Maytag 3397600 Installation Manual

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions

with the homeowner.

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for local

electrical inspector’s use.

~.-

Electric Dryer

Appliance as received from factory is

equipped for 2-wire, 230-volt, single- phase,

50-Hz electrical power supply.

It may also be wired for 3-wire, 230-volt,

single-phase, 50-Hz or 3-wire, 240-volt,

single-phase, 60-Hz electrical power supply.

L

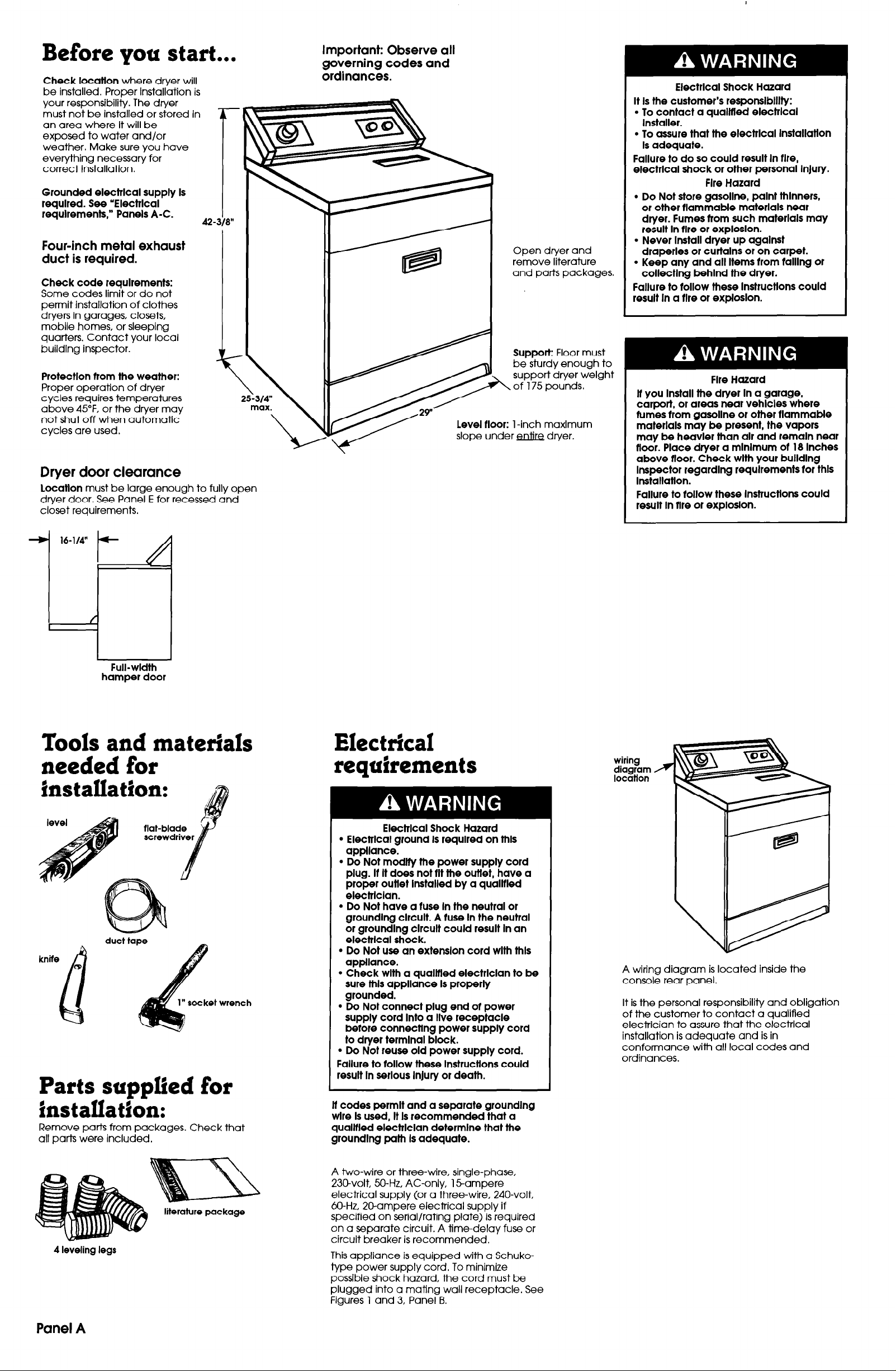

Before you start...

