Page 1

Owner's ManualOwner's Manual

Owner's Manual

Owner's ManualOwner's Manual

Side by Side

Refrigerator

English........................................................... 2

Deutsch ....................................................... 27

Français....................................................... 51

Sección española......................................... 75

Svenskt avsnitt............................................. 99

Suomalainen osa ....................................... 123

Nederlands................................................. 147

Sezione italiana ......................................... 171

Norsk seksjon............................................ 195

Dansk afsnit............................................... 219

ЕгчейсЯдйп ЙдйпкфЮфз .................................... 243

Secção portuguesa .................................... 267

Türkçe........................................................ 291

Part No. 12591308

Printed in U.S.A. 02/02

Page 2

Please read this Owner's Manual thoroughly. This manual provides proper

maintenance information.

Warranty service must be performed by an authorized servicer. The

manufacturer also recommends contacting an authorized servicer if service is

required after warranty expires. To locate an authorized servicer, contact your

distributor.

When contacting your servicer, please provide the following information. Product

information is on the serial plate, located on ceiling of fresh food section.

Model Number _____________________________________________________

'P' Number ________________________________________________________

Serial Number _____________________________________________________

Purchase Date _____________________________________________________

Dealer Name ______________________________________________________

Dealer Address _____________________________________________________

Dealer Phone ______________________________________________________

Contents

Introduction.............................................................................. 2

Contents ..................................................................................2

Important Safety Information ...................................................3

Installing Your Refrigerator......................................................4

How to Transport Your Unit ................................................. 4

How to Select the Best Location ......................................... 4

How to Install and Remove Handles .................................. 5

How to Level Your Refrigerator ............................................6

How to Adjust the Temperature Controls ............................ 7

About Your Filtration System ................................................... 8

Refrigerator Features ..............................................................9

Interior Shelves .................................................................... 9

Door Storage ......................................................................1 0

Drawers ............................................................................. 11

Freezer Features ................................................................... 1 2

Primary Features ............................................................... 1 2

Shelves ..............................................................................13

Door Storage ......................................................................1 3

Dispenser Features ..............................................................14

Primary Features ............................................................... 1 4

Water Dispenser Operation ..............................................14

Control Features (5-button control) ................................... 1 5

Control Features (Electronic control) ................................ 1 6

Hints and Care ...................................................................... 1 9

How to Clean Your Unit .....................................................1 9

How to Remove and Replace Light Bulbs........................2 0

Before Calling Service...........................................................2 1

Water Filter Data....................................................................2 5

How to Obtain Replacement

Parts and Services?

Problems? Save yourself the nuisance

of unnecessary service calls; check the

“Before Calling Service” section of the

owner’s manual.

Your new refrigerator has been carefully

engineered and manufactured under

strict quality standards and should give

you satisfactory and dependable

operation. However, like all mechanical

merchandise, it may occasionally

require adjustment, replacement parts,

or maintenance. Should you ever need

assistance, please contact the dealer

from whom you purchased the

refrigerator.

Provide the following:

• Model

• Manufacturing Number

• Serial Number and all of the other

data shown on the model serial

plate.

• State briefly the trouble you are

having.

The page area to the left has been

provided to record valuable information.

This book is intended to show the

variety of features that are available in

the product line. If interested in

purchasing additional items available

for your unit, please contact your

distributor.

2

Page 3

3

Page 4

Installing Your Refrigerator

These instructions were provided to aid you in the installation of your unit. The manufacturer cannot be responsible for

improper installation.

Steps to Follow...

A qualified engineer must connect refrigerator in accordance with these installation instructions. Measure door opening

and depth and width of refrigerator. Remove handles or doors if required. Engineer must also do the following:

1. Follow local water and electrical company connection regulations.

2. Complete water supply connection before electrical supply connection.

Service to or replacement of power cord must be performed by a qualified servicer.

Installation Requirements

1. Install on an earthed outlet with a separate 230-240 volt, 50hz., 10A circuit Y-connection type power cord.

2. Protect soft flooring with cardboard or rugs.

3. Install on a floor which supports up to 429 kg.

4. Provide 5 mm clearance at side of refrigerator and for models more than 60 cm deep, provide 25 mm clearance at top of

refrigerator.

5. 60 cm deep models.

Trim corners of counter top to a 45° angle if counter top has 25 mm overhang.

How to Remove Wooden Base

CAUTION

!

To avoid personal injury or property damage, two people must remove wooden base.

1. Tape doors shut to prevent doors from opening unexpectedly.

2. Slide appliance cart under side of refrigerator.

3. Wrap refrigerator with blanket or pad. Thread strap around refrigerator. Put foam shipping pads, located in shipping

carton, under strap. Tighten strap securely.

4. Lower appliance cart to floor with appliance cart handles on bottom.

5. Remove top two bolts from skid.

6. Return refrigerator and appliance cart to an upright position. Remove strap.

7. Slide appliance cart under opposite side of refrigerator.

8. Repeat steps 3–5.

9. Remove wooden base.

10. Return refrigerator and appliance cart to an upright position and remove appliance cart.

IMPORT ANT:

Do not leave refrigerator on its side longer than necessary to remove bolts.

How to Remove and Replace Doors and Hinges

• Contact a qualified engineer to perform this task.

