Page 1

For Future Reference

Write down the model and serial numbers

The model and serial numbers can be found

on the side of the cabinet. Use these num-

bers in any correspondence or service calls

concerning your air conditioner.

Para referencia futura

Escriba los numeros del modelo y de la eerie

Puede encontrar los nfimeros de modelo v de serie en el

costado de la rejilla del frente decorativo. Use estos

nfimeros en cualquier correspondencia o llamada de servi-

cio con relaci6n a su acondicionador de aire.

Room Air Conditioners for

Double-Hung Windows

Acondicionadores de aire

ambientales para ventanas

de guillotina

Climatiseur d' air individuel

pour flel_Otres h guillotine

Pour r6f6rence ult6rieure

Inscrivez lee numeros de modele et de eerie

Les num_ros de module et de s_rie se trouvent sur le c6t_ de

la grille d_corative avant. Utilisez ces num_ros lors de toute

correspondance ou appel au service aprbs-vente ayant trait

votre climatiseur.

Model No.. Modelo No.. N °de modi,h

l)ate of Pm_'hase, Fecha de la compra, Date d'achat ®

@

@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@

@

@

@

@

@

@

@

@

@

@

@

@

Keep_hese instructions for future reference

@

@

@

@

For additional questions please call

Toll Free: 866-MAYTAG 1Serial No.. NTlmerode serif, N °de s_rie _"

@

@

@

@

@

@

Page 2

Important Safety Instructions ooooooooooooooooooooooo

Electrical Shock Hazard

1. Plug unit only into grounded electrical outlet.

2. Do not use an extension cord or plug adapter with this unit,

3. Do not operate unit with front removed.

Failure to follow the above precautions could result in electrical

shock, fire or personal injury.

If the air conditioner has a serial plate rating of 115 volts and up to

and including 7.S amps the unit may be on a fuse or circuit breaker

with other devices. However, the maximum amps of all devices on

tbat fuse or circuit breaker can not exceed tbe amps of tbe f!lse or

circuit breaker.

If the air conditioner has a serial plate rating ofllS volts and greater

than 7.5 amps it must have its own fuse or circuit breaker, and no

other device or unit should be operated on that fuse or circuit breaker.

If the air conditioner has a serial plate rating of 230 volts it must

have its own fuse or circuit breaker, and no other device or unit

should be operated on that fuse or circuit breaker.

The location of the serial plate that applies to this inodel can be

found on the front page of this manual.

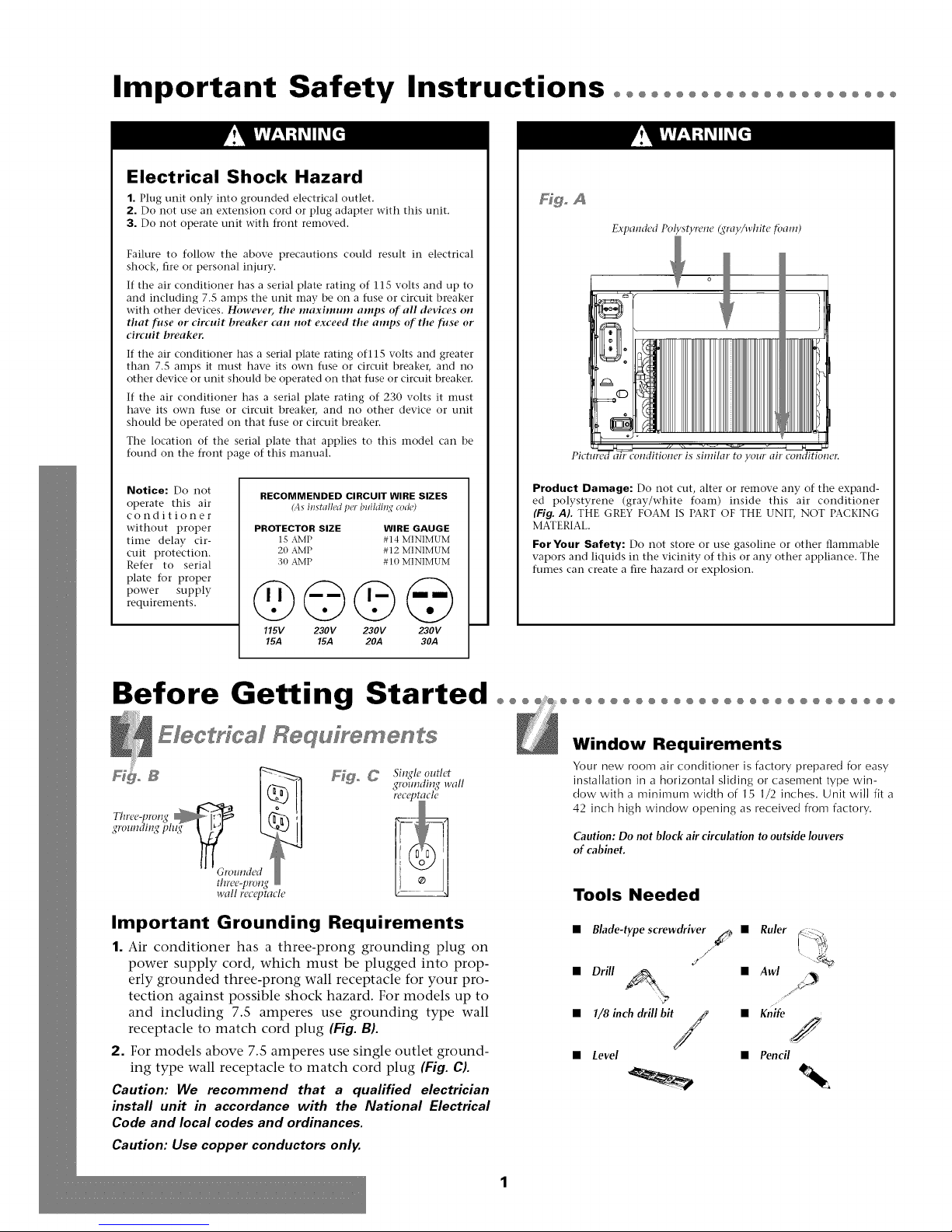

Hgo A

Expamled Polystyrene gray/white foam)

similar to yourairconditioueT:

Notice: Do not

operate this air

conditioner

without proper

time delay cir-

cuit protection,

Refer to serial

plate for proper

power supply

requirements,

RECOMMENDED CIRCUIT WIRE SIZES

(As iustalled per buildi_l,,¢ co&)

PROTECTOR SIZE WIRE GAUGE

1S AMP #14 MINIMUM

20 AMP #12 MINIMUM

30 AMP # 10 MINIMUM

@©©@

115V 230V 230V 230V

15.4 15.4 20A 30A

Before Getting Started o°°

Electrical Requfyements

Si1_?le outlet

groundin,,q wall

Important Grounding Requirements

1. Air conditioner has a three-prong grounding plug on

power supply cord, which must be plugged into prop-

erly grounded three-prong wall receptacle for your pro-

tection against possible shock hazard, For models up to

and including 7,5 amperes use grounding type wall

receptacle to match cord plug (Fig. B).

2. For models above 7,5 amperes use single outlet ground-

ing type wall receptacle to match cord plug (Fig. C).

Caution: We recommend that a qualified electrician

install unit in accordance with the National Electrical

Code and local codes and ordinances.

Caution: Use copper conductors only.

Product Damage: Do not cut, alter or remove any of the expand-

ed polystyrene (gray/white foam) inside this air conditioner

(Fig. AI. THE GREY FOAM IS PART OF THE UNIT, NOT PACKING

MATERIAL.

For Your Safety: Do not store or use gasoline or other flaInmable

vapors and liquids in the vicinity of this or any other appliance. The

fumes can create a fire hazard or explosion.

°°°°°°°°°°°°°°°°°°°°°°°°°°O

Window Requirements

Your new room air conditioner is factory prepared for easy

installation in a horizontal sliding or casement type win-

dow with a minimum width of 15 1/2 inches. Unit will fit a

42 inch high window opening as received from factory.

Caution: Do not block air circulation to outside louvers

of cabinet.

Tools Needed

• Blade-typescrew&iverj_ • Ruler (__)

• Drill _ • Awl _C/_

• 1/Sinch &illbit /_

• Level

X/

°"

