Installation and Operational Instructions for

CAUTION

Danger of injury to personnel and

damage to machines.

Please Observe!

Guidelines on important points.

Safety Regulations

These Installation and Operational Instructions (I + O) are part of the clutch delivery.

Please keep them handy and near to the clutch at all times.

It is forbidden to start use of the product until you have ensured that all applicable EU directives and directives for the

machine or system into which the product has been installed have been fulfilled.

At the time these Installation and Operational Instructions go to print, the EAS®-smartic® clutches accord with the known

technical specifications and are operationally safe at the time of delivery.

Without a conformity evaluation, this product is not suitable for use in areas where there is a high danger of explosion.

This statement is based on the ATEX directive.

CAUTION

If the EAS®-smartic® clutches are modified.

If the relevant standards for safety and / or installation conditions are ignored.

User-implemented Protective Measures

Cover all moving parts to protect against seizure, dust or foreign body impact.

The clutch may not be put into operation without a limit switch unless mayr ® has been contacted and has agreed

otherwise.

To prevent injury or damage, only professionals and specialists should work on the devices, following the

relevant standards and directives. Please read the Installation and Operational Instructions carefully before

installation and initial operation of the device.

These Safety Regulations are user hints only and may not be complete!

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Please read these Operational Instructions carefully and follow them accordingly!

Ignoring these Instructions may lead to malfunctions or to clutch failure, resulting in damage to other parts.

Contents:

Page 1: - Contents

- Safety and Guideline Signs

- Safety Regulations

Page 2: - Illustrations Type 481._ _5._

- Illustrations Type 484._ _5._

Page 3: - Illustrations Type 486._ _5._

Page 4: - Parts List

Page 5: - Table 1: Technical Data

Page 6: - Table 2: Screws Overview

Page 7: - Design

- State of Delivery

- Function

- Installation of the Output Elements

Page 8: - Mounting onto the Shaft on Type 481

Page 9: - Mounting onto the Shaft on Type 484

Page 10: - Mounting onto the Shaft on Type 486

Page 11: - Permitted Shaft Misalignments

- Shaft Alignment

Page 12: - Torque Adjustment

- Cup Spring Layering

- Changing the Torque

- Table 3: Cup Spring Layering and

Torque Ranges

Page 13: - Changing the Torque Adjustment Range

by Changing the Cup Spring Layering

Page 14: - Limit Switch Installation

- Maintenance

- Disposal

Page 15: - General Malfunctions / Breakdowns

Page 16: - Malfunctions / Breakdowns Type 484.

Page 17: - Malfunctions / Breakdowns Type 484.

Page 18: - Malfunctions / Breakdowns Type 486.

Safety and Guideline Signs

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 1 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

15 14 13

17

16/16.1

23

24

Item 18 (contactless limit switch)

8 87 73 39 912 1210 105

22

21

20

1.2

19

6

1/1.1

2

11

11

44 4 Item 18

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Type 481._ _ _._

Clamping ring hub with and without keyway Hub key design

Fig. 1

Type 484._ _ _._

Clamping hub Clamping ring hub

with and without with and without

keyway keyway

Hub Hub

key key

design design

Fig. 2

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 2 of 18 Germany E-Mail: info@mayr.de

28

27

27

27

37

31

30

30

30

29

31

26

263825

30 3827

38

25

32/32.1

35

33

33

34

36/36.1

29

29

40

29

39

Installation and Operational Instructions for

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Type 486._ _ _._

Clamping hub

with and without

keyway Single-jointed

Size 2 design

Hub

key

design

Size 2

Clamping ring hub

with and without

keyway

Hub large Double-jointed

keyway design

design

Size 2

Flange

Size 2

Single-jointed

design

Hub

key design

Clamping hub

with and without

keyway

Sizes 01 to 1

Double-jointed

design

Fig. 3

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 3 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Item

Name

Item

Name

1

Clamping ring hub

20

Adjusting nut (for key design)

1.1

Clamping ring hub with keyway

21

Locking ring (for key design)

1.2

Clamping ring

22

Hexagon head screw (for key design)

1.3

Spring pin (Fig. 15 / page 13)

23

Hub Type 484. (key design)

2

Cap screw

24

Set screw

3

Pressure flange

25

Connection flange Type 486.

