

Blower Motor ....................................................14

Auto Latch Motor ..............................................15

Convection Fan Motor ........................................15

Convection Element Testing ...............................15

Broil Element Testing ........................................15

Bake Element Testing .......................................15

Disassembly Procedures

Removing and Replacing Oven ...........................16

Control Panel ....................................................16

ERC/P.C. Board................................................16

Transformer/Relay Board....................................16

Oven High Limit/Fan Control Switch....................16

Oven Sensor .....................................................17

Bake Element ...................................................17

Broil Element/Broil Element Reflector .................17

Convection Heating Element ..............................17

Convection Fan Blade ........................................17

Convection Fan Motor ........................................17

Automatic Oven Door Latch Assembly ................17

Door Plunger Light Switch ..................................17

Oven Light Bulb/Oven Light Socket .....................18

Oven Tank Removal ...........................................18

Oven Door Removal ...........................................18

Frameless Door Disassembly ............................18

Oven Door Hinge ...............................................19

Blower Motor ....................................................19

Vent Assembly/Smoke Eliminator ......................19

Outer Trim Assembly.........................................19

Appendix A

Installation Instructions

Packing Material ......................................... A-2

Oven Dimensions ........................................ A-2

Oven Location............................................. A-2

Line Voltage Requirements .......................... A-2

Connecting Wiring....................................... A-3

Wall Oven and Cooktop Combination

Installation Specifications ............................ A-4

AKED3060 or AKES3060 Downdraft Cooktop

above AOES3030 or AOCS3040 Wall Oven... A-4

AKED3060 or AKES3060 Downdraft Cooktop

above AOES3030 or AOCS3040 Wall Oven

in an Island Application................................ A-5

AK2H36, AK2T36, 36" Electric Cooktop

Installed above AOES3030 or AOCS3040

Wall Oven .................................................. A-5

30" Electric Cooktop AK2H30, AK2T30,

AKR3000, AKT3000, CAK2H30, CAK2T30

Installed above AOES3030 or AOCS3040

Wall Oven .................................................. A-6

AOES3030 or AOCS3040 Wall Oven

Stacked Installation..................................... A-6

AOES3030 or AOCS3040 Wall Oven

Installed Side-by-Side.................................. A-7

Tilting Control Panel .................................... A-7

2 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 3

Table of Contents

Appendix B

Programming Instructions—ERC for

AOES3030

Electronic Oven Control Options ................... B-2

Special Oven Control Functions .................... B-2

Quick Reference Instructions ....................... B-3

Bake .......................................................... B-4

Timed Bake ................................................ B-4

Delayed Bake ............................................. B-4

Broiling ....................................................... B-4

Self-Cleaning .............................................. B-5

Interrupt Self-Cleaning Cycle ........................ B-5

Delayed Self-Cleaning.................................. B-5

Interrupt Self-Cleaning Cycle ........................ B-5

Adjusting Oven Temperature ........................ B-6

Service Tones and Codes ............................. B-6

Testing Procedures

Service Information ...................................... B-7

Quick Test Procedure .................................. B-7

ERC Warnings and Failure Codes ................ B-8

Temperature Calibration Offset ..................... B-8

Function Switch Connection

Check Procedure ........................................ B-8

Transformer/Relay Module............................ B-8

Double Line Break—K6 ................................ B-8

Bake Relay—K4 ......................................... B-8

Broil Relay—K5 .......................................... B-8

Oven Light Relay—K10 ................................ B-9

Door Lock Relay—K3 .................................. B-9

Display (Filament) Voltage ........................... B-9

Appendix C

Programming Instructions—ERC for

AOCS3040

Electronic Oven Control Options ................... C-2

Special Oven Control Functions .................... C-2

Quick Reference Instructions ....................... C-3

Bake and Convection Bake .......................... C-4

Timed Bake or Convection Bake................... C-4

Delayed Bake or Convection Bake................ C-4

Convection.................................................. C-4

Timed Convection ........................................ C-4

Delayed Convection ..................................... C-5

Broil and Convection Broil ............................ C-5

Convection Dehydration ............................... C-5

Dehydration Tips ......................................... C-5

Self-Cleaning .............................................. C-6

Interrupt Self-Cleaning Cycle ........................ C-6

Delayed Self-Cleaning.................................. C-6

Canceling Self-Cleaning Cycle...................... C-6

Adjusting Oven Temperature ........................ C-6

Testing Procedures

Service Information ...................................... C-7

Quick Test Procedure .................................. C-7

ERC Warnings and Failure Codes ................ C-8

Temperature Calibration Offset ..................... C-8

Function Switch Connection

Check Procedures ....................................... C-8

Transformer/Relay Module............................ C-8

Double Line Break—K6 ................................ C-8

Bake Relay—K4 ......................................... C-8

Broil Relay—K5 .......................................... C-8

Convection Element Relay—K2.................... C-9

Convection Fan Relay—K1 ........................... C-9

Oven Light Relay—K10 ................................ C-9

Door Lock Relay—K3 .................................. C-9

©2003 Maytag Appliances Company 16021875 Rev. 0 3

Page 4

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible,

however, that during its lifetime a product may require service. Products should be serviced only by a qualified

service technician who is familiar with the safety procedures required in the repair and who is equipped with the

proper tools, parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE

INFORMATION IN THE APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

Important Information

Important Notices for Consumers and Servicers

!

To avoid risk of serious injury or death, repairs should not be attempted by an unauthorized person, dangerous

conditions (such as exposure to electrical shock) may result.

!

Amana will not be responsible for any injury or property damage from improper service procedures. If performing

service on your own product, assume responsibility for any personal injury or property damage which may result.

To locate an authorized servicer, consult your telephone book or the dealer from whom you purchased this product.

For further assistance, contact: 1 (800) 628-5782 first, if no answer call number listed below.

CONSUMER AFFAIRS DEPT. OR 1 (800) 843-0304

AMANA REFRIGERATION, INC. CALL

AMANA, IOWA 52204

If outside the United States contact:

AMANA

ATTN: CONSUMER AFFAIRS DEPT

AMANA, IOWA 52204, USA

Telephone: (319) 622-5511

Facsimile: (319) 622-2180

TELEX: 4330076 AMANA

CABLE: "AMANA", AMANA, IOWA, USA

WARNING

CAUTION

Recognize Safety Symbols, Words, and Labels

DANGER

!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

4 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 5

Important Safety Information

Recognize this symbol as a safety precaution

WARNING

!

This appliance contains or produces a chemical or

chemicals which can cause death or serious illness

and which are known to the state of California to cause

cancer, birth defects or other reproductive harm. To

reduce the risk from substances in the fuel or from fuel

combustion make sure this appliance is installed,

operated, and maintained according to the instructions

in this booklet.

T o avoid personal injury, do not sit, stand or lean on

oven door.

T o avoid risk of electrical shock, personal injury , or

death, make sure your oven has been properly

grounded and always disconnect it from main power

supply before any servicing.

T o avoid risk of fire, do not store combustible materials,

gasoline or other flammable vapors and liquids near or

in the oven.

T o avoid burns caused by steam, do not use a wet

sponge or cloth to wipe up spills on a hot cooking

area.

Oven

Use care when opening door

Let hot air or steam escape before removing or replacing

food.

Do not heat unopened food containers

Build-up of pressure may cause container to burst and

result in injury .

Keep oven vent ducts unobstructed.

Placement of oven racks

Always place oven racks in desired location while oven is

cool. If rack is removed while oven is hot, do not let

potholder contact hot heating element in oven.

Do not use aluminum foil to line the oven bottom

Aluminum foil can cause fire, damage oven interior , and

will seriously affect baking results.

Do not touch interior surfaces of oven during or

immediately after use

Do not let clothing or other flammable materials contact

elements. Although these surfaces may be dark in color

they can still be hot enough to burn.

Use caution when touching oven while in use

Other areas of the oven can become hot enough to cause

burns, such as vent openings, window, oven door and

oven racks.

All Appliances

Proper installation

Be sure your appliance is properly installed and grounded

by a qualified technician.

Never use your appliance for warming or heating

the room.

Do not leave children alone

Children should not be alone or unattended in the area

where the appliance is in use. They should never be

allowed to sit or stand on any part of the appliance.

Wear proper apparel

Loose fitting or hanging garments should never be worn

while using appliance.

User servicing

Do not repair or replace any part of the appliance unless

specifically recommended in this manual. All other

servicing should be referred to a qualified technician.

Storage in or on appliance

Flammable materials should not be stored in an oven or

near surface units.

Do not use water on grease fires

Smother fire or flame, or use dry chemical or foam-type

extinguisher.

Use only dry potholders

Moist or damp potholders on hot surfaces may result in

burns from steam. Do not let potholder touch elements.

Do not use a towel or other bulky cloth.

Do not leave oven unattended

Boilovers can cause smoke and may ignite.

Self-Cleaning

Do not clean door gasket

The door gasket is essential for a good seal. Care should

be taken not to rub, move, or damage the gasket.

Do not use oven cleaners

No commercial oven cleaner or oven liner protective

coating of any kind should be used in or around any part

of the liner.

Clean only parts listed in manual.

Before self-cleaning the oven

Remove broiler pan, oven racks, and other utensils.

In Case of Fire

Fires can occur as a result of over cooking or excessive

grease. Though a fire is unlikely , if one occurs, proceed

as follows.

1. If you see smoke from oven, do not open oven door .

2. Turn oven control to OFF.

3. As an added precaution, turn off power at main circuit

breaker or fuse box.

4. Turn on vent to remove smoke.

5. Allow food or grease to burn itself out in oven.

6. If smoke and fire persist, call fire department.

7. If there is any damage to components, call an

authorized servicer before using oven.

