Page 1

Side by Side

Refrigerator

Use & Care Guide

Table of Contents

Important Safety Instructions ...... 1-2

Installation ...................................... 3-6

Temperature Controls......................... 7

Fresh Food Features........................... 8

Freezer Features.................................. 9

Ice and Water.............................. 10-12

Water Filter.................................. 13-15

Food Storage Tips ...................... 16-18

Troubleshooting .......................... 24-27

Warranty & Service............................31

Care and Cleaning ..................... 19-22

Operating Sounds............................. 23

Form No. A/01/06 Part No. 12842130 Litho U.S.A.

Guide d’utilisation

et d’entretien ............................... 32

Guía de uso y cuidado..................... 64

Page 2

Important Safety Instructions

Installer: Please leave this guide with this appliance.

Consumer: Please read and keep this Use and

Care Guide for future reference; it provides the

proper use and maintenance information.

Keep sales receipt and/or canceled check as proof

of purchase.

Call: 1-800-688-9900 U.S.A.

1-800-688-2002 Canada

1-800-688-2080 (U.S. TTY for hearing or

speech impaired)

(Mon.-Fri., 8 am-8 pm Eastern Time)

Have complete model and serial number

identification of your refrigerator. This is located on a

data plate inside the fresh food compartment, on the

upper right side. Record these numbers below for

easy access.

Model Number _______________________________

Serial Number ________________________________

Date of Purchase______________________________

In our continuing effort to improve the quality and

performance of our appliances, it may be necessary

to make changes to the appliance without revising

this guide.

What You Need to Know About

Safety Instructions

Warning and Important Safety Instructions appearing in

this guide are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining or operating appliance.

DANGER

To reduce risk of injury or death, follow basic

precautions, including the following:

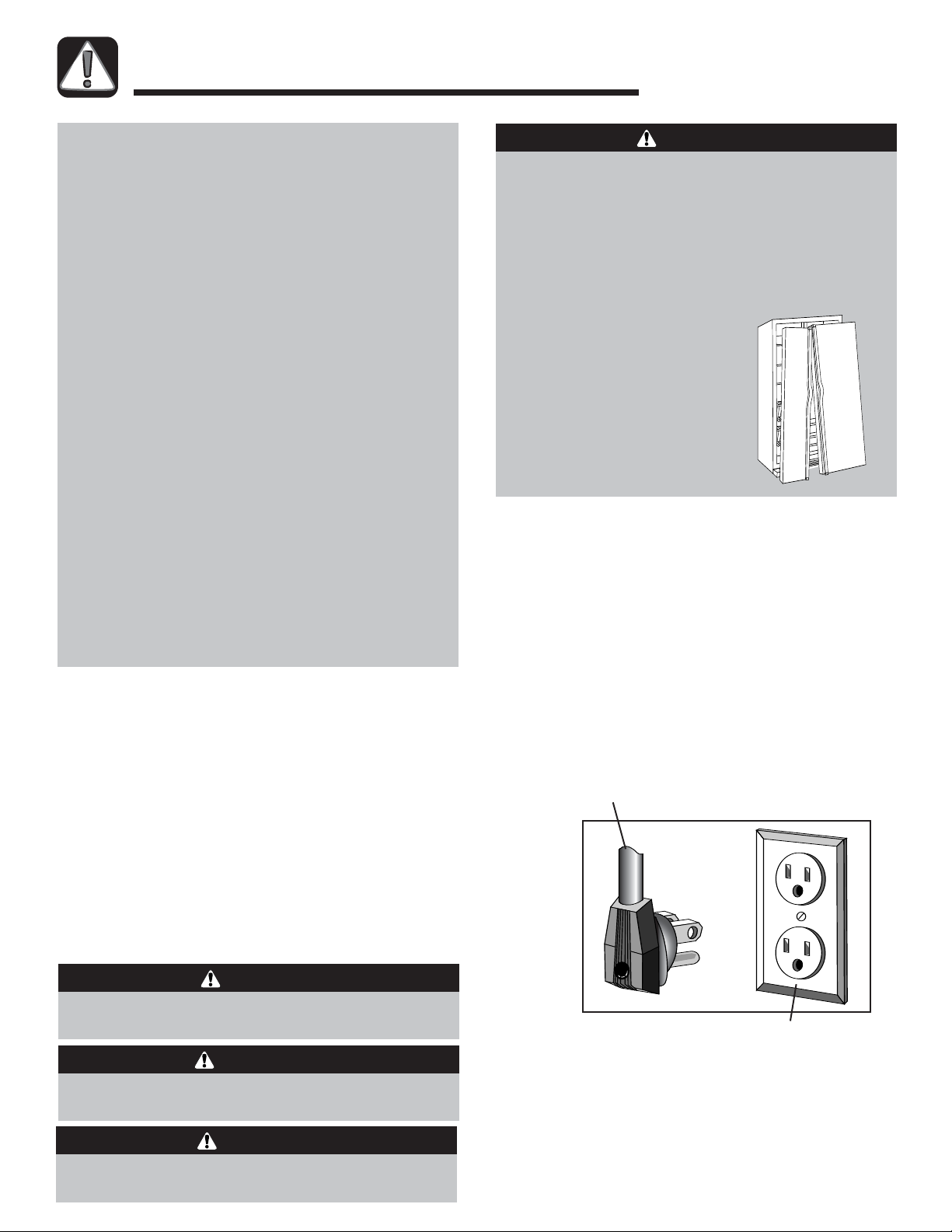

IMPORTANT: Child entrapment and suffocation

are not problems of the past. Junked or abandoned

refrigerators are still dangerous – even if they sit out

for “just a few days.” If you are getting rid of your old

refrigerator, please follow the instructions below to

help prevent accidents.

Before you throw away your old

refrigerator or freezer:

• Take off the doors.

• Leave the shelves in place so

children may not easily climb

inside.

This appliance is equipped with a three-prong

grounding plug for your protection against possible

electrical shock hazards. It must be plugged into a

grounding receptacle. Where a standard two-prong

wall receptacle is encountered, it is the personal

responsibility and obligation of the customer to have it

replaced with a properly grounded three-prong wall

receptacle. Do not under any circumstances, cut or

remove the third (ground) prong from the power cord.

Do not use an adapter plug.

Power supply cord with

three-prong grounding plug

Always contact the manufacturer about problems or

conditions you do not understand.

Recognize Safety Symbols, Words,

Labels

DANGER

DANGER – Immediate hazards which WILL result

in severe personal injury or death.

WARNING

WARNING – Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION

CAUTION – Hazards or unsafe practices which COULD

result in minor personal injury or property damage.

1

Grounding type

wall receptacle

Page 3

Important Safety Instructions

WARNING

To reduce risk of fire, electric shock, serious injury or

death when using your refrigerator, follow these basic

precautions, including the following:

1. Read all instructions before using the refrigerator.

2. Observe all local codes and ordinances.

3. Be sure to follow grounding instructions.

4. Check with a qualified electrician if you are not

sure this appliance is properly grounded.

5. Do not ground to a gas line.

6. Do not ground to a cold-water pipe.

7. Refrigerator is designed to operate on a separate

115 volt, 15 amp., 60 cycle line.

8. Do not modify plug on power cord. If plug does

not fit electrical outlet, have proper outlet installed

by a qualified electrician.

9. Do not use a two-prong adapter, extension cord

or power strip.

10. Do not remove warning tag from power cord.

11. Do not tamper with refrigerator controls.

12. Do not service or replace any part of refrigerator

unless specifically recommended in Use & Care

Guide or published user-repair instructions. Do

not attempt service if instructions are not under-

stood or if they are beyond personal skill level.

13. Always disconnect refrigerator from electrical

supply before attempting any service. Disconnect

power cord by grasping the plug, not the cord.

14. Install refrigerator according to Installation

Instructions. All connections for water, electrical

power and grounding must comply with local

codes an

required.

15. Keep your refrigerator in good condition. Bumping

or dropping refrigerator can damage refrigerator

or cause refrigerator to malfunction or leak. If

damage occurs, have refrigerator checked by

qualified service technician.

16. Replace worn power cords and/or loose plugs.

17. Always read and follow manufacturer’s storage

and ideal environment instructions for items being

stored in refrigerator.

18. Your refrigerator should not be operated in the

presence of explosive fumes.

19. Children should not climb, hang or stand on any

part of the refrigerator.

20. Clean up spills or water leakage associated with

water installation.

d be made by licensed personnel when

SAVE THESE INSTRUCTIONS

2

Page 4

Installation

Location

• Do not install refrigerator near oven, radiator or other

heat source. If not possible, shield refrigerator with

cabinet material.

• Do not install where temperature falls below 55° F

(13° C) or rises above 110° F (43° C). Malfunction

may occur at this temperature.

• Refrigerator is designed for indoor household

application only.

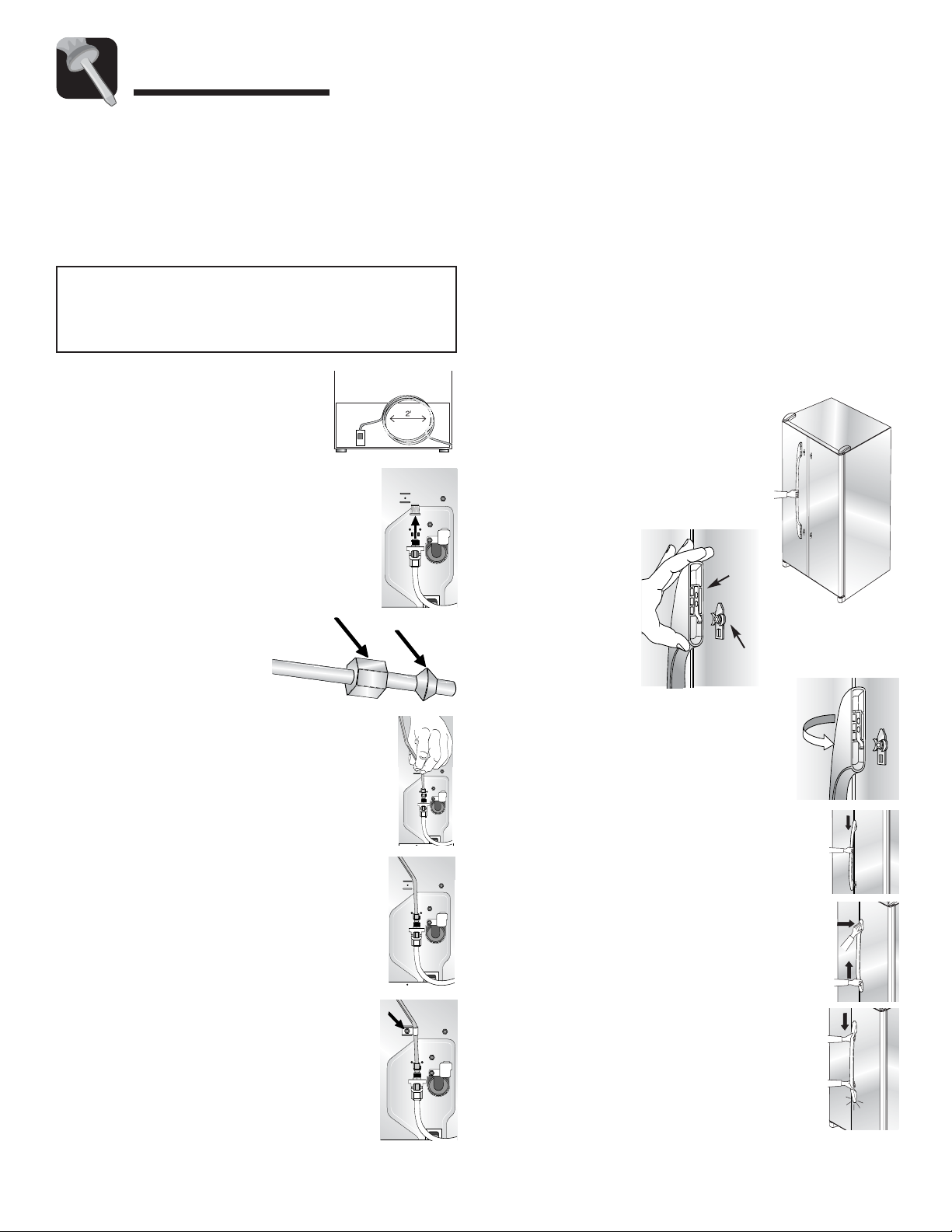

Measuring the Opening

When installing your refrigerator, allow

1

⁄2" space behind machine compartment cover

and

(located in the rear) for proper air circulation. If the

refrigerator is placed with the door hinge side against

a wall, you may want to allow additional space so the

door can be opened wider.

Subflooring or floor coverings (i.e. carpet, tile, wood

floors, rugs) may make your opening smaller than

anticipated.

Some clearance may be gained by using the leveling

procedure under Leveling.

1

⁄2" space at top

Door and Hinge Removal

Some installations require door removal to get

refrigerator to final location.

WARNING

To avoid severe personal injury or death, observe the

following:

• Disconnect power to refrigerator before removing

doors. Connect power only after replacing doors.

• Green ground wire must be attached to top hinge

while performing door removal and replacement.

• Tape decorative panels (select models) securely

into place before removing door handles.

CAUTION

To avoid property damage, observe the following:

• Protect vinyl or other flooring with cardboard, rugs

or other protective material, prior to moving

refrigerator.

• Do not adjust refrigerator to be any shorter than

1

68

⁄2" tall (minus hinge and cap). Doing so may

damage underside components.

IMPORTANT: If refrigerator is to be installed into a

recess where the top of the refrigerator is completely

covered, use dimensions from floor to top of hinge cap

to verify proper clearance.

Transporting You r Refrigerator

• NEVER transport refrigerator on its side. If an

upright position is not possible, lay refrigerator on its

back. Allow refrigerator to sit upright for

approximately 30 minutes before plugging it in to

assure oil returns to the compressor. Plugging

refrigerator in immediately may cause damage to

internal parts.

• Use an appliance dolly when moving refrigerator.

ALWAYS truck refrigerator from its side or

back–NEVER from its front.

• Protect outside finish of refrigerator during transport

by wrapping cabinet in blankets or inserting padding

between the refrigerator and dolly.

• Secure refrigerator to dolly firmly with straps or

bungee cords. Thread straps through handles when

possible. Do not overtighten. Overtightening

restraints may dent or damage outside finish.

1. Unplug power cord from power source.

2. Remove toe grille and bottom bracket covers (see

page 6).

• Open both doors 180°, or as wide as possible.

For ice and water dispensing models only:

Remove the left side bracket cover by carefully

pulling the water line to pry the cover loose. Then

continue to maintain downward pressure to the

notched side of the cover while swinging it off

(see page 6).

