Page 1

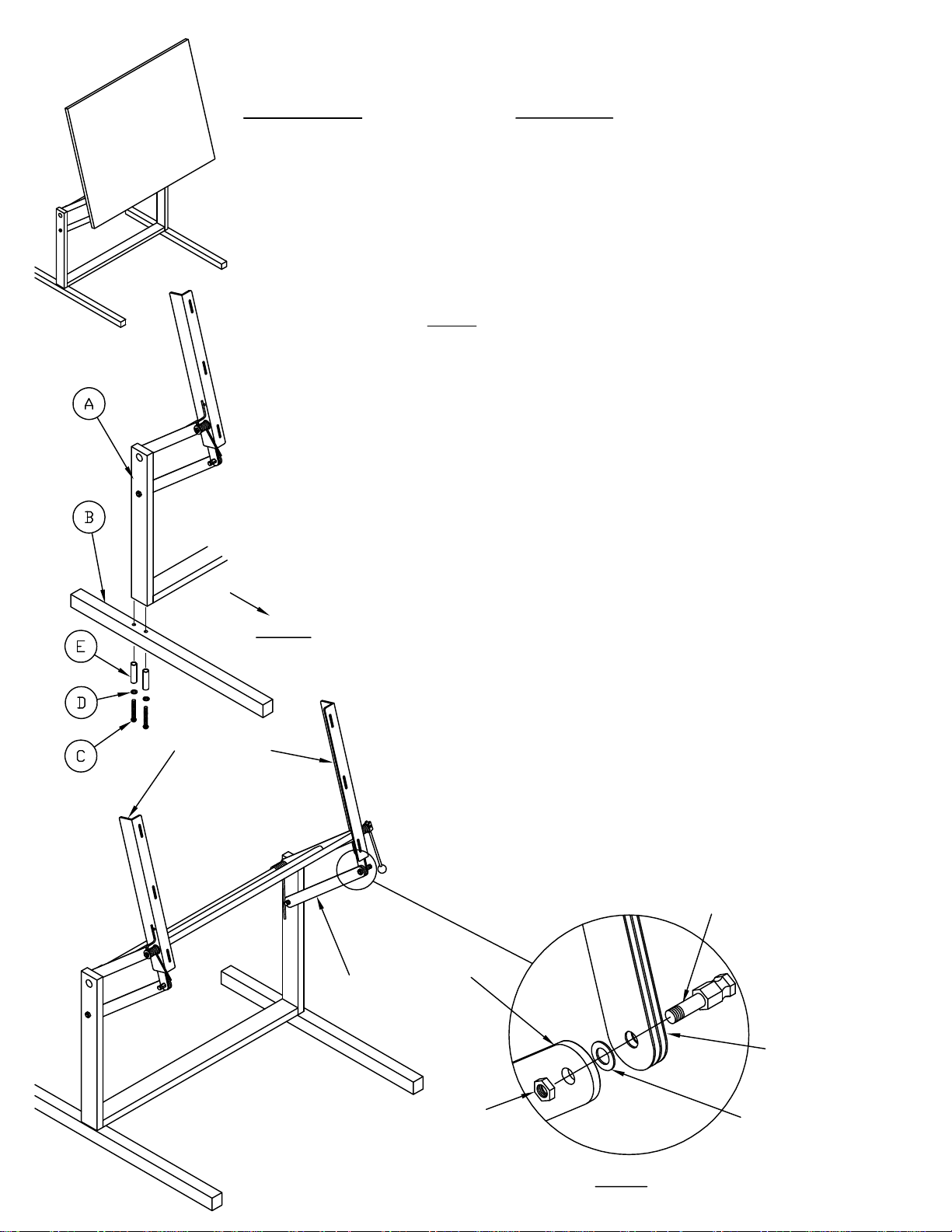

ASSEMBLY INSTRUCTIONS

Washer (between Arm

COMPONENTS:

A. Stand Sub-Assembly.........1

B. Table Feet w/ Glides..........2

Table Mount

HARDWARE:

C. M8 x 80mm Socket Head Cap Screw...............4

D. Large Washer....................................................4

E. Sleeve................................................................4

F. Tension Cube.....................................................2

G. M8 x 16 Hex Head Screw..................................2

H. 13 mm x 17 mm Combination Wrench...............1

J. Spring Spanner Tube..........................................1

NOTE: Assembly is best performed by 2 people.

