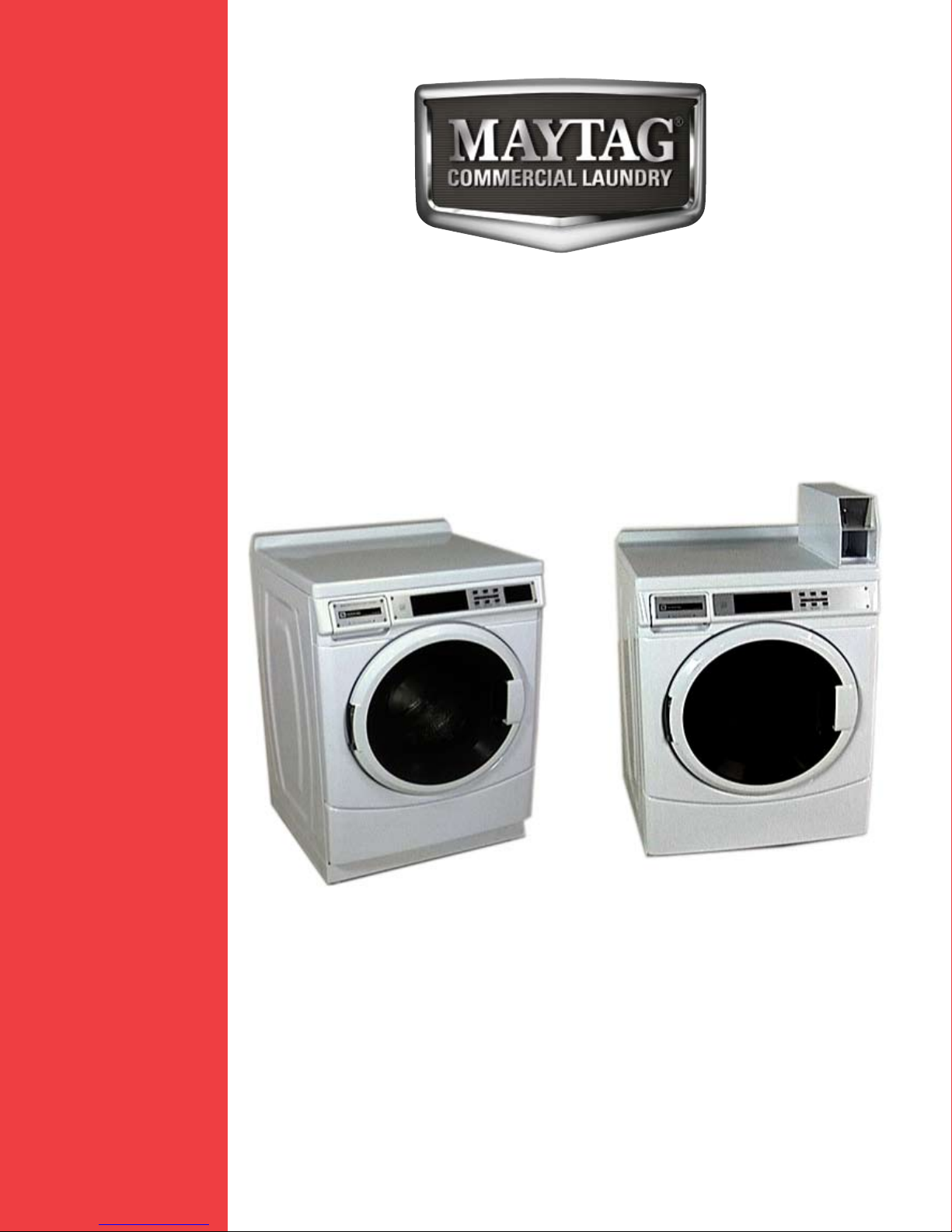

Page 1

W10251148

SERVICE MANUAL

Maytag

Model 30 Commercial

Front Loading Washers

MODELS:

MHN30PDAWW0

MHN30PDAXW0

MHP30PRAWW0

MHN30PRAWW0

TECHNICAL EDUCATION

Page 2

FORWARD

This Maytag Service Manual, (Part No. W10251148), provides the Commercial

Laundry Service Professional with information on the installation, operation, and

service of the single load coin and non coin Model 30 Series Commercial Front

Loading Washers. For specic information on the model being serviced, refer to

the “Installation Instructions,” or “Tech Sheet” provided with the washer. The Wiring

Diagrams used in this Service Manual are typical and should be used for training

purposes only. Always use the Wiring Diagram supplied with the product when

servicing the washer.

GOALS AND OBJECTIVES

The goal of this Service Manual is to provide information that will enable the

Commercial Laundry Service Professional to properly diagnose malfunctions and

repair the Commercial Front Loading Washers. The objectives of this Service

Manual are to:

Understand and follow proper safety messages.

•

Understand and diagnose improper installations.

•

Successfully troubleshoot and diagnose malfunctions.

•

Successfully perform necessary repairs.

•

Successfully return the washer to its proper operational status.

•

WHIRLPOOL CORPORATION assumes no responsibility

for any repairs made on our products by anyone other than

authorized Commercial Laundry Service Professionals.

Copyright © 2011, Whirlpool Corporation, Benton Harbor, MI 49022

ii

Page 3

TABLE OF CONTENTS

View entire service video ..................................................................................................vi

Links to documents ........................................................................................................... vi

Installation Instructions................................................................................................ vi

Tech Sheet - (English) .................................................................................................vi

Tech Sheet - (French) ................................................................................................. vi

Page

GENERAL .................................................................................................................................

Model number designations .............................................................................................. 1-2

Serial number designations .............................................................................................. 1-2

Model & serial number label and tech sheet location ....................................................... 1-3

Specications .................................................................................................................... 1-4

Warranty ........................................................................................................................... 1-5

INSTALLATION REQUIREMENTS ...........................................................................................

Tools and parts .................................................................................................................2-1

Alternate parts ..................................................................................................................2-2

Accessories ......................................................................................................................2-2

Options .............................................................................................................................2-2

Location requirements ...................................................................................................... 2-3

Drain system ..................................................................................................................... 2-4

Electrical requirements ..................................................................................................... 2-5

Remove shipping bolts .....................................................................................................2-6

Reinstall shipping bolts .....................................................................................................2-6

BASIC OPERATION .................................................................................................................

Set up instructions ............................................................................................................ 3-1

General user information .................................................................................................. 3-2

Control set-up procedures ................................................................................................ 3-4

Remove AA1 jumper ......................................................................................................... 3-5

Set-up codes ..................................................................................................................... 3-6

1-1

2-1

3-1

COMPONENT ACCESS ...........................................................................................................

Component locations ........................................................................................................4-1

Chemical dispenser drawer and parts .............................................................................. 4-2

Remove facia and control panel cover .............................................................................4-2

Lift washer top ..................................................................................................................4-3

Remove control panel ....................................................................................................... 4-4

Remove user interface control (UIC) ................................................................................ 4-5

Remove key pad assembly ............................................................................................... 4-6

Remove control panel bracket .......................................................................................... 4-7

Remove central control unit (CCU) ................................................................................... 4-8

CCU connections .............................................................................................................. 4-9

Remove water inlet valves ................................................................................................ 4-10

Remove pressure switch ..................................................................................................4-11

Remove RFI line lter ....................................................................................................... 4-12

Remove power supply cord .............................................................................................. 4-13

Remove chemical dispenser assembly ............................................................................4-14

4-1

iii

Page 4

TABLE OF CONTENTS - CONTINUED

Page

Remove transformer .........................................................................................................4-15

Remove door lock / switch assembly ................................................................................ 4-16

Remove door hook ...........................................................................................................4-18

Remove door and hinge assembly ................................................................................... 4-18

Door parts and disassembly ............................................................................................. 4-19

Remove lower service panel ............................................................................................. 4-21

Remove drain pump .........................................................................................................4-22

Remove drain pump motor ............................................................................................... 4-24

Remove tub to pump hose ................................................................................................ 4-25

Remove ground switch ..................................................................................................... 4-26

Remove rear panel ........................................................................................................... 4-28

Remove motor control unit (MCU) ....................................................................................4-29

Remove temperature sensor ............................................................................................ 4-30

Remove drive belt ............................................................................................................. 4-31

Remove motor .................................................................................................................. 4-32

Remove basket pulley ......................................................................................................4-33

Remove air gap damper ................................................................................................... 4-34

Remove vent tube ............................................................................................................. 4-35

Remove water inlet valve - from the back ......................................................................... 4-35

Remove front panel ..........................................................................................................4-36

Remove the bellow ........................................................................................................... 4-37

Remove a pedestal ........................................................................................................... 4-38

Remove tub and spin basket assembly ............................................................................ 4-39

Replace bafe ................................................................................................................... 4-42

Remove metercase (model MHN30PD) ........................................................................... 4-43

Remove coin drop (model MHN30PD) ............................................................................. 4-44

Remove coin vault switch (model MHN30PD) .................................................................. 4-45

Remove service switch (model MHN30PD) ...................................................................... 4-46

Main top support ...............................................................................................................4-46

COMPONENT TESTING ...........................................................................................................

Inlet valve solenoids .........................................................................................................5-1

Pressure switch ................................................................................................................5-2

RFI line lter ...................................................................................................................... 5-3

Door lock assembly ..........................................................................................................5-4

Drain pump motor .............................................................................................................5-5

Temperature sensor .......................................................................................................... 5-6

Drive motor ....................................................................................................................... 5-7

Ground switch ................................................................................................................... 5-7

User interface membrane switch ...................................................................................... 5-8

Coin drop acceptor ...........................................................................................................5-9

Transformer ...................................................................................................................... 5-10

5-1

iv

Page 5

TABLE OF CONTENTS - CONTINUED

Page

DIAGNOSIS & TROUBLESHOOTING ..................................................................................... 6-1

Washer diagnostic mode .................................................................................................. 6-1

Failure / error display codes .............................................................................................6-2

Diagnostic test .................................................................................................................. 6-6

Code display .....................................................................................................................6-6

Flashing mode .................................................................................................................. 6-7

Special cycle mode ........................................................................................................... 6-7

Quick overview test ........................................................................................................... 6-8

Manual overview test ........................................................................................................6-9

Diagnostic test quick guide ............................................................................................... 6-10

Help mode ........................................................................................................................6-10

Button functions in help mode table .................................................................................. 6-11

Help mode symbols and elements .................................................................................... 6-11

Help codes ........................................................................................................................ 6-12

Help mode submenu ......................................................................................................... 6-12

Pump motor continuity test ............................................................................................... 6-13

Drive motor ohm test ........................................................................................................6-13

Transformer ohm test ........................................................................................................6-13

Water temperature sensor ................................................................................................6-13

Cycle temperature selections ...........................................................................................6-13

CCU wire harness connector table ...................................................................................6-14

Manually unlocking the door latch ....................................................................................6-15

Manually unlatching tripped door latch ............................................................................. 6-15

Washer care ......................................................................................................................6-15

Washer clean-out cycle procedure ................................................................................... 6-16

Troubleshooting guide ...................................................................................................... 6-17

WIRING DIAGRAM ...................................................................................................................

