Installation and Operational Instructions for

CAUTION

Danger of injury to personnel and

damage to machines.

Please Observe!

Guidelines on important points.

Safety Regulations

These Installation and Operational Instructions (I + O) are part of the clutch delivery.

Please keep them handy and near to the clutch at all times.

It is forbidden to start use of the product until you have ensured that all applicable EU directives and directives for the

machine or system into which the product has been installed have been fulfilled.

At the time these Installation and Operational Instructions go to print, the EAS®-smartic® clutches accord with the known

technical specifications and are operationally safe at the time of delivery.

Without a conformity evaluation, this product is not suitable for use in areas where there is a high danger of explosion.

This statement is based on the ATEX directive.

CAUTION

If the EAS®-smartic® clutches are modified.

If the relevant standards for safety and / or installation conditions are ignored.

User-implemented Protective Measures

Cover all moving parts to protect against seizure, dust or foreign body impact.

The clutch may not be put into operation without a limit switch unless mayr ® has been contacted and has agreed

otherwise.

To prevent injury or damage, only professionals and specialists should work on the devices, following the

relevant standards and directives. Please read the Installation and Operational Instructions carefully before

installation and initial operation of the device.

These Safety Regulations are user hints only and may not be complete!

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Please read these Operational Instructions carefully and follow them accordingly!

Ignoring these Instructions may lead to malfunctions or to clutch failure, resulting in damage to other parts.

Contents:

Page 1: - Contents

- Safety and Guideline Signs

- Safety Regulations

Page 2: - Illustrations Type 481._ _5._

- Illustrations Type 484._ _5._

Page 3: - Illustrations Type 486._ _5._

Page 4: - Parts List

Page 5: - Table 1: Technical Data

Page 6: - Table 2: Screws Overview

Page 7: - Design

- State of Delivery

- Function

- Installation of the Output Elements

Page 8: - Mounting onto the Shaft on Type 481

Page 9: - Mounting onto the Shaft on Type 484

Page 10: - Mounting onto the Shaft on Type 486

Page 11: - Permitted Shaft Misalignments

- Shaft Alignment

Page 12: - Torque Adjustment

- Cup Spring Layering

- Changing the Torque

- Table 3: Cup Spring Layering and

Torque Ranges

Page 13: - Changing the Torque Adjustment Range

by Changing the Cup Spring Layering

Page 14: - Limit Switch Installation

- Maintenance

- Disposal

Page 15: - General Malfunctions / Breakdowns

Page 16: - Malfunctions / Breakdowns Type 484.

Page 17: - Malfunctions / Breakdowns Type 484.

Page 18: - Malfunctions / Breakdowns Type 486.

Safety and Guideline Signs

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 1 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

15 14 13

17

16/16.1

23

24

Item 18 (contactless limit switch)

8 87 73 39 912 1210 105

22

21

20

1.2

19

6

1/1.1

2

11

11

44 4 Item 18

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

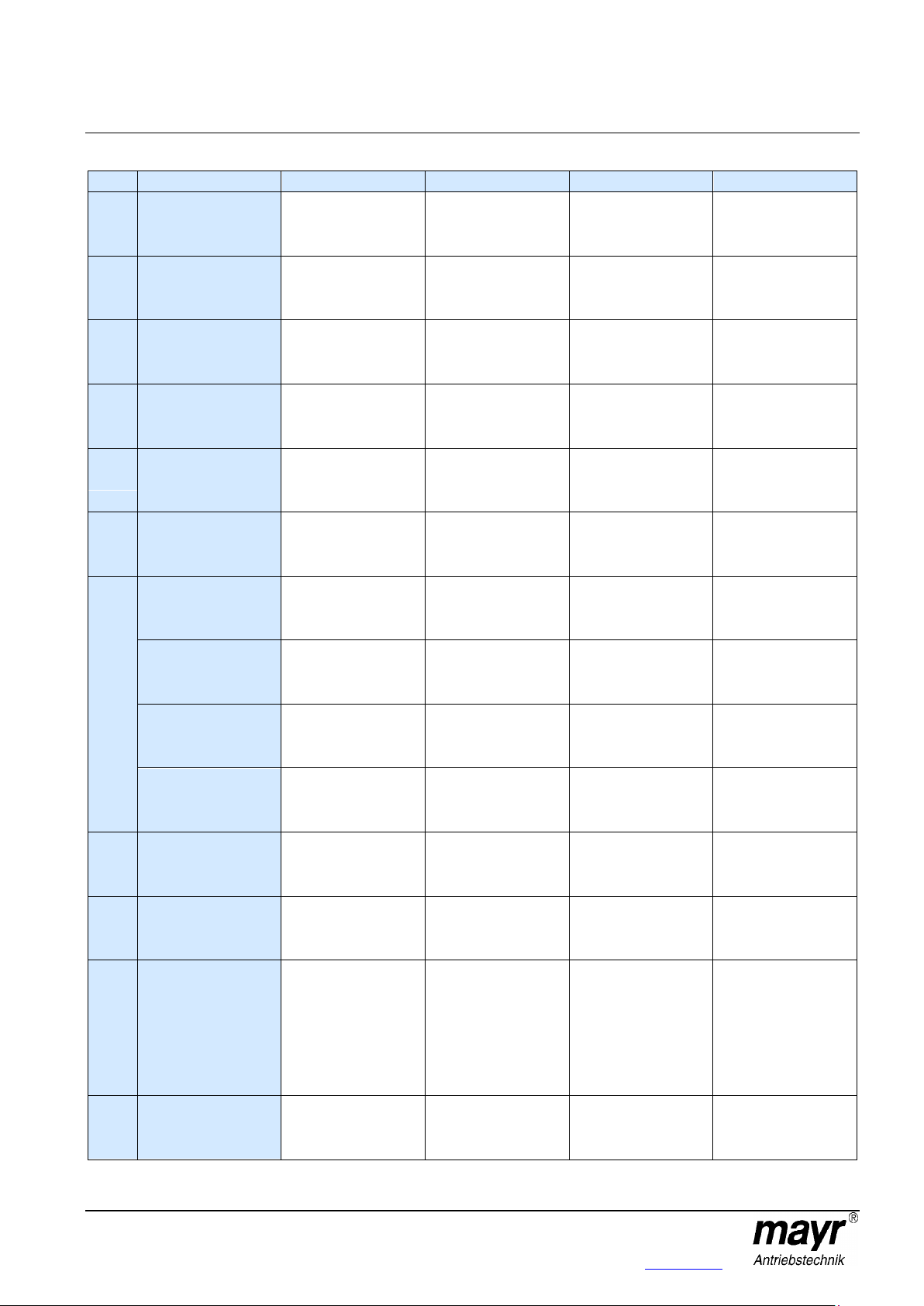

Type 481._ _ _._

Clamping ring hub with and without keyway Hub key design

Fig. 1

Type 484._ _ _._

Clamping hub Clamping ring hub

with and without with and without

keyway keyway

Hub Hub

key key

design design

Fig. 2

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 2 of 18 Germany E-Mail: info@mayr.de