Note

• For refrigerators in operation, shut off water before

removing water line from the door.

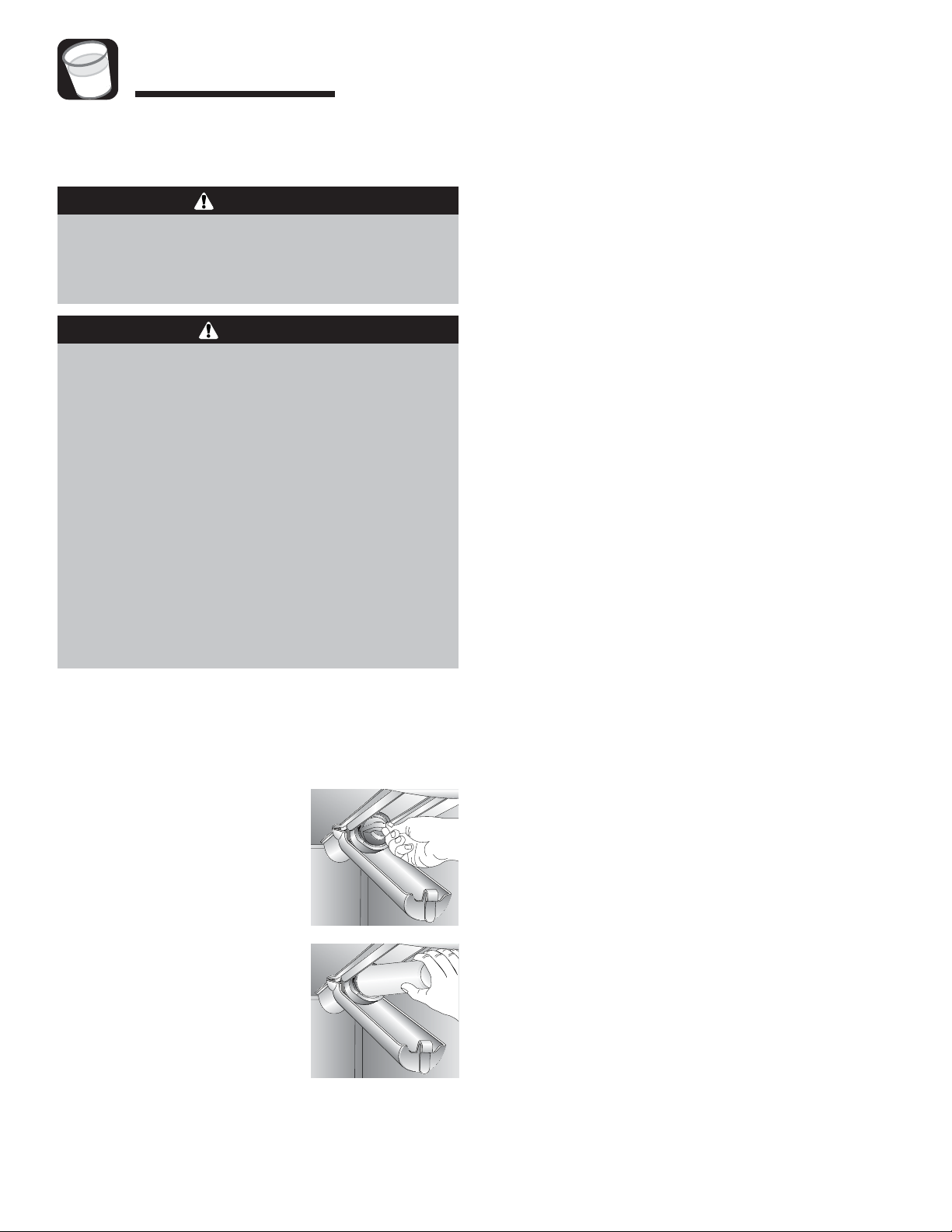

To Disconnect the Water Line:

• Push in white collar (A) and hold.

• Pull the door-side tube from the connector (B).

To Reconnect the Water Line:

5

• Firmly push tube

lines on the tube as a guide for full insertion.

⁄8" into the connector. Use

3

Page 5

Installation

• If tube end is damaged, cut off

reconnecting.

• If leaking occurs, reconnect the line.

3. Close doors.

4. Remove top hinge covers by

removing Phillips screws.

5. Unscrew

top hinges.

For ice and water

dispensing models only:

• Do not remove screw

connecting green ground

wire.

6. For ice and water

dispensing models only: Detach main wire

connector harness and red wire harness.

•To detach main wire

harness, use a flat blade

tool or fingernail to press

junction point between two

connectors to release.

•To detach red wire harness,

press tab on underside of

connector to release.

7. Remove top hinges along with

doors.

8. Remove bottom hinges with a

5

⁄16" hex head screws from

5

⁄8" before

3

⁄8" hex head driver.

Replacing the Doors

• To replace the doors, follow the steps in Door and

Hinge Removal in reverse order.

IMPORTANT: If water line tube end is damaged, cut

5

⁄8" before reconnecting.

off

Connecting the Water Supply

(select models)

WARNING

To reduce the risk of injury or death, follow

basic precautions, including the following:

• Read all instructions before installing ice maker.

• Do not attempt installation if instructions are not

understood or if they are beyond personal skill

level.

• Observe all local codes and ordinances.

• Do not service ice maker unless specifically

recommended in Use & Care Guide or published

user-repair instructions.

• Disconnect power to refrigerator before installing

ice maker.

• Water damage due to an improper water

connection may cause mold/mildew growth. Clean

up spills or leakage immediately!

CAUTION

To avoid property damage or possible injury,

follow basic precautions, including the

following:

• Consult a plumber to connect

tubing to household plumbing to assure

compliance with local codes and ordinances.

• Confirm water pressure to water valve is between

35 and 100 pounds per square inch, 20 pounds

per square inch without filter.

• Do not use a self-piercing, or

Both reduce water flow can become clogged over

time, and may cause leaks if repair is attempted.

• Tighten nuts by hand to prevent cross threading.

Finish tightening nuts with pliers and wrenches.

Do not overtighten.

• Wait two to three hours before placing refrigerator

into final position to check and correct any water

leaks. Recheck for leaks after 24 hours.

• Verify the copper tubing under the sleeve is

smooth and free from defects. Do not reuse an old

sleeve.

1

⁄4" O.D. copper

3

⁄16" saddle valve.

4

Page 6

Installation

Materials Needed

1

•

⁄4" outer diameter flexible copper tubing

• Shut-off valve (requires a

water supply line before valve attachment)

•Adjustable wrench

1

⁄4" hex nut driver

•

1

⁄4" hole to be drilled into

Note

•Add 8' to tubing length needed to reach water

supply for creation of service loop.

1. Create service loop with copper

tubing (minimum 2' diameter).

Avoid kinks in the copper tubing

when bending the service loop.

2. Remove plastic cap from water valve

inlet port.

3. Place brass nut (A) and

sleeve (B) on copper

tube end as illustrated.

(Do not use old sleeve.)

4. Place end of copper tubing into water

valve inlet port. Shape tubing slightly. Do

not kink – so that tubing feeds straight

into inlet port.

5. Slide brass nut over sleeve and screw nut

into inlet port. Tighten nut with wrench.

2' diameter

minimum

A

Handle Installation

If not installed, the handle is located in the interior of the

fresh food section or attached to the back of your refrigerator. Remove and discard handle packaging and tape.

Front Mount Handle

Materials Needed

• Gloves to protect hands

• Phillips screwdriver

• Plastic door handle removal card (or

card), retain the card

To Install:

1. The handles are to be oriented

as shown.

2. Align front mount door handle

clip with the door tabs.

3. Ensure the

handle clips

are positioned

slightly above

B

the door tabs.

4. Rotate the handle so that the

handle is flat against the door.

5. Push the handle down against the upper

door tab just enough to allow it to hang

unsupported.

Handle

1

⁄32" thick plastic

Clip

Door

Tab

IMPORTANT: Do not overtighten. Cross

threading may occur.

6. Pull on tubing to confirm connection is

secure. Connect tubing to frame with

water tubing clamp (C) and turn on

water supply. Check for leaks and

correct if necessary. Continue to

observe the water supply connection

for two to three hours prior to moving

the refrigerator to its permanent

location.

7. Monitor water connection for 24 hours.

Correct leaks, if necessary.

5

6. Align bottom of handle with lower door

tab. Press upper handle end to door

surface and firmly grasp lower end of

handle. Gently slide handle upward until

C

bottom of handle settles on door surface,

then reverse direction, sliding down-

ward to almost engaging tab with clip.

7. Grasp the handle firmly and slide down

until it clicks. The audible click indicates

fastening clips are securely interlocked.

To Remove:

1. Flex the handle away from the door panel.

Simultaneously place door handle removal card

Page 7

Installation

underneath the base of the lower

handle. Insert the card to the line or

until it stops.

2. Grasp the lower part of the handle

firmly and lift to remove.

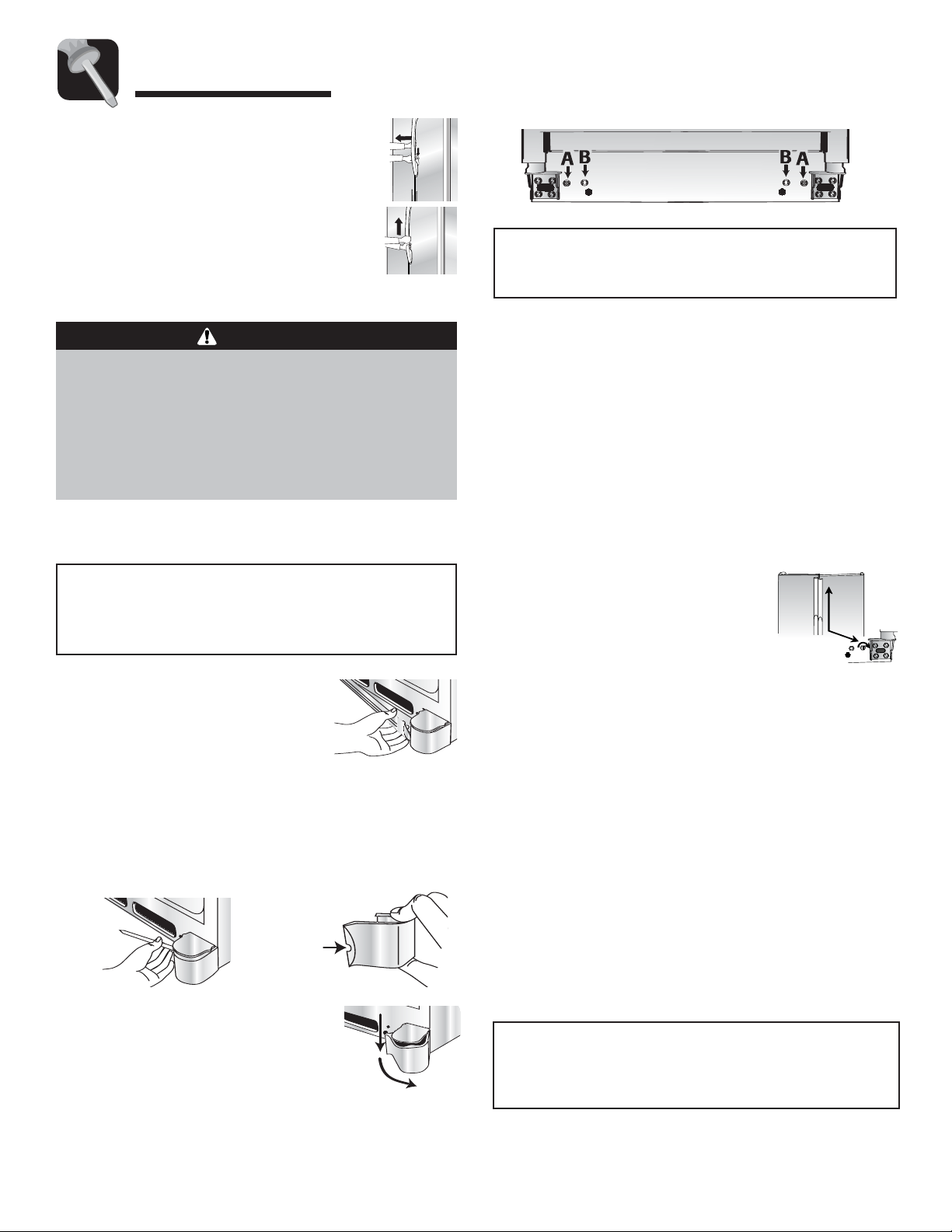

Leveling

CAUTION

To protect personal property and refrigerator from

damage, observe the following:

Note

• Some models only have adjustment screws “A.”

4. Select models also have rear adjustment screws (B).

Using the hex head driver, turn each of these

adjustment screws (B) to raise or lower the rear of

the refrigerator.

• Protect vinyl or other flooring with cardboard, rugs,

or other protective material.

• Do not use power tools when performing leveling

procedure.

To enhance the appearance and maintain performance,

the refrigerator should be level.

Note

• Complete any required panel installation and/or a

water supply connection, before leveling.

Materials Needed

3

⁄8" hex head driver

•

• Carpenter’s level

1. Remove toe grille.

• Grasp firmly and pull bottom outward to unclip.

2. Remove bottom bracket cover(s).

• Place the eraser end of a pencil or similar blunt

tool in the cover notch.

5. Using the carpenter’s level, make sure front of

refrigerator is

back of refrigerator and that the refrigerator is level

from side to side.

6. If required, correct rocking of refrigerator by turning

rear adjustment screw clockwise to raise rocking

corner. If doors are uneven, do the following:

• Determine which door needs to

be raised.

• Turn front roller adjustment

screw (A) clockwise to raise

front corner of door.

• If one refrigerator door has reached the limit of its

adjustment range and doors are still not level,

raise or lower the opposite door by turning roller

adjustment screw counterclockwise.

• Check with level to verify

proper door closure.

• If refrigerator is aligned and stable, replace toe

grille and hinge covers.

7. Replace bracket cover(s).

1

⁄4" (6 mm) or 1⁄2 bubble higher than

1

⁄4" tilt to the back for

Notch

Location

• Use slight pressure to pry the

cover loose.

• Continue to maintain downward

pressure to the notched side of

the cover while swinging it off.

3. Using hex head driver, turn both of the front

adjustment screws (A) clockwise to raise and

counterclockwise to lower the front of the

refrigerator.

• Position cover into the outer edge of the hinge.

• Swing the cover toward the cabinet and snap it

into place.

8. Replace the toe grille.

Note

• For proper reinstallation, ensure the “top” marking

on the interior of the toe grille is oriented correctly.

