Page 1

11/07/2017 PK

SERVICE, INSTALLATION, AND INSTRUCTION MANUAL

MANUEL D’ENTRETIEN, D’INSTALLATION ET D’INSTRUCTIONS

MANUAL DE INSTRUCCIONES, INSTALACIÓN Y MANTENIMIENTO

MIM50 / MIM50P MIM50P-O MIM50V MIM50-O

For AUTHORIZED PARTS or TECHNICAL SERVICE, please contact:

Pour les PIÈCES AUTORISÉES ou un SERVICE TEC H NIQUE, veuillez composer le :

Para PIEZAS AUTORIZADAS o SERVICIO TÉCNICO, llame al

1-877-368-2797 or│ou visiter le site│o visite Service@MaxxHelp.com

3355 Enterprise Avenue , Suite 160, Fort Laud erdale, FL 33331 USA

Phone│Téléphone│Teléfono: (954) 202-7419 • Website│Site Web│Sitio Web: MaxximumFoodService.com

MIM50, MIM50P

MIM50P-O, MIM5 0V, MIM50-O

SELF CONTAI N E D I C E MA K ER │

MÁQUINA AUTÓNOMA PARA HACER HIELO

PLEASE READ CAREFULLY │

VEUILLEZ LIRE AVEC SOIN │ POR FAVOR, LEER CON CUIDADO

MACHINE À GLAÇONS AUTONOME │

Page 2

11/07/2017 PK

Table of Contents

ICE MAKER SAFETY ................................................................................................................................................................... 1

IMPORTANT SAFEGUARDS ....................................................................................................................................................... 1

TECHNICAL INFORMATION ...................................................................................................................................................... 3

INTRODUCTION ........................................................................................................................................................................ 3

COMPONENT LOCATIONS ........................................................................................................................................................ 4

ICE MAKER INSTALLATION ....................................................................................................................................................... 5

Remove Packaging Materials .......................................................................................................................................... 5

Cleaning Before Use ....................................................................................................................................................... 5

Installation Clearances ................................................................................................................................................... 5

Electrical Requirements ................................................................................................................................................. 6

Recommended Grounding Method ............................................................................................................................... 6

Leveling The Ice Maker ................................................................................................................................................... 6

Reversing The Door Swing For MIM50-O and MIM50V ................................................................................................. 7

Reversing The Door Swing For MIM50, MIM50P and MIM50P-O ................................................................................. 8

Water Supply .................................................................................................................................................................. 8

Tools Required ............................................................................................................................................................... 8

Drain ............................................................................................................................................................................... 9

INSTALLATION TYPES ............................................................................................................................................................. 10

Mobile Installation ....................................................................................................................................................... 10

Enclosed Installation .................................................................................................................................................... 10

Built-in installation ....................................................................................................................................................... 10

OPERATION ............................................................................................................................................................................ 11

Final Check List Prior To Operation .............................................................................................................................. 11

Operating Method........................................................................................................................................................ 11

How The Ice Maker Makes Ice ..................................................................................................................................... 12

How The Ice Maker Uses The Water ............................................................................................................................ 12

MIM50P and MIM50P-O DRAIN SYSTEM OPERATION .......................................................................................................... 12

How the drain system operates when water is pumped out ....................................................................................... 12

Drain Pump Operation ................................................................................................................................................. 12

Normal Sounds ............................................................................................................................................................. 14

Preparing The Ice Maker For Long Storage .................................................................................................................. 14

CLEANING AND MAINTENANCE ............................................................................................................................................. 15

What Shouldn’t Be Done? ............................................................................................................................................ 15

What Parts Should Be Kept Clean? .............................................................................................................................. 15

Exterior Cleaning .......................................................................................................................................................... 15

Interior Cleaning ........................................................................................................................................................... 15

Condenser Cleaning ..................................................................................................................................................... 16

Water Distribution Tube Cleaning ................................................................................................................................ 16

Ice-Making System Cleaning and Sanitizing ................................................................................................................. 16

CONTROL PANEL .................................................................................................................................................................... 17

Description Of LEDs And Buttons ................................................................................................................................. 17

MAJOR FUNCTIONS ................................................................................................................................................................ 18

TROUBLE SHOOTING .............................................................................................................................................................. 18

The Legacy Companies reserve the right to make changes in specifications and design without prior notice.

Page 3

11/07/2017 PK

ICE MAKER SAFETY

We have provided many important safety messages in this manual and on your appliance.

This is the Safety Alert Symbol. This symbol alerts you to potential hazards that can injure or cause

death to you and others. All safety messages will follow the Safety Alert Symbol and either the words

“DANGER”, “WARNING” OR “CAUTION”.

SAVE THESE INSTRUCTIONS

Your safety and the safety of others are very important.

Always read and obey all safety messages.

DANGER

WARNING

CAUTION

All safety messages will alert you to what the potential hazard is, tell you how to reduce the chance of injury, and let you

know what can happen if the instructions are not followed.

DANGER means that failure to heed this safety statement may result in severe personal injury

or death.

WARNING means that failure to heed this safety statement may result in extensive product damage,

serious personal injury or death.

CAUTION means that failure to heed this safety statement may result in minor or moderate

personal injury, or property or equipment damage.

WARNING

To reduce the risk of fire, electric shock or injury when using your ice maker, follows these basic precautions:

• Plug into grounded 3-prong outlet. • Disconnect power before cleaning.