28

27

27

27

37

31

30

30

30

29

31

26

263825

30 3827

38

25

32/32.1

35

33

33

34

36/36.1

29

29

40

29

39

Installation and Operational Instructions for

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

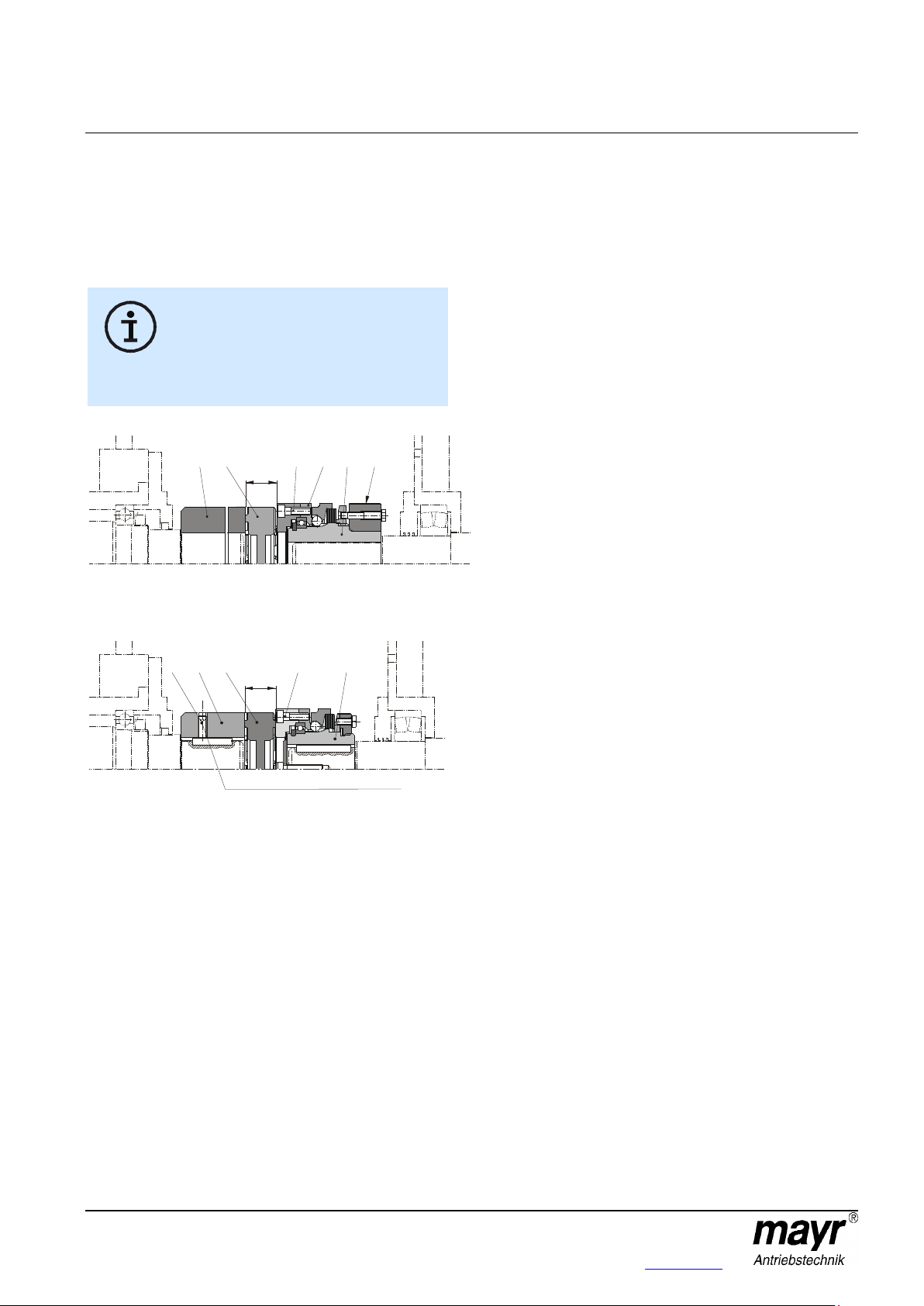

Type 486._ _ _._

Clamping hub

with and without

keyway Single-jointed

Size 2 design

Hub

key

design

Size 2

Clamping ring hub

with and without

keyway

Hub large Double-jointed

keyway design

design

Size 2

Flange

Size 2

Single-jointed

design

Hub

key design

Clamping hub

with and without

keyway

Sizes 01 to 1

Double-jointed

design

Fig. 3

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 3 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Item

Name

Item

Name

1

Clamping ring hub

20

Adjusting nut (for key design)

1.1

Clamping ring hub with keyway

21

Locking ring (for key design)

1.2

Clamping ring

22

Hexagon head screw (for key design)

1.3

Spring pin (Fig. 15 / page 13)

23

Hub Type 484. (key design)

2

Cap screw

24

Set screw

3

Pressure flange

25

Connection flange Type 486.

4

Thrust washer

26

Cap screw

5

Adjusting nut (for clamping ring hub design)

27

Screw

6

Hexagon head screw (for clamping ring hub design)

28

Hexagon head screw

7

Deep groove ball bearing

29

Hexagon nut

8

Locking ring

30

Disk pack assembly

9

Steel ball

31

Connection plate

10

Cup spring (layering dependent on Type)

32

Clamping hub Type 486. (Size 2)

11

Adjustment Table

32.1

Clamping hub Type 486. with keyway (Size 2)

12

Type tag

33

Cap screw

13

Connection flange Type 484.

34

Hub Type 486. (key design / Size 2)

14

Cap screw

35

Set screw

15

Flexible elastomeric element

36

Clamping hub Type 486. (Sizes 01 to 1)

16

Clamping hub Type 484.

