Page 1

Kwik-File

Kwik-File

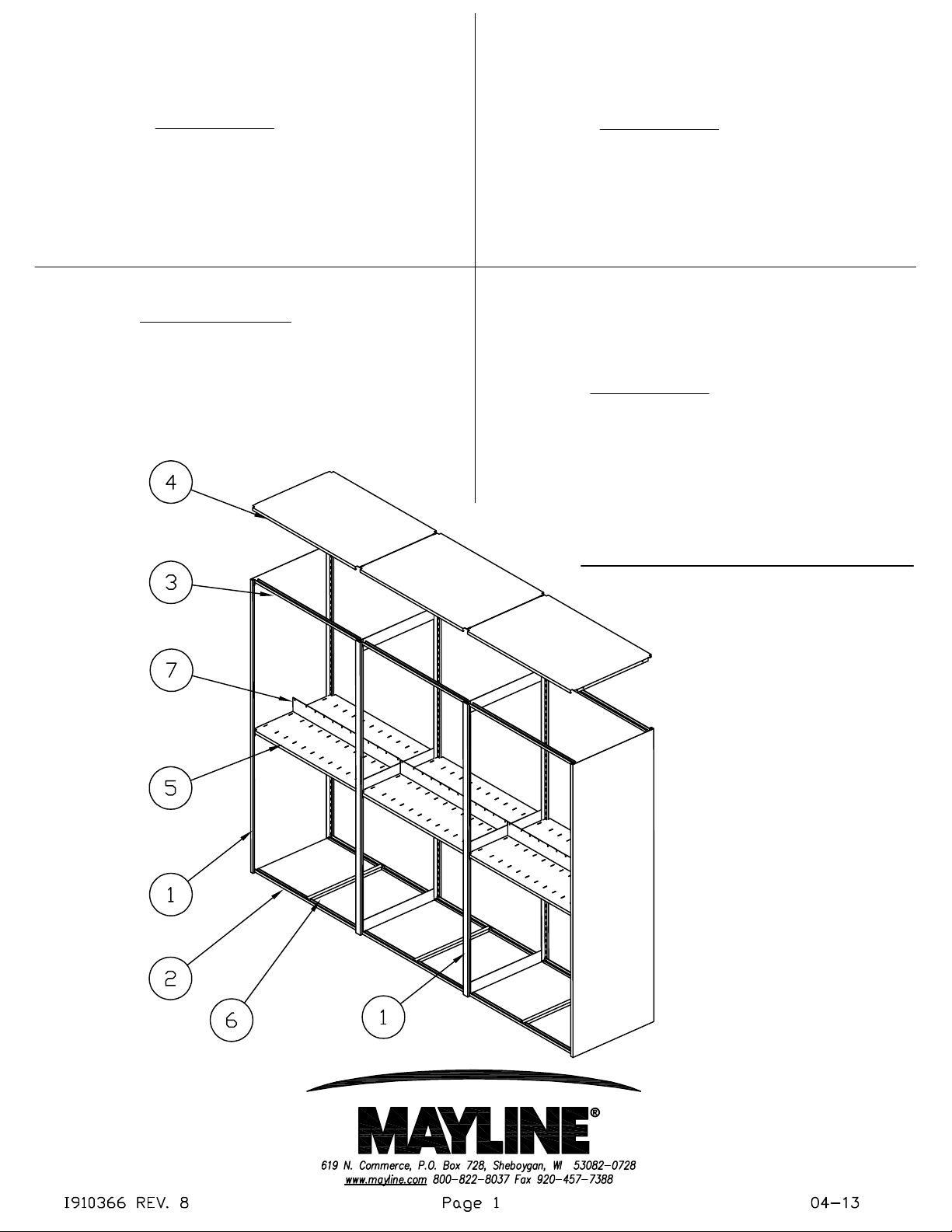

4-POST SHELVING

(See Pages 1 thru 4)

COMPONENTS:

1. Uprights

2. Bottom Shelf Support

3. Standard Shelf Support

4. Unslotted Shelf Canopy

5. Slotted Shelf

6. Shelf Reinforcement

7. Common Stop

TOOLS REQUIRED:

