Maytag 23-11-2204N-003 User Manual

_u, __

Room Air Conditioners for

Double-Hung Windows

Acondicionadores de aire

ambientales para ventanas

de guillotina

Climatiseur d' air individuel

pour fenOtres h guillotine

For Future Reference

Write down the model and serial numbers

The model and serial numbers can be found

on the side of the cabinet near the control

panel. Use these numbers in any correspon-

dence or service calls concerning your air

conditioner.

Para referencia futura

Escriba los numeros del modelo y de la serie

Puede encontrar los nfmeros de modelo y de serie en el

costado de la rejilla del frente decorativo cerca del panel

de control. Use estos nOmeros en cualquier corresponden-

cia o llamada de servicio con relaci6n a su acondicionador

de aire.

Pour r6f6rence ult6rieure

Inscrivez les numeros de modele et de serie

Les num6ros de mod61e et de s6rie se trouvent sur le c6t6 de

la grille d6corative avant, pr6s du panneau de commande.

Utilisez ces num6ros lors de toute correspondance ou appel

au service apres-vente ayant trait it votre climatiseur.

Model No.. Modelo No,. N °de modOh

cr,,,,No 866-MAYTAG 1 ;,

Date of Pmvhase, Fecha de la compra, Date d2ichat

@@ @@

_ ,i¸ i!TZ_ Z

@

@

@

@

@

leep_hese instructions for future reference

@

@

@

@

For additional questions please call: ;

@

@

@

@

@

@

@

@

MAYIAG

Important Safety Instructions ooooooooooooooooooooooo

Electrical Shock Hazard

1. Plug unit only into grounded electrical outlet,

2. Do not use an extension cord or plug adapter with this unit,

3. Do not operate unit with front removed,

Failure to follow the above precautions could result in electrical

shock, fire or personal injury.

If the air conditioner has a serial plate rating of 11S volts and greater

than 7.5 amps it must have its own fuse or circuit breaker, and no

other device or unit should be operated on that fuse or circuit breaker.

If the air conditioner has a serial plate rating of 230 volts it must

have its own fuse or circuit breaker, and no other device or unit

should be operated on that fuse or circuit breaker.

The location of the serial plate that applies to this inodel can be

found on the back page of this manual.

Hgo A

Expanded Polystyrem! (gray/white tbam)

Notice: Do not

operate this air

conditioner

without proper

time delay cir-

cuit protection.

Refer to serial

plate for proper

power supply

requireInents.

RECOMMENDED CIRCUIT WIRE SIZES

(As installed per blfildi_l,¢ co&)

PROTECTOR SIZE WIRE GAUGE

1S AMP #14 MINIMUM

20 AMP #12 MINIMUM

30 AMP # 10 MINIMUM

@©©@

115V 230V 230V 230V

15.4 15.4 20A 30A

Pictured air conditioner is similar to your air conditioner

Product Damage: Do not cut, alter or remove any of the expand-

ed polystyrene (gray/white foam) inside this air conditioner

(Fig. AL THE WHITE FOAM IS PART OF THE UNIT, NOT PACKING

MATERIAL,

For Your Safety: Do not store or use gasoline or other flaInmable

vapors and liquids in the vicinity of this or any other appliance. The

fumes can create a fire hazard or explosion.