4

Page 5

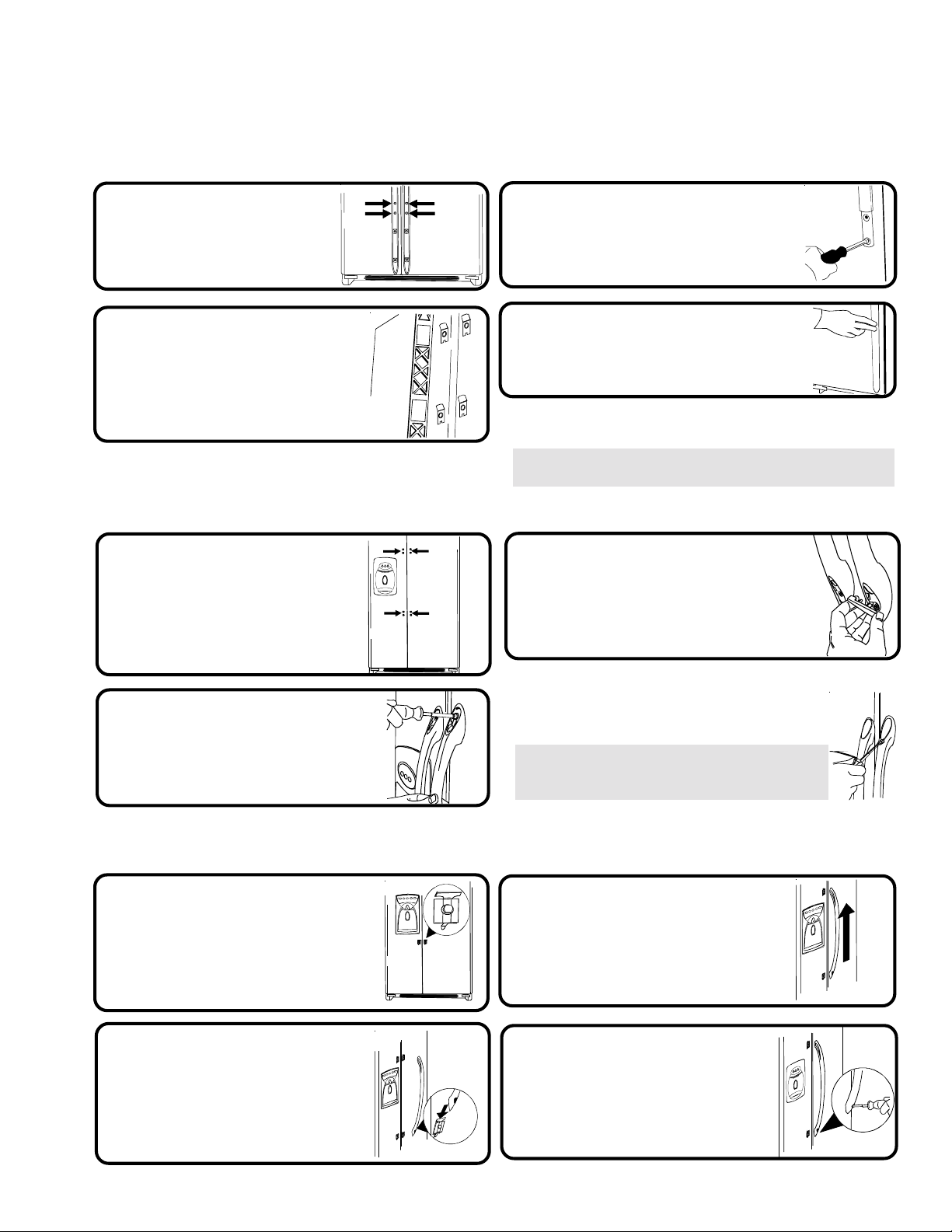

Installing Your Refrigerator

How to Install and Remove Handles

Handles are located within fresh food section of refrigerator. Trim, plugs, and accent pieces will be located within the

literature assembly.

Full-Length Grab Handles (non-stainless steel)

Remove two 1/4" hex nut

1

screws from bottom of

refrigerator

and freezer door.

Align door handles with top

2

and bottom sets of door clips,

and slide down until screw

holes on bottom of handles

match with door screw holes.

Half-Length Grab Handles (non-stainless steel)

Remove four 1/4" hex nut

1

screws from top and

bottom of doors.

Insert screws removed in step 1

3

into screw holes at bottom of

handle section.

Snap trim over bottom portion

4

of handles and retainers on

bottom of door

To remove after initial install...

• Follow steps 3 through 4 in reverse order.

NOTE: Fit may be tight. When removing handle, pull up and

out.

Snap colored handle trim over

3

screw holes at top and bottom of

handles.

• Snap in trim by inserting large round

end first.

Align door handles with

2

screw holes and insert screws

removed in step 1.

Stainless Steel Models

Loosen lower door clip on

1

refrigerator door with 1/4"

hex nut driver.

Locate predrilled hole at

2

base of handle, and fit

hollow end of handle over

lower door clip.

To remove after initial install...

Handles may need to be removed if transporting unit

through tight spaces.

• Follow steps 2 and 3 in reverse order.

IMPORTANT: To avoid damage to handle, use a

flat blade screwdriver edge wrapped in masking

tape to remove colored handle trim.

Fit other end of handle over

3

upper door clip and slide

up as far as possible.

Insert 1/4" hex nut

4

driver into predrilled hole at

base of handle and tighten

screw.

5

Page 6

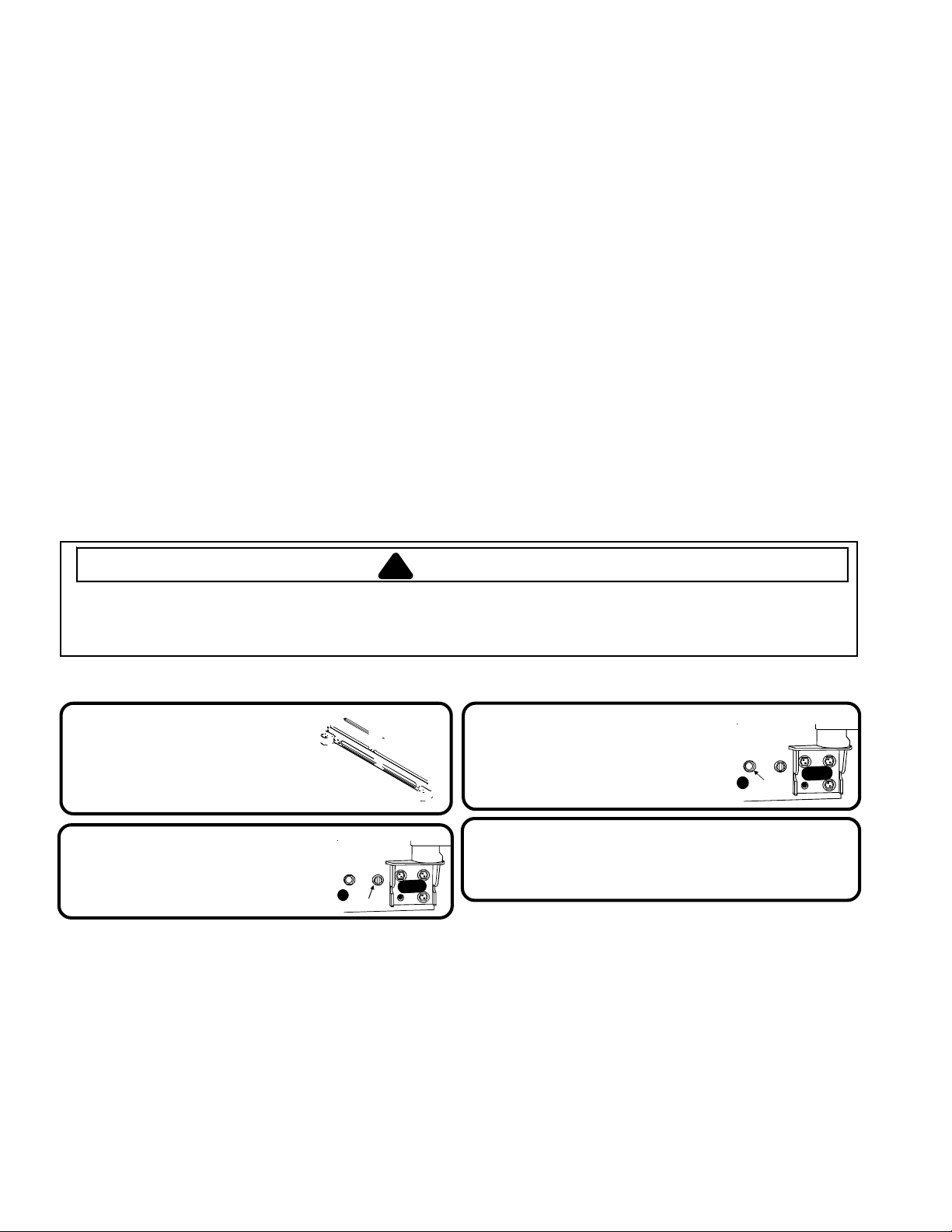

Installing Your Refrigerator

How to Install the Handles continued

How to Connect the Water Supply

• Contact a qualified engineer to perform this task.

