Page 1

Maytag Neptune

27” Front Load Washer

Troubleshooting Guide

© Maytag Technical Training Services 2005

L2005-005

Page 2

Page 3

Page 4

Page 5

Slide 1 – Troubleshooting

Slide 2

Always refer to the Technical Data Sheet shipped with the product for detailed information

for the model you are servicing. Follow all Caution and Safety Warnings

The following is an example of the information available on the Technical Data Sheet

Will Not Start

• Plug cord into live electrical outlet. Check for proper voltage.

• Check fuse or reset circuit breaker.

• Push any key to turn on the clothes washer. Push the rotary selector knob to start the washer.

• Close door and push the rotary selector knob to start the clothes washer.

• Check to see if the washer is in a pause or soak period in the cycle. Wait briefly for machine

to start. (If washer is in suds period, “SUDs” will display instead of remaining time.

• Check for restricted drain system. During an electrical drain problem, “nd” error will occur

after 15 minutes.

• Check water supply is working.

• Check water valve connections are good.

• Check the line filter and water valve filter.

• Check the machine control board terminal connections CN5, CN6 for good connections.

• Replace console control board.

Leaking

• Make sure inlet hose connections are not leaking. Check for rubber gasket damage due to

over-tightening.

• Check standpipe for leak. Wrap a dry rag around the standpipe opening. If rag becomes wet,

leak is fault of home plumbing. Be sure the standpipe is capable of accepting the flow of

water from the washer.

• Make sure end of drain hose is correctly inserted and secured to drain standpipe.

• Check internal hose connections (fill, drain systems, dispenser hoses & clamps).

• Check rubber boot. Remove, reposition and reinstall, if necessary.

• Check for possible kinked dispenser to outer tub hose. Hot water pressurization may force

door open.

No Tumble

• Start normal cycle with an empty machine and allow a fill to check tumble.

• Perform Board Output Test, or Quick Spin Test (Before test, make sure that the tumbler is

empty.)

• Check for loose connections at Machine Control Board, Pressure Switch, Motor, Tach

Harness and Motor Control. (Refer to the component testing procedure)

• Check motor windings resistance. (CN9 pins 1 &3 = 11.6ohms(±7% 20°C/68°F basis), pins 1

& 2 = 11.6ohms(±7%20°C/68°F basis), Pin2 & 3 = 11.6 ohms (±7% 20°C/68°Fbasis)

• Check belt.

• Faulty Main Control Board.

• Faulty motor.

1

Page 6

Will Not Spin

• Check to make sure the door is fully closed.

• Check for water left inside the washer. If present, see Will Not Drain.

• Perform Board Output Test or Quick Spin Test. (Before test, make sure that the tumbler is

empty.) If it doesn’t tumble after the test above, check unbalanced load scenario, Main

Control Board, and motor.

• Check for loose connections at Machine Control Board, Pressure Switch, Motor, Tach

Harness and Motor Control. (CN8, CN9, CN3) Refer to the component testing procedure.

• Check motor winding resistance (CN9 pins 1&3=11.6ohms ±7%@68F, pins 1&2=11.6ohms

±7%@68F, pins 2&3=11.6ohms. ±7%@68F.

Tub Full of Suds

• Check for restricted drain system. See Will Not Drain and Will Not Spin.

• Check for loose wire connections at Control Board and pump.

• Perform Board Output Test.

• Use high efficiency or low sudsing detergent specially formulated for front load washers.

• Reduce detergent amount for that specific load size and soil level. Towel loads have a

minimal amount of soil present and typically create more suds.

• Run the clothes washer through another complete cycle using the coldest water, tablespoon

of salt and no detergent.

Wet Clothes

• Very small clothes loads can cause unbalanced loads. Add additional towels.

• Excessive suds may have been present, due to not using High-Efficiency detergent. Reduce

amount of detergent usage.

• See Will Not Spin.

• Low Spin Speed or Drain Only was selected.

Will Not Drain

• Check for restricted drain system.

• In cold climates check for frozen drain hose.

• Check for 120 VAC at the pump when a spin cycle is selected.

• Check pump motor winding resistance. (14.2 ±7% ohms)

• Check that the machine control correctly senses the water level in the washer. See Board

Input Test.

• Go to Board Output Test and perform Pump Out Test.

• Check the Machine Control Board connections at CN10 (Pin 6) for the pump. Should see

110-120VAC.(Refer to the component testing procedure).

• Check tub to pump hose for twist in hose.

Wrong Water Temperature

• Check that both faucets are turned on fully.

• Make sure water heater is set to deliver a minimum of 120°F (49°C) hot water at the tap. Also

check water heater capacity and recovery rate.

• If the water heater is located a long distance from washer, the water line may need to be

purged prior to starting wash cycle.

• Too Hot/Too Cold: This washer uses a reduced amount of water, while the control board

meters the incoming flow to regulate the actual temperature of the water in the tub. This may

appear to be significantly warmer/cooler than expected.

• Make sure the temperature selection is correct.

• Disconnect inlet hoses from the Water Valve and clean the valve screens of any debris.

2

Page 7

Noisy and/or Vibration/Walking

• Check if the washer was properly leveled and the locking nuts are securely tightened up

against the base frame of the washer.

• Check and determine all four of the shipping bolts and spacers have been fully removed from

the rear panel of the washer.

• Check for proper load size and distribution. If clothes load is too small, add a few towels to

balance the clothes load better.

• Check the tightness of the rear pulley bolt. Tighten if necessary.

• Clean floor and bottom side of washer feet. Check clearance. Refer to the back of machine

and Installation Instruction.

Rubber Feet Leaving Marks on Floor

• Use a pencil eraser to remove mark.

• Walk washer into location, do not drag.

Additive Cups Full of Water

• Small amount of water in bottom of additive cups is normal.

• Remove and wash Dispenser Tray, removable Cup, and Rinse Cap.

• Level washer.

•

Buttons do not Respond

• Option and Function buttons respond differently according to each cycle.

• Child Lock feature has been selected. To disable feature press and hold Wash/Rinse Temp

and Spin Speed simultaneously until a beep is heard.

• When display shows "End", only the Power Off button will function. Press Power Off and

make new cycle selections.

Consumer Information Codes

If the consumer observes codes on display, see table below.

LED

Display

nd

The water level fails to drop below the Low Water level

reset within 15 minutes, before a spin begins.

Description Diagnostic code

Door failed to unlock after 3 attempts.

LO

Continuous fill of 12minutes. Total fill of 14minutes.

nF

FL

LE

Door failed to lock after3 attempts.

Water sensor level fault.

A fault is detected in the water level sensor. Data

OE

(frequency) shows the water level is at or above the

overflow level.

1

2

3

4

8

E

3

Page 8

LED

Display

Description Diagnostic code

E2

dc

od

dL

dS

bE

tE

E3

Detected a key pressed more than 30seconds, the key

will be assumed to be stuck.

Never exceeded 400rpm due to an unbalanced load. 10

The door has not been opened after two complete wash

cycles. Door switch was not seen open since the last two

final spins.