©2003 Maytag Appliances Company 16021875 Rev. 0 5

Page 6

General Information

Oven Operation

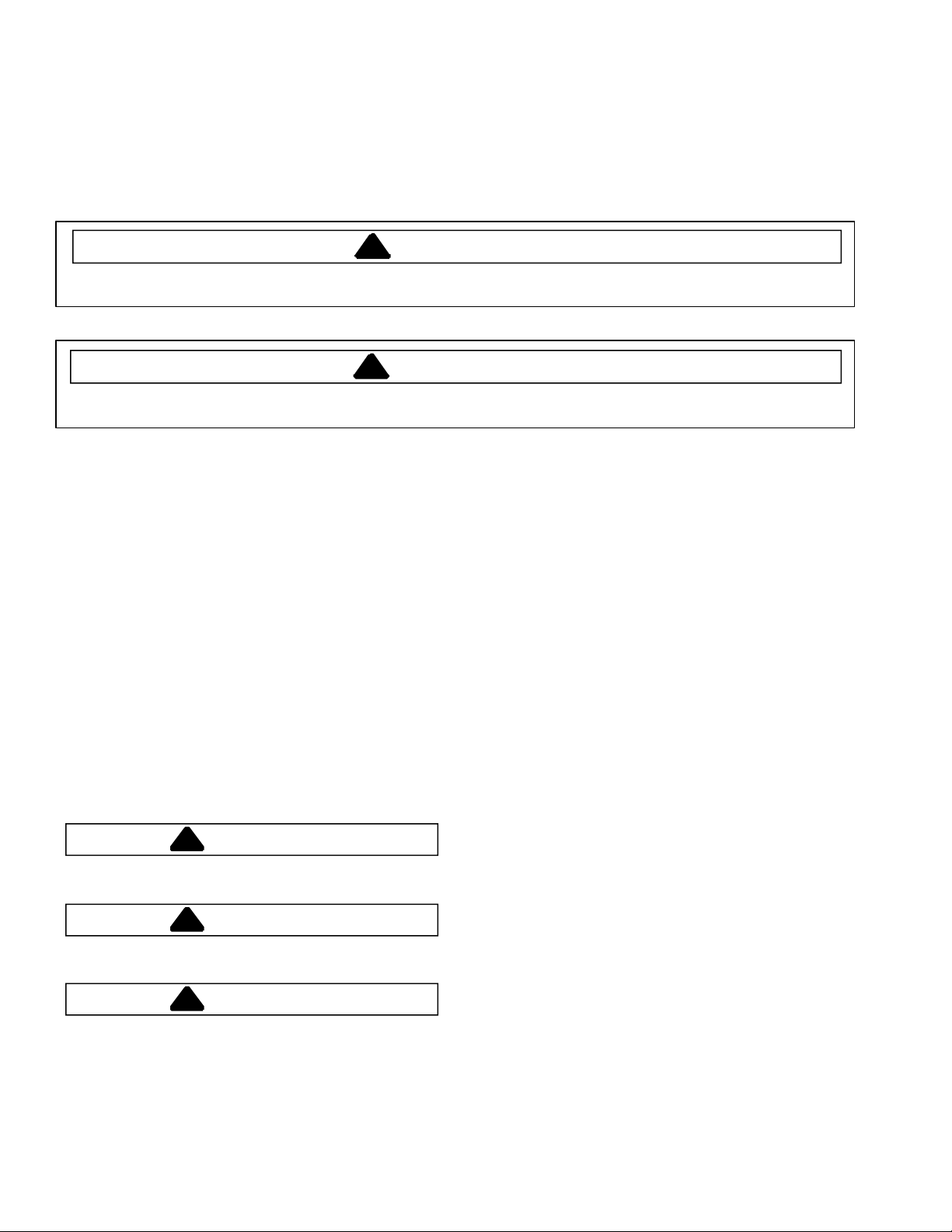

Bake

T op and bottom element s operate during bake. Bake can

be used to cook foods which are normally baked. Oven

must be preheated.

ON

Broil

T op element operates during broil. Broil can be used to

cook foods which are normally broiled. Preheating is not

required when using broil. All foods should be turned at

least once except fish, which does not need to be turned.

Convection Broil

T op element and fan operate when using convection broil.

Convection broil can be used to cook foods that are

normally broiled. Oven does not require preheating when

using convection broil. Food does not need to be turned

during cooking. Cooks approximately 25% quicker than

broil.

ON

Convection

Rear element and fan operate during convection.

Convection should be used for cooking pastries, souffles,

yeast bread, cakes and cookies. Oven should be

preheated for best results when using convection. Pans

do not need to be staggered. Cooks approximately 25%

quicker than bake. Broil is on during preheat conditions.

ON

Convection Bake

Upper element, lower element, and fan operate during

convection bake. Convection bake should be used for

cooking casseroles and roasting meats. Oven should be

preheated for best results when using convection bake.

Pans do not need to be staggered. Cooks approximately

25% quicker than bake.

ON

ON

Cooking Guide

Refer to owners manual, for following recommendations

only as a guide for times and temperature. Times, rack

position, and temperatures may vary depending on

conditions and food type. For best results, always check

food at minimum time. When roasting, choose rack

position based on size of food item.

6 16021875 Rev . 0 ©2003 Maytag Appliances Company

Page 7

General Information

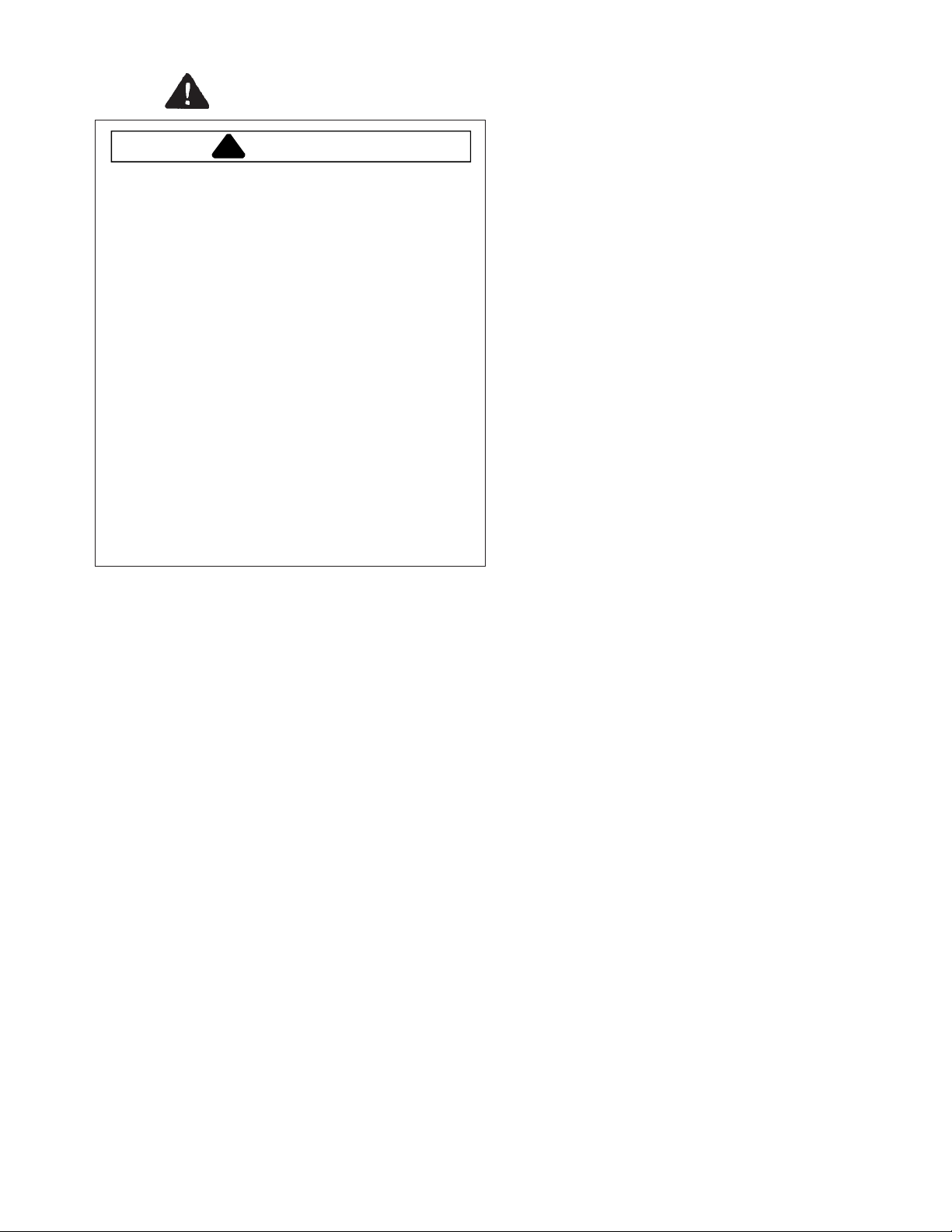

Convection Broiling Rack

Oven includes a special broiling rack. This rack should

be placed on top of broiler pan and grid. This allows air to

circulate around food and cook evenly without turning. If

convection broiling rack is not used, foods must be

turned at least once during cooking.

Oven Rack Placement

Position oven rack before turning oven on.

1. Pull rack forward to stop position.

2. Raise front edge of rack and pull until rack is out of

oven.

3. Place rack in new rack position.

• Curved edge of rack must be toward rear of oven.

Convection Pan Placement

Baking pans and cookie sheets should not touch side or

rear walls of oven. If pans are placed on different racks,

they can be placed directly over each other . Convection

cooking circulates air around oven providing even

browning on all rack positions. When using convection,

oven can be loaded on all racks with excellent cooking

results.

Pan Placement

• Keep pans and cookie sheets 2 inches from oven

walls.

• Stagger pans placed on different racks so one is not

directly over the other .

Spacesaver™ Convection Rack

Sp acesaver™ convection rack sets 1/2" off the oven floor

when in lowest rack postion to allow air to circulate

around food and cook evenly . This rack provides more

usable oven space for cooking large items or several food

items at once.

Position oven rack before turning oven on. T o remove

rack:

1. Pull rack forward to stop position.

2. Raise front edge of rack and pull until rack is out of

oven.

3. Place rack in new rack position.

• Curved edge of rack must be toward rear of oven.

©2003 Maytag Appliances Company 16021875 Rev . 0 7

Slo-Cook™ Roasting Rack

Oven includes a Slo-Cook™ roasting rack. This rack

should be placed in pan or roaster . Slo-Cook™ roasting

rack elevates food keeping it out of grease and fat.

Page 8

w

0

e

General Information

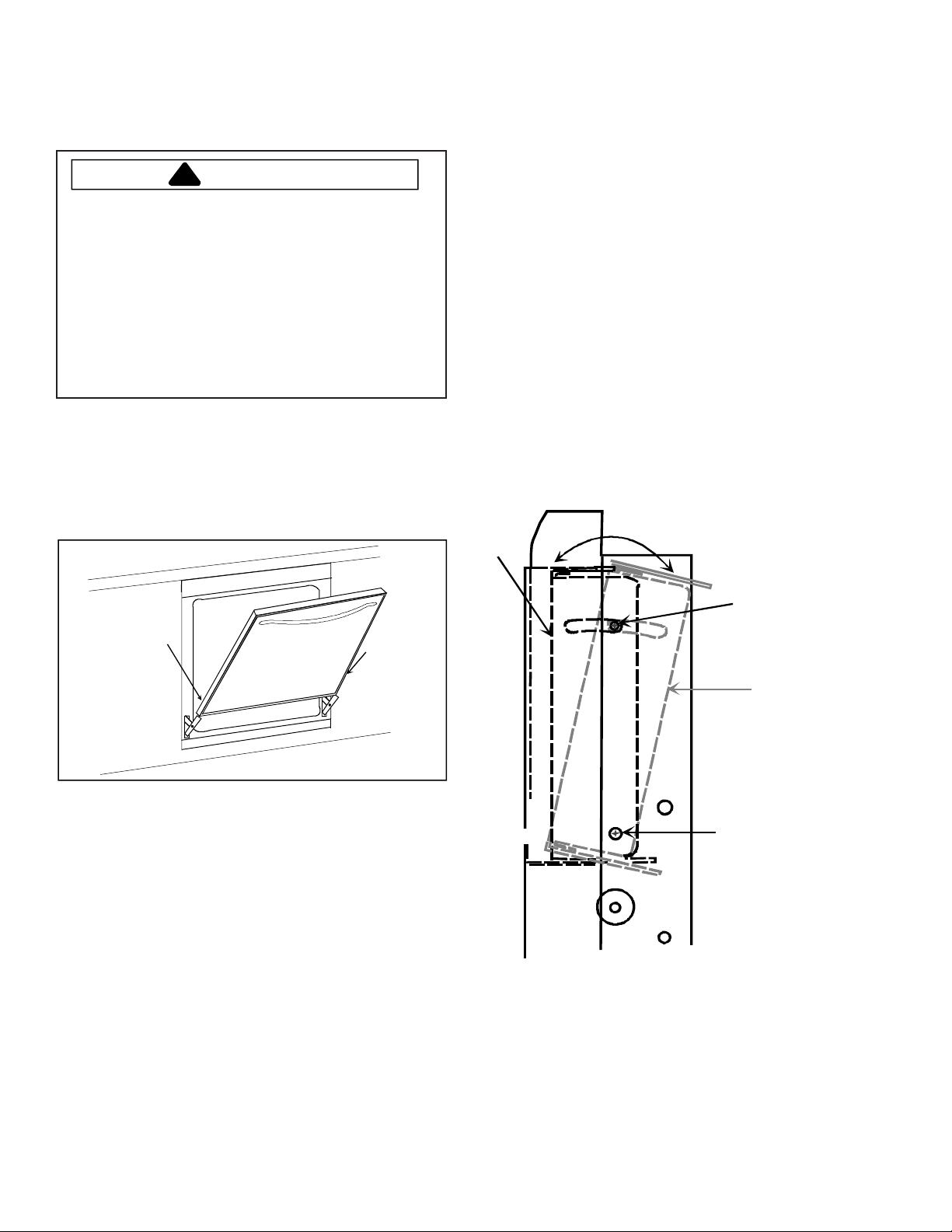

Removing Oven Door

The oven door can be removed for ease in cleaning large

spills.