How to Level Your Refrigerator

CAUTION

!

• To avoid damage to walls and flooring, protect soft vinyl or other flooring with cardboard, rugs, or other protective material.

• To avoid damage or breakage to adjusting bolt, do not use power tools to correct leveling.

• DO NOT adjust unit to be any shorter than 173.9 cm tall (minus hinge and cap). Doing so may damage underside

components.

Materials Needed

•3/8" hex head driver • Level

Remove Toe Grille and

1

Bottom Hinge Covers

• Open both doors 180°, or as wide as

possible, to remove.

Turn both front adjustment

2

screws (A) clockwise to raise

and counterclockwise to

lower.

A

What if my doors are not aligned?

• Locate the higher door, and turn front adjustment screw

counterclockwise. Continue until doors are level.

• If bottom of adjustment range is reached, and doors are

not level–raise opposite door by turning front

adjustment screw clockwise.

• Replace toe grille

Turn both rear adjustment

3

screws (B) clockwise to raise

and counterclockwise to

lower.

Check with level to verify 6 mm tilt to the

4

back for proper door closure.

• If unit is aligned and stable, replace toe grille.

What if my unit rocks?

• Turn rear adjustment screw clockwise to raise

rocking corner.

• Replace toe grille.

B

6

Page 7

Installing Your Refrigerator

How to Adjust the Temperature Contr ols

This refrigerator is designed to operate at a household temperature of 16° to 43° C.

Locate refrigerator and freezer controls on

1

upper left wall of fresh food section, and

set both controls to 4.

IMPORTANT: Neither section will cool if freezer control is

set to Off.

Check to see that fresh food section

4

is 3° to 4° C.

• Turn control to next highest number if too warm.

• Turn control to next lowest number if too cold.

• Allow 5 to 8 hours for adjustments to take effect.

r

e

z

e

e

r

F

r

o

t

a

r

e

g

i

r

f

e

R

Allow 24 hours for temperatures to stabilize.

2

IMPORTANT: Due to design of unit, always start temperature

adjustments with freezer section.

Check to see if freezer temperature is -17°

3

to -16° C.

• Turn control to next highest number if too warm.

• Turn control to next lowest number if too cold.

• Allow 5 to 8 hours for adjustments to take effect.

Repeat process, as necessary.

5

How do I perform a temperature test?

Materials needed

• 2 thermometers measuring -21° to 10°C

• 2 drinking glasses

For Freezer

• Place thermometer in glass

of vegetable oil in middle

of freezer and continue

with step 3 of Temperature

Adjustment section.

Electronic Temperature Control Models

To set temperature of the freezer, use the buttons next to the

1

button. A setting of 0° to 2° F (-17° to -16° C) is recommended.

• Use the button to raise the temperature of the freezer section, or the to lower it.

• Press the

button to confirm the settings.

For Refrigerator

• Place thermometer in glass

of water in middle of unit

and continue with step 3

of Temperature Adjustment

section.

To set temperature of the fresh food section, use the buttons next to the

2

button. A setting of 38° to 40° F (3° to 4° C) is reommended.

• Use the button to raise the temperature of the fresh food section, or the to lower it.

• Press the button to confirm the settings.

Allow 24 hours for temperatures to stabilize.

3

NOTE: If adjusting the temperature of an operational unit, only 5 to 8 hours is

required for temperatures to take effect.

7

Page 8

About Your Filtration System...

Water Filter Removal and Installation

WARNING

!

To avoid serious illness or death, do not use unit where water is unsafe or of unknown quality without adequate

disinfection before or after use of filter.

CAUTION

!

• Bypass cartridge DOES NOT filter water. Be sure to have replacement cartridge available when filter change is required.

• If water filtration system has been allowed to freeze, replace filter cartridge.

• If system has not been used for several months, and water has an unpleasant taste or odor, flush system by dispensing

2–3 glasses of water. If unpleasant taste or odor persists, change filter cartridge.

Initial Install of Water Filter

Remove blue bypass cap and

1

retain for later use.

Remove sealing label from

2

end of filter and insert into

filter head.

• Rotate gently clockwise until filter stops

and snap filter cover closed.

Reduce water spurts by flushing air from

3

system. Run water continuously

(approximately 2 minutes) through

dispenser until water runs steady.

• Additional flushing may be required in some households

where water is of poor quality.

I'm trying to dispense water to

flush the system. Where's the water?

During initial use, allow about a 1 to 2 minute delay to

allow internal water tank to fill.

Replacing Water Filter

IMPORTANT: Air trapped in system may cause water and

cartridge to eject. Use caution when removing.

Turn filter counterclockwise until it

1

releases from filter head.

Drain water from filter into sink or toilet,

2

and dispose in normal household garbage.

Wipe up excess water in filter cover and

3

continue with installation steps 2 and 3.

When do I change the water filter?

Select dispenser models feature a water filter change indicator.

For instructions on how to operate and reset this feature, refer

to the dispenser features section in your manual.

For units without indicator feature, filter should be changed

approximately every 6 months.

IMPORTANT: Condition of water and amount used

determines life span of water filter cartridge. If water use is

high, or if water is of poor quality, replacement may need to

take place more often.

What if I choose not to use the water

filtration system?

Dispenser feature may be used without water filter cartridge.

If you choose this option, replace filter with blue bypass

cap.

How do I order a replacement filter

cartridge?

Replacement Water Filter cartridge model OWF51

is available through your dealers and servicers. Contact

your local distributor for more information.

8

Page 9

Fresh Food Features

9

Page 10

Fresh Food Features

A

Door Storage

Dairy Center

The dairy center provides convenient storage

for items such as butter, yogurt, cheese, etc.

This compartment is an adjustable feature

located in the door. It can be moved to

several different locations to

accommodate storage needs.

• To remove, slide dairy center

up and pull straight out.

• To install, reverse above

procedure.

Tilt-Out Door Buck ets

(some models)

The Tilt-Out Bucket assembly consists of a bucket and

frame, providing adjustable, convenient storage for

food items in door. The bucket assembly tilts forward

for easy access of items, and lifts out for ease in

cleaning and adjusting.

T o remove and install bucket:

• To remove bucket, tip bucket

forward and pull straight out

to remove.

• To install bucket, slide bucket

into bucket frame and push

bucket upright.

