Page 1

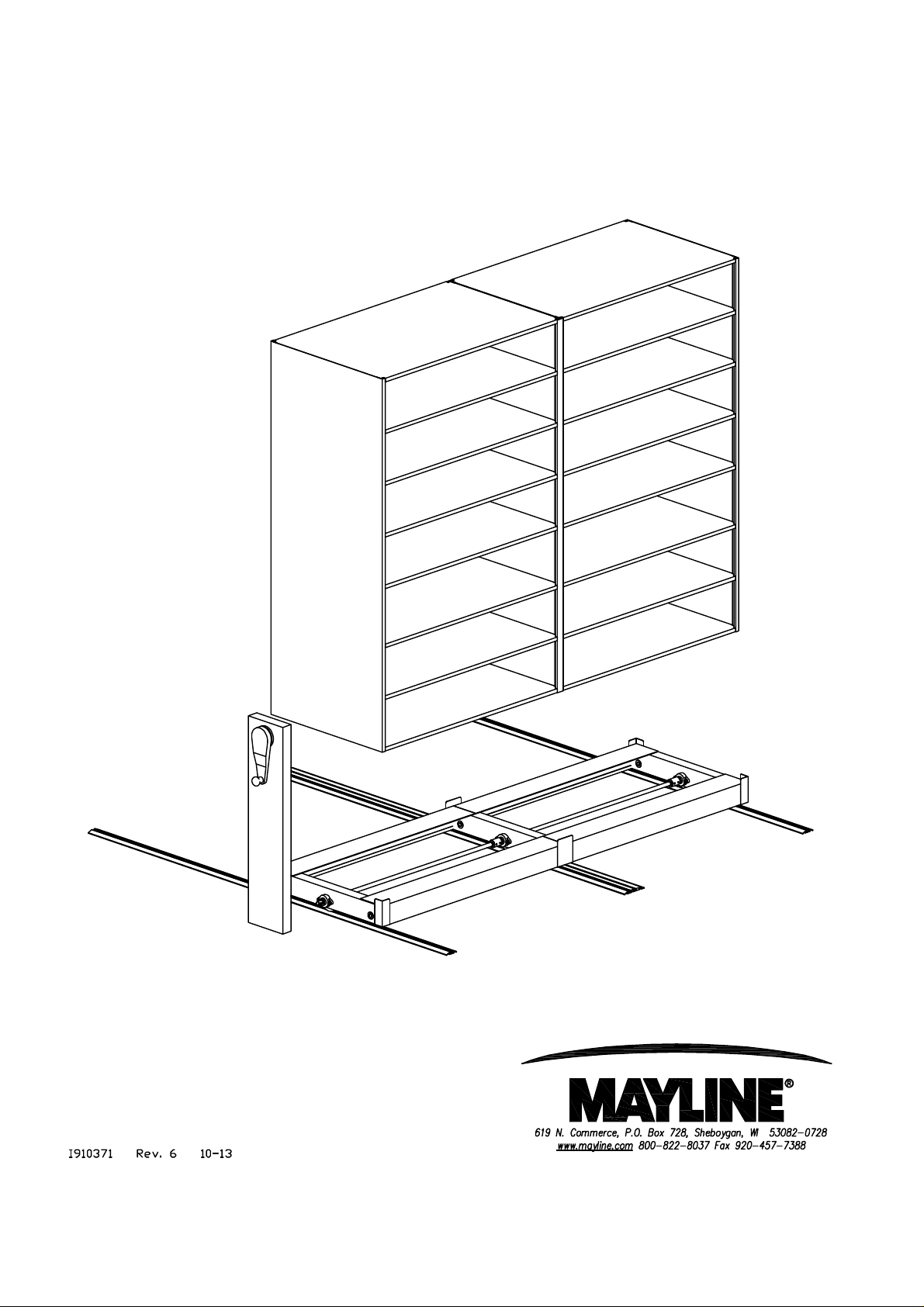

Assembly Procedures

for Mobile Lite

(1)

Page 2

MOBILE LITE SYSTEM INSTALLATION

Kwik-File recommends the removal of all carpet and padding prior to installing Mobile Lite. We suggest

that carpet be removed the length and width of each track. Product performs best when installed on

concrete or tile. NOTE: Kwik-File cannot assure proper leveling if track is installed on low-pile

carpet.