• Knife

,/

• Pencil

Page 3

Installation°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

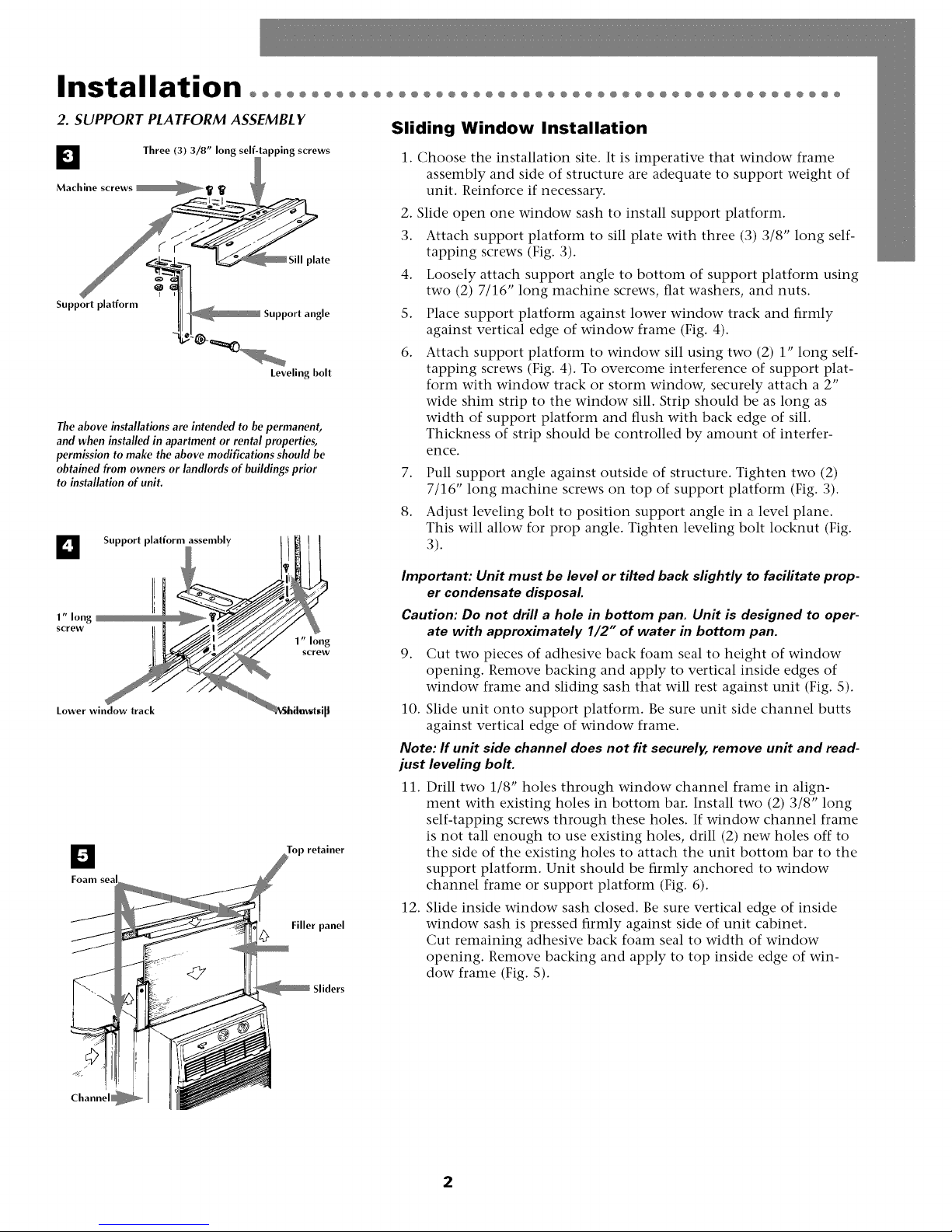

2. SUPPORT PLATFORM ASSEMBL Y

D Three (3) 3/8" long sel| apping screws

Machine screws __ _,

Support platform

The above installations are intended to be permanent,

and when installed in apartment or rental properties,

permission to make the above modifications should be

obtained from owners or landlords of buildings prior

to installation of unit.

_ plate

II _ Support angle

Leveling bolt

Support platform assembly !

..............

El

Foam seal

J

J

J

oP retainer

Filler panel

Sliding Window Installation

1. Choose the installation site. It is imperative that window frame

assembly and side of structure are adequate to support weight of

unit. Reinforce if necessary.

2. Slide open one window sash to install support platform.

3. Attach support platform to sill plate with three (3) 3/8" long self-

tapping screws (Fig. 3).

4. Loosely attach support angle to bottom of support platform using

two (2) 7/16" long machine screws, flat washers, and nuts.

S. Place support platform against lower window track and firmly

against vertical edge of window frame (Fig. 4).

6. Attach support platform to window sill using two (2) 1" long self-

tapping screws (Fig. 4). To overcome interference of support plat-

form with window track or storm window, securely attach a 2"

wide shim strip to the window sill. Strip should be as long as

width of support platform and flush with back edge of sill.

Thickness of strip should be controlled by amount of interfer-

ence.

7. Pull support angle against outside of structure. Tighten two (2)

7/16" long machine screws on top of support platform (Fig. 3).

8. Adjust leveling bolt to position support angle in a level plane.

This will allow for prop angle. Tighten leveling bolt locknut (Fig.

3).

Important: Unit must be level or tilted back slightly to facilitate prop-

er condensate disposal.

Caution: Do not drill a hole in bottom pan. Unit is designed to oper-

ate with approximately 1/2" of water in bottom pan.

9. Cut two pieces of adhesive back foam seal to height of window

opening. Remove backing and apply to vertical inside edges of

window frame and sliding sash that will rest against unit (Fig. S).

10. Slide unit onto support platform. Be sure unit side channel butts

against vertical edge of window frame.

Note: If unit side channel does not fit securely, remove unit and read-

just leveling bolt.

11. Drill two 1/8" holes through window channel frame in align-

ment with existing holes in bottom bar. Install two (2) 3/8" long

self-tapping screws through these holes. If window channel frame

is not tall enough to use existing holes, drill (2) new holes off to

the side of the existing holes to attach the unit bottom bar to the

support platform. Unit should be firmly anchored to window

channel frame or support platform (Fig. 6).

12. Slide inside window sash closed. Be sure vertical edge of inside

window sash is pressed firmly against side of unit cabinet.

Cut remaining adhesive back foam seal to width of window

opening. Remove backing and apply to top inside edge of win-

dow frame (Fig. S).

Sliders

2

Page 4

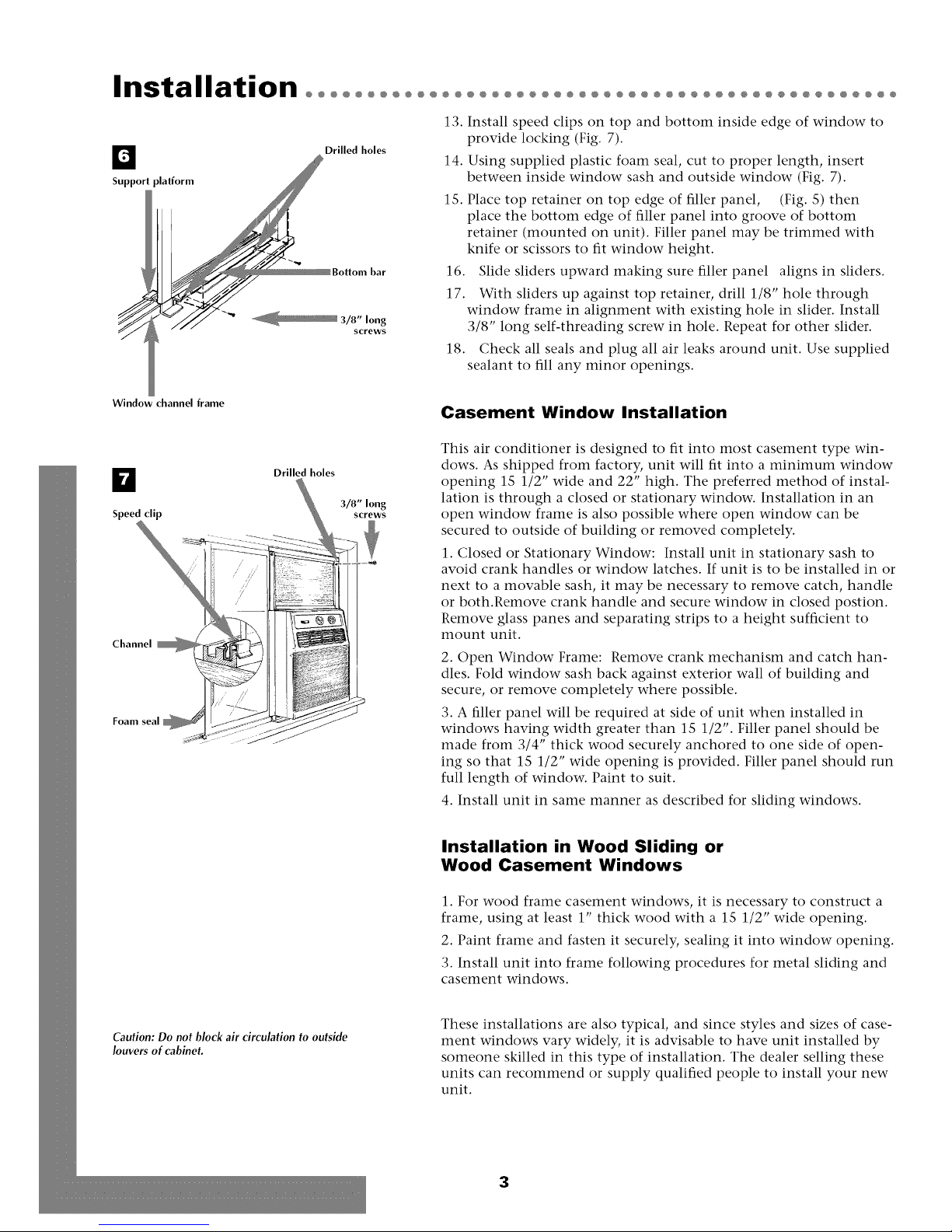

Installation°°°°°°°°°°°°°

13.

D Drilled holes 14.

Support

1S. Place top retainer on top edge of filler panel, (Fig. S) then

16. Slide sliders upward making sure filler panel aligns in sliders.

17. With sliders up against top retainer, drill 1/8" hole through

18. Check all seals and plug all air leaks around unit. Use supplied

@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@

Install speed clips on top and bottom inside edge of window to

provide locking (Fig. 7).

Using supplied plastic foam seal, cut to proper length, insert

between inside window sash and outside window (Fig. 7).

place the bottom edge of filler panel into groove of bottom

retainer (mounted on unit). Filler panel may be trimmed with

knife or scissors to fit window height.

window frame in alignment with existing hole in slider. Install

3/8" long self-threading screw in hole. Repeat for other slider.

sealant to fill any minor openings.

Window channel frame

D

Speed clip

Channel

Drilled holes

3/8" long

screws

Casement Window Installation

This air conditioner is designed to fit into most casement type win-

dows. As shipped from factory, unit will fit into a minimum window

opening 1S 1/2" wide and 22" high. The preferred method of instal-

lation is through a closed or stationary window. Installation in an

open window frame is also possible where open window can be

secured to outside of building or removed completely.

1. Closed or Stationary Window: Install unit in stationary sash to

avoid crank handles or window latches. If unit is to be installed in or

next to a movable sash, it may be necessary to remove catch, handle

or both.Remove crank handle and secure window in closed postion.

Remove glass panes and separating strips to a height sufficient to

mount unit.

2. Open Window Frame: Remove crank mechanism and catch han-

dles. Fold window sash back against exterior wall of building and

secure, or remove completely where possible.