• Do not remove grounding prong. • Disconnect power before servicing.

• Do not use an adapter. • Replace all panels before operating.

• Do not use an extension cord. • Use two or more people to move & install ice maker.

IMPORTANT SAFEGUARDS

Before the ice maker is used, it must be properly positioned and installed as described in this manual, read

the manual carefully. Maxx Ice strongly recommends that you have a professional install your new ice maker.

The warranty may be affected or voided by an incorrect installation. To reduce the risk of fire, electrical shock

or injury when using the ice maker, follow basic precautions, including the following:

• Plug into a grounded 3-prong outlet; do not remove grounding prong, do not use an adapter, and do not use an

extension cord.

• It is recommended that a separate circuit, serving only for your ice maker, be provided.

• Use receptacles that cannot be turned off by a switch or pull chain.

• Do not connect or disconnect the electric plug when your hands are wet.

• Never unplug the ice maker by pulling on the power cord. Always grip the plug firmly and pull straight out from

the outlet.

• Never clean ice maker parts with flammable fluids. Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliances. The fumes can create a fire hazard or explosion.

• Before proceeding with cleaning and maintenance operations, make sure the power line of the unit is

disconnected and the water line is shut off.

• Before operating, pull all panels back into place.

• Never allow children to operate, play with or crawl inside the ice maker.

• Do not touch the evaporator with your hand when the ice maker is operating.

• Unplug the ice maker or disconnect power before cleaning or servicing. Failure to do so can result in electrical

shock or death. Do not attempt to repair or replace any part of your ice maker unless it is specifically

recommended in this manual. All other servicing should be referred to a qualified technician.

1

Page 4

11/07/2017 PK

WARNING

• Use two or more people to move and install ice maker. Failure to do so can result in back or other injury.

• Never install or operate the unit behind closed doors. To ensure proper ventilation for your ice maker, the

front of the unit must be completely unobstructed. Choose a well-ventilated area with an ambient

temperature range of between 50°F (10°C) to 99°F (37°C). This unit MUST be installed in an area protected

from the elements, such as wind, rain, water spray or drips.

• The ice maker should not be located next to ovens, grills or other sources of high heat.

• The ice maker must be installed with all electrical and water connections in accordance with state and local

codes. A standard electrical supply, properly grounded in accordance with the National Electrical Code and local

codes and ordinances, is required.

• Do not kink or pinch the power supply cord between the ice maker and cabinet.

• The fuse (or circuit breaker) size is rated at 15 amperes.

• It is important for the ice maker to be leveled in order to work properly. Otherwise water may not flow properly

through the evaporator (ice mold). The ice production will be less than normal. You may need to make several

adjustments to level it.

• All installations must be in accordance with local plumbing code requirements.

• Make certain that hoses are not pinched, kinked or damaged during installation.

• Check for leaks after water line is connected.

• Although the unit has been tested and cleaned at the factory, due to long-term transit and storage, the first

batch of cubes must be discarded.

• Remove the packing materials and clean the ice maker before using.

• Turn on the water supply tap before switching on the ice maker. Never turn the water supply tap off when the

ice maker is working.

• Except to take ice from the unit, keep the door closed in order to reduce ice melting and to promote proper ice

formation.

• If the ice maker will not be used for a long time, before the next use it must be thoroughly cleaned. Follow

carefully, instructions provided for cleaning. Do not leave any sanitizing solution inside the ice maker after

cleaning. DO NOT use solvent-based cleaning agents or abrasives on the interior. These cleaners may transmit

taste to the ice cubes, or damage or discolor the interior. The ice machine cleaner contains acids. Do not use

or mix with any other solvent-based cleaners products. Use rubber gloves to protect hands. Carefully read the

safety instructions on the container of the ice machine cleaner.

• Do not use the apparatus other than for its intended purpose.

• Do not touch the condenser fins, they are sharp and can be easily damaged.

Electrical Connection

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. For personal safety, this

appliance must be properly grounded. The power cord of this appliance is equipped with a 3-prong grounding plug that

mates with a standard 3-prong grounding wall outlet to minimize the possibility of electric shock hazard from the appliance.

Have the wall outlet and circuit checked by a qualified electrician to make sure the outlet is properly grounded. When

a standard 2-prong wall outlet is encountered, it is your responsibility and obligation to have it replaced with a properly

grounded 3-prong wall outlet. The ice maker should always be plugged into its own dedicated electrical outlet which

has a voltage rating that matches the rating label on the appliance. This provides the best performance and also

prevents overloading house wiring circuits which could cause a fire hazard from overheated wires. Never unplug your

ice maker by pulling on the power cord. Always grip the plug firmly and pull straight out from the outlet. Repair or

replace immediately all power cords that have become frayed or otherwise damaged. Do not use a cord that shows

cracks or abrasion damage along its length or at either end. When moving the ice maker, be careful not to damage the

power cord.

Extension Cord

Because of potential safety hazards under certain conditions, it is strongly recommended that you do not use an

extension cord with this ice maker.

