Maytag 318064000 Installation Manual

Part No. 318064000 Rev. B/4372426 Rev. A

Before you start.. . ~;~;,g;;$gy;g~&~~~

Grounded electrical

Instsllation must be done by a qualified

outlet is required. See

supply

requirements,” panel B,

“Electrical requirements,”

installer.

Important: Observe all governing

Panel B.

Proper installation is your responsibility.

codes and ordinances.

Recessed installation

Make sure you have everything

Failure to meet codes and

area must provide

necessary for correct installation. It is the

ordinances could lead to fire or

complete enclosure

responsibility of the installer to comply

electrical shock hazard. around the recessed

with the installation clearances specified

ADDITIONAL SAFEGUARDS

portion of oven.

on the seriaurating plate. The

seriavrating plate is located behind the

. Do not install wall oven

oven door on the front frame.

beneath the work counter.

. The flue discharge shall not be

located below the 36 inch level.

WARNING: If the information

in this manual is not followed

exactly, a fire or explosion

may result causing property

damage, personal injury or

death.

- Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SM.SLL

GAS

. Do not try to light any

appliance.

. Do not touch any electrical

switch; Do not use any

phone in your building.

. Immediately call your gas

supplier from a neighbor’s

phone. Follow the gas

supplier’s instructions.

. If you cannot reach your

gas supplier, call the fire

department.

- Installation and service

must be performed by a

qualified installer, service

agency or the gas supplier.