* Read all instructions before attempting assembly.

* Check floor plan layout. Measure and mark floor for intended

layout, preplan exact location of all units with regards to columns,

lights, windows and obstructions.

GENERAL NOTES:

1. Installation of the in-track anti-tip track begins with the floor plan layout . It is imperative for the

proper operation of this system that the tracks be parallel and square. On a two track system, the

in-track anti-tip is the rear track. On a three or more track system, the anti-tip track is the second (from

the front) track.

2. The carriage with the anti-tip guide is designed to be inserted into the track after the track is in the

approximate location, but prior to completely securing it to the floor. This will eliminate the need to

disassemble the guide from the carriage.

3. The carriage is shipped completely assembled, however if the anti-tip guide assembly cannot be

inserted into the track it is possible to remove and reinstall the mount assembly. Care must be taken to

properly place the mount tightly to the channel and angle of the carriage.

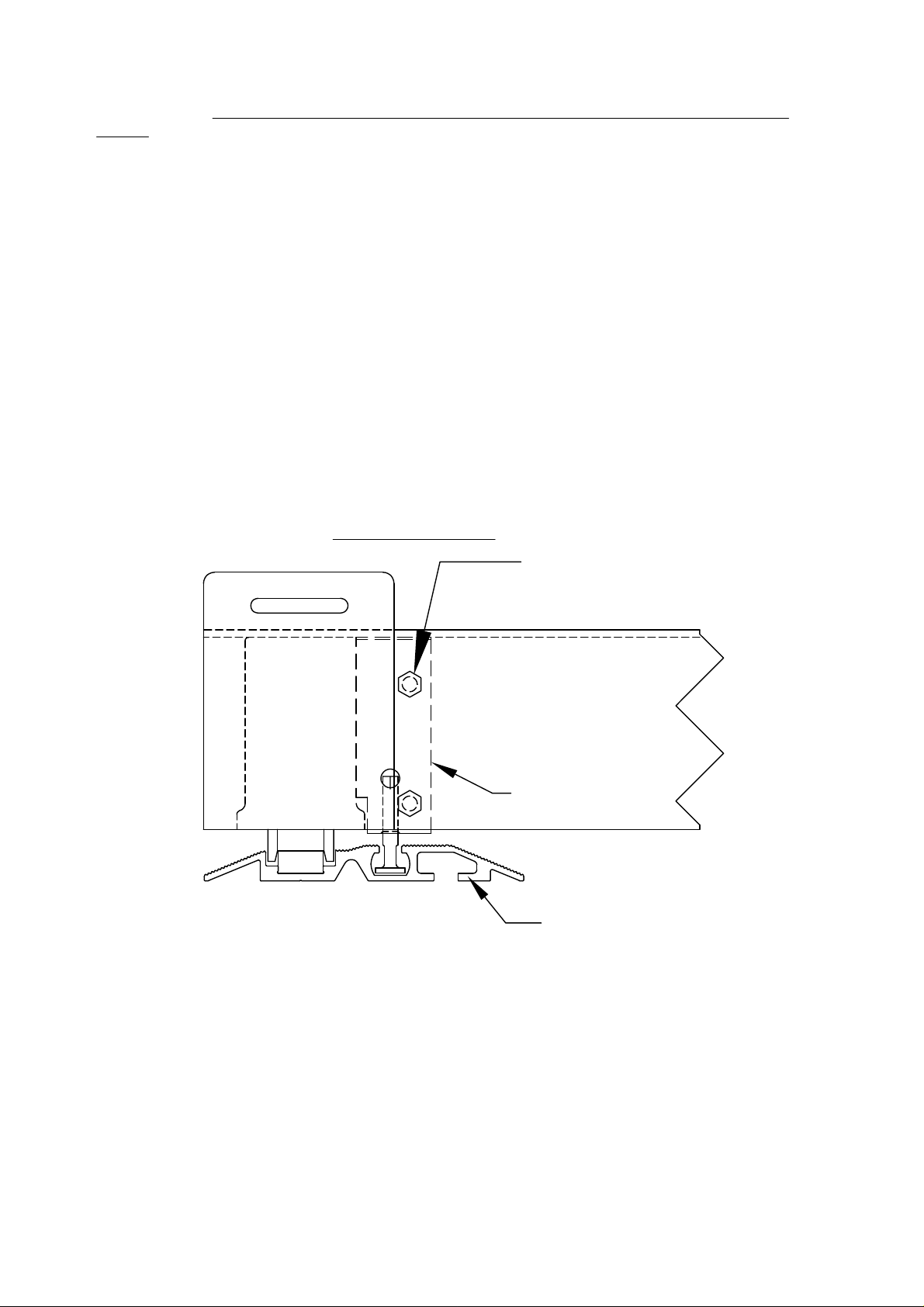

Detail of Anti-Tip Guide

4. Required tools:

- Hammer drill (cement drill bit provided)

- Drill with Phillips screw adapter

- Flat and Phillips screwdriver

- 9/16" socket

- 1-1/16" thin wall socket

- 3/4" socket

- Level

- Chalk line

- Measuring tape

- #2 Phillips driver bit

- Hammer

ATTACHED WITH (2)

1/4-20 X 3/4" BOLTS

ANTI-TIP GUIDE

MFTA TRACK

(2)

