Page 1

Kwik-File, LLC

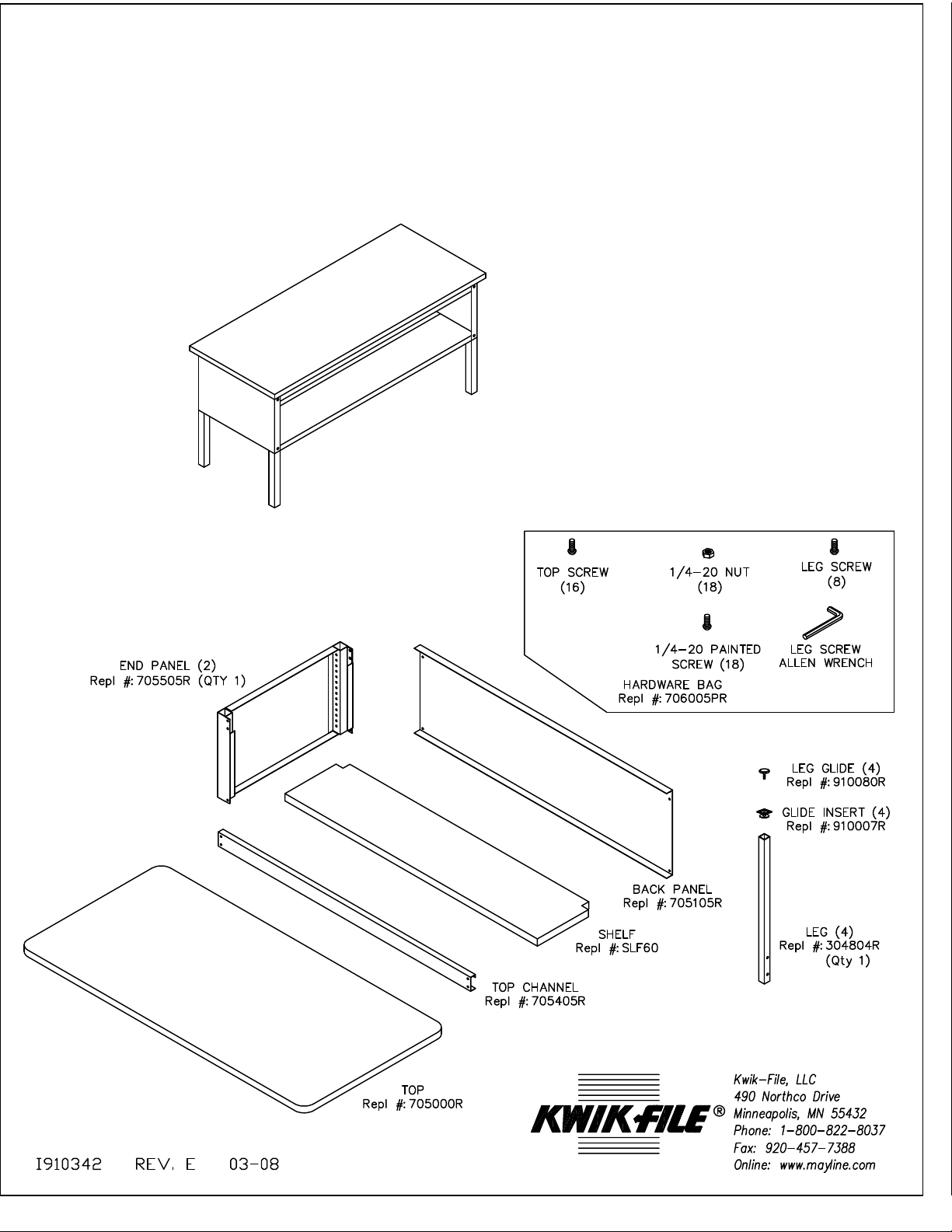

Mailflow-To-Go

TB60 Work Table and SLF60 Shelf

Work Table (shown with shelf), 60"W x 39"D x 29" - 36"H

Parts list and drawings for Work Table (shown with shelf)

TM

Page 2

Tool required: a blade screwdriver (allen wrench provided).