Before Getting Started °°° °°°°°°°°°°°°°°°°°°°°°°°°°°o

Electrical Requ[yements

Thme-pro1_q

gmundingplug _

"" (;l'OllHddt

three-prong

wall receptacle

_o _ Single outlet

_#rolmdin_#wall

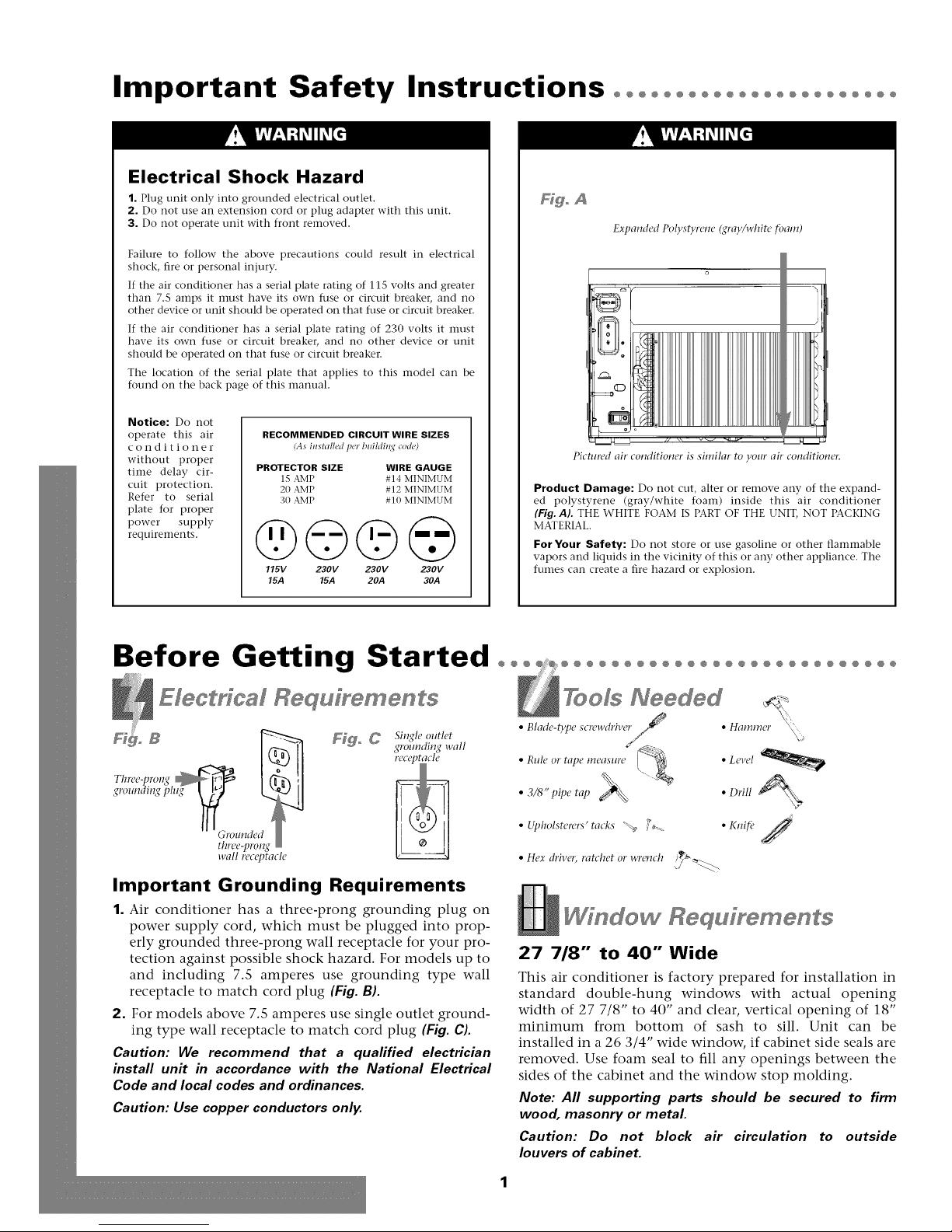

Important Grounding Requirements

1. Air conditioner has a three-prong grounding plug on

power supply cord, which must be plugged into prop-

erly grounded three-prong wall receptacle for your pro-

tection against possible shock hazard. For models up to

and including 7.5 amperes use grounding type wall

receptacle to match cord plug (Fig. B).

2. For models above 7.5 amperes use single outlet ground-

ing type wall receptacle to match cord plug (Fig. C).

Caution: We recommend that a qualified electrician

install unit in accordance with the National Electrical

Code and local codes and ordinances.

Caution: Use copper conductors only.

Window Requ[rements

27 718" to 40" Wide

This air conditioner is factory prepared for installation in

standard double-hung windows with actual opening

width of 27 7/8" to 40" and clear, vertical opening of 18"

minimum from bottom of sash to sill. Unit can be

installed in a 26 3/4" wide window, if cabinet side seals are

removed. Use foam seal to fill any openings between the

sides of the cabinet and the window stop molding.

Note: All supporting parts should be secured to firm

wood, masonry or metal

Caution: Do not block air circulation to outside

louvers of cabinet.

Installation°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

Decoraffve & ChassT RemovM

F_goD F_goE

Air filter

i SCI'PWS

0" _ Cabinet Chassis

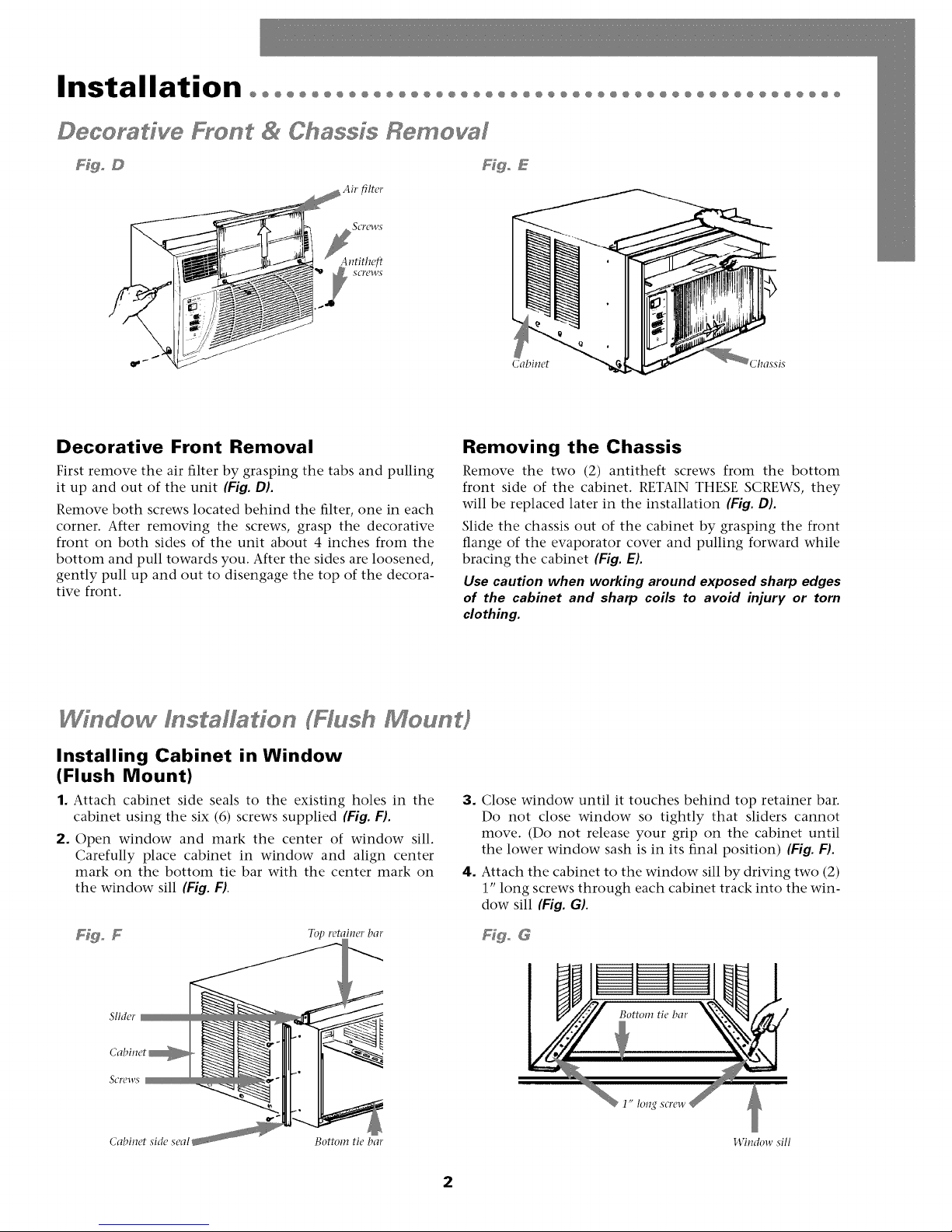

Decorative Front Removal

First remove the air filter by grasping the tabs and pulling

it up and out of the unit (Fig. DL

Remove both screws located behind the filter, one in each

corner. After removing the screws, grasp the decorative

front on both sides of the unit about 4 inches from the

bottom and pull towards you. After the sides are loosened,

gently pull up and out to disengage the top of the decora-

tive front.

Wfndow f staffaffon (Hash Mo n#

Installing Cabinet in Window

(Flush Mount)

1. Attach cabinet side seals to the existing holes in the

cabinet using the six (6) screws supplied (Fig. F).