7-1

v

Page 6

INTERACTIVE SERVICE MANUAL INSTRUCTIONS

Click the mouse on any topic in the table of contents to go directly to that section.

Click the mouse on any link that says (See page ?-?) to go directly to the page referenced.

Click the mouse on any button in the links section to open the attached document.

This symbol means a video clip is available. Click the mouse on the camera icon

to view the video. To close the movie, click the X box at the top corner of the video window.

System requirements to view the video clips in this manual are:

Windows 2000 or higher, Adobe® Acrobat® Reader® version 6 or higher,

Windows Media Player for PC and Quicktime Player for Macintosh computers.

LINKS TO DOCUMENTS

vi

Page 7

GENERAL

WASHER SAFETY

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken

the electronic control assembly. The new control assembly may appear

to work well after repair is nished, but failure may occur at a later date

due to ESD stress.

• Use an anti-static wrist strap. Connect wrist strap to green ground

connection point or unpainted metal in the appliance

-OR-

Touch your nger repeatedly to a green ground connection point or

unpainted metal in the appliance.

• Before removing the part from its package, touch the anti-static bag

to a green ground connection point or unpainted metal in the

appliance.

• Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

• When repackaging failed electronic control assembly in anti-static

bag, observe above instructions.

1-1

Page 8

n

Horizontal

Axis Washer Non-Pedestal

Horizontal Axis Washer w/Pedestal

MODeL nUMBer M Hn 30 PD A W W 0

BrAnD

M Maytag

DrIVe TYPe

HN

PrODUCT

30 Commercial HE Front Load W

asher

COnTrOL TYPe

PD

Processor Coindrop

PR Processor Reader

PN Processor Non-coin

CS Mechanical Coinslide

MN Mechanical Non-coin

M

ArKeTInG CODe

A

First series

B Second series

VOLTAGe CODe

W 120V

-60Hz (US)

X

120V

-60Hz (Canada)

G

220-240V

-50Hz (Export Models)

COLO

r

W White

enGIneerInG CHAnGe (nUMerIC)

-

SerIAL nUMBer HL

0 35 10901

D

IVISIOn reSPOnSIBILITY

M

Marion, Ohio

HL Monterrey

, MX

Y

eAr OF PrODUCTIO

W

2008

Y

2009

0

2010

1

201

1

W

eeK OF PrODUCTIOn

35 35th W

eek in the calendar year

M

AnUFACTUrInG SeQUenCe nUMBer

HP

AH

Automatic Horizontal Axis Washer

22

Commercial HE Front Load Washer

2 2012

2013

2014

3

4

2015

5

C Clyde, Ohio

MODEL NUMBER DESIGNATIONS

SERIAL NUMBER DESIGNATIONS

1-2

Page 9

MODEL & SERIAL NUMBER LABEL AND

TECH SHEET LOCATION

Location of

Model & Serial Number Label

Location of

Tech Sheet

Parts List

Wiring Diagram

1-3

Page 10

SPECIFICATIONS

Door

MHN-

MHP -

44.65

Total Hot Water use/cycle*

Total water use/cycle*

(Owner

Adjustable)

Pedestal Equipped

& K nits, Q uick

Whites, Colors, Brights, Perm Press, Delicates

6 Cycles

245 lbs

254 lbs

MHP - 234 lbs /

MHN-230 lbs

Product Weight (uncrated)

Card Reader Not Included

Product Weight (crated)

2 mm)

(7

30.

(68.58 cm)

15 Amps

3.2 ft

Normal = 40 RPM

MHP only

SPeCiFiCaTiOnS

Width

Capacity

Front Load HE Washer

Model Number

MHN30PDAWW

MHN30PRAWW

MHP30PRAWW

Model Description

Color

White / Black Accents

Stainless Steel Trim

Temperature Control

NTC - Thermister

No

Sensors

Suds Sensor

NTC (Thermistor)

Water Level Sensor

W

ash Speed

Spin Speeds

Max = 1000 RPM

Medium = 850 RPM

Low = 750 RPM

Extra Low = 600 RPM

Rated Load Size

18 lbs

V

oltage

120 volts

Frequency

60 Hz

Max

Amp Draw

12

Amps

US Breaker Rating

Amps

Power Cord Length

6 ft

MEF

2.5

W

ater Factor

3.7

11.955 gallons/cycle*

Controlled Induction Motor

Motor Protection

HP

Variable Speed, Reversing

Thermally Protected

1/4 HP

Height

”

Install Depth: Min - Max

28.75”

Money Acceptor

US = Single Coin Drop

Canada = Dual Coin Drop

27"

MHN30PDAY

W

3

MHP - 234 lbs /

MHN-230 lbs

44.65

” /

44.65

”

180° Opening / Non-Reversible

verage loads based on testing using* A

CSA Standard C360-03/DO E Appendix J1/

T396

Hot wash 3.53 gal (13.36 liters) /

Warm wash 1.38 gal (5.22 liters)

1-4

Page 11

WARRANTY

MAYTAG® COMMERCIAL SINGLE-LOAD AND VENDED

MULTI-LOAD WASHER & DRYER

WARRANTY

LIMITED WARRANTY ON PARTS

For the rst ve years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for factory

specied parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, re, ood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag® Commercial Laundry distributor. To locate your authorized Maytag®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

3/10

For written correspondence:

Maytag

®

Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

10. Repairs made by a non-Whirlpool authorized service technician.

1-5

Page 12

---- NOTES ----

1-6

Page 13

INSTALLATION REQUIREMENTS

For complete installation instructions

See Links to documents page.

Tools and parts

Gather the required tools and parts before

starting installation. The parts supplied are in

the washer spin basket.

Tools needed for connecting the water inlet

hoses:

Pliers (that open to 1 9/16th” {39.5 mm})

•

Flashlight (optional)

•

Tools needed for installation:

1/2” inch wrench

•

9/16” open end wrench

•

T-20 security screwdriver

•

1/4” nut driver

•

Level

•

Wood block

•

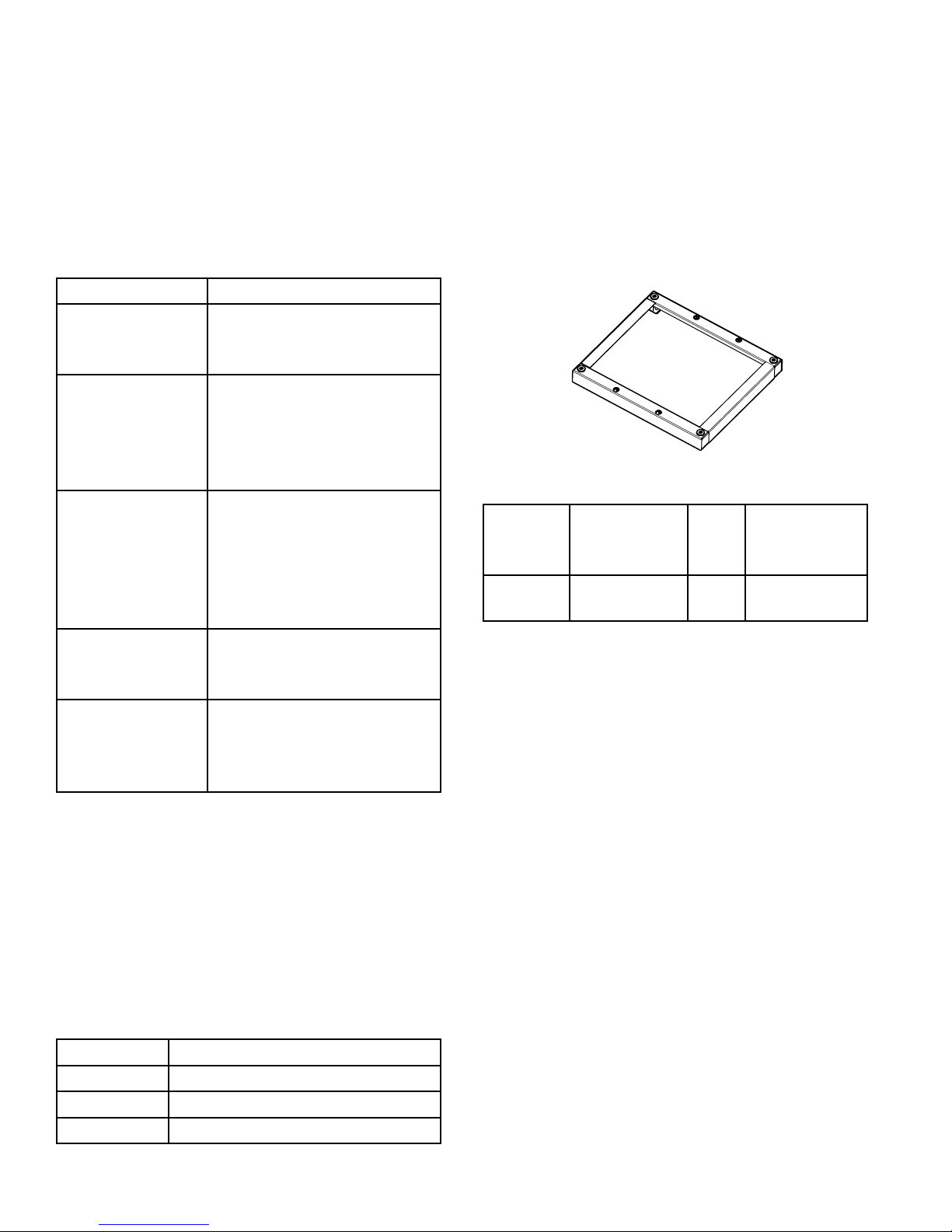

Parts supplied:

A B

C

D E G

A. U-shaped hose form

B. Water inlet hoses (2)

C. Inlet hose washers (4)

D. Transit bolt hole plug (4)

E. Beaded tie strap

F. Drain hose

G. Hose clamp

Parts supplied for PD Models:

F

Ruler or measuring tape

•

Service Door Foam Pads

Lock Cam

Parts supplied for PR Models:

Card Reader Screws

Bezel (2)

2-1

Page 14

ALTERNATE PARTS OPTIONS

Your installation may require additional parts.

If you are interested in purchasing one of the

items listed here, call the toll-free number in

the “Assistance or Service” section.

If You Have You Will Need to Buy

Laundry tub or

standpipe taller

than 96” (2.4 m)

Overhead sewer Standard 20 gal. (76 L),

Floor drain Siphon break, Part

Drain hose too

short

Water faucet

beyond reach of

ll hoses

Sump pump system (if not

already available)

30” (762 mm) tall drain tub

or utility sink and sump

pump (available from local

plumbing suppliers)

Number 285834;

additional drain hose,

Part Number 8318155;

and connector kit, Part

Number 285835

4 ft. (1.2 m) drain hose

extension kit, Part Number

285863

2 longer water ll hoses:

6 ft (1.8 m) Part Number

76314, 10 ft (3.0 m) Part

Number 350008

Pedestal

An optional pedestal is available for the other

versions of this model washer. The pedestal

will add to the total height of the washer.

Optional Pedestal

Pedestal

Height

2 7/8”

(73 mm)

NOTE: Model MHP30 has pedestal

pre-installed.