Open door lock switch with motor running. 18

Door switch is read as open and the door locked switch

is read as locked.

Motor tach signal exists without motor running. 25

Abnormal high/low temp or ohm resistance seen. 29

Machine control is attempting to drive the motor but is

not seeing any tach response. Visual check shows motor

is not moving. (Locked, Hall Sensor fault)

15

17

22

2E

System Relay failure. 34

Heater Relay failure. 36

Over Current is detected. Motor won't turn. 3E

Voltage for motor control bus is over specified limit. 91

Voltage for motor control bus is under specified limit. 92

Slide 3

Sr

Hr

3E

2E

2E

Service Mode

Service Mode enables service personnel to verify the operation of the washing machine and

diagnose problems. Service Mode can be entered in the middleof any wash cycle without

interrupting the cycle. While in Service Mode, the technician can cancel the current cycle,

set a continuous running mode, start a variety of special service tests and view diagnostic

displays

4

Page 9

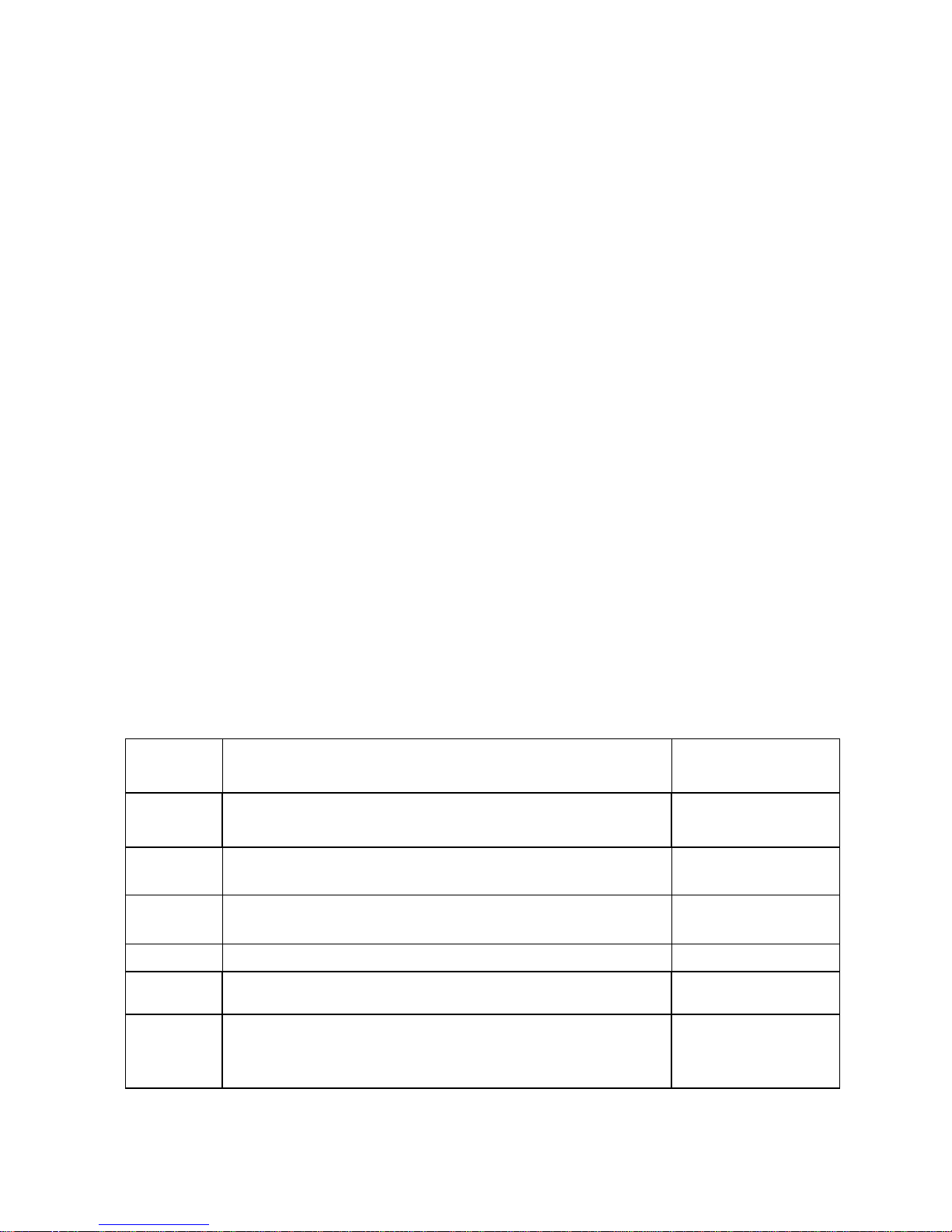

Slide 4

Press and

hold 3 Sec.