2. Open window and mark the center of window sill.

Carefully place cabinet in window and align center

mark on the bottom tie bar with the center mark on

the window sill (Fig. FI.

Removing the Chassis

Remove the two (2) antitheft screws from the bottom

front side of the cabinet. RETAIN THESE SCREWS, they

will be replaced later in the installation {Fig. DL

Slide the chassis out of the cabinet by grasping the front

flange of the evaporator cover and pulling forward while

bracing the cabinet (Fig. E).

Use caution when working around exposed sharp edges

of the cabinet and sharp coils to avoid injury or torn

clothing.

3. Close window until it touches behind top retainer bar.

Do not close window so tightly that sliders cannot

move. (Do not release your grip on the cabinet until

the lower window sash is in its final position) {Fig. FL

4. Attach the cabinet to the window sill by driving two (2)

1" long screws through each cabinet track into the win-

dow sill (Fig. G).

SIMer

Cabinet

SCl'PWS

Cabinet side seal Bottom tie bar

Ffgo G

145ndow sill

2

Installation°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

Wi dew l staHade FHush Meu t)

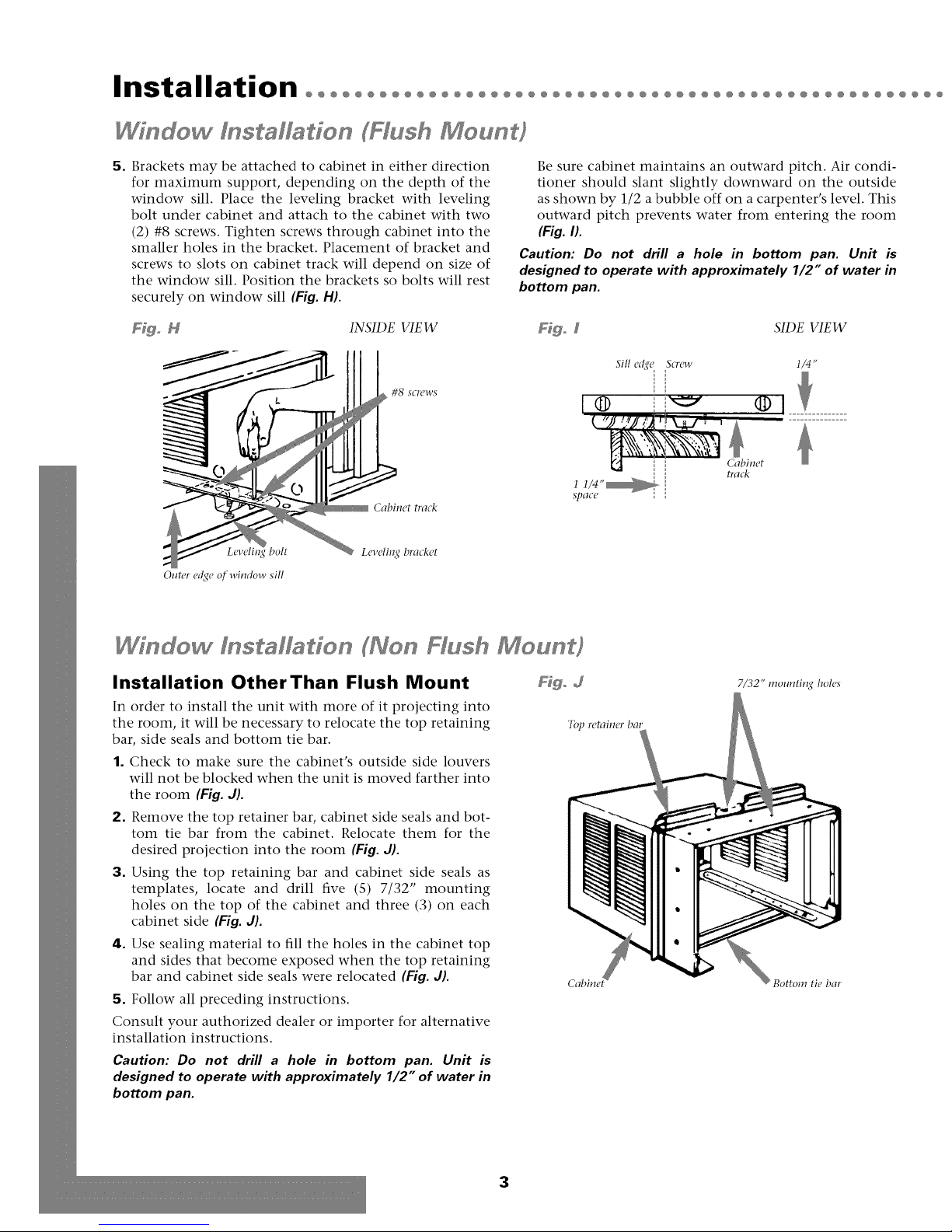

5. Brackets may be attached to cabinet in either direction

for maximum support, depending on the depth of the

window sill. Place the leveling bracket with leveling

bolt under cabinet and attach to the cabinet with two

(2) #8 screws. Tighten screws through cabinet into the

smaller holes in the bracket. Placement of bracket and

screws to slots on cabinet track will depend on size of

the window sill. Position the brackets so bolts will rest

securely on window sill (Fig. H).

Be sure cabinet maintains an outward pitch. Air condi-

tioner should slant slightly downward on the outside

as shown by 1/2 a bubble off on a carpenter's level. This

outward pitch prevents water from entering the room

(Fig. I).

Caution: Do not drill a hole in bottom pan. Unit is

designed to operate with approximately 1/2" of water in

bottom pan.

F@o N INSIDE VIEW Fdgo 5 SIDE VIEW

Sill e_qe Screw

Outer edge of window sill

bolt

#8 SCI'CWS

Cabinet track

Leveli1_q bracket

/i i _ l; i i_1 n

1 1/4"_

SpaCC

® .........

i',: . =_

Cabinet

Ira&

I/4"

Installation OtherThan Flush Mount

In order to install the unit with more of it projecting into

the room, it will be necessary to relocate the top retaining

bar, side seals and bottom tie bar.

1. Check to make sure the cabinet's outside side louvers

will not be blocked when the unit is moved farther into

the room (Fig. d).

2. Remove the top retainer bar, cabinet side seals and bot-

tom tie bar from the cabinet. Relocate them for the

desired projection into the room (Fig. d).