2

Page 5

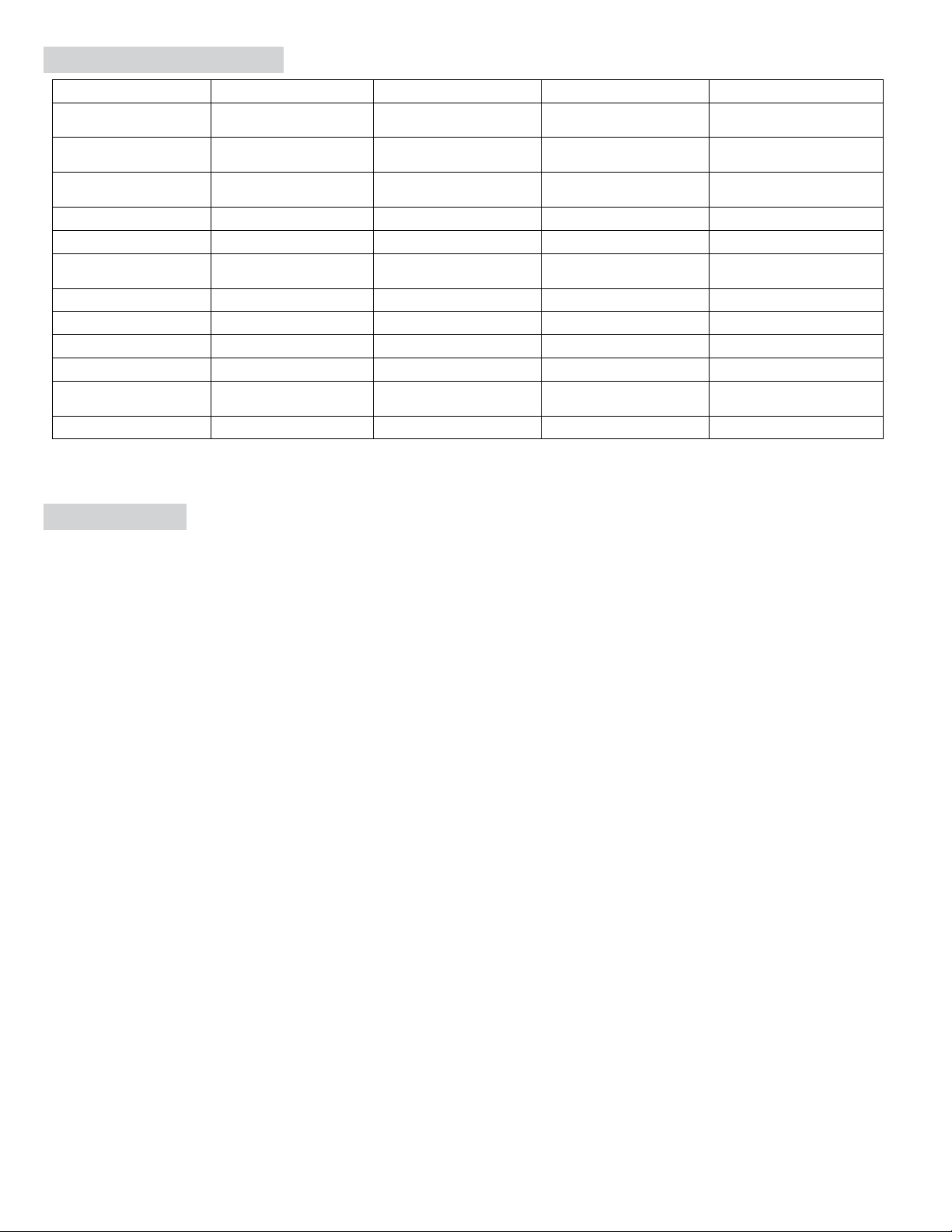

Model:

MIM50 / MIM50V

MIM50-O

MIM50P

MIM50P-O

50lb Outdoor Ice

Maker

50lb Outdoor Ice

Maker

120V/60Hz/1Ph,

220V/50Hz/1Ph

120V/60Hz/1Ph,

220V/50Hz/1Ph

120V/60Hz/1Ph,

220V/50Hz/1Ph

120V/60Hz/1Ph,

220V/50Hz/1Ph

Amps

harvesting):

Ice Type:

Slab Cube

Slab Cube

Slab Cube

Slab Cube

Ice Cube Size:

7/8" x 7/8" x 7/8"

7/8" x 7/8" x 7/8"

7/8" x 7/8" x 7/8"

7/8" x 7/8" x 7/8"

12.2kWh / 100lbs of

ice

12.2kWh / 100lbs of

ice

12.2kWh / 100lbs of

ice

Unit weight:

84 lbs / 38 kg

83 lbs / 38 kg

86 lbs / 39 kg

86 lbs / 39 kg

Maximum ice storage:

25 lbs

25 lbs

25 lbs

25 lbs

Ice-making capacity:

50 lbs/day*

50 lbs/day*

50 lbs/day*

50 lbs/day*

Unit Dimensions:

145/8" x 235/8" x 33"

145/8" x 235/8" x 33"

145/8" x 235/8" x 33"

145/8" x 235/8" x 33"

Internal blue LED light

when door is open

No

No

Yes

Yes

11/07/2017 PK

TECHNICAL INFORMATION

Description 50lb Indoor Ice Maker

50lb Indoor Ice Maker

Voltage:

(ice making/

Power Consumption:

3.0 / 4.0 3.0 / 4.0 3.0 / 4.0 3.0 / 4.0

12.2kWh / 100lbs of ice

No No Yes Yes

Drain Pump

*The actual quantity of ice produced per day can vary with room and water conditions.