Service Mode

Enter / Exit Service Mode

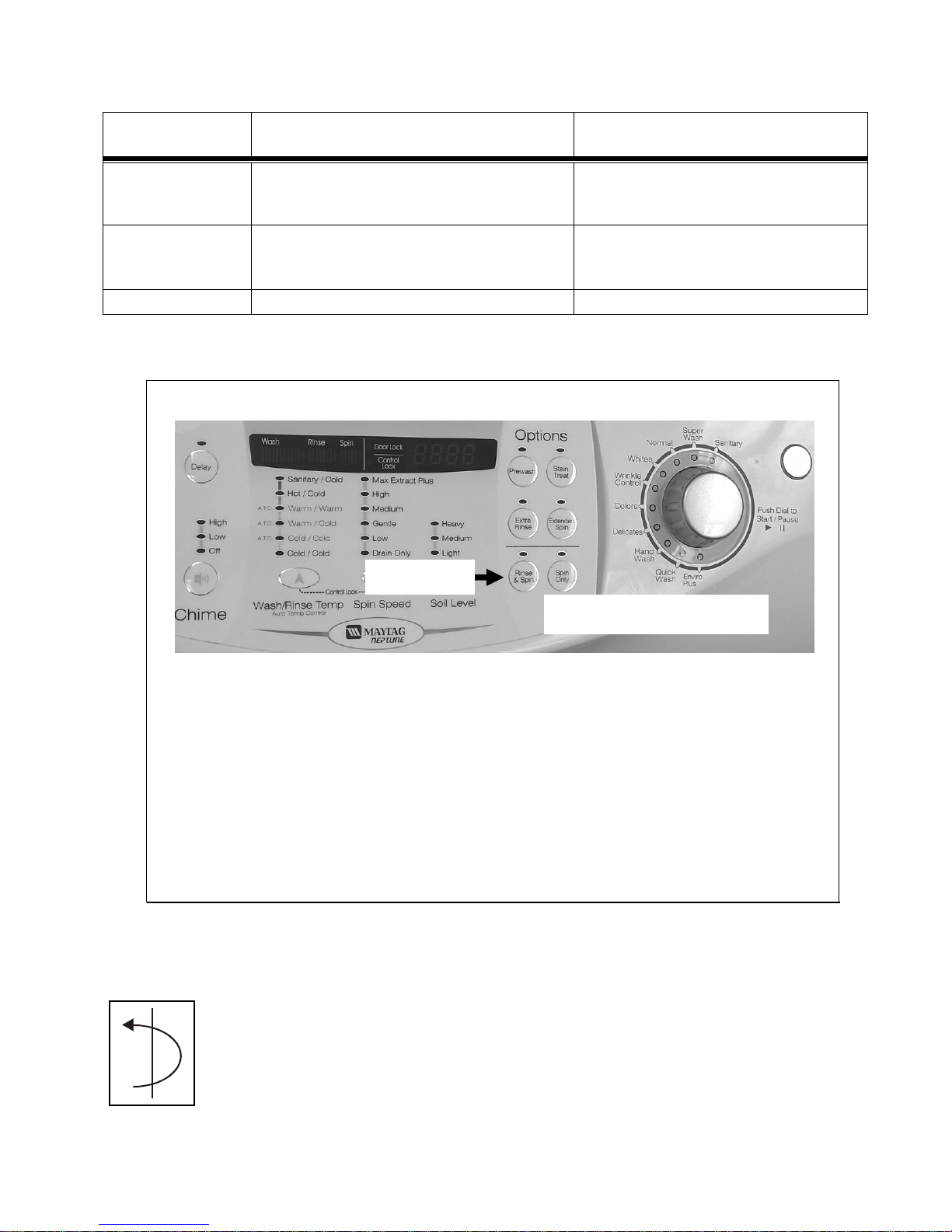

To enter Service Mode press the Chime and Extra Rinse

keys for three seconds or until the control beeps.

NOTE: The washer must be on before the Service Mode

can be entered.

Refer to Technical Data Sheet for Detailed Instructions

The motor speed will be displayed when started (motor not running display will be 0). The present

state of the machine will not be changed (i.e., the current cycle in progress will not be interrupted

and only the display will change). All LED’s will be turned off except the “Door Lock” LED. It will

continue to display the condition of the door lock.

To exit:

1) Press Chime and Extra Rinse keys for 3 seconds again, or

2) press Off, or

3) unplug the machine. Pressing the Rotary Selector knob while running a test will pause the

individual test, while remaining in Service Mode.

The following table summarizes special tests and features available in Service Mode, along with

methods of activation and cancellation.

Access Service Tests and Diagnostic Features while in Service Mode.

Test or Display

Quick Spin

Test

Press LED to Start

Press Delay Start and Rinse&Spin Press Delay start and Rinse&Spin

Press LED to Cancel

Press Off (exits Service Mode)

5

Page 10

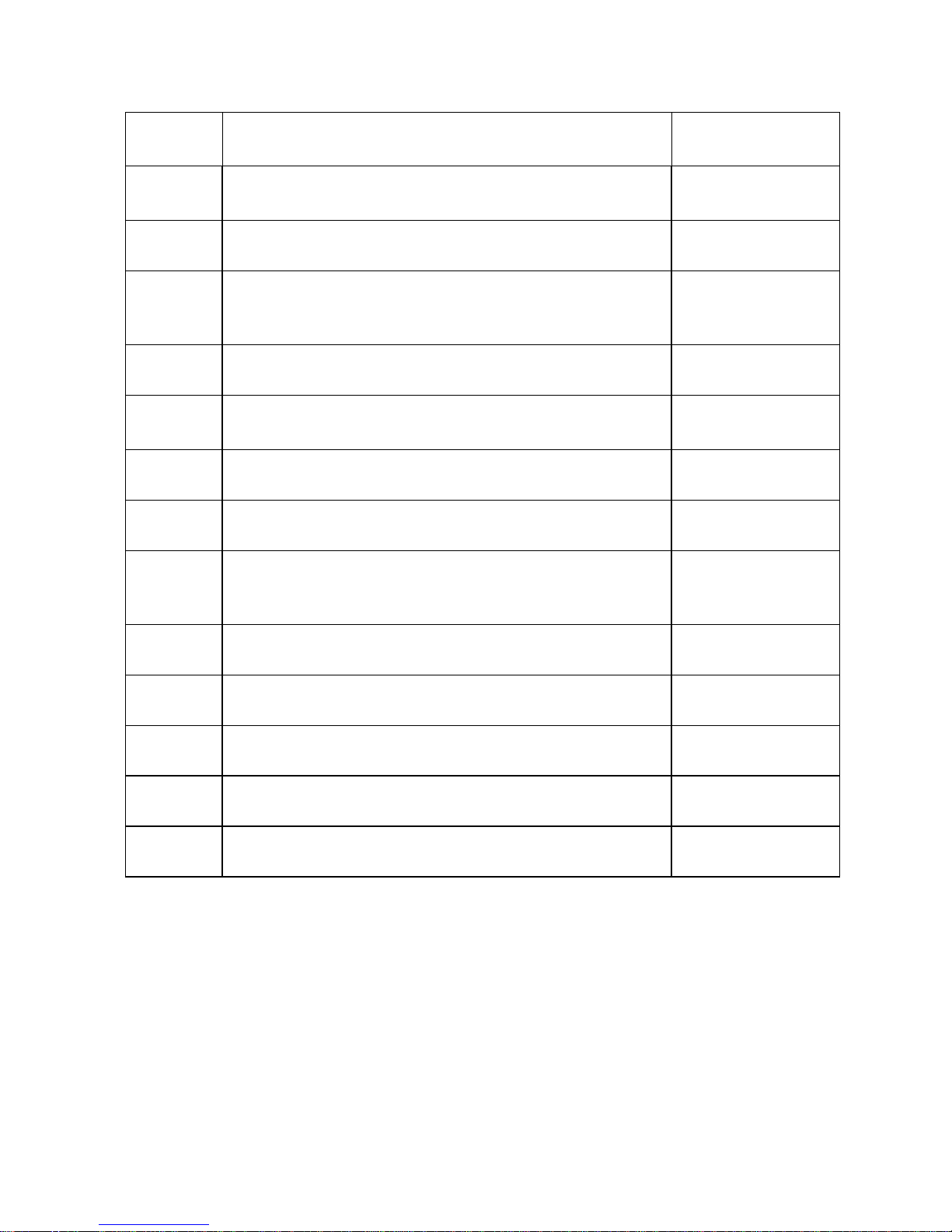

Test or Display

Press LED to Start

Press LED to Cancel

Hold Quick

Spin Step

(holds

predefined

RPM)

#

Cycle

Hold Quick

Service Cycle

Step

IN

System Check

Diagnostic

Code Display

(Initial)

All Diagnostic

Codes

Cycle Count

No. for

Diagnostic

Code

Fast

TimeDown /

Advance to

Next Step

Quick

Service

LED/Switch

Test

Board

Input

Test

Board

Output

Test /

Press Rotary Selector (during test) Press Rotary Selector (cancels

hold & resumes next step)

Press Temperature to start test. Press

Temperature during cycle to advance.