3. Using the top retaining bar and cabinet side seals as

templates, locate and drill five (S) 7/32" mounting

holes on the top of the cabinet and three (3) on each

cabinet side (Fig. J).

4. Use sealing material to fill the holes in the cabinet top

and sides that become exposed when the top retaining

bar and cabinet side seals were relocated (Fig. J).

5. Follow all preceding instructions.

Consult your authorized dealer or importer for alternative

installation instructions.

Caution: Do not drill a hole in bottom pan. Unit is

designed to operate with approximately 1/2" of water in

bottom pan.

Fdgo d

T(Q retainerbar

7/32" mounting boles

Bottom tie bar

3

@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@

Filler P3 el f s Mf3ffo

Installing the Window Filler Panels

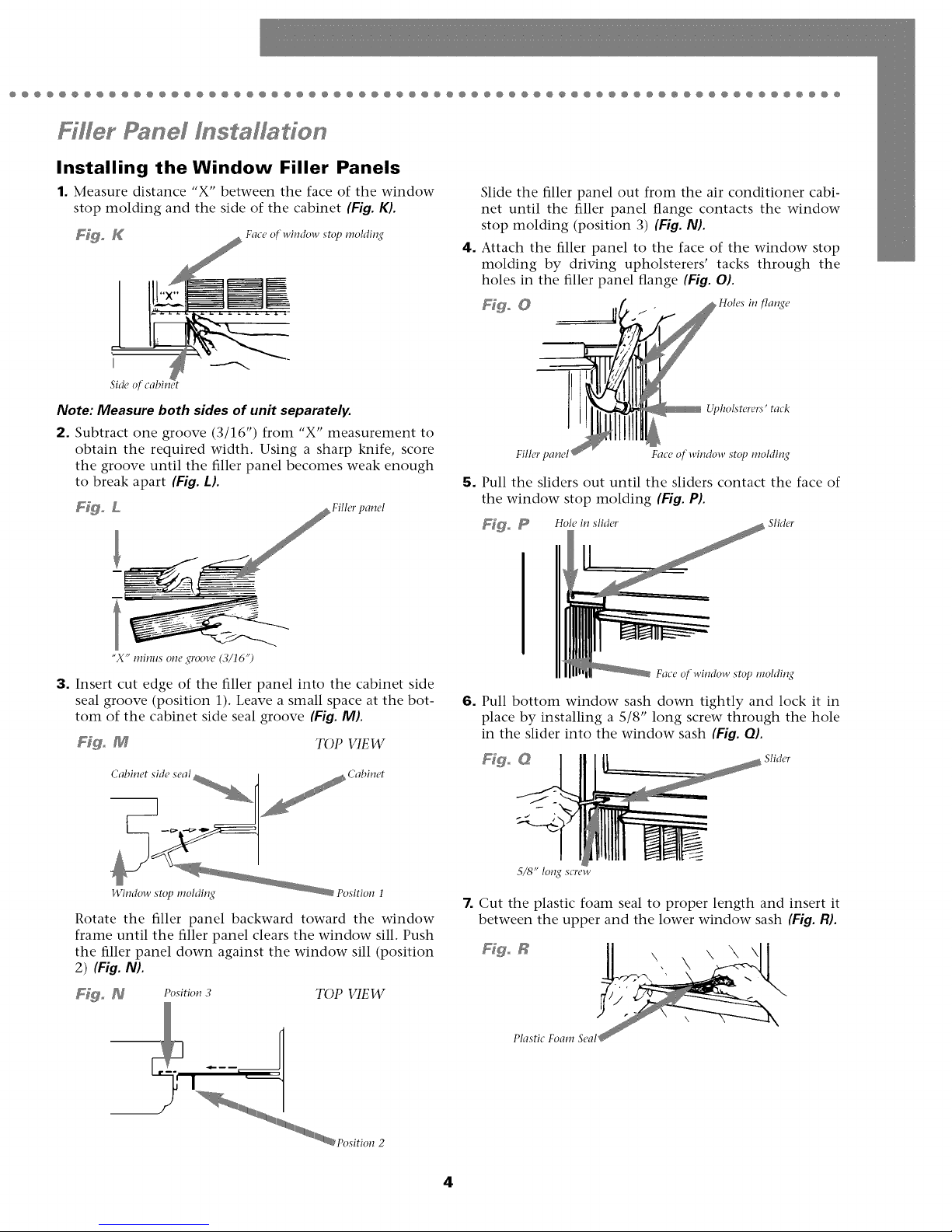

1. Measure distance "X" between the face of the window

stop molding and the side of the cabinet (Fig. K).

Fig_ K Face o[ window stop molding

Side o[ cabinet

Note: Measure both sides of unit separately.

2. Subtract one groove (3/16") from "X" measurement to

obtain the required width. Using a sharp knife, score

the groove until the filler panel becomes weak enough

to break apart (Fig. L).

Fig° L Fillerpanel

Slide the filler panel out from the air conditioner cabi-

net until the filler panel flange contacts the window

stop molding (position 3) (Fig. NL

4. Attach the filler panel to the face of the window stop

molding by driving upholsterers' tacks through the

holes in the filler panel flange (Fig. OL

Ffgo 0 _ _Holes in flange

5. Pull the sliders out until the sliders contact the face of

the window stop molding (Fig. PL

F_go _ Hole in slider Slider

Upholsterers j tack

Fillet' panel Face of-window stop rooMing

"X j" minus one 2(roove (3/16'9

3. Insert cut edge of the filler panel into the cabinet side

seal groove (position 1). Leave a small space at the bot-

tom of the cabinet side seal groove (Fig. ML

Fig° M TOP VIEW

Wimlow stop moldin2(

Rotate the filler panel backward toward the window

frame until the filler panel clears the window sill. Push

the filler panel down against the window sill (position

2) (Fig. N).

Fig. _ Position 3 TOP VIEW

_--mm

Face of window stop rooMing

6. Pull bottom window sash down tightly and lock it in

place by installing a 5/8" long screw through the hole

in the slider into the window sash (Fig. OL

Figo G Sli,let'

5/8" long screw

7. Cut the plastic foam seal to proper length and insert it

between the upper and the lower window sash (Fig. R}.

Figo R \ \ \\\

Plastic Foam Seal

4

Installation°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

Ffffer P3 el f sta/f3do

Installing the Chassis into the Cabinet

1. Slide the chassis into the cabinet.

2. To replace the front, place the top of the decorative

front in position and pivot back towards the unit and

snap into place. Replace screws and air filter.

