MAYEKAWA 4M, 6M, 8M Operation Manual

2202G1JE-DA-M-N_2010.01.

Third Edition 2010/1/5

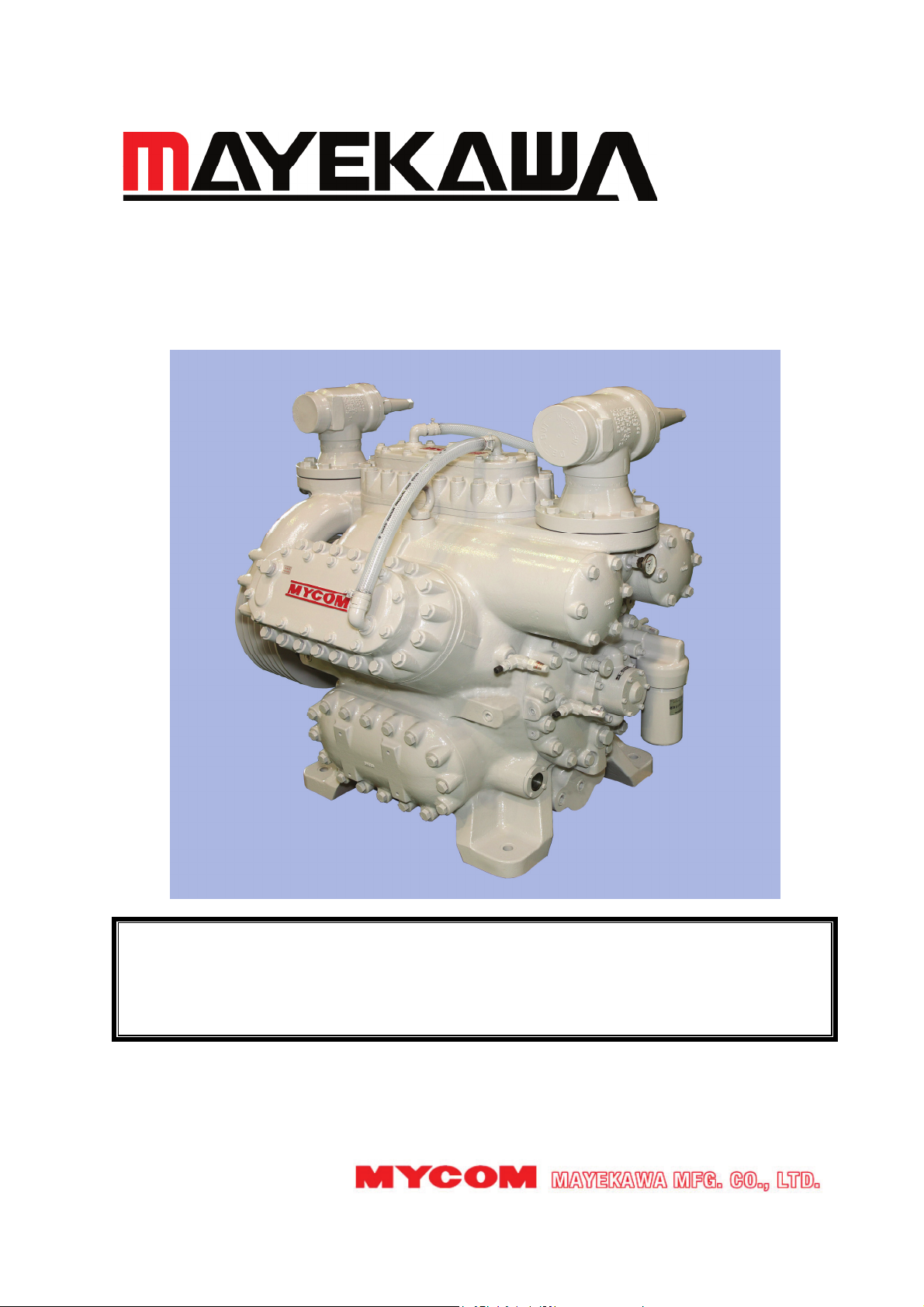

Reciprocating Compressor

M Series Operation Manual

4M/6M/8M/62M/62M-FM

CAUTION

Before operating, inspecting, or servicing the compressor, read this manual thoroughly to fully

understand the contents.

Keep this operation manual in a safe, designated place for future reference whenever the

manual is needed.

3–14–15 Botan Koto-ku, Tokyo 135-8482, Japan

2202G1JE-DA-M-N_2010.01.

Preface

Thank you for having purchased our M series reciprocating compressor (hereinafter indicated as "this

machine").

This operation manual (hereinafter indicated as "this manual") describes safety information, operational and

maintenance procedures in detail for safe and effective use of this product.

Before installing or using this product, make sure you read this manual.

Keep this manual in a safe place near the product for quick reference.

Preface

Reciprocating Compressor M Series

i

2202G1JE-DA-M-N_2010.01.

Warranty and Disclaimer

Warranty and Disclaimer

Warranty Clauses

If malfunctions or damages occur under proper usage (conditions) following documents such as operation

manual or drawings of this product, or, if MAYEKAWA judges that malfunctions or damages are related to

design or manufacture of the product, and if the malfunctions or damages are within the warranty period, we

will repair or replace the product without any charges.

The warranty period is "12 months from factory shipment of this product".

MAYEKAWA is not liable for production or man made disaster compensation due to malfunction or damage

of this product.

Disclaimer Clauses (Exclusion of Warranty Clauses)

Although MAYEKAWA warrants the clauses mentioned above, the following clauses are exempted.

Malfunction or damage of this product caused by natural disaster, or other accidental forces (such as

fire, thunderbolt, windstorm, intense rainfall, flood, tidal wave, earthquake, land subsidence, e.t.c).

Malfunction or damage caused by misusage described below.

Malfunction, damage, or defect of this product due to abnormal or improper use (such as storing

this product for middle to long term outside the building or in locations subject to high

temperatures and high humidity, unexpected inspections, tests, operations, and excessive repetition

start-up/stoppage of the product.)

Malfunction or damage caused by devices or equipments not provided by MAYEKAWA including

operation control methods of those devices.

Malfunction or damage caused by refrigerants, gases, or refrigerant oils, and operating conditions

(design conditions) not approved for this product.

Malfunction or damage caused by maintenance or inspection not recommended by MAYEKAWA.

Malfunction or damage caused by parts that are not Mayekawa genuine.

Malfunction or damage caused by remodeling the product without approval of MAYEKAWA.

Malfunction or damage caused by unexpected misusage

Reciprocating Compressor M Series

ii

2202G1JE-DA-M-N_2010.01.

Important Information

Important Information

Intended Use of the Product

This product is a universal screw compressor intended for refrigeration, cold storage, and air conditioning. Do

not use the product for any other purposes that are not intended for or which depart from the specifications.

For specifications of this product, refer to "2.2 Compressor Specifications".

When performing maintenance use qualified refrigeration personnel.

Important Information for Safe Use of the Product

Although MAYEKAWA has paid a lot of attention to safety measures for this product, all hazards including

potential hazards caused by human errors, or due to environmental conditions can not be anticipated.

There are guidelines that must be observed for operating this product. However, the warnings in this manual

and safety labels on the product are not all inclusive. When operating this product, pay extreme caution on

personnel safety as well as on items described in this manual.

Important rules for safety work with the product that apply to all workers including managers and supervisors

are listed below.

Before using this product, carefully read and fully understand the contents written in this manual and pay

attention to safety.

Operation, maintenance, and inspection of this product should be performed by qualified personnel

educated about the fundamentals of the product and trained about hazards involved and measures to

avoid danger.

Do not allow any person other than those educated on the fundamental expertise of the product and

trained about hazards involved and measures to avoid dangers to approach the product while it is

operating or during maintenance.

Observe all related federal/national and local codes and regulations.

To prevent accidents, do not carry out any operation or maintenance other than those described in this

manual, or use the product for any unapproved purpose.

Replace the parts with the

Not only workers but also managers should actively participate safety and health activities in the

workplace to prevent accidents.

Observe the following precautions when performing maintenance work on electrical control.

Electrical maintenance of the product must be performed by certified/qualified personnel and only those

educated about the electrical control of the product.

Before servicing or inspecting the electrical equipments or devices, turn "OFF" the motor main power

and control power, and perform lockout/tagout to prevent the power from being turned on during work.

Even when the motor main power and control power are turned "OFF", the product may be turned on if the

power is supplied from outside the refrigeration system, cold storage, and air conditioning system. Make sure

the power supply on the power source side is shut off, and perform lockout/tagout to prevent the product from

being turned on during work.

genuine parts.

Reciprocating Compressor M Series

iii

2202G1JE-DA-M-N_2010.01.

Important Information

About This Manual

This product may be modified without prior notice. Therefore, the appearance of actual machine may

differ from the descriptions in this manual. If you have any questions contact your sales offices or

service centers.

This manual is in English. If any other language is required it is the customers responsibility to prepare

a manual for safety education and operation instructions.

This manual is copyrighted. Drawings and technical references including this manual shall not, in

whole or part, be copied, photocopied, or reproduced into any electronic medium or machine-readable

form without prior permission from MAYEKAWA.

Photographs or drawings included in this manual may differ from the appearance of actual product.

If this manual is lost or damaged, immediately place a purchase order to your local sales office or

service center for a new manual. Using the product without the manual may result in safety issues.

If you resell the product, never fail to attach this manual to the product.

Construction of This Manual

Title of section and chapter Description details

Preface Describes the outline of this manual and how to read this manual.

Warranty and Disclaimer

Important Information Describes important information related to the machine and this manual.

1. Safety

2. Configuration and

Specification of Compressor

3. Installation Describes the installation procedure of the machine.

4. Operation of the Compressor

and the System

5. Maintenance

6. Troubleshooting

7. Related Document Describes information such as illustrated parts breakdown and parts list.

Describes clauses and coverage of warranty.

Exclusion of warranty clauses is described as disclaimer.

Describes safety information for the worker, safety rules for this machine,

and management details regarding the work safety that is required for

handling the machine.

Describes the main components of the machine, functional information,

specification, and service limits.

Describes the precautions for operating the machine.

Describes sections and period for inspecting, and assembly and

disassembly of this product.

Describes the methods of the machine in case of problem occurring during

operation of the machine.

How to Order Genuine Parts

Confirm the applicable parts in "7.1 Development View and Configuration Table of the Parts" of "Chapter 7,

Related Document". And inform the “Product Name, Part Number, Part Name, and required quantity” to your

local sales offices or service centers.

Reciprocating Compressor M Series

iv

2202G1JE-DA-M-N_2010.01.

Important Information

Inquiry

If you need further information or have any questions, please contact your local sales offices or service

centers.

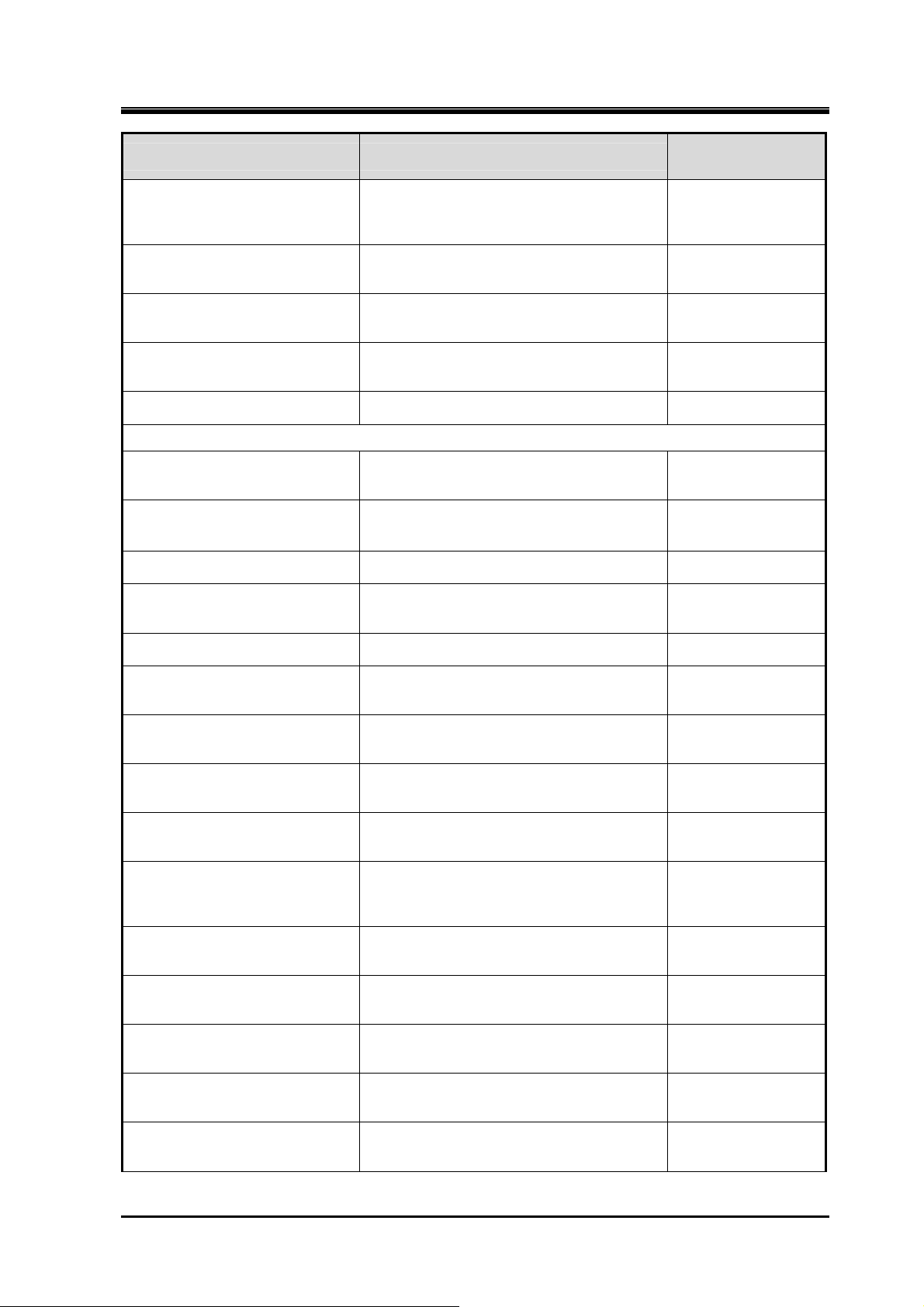

1. Domestic

Description Address Tel/Facsimile

Head office

Moriya plant

Hokkaido office

Tohoku office

Hokushinetsu

office

Kanto office

Tokai office

Chubu office

Kansai office

Chugoku office

Shikoku office

Kyushu office

2. Overseas

〒135-8482

3–14–15 Botan Koto-ku, Tokyo

〒302-0118

2000, Taysuzawa Moriya-shi, Ibaraki-pref

〒063-0803

2-5-1, 3-jyo Nijuuyonken Nishi-ku, Sapporo-city, Hokkaido

〒983-0012

2-5-12, Ideka, Miyagino-ku, Sendai-shi, Miyagi-pref.