4

Thrust washer

26

Cap screw

5

Adjusting nut (for clamping ring hub design)

27

Screw

6

Hexagon head screw (for clamping ring hub design)

28

Hexagon head screw

7

Deep groove ball bearing

29

Hexagon nut

8

Locking ring

30

Disk pack assembly

9

Steel ball

31

Connection plate

10

Cup spring (layering dependent on Type)

32

Clamping hub Type 486. (Size 2)

11

Adjustment Table

32.1

Clamping hub Type 486. with keyway (Size 2)

12

Type tag

33

Cap screw

13

Connection flange Type 484.

34

Hub Type 486. (key design / Size 2)

14

Cap screw

35

Set screw

15

Flexible elastomeric element

36

Clamping hub Type 486. (Sizes 01 to 1)

16

Clamping hub Type 484.

36.1

Clamping hub Type 486. with keyway (Sizes 01 to 1)

16.1

Clamping hub Type 484. with keyway

37

Cap screw

17

Cap screw

38

Screw

18

Limit switch

39

Hub, large (key design)

19

Hub (key design)

40

Flange

The limit switch Item 18 is not included in the

standard delivery.

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Parts List (Only use mayr

original parts)

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 4 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

Size

01 0 1

2

Thread in the pressure flange (Item 3)

8 x M4

8 x M4

8 x M5

8 x M6

Max. screw-in depth b

max

in the pressure flange (Item 3) [mm]

6

6,5 7 9,5

Connection dimension "a" +0,1 [mm]

2,5

2,5

2,5

3

Connection dimension "e" [mm]

42 h5

52 h5

65 h5

78 h5

Tightening torque (Item 2) [Nm]

40

40

83

140

Tightening torque (Item 14) 1) [Nm]

4

4,5 9 16

Tightening torque (Item 17) [Nm]

Types 484.2_5._ to 484.7_5._

10 25 25 120

Type 484.8_5._

17

40

40

140

Tightening torque (Item 26) 1) [Nm]

4

4,5 9 16

Tightening torque (Items 27 / 28 / 38) [Nm]

8,5

8,5

8,5

8,5

Tightening torque (Item 33) [Nm]

13

33

33

42

Tightening torque (35) up to bore Ø 22 [Nm]

more than bore Ø 22 [Nm]

2

4,1

Tightening torque (37) [Nm]

8,5

8,5

8,5

-

Axial forces [N]

400

500

800

1200

Radial forces [N]

400

500

800

1200

Transverse force torques 2) [Nm]

3 5 10

15

Distance dimension "E" (see Figs. 5 and 6) [mm]

18

20

24

28

Distance dimension "U1" (see Figs. 7 and 8) [mm]

14,7

15,5

15,8

26,4

Distance dimension "S" (see Fig. 9) [mm]

2,6 3 2,9

7,2

Permitted shaft misalignments Type 484._ _ 5._

Radial misalignment ΔK

r

92 Sh A [mm]

98 Sh A [mm]

0,14

0,10

0,15

0,11

0,17

0,12

0,21

0,16

Axial displacement ΔKa [mm]

1,4

1,5

1,8

2,1

Angular misalignment ΔKw 92 Sh A [°]

98 Sh A [°]

1,0

0,9

1,0

0,9

1,0

0,9

1,0

0,9

Permitted shaft misalignments Type 486._ _ 5.0 (Double-jointed coupling)

Radial misalignment ΔKr [mm]

0,15

0,2

0,2

0,3

Axial displacement ΔKa [mm]

0,7

0,9

1,1

1,3

Angular misalignment ΔKw [°]

2,0

2,0

2,0

2,0

Permitted shaft misalignments Type 486._ _ 5.8 (Single-jointed coupling)

Radial misalignment ΔK

r

[mm]

- - -

-

Axial displacement ΔKa [mm]

0,35

0,45

0,55

0,65

Angular misalignment ΔKw [°]

1,0

1,0

1,0

1,0

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Table 1: Technical Data

1)

Secure Items 14 and 26 wit Loctite 243.

2)

Torques, which put strain on the deep groove ball bearing due to the non-centric axial forces having an effect on the pressure flange.