The technical data and performance index listed above is subject to change and should be used for reference only.

INTRODUCTION

The Maxx Ice MIM50 ice maker series produce hard, gourmet cube ice and offers convenience for homeowners, restaurants and

hotel guests. An insulated ice storage bin is built in.

• A cold water supply is needed.

• A gravity drain is needed.

This user’s manual is intended as a resource for persons installing, using and servicing the MIM50 series. It contains valuable

information on safety and maintenance. Maxx Ice strongly recommends that this manual be kept in a place where it can be accessed

when needed.

The MIM50 series is designed and manufactured according to the highest standards of safety and performance. It meets or

exceeds the safety standard of UL563 and sanitation standard NSF12.

Maxx Ice assumes no liability or responsibility of any kind for products manufactured by Maxx Ice that have been altered in any way,

including the use of any parts and/or other components not specifically approved by Maxx Ice Warranty & Parts. Maxx Ice reserves the right

to make design changes and/or improvements at any time. Specifications and designs are subject to change without notice.

3

Page 6

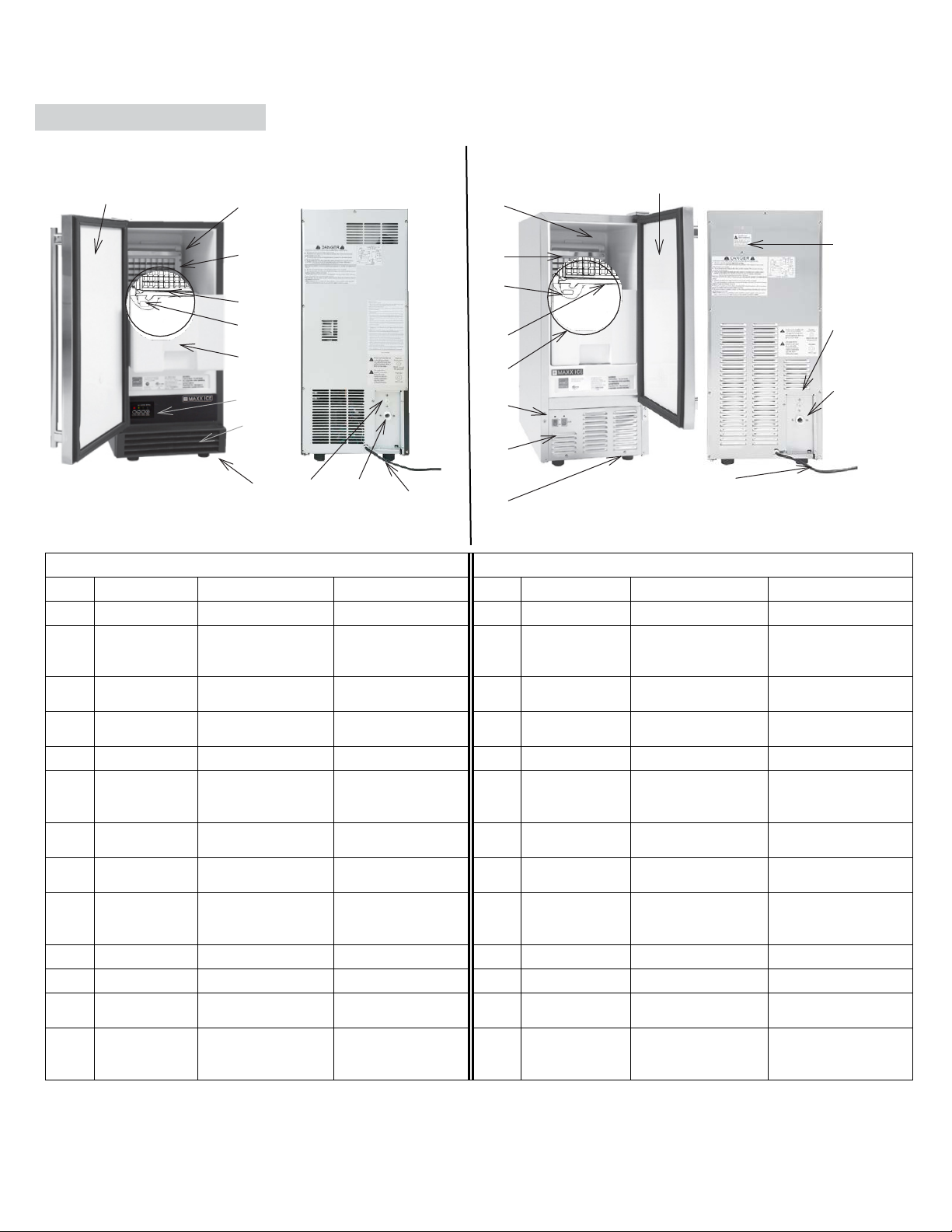

MIM50V / MIM50 / MIM50P/MIM50P-O

MIM50-O

Water

Tube

Control Panel

panel)

Panneau de

configuration (derrière

le panneau d'accès)

Evaporator

(ice mold)

Évaporateur (moule à

glace)

Evaporador (molde de

hielo)

Water

Trough

Compartimiento de

hielo

Front Louver

Panel

Panneau de louvres

avant

Panel frontal de la

persiana

Front Louver

Panel

Panneau de louvres

avant

Panel frontal de la

persiana

On/Off/Clean

Buttons

Boutons On / Off /

Clean

Botones de encendido /

apagado / limpieza

Compartimiento de

hielo

Evaporator

(ice mold)