Beverage Chiller™/

Mini-Chiller™

The Temperature-Controlled Beverage Chiller™ and

Temperature-Controlled Mini Beverage Chiller™ keep

beverages and other items up to 3°C colder than the

rest of the fresh food section. Air inlet allows air from

the freezer section to pass to Beverage Chiller™.

The Beverage Chiller™ control is located

on the left wall of fresh food section.

Control adjusts amount of air circulating in

Beverage Chiller™. Turn control toward the

large snowflake icon for colder temperature.

To remove and inst all Beverage Chiller™:

• If located directly above Chiller,

dairy center or door bucket may

need to be removed. Refer to

appropriate instructions and

remove item. Slide Beverage

Chiller™ assembly up and pull

straight out.

• To install, align one of the

Beverage Chiller™ cold air

intake holes (A) with one of

the two air inlets (B) in door

liner. Push assembly down

onto door liner retainer until

it stops.

(some models)

B

T o adjust bucket frame:

• Remove bucket per above instructions.

• Lift frame off door support and place in desired

door location.

Grip Pads

The Grip Pads prevent objects

from sliding in the door bucket.

Grip Pads are removable and are

top-rack dishwasher safe for easy

cleaning.

IMPORTANT: Beverage Chiller™ will not operate

properly if air intake holes are not aligned with air

inlet in door liner.

Door Buckets

Door buckets adjust to meet

individual storage needs.

• To remove, slide bucket up and

pull straight out.

• To install, reverse above procedure.

10

Page 11

Drawers

Deli/Crisper Drawer climate controlled

The Deli/Crisper system provides a drawer with a

variable temperature control that keeps the

compartment up to 3°C colder than refrigerator

temperature. This drawer can be used for deli storage

or additional produce storage.

NOTE: Cold air directed to the Deli/Crisper System

can decrease refrigerator temperature. Refrigerator

control may need to be adjusted.

Controls

Located on the wall to the left of the drawer, the

climate controls regulate the air temperature in the

Deli/Crisper drawer. Set control level to cold to provide

normal refrigerator temperature for produce with outer

skins. Use the coldest setting for meats or other deli

items.

Crisper Drawer climate controlled

Garden Fresh™ crisper keeps produce fresh longer

by providing an environment with adjustable humidity.

Controls

The Garden Fresh™ controls regulate the amount of

humidity in the crisper drawer. Use the low setting for

produce with outer skins. Use the high setting for leafy

produce.

Fresh Food Features

T o remove and install drawers:

• To remove drawer, pull drawer out

to full extension. Tilt up front of

drawer and pull straight out.

• To install, reverse above

procedure.

T o remove and install crisper shelf:

• Lift off wall supports and remove.

• To install shelf, lower shelf onto wall supports

and push in until shelf is flush with rear wall.

11

Page 12

Freezer Features

Automatic Dispensing Ice Maker

This ice maker creates the ice used in the dispensing

system.

Using Ice Maker for the First Time

• Confirm ice bin is in place

and ice maker arm is down.

• After freezer section reaches

between -18° to -17° C, ice

maker fills with water and

begins operating.

• Allow approximately 24 hours

after installation to receive first harvest of ice.

• Discard ice created within first 12 hours of

operation to verify system is flushed of impurities.

Operating Instructions

• Confirm ice bin is in place and ice maker arm is

down.

• After freezer section reaches -18° to -17° C, ice

maker fills with water and

begins operating. You will

have a complete harvest

of ice approximately every

3 hours.

• Stop ice production by

raising ice maker arm until

click is heard.

• Ice maker will remain in the off position until arm is

pushed down.

Ice Cream Shelf

The Ice Cream Shelf provides a space for items to be

chilled or frozen quickly.

• To remove, lift Ice Cream Shelf

from ice bin rails and pull

straight out.

• To install, reverse above

procedure.

Ice Storage Bin

The ice storage bin is located below the automatic

dispensing ice maker.

T o remove and install ice storage bin:

• To remove bin, remove Ice Cream

Shelf. Raise ice maker arm to

deactivate ice maker.

• Lift front of bin and pull out to its full extension. Lift up

front of bin and remove.

• To install, slide bin into rails below ice maker until

bin locks into place. Drop ice maker arm to activate

ice maker, and replace Ice Cream Shelf.

IMPORT ANT: Ice bin must

be locked in proper place for

proper ice dispensing. If freezer

door does not close, bin is not

in proper location. Turn auger

driver as shown to properly align

ice bin with back of unit.

12

Page 13

Shelves

Stor-Mor® System

Baskets slide out for easy access of items in back.

Shelves can be removed to meet individual storage

needs.

®

T o remove and install Stor-Mor

• To remove, snap right side of

shelf from cabinet railing and

remove from wall mounting

clips.

• To install, reverse above procedure.

NOTE: Back of shelf must be flush with back of

cabinet to secure firmly in cabinet railing. Improper

alignment will cause shelf to slide.

T o remove and install basket s:

• To remove, pull basket forward

to full extension. Lift front handle

to release basket from rails and

remove.

• To install, reverse above procedure.

shelf:

Freezer Features

Door Storage

13

Page 14

Dispenser Features

Primary Features

Dispenser Light not shown

A light activates within the dispenser area at full power when dispensing ice or water.

Front Fill Button (some models)

14

Page 15

Dispenser Features

Control Features

(Five button control)

Ice Dispenser Operation

To dispense ice:

• Select Cubed or Crushed ice mode by pushing button on dispenser control panel. A green

indicator light above button shows mode selection.

• Press container against dispenser pad. When dispensing crushed ice, hold container as close

to chute as possible to reduce spraying. Selection mode may not be changed while ice dispenser

is in operation.

NOTE: If dispenser is active for more than 3 minutes, an automatic lock out sensor will shut down power

to dispenser area. See Automatic Lock Out for further information.

Dispenser Lock

This feature prevents ice or water from being dispensed.

To lock and unlock dispenser:

• To lock dispenser, press and hold Dispenser Lock button for

3 seconds. A green indicator light above button confirms

dispenser is locked.

• To unlock dispenser, hold Dispenser Lock button for 3 seconds.

Green indicator light above button will go out.

What is the Automatic Lock Out feature?

The Automatic Lock Out feature shuts down power to the

water and ice dispenser when either dispenser has run

continuously for approximately 3 minutes. If this mode goes

into effect, the green light will activate above the Dispenser

Lock button.

To unlock dispenser:

• T o unlock dispenser, hold Dispenser Lock button for 3

seconds. Green indicator light above button will go out.

Filter Status Indicator Light

The Filter Status Indicator Light serves as a reminder to replace the water filter. A green light indicates that the

filter is in good condition. A red light indicates the filter should be changed. Once light turns red, it will remain

red until function is reset.

To reset indicator:

• Press and hold both Dispenser Lock and Water buttons simultaneously for 4 seconds. The green Filter Status

Indicator Light will flash 3 times when the function has successfully reset.