!

CAUTION

T o avoid personal injury or property damage, handle

oven door with care. Door is heavy and can be

damaged if dropped.

Do not place hands in hinge area when door is

removed. Hinge can snap closed and pinch your

hands.

Door contains tempered glass. If glass is scratched,

chipped, impacted or twisted it may break suddenly . If

door glass appears damaged it should be replaced

immediately.

1. Open door to first stop.

2. Remove screws in door liner.

3. Grasp door firmly on each side and lift it upward off

hinges. Do not push hinges closed once oven door is

removed.

• Do not lift door using door handle.

Replacing Oven Light

Protective gloves must be worn when changing light bulb.

1. Disconnect electrical supply by turning off power at

fuse box.

2. Remove oven door.

3. Remove light cover by inserting a screwdriver , blade

end covered in masking tape, into slot at front of lens

cover and prying lens cover downward.

4. Unscrew bulb from receptacle.

• Replacement bulbs are available through your local

Amana service or parts center.

Tilting Control Panel

Control panel can be adjusted to tilt from 0° to 12° to

make more visible.

1. Loosen screws on top, and sides of control panel and

pivot screw on bottom, sides of control panel before

installing oven, or while oven partially pulled from

opening.

2. Adjust control panel to desired angle and retighten

screws.

° tilt

Loosen scre

remove

screw here

remove

screw her

12° tilt

Replacing Oven Door

1. Make sure the hinges are open to the first stop

position. If hinges have been accidentally closed,

carefully pull them open to first stop. Align door with

hinge arms.

2. Slide door down and into place. Be sure door is

completely down on hinges.

3. Replace screws in door liner.

Pivot screw

8 16021875 Rev . 0 ©2003 Maytag Appliances Company

Page 9

Care and Cleaning

Oven Part

Cleaning Materials

General Directions

Broil element

Do not clean broil element. Any soil will

burn off during cooking.

Broiler pan and grid

Soap, a nonabrasive plastic scouring

pad and water

Drain fat. Cool pan and grid slightly. (Do

not let soiled pan and grid stand in oven

to cool.) Sprinkle with soap. Fill pan with

warm water. Let pan and and grid stand

for a few minutes. Wash and scour if

necessary. Rinse and dry. Broiler pan and

grid may also be cleaned in the

dishwasher.

Interior oven door, outside

door gasket

Soap and water

Cool before cleaning. Frequent wiping

with mild soap and water will prolong the

time between major cleanings. Be sure to

rinse thoroughly. For extra dried on soil a

mild abrasive can be used. Never use

strong abrasives, gritty cleaners,

commerc ial oven cleaners or steel wool.

Oven door gasket

Do not clean

Gaskets should not be cleaned. Care

should be taken not to wet or rub the

gasket.

Oven racks

Soap and water

For heavy soil, clean by hand and rinse

thoroughly. Remove oven racks for ease

in cleaning.

Outside of oven

Soap and water

W as h all glass with cloth dampened in

soapy water. Rinse and polish with a dry

cloth. Do not use cleaning products

containing ammonia.

Cleaning Oven Parts

©2003 Maytag Appliances Company 16021875 Rev . 0 9

Page 10

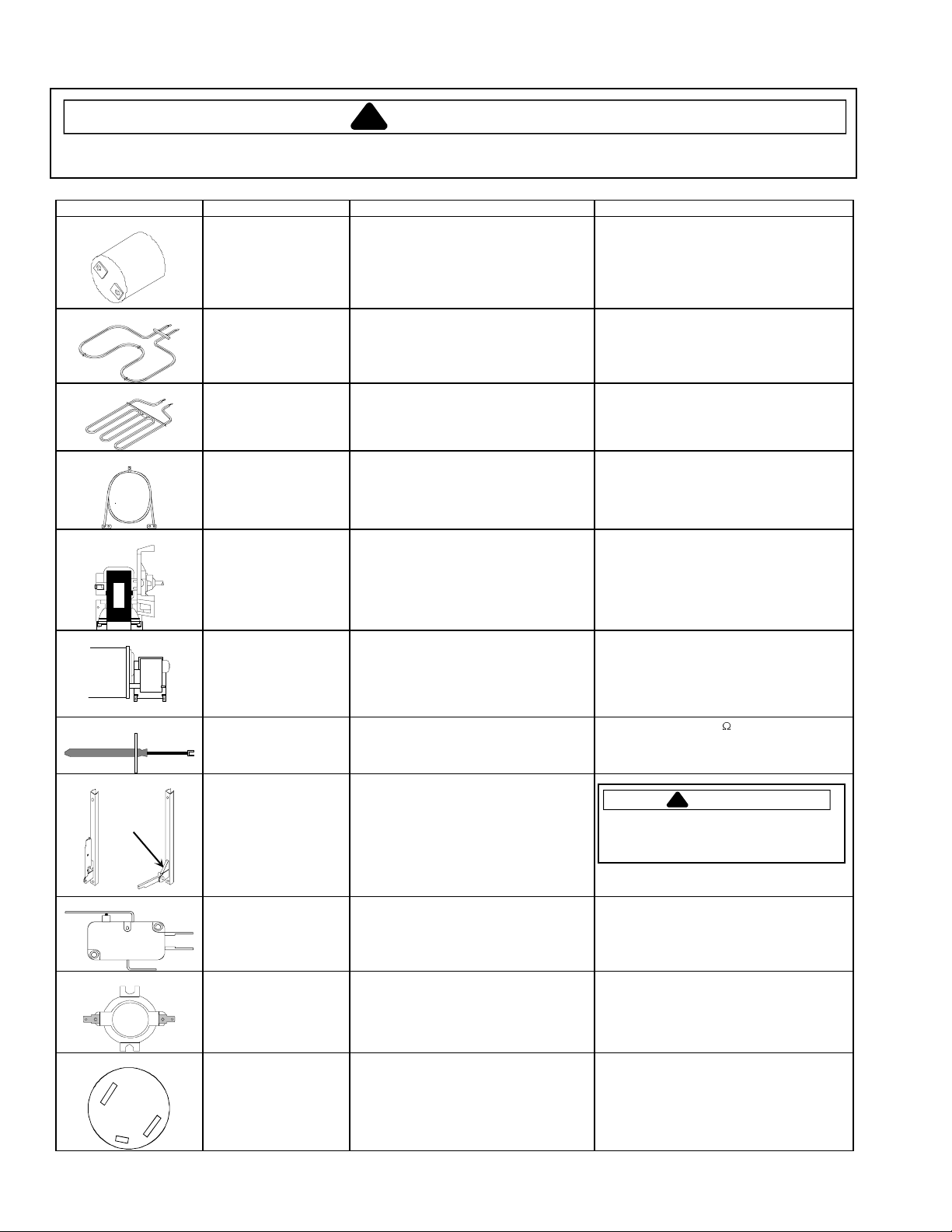

Component Testing Information

!

WARNING

To avoid risk of electrical shook, personal injury or death: disconnect power to oven before servicing, unless

testing requires it.

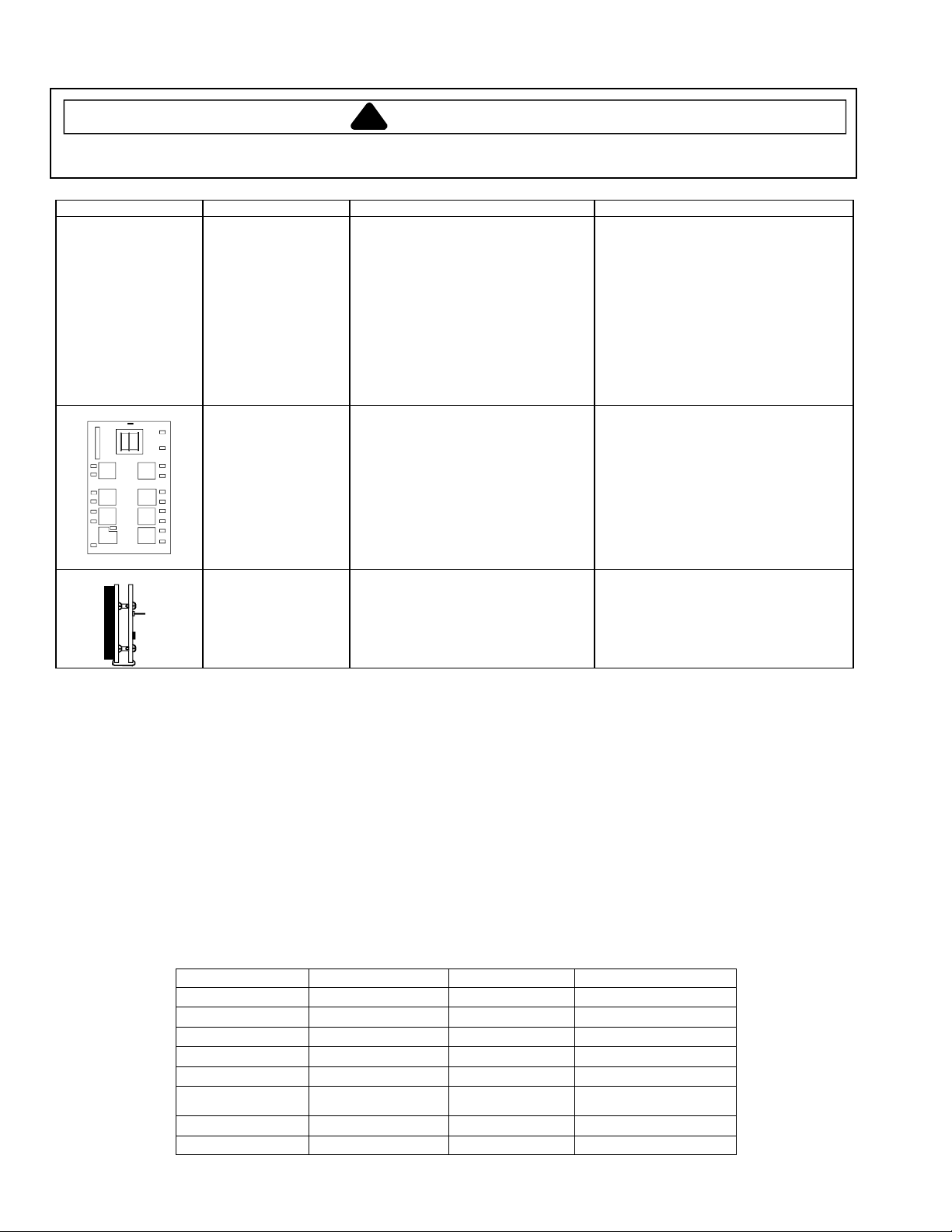

Illustration Component Test Procedure Results

Oven light socket Test continuity of receptacle terminals.

Measure voltage at oven light.

Bake element Test continuity of terminals.

Test voltage to term inals.

Broil element Test continuity of terminals.

Test voltage to term inals.

Convection element Test continuity of terminals.

Test voltage to term inals.

Convection motor fan Verify supply voltage.

Check continuit y of terminals, and

verify terminal s are not shorted to

chassis.

Indicates cont inuity with bulb screwed in.

120 VAC, see wiring diagram for terminal

identification.

If no voltage is present at oven light

check wiring.

Indicates continuity.

240 VAC

Indicates continuity.

240 VAC

Indicates continuity.