Check location

be installed. Proper Installation is

your responsibility. The dryer

must not be installed or stored in

an area where It will be

exposed to water and/or

weather. Make sure you have

everything necessary for

correct installation.

Grounded electrlcal supply Is

required. See ‘ElectrIcal

requlrements,” Panels A-C.

Four-inch metal exhaust

duct is required.

Check code requirements:

Some codes limit or do not

permit installation of clothes

dryers in garages, closets,

mobile homes, or sleeping

quarters. Contact your local

buildlng inspector.

Protectlon from the weather:

Proper operation of dryer

cycles requires temperatures

above 45°F. or the dryer may

not shut off when automatic

cycles are used.

Dryer door clearance

Locatlon

dryer door. See Panel E for recessed and

closet requirements.

must be large enough to fully open

where dryer will

42-

3)

8”

Important: Observe all

governing codes and

ordinances.

Open dryer and

remove literature

and parts packages.

Support:

be sturdy enough to

support dryer welght

z of 175 pounds,

Floor must

Electrlcal Shock Hazard

It Is the customer’s responslblllty:

l

To contact a quallfled electrlcal

Installer.

. To assure that the electrlcal lnstallatlon

Is adequate.

Failure to do so could result In tlre,

electrlcal shock or other personal Injury.

Fire Hazard

l

Do Not store gasoline, palnt thinners,

or other tlammable materials near

dryer. Fumes tram such materials may

result In tire or exploslon.

l

Never Install dryer up agalnst

draperies or curtalns or on carpet.

. Keep any and all Items tram talllng or

collecting behlnd the dryer.

Failure to tallow these lnstructlons could

result In a fire or exploslon.

Fire Hazard

lt you Install the dryer In a garage,

carport, or areas near vehicles where

fumes tram gasoline or other tlammable

materials may be present, the vapors

may be heavier than alr and remain near

floor. Place dryer a mlnlmum ot 18 Inches

above tloor. Check wlth your bulldlng

Inspector regarding requlrements tar thls

Installation.

Failure to follow these lnstructlons could

result In flre or explosion.

Full-wldth

hamper door

Tools and materials

needed for

hstallation:

kniie

“socket wrench

Parts supplied for

installation:

Remove parts from packages. Check that

all parts were included.

Electrical requirements

Electrlcal Shock Hazard

l

Electrlcal ground Is required on thls

appliance.

l

Do Not modlty the power supply cord

plug. It It does not tlt the outtet, have a

proper outlet Installed by a qualltled

electrlclan.

l

Do Not have a tuse In the neutral or

groundlng clrcult. A tuse In the neutral

or grounding clrcult could result In an

electrlcal shock.

l

Do Not use an extension cord wlth thls

appliance.

l

Check wlth a qualltled electrlclan to be

sure ltils appliance Is properly

grounded.

l

Do Not connect plug end ot power

supply cord Into a live receptacle

before connecting power supply cord

to dryer terminal block.

l

Do Not reuse old power supply cord.

Failure to kllow these Instructions could

result In serious Injury or death.

lt codes permit and a separate groundlng

wire Is used, It Is recommended that a

quallfled electrlclan determlne that the

groundlng path Is adequate.

A wiring diagram is located inside the

console rear panel.

It is the personal responsibility and obligation

of the customer to contact a qualified

electrlcian to assure that the electrical

installation is adequate and is in

conformance with all local codes and

ordinances.