Auto Light

The Auto Light function offers the ability to activate the dispenser light at half-power when the Light Sensor

detects that the light levels in room are low.

To activate and deactivate Auto Light:

• To activate, press Auto Light button located on control panel. A green

indicator light above button displays to show that sensor is active.

• To deactivate, press Auto Light button. Green indicator light will go out.

NOTE: Dispenser light will operate whether

or not Auto Light is selected.

Sabbath Mode (some models)

This mode is intended to deactivate power to the LED and dispenser lights,

while allowing the controls to remain operational.

To activate Sabbath Mode:

• Press and hold both Dispenser Lock and Auto Light buttons simultaneously

for 3 to 4 seconds. After 3 to 4 seconds, the LED and dispenser lights will turn

off. Dispenser light will not activate during dispensing while in this mode.

To deactivate Sabbath Mode:

• Press and hold both Dispenser Lock and Auto Light buttons simultaneously for 3 to 4 seconds. After 3 to 4 seconds,

the LED and dispenser lights will activate.

NOTE: In the event that power is

interrupted while the Sabbath Mode

is active, the control will remain in

Sabbath Mode when power returns.

+

15

Page 16

Dispenser Features

Control Features

(Electronic control)

Water and Ice Dispensing (main activator)

The water and ice dispensing functions work independently of each other.

T o dispense water:

To dispense ice:

• Press the

button

• Press water activator

• Press the

• Press the

button for crescent ice.

button for crushed ice.

Dispenser Lock

This feature prevents ice or water from being dispensed.

T o lock and unlock dispenser:

• To lock dispenser, press and hold the button for 3 seconds. A green indicator light above button confirms dispenser

is locked.

• To unlock dispenser, hold the button for 3 seconds. Green indicator light above button will go out.

Light Function

The Light function offers offers two setting: OFF and AUTO.

The OFF setting allows the light to function only as a dispenser cavity light.

The AUTO setting allows the SENSOR to measure the surrounding light levels and adjust the power of

the cavity light accordingly. When the sensor registers lower light levels (night time, darkened kitchen), the cavity light will

respond at 50% power. When the sensor registers high light levels (lighted kitchen, direct sunlight), the cavity light will not

activate.

T o deactivate the AUTO setting:

• Press the

function only when dispensing ice or water.

• To activate the AUTO setting, press the

cavity dispenser light will use the AUTO setting.

button located on control panel. When the green indicator light above button display is off, the light will

button. When the green indicator light above the button display is on, the

NOTE: Dispenser light will operate at full

power when ice or water functions are in use.

Filter Status Indicator Light

The Filter Status Indicator Light serves as a reminder to replace the water filter. A green light indicates that the

filter is in good condition. A red light indicates the filter should be changed. Once light turns red, it will remain red

until function is reset.

T o reset indicator:

• Press and hold both the

will flash 3 times when the function has successfully reset.

and the buttons simultaneously for 4 seconds. The green Filter Status Indicator Light

What is the Automatic Lock Out feature?

The Automatic Lock Out feature shuts down power to the water and ice dispenser when either dispenser has run continuously for approximately

2 minutes. If this mode goes into effect, the green light will activate above the

To unlock dispenser:

• T o unlock dispenser , hold

button for 3 seconds. Green indicator light above button will go out.

button.

16

Page 17

Dispenser Features

Temper ature Keys

These keys will lower or raise the freezer or fresh food compartment temperature.

T o set the fresh food temperature:

• Press the

Control Features continued

(Electronic control)

button to confirm the setting.

• Locate the

button to raise the temperature of the fresh food

section, or the to lower it.

Max Cool

This function causes the fresh food temperature to drop to the Minimum Refrigerator Temperature Setting preset

by the control. This setting remains in effect for approximately 10 hours.

T o activate Max Cool:

• Press the

button will indicate active status.

Max Freeze

This function causes the freezer temperature to drop to the Minimum Freezer Temperature Setting preset by

the control. This setting remains in effect for approximately 24 hours.

T o activate Max Freeze:

• Press the button. The green light above the

button will indicate active status.

next to the button. Use the

NOTE: The temperature setting cannot be changed if Max Cool or Max Freeze setting is active.

button. The green light above the

NOTE: The temperature setting cannot be changed if Max Cool or Max Freeze setting is active.

To set the freezer temperature:

• Repeat the above instructions with the

the

To deactivate Max Cool:

• Press the

turn off.

T o deactivate Max Freeze:

• Press the

button will go out.

button on the display.

button. The green light above the button will

button. The green light above the

buttons next to

Display On/Off

The Display On/Off switch controls power to the LED display.

To deactivate display:

• Press the button. The display will turn off.

To reactivate display:

• Press the button. The display will turn back on.

Vacation Mode

This key, if enabled, causes less frequent defrost cycles. This conserves energy.

T o place refrigerator into Vacation Mode:

• Press the button.

Alarm Off

This key is used to turn the HI TEMP Warning Indicator and

audio alarm, as well as the OPEN DOOR audio

alarm off.

T o deactivate Vacation Mode:

• Press the button, or open either refrigerator door.

To turn the alarm off:

• Press the

17

button.

Page 18

Dispenser Features

Hidden Control Features (Electronic Control)

Sabbath Mode

This mode is intended to deactivate power to the LED and dispenser lights, while allowing the

controls to remain operational. No visual or audio alarms will be available while in this mode.

T o activate Sabbath Mode:

• Press and hold both the

simultaneously for 3 seconds. After 3 seconds, the

LED and dispenser lights will turn off. Dispenser

light will not activate during dispensing while in

this mode.

and buttons

NOTE: In the event that power is interrupted while the Sabbath Mode is active, the control will remain in

Sabbath Mode when power returns.

T o deactivate Sabbath Mode:

• Press and hold both

seconds. After 3 seconds, the LED and dispenser lights will

activate.

and buttons simultaneously for 3

Auto Display

The AUTO Display controls the illumination of the LED display based on the light readings received from the SENSOR.

In AUTO mode, if the SENSOR indicates low light levels, the display will be dimmer than if displaying during well-lit

periods. In ON mode, the display will have only one illumination setting and will not change due to light levels.

T o set the power level of the display:

+

• Press and hold both the

the display by using

• Use the refrigerator

• Activate the chosen setting by pressing the

O for on, AL for auto.

Temper atur e Conver sion Mode

This mode is available to change the Temperature

Display between Fahrenheit and Celsius.

button and the freezer button for 3 seconds. The current active state will show in

button to scroll through the display states.

button.

T o change temperature reading:

• Press the

for 3 seconds. Pressing the same button combination will allow

the user to toggle between the two selections .

and freezer buttons simultaneously

Hidden Lockout for Upper Keypad

The purpose of this mode is to prevent tampering with the upper set of dispenser controls.

This includes the Display On/Off , Max Freeze, Max Cool, Vacation Mode, and Temperature Set

functions.