Page 3

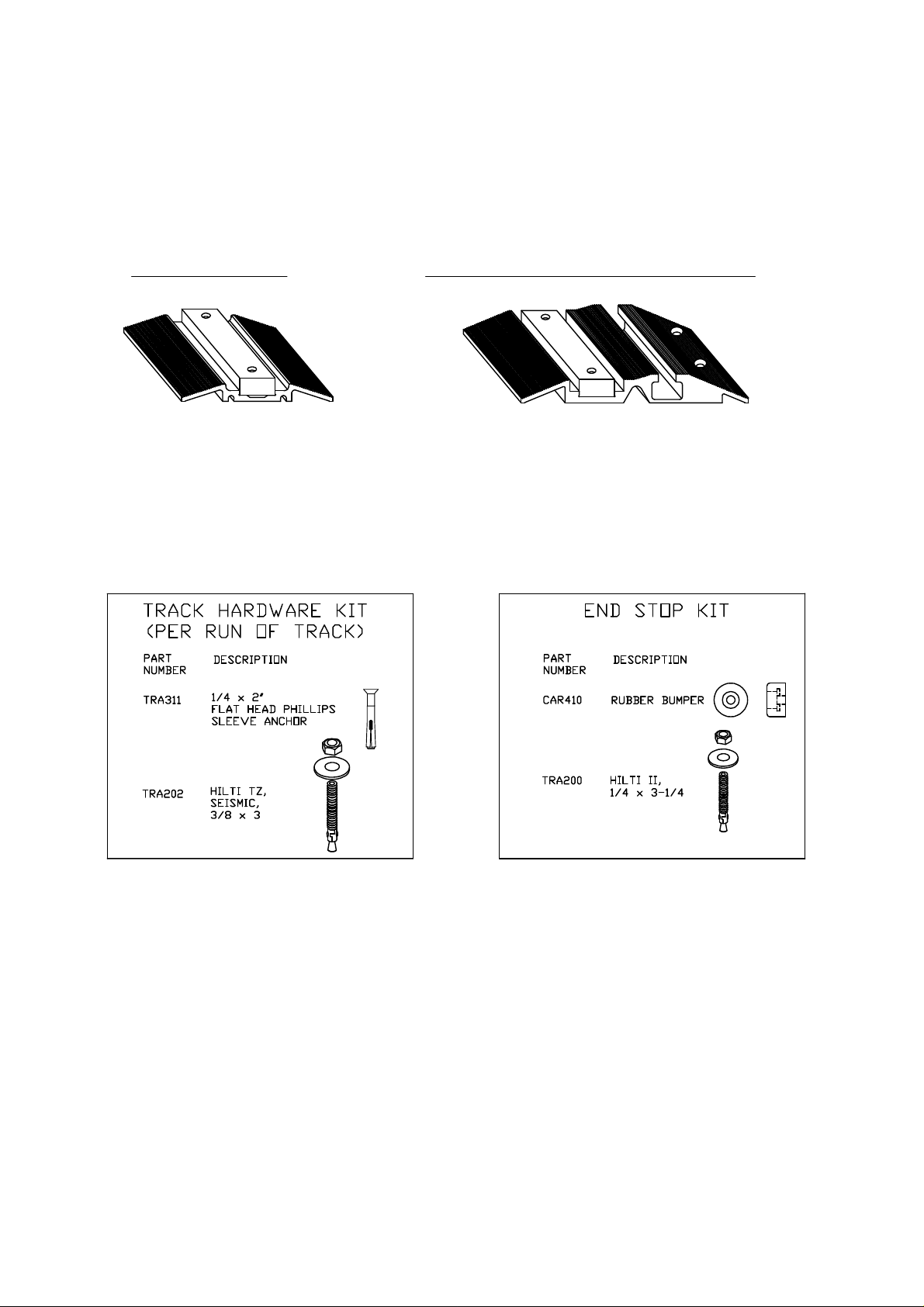

Flat Track (MFT) In-Track Anti-Tip Flat Track (MFTA)

(3)

Page 4

TRACK INSTALLATION:

STEP 1.

If included: Assemble one stationary unit at

the end of the track run per layout. Use

stationary shelving to assist in aligning track

and mobile carriage. If the stationary

shelving is installed on a fixed base you

must install the MLFANTITIP to the fixed

base.

#12 X 3/4"

TEK SCREW

HILTI TZ 3/8X3

STATIC BASE

MLFANTITIP INSTALLATION

STATIC BASE

ANCHOR BRACKET

STEP 2.

Layout all track (use carriage to affirm track

spacing by rolling carriage on loose track).

The track closest to the wall will be no less

than 1 1/2" from the rear edge of track to the

wall. On a single section carriage, the In-Track

AntI-Tip will be the rear track. On a two section

carriage, the In-Track Anti-Tip will be the

center track. Review the layout determining

where the anti-tip track will lie. Position the

track in place.

SAMPLE LAYOUT:

STEP 3.

Verify you will end up with 1 1/2" wall clearance

on the track run when system complete.

STEP 4.

When wall spacing has been met and the

carriage moves freely the length of the track

run, proceed to install the anti-tip track.

Track placed touching

stationary shelving

Track

Anti−Tip Track

(4)

Spacing From Wall 1

Track

1

"

2

Page 5

Caution: Steel track insert and Aluminum track splices must stagger.

Note: Track has been pre-assembled and match drilled for ease of assembly.

Hilti II

Washer

Rubber Bumper

Each End Typ.

all Track

Steel Insert

Hilti Screw

1/4" x 2"

Staggered

Joints

FLOOR

3/8" x 3/4"

Steel Insert

Align Steel to Aluminum track.