3. A filler panel will be required at side of unit when installed in

windows having width greater than 1S 1/2". Filler panel should be

made from 3/4" thick wood securely anchored to one side of open-

ing so that 1S 1/2" wide opening is provided. Filler panel should run

full length of window. Paint to suit.

4. Install unit in same manner as described for sliding windows.

Installation in Wood Sliding or

Wood Casement Windows

Caution:Do not block air circulation to outside

louvers of cabinet.

1. For wood frame casement windows, it is necessary to construct a

frame, using at least 1" thick wood with a 1S 1/2" wide opening.

2. Paint frame and fasten it securely, sealing it into window opening.

3. Install unit into frame following procedures for metal sliding and

casement windows.

These installations are also typical, and since styles and sizes of case-

ment windows vary widely, it is advisable to have unit installed by

someone skilled in this type of installation. The dealer selling these

units can recommend or supply qualified people to install your new

unit.

3

Page 5

Operation°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

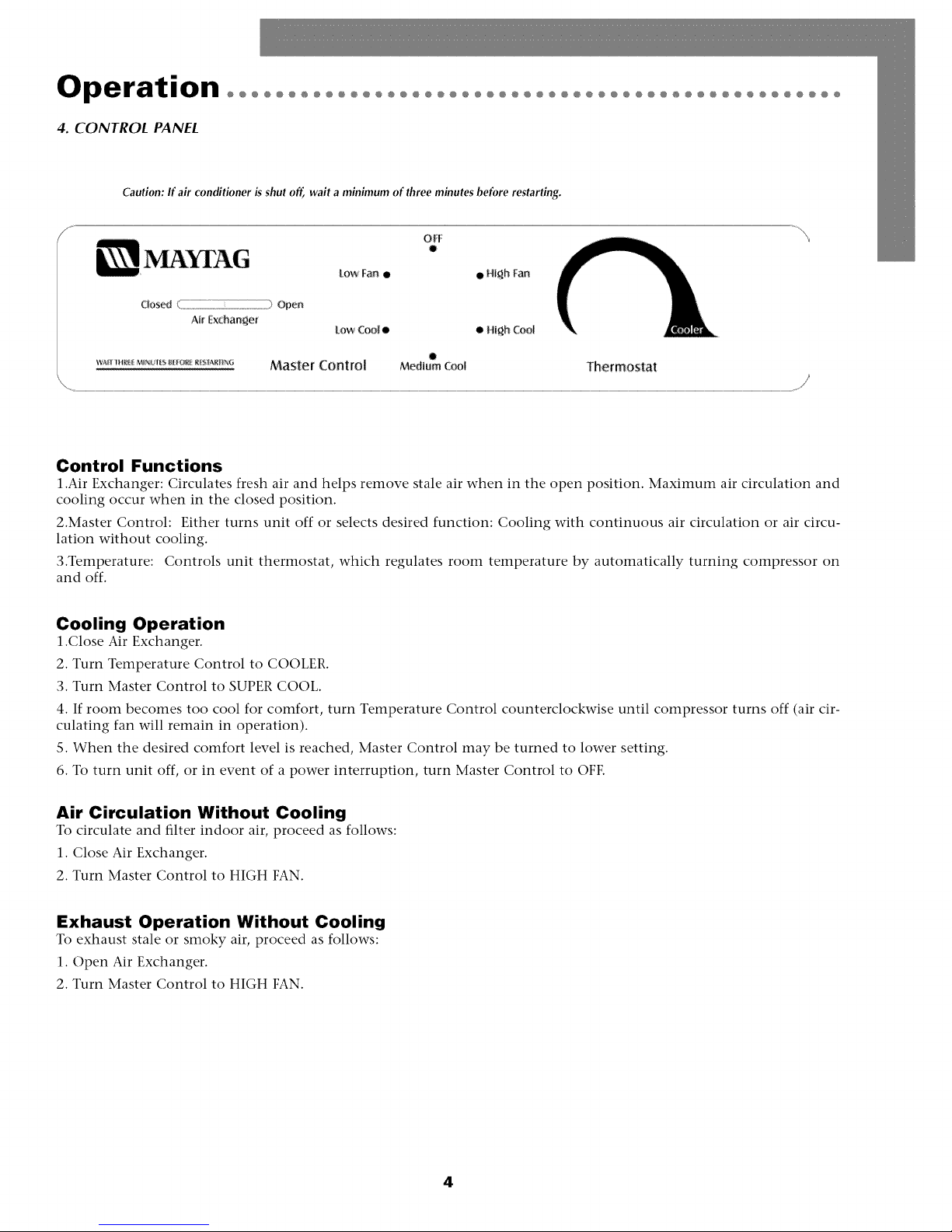

4. CONTROL PANEL

Caution: If air conditioner is shut off, wait a minimum of three minutes before restarting.

LowFan • • High Fan

Closed .............................................................................................................Open

AirExchanger

Master CoNtro[ Mediumcool Thermostat

Control Functions

1.Air Exchanger: Circulates fresh air and helps remove stale air when in tile open position. Maximum air circulation and

cooling occur when in the closed position.

2.Master Control: Either turns unit off or selects desired function: Cooling with continuous air circulation or air circu-

lation without cooling.

3.Temperature: Controls unit thermostat, which regulates room temperature by automatically turning compressor on

and off.

LowCool• • High Co_l

o

Cooling Operation

1.Close Air Exchanger.

2. Turn Temperature Control to COOLER.

3. Turn Master Control to SUPER COOL.

4. If room becomes too cool for comfort, turn Temperature Control counterclockwise until compressor turns off (air cir-

culating fan will remain in operation).

S. When the desired comfort level is reached, Master Control may be turned to lower setting.

6. To turn unit off, or in event of a power interruption, turn Master Control to OFF.

Air Circulation Without Cooling

To circulate and filter indoor air, proceed as follows:

1. Close Air Exchanger.

2. Turn Master Control to HIGH FAN.

Exhaust Operation Without Cooling

To exhaust stale or smoky air, proceed as follows:

1. Open Air Exchanger.

2. Turn Master Control to HIGH FAN.

4

Page 6

Maintenance°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

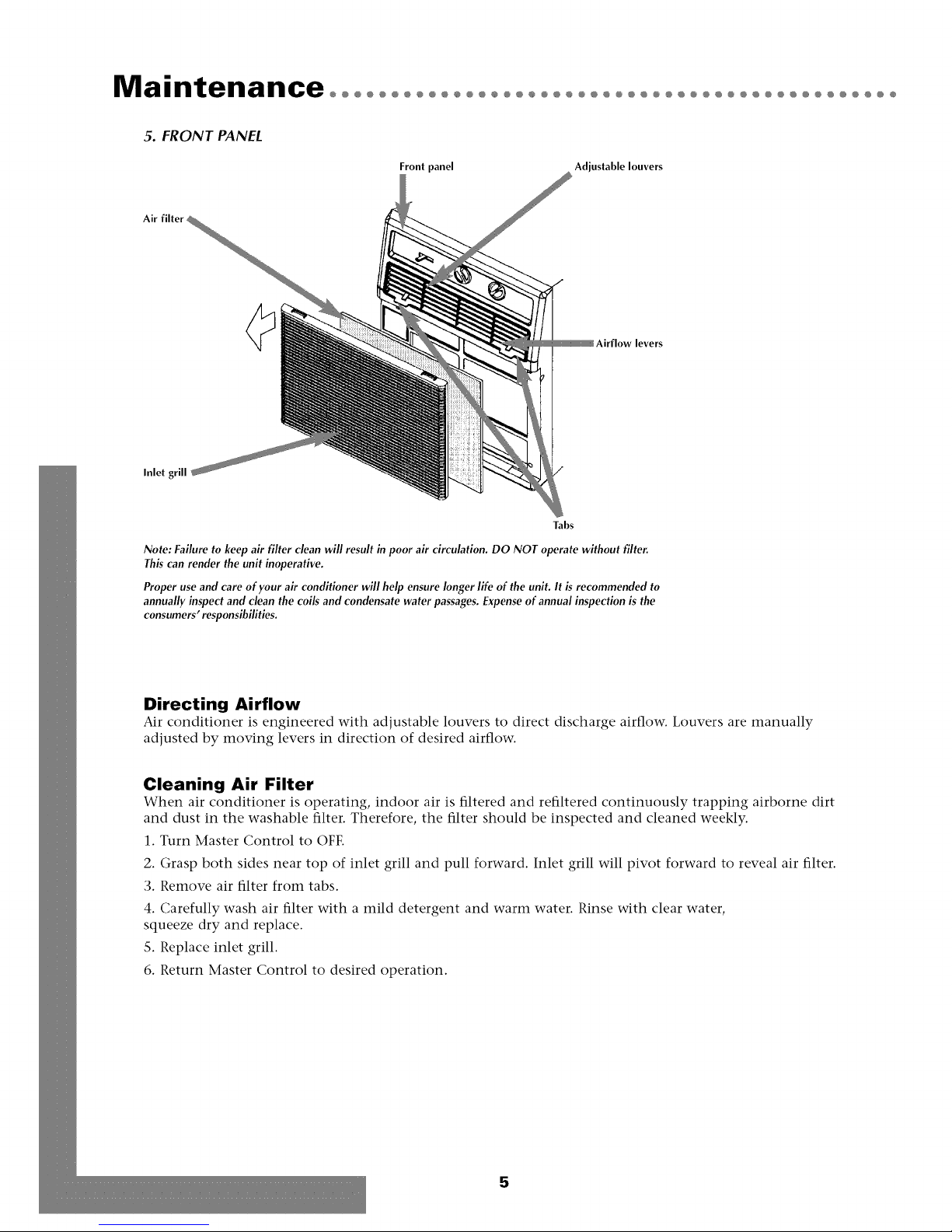

5. FRONT PANEL

Front panel Adjustable louvers

Air filter _

Inlet gl

Tabs

Note: Failure to keep air filter clean will result in poor air circulation. DO NOT operate without filter

This can render the unit inoperative.

Proper use and care of your air conditioner will help ensure longer life of the unit. It is recommended to

annually inspect and clean the coils and condensate water passages. Expense of annual inspection is the

consumers' responsibilities.