Approximate

Height with

Washer

47.5”

(1207 mm)

Color Model

number

White WHP0400VW

ACCESSORIES

Enhance your washer with these premium

accessories. For more high-quality items or to

order, call 1-800-901-2042,

or visit us at www.maytag.com/accessories.

In Canada call: 1-800-807-6777

or visit us at www.whirlpoolparts.ca.

Part # Accessory

8212526 Washer drip tray, ts under all

31682 All purpose appliance cleaner

1903WH Laundry supply storage cart

2-2

Page 15

LOCATION REQUIREMENTS

Selecting the proper location for your washer

improves performance and minimizes noise

and possible washer “walk.” Your washer can

be installed under a custom counter, or in a

basement, laundry room, or recessed area.

Companion appliance location requirements

should also be considered. Proper installation

is your responsibility. You will need

A water heater set to deliver 120°F (49°C)

•

water to the washer.

A grounded electrical outlet located within

•

6 ft (1.8 m) of where the power cord is

attached to the back of the washer.

(See page 2-5).

Hot and cold water faucets located within

•

4 ft (1.2 m) of the hot and cold water fill

valves, and water pressure of 20-100 psi

(137.9-689.6 kPa).

A level floor with a maximum slope of 1”

•

(25 mm) under entire washer. Installing

the washer on soft floor surfaces, such as

carpets or surfaces with foam backing, is

not recommended.

A sturdy and solid floor to support the

•

washer with a total weight (water and load)

of 400 lbs (180 kg).

Do not operate your washer in temperatures

below 32°F (0°C). Some water can remain

in the washer and can cause damage in low

temperatures.

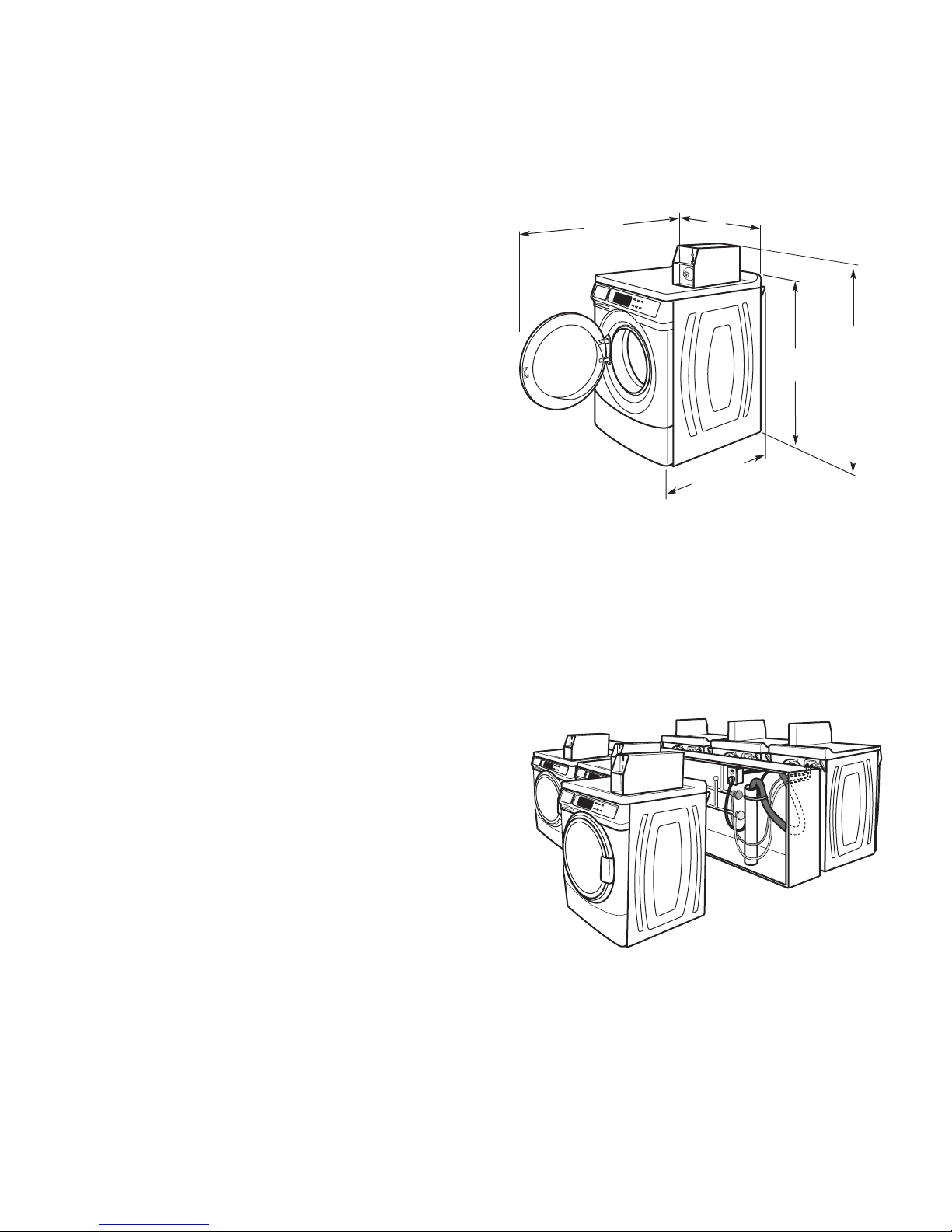

Installation clearances

The location must be large enough to allow

•

the washer door to be fully opened.

Additional spacing should be considered for

•

ease of installation and servicing. The door

opens more than 90° and it is not reversible.

Additional clearances might be required for

•

wall, door, and floor moldings.

Additional spacing of 1” (25 mm) on all

•

sides of the washer is recommended to

reduce noise transfer.

Companion appliance spacing should also

•

be considered.

Washer dimensions:

501/2"

(1282 mm)

27"

(686 mm)

13

28

/16"

(732 mm)

3713/16"

(961 mm)

445/8"

(1134 mm)

Door opens 180° and is not reversible.

A oor drain should be provided under the

bulkhead. Prefabricated bulkheads with

electrical outlets, water inlet lines, and drain

facilities should be used only where local

codes permit.

2-3

Page 16

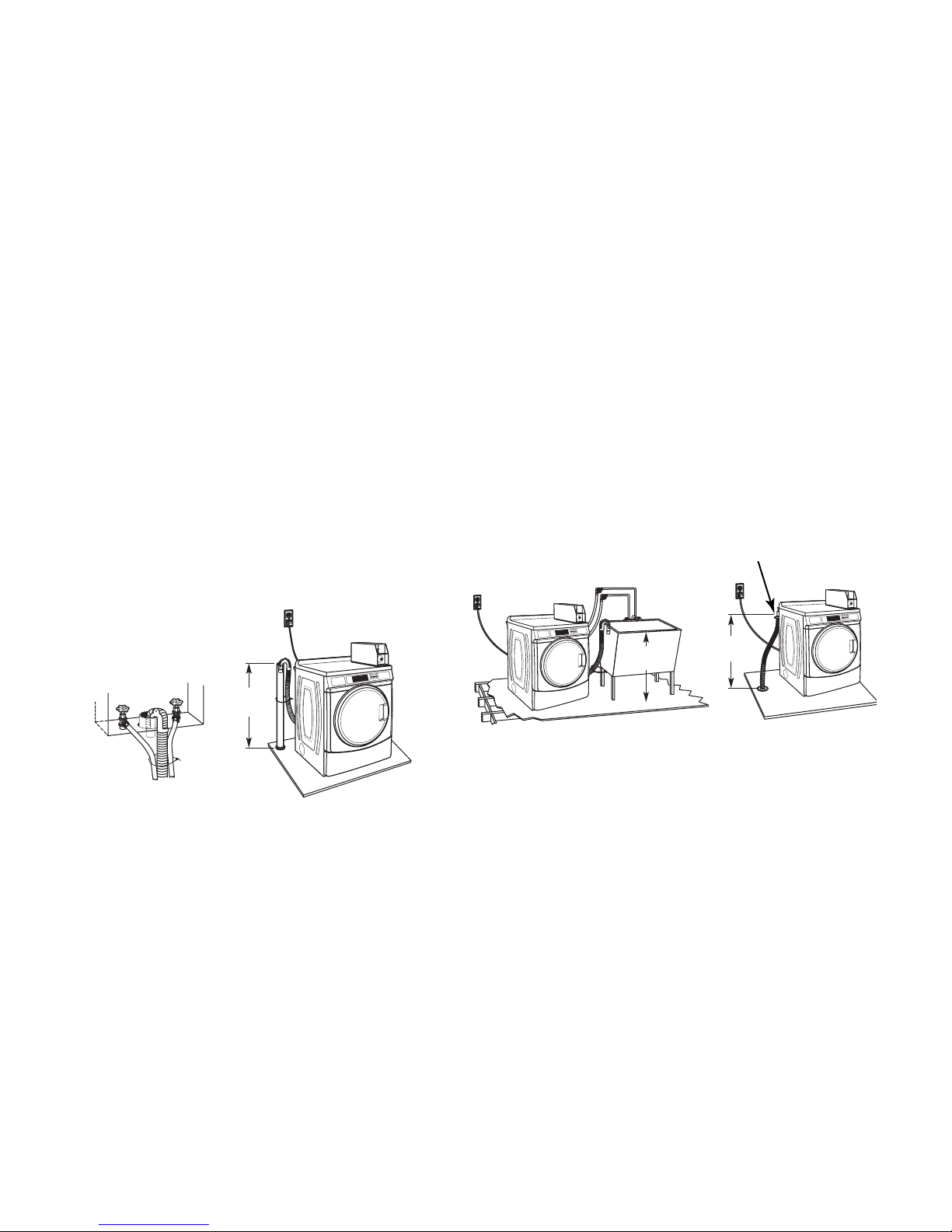

DRAIN SYSTEM

The washer can be installed using the

standpipe drain system (oor or wall), the

laundry tub drain system, or the oor drain

system. Select the drain hose installation

method needed.

Standpipe drain system: wall or oor

(Views A & B)

The standpipe drain requires a minimum

diameter standpipe of 2” (50 mm). The

minimum carry-away capacity can be no less

than 10 gal. (38 L) per minute.

The top of the standpipe must be at least 30”

(762 mm) high and no higher than 96” (2.4 m)

from the bottom of the washer. A drain hose

extension must be added to reach maximum

drain height capability.

Laundry tub drain system (view C)

Laundry tub needs a minimum 20 gal. (76 L)

capacity. The top of the laundry tub must be

at least 30” (762 mm) above the oor.

Floor drain system (view D)

The oor drain system requires a siphon break

that may be purchased separately.

The siphon break must be a minimum of 28”

(710 mm) from the bottom of the washer.

Additional hoses might be needed.

Siphon Break

(Anti-Siphon Device)

30" min.

(762 mm)

A B

30" min.

(762 mm)

28" min.

(710 mm)

C D

2-4

Page 17

ELECTRICAL REQUIREMENTS

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

A 120 volt, 60 Hz., AC only, 15 or 20

•

amp, fused electrical supply is required.

A time-delay fuse or circuit breaker is

recommended. It is recommended that a

separate circuit serving only this appliance

be provided.

Export models require a 220 / 240 volt, 50

•

Hz, AC power supply and a 10 or 15 amp

circuit breaker or time delay fuse. It is

recommended that each washer be on its

own circuit.