Press Temperature and Soil Level Press Off (also exits Service Mode)

Press Rinse&Spin and Spin Only

together

Press Delay for 3 seconds (then

individual buttons to test) Rotate Cycle

Selector clockwise, the LED’s around it

will be toggled. Rotate

counterclockwise, the7-segment LED’s

toggle. Press Rotary Cycle Selector, all

of the LED’s around the Rotary Cycle

Selector will be toggled.

Press Spin Only Press Spin Only

Press Spin Speed Press Off

Press Rinse& Spin – displays “d” Press Rinse&Spin again

Rotate Cycle Selector either direction N/A

Press and hold Rotary Selector, while

diagnostic code is displayed

Press Power Off

Press Rinse&Spin and Spin Only

to resume

Press Off twice after starting test

Release Rotary Selector (returns

to diagnostic code display)

6

Page 11

Test or Display

Press LED to Start

Press LED to Cancel

Clear All

Diagnostic

Codes

Display

Software

Version

Cycle Count

Slide 5

Press Delay and Chime together while

displaying diagnostic codes

Press Soil Level. Press 2 times for

displays with only 2 character positions.

Press Chime

Press

Quick Spin Test

Press Soil Level a 3

rd

time

Quick Spin Test

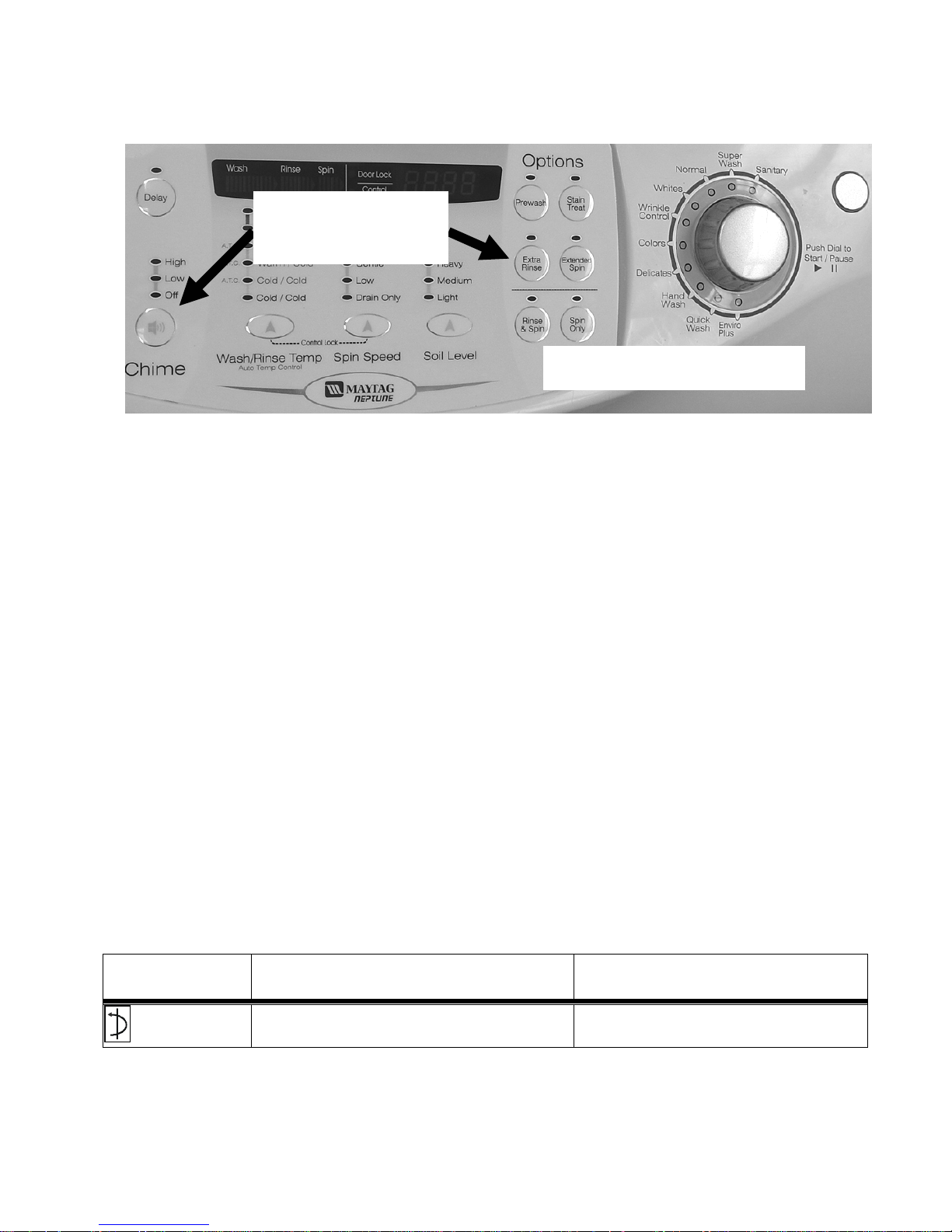

While in Service Mode, press Delay and Rinse&Spin key to

start a Quick Spin Test. Quick Spin test steps are as follows:

• Start spinning and after reaching a maximum spin speed,

stay at maximum spin speed for 2 minutes and stop Quick

Spin Test

Refer to Technical Data Sheet for Detailed Instructions

Quick Spin Test

While in Service Mode, press Delay and Rinse&Spin keys to start a Quick Spin Test.

Quick Spin test steps are as follows:

• Start spinning and after reaching a maximum spin speed.

• stay at maximum spin speed for 2 minutes and stop Quick Spin Test.

7

Page 12

Slide6

Press

Hold Quick Spin Test

Hold Quick Spin Step

If the Rotary Selector key is pressed during the Quick Spin

test, the machine will hold at the next highest index speed

for up to 10 minutes. At the end of 10 minutes, the machine

will resume and finish the Quick Spin test. To cancel the

Hold and allow the Spin Test to continue, press the Delay

and Rinse&Spin keys.

Refer to Technical Data Sheet for Detailed Instructions

Hold Quick Spin Step

If the Rotary Selector key is pressed during the Quick Spin test, the machine will hold at the

next highest index speed for up to 10 minutes. At the end of 10 minutes, the machine will

resume and finish the Quick Spin test. To cancel the Hold and allow the Spin Test to

continue, press the Delay and Rinse&Spin keys.

8

Page 13

Slide 7

Press

Fast Time Down Test

Fast Time Down Test

While any test or cycle is running in Service Mode, pressing

the Temperature key will advance the program to the next

cycle stage.

Refer to Technical Data Sheet for Detailed Instructions

Fast Time Down Test

¤

Cycle stages are located at key locations in the machine operation. As the program is advanced

it will index as follows: The end of each fill (the same as the beginning of a tumble session for

Wash, or Rinse); at the beginning of a drain session; at the beginning of a spin session (at this

position, check the water level, if over reset level, drain first before entering the spin function); at

the beginning of a fill session; at the beginning of Bleach fill; at the beginning of Fabric Softener

fill; and every 3 minutes during the tumble sessions (Wash, and Rinses).

While any test or cycle is running in Service Mode, pressing the Temperature key will

advance the program to the next cycle stage.