Évaporateur (moule à

glace)

Evaporador (molde de

hielo)

Water

Tube

2

1

3

4

5

6

7

8

9

10

11

12

4

5

8

1

11/07/2017 PK

COMPONENT LOCATIONS

MIM50V / MIM50 / MIM50P/MIM50P-O MIM50-O

Front Back Front Back

13

2

12

11

3

10

9

7

6

ITEM # ENGLISH FRANÇAIS ESPAÑOL ITEM # ENGLISH FRANÇAIS ESPAÑOL

1 Door Porte Puerta 1 Door Porte Puerta

2

Distribution

3

4

5 Float Flotte Flotador 5 Power Cord Cordon d'alimentation Cable de alimentación

Ice Storage

6

Bin

7 Control Panel Panneau de contrôle Panel de control 7

8

9 Caster Roulette Castor 9 Ice Storage Bin Bac à glaçons

10 Water Inlet Arrivée d'eau Entrada de agua 10 Water Trough Auge d'eau Abrevadero

11 Drain Outlet Drain Outlet Drenaje de salida 11 Float Flotte Flotador

12 Power Cord Cordon d'alimentation Cable de alimentación 12

Tube de distribution

d'eau

Auge d'eau Abrevadero 4 Drain Outlet Drain Outlet Drenaje de salida

Bac à glaçons

Tubo de distribución

de agua

almacenamiento de

2

(Behind access

3 Water Inlet Arrivée d'eau Entrada de agua

6 Caster Roulette Castor

8

Panel de control (detrás

del panel de acceso)

almacenamiento de

13

4

Distribution

Tube de distribution

d'eau

Tubo de distribución de

agua

Page 7

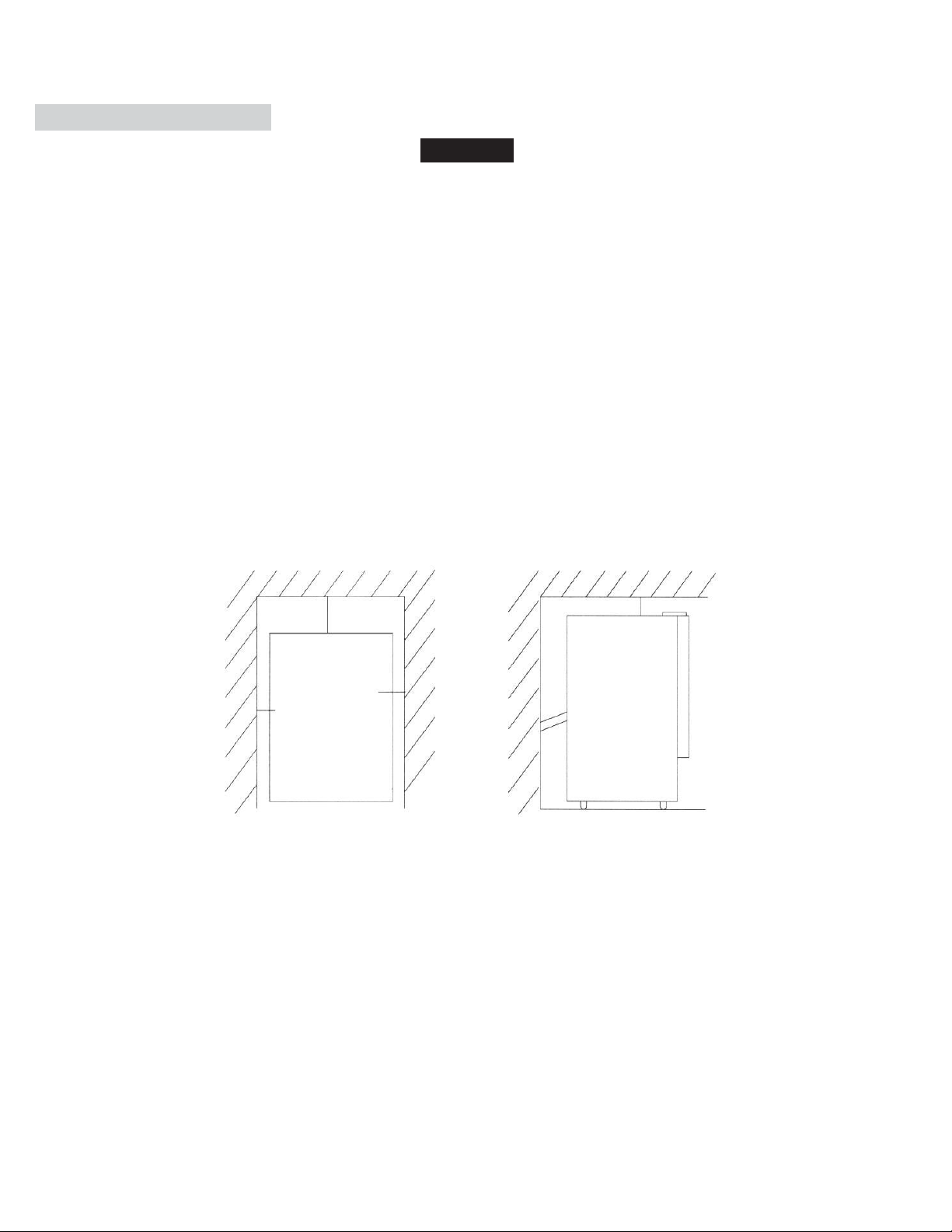

TOP VIEW

SIDE VIEW

4"

Rear of unit

1"

Top of unit

1"

Side

1"

Side

Front of unit

11/07/2017 PK

ICE MAKER INSTALLATION

WARNING

Excessive Weight Hazard

Use two or more people to move and install ice maker.

