Page 1

INSTRUCTIONS FOR RESTRINGING ABOVE

CATALOG No.

7355100

7355300

7355A

7355B

7355C

BOARD MAYLINE STRAIGHTEDGE

NOTE: Please count and inspect all pieces before disposing of any carton or packing materials.

COMPONENTS:

REF.# QTY. DESCRIPTION PART No.

1 CALL~~ Cable Coil CALL~~

2 2 * Ring Terminal Q6

* Ring Terminal (Item 2) must be ordered separately when

buying cable in Bulk Spool

When ordering components, specific color and/or size information may be required.

Contact a Mayline Customer Service Representative. 1-800-822-8037

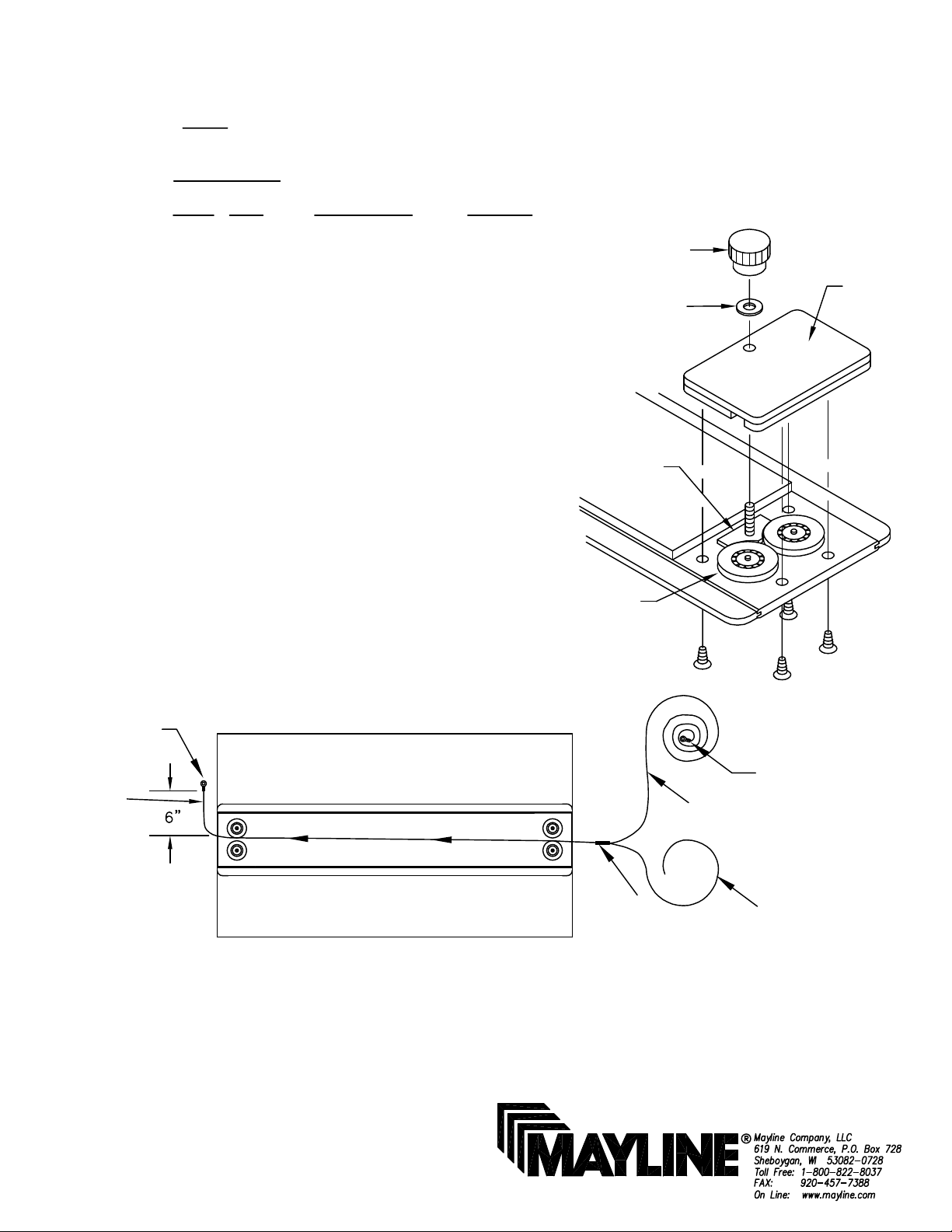

1. Remove Pulley Housing, Brake Know Washer and Brake Knob.

Repeat procedure on other end. Fig. 1

2. Remove old cable by pulling cable out of slot in Straightedge.

3. If using Bulk Cable, total cable length required: (3) x (length of

straightedge) + 8 feet.

4. Cut total cable length into two equal lengths.

5. Feed on end of Cable 1B through slot in straightedge cap until

approximately 6 inches extends through opposite end. Fig. 2

6. Tape end of Cable 1A to Cable 1B and pull through until 6

inches of Cable 1A is through opposite end. Fig. 2 Remove

tape.

Brake Knob

Brake Shoe

Ball bearing

Pulley

Fig. #1

Washer

Pulley

Housing

Ring

Terminal (2)

Cable (1B)

Fig. 2

7. Crimp ring Terminal (2) onto the upper ends of cables 1A and 1B.

8. Replace pulley housing / brake assembly. Fig. 1

Tape

Ring

Terminal (2)

Cable (1A)

Cable (1B)

(1)