〒950-0925

Oyama-build. 303, 1-2-34, Bentenbashi-dori, Chuo-ku, Niigata-shi,

Niigata-pref.

〒135-8482

3–14–15 Botan Koto-ku, Tokyo

〒422-8034

1-15-36, Takamatsu, Suruga-ku, Shizuoka-shi, Shizuoka-pref.

〒460-0002

2-9-6, Marunouchi, Naka-ku, Nagoya-shi, Aichi-pref.

〒553-0001

1-4-27, Ebie, Fukushima-ku, Osaka-shi, Osaka

〒739-2117

2-3-40, Takayadai, Higashihiroshima-shi, Hiroshima-pref.

〒761-8074

410-1, Otakamimachi, Takamatsu-shi, Kagawa-pref.

〒810-0802

Fukuoka-fujiland-build. 10F, 2-3, Nakajima-cho, Nakasu,

Hakata-ku, Fukuoka-shi, Fukuoka-pref.

TEL:03-3642-8181

FAX:03-3643-7094

TEL:0297-48-1361

FAX:0297-48-5269

TEL:011-631-2052

FAX:011-631-2053

TEL:022-259-5211

FAX:022-259-5223

TEL:025-257-1626

FAX:025-286-6165

TEL:03-3643-2886

FAX:03-3641-8468

TEL:054-236-5350

FAX:054-236-5355

TEL:052-218-3307

FAX:052-218-3308

TEL:06-4795-6000

FAX:06-4795-6033

TEL: 082-491-1830

FAX: 082-491-1838

TEL:087-868-3400

FAX:087-868-3399

TEL:092-262-0016

FAX:092-262-0115

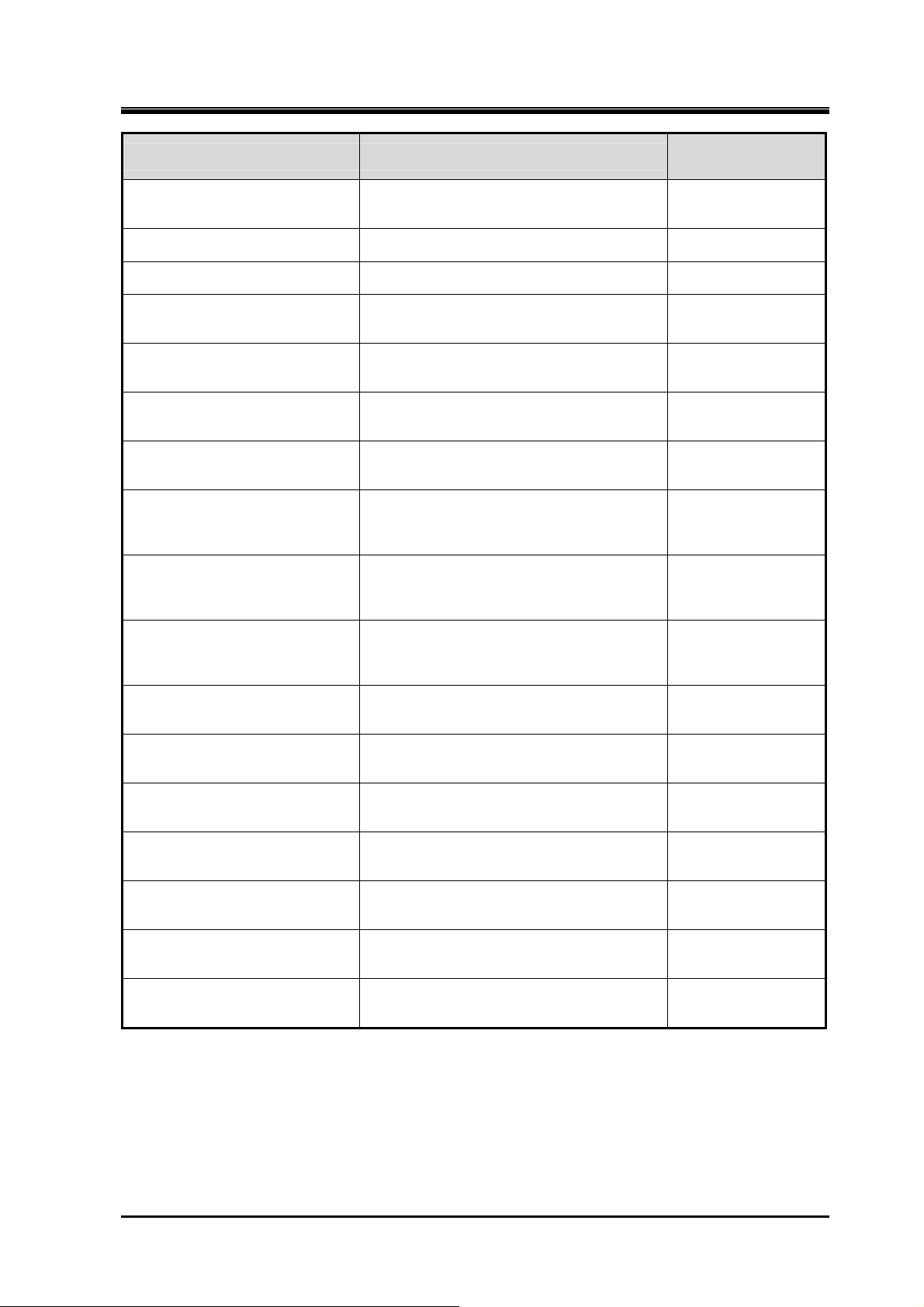

Description Location

NORTH AMERICA

MYCOM CANADA LTD.

(VANCOUVER OFFICE)

MYCOM CANADA LTD.

(TORONTO OFFICE)

MAYEKAWA U.S.A. INC.

(HEAD OFFICE)

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION (MIAMI OFFICE)

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION (CHARLOTTE OFFICE)

Reciprocating Compressor M Series

UNIT 110, 6620 MCMILLAN WAY,

RICHMOND, B.C., V6W 1J7, CANADA

1745 BONHILL ROAD,

UNIT #6&7 MISSISSAUGA,

ONTARIO, L5T 1C1, CANADA

8750 WEST BRYN MAWR AVENUE,

SUITE 190 CHICAGO, IL 60631, U.S.A.

7220 N.W. 32TH AVE., SUITE 303,

MIAMI, FL 33166, U.S.A.

15905 BROOKWAY DRIVE UNIT 4208

HUNTERSVILLE, NC 28078, U.S.A.

Telephone and

facsimile No.

TEL: (1) 604-270-1544

FAX: (1) 604-270-9870

TEL: (1) 905-564-0664

FAX: (1) 905-564-7614

TEL: (1) 773-516-5070

FAX: (1) 773-516-5071

TEL: (1) 305-477-5741

FAX: (1) 305-477-5681

TEL: (1) 704-896-3632

FAX: (1) 704-896-3697

v

2202G1JE-DA-M-N_2010.01.

Important Information

Description Location

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION (NASHVILLE OFFICE)

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION (LA OFFICE, FACTORY)

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION (SEATTLE OFFICE)

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION

(MODESTO OFFICE)

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION

(SAN FRANCISCO OFFICE)

MAYEKAWA U.S.A.INC.

INDUSTRIAL REFRIGERATION

DIVISION (SAN ANTONIO OFFICE)

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION (NY OFFICE)

MAYEKAWA U.S.A. INC.

INDUSTRIAL REFRIGERATION

DIVISION (YORK OFFICE)

MAYEKAWA U.S.A.INC.

MANUFACTURING DIVISION

(SAN ANTONIO OFFICE, FACTORY)

MAYEKAWA U.S.A. INC.

CHEMICAL PROCESS DIVISION

MAYEKAWA U.S.A. INC.

CHEMICAL PROCESS DIVISION

(HUSTON OFFICE)

EUROPE

N.V.MAYEKAWA EUROPE S.A.

(HEAD OFFICE, FACTORY)

N.V.MAYEKAWA EUROPE S.A.

ZWEGNIEDEALASSUNG

DEUTSHLANSD

MAYEKAWA UK REPRESENTATIVE

OFFICE

MAYEKAWA. S.L. CALLE MONTEVIDEO 5, NAVE 13 POL.

MAYEKAWA EUROPE S.A.

SUCCURSALE FRANCAISE

MAYEKAWA MFG. CO., LTD.

MOSCOW LIAISON OFFICE

MYCOM INTERTEC AG ROSENBERGSTRASSE 31, CH-6300 ZUG,

MAYEKAWA EUROPE S,A,

DUBAI OFFICE

MAYEKAWA BULGARIA

REPRENSETATIVE OFFICE

MYCOM REFRIGERATION

INDIA PVT.LTD.

MAYEKAWA AUSTRALIA

PTY.LTD.

SUITE 203 BROOKSIDE LANDING

1550 N MT JULIET RD.,

MT JULIET, TN 37122, U.S.A

19475 GRAMERCY PLACE,

TORRANCE, CA 90501, U.S.A.

2615 W CASINO ROAD, UNIT-3D,

EVERETT, WA 98204, U.S.A.

4718 GREEN LEAF COURT,

SUITE 5 MODESTO, CA 95356, U.S.A.

1840 GATEWAY DRIVE, # 226 SAN MATEO,

CA 94404, U.S.A.

16825 IH 35 NORTH SELMA,

TX 78154, U.S.A.

303 SOUTH BROADWAY,

SUITE 102 TARRYTOWN,

NEW YORK 10591, U.S.A.

3395 FARMTRAIL ROAD YORK,

PA 17406, U.S.A.

16825 IH 35 NORTH SELMA,

TX 78154, U.S.A.

19475 GRAMERCY PLACE,

TORRANCE, CA 90501, U.S.A.

3222 PASADENA FREEWAY PASADENA,

TX 77503, U.S.A.

LEUVENSESTEENWEG 605,

1930 ZAVENTEM, BELGIUM

NUERNBERGER STRASSE 118,

97076 WUERZBURG, DEUTSCHLAND

16 OAKHURST GARDENS, BEXLEYHEATH,

KENT DA7 5JP, UNITED KINGDOM

INDUSTRIAL CAMPORROSO 28806 ALCALA

DE HENARES, MADRID, SPAIN

9, RUE MICHAEL FARADAY, 78180

MONTIGNY-LE-BRETONNEUX, FARNCE

HOUSE 3, FLAT 54, MYTNAYA ST,

MOSCOW, 119049 RUSSIA

SWITZERLAND

P.O.BOX.61349, LOB.11.NO.126,

JEBEL ALI FREE ZONE, DUBAI, U.A.E.

94, HRISTO BOTEV STR. 1202, SOFIA,

BULGARIA

#30 CENTRUM PLAZA,

GOLF COURESE ROAD, SECTOR 53,

GURAGAON, HARYANA, 122002,

REPBLIV OF INDIA

UNIT 2, 44 MCCAULEY STREET

MATRAVILLE NSW 2036, AUSTRALIA

Telephone and

facsimile No.

TEL: (1) 615-773-2859

FAX: (1) 615-758-7743

TEL: (1) 310-328-1362

FAX: (1) 310-782-6759

TEL: (1) 425-348-3404

FAX: (1) 425-348-3419

TEL: (1) 209-545-9752

FAX: (1) 209-545-3654

TEL: (1) 650-378-1235

FAX: —

TEL: (1) 210-599-4536

FAX: (1) 210-599-4538

TEL: (1) 914-301-9770

FAX: (1) 914-332-0400

TEL: (1) 717-779-0138

FAX: (1) 717-779-0109

TEL: (1) 210-599-4518

FAX: (1) 210-599-1788

TEL: (1) 310-328-6279

FAX: (1) 310-328-8487

TEL: (1) 281-447-2599

FAX: (1) 281-447-6623

TEL: (32) 2-757-9075

FAX: (32) 2-757-9023

TEL: (49) 931-389388-0

FAX: (49) 931-359388-20

TEL: (44) 1322-433558

FAX: (44) 1322-433164

TEL: (34) 91-830-0392

FAX: (34) 91-830-0397

TEL: (33) 1-30-58-26-00

FAX: (33) 1-30-58-19-37

TEL: (7) 499-230-01-76

FAX: (7) 495-230-21-12

TEL: (41) 41-726-8626

FAX: (41) 41-726-8620

TEL: (971) 4-887-2232

FAX: (971) 4-887-2238

TEL: (359) 2-8319002

FAX: (359) 2-8319002

TEL: (91) 12-4420-6616

FAX: (91) 12-4420-6618

TEL: (61) 2-9695-7000

FAX: (61) 2-9695-7001

Reciprocating Compressor M Series

vi

2202G1JE-DA-M-N_2010.01.