3. Replace the two (2) antitheft screws at the bottom side

of cabinet.

Drafn Instalfadon

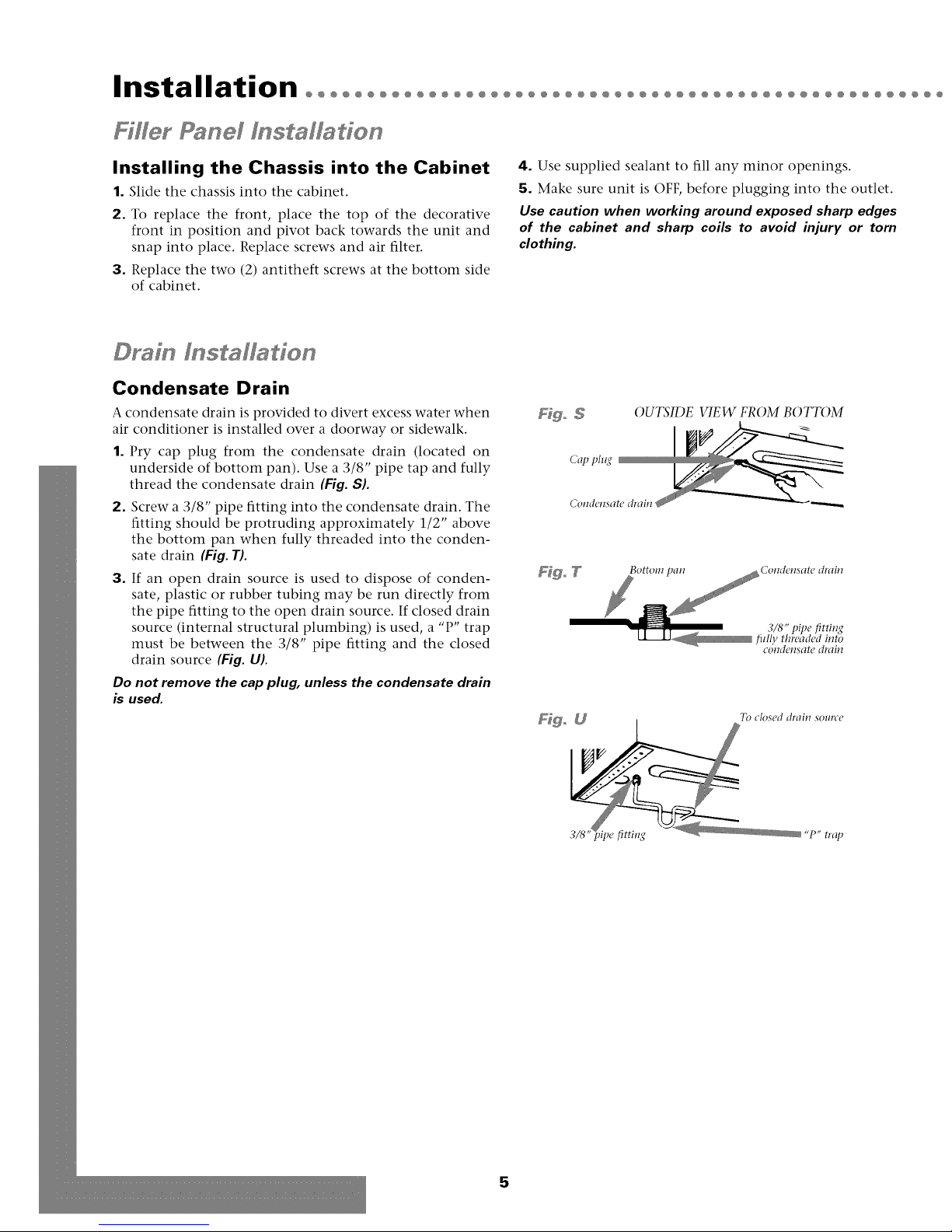

Condensate Drain

A condensate drain is provided to divert excess water when

air conditioner is installed over a doorway or sidewalk.

1. Pry cap plug from the condensate drain (located on

underside of bottom pan). Use a 3/8" pipe tap and fully

thread the condensate drain (Fig. S).

2. Screw a 3/8" pipe fitting into the condensate drain. The

fitting should be protruding approximately 1/2" above

the bottom pan when fully threaded into the conden-

sate drain (Fig. T).

3. If an open drain source is used to dispose of conden-

sate, plastic or rubber tubing may be run directly from

the pipe fitting to the open drain source. If closed drain

source (internal structural plumbing) is used, a "P" trap

must be between the 3/8" pipe fitting and the closed

drain source (Fig. U).

Do not remove the cap plug, unless the condensate drain

is used.

4. Use supplied sealant to fill any minor openings.

5. Make sure unit is OFF, before plugging into the outlet.

Use caution when working around exposed sharp edges

of the cabinet and sharp coils to avoid injury or torn

clothing.