Page 2

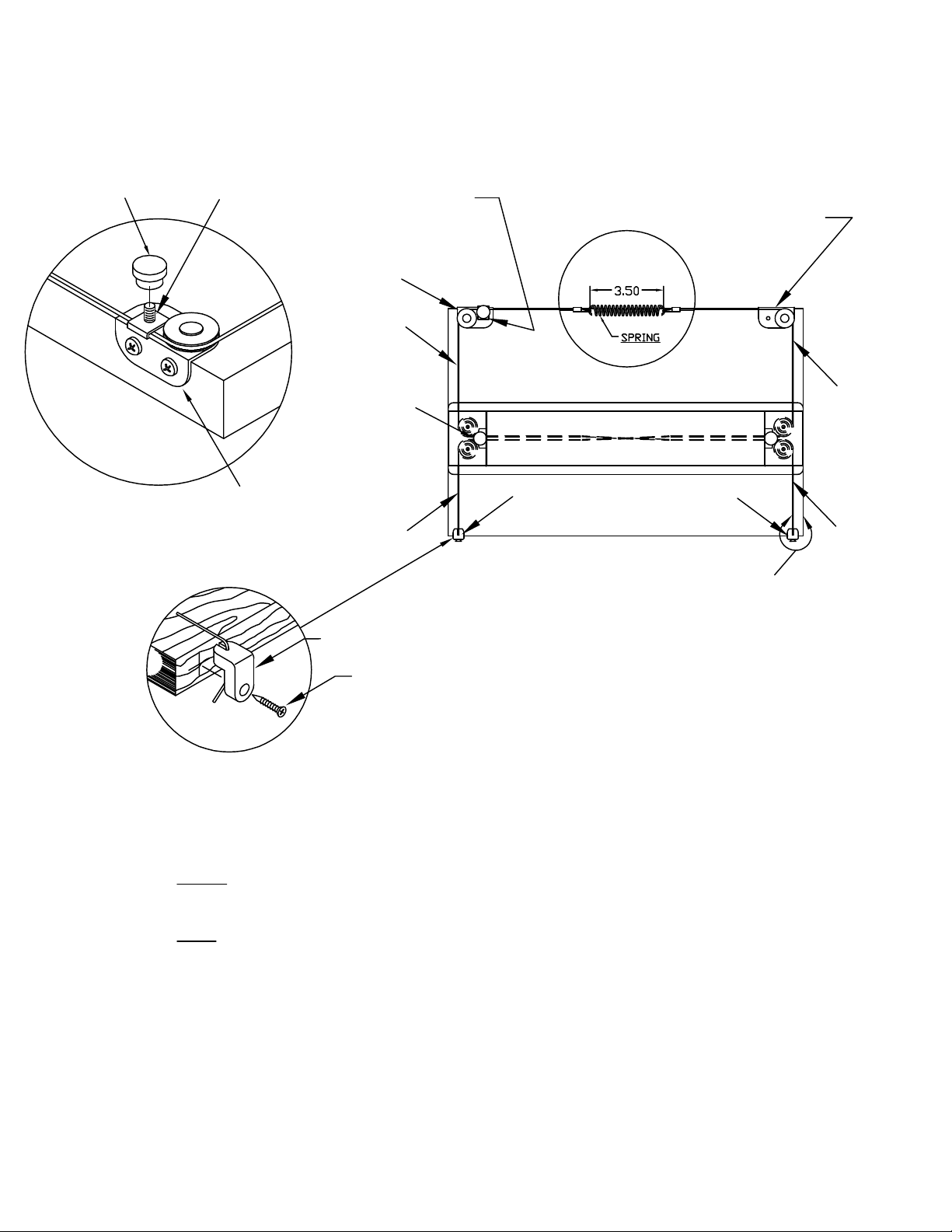

9. Attach cable ends with terminals to spring. Align cable parallel

with edge of board as shown in Fig. 3. Be sure that the cable

passes between cable clamp and L.H. Plate Assembly.

Knob

Cable Clamp

LEFT Corner

Plate

L.H. Corner

Plate Assembly

Cable (1B)

Cable Brake

Knob

Cable (1A)

Cable Clamp

R.H. Corner

Plate Assembly

Spring Length

Not to Exceed

(CENTER Spring between Plate Assemblies)

Stedge Stop

Stedge Stop

Align Cable Parallel with

edge of Board

Fig. 3

Cable (1A)

Cable (1B)

Stedge Stop

Screw

10. Insert cable through top of stop.

11. Pull cable on RIGHT side of work surface to remove slack from

this portion. Tighten Stedge Clamp Screw at this time.

12. Pull cable on LEFT side to remove slack. DO NOT Exceed

spring tension (Fig. 3). Tighten Stedge Clamp Screw at this time.

13. Excess cable can be trimmed off leaving several inches for

future adjustments.

14. Straightedge may be locked in positio by tightening Knobs

installed in Step #1 on both ends of Straightedge or left loose to

allow free movement up or down.

(2)