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 5 of 18 Germany E-Mail: info@mayr.de

Installation and Operational Instructions for

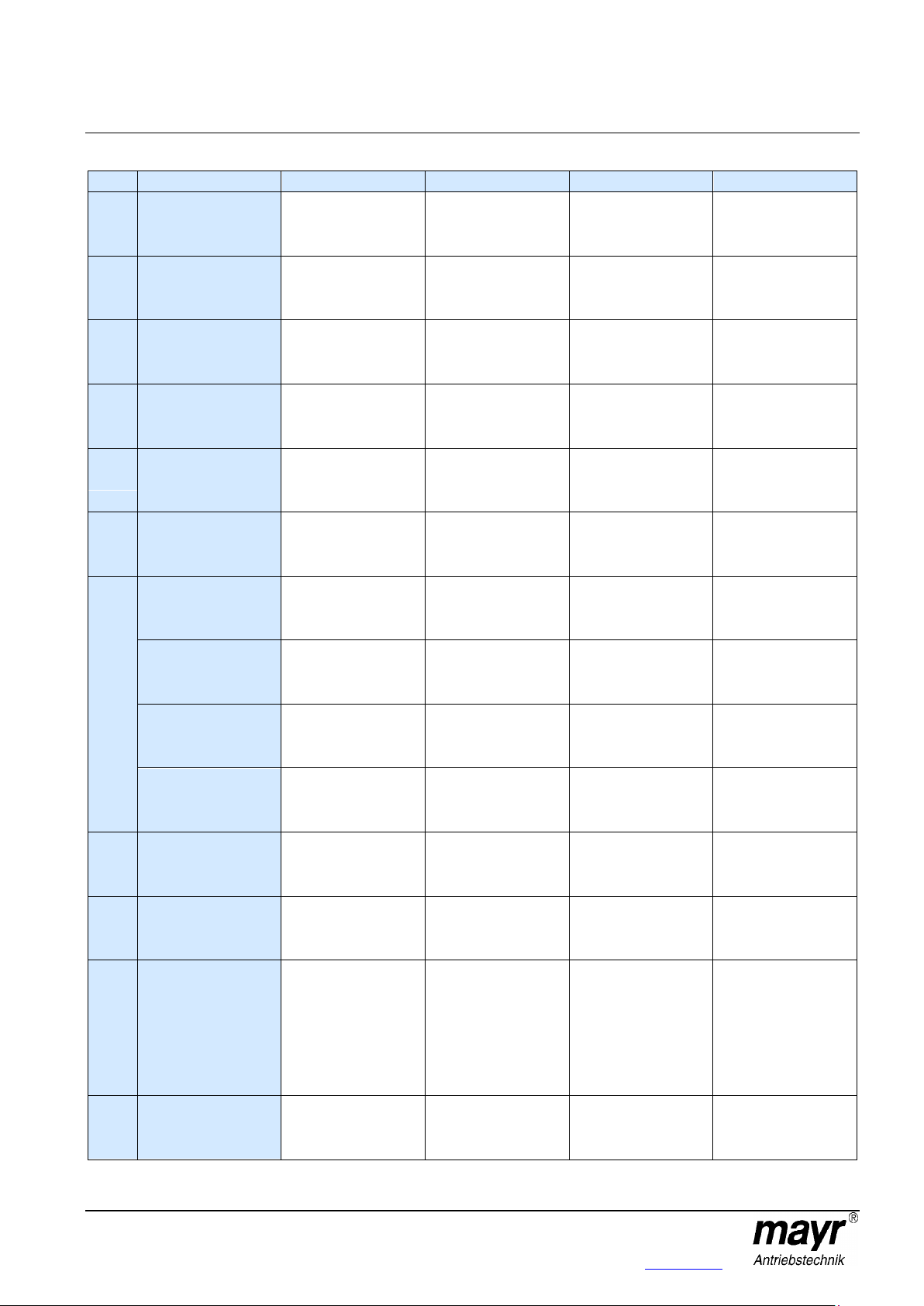

Item

Design

Size 01

Size 0

Size 1

Size 2

2

with hub

Items 1 / 1.1

1x cap screw

M8 x 25

DIN EN ISO 4762

12.9

1x cap screw

M8 x 25

DIN EN ISO 4762

12.9

1x cap screw

M10 x 30

DIN EN ISO 4762

12.9

1x cap screw

M12 x 35

DIN EN ISO 4762

12.9

6

with hub

Items 1 / 1.1

1x hexagon head screw

M4 x 24,2 SO

(DIN EN ISO 4014)

8.8

1x hexagon head screw

M4 x 24,2 SO

(DIN EN ISO 4014)