9

Page 14

Slide 8

Press and hold 3 sec.

Quick Service Cycle

Quick Service Cycle

While in Service Mode, pressing the Temperature and Soil

Level key for 3seconds will start a Quick Service Cycle.

This will be a quick check of all systems. If display shows od

then open and close door. Pressing Spin Speed will advance

to the next cycle. The following steps are performed: Display

shows “SC”.

Refer to Technical Data Sheet for Detailed Instructions

While in Service Mode, pressing the Temperature and Soil Level key for

The “SC” in the display will blink as an indication of failure, and continue blinking until the quick

service cycle test has reached the end. Any diagnostic code logged during this test will result in

failure of the test, but will not necessarily stop the test. During the Quick Service Cycle, pressing the

Spin Speed key will advance to the next step. Pressing the Rinse&Spin and Spin Only keys will

suspend the machine at the current step for up to 10 minutes or until Delay Start and Chime are

pressed again. All LED’s should flash on and off while the system is suspended or on hold.

#

advance to the next cycle. The following steps are performed: Display shows “SC”.

1. Hot water for 5 seconds and then turn off.

2. Cold water for 5 seconds and then turn off.

3. Bleach valve for 5 seconds and then turn off.

4. Dispenser softener using cold water and bleach water for 5 seconds and then turn off.

5. Turn on Cold valves until the control detects proper water level. During this time, tumble at

45 rpm for 5seconds in a clockwise direction, pause for 2seconds, tumble at 45 rpm for 5

seconds in a counterclockwise direction, pause for 2 seconds. Continue pattern until the

water level is detected. Minimum time for this segment to be 5 seconds. After water height is

achieved, continue tumble pattern for another 14 seconds. If the washer is equipped, turn on

heater for first 5 seconds of this tumble pattern. Advance the washer to next step if water is

not connected to machine.

6. Drain and spin to maximum speed. Machine will achieve maximum speed using the safest,

fastest method.

7. Display a “PA” (Passed) continuously for 5 seconds I no diagnostic codes were logged

during the test. Washer will return to the normal Service Mode at the end of the 10 second

period.

Quick Service Cycle

3seconds will start a Quick Service Cycle. This will be a quick check of all

systems. If display shows od then open and close door. Pressing Spin Speed will

10

Page 15

Slide 9

Press

LED/ Switch Test

LED/Switch Test

While in Service Mode, press the Delay key to start a LED/Switch check.

All the LED’s can be toggled or slewed by pressing the key associated

with the LED or set of LED’s. All keys (including the OFF button) must be

pressed within 5 minutes for this test to pass. “PA” will be displayed for

five (5) seconds once all keys have been pressed and the test is

completed. Following 20seconds of inactivity at any point, this test will exit

without any display. The Power Off switch pad must be pressed twice

within 30 seconds to cancel this test.

Refer to Technical Data Sheet for Detailed Instructions

LED/Switch Test

While in Service Mode, press the Delay key to start a LED/Switch check. All the

LED’s can be toggled or slewed by pressing the key associated with the LED or set of LED’s. All

keys (including the OFF button) must be pressed within 5 minutes for this test to pass. “PA” will be

displayed for five (5) seconds once all keys have been pressed and the test is completed. Following

20seconds of inactivity at any point, this test will exit without any display. The Power Off switch pad

must be pressed twice within 30 seconds to cancel this test.

Switch Action

Delay Start Press once

Chime Press 3 times

Extra Rinse Press once

Soil Level Press 4 times

Spin Speed Press 5 times

Temperature Press 5 times

Rinse&Spin Press once

Spin Only Press once

Prewash Press once

Extended Spin Press once

Selector Knob Rotate 1 full revolution clockwise

Selector Knob 1 position counterclockwise

Start Pause Press once

Selector Knob Press once

Power Off Press once

11

Page 16

Slide 10

Press

Board input Test

Board Input Test

While in Service Mode, pressing the Spin Only key will

begin the Board Input Test. This test turns on a specified

output after a key press. Pressing the Spin O n ly key again

cancels the test. (Display shows in). While in Service Mode

follow chart to check respective function.

Refer to Technical Data Sheet for Detailed Instructions

Board Input Test

IN

respective function.

• When the “Rotary Cycle Selector” is set to “Super Wash” and the “Rotary Cycle Selector” is

• When the “Rotary Cycle Selector” is set to “Normal” and the “Rotary Cycle Selector” is

• When the “Rotary Cycle Selector” is set to “Whites ”and the “Rotary Cycle Selector” is

• When the “Rotary Cycle Selector” is set to “Wrinkle Control” and the “Rotary Cycle

• When the “Rotary Cycle Selector” is set to “Colors” and the “Rotary Cycle Selector” is

While in Service Mode, pressing the Spin Only key will begin the Board Input Test.

This test turns on a specified output after a key press. Pressing the Spin Only key again

cancels the test.(Display shows in).While in Service Mode follow chart to check

pressed, the door position will be displayed: “OP” if open, “CL” if closed.

pressed, the Lock position will be displayed: “UL” if unlocked, “LO” if locked.

pressed, the High water level will be displayed: “

High water level is defined as the over flow water level.

Selector” is pressed, the Medium water level will be displayed: “-0” if below level, “-1” if

above level. The Medium water level is defined as the minimum water level needed to turn

the heater on.

pressed, the Low water level will be displayed: “_0” if below level, “_1” if above level. The

Low water level is defined as the reset water level.

–

0” if below level, “–1” if above level. The

12

Page 17

• When the “Rotary Cycle Selector” is set to “Hand Wash” and the “Rotary Cycle Selector” is

pressed, the level of Tub unbalance will be displayed: “UC” if balanced, “UO” if unbalanced.

“U0” will be displayed during the time when the machine is correcting for the unbalance; e.g.

slowing down to redistribute the load or to get to a lower spin speed. Once the situation has

been corrected (i.e. the load has begun tumbling or the lower speed has resulted in an

acceptable amount of balance); “UC” will once again be displayed.

• When the “Delay” switch pad is pressed, the water temperature will be displayed in Degrees

F.

• When the “Rotary Cycle Selector” is set to “Delicates” and the “Rotary Cycle Selector” is

pressed, the water temperature will be displayed in degrees C (Celsius).

While in Service Mode follow chart to check respective function.

Selection Function Display

Rotary cycle selector set to Super Wash. Press

Door position “OP” or “CL”

Rotary Selector Knob.

Rotary cycle selector set to Normal. Press Rotary

Lock state “UL” or “LO”

Selector Knob.

Rotary cycle selector set to Whites. Press Rotary

High water level “

Selector Knob.

Rotary cycle selector set to Wrinkle Control. Press

Rotary Selector Knob.

Rotary cycle selector set to Colors. Press Rotary

Medium water

level

Low water level “_0” if below level. “_1” if

Selector Knob.

Rotary cycle selector set to Hand Wash. Press

Tub balance “UC” Balanced “UO”

Rotary Selector Knob.