This washer is equipped with a power

•

supply cord having a 3 prong grounding

plug. Export models have various power

cord adapters available for use.

To minimize possible shock hazard, the

•

cord must be plugged into a mating, 3

prong, grounding-type outlet, grounded

in accordance with local codes and

ordinances. If a mating outlet is not

available, it is the personal responsibility

and obligation of the customer to have the

properly grounded outlet installed by a

qualified electrician.

If codes permit and a separate ground wire

•

is used, it is recommended that a qualified

electrician determine that the ground path is

adequate.

2-5

Do not ground to a gas pipe.

•

Check with a qualified electrician if not sure

•

that the washer is properly grounded.

Do not have a fuse in the neutral or ground

•

circuit.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the

event of a malfunction or breakdown,

grounding will reduce the risk of

electrical shock by providing a path of

least resistance for electric current. This

washer is equipped with a cord having

an equipment-grounding conductor

and a grounding plug. The plug must

be plugged into an appropriate outlet

that is properly installed and grounded

in accordance with all local codes and

ordinances.

WARNING: Improper connection of the

equipment grounding conductor can

result in a risk of electric shock. Check

with a qualied electrician or serviceman

if you are in doubt as to whether the

appliance is properly grounded.

Do not modify the plug provided with the

appliance – if it will not t the outlet, have

a proper outlet installed by a qualied

electrician.

For a permanently connected washer:

This washer must be connected to

a grounded metal, permanent wiring

system, or an equipment grounding

conductor must be run with the circuit

conductors and connected to the

equipment-grounding terminal or lead on

the appliance.

Page 18

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

REMOVE SHIPPING BOLTS

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

WARNING

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

WARNING

There are 4 shipping bolts in the rear panel

1.

of the washer that support the suspension

system during transportation.

Use a 1/2” wrench to loosen each of the

2.

bolts.

Once the bolts are loose, move each one to

3.

the center of the hole and remove the bolt,

including the plastic spacer covering the

bolt.

REINSTALL SHIPPING

BOLTS

If washer must be transported after the

1.

shipping bolts have been removed, at

least 2 shipping bolts must be re-installed

to protect the washer components from

damage due to movement of the weights

and the tub.

Unplug washer or disconnect power.

2.

Turn off the water supply to the washer.

3.

Once all 4 bolts are removed, push the

4.

power cord plug into the hole in the back of

the washer and pull the cord out of the hole

at the other side.

Cover the holes that the power cord came

5.

out of with the plastic caps attached to the

back of the washer.

Pull the drain hose from inside of wash

6.

basket and install, with a clamp, on the

drain port at the top right corner of the rear

panel.

Cover the holes that the shipping bolts

7.

came out of with the plastic hole plugs

shipped with the washer.

2-6

Remove the back panel from the washer.

4.

Assemble plastic tub spacers onto shipping

5.

bolts. Insert each shipping bolt assembly

through hole in the rear brace and into the

hole in the tub. Tighten loosely with a 1/2”

wrench.

Slide shipping bolt towards the outer edge

6.

of the washer before tightening the bolt

completely to secure the spacer in place.

Reinstall the back panel before transporting

7.

the washer.

Page 19

Shown is Model MHN30PD

BASIC OPERATION

SET UP INSTRUCTIONS

This washer can hold up to an 18 lb (8.2 kg)

load of laundry.

PD Models: Insert coins until “SELECT

1.

CYCLE” flashes in display.

PR Models: A debit card is required rather

2.

than coins. In Enhanced Debit mode, the

card balance will also display when a debit

card is inserted into the reader. When set

for free vend, “SELECT CYCLE” will be

displayed.

Door must be closed before cycle selection

3.

is made.

Door locks at the beginning of a cycle and

4.

remains locked for the entire cycle.

Press fabric setting button or the wash cycle

5.

desired. After the cycle is started, the time

will display and count down.

DEBIT CARD READY: This appliance is card

reader ready. It will accept a variety of debit

card systems, but does not come with a debit

card reader. Refer to the debit card reader

manufacturer for proper washer set up. In

models converted to a Generation 1 debit

card system, a debit pulse represents the

equivalent of 1 coin.

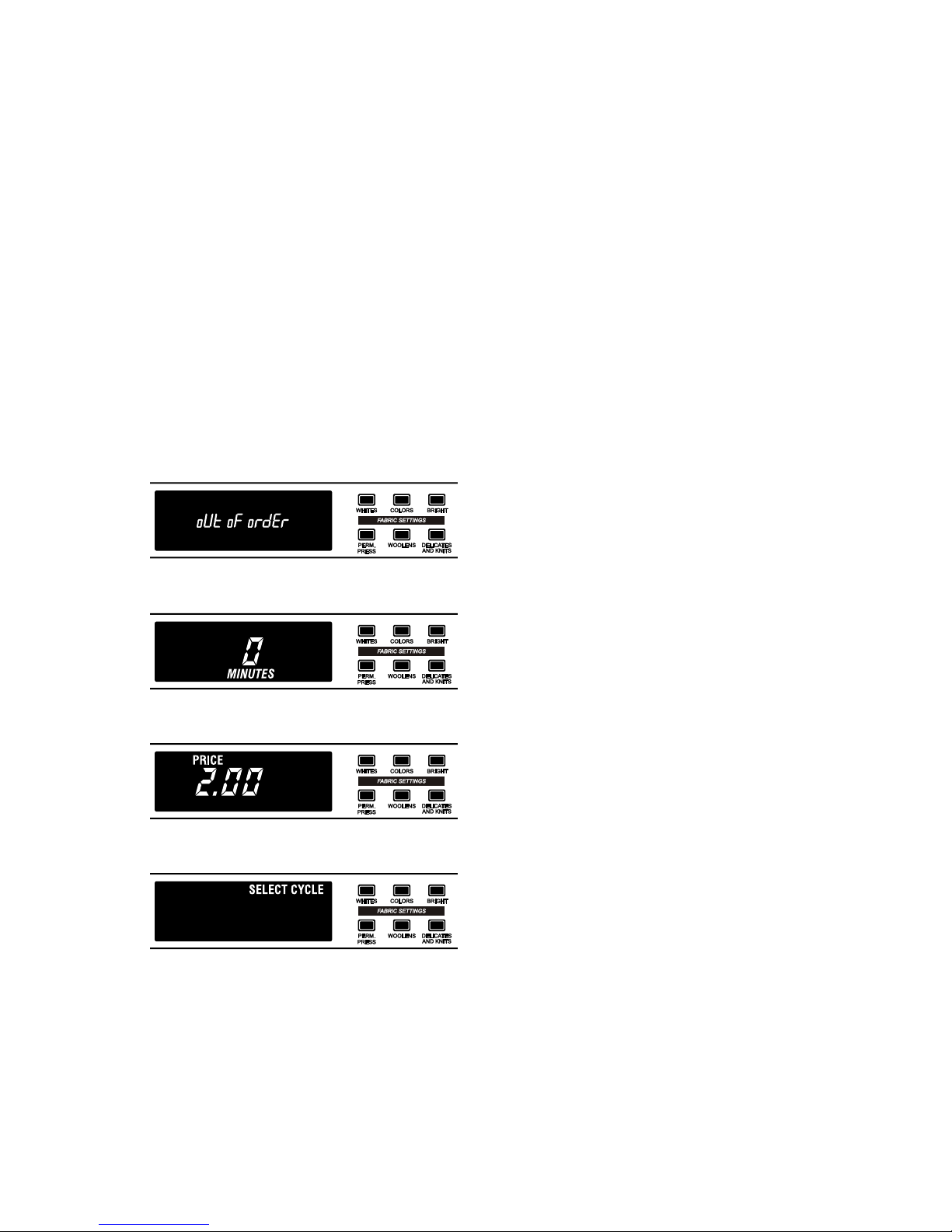

DISPLAY: After the washer has been installed

and plugged in, the display may show

“0 MINUTES”. Once the washer has been

plugged in and the washer door opened and

closed, the display will show the price. In

washers set for free cycles, the display will

ash “SELECT CYCLE”. Otherwise the cycle

price will be displayed in dollars and cents. If

Super Cycle is enabled then the regular cycle

price and the Super Cycle price will alternate

on the display.

When a cycle is interrupted, “RESELECT

6.

CYCLE” will flash in the display. To restart

the washer, press any button.

3-1

Page 20

IMPORTANT

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere.

ESD may damage or weaken the

electronic control assembly. The new

control assembly may appear to work

well after repair is nished, but failure

may occur at a later date due to ESD

stress.

GENERAL USER

INFORMATION

Scrolling “out of order” message followed by a

Failure Code:

This condition showing in the display indicates

the washer is in an inoperative state and

requires service. The failure code displayed is

the best indication of the reason the washer

has become inoperative.

‘0 Minutes’ showing in display:

This condition indicates the appliance cannot

be operated. Coins dropped or debit inputs

during this condition will be stored in escrow

but cannot be used until normal operation is

restored by opening and closing the door. If

a door switch has failed, it must be replaced

before normal operation can be restored.

Cold Start (initial rst use):

Appliance is programmed at the factory as

follows:

11 minute wash period

n

Use an anti-static wrist strap. Connect

n

wrist strap to green ground connection

point or unpainted metal in the

appliance.

-OR-

Touch your finger repeatedly to a green

ground connection point or unpainted

metal in the appliance.

Before removing the part from its

n

package, touch the antistatic bag to

a green ground connection point or

unpainted metal in the appliance.

Avoid touching electronic parts or

n

terminal contacts; handle electronic

control assembly by edges only.

When repackaging failed electronic

n

control assembly in antistatic bag,

observe above instructions.

3 rinses (extra rinse not enabled)

n

$1.75 wash price (PD models)

n

$0.00 wash price (PR Models)

n

Warm Start (after power failure):

A few seconds after power is restored, if a

cycle was in progress at the time of the power

failure, ‘RESELECT CYCLE’ will ash in the

display, indicating the need for a button press

to restart the washer.

3-2

Page 21

Door Lock

NOTE: Not displayed on washer as shown. Message scrolls

followed by the failure code.

Door lock does a Child Safety Routine at start

of every cycle. Child Safety Routine is: Lock,

turn spin basket 1/2 revolution, Unlock, then

Relock. The door will be locked when the

cycle starts. The door will remain locked until

the end of a cycle or approximately 2 minutes

after a power interruption.

NOTE: If power is interrupted prior to 2

minutes of operation the automatic door

unlocking mechanism may fail, and door will

remain locked until the power is restored or

the lock is manually opened by pulling on the

safety release tab.

(See page 4-17)

Free Cycles

This is established by setting the cycle price to

zero. When this happens, ‘SELECT CYCLE’

will be displayed rather than a cycle price.

Debit Card Ready

This washer is debit card ready. It will accept

a variety of debit card systems, but

DOES NOT come with a debit card reader.

Refer to the debit card reader manufacturer for

proper washer set-up. In models converted to

a Generation 1 debit card system, each debit

pulse represents the equivalent of one coin

(Coin 1).