240 VAC

120 VAC

Continuity

Convection fan will stay ON, when

oven door is opened.

Opening

COM

C

NO

NC

NC

NO

Blower motor Verify supply voltage.

Heraeus sensor Measure resistance.

Hinge Carefully open the hinge fully, and

Door lock switch Switch connection in following

Controls Verify proper operation.

Door plunger swit ch Remove switch from unit and measure

Check continuit y of terminals, and

verify terminal s are not shorted to

chassis.

insert a wooden dowel or screwdriver

bit into opening.

Remove top and bottom screws

securing hinge.

Slide hinge top towards rear of unit

and guide hinge out through frame

opening or storage drawer.

positions:

Unlocked

Locked

31–308417–02–0 Fan control

31–31751801–0 Control limit

the following points :

C-NC

C NO

120 VAC

Continuity

Approximately 1100

temperature 75ºF.

!

Do not place hands in hi nge area when

oven door is removed. Hinge can snap

closed and pinch hands or fingers.

COM-NO=Open, COM-NC=Closed

COM-NO=Closed, COM-NC=Open

Open at 115°F, Closes at 155°F

Open at 260°F, Closes at 220°F

Plunger in infinite, Plunger out continuity.

Plunger in continuity, Plunger out infinite.

Ω

at room

CAUTION

10

16021875 Rev. 0 ©2003 Maytag Appliances Company

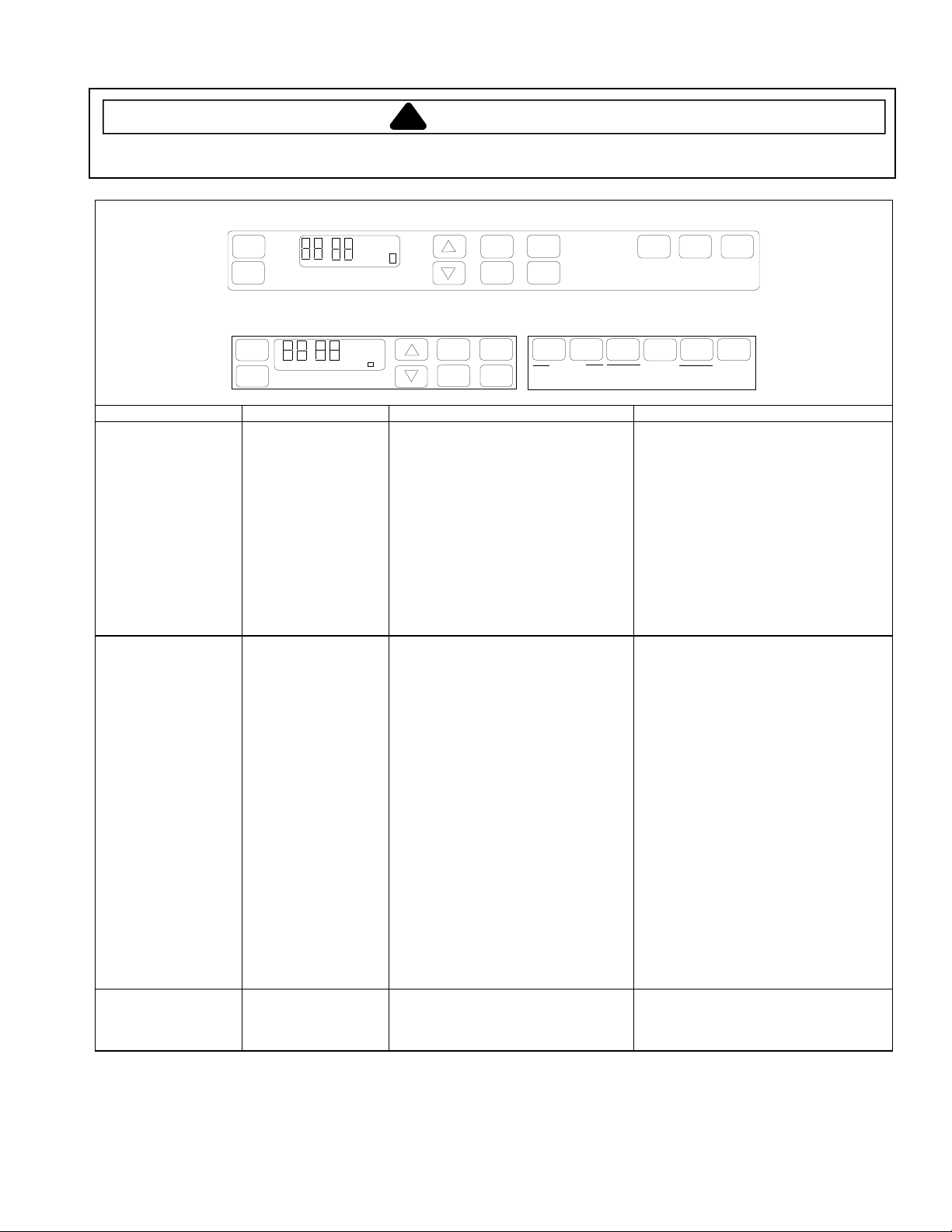

Page 11

Component Testing Information

!

WARNING

To avoid risk of electrical shook, personal injury or death: disconnect power to oven before servicing, unless

testing requires it.

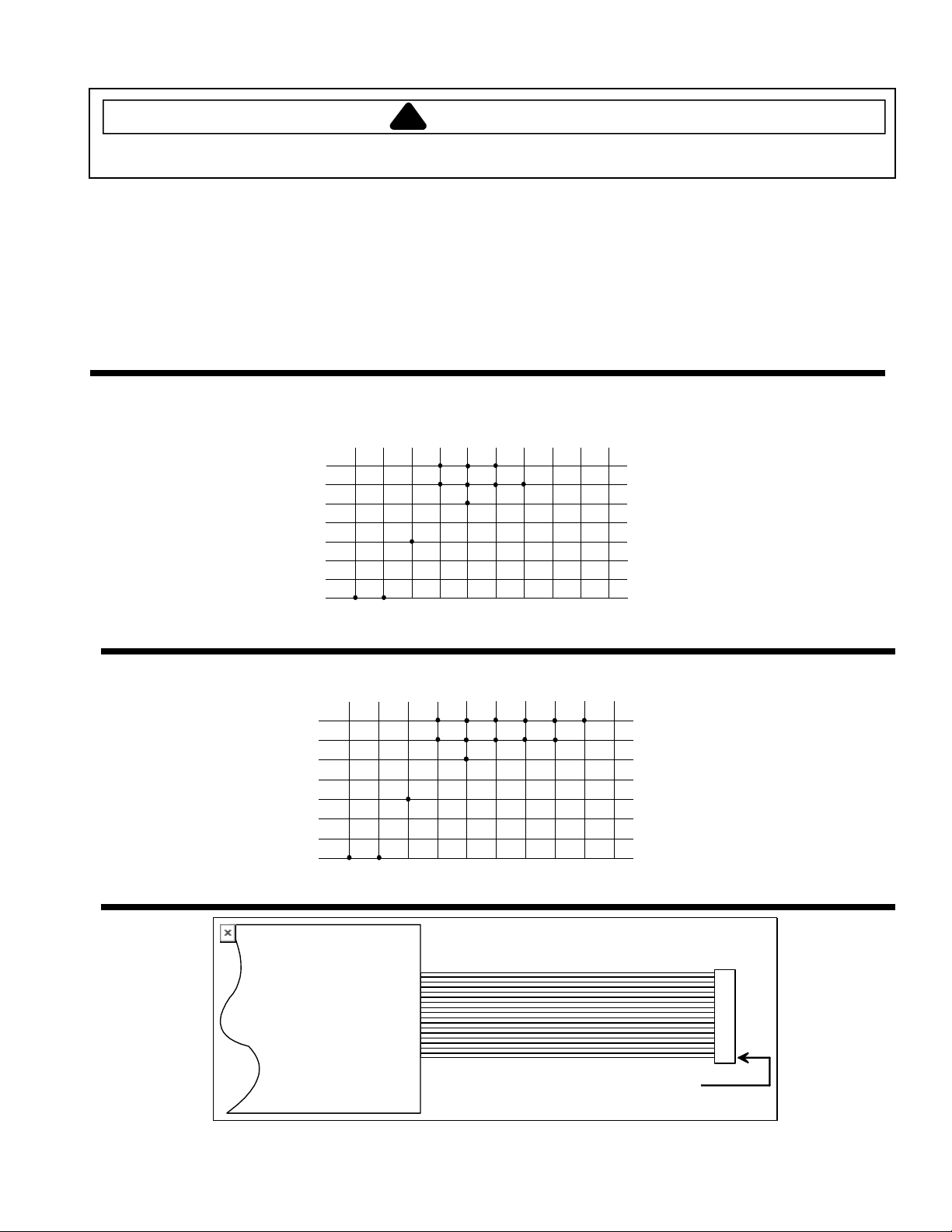

ERC mylar touch system

LIGHT

OVEN

CANCEL

LIGHT

OVEN

CANCEL

HR

DELAY BAKE CLN

TIME CONTROL

AM

HR

:

PM

CLEAN OVEN

STOP ON TIMER

TIME CONTROL

:

STOP TIME

°

350°

E

BROIL

DELAY BAKE

CLEAN LOCKED

P

R

350

E

CONV BROIL PRE-

DELAY TIMED BAKE

CLEAN LOCK ON

O

N

+

-

P

R

Illustration Component Test Procedure Results

See illustrations

above.

Mylar touch system

ERC4800

F1 - Control malfuct ion.

F2 - Oven over temperature.

F3 - Open sensor or sensor circuit.

F4 - Shorted sensor or sensor circuit.

F7 - Shorted input key.

F9 - Door lock or door l ock circuitry

malfuction.

FF - door lock circuitry malfuction at

clean temperature.

DOOR - Lock status is not sensed

within 90 seconds of energizing door

lock relay.

ERC4800 Controlled

Oven temperature

adjustment

Press BAKE.

Press + slew pad until an oven

temperature greater than 500° shows

on display.

Immediately press and hold BAKE

until “00” appears in display,

approximately 5 seconds.

To decrease oven temperature (for a

cooler oven), press - slew pad until

negative numbers appear.Oven can

be adjusted from -5 to -35 degrees

lower. To avoid overa djusting oven

move temperature -5 degrees each

time.

To increase oven tem perature (for

warmer oven), press + slew pad until

positive numbers app ear. Oven can be

adjusted 5 to 35 degrees higher. To

avoid overadjust ing oven move

temperature 5 degrees each time.

Press OVEN CANCEL. Temperature

adjustment will be retained even

though power failure

ERC4800 Controlled

Twelve hour off Control will automat ically cancel any

cooking operation a nd remove all relay

drives 12 hours aft er the last pad

touch.

AOES3030

+

-

AOCS3040

TIMER

ON / OFF

CLOCK

TIMER

ON / OFF

CLOCK

STOP

TIME

COOK

TIME

STOP

TIME

COOK

TIME

BAKE

BROIL

THERMAL CONVECTION

.

BROIL CLEAN

BAKE

OVEN CONTROL

CONV

CONV

BAKE

MULTI-MO D E O V EN

CONV

BROIL

CLEAN

Replace ERC.

Check sensor wiring, sensor , and

temperature limiter.

Check sensor resistance and wiring.

Check sensor resistance and wiring.

Verify glass to adaptor board connection,

replace glass panel.

Check latch switch.

Check latch switch and door motor.

Verify operation of door latch switc hes.

While increasing or decreasing oven

temperature, this does not affect selfcleaning temperat ure.

©2003 Maytag Appliances Company 16021875 Rev. 0

11

Page 12

Component Testing Information

!

WARNING

To avoid risk of electrical shook, personal injury or death: disconnect power to oven before servicing, unless

testing requires it.