Directing Airflow

Air conditioner is engineered with adjustable louvers to direct discharge airflow. Louvers are manually

adjusted by moving levers in direction of desired airflow.

Cleaning Air Filter

When air conditioner is operating, indoor air is filtered and refiltered continuously trapping airborne dirt

and dust in the washable filter. Therefore, the filter should be inspected and cleaned weekly.

1. Turn Master Control to OFE

2. Grasp both sides near top of inlet grill and pull forward. Inlet grill will pivot forward to reveal air filter.

3. Remove air filter from tabs.

4. Carefully wash air filter with a mild detergent and warm water. Rinse with clear water,

squeeze dry and replace.

S. Replace inlet grill.

6. Return Master Control to desired operation.

5

Page 7

Warrantyooooooooooooooooooooooooooooooooooooooooooooooooooo

For Models Installed

in North America - If Service

or Parts are Required

First, make the recommended checks. If it appears that ser-

vice or parts are still required, see your room air condition-

er warranty "How to Obtain Warranty Service or Parts".

For Models Installed

Outside North America

For room air conditioners purchased for use outside North

America, the manufacturer does not extend any warranty

either expressed or implied. Consult your local dealer for

any warranty terms extended by the importer in your

country.

Room Air Conditioner Warranty

(Within the 48 contiguous United States, state of Hawaii,

the District of Columbia, Puerto Rico and Canada)

Full (FiveYear) Parts and Labor Warranty

During the five years after the date of original purchase,

Fedders Appliances will, through its authorized servicers

and free of charge to the owner or any subsequent user,

repair or replace any parts which are defective in material

or workmanship due to normal use. Ready access to the air

conditioner is the responsibility of the owner.

Note: In the event of any required parts replacement with-

in the period of this warranty, Fedders Appliances replace-

ment parts shall be used and will be warranted only for the

period remaining on the original warranty.

Exceptions

The above warranty does not cover failure to function

caused by damage to the unit while in your possession

(other than damage caused by defect or malfunction), or

by its improper installation, or by unreasonable use of the

unit, including without limitation, failure to provide rea-

sonable and necessary maintenance or to follow the writ-

ten Installation and Operating Instructions. If the unit is

put to commercial, business, rental, or other use or appli-

cation other than for consumer use, we make no war-

ranties, express or implied, including but not limited to,

any implied warranty of merchantability or fitness for par-

ticular use or purpose.

THE REMEDIES PROVIDED FOR IN THE ABOVE EXPRESS

WARRANTY ARE THE SOLE AND EXCLUSIVE REMEDIES

THEREFOR, NO OTHER EXPRESS WARRANTIES ARE

MADE. ALL IMPLIED WARRANTIES, INCLUDING BUT NOT

LIMITED TO ANY IMPLIED WARRANTY OF MER-

CHANTABILITY OR FITNESS FOR A PARTICULAR USE OR

PURPOSE, ARE LIMITED IN DURATION TO FIVE YEARS

FROM THE DATE OF ORIGINAL PURCHASE. IN NO EVENT

SHALL Fecldet:_Appliances BE LIABLE FOR INDIRECT, INCI-

DENTAL, OR CONSEQUENTIAL DAMAGES, EVEN IF

ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH

DAMAGES. NO WARRANTIES, EXPRESS OR IMPLIED, ARE

MADE TO ANY BUYER UPON RESALE.

Some states do not allow limitations on how long an

implied warranty lasts or do not allow the exclusion or

limitation of incidental or consequential damages, so the

above limitations or exclusions may not apply to you.

This warranty gives you specific legal rights, and you may

also have other rights which may vary from state to state.

No warranties are made for units sold outside of the above

stated areas. Your distributor or final seller may provide a

warranty on units sold outside of these areas.

How to Obtain

Warranty Service or Parts

Service for your room air conditioner will be provided by

CareCo, a division of the manufacturer with authorized

independent CareCo servicers nationwide.

Note: Before calling for service, carefully read the

Installation and Operating Instructions booklet. Then ff

you need service:

1. Call a CareCo authorized servicer and advise them of

model number, serial number, date of purchase and

nature of complaint. Service will be provided during

normal working hours. Contact your dealer for the

name of an authorized servicer if unknown to you.

2. If your dealer is unable to give you the name of a ser-

vicer or if you need other assistance, call the following

toll-free number for the name of an authorized servicer

or authorized parts distributor:

1-866-MAYTAG 1

or you may write:

CareCo, Service Department

415 W. Wabash Ave., RO. Box 200

Effingham, IL 62401

Proof of Purchase Date

It is the responsibility of the consumer to establish the

original purchase date for warranty purposes. We recom-

mend that a bill of sale, cancelled check, or some other

appropriate payment record be kept for that purpose.

6

Page 8

Instrucciones importantes de seguridadoooooooooo

Peligro de descarga el6ctrica

1. Enchufe la unidad en till tonlacorriente con conexi6n a tierra,

2. No use un cable de extensi6n ni un adaptador de enchufe con este

aparato.

3. No 1o haga funcionar sin la cubierta delantera.

El no seguir las precauciones enumeradas anteriormente podria

causar descargas elOctricas, incendio o lesiones personales,

Si el acondicionador de aim trae en la placa tma clasificaci6n de 115

voltios y hasta 7,S amperios inclusive, la unidad puede ir conectada

al mismo fusible o cortacircuitos junto con otros aparatos, Sin

embargo, el mdximo amperaje de todos los aparatos conectados a

la vez a ese fusible o cortacilx'uitos no debe ser mayor que la capaci-

dad (amperios) de dicho fusible o cortacircuitos.

Si el acondidonador de aim trae en la placa una clasificad6n de 115

voltios v m,_s de 7.5 amperios, entonces debe ir conectado a su pro-

pio fusible o cortadrcuitos y ningfn otro aparato o unidad se podrfi

conectar a dicho fusible o cortadrcuitos.

Si el acondicionador de aire trae en la placa una clasificaci6n de 230

voltios, entonces debera ir conectado a su propio fusible o cortacir-

cuitos y ningfin otro aparato o unidad se podra conectar a dicho

fusible o cortacircuitos.

La ubicaci6n de la placa con la serie correspondiente a este modelo

se encuentra en la pfigina del frente de este manual.

Aviso: No haga tim.

cionar estre aire acondi-

cionado sin un circuito

temporizador que

brinde la protecci6n

adecuada. En la placa

de identificaci6n apare-

cen los requisitos cor-

rectos de alimentaci6n.

TAIVIAI_IOSRECOMENDADOS PARA LOS

ALAMBRES DEL CIRCUITO

(Instalado s(',qfiHlos n'ghmlentos d_"constrl_ccidn)

TAMAI_O DEL CALIBRE DEL

PROTECTOR ALAMBRE

15 AMP #14 MINLMO

20 AMP #12 MINIMO

O) AMP #10 MINIMO

Figo A

Poliestirem_ ex/)anditlo (Es])llllltl _{l'is//)lanca)

o

_' V¸

El aire acoudicionado de la foto es similar al suyo.

Dafio al producto: No corte, altere o retire ningdn pedazo de poli-

estireno expandido (espuma gris/blanca) que se encuentre dentro del

acondicionador de aim (Fig. A). EL POLIESTIRENO EXPANDIDO

FORMA PARTEDE LAUNIDAD, NO ES MATERIAL DE EMBALAJE,

Para su seguridad: No ahnacene ni utilice gasolina u otros vapores

y liquidos inflamables cerca de este artefacto o de cualquier otro arte-

facto, Los vapores pueden provocar un incendio o una explosi6n,

@©©@

116V 230V 230V 230V

15.4 15.4 20.4 30.4

Antes de empezarooooooooooooo

Req dstoa Data/a eleetdcoa

Recept&rulo mural

con salMa simple

de tmesta a tierra

Requistos importantes

para la conexi6n a tierra

1. E1 equipo de aire acondicionado tiene en el cord6n de

corriente un enchufe a tierra de tres puntas, el cual debe

set introducido en un tomacorriente de tres puntas

debidamente conectado a tierra para protecci6n contra

posibles descargas el_ctricos. Para modelos de hasta 7.S

amperios utilice un tipo de tomacorriente con conexi6n

a tierra, adecuado para el enchufe del equipo (Fig. BL

2. Para modelos de mils de 7.S amperios, utilice un tomacor-

riente con conexi6n a tierra para un solo enchufe (Fig.eL

Precaucion: Recomendamos que un electricista calificado

instale la unidad de acuerdo alas normas electicas

nacionales y las normas y regulaciones locales.

Precaucion: Utifice solamente conductores de cobre.

°°°°°°°°°°°°°°°°°°°°°°°°°O

de fdbrica para permitir una f;ici] instalaci6n en una

ventana con pane]es corredizos horizonta]es o de tipo

caja con un ancho mfnimo de 15 1/2 pulgadas, La

pulgadas de altura,

Precauci6n: No bloquee la circulaci6n del aire de lasrejil-

las exteriores del gabinete.

• Destornilladorcomfn _ Regla

• Taladro /_ • tezna

• Punta de tala&o de x?ll Cuchillo

• Nivel _._o__ • t_plz

Requisitos de la ventana

El nuevo acondicionador de aire viene preparado

unidad cabr4 en una ventana con una abertura de 42

Herramientas necesarias

/

J

1/8 de pulgada

/

/

Page 9

Instalaci6n oooooooooooooooooooooooooooooooooooooooooooooooo

D Tres (3) tornillos 3/8" de

Tornillos para metal __

D Plataforma de

Tornillo

de 1"

de largo

Via inferior de la ventana la ventana

D Retenedor superior

Sellsdor de espuma

apoyo de montaje

largo autorroscantes

nivelaci6n

Tornillo

de largo

_uicio de

Franja de madera

de relleno

de 1"

Instalaci6n en ventana corrediza

l.Escoja el lugar de la instalaci6n. Es imperativo que el conjunto del

marco de la ventana y el lado de la estructura sean adecuados

para soportar el peso de la unidad; de lo contrario, los deberfi reforzar.

2. Abra un bastidor de la ventana para instalar la plataforma de soporte.

3. Conecte la plataforma de soporte al alf4izar mediante los tres (3)

tornillos autorroscantes de 3/8" de largo (Fig. 3).