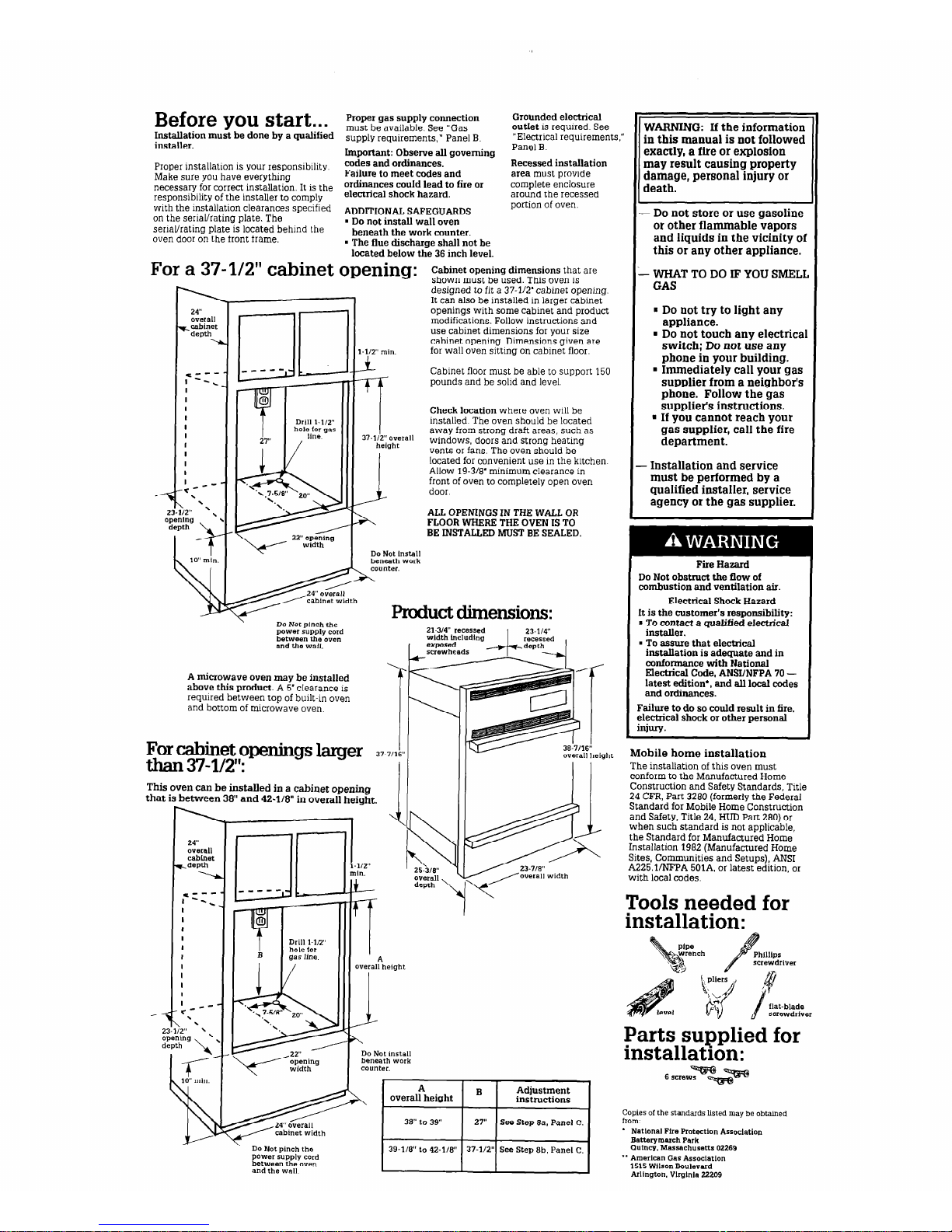

For a 37-l/2” cabinet opening:

1

24”

overall

r_cabinet

depth

\

nr

1.112” min.

Cabinet opening dimensions that are

shown must be used. This oven is

designed to fit a 37-l/2’ cabinet opening.

It can also be installed in larger cabinet

openings with some cabinet and product

modifications. Follow instructions and

use cabinet dimensions for your size

cabinet opening. Dimensions given are

for wall oven sitting on cabinet floor.

,= z

--

-.

I

I

I

I

I

I

I

I

I

I

I

*---

\

\

iz*s '\

Cabinet floor must be able to support 150

pounds and be solid and level.

Check location where oven will be

installed. The oven should be located

away from strong draft areas, such as

windows, doors and strong heating

vents or fans. The oven should be

located

for convenient use in the kitchen.

Allow 19-318’ minimum clearance in

front of oven to completely open oven

3

door

A

ALL OPENINGS IN THE WALL OR

FLOOR WHERE THE OVEN IS TO

BE INSTALLED MUST BE SEALED.

Do Not Install

beneath work

_ counter.

$s&zP

Pmduct dimensions:

\

Do Not pinch the

power supply cord

between the oven

and the wall.

Fire

Hazard

Do Not obstruct the flow of

combustion and ventilation air.

Electrical Shock Hazard

It is the customer’s responsibility:

* To

contact

a guaMfad electrical

installer.

. To assure that electrical

installation is adequate and in

conformance with National

Electrical Code, ANSUNFPA 70 latest edition*, and all local codes

and ordinances.

Failure to do so could result in fire,

electrical shock or other personal

injury.

21-X4"

recessed

width Lncludlng

A microwave oven may be installed

above this product. A 5’ clearance is

required between top of built-in oven

and bottom of microwave oven.

For cabinet openhgs larger

37-711br

than 37-l/2”:

I

Mobile home installation

The installation of this oven must

conform to the Manufactured Home

Construction and Safety Standards, Title

24 CFR, Part 3280 (formerly the Federal

Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 290) or

when such standard is not applicable,

the Standard for Manufactured Home

Installation 1982 (Manufactured Home

Sites, Communities and Setups), ANSI

A225.VNFPA 501A, or latest edition, or

with local codes.

This oven can be installed in a cabinet opening

that is between 38” and 42-l/8” in overall height.

Ir

24"

overall

cabinet

t,depth

---I

I’ c.

--

-.

I

I

I

I

I

I

I

I

I

I

I

c---

.

\ '

overall

depth

Tools needed for

installation:

Parts supplied for

installation:

6 scr.wF~-

A

overall height

B

Adjustment

instructions

Copies of the standards listed may be obrained

hl”:

* Netlonal Fire Protection Association

Batterymarch Park

Qut"cg.Massachuse~s02269

*’ American Gas Association

1515 WilsonBoulevard

Arlington. Vlrghlla 22209

39-118” to 42-118”

\

Do Not pinch the

Power Supply cord

between the oven

and the wall

Gas supply

requirements

Observe all governing codes and

ordinances.

Fire Hazard

. Oven must be connected to a

regulated gas supply.

m L.P. gas supply must Not exceed

a pressure of 14” water column.

This must be checked by a

qualified technician before

installing this oven.

. Do Not use an open flame to test

for leaks from gas connections.

. New A.G.A.-design-certified.

flexible gas line should be used

when local codes permit.