Drill 1/4" dia. hole 2 3/4"

minimum depth.

Hilti II - 1/4"-20 x 3 1/4"

Washer

Rubber Bumper

Hole without

Countersink

Aluminum

Track

STEP 5.

Confirm anti-tip track is parallel to the wall. Use

3/8" Hilti drill bit to drill holes in floor for the

anti-tip fastening. Fasteners for the In-Track

Anti-Tip are Hilti TZ's.

STEP 6.

Use the Hilti drill bit (1/4" dia.) for securing track.

The Steel Insert and Aluminum track has been

pre-drilled. Be sure the holes in the steel insert

and the holes in the aluminum track line up.

Using the track as a guide, drill through the steel

and aluminum into the floor. Carefully clean

out the hole. Hammer in the Hilti 1/4" x 2"

Sleeve Anchors and tightened properly.

Note: Heads of screws must be below

running surface of track. File heads of

screws if necessary to ensure smooth

surface.

STEP 7.

Track piece on one end may need to be drilled

out to accommodate 1/4" Hilti II fastener.

STEP 8.

Maintaining careful alignment of the In-Track

Anti-Tip track, drill and install mid-track Hilti

KBTZ 3/8" Anchors in every available anchor

point in the track. The strength of the anti-tip is in

the anchors. Make sure they are tightened

properly.

Note: Hole depth for Hilti Anchor must be

consistent to prevent tripping hazard.

(5)

Page 6

STEP 9.

Once first track (the Anti-Tip track) is secure,

the remaining tracks may be set into place.

Use carriages as a guide for track placement.

Measure to ensure tracks are truly parallel and

square.

STEP 12.

Install all end stops nearest the stationary shelving

and install the balance of the carriages. Shelving

end only.

STEP 13.

Install remaining track anchors.