Display

After the washer has been installed and

plugged in, the display may show

‘0 MINUTES’. Once the washer has been

plugged in and the washer door opened and

closed, the display will show the cycle price

or amount of coins needed to start a cycle. If

Super Cycle is enabled the Regular price and

Super Cycle price will alternate in the display.

In washers set for free vend, the display will

ash ‘SELECT CYCLE’ rather than a cycle

price.

Pricing in the display

After the door is opened following the

completion of a cycle, the display indicates the

cycle price (unless set for free operation). As

coins are dropped or debit inputs arrive, the

display will change to lead the user through

the initiation of a cycle.

During a cycle the display will show the

approximate time remaining unless the

washer is going through a “Suds Removal

Routine.” During the routine the display will

alternate between the word “SudS” and the

time remaining in the routine. At the end of

the 5 minutes needed for this routine, the

display returns to the same time displayed

prior to entering it.

3-3

Page 22

CONTROL SET-UP PROCEDURES

IMPORTANT: Read all instructions before

operating.

PD Models: Use service key to remove

n

service access door. Lifting the service

access door engages the service switch.

PR Models: Once a Generation - 2 debit

n

card reader is installed (according to the

reader manufacturer’s instructions), the

set-up codes can be changed by inserting

a manual set-up card (supplied by the

reader manufacturer) into the card slot or

by the use of a handheld device with DA

communication and AccuTrac software. If a

manual set-up card or a handheld AccuTrac

device is not available, only diagnostic

mode can be entered by removing the

connector AA1 on the circuit board.

PR Models set up as PNs :

n

Service Access Code: This code can be

entered to access service mode without

removing the console. It only functions on

washers set up for 0 vend price without any

Special Pricing set-up, and the Coin/Debit

Option must be set to “J._d”. If the washer

is not in failure mode, the door must be

opened to proceed. Service Access Code

contains 6 steps and some are timed. Using

only the three bottom buttons (numbered 1,

2, and 3 from left to right):

Press 2 for longer than 2 seconds but less

1.

than 10 seconds.

Press 1 & 3 together for 2 seconds, then

2.

release. Displays S 3.

Press 1 & 2 together, then release.

3.

Displays S 4.

Press 2 & 3 together, then release.

4.

Displays S 5.

Press 2, then release.

5.

Displays “codE”.

Wait at least 2 seconds, but not more than

6.

15 seconds, then press in succession:

3, 2, 1, 3.

NOTE:

is not completed properly, as noted above,

there is a 15 second delay before it can be

attempted again.

n

1.

2.

3.

If the Service Access Code procedure

There are 3 options to exit from the Service

Mode when the Service Access code has

been used to enter it:

From Set-up Code 8, press PERM. PRESS

for 4 seconds.

Wait 2 minutes without touching any buttons

(without diagnostic modes running).

Power down the washer, then reapply

power.

3-4

Page 23

REMOVE AA1 JUMPER

PR Models Only:

IMPORTANT: Unplug washer or disconnect

power before opening the console to access

connector AA1:

Unplug washer or disconnect power.

Ë

Open console, remove and retain plug on

Ë

AA1, close console.

Plug in washer or reconnect power.

Ë

The washer is now in the set-up mode. The

lower fabric setting key pads and the digital

display are used to set up the controls. The

control can display 4 numbers and/or letters

and a decimal point. These are used to

indicate set-up codes and related code values

available for use in programming the washer.

How to use the key pad to program the

controls

Start Operating Set-Up

Before proceeding, it is worth noting that,

despite all of the options available, an

owner can simply choose to uncrate a new

commercial washer, add appropriate payment

device or OPL Kit as needed and a service

lock for PD models, plug it in, and have a

washer that operates. Washers are preset at

the factory for a 11-minute wash period and 3

rinses (no extra rinse).

The PERM. PRESS button is used to

1.

adjust the values associated with set-up

codes. Pressing and releasing the button

will change the value by increments. Rapid

adjustment is possible by holding the button

down.

The DELICATES AND KNITS button

2.

advances the display through the set-up

codes. Pressing the button will advance

to the next available set-up code. Holding

the button down will automatically advance

through the set-up codes at a rate faster

than 1 per second.

The QUICK CYCLE button is used to select

3.

or deselect options.

3-5

Page 24

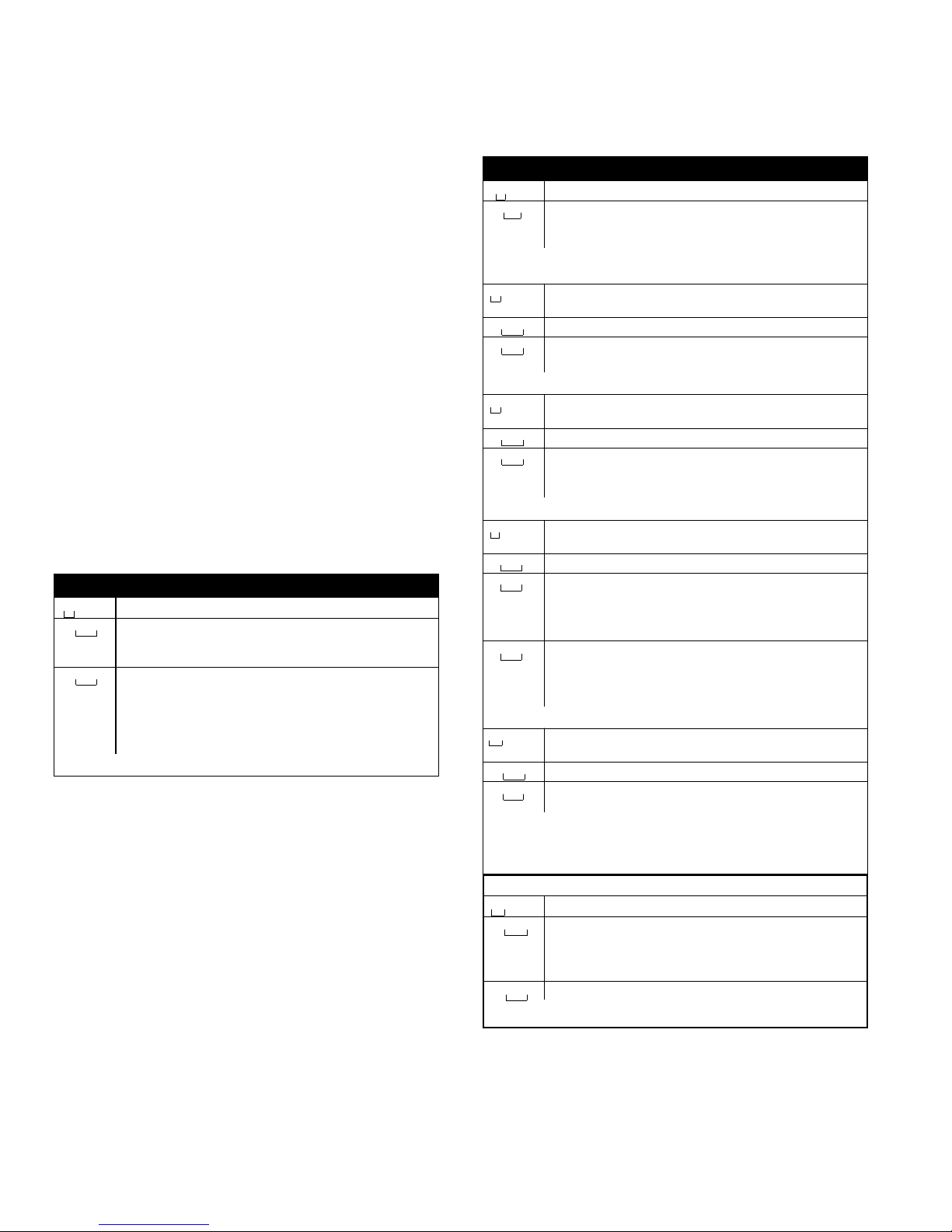

SET-UP CODES

NOTE: First code shown in each section is default code for coin equipment.

CODE EXPLANATION

R

EGULAR CYCLE PRICE

Represents the number of quarters needed to start the washer(coin 1

)

;

may adjust from 0-39. (SeeVALUE OF COIN 1.) Advance from 0-39 by

pressing the PERM. PRESS key pad. Factory default of 7 quarters = $1.75.

PR MODELS ONLY: Factory default of 0 quarters .

With coin slide activation,this represents the number of push-in

actuations of a coin slide to start the washer.

6 01 setting would represent one coin slide actuation.

NOTE: For coin slide activation, replacement of themeter case is necessary.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

6 0

7

6 0 7

6 00

(coin 1

)

CODE EXPLANATION

WASH LENGTH

This is the number of minutes for WASH. Washer comes from the

factory preset with 11 minutes. Choose from 9-17 minutes by

p

ressing the PERM. PRESS key pad. Wash time does not include

fill time.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

ADDITIONAL RINSE OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

S

elected ‘ON’.Cannot be combined with the Super Cycle rinse option.

Press the QUICK CYCLE key pad once for this selection.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

CYCLE COUNTER OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’ and not able to be deselected.

Press the QUICK CYCLE key pad 3 consecutive times to select

‘ON’. Once selected ‘ON’ it cannot be deselected.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

MONEY COUNTER OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’.

Press the QUICK CYCLE key pad 3 consecutive times

to select‘ON’ and 3 consecutive times to deselect (Not

Selected ‘OFF’.) Counter resets by going from ‘OFF’ to ‘ON’.

Selected ‘ON’ and not able to be deselected.

To select ‘ON’ and not able to be deselected,first select ‘ON’,

then within two seconds press the QUICK CYCLE key pad twice,

the PERM. PRESS key pad once,and exit the set-up mode.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

SPECIAL PRICING OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’, and next available code will be A.00.

Selected ‘ON’. Press the QUICK CYCLE key pad once

for this selection.

If SPECIAL PRICING OPTION is selected, you have access to codes ‘3.XX’

through ‘9.XX’.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

7 1 1

7 1 1

9 0 0

9 0 0

9 0

C

1.0 0

1.0 0

1.0

C

1.C0

2.0 0

2.0 0

2.

S P

OPTIONSTOUSE IF SPECIAL PRICING IS SELECTED:

SPECIAL CYCLE PRICE

Represents the number of quarters (coin 1) to start a cycle:

may adjust from 0-39. (See VALUE OF COIN 1.) Advance from

0-39 by pressing the PERM. PRESS key pad. Factory default

of 7 quarters = $1.75.

PR MODELS ONLY: Factory default of 0 quarters.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

3. 0 7

3. 0 7

3. 0 0

8 0 0

8 0 0

8A8

The DELICATES AND KNITS button will

n

advance from code to code.

The PERM. PRESS button will change the

n

code value.

The QUICK CYCLE button will select or

n

deselect options.

FOR PR MODELS: The set-up codes are the

same as for the ‘PD’ models except where

noted.

The set-up code is indicated by the one or two

left-hand characters. The set-up code value

is indicated by the two or three right-hand

characters. NOTE: First code shown in each

section is default code for coin equipment.