Failure to do so can result in back or other injury.

Remove Packaging Materials

IMPORTANT: Do not remove any permanent instruction labels or the data label on your ice maker.

Remove tape and glue from your ice maker before using.

• To remove any remaining tape or glue, rub the area briskly with your thumb. Tape or glue residue can also

be easily removed by rubbing a small amount of liquid dish soap over the adhesive with your fingers. Wipe

with warm water and dry.

• Do not use sharp instruments, rubbing alcohol, flammable fluids, or abrasive cleaners to remove tape or glue.

These products can damage the surface of your ice maker.

Cleaning Before Use

After you remove all of the packaging materials, clean the inside of your ice maker before using it. See the

“Interior Cleaning” in the Cleaning and Maintenance section.

Installation Clearances

• This ice maker should be properly installed by qualified personnel.

• To ensure proper ventilation for your ice maker, the front of the unit must be completely unobstructed.

• When installing the ice maker under a counter, follow the recommended spacing dimensions shown. Allow

at least 4" (102mm) clearance at rear, and 1"(25mm) at top and sides for proper air circulation. The

installation should allow the ice maker to be pulled forward for servicing if necessary.

• Choose a well ventilated area with an ambient temperature range of between 50°F (10°C) to 99°F (37°C). This

unit MUST be installed in an area protected from the elements, such as wind, rain, water spray or drips.

• The unit should not be located next to ovens, grills or other high heat sources.

• Installation of the ice maker requires a cold water supply inlet of ¼" (6.35mm) soft copper tubing with

a shut-off valve.

• The ice maker requires a continuous water supply with a minimum pressure of 15 psi (1 bar or 103 kPa) and a

static pressure not to exceed 75 psi (5.2 bar or 517 kPa). The temperature of the water feeding into the ice

maker should be between 40°F (4°C) and 90°F (32°C) for proper operation.

5

Page 8

11/07/2017 PK

WARNING

Normal operating ambient temperature should be between 50°F (10°C) to 99°F

(37°C).

Normal operating water temperature should be between 40°F (4°C) and 90°F (32°C).

Operation of the ice maker for extended periods outside of these normal temperature

ranges may affect production capacity.

• It is strongly recommended that a water filter be used. A filter, if it is of the proper type, can remove taste and

odors as well as particles. Some water is very hard, and softened water may result in white, mushy cubes that

stick together. Deionized water is not recommended.

• The ice maker must be installed with all electrical and water connections in accordance with all state and local codes.

• The unit should be located on a firm and level surface. It is important for the ice maker to be leveled in order to

work properly. If needed, you can adjust the height of the ice maker by revolving the caster. See the “Leveling

the Ice Maker” section.

• A standard electrical supply (115V AC only, 60Hz, 15A), properly grounded in accordance with the National

Electrical Code and local codes and ordinances, is required.

IMPORTANT: Do not kink or pinch the power supply cord between the icemaker and wall or cabinet.

Electrical Requirements

DANGER

Electrical Shock Hazzard

Plug into a grounded 3-prong outlet. Never remove the ground prong from the plug. Never use

an adapter. Never use an extension cord.

Failure to follow these instructions can result in fire, electrical shock or death.

It is important to make sure you have the proper electrical connection:

A standard electrical supply, properly grounded in accordance with the National Electrical Code and local codes

and ordinances, is required. The ice maker should always be plugged into its own dedicated electrical outlet. It is

recommended that a separate circuit, serving only your ice maker, be provided. Use receptacles that cannot be turned

off by a switch or pull chain. The fuse (or circuit breaker) size should be 15 amperes.

Recommended Grounding Method

For your personal safety, this appliance must be grounded. This appliance is equipped with a power supply cord having

a 3-prong grounding plug. To minimize possible shock hazard, the cord must be plugged into a mating 3-pronged and

grounding-type wall receptacle, grounded in accordance with the National Electrical Code and local codes and

ordinances. If a mating wall receptacle is not available, it is the personal responsibility of the customer to have a

properly grounded, 3-prong wall receptacle installed by a qualified electrician.

Leveling The Ice Maker

It is important for the ice maker to be leveled in order to work properly. Otherwise water

will not flow properly through the evaporator (ice mold). The ice production will be less

than normal, and may be noisy. If you find that the surface is not level, rotate the casters

until the ice maker becomes level. You may need to make several adjustments to level it.

We recommend using a carpenter’s level to check the ice maker.

1. Place a carpenter’s level on top of the unit to see if the ice maker is level from

front to back and side to side.

2. Adjust the height of the casters as follows:

Turn the leveling casters clockwise to lower that side of the ice maker.

Turn the leveling casters counterclockwise to raise that side of the ice

maker.

You will find that the casters make it easy for one person to move the ice maker. This is useful for cleaning and

sanitizing the surface on which the ice maker is installed because it allows you to move the unit and have easy access

to the surface to be cleaned.