36.1

Clamping hub Type 486. with keyway (Sizes 01 to 1)

16.1

Clamping hub Type 484. with keyway

37

Cap screw

17

Cap screw

38

Screw

18

Limit switch

39

Hub, large (key design)

19

Hub (key design)

40

Flange

The limit switch Item 18 is not included in the

standard delivery.

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Parts List (Only use mayr

original parts)

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 4 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Size

01 0 1

2

Thread in the pressure flange (Item 3)

8 x M4

8 x M4

8 x M5

8 x M6

Max. screw-in depth b

max

in the pressure flange (Item 3) [mm]

6

6,5 7 9,5

Connection dimension "a" +0,1 [mm]

2,5

2,5

2,5

3

Connection dimension "e" [mm]

42 h5

52 h5

65 h5

78 h5

Tightening torque (Item 2) [Nm]

40

40

83

140

Tightening torque (Item 14) 1) [Nm]

4

4,5 9 16

Tightening torque (Item 17) [Nm]

Types 484.2_5._ to 484.7_5._

10 25 25 120

Type 484.8_5._

17

40

40

140

Tightening torque (Item 26) 1) [Nm]

4

4,5 9 16

Tightening torque (Items 27 / 28 / 38) [Nm]

8,5

8,5

8,5

8,5

Tightening torque (Item 33) [Nm]

13

33

33

42

Tightening torque (35) up to bore Ø 22 [Nm]

more than bore Ø 22 [Nm]

2

4,1

Tightening torque (37) [Nm]

8,5

8,5

8,5

-

Axial forces [N]

400

500

800

1200

Radial forces [N]

400

500

800

1200

Transverse force torques 2) [Nm]

3 5 10

15

Distance dimension "E" (see Figs. 5 and 6) [mm]

18

20

24

28

Distance dimension "U1" (see Figs. 7 and 8) [mm]

14,7

15,5

15,8

26,4

Distance dimension "S" (see Fig. 9) [mm]

2,6 3 2,9

7,2

Permitted shaft misalignments Type 484._ _ 5._

Radial misalignment ΔK

r

92 Sh A [mm]

98 Sh A [mm]

0,14

0,10

0,15

0,11

0,17

0,12

0,21

0,16

Axial displacement ΔKa [mm]

1,4

1,5

1,8

2,1

Angular misalignment ΔKw 92 Sh A [°]

98 Sh A [°]

1,0

0,9

1,0

0,9

1,0

0,9

1,0

0,9

Permitted shaft misalignments Type 486._ _ 5.0 (Double-jointed coupling)

Radial misalignment ΔKr [mm]

0,15

0,2

0,2

0,3

Axial displacement ΔKa [mm]

0,7

0,9

1,1

1,3

Angular misalignment ΔKw [°]

2,0

2,0

2,0

2,0

Permitted shaft misalignments Type 486._ _ 5.8 (Single-jointed coupling)

Radial misalignment ΔK

r

[mm]

- - -

-

Axial displacement ΔKa [mm]

0,35

0,45

0,55

0,65

Angular misalignment ΔKw [°]

1,0

1,0

1,0

1,0

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Table 1: Technical Data

1)

Secure Items 14 and 26 wit Loctite 243.

2)

Torques, which put strain on the deep groove ball bearing due to the non-centric axial forces having an effect on the pressure flange.

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 5 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Item

Design

Size 01

Size 0

Size 1

Size 2

2

with hub

Items 1 / 1.1

1x cap screw

M8 x 25

DIN EN ISO 4762

12.9

1x cap screw

M8 x 25

DIN EN ISO 4762

12.9

1x cap screw

M10 x 30

DIN EN ISO 4762

12.9

1x cap screw

M12 x 35

DIN EN ISO 4762

12.9

6

with hub

Items 1 / 1.1

1x hexagon head screw

M4 x 24,2 SO

(DIN EN ISO 4014)

8.8

1x hexagon head screw

M4 x 24,2 SO

(DIN EN ISO 4014)

8.8

1x hexagon head screw

M5 x 28 SO

(DIN EN ISO 4014)

8.8

1x hexagon head screw

M6 x 31,5 SO

(DIN EN ISO 4014)