4. Conecte flojamente el fingulo de apoyo a la base de la plataforma de

apoyo mediante dos (2) tornillos para metal de 7/16 pulgada de

largo, arandelas planas y tuercas.

S. Coloque la plataforma de apoyo contra la via inferior de la ventana y

firmemente contra el borde vertical del marco de la ventana(Fig.4).

6. Fijar la plataforma de soporte al alfhizar o tablilla de la ventana usando

dos (2) tornillos de 1" de largo (Fig. 4). Para superar la interfer-

encia de la plataforma de soporte con el canal de la ventana o la con-

traventana, sujete fijamente una curia de madera de 2" de ancho al

alfhizar o tablilla de la ventana. La franja de madera debera ser tan

larga como es el ancho de la ventana y a nivel del alfhizar o tablilla de

la ventana. Determine el espesor de la franja de madera de

acuerdo al espacio entre el canal de la ventana y la plataforma de

soporte.

7. Empuje el _ngulo de apoyo hacia la parte exterior de la estructura.

Apriete dos (2) tornillos para metal de 7/16" de largo en laparte

superior de la plataforma de apoyo (Fig. 3).

8. Ajuste un perno nivelador para ubicar el _ngulo de apoyo en un piano

nivelado. Esto permitir_ establecer un _ngulo adecuado. Apriete la

tuerca de sujeci6n del perno nivelador (Fig. 3).

Importante: La unidad debe estar nivelada o inclinada levemente hacia

atras para facilitar la eliminacion de la condensacion.

Precauci6n: No perfore un agujero en la bandeja inferior. La unidad se

ha dise_ado para que funcione con aproximadamente 1/2 pulgada de

agua en la bandeja.

9.Corte dos trozos de sellador de espuma con un lado adhesiw_ de la

misma altura de la abertura de la ventana. Retire el revestimiento y

aplique a los bordes interiores verticales del marco de la ventana y al

bastidor deslizante que se apoye contra la unidad (Fig. S).

10.Deslicelo sobre la plataforma de apoyo.

Cerci6rese de que del canal lateral de la unidad hace tope con el borde

vertical del marco de la ventana.

Las instalaciones descritas son de tipo permanente; cuando se

efectdan en un departamento o en propiedades alquiladas, se debe

solicitar un permiso especial a los propietarios o duefios para Ile-

var a cabo dichas modificaciones antes de instalar la unidad.

Nota: Si el canal lateral de la unidad no encaja firmemente, retire la

unidad y vuelva a ajustar el perno nivelador.

8

Page 10

Instalaci6n oooooooooooooooooooooooooooooooooooooooooooooooo

D Orificios laterales

Plataforma de apoyo

11.Taladre dos agujeros de 1/8" a tray,s del marco del canal

de la ventana alinefindolos con los agujeros al fondo del

canal. Instale dos (2) tornillos de 3/8" de largo por estos

agujeros. Si el marco del canal de la ventana es lo suficiente-

mente alto para usar los agujeros existentes, taladre dos (2)

agujeros nuew)s a los lados de esos agujeros para sujetar el

fondo de la unidad con la plataforma de soporte. La unidad

debe estar firme mente sujeta al canal del marco de la ven-

tana o a la plataforma de soporte (Fig. 6).

12. Deslice el bastidor interior de la ventana cerrada.

CerciSrese de que el borde vertical del bastidor interior de la

ventana est_ firmemente apoyado contra el costado del

gabinete de la unidad. Corte el resto del sellador de espuma

con respaldo adhesivo del mismo ancho de la abertura de la

ventana. Retire el revestimiento y aplique al borde interior

superior del marco de la ventana (Fig. S).

13.Instale sujetadores tipo "speed clips" en el borde interior

superior e inferior de la ventana para poder cerrarla (Fig. 7).

14. Utilizando el sello de espuma plfistica suministrado,

corte un pedazo adecuado e introdfizcalo entre el bastidor

interno de la ventana y la ventana externa (Fig. 7).

15. Coloque el retenedor superior en el borde superior del

panel de relleno, (Fig. S) luego coloque el borde inferior del

panel de relleno en la ranura del retenedor inferior

(montado en la unidad). E1panel de relleno puede recor-

tarse con un cuchillo o tijeras para que encaje en la altura

de la ventana.

16. Haga deslizar las deslizadoras hacia arriba cerciorfindose

de que est_n alineadas con el panel de relleno.

17.Con las correderas apegadas al ret_n superior, perfore un

orificio de 1/8" a trav_s del marco de la ventana de modo

que quede alineado con el orificio existente en la corred-

era. Instale el tornillo autorroscante de 3/8" en el orificio.

Repita el procedimiento en la otra corredera.

18. Verifique todos los selladores y obstruya todas las filtra-

clones de aire alrededor de la unidad. Usar el sellador

proveido para llenar pequefias aberturas.

Marco acanalado de la ventana

D

Sujetadores tipo "Speed clip"

Canal

Sellador de

Barra inferior

Orificios laterales

Tornillo

de 3/8"

de largo

Tornillo

de 3/8"

de largo

9

Page 11

FuncionamientOoooooooooooooooooooooooooooooooooooooooooo

4. TABLERO DE CONTROL Precauci6n: Si apaga el acondicionador de aire, espere por Io menos tres minutos antes de volver a encenderlo.

LowFan t i Ht_h Fan

Closed .............................................................................................................Open

AirE×chan_er

Master CoNtfo[ Medium Cool Thermostat

Funciones de los controles

1.1ntercambiador de aire "Air Exchanger":

Cuando se abre el acondicionador, circula air fresco y se elimina el air viciado. AI cerrarse, circula el

ma'ximo de aire y se produce enfriamiento.

2. Control maestro "Master Control":

Sirve para encender y apagar la unidad. Permite seleccionar la funci6n deseada de la unidad: enfri-

amiento con circulaci6n de aire o circulaci6n de aire sin enfriamiento.

LowCool• • High Cool

i

3, Temperatura "Temperature":

Controla el termostato de la unidad, que regula la temperatura de la habitaci6n al prender y apagar

automa'ticamente el compresor.

Funcionamiento del enfriamiento

1. Ponga el intercambiador de aire en la posici6n de cerrado.

2. Ponga el control de temperatura en la posici6n ma's frfa "COOLER".

3. Ponga el control maestro en fifo ma'ximo "SUPER COOL".

4.. Si la habitaci6n se enfrfa demasiado, haga girar la perilla del termostato de derecha a izquierda

hasta que se apague el compresor (el ventilador de circulaci6n de aire seguira" en funcionamiento).

5. Cuando se alcanza el nivel de confort deseado podra" ponerse el control maestro en un valor ma's

bajo "NORMAL COOL" o "LOW COOL".

6. Para apagar la unidad, o en el caso de una interrupci6n de corriente, ponga el control maestro en

posici6n apagado "OFF".

Circulaci6n de aire sin enfriamiento

Para que el aire circule y se filtre, hay que proceder de la siguiente manera:

1. Ponga el intercambiador de aire en la posici6n de cerrado.

2. Ponga el control maestro en ventilador alto "HIGH FAN".

Funcionamiento de ventilaci6n sin enfriamiento

Para expulsar el aire viciado, es necesario hacer Io siguiente:

1. Ponga el intercambiador de aire en la posici6n de abierto.

"& Ponga el control maestro en ventilador alto.

10

Page 12

Mantenimiento oooooooooooooooooooooooooooooooooooooooooo

5. PANEL FRONTAL

Panel frontal Rejillas

Filtro de aire

Advertencia: El no mantener limpio el filtro podda resultar en baja circulaci6n del aim. NUNCA haga funcionar la

unidad sin el filtro ya que puede quedar inutilizable.

El uso y mantenimiento adecuados del acondicionador de air prolongar_ la vida 6til de la unidad. Se recomienda

inspeccionar y limpiar anualmente el serpentfn y los pasajes para agua de condensaci6n. El cliente deber_ cubrir los

gastos de inspecci6n anual.

directrices ajustables

Palancas de

corriente de aire

Presillas

Orientaci6n de la

corriente de aire

La unidad viene equipada con rejillas directrices ajustables que permiten dirigir la descarga de la corriente de aire. Las rejillas

pueden ajustarse manua]mente moviendo ]as pa]ancas en ]a direcci6n deseada.

Limpieza del filtro de aire

Cuando el acondicionador de aire est4 en funcionamiento, el aire interior se filtra y refi]tra continuamente, atrapando ]a suciedad

y e] po]vo suspendidos en e] aire en e] fi]tro ]avab]e. Por ]o tanto, e] fi]tro deber_i inspeccionarse y ]impiarse una vez por semana.

1, Ponga e] contro] maestro en posici6n apagado.

2, Tome ambos ]ados cerca de ]a parte superior de ]a reji]]a de entrada y ja]e hacia adelante. La reji]]a girard1 hacia ade]ante y

dejar_i e] fi]tro de aire a] descubierto.

3, Desmonte e] fi]tro de aire de ]as presi]]as.

4, Lave cuidadosamente e] fi]tro de aire con un detergente suave y agua tibia. Enju_igue]o con agua ]impia, deje escurrir bien y

vuelva a co]ocarlo.

5, Vue]va a co]ocar e] parri]]a de entrada.

6, Ponga e] contro] maestro en ]a operaci6n deseada.

11

Page 13

Garantiaoooooooooooooooooooooooooooooooooooooooooooooooooooo

Para modelos instalados en

Norteam6rica - En caso de necesidad

de servicio o piezas

Haga primer() las verificaciones recomendadas. En caso

de necesitarse servicio o piezas, consulte en la garantia de

su acondicionador de aire en la secci6n "C6mo obtener

servicio o piezas de garantia'.

Para modelos instalados

fuera de Norteam_rica

Para aires acondicionados comprados para uso fuera de

Norteam_rica el fabricante no otorgarfi ninguna garantia

implicita o explicita. Consulte a su distribuidor autoriza-

do sobre las condiciones de la garantia extendida pot el

importador de los equipos de su pais.