6

Page 9

Top hinge cover

Cabinet

Top hinge mat

Top hinge

Top hinge

Door

Bottom hinge

Bottom hinge

MIM50V black top hinge

no cover or mat.

11/07/2017 PK

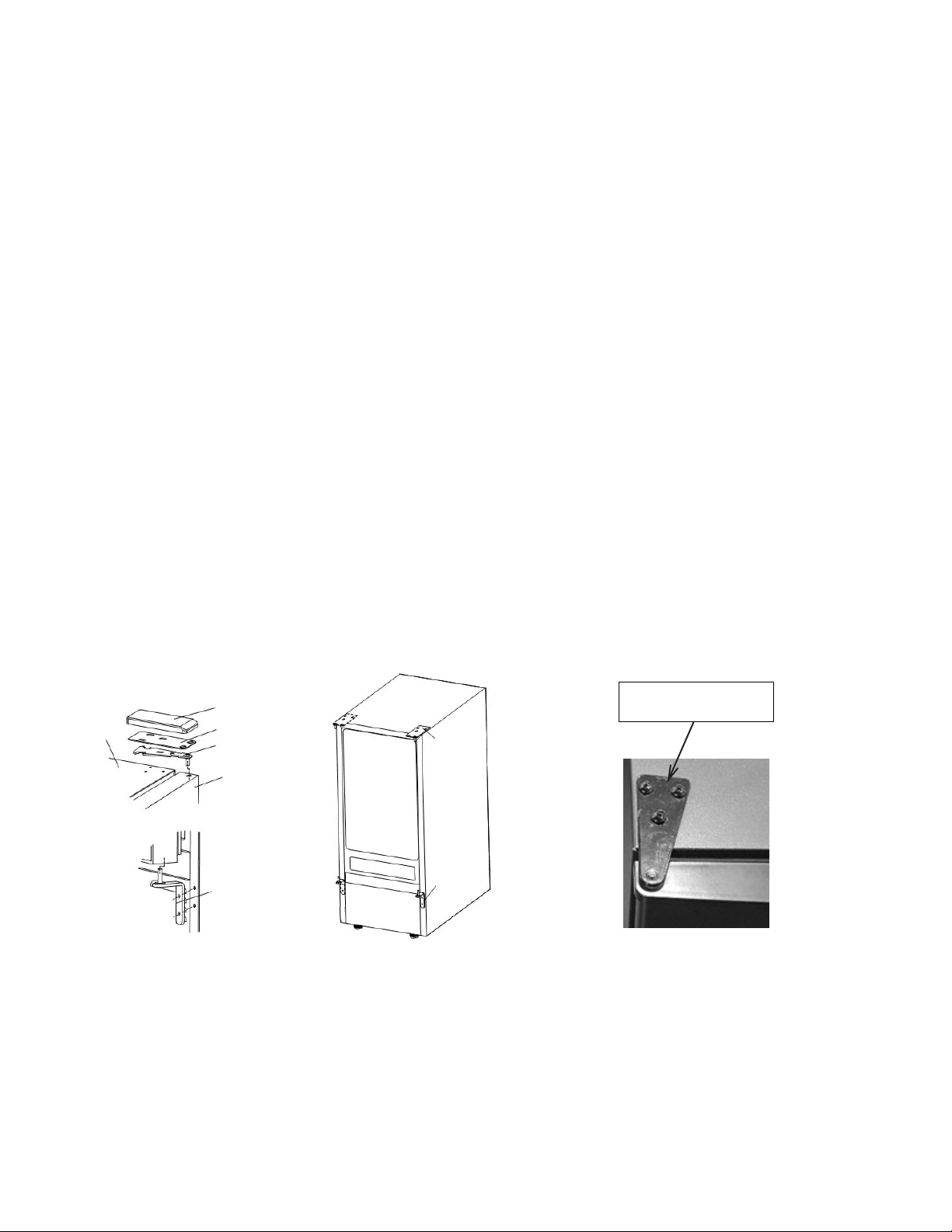

Reversing The Door Swing For MIM50-O and MIM50V

Tools needed: Flathead screwdriver, Phillips screwdriver

NOTE: Before you begin, unplug the ice maker or disconnect power.

To Remove Door From Hinges

1. Remove the top hinge cover.

2. Using a Phillips screwdriver, remove the screws, remove the top hinge mat and top hinge. Keep the parts

together and set them aside. (The MIM50V has a black hinge and no cover or mat, but is removed same

way as MIM50-O top hinge.)

3. Lift the door off of the bottom hinge and set the door aside.

To Replace Door On Hinges

1.

Using a flathead screwdriver, remove the plug buttons from the screw holes opposite the door hinges, top and

bottom. Set aside.

2.

Remove the front louver. Set aside.

3.

Remove the bottom hinge and place it on the opposite side at the bottom of the door. (The MIM50V bottom

hinge removed and installed same way as MIM50-O bottom hinge.)

4.

Position the door on the bottom hinge.

5.

Align the door on the bottom hinge and replace the top hinge and top hinge mat.

6.

Replace top hinge cover.

7.

Push the plug buttons into the original screw holes.