Press Delay switch pad. Water

–

0” if below level. “–1” if

above level.

“—0” if below level. “—1”

if above level.

above level.

Unbalanced

Degrees F

temperature

Rotary cycle selector set to Delicates. Press Rotary

Selector Knob.

Water

temperature

Degrees C

13

Page 18

Slide 11

Press

Board Output Test

Board Output Test

While in Service Mode, pressing the Spin Speed key will

begin the Board Output Test. This test turns on a specified

output after a key press. Pressing the Spin Speed key again

cancels the test. Only one output can be “on” at any time. All

outputs will be turned off after five (5) minutes of inactivity.

Refer to Technical Data Sheet for Detailed Instructions

Board Output Test

While in Service Mode, pressing the Spin Speed key will begin the Board Output Test. This

test turns on a specified output after a key press. Pressing the Spin Speed key again

cancels the test. Only one output can be “on” at any time. All outputs will be turned off after

five (5) minutes of inactivity.

While in Service Mode follow to check respective function.

• When the “Rotary Cycle Selector” is set to “Super Wash” and the “Rotary Cycle Selector”

button is pressed, the Main relay will be toggled (either from “on” to “off” or from“ off” to “on”).

• When the “Rotary Cycle Selector” is set to “Normal” and the “Rotary Cycle Selector” button

is pressed, the hot water valve will be turned on. This output will remain on until the “Rotary

Cycle Selector” button is pressed again to turn off the output. The control will not allow the

machine to fill past the High water level.

• When the “Rotary Cycle Selector” is set to “Wrinkle Control” and the “Rotary Cycle

Selector” button is pressed, the cold water valve will be turned on. This output will remain on

until the “Rotary Cycle Selector” button is pressed again to turn off the output. The control

will not allow the machine to fill past the High water level.

• When the “Rotary Cycle Selector” is set to “Delicates” and the “Rotary Cycle Selector”

button is pressed, the bleach valve will be turned on. This output will remain on until the

“Rotary Cycle Selector” button is pressed again to turn off the output. The control will not

allow the machine to fill past the High water level.

• When the “Rotary Cycle Selector” is set to “Hand Wash” and the “Rotary Cycle Selector”

button is pressed, the pre wash valve will be turned on. This output will remain on until the

“Rotary Cycle Selector” button is pressed again to turn off the output. The control will not

allow the machine to fill past the High water level.

• When the “Rotary Cycle Selector” is set to “Quick Wash” and the “Rotary Cycle Selector”

14

Page 19

button is pressed, the drain pump will be turned on. This output will remain on until the

“Rotary Cycle Selector” button is pressed again to turn off the output.

• Pressing the “Delay” switch pad will turn on the motor and the “Delay” LED. This output and

the LED will remain on until the “Delay” switch pad is pressed again to turn off the output.

When activated, the machine will tumble for 5 seconds in the CW direction, pause for

2seconds, tumble in the CCW direction for 5 seconds, pause for 2 seconds; repeating this

pattern until “ Delay” button is pressed again to turn off the tumbling. Note that all tumble

speeds are assumed to be 45 rpm.

• Pressing the “Chime” switch pad will unlock the door and turn on the all the LED’s above the

“Chime” button. This output will attempt to unlock one time, if safe to do so.

• Pressing the “Temperature” switch pad will lock the door and all the Temperature LED’s will

turn ON. Pressing the “Chime” button will unlock the door and the all the Chime LED’s will

turn ON.

• When the “Rotary Cycle Selector” is set to “Colors” and the “Rotary Cycle Selector” is

pressed, the bleach valve and the cold water valve will be turned on to check the fabric

softener fill. This output will remain on until the “Rotary Cycle Selector” button is pressed

again to turn off the output. The control will not allow the machine to fill past the High water

level.

• When the “Rinse & Spin” keypad is pressed, the Heater will be turned on if the water level is

above the Heater Safety Level. If the water level is below the Heater Safety Level, a warning

beep will be given and the heater will not be turned on. The Heater output will remain on until

the “Rinse & Spin” keypad is pressed again to turn off the output.

Selection Component Function

Rotary cycle selector set to Super Wash.

Press Rotary Selector Knob.

Rotary cycle selector set to Normal. Press

Rotary Selector Knob.

Rotary cycle selector set to Wrinkle

Control. Press Rotary Selector Knob.

Rotary cycle selector set to Delicates.

Press Rotary Selector Knob.

Rotary cycle selector set to Hand Wash.

Press Rotary Selector Knob.

Rotary cycle selector set to Quick Wash.

Press Rotary Selector Knob.

Press Delay switch pad

Press Chime switch pad Door Lock 1 Attempt to unlock

Press Temperature switch pad Door Lock Lock Door

Rotary cycle selector set to Colors. Press

Rotary Selector Knob.

Press Rinse & Spin switch pad

Main Relay

Hot Water Valve

Cold Water Valve

Bleach Valve

Pre Wash Valve

Drain Pump

Motor

Bleach Valve and

Cold Water Valve

Heater

1st press valve on. 2nd press valve

off.

st

1

press valve on. 2nd press valve

off.

1st press valve on. 2nd press valve

off.

st

1

press valve on. 2nd press valve

off.

1st press Drain Pump on. 2nd press

Drain Pump off.

1st press Motor on. 2nd press Motor

off.

1st press Fabric Softener fill. 2nd

press valves off

1st press heater on. 2nd press heater

off.