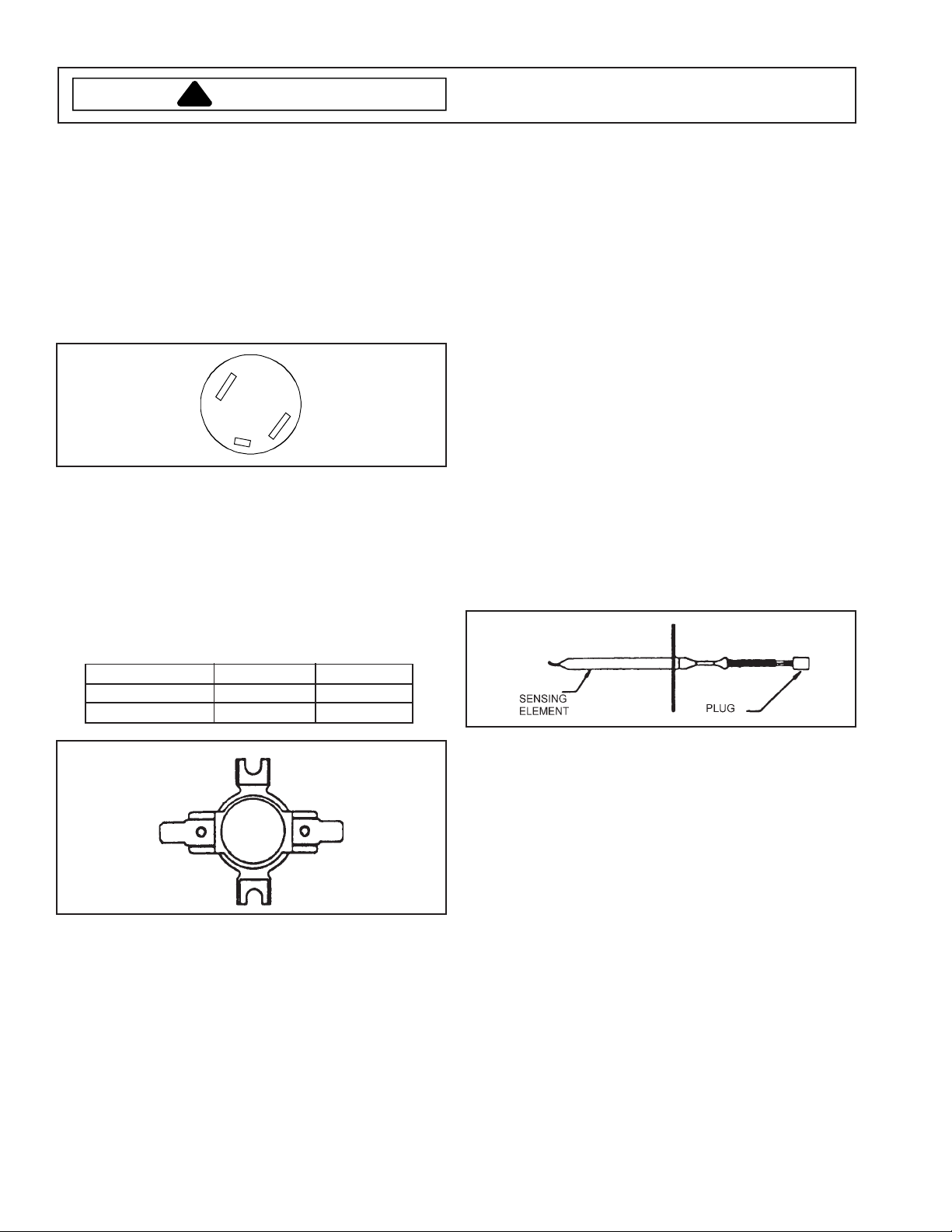

Illustration Component Test Procedure Results

ERC4800 Controlled

E1

E3

K10

E17

Oven

Light

E16

K4 K2

E11

Bake

E10

K5

E13

Broil

E12

K6

Double

Line Brk

E18

E2

K11

E14

Panel

Light

E15

E6

Conv.

Element

E7

K3

E8

Door

Lock

E9

E19

K1

E4

Conv.

Fan

E5

Child lock out This is a safety feature that can be

used to prevent chi ldren from

accidentally programming the oven. It

disables the elec tronic oven control .

Press and hold Bake and Cook Time

for 10 seconds. “OFF” will display

where the temperature normally

appears.

To reactivate the c ontrol, press and

hold Bake and Cook Time for 10

seconds. Child l ockout features must

be reset after a power failure.

Relay board Listen for relay to actuate.

Verify input and output power.

ERC/Adapter board

F1 - Control malfuct ion. Replace ERC.

assembly

If relay does not ac tuate, verify power to

relay.

Field Selectable Options

Standard: The standard setup is 8. This is a 12 hour type of clock, 60 Hz line frequency and an oven with a

convection fan.

Clock Time Format 12 or 24 hour format

The time of day and the stop time can be displayed in either a 12 or 24 hour format. The control will come in a 12

hour format and can be changed to a 24 hour format from the front control panel.

Clock Time Base 60 or 50 Hz input line frequency

This is a time reference for the clock, timer, and internal timing of the control. The control will select the frequency

automatically when the control is powered up.

Selecting Options

In order to select the field selectable options, Press and hold the CLOCK pad on power up of the control. To change

the options press one of the slew pads until the desired option appears and in approximately 9 seconds the control

will change to the normal operation or once selected press the CANCEL pad. The right time digit will indicate the

current options selected as listed in the table below. (Standard setting is 8.)

Code Number 24 Hour Clock 50 Hz No Convection Fan

8

9 X

H

r X X

o

d X

X

X

X

−

X X

Blank X X X

X = indicates Selected = indicates Not Selected

12

16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 13

Component Testing Information

!

WARNING

To avoid risk of electrical shook, personal injury or death: disconnect power to oven before servicing, unless

testing requires it.

Element Conditions

Relay drive requirements are defined as a percentage of on time based on a 60 second cycle.

Bake .......................First rise to temperature = 100% bake, 50% broil, then 100% bake, 25% broil

Broil........................100% broil, 0% bake

Clean......................100% broil, 25% bake

Convection ............First rise to temperature = 100% bake, 50% broil, then 100% Convection element

For convection bake or convection broil refer to bake and broil specifications

Continuity is indicated as 100Ω and below. Each pad must be pressed to perform the following test.

J1-19

SLEW

UP

J1-8

BAKE

TIMER

J1-9

BROIL

CLOCK

COOK

TIME

J1-16

J1-18

CANCEL

SLEW

DOWN

Switch Matrix f or A OE S 3 03 0

J1-10

CLEAN

STOP

TIME

J1-11

OVEN

LIGHT

J1-12

J1-14

J1-13

J1 - 2

J1 - 3

J1 - 4

J1 - 5

J1 - 7

J1 - 6

J1 - 1

J1 - 20

J1-19

SLEW

UP

J1-8

J1-16

J1-18

CANCEL

1

SLEW

DOWN

Switch Ma tr ix for A OCS3 0 4 0

J1-9

BROIL

BAKE

1

1

TIMER CLOCK

COOK

TIME

1

J1-10

CLEAN

1

STOP

TIME

J1-11

CONV

BAKE

1

OVEN

LIGHT

J1-12

CONV

BROIL

1

PANEL

LIGHT

J1-13

CONV

1

J1-14

J1 - 2

J1 - 3

J1 - 4

J1 - 5

J1 - 7

J1 - 6

J1 - 1

J1 - 20

Top

Ribbon Cable

Control

Panel

Pin 1 is located at the

Bottom

bottom of the connector.

©2003 Maytag Appliances Company 16021875 Rev. 0

13

Page 14

Testing Procedures

C

!

WARNING

Oven Door Switch

Clean Safety/Light Switch (Power Off)

1. The switch has NO (normally open), NC (normally

closed), and C (common) contacts.

2. Check the switch with an ohmmeter between C and

NC with the plunger out. Continuity should exist.

With the plunger in, no continuity.

3. Check the switch with an ohmmeter between C and

NO with the plunger in. Continuity should exist. With

the plunger out, no continuity.

C

NOTE: When facing the range, the switch is on the left.

N

NO

Oven High Limit/Fan Switch

Oven high limit is located on the rear of insulation

retainer and connecting to the L2 side of electric supply,

this switch is normally closed but will open if external

temperature exceeds 260°F or 115°F, see chart below.

Fan limit switch is located on the right side of insulation

retainer.

Part Number Open Close

31751801 260°F 220°F

308417 115°F 155°F

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Oven Temperature Sensor

The oven temperature sensor can be checked by using

the "Quick Test Mode" covered in this section of

manual or detail testing can be accomplished as

follows.

The oven temperature sensor is mounted in the oven

cavity and electrically connected to the ERC. Following

is approximate resistance.

75°F—1082 ohms

350°F—1656 ohms

550°F—2056 ohms

880°F—2686 ohms

Sensor resistance can be checked by removing the

sensor interconnect harness plug from the ERC and

inserting ohmmeter leads into the harness connector

plug. A resistance reading of approximately 1100 ohms

should be indicated at ambient room temperature

(75°F.). If a higher resistance is indicated then remove

sensor from oven, disconnect sensor from harness at

plug, and recheck sensor resistance to assure that the

problem is in the sensor and not in the interconnect

harness or due to a bad connection.

NOTE: Sensor resistance will increase if held in your

hand.

Blower Motor

Fan may come on at any time to cool components

down.

1. Turn off power to oven.

2. Remove oven from wall cutout.

3. Remove screws securing outer cabinet top shield to

outer cabinet wrapper shield.

4. Disconnect wires from motor terminal connectors.

5. Attach ohmmeter leads to terminal tabs on motor.

1. Turn off power to range.

2. Remove oven from wall cutout.

3. Remove screws securing outer cabinet top shield to

outer cabinet wrapper shield.

4. Disconnect wires from switch terminal connections.

5. Attach ohmmeter leads to switch terminals. At

ambient room temperature (70°F.) continuity should

be indicated.

14 16021875 Rev. 0 ©2003 Maytag Appliances Company

6. A resistance of ohms should be indicated but may

vary with each motor tested. This test is to check

the motor winding for an open or shorted winding. If

zero or infinite ohms is indicated, the motor winding

has failed and the motor must be replaced.

Page 15

Testing Procedures

.

!