Failure to follow these instructions

could result in a fire, explosion or

personal injury.

A

. This installation must conform

with local codes and ordinances. In the

absence of local codes, installations must

conform with American National

Standard, National Fuel Gas Code ANSI

2233.1 - latest edition**.

B

. Input ratings shown on the

serial/rating plate are for elevations up to

2,000 feet. For elevations above 2,000

feet, ratings are reduced at a rate of 4%

for each 1,000 feet above sea level.

C

n

This oven is equipped for use with

NATURAL and L.P. gases. It is designcertified by A.G A. for NATURAL and

L.P. gases with appropriate conversion

The seriaurating plate, located behind

the oven door on the oven frame, has

information on the type of gas that can

be used. If this information does not

agree with the type of gas available,

check with the local gas supplier. See

Panel E for L.P. gas conversion

instructions.

D

. Provide a gas supply line of 314”

rigid pipe to the oven location, A smaller

size pipe on long runs may result in

insufficient gas supply. Pipe-joint

compounds made for use with L.P. gas

must be used. With L.P. gas, piping or

tubing size can be l/2’ minimum. L.P gas

suppliers usually determine the size and

materials used on their system.

E

n

If local codes permit, A.G.A.design-certified flexible metal tubing is

recommended for connecting this oven to

the gas supply line. Do Not kink or

damage the flexible tubing when moving

the oven. A l/2” male pipe thread is

needed for connection to pressure

regulator female pipe threads.

n

line

r

. The supply line shall be equipped

with an approved shutoff valve. This

valve should be located in the same room

as the oven and should be in a location

that allows ease of opening and closing.

Do Not block access to shutoff valve.

The oven regulator (located in the lower,

right rear of broiler drawer opening) is

equipped with a shutoff valve.

G

. If rigid pipe is used as a gas

supply line, a combination of pipe

fittings must be used to obtain an in-line

connection to the oven. All strains must

be removed from the supply and fuel

lines so oven will be level and in line.

H

n

The reoulator must be checked at

a minimum ofj-inch water column

above the set pressure. The inlet

pressure to the regulator should be as

follows for operation:

NATURAL GAS:

Set pressure 4 inches

Maximum pressure 14 inches

L.P. GAS:

Set pressure 10 inches

Maximum pressure 14 inches

I

. Line pressure testing:

Testing above l/2 psi (gauge)

The oven and its individual shutoff valve

must be disconnected from the gas

supply piping system during any

pressure testing of that system at test

pressures greater than l/2 psig (3.5 kPa).

Testing at 112 psi (gauge)

The oven must be isolated from the gas

supply piping system by closing its

individual manual shutoff valve during

any pressure testing of the gas supply

piping system at test pressures equal to

or less than l/2 psig (3.5 kPa).

Electrical

requirements

Electrical Shock Hazard

. Electrical ground is required on

this appliance.

l

Do Not ground to a gas pipe.

- Do Not modify the power supply

cord plug. If it does not fit the

outlet. have a proper outlet

installed by a qualified

electrician.

m Do Not have a fuse in the neutral

or grounding circuit. A fuse in the

neutral or grounding circuit could

result in electrical shock.

n

Do Not use an extension cord with

this appliance.

m Check with a qualified electrician

if you are in doubt as to whether

the appliance is properly

grounded.

Failure to follow these instructions

could result in serious injury or

death.

If codes permit and separate grounding

wire is used, it is recommended that a

qualified electrician determine that the

grounding path is adequate.

A 120~volt, 60-Hz. AC-only, 15-ampere.

fused electrical supply is required. A

time-delay fuse or circuit breaker is

recommended. It is recommended that a

separate circuit serving only this

appliance be provided.

Electronic ignition systems operate

within wide voltage limits but proper

grounding and polarity is necessary. In

addition to checking that the outlet

provides 120~volt power and is correctly

grounded, the outlet must be checked by

a qualified electrician to see if it is wired

with correct polarity.

A wiring diagram is included in the

literature package. The wiring diagram

is also located behind the control panel.