1. Rubber Mallet

X-RAY SHELVING

(See Pages 1, 5 & 6)

COMPONENTS:

1. Uprights

2. Bottom Shelf Support

3. X-ray Shelf Support

4. Unslotted Shelf Canopy

5. Slotted Shelf

6. X-ray Std./Btm. Shelf Reinforcement

7. Common Stop

Kwik-File

4-POST ACCESSORIES

(See Pages 7 thru 16)

COMPONENTS:

1. Upper and lower spreaders

2. Shelf reinforcements

3. Slide attachment bracket kits

4. Drawers

5. Drawer lock

6. Partition supports and partitions

7. Support bar

8. 18" Shelves

9. 36" Shelves

Page 2

The components of the basic 4-Post System are:

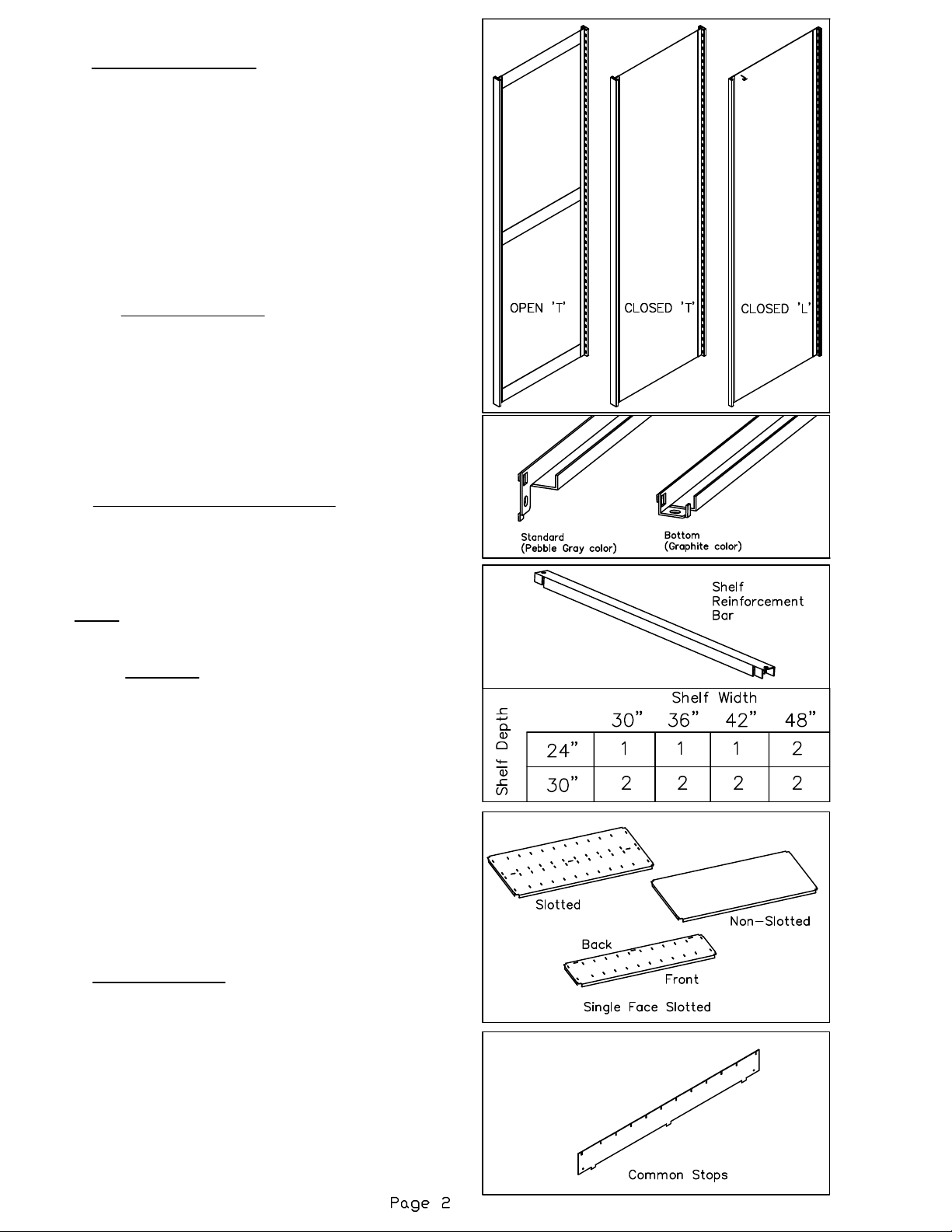

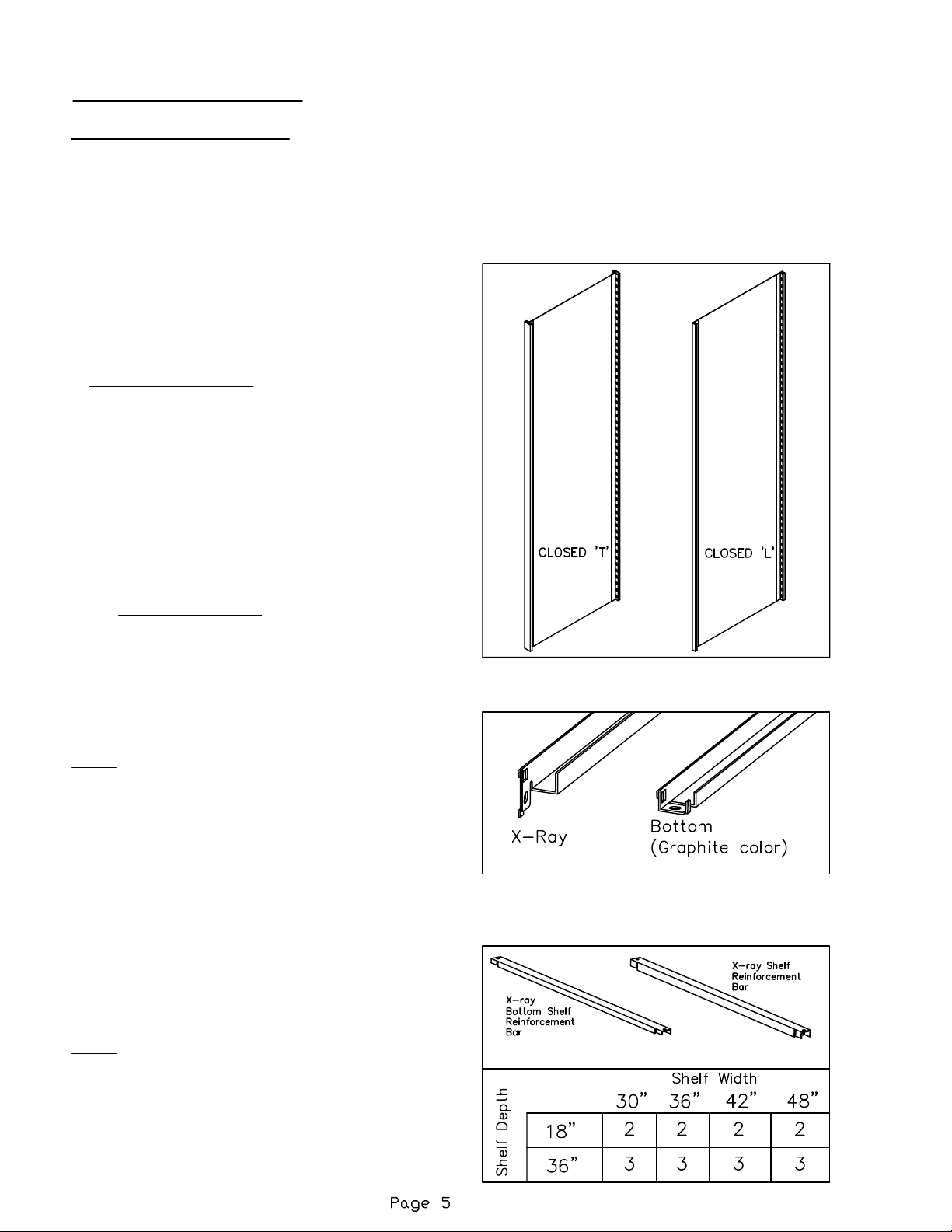

1. VERTICAL UPRIGHTS: Three styles are used:

A.) Open 'T'

B.) Closed 'T'

C.) Closed 'L'

Closed 'L' uprights are located at either end of a

4-Post range. Open and Closed 'T' are located

internally in a 4-Post range. Each style contains

tapered slots vertically along the uprights to accept

the shelf supports that are positioned horizontally.