3-6

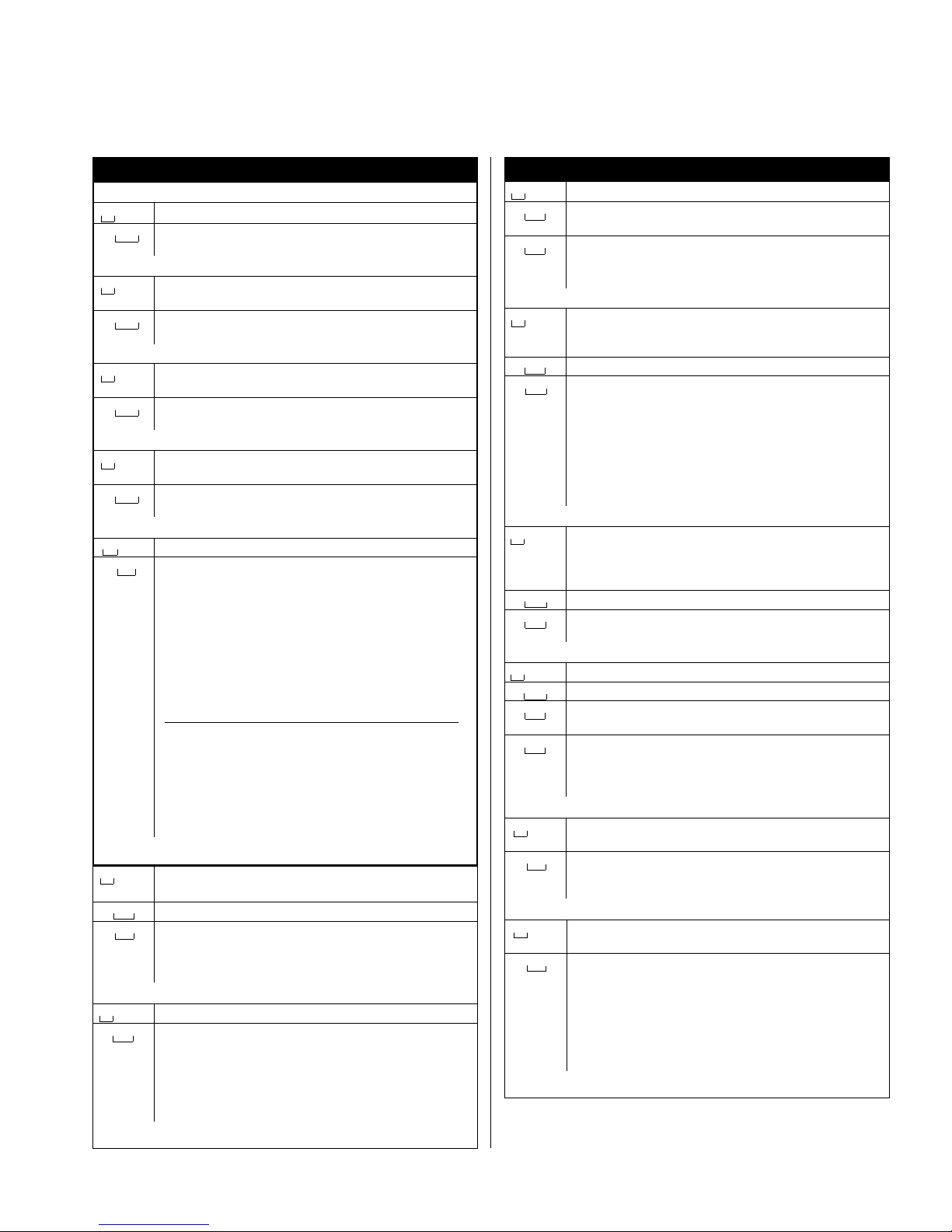

Page 25

C

ODE EXPLANATION

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED (cont.):

TIME-OF-DAY CLOCK, MINUTES

This is the TIME-OF-DAY CLOCK, minute setting; select 0-59

m

inutes by pressing the PERM.PRESS key pad.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

TIME-OF-DAY CLOCK, HOURS

N

OTE: Uses military time or 24 hr. clock.

This is the TIME-OF-DAY CLOCK, hour setting; select 0-23 hours

by pressing the PERM.PRESS key pad.

�

P

ress the DELICATES AND KNITS key pad once to advance to next code.

SPECIAL PRICE START HOUR

NOTE: Uses military time or 24 hr. clock.

This is the start hour; 0-23 hours. Select START HOUR by pressing

the PERM.PRESS key pad.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

SPECIAL PRICE STOP HOUR

NOTE: Uses military time or 24 hr. clock.

This is the stop hour; 0-23 hours. Select STOP HOUR by pressing

the PERM.PRESS key pad.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

SPECIAL PRICE DAY

This represents the day of the week and whether special pricing

is selected for that day. A number followed by ‘0’ indicates no

selection that particular day (9.10). A number followed by an ‘S’

indicates selected for that day (9.1S). To change the value of ‘0’

and ‘S’, use the QUICK CYCLE key pad.

Days of the week (1-7) are selected by pressing the PERM.

PRESS key pad.

When exiting set-up code ‘9’, the display must show current day

of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

�

Press the DELICATES AND KNITS key pad once to advance to next code.

8.0 0

8.0 0

9. 1 0

9. 1 0

VAULT VIEWING OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Press the QUICK CYCLE key pad once for

this selection.When selected, the money and/or cycle counts

will be viewable (if counter option(s) is selected) when the coin

box is removed.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

VALUE OF COIN 1

This represents the value of coin 1 in number of nickels:

05 = $0.25.

By pressing the PERM.PRESS key pad, you have the option

of 1-199 nickels.

With coin slide activation,this represents the total vend price

in nickels. Example: b.30 is equal to $1.50.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

A.

00

A.

00

6.0 5

6.0 5

A.SC

C

ODE EXPLANATION

VALUE OF COIN 2

This represents the value of coin 2 in number of nickels:

20 = $1.00.

PR MODELS ONLY: Factory default of $0.25.

By pressing the PERM. PRESS key pad, there is the option

of 1-199 nickels.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

COIN SLIDE OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

R

eplacement of meter case will be needed for coin slide mounting.

Not Selected ‘OFF’.

NOTE: This option needs to be set to “00” unless the meter case

has been changed to accept a coin slide device.

Selected ‘ON’. Press the QUICK CYCLE key pad 3 consecutive

times for this selection.

When coin slide mode is selected, set ‘b.’ equal to value of vend price

in nickels.Set set-up code 6 xx (regular cycle price) and set-up code

3.xx (special cycleprice) to number of slide operations.If the installer

sets up ‘CS’ on a model with a coin drop, it will not register coins.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

ADD COINS OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’. This

option causes the customer display to show the number of coins

(coin 1) to enter, rather than the dollars-and-cents amount.

Not Selected ‘OFF’.

Selected ‘ON’. Press the QUICK CYCLE key pad 3 consecutive

times for this selection.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

ENHANCED PRICING OPTION

Not Selected ‘OFF’.

Cycle-Based pricing enabled. This option allows configuration

of different prices for cold, warm, and hot water cycles.

Super Cycle pricing enabled.This option allows customers

to upgrade cycles by depositing extra money. Set-up codes

‘H.’ and ‘h.’ will be displayed only when this option is enabled.

Press the QUICK CYCLE key pad for this selection.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

SUPER CYCLE UPGRADE PRICE

(Skipped unless Super Cycle pricing is enabled.)

This represents the number of coin 1 required to upgrade a

base cycle to a super cycle. Advance from 0-39 by pressing

the PERM. PRESS key pad.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

SUPER CYCLE TYPE

(Skipped unless Super Cycle pricing is enabled.)

This represents the Super Cycle upgrade option.Press the

PERM. PRESS key pad to step through upgrade options 1

through 3 as follows:

01 - enhanced wash, extra 3 minutes of wash tumble in addition

to the programmed wash time.

02 - extra rinse for all cycles.

03 - both 01 and 02.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

8.0 0

E

. 0 0

E

. 0 0

E.A C

8.0 0

8.

CS

F

. 0 0

F

. 0 0

F.CP

F.S

8

H

.0 1

H

.0 1

H

.0 1

H

.0 1

5.0 0

5.0 0

6.0 0

6.0 0

7.0 0

7.0 0

C

.20

C

.20

C

.05

3-7

Page 26

If cycle counter (9 0C) is selected, the

CODE EXPLANATION

COIN/DEBIT OPTION

Both coin & debit selected.

Coins selected, debit disabled. Press the QUICK CYCLE key pad

3 consecutive times to change this selection.

PR models factory default to J._d. Debit Card selected, coins

disabled. Press the QUICK CYCLE key pad 3 consecutive times

to change this selection.

Enhanced Debit is self-selected when a Generation 2 card reader

is installed in the washer.The Ed option cannot be manually

selected or deselected.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

PRICE SUPPRESSION OPTION

This option causes the customer display to show‘ADD’ or

‘AVAILABLE’ rather than the amount of money to add. (Used

mainly in debit installations.)

Not Selected ‘OFF’.

Selected ‘ON’.Press the QUICK CYCLE key pad once

for this selection.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

CLEAR ESCROW OPTION

When selected, money held in escrow for 30 minutes without

further escrow or cycle activity will be cleared.

Not selected ‘OFF’.

Selected ‘ON’.Press the QUICK CYCLE key pad once to change

this selection.

�

P

ress the DELICATES AND KNITS key pad once to advance to next code.

TOP SPIN SPEED RPM

This can be selected from the following spin speeds: 600 rpm,

750 rpm, 800 rpm, 1000 (displays as 999) rpm.Step between

speeds by pressing the PERM.PRESS key pad. Factory

default of 800 rpm.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

P

ENNY INCREMENT OFFSET

This represents the penny increment price offset used in

Generation 2 (Enhanced Debit) PR models. Choose from 0-4

pennies by pressing the PERM. PRESS key pad.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

PREWASH LENGTH

This is the number of minutes of PREWASH. Choose 0 to disable

the prewash or select between 2 and 7 minutes by pressing the

PERM. PRESS key pad.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

FINAL SPIN LENGTH

This is the number of minutes of final high speed spin. Choose

from 3-8 minutes by pressing the PERM.PRESS key pad.

�

Press the DELICATES AND KNITS key pad once to advance to next code.

J.C

8

L

. 0 0

L

. 0 0

L.PS

8.

C E

J.C

8

J.C

8

J.C

8

J.E

8

8.

C E

8.00

0.0 0

0.0 0

8.8

00

8.800

8 1. 0 0

8 1. 0 0

82.03

82.03

following is true:

1 00 Cycles in Hundreds 1 02 = 200

2 00 Cycles in Ones 2 25 = 25

TOTAL CYCLES = 225

This is “VIEW ONLY” and cannot be cleared.

Press the DELICATES AND KNITS button

once to advance to next code.

_____________________________________

If money counter (1.0C or 1.C0) is selected,

the following is true:

3 00 Dollars in Hundreds 3 01 = $ 100.00

4 00 Dollars in Ones 4 68 = $ 68.00

5 00 Number of Cents 5 75 = $ .75

TOTAL = $ 168.75

END OF SET-UP PROCEDURES

_____________________________________

EXIT FROM MANUAL SET-UP MODE

PD Models: Reinstall service access door

n

PR Models: Remove Smart Card

n

PR Models without card reader installed:

n

Unplug washer or disconnect power.

Ë

Open console, reinsert plug into AA1,

Ë

close console.