8.8

1x hexagon head screw

M5 x 28 SO

(DIN EN ISO 4014)

8.8

1x hexagon head screw

M6 x 31,5 SO

(DIN EN ISO 4014)

8.8

14

Type

484._ _5._

8x cap screw

M4 x 16

DIN EN ISO 4762

12.9

8x cap screw

M4 x 16

DIN EN ISO 4762

12.9

8x cap screw

M5 x 18

DIN EN ISO 4762

12.9

8x cap screw

M6 x 22

DIN EN ISO 4762

12.9

17

with hub

Items 16 / 16.1

1x cap screw

M6 x 20

DIN EN ISO 4762

8.8

1x cap screw

M8 x 25

DIN EN ISO 4762

8.8

1x cap screw

M8 x 30

DIN EN ISO 4762

8.8

1x cap screw

M12 x 35

DIN EN ISO 4762

12.9

22

with hub

Item 19

1x hexagon head screw

M3 x 8

DIN EN ISO 4017

8.8

1x hexagon head screw

M4 x 10

DIN EN ISO 4017

8.8

1x hexagon head screw

M5 x 10

DIN EN ISO 4017

8.8

1x hexagon head screw

M5 x 12

DIN EN ISO 4017

8.8

26

Type

486._ _5._

4x cap screw

M4 x 16

DIN EN ISO 4762

12.9

8x cap screw

M4 x 16

DIN EN ISO 4762

12.9

6x cap screw

M5 x 20

DIN EN ISO 4762

12.9

6x cap screw

M6 x 20

DIN EN ISO 4762

12.9

27

with hub

Items 32 / 32.1 / 34 /

36 / 36.1 on

double-jointed design

2x cap screw

M5 x 16

DIN EN ISO 4762

10.9

2x cap screw

M5 x 18

DIN EN ISO 4762

12.9

3x cap screw

M5 x 20

DIN EN ISO 4762

12.9

3x cap screw

M5 x 20

DIN EN ISO 4017

10.9

with hub

Items 32 / 32.1 / 34 /

36 / 36.1 on

single-jointed design

2x cap screw

M5 x 16

DIN EN ISO 4762

10.9

2x cap screw

M5 x 18

DIN EN ISO 4762

12.9

3x hexagon head screw

M5 x 16

DIN EN ISO 4017

10.9

3x cap screw

M5 x 20

DIN EN ISO 4017

10.9

with hub

Item 39

- - -

- - -

- - -

3x hexagon head screw

M5 x 50

DIN EN ISO 4014

10.9

with flange

Item 40

- - -

- - -

- - -

3x hexagon head screw

M5 x 23

DIN EN ISO 4017

10.9

28

Type

486._ _5.0

- - -

- - -

- - -

3x hexagon head screw

M5 x 35

DIN EN ISO 4014

10.9

33

with hub

Items 32 / 32.1 /

36 / 36.1

1x cap screw

M6 x 20

DIN EN ISO 4762

12.9

1x cap screw

M8 x 25

DIN EN ISO 4762

12.9

1x cap screw

M8 x 30

DIN EN ISO 4762

12.9

2x cap screw

M8 x 25

DIN EN ISO 4762

12.9

37

Type

486._ _5.0

4x cap screw

M5 x 16

DIN EN ISO 4762

10.9

4x cap screw

M5 x 16

DIN EN ISO 4762

12.9

3x hexagon head screw

M5 x 16

DIN EN ISO 4017

10.9

+

3x cap screw

M5 x 16

DIN EN ISO 4762

12.9

- - -

38

Type

486._ _5._

2x cap screw

M5 x 16

DIN EN ISO 4762

10.9

2x cap screw

M5 x 18

DIN EN ISO 4762

12.9

3x cap screw

M5 x 16

DIN EN ISO 4762

12.9

3x hexagon head screw

M5 x 23

DIN EN ISO 4017

10.9

EAS®-smartic

®

synchronous clutch Type 48_._ _5._

Sizes 01 – 2 (B.4.17.1.GB)

Table 2: Screws Overview (dependent on Type or hub connection)

25/11/2011 TK/NU/SU Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0

Eichenstraße 1 Fax: +49 8341 804-421

D-87665 Mauerstetten http://www.mayr.com

Page 6 of 18 Germany E-Mail: info@mayr.de

Loading...

Loading...