WARNING

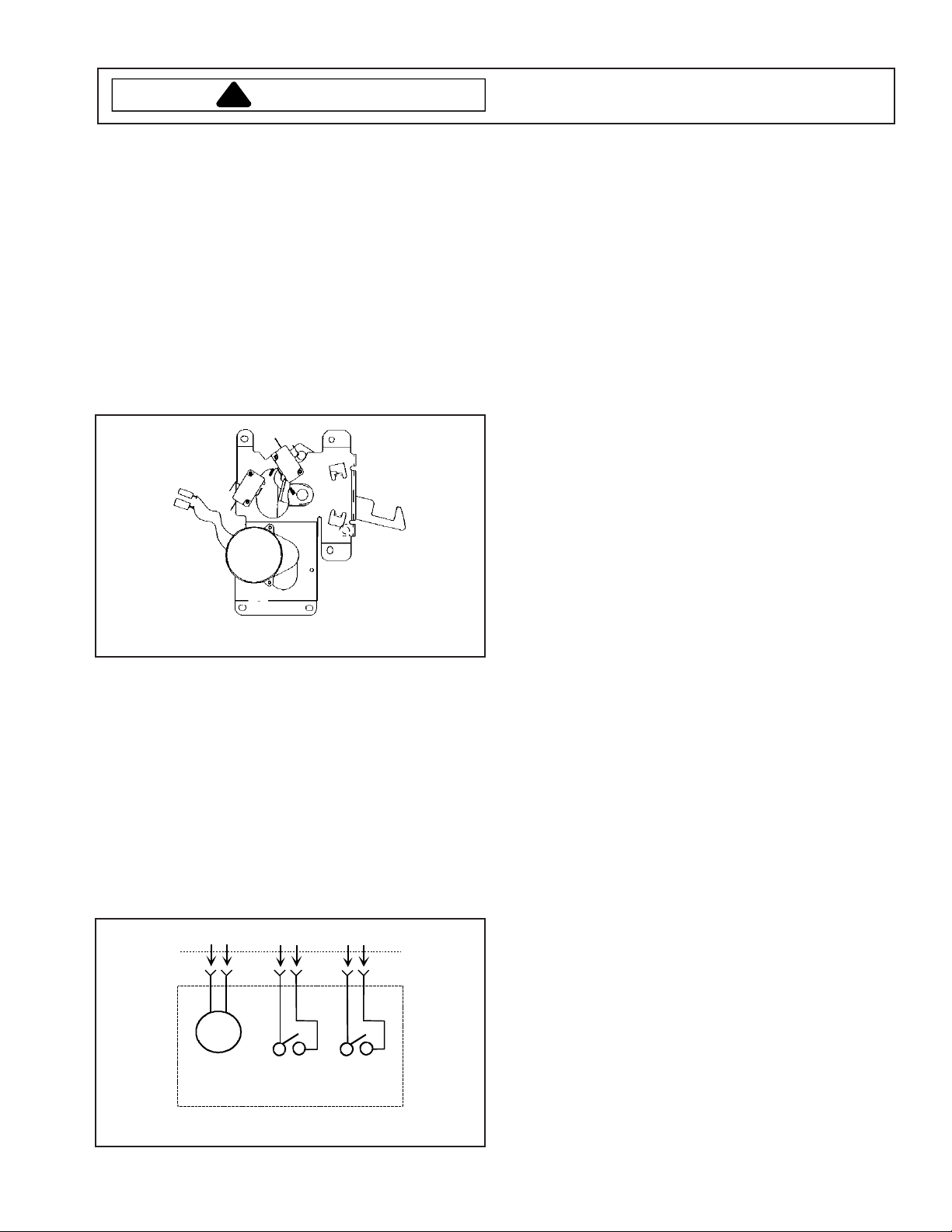

Auto Latch Motor

Do not remove latch motor from latch assembly. If latch

motor is defective, replace latch assembly.

1. Disconnect power .

2. Slide oven out from wall cutout approximately 6

inches to gain access to control panel screws.

3. Remove screws securing control panel to unit, and

pull control panel out of unit to gain access to latch

assembly.

4. Disconnect lead wires from latch motor.

5. Connect jumper cord leads to latch motor.

6. Connect jumper cord to 110 AC power source.

7. Replace if latch motor fails to operate.

8. Reverse procedure to reconnect.

Door Latch Assembly

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Convection Fan Motor

1. Turn off power to oven.

2. Remove oven from wall cutout.

3. Remove access fan plate to gain access to

convection fan motor.

4. Disconnect wires from motor terminal connectors.

5. Attach ohmmeter leads to terminal tabs on motor.

6. A resistance reading of 15-30 ohms should be

indicated but may vary with each motor tested. This

test is to check the motor winding for an open or

shorted winding. If zero or infinite ohms is

indicated, the motor winding has failed and the

motor must be replaced.

Convection Element Testing

1. Disconnect power to oven.

2. Remove screws securing oven door to hinges and

remove door.

3. Remove screws securing fan cover to gain access

to convection element.

4. Remove screws securing convection element, and

pull gentally outward to gain access to wire

terminals.

5. Remove wire connector from element.

6. Attach ohmmeter leads to each of the element

terminals. Set ohmmeter to RX1 or RX10 scale.

7. Low ohms or continuity should be indicated.

Auto Latch Switches

Both unlock and lock door latch switches may be

replaced.

1. Perform steps 1 through 3, from “Auto Latch Motor”.

2. Disconnect lead wires from door latch switch

(unlock).

3. Set ohmmeter to the RX1 scale.

4. Attach meter leads to door latch switch (unlock).

5. Depress actuator arm. The meter should read

continuity.

6. Reverse procedure to reconnect.

7. Use the same procedure to test the door latch switch

(lock).

L1 L2

M

120 VAC

Motor

COM NO

Lock

Switch

S.P.N.O.

COM NO

Unlock

Switch

S.P.N.O

Broil Element Testing

1. Disconnect power to oven.

2. Remove screws securing oven door to hinges and

remove door.

3. Remove screws securing broil element reflector.

4. Gentally pull downward and out to gain access to

wire terminals.

5. Remove wire connector from element.

6. Attach ohmmeter leads to each of the element

terminals. Set ohmmeter to RX1 or RX10 scale.

7. Low ohms or continuity should be indicated.

Bake Element Testing

1. Disconnect power .

2. Remove oven from wall cutout.

3. Remove screws securing element panel.

4. Remove screws securing element access plate.

5. Remove wire connector from element.

6. Attach ohmmeter leads to each of the element

terminals. Set ohmmeter to RX1 or RX10 scale.

7. Low ohms or continuity should be indicated.

Double Switch

©2003 Maytag Appliances Company 16021875 Rev. 0 15

Page 16

Disassembly Procedures

Electrical

F

r

r

et

!

WARNING

WARNING

!

To avoid risk of personal injury or property damage

this unit requires a two man lift when lifting unit in or

out of cutout.

Removing and Replacing Oven

1. Turn off power to the oven at the circuit breaker.

2. Open oven door and remove screws securing unit to

the wall.

3. Pull the oven forward out of the cabinet opening.

4. Disconnect or unplug the power cord leading from

unit to fuse box or junction box depending on unit.

5. Replace the oven using the installation instructions.

Control Panel

1. Turn off power to unit.

2. Open oven door and remove screws securing unit to

the wall.

3. Slide unit approximately 6 inches out of wall cutout.

4. Remove screws securing control panel to unit,

located on the outer portion of trim.

5. Gently pull control panel forward to gain access to

wire terminals.

WARNING

!

While unplugging electrical connections, pins may be

damaged, use extreme care when disconnecting.

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

WARNING

!

While unplugging electrical connections, pins may be

damaged, use extreme care when disconnecting.

3. Disconnect all electrical connection from E.R.C. unit.

4. Remove screws securing E.R.C. to control glass

panel.

5. Reverse procedure to reinstall E.R.C..

Transformer/Relay Board

1. Turn power off to unit.

2. See “Control Panel” for removal.

3. Disconnect and label wire terminals.

4. Release plastic tabs securing circuit board to control

glass panel.

5. Reverse procedure to reinstall.

Oven High Limit/Fan Control Switch

1. Turn power off to unit.

2. Open oven door and remove screws securing unit to

the wall.

3. Remove oven from cutout opening.

4. Disconnect or unplug the power cord leading from

unit to fuse box or junction box depending on unit.

5. Remove screws securing outer wrapper top cover to

outer wrapper cover.

6. Disconnect and label wire terminals connected to

limit switch.

6. Disconnect and label wire terminals.

7. Reverse procedure to reinstall control panel.

insulator

Contr ol

panel

assembly

ERC/P.C. Board

1. Turn off power to unit.

2. See “Control Panel” for removal.

Blowe

moto

brack

Blower

motor

Oven

high

limit

Fan

control

switch

ront of Unit

7. Remove screws securing high limit switch.

8. Reverse procedure to reinstall switches.

16 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 17

Disassembly Procedures

!

WARNING

Oven Sensor

1. Turn off power to unit

2. Open oven door or remove oven door, see “Door

Removal”.

3. Remove screws securing sensor to top right rear

corner of oven cavity.

4. Pull sensor forward, manuver wires through

insulation to disconnect wire plug connector.

5. Reverse procedure to reinstall sensor.

Bake Element

1. Turn off power to unit.

2. Open oven door and remove screws securing unit to

the wall.

3. Remove oven from cutout opening.

4. Disconnect or unplug the power cord leading from

unit to fuse box or junction box depending on unit.

5. Remove screws securing access element panel.

6. Remove screws securing element panel.

7. Disconnect wire terminals from bake element.

8. Remove screws securing element support bracket.

9. Gently pull element support bracket out.

10. Remove screws securing bake element to support

element bracket.

11.Reverse procedure to reinstall bake element.

Broil Element/Broil Element Reflector

1. Turn off power to unit.

2. Open oven door or remove oven door, see “Door

Removal”.

3. Remove screws securing broil element reflector to

top of oven cavity.

4. Pull front of broil element reflector down and forward

to allow disconnection of terminals on each element

leg.

5. Remove rivets securing broil element brackets to

broil element reflector.

6. Reverse procedure to reinstall broil element.

NOTE: Use rivets to fasten broil element brackets to

broil element reflector.

Convection Heating Element

1. Turn off power to unit.

2. Open oven door or remove oven door, see “Door

Removal”.

3. Remove screws securing fan cover to rear of oven

cavity.

4. Remove screws securing convection heating

element to rear wall of oven cavity.

5. Pull element forward to expose wire connections for

disconnection.

6. Reverse procedure to reinstall convection heating

element.

©2003 Maytag Appliances Company 16021875 Rev. 0 17

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Convection Fan Blade

1. Turn off power to unit.

2. Open oven door or remove oven door, see “Door

Removal”.

3. Remove screws securing fan cover to rear of oven

cavity.

4. Using an adjustable wrench, and turning clockwise,

remove the nut in center of convection fan blade.

(Nut is Left Hand Thread).

5. Remove fan blade from D stem motor shaft.

NOTE: Behind fan blade is a washer and C clip on

motor shaft which must be in position for

correct reassembly. (To prevent Fan Blade

hitting cavity).

Convection Fan Motor

1. Turn off power to unit.

2. Open oven door and remove screws securing unit to

the wall.

3. Remove oven from cutout opening.

4. Disconnect or unplug the power cord leading from

unit to fuse box or junction box depending on unit.

5. Remove convection fan blade and spacer washer,

see "Convection Fan Blade" procedure.

6. Remove access fan panel from outer wrapper cover.

7. Disconnect and label wires from convection fan

motor.

8. Remove screws securing convection fan motor

assembly to convection motor mounting bracket.

9. Reverse procedure to reinstall.

Automatic Oven Door Latch Assembly

1. Turn off power to unit.

2. See “Control Panel” for removal.

3. Disconnect and label wire terminals.

4. Remove screws securing latch assembly to chassis.

5. Reverse procedure to reinstall door latch assembly.

Door Plunger Light Switch

1. Turn off power to unit.

2. Remove control glass panel, see “Control Panel”.

3. Squeeze metal tab and push switch outward to gain

access to wire terminals.

4. Label and disconnect wire terminals from switch.

5. Reverse procedure to reinstall.

Page 18

Disassembly Procedures

!

WARNING

Oven Light Bulb/Oven Light Socket

1. Turn off power to unit.

2. Open oven door to gain access to oven light.

3. Unscrew (counterclockwise) glass knurled dome.

4. Using a glove, unscrew (counterclockwise) oven light

bulb.

NOTE: Proceed with the following steps for oven light

socket removal.

5. Remove screws securing unit to the wall.

6. Remove oven from cutout opening.

7. Disconnect or unplug the power cord leading from

unit to fuse box or junction box depending on unit.

8. Remove screws securing outer wrapper top cover

and remove.

9. Carefully displace fiberglass insulation away from rear

of light socket.

10. Push inner assembly of light socket towards rear of

range.

11.Disconnect wires from light socket.

12. Reverse procedure to reinstall light socket.

Reposition insulation around lamp socket. Do not

overtighten.

NOTE: Reposition fiberglass insulation around oven

light socket to eliminate possibility of heat

related problems.