OUTSIDE VIEW FROM BOTTOM

Cap plug

3/8" t)ipe fittiug

fiflly threaded into

COIldCIISatP drain

5

@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@

T rougho heoWaff I s affado

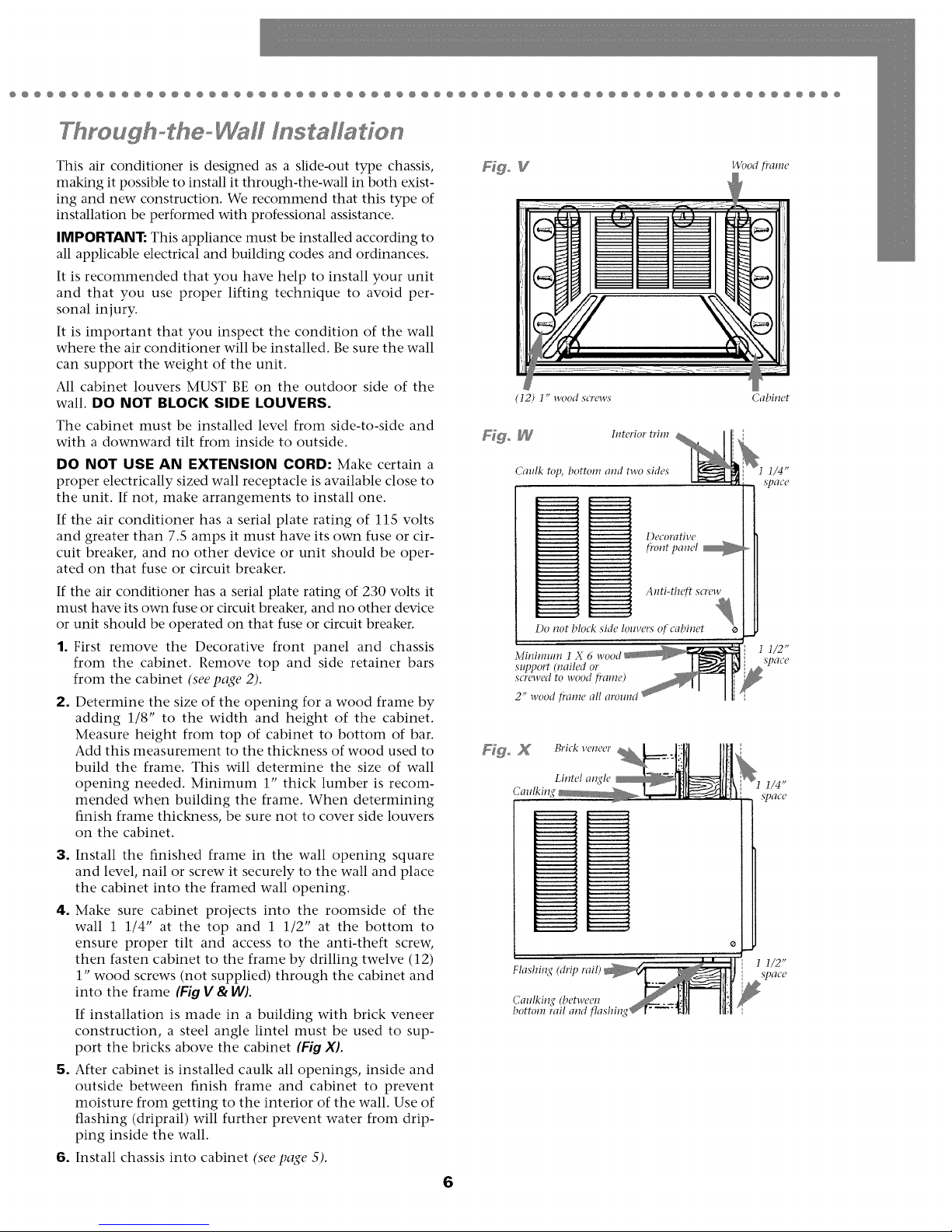

This air conditioner is designed as a slide-out type chassis,

making it possible to install it through-the-wall in both exist-

ing and new construction. We recommend that this type of

installation be performed with professional assistance.

IMPORTANT: This appliance must be installed according to

all applicable electrical and building codes and ordinances.

It is recommended that you have help to install your unit

and that you use proper lifting technique to avoid per-

sonal injury.

It is important that you inspect the condition of the wall

where the air conditioner will be installed. Be sure the wall

can support the weight of the unit.

All cabinet louvers MUST BE on the outdoor side of the

wall. DO NOT BLOCK SIDE LOUVERS.

The cabinet must be installed level from side-to-side and

with a downward tilt from inside to outside.

DO NOT USE AN EXTENSION CORD: Make certain a

proper electrically sized wall receptacle is available close to

the unit. If not, make arrangements to install one.

If the air conditioner has a serial plate rating of 115 volts

and greater than 7.5 amps it must have its own fuse or cir-

cuit breaker, and no other device or unit should be oper-

ated on that fuse or circuit breaker.

If the air conditioner has a serial plate rating of 230 volts it

must have its own fuse or circuit breaker, and no other device

or unit should be operated on that fuse or circuit breaker.

1. First remove the Decorative front panel and chassis

from the cabinet. Remove top and side retainer bars

from the cabinet (see page 2).

2. Determine the size of the opening for a wood frame by

adding 1/8" to the width and height of the cabinet.

Measure height from top of cabinet to bottom of bar.

Add this measurement to the thickness of wood used to

build the frame. This will determine the size of wall

opening needed. Minimum 1" thick lumber is recom-

mended when building the frame. When determining

finish frame thickness, be sure not to cover side louvers

on the cabinet.

3. Install the finished frame in the wall opening square

and level, nail or screw it securely to the wall and place

the cabinet into the framed wall opening.

4. Make sure cabinet projects into the roomside of the

wall 1 1/4" at the top and 1 1/2" at the bottom to

ensure proper tilt and access to the anti-theft screw,

then fasten cabinet to the frame by drilling twelve (12)

1" wood screws (not supplied) through the cabinet and

into the frame (Fig V & W).

If installation is made in a building with brick veneer

construction, a steel angle lintel must be used to sup-

port the bricks above the cabinet (Fig XL

5. After cabinet is installed caulk all openings, inside and

outside between finish frame and cabinet to prevent

moisture from getting to the interior of the wall. Use of

flashing (driprail) will further prevent water from drip-

ping inside the wall.

6. Install chassis into cabinet (see page 5).

6

(12) 1" wood screws

Fd_ _ Interior trim

Caulk top, bottom and two sides

Anti-theft screw

Do not block sMe louvers of cabinet

Minimum 1

support (nailed or

screwed to wood fi'ame)