The narrow portion of the tapered slots must face

downward. Tapered slots are at 1-1/2"

center-to-center vertical spacing.

2 & 3. SHELF SUPPORTS: Two styles are used:

A.) Standard shelf supports (Pebble Gray)

B.) Bottom shelf supports (Graphite)

The supports are inserted into the slots of the vertical

upright to form the horizontal support for the shelf.

Standard shelf supports are Pebble Gray in color.

The bottom shelf supports are Graphite in color and

are used only at the bottom of the unit. Supports

should be secured into place with a rubber mallet.

4. SHELF REINFORCEMENT BARS:

Reinforcements are used on "Double Face Shelves

(24" and 30" shelving only). These bars are

positioned across the shelf supports to add strength

to the shelf. Shelf reinforcement quantities are

illustrated in the matrix.

NOTE: Adjust the reinforcement position if it

interferes with shelf slots.

5 & 6. SHELVES: three styles are used:

A.) Single Face Slotted.

Depth is either 12" or 15". Two rows of slots exist for

divider installation. Three slots are also located in

the back of the shelf for the center/back stop

installation.

B.) Double Face Slotted.

Depth is either 23" or 30". Four rows of slots exist

for the divider installation. Three slots are also

located in the middle of the shelf for the center/back

stop installation.

C.) Single & Double Face Non-slotted.

Shelves are positioned on the shelf supports and

also used as the canopy top. which is typically a

non-slotted shelf.

7. COMMON STOPS:

Placed in the back of single face and middle of

double face shelves. Held in place by dividers.