On to Off or

Off to On

15

Page 20

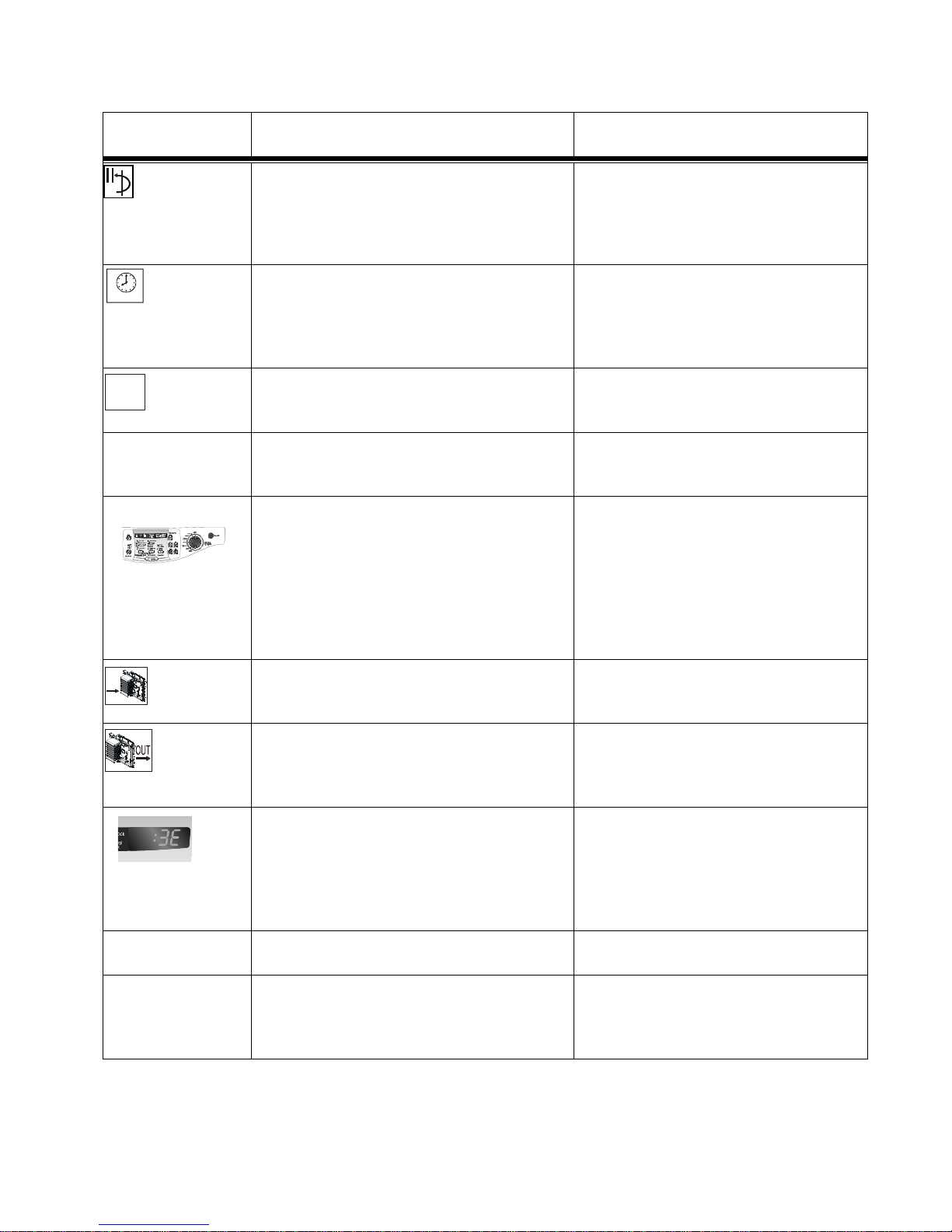

Slide 12

Press

Display Diagnostic Codes

Display Diagnostic Codes

The diagnostic code display can be toggled on and off from

Service Mode by pressing the Rinse&Spin key and rotating

the cycle select knob. The display will show a “d”. Rotating

the Cycle Selector knob in either direction will cycle through

the list of codes one code at a time with no wrap.

Refer to Technical Data Sheet for Detailed Instructions

Display Diagnostic Codes

The diagnostic code display can be toggled on and off from Service Mode by

pressing the Rinse&Spin key and rotating the cycle select knob. The display will

show a “d”. Rotating the Cycle Selector knob in either direction will cycle through the

list of codes one code at a time with no wrap. Once an initial direction is selected by the user (either

Clockwise or Counterclockwise), subsequent movements of the knob in the same direction will show

older codes. If the user changes direction and turns the knob in the opposite direction, the more

recent code will be displayed. If rotation is continued to the limits of the list, the display will remain at

the top or the end of the list. A pair of dashes “- -” will be displayed at the end of the list of codes,

when the control reaches the top, it will again show “d”. A code generated during the current cycle

will be displayed with the Spin Indicator LED turned “ON”. If no cycle is currently running, a code

generated during the previous cycle will be displayed with the Spin Indicator LED turned “ON”.

Access Other Features While a diagnostic code is displayed, if the Rotary Selector is pressed and

held, the machine will display the number of cycles since the diagnostic code occurred. To clear the

diagnostic list press the Delay and Chime keys for 3 seconds while viewing the list.

A code generated during the current cycle will be displayed with the Spin Indicator LED turned “ON”.

If no cycle is currently running, a code generated during the previous cycle will be displayed with the

Spin Indicator LED turned “ON”.

Cycle Count Since A Diagnostic Code Occured/Clearing Diagnostic Codes

While a diagnostic code is displayed, if the Rotary Selector is pressed and held, the machine will

display the number of cycles since the diagnostic code occurred. To clear the diagnostic list press

the Delay and Chime keys for 3 seconds while viewing the list.

16

Page 21

Diagnostic Codes

Diag.

Description Trigger Action to be taken

Code

The water level fails to drop below the Low

1 No Drain

Water level reset within 15 minutes, before

a spin begins.

Displays "nd"

Go to "Will Not Drain"

Troubleshooting Section

The door

2

fails to

unlock

Door failed to unlock after 3attempts

Displays "LO" Go to "Will Not

Unlock" Troubleshooting Section

3 No Fill

The door

4

fails to lock

Continuous fill of 12 minutes. Total fill of

14minutes.

Door failed to lock after 3 attempts

Displays "nF"

Go to "No Water Fill"

Troubleshooting Section

Displays "FL" Go to "Will not lock"

Troubleshooting Section.

5-7 Not Used

Water level

8

sensor fault.

Input signal from water level Sensor

is out of range, Washer will beep and

pause the wash cycle.

Displays "LE"

Go to “No water fill

Troubleshooting”.

9 Not Used

Unbalance

detected

during final

LED – Will display “dc”

Go to "Wet Clothes

"Troubleshooting Section"

10

spin, which

prevented

the spinner

Never exceeded 400rpm due to an

unbalance load.

from

exceeding

400 rpm

Water level in the machine is believed to be

E

sensor level

Water

fault.

above the overflow level. When this

condition is detected, the machine will

automatically begin pumping water out of

the machine until it falls below the overflow

First check to see that water valve

is not stuck. If water valve is OK,

check water level sensor

level.

Go to "Clear diagnostic codes"

11

Will not

remember

machine

settings

Difficulty in reading memory

Disconnect and reconnect the

washer power cord at power

supply outlet.

If condition still exists, replace

machine control board.

12-14 Not Used

17

Page 22

Diag.

Description Trigger Action to be taken

Code

Display "E2". Go to "Membrane

Pad Check" Check connection of

keypad to control board. Replace

LED Board if necessary.

15 Stuck Key

A key is sensed to be pressed more than

30 seconds, the key will be assumed to be

stuck

Door switch

17

seen open

since the last

was not

three final

The door has not been opened after two

complete wash cycles. Door switch was not

seen open since the last two final spins

Will display "od" If door open

sensing, will cleared.

spins

Check for loose wire connections

Clear the diagnostic code and

recheck; if reoccurs, perform

Diagnostic Motor/Machine Control

Board test Check for

faulty motor relay on the machine

control board.

18

Detected

door lock

switch open

during cycle

when not

expected.

Open door lock switch with motor running.

19-21 Not Used

Door switch

22

detected

open during

cycle (when

Door switch is detected open and the door

locked switch is read as locked.

Go to "Door Lock Test"

Troubleshooting Section

not paused).

23-24 Not Used

Motor tach

25

signal exists

without

motor

Tach signal exists without torque command

or when not expected (Abnormal condition

only).

Displays " bE". Replace Machine

Control Board.

running.