Important Information

Description Location

MAYEKAWA AUSTRALIA PTY.

LTD.(NEW ZEALAND BRANCH)

ASIA

P.T.MYCOM INDONESIA GRAHA PRATAMA BUILDING, 9TH FLOOR

MAYEKAWA (M) SDN. BHD. 35-1, BLOCK D1, DATARAN PRIMA,

MYCOM PHILIPPINES CORP. UNIT 2706 UNION BANK PLAZA

MYCOM PHILIPPINES CORP.

(GENARAL SANTOS OFFICE)

MAYEKAWA SINGAPORE

PTE.LTD.

MYCOM INDUSTRY CO., LTD.

(HEAD OFFICE)

MYCOM INDUSTRY CO., LTD.

CHEMICAL DEPARTMENT

MYCOM INDUSTRY CO., LTD.

TAIPEI BRANCH

MYCOM INDUSTRY CO., LTD.

TAICHUNG BRANCH

MAYEKAWA CHINA INDUSTRIES

CO., LTD.

MAYEKAWA CHINA INDUSTRIES

CO., LTD.

QINGDAO OFFICE

MAYEKAWA MFG. CO., LTD

BEIJING LIAISON OFFICE

MAYEKAWA (THAILAND) CO.,

LTD.

MAYEKAWA (THAILAND) CO.,

LT D.

TRANG BRANCH

MAYEKAWA HOLDING

(THAILAND) CO., LTD.

MAYEKAWA MFG.CO., LTD.

HO CHI MINH CITY

REPRESENTATIVE OFFICE

30 TUI STREET OTAHUHU PO. BOX 12106

AUCKLAND NEWZELAND

JI. M. T. HARYONO KAV.15 JAKARTA 12810,

INDONESIA

JALAN PJU 1/41, KELANA JAYA,

47301 PETALING JAYA,

SELANGOR, MALAYSIA

MERALCO AVENUE CORNER ONYX St.

ORTIGAS CENTER, PASIG CITY 1605,

PHILIPPINES

ROOM 4, LEAH DAPROZA BUILDING

FISCAL DAPROZA AVENUE

GENERAL SANTOS CITY 9500

6 TAGORE LANE SINGAPORE 787470

1F., NO.2, SHIN JANN ROAD,

CHIEN CHEN DIST., KAOHSIUNG,

TAIWAN 80672, REP.OF CHINA

1F., NO.2, SHIN JANN ROAD,

CHIEN CHEN DIST., KAOHSIUNG,

TAIWAN 80672, REP.OF CHINA

10F-4, NO, 421, SONG-SHAN ROAD, TAIPEI,

TAIWAN 11083, REP. OF CHINA

NO. 19, SEC.3, HUANJUNG RD., TAICHUNG,

TAIWAN, REP. OF CHINA

ROOM 705,

WISE LOGIC INTERNATIONAL CENTER,

NO.66 NORTH SHANXI RD.,

SHANGHAI, 200041, CHINA

ROOM 503, FULIN BUILDING

NO.87 SOUTH FUZHOU ROAD,

SOUTH DISTRICT, QINGDAO CITY, 266071,

CHINA

NO.7B222 HANWEI PLAZA,

NO.7 GUANGHUA ROAD,

CHAOYANG DISTRICT,

BEIJING 100004, CHINA

2/3 MOO 14,

9TH FLOOR BANGNA TOWER BLDG., TOWER

A,

BANGNA-TRAD RD, K.M.6.5,

BANGKAEW BANGPLEE,

SAMUTPRAKARN 10540, THAILAND

1/7 TRANG-PALIAN RD., MUANG,

TRANG 92000, THALAND

2/3 MOO 14,

9TH FLOOR BANGNA TOWER BLDG., TOWER

A,

BANGNA-TRAD RD, K.M.6.5,

BANGKAEW BANGPLEE,

SAMUTPRAKARN 10540, THAILAND

ROOM 305, 3FL, TOUI TRE TOWER,

60A HOANG VAN THU, WARD 9,

PHU NHUAN DIST., HO CHI MINH CITY,

VIETNAM

Telephone and

facsimile No.

TEL: (64) 9-276-2305

FAX: (64) 9-276-2306

TEL: (62) 21-8370-9484

FAX: (62) 21-8370-9483

TEL: (60) 3-78051406

FAX: (60) 3-78051409

TEL: (63) 2-706-0473

FAX: (63) 2-706-0475

TEL: (63) 83-552-3282

FAX: (63) 83-301-2698

TEL: (65) 6451-1565

FAX: (65) 6451-4932

TEL: (886) 7-821-0886

FAX: (886) 7-821-4688

TEL: (886) 7-821-7709

FAX: (886) 7-821-9019

TEL: (886) 2-2727-9711

FAX: (886) 2-2759-8484

TEL: (886) 4-2251-4128

FAX: (886) 4-2251-4129

TEL: (86) 21-5116-8958

FAX:(86) 21-5116-8928

TEL: (86) 532-8602-6169

FAX:

(86) 532-8602-6269

TEL: (86) 10-6561-7811

FAX: (86) 10-6561-1997

TEL: (66) 2-751-9610

FAX: (66) 2-751-9565

TEL: (66) 75-224-784

FAX: (66) 75-224-351

TEL: (66) 2-751-9610

FAX: (66) 2-751-9565

TEL: (84) 8-3997-5284

FAX: (84) 8-3997-5287

Reciprocating Compressor M Series

vii

2202G1JE-DA-M-N_2010.01.

Important Information

Description Location

MAYEKAWA VIETNAM ONE

MEMBER COMPANY LIMITED

(MAYEKAWA VIETNAM)

MYCOM KOREA CO., LTD.

HEAD OFFICE

MYCOM KOREA CO., LTD.

CHANGWON FACTORY

MYCOM KOREA CO., LTD.

PUSAN BRANCH

MYCOM KOREA CO., LTD.

GWANGJU BRANCH

LATIN AMERICA

MAYEKAWA ARGENTINA S.A.

(BUENOS AIRES OFFICE)

MAYEKAWA ARGENTINA S.A.

(PUERTO MADRYN OFFICE)

MYCOM PERU S.A.C. CALLE LUIS PASTEUR 1490,

MAYEKAWA CHILE S.A.C.el.

(SANTIAGO OFFICE)

MAYEKAWA CHILE S.A.C.el.

(CONCEPCION OFFICE)

MAYEKAWA CHILE S.A.C.el.

(PUERTO MONTT OFFICE)

ANREC LTDA TRANSVERSAL 93 NO.53-48 INTERIOR 37,

MAYEKAWA DO BRASIL REF.

LTDA.

MAYEKAWA DO BRASIL LTDA.

(BAHIA BRANCH)

MAYEKAWA DO BRASIL LTDA.

(BELO HORIZONTE BRANCH)

MAYEKAWA DO BRASIL LTDA.

(CHAPECO BRANCH)

MAYEKAWA DO BRASIL LTDA.

(CUIABA BRANCH)

MAYEKAWA DO BRASIL LTDA.

(CURITIBA BRANCH)

MAYEKAWA DO BRASIL LTDA.

(CAMPO GRANDE BRANCH)

MAYEKAWA DO BRASIL LTDA.

(GOIANIA BRANCH)

ROOM 305, 3FL, TOUI TRE TOWER,

60A HOANG VAN THU, WARD 9,

PHU NHUAN DIST., HO CHI MINH CITY,

VIETNAM

JUYEON BUILDING 2F, SEOGYE-DONG 209,

YONGSAN-KU, SEOUL, 140-710,

REP.OF KOREA

PALYONG DONG 24-20,

CHANGWON KYUNGSANGNAM-DO 641847,

REP.OF KOREA

TONG YOUNG SU SAN 6F,

763-20 KAMCHEON-DONG, SAHA-KU,

PUSAN 604-806, REP.OF KOREA

970-6 WOLCHUL-DONG PUK-KU GWANGJU

500-460, REP. OF KOREA

AV. VELEZ SARSFIELD 670/74 C1282

AFT-CAPITAL FEDERAL BUENOS AIRES,

REPUBLICA ARGENTINA

OFICINA PTO. MADRYN LEOPOLDO

LUGONES 45 (U9129KDA)-PUERTO MADRYN

PCIA DE CHUBUT REPUBLICA ARGENTINA

LINCE, LIMA, PERU

CORDILLERA No.331, MODULO D14,

FLEX CENTER, PUERTO VESPUCIO,

QUILICURA, SANTIAGO, CHILE

ANIBAL PINTO No.215, OFICINA 403,

CONCEPCION, CHILE

BERNARDINO 1057 MODULO 6,

PARQUE INDUSTRIAL SAN ANDRES

PUERTO MONTT, CHILE

PAQUE INDUSTRIAL EL DORADO, BOGOTO,

COLOMBIA

RUA LICATEM 250, JARDIM FAZENDA

RINCAO POLO INDUSTRIAL DE ARUJA-SP,

CEP 07400-000, BRASIL

RUA DR. JOSE PEROBA, 275 - SALA 902

EDIFICIO METROPOLIS - BAIRRO STIEPE,

SALVADOR-BA, CEP 41770-2325, BRASIL

AV. BARAO HOMEM DE MELLO,

4386 – S 401 ED.EMYR SOARES - BAIRRO

ESTORIL BELO HORIZONTE-MG,

CEP 30450-250, BRASIL

RUA FERNANDO MECHADO,

593 D-S 201 CHAPECO-SC

CAIXA POSTAL 177, CEP 89801-973, BRASIL

AVENIDA ISSAC POVOAS, 586 – SALA 405

EDIFICIO WALL STREET - CENTRO

CUIABA-MT, CEP 78055-560, BRASIL

RUA ISABEL A. REDENTORA, 1826 – SALA 8

CENTRO - SAO JOSE DOS PINHAIS-PR,

CEP 83095-980, BRASIL

RUA JOSE ANTONIO PEREIRA, 2200 – S 02

CONDOMINIO COSTA D’OURO CAMPO

GRANDE-MS, CEP 79010-190, BRASIL

RUA C, 255 – QUADRA 588 – LOTE 4/8 SALA

1004 – CENTRO EMPRESARIAL SEBBA

GOIANIA-GO, CEP 74280-010, BRASIL

Telephone and

facsimile No.

TEL: (84) 8-3997-5284

FAX: (84) 8-3997-5287

TEL: (82) 2-796-1766

FAX: (82) 2-798-7715

TEL: (82) 55-294-8678

FAX: (82) 55-299-7678

TEL: (82) 51-242-3737

FAX: (82) 51-243-8542

TEL: (82) 62-973-8471

FAX: (82) 62-973-8475

TEL: (54) 11-4302-2791

FAX: (54) 11-4304-3015

TEL: (54) 2965-475414

FAX: (54) 2965-475414

TEL: (51) 1-441-8552

FAX: (51) 1-222-1543

TEL: (56) 2-739-0202

FAX: (56) 2-739-2700

TEL: (56) 41-223547

FAX: (56) 41-212443

TEL: (56) 65-257570

FAX: (56) 65-288073

TEL: (57) 1-224-3028

FAX: (57) 1-224-3203

TEL: (55) 11-4654-8000

FAX: (55) 11-4654-8002

TEL: (55) 71-3341-0737

FAX: —

TEL: (55) 31-3297-6166

FAX: —

TEL: (55) 49-3322-4241

FAX: (55) 49-3322-4241

TEL: (55) 65-3023-7559

FAX: —

TEL: (55) 41-3383-1518

FAX: —

TEL: (55) 67-3042-7200

FAX: —

TEL: (55) 62-3093-5062

FAX: —

Reciprocating Compressor M Series

viii

2202G1JE-DA-M-N_2010.01.

Important Information

Description Location

MAYEKAWA DO BRASIL LTDA.

(OESTE PAULISTA BRANCH)

MAYEKAWA DO BRASIL LTDA.

(RECIFE BRANCH)

MAYEKAWA DO BRASIL LTDA.

(RIO GRANDE DO SUL BRANCH)

MAYEKAWA DO BRASIL LTDA.

(MACAE)

MAYEKAWA DO BRASIL LTDA.

(RIO DE JANEIRO BRANCH)

MYCOM CENTROAMERICA S.A BODEGA #63, CONDOMINIO COMERCIAL

MYCOM VENEZUELA

SALES & SERVICES,C.A.

(CARACAS OFFICE)

MYCOM VENEZUELA

SALES & SERVICE, C.A.

(MARACAY OFFICE)

MYCOM VENEZUELA

SALES & SERVICE, C.A.

(MARACAIBO OFFICE)

MYCOM CHEMICAL PROCESS

CORP. DE VENEZUELA S.A.

MAYEKAWA DE MEXICO,

S.A. DE C.V.

(CUERNAVACA OFFICE)

MAYEKAWA DE MEXICO,

S.A. DE C.V.

(MEXICO CITY OFFICE)

MAYEKAWA DE MEXICO,

S.A. DE C.V.

(GUADALAJARA OFFICE)

MAYEKAWA DE MEXICO,

S.A. DE C.V.