• Align the toe grille mounting clips with the lower

cabinet slots.

• Push the toe grille firmly until it snaps into place.

6

Page 8

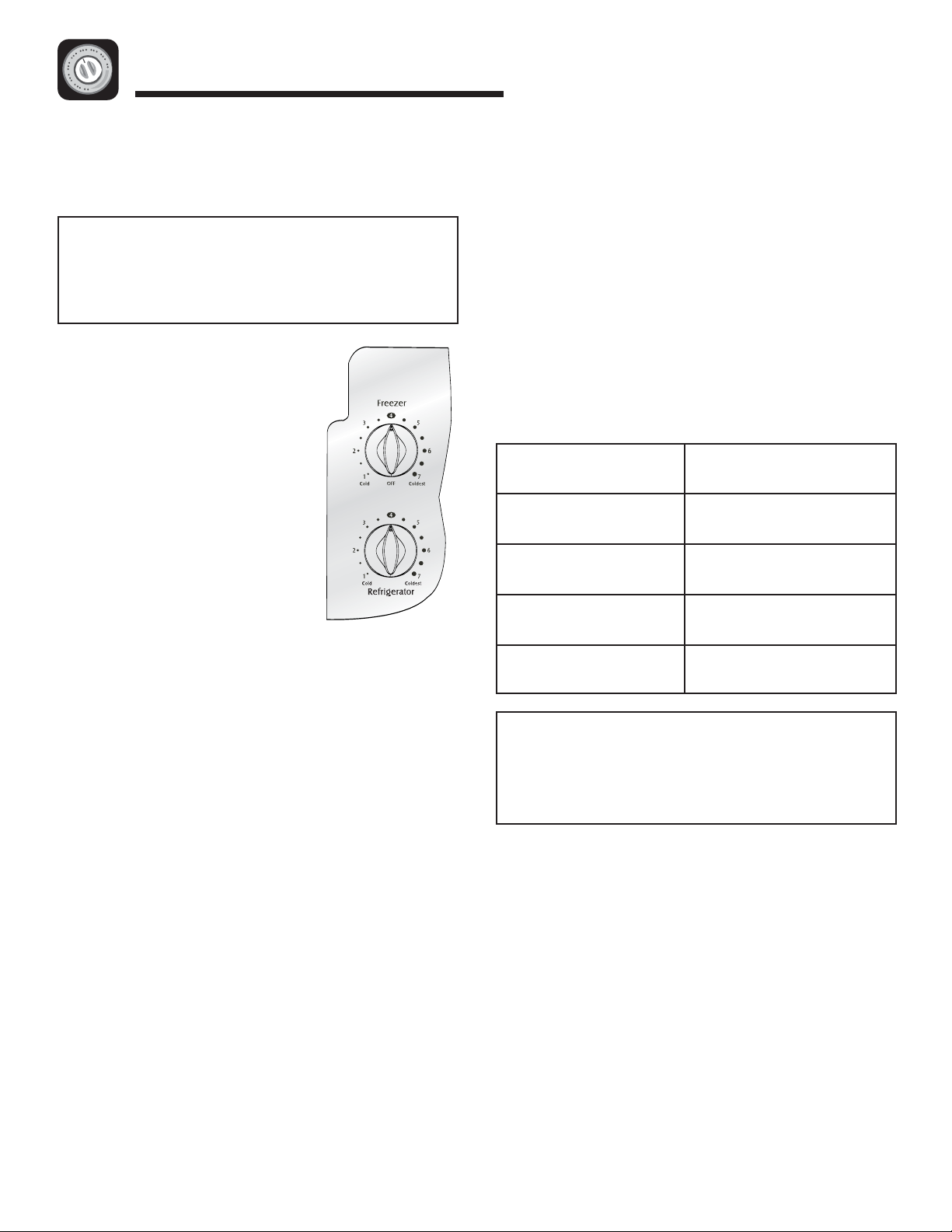

Temperature Controls

Dial Temperature Controls

The controls are located at the back left of the

refrigerator compartment.

Note

• The freezer control turns the cooling system on.

Neither section will cool if freezer control is set to

OFF.

Initial Control Settings

After plugging the refrigerator in,

set the controls.

• To adjust the controls, turn the

control knob to the left or right

as desired.

• Set the freezer control on 4.

• Set the refrigerator control on 4.

• Let the refrigerator run at least 8

to 12 hours before adding food.

Warm Cabinet Surfaces

Adjusting the Controls

• 24 hours after adding food, you may decide that one

or both compartments should be colder or warmer. If

so, adjust the control(s) as indicated in the

Temperature Control Guide table below. See page 16

for instructions on checking compartment

temperature.

• Except when starting the refrigerator, do not change

either control more than one number at a time.

• Allow 24 hours for temperatures to stabilize.

• Changing either control will have some effect on the

temperature of the other compartment.

Temperature Control Guide

Refrigerator too warm

Refrigerator too cold

Freezer too warm

Freezer too cold

Turn the refrigerator control

to next higher number.

Turn the refrigerator control

to next lower number.

Turn the freezer control to

next higher number.

Turn the freezer control to

next lower number.

At times, the front of the refrigerator cabinet may be

warm to the touch. This is a normal occurrence that

helps prevent moisture from condensing on the

cabinet. This condition will be more noticeable when

you first start the refrigerator, during hot weather and

after excessive or lengthy door openings.

Turn refrigerator OFF

Turn the freezer control to

OFF.

Note

• Turning freezer control to OFF stops cooling in

both compartments. It does not shut off power to

the refrigerator.

7

Page 9

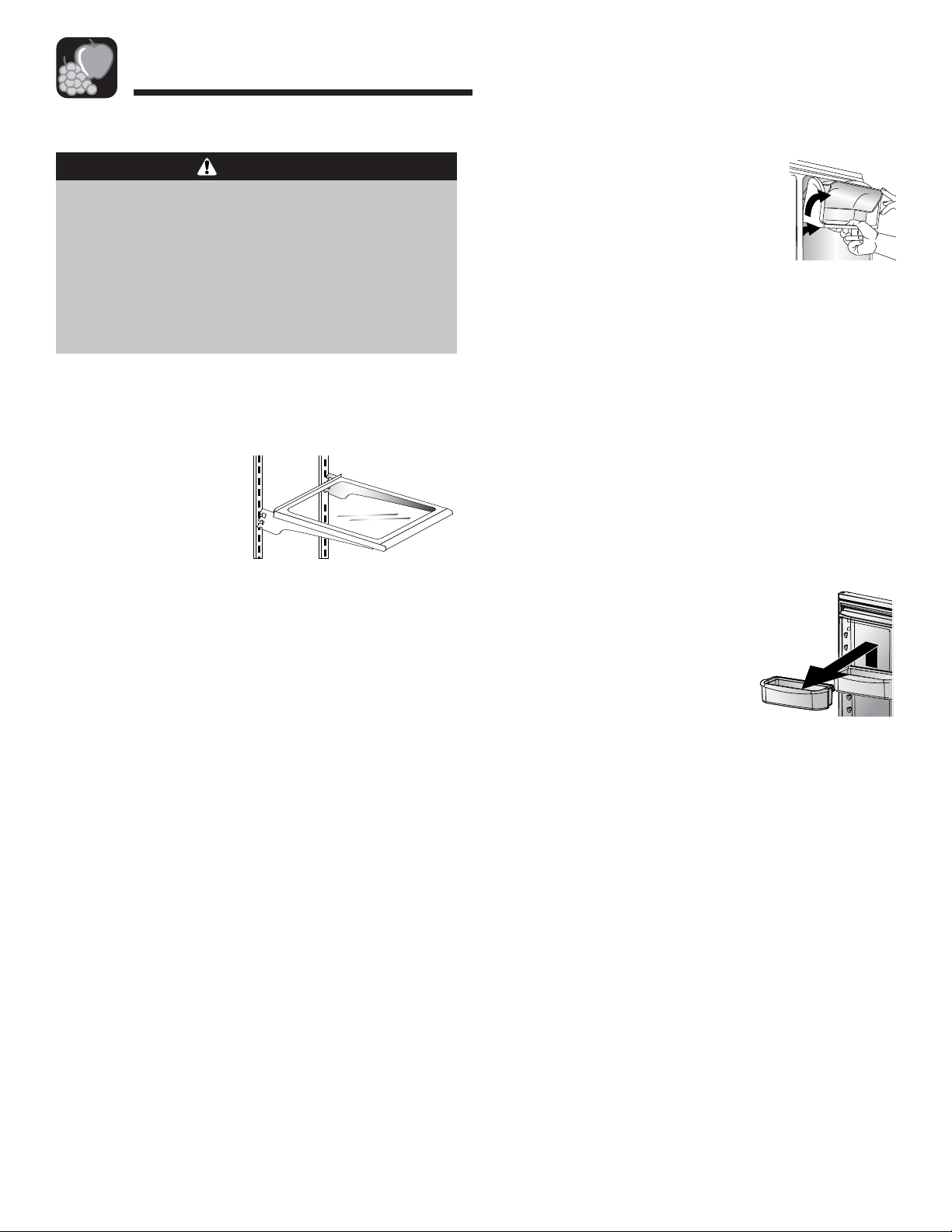

Fresh Food Features

Shelves

CAUTION

To avoid personal injury or property damage,

observe the following:

• Confirm shelf is secure before placing items on

shelf.

• Handle tempered glass shelves carefully. Shelves

may break suddenly if nicked, scratched, or

exposed to sudden temperature change.

Your refrigerator has either spill-retaining or nonsealed shelves. Spill-retaining shelves have a sealed

edge which contains spills and allows for easier clean

up.

To Remove a Shelf:

• Slightly tilt up the

front and lift up the

rear of the shelf, then

pull the shelf straight

out.

To Lock the Shelf Into Another Position:

• Tilt up the front edge of the shelf.

• Insert the hooks into the desired frame openings and

let the shelf settle into place.

• Be sure the shelf is securely locked at the rear.

The Crisper Top serves as the lower fresh food shelf.

To Remove the Crisper Top:

• Place hand under the frame to push up the glass. Lift

glass out.

Dairy Center

The Dairy Center provides convenient

door storage for spreadable items such

as butter and margarine. On select

models, this compartment can be

moved to several different locations to

accommodate storage needs.

To Remove:

• Slide dairy center up and pull out.

To Install:

• Slide assembly in and down so that the hooks are

firmly seated on the door liner.

To Remove Dairy Door:

• Press in sides of dairy door and pull out.

To Install Dairy Door:

• Slide sides of dairy door inside dairy center until

hinge points snap into place.

Door Buckets

Door Buckets can be moved to meet

individual storage needs.

To Remove:

• Lift bucket up and pull straight

out.

To Install:

• Place bucket in desired door liner retainer, push

down until bucket stops.

To Install:

• Repeat above instructions in reverse order.

Storage Drawers

The Crisper Drawers provide a higher humidity

environment for fresh fruit and vegetable storage.

8

Page 10

Freezer Features

Shelves and Baskets

Fixed Freezer Shelf

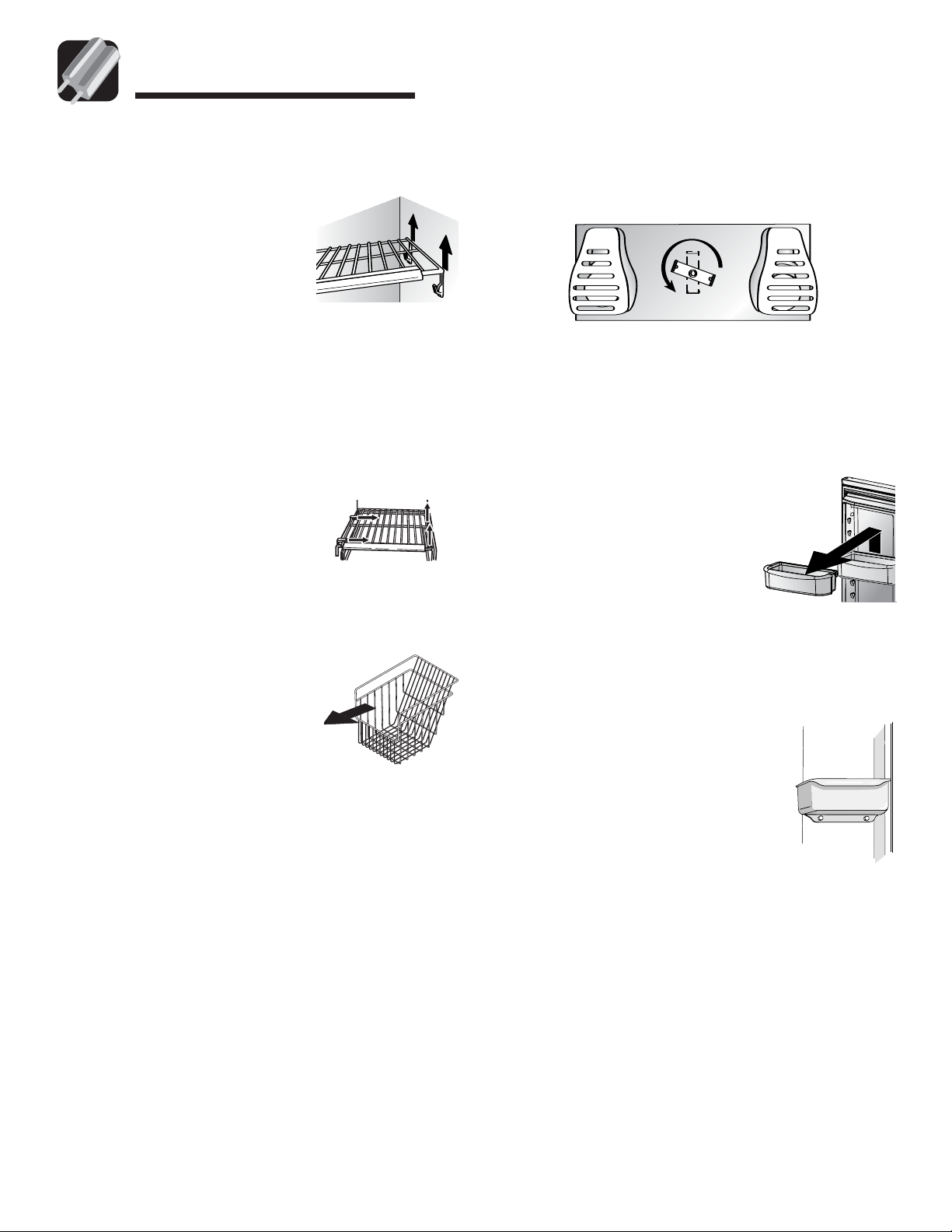

To Remove Clip-mounted Shelves:

• Lift shelf from wall mounting

clips and pull left side of shelf

out of wall mounting holes.