4 leveling legs

Panel A

literature package

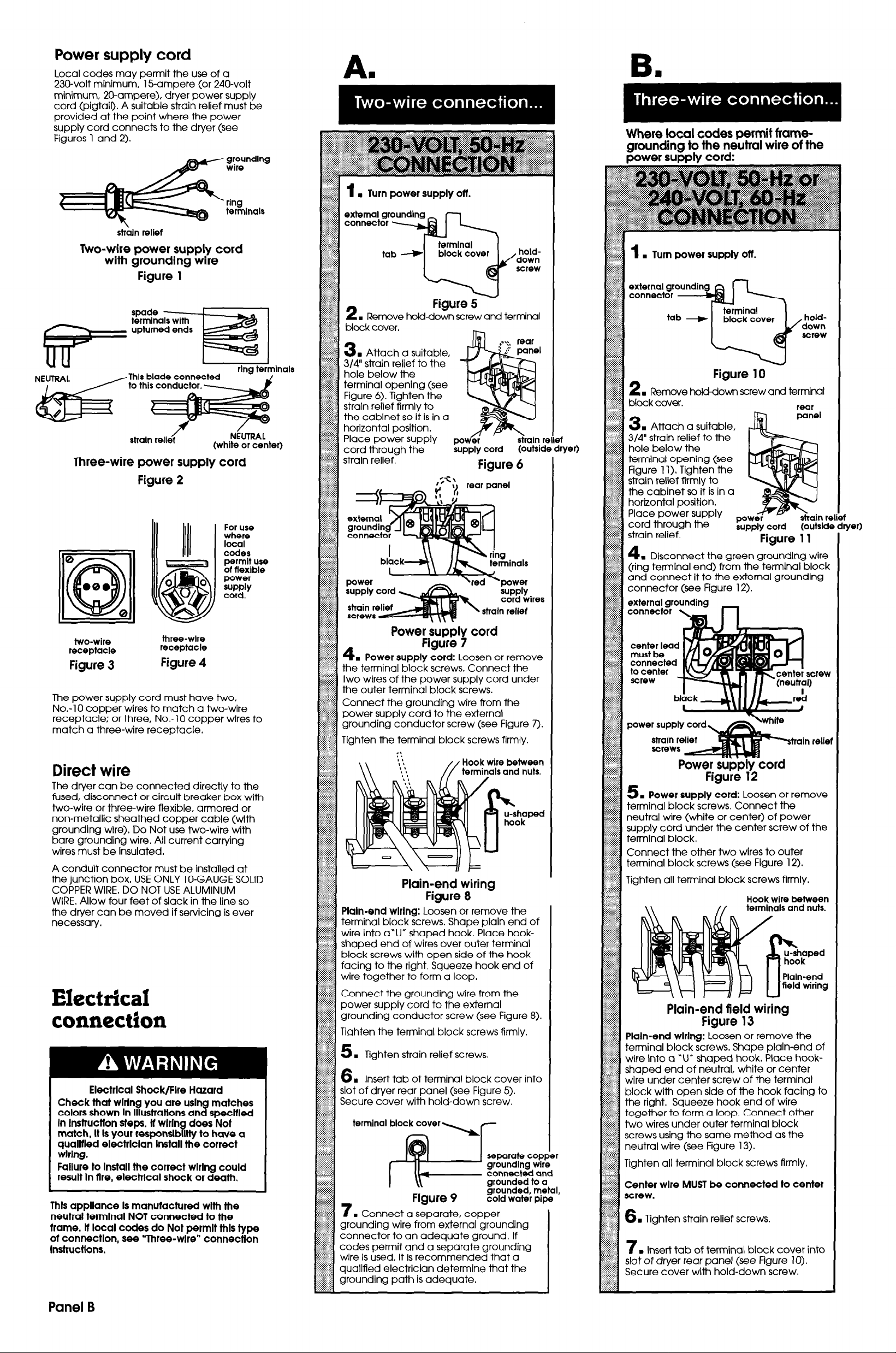

A two-wire or three-wire, single-phase,

23Dvolt, 50-Hz, AC-only, 1 Sampere

electrical supply (or a three-wire, 240-volt,

60-Hz, 20-ampere electrical supply if

specified on serial/rating plate) is required

on a separate circuit. A time-delay fuse or

circuit breaker is recommended.

This appliance is equipped with a Schukotype power supply cord. To minimize

possible shock hazard, the cord must be

plugged into a mating wall receptacle. See

Figures 1 and 3, Panel B.

Power supply cord

Local codes may permit the use of a

230-volt minimum, 15-ampere (or 240-volt

minimum, 20-ampere), dryer power supply

cord (pigtail). A suitable strain relief must be

provided at the point where the power

supply cord connects to the dryer (see

Figures 1 and 2).

grounding

wire

strbln relief

Two-wire power

with grounding wire

Figure 1

strain reliec

Three-wire power

Figure 2

supply

supply

cord

NiUl’RAL

(white or center)

cord

For use

where

local

codes

permit use

of flexible

power

SwPlY

cord.

inals

1

. Turn power supply off.

tab --t

Figure 5

2

. Remove holddown screw and terminal

block cover.