(MONTERREY OFFICE)

MAYEKAWA DE MEXICO,

S.A. DE C.V.

(OBREGON OFFICE)

MAYEKAWA DE MEXICO,

S.A. DE C.V.

(IRAPUATO OFFICE)

MAYEKAWA DE MEXICO,

S.A. DE C.V.

(CULIACAN OFFICE)

AV. FRANCISCO DE CHAGAS OLIVEIRA,

344 JARDIM PINHEIRO SAO JOSE DO RIO

PRETO-SP, CEP 15091-330, BRASIL

RUA SA E SOUZA, 687 – SALA 103 SETUBAL

RECIFE-PE, CEP 51030-065, BRASIL

RUA MUCK, 298 – SALA 601 EDIFICIO

SANTA HELENA CANOAS-RS, BRASIL

RUA PROFESSOR MARIETA PEIXOTO,

62 CENTRO - MACAE – RJ,

CEP 27910-250, BRASIL

AV. DAS AMERICA, 8445 - LOJA 1309 BARRA

DA TIJUCA, RIO DE JANEIRO-RJ,

CEP 22793-081, BRASIL

TIERRA DOS, EL CACIQUE DE RIO SEGUNDO,

ALAJUELA, COSTA RICA

CALLE LOS MANGOS,

EDIFICIO SELEMAR, PISO 8,

SABANA GRANDE, CARACAS, VENEZUELA

AV.INTERCOMUNAL TURMERO,

EDF.TECHOMAT METROPOLITANO, PISO 1,

OFICINA 3, MARACAY, EDO.ARAGUA,

VENEZUELA

AV.17 SECTOR LOS HATICOS C.C. PARQUE

INDUSTRIAL ANGELINI, LOCAL #14,

PLANTA ALTA, MARACAIBO, EDO. ZULIA,

VENEZUELA

AV.17 SECTOR LOS HATICOS C.C. PARQUE

INDUSTRIAL ANGELINI, LOCAL #14,

PLANTA ALTA, MARACAIBO, EDO. ZULIA,

VENEZUELA

AV.DE LOS 50MTS.NO.381,

CIVAC. JIUTEPEC MORELOS, C.P.62578,

MEXICO

AV.COYOACAN #945 COL .DEL VALLE DEL.

BENITO JUAREZ C.P.03100, MEXICO,

D.F. MEXICO

SANTA MARIA No.3086, COL. VALLARTA SAN

LUCAS GUADALAJARA, JALISCO, C.P.44690,

MEXICO

AV. HIDALGO 2258 LOCAL 8 COL. OBISPADO

MONTERREY, N.L., C.P.64060, MEXICO

CALLE SINALOA NO.611 (ENTRE NICOLAS

BRAVO Y 6 DE ABRIL), COL. CENTRO,

C.P.85000, CD. OBREGON, SON, MEXICO

CALLE AGUSTIN ZARAGOZA NO.219 LOCAL-2

COL.DEPORTIVA, C.P.36612, IRAPUATO, GTO.

MEXICO

AV. NICOLAS BRAVO 1572, LOCAL 1

COL.MORELOS CULIACAN, SINALOA,

C.P.80170, MEXICO

Telephone and

facsimile No.

TEL: (55) 17-3227-0235

FAX: —

TEL: (55) 81-3342-7670

FAX: TEL: (55) 51-3429-1860

FAX: TEL: (55) 22-2772-6069

FAX: (55) 22-2759-3112

TEL: (55) 21-2431-0266

FAX: (55) 21-2431-0266

TEL: (506) 2441-4464

FAX: (506) 2441-4465

TEL: (58) 212-216-6026

FAX: (58) 212-216-0608

TEL: (58) 243-269-4913

FAX: (58) 243-269-3952

TEL: (58) 261-764-8055

FAX: (58) 261-765-0853

TEL: (58) 261-765-1059

FAX: (58) 261-765-2176

TEL: (52) 77-73-19-0925

FAX: (52) 77-73-20-5762

TEL: (52) 55-5062-0870

FAX: (52) 55-5062-0898

TEL: (52) 3336-15-5765

FAX: (52) 3336-15-1307

TEL: (52) 81-8347-3085

FAX: (52) 81-8347-5830

TEL: (52) 644-415-4302

FAX: (52) 644-415-3500

TEL: (52) 462-624-9353

FAX: (52) 462-624-9264

TEL: (52) 66-7715-4199

FAX: (52) 66-7715-4150

Reciprocating Compressor M Series

ix

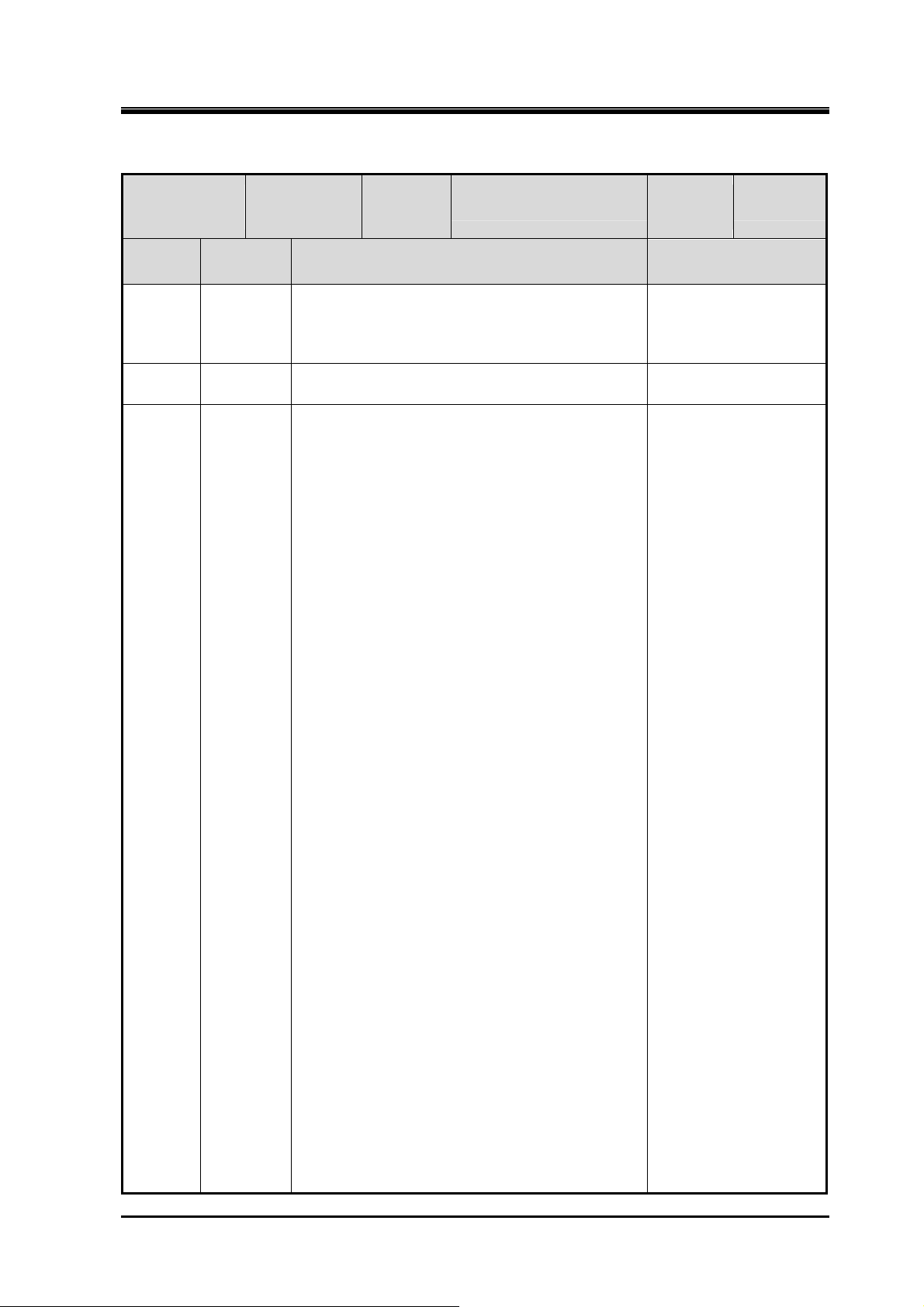

Revision Description

2202G1JE-DA-M-N_2010.01.

Revision Description

Date

M Series

Operation

Manual

Development View and Configuration Table of the

Parts - Parts Configuration Table/7.7 Parts Inspection

and Replacement Standards - “O”ring List

62M/62M-FM

Document

No.

Contents of revisions

(modified clause, page, and details)

2202G1JE-DA-M-N_2010.01.

First edition

issue date

Created/approved by:

Yamamoto, Yamada

Yamamoto, Yamada

Operation

manual name

Revision

No.

2 2009/2/2 2.2.1 Specification/ 2.3 Selection of V-belt/7.1

3 2010/1/5 Parts drawing change due to design change, addition of

Issuance

2008/4/1

Reciprocating Compressor M Series

x

2202G1JE-DA-M-N_2010.01.

Table of Contents

Table of Contents

1 Safety

1.1 Observation/Prevention ..............................................................................1-1

1.1.1 Observance (Do's) ................................................................................................. 1-1

1.1.1.1 Do's on Operation........................................................................................ 1-1

1.1.1.2 Do's on Maintenance................................................................................... 1-1

1.1.1.3 Do's on Lockout/Tagout after Shutting off the Power .................................. 1-1

1.1.1.4 Do's about Personal Protective Devices ..................................................... 1-2

1.1.1.5 Do's about Handling of Hazardous and Toxic Substances.......................... 1-2

1.1.1.6 Do's about Handling Emergency Situation.................................................. 1-2

1.1.1.7 Do's about Waste Oil, Fluid, and Materials ................................................. 1-2

1.1.1.8 Other Do's.................................................................................................... 1-2

1.1.2 Don'ts..................................................................................................................... 1-2

1.2 Warnings....................................................................................................... 1-3

1.2.1 Types and Meanings of Warnings ......................................................................... 1-3

1.2.2 Safety labels .......................................................................................................... 1-4

1.3 Remaining Hazard........................................................................................ 1-6

1.4 Safety Devices.............................................................................................. 1-8

1.4.1 Emergency Stop Button......................................................................................... 1-8

1.4.2 Breakers of Motor Main Power and Control Power

(with Lockout/Tagout Devices) .............................................................................. 1-8

1.4.3 Safety Belt/coupling Guard .................................................................................... 1-9

1.4.4 Safety valve ......................................................................................................... 1-10

1.4.5 Automatic Control and Protection Equipment M compressor.............................. 1-11

1.4.6 Compressor Cooling Fluid Temperature Failure Alarm....................................... 1-14

1.4.7 Oil Heater and Thermometer Switch ................................................................... 1-14

1.5 Example of Material Safety Data Sheet (MSDS) ...................................... 1-15

2 Configuration and Specification of Compressor

2.1 Configuration of Compressor ..................................................................... 2-1

2.1.1 Overall View of Compressor .................................................................................. 2-1

2.1.2 Cross-Sectional View of Assembly ........................................................................ 2-3

2.1.3 Oil Supply Mechanism ........................................................................................... 2-5

2.1.4 Unloader Mechanism............................................................................................. 2-6

2.2 Specification of Compressor ...................................................................... 2-7

2.2.1 Specification........................................................................................................... 2-7

2.2.2 Service Limits and Range...................................................................................... 2-8

2.2.3 External Dimensions .............................................................................................. 2-9

2.3 Selection of V-belt...................................................................................... 2-12

Reciprocating Compressor M Series

xi

2202G1JE-DA-M-N_2010.01.

Table of Contents

3 Installation

3.1 Safety Precautions for Installation............................................................. 3-1

3.2 Installation Works ........................................................................................3-2

3.2.1 Unpacking .............................................................................................................. 3-2

3.2.2 Storage .................................................................................................................. 3-2

3.2.3 Transfer..................................................................................................................3-2

3.2.4 Preparation for Installation..................................................................................... 3-4

3.2.5 Installation..............................................................................................................3-6

3.2.5.1 Installation.................................................................................................... 3-6

3.2.5.2 Position of the Oil Returning Point in the Oil Separator /

Procedure of Oil Returning.......................................................................... 3-6

3.2.5.3 Protection Switch......................................................................................... 3-6

3.2.5.4 Centering of the Compressor/Driving Machine and

Attachment of the V-belt .............................................................................. 3-7

3.2.5.5 Centering of the Compressor/Driving Machine and

Attachment of the Direct Coupling............................................................. 3-10

3.2.5.6 Piping......................................................................................................... 3-12

3.2.5.7 Charging of Refrigerant Oil........................................................................ 3-14

3.2.6 Check after Installation ........................................................................................ 3-14

3.3 Documents Related to Installation *1....................................................... 3-15

4 Operation of the Compressor and the System

4.1 Refrigerant Oil ..............................................................................................4-1

4.1.1 Precautions for Selecting the Refrigerant Oil ........................................................ 4-1

4.1.2 Initial Charging Method.......................................................................................... 4-2

4.1.3 Replenishment of the Refrigerant Oil .................................................................... 4-2

4.1.4 Set Oil Pressure..................................................................................................... 4-2

4.1.5 Oil Quantity ............................................................................................................ 4-3

4.2 Initial Operation............................................................................................ 4-4

4.2.1 Initial Operation Method......................................................................................... 4-4

4.3 Operation Order of the Unloader ................................................................4-5

4.4 Operation Notices ........................................................................................ 4-7

4.4.1 Start/Stop Limitation .............................................................................................. 4-7

4.4.2 Action for Stopping the Compressor for Long Period of Time ............................... 4-7

4.4.3 Operation after the Compressor has been stopped for Long Period of Time ....... 4-7

5 Maintenance

5.1 Safety Precautions for Maintenance .......................................................... 5-1

5.2 Periodic Inspection...................................................................................... 5-2

5.2.1 Daily Inspection ..................................................................................................... 5-2

5.2.2 Monthly Inspection................................................................................................. 5-3

5.2.3 Biannual Inspection ............................................................................................... 5-3

Reciprocating Compressor M Series

xii

2202G1JE-DA-M-N_2010.01.