8.8

14

Type

484._ _5._

8x cap screw

M4 x 16

DIN EN ISO 4762

12.9

8x cap screw

M4 x 16

DIN EN ISO 4762

12.9

8x cap screw

M5 x 18

DIN EN ISO 4762

12.9

8x cap screw

M6 x 22

DIN EN ISO 4762

12.9

17

with hub

Items 16 / 16.1

1x cap screw

M6 x 20

DIN EN ISO 4762

8.8

1x cap screw

M8 x 25

DIN EN ISO 4762

8.8

1x cap screw

M8 x 30

DIN EN ISO 4762

8.8

1x cap screw

M12 x 35

DIN EN ISO 4762

12.9

22

with hub

Item 19

1x hexagon head screw

M3 x 8

DIN EN ISO 4017

8.8

1x hexagon head screw

M4 x 10

DIN EN ISO 4017

8.8

1x hexagon head screw

M5 x 10

DIN EN ISO 4017

8.8

1x hexagon head screw

M5 x 12

DIN EN ISO 4017

8.8

26

Type

486._ _5._

4x cap screw

M4 x 16

DIN EN ISO 4762

12.9

8x cap screw

M4 x 16

DIN EN ISO 4762

12.9

6x cap screw

M5 x 20

DIN EN ISO 4762

12.9

6x cap screw

M6 x 20

DIN EN ISO 4762

12.9

27

with hub

Items 32 / 32.1 / 34 /

36 / 36.1 on

double-jointed design

2x cap screw

M5 x 16

DIN EN ISO 4762

10.9

2x cap screw

M5 x 18

DIN EN ISO 4762

12.9

3x cap screw

M5 x 20

DIN EN ISO 4762

12.9

3x cap screw

M5 x 20

DIN EN ISO 4017

10.9

with hub

Items 32 / 32.1 / 34 /

36 / 36.1 on

single-jointed design

2x cap screw

M5 x 16

DIN EN ISO 4762

10.9

2x cap screw

M5 x 18

DIN EN ISO 4762

12.9

3x hexagon head screw

M5 x 16

DIN EN ISO 4017

10.9

3x cap screw

M5 x 20

DIN EN ISO 4017

10.9

with hub

Item 39

- - -

- - -

- - -

3x hexagon head screw

M5 x 50

DIN EN ISO 4014

10.9

with flange

Item 40

- - -

- - -

- - -

3x hexagon head screw

M5 x 23

DIN EN ISO 4017

10.9

28

Type

486._ _5.0

- - -

- - -

- - -

3x hexagon head screw

M5 x 35

DIN EN ISO 4014

10.9

33

with hub

Items 32 / 32.1 /

36 / 36.1

1x cap screw

M6 x 20

DIN EN ISO 4762

12.9

1x cap screw

M8 x 25

DIN EN ISO 4762

12.9

1x cap screw

M8 x 30

DIN EN ISO 4762

12.9

2x cap screw

M8 x 25

DIN EN ISO 4762

12.9

37

Type

486._ _5.0

4x cap screw

M5 x 16

DIN EN ISO 4762

10.9

4x cap screw

M5 x 16

DIN EN ISO 4762

12.9

3x hexagon head screw

M5 x 16

DIN EN ISO 4017

10.9

+

3x cap screw

M5 x 16

DIN EN ISO 4762

12.9

- - -

38

Type

486._ _5._

2x cap screw

M5 x 16

DIN EN ISO 4762

10.9

2x cap screw

M5 x 18

DIN EN ISO 4762

12.9

3x cap screw

M5 x 16

DIN EN ISO 4762

12.9

3x hexagon head screw

M5 x 23

DIN EN ISO 4017

10.9

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Table 2: Screws Overview (dependent on Type or hub connection)

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 6 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

The radial forces, axial forces or transverse

force torques, which are introduced into the

clutch bearing must not exceed the permitted

values acc. Table 1.

Please observe the connection dimensions "a"

and "e" for the output elements as well as the

maximum permitted screw-in depth "b

max.

" in

the pressure flange (3); see Fig. 4 and Table 1

on page 5.

73

a

Ø e

b

max.

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Design

The EAS®-smartic® clutch is designed as a mechanical

disengaging overload clutch according to the ball detent

principle.

State of Delivery

The EAS®-smartic® clutch is manufacturer-assembled ready for

installation.

If no particular torque adjustment is requested customer-side,

the EAS®-smartic® clutch will always be pre-set to approximately

80 % of the maximum torque.

The reference marking on the adjusting nut (5) or on the locking

ring (21) and the torque specification on the Adjustment Table

(11) directly show the set value.

The hexagon head screw (6/22) is not secured with Loctite on a

pre-set clutch.

Before initial operation of the clutch, please secure the locking

screw (6/22) with Loctite 243.

Please check the state of delivery immediately according to the

Parts List!

mayr ® will take no responsibility for belated complaints.

Please report transport damage immediately to the deliverer.

Please report incomplete delivery and obvious defects to the

manufacturer.

Function

Function in Normal Operation

The EAS®-smartic® clutch Type 481. transmits the torque from

the input shaft onto the output element, which can be mounted

onto the ball bearing supported pressure flange (3) of the clutch.

The torque is transmitted backlash-free over the entire service

lifetime of the clutch.

The EAS®-smartic® Types 484. and 486. connect two shafts and

compensate for shaft misalignments.

Function on Overload

If the set limit torque is exceeded, the clutch disengages. The

torque drops immediately.

The residual torque is approx. 5 - 20 % of the set torque (at

approx. 1500 rpm).

Therefore, the EAS®-smartic® clutch is not load-holding.

An installed limit switch (Item 18 / not included in delivery)

registers the disengagement movement and switches off the

drive.

Once the cause of malfunction has been removed, the clutch is

automatically ready for operation after having reached the

synchronous position:

Re-engagement after 360°.

Installation of the Output Elements (Fig. 4)

The output elements are centred on the deep groove ball

bearing (7) (tolerance H7/h5) and screwed together with the

pressure flange (3).

Please use screws with a strength class of 12.9 with the

corresponding tightening torques acc. Table 1 (tightening

torque Item 14) for screwing onto the pressure flange (3).

The output element must be made of a material with a

minimum tensile strength of approx. 600 N/mm2.

Please contact the manufacturers if this is not the case.

If the resulting radial force from the output element is anywhere

near the centre of the ball bearing, an additional bearing for the

output element is not necessary.

No appreciable axial forces should be transmitted from the

output element onto the clutch pressure flange (3).

Output elements with a very small diameter can be screwed

together with the clutch pressure flange (3) via a customer-side

intermediate flange.

Ball bearings, needle bearings or bearing bushings are suitable

as bearings for the output element, depending on the

installation situation and the installation space.

Please make sure that the output element bearing is designed

as a location bearing (Fig. 4).

Fig. 4

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 7 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Mounting onto the Shaft

General Shaft Requirements:

Tolerance: up to Ø38 h6.

from Ø38 h6 on clamping ring hubs

from Ø38 k6 on clamping hubs

Surface: finely turned or ground

(Ra = 0,8 µm)

Material: yield point

min. 350 N/mm2 ,

e.g. St60, St70, C45, C60.

1. EAS®-smartic® flange design without shaft coupling

1.1 Clamping ring hub design Type 481._35.0:

The shafts must be solid shafts without a keyway.

Degrease or remove preservation layers on the shafts and

bores before installing the clutch.

Greasy or oily bores or shafts do not transmit the

torque TR specified on order.

Mount the clutch onto the shaft end and bring it into the

correct position.

Tighten the clamping screw (2) using a torque wrench to

the torque stated in Table 1.

1.2 Key design Type 481._25.0:

Mount the clutch onto the shaft end and bring it into the

correct position.

On the EAS®-smartic® with keyway, the clutch must be

secured axially after mounting onto the shaft, e.g. using a

press cover and a screw screwed into the shaft threaded

centre hole.

1.3 Clamping ring hub design with keyway Type 481._45.0:

Degrease or remove preservation layers on the shafts and

bores before installing the clutch.

Greasy or oily bores or shafts do not transmit the

torque TR specified on order.

Mount the clutch onto the shaft end and bring it into the

correct position.

Tighten the clamping screw (2) using a torque wrench to

the torque stated in Table 1.

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 8 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Only use PU - compatible lubricants (e.g.

Vaseline)!

After joining both coupling hubs, do not

place axial pressure on the elastomeric

element (15).

Please observe the distance dimension "E"

acc. Figs. 5/6 and Table 1!