To Install Clip-mounted Shelves:

• Place left side of shelf in mounting holes and press

down into wall mounting clips.

Shelves

Shelves can be removed to meet individual storage

needs.

To Remove Shelf:

• Snap right side of shelf up from

cabinet railing and slide to right.

To Install Shelf:

IMPORTANT: Ice bin must be locked in place for

proper ice dispensing. Turn auger driver behind bin

counterclockwise (as shown) to properly align ice bin

with auger driver.

Door Storage

Adjustable Door Buckets

Door Buckets can be moved to meet individual

storage needs.

To Remove:

• Lift the door bucket up until it clears the

retainers on the door liner, then

pull the door bucket straight out.

• Replace shelf in left side cabinet railing. Snap shelf

into right side cabinet railing.

Baskets

Baskets (style may vary) slide out for

easy access to items in back.

To Remove:

• Pull out to its full extension. Lift

up front of basket and remove.

To Install:

• Slide basket into cabinet railing. Lift up front of

basket, and slide to the back of refrigerator.

Ice Storage Bin

The Ice Storage Bin is located below the automatic

ice maker.

To Remove:

• Raise ice maker arm to deactivate ice maker. Lift

front of bin and pull out to its full extension. Lift up

front of bin and remove.

To Install:

• Slide bucket in above desired door liner retainer and

push down until bucket stops.

Fixed Door Bucket

(non-dispenser models)

The Fixed Door Bucket is located in

the upper section of the freezer door.

IMPORTANT: Fixed door bucket is not

adjustable. If bucket is removed, freezer

light will not deactivate when door is

closed.

To Install:

• Slide bin into railing below ice maker until bin locks

into place. Drop ice maker arm to activate ice maker.

9

Page 11

Ice and Water

Automatic Ice Maker

Note

• Energy rating guides that are posted on the

refrigerator at the time of purchase do not include

optional ice maker energy usage.

Some models are automatic ice maker ready. The

number of the appropriate ice maker kit is IC10S. The

kit contains installation instructions and water

connection instructions.

Other models have a factory installed ice maker.

Connect the ice maker to the water supply as

instructed on pages 4-5. Proper water flow and a

level refrigerator are essential for optimal ice

maker performance.

Operating Instructions

• Confirm ice bin is in place and ice maker arm is

down.

• After freezer section reaches

between 0° to 2° F (-18° to -17° C),

ice maker fills with water and

begins operating. You will have a

complete harvest of ice

approximately every three hours.

• Allow approximately 24 hours after installation to

receive first harvest of ice.

• Discard ice created within first 12 hours of operation

to verify system is flushed of impurities.

• Stop ice production by raising ice maker arm until

click is heard.

• Ice maker will remain in the OFF position until arm is

pushed down.

• The first one or two batches will probably contain

undersized and irregular cubes because of air in the

supply line.

• When the ice cubes are ejected it is normal for

several cubes to be joined together at the ends. They

can easily be broken apart. The ice maker will

continue to make ice until the supply of ice cubes

raises the sensor arm, shutting the ice maker off.

• Certain sounds may accompany the various cycles of

the ice maker. The motor may have a slight hum, the

cubes will rattle as they fall into an empty storage

pan and the water valve may click or “buzz”

occasionally.

• If the ice is not used frequently, the ice cubes will

become cloudy, shrink, stick together and taste stale.

Empty the ice storage bin periodically and wash it in

lukewarm water. Be sure to dry the bin thoroughly

before replacing it.

• Beverages and foods should not be placed in the ice

storage bin for quick chilling. These items can block

the sensor arm, causing the ice maker to

malfunction.

• Turn off (arm up) the ice maker when the water

supply is to be shut off for several hours.

To Remove the Ice Bin:

• Pull it forward, away from the ice maker. To avoid the

ice maker dumping ice while the bin is removed, turn

the ice maker off by raising the sensor arm.

To Install the Ice Bin:

• Reverse the above procedure. Turn the ice maker on

by lowering the sensor arm.

WARNING

To avoid personal injury or property damage,

observe the following:

• Do not place fingers or hands on the automatic ice

making mechanism while the refrigerator is

plugged in. This will help protect you from possible

injury. It will also prevent interference with moving

parts of the ejector mechanism and the heating

element that releases the cubes.

•Under certain rare circumstances, ice cubes may

be discolored, usually appearing with a greenbluish hue. The cause of this unusual discoloration

can be a combination of factors such as certain

characteristics of local waters, household

plumbing and the accumulation of copper salts in

an inactive water supply line which feeds the ice

maker. Continued consumption of such discolored

ice cubes may be injurious to health. If such

discoloration is observed, discard the ice cubes

and contact your dealer to purchase and install a

water line filter.

• Water damage due to improper water connection

may cause mold/mildew growth.

• Clean up water and ice spills to avoid personal

injury and to prevent mold/mildew growth.

10

Page 12

Ice and Water

Dispenser Features

(select models)

Main

Dispenser

Pad

Dispenser Light (select models)

A light activates within the dispenser area at full power

when dispensing ice or water with the main dispenser

pad.

Dispenser Pad

The Dispenser Pad is located on the back wall of the

dispensing area. When the dispenser pad is pressed,

the selection chosen on the dispenser control panel

will dispense.

Removable Tray

Removable

Tray

Water Dispenser Operation

CAUTION

To avoid personal injury or property damage,

observe the following:

• Do not put fingers, hands or any foreign object

into dispenser opening.

• Do not use sharp objects to break ice.

• Do not dispense ice directly into thin glass, fine

china or delicate crystal.

Note

• During initial use of water dispenser, allow a delay

of approximately one minute while water tank fills

before water dispenses. Discard first 10-14 glasses

of water after initially connecting refrigerator to

household water supply and after extended

periods of nonuse.

To Use Dispenser Pad:

• Choose water selection from dispenser control panel.

• Press sturdy, wide-mouthed container against

dispenser pad. When dispensing crushed ice, hold

container as close to chute as possible to reduce

spraying.

The Removable Tray at the bottom of the dispenser

area is designed to collect small spills and may be

easily removed for cleaning and emptying purposes.

IMPORTANT: Removable tray does not drain. Do not

allow tray to overflow. If it does, remove tray and wipe

up overflow.

• Release pressure on dispenser pad to stop water

dispensing. A small amount of water may continue to

dispense and collect in dispenser tray. Large spills

should be wiped dry.

11

Page 13

Ice and Water

Dispenser Control (select models)

(control features vary by model)

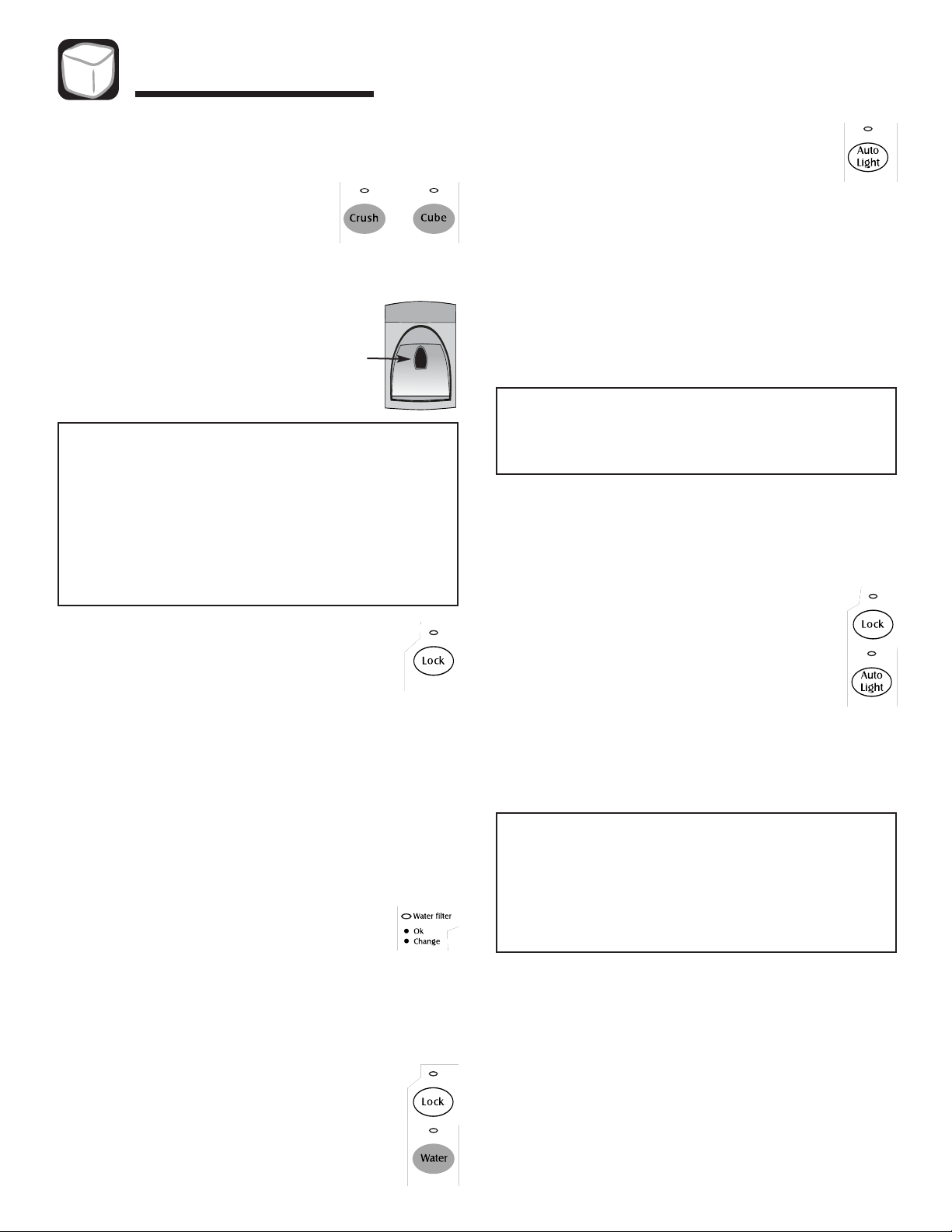

Ice Dispenser Operation

To Dispense Ice:

• Select Crush or Cube ice mode by pushing button

on dispenser control panel. A green light above

button indicates mode selection.

• Press container against dispenser pad.

When dispensing crushed ice, hold

container as close to chute as possible to

reduce spraying.

Notes

•Mode may not be changed while ice dispenser is

in operation.

• If dispenser (select models) is active for more than

five minutes, an automatic lock out sensor will

shut down power to dispenser area. See Dispenser

Lock for unlocking information.

Dispenser

Pad

Auto Light (select models)

The Auto Light function activates the dispenser

light at half-power when the Light Sensor

detects that the light levels in room are low.

To Activate Auto Light:

• Press Auto Light button. A green indicator light

above button illuminates when the sensor is active.

To Deactivate Auto Light:

• Press Auto Light button. The green indicator light

will go out.

Note

• The dispenser light will operate when Auto Light is

ON or OFF.

Sabbath Mode (select models)

When activated, the Sabbath Mode deactivates the

control lights while leaving the control operational.

To Activate Sabbath Mode:

Dispenser Lock (select models)

The Dispenser Lock prevents ice or water from

being dispensed.

To Lock Dispenser:

• Press and hold the Lock button for three seconds. A

green indicator light above button will illuminate

when the dispenser is locked.

To Unlock Dispenser:

• Hold the Lock button for three seconds. The green

indicator light above button will go out.

Water Filter Status Indicator

Light (select models)

The Water Filter Status Indicator Light serves as a

reminder to replace the water filter. A green light

indicates that the filter is in good condition. A red light

indicates the filter should be changed. Once light turns

red, it will remain red until function is reset.

• Press and hold the Lock and Auto Light

buttons simultaneously for three to four

seconds. After three to four seconds, the

dispenser lights will turn off.

To Deactivate Sabbath Mode:

• Press and hold both the Lock and Auto Light

buttons simultaneously for three to four seconds.

After three to four seconds, the dispenser lights will

activate.

Notes

• Dispenser light will not activate during dispensing

while in this mode.

• If the power fails, the control will remain in

Sabbath Mode when power returns.

To Reset Indicator:

• Press and hold both the Lock and Water

buttons simultaneously for four seconds. The

green filter status indicator light will flash

three times when the function has

successfully reset.

12

Page 14

Water Filter

Water Filter Removal and

Installation (select models)

WARNING

To avoid serious illness or death, do not use

refrigerator where water is unsafe or of unknown

quality without adequate disinfection before or after

use of filter.

CAUTION

After installing a new water filter, always dispense

water for two minutes before removing the filter for

any reason. Air trapped in system may cause water

and cartridge to eject. Use caution when removing.

• The bypass cap does not filter water. Be sure to

have replacement cartridge available when filter

change is required.

• If water filtration system has been allowed to

freeze, replace filter cartridge.

• If system has not been used for several months, or

water has an unpleasant taste or odor, flush

system by dispensing water for two to three

minutes. If unpleasant taste or odor persists,

change filter cartridge.

Replacing Water Filter

IMPORTANT: Air trapped in system may cause

water and cartridge to eject. Use caution when

removing.

1. Turn filter counterclockwise until it releases from

filter head.

2. Drain water from filter into sink, and dispose in

normal household trash.

3. Wipe up excess water in filter cover and continue

with Initial Installation, steps 2 and 4.

The filter should be changed at least every 12 months.

IMPORTANT: Condition of water and amount used

determines life span of water filter cartridge. If water

use is high, or if water is of poor quality, replacement

may need to take place more often.

To purchase a replacement water filter cartridge,

contact your dealer.

The dispenser feature may be used without a water

filter cartridge. If you choose this option, replace filter

with blue bypass cap.

Initial Installation

The water filter is located in the upper right-hand

corner of the fresh food compartment.

1. Remove blue bypass cap and

retain for later use.

2. Remove sealing label from

end of filter and insert into

filter head.

3. Rotate gently clockwise until

filter stops. Snap filter cover

closed.

4. Reduce water spurts by

flushing air from system.

Run water continuously for

two minutes through

dispenser until water runs

steady. During initial use,

allow a delay of approximately one minute in water

dispersal to allow internal water tank to fill.

•Additional flushing may be required in some

households where water is of poor quality.