. Attach a suitable,

3

3/B” strain relief to the

hole below the

terminal opening (see

Figure 6). Tighten the

strain relief firmly to

the cabinet so it is in a

horizontal position.

Place power supply

cord through the

strain relief.

~ppiy cord

Figure 6

,;c\

1 rear panel

&bply

cord wires

strain relief

holddown

screw

(outsids

Ilie

,d

Where local codes permit framegrounding to the neutral wire of the

Dower surmlv cord:

1

. Turn power supply ott.

holddown

screw

Figure 10

. Remove hold-down screw and terminal

2

block cover.

. Attach a suitable.

3

3/4” strain relief to the

hole below the

terminal opening (see

Figure 11). Tighten the

strain relief firmly to

the cabinet so it is in a

horttontal position.

Place power supply

cord through the

strain relief.

4

. Disconnect the green groundlng wire

(ring termlnal end) from the terminal block

and connect it to the external grounding

connector (see Figure 12).

external grounding

connector \,

supply cord (outsldc

Figure 11

rear

two-wire

receptacle

Figure 3

The power supply cord must have two,

No.-10 copper wires to match a two-wire

receptacle; or three, No.-1 0 copper wires to

match a three-wire receptacle.

three-wlre

receptacle

Figure 4

Direct wire

The dryer can be connected directly to the

fused, disconnect or circuit breaker box with

two-wire or three-wire flexible, armored or

non-metallic sheathed copper cable (with

grounding wire). Do Not use two-wire with

bare groundlng wire. All current carrying

wires must be Insulated.

A conduit connector must be installed at

the junction box. USE ONLY lo-GAUGE SOLID

COPPER WIRE. DO NOT USE ALUMINUM

WIRE. Allow four feet of stack in the line so

the dryer can be moved if servicing is ever

necessary.

Power SUDDIV cord

1

4. Power supply cord:

the terminal block screws. Connect the

two wires of the power supply cord under

the outer terminal block screws.

Connect the grounding wire from the

power supply cord to the external

grounding conductor screw (see Figure 7).

Tighten

fie terminal block screws firmly.

Loosen or remove

Hook wire

between

Plain-end wiring

plaInmend

terminal block screws. Shape plain end of

wire into a”U” *aped hook. Place hook-

shaped end of wires over outer terminal

block screws with open side of the hook

wiring:

Loosen or remove the

connected

to center

screw

power supply cord

train relic

Figure 12

. Power supply cord:

5

terminal block screws. Connect the

neutral wire (white or center) of power

ther two wires to outer

screws (see Figure 12).

inal block screws firmly.

Loosen or remove

:rew

Electrical connection

Electrlcal Shock/Fire Hazard

Check that wlrlng you are using matches

colors shown In lllustratlons and specltled

In lnstructlon steps. lf wlrlng does Not

match, It ls your responslblllty to have a

qualltled electrlclan Install the correct

wlrlng.

Failure to Install the correct wlrlng could

result In flre, electrlcal shock or death.

I

This appliance Is manutactured wlth the

neutral terminal NOT connected to the

trame. lt local codes do Not permit thls type

ot connectlon, see “Three-wire” connection

Instructions.

1

wire together to form a loop,

Connect the

power supply cord to the external

grounding conductor screw (see Figure 8).

Tighten

5

. Tighten strain relief screws.

6

. Insert tab of terminal block cover into

slot of dryer rear panel (see Figure 5).

Secure cover with hold-down screw.

terminal

7

. Connect a separate, copper

grounding wire from external grounding

connector to an adequate ground, If

codes permit and a separate grounding

wire is used, it is recommended that a

qualified electrician determine that the

grounding path is adequate.

grounding

the terminal block screws

Figure 9

wire from +he

separate copper

groundlng wire

connected and

grounded to a

grounded, metal,

cold water pipe

firmly.

. Tighten strain relief screws.

6

. Insert tab of terminal block cover into

7

slot of dryer rear panel (we Figure 10).

Secure cover witi hold-down screw,

Panel B

Loading...

Loading...