E

1 2316 15 14

E

1923 1524 14

Locking set screw depicted 180° offset

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

2. EAS®-smartic® dual-shaft connection with elastomer coupling ROBA®-ES

General:

The elastomer coupling used is backlash-free and requires a

certain axial installation force for joining. The amount of force

required can be reduced by lightly greasing the elastomeric

element (15).

Fig. 5

Clamping (ring) hub design Type 484._ 35._

Fig. 6

Key design Type 484._25._

2.1 Clamping (ring) hub design Type 484._35._:

Install the overload clutch side as described in section 1.1.

Degrease or remove preservation layers on the shafts and

bores before installing the elastomer coupling.

The clamping hub (16) must be completely relaxed before

installation; if necessary loosen the screw (17) by several

thread turns.

Mount the elastomer coupling hub (16) onto the shaft end

and bring it into the correct position.

Tighten the clamping screw (17) using a torque wrench to

the torque stated in Table 1.

Joining the two clutch hubs:

Due to the pre-tensioning of the flexible elastomeric

element (15), an axial installation force is required for

joining both clutch hubs (1 and 16). The amount of force

required can be reduced by lightly greasing the elastomeric

element (15).

2.2 Key design Type 484._25._:

Install the overload clutch side as described in section 1.2.

Mount the elastomer coupling hub onto the shaft end and

bring it into the correct position.

The elastomer coupling hub (23) must be secured axially

onto the shaft, e.g. using a set screw (Item 24, see Fig. 6).

Joining both clutch hubs:

Due to the pre-tensioning of the flexible elastomeric

element (15), an axial installation force is required for

joining both clutch hubs (19 and 23). The amount of force

required can be reduced by lightly greasing the elastomeric

element (15).

2.3 Clamping (ring) hub design with keyway Type 484._45._:

Install the overload clutch side as described in section 1.3.

Degrease or remove preservation layers on the shafts and

bores before installing the elastomer coupling.

The clamping hub (16.1) must be completely relaxed

before installation; if necessary loosen the screw (17) by

several thread turns.

Mount the elastomer coupling hub (16.1) onto the shaft

end and bring it into the correct position.

Tighten the clamping screw (17) using a torque wrench to

the torque stated in Table 1.

Joining both clutch hubs:

Due to the pre-tensioning of the flexible elastomeric

element (15), an axial installation force is required for

joining both clutch hubs (1 and 16.1). The amount of force

required can be reduced by lightly greasing the elastomeric

element (15).

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 9 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

After joining both coupling halves, please test

and keep to distance dimensions "U1" or "S"

acc. Figs. 7 / 8 / 9 and Table 1!

U

1

1 2332/36 31 26

1934 3135 26

U

1

Locking set screw depicted 180° offset

S

1 2332/36 26

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

3. EAS®-smartic® dual-shaft connection with torsionally rigid shaft coupling ROBA®-DS

General:

On clamping hubs (36/36.1), the clamping screw (33) is lightly

greased manufacturer-side in the thread area.

If the grease layer is washed off, the customer must re-grease

the appropriate parts. For greasing, please use NLGI Class 2

grease with a basic oil viscosity of 220 mm2/s at 40 °C,

e.g. Mobilgrease XHP222.

Fig. 7

Clamping (ring) hub design Type 486._35.0

Fig. 8

Key design Type 486._25.0 (Size 2)

Fig. 9

Type 486._ _5.8 (Single-jointed design)

3.1 EAS®-smartic® Clamping (ring) hub design Type 486._35.0:

On clamping (ring) hubs, the torque is transmitted via

frictional locking, which means that the hub bores and

shafts must be completely grease-free during installation.

Greasy or oily bores or shafts do not transmit the

maximum clutch torque.

The shafts must not have a keyway.

The clamping hubs (32/36) must be completely relaxed

before installation; if necessary the screws (33) must be

loosened by several thread turns.

Mount the first clutch hub of the entire clutch onto the

respective shaft and bring it into the correct position.

Tighten the clamping screw(s) of the first clutch hub using

a torque wrench to the torque stated in Table 1.

Mount the second clutch hub of the entire clutch onto the

respective shaft and bring it into the correct position.

Tighten the clamping screw(s) of the second clutch hub

using a torque wrench to the torque stated in Table 1.

3.2 EAS®-smartic® key design Type 486._25.0:

Mount the ROBA®-DS-side clutch hub (34/36.1) of the

entire clutch onto the respective shaft and bring it into the

correct position.

Tighten the clamping screw (33) or the radial set screw

(35) of this first clutch hub using a torque wrench to the

torque stated in Table 1.

Mount the second EAS®-side clutch hub of the entire clutch

onto the respective shaft.

3.3 EAS®-smartic® Clamping (ring) hub design with keyway Type 486._45.0:

The clamping hubs (32.1/36.1) must be completely relaxed

before installation; if necessary the screws (33) must be

loosened by several thread turns.

Degrease or remove preservation layers on the shafts and

bores before installing the clutch.

Mount the first clutch hub of the entire clutch onto the

respective shaft and bring it into the correct position.

Tighten the clamping screw(s) of the first clutch hub using

a torque wrench to the torque stated in Table 1.

Mount the second clutch hub of the entire clutch onto the

respective shaft and bring it into the correct position.

Tighten the clamping screw(s) of the second clutch hub

using a torque wrench to the torque stated in Table 1.

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 10 of 18 Germany E-Mail: info@mayr.de

20

3

0

%

2

5

%

7

5

%

0

%

5

0

%

20

40%

40

30%

60608080100

100

Δ K

w

Angular misalignment

[%]

Δ K [%] Axial displacement

a

Δ K [%] Radial misalignment

r

ΔK

r

ΔK

a

ΔK

w

ΔK

a

Δ

K

w

ΔK

r

ΔKa

Δ

K

w

Installation and Operational Instructions for

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Permitted Shaft Misalignments

EAS®-smartic® clutch Types 484._ _ 5._ and 486._ _ 5.0

(double-jointed coupling) compensate for angular, axial and

radial shaft misalignments (Figs. 10 and 11) without losing their

backlash-free function.

EAS®-smartic® clutches Type 486._ _ 5.8 (single-jointed

coupling) only compensate for angular and axial shaft

misalignments.

However, the permitted shaft misalignments indicated in

Table 1 must not simultaneously reach their maximum value.

If more than one kind of misalignment takes place

simultaneously, they influence each other.