13

Page 15

Water Filter

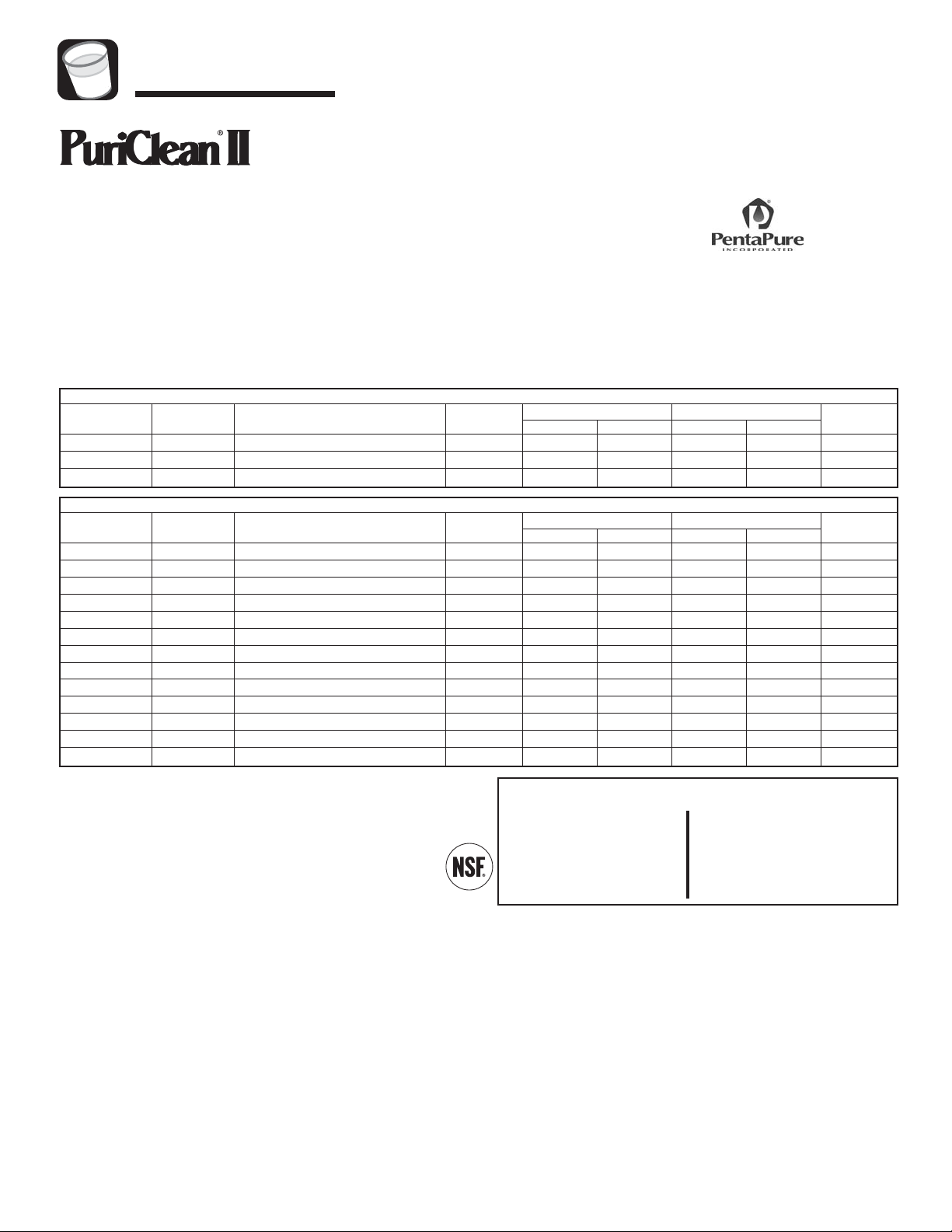

System Specification and Performance Data Sheet

Refrigerator Water Filter Cartridge Model UKF8001AXX

Specifications

Service Flow Rate (Maximum).............................................0.78 GPM (2.9 L/min)

Rated Service Life UKF8001AXX-750 (Maximum)......750 gallons/2838 liters

Maximum Operating Temperature.....................................100° F / 38° C

Minimum Pressure Requirement........................................35 psi/241 kPA

Minimum Operating Temperature......................................33° F/ 1° C

Maximum Operating Pressure.............................................120 psi / 827 kPA

1000 Apollo Road

Eagan, Minnesota 55121-2240

651.450.4913

EPA EST #35917-MN-1

Performance Data

Standard No. 42: Aesthetic Effects

Parameter

Chlorine

T & O

Particulate**

Parameter

Turbidity

Cysts

Asbestos

Lead at pH 6.5

Lead at pH 8.5

Mercury at pH 6.5

Mercury at pH 8.5

Atrazine

Benzene

Carbofuran

p-Dichlorobenzene

Lindane

Toxaphene

* Tested using a flow rate of 0.78 gpm; pressure of 60 psig; pH of 7.5 + 0.5; temp. of

68° + 5° F (20° + 3° C)

** Measurement in Particles/ml. Particles used were 0.5 - 1 microns

*** NTU - Nephelometric Turbidity Units

USEPA

MCL

—

—

—

USEPA

MCL

1 NTU**

99.5% Reduction

99% Reduction

0.015 mg/L

0.015 mg/L

0.002 mg/L

0.002 mg/L

0.003 mg/L

0.005 mg/L

0.04 mg/L

0.075 mg/L

0.0002 mg/L

0.003 mg/L

Standard No. 53: Health Effects

107108fibers/L; fibers >10 micrometers in length

Influent

Challenge Concentration

2.0 mg/L ± 10%

—

at least 10,000 particles /ml

Influent

Challenge Concentration

11 ± 1 NTU***

Minimum 50,000/L

0.15 mg/L + 10%

0.15 mg/L + 10%

.006 mg/L ± 10%

.006 mg/L ± 10%

0.009 mg/L + 10%

0.015 mg/L ± 10%

0.08 mg/L ± 10%

.225 mg/L ± 10%

0.002 mg/L + 10%

0.015 ± 10%

Influent

Average

1.88 mg/L

—

5,700,000 #/ml

Influent

Average

10.7 NTU

166,500 #/L

155 MF/L

0.153 mg/L

0.150 mg/L

0.006 mg/L

0.006 mg/L

0.009 mg/L

0.014 mg/L

0.081 mg/L

0.208 mg/L

0.002 mg/L

0.015 mg/L

Tested and certified by NSF International against ANSI/NSF Standards 42 & 53

in models UKF8001AXX-750 for the reduction of:

Standard No. 42: Aesthetic Effects

Taste and Odor Reduction

Chlorine Taste & Odor

Mechanical Filtration Unit

Particulate Reduction Class 1

Effluent % Reduction

Average

<0.05136364 mg /L

—

30,583 # /ml

Effluent % Reduction

Average

0.31 NTU

<1 #/L

<1 MF/L

<.001 mg/L

<.001 mg/L

0.0003 mg/L

0.0008 mg/L

<0.002 mg/L

0.0006 mg/L

<0.001 mg/L

<0.0005 mg/L

0.000 mg/L

<0.001 mg/L

Maximum

0.06 mg/L

—

69,000 #/ml

Maximum

.049 NTU

<1 #/L

<1 MF/L

<.001 mg/L

<.001 mg/L

0.0005 mg/L

0.0015 mg/L

0.002 mg/L

0.0011 mg/L

<0.001 mg/L

<0.0005 mg/L

<0.0001 mg/L

<0.001 mg/L

100834/B

—

Min. Required

Reduction

50%

—

85%

Min. Required

Reduction

0.5 NTU

>99.95%

99%

0.10 mg/L

0.10 mg/L

0.002 mg/L

0.002 mg/L

0.003 mg/L

0.005 mg/L

0.04 mg/L

0.075 mg/L

0.0002 mg/L

0.003 mg/L

Average

>97.26%

—

99.52%

Average

97.09%

>99.99%

>99.99%

>99.35%

>99.33%

95.70%

86.22%

76.99%

95.71%

98.74%

99.76%

98.72%

92.97%

Standard No. 53: Health Effects

Chemical Reduction Unit

Lead, Atrazine, Lindane, Benzene,

Carbofuran, p-Dichlorobenzene, Mercury

& Toxaphene Reduction

Mechanical Filtration Unit

Cyst, Turbidity and Asbestos Reduction

Minimum

96.84%

98.94%

Minimum

95.20%

>99.99%

>99.99%

>99.29%

>99.29%

90.91%

75.93%

75.31%

92.14%

98.46%

99.74%

96.50%

91.67%

General Use Conditions

Read this Performance Data Sheet and compare the

capabilities of this unit with your actual water treatment

needs.

DO NOT use this product where water is microbiologic-

ally unsafe or of unknown quality without adequate

disinfection before or after the system. System certified

for cyst reduction may be used on disinfected water

that may contain filterable cysts.

USE ONLY WITH COLD WATER SUPPLY. CHECK FOR

COMPLIANCE WITH THE STATE AND LOCAL LAWS

AND REGULATIONS.

The PuriClean® II retractable water filtration system uses a

UKF8001AXX replacement cartridge. Timely replacement of

filter cartridge is essential for performance satisfaction from

this filtration system. Please refer to the applicable section of

your Use & Care Guide for general operation, maintenance

requirements and troubleshooting. Suggested retail price of

replacement water filter is $39.99.

This system has been tested according to ANSI/NSF 42 and

53 for reduction of the substance listed above. The

concentration of the indicated substances in water entering

the system was reduced to a concentration less than or equal

to the permissible limit for water leaving the system, as

specified in ANSI/NSF 42 and 53.

14

Page 16

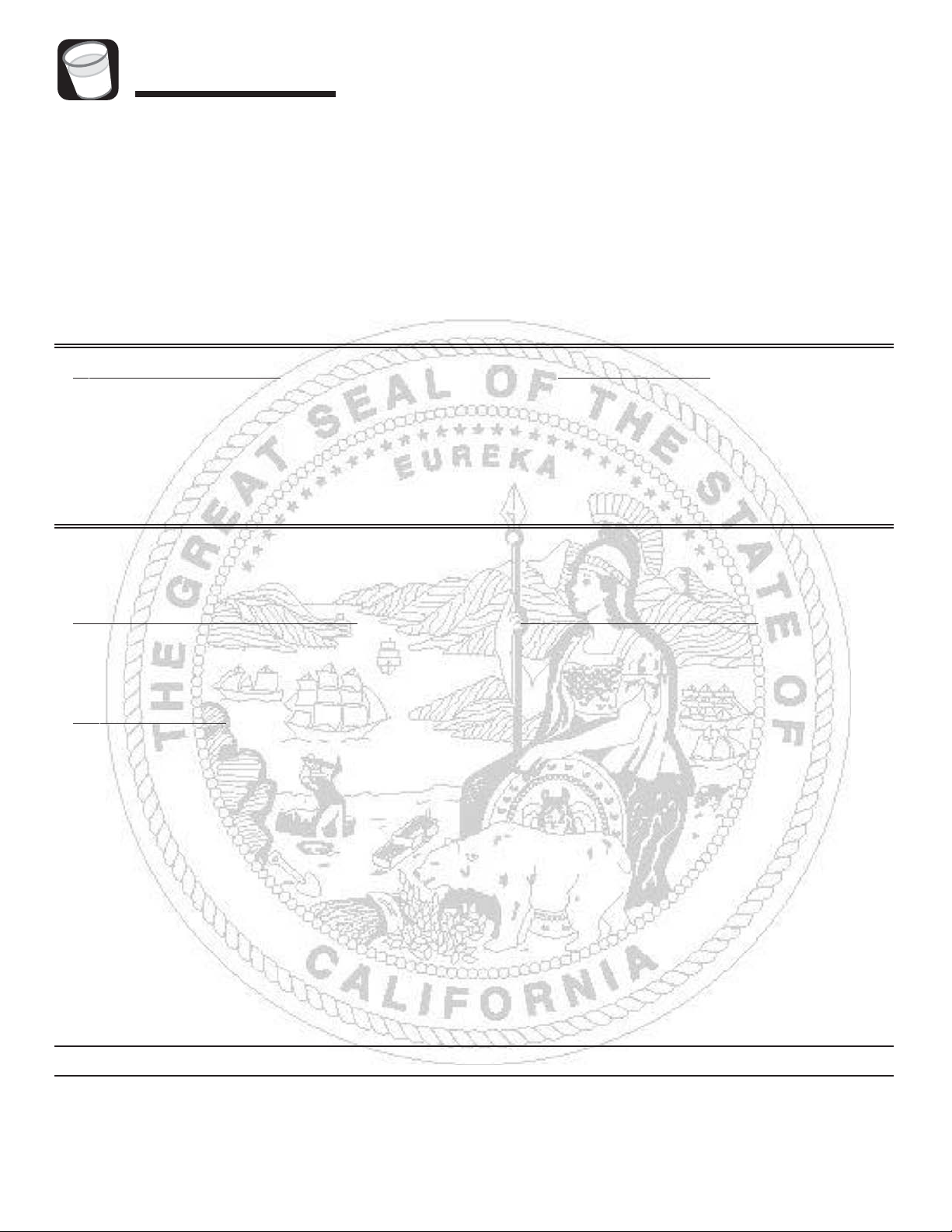

Water Filter

State of California

Department of Health Services

Water Treatment Device

Certificate Number

03 - 1583

Date Issued: September 16, 2003

Date Revised: April 22, 2004

Trademark /Model Designation Replacement Elements

UKF8001AXX750 UKF8001AXX

469006-750 46 9006

67003523-750 67003523

Manufacturer: PentaPure Inc.

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section 116830 of the

Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity Inorganic/Radiological Contaminants

Cysts Asbestos

Turbidity Lead

Mercury

Organic Contaminants

Atrazine

Lindane

Benzene

Carbofuran

p-dichlorobenzene

Toxaphene

Rated Service Capacity: 750 gal. Rated Service Flow: 0.78 gpm

Conditions of Certification:

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems certified for cyst

reduction may be used on disinfected waters that may contain filterable cysts.

15

Page 17

Food Storage Tips

Fresh Food Storage

• The fresh food compartment of a refrigerator should

be kept between 34°-40° F (1°-4° C) with an

optimum temperature of 37° F (3° C). To check the

temperature, place an appliance thermometer in a

glass of water and place in the center of the

refrigerator. Check after 24 hours. If the temperature

is above 40° F (4° C) adjust the controls as explained

on page 7.

• Avoid overcrowding the refrigerator shelves. This

reduces the circulation of air around the food and

results in uneven cooling.

Fruits and Vegetables

• Storage in the crisper drawers traps humidity to help

preserve the fruit and vegetable quality for longer

time periods.

• Sort fruits and vegetables before storage and use

bruised or soft items first. Discard those showing

signs of decay.

• Always wrap odorous foods such as onions and

cabbage so the odor does not transfer to other foods.