26-28 Not Used

29

Sump

thermistor

failure

(Optional)

Abnormal high/low temp or ohm resistance

seen

Displays " tE".

- Loose or pinched wires

- Bad sump thermistor

30-33 Not Used

18

Page 23

Diag.

Description Trigger Action to be taken

Code

Display “E3” Evaluate wire

Motor Drive

2E

(Locked, Hall

sensor fault)

failure

Machine control is attempting to drive the

motor but is not seeing any tach response.

Visual check shows motor is not moving.

harness for loose or unhooked

connections. If machine has

separate motor control, perform

self diagnostic motor test. See

“Board Output Test”

34

Relay failure

System

Machine control does not see relay open

when it should.

Display "Sr". Replace machine

control board.

35 Not Used

Heater relay

36

Motor failure

3E

failure.

(Over

current)

Heater Relay Check signal not sensed.

Over Current is detected. Motor won't turn.

Display "Hr". Replace Machine

Control Board.

Displays "3E".Check the motor

windings, the speed sensor,

wiring connections, or Control

Board.

40-49 Not Used

Voltage for

91

motor control

bus is over

specified

Voltage for motor control bus is over limit

Display "2E".Replace Machine

Control Board.

limit

Voltage for

92

motor control

specified

Voltage for motor control bus is under

specified limit

Display "2E".Replace Machine

Control Board.

limit

19

Page 24

Slide 13

Press and

Or press Off

hold 3 Sec.

Exit Service Mode

Exit Service Mode

1) Press Chime and Extra Rinse keys for 3seconds again, or 2) Press Off, or

3) Unplug the machine. After five (5) minutes of inactivity (user key presses)

in Service Mode, the machine will exit the Service Mode and resume normal

operations. Pressing the Off key will completely exit Service Mode. If a cycle

is running, cancel the cycle. Pressing the Rotary Selector knob while

running a test will pause the individual test, while remaining in Service Mode.

A power loss during Service Mode will cancel this mode.

Refer to Technical Data Sheet for Detailed Instructions

Exit Service Mode

To exit:

1) Press Chime and Extra Rinse keys for 3seconds again, or

2) Press Off, or

3) Unplug the machine. After five (5) minutes of inactivity (user key presses) in Service Mode,

the machine will exit the Service Mode and resume normal operations. Pressing the Off key

will completely exit Service Mode. If a cycle is running, cancel the cycle. Pressing the Rotary

Selector knob while running a test will pause the individual test, while remaining in Service

Mode. A power loss during Service Mode will cancel this mode.

20

Page 25

21

Slide 14

Maytag Neptune MAH9700 27” FL Washer Schematic

Page 26

22

Slide 15

Maytag Neptune MAH8700 27” FL Washer Schematic

Page 27

23

Slide 16

Maytag Neptune MAH6700 27” FL Washer Schematic

Page 28

24

Slide 17

A resistance check can be made on most

components at the control board. Always

make resistance checks with the power off.

Page 29

25

Slide 18

Check the fill valves at CN5

Hot valve - red & black – 1100 OHMS

Pre valve – yellow & black – 1100 OHMS

Bleach valve – pink & black – 1100 OHMS

Main valve-blue & black-1100 OHMS

Page 30

Slide 18 information - Troubleshooting a no fill complaint

No Water Fill

• Test water fill. Perform Board Output Test.

• Check to make sure water supply is turned on fully.

• Check electrical circuit and connections at the Water Valve, and Pressure Switch.

• Check for kinks in inlet hoses.

• Check for clogged inlet screens.

• Visually check hot, cold, bleach and softener water valves separately for fill.

• Check for low water pressure. May be dependent on pressure entering home. Variations may

occur due to usage in the home at the time machine is used.

• Check for frozen pipes and hoses.

• Check resistance of Water Valve coils. (Normal 1.18Kohms; Check resistance of water valve

coils. Check Pin #1 of CN5 and Pin # 1,2,3,4 of CN10.

• Check for loose connections at the Pressure Switch or on the Machine Control Board, CN3.

(Refer to the component Testing procedure).

26

Page 31

27

Slide 19

Check door switch coils:

CN5, Pin 7 Sky Blue & CN9 Pin 3 Black -60 OHMS

CN5, Pin 8 White & CN9 Pin 3 Black – 60 OHMS

Page 32

Slide 19 Door Lock information

Troubleshooting a door lock complaint

Will Not Lock

• Door not all the way closed or not properly aligned. Possible laundry load is too large to close

door.

• Place washer into Service Mode and check for diagnostic codes 4,18 & 22.

• Perform Board Output Test. Check door lock system. Check the output voltage of Door

Lock Coil. If normal, change door Lock switch, If not normal, change Main Control Board.

(Refer to the Component Testing procedure.)

• Check electrical connections at lock switch assembly and machine control board (CN10).

(Refer to the Component Testing procedure.).

Will Not Unlock

• Push door closed to make sure nothing from inside is pressing against it, which may keep it

from unlocking.

• Door locked from water level too high. Opening door will result in water draining from door

opening.

• Check for water remaining in the tub. Check the temperature inside the drum is higher than

50°C/122°F. If water is present inside drum, refer to “Will not drain”, If there is no problem

with temperature, check wiring of Main Control Board and Door Lock Switch.

• Drain manually by removing drain hose clamp.

• Display shows LO. Press power Off Key to turn off the washer and unplug and reconnect

washer. Press any key to turn on the washer. if LO is displayed, Main Control Board and

Door Lock Switch should be checked.

• Place washer into Service Mode and check for diagnostic codes 4,18 & 22..

• Check electrical connections at lock switch assembly and Machine Control Board (CN10).

(Refer to the component Testing procedure.)

• Perform Board Output Test. Check door lock system for loose connections.

• Perform Board Output Test. Check door lock system. Check the output voltage of Door

Lock Coil If 120V present change door Lock switch , If not present, change Main Control

Board. (Refer to the component Testing procedure.)

Voltage Checks

Door Switch Check

Check voltage at Pin #6 and #4 of CN3

With Door Open = DC5V

With Door Closed = DC0V

Door Lock Check

Check Voltage at Pin #1 of CN5 and Pin #7of CN10 With Door Locked = AC120V

Check Voltage at Pin #1 of CN5 and Pin #2of CN7 With Door Locked = AC120V

Door Unlock Check

Check Voltage at Pin #1 of CN5 and Pin #8of CN10 With Door Unlocked = AC120V

Drain Motor Check

28

Page 33

Slide 20

To check thermistor,

measure across the

orange and white

wires in connector 9P.

The resistance should

be approximately

13,000 OHMS@ 70 F

Page 34

2

Slide 21

1

2

3

CN9

CN8

Motor Resistance Checks

Resistance checks can be made at Connector CN9 on

the machine control board or at the motor

Check

Resistance at Pin #1 and #2 of CN9 =11.6Ω

Resistance at Pin #1 and #3 of CN9 =11.6Ω

Page 35

Page 36

Be Aware, Be Alert

Always work safely.

On the Job, On the Road, In the Home

Every Time, All the Time

Loading...

Loading...