2" wood fi'ame all around

Fdgo X Brick ve,eer

Lintel al_(le

Calflkin

Flashin

Caulkin,¢ (bel-weeu

bottom rail and flashing

Cabinet

Operation°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°•

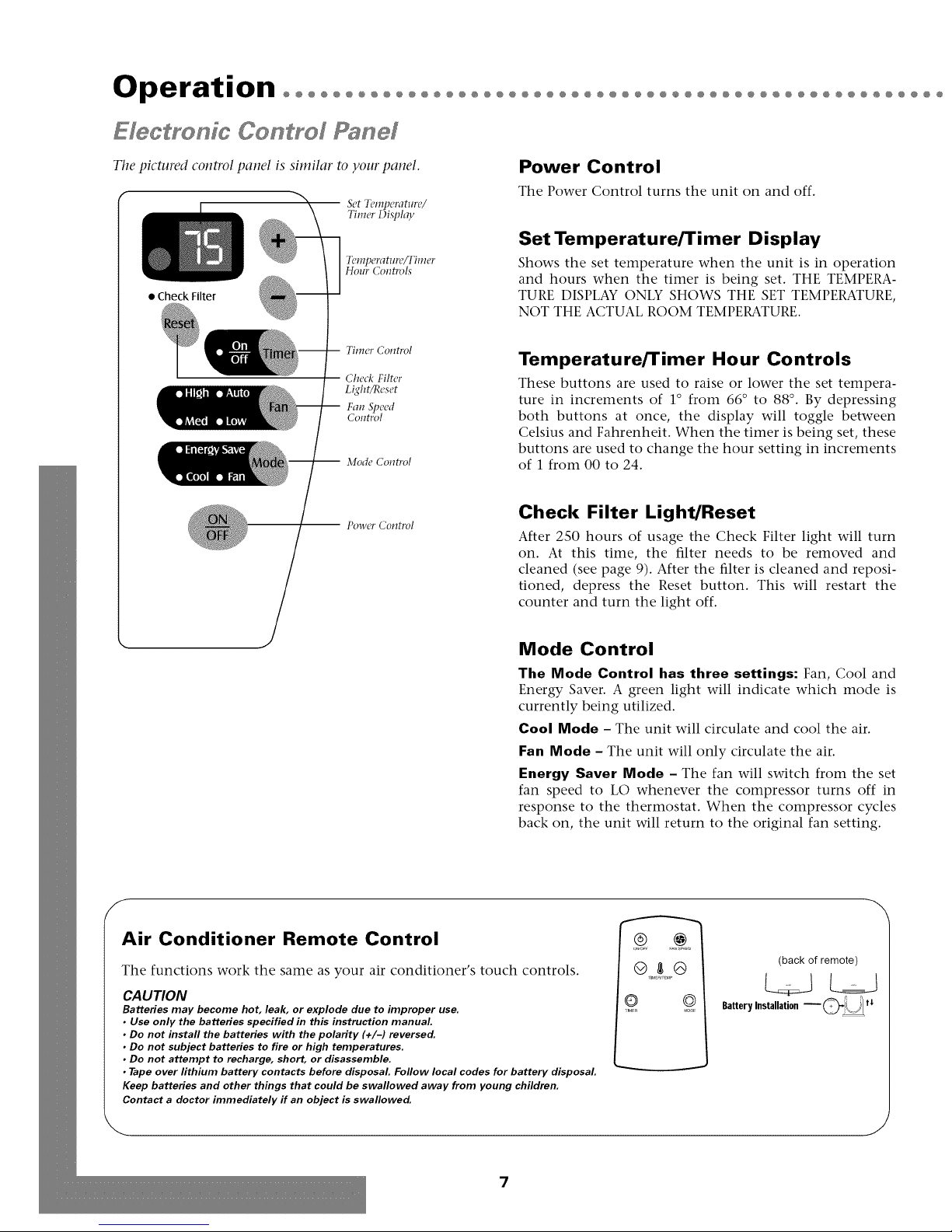

Electmnfc Central Panel

Tile pictured control panel is similar to your panel.

Set Temperature/

Timer i)iqflay

TL!lllpPl'f?tlll'P/TllllPl'

Hour Controls

• Check Filter

Timer Control

Check Filter

Light/Reset

Fan Speed

Control

Mode Control

-- Power Control

Power Control

The Power Control turns the unit on and off.

Set Temperature/Timer Display

Shows the set temperature when the unit is in operation

and hours when the timer is being set. THE TEMPERA-

TURE DISPLAY ONLY SHOWS THE SET TEMPERATURE,

NOT THE ACTUAL ROOM TEMPERATURE.

Temperature/Timer Hour Controls

These buttons are used to raise or lower the set tempera-

ture in increments of 1 ° from 66 ° to 88 °. By depressing

both buttons at once, the display will toggle between

Celsius and Fahrenheit. When the timer is being set, these

buttons are used to change the hour setting in increments

of 1 from 00 to 24.

Check Filter Light/Reset

After 2S0 hours of usage the Check Filter light will turn

on. At this time, the filter needs to be removed and

cleaned (see page 9). After the filter is cleaned and reposi-

tioned, depress the Reset button. This will restart the

counter and turn the light off.

Mode Control

The Mode Control has three settings: Fan, Cool and

Energy Saver. A green light will indicate which mode is

currently being utilized.

Cool Mode - The unit will circulate and cool the air.

Fan Mode - The unit will only circulate the air.

Energy Saver Mode - The fan will switch from the set

fan speed to LO whenever the compressor turns off in

response to the thermostat. When the compressor cycles

back on, the unit will return to the original fan setting.

f

Air Conditioner Remote Control

The functions work the same as your air conditioner's touch controls.

CAUTION

Batteries may become hot, leak, or explode clue to improper use.

• Use only the batteries specified in this instruction manual

• Do not install the batteries with the polarity (+11-) reversed.

• Do not subject batteries to fire or high temperatures.

• Do not attempt to recharge, short, or disassemble.

• Tape over lithium battery contacts before disposal Follow local codes for battery disposal

Keep batteries and other things that could be swallowed away from young children.

Contact a doctor immediately if an object is swallowed.

@l@

@ @

,IMER _O,X

(back of remote)

BatteryInstallation _J/\_/

J

7

@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@@

Fyon Panel

Fan Speed Control

The Fan Speed Control has four settings: High,

Medium, Low and Auto. The settings are adjusted with the

Fan Speed Control, each time the button is depressed it

changes the setting. A green light will indicate which set-

ting is currently being used.

When the Auto feature is selected while the air condition-

er is in the COOL mode, the fan speeds will change auto-

matically as the temperature in the room changes.

• 7° or more above the set temperature will use HI fan.

• 4 ° - 7 ° above the set temperature will use MED fan.

• 4 ° or less above the set temperature will use LO fan.

Timer Control

The timer can be set to either turn the unit on or off.

To turn the unit on using theTimer:

Depress the timer key when the power is off, the display

will read 00. Adjust to the desired number of hours before

TURN ON using the up/down arrows.

The display will show the time by hours left until TURN

ON.

To turn the timer off, depress the timer key

A green light next to the Timer Control indicates that the

timer is set.

Directing Airflow

Unit is engineered with adjustable louvers to direct dis-

charge airflow. Louvers are manually adjusted by moving

levers in direction of desired airflow (Fig. YI.

To turn the unit OFF using theTimer.

Depress the timer key when the power is on, the display will

read 00. Adjust to the desired number of hours before TURN

OFF using the up/down arrows. The display will automati-

cally go back to the set temperature after ]0 seconds.