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

5. Remove broil reflector/element, convection fan cover,

convection element, convection fan blade, oven light

cover , light bulb, oven light socket,heat sensing

element, smoke eliminator screws, and disconnect

ground wire from oven light bracket.

6. Remove screws securing outer wrapper top cover,

and outer wrapper cover.

7. Remove screws securing chip cover and remove

chip cover.

8. Remove screws securing tank hooks, located on the

outside rear of the unit.

9. Using both hands, press upward in the back of oven

cavity to release tank hooks.

10. Grasp either the right or left corners of oven cavity

to manuver cavity outward. If problems arise getting

cavity started outward, use a small thin plastic or

wood prying device in the corners of the cavity to

start cavity moving outward.

11.Transfer oven light bracket to replacement tank.

12. Reverse procedure to assemble.

NOTE: Unit should be run through at least one clean

cycle to set insulation.

Oven Door Removal

1. Open oven door and remove screws securing door

to hinge assembly.

2. Place oven door in first stop position, then grasp

both sides and lift up off the hinges.

3. Reverse procedure to assemble.

Oven Tank Removal

1. Turn off power to unit.

2. Open oven door and remove screws securing unit to

the wall.

3. Remove oven from cutout opening.

4. Disconnect or unplug the power cord leading from

unit to fuse box or junction box depending on unit.

Frameless Door Disassembly

1. Remove oven door, see “Door Removal”.

2. Remove screws on right and left sides of oven door.

3. Remove screws securing door liner to door face

assembly

4. Remove screws securing bottom shield and door

bottom insulation.

5. Remove screws securing inner glass support

securing top glass mounting brackets and bottom

glass mounting brackets.

6. Remove glass mounting bracket and glass window.

7. Remove screws securing heat door liner shield and

remove.

8. Remove screws securing door handle.

9. Reverse procedure to reassemble.

NOTE: When reassembling door, verify HB II marking

on the glass is facing towards the heat (in side

of the oven).

18 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 19

Disassembly Procedures

!

WARNING

Oven Door Hinge

1. Turn off power to unit.

2. Remove oven door, see “Door Removal”.

3. Carefully open the hinge fully, and insert a wooden

dowel or screwdriver bit into opening marked A on

the following diagram.

4. Remove the top and bottom screws securing hinge

assembly to the front frame.

5. Slide the hinge assembly up and move top of hinge

towards rear of the range. Withdraw hinge

assembly through the frame opening.

6. Reverse procedure to reinstall oven door hinge

assembly.

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Vent Assembly/Smoke Eliminator

1. Perform steps 1 through 8 of “Blower Motor”.

2. Remove screws securing vent assembly to outer

cabinet top wrapper.

3. Raise back of vent assembly and slowly maneuver

vent assembly away from unit.

4. Remove screws securing smoke eliminator, located

inside oven on top of oven cavity.

5. Reverse procedure to reinstall.

Outer Trim Assembly

1. Turn off power to unit.

2. Open oven door and remove screws securing unit to

the wall.

3. Slide unit approximately 6 inches out of wall cutout

being carefull to not damage control panel.

4. Remove screws securing outer trim assembly to unit.

5. Reverse procedure to reinstall.

Blower Motor

1. Turn power off to unit.

2. Open oven door and remove screws securing unit to

the wall.

3. Remove oven from cutout opening.

4. Disconnect or unplug the power cord leading from

unit to fuse box or junction box depending on unit.

5. Remove screws securing outer wrapper top cover to

outer wrapper cover.

6. Remove screws securing blower vent bracket to

outer wrapper cover and blower motor assembly.

7. Disconnect and label wire terminals connected to

blower motor.

8. Remove screws securing blower motor assembly to

vent assembly.

9. Reverse procedure to reinstall.

©2003 Maytag Appliances Company 16021875 Rev. 0 19

Page 20

Disassembly Procedures

h

Door face

assembly

!

WARNING

Glass

window

Door linner

shield

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Oven door

gasket

Door

insulation

retainer

Window

frame

Door

linner

Glass window

double coated

Oven door

insulation

Door

andle

Insulation

Bottom shield

Door Assembly

20 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 21

Appendix A

©2003 Maytag Appliances Company 16021875 Rev. 0 A—1

Page 22

Installation Instructions

Packaging Material

Remove protective packing materials from oven. Tape

residue can be removed with a soft cloth and alcohol.

Oven DImensions

A

B

I

H

A. 28 1/4"B.3

D. 23 1/8" E.. 26 5/8"F.1

G. 1 1/4" H. 29 3/4" I. 28 3/8"

Depth of oven with handle 26 1/2"

Depth without handle 24 1/2"

1

F

C

D

E

F

G

/2" C. 23 1/4"

1

/16"

Line Voltage Requirements

Line voltage must not exceed rated voltage. Line

voltage less than rated voltage will result in slow

heating. Wiring system must conform to U.L. Standards

and National Electrical Code. Installation must conform

to all local, municipal and state building codes, and local

utility regulations. Oven must be connected only to a

supplied circuit as specified on rating plate.

This oven requires 3 wires, 115/230-120/240 volts, 60

Hertz A.C. Unit is equipped with a No. 10 ground wire in

conduit. Oven should be fused separately from other

appliances. Verify electric power is off from fuse box to

junction box until oven is installed and ready to operate.

Junction box should be installed in shaded area as

shown and connected to a suitable ground.

A

B

C

Oven Location

Oven can be installed in wall or in an undercounter

kitchen cabinet. For installation below cooktops see

source from whom cooktop was purchased, or refer to

cooktops owner’s manual.

Cutout measures 28 1/2" wide x 27 1/4" high. Provide flat

bottom for oven to rest on. Bottom must be level and

flush with bottom edge of opening, and square to front

of cabinet for proper installation.

A. Center of wall oven cutout

B. 2 1/2" from bottom of countertop

C. 14 1/4" from center of cutout

House wiring and fusing must comply with local wiring

codes. If no local codes are applicable, wire in

accordance with the National Electrical Codes.

A. 36" B. 23 1/2" minimum

C. 3 1/2" from floor D. 28 1/2"

E. 27 1/4"

A—2 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 23

G

Installation Instructions

Connecting Wiring

!

WARNING

To avoid risk of personal injury or electrical shock, do

not ground through neutral wire if installation is in a

mobile home or if local codes do not permit

grounding through a neutral.

Improper connections of aluminum house wiring to

copper lead can result in property damage, personal

injury or fire. Use only connectors designed for

joining copper to aluminum and follow manufacturers'

recommended procedure closely.

1. With oven positioned in front of cabinet opening,

connect wire leads extending from conduit to

junction box. Verify neutral (white) wire is connected

to appropriate terminal. Check local code to see

which option should be used in grounding unit.

Option 1

Attach oven ground wire (green or bare) to junction box

(if grounded) or a suitable ground.

Option 2

Connect oven ground wire (green or bare) to house

ground feed wire (green, bare, or white). If grounding

through white wire, observe above warning.

If oven is used in a mobile home or if local codes do not

permit grounding through neutral, open connection and

use grounding lead to ground unit in accordance with

local codes. Connect neutral lead to branch circuit

neutral conductor in usual manner.

2. Connect red and black wires to appropriate house

electrical wiring.

3. Verify wiring by connecting electrical power at fuse

box and checking for proper operation of unit.

• Some interior parts are finished with a protective

coating of oil. When heated for first time oil will

burn off and there will be some odor and smoke.

• Do not block air openings in bottom front of oven

when making installation.

4. Insert oven into cabinet and check for flush fit to face

of cabinet. If necessary screw unit to cabinet using

holes in top and bottom of trim and screws provided.

RD

W

A

A. Conduit

W. White neutral wire

GRD. Bare ground wire

©2003 Maytag Appliances Company 16021875 Rev. 0 A—3

Page 24

C

Oven and Cooktop

adjacent cabinet

Centerline of cabinet

Installation Instructions

Wall Oven and Cooktop Combination

Installation Specifications

Installer

NOTE: Save these instructions for local electrical

inspectors use.

Leave these instructions and other literature with

consumer for future reference.

Installations specified in these instructions are approved

for the AKT3000, AK2T30, AK2T36, AK2H30, AK2H36,

AKR3000 cooktops, and AKED3060, AKES3060

downdraft cooktops, above AOCS3040 and AOES3030

Amana wall ovens. Stacked and side-by-side wall oven

installation applies to Amana AOCS3040 and AOES3030

wall ovens only.

For additional individual unit requirements and clearances

refer to the installation instructions packaged with the wall

oven and cooktop.

All installations specified are for a 36" cabinet height,

23 1/2" minimum depth, and 3 1/4 x 10" venting.

WARNING

!

To avoid property damage or personal injury,

information in these installation specifications must be

followed exactly.

cutout

junction box

installed in

C

C

Listed by Underwriter's Laboratories

AKED3060 or AKES3060 Downdraft

Cooktop above AOES3030 or AOCS3040

Wall Oven

Junction box location and 10 1/8 x 3 3/8 inch vent location

indicated in black.

A — 6 inches

B — 4 1/2 inches (from top of countertop)

C — 24 inches

D — 4 3/8 inches from top of countertop to top of vent

cutout

H — 28 1/2 inch wall oven cutout width

I — 27 1/4 inch wall oven cutout height

J — 28 7/8 inch cooktop cutout width

K — 20 5/8 inch cooktop cutout depth

L — 4 1/2 inches from top of countertop to top of wall

oven cutout

K

L

I

H

J

A—4 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 25

n

n

H

Installation Instructions

AKED3060 or AKES3060 Downdraft

Cooktop above AOES3030 or AOCS3040

Wall Oven in an Island Application

Illustration shows dimensions for venting behind, and to

the left side of the wall oven. Left side venting for wider

AK2H36, AK2T36, 36" Electric Cooktop

Installed above AOES3030 or AOCS3040

Wall Oven

Cooktop and wall oven junction box location indicated in

black.

island applications only. Junction box and vent locations

indicated in black. Grey shaded area indicates wall oven

floor.

N

H

M

I

G

Shaded area

represents

bottom of

wall oven

Centerline of

island

top cutout

J

L

F

A

B

Junctio

K

C

box

locatio

D

E

E

G

F

D

Centerline of cabinet

top cutout

A

B

C

A — 6 inches

B— 4 1/2 inches (From top of countertop)

C — 24 inches

D— 3 1/2 inches minimum from back wall of island

cabinet and back of wall oven

E — 28 inch minimum island depth

F — 23 1/2 inch minimum

G — 28 1/2 inches

H — 27 1/4 inches

I—3 1/2 inch minimum from side wall of island to

side wall of oven

J — 6 inches from back of cooktop cutout to back of

vent cutout

A— 4 1/2 inches minimum from top of countertop

B — 8 inches maximum

C — 24 inches minimum

D — 28 1/2 inches wall oven cutout width

E — 27 1/4 inches wall oven cutout height

F — 34 1/8 inches cooktop cutout width

G — 20 3/4 inches cooktop cutout depth

H— 3 3/16 inches from top of counter top to top of

wall oven cutout

K— 4 7/32 inches from centerline to vent cutout

L — 28 7/8 inches

M — 20 5/8 inches

N— 4 1/2 inches from top of countertop to top of wall

oven cutout

©2003 Maytag Appliances Company 16021875 Rev. 0 A—5

Page 26

Installation Instructions

30" Electric Cooktop AK2H30, AK2T30,

AKR3000, AKT3000, CAK2H30, CAK2T30

Installed above AOES3030 or AOCS3040

Wall Oven

Cooktop and wall oven junction box location indicated in

black.

G

H

F

E

Centerline

of cabinet

top cutout

A

B

C

AOES3030 or AOCS3040 Wall Oven Stacked

Installation

Wall oven junction box location indicated in grey.