Page 3

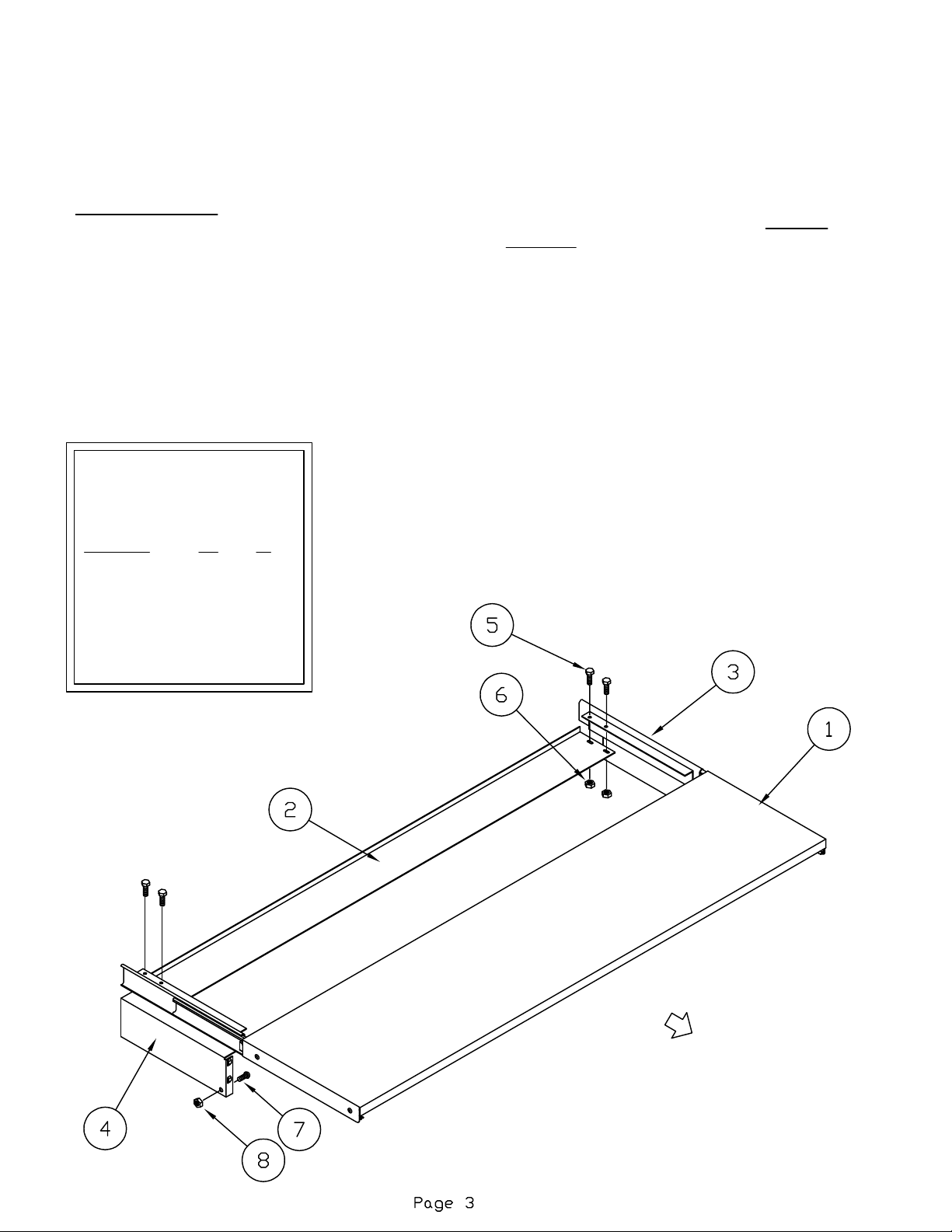

Kwik-File

4-POST Reference Shelf

Assembly Instructions

COMPONENTS:

1. Reference Shelf Assembly (1)

2. Stabilizer Bracket (1)

3. R.H. End Bracket Slide Assembly (1)

4. L.H. End Bracket Slide Assembly (1)

5. 10-32 x 3/8 Pan Head Screw (4)

6. 10-32 KEPS Nut (4)

7. 1/4-20 x 1/2 Hex Head Screw (2)

8. 1/4-20 KEPS Nut (2)

Pullout Reference Shelf

Model numbers:

Model: W H

EF24RS 24" 12"

EF30RS 30" 12"

EF36RS 36" 12"

EF42RS 42" 12"

EF48RS 48" 12"

Secure stabilizer bracket to reference shelf end with

#10-32 x 1/2 screws and KEPS nut. DO NOT

TIGHTEN hardware until reference shelf is installed.

Slide the reference shelf on the end bracket slide

assemblies, notches are provided on the back side of

the shelf. Slide the shelf back until the front of the

slide is resting with the flat fold of the shelf.

Now tighten the stabilizer bracket hardware. Be sure

that the slide brackets are parallel.