To activate Hidden Dispenser Lockout:

• Press the

3 seconds.

and buttons simultaneously for

To deactivate Hidden Dispenser Lockout:

• Press the

for 3 seconds.

and buttons simultaneously

° F

° C

+

ON/OFF Function

The ON/OFF function turns off cooling to the

fresh food and freezer sections.

To turn the unit off:

• Press the freezer button until the readout registers

beyond the maximum allowable freezer temperature. At

this point, the LED displays:

• Press the button to confirm the selection.

-- --

WARNING

!

To avoid electrical shock which can cause severe personal

injury or death, do not perform maintenance or service on

refrigerator unless unit is unplugged.

To reactivate the unit:

• Press the freezer

• Press the

button to confirm the selection.

button.

18

Page 19

How to Clean Your Unit

WARNING

!

To avoid electrical shock which can cause severe personal injury or death,

disconnect power to refrigerator before cleaning. After cleaning, connect power.

CAUTION

!

To avoid personal injury or property damage:

• Read and follow manufacturer's directions for all cleaning products.

• Do not place buckets, shelves, or accessories in dishwasher. Cracking or

warping of accessories may result.

• Handle tempered glass shelves carefully. Shelves may break suddenly if

nicked, scratched, or exposed to sudden temperature change.

• Protect soft vinyl or other flooring with cardboard, rugs, or other protective

material.

Hints and Care

General

1. Wash surfaces with a warm water and baking soda solution. Use a soft clean

cloth to clean surfaces.

2. Rinse surfaces with warm water. Dry surfaces with a soft, clean cloth.

Adhesives

1. Remove glue residue by rubbing toothpaste into adhesive with fingers until

adhesive loosens.

2. Rinse surface with warm water. Dry surface with a soft, clean cloth.

Door Gaskets

1. Keep gaskets clean at all times. Clean door gaskets thoroughly every 3 months

according to “General” instructions.

Condenser Coils

Clean condenser coil every 3 months to ensure maximum performance of

refrigerator. Accumulated dust and lint may cause the following:

• reduced cooling performance

• increased energy usage

• in extreme cases, premature compressor failure

1. Remove toe grille and bottom hinge covers as

shown right.

2. Clean front surface of condenser coil with a vacuum cleaner hose nozzle.

3. Replace toe grille by inserting clips in holes and snapping in. Snap bottom

hinge covers over bottom hinges.

Glass Shelves

Remove shelf by lifting front, releasing hooks from metal track then pulling out.

Place shelf on a towel. Allow shelf to adjust to room temperature before cleaning.

Clean crevices by completing the following steps:

1. Dilute mild detergent and brush solution into crevices using a plastic bristle

brush. Let set for 5 minutes.

2. Spray warm water into crevices using faucet spray attachment.

3. Dry shelf thoroughly and replace shelf by inserting hooks into metal track and

lowering front.

19

Page 20

Hints and Care

A

How to Remove and Replace Light Bulbs

WARNING

!

To avoid electrical shock which can cause severe personal injury or death,

disconnect power to refrigerator before replacing light bulb. If unable to

disconnet power by unplugging power cord then remove the fuse at mains.

After replacing light bulb, connect power.

CAUTION

!

To avoid personal injury or property damage, observe the following:

• Allow light bulb to cool.

• Wear gloves when replacing light bulb.

Upper fresh food section

1. Locate finger gaps on each side of clear light

shield. Insert fingers and press in on each side

of shield. Pull shield down and remove.

2. Remove light bulbs.

3. Replace with appliance bulbs, type Krypton E27,

no greater than 25 watts.

4. Replace light bulb cover by inserting front tabs of

light shield into holes in liner directly in front of light assembly.

5. Snap back of light cover into place.

Lower fresh food section and

Non-dispensing model freezer section

1. Pinch bottom tabs (A) on light cover and pull straight

out.

2. Remove light bulb.

3. Replace with appliance bulbs, type Krypton E27,

no greater than 25 watts.

4. Insert top tabs (B) of light cover into refrigerator liner and

snap bottom portion over light assembly.

B

Dispensing model freezer section

1. Remove ice bin by lifting front of bin and pulling out.

2. Remove light bulb cover by pinching top tab (A) and

pulling cover out of liner.

3. Replace with appliance bulbs, type Krypton E27,

no greater than 25 watts.

4. Insert bottom tab (B) of light cover into liner and snap

top portion over light assembly.

5. Replace ice bin by sliding in until bin locks into place.

A

B

Ice ’N Water dispenser

1. Locate light bulb inside top edge of dispenser frame. Unscrew to remove.

2. Replace bulbs with a 230/240VAC bulb no greater than 12 watts. Extra

light bulbs are provided in crisper due to local unavailability.

20

Page 21

Before Calling Service

Today’ s refrigerators have new features and are more ener gy efficient. Foam insulation is very energy efficient and has

NOISE

TOPIC POSSIBLE CAUSE SOLUTION

excellent insulating capabilities, however, foam insulation is not as sound absorbent. As a result, certain sounds may be

unfamiliar. In time, these sounds will become familiar . Please refer to this information before calling service.

Clicking

Air rushing or

whirring

Gurgling or

boiling sound

Thumping

Vibrating noise

Buzzing Ice maker water valve (J) hookup (some

Humming

Freezer control (A) clicks when starting or

stopping compressor.

Defrost timer (B) sounds like an

electric clock and snaps in and out

of defrost cycle.

Freezer fan (C) and condenser fan (D)

make this noise while operating.

Evaporator (E) and heat exchanger (F)

refrigerant makes this noise when flowing.

Ice cubes from ice maker(some models)

drop into ice bucket (G).

Dispenser ice chute (H) closing. Normal operation

Compressor (I) makes a pulsating sound

while running.

Refrigerator is not level.

models) buzzes when ice maker fills

with water.

Ice maker (K) is in the ‘on’ position without

water connection.

Ice auger (L) (some models) hums as

auger agitates ice during dispensing.

Compresser (I) can make a high pitched

hum while operating.

Solenoid valve (M) operating ice

chute door.

OPERATION

Freezer control

and lights are on,

but compressor

is not operating.

Deli/Crisper

system

temperature

is too warm

Refrigerator does

not operate

Refrigerator still

won’t operate

Fresh food

temperature is

too cold

Refrigerator is in defrost mode.

Control settings are too low. See section on Deli/Crisper system to adjust controls.

Freezer controls are set too low.

Drawer is improperly positioned.

Refrigerator is not plugged in. Plug in unit.

Freezer control is not on. See section on controls in your Owner’s Manual.

Fuse is blown, or circuit breaker needs

to be reset.

Power outage has occurred Call local power company listing to report outage.

Unit is malfunctioning.

Condenser coils are dirty.

Refrigerator or freezer controls are set

too high.

Beverage Chiller™ (some models) is

improperly positioned.

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

See Installation

Instructions for details

on how to level your unit.

Normal operation

Stop sound by raising ice

maker arm to ‘off’ position.

See Automatic Ice Maker

section in your owner’s

manual for details.