Plug in washer or reconnect power.

Ë

PR Models set up as PN with programming

n

switch: Turn key clockwise and remove.

PR Models set up as PN without

n

programming switch: Set-up mode can be

exited by using procedures from Service

Access Code (See page 3-4).

3-8

Page 27

COMPONENT ACCESS

COMPONENT ACCESS

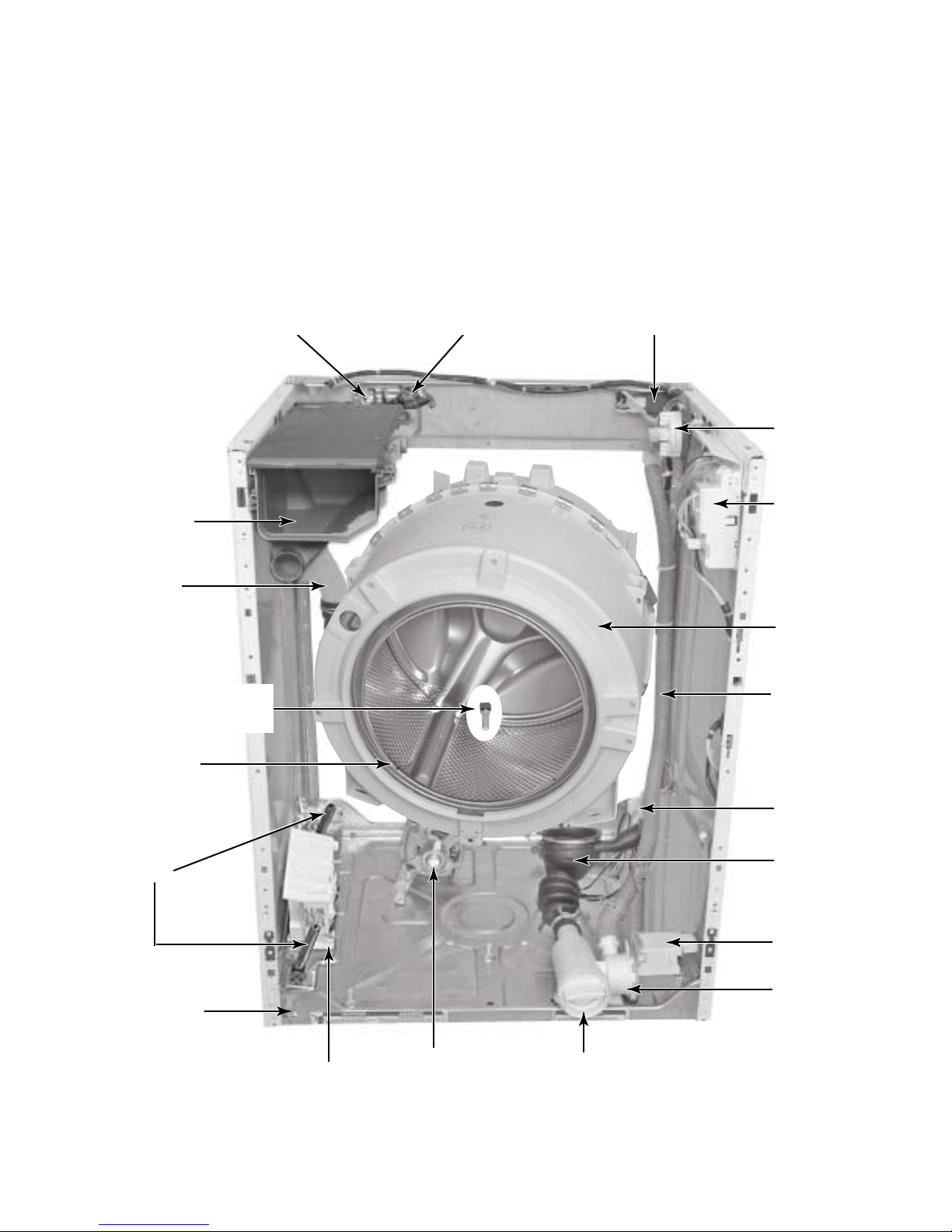

COMPONENT LOCA

TIONS

This section shows how to service each component within the Whirlpool Commercial Front

Loading W

ashers Model 8990. The components and their locations are shown below.

RFI Line Filter

Rear Panel

Ground Switch

T

ub-To-Pump

Hose

Front Panel

Ground Switch

Drive Motor

2 of 3

Air Gap

Dampers

Spin Basket

T

emperature Sensor:

(On rear of outer tub)

Chemical

Dispenser

&

Assembly

Dual Cold W

ater

Inlet Valve

Single Hot W

ater

Inlet Valve

Not Shown:

Key pad

Assembly,

User Interface Control

Transformer and

Door Latch Assembly

Central

Control Unit

Pressure

Switch

Pump-T

o-Drain

Hose

V

ent Tube

Motor Control

Unit

Outer

Tub

Assembly

Drain Pump

Filter

Drain Pump

Motor

Drain Pump

COMPONENT LOCATIONS

This section shows how to service each component within the Maytag Model 30 Commercial Front

Loading Washer. The components and their locations are shown below.

4-1

Page 28

CHEMICAL DISPENSER

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

REMOVE FACIA AND

DRAWER AND PARTS

Pull the drawer out as far as it will go and

1.

press the release tab down in the top left

rear corner with a flat blade screwdriver.

Pull the drawer out of the washer.

2.

CONTROL PANEL COVER

Unplug washer or disconnect power.

1.

Turn off the water supply to the washer.

2.

Remove four T-20 security machine screws

3.

from the front of the facia.

Lift the detergent cup insert out of the

3.

detergent drawer for cleaning.

Remove the locking tab by unclipping it from

4.

the slots in the top left rear corner. Replace

it by clipping it into the slots.

Remove front decorative plate by removing

5.

four T-20 security sheet metal screws.

TECH TIP:

The decorative front plate is secured with

n

sheet metal screws. The facia is secured

with machine screws. Do not interchange

these screws.

The front of the chemical dispenser drawer

n

is called the handle, and it can come off if

pulled on too hard. To reinstall the handle

straighten the tabs, hook the top 3 tabs

onto the drawer and rotate the front down to

engage 3 tabs at the bottom.

If softener fails to dispense properly or

n

completely, remove the bottom cover of

the dispenser assembly and make sure the

siphon holes are clean.

4-2

Remove the chemical dispenser drawer

4.

from the washer.

Remove two T-20 security sheet metal

5.

screws, that were hidden by the chemical

dispenser drawer, on the left end of the

control panel.

Two T-20

Security Screws

Page 29

Pull the control panel cover, facia and

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

6.

display lens off the washer.

Depress the clips on the edges of the

7.

display lens on the back side of the control

panel cover. Remove the display lens from

the front of the cover.

On PR Models the card reader cover has

8.

two clips on the back side of the control

panel cover that hold it in place. Depress

the clips and remove the cover, along with

the facia, from the front of the control panel

cover.

Unclip the two clips from the back side of

9.

the facia and remove the card reader cover

from the front of the facia.

NOTE: To avoid damage, lay a towel, or

another covering, on the washer top and

place removed hardware and tools on the

covering.

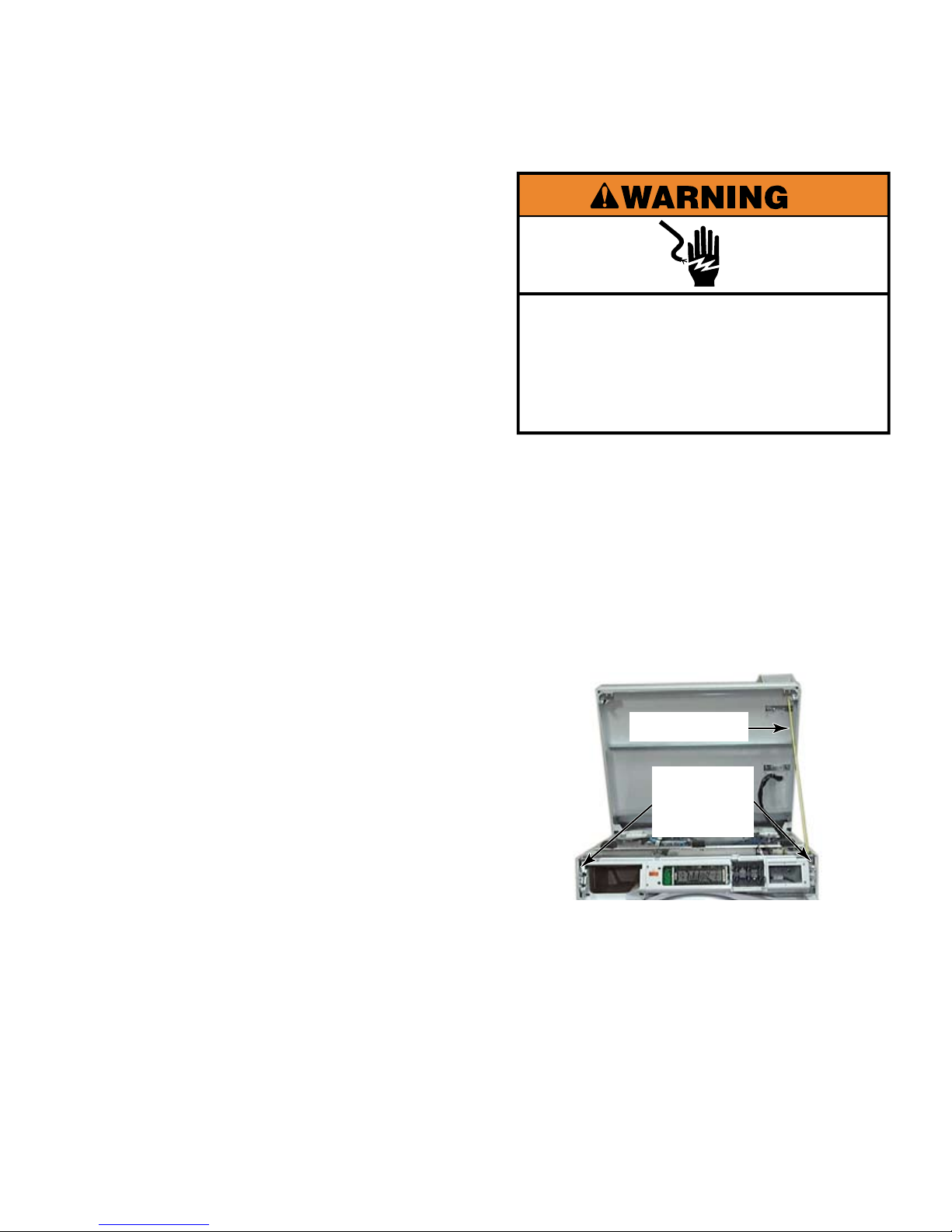

LIFT WASHER TOP

Unplug washer or disconnect power.

1.

Turn off the water supply to the washer.

2.

Remove the control panel cover

3.

(See page 4-2).

Remove two 1/4” hex head screws, one

4.

in each top front corner behind the control

panel cover.

TECH TIPS:

Machine screws must be used for the facia,

n

not sheet metal screws.

In the opening for the card reader is the

n

cable for a card reader that is now installed

on the control board at the factory.