Frozen Food Storage

• The freezer compartment of a refrigerator should be

kept at approximately 0° F (-18° C). To check the

temperature, place an appliance thermometer

between the frozen packages and check after 24

hours. If the temperature is above 0° F (-18° C),

adjust the control as described on page 7.

• A freezer operates more efficiently when it is at least

two-thirds full.

Packaging Foods for Freezing

• To minimize dehydration and quality deterioration use

aluminum foil, freezer wrap, freezer bags or airtight

containers. Force as much air out of the packages as

possible and be sure they are tightly sealed. Trapped

air can cause the food to dry out, change color and

develop an off-flavor (freezer burn).

• Overwrap fresh meats and poultry with suitable

freezer wrap prior to freezing.

• Do not refreeze meat that has completely thawed.

Loading the Freezer

• While vegetables need a certain amount of humidity

to remain fresh, too much humidity can shorten

storage times (especially leafy vegetables). Drain

vegetables well before storing.

• Wait to wash fresh produce until right before use.

Meat and Cheese

• Raw meat and poultry should be wrapped securely

so leakage and contamination of other foods or

surfaces does not occur.

• Occasionally mold will develop on the surface of

hard cheeses (Swiss, Cheddar, Parmesan). Cut off at

least an inch around and below the moldy area. Keep

your knife or instrument out of the mold itself. Do not

try to save individual cheese slices, soft cheese,

cottage cheese, cream, sour cream or yogurt when

mold appears.

Dairy Food

• Most dairy foods such as milk, yogurt, sour cream

and cottage cheese have freshness dates on their

cartons for appropriate length of storage. Store these

foods in the original carton and refrigerate

immediately after purchasing and after each use.

• Avoid adding too much warm food to the freezer at

one time. This overloads the freezer, slows the rate of

freezing and can raise the temperature of frozen

foods.

• Leave space between the packages so cold air can

circulate freely, allowing food to freeze as quickly as

possible.

• Avoid storing hard-to-freeze foods such as ice cream

and orange juice on the freezer door shelves. These

foods are best stored in the freezer interior where the

temperature varies less with door openings.

Refer to the Food Storage Chart for approximate

storage times, pages 17-18.

16

Page 18

Food Storage Tips

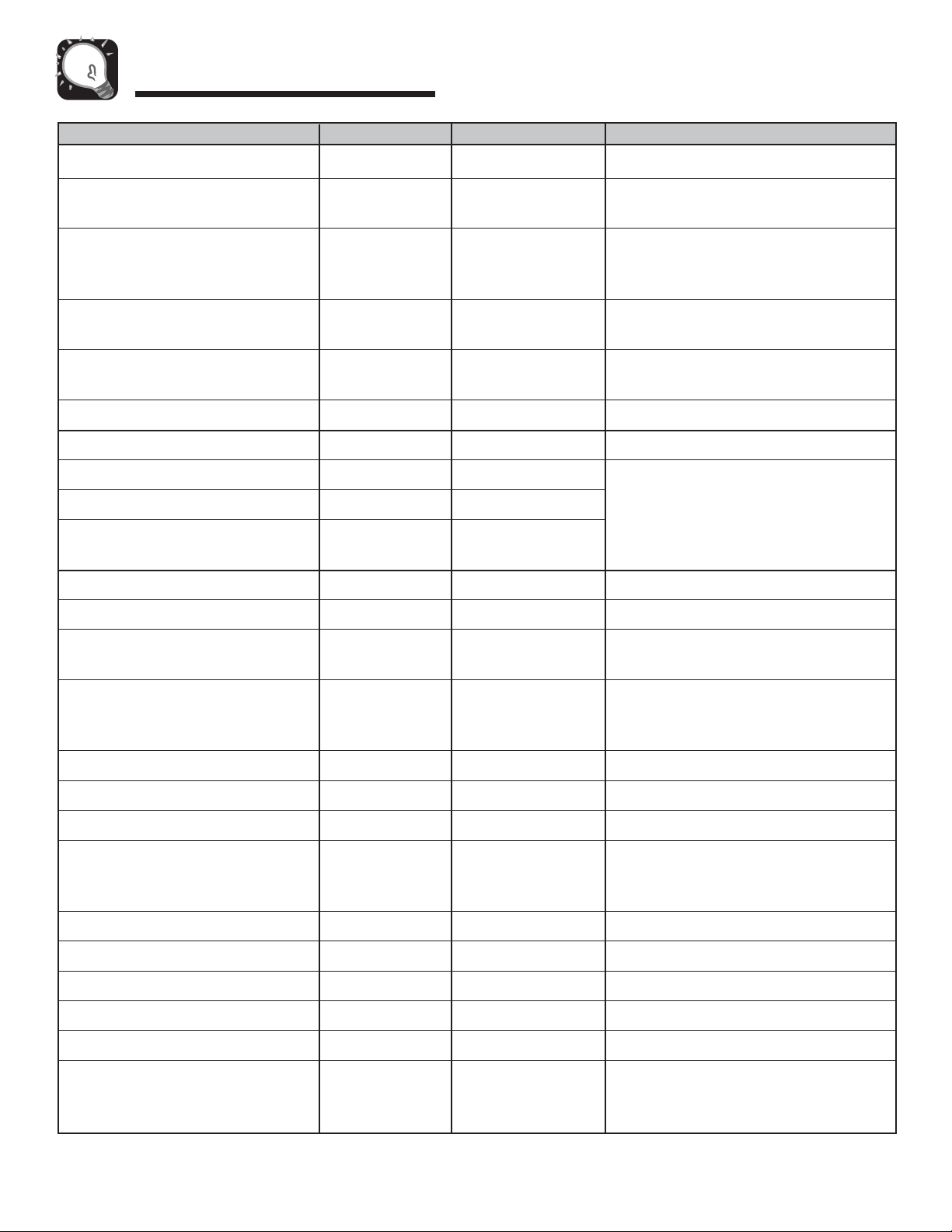

Food Storage Chart

Storage times are approximate and may vary depending on type of packaging, storage temperature, and the quality

of the food when purchased.

FOODS

DAIRY PRODUCTS

Butter

Milk and cream

Cream cheese, cheese

spread and cheese food

Cottage cheese

Sour cream

Hard cheese

(Swiss, Cheddar and Parmesan)

EGGS

Eggs in the shell

REFRIGERATOR

1 month

1 week

1 to 2 weeks

3 to 5 days

10 days

1 to 2 months

3 weeks

FREEZER

6 to 9 months

Not recommended

Not recommended

Not recommended

Not recommended

4 to 6 months

May become

crumbly

Not recommended

STORAGE TIPS

Wrap tightly or cover.

Check carton date. Close tightly.

Don’t return unused portions to

original container. Don’t freeze

cream unless whipped.

Wrap tightly.

Store in original carton.

Check carton date.

Store in original carton.

Check carton date.

Wrap tightly.

Cut off any mold.

Refrigerate small ends down.

Leftover yolks or whites

FRUITS

Apples

Bananas

Pears, plums, avocados

Berries, cherries, apricots

Grapes

Citrus fruits

Pineapples, cut

2 to 4 days

1 month

2 to 4 days

3 to 4 days

2 to 3 days

3 to 5 days

1 to 2 weeks

2 to 3 days

9 to 12 months

8 months (cooked)

6 months

(whole/peeled)

Not recommended

6 months

1 month (whole)

Not recommended

6 to 12 months

For each cup of yolks to be frozen,

add 1 tsp. sugar for use in sweet, or

1 tsp. salt for non-sweet dishes.

May also store unripe or hard apples

at 60° to 70° F (16° to 21° C).

Ripen at room temperature before

refrigerating. Bananas darken when

refrigerated.

Ripen at room temperature before

refrigerating. Avocados darken when

refrigerated.

Ripen at room temperature before

refrigerating.

Ripen at room temperature before

refrigerating.

May also store at 60° to 70° F (16° to

21° C). If refrigerated, store uncovered.

Will not ripen after purchase.

Use quickly.

17

continued…

Page 19

Food Storage Tips

FOODS

VEGETABLES

Asparagus

Brussels sprouts, broccoli,

cauliflower, green peas,

lima beans, onions, peppers

Cabbage, celery

Carrots, parsnips, beets and

turnips

Lettuce

POULTRY and FISH

Chicken and Turkey, whole

Chicken and Turkey, pieces

Fish

MEATS

REFRIGERATOR

1 to 2 days

3 to 5 days

1 to 2 weeks

7 to 10 days

7 to 10 days

1 to 2 days

1 to 2 days

1 to 2 days

FREEZER

8 to 10 months

8 to 10 months

Not recommended

8 to 10 months

Not recommended

12 months

9 months

2 to 6 months

STORAGE TIPS

Do not wash before refrigerating.

Store in crisper.

Wrap odorous foods.

Leave peas in pods.

Wrap odorous foods and refrigerate

in crisper.

Remove tops. Wrap odorous foods

and refrigerate in the crisper.

Keep in original packaging for

refrigeration. Place in the meat and

cheese drawer. When freezing longer

than two weeks, overwrap with

freezer wrap.

Bacon

Beef or lamb, ground

Beef or lamb, roast and steak

Ham, fully cooked, whole

half

slices

Luncheon meat

Pork, roast

Pork, chops

Sausage, ground

Sausage, smoked

Veal

7 days

1 to 2 days

3 to 5 days

7 days

5 days

3 days

3 to 5 days

3 to 5 days

3 to 5 days

1 to 2 days

7 days

3 to 5 days

1 month

3 to 4 months

6 to 9 months

1 to 2 months

1 to 2 months

1 to 2 months

1 to 2 months

4 to 6 months

4 months

1 to 2 months

1 to 2 months

4 to 6 months

Fresh meats can be kept in original

packaging for refrigeration.

Place in the meat and cheese drawer.

When freezing longer than two

weeks, overwrap with freezer wrap.

Unopened, vacuum-packed luncheon

meat may be kept up to two weeks

in the meat and cheese drawer.

Frankfurters

Sources: United States Department of Agriculture; Food Marketing Institute; Cooperative Extension Service, Iowa

State University

7 days

1 month

Processed meats should be tightly

wrapped and stored in the meat and

cheese drawer.

18

Page 20

Care and Cleaning

WARNING

To avoid electrical shock which can cause severe

personal injury or death, disconnect power to

refrigerator before cleaning. After cleaning,

reconnect power.

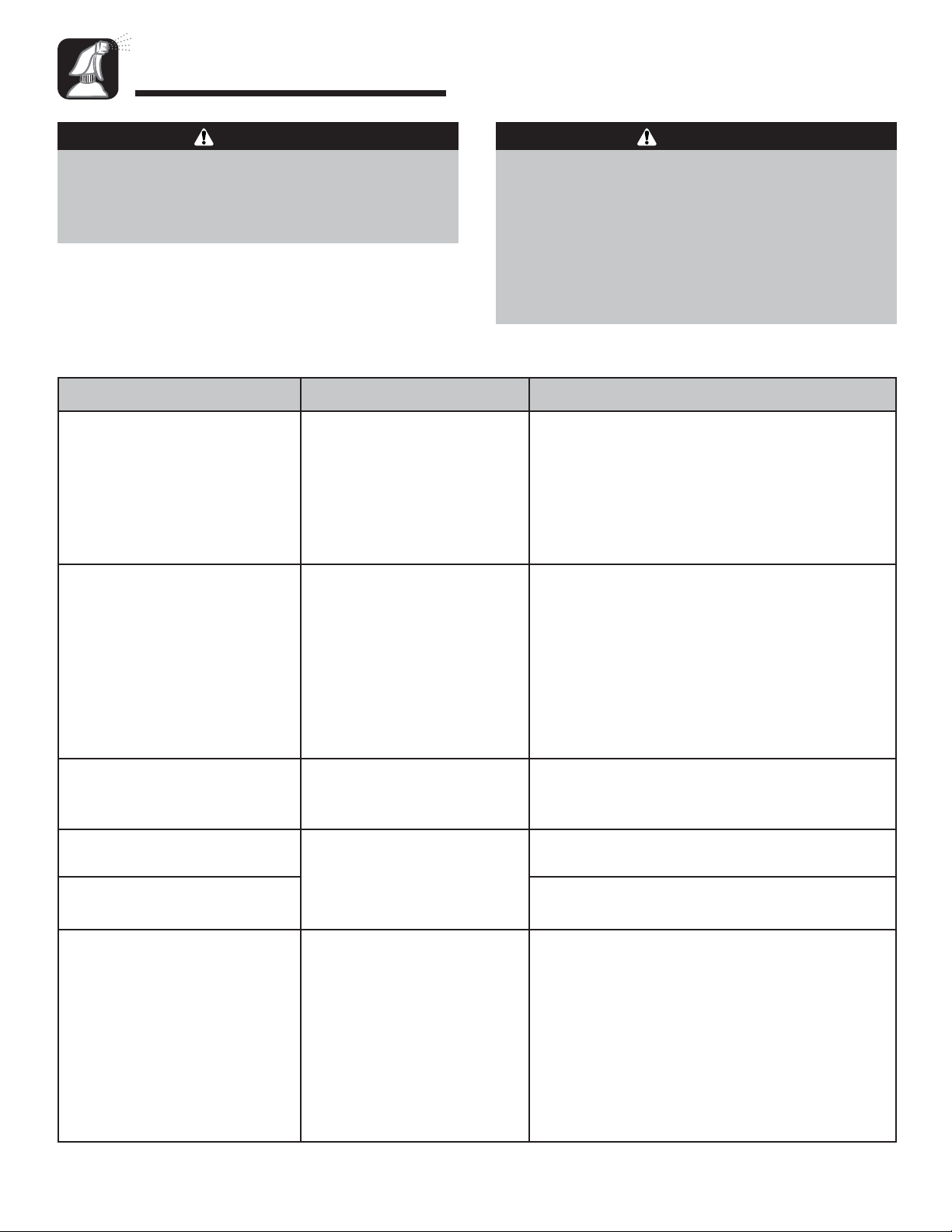

Refrigerator Cleaning Chart

PART

Textured Doors,

Exterior and

Cabinet Interior

Stainless Steel Doors and

Exterior (select models)

IMPORTANT:

Damage to stainless steel

finish due to improper use

of cleaning products or

non-recommended products

is not covered under this

product’s warranty.

Abrasive or harsh cleaners

Ammonia

Chlorine bleach

Concentrated detergents

Metal or plastic-textured

Abrasive or harsh cleaners

Ammonia

Chlorine bleach

Concentrated detergents

Metal or plastic-textured

Vinegar-based products

Citrus-based cleaners

DO NOT USE

or solvents

scouring pads

or solvents

scouring pads

CAUTION

To avoid personal injury or property damage,

observe the following:

• Read and follow manufacturer’s directions for all

cleaning products.