1. Remove the stand components from the shipping carton

and inspect for shipping damage. Reject if any damage is

evident.

2. Check the parts list to assure that the parts received are

the same as the parts required to assemble the unit. Also

assure the quantities are correct.

3. Assemble the Table Feet (B) to the bottom of the Stand

Sub-Assembly (A) with two Screws (C), two Sleeves (E), and

two Large Washers (D) per Foot. Position the longer portion

of the foot toward the front. Tighten these screws with

Combination Wrench (H) provided.

FRONT

4. Swing the table mount to a vertical position and carefully

release Brake Lever. Temporarily remove the nut from the

bolt holding the Brake Leaves. Swing Tilt Support Arm up

and slide arm onto end of brake leaf bolt. Tighten Hex nut to

secure Arm and Leaves. Repeat this step for both Tilt

Support Arms.

Tilt Support Arm

Hex Nut

(inside)

Brake Leaf Bolt

Brake Leaves

and Brake Leaves)

Fig. 1

Page 2

5. For the BOTTOM Height Assist tension springs, slide a Tension

Cube (F) over the short end of the Tension Spring. Align the tension

cube mounting hole with either hole in the support bracket.

NOTE: Use "FRONT" bracket hole for MORE assist

Use "REAR" bracket hole for LESS assist

Place the tension cube in the same position on both sides. Attach

with Hex Head Screw (G). Fig. 2

6. The UPPER Tilt Assist tension springs have tension cubes

installed on the Board Brackets for shipment. Assist for top control is

adjustable by position tension "UP" or "DOWN" as shown. Tension

Cube must be in same position on both sides. Tighten hardware for

both sides.

FRONT

Fig. 2

NOTE: Place Tension Cube "DOWN" for LESS assist. Fig. 3

Place Tension Cube "UP" for MORE assist. Fig. 4

Tension Cube

"DOWN"

Fig. 3

7. Charge Bottom and upper tension springs by placing Spanner Tube

(J) over the spring end and pulling the spring leg to its seat. Fig. 5 & 6

NOTE: USE EXTREME CAUTION WHEN CHARGING THE SPRING.

8. Attach the top to the board brackets using bolts supplied with Top.

Tension Cube

"UP"

Fig. 4

Fig. 5

Fig. 6

(2)

Page 3

ADJUSTMENTS:

(3)

This Base was designed to accommodate various top sizes:

NOTE: USE EXTREME CAUTION WHEN RELEASING OR

CHARGING THE SPRINGS

* If work surface lifts hard or to quickly, the tension cubes may be

adjusted per step 5 to increase or decrease 'LIFT' assist.

* If work surface tilts hard or tilts to fast, the tension cubes may be

repositioned per step 6 to increase or decrease 'TILT' assist.

* If work surface will not stay in position after placing tilt rod control in

LOCK position it may be necessary to increase tension on Brake

Leaves.

A). Release Tilt Control Rod and position work surface in vertical

position - do not lock Control Rod. Have second person hold work

surface and the Tilt Control Rod in this position. On the opposite

end of this pivot tube, turn Adjustment Nut 1/4 turn clockwise.

B). Position work surface at desired location and lock Tilt Control

Rod. If work surface does no stay in position, repeat above.

DO NOT OVER TIGHTEN damage to leaf springs and pivot tube

may occur. Tilt Control Rod may no engage or stay engaged in

locked position if overtightened.

Tilt Control Rod

Pivot Tube

Adjustment Nut

Shown with work

surface removed for

clarity only.

Loading...

Loading...