This means that the permitted misalignment values are

dependent on one another, see Fig. 13.

The sum total of the actual misalignments in percent of the

maximum value must not exceed 100 %.

The misalignment values stated in Table 1 refer to clutch

operation at nominal torque, an ambient temperature of +30 °C

and an operating speed of 1500 rpm.

In other or more extreme clutch operating conditions,

please contact the manufacturers.

Radial Axial Angular

misalignment displacement misalignment

Fig. 10

Type 484._ _ 5._

Axial Radial Angular

displacement misalignment misalignment

Fig. 11

Type 486._ _ 5.0 (double-jointed coupling)

Axial Angular

displacement misalignment

Fig. 12

Type 486._ _ 5.8 (single-jointed coupling)

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 11 of 18 Germany E-Mail: info@mayr.de

Fig. 13

Example (Size 0 / Type 486._ _ 5.0):

Axial displacement occurrence ΔKa = 0,36 mm equals 40 % of

the permitted maximum value ΔKa = 0,9 mm.

Angular misalignment occurrence ΔKw = 0,6°, equals 30 % of the

permitted maximum value ΔKw = 2,0°.

=> Permitted radial misalignment Kr = 30 % of the maximum

valueΔKr = 0,2 mm => ΔKr = 0,06 mm

Shaft Alignment

Exact alignment of the shafts reduces the load on the shaft

bearings and increases the clutch lifetime substantially. In very

high-speed drives, we recommend alignment using a suitable

alignment device (e.g. a laser). However, in most of the

applications, shaft alignment using a straight edge in two levels

vertical to each other is sufficient.

Installation and Operational Instructions for

Adjusting the adjusting nut (5/20) or distorting

the cup springs (10) outside of the cup spring

characteristic curve (see Fig. 14) stops the

clutch functioning.

Size 01

Size 0

Size 1

Size 2

Type

Cup spring

layering 3)

[Nm]

Graduation

lines for

M = 80 %

[Nm]

Graduation

lines for

M = 80 %

[Nm]

Graduation

lines for

M = 80 %

[Nm]

Graduation

lines for

M = 80 %

48_.2_5._

1x1 times

1 \ /////// 7

2,7 – 5

19

5 – 10

21

10 – 20

16

20 – 40

25

48_.3_5._

1x2 times

2 \\ ////// 6

5 – 10

19

10 – 20

22

20 – 40

17

40 – 80

26

48_.4_5._

1x3 times

3 \\\ ///// 5

8 – 15

20

15 – 30

23

30 – 60

19

60 – 120

28

48_.5_5._

1x4 times

4 \\\\ //// 4

11 – 20

20

20 – 40

23

40 – 80

19

80 – 160

28

48_.6_5._

1x6 times

6 \\\\\\ // 2

18 – 33

20

35 – 65

24

70 – 125

20

140 – 250

30

48_.7_5._

1x8 times

8 \\\\\\\\ 0

32 – 40

21

60 – 80

27

120 – 160

25

240 – 320

32

48_.8_5._

4)

1x8 times

8 \\\\\\\\ 0

35 – 60

24

70 – 120

31

150 – 240

25

300 – 500

35

Path to

operating range

Force F

Graph of

spring characteristic

curve

Operating

range

Spring path S

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Torque Adjustment

In order to guarantee low-wear clutch operation, it is essential to

adjust the torque to a sufficiently high service factor (overload

torque to operating torque). Our experience has shown that an

adjustment factor of 1,3 to 3 gives good results.

For very high load changes, high accelerations and uneven

operation, please set the adjustment factor higher.

The respective torque adjustment range is printed on the

Adjustment Table (11). Torque adjustment is carried out by

turning the adjusting nut (5/20). The installed cup springs (10)

are operated in the negative range of the characteristic curve

(see Fig. 14). This means that tightening the adjusting nut

(5/20) causes the spring force to decrease, and loosening the

adjusting nut (5/20) causes the spring force to increase.

If no torque is specified on order, the clutch is pre-set to

approx. 80 % of the maximum torque. The reference marking

and the torque specification show the set value directly.

If no changes to the pre-set clutch torque are required

customer-side, the hexagon head screws (6/22) must

nevertheless be screwed out, painted with Loctite 243 and

screwed back in again by the customer.

Fig. 14

Table 3: Cup Spring Layering and Torque Ranges

Cup Spring Layering

Correct cup spring layering is a prerequisite for problem-free

clutch function and torque adjustment.

On all Sizes, 7 torque ranges (see Table 3) are possible.

Changing the Torque

On clamping ring hub designs Type 48_._35._ and Type 48_._45._

In order to adjust the torque to a different value, simply

1. loosen and unscrew the hexagon head screw (6),

2. adjust the adjusting nut (5) using a hook wrench until the

reference marking shows the required torque value,

3. if necessary, correct the adjusting nut (5) position slightly

until the marking notches between the clamping ring hub

(1/1.1) and the adjusting nut (5) align, and

4. paint the hexagon head screw (6) with Loctite 243 before

screwing it back in again.

On key design Type 48_._25._

In order to adjust the torque to a different value, simply

1. loosen and unscrew the hexagon head screw (22),

2. adjust the adjusting nut (20) using a hook wrench until the

reference marking shows the required torque value,

3. if necessary, correct the adjusting nut (20) position slightly

until the marking notches between the locking ring (21) and

the adjusting nut (20) align, and

4. paint the hexagon head screw (22) with Loctite 243 before

screwing it back in again.

3)

Example: On Type 481.425.0, the cup spring layering is 1x3 times, which means that three cup springs are engaged thrust washer-side

and five cup springs are not engaged (adjusting nut-side) => 3 \\\ ///// 5.

4)

Types 48_.8_5._ require a special pressure flange as well as a special thrust washer.

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 12 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

1/1.1 1.2 1.3

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Changing the Torque Adjustment Range by Changing the Cup Spring Layering

If a customer realises that the selected clutch adjustment range

is too high or too low, the cup spring layering (10) on the

respective clutch must be changed (every clutch delivered

contains a maximum of 8 cup springs).

The adjustment scale on the clamping ring (1.2) or the adjusting

nut (20) is no longer applicable after alteration!

Principally, we recommend that modification and re-calibration of

the clutch be carried out at the company mayr ® headquarters,

where we can provide a higher torque adjustment accuracy than

any customer-side alterations.