D

A— 4 1/2 inches minimum from top of countertop

B — 8 inches maximum

C — 24 inches minimum

D — 28 1/2 inch wall oven cutout width

E — 27 1/4 inch wall oven cutout height

F — 28 7/8 inch cooktop cutout width

G — 20 3/4 inch cooktop cutout depth

H— 3 3/16 inches from top of countertop to top of wall

oven cutout

A— 2 1/2 inches minimum from top of inside cabinet

B — 14 1/4 inches from center of cutout

C — 24 inches minimum

D — 28 1/2 inch wall oven cutout width

E — 27 1/4 inch wall oven cutout height

F — 3 inch minimum space between wall ovens

For a single wall oven installation recommended height

from floor to bottom of cutout is 32 inches.

A—6 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 27

w

0

Installation Instructions

AOES3030 or AOCS3040 Wall Oven Installed Side-by-Side

Wall oven junction box location indicated in grey.

G

E

F

D

A — 1 inch minimum from bottom of countertop

B — 14 1/8 inches maximum from center of cutout

C — 24 inches minimum

D — 28 1/2 inch wall oven cutout width

E — 27 1/4 inch wall oven cutout height

F— 1 3/4 inches minimum

G—7/8 inches minimum from bottom of countertop

to top of cabinet

A

B

C

D

Full divider

A

B

C

E

° tilt

Loosen scre

Tilting Control Panel

Control panel can be adjusted to tilt from 0° to 12° to

make more visible.

1. Loosen screws on top, and sides of control panel and

12° tilt

pivot screw on bottom, sides of control panel before

installing oven, or while oven partially pulled from

opening.

2. Adjust control panel to desired angle and retighten

screws.

Pivot screw

©2003 Maytag Appliances Company 16021875 Rev. 0 A—7

Page 28

This page intentionally left blank for notes:

A—8 16021875 Rev. 0 ©2003 Maytag Appliances Company

Page 29

Appendix B

©2003 Maytag Appliances Company 16021875 Rev. 0 B—1

Page 30

Programming Instructions—ERC for AOES3030

P

STOP TIME

R

350°

E

BROIL

DELAY BAKE

CLEAN LOCKED

O

N

+

-

LIGHT

OVEN

CANCEL

HR

:

DELAY BAKE CLN

TIME CONTROL

Electronic Oven Control Options

LIGHT— Use to turn light on and off inside oven. Light

will automatically turn on when oven door is opened.

TIMER ON/OFF— Use to time any kitchen function or

cancel timer.

STOP TIME— Use to set delayed bake and delayed self

clean.

CLOCK — Use to set time of day .

OVEN CANCEL— Cancels any cooking or cleaning

function.

COOK TIME — Use to set timed or delayed baking.

BAKE— Use to set bake.

BROIL— Use to set broil

CLEAN— Use to set self-clean.

-

— Use to select temperature or time.

or

+

TIMER

ON / OFF

CLOCK

STOP

TIME

COOK

TIME

BAKE

BROIL CLEAN

OVEN CONTROL

Special Oven Control Functions

Preheat Signal

After setting the oven to cook and selecting a

temperature, oven will preheat. When oven reaches set

temperature, a 1-second signal will sound.

End-of-Cycle Signal

When a timed cycle is complete, three long signals will

sound. End of cycle signal will continue to sound until

CANCEL is touched. If TIMER ON/OFF end-of-cycle

signal is sounding, touch TIMER ON/OFF.

Child Lockout

This is a safety feature used to prevent children from

accidentally programing oven. It disables electronic oven

control. Touch and hold BAKE and COOK TIME for 5

seconds. “OFF” will display where the temperature

normally appears. To reactivate control, press and hold

BAKE and COOK TIME pads for 5 seconds. Child

lockout feature must be reset after a power failure.

12-hour Automatic Cancel

This is a safety feature that prevents oven from continuing

to operate if it has been left on for over 12 hours. If a

cooking function continues longer than 12 hours without

any oven control options being touched, this feature turns

oven off. Any time an option is touched 12-hour

automatic cancel is reset.

Timer Signal

When time elapses, timer beeps 3 times then once every

10 seconds until cancelled.

Increasing

+

or

-

Pad Speed

When setting time and temperature, hold pad to

accelerate rate at which numbers increase or decrease.

Self-diagnostic System

Electronic range control has a self-diagnostic system.

Self-diagnostic system sounds a series of short, rapid

beeps and shows an "F-code" in display when there is a

problem.

B—2 16021875 Rev . 0 ©2003 Maytag Appliances Company

Page 31

Programming Instructions—ERC for AOES3030

o

Quick Reference Instructions

Read “Important Safety Information” before using “Quick

Reference Instructions”. If there are unanswered

questions, refer to detailed sections of this manual.

• Oven cooling fan will come on every time an oven

function is selected and may come on during extended

oven operation.

• Oven display will blink once per second after

disconnection of power or initial start up until clock is

reprogrammed.

Setting Clock

1. Press CLOCK pad.

2. Press

"PM" appears in display .

Setting Minute Timer

1. Press TIMER ON/OFF pad.

2. Press

displayed.

• Timer can be set from 5 seconds to 9 hours and 55

minutes.

3. When time elapses timer beeps 3 times then

approximately once every 7 seconds.

• Press TIMER ON/OFF to cancel beep for up to 5

minutes, or press TIMER ON/OFF and

return to 0:00 .

-

pad until correct time of day "AM", or

or

+

pad until desired amount of time is

+

+

or

-

to

Baking or Broiling

1. Press BAKE or BROIL pad.

2. Press

-

pad until desired temperature or broiler

or

+

setting is displayed.

3. Oven begins baking or broiling automatically .

Canceling Bake or Broil

Press OVEN CANCEL pad.

Self Cleaning

1. Remove oven racks and all utensils from oven. Clean

excess spills from oven.

2. Press CLEAN pad.

3. Press

-

pad to adjust clean time. Clean can be

or

+

set from 2 to 4 hours. Minimum recommended

cleaning time is 3 hours.

4. Oven begins cleaning automatically .

Canceling Self-Cleaning Cycle

1. Press OVEN CANCEL pad.

2. When oven has cooled to a safe temperature, door

will unlock.

• When “LOCKED” no longer displays, oven

temperature is safe. Do not force door while

“LOCKED” displays.

Canceling Minute Timer

• Press TIMER ON/OFF pad for approximately 5

seconds.

• When canceling minute timer do not press OVEN

CANCEL pad. Pressing OVEN CANCEL pad cancels

cooking function.

©2003 Maytag Appliances Company 16021875 Rev. 0 B—3

Page 32

Programming Instructions—ERC for AOES3030

Bake

Open oven door to confirm nothing is stored in oven

cavity and set racks to proper height before baking.

Preheat before placing food inside oven. Bake element is

concealed under the Spillsaver™ oven bottom.

1. Press BAKE pad.

2. Press

-

pad until desired temperature is

or

+

displayed.

• T emperature begins at 350°F and can be set from

170° to 550°F in 5° increments.

• Time of day , temperature, “BAKE”, and “ON”

display.

• T emperature start s at 100°F and increases in 5°

increments until reaching set temperature. Some

minor smoking is normal when using oven for first

time. When cook temperature is reached, oven

signal sounds for approximately 1 second.

3. Press OVEN CANCEL pad when finished.

• Remove food from oven when cooking time has

elapsed. Food left in oven can overcook.

Timed Bake

1. Place food in oven, or preheat oven depending on food

item.

2. Press COOK TIME pad.

3. Press

displayed. Time can be set up to 11 hours and 50

minutes.

4. Press BAKE pad.

5. Press

displayed. Temperature can be set from 170° to

550°F.

• “TIMED”, “BAKE”, will light in display. Oven will

begin to bake at preset time and "ON" will light in

display . When cooking time has elapsed, end-ofcycle signals 3 times and oven will automatically

turn off. End-of-cycle signals every 7 seconds until

cancel is pressed.

• T o cancel remaining cooking time press OVEN

CANCEL pad.

• Food should be removed from oven when cooking

time has elapsed. Food left in oven may overcook.

-

pad until desired cook time is

or

+

-

pad until desired temperature is

or

+

Delayed Bake

1. Place food in oven.

!

CAUTION

T o reduce risk of food poisoning due to bacterial growth

and production of toxins, never hold meat, milk, fish or

eggs for more than 2 hours before cooking.

2. Press COOK TIME pad.

3. Press

-

pad until desired cooking time appears

or

+

in display . T ime can be set up to 11 hours and 50

minutes.

4. Press STOP TIME pad.

5. Press

-

pad until desired stop time appears in

or

+

display. Electronic control will calculate start time.

6. Press BAKE pad. 350° will appear in display .

-

7. Press

pad until desired temperature appears

or

+

in display . Temperature can be set from

170° to 550° F.

• "DELAY", "TIMED", "BAKE", will light in display.

Oven will begin to bake at preset time and "ON"

will light in display. When cooking time has

elapsed, end-of-cycle signals 3 times and oven will

automatically turn off. End-of-cycle signals every 7

seconds until OVEN CANCEL pad is pressed.

8. When finished press OVEN CANCEL pad.

• T o cancel remaining cooking time press OVEN

CANCEL pad.

• Food should be removed from oven when cooking

time has elapsed. Food left in oven may overcook.

Broiling

• Oven door must be closed while broiling.

• Remove excess fat from meat before broiling. Cut

edges of meat to prevent curling.

• Place food on a cold ungreased broiling pan. If pan is

hot, food sticks.

• All food should be turned at least one time, except fish.

Begin broiling with skin side down.

• Season meat after it has browned.

• Broiling does not require preheating.

• Begin cooking using suggested rack levels. See

“ Broiling Guide” section to test broiler results. If food is

not brown enough, cook on a higher rack position. If

food is too brown, cook on a lower rack position.

!

WARNING

• To avoid risk of fire, do not line broiler grid with foil.

Foil may trap grease on top of grid, close to element,

causing a fire.

• Never leave oven unattended while broiling.

Overcooking may result in a fire.

B—4 16021875 Rev . 0 ©2003 Maytag Appliances Company

Page 33

Programming Instructions—ERC for AOES3030

1. Center food on broiling grid and pan, place in oven.

• Oven door must be closed while broiling.

2. Press BROIL pad.

• “BROIL”, and “---” displays.

3. Press

can be set from 170°F to HI.

• Oven will begin to broil automatically . "ON",

"BROIL", and the selected setting will be

displayed.

4. When finished press OVEN CANCEL pad.

-

until desired setting is displayed. Broil

or

+

Self-Cleaning

!

WARNING

T o avoid risk of fire, clean excess spills from oven

interior.

• A small amount of smoke is normal when cleaning.

Excessive smoke may indicate too much food residue

has been left in oven or a faulty gasket.

• Clean oven before it gets too dirty . W ipe up large spills

before self-cleaning.

• Do not use cleaning cycle if oven light cover is not

properly in place.

• Oven light will not work during clean cycle.

1. Remove oven racks and all cooking utensils from

oven. Clean excess spills from oven interior.

2. Press CLEAN pad.

3. Press

displayed. Clean can be set from 2 to 4 hours.

Recommended clean time is 3 hours.

• Oven will begin to clean automatically. "CLEAN",

"LOCK", and "ON" will light in display. As oven

door locks and unlocks "LOCK" will flash in

display . When door is locked, "LOCK" will remain

in display. When cleaning cycle has elap sed, oven

will automatically turn off. End-of-cycle signal will

not sound.

-

pad until desired cleaning time is

or

+

Interrupt Self-Cleaning Cycle

1. Press OVEN CANCEL pad.

2. When oven has cooled to a safe temperature, door

will unlock and can be opened.

Delayed Self-Cleaning

1. Remove oven racks and all cooking utensils from

oven. Clean excess spills from oven interior.

2. Press CLEAN pad.

-

3. Press

displayed.

4. Press STOP TIME pad.

5. Press

displayed. A starting time will automatically be