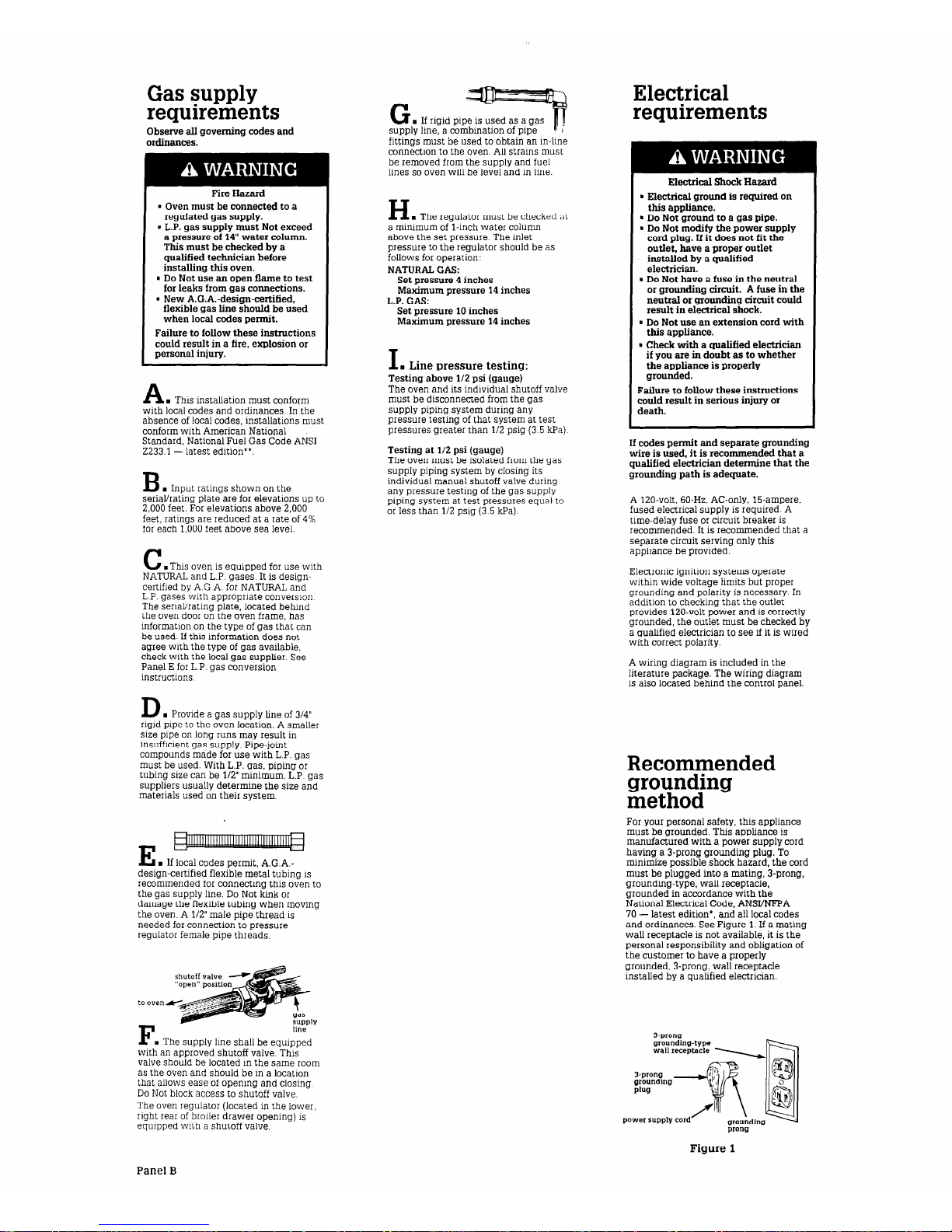

Recommended

grounding

method

For your personal safety, this appliance

must be grounded. This appliance is

manufactured with a power supply cord

having a 3-prong grounding plug. To

minimize possible shock hazard, the cord

must be plugged into a mating, 3-prong,

grounding-type, wall receptacle,

grounded in accordance with the

National Electrical Code, ANSYNFPA

70 - latest edition*, and all local codes

and ordinances. See Figure 1. If a mating

wall receptacle is not available, it is the

personal responsibility and obligation of

the customer to have a properly

grounded, 3-prong, wall receptacle

installed by a qualified electrician.

3-Prong

grounding-type

wall receptxle

3.prong

grounding

Plug

power supply cord

prong

Figure 1

Panel B

Loading...

Loading...