To display the amount of time left until TURN OFF,

depress the timer button once.

To turn the TIMER OFF, depress the timer button twice.

A green light next to the Timer Control indicates that the

timer is set.

Built-in three minute timing delay.

This electronic controlled unit will not automatically

resume operation after a power failure.

ff this electric unit will not respond to touch pad or

remote control commands, it is necessary to unplug the

unit from the electrical outlet for five seconds and then

plug the unit back in.

8

Maintenance°°°°°°°°°°°°°°°

°00°°00°00°°00°00°000°00°00°°00

Cleaning Air Filter

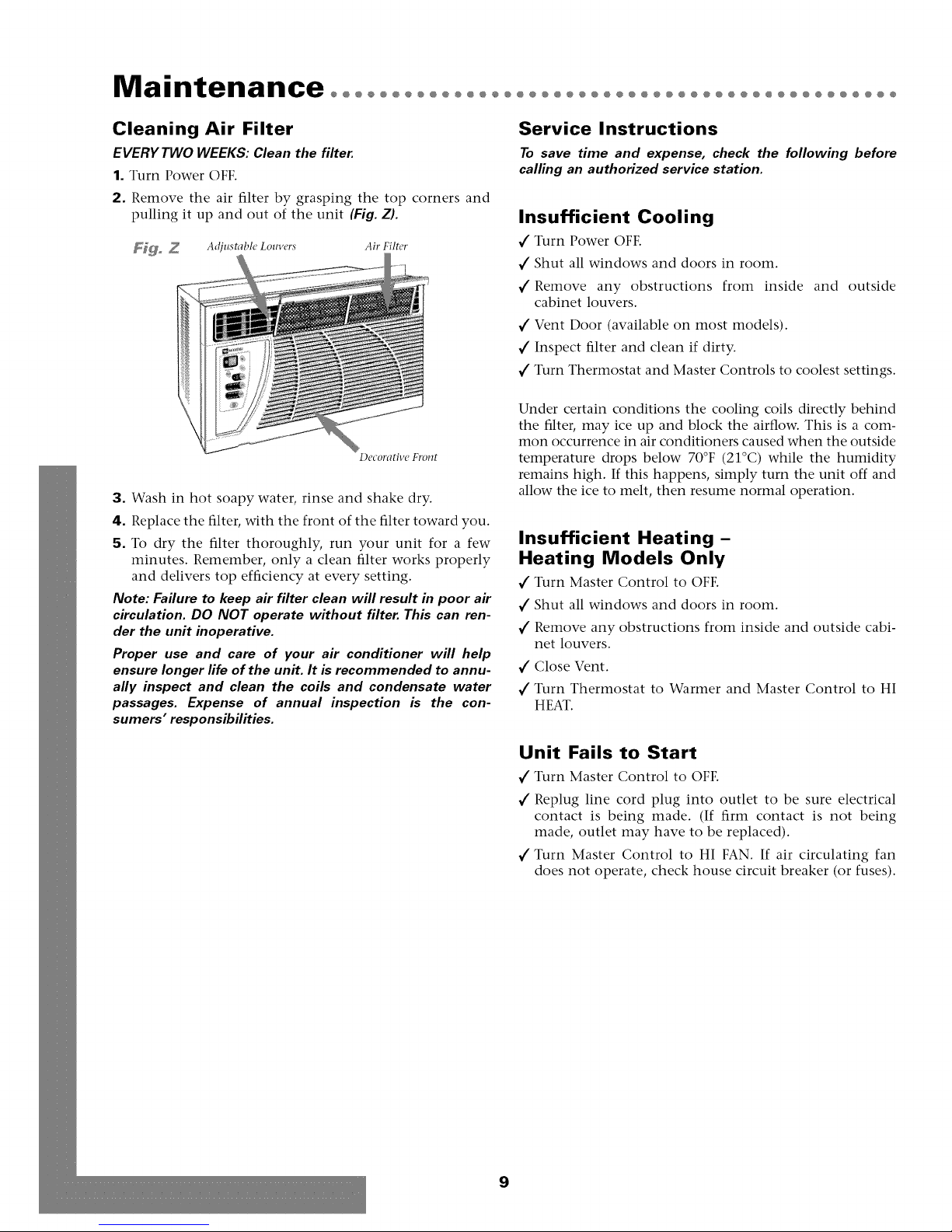

EVERY TWO WEEKS: Clean the filter.

1. Turn Power OFF.

2. Remove the air filter by grasping the top corners and

pulling it up and out of the unit (Fig. Z).

_ _ Adjustabk' Lo_n,ers Air Filter

Decorative Front

3. Wash in hot soapy water, rinse and shake dry.

4. Replace the filter, with the front of the filter toward you.

5. To dry the filter thoroughly, run your unit for a few

minutes. Remember, only a clean filter works properly

and delivers top efficiency at every setting.

Note: Failure to keep air filter clean will result in poor air

circulation. DO NOT operate without filter. This can ren-

der the unit inoperative.

Proper use and care of your air conditioner will help

ensure longer life of the unit. It is recommended to annu-

ally inspect and clean the coils and condensate water

passages. Expense of annual inspection is the con-

sumers" responsibilities.

Service Instructions

To save time and expense, check the following before

calling an authorized service station.

Insufficient Cooling

1" Turn Power OFF.

1" Shut all windows and doors in room.

1" Remove any obstructions from inside and outside

cabinet louvers.

1" Vent Door (available on most models).

1" Inspect filter and clean if dirty.

1" Turn Thermostat and Master Controls to coolest settings.

Under certain conditions the cooling coils directly behind

the filter, may ice up and block the airflow. This is a com-

mon occurrence in air conditioners caused when the outside

temperature drops below 70°F (21°C) while the humidity

remains high. If this happens, simply turn the unit off and

allow the ice to melt, then resume normal operation.

Insufficient Heating-

Heating Models Only

1" Turn Master Control to OFF.

1" Shut all windows and doors in room.

1" Remove any obstructions from inside and outside cabi-

net louvers.

1" Close Vent.

1" Turn Thermostat to Warmer and Master Control to HI

HEAT.

Unit Fails to Start

1" Turn Master Control to OFF.

1" Replug line cord plug into outlet to be sure electrical

contact is being made. (If firm contact is not being

made, outlet may have to be replaced).

1" Turn Master Control to HI FAN. If air circulating fan

does not operate, check house circuit breaker (or fuses).

9

Loading...

Loading...