F

R

O

N

T

Page 4

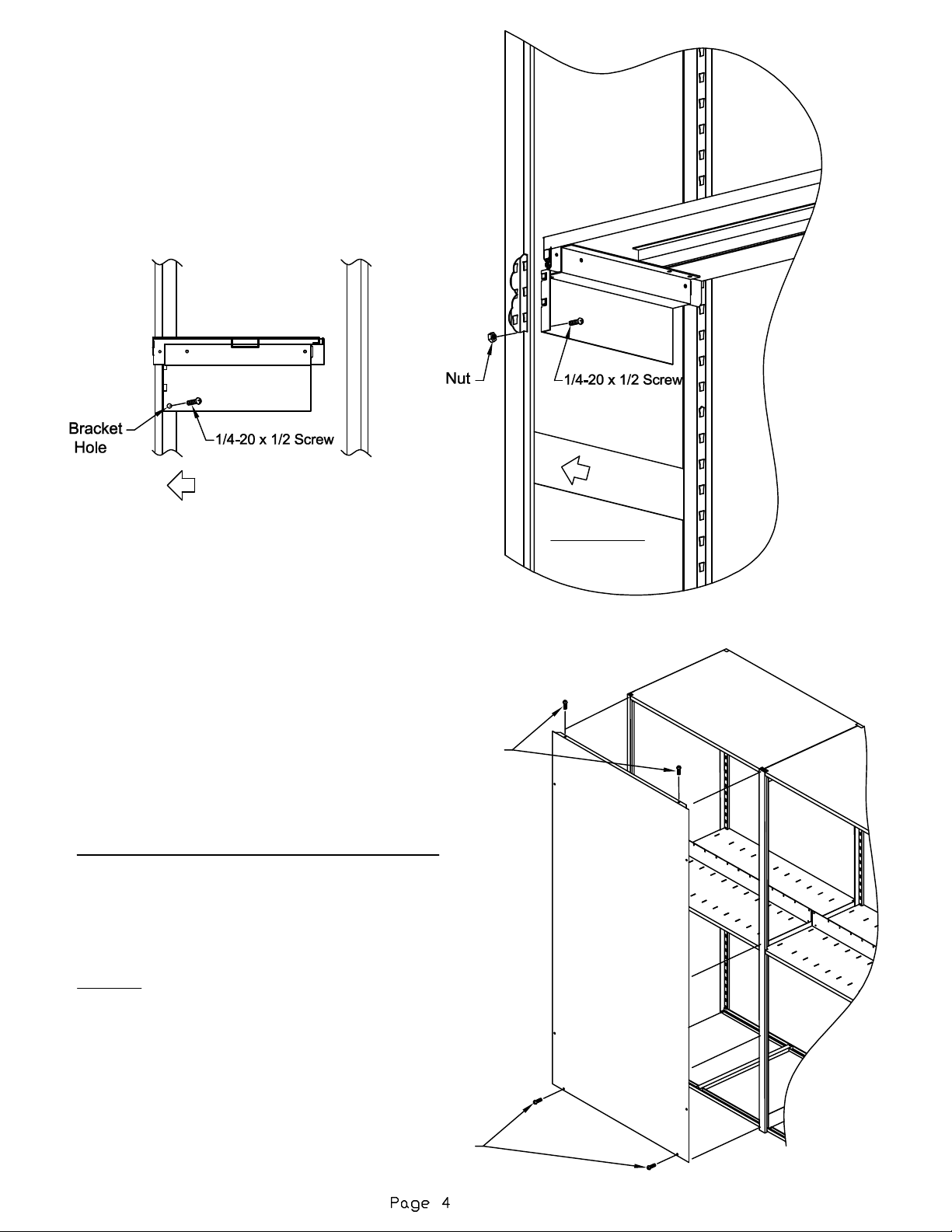

When a Pull-Out Reference Shelf is used,

Set each reference shelf end bracket assembly into

slots in upright.

Using the holes in the bracket as pilot holes, drill 2

holes (1/4" diameter) into the upright. Secure the

bracket to the upright with 1/4-20 x 1/2 screw and

nut. Do both brackets.

FRONT

F

R

O

N

T

These screws

are optional

BACK PANEL or CENTER PANEL INSTALLATION

Rest the panel flange on top of the 4-Post assembly

and center the panel side to side. Peal away

protective film from tape on inside of panel and press

firmly into position.

Optional: Attach the panel using (4) #10 TEK

self-drilling screws. Located at the top flange into top

shelf and along the bottom into the bottom shelf. A

power driver must be used to thread the screws into

the uprights.

UNDERSIDE of

Sliding Shelf shown

These screws

are optional

Page 5

X-Ray Product

Specifications:

86" tall uprights provide for (3) 15.125" openings

and (2) 16.625" openings.

Shelving to hold 8 pounds per linear filing inch.

48"x18" shelf = 384 pounds per shelf

48"x36" shelf = 768 pounds per shelf

The components of the basic X-Ray Shelving

System are:

1. VERTICAL UPRIGHTS: Two styles are used:

A.) Closed 'T'

B.) Closed 'L'

Closed 'L' uprights are located at either end of a

4-post range. Closed 'T' are located internally in a

X-ray range. Each style contains tapered slots

vertically along the uprights to accept the shelf

supports that are positioned horizontally. The

narrow portion of the tapered slots must face

downward. Tapered slots are at 1-1/2"

center-to-center vertical spacing.