Normal operation

Normal operation

E

D

F

I

J

C

Normal operation

Normal operation Wait 40 minutes to see if refrigerator

restarts.

See controls section in Owner’s Manual on how to adjust

your controls.

See section on Deli/Crisper system to verify drawer

positioning.

Replace any blown fuses. Check circuit breaker and reset

if necessary.

Unplug refrigerator and transfer food to another unit. If

another unit is not available, place dry ice in freezer

section to preserve food. Warranty does not cover

food loss . Contact service for assistance.

Clean according to cleaning instructions in your

Owner’s Manual.

See controls section in Owner’s Manual on how to adjust

your controls.

See section on Temperature-Controlled Beverage Chiller™

to verify proper positioning.

21

K

G

L

H

M

B

A

Page 22

Before Calling Service

OPERATION

TOPIC POSSIBLE CAUSE SOLUTION

Food temperature

appears too warm

Refrigerator has an odor

Water droplets form on

outside of refrigerator

Water droplets form on

inside of refrigerator

Refrigerator or ice maker

make unfamiliar sounds

or seems too loud

Deli/Crisper System and/or

crisper drawers do not

close freely

Refrigerator runs

too frequently

Door is not closing properly.

Controls need to be adjusted.

Condenser coils are dirty.

Rear air grille is blocked on models

over 60 cm deep.

Door has been opened frequently,

or has been opened for long periods

of time.

Food has recently been added.

Compartment is dirty or has odorcausing food.

Air filter (some models) needs to

be changed.

Check gaskets for proper seal.

Humidity levels are high. Normal during times of high humidity.

Controls require adjustment

Humidity levels are high or door has

been opened frequently.

Check gaskets for proper seal.

Normal operation

Contents of drawer, or positioning of

items in the surrounding compartment

could be obstructing drawer

Drawer is not in proper position

Refrigerator is not level. See Installation Instructions for details on how to level your unit.

Drawer channels are dirty or

need treatment.

Doors have been opened frequently

or have been opened for long periods

of time.

Humidity or heat in surrounding area

is high.

Food has recently been added.

Unit is exposed to heat by

environment or by appliances nearby.

Condenser coils are dirty.

Refrigerator is not level. See Installation Instructions for details

on how to level your unit.

Check gaskets for proper seal. Clean, if necessary, according to

cleaning instructions in Owner’s Manual.

Check for internal obstructions that are keeping door from

closing properly (i.e. improperly closed drawers, ice buckets,

oversized or improperly stored containers or foodstuffs, etc.).

See the controls section in your Owner’s Manual for assistance

in how to adjust your controls.

Clean according to cleaning instructions in your

Owner’s Manual.

Check the positioning of food items in refrigerator to make

sure grille is not blocked. Rear air grille is located behind

crisper drawers.

Reduce time door is open. Organize food items efficiently to

assure door is open for as short a time as possible.

Allow interior environment to adjust for period the door has

been open.

Allow time for recently-added food to reach refrigerator or

freezer temperature.

Refer to odor removal instructions in Owner’s Manual.

Change air filter.

Clean, if necessary, according to cleaning instructi ons i n

Owner’s Manual.

See the controls section in your Owner’s Manual for assistance

in how to adjust your controls.

See the controls section in your Owner’s Manual for assistance

in how to adjust your controls.

Reduce time door is open. Organize food items efficiently to

assure door is open for as short a time as possible.

Clean, if necessary, according to cleaning instructi ons i n

Owner’s Manual.

Refer to “Noise” section of Before Calling Service in your

Owner’s Manual.

Reposition food items and containers to avoid interference with

the drawers.

See section on Deli/Crisper System and/or crisper drawer

section for proper placement.

Clean drawer channels with warm, soapy water. Rinse and

dry thoroughly.

Apply a thin layer of petroleum jelly to drawer channels.

Reduce time door is open. Organize food items efficiently to

assure door is open for as short a time as possible.

Allow interior environment to adjust for period the door has

been open.

Normal operation

Allow time for recently-added food to reach refrigerator or

freezer temperature.

Evaluate your unit’s environment. Unit may need to be moved

to run more efficiently.

Clean according to cleaning instructions in your

Owner’s Manual.

22

Page 23

Before Calling Service

OPERATION (continued)

TOPIC POSSIBLE CAUSE SOLUTION

Refrigerator runs too

frequently (continued)

ICE & WATER

Water appears cloudy

Particles in wate r and/or

ice cubes.

No indicator lights are lit

on dispenser control

(some models)

Neither ice nor water is

dispensed when pads are

pushed (some models)

Ice maker is not producing

enough ice or ice is

malformed (some models)

Ice maker is not producing

ice (some models)

Controls need to be adjusted.

Door is not closing properly

Air or air bubbles in water.

Carbon dust from water filter cartridge.

Concentrations of minerals in water will

form particles when water becomes frozen

and melts.

Freezer door is not closed.

Refrigerator is not plugged in. Plug in unit.

Fuse is blown, or circuit breaker needs to

be reset.

Power outage has occurred. Call local power company listing to report outage.

Freezer door is not closed. Verify that freezer door is closed. Power is removed from the

Controls are in lock m ode. See Dispenser control instructions.

Water tank is filling. At initial use, there is an approximate 45-second delay in

Ice maker or ice maker-equipped unit has just

recently been installed or a large amount of ice

has just been used.

Water filter is clogged or needs to be changed. Change water filter.

Ice maker has just recently been installe d or a

large am ount of ice ha s just been used.

Water pre s sure is too low. Low water press ure can caus e v alve to leak . W ater press ure

Water filter is clogged or needs to be changed. Change water filter.

Ice maker arm is not in correct position Confirm ice maker arm is down. See Automatic Ice Maker

Household water supply is not reaching

water valve

Water supply tubing has kinks. Turn off water supply and remove kinks. If kinks cannot be

Water pressure is too low. Water pressure must be between 20 to 100 pounds per square

Check freezer temperature. See the controls section in your Owner’s Manual for assistance

Ice bin is not installed properly See ice bin section for proper installation and alignment.

See the controls section in your Owner’s Manual for

assistance in how to adjust your controls.

Refrigerator is not level. See Installation Instructions for

details on how to level your unit

Check for internal obstructions that are keeping door

from closing properly (i.e. improperly closed drawers,

ice buckets, oversized or improperly stored containers

or foodstuffs, etc.).

Check gaskets for proper seal. Clean, if necessary,

according to cleaning instructions in Owner’s Manual.

This is normal when first using dispenser and will

disappear with use.

Initial water ejected through cartridge may contain

harmless carbon dust flushed from cartridge. Particles are

safe for consumption. Will disappear after the first few

uses.

Particles are not harmful and naturally occur in

water supplies.

Verify that freezer door is closed. Power is removed from

the control when freezer door is opened.

Replace any blown fuses. Check circuit breakers for any

tripped circuits.

control when freezer door is opened.

dispensing while the internal water tank is filling.