Garantia del acondicionador de aire

(Dentro de los 48 estados contiguos de los Estados

Unidos, estado de Hawai, Distrito de Columbia, Puerto

Rico y Canada)

Garantia para todas las piezas (cinco a_os)

y mano de obra

A partir de la fecha de compra y durante un periodo de

cinco aflos, Fedders Appliances, mediante sus estaciones

de servicio autorizadas, repararfi o reemplazarfi sin costo

alguno para el propietario o usuario, cualquier pieza que

presente daflos de material o mano de obra derivados del

uso normal del producto. Es responsabilidad del propi-

etario facilitar el acceso al acondicionador de aire para

realizar los servicios de reparaci6n.

Nota: En caso de que se requiera reemplazar una pieza

mientras la garantia esta vigente, se utilizaran los

repuestos de Fedders Appliances los cuales continuaran

en vignecia solamente durante el resto del periodo de

garantia de la unidad.

Excepciones

La garantia antes indicada no cubre las fallas de fun-

cionamiento causadas por daflos que sufra la unidad

mientras _sta est_ en posesi6n del usuario (excluyendo los

daflos causados por defecto o funcionamiento defectu-

oso), o por la instalaci6n incorrecta, o la utilizaci6n inde-

bida de la unidad, incluyendo pero sin limitarse a ello, la

negligencia en proporcionar el mantenimiento necesario

y adecuado o en seguir las "instrucciones de Instalaci6n y

Uso" indicadas por escrito. En caso de utilizarse la unidad

para fines comerciales, de negocios, de arriendo u otto uso

o aplicaci0n que no sea el uso del consumidor, no otorg-

amos garantia explicita ni implicita, incluyendo, pero sin

limitarse a, toda garantia implicita de negociabilidad o

idoneidad para un uso o finalidad particular.

LAS SOLUCIONES EXPUESTAS EN LA GARANTIA ANTERI-

OR SON EXCLUSIVAS. SE RECHAZA CUALQUIER OTRA

GARANTIA YA SEA EXPRESA 0 IMPLICITA, INCLUYENDO,

PERO SIN LIMITARSE A ELL(), TODAS LAS GARANTIAS DE

COMERCIABILIDAD 0 IDONEIDAD PARA UN FIN EN PAR-

TICULAR DURANTE CINCO ANOS A PARTIR DE LA FECHA

DE COMPRA. BAJO NINGUNA CIRCUNSTANCIA Fedders

Appliances SE HARA RESPONSABLE POR NINGUN DANO

DIRECT(), INDIRECT() 0 CONSECUENCIAL, SIN IMP(JR-

TAR LA CAUSA DE LA ACCION, AUN CUANDO Feddet_s

Appliances HAYA SIDO ADVERTIDO CON ANTERIORIDAD

DE LA POSIBILIDAD DE DICHOS DANOS. NO SE OFRECE

NINGUNA GARANTIA EXPRESA 0 IMPLICITA A COM-

PRADORES DESPUES DE LA RE VENTA.

Algunos estados no permiten limitar el tiempo de

duraci6n de una garantia implicita ni permiten excluir ni

limitar los daflos incidentales o emergentes, de modo que

las limitaciones o exclusiones antes indicadas podrian no

aplicarse en su caso. Esta garantia le otorga derechos

legales especificos. Usted podria tener tambi_n otros dere-

chos que pueden variar de estado a estado.

No se ofrecen garantias para las unidades vendidas fuera

de las fireas antes indicadas. Su distribuidor o vendedor

final podria proporcionar una garantia para las unidades

vendidas fuera de estas fireas.

C6rno obtener servicio

o piezas de garantia

E1 servicio para su acondicionador de aire serfi provisto por

CareCo, una divisi6n del fabricante con estaciones de ser-

vicio independientes CareCo autorizadas en todo el pais.

Nota: Antes de solicitar servicio, lea cuidadosamente el

folleto de "lnstrucciones de Instalacion y Uso'." Luego, si

necesita servicio:

1. Llame a un taller de servicio autorizado CareCo y sum-

inistreles el nfimero de modelo, nfimero de serie, la fecha

de compra y la naturaleza del problema. E1 servicio se

prestarfi durante horas normales de trabajo.

Comuniquese con su distribuidor para obtener recomen-

daciones sobre una estaci6nde servicio autorizada.

2. Si su distribuidor no puede proporcionarle el nombre

de un taller de servicio o si necesita otro tipo de asis-

tencia, llame al siguiente nfimero gratis para obtener el

nombre de un taller de servicio autorizado o dis-

tribuidor de piezas autorizado:

1-866-MAYTAG 1

o escriba al:

Departamente de Servicio de CareCo

415 W. Wabash Ave., RO. Box 200

Effingham, IL 62401 EE. UU.

Prueba de la fecha de compra

E1 establecimiento de la fecha de compra original para

efectos de la garant{a es responsabilidad del consumidor.

Recomendamos mantener la factura de compra, el cheque

cancelado o algfin otto registro de pago apropiado para

dicho efecto.

12

Page 14

Directives de s6curit6 importanteSooooooooooooooooo

Danger de choc 41ectrique

1. N'enficher le cliinatiseur que clans une prise _lectrique raise fl la

term,

2. Ne pas se servir d'une rallonge ou d'un adaptateur avec cet

appareil.

3. Ne pas faire marcher le climatiseur si le panneau avant a OtO retir&

Suivre les prOcautions indiquOes ci-dessus pour Oviter tout risque

d'Olectrocution, d'incendie ou de lOsion corporelle.

Si la plaque de sOrie du clilnatiseur indique une tension nominale de

11 S volts et une intensitO en amperes nominale allant iusqu' fi 7,SA,

l'appareil peut _tre branchO sur le m&ne fusible ou disjoncteur que

d'autres appareils. Toutef!_is, l'intensit( maximale en ampfres de

l'ensemble des appareils branchds sur ce fusible ou disjoucteur ne

dolt pas d(passer celle du filsible ou du disjoncteur.

Si la plaque de sOrie du clilnatiseur indique une tension en volts

nominale de 11,5 volts et une intensitO en amperes nominale

supOrieure fl 7,S A, l'appareil doit _tre dotO de son propre fusible ou

disjoncteur et aucun autre appareil ne dolt y &re branch&

Si la plaque de sOrie du clilnatiseur indique une tension en volts

nominale de 230 volts, l'appareil doit &re dotO de son propre fusible

ou disioncteur et aucun autre appareil ne dolt y _tre branchO.

L'emplacement de la plaque signaDtique applicable flce inod_le est

indiquO sur la page couverture du pr&ent manuel.

Avis: Ne pas utiliser

le climatiseur sans la

protection d'un circuit

de temporisation. Se

reporter fi la plaque sig-

nabtique pour toute

indication de puissance

exig_e.

CALIBRES DE FIL RECOMMANDI_S

(3ehm lOlstallatO_ stJ/ml&

/)ar ]d dodd 0" dO!_5[FHcOI!_)

PROTECTION CALIBRE

DU CIRCUIT DE FIL

1S ,4 N°14 MINIMUM

20 A N°12 MINIMUM

30 A N°I0 MINIMUM

Endommagement du produit: Ne pas couper, altOrer ou retirer le

polystyrene expansO (mousse grise/blanche) se trouvant 5 l'intOrieur

du climatiseur (Fig.A). LE STYROFOAM N'EST PAS UN EMBALLAGE,

IL FAIT PARTIE INTEGRALE DE L'APPAREIL.

Pour votre s4curit& Ne pas stocker ou utiliser de l'essence ou toute

autre vapeur ou liquide inflammable 5 proxilnitO de cet appareil ou

de tout autre. Les Omanations peuvent crOer un risque d'incendie ou

d'explosion.

Polystyr?ne expans(, (Mousse grise/bhmche)

o

L_q)pareil illuslT(, est semblable h votre cliumtiseur

@©©@

I15V 230V 230V 230V

16A 16A 20A 30A

Pr6paratifSooooooooooooooooooo

EMgences elec dque

• Tournevis h lame • R('gle

B

Fk:he h trois

DI'OC[I('S _1'('C

terre

Prise mill'ale h trois

l)l'oches l?l/ec teH'e

N_o C Prise murah,

UHiqlle avec tel'l'e

Importantes exigences de mise _ la terre

1. E1climatiseur est pourvu d'une fiche de mise _ la terre

trois broches sur le cordon _lectrique. Cette fiche dolt

&re branchhe sur une prise murale _ trois broches

dfiment mise _ la terre afin de prot_ger contre

d'_ventuels risques de chocs. Pour les modules allant

jusqu'au 7.S A inclusivement, utiliser une prise murale

de type mise _ la terre correspondant _ la fiche (Fig. B).

2. Pour les modhles de plus de 7.S A, utiliser une prise

murale simple de mise _ la terre correspondant _ la

fiche (Fig. C).

Attention: Nous recommandons que I'appareil soit monte

par un electricien competent conformement au Code elec-

trique national ainsi qu'au code et reglements Iocaux.

Attention: Utiliser uniquement des conducteurs en cuivre.

• Niveau __ • Crayon %

1. Le climatiseur est pr_par_ fi l'usine en vue d'un mon-

2. Faire la pose du climatiseur dans une fen&re 06 il y a

Mise en garde: Ne pas empOcher I'air de circuler vers

I'exterieur des Iouvres du coffret.

3. Toutes les pi_ces de soutien doivent &re fix&s solide-

°°°°°°°°°°°°°°°°°°°°°°°°°°°

ndcessa es

Spddffcado s de fa fe 8 re

tage dans des fen&res _ guillotine standard (le clima-

tiseur ne peut pas &re mont_ dans d'autres types de

fen&re sans modification, pri_re de consulter un tech-

nicien de montage comp&ent).

un d_gagement suffisant pour assurer un apport d'air

abondant _ l'appareil.

ment _ des surfaces fermes en bois, magonnerie ou

m&al.