2 & 3. SHELF SUPPORTS: Two styles are used:

A.) X-ray shelf supports

B.) Bottom shelf supports

The supports are inserted into the slots of the

vertical upright to form the horizontal support for

the shelf. The bottom shelf supports are used only

at the bottom of the unit. Supports should be

secured into place with a rubber mallet.

NOTE: X-ray shelf supports are 1/2" deeper than

the bottom X-ray shelf supports.

4. SHELF REINFORCEMENT BARS: Two styles

are used:

A.) X-ray shelf reinforcement (deep channel)

B.) Bottom shelf reinforcement (shallow channel)

Reinforcements are used on all X-ray shelves with

the exception of the canopy top. These bars are

positioned across the shelf supports to add

strength to the shelf. Shelf reinforcement

quantities are illustrated in the matrix.

Adjust the reinforcement position if it interferes

with shelf slots.

NOTE: X-ray shelf reinforcements are 1/2" deeper

than the X-ray bottom shelf reinforcements.

Page 6

5 & 6. SHELVES: Two styles are used:

A.) Single Face Slotted

Depth is 18". Two rows of slots exist for

divider installation. Three slots are also

located in the back of the shelf for the

center/back stop installation.

B.) Double Face Slotted

Depth is 36". Four rows of slots exist for the

divider installation. Three slots are also

located in the middle of the shelf for the

center/back stop installation.

C.) Single & Double Face Non-slotted

Shelves are positioned on the shelf supports

and also used as the canopy top, which is

typically a non-slotted shelf.

7. COMMON STOPS:

Placed in the back of single face and middle

of double face shelves. Held in place by

dividers.

Back / Center Panel

Assembly Instructions

(Optional Item)

Back Panel (indicated by offsets running

the long length of the panel) & Center

Panel (no offsets) installation

Rest the panel flange on the top of the

4-Post assembly and center the panel

side to side. Peal away protective film

from tape on inside of panel and firmly

press into position.

Optional: Attach the panel using (4) #10

TEK self-drilling screws located at the

top flange into top shelf and along the

bottom into the bottom shelf (hardware

bag of 30 screws is provided). A power

driver must be used to thread the

screws into the uprights. Verify with end

user if they would like the screws

installed into the panel.

Page 7

Rollout Drawer Assembly / Installation

UPPER AND LOWER SPREADERS: When

specifying roll out drawers you will use two

lower spreaders and two upper spreaders for

each 4-Post unit. The lower spreader will

replace the lower shelf support, its additional

height will help to stabilize the unit. The upper

spreader would replace a shelf support in the

area above the top drawer, again the additional

height will help to stabilize the unit. Both upper

and lower spreaders are installed the same as

our standard shelf support. Place the tabs in

the holes in uprights and use a rubber mallet to

seat in place.

When attaching shelving to the floor

use (4) 1/4" masonry wedge anchors

for concrete or (4) 1/4" wood screws

when going into another material.

Not recommended for mounting on a

carpeted floor.

Page 8

SHELF REINFORCEMENTS: A special shelf

reinforcement is used above the upper spreader, all

other shelves will use the X-ray bottom shelf

reinforcements (X18SRB, X36SRB)

Shelf

Reinforcement

Bar

Page 9

18"/36" LH

18" Bracket / Slide Installation

SLIDE ATTACHMENT BRACKET KITS:

These kits include four brackets for both the 18" and

36" 4-Post. The 18" bracket kit will include two slides.

The 36" bracket kit will include four slides.

The brackets are attached much like the shelf

supports. The two pieces are slid together and the tabs

get located into the slots in the vertical uprights and are

seated in place with a rubber mallet. After they are

seated four screws get added to each bracket, two for

bracket stops and the other two to complete bracket

assembly.

A hardware kit (707900) with eight screws and six

brackets stops is included to complete each bracket kit.

1/4-20 X

BRACKET

STOP (6)

1

" SCREW (8)

2

BRACKET ASM.

18"/36" RH

1/4-20 X

1

" SCREW (8)

2

NOTE:

L.H. Brackets have

SQUARE holes.

R.H. Brackets have

ROUND holes

1/4-20 X

1

" SCREW (8)

2

BRACKET ASM.