Page 3

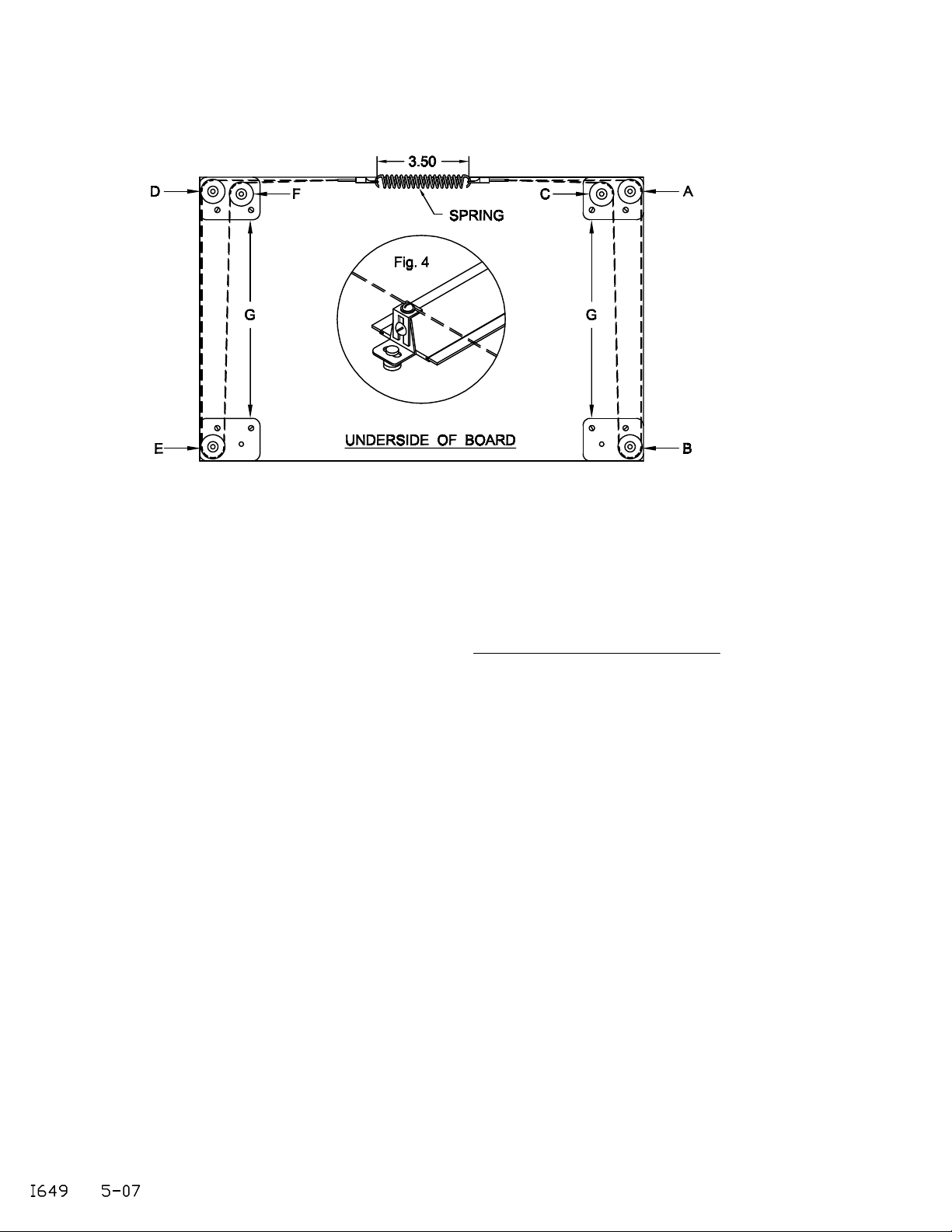

INSTRUCTIONS FOR RESTRINGING

UNDER-BOARD PARALLEL RULE

Spring Length

Not to Exceed

1. Remove old cable by loosening screw retaining cable on attachment clamp. Fig. 4

2. Crimp Ring Terminal (2) to one end of Cable (1).

3. Starting from Inside of board, thread end of cable around pulley 'A' to front of board around pulley

'B', then back around pulley 'C'. Now cross the board and thread around pulley 'D', then to front of

board around pulley 'E' and back around pulley 'F'. DO NOT TWIST OR KINK CABLE.

4. Connect Ring Terminal to Spring.

5. Slide 2nd Ring Terminal on opposite end of Cable. Hook the Terminal onto other end of spring.

Hold Ring Terminal and pull end of cable until spring is extended approximately 1/2". Crimp terminal

at this position. Be sure cable runs freely.

6. Place straightedge in position on board and fasten blade clamps (shown upside down, Fig.4) to

ends of straightedge with knurled nuts. Adjust sliding bar to correct length and tighten screws.

7. Loosen cable clamp screws on bottom of blade clamps and place cable between washer and

groove in blade clamps. Align straightedge and lamp cable by tightening cable clamp screws.

Straightedge can be removed from blade and replaced without changing alignment by simply

removing knurled nuts.

(3)

Loading...

Loading...