Table of Contents

5.3 Maintenance (Overhaul) ..............................................................................5-4

5.3.1 Maintenance Period and Operation Conditions ..................................................... 5-4

5.3.2 First Maintenance Period....................................................................................... 5-5

5.3.3 Second Maintenance Period.................................................................................. 5-5

5.4 Refrigerant Oil Control Standard................................................................5-6

5.5 Disassembly/Assembly ...............................................................................5-7

5.5.1 Exterior Equipment ................................................................................................ 5-7

5.5.1.1 Attentions for Removing the Oil Cooler Piping/

Water Cooled Type Oil Cooler..................................................................... 5-9

5.5.1.2 Attentions for Removing the Mechlock........................................................ 5-9

5.5.1.3 Attentions for Removing the Flywheel......................................................... 5-9

5.5.1.4 Attentions for Removing the Motor End Bearing Assembly ...................... 5-10

5.5.1.5 Attentions for Removing the Motor Rotor .................................................. 5-10

5.5.1.6 Attentions for Removing the Motor Cage .................................................. 5-10

5.5.1.7 Attentions for Attaching the Flywheel ........................................................ 5-11

5.5.1.8 Attentions for Attaching the Mechlock ....................................................... 5-11

5.5.1.9 Attentions for Attaching the Motor Rotor ................................................... 5-11

5.5.1.10 Attentions for Attaching the Oil Cooler Piping/

Water Cooled Type Oil Cooler................................................................... 5-12

5.5.2 Suction/Discharge Area ....................................................................................... 5-13

5.5.2.1 Attentions for Removing the Suction/Discharge Shut-off Valve ................ 5-14

5.5.2.2 Attentions for Attaching the Suction/Discharge Shut-off Valve.................. 5-14

5.5.2.3 Attentions for Removing the Discharge Manifolds .................................... 5-14

5.5.2.4 Attentions for Attaching the Discharge Manifolds...................................... 5-15

5.5.3 Head Cover/Hand Hole Cover ............................................................................. 5-17

5.5.3.1 Attentions for Removing the Head Jacket Cover ...................................... 5-18

5.5.3.2 Attentions for Removing the Head Cover.................................................. 5-18

5.5.3.3 Attentions for Removing the Hand Hole Cover ......................................... 5-19

5.5.3.4 Attentions for Attaching the Hand Hole Cover........................................... 5-20

5.5.3.5 Attentions for Attaching the Head Cover ................................................... 5-20

5.5.3.6 Attentions for Attaching the Head Jacket Cover........................................ 5-21

5.5.4 Valve Plate/Piston Assembly/Cylinder Sleeve Assembly .................................... 5-22

5.5.4.1 Attachment of the Spacer (4M/6M/8M/62M)............................................ 5-23

5.5.4.2 Attachment of Knob Bolt (62M-FM) .......................................................... 5-23

5.5.4.3 Attentions for Removing the Valve Plate ................................................... 5-24

5.5.4.4 Attentions for Removing the Piston Assembly .......................................... 5-24

5.5.4.5 Attentions for Attaching the Cylinder Sleeve Assembly............................. 5-24

5.5.4.6 Attentions for Attaching the

5.5.4.7 Attentions for Attaching the Suction Plate Valve/Suction Valve Spring ..... 5-27

5.5.4.8 Attentions for Attaching the Valve Plate .................................................... 5-27

5.5.4.9 Removal of the Spacer (4M/6M/8M/62M).................................................. 5-27

5.5.4.10 Removal of Knob Bolt (62M-FM) .............................................................. 5-28

5.5.5 Unloader .............................................................................................................. 5-29

5.5.5.1 Attentions for Attaching the Unloader Push Rod Washer.......................... 5-30

5.5.5.2 Attentions for Attaching the Unloader Push Rod Assembly ...................... 5-30

5.5.5.3 Attentions for Attaching the Solenoid Valve Unloader Cover Integrated ... 5-31

Piston Assembly............................................ 5-25

Reciprocating Compressor M Series

xiii

2202G1JE-DA-M-N_2010.01.

Table of Contents

5.5.6 Seal Cover/Mechanical Seal/Oil Seal.................................................................. 5-32

5.5.6.1 Attentions for Removing the Seal Cover Assembly................................... 5-33

5.5.6.2 Attentions for Removing the Oil Seal Retainers........................................ 5-33

5.5.6.3 Attentions for Removing the Oil Seal ........................................................ 5-33

5.5.6.4 Attentions for Attaching the Oil Seal.......................................................... 5-33

5.5.6.5 Attentions for Attaching the Mechanical Seal Collar ................................. 5-34

5.5.6.6 Attentions for Attaching the Seal Cover Assembly .................................... 5-34

5.5.7 Main Bearing Head Assembly/Oil Pump Assembly/Oil Filter Assembly.............. 5-35

5.5.7.1 Attentions for Removing the Main Bearing Head Assembly...................... 5-36

5.5.7.2 Attentions for Attaching the Main Bearing Head Gasket ........................... 5-36

5.5.7.3 Attentions for Attaching the Main Bearing Head Assembly ....................... 5-36

5.5.8 Crankshaft............................................................................................................ 5-37

5.5.8.1 Attentions for Removing the Crankshaft.................................................... 5-38

5.5.8.2 Attentions for Attaching the Thrust Roller Bearing (Shaft Side) ................ 5-39

5.5.8.3 Attentions for Attaching the Crankshaft ..................................................... 5-40

5.5.9 Bearing Head....................................................................................................... 5-41

5.5.9.1 Attentions for Removing the Bearing Head (4M/6M/8M/62M) .................. 5-42

5.5.9.2 Attentions for Replacing the Main Bushing (Bearing Head Side) ............. 5-42

5.5.9.3 Attentions for Attaching the Thrust Roller Bearing (Bearing Head Side)... 5-42

5.5.9.4 Attentions for Attaching the Bearing Head (4M/6M/8M/62M).................... 5-43

5.5.10 Discharge Valve Cage Assembly ........................................................................ 5-44

5.5.10.1 Attentions for Attaching the Discharge Valve Spring ................................. 5-44

5.5.11 Piston Assembly .................................................................................................. 5-45

5.5.11.1 Attentions for Attaching the Connecting Rod Bushing/Needle Bearing .... 5-46

5.5.11.2 Attentions for Attaching the Piston Rings .................................................. 5-46

5.5.12 Cylinder Sleeve Assembly ................................................................................... 5-47

5.5.12.1 Attentions for Attaching the Cam Ring ...................................................... 5-47

5.5.13 Seal Cover Assembly .......................................................................................... 5-48

5.5.13.1 Attentions for Removing the Shower Flushing Sleeve .............................. 5-48

5.5.13.2 Attentions for Attaching the Mechanical Seal Mating Ring........................ 5-49

5.5.13.3 Attentions for Attaching the Shower

5.5.14 Main Bearing Head Assembly ............................................................................. 5-50

5.5.14.1 Attentions for Replacing the Main Bushing (Pump Side) .......................... 5-50

5.5.14.2 Attentions for Attaching the Thrust Washer (Pump Side).......................... 5-50

5.5.15 Oil Filter Assembly ............................................................................................... 5-51

Flushing Sleeve ............................... 5-49

6 Troubleshooting

6.1 Troubleshooting Table ................................................................................6-1

7 Related Document

7.1 Development View and Configuration Table of the Parts ........................ 7-1

7.2 List of Tightening Torques for Bolts and Nuts........................................7-12

7.3 List of Tools for Disassembly................................................................... 7-13

Reciprocating Compressor M Series

xiv

2202G1JE-DA-M-N_2010.01.

Table of Contents

7.4 Vibration and Sound Data ......................................................................... 7-15

7.4.1 Vibration............................................................................................................... 7-15

7.4.2 Sound Data .......................................................................................................... 7-16

7.5 Oil Cooler Heat Rejection (OHR)/

Head Jacket Heat Rejection (JHR) (N4M, N6M, N8M) .............................7-17

7.6 Starting Torque ..........................................................................................7-27

7.7 Parts Inspection and Replacement Standards........................................7-31

Reciprocating Compressor M Series

xv

2202G1JE-DA-M-N_2010.01.

Table of Contents

Reciprocating Compressor M Series

xvi

2202G1JE-DA-M-N_2010.01.

1 Safety

1.1 Observation/Prevention

1.1.1 Observance (Do's)

1.1.1.1 Do's on Operation

Attach safety and protection devices into compressors operation sequence.

Regularly inspect the safety and protective devices function properly.

If safety and protective devices do not work properly or the machine continues to run even during test

of these devices, stop the operation! Inform your supervisor of it immediately.

If the compressor stops for unknown reasons, immediately inform your supervisor of it. Obtain his/her

approval before restarting the compressor.

Some refrigerants in use generate bad smell or toxic gases, or may cause deficiency of oxygen. Make

sure to ventilate the air during operation.

The properties of refrigerant and refrigerant oil can be corrosive, decomposable, and/or toxic, insure to

obtain the Material Safety Data Sheet (MSDS) and follow its instructions.

When stopping the operation of this compressor, turn "OFF" the motor (main power), heater power,

and control power. Close the suction and discharge side shut-off valves. Follow proper compressor

evacuation procedures.

1 Safety

1.1.1.2 Do's on Maintenance

Before performing the work together with at least one other person, thoroughly confirm the work

details and acknowledge other worker's movement.

Always turn OFF and lock out/tag out the motor (main power), control power, and other devices before

troubleshooting during operation, and before setup, cleaning, or maintenance and inspection of the

compressor.

Always lock out/tag out the fluid supply/stop valve and the valves at downstream or upstream side of

an opening part before troubleshooting during operation, setup, cleaning, or maintenance and

inspection of the compressor to prevent the valves from opening during work.

Some refrigerants in use generate bad smell or toxic gases, or may cause deficiency of oxygen. Make

sure to ventilate the air during work.

The properties of refrigerant and refrigerant oil can be corrosiveness, decomposability, and/or toxicity,

insure to obtain the Material Safety Data Sheet (MSDS) and follow its instructions.

After using tools always restore to designated place and never leave tools in the compressor.

1.1.1.3 Do's on Lockout/Tagout after Shutting off the Power

Prepare lockout/tagout devices for the main breakers of motor main power and control power.

Performing lockout/tagout after shutting off the power is very effective for preventing mis-operation of

the worker, and for preventing injury of all workers that are working in the power facility and on the

compressor.

If there are any possibilities of danger during works (especially during cleaning, maintenance and

inspection, and troubleshooting), turn "OFF" the motor main power and control power, and perform

lockout/tagout.

The worker himself must always lock out/tag out the compressor before working in the compressor for

troubleshooting during operation, setup, cleaning, or maintenance and inspection of the compressor.

The worker who performed lockout/tagout should release them after checking that all procedures have

completed.

Reciprocating Compressor M Series 1.1 Observation/Prevention

1-1

2202G1JE-DA-M-N_2010.01.

1 Safety

1.1.1.4 Do's about Personal Protective Devices

Prepare and use protective devices complying with the safety standards of the regulations.

Check the function of each protective device before using.

Wear designated clothes such as work outfits.

Do not wear any neckties or jewelry as there is a possibility of being entangled by a movable part or

rotating part. Put on a helmet as your hair may get entangled.

Do not have anything in your pocket to prevent objects from falling into the machine.

1.1.1.5 Do's about Handling of Hazardous and Toxic Substances

Obtain Material Safety Data Sheet (MSDS) from manufacturers of hazardous and toxic substances.

Check the MSDS and follow the handling instructions recommended by the manufacturers to handle

and store those substances.

An example of Material Safety Data Sheet (MSDS) is provided as a reference at the end of this

chapter.

1.1.1.6 Do's about Handling Emergency Situation

Formulate an emergency action plan complying with the regulations, and post it on a safe place.

1.1.1.7 Do's about Waste Oil, Fluid, and Materials

Disposing of refrigerant and oil used for the compressor are subject to a number of regulations for the

environmental protection purposes. Follow the local, state, federal acts and regulations and your

company's rules when disposing of such waste oil, fluid and materials.

1.1.1.8 Other Do's

Keep the floor clean around the refrigerating, cold storage, and air conditioning systems, and keep

passages and walkways clear.

Walk only on the areas set up as a work floor. Also, do not leave tools and cleaning solutions in that

area.

If water or oil is spilled on the compressor or the floor, immediately wipe it off to prevent workers

from injury caused by slipping.

1.1.2 Don'ts

Do not remove or relocate any safety device, including electrical interfaces.

Do not disable any safety device by short-circuiting or bypassing without any permission.

Do not leave the compressor unsafe and unattended, by removing a safety cover or some other

measures.

Do not touch, clean, or lubricate any moving part of the compressor during operation.

Do not touch, clean, or lubricate the compressor during its operation.

Do not touch relays or electric systems such as terminal block with bare hands when turning on the

power.

Reciprocating Compressor M Series 1.1 Observation/Prevention

1-2

2202G1JE-DA-M-N_2010.01.