1. Unpack carton(s) and identify all parts.

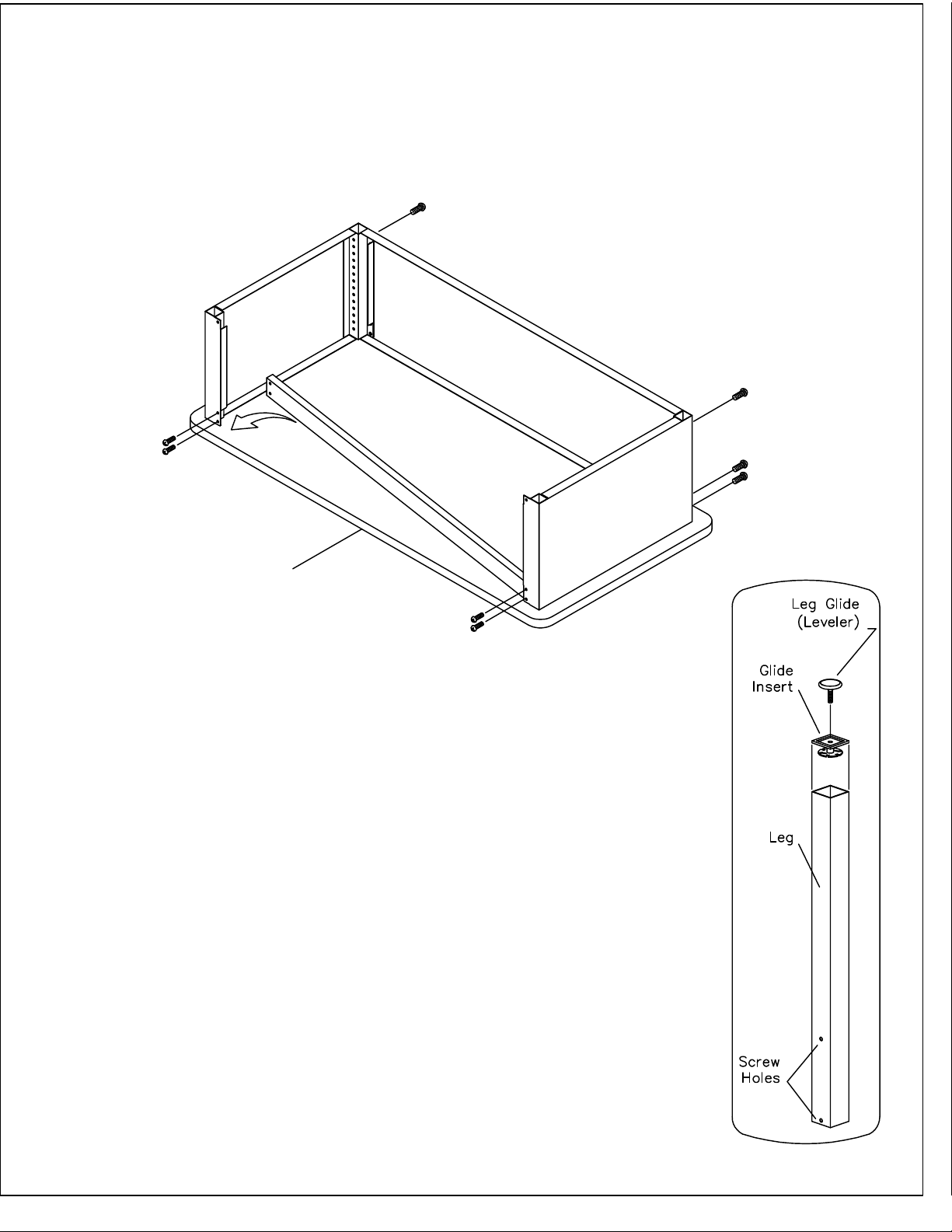

2. Place table top upside down (screw holes up) on a clean, flat, smooth surface.

3. Assemble back panel, two end panels, and front support rail; it is easiest to do this with these

parts upside down on the table top.

FRONT

a. Bolt together back panel and two end panels with six painted matching

screws and Kepsnuts

(three on each side). (if you ordered the TBS60 table with shelf, omit the

one screw on each

side farthest away front the top at this time).

b. Bolt together front support rail with open flange facing inside with angled

side against top; use

four painted matching screws and Kepsnuts (two on each side).

4. Locate the assembled table frame so that the 10 holes in the end and back

panel flanges line up with the 10 pre drilled holes in the top. Insert the sheet

metal screws provided through the holes and tighten into the top. Additional top

screws are self tapping and can be installed without pre-drilling.

5. Using a hammer or rubber mallet, pound the glide insert into the leg. Then

screw the leg glide into the glide insert. Place legs into the leg sleeves at the

corners of the table. Each leg has two threaded holes at the upper end; legs

should be inserted so that the holes line up with the adjustment holes in the leg

socket. Table height can be adjusted between 29" and 36" in one inch

increments.

Page 3

Table Height Max. 36"

Table Height

Adjustment

Range 29" to 36" in

One Inch Increments

Table Height Min. 29"

6. After deciding on table height, line up the threaded holes in each leg with the proper holes in the

leg sleeve; use two socket-head screws to assemble the leg in place (allen wrench provided)

7. Once all four legs have been assembled in place, carefully set table upright in place (be sure to

get help from another person).

8. Each leg has an adjustable glide. If the table needs to be leveled, turn the glide as needed to

shorten of lengthen any leg. While not essential, a carpenter's level may be helpful.

9. If you ordered the SLF60 Shelf, install it now as follows:

a. The shelf is made of (2) pieces (half shelves) which slide next to each other, flange side down.

The half - shelves are supported by the flanges at the bottom of the table end and back

panels.

b. Each half - shelf has one side with two notched corners; this side should be placed towards

the outside of the table (notches provide space for table legs).

c. Before installing the two half - shelves in place, check to make sure the two screws at the

bottom of the back of the table have been removed.

d. Carefully put the two half - shelves in place, first one, then the other. They should now be

next to each other, resting on the flanges at the bottom of the back and side panels.

e. Insert four painted machine screws. Each one will go through the hole at the bottom of the

table leg frame and the front corner of one of the half - shelves. Secure them with the

Kepsnuts provided.

f. Connect the two half - shelves from underneath through the bottom flanges using the three

painted machine screws and three Kepsnuts provided.

Loading...

Loading...