Changing the cup spring layering (10) between Type

48_.2_5._ and Type 48_.7_5._ is generally possible.

If the required torque lies over the torque range of Type

48_.7_5._, modification to Type 48_.8_5._ is necessary (for

modification, a special pressure flange as well as a special

thrust washer are necessary) or the next larger construction

size must be selected. Types 48_.8_5._ have a max. speed of

250 rpm.

If the required torque lies below the torque range of Type

48_.2_5._, the next smaller construction size must be selected.

Before changing the cup spring layering (10), the clutch must be

removed from the system and placed on a suitable auxiliary

shaft, for example in a vice; it must be re-installed with the

adjusting nut side facing upwards.

When doing this, the clamping ring (1.2) on the clamping ring

design must be re-clamped.

Changing the cup spring layering and torque adjustment on clamping ring design Type 48_._35._ and Type 48_._45._:

1. Turn back the locking screw (6) and remove it from the

clamping ring (1.2).

Please Observe! The locking screw (6) is glued into the

clamping ring (1.2).

2. Turn the adjusting nut (5) back anti-clockwise until the cup

spring package (10) is completely relaxed.

3. Loosen the clamping screw (2) of the clamping ring (1.2)

and remove the clamping ring (1.2) from the hub (1).

4. Screw the adjusting nut (5) completely off the hub (1).

5. Change the cup spring layering (10) acc. Table 3.

6. Screw the adjusting nut (5) clockwise onto the hub (1) up to

contact on the cup springs (10).

7. Push the clamping ring (1.2) into the correct position (for

position of the spring pin (1.3) in the clamping ring (1.2),

please see Fig. 15) up to contact on the hub shoulder (1),

and tighten the clamping screw (2) to the specified torque

(acc. Table 1).

8. Turn the adjusting nut (5) clockwise by the number of

graduation lines acc. Table 3. This achieves a torque of

approx. 80 % of the maximum value on the respective cup

spring layering (10). By turning the adjusting nut (5)

clockwise, the clutch torque can be reduced even further. By

turning the adjusting nut anti-clockwise, the clutch torque

can be increased.

The permitted operating range acc. Fig. 14 must be

observed.

9. One of the marking notches on the adjusting nut (5) must be

aligned with a notch on the clamping ring (1.2). The locking

screw (6) must be painted with Loctite 243 and screwed up

to its limit into the clamping ring (1.2).

10. Remove the clutch from the auxiliary shaft and re-install it

into the system.

Fig. 15

Changing the cup spring layering and torque adjustment on key design Type 48_._25._:

1. Turn back the locking screw (22) and remove it from the

adjusting nut (20).

Please Observe! The locking screw (22) is glued into the

adjusting nut (20).

2. Turn the adjusting nut (20) back anti-clockwise completely

and remove it from the clutch.

3. Remove the locking ring (21) from the hub (19).

4. Change the cup spring layering (10) acc. Table 3.

5. Place the locking ring (21) again up to the cup springs (10)

onto the hub (19).

6. Screw the adjusting nut (20) up to contact on the locking

ring (21) or up to contact of the locking ring (21) on the cup

springs (10) onto the hub (19).

7. Turn the adjusting nut (20) clockwise by the number of

graduation lines acc. Table 3. This achieves a torque of

approx. 80 % of the maximum value on the respective cup

spring layering (10). By turning the adjusting nut (20)

clockwise, the clutch torque can be reduced even further.

By turning the adjusting nut anti-clockwise, the clutch torque

can be increased.

The permitted operating range acc. Fig. 14 must be

observed.

8. One of the marking notches on the adjusting nut (20) must

be aligned with a notch on the locking ring (21). The locking

screw (22) must be painted with Loctite 243 and screwed up

to its limit into the adjusting nut (20).

9. Remove the clutch from the auxiliary shaft and re-install it

into the system.

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 13 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

SW7 SW7

1,0

1,0

1,0

0,7

Schaltrichtung

SW7

1,2

0,2

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Limit Switch Installation (Figs. 16 and 17)

The switching direction arrow on the mechanical limit switch

housing cover points in the direction of the adjusting nut (5/20) or

in the stroke direction of the thrust washer (4).

Adjust the switch distances for the contactless and mechanical

limit switch acc. Fig. 16 and Fig. 17.

The distance of the thrust washer (4) to the switching point can

be easily adjusted using a hexagon head screw, wrench

opening 7.

Contactless limit switch

Undamped installation Damped installation

Limit switch is damped Limit switch is not damped

when clutch when clutch

disengages. disengages.

Fig. 16

Mechanical limit switch (only available on Size 2)

Maintenance

The EAS®-smartic® clutch is mainly maintenance-free.

The only maintenance work needed is a regular inspection of

functionality and torque adjustment => yearly.

Special maintenance work may be necessary should the device

be subject to very dirty, dusty or extreme ambient and load

conditions. These include:

Bearing inspection

Tightening torque inspection

Lubrication of the transmission geometries, balls,

recesses and sealing elements

Under these conditions, it may be necessary to carry out

inspections at much shorter intervals.

We recommend that maintenance work is carried out at the

site of manufacture.

Disposal

Electronic Components (Limit switch):

Products which have not been disassembled can be disposed of

under Code No. 160214 (mixed materials) or components under

Code No. 160216, or can be disposed of by a certified disposal

firm.

All steel components:

Steel scrap (Code No. 160117)

Aluminium components:

Non-ferrous metals (Code No. 160118)

Seals, O-rings, V-seals, elastomers:

Plastic (Code No. 160119)

Fig. 17

On EAS®-smartic® clutches Size 01, we generally recommend

the use of smaller, contactless limit switches, e.g. M8 x 1 or

similar devices.

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 14 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Malfunction

Possible Causes

Solutions

Premature clutch release

Incorrect torque adjustment

1) Set the system out of operation

2) Check the torque adjustment

3) Secure the adjusting nut

4) If the cause of malfunction cannot be found, the clutch

must be inspected at the place of manufacture

Adjusting nut position has changed

Clutch does not release

on overload

Incorrect torque adjustment

1) Set the system out of operation

2) Check whether foreign bodies influence the clutch

function

3) Check the torque adjustment

4) Secure the adjusting nut

5) If the cause of malfunction cannot be found, the clutch

must be inspected at the place of manufacture

Adjusting nut position has changed

Running noises in normal

operation

Insufficient clutch securement

1) Set the system out of operation

2) Check the clutch securement

3) Check the screw tightening torques

4) Check the torque adjustment and that the adjusting nut

sits securely

5) If the cause of malfunction cannot be found, the clutch

must be inspected at the place of manufacture

Loosened screws

Loosened adjusting nut

mayr ® will take no responsibility or guarantee for replacement parts and accessories which have not been delivered by

mayr ®, or for damage resulting from the use of these products.