1.2 Warnings

To alert workers to possible danger, the following two measures are always provided with the compressor.

Warnings described in this manual

Safety labels affixed on the compressor

1.2.1 Types and Meanings of Warnings

This manual includes the following four types of warnings to be used for expected hazards during operation

and maintenance of the compressor.

Neglecting such warnings may cause accidents, resulting in personal injury or even death.

Also, the compressor or its auxiliary equipment may be heavily damaged. Therefore, be sure to always

observe the instructions of the warnings.

Indicates an imminently hazardous situation which, if not avoided, will result in serous

injury or death.

Indicates a potential hazardous situation which, if not avoided, could result in serous injury

or death.

Indicates a potential hazardous situation which, if not avoided, may result in minor or

moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may result in property

damage.

Emphasizes important items and indicates profitable information.

1 Safety

Reciprocating Compressor M Series 1.2 Warnings

1-3

2202G1JE-DA-M-N_2010.01.

1 Safety

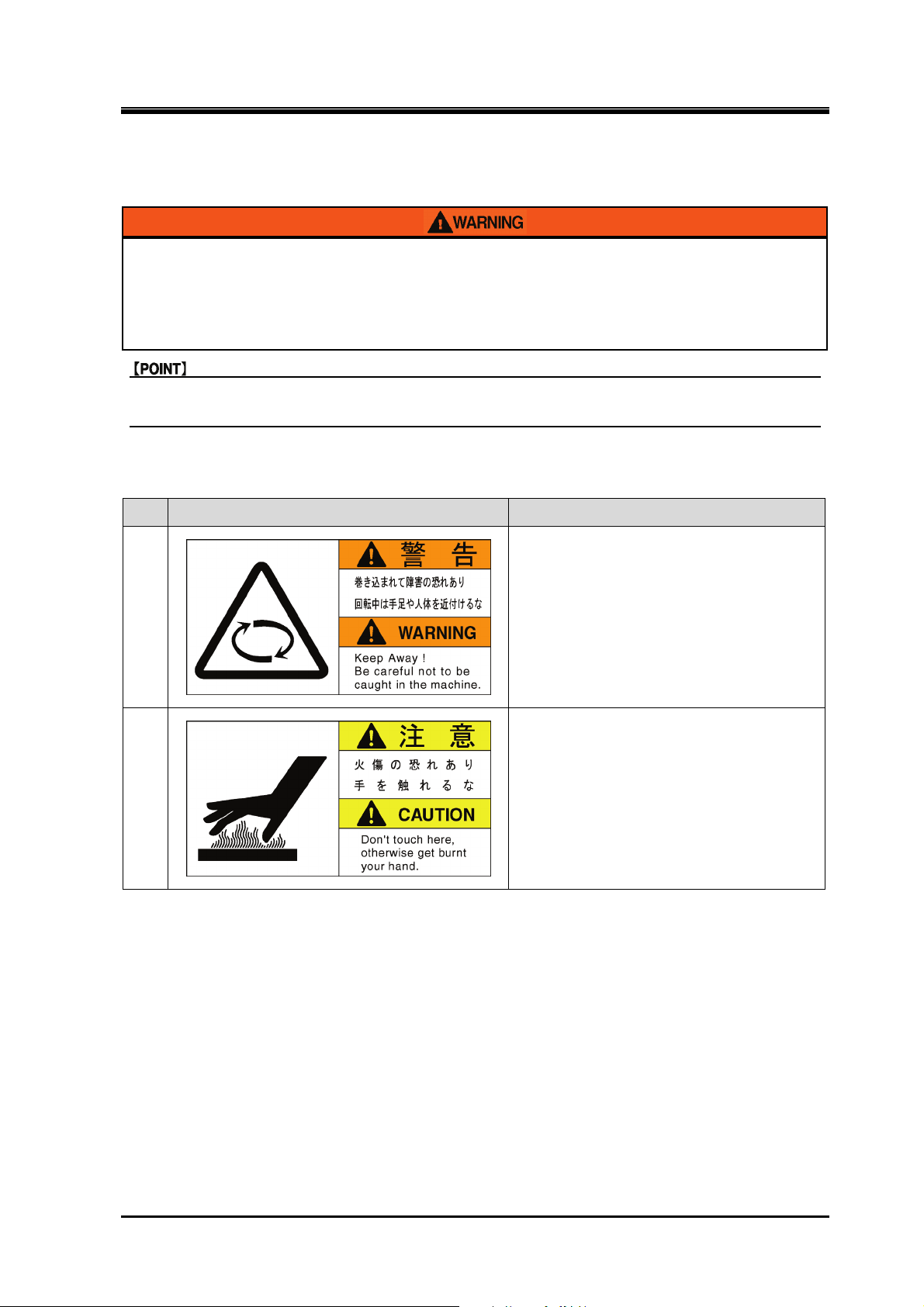

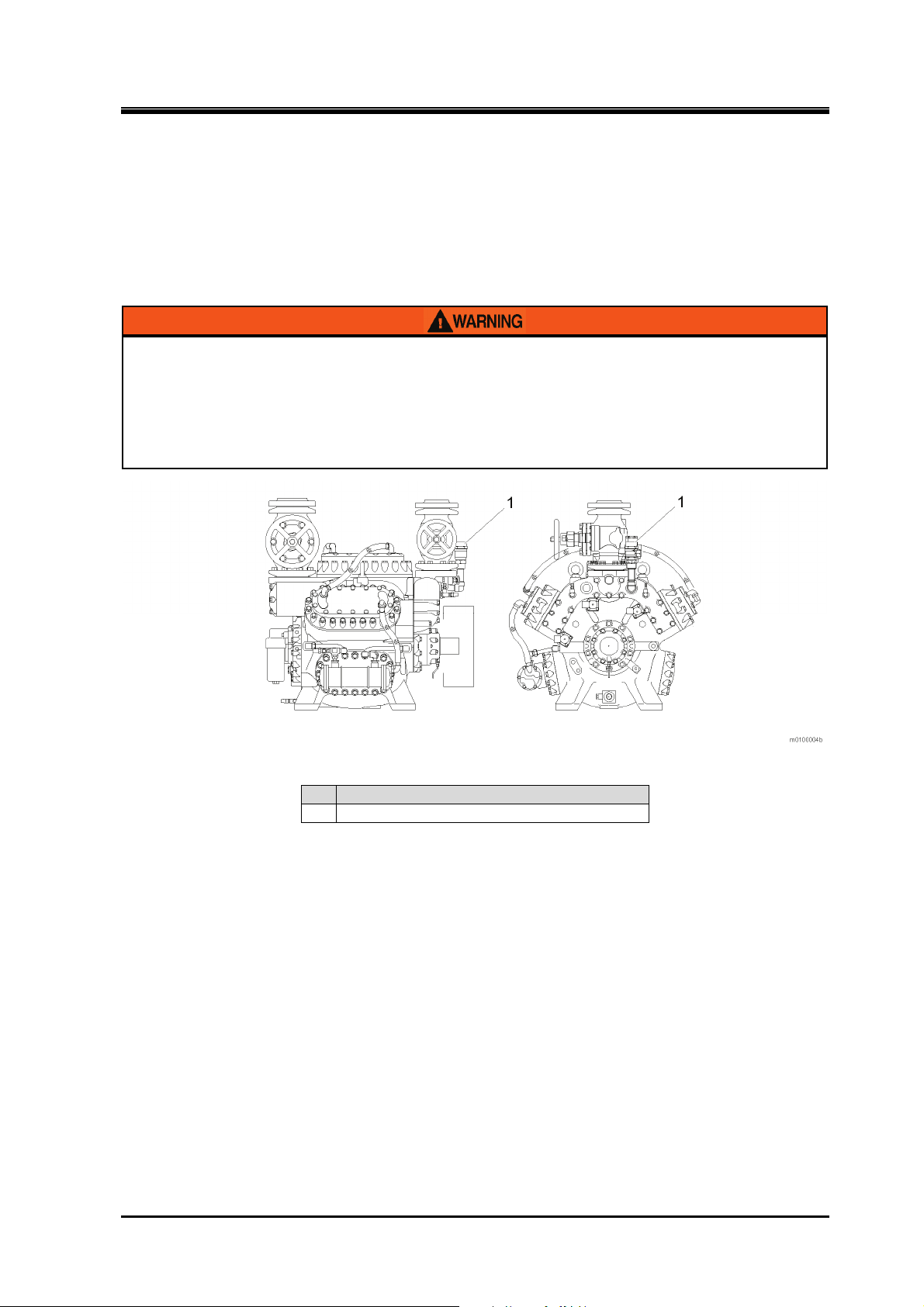

1.2.2 Safety labels

The following shows the types of the safety labels and their positions affixed on the compressor. Always

follow the warnings instructed on the safety label affixed on the compressor.

Be sure to follow the instructions of the safety labels. Otherwise, danger

resulting in personal injury, death, or property damage may arise.

Do not smear, cover, or peel off the safety labels.

If the safety labels are damaged or missing, purchase and affix new labels to their

proper positions according to this manual.

Inform our service center of the product name and safety label No when placing a purchase

order for safety labels.