• Do not place buckets, shelves or accessories in

dishwasher. Cracking or warping of accessories

may result.

DO

Use 4 tablespoons of baking soda dissolved in

1 quart (1 liter) warm soapy water.

Rinse surfaces with clean warm water and dry

immediately to avoid water spots.

Use warm, soapy water and a soft, clean cloth

or sponge.

Rinse surfaces with clean warm water and dry

immediately to avoid water spots.

To polish and help prevent fingerprints, follow

with Stainless Steel Magic Spray (part no.

20000008).*

Door Gaskets

Condenser Coil

Remove base grille to access.

Condenser Fan Outlet Grille

See back of refrigerator.

Accessories

Shelves, buckets,

drawers, etc.

* To order, call 1-877-232-6771 U.S.A. or 1-800-688-8408 Canada.

19

Abrasive or harsh cleaners

Metal or plastic-textured

scouring pads

A dishwasher

Use warm, soapy water and a soft, clean cloth

or sponge.

Use a vacuum cleaner hose nozzle.

Use a vacuum cleaner hose nozzle with brush

attachment.

Follow removal and installation instructions

from appropriate feature section.

Allow accessories to adjust to r

temperature.

Dilute mild detergent and use a soft clean cloth

or sponge for cleaning.

Use a plastic bristle brush to get into crevices.

Rinse surfaces with clean warm water.

Dry glass and clear items immediately to avoid

spots.

oom

Page 21

Care and Cleaning

Removing Odors From

Refrigerator

WARNING

To avoid electrical shock which can cause severe

personal injury or death, disconnect power to

refrigerator before cleaning. After cleaning,

reconnect power.

1. Remove all food and turn the refrigerator OFF.

2. Disconnect power to the refrigerator.

3. Clean the walls, floor, ceiling of cabinet interior,

drawers, shelves and gaskets according to the

instructions.

4. Dilute mild detergent and brush solution into

crevices using a plastic bristle brush. Let stand for

five minutes. Rinse surfaces with warm water. Dry

surfaces with a soft, clean cloth.

5. Wash and dry all bottles, containers and jars.

Discard spoiled or expired items.

6. Wrap or store odor-causing foods in tightly sealed

containers to prevent reoccurring odors.

7. Reconnect power to refrigerator and return food to

refrigerator.

Energy Saving Tips

• Avoid overcrowding refrigerator shelves. This reduces

air circulation around food and causes refrigerator to

run longer.

• Avoid adding too much warm food to refrigerator at

one time. This overloads compartments and slows

rate of cooling.

• Do not use aluminum foil, wax paper, or paper

toweling as shelf liners. This decreases air flow and

causes refrigerator to run less efficiently.

• A freezer that is two-thirds full runs most efficiently.

• Locate refrigerator in coolest part of room. Avoid

areas of direct sunlight, or near heating ducts,

registers or other heat producing appliances. If this is

not possible, isolate exterior by using a section of

cabinet or an added layer of insulation.

• Clean door gaskets every three months according to

cleaning instructions. This will assure that door seals

properly and refrigerator runs efficiently.

• Take time to organize items in refrigerator to reduce

time that door is open.

• Be sure your doors are closing securely by leveling

refrigerator as instructed in your installation

instructions.

8. Allow the refrigerator to cool.

9. After 24 hours, check if odor has been eliminated.

If odor is still present:

1. Remove drawers and place on top shelf of

refrigerator.

2. Pack refrigerator and freezer sections – including

doors – with crumpled sheets of black and white

newspaper.

3. Place charcoal briquettes randomly on crumpled

newspaper in both freezer and refrigerator

compartments.

4. Close doors and let stand 24 to 48 hours.

• Clean condenser coils as indicated in the cleaning

instructions every three months. This will increase

energy efficiency and cooling performance.

20

Page 22

Care and Cleaning

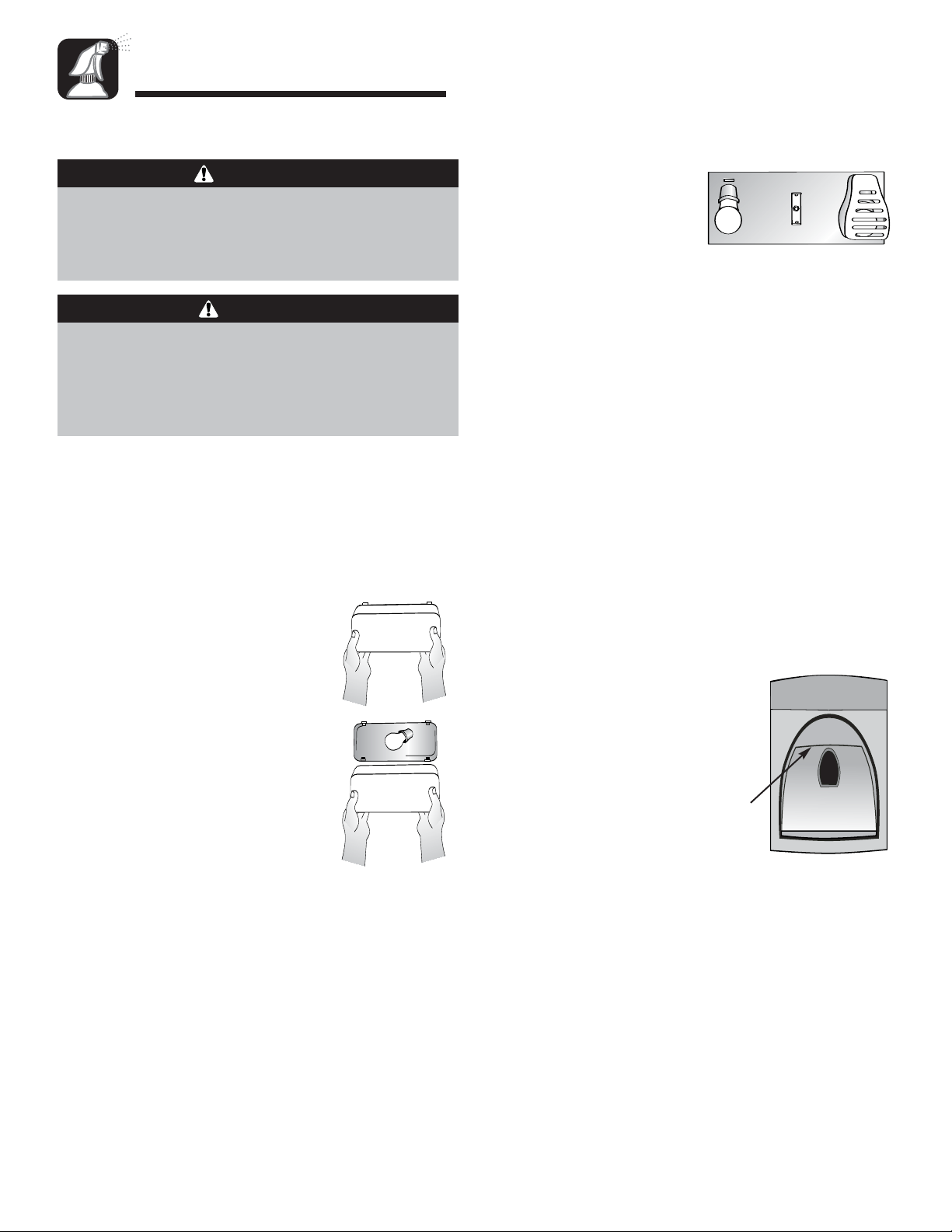

Replacing Light Bulbs

WARNING

To avoid electrical shock which can cause severe

personal injury or death, disconnect power to

refrigerator before replacing light bulb. After

replacing light bulb, reconnect power.

CAUTION

To avoid personal injury or property damage,

observe the following:

• Allow light bulb to cool.

• Wear gloves when replacing light bulb.

Upper Fresh Food Section

The upper fresh food light bulbs are located behind the

front panel. Reach behind the panel to remove the

bulbs.

Lower Fresh Food Section

1. Push up on bottom tabs on light

cover. Rotate cover up and release

tabs.

2. Remove light bulb.

3. Replace bulb with appliance bulb

no greater than 40 watts.

4. Insert top tabs of light cover into

liner slots and snap bottom tabs

into liner slots.

Upper Freezer Section

1. Remove ice bin by

lifting front of bin and

pulling out.

2. Remove light shield by

pressing the upper

right side of the shield and rotating downward.

3. Remove light bulb. Replace with appliance bulb no

greater than 40 watts.

4. Rotate the shield upward, press in slightly and

snap into place.

5. Replace ice bin by sliding in until bin locks into

place.

Lower Freezer Section

1. Pinch both sides of light cover to remove.

2. Remove light bulb. Replace with appliance bulb no

greater than 40 watts.

3. Pinch both sides of the light cover to snap into

place.

Ice and Water Dispenser

1. Locate light bulb inside top

edge of dispenser frame.

Unscrew to remove.

2. Replace light bulb with a

7-watt, 120 volt bulb.

Light Bulb

Location

21

Page 23

Care and Cleaning

Preparing for Vacation

CAUTION

If your refrigerator has a dispenser and there is any

possibility that the temperature can drop below

freezing where the refrigerator is located, the water

supply system (including the water tank and the

water valve) must be drained by a qualified servicer.

For short vacations or absences (three months or

less):

1. Remove all perishables.

2. If no one will be checking in on the refrigerator

during your absence, remove all frozen items also.

3. If your refrigerator has an automatic ice maker:

• Shut off the water supply to the ice maker at

least one day ahead of time.

• After the last load of ice drops, raise the wire

shut off arm to the OFF position.

• Empty the ice bin.

4. If the room temperature will drop below 55° F

(13° C), follow the instructions for longer absences.

For long vacations, absences (more than three

months) OR if the room temperature will drop below

55° F (13° C):

1. Remove food.

2. If your refrigerator has an automatic ice maker:

• Shut off the water supply to the ice maker at

least one day ahead of time.

• After the last load of ice drops, raise the wire

shut off arm to the OFF position.

• Empty the ice bin.

Upon Your Return:

After a Short Vacation or Absence:

For models with automatic ice makers or dispensers:

• Reconnect the water supply and turn on supply valve

(see pages 4-5).

• Monitor water connection for 24 hours and correct

leaks if necessary.

• Run 10-15 glasses of water from the dispenser to

flush out the system.

• Restart the ice maker.

• Discard at least the first three ice harvests.

After a Long Vacation or Absence:

• If your refrigerator has an automatic ice maker,

reconnect the water supply and turn on supply valve

(see pages 4-5).

• Plug the refrigerator back in and reset controls (see

pages 7).

• Monitor water connection for 24 hours and correct

leaks, if necessary.

For dispenser models, run water through the dispenser

for at least three minutes with the filter bypass in

place, then install water filter.

• After installing the water filter, run water through the

dispenser continuously for at least two minutes, or

until water runs steady. Initially you may notice a

one to two minute delay in water dispersal as the

internal tanks fills.

• Restart the ice maker.

• Discard ice produced within the first 12 hours (at

least the first three harvests).

3. If your refrigerator has a dispenser system with

water filter, remove the water filter cartridge and

install the filter bypass. Dispose of the used

cartridge.

4. Turn the freezer control to OFF.

5. Unplug the refrigerator.

6. Thoroughly clean the interior of both compartments

with a baking soda solution and a clean soft cloth

(four tablespoons of baking soda in one quart of

warm water.).

7. Dry thoroughly.

8. Leave the

mold and mildew.

doors open to prevent the formation of

Preparing to Move

• Follow the above instructions for long

vacations/absences, through step 7.

• Secure all loose items such as shelves and drawers

by taping them securely in place to prevent damage.

• Tape the doors shut.

• Use an appliance dolly when moving the refrigerator.

Always truck the refrigerator from its side or backnever from its front.

• Be sure the refrigerator stays in an upright position

during moving.

22

Page 24

Operating Sounds

Improvements in refrigeration design may produce sounds in your new refrigerator that are different or were not

present in an older model. These improvements were made to create a refrigerator that is better at preserving food,

is more energy efficient, and is quieter overall. Because new units run quieter, sounds may be detected that were

present in older units, but were masked by higher sound levels. Many of these sounds are normal. Please note that

the surfaces adjacent to a refrigerator, such as hard walls, floors and cabinetry may make these sounds seem even

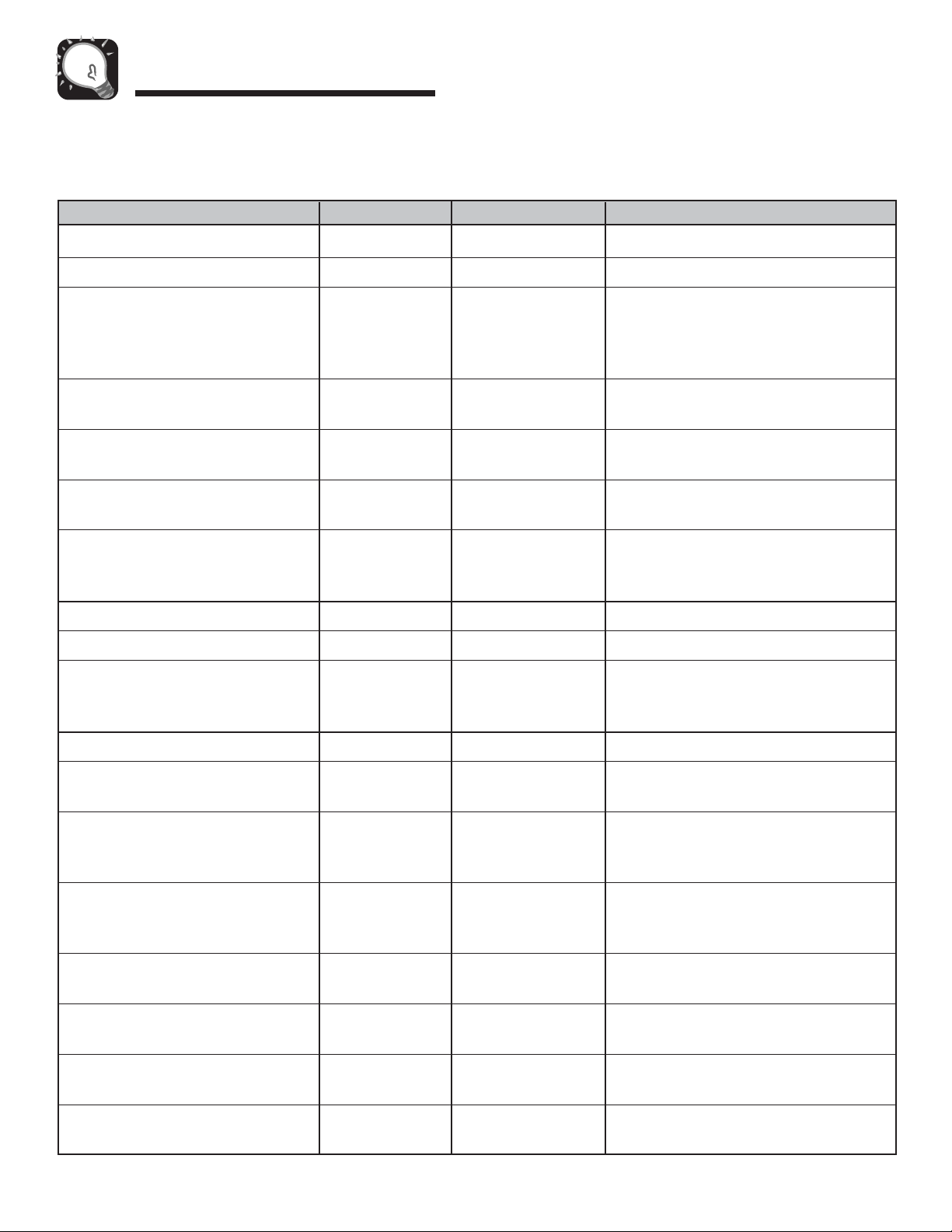

louder. The following are some of the normal sounds that may be noticed in a new refrigerator.