13

Page 15

Montage°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

D Trois (3) vis autotaraudeuses

_] Plaq base

Plate-forme de soulier IIII

3/8 po de long

.... II _ Eguerredesout,e.

de calage

D Plate-forme de soutien

I'assemblage

llp o_ies

Rail de fen_tre inf6rieur

D Didpoditif de

Joint de mousse sup6rieur

la fen_tre

Entretoise

retenue

J

J

J

Panneau de

remplissage

Glissi6res

2. PLATE-FORME DE SOUTIEN DE L'ASSEMBLAGE

Les installations ci-dessus sont permanentes. Pour une installation dans

un appartement ou un Iogement _ location, les modifications d6crites ci-

dessus doivent _tre approuv6es par le propri6taire de ces Iogements

avant de proc6der aux installations.

Montage dans une fen_tre coulissante

1.Choisir le lieu du montage. I1 est essentielque

l'ensemble de cadre de fen_tre et le c6t4 de

la structure puissent supporter ad_quatement

le poids de l'appareil. Renforcer au besoin.

2.Ouvrir l'un des cadres de vitre et installer la plaque de fixa-

tion.

3. Fixer la plaque de fixation sur l'appui de fen_tre _ l'aide de

trois (3) vis autotaraudeuses de 3/8" de long (Fig. 3).

4. Fixer, sans setter, l'_querre de soutien au bas de la plate-

forme de soutien _ l'aide de deux (2) vis _ m4taux de 7/16 de

po de long, de rondelles plates et d'_crous.

5. Placer la plate-forme de soutien contre le rail

de fen_tre inf_rieur et fermement contre le

bord vertical du cadre de fen_tre (Fig. 4).

6. Attacher la plate-forme de support _ l'appui de la fen_tre

l'aide de deux (2) vis autotaraudeuses de 1 po de longueur

(Fig. 4). Pour emp_cher que cette plate-forme n'empi_te sur la

glissi_re de la fen_tre coulissante ou la contre-fen_tre, attach-

er solidement une entretoise de 2 po de largeur _ l'appui de

fen_tre. La longueur de cette entretoise devrait _tre _gale _ la

largeur de la plate-forme de support, et son chant devrait _tre

align_ sur la rive artiste de l'appui. U_paisseur de l'entretoise

devrait _tre fonction de l'empi_tement de la plate-forme.

7. Tirer l'_querre de soutien contre l'ext4rieur de la structure.

Setter deux (2) vis _ m4taux de 7/16 de po de long sur le

dessus de la plate-forme de soutien (Fig. 3).

8. R_gler le boulon de nivellement afin de positionner l'_-

querre de soutien _ niveau. Ceci permettra d'obtenir l'angle

appropri_. Setter le contre-_crou du boulon de nivellement

(Fig. 3).

Remarque Importante: Le dispositif doit _tre de niveau ou

l_g_rement inclin4 vers l'arri_re pour faciliter l'_vacuation des

condensats.

i

Rainure

Attention: Ne pas percer de trous dans la cuvetteinf4rieure.

L'appareil est congu de mani_re /_ fonctionner avec environ

1/2 po d'eau dans la cuvette inf4rieure.

9. Couper deux pihces de joint de mousse _ dos adh4sif/_ la

hauteur de l'ouverture de la fenhtre. Enlever le dos protecteur

et appliquer sur les bords inthrieurs verticaux du cadre de la

fenhtre et du chfissis coulissant qui reposera contre l'appareil

(Fig. 5).

14

Page 16

@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@

D

Plate-forme

de_

//7 Profil6 inf6rieur

Cadre de rainure de fen_tre

ii

Pince rapide

Rainure

Trous perc_s

de long

Trous perc6s

)o de

Vis

10. Faire glisser l'appareil sur la plateforme de soutien. S'assurer

que la rainure lat_rale de l'appareil vient s'abouter contre le bord

vertical du cadre de la fen_tre.

Remarque: Si la rainure lat_rale de l'appareil n'est pas solide,

enlever l'appareil et r_gler/_ nouveau le boulon de nivellement.

11.Percer deux trous de 1/8 po dans le profil_ constituant le

cadre de la fen_tre, de mani_re/_ ce qu'ils soient align_s sur les

trous d_jit perc_s dans la traverse inf_rieure. Installer

deux (2) vis autotaraudeuses de 3/8 po de longueur dans ces

trous. Si la hauteur du cadre de fen_tre n'est pas suffisantepour

permettre l'utilisation des trous d_jit perc_s, percer deux (2) nou-

veaux trous it c6t_ des trous existants pour attacher la tra-

verse inf_rieure de l'appareil it la plate-forme de support.

L'appareil dolt _tre fermement fix_ au cadre de fen_tre ou /_la

plate-forme de support (Fig. 6).

12.Faire glisser la fen_tre int_rieure pour la fermer. S'assurer que

le bord vertical de la fen_tre int_rieure est appuy_ fermement

contre le c6t_ du boitier de l'appareil. Couper le joint de mousse

/_dos adh_sif restant/_ la largeur de l'ouverture de la fen_tre.

Enlever le dos protecteur et appliquer sur le bord int_rieur

sup_rieur du cadre de la fen_tre (Fig. S).

13.Poser les pinces rapides sur le bord int_rieur sup_rieur et

inf_rieur de la fen_tre afln de bloquer (Fig. 7).

14. Se munir du joint en mousse, le couper ceux-ci it la longueur

d_sir_e et l'ins_rer entre le cadre de fen_tre int_rieure et la fen_tre

ext_rieure (Fig. 7).

1S. Placer le dispositif de retenue sup_rieur sur le bord sup_rieur

du panneau de remplissage, (Fig. S) puis placer le bord inf_rieur

du panneau de remplissage dans la rainure du dispositif de

retenue inf_rieur (mont_ sur

l'appareil). Le panneau de remplissage peut _tre dress_ au

couteau ou aux ciseaux suivant la hauteur de la fen_tre.

16.Faire glisser les glissi_res vers le haut en s'assurant que le pan-

neau de remplissage est align_ dans les glissi_res.

17. Avec le dispositif coulissant contre l'arr_toir sup_rieur, percer

un trou de 1/8" dans le cadre de fen_tre en l'alignant avec l'a-

vanttrou du dispositif coulissant. InsUrer une vis autotaraudeuse

de 3/8" dans le trou. Effectuer la m_me operation pour

l'autre c6t_.

18. V_rifier tousles joints et colmater toutes les fuites d'air

autour de l'appareil. Utiliser le sealant fourni pour boucher toute

ouverture mineure.

15

Page 17

Fonctionnemento ooooooooooooooooooooooooooooooooooooooooooo

4. TABLEAU DE COMMANDE

Clos_;d _:............................................................................................................} Open

Air Exchan_e_

Attention: Si le climatiseur est fermi, attendre au moins trois minutes avant de le

Low Fan • • High Fan

l.ow Cool • • High Cool

Fonctions de commande

1. ¢changeur d'air "Air Exchanger": Permet ]a circulaton de ]'air frais et aide _ _liminer ]'air vici_ ]orsqu'en

position ouverte. La circulation et ]e refroidissement d'air sont

b. ]eur maximum ]orsqu'en position ferm6e.

2, Commande principale "Master Control": Met ]'apparel] en marche et

]'arr6te, S6lectionne ]a fonction d6sir6e de ]'apparel], refroidissement avec circulation d'air

continue ou circulation d'air sans refroidissement.

3, Temperature "Temperature": Commancle ]e thermostat de ]'apparei], ]equel contr6le ]a temperature de ]a

piece en mettant ]e compresseur ou ]es 6]6ments chauffants en marche et en ]es arr6tant automatiquement.

Refroidissement

1. Mettre ]'6changeur d'air _ ]a position de fermeture.

2, Tourner ]a commande de temperature b."COOLER".

3, Tourner ]a commande principa]e b. "SUPER COOL".

4, Si ]a piece devient trop fratche et n'est plus confortab]e, tourner ]a commande de temperature en sens anti-horaire

jusqu'_ ce que ]e compresseur s'arr6te (]e venti]ateur de cir-culation d'air continuera b. fonctioner).

5, Une fois atteint ]e niveau de confort d_sir_, ]a commande principa]e peut 6tre tourn_e _ un r_g]age plus bas.

6, Pour fermer ]'apparel] ou en cas de panne de courant, tourner ]a commande principa]e _ ]a position d'arr6t.

Circulation d'air sans refroidissement

Pour faire circuler et flitter/'air int6rieul;

proc6der de/a rnani_re suiwmte:

1, Mettre ]'6changeur d'air b. ]a position de fermeture.

2, Tourner ]a commande principale _ ]a position "HIGH FAN".

Sortie d'air sans refroidissement

Pour faire sortir I'air vici6 ou enfum6,

proc6der de/a mani_re suiwmte:

1, Mettre ]'6changeur d'air b. ]a position d'ouverture.

2, Tourner ]a commande pricipale _ ]a position "HIGH FAN".

16

Page 18

Entretien oooooooooooooooooooooooooooooooooooooooooooooooooo

5. PANNEAU AVANT

Panneau avant A_rateurs r_glables

Filtre _ air

Leviers de

orientation

de I'air

Grille d'entr_e d'air

LangueHes

Note: L'omission de garder le filtre _ air propre causera une mauvaise circulation d'air. NE PAS faire fonctionner

I'appareil sans filtre, ce qui peut mettre I'appareil hors service.

La dur_e de vie de votre conditionneur d'air est prolong_e par un usage et un entretien ad_quats. II est recom-

mand_ d'effectuer annuellement une inspection et un nettoyage des serpentins et des conduites d'eau de condensa-

tion. Les co_ts associ_s _ cet entretien annuel sont aux frais de I'acheteur.

Orientation de l'air

Le climatiseur est pourvu d'a4rateurs rhglables qui dirigent l'air 5 droite ou 5 gauche. Les a4rateurs se r_g-

lent manuellement en d4pla_ant les leviers des d4flecteurs darts la direction d4sir4e.

Nettoyage du filtre 5 air

Lorsque le climatiseur fonctionne, l'air int4rieur est filtr4 et refiltr4 continuellement, captant ainsi darts le

filtre lavable la poussi_re et salet4 en suspension darts l'air. Le filtre doit doric htre inspect4 et nettoy4

toutes les semaines.

1.Tourner la commande principale 5 la position d'arrht.