Note: Wheel channel closest to the anti-tip

tab is a non-floating wheel channel.

STEP 10.

Slide one carriage on the track to determine

spacing. Verify carriage wheels are centered

in the channels and in the track.

STEP 11.

The tracks must be parallel and square to each

other to ensure proper operation. Measure

each set of tracks and the entire system,

corner to corner, to verify that each distance is

the same.

STEP 14.

Slide the remaining carriages on the track, verify

smooth operation. Install the remaining end stops

Anti-Tip Track location

in 2 Track Layout

Spacing From

1

Wall 1

"

2

Anti-Tip Track location in

3 or more Track Layout

Track placed touching

stationary shelving

Track

Track placed touching

stationary shelving

Spacing From

1

Wall 1

"

2

Track

Anti-Tip Track

(6)

Anti−Tip Track

Track

Page 7

Drive Box Installation:

1. Remove the cover (fig. E) from the Responsive Drive Box (RDB).

2. Slide the RDB using top two mounting holes over the two 1/2"-13 bolts (fig. B) extending from

the center of the carriage. These bolts are held in place by (4) jam nuts (fig. A) which are left in

position.

3. When the RDB is seated against the jam nuts (fig. A), install 1/2" washers (fig. C) and tighten

the two 1/2"-13 nylon nuts (fig. D) which are in the accessory bag.

4. Attach chain to middle sprocket assembly, to the bottom sprocket assembly (front drive

channel) and around the chain idler. ONLY USE MASTER LINK (half link not required).

5. Assemble the end shelving unit. This can be done after the RDB assembly has begun. The

type of shelving used will determine how the RDB is fastened to the shelving

6. At this time secure the drive box at the top as well as the bottom. Make sure the Responsive

Drive Box is square and parallel to the shelving. Drill two 1/4" holes at the top of the drive box

into the 4-post upright and secure with (2) 1/4"-20 screws and nuts. The head of the screw

should be on the inside of the 4-post upright to prevent interference with filing media. When the

upper screws are secure and the Responsive Drive is properly positioned, you may tighten the

two 1/2" nuts at the bottom (fig. D).

7. Install the cover (fig. E) using the six sheet metal screws provided (fig. F). ATTACH E-CLIP

TO HANDLE SHAFT.

8. Insert square key into key slot on handle shaft.

9. Attach 3/4" E-Clip (fig P) over square key in slot on shaft. Note: the tab on the interior of

E-Clip should rest next and NOT on top of square key, so that E-Clip snaps firmly into place on

shaft.

10. Install (fig N, fig O), detent locking plate, using two 1/4-20 Countersunk screws.

11. Install the handle (fig K) using the 3/16" x 3/16" x 1/2" square key (fig J). Install the 1-1/16"

Jam Nut (fig L). Tighten the jam nut (fig L) with the 1-1/16" thin wall socket (not provided). BE

SURE BACK OF HANDLE IS SEATED AGAINST THE E-CLIP ON THE SHAFT . Install the

black dome plug (fig M).

NOTE: The black dome plug (fig. M) is notched so that it will only fit one way into handle.

Line up black dome cut away with detent in handle. DO NOT force black dome into place.

12. The Responsive Drive Installation is complete and you may now install the remainder of the

shelving. Install shelving per manufacture's specs. Secure shelving through corner / center

plates. TEK screws are found in accessory box.

(7)

Page 8

FIG. QTY. DESCRIPTION

A 4 1/2-13 NUT (INSTALLED ON CARRIAGE)

B 2 1/2-13 HEX BOLT (INSTALLED ON CARRIAGE)

C 2 1/2 INCH FLAT WASHER

D 2 1/2-13 NYLOCK NUT

E 1 COVER

F 6 COLOR COORDINATED S/M SCREW

G 2 CHAIN TENSIONER

H MISC MOUNTING SCREWS (IN ACC. BAG)

I 1 MECHANICAL ASSIST HOUSING

J 1 3/16" SQUARE KEY FOR HANDLE

K 1 HANDLE ASSEMBLY

L 1 3/4 INCH NYLOCK NUT

M 1 DOME PLUG

N 1 DETENT LOCKING PLATE

O 2 1/4-20 COUNTERSINK SCREWS

P 1 3/4" E-CLIP

(8)

Loading...

Loading...