18" RH

(ROUND HOLES)

BRACKET ASM.

18" RH

(ROUND HOLES)

BRACKET

STOP (6)

BRACKET ASM. 18" LH

(SQUARE HOLES)

F

R

O

BRACKET ASM.

BRACKET ASM.

18"/36" RH

N

T

Page 10

36" Bracket / Slide Installation

I

NSTALLATION OF BRACKETS FOR ROLLOUT DRAWERS.

For proper spacing and installation of drawers, brackets should be installed

from the bottom up. The location of the bottom drawer and remaining brackets

will be different depending on the height of the drawer being installed. Each

bracket has two tabs on each end of each bracket assembly that get installed

into corresponding open slots on the four post upright.

BOTTOM DRAWER BRACKET INSTALLATION:

10.5" drawer (use 3rd & 4th slots above lower spreader)

6" drawer (use 2nd & 3rd slots above lower spreader)

4.5" drawer (use 1st & 2nd slots above lower spreader)

REMAINING DRAWER BRACKET INSTALLATION:

10.5" drawer (use 3rd & 4th slots above drawer front)

6" drawer (use 2nd & 3rd slots above drawer front)

4.5" drawer (use 1st & 2nd slots above drawer front)

NOTE:

L.H. Brackets have

SQUARE holes.

R.H. Brackets have

ROUND holes

1/4-20 X

1

" SCREW (8)

2

BRACKET ASM.

18" / 36" RH

1/4-20 X

BRACKET

STOP (6)

1

" SCREW (8)

2

BRACKET ASM.

BRACKET

STOP (6)

36" RH

F

R

O

N

T

Page 11

DRAWERS: Drawers are available in

three heights: 4.5", 6", and 10.5" and in

four widths, 30", 36", 42" and 48" and

depths of all are 15.738".

The drawers are available only for the

18" and 36" deep 4-Post units.

4-Post drawers can be configured

using any of the different drawer heights

in each of the different cabinet widths.

To install drawers place tabs in

drawers into slots on the slides. (see

picture)

4-Post Upright

Slide

F

R

O

N

T

Page 12

DRAWER LOCK: There is a cam lock for the 6" and

10.5"drawers. To install you must carefully remove

the knockout on the lower right hand side of drawer

face. Using a hammer and a screw driver, tap on

the areas not retained going back and forth till

knockout drops out.

Remove nut from lock, add rotation stop washer,

cam and screw to the lock and feed through hole in

drawer, replace the nut and tighten. Lock cam

should be in the down position and turn 90 degrees

to the lock position. The lock should catch on the

inside of the upright but may require a slight

adjustment.

Replacement Parts:

FPALOCKREPL - Lock Assembly FPA

NOTE:

4-Post drawers are

keyed alike from factory

Lock assembly shown

Locked and Unlocked

LOCKED

UN-LOCKED

Page 13

PARTITION SUPPORTS: If partitions

are going to be used, a partition

support will be required at the front of

each drawer. This option is available

only on the 4.5" and 6" drawers, it is not

an option on the 10.5" drawer.

Partition Support

PARTITIONS: There are two

different heights used, the 4.5" and

the 6". They are used along with

the partition supports for the

separation of media. They will

hook into slots in the partition

support at the front and into the

slots in the drawer bottom.

Page 14

SUPPORT BAR: A support bar is required at the

front of the 10.5" drawer when hanging files are

going to be used. It hooks into the slots at the top

front of the drawer.

FELT PADS: The hardware kit includes 4 felt

pads which may be added to the back of the

drawer fronts. The pads should be placed near

the edge of the drawer approximately 1" up from

the bottom or 1" above the lock if lock is used and

1" down from the top (as shown).

Support Bar

Pad Loation

when Lock is used

Page 15

18" SHELVES: The four post units with drawers

will use a shelf that has slots for the back stop and

dividers arranged for both letter and legal media.

The top shelf will not be slotted.

Slotted

Shelf

Page 16

36" SHELVES: The four post units with drawers

will use a shelf that has slots for the back stop and

dividers arranged for both letter and legal media.

The top shelf will not be slotted.

Slotted

Shelf

Loading...

Loading...