2. Saisir les deux c6ths pros de la partie sup4rieure de la grille d'entr4e d'air et tirer

vers l'avant. La grille pivote vers l'avant pour permettre l'acc_s au filtre 5 air.

3. D4crocher le filtre 5 air des languettes.

4. Passer l'aspirateur sur le c6th poussihreux du filtre pour enlever la poussi_re non

incrust4e. Laver soigneusement le filtre 5 air darts de l'eau tilde et un d4tersif doux. Rincer 5 l'eaclaire,

essorer pour s4cher, et remettre en place.

5. Remettre le grille d'entr4e d'air en place.

6. Remettre la commande principale 5 la position de fonctionnement d4sir4e.

17

Page 19

Garantieoooooooooooooooooooooooooooooooooooooooooooooooooooo

Pour les modules install4s en

Am4rique du Nord - Si des r4para-

tions ou pi_ces s'av_rent n6cessaires

S'il s'av_re, apr_s les v_rifications recommand_es, qu'il est

n4cessaire d'effectuer des r_parations ou de se procurer des

pi_ces, reportez-vous fi <<Comment obtenir des r_para-

tions ou pi_ces dans le cadre de la garantie>> dans la

garantie de votre climatiseur.

Pour les modules mont6s

I'ext6rieur de I'Am6rique du Nord

Pour les climatiseurs de piece achet4s en vue de leur utili-

sation fi l'ext_rieur de l'Am4rique du Nord, le fabricant ne

donne aucune garantie, explicite ou implicite. Consultez

votre vendeur local pour connaitre les modalit4s de la

garantie offerte par l'importateur dans votre pays.

Garantie du climatiseur

(Applicable clans les 48 Etats-Unis limitrophes, I_tat

d'Hawa), le District de Columbia, a Porto-Rico, au Canada)

Garantie complete (cinq ans) sur les pi_ces et la

main d'oeuvre

Pour une p_riode de cinq ans suivant la date d'achat par l'a-

cheteur original, Fedders Appliances s'engage, par le biais de

ses postes de service agr_4s et sans aucun frais de la part de

l'acheteur ou de tout utilisateur subsequent, fi r@arer ou

remplacer toute piece d_fectueuse dans la mati_re ou la fab-

rication dans des conditions normales d'utilisation. Un

acc_s rapide au conditionneur d'air pour en permettre Fen-

tretien est la responsabilit_ du propri_taire.

Remarque: Dans le cas o£1tout remplacement de pieces

est requis clans les limites de temps de cette garantie, les

pieces de rechange de Fedders Appliances sont usagees

et ne sont garanties que pour la periode restante de la

garantie originale.

Exceptions

La garantie susmentionn_e ne couvre pas les d_faillances

caus_es par des dommages subis par l'appareil tant qu'il est

en votre possession (autres que les dommages dus fi un

d_faut ou fi un d_r_glement), par son installation incorrecte

ou par une utilisation d_raisonnable de l'appareil, y com-

pris, entre autres, l'absence d'entretien r_gulier et n_cessaire

ou le non-respect des instructions _crites d'installation et

d'utilisation. Si l'appareil est utilis_ fi des fins commerciales,

de location ou autres que domestiques, nous n'offrons

aucune garantie expresse ou tacite, y compris, entre autres,

des garanties tacites de qualit_ marchande ou d'adaptation

un usage ou objet particulier.

PARTIR DE LA DATE DE L 'ACHAT INITIAL. Feddet:s Appliances

NE 8AURAIT EN AUCUN CAS ETRE TENU RESPONSABLE

POUR LES DOMMAGES INDIRECT& SECONDAIRES OU

ACCESSOIRE8, 8AN8 E(;ARD Jt LA CAUSE, MEME AU CA8 0U

FEDDERS APPLIANCESW AURAIT ETE PREVENU DE LA

PO88IBILITE DE TELS DOMMAGES. AUCUNE GARANTIE,

EXPRESSE OU IMPLICITE, N'EST OFFERTE Jt UN ACHETEUR

QUELCONQUE EN CAS DE REVENTE.

Certains _tats n'autorisent pas les limitations de dur_e des

garanties tacites, ni les exclusions ou limitations frappant

les dommages accessoires ou indirects. I1se peut donc que

les exclusions ou limitations susmentionn4es ne vous

soient pas opposables. La pr_sente garantie vous confute

des droits precis; w)us pouvez _galement jouir d'autres

droits qui varient d'un _tat fil'autre.

Les appareils vendus en dehors des r_gions susmention-

n4es ne sont couverts par aucune garantie. I1 se peut que

w_tre distributeur ou revendeur vous offre une garantie si

wins r_sidez en dehors de ces r_gions.

Comment obtenir des r6parations ou

pi_ces dans le cadre de la garantie

Le service apr_s-vente pour w_tre climatiseur sera assur_

par CareCo, une division du fabricant qui dispose d'un

r_seau de centres de service agr_s ind_pendants dans tout

le pays.

Remarque: Avant de demander une intervention, lisez

attentivement le livret d'instructions d'installation et d'u-

tilisation. Si vous devez ensuite avoir recours au service

apres-vente:

1. Appelez un centre de service apr_s-vente agr_4 CareCo

en indiquant le num_ro de module, le num_ro de s_rie,

la date de l'achat et la nature du probl_me. La r@ara-

tion sera effectu_e pendant les heures ouvrables. En cas

de besoin, demandez fivotre revendeur les coordonn4es

d'un centre de service apr_s-vente agree.

2. Sivotre revendeur n'est pas en mesure de vous indiquer

les coordonn4es d'un centre de service apr_s-vente

agr_ ou si vous avez besoin d'une autre assistance

quelconque, appelez sans frais le num4ro suivant pour

obtenir les coordonn4es d'un centre de service apr_s-

vente ou distributeur de pi_ces agr_4:

1-866-MAYTAG 1

Vous pouvez egalement ecrire a:

CareCo, Service Department

415 W. Wabash Ave., RO. Box 200

Effingham, IL 62401 E.-U.

LES RECOURS STIPULES DANS LA GARANTIE EXPRESSE

SUSMENTIONNEE REPRESENTENT LES SEULS RECOURS

EXCLUSIFS DISPONIBLES. IL N'EXISTE AUCUNE AUTRE

GARANTIE EXPRESSE. TOUTES LES GARANTIES IMPLICITES,

Y COMPRIS it TITRE NON LIMITATIF TOUTES (;ARANTIES

IMPLICITES DE QUALITE LOYALE ET MARCHANDE ET

D'UTILITE PARTICULIERE, SONT LIMITEES it CINQ ANS it

Preuve de la date de I'achat

I1 incombe au client de fournir la preuve de la date de

l'achat initial pour des raisons tenant fi la garantie. Nous

wins recommandons de conserver dans ce but une facture,

un cheque annul_ ou tout autre document appropri_

apportant la preuve du r_glement.

18

Page 20

23-11-2214N-002

Closed( ) Open

AirE×chan_er j'

Master Co.... ' _ .... emCool

Ww _n •

Low CoN • _

M_IU

OFF

Q

• Hl_h [:an

b)

Controls unit thermostat, which regulates room tem-

perature by automatically turning compressor or heat-

ing elements on and off.

Termostato -

Controla el termostato de la unidad que regula la tem-

peratura ambiental encendiendo o apagando automfiti-

camente el compresor o los elementos de calefaccidn.

Thermostat -

La commande du thermostat permet de r_gler la sensi-

bilit_ du thermostat de l'appareil qui ajuste la tempera-

ture de la piece en d_clenchant ou en arr_tant le

compresseur de fagon automatique.

a) Master Control -

Turns unit on and off. Selects desired function

of unit, cooling or heating with continuous

air circulation or air circulation without cool-

ing or heating (Fan Only).

Control maestro - Enciende y apaga la

unidad. Selecciona la funcidn deseada de la

unidad, enfriamiento o calefaccidn con circu-

lacidn de aire permanente o circulation de aire

sin enfriamiento ni calefaccidn.

Commande principale -

Permet de mettre le dispositif hors tension et

sous tension. Permet de s_lectionner la fonc-

a)

b)Thermostat -

tion d_sir_e, refroidissement ou chauffage avec

une circulation d'itir seulement (san

refroidissement ni chauffage).

• Do not introduce objects in the air discharge area. This could cause permanent damage to your unit.

• Do not pour liquids on the unit as this could cause a malfunction. Use a damp cloth for cleaning your unit. Avoid strong solvents.

• Clean the units filter frequently to avoid overheating caused by air obstruction.

• Do not obstruct the air intake area of your unit, as this could cause overheating, thus activating the units security switch and shutting

off the unit.

• No introduzca objectos dentro de la salida de aire. Esto podria causar daho permanente.

• No vierta liquidos detro de la unidad ya que podriaocasionar un corto circuito. Para limiar su unidad utilce un trapo hfimedo, cuidando no

mojar el interior.

• No obstruya la entrada de aire de su unidad ya que puede causar un sobrecalentamiento activando asi el switch de seguridad provo-

cando asi que la unidad se apague.

• Limpie frecuentemente el filtro de la unidad para evitar sobrecalentamiento por obstrucci6n de aire.

• Nintroduisez pas dobjets dans la bouche da6ration. Cela purrait endommager gravement votre unit6.

• Ne versez pas de liquides sur lunit6, puisque cela pourrait provoquer un sur-chauffage d6clenchant ainsi linterrupteur de s6curit6 qui

fera que lunit6 s6teint.

• Nettoyez r6gulibrement le filtre de vbotre unit6 pour 6viter des sur-chauffages provoqu6s par blocage dair.

• Ne pas emp_cher l'air de circuler vers l'ext6rieur des louvres du coffret.

For additional questions please call: 866-MAYTAG 1

Maytagisa trademarkoftheMaytagCorporationandis usedunderlicenseby FeddersNorthAmerica,Inc.

Maytages unamarcaregistradadeMaytagCorporationy seusabaio licenciaotorgadaaFeddersNorthAmericaInc.

Maytagestune marquedecommercedeMaytagCorporation,utiiisdesous [iceneeparFeddersNorthAmerica,Inc.

Loading...

Loading...