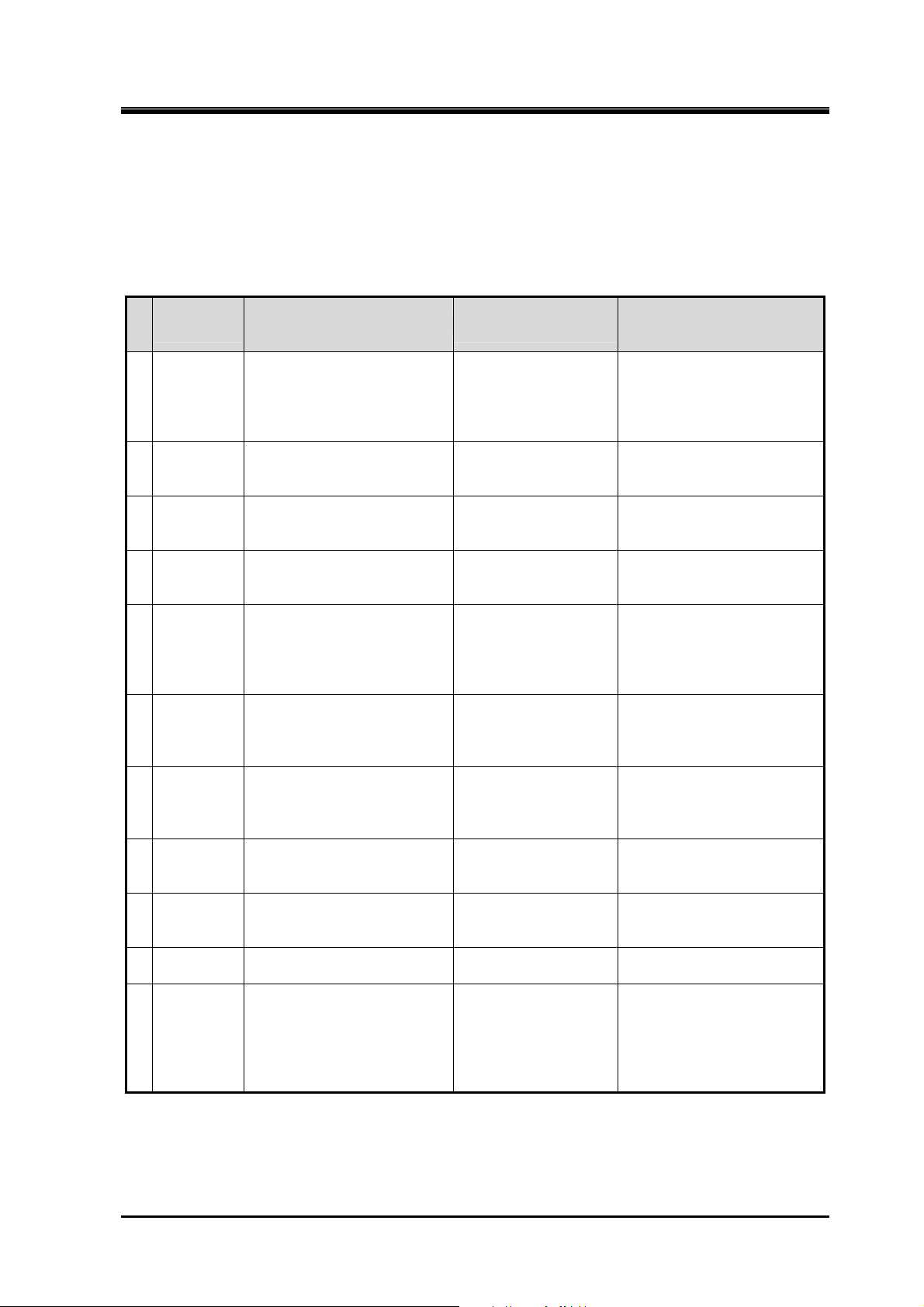

Types of Safety Labels

Table 1-1 Safety label

No. Safety labels Remarks

1

2

For specification with belt cover

Reciprocating Compressor M Series 1.2 Warnings

1-4

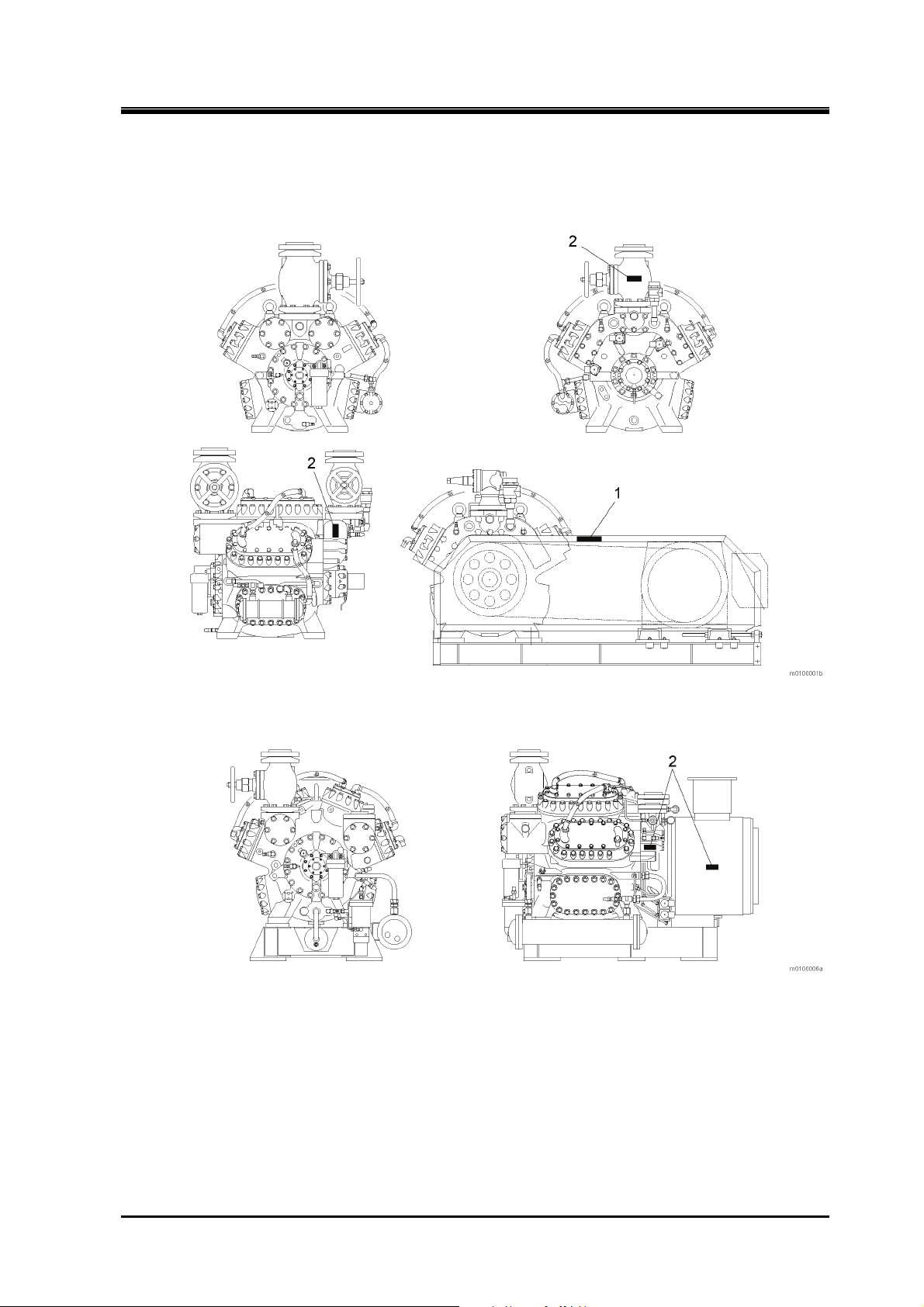

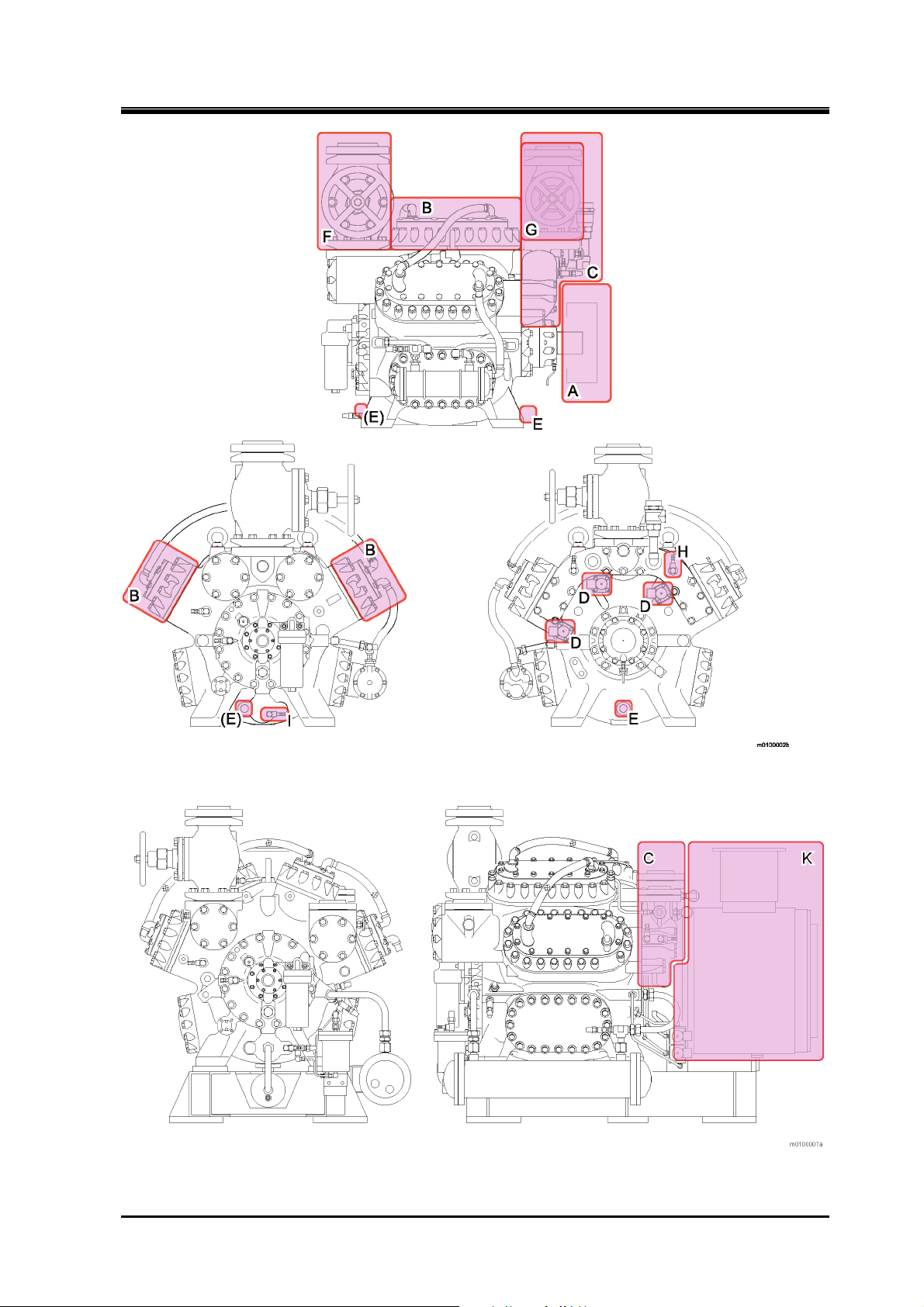

Affixing Positions of Safety Labels

The figure below shows the affixing positions of safety labels.

The numbers in the figure correspond to the ones in Table 1-1 Safety label.

2202G1JE-DA-M-N_2010.01.

1 Safety

Fig. 1-1 Affixing positions of safety labels (Ex: 6M)

Fig. 1-2 Affixing positions of safety labels (Ex:

62M-FM)

Reciprocating Compressor M Series 1.2 Warnings

1-5

2202G1JE-DA-M-N_2010.01.

1 Safety

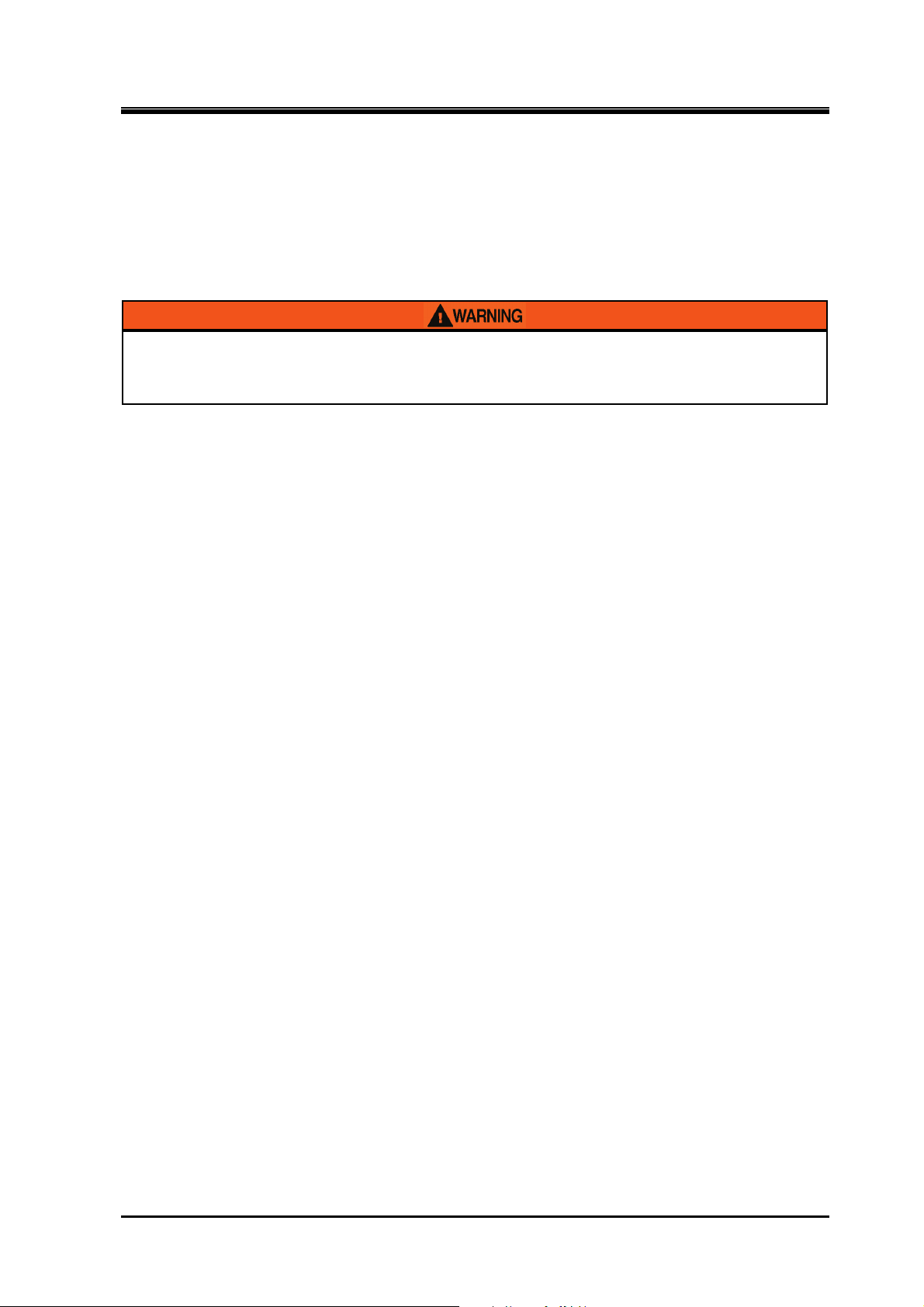

1.3 Remaining Hazard

The following information is provided on the assumption that this compressor is operated, inspected, and

maintained while being used in general refrigerating, cold storage, and air conditioning systems. Note that all

hazardous sources cannot be predicted for the refrigerating, cold storage, and air conditioning systems you

actually use.

Devise appropriate countermeasures for hazardous sources in your systems.

Table 1-2 Hazardous sources

Hazardous

parts

A Driving

section

B Head cover Damage caused by

C Discharge

piping

D Unloader

solenoid

valve

E Heater Electric Shock

F Suction

(side)

shut-off

valve

G Discharge

(side)

shut-off

valve

H Gas purge

valve

I Oil drain Burns

J Noise and

vibration

K Motor Damage caused by high

Predicted hazard

Contact and entanglement in

rotational part

Drop-off of moving part

Recovery after interruption

of energy supply

contacting hot part

Damage caused by

contacting hot part

Electric Shock Installation of guard

Burns

Contact with and inhale of

toxic substances

Low temperature burns

Contact with and inhale of

toxic substances

Burns

Contact with and inhale of

toxic substances

Contact with toxic

substances

Damage caused by noise Wearing protective

temperature

Electric Shock

Counter measures in

operation

Installation of guard

and cover

Installation of guard

Wearing protective

devices

Installation of guard

Wearing protective

devices

Wearing protective

devices

Installation of guard

and cover

Wearing protective

devices

Wearing protective

devices

Sufficient ventilation

Installation of guard

Wearing protective

devices

Sufficient ventilation

Installation of guard

Wearing protective

devices

Sufficient ventilation

Do not contact with it

during operation

devices

Wearing protective

devices

Counter measures in

cleaning, inspection, and

parts exchange

Lockout/tagout of motor

main power and control

power

Wearing protective devices

Operation with a

temperature of 40°C or less

Wearing protective devices

Operation with a

temperature of 40°C or less

Lockout/tagout of control

power

Lockout/tagout of the heater

power

Wearing protective devices

Operation with a

temperature of 40°C or less

Wearing protective devices

Sufficient ventilation

Wearing protective devices

Sufficient ventilation

Operation with a

temperature of 40°C or less

Wearing protective devices

Sufficient ventilation

Wearing protective devices

Operation with a

temperature of 40°C or less

—

Lockout/tagout of motor

main power and control

power

Wearing protective devices

Operation with a

temperature of 40°C or less

Reciprocating Compressor M Series 1.3 Remaining Hazard

1-6

2202G1JE-DA-M-N_2010.01.