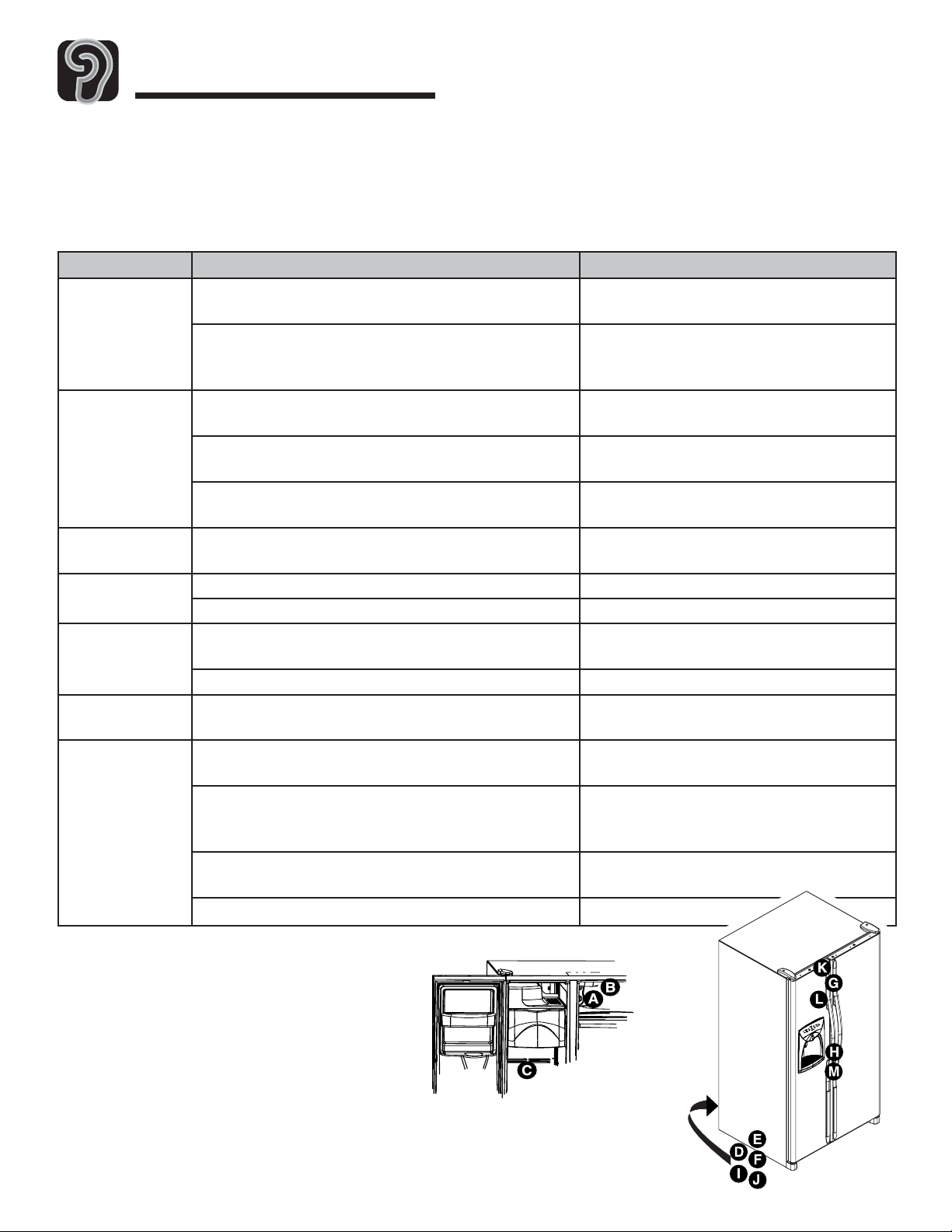

SOUND

Clicking

Air rushing

or whirring

Gurgling or

boiling sound

Thumping

Vibrating

noise

Buzzing

Humming

POSSIBLE CAUSE

Freezer control (A) clicks when starting or

stopping compressor.

Defrost timer or electric damper control (select

models) (B) sounds like an electric clock and

snaps in and out of defrost cycle.

Condenser fan (D) makes this noise while

operating.

Freezer fan (C) makes this noise while

operating.

Freezer fan (C) slows to a stop as the freezer

door is opened.

Evaporator (E) and heat exchanger (F)

refrigerant make this noise when flowing.

Ice cubes from ice maker drop into ice bucket (G).

Dispenser ice chute (H) closing.

Compressor (I) makes a pulsating sound while

running.

Refrigerator is not level.

Ice maker water valve (J) hookup buzzes when

ice maker fills with water.

Ice maker (K) is in the ‘on’ position without

water connection.

Ice auger (L) hums as auger agitates ice during

dispensing.

Compressor (I) can make a high pitched hum

while operating.

Solenoid valve (M) operating ice chute door.

SOLUTION

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

See Leveling (see page 6).

Normal operation

Normal operation

Stop sound by raising ice maker arm to

OFF position. See Automatic Ice Maker

for details (page 10).

Normal operation

Normal operation

23

Page 25

Troubleshooting

PROBLEM

Freezer control and

lights are on, but

compressor is not

operating

Refrigerator does

not operate

Refrigerator still

won’t operate

Food temperature

is too cold

Food temperature

is too warm

Refrigerator has

an odor

POSSIBLE CAUSES

Refrigerator is in defrost mode.

Refrigerator is not plugged in.

Dial control in freezer is set to OFF

(select models).

Fuse is blown, or circuit breaker needs

to be reset.

Power outage has occurred.

Refrigerator is malfunctioning.

Condenser coils are dirty.

Refrigerator or freezer controls are set

too high.

Food is too close to upper left air inlet.

Door is not closing properly.

Controls need to be adjusted.

Condenser coils are dirty.

Rear air grille is blocked.

Door has been opened frequently, or has

been opened for long periods of time.

Food has recently been added.

Odor producing foods should be covered

or wrapped.

The interior needs cleaning.

WHAT TO DO

Normal operation.

Wait 40 minutes to see if refrigerator restarts.

Plug in refrigerator.

See page 7 to adjust controls.

Replace any blown fuses.

Check circuit breaker and reset, if necessary.

Call local power company listing to report outage.

Unplug refrigerator and transfer food to another

refrigerator. If another refrigerator is not available,

place dry ice in freezer section to preserve food.

Warranty does not cover food loss.

Contact service for assistance.

Clean according to the chart.

See page 7.

Relocate food.

Refrigerator is not level. See page 6 for details on how

to level your refrigerator.

Check gaskets for proper seal. Clean, if necessary.

Check for internal obstructions that are keeping door

from closing properly (i.e. improperly closed drawers,

ice buckets, oversized or improperly stored containers,

etc.)

See page 7 to adjust controls.

Clean according to the cleaning chart on page 19.

Check the positioning of food items in refrigerator to

make sure grille is not blocked. Rear air grilles are

located under crisper drawers.

Reduce time door is open. Organize food items

efficiently to assure door is open for as short a time as

possible.

Allow time for recently added food to reach

refrigerator or freezer temperature.

Clean according to cleaning chart on page 19.

continued…

24

Page 26

Troubleshooting

PROBLEM

Water droplets

form on outside

of refrigerator

Water droplets form

on inside of

refrigerator

Refrigerator or ice

maker makes

unfamiliar sounds

or seems too loud

Temperaturecontrolled drawer

and/or crisper

drawer do not

close freely

Refrigerator runs

too frequently

POSSIBLE CAUSES

Door gaskets are not sealing properly.

Humidity levels are high.

Controls require adjustment.

Humidity levels are high or door has

been been opened frequently.

Door gaskets are not sealing properly.

Normal operation.

Contents of drawer, or positioning of

items in the surrounding compartment

could be obstructing drawer.

Drawer is not in proper position.

Refrigerator is not level.

Drawer channels are dirty.

Doors have been opened frequently or

for long periods of time.

Humidity or temperature in surrounding

area is high.

Food has recently been added.

Refrigerator is exposed to heat by

environment or by appliances nearby.

Condenser coils are dirty.

Controls need to be adjusted.

Door is not closing properly.

Door gaskets are not sealing properly.

WHAT TO DO

Clean according to the chart on page 19.

Normal during times of high humidity.

See page 7 to adjust controls.

Reduce time door is open. Organize food items

efficiently to assure door is open for as short a time as

possible.

Clean according to the chart on page 19.

See page 23.

Reposition food items and containers to avoid

interference with the drawers.

See page 9 for proper drawer placement.

See page 6 for details on how to level your

refrigerator.

Clean drawer channels with warm, soapy water.

Rinse and dry thoroughly.

Apply a thin layer of petroleum jelly to drawer

channels.

Reduce time door is open.

Organize food items efficiently to assure door is open

for as short a time as possible.

Allow interior environment to adjust for period the

door has been opened.

Normal operation.

Allow time for recently added food to reach

refrigerator or freezer temperature.

Evaluate your refrigerator’s environment. Refrigerator

may need to be moved to run more efficiently.

Clean according to the chart on page 19.

See page 7 to adjust controls.

Refrigerator is not level, see page 6 Leveling.

Check for internal obstructions that are keeping door

from closing properly (i.e. improperly closed drawers,

ice buckets, oversized or improperly stored containers,

etc.)

Cleaning according to the chart on page 19.

25

Page 27

Troubleshooting

Ice and Water

PROBLEM

No indicator lights

are lit on dispenser

control

Ice or water are

not dispensed

when pads are

pressed

Ice maker is not

producing enough

ice or ice is

malformed

Ice maker is not

producing ice

Water filter

indicator light is

red

POSSIBLE CAUSES WHAT TO DO

Freezer door is not closed.

Refrigerator is not plugged in.

Fuse is blown, or circuit breaker needs to

be reset.

Power outage has occurred.

Refrigerator is in Sabbath Mode (select

models).

Freezer door is not closed.

Controls are in lock mode (select models).

Water tank is filling.

Ice maker has just been installed or a

large amount of ice has been used.

Water filter is clogged or needs to be

changed.

Ice maker has just been installed or a

large amount of ice has been used.

Water pressure is too low.

Water filter is clogged or needs to be

changed.

Ice maker arm is up.

Househol

water valve.

Copper tubing has kinks.

Water pressure is too low.

Check freezer temperature.

Ice bin is not installed properly.

Improper water valve was installed.

Water filter needs to be replaced.

Filter indicator sensor needs to be reset.

d water supply is not reaching

Verify that freezer door is closed. Power is removed

from the control when freezer door is opened.

Plug in refrigerator.

Replace any blown fuses.

Check circuit breakers for any tripped circuits.

Call local power company listing to report outage.

See Sabbath Mode page 12.

Verify that freezer door is closed. Power is removed

from the control when freezer door is opened.

See Dispenser Lock page 12.

At initial use, there is an approximate one- to two-

minute delay in dispensing while the internal water

tank is filling.

Wait 24 hours for ice production to begin or for ice

maker to restock after emptied.

Change water filter (see page 13).

Wait 24 hours for ice production to begin or for ice

maker to restock after emptied.

Low water pressure can cause valve to leak.

Water pressure must be between 35 to 100 pounds

per square inch to function properly. A minimum

pressure of 35 pounds per square inch is

recommended for refrigerators with water filters.

Change water filter (see page 13).

Confirm ice maker arm is down. See Automatic Ice

Maker page 15.

See Connecting the Water Supply pages 4 and 5.

Turn off water supply and remove kinks.

If kinks cannot be removed, replace tubing.

Water pressure must be between 35 to 100 pounds

per square inch to function properly.

A minimum pressure of 35 pounds per square inch is

recommended for refrigerators with water filters.

See Temperature Controls page 7 to adjust controls.

Freezer must be between 0° to 2° F (-18° to -17° C)

to produce ice.

See Ice Storage Bin page 9.

See Connecting the Water Supply pages 4 and 5.

Self-piercing and

pressure and may clog the line over time. The

manufacturer is not responsible for property damage

due to improper installation or water connection.

If filter is not available, replace with bypass filter.

See Water Filter page 13.

See Filter Status Indicator Light page 12.

3

⁄16" saddle valves cause low water

continued…

26

Page 28

Troubleshooting

PROBLEM

Ice forms in inlet

tube to ice maker

Refrigerator is

leaking water

Water flow is

slower than normal

Dispenser water

is not cold

Water appears

cloudy

Particles in water

and/or ice cubes.

POSSIBLE CAUSES

Water pressure is low.

Saddle valve not open completely.

Freezer temperature is too high.

Plastic tubing was used to complete

water connection.

Improper water valve was installed.

Water pressure is low.

Saddle valve not open completely.

Improper water valve was installed.

Copper tubing has kinks.

Water filter is clogged or needs to be

changed.

Water valve not opened completely.

Refrigerator has been recently installed.

Water supply in holding tank has been

depleted.

Water has settled into water lines

outside holding tank and has warmed to

room temperature.

Air or air bubbles in water.

Carbon dust from water filter cartridge.

Concentrations of minerals in water will

form particles when water becomes

frozen and melts.

WHAT TO DO

Water pressure must be between 35 to 100 pounds per

square inch to function properly.

A minimum pressure of 35 pounds per square inch is

recommended for refrigerators with water filters.

Open saddle valve completely.

See Temperature Controls page 7. Freezer temperature