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

General Malfunctions / Breakdowns

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 15 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Malfunction

Possible Causes

Solutions

Changes in running noise

and / or vibration

occurrence

Type 484.

Incorrect alignment

1) Set the system out of operation

2) Find / resolve the cause of incorrect alignment

(e.g. loose foundation screw, broken motor attachment,

warmth expansion of system components, changes in

coupling installation dimension "E")

3) Check the coupling for wear

Worn elastomeric element, short-term

torque transmission via metal contact

1) Set the system out of operation

2) Dismantle the coupling and remove the remainders of the

elastomeric element

3) Check the coupling parts and replace if damaged

4) Insert new elastomeric element, mount the coupling parts

5) Check the alignment and correct if necessary

Tensioning and clamping screws or locking

set screw for axial hub securement are

loose

1) Set the system out of operation

2) Check the coupling alignment

3) Tighten the tensioning and clamping screws for axial hub

securement as well as connection screws to the required

torque or tighten the locking set screw and secure it

against self-loosening using sealing lacquer

4) Check the coupling for wear

Loose connection screws

Cam breakage

Type 484.

Worn elastomeric element, torque

transmission via metal contact

1) Set the system out of operation

2) Replace the entire coupling

3) Check the alignment

Cam breakage due to high impact energy /

overloading

1) Set the system out of operation

2) Replace the entire coupling

3) Check the alignment

4) Find the cause of overload

Operating parameters are not appropriate

for the coupling performance

1) Set the system out of operation

2) Check the operating parameters and select a suitable

coupling (observe installation space)

3) Install a new coupling

4) Check the alignment

Operating errors on the system unit by

exceeding coupling characteristic data

1) Set the system out of operation

2) Check the coupling dimensioning

3) Replace the entire coupling

4) Check the alignment

5) Train and advise operating personnel

mayr ® will take no responsibility or guarantee for replacement parts and accessories which have not been delivered by

mayr ®, or for damage resulting from the use of these products.

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Malfunctions / Breakdowns Type 484._ _5._

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 16 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Malfunction

Possible Causes

Solutions

Premature wear on the

elastomeric element

Type 484.

Incorrect alignment

1) Set the system out of operation

2) Find / resolve the cause of incorrect alignment

(e.g. loose foundation screw, broken motor attachment,

warmth expansion of system components, changes in

coupling installation dimension "E")

3) Check the coupling for wear

4) Insert new elastomeric element

e.g. contact with aggressive fluids / oils,

ozone influence,

too high ambient temperatures etc.,

which cause physical changes in the

elastomeric element

1) Set the system out of operation

2) Dismantle the coupling and remove the remainders of the

elastomeric element

3) Check the coupling parts and replace if damaged

4) Insert new elastomeric element, mount the coupling parts

5) Check the alignment and correct if necessary

6) Make sure that further physical changes in the

elastomeric element can be excluded

The ambient or contact temperatures

permitted for the elastomeric element are

exceeded

1) Set the system out of operation

2) Dismantle the coupling and remove the remainders of the

elastomeric element

3) Check the ambient or contact temperature and regulate

them (possibly using other elastomeric element materials)

4) Check the coupling parts and replace if damaged

5) Insert new elastomeric element, mount the coupling parts

6) Check the alignment and correct if necessary

Premature wear on the

elastomeric element

(material liquefaction in

the elastomeric element

tooth interior)

Type 484.

Drive vibrations

1) Set the system out of operation

2) Dismantle the coupling and remove the remainders of the

elastomeric element

3) Determine the cause of vibration (maybe the problem can

be resolved by using an elastomeric element with lower or

higher shore hardness)

4) Check the coupling parts and replace if damaged

5) Insert new elastomeric element, mount the coupling parts

6) Check the alignment and correct if necessary

mayr ® will take no responsibility or guarantee for replacement parts and accessories which have not been delivered by

mayr ®, or for damage resulting from the use of these products.

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Malfunctions / Breakdowns Type 484._ _5._ (continued)

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 17 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Malfunction

Possible Causes

Solutions

Changes in running noise

and / or vibration

occurrence

Type 486.

Incorrect alignment, incorrect installation

0) Set the system out of operation

1) Find and remove the cause of incorrect alignment

2) Check the coupling for wear

Loose connecting screws,

minor friction corrosion under the screw

head and on the disk pack

1) Set the system out of operation

2) Check the coupling parts and replace if damaged

3) Tighten the connecting screws to the specified torque

4) Check the alignment and correct if necessary

Tensioning screws or locking set screw for

axial securement of the hubs are loose

1) Set the system out of operation

2) Check the coupling alignment

3) Tighten the tensioning and clamping screws for axial hub

securement to the required torque or tighten the locking

set screw and secure it against self-loosening using

sealing lacquer

4) Check the coupling for wear

Disk pack breakage

Type 486.

Disk pack breakage due to high load

impacts / overload

1) Set the system out of operation

2) Dismantle the coupling and remove the remainders of the

disk packs

3) Check the coupling parts and replace if damaged

4) Find the cause of overload and remove it

Operating parameters are not appropriate

for the coupling performance

1) Set the system out of operation

2) Check the operating parameters and select a suitable

coupling (observe installation space)

3) Install a new coupling

4) Check the alignment

Incorrect operation of the system unit

1) Set the system out of operation

2) Dismantle the coupling and remove the remainders of the

disk packs

3) Check the coupling parts and replace if damaged

4) Train and advise operating personnel

Disk pack / connecting

screw cracks or breakage

Type 486.

Drive vibrations

1) Set the system out of operation

2) Dismantle the coupling and remove the remainders of the

disk packs

3) Check the coupling parts and replace if damaged

4) Check the alignment and correct if necessary

5) Find the cause of vibration and remove it

mayr ® will take no responsibility or guarantee for replacement parts and accessories which have not been delivered by

mayr ®, or for damage resulting from the use of these products.

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Malfunctions / Breakdowns Type 486._ _5._

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 18 of 18 Germany E-Mail: info@mayr.de

Loading...

Loading...