1 Safety

Fig. 1-3 Hazardous sources (Ex: 6M)

Fig. 1-4 Hazardous sources (Ex: 62M-FM)

Reciprocating Compressor M Series 1.3 Remaining Hazard

1-7

2202G1JE-DA-M-N_2010.01.

1 Safety

1.4 Safety Devices

For safe use and protection of the compressor, make sure to attach safety devices to your compressor,

complying with the regulations and the following instructions for each devices.

Periodically perform inspection and maintenance of devices for normal/proper operation. Maintenance and

inspection must be performed as an important part for the safety of machine and personnel. Provide users of

the compressor with necessary information on the safety devices, for example, types of the safety devices,

installation position, function, and inspection method of safety related devices.

Check the safety devices after turning on the power and before operation of the

compressor. If they do not operate normally, immediately take repair or replace

safeties before starting compressor.

1.4.1 Emergency Stop Button

Overview/Function/Purpose

Used to stop the compressor immediately if an emergency occurs in the compressor.

Installation Positions

On the control board on the compressor and in the operation control room

Stop/Restoration Methods

Specify the stop/restoration methods of emergency stop button, and make sure to provide users of this

compressor with them.

Inspection Method/Cycle

The emergency stop button requires test to ensure compressor is shut down when pressed, insure this is done

before testing the operation of compressor and periodically after compressor is put into service. Specify the

inspection methods/cycle of the emergency stop button, and make sure to provide users of this compressor

with them.

1.4.2 Breakers of Motor Main Power and Control Power (with Lockout/Tagout Devices)

Overview/Function/Purpose

When working on compressor (especially during cleaning, maintenance, inspection, and troubleshooting),

ensure to lockout/tagout main and control power to prevent mis-operation and hazards to workers while the

motor main power and control power are turned "OFF".

Methods of Performing and Releasing Lockout/Tagout

Make sure to clearly notify methods of performing and releasing lockout/tagout referring to the regulations

created by Occupational Safety & Health Administration (OSHA) or local governing body.

Reciprocating Compressor M Series 1.4 Safety Devices

1-8

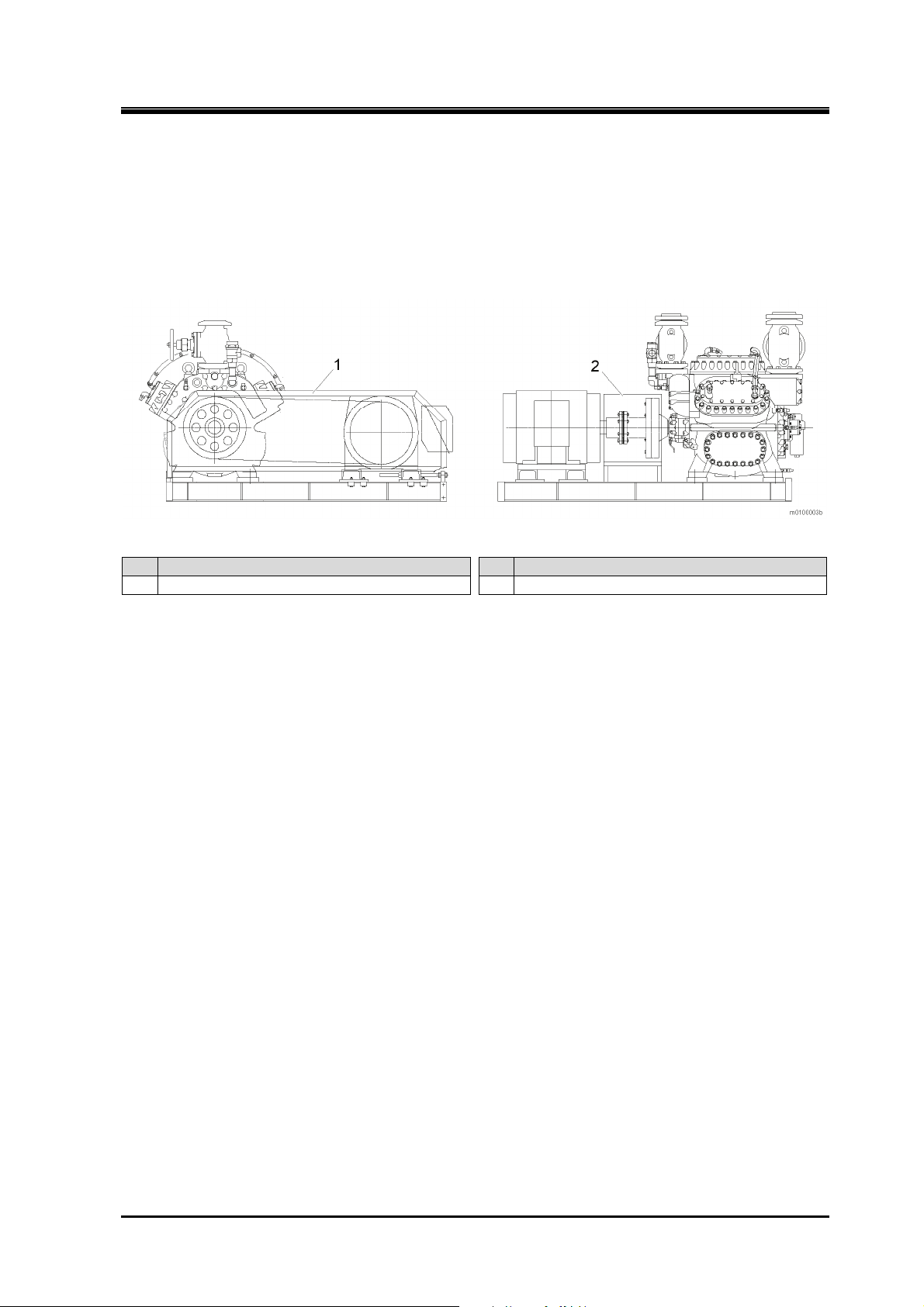

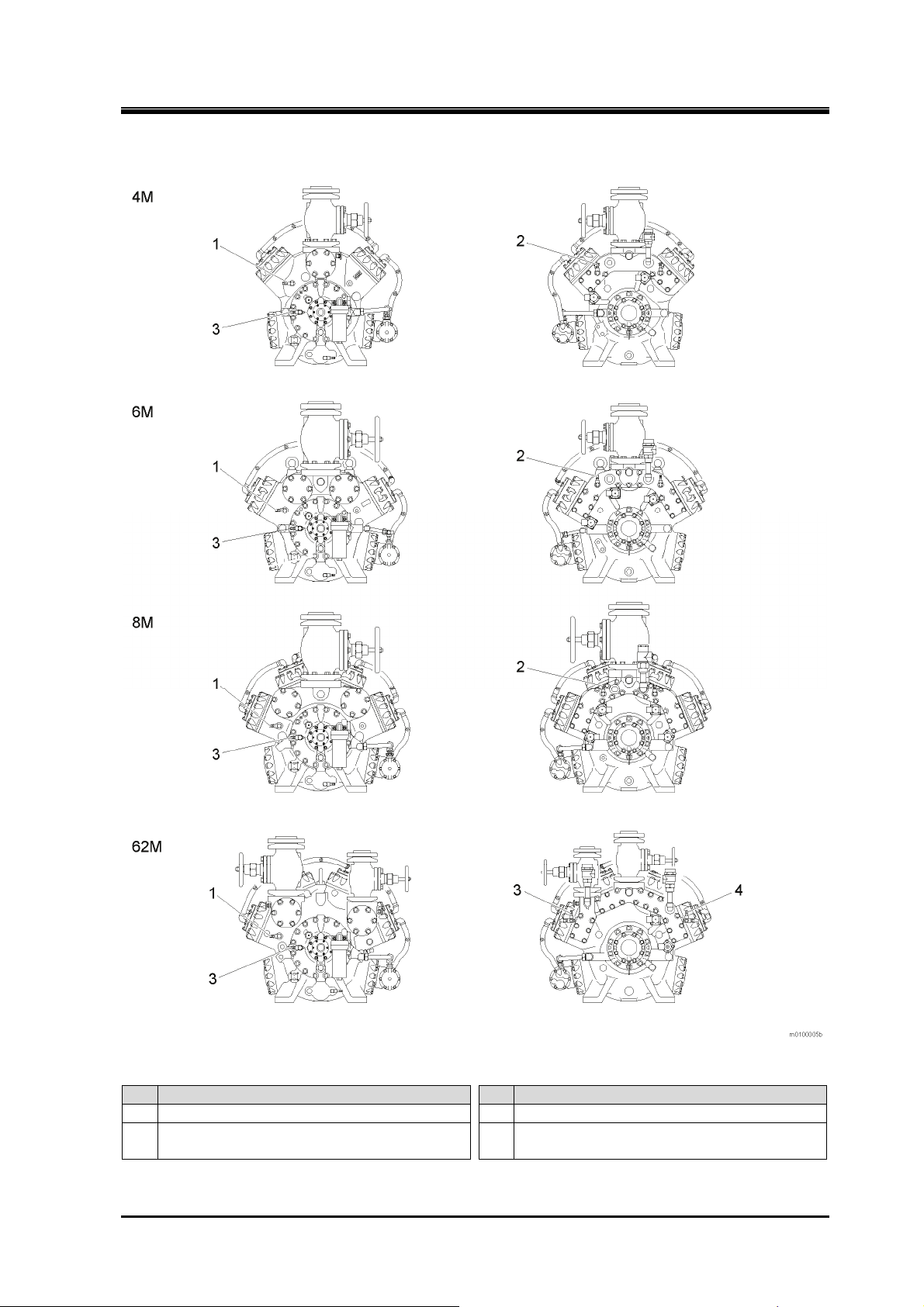

1.4.3 Safety Belt/coupling Guard

Overview/Function/Purpose

Prevents contact and entanglement in the driving section of this compressor.

Installation Positions

Driving section

Fig. 1-5 Attachment of driving section safety cover (6M)

2202G1JE-DA-M-N_2010.01.

1 Safety

No. Description No. Description

Driving section safety cover (for belt) 2 Driving section safety cover (for coupling)

1

Inspection Method/Cycle

Specify the inspection methods/cycle of the safety cover, and make sure to provide users of this compressor

with them.

Reciprocating Compressor M Series 1.4 Safety Devices

1-9

2202G1JE-DA-M-N_2010.01.

1.4.4 Safety valve

Overview/Function/Purpose

A safety valve is used to prevent the compressor from bursting when its internal pressure rises abnormally.

Installation Positions

Install a safety valve on discharge outlet between the shut-off valve (service valve) and the compressor. Set

the safety valve so that it operates even when the shut-off valve is closed during operation.

Properly terminate the discharge outlet of safety valve according to the type of

refrigerant, following the local, state, federal acts and regulations. If ammonia is

discharged into the atmosphere, it highly possibly causes health damage such as

intoxication and bad smell. And if it is discharged into enclosed space such as

inside of the compressor, it may cause serious accident such as deficiency of

oxygen.

1 Safety

Fig. 1-6 Attachment example of safety valve

No. Description

Safety valve

1

Settings

Set the pressure of safety valve to the designed system pressure or lower. Specify the safety valve settings,

and make sure to provide users of this compressor with them.

Inspection Method/Cycle

Insure to replace or repair safety relief valve following the local, state, federal acts and regulations.

Reciprocating Compressor M Series 1.4 Safety Devices

1-10

2202G1JE-DA-M-N_2010.01.

1 Safety

1.4.5 Automatic Control and Protection Equipment M compressor

Overview/Function/Purpose

Low oil pressure failure protection equipment (OP)

When the oil pressure in compressor (Gauge pressure minus crank case pressure) drops from

deficiency of refrigerant oil, clogging of filter, and interfusion of refrigerant, automatically shuts off

the motor circuit and stops the operation of compressor.

This intended to prevent damage to the compressor from abnormal friction. Can also cause the

unloader mechanism from malfunctioning

High pressure protection equipment (HP)

When the discharge pressure on compressor becomes abnormally high because the compressor is

operated incorrectly or the water supply for condenser is cut. HP switch shuts off the motor circuit

automatically to stop the operation of compressor.

Prevents system ruptures and refrigerant leaks.

Control of the compressor capacity: Low pressure control equipment (LP)

The number of capacity control step in the compressor is determined by the number of cylinder.

Generally two cylinders are considered as one bank. Therefore, capacity control of four steps is

available for eight cylinders, three steps for six cylinders, and two steps for four cylinders. Capacity

control is performed by detecting suction pressure the low pressure control switch is used.

It automatically controls opening/closing of the solenoid valve connected to the unloader piston in the

capacity control mechanism of compressor.

Reciprocating Compressor M Series 1.4 Safety Devices

1-11

Connecting Positions

2202G1JE-DA-M-N_2010.01.

1 Safety

Fig. 1-7 Connections of low oil pressure failure protection equipment (OP)/

high pressure protection equipment (HP)/low pressure control equipment (LP)

No. Description No. Description

Low pressure gauge connection φ 6 (LP/OP) 3 Oil pressure gauge connection φ 6 (OP)

1

High pressure gauge connection φ6 (HP) 4 Intermediate pressure gauge connection φ 6

2

(OP)

Reciprocating Compressor M Series 1.4 Safety Devices

1-12

Loading...

Loading...