There is a wire harness in the card reader

n

opening that is connected to the edge of the

UIC used in the manufacturing process only.

It can be left in the control panel or removed

if desired.

4-3

Support Rod

Two 1/4”

Hex Head

Screws

Lift the front edge of the washer top to open

5.

it. When it is open all the way it will rest

on the 2 retaining supports attached to the

back of the washer just below the top.

NOTE: If the washer is not level the top may

not be stable to leave in the upright position

without using a support rod.

The top has 2 hinges, secured with star

6.

head screws, that are hidden once the top is

closed.

Page 30

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

REMOVE CONTROL PANEL

Unplug washer or disconnect power.

1.

Turn off the water supply to the washer.

2.

Lift the washer top (See page 4-3).

3.

Remove two T-20 1/4” hex head screws on

4.

each end that secure the control panel to

the washer.

Rotate the control panel down to access the

6.

components located behind it.

Disconnect the power connector from

7.

the transformer at AA6 on the UIC, by

depressing the tab and pulling the plug off

of the connector.

Disconnect the wire harness from the CCU

8.

to the UIC by depressing the locking tab

and pulling the Rast connector off of the

control board edge.

Each Rast connector has keyed tabs on

9.

the top, which are located in different

places on each connector to assist in

proper placement of the connector during

reassembly.

Disconnect the ground wire from the

10.

control panel by depressing the locking

tab and pulling the connector off the spade

which is secured to the control panel with a

screw.

Left end

Four T-20 1/4”

Hex Head

Screws

Lift the control panel up to release the two

5.

tabs from the top edge of the washer.

2 Tabs

Right end

4-4

The control panel can now be removed

11.

from the washer.

The control panel has brass inserts in

12.

the screw holes that can be removed and

changed if they become stripped. The

brass inserts are threaded on the outside

and on the inside. Use a pair of pliers to

unscrew the insert from the control panel.

CCU to UIC

Rast Connector

Transformer

Connector AA6

NOTE: CCU to UIC cable can be

connected to either of the top 2 connections

on the UIC edge. (WB3 or WA3).

Ground Wire

Connector

Page 31

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

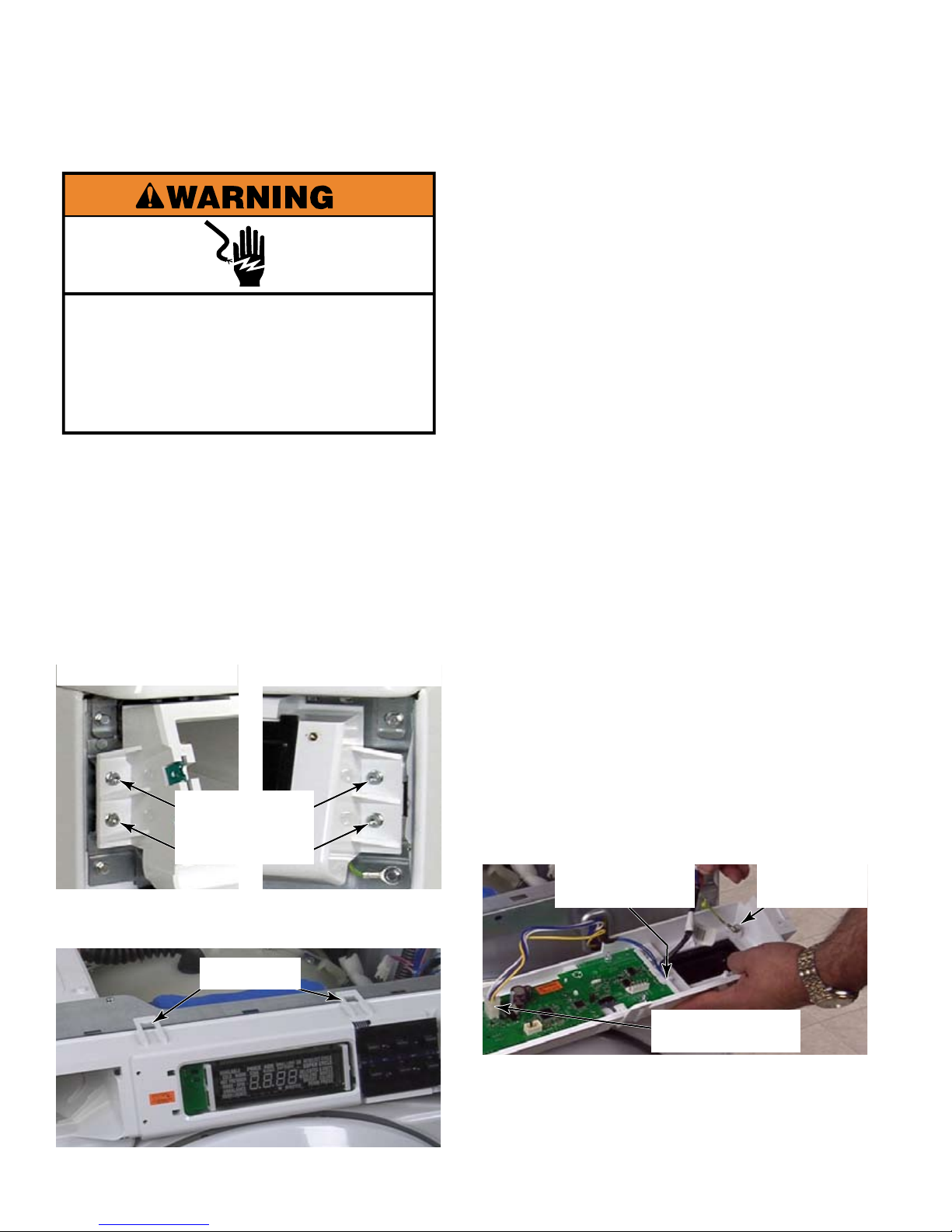

REMOVE USER INTERFACE CONTROL (UIC)

Squeeze the 2 tabs at the left end of the

7.

board together and lift the board up off the

squeeze tabs. Remove the board by sliding

it out of the control board edge connector

mounting bracket.

Unplug washer or disconnect power.

1.

Turn off the water supply to the washer.

2.

Remove the control panel (See page 4-4).

3.

Disconnect all of the wire connectors from

4.

the UIC.

Remove the key pad assembly ribbon

5.

connector by gently pulling it out of the

connector GG5 on the board.

2 Star Head

Screws

2 Tabs

Two 5/16”

Nuts

Push Button

Ribbon Cable

Remove the 2, number 1, star head screws

6.

from the left end and two 5/16” nuts from

the right end of the UIC.

4-5

Page 32

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

REMOVE KEY PAD ASSEMBLY

Unplug washer or disconnect power.

1.

Turn off the water supply to the washer.

2.

Remove the control panel (See page 4-4).

3.

Press the end of the bolts down and remove

7.

the key pad assembly from the front side of

the control panel.

NOTE: Key pad assemblies may look

similar across Maytag product lines, but

the hardware may be different and not

interchangeable.

Remove two 5/16” hex head nuts from the

4.

right end of the UIC.

Two 5/16”

Nuts

Ribbon

Connector

Gently pull the ribbon connector out of the

5.

connector GG5 on the UIC.

The extra length of plastic at the end of the

6.

ribbon connector must be bent back over

the top of the end of the ribbon connector,

not down and under or it will block the

connections preventing operation. (See first

picture in next column)

To remove the buttons from the

8.

subassembly, release the locking tab that

holds each row of push buttons on the back

side of the subassembly. The other end

simply slides out of the slot in the metal

backer plate.

Slot

Tab

Tab

Slot

The electronic membrane pad is glued to

9.

the metal plate of the subassembly and

cannot be separated.

4-6

Page 33

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

REMOVE CONTROL PANEL BRACKET

Unplug washer or disconnect power.

1.

Turn off the water supply to the washer.

2.

Disconnect the transformer primary wire

6.

harness connector from near the CCU.

Push the free end of wires from the control

7.

panel through the hole in the control panel

bracket and remove the bracket.

Transformer

Wire Harness

Connector

Control Panel

Bracket

CCU

Remove the control panel (See page 4-4).

3.

Remove three 1/4” hex head screws at each

4.

end of the bracket.

Remove two T-20 screws from the control

5.

panel bracket that secure the front and top

of the chemical dispenser.

NOTE: These screws have higher, wider

spaced threads that are made for holding

tightly to plastic. The head shape on these

two screws is also different, a round flat top,

for easy identification.

Three 1/4” Hex

Head Screws

Free End Of Wires

From Coin Meter

Two T-20

Screws

4-7

Page 34

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

REMOVE CENTRAL CONTROL UNIT (CCU)

Unplug washer or disconnect power.

1.

With a small flat blade screwdriver, lift the

6.

locking tab that secures the CCU to the

washer.

CCU Locking tab

Turn off the water supply to the washer.

2.

Lift the washer top (See page 4-3).

3.

Remove two 1/4” hex screws to remove the

4.

cross brace below the top (See page 4-46).

Use a small flat blade screwdriver to press

5.

on the locking tab that secures each wire

connector to the CCU, and remove the

connectors.

Central

Control Unit

Transformer

Connection

Slide the CCU towards the back of the

7.

washer to release the tabs from the keyhole

slots in the side panel of the washer and

remove it.

Wire Clamps

Keyhole Slots

CCU Tabs

4-8

Page 35

CCU CONNECTIONS

Ensure that

connectors are rmly seated

onto the circuit board edge, and that the

locks are properly engaged.

S

e

riel Port

Not Used

PR6 - Pressure Switch

6 BU Wires

D

S2 - Door Switch

2 BU Wires

Blue Stripe

4 BU Wires

RD Stripe

DP2 - Drain Pump

2 BK Wires

BK Stripe

DL3 - Door Lock

3 BK Wires

GN Stripe

4 BU Wires

BU Stripe

TH2 - Temp Sensor

2 BK Wires

No Stripe

MI3

3 BU Wires

MS2 - Drive Motor

WH Stripe

DLS2 - Door Lock Switch

IF2 - Line Filter

(2 Pink Wires)

Board Edge Connectors

Connector Locking Tabs

CENTRAL CONTROL

UNIT

Not Used

MCU Interface

HE2 - Wax Moto

r

Not Used

User Interface

MS2-MCU

(Drive Motor Power)

3 BK Wires

GN Stripe

DI6 -

Hot W

ater Inle

t #1

VC

H7

- Cold W

ater Inlet 2

- Cold W

ater Inle

t #3

DL3'

'-'''Doorq***** Lock ''''Sol'%enoi%%d

(L1 is on the right)

4-9

Page 36

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

REMOVE WATER INLET VALVES

Locking Tab

Unplug washer or disconnect power.

1.

Turn off the water supply to the washer.

2.

Remove the washer hoses from the hot and

3.

cold water inlet valves.

Lift the washer top (See page 4-3).

4.

Water Inlet

Valves

Lift The locking tabs and disconnect the

5.

wire connectors to the water inlet valves.

The blue connector is for the hot water

valve number 1, the white connector is for

cold water valve number 3 and the grey

connector is for cold water valve number 2.

Inlet Hoses

& Clamps

Remove the T-20 screw, on the back of the

7.