Wait 24 hours for ice production to begin and for ice make r to

restock after emptied.

Wait 24 hours for ice production to begin and for ice make r to

restock after emptied.

must be between 20 to 100 pounds per square inch to function

properly. A minimum pressure of 35 pound s per squa re inc h is

recommended for units with water filters.

section in your Owner’s Manual for details.

Check water connection procedure in your Installation

Instructions.

removed, replace tubing.

inch to function properly. A minimum pressure of 35 pounds

per square inch is recommended for units with water filters.

on how to adjust your c ontrols. Freezer must be between 0 to

2°F (-18 to –17°C) to produce ice.

23

Page 24

Before Calling Service

ICE & WATER

TOPIC POSSIBLE CAUSE SOLUTION

Ice maker is not producing

ice (some models-continued)

Unit is leaking water

Ice forms in inlet tube to

ice maker

Water fl ow is slow er

than normal

Dispenser water is not cold

Improper water valve was installed. Check water connection procedure in your Installation

Plastic tubing was used to complete

water connection.

Improper water valve was installed.

Water pressure is low.

Freezer temperature is too high.

Water pressure is low.

Improper water valve was installed.

Water inlet tubing has kinks.

Water filter is clogged or needs to

be changed.

Refrigerator has been recently installed

Water supply in holding tank has

been depleted.

Water has settle into water lines outside

holding tank and has warmed to

room temperature.

Instructions. Se lf-piercing and

low water pressur e and may clog the line over time. The

manufacturer is not responsible for prope rty damage

due to improper installation or water c onne c ti on.

The manufacturer recommends using copper tubing

for installation. Plastic is l ess durabl e and can cause

leakage. The manufacturer is not responsible for

property damage due to improper installation or

water connection.

Check water connection procedure in your Installation

Instructions. Self-piercing and

low water pressure and may clog the line over time. The

manufacturer is not responsible for property damage

due to improper installation or water connection.

Water pressure must be between 20 to 100 pounds per

square inch to function properly. A minimum pressure of

35 pounds per square inch is recommended for units with

water filters.

See the controls section in your Owner’s Manual for

assistance on how to adjust your controls. Freezer is

recommended to be between 0 to 2°F (-18 to –17°C).

Water pressure must be between 20 to 100 pounds per

square inch to function properly. A minimum pressure of

35 pounds per square inch is recommended for units with

water filters.

Check water connection procedure in your Installation

Instructions. Self-piercing and

low water pressure and may clog the line over time. The

manufacturer is not responsible for property damage

due to improper installation or water connection.

Turn off water supply and remove kinks. If kinks cannot be

removed, replace tubing.

Change water filter.

Allow approximately 12 hours for water in holding tank

to chill.

Discard first glass of water and refill.

3

/16” saddle valves cause

3

/16” saddle valves cause

3

/16” saddle valves cause

24

Page 25

Water Filter Data

System Specification and Performance Data Sheet

Refrigerator Water Filter Cartridge Model OWF51

Specifications

Service Flow Rate (Maximum) ............................................. 0.75 GPM (2.83 L/min)

Rated Service Life OWF50-NI300 (Maximum) ..................... 300 gallons/ 1135 liters

Rated Service Life OWF50-WI500 (Maximum) ..................... 500 gallons/ 1892 liters

Maximum Operating Temperature........................................ 100° F/38° C

Minimum Pressure Requirement .......................................... 35 psi/ 138 kPa

Minimum Operating Temperature......................................... 33° F/ 1° C

Maximum Operating Pressure .............................................. 120 psi/ 827 kPa

General Use Conditions: Read this Performance Data Sheet and compare the capabilities of this unit with your actual

water treatment needs.

DO NOT use this product where water is microbiologically unsafe or of unknown quality without adequate disinfection

before or after the system. System certified for cyst reduction may be used on disinfected water that may contain

filterable cysts.

The retractable water filtration system uses a OWF51 replacement cartridge (see your distributor to order). Timely

replacement of filter cartridge is essential for performance satisfaction from this filtration system. Please refer to the

applicable section in this Owner's Manual for general operation, maintenance requirements and troubleshooting.

This systems has been tested according to ANSI/NSF 42 and 53 for reduction of the substances listed

below. The concentration of the indicated substances in water entering the system was reduced to a

concentration less than or equal to the permissible limit for water leaving the system, as specified in

ANSI/NSF 42 and 53.

Average

Substance

Influent challenge

concentration

Effluent

Average

%

Reduction

Maximum

Effluent

Min. Required

Reduction

Inlet

pH

Lead 0 . 1 5 m g / L + / - 10 % 0.001 mg/L 99.33% 0.001 mg/L 0.010 mg/L 6.5

Lead 0 . 1 5 m g / L + / - 10 % 0.002 mg/L 98.66% 0.003 mg/L 0.010 mg/L 8.5

Cyst Minimum 50,000/L 1count/mL 99.99% 3 count/mL > 99.95% NA

Turbidity 1 1 + / - 1 NT U 0.12 NTU 98.98% 0.18 NTU 0.5 NTU NA

Lindane 0.002 mg/L +/- 10% 0.00005 mg/L 92.06% 0.00005 mg/L 0.00001 mg/L NA

97.62%

2

Atrazine 0 . 0 0 9 m g / L + /- 1 0 % 0.0002 mg/L 97.93% 0.0006 mg/L 0.003 mg/L NA

Chlorine 2 . 0 m g / L +/ - 1 0 % 0.09 mg/L 95.26% 0.17 mg/L

Particulate**

at least 10,000

particles/mL

900 count/mL 99.68% 2400 count/mL

≥75%

≥85%

NA

NA

2,4-D 0 . 2 1 0 m g / L + / - 1 0 % 45.45 ug/L 84.42% 100 ug/L 0.0017 mg/L NA

Asbestos

* Tested using a flow rate of 0.75 GPM (2.83 L/min.) and a maximum pressure of 120 psi (827 kPa)

107 to 108 fibers/L; fibers greater than

10 micometers in length

0.16 MFL/mL 99.96% 0.16 MFL/mL 99% NA

under standard laboratory conditions, however, actual performance may vary. Health Claim

Performance tested and certified by NSF International

** Particle size range classification of test. Particles used were 0.5 –1 microns.

Pentapure, Incorporated

1000 Apollo Road

Eagan, Minnesota U.S.A.

EPA EST #35917-MN-1

Tested and Certified by NSF International against ANSI/NSF Standards

42 & 53 in models OWF50-WI500 and OWF50-NI300 for the reduction of:

Standard No. 42: Aesthetic Effects

T aste & Odor Reduction

®

Chlorine Reduction

Mechanical Filtration Unit

Particlate Reduction Class 1

Standard No. 53: Health Effects

Chemical Reduction Unit

Lead, Atrazine, Lindane & 2,4-D Reduction

Mechanical Filtration Unit

Cyst, Turbidity, & Asbestos Reduction

25

Loading...

Loading...