See Figure below:

7

Page 10

11/07/2017 PK

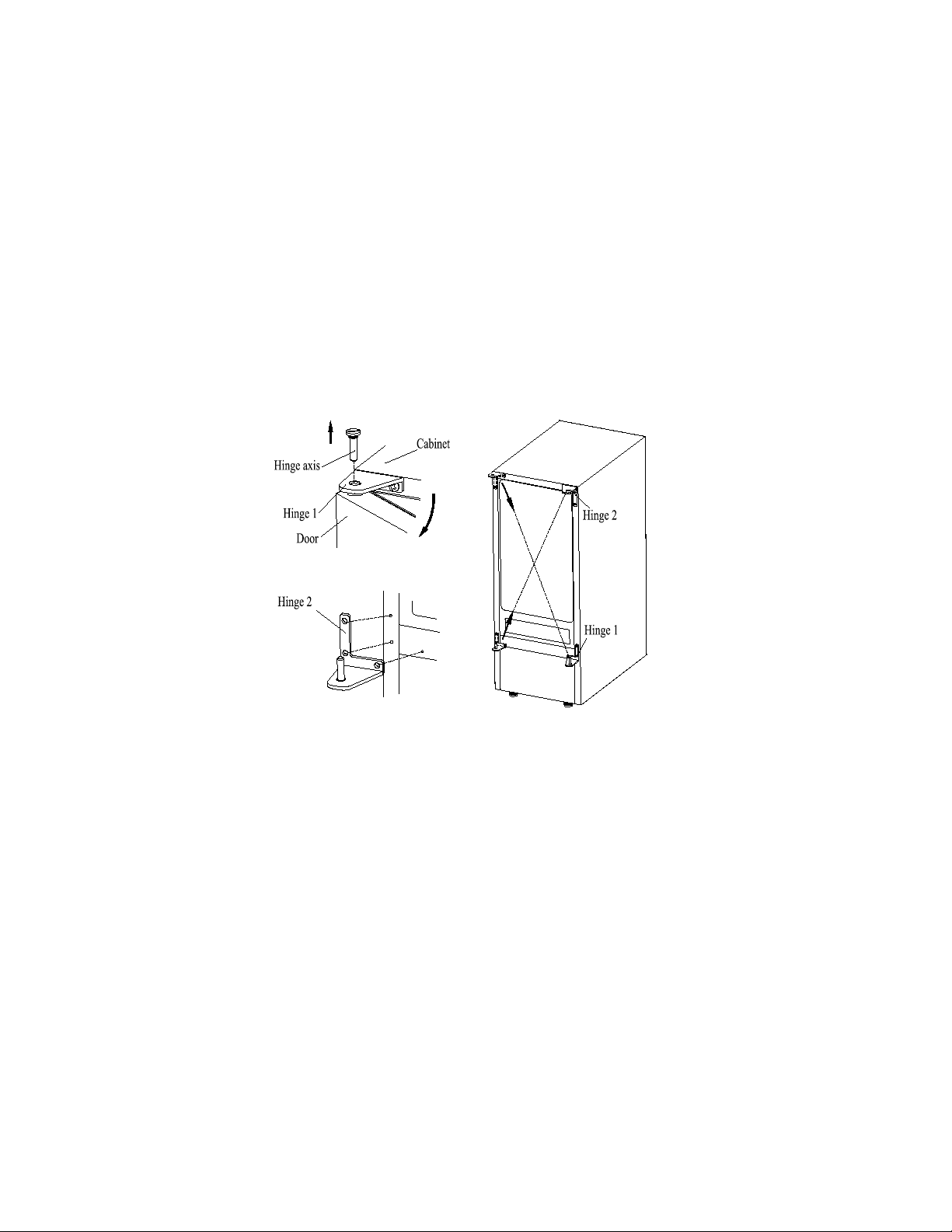

Reversing The Door Swing For MIM50, MIM50P and MIM50P-O

To remove door from hinges:

1. Using a flathead screwdriver, separate the axis from Hinge 1. Set aside.

2. Open the door about 20°around the axis of Bottom Hinge 2, then lift the door off Bottom Hinge 2 and set door aside.

To replace door on hinges:

1. Using a flathead screwdriver, remove the plug buttons from the screw holes opposite the door hinges, top and

bottom. Set aside.

2. Replace the axis on the Hinge 1 and tighten it firmly. Remove Hinge 1 and place it on the opposite bottom side.

3. Remove Hinge 2 and place it on the opposite top side. Separate the axis from Hinge 2 and set it aside.

4. Align the door on Bottom Hinge 1 and replace axis on Hinge 2. Tighten it firmly. Place the handle on the side of the

door away from the hinge side.

5. Push the plug buttons into the original screw holes.

See Figure below.

Water Supply

The water supply should be ready at the point of installation. The water supply pressure should be a minimum of 15 psi (1

bar or 103 kPa) with a static pressure not more than 75 psi (5.2 bar or 517 kPa). (A wall outlet directly behind the ice maker

will make installation easier.)

NOTE:

All installations must be in accordance with local plumbing code requirements.

Professional installation is recommended. Make certain the hoses are not pinched, kinked or damaged

during installation. Check for leaks after connection.

Tools Required

½" open-end wrench, Phillips screwdriver

Connecting The Water Line

1.

Turn off main water supply. Turn on the nearest faucet long enough to clear line of water.

2.

Find a ½" to ¾" vertical cold water pipe near the installation location. The distance should be less than 6 feet.

The water supply hose provided with the ice maker is about 6 feet long.

3.

A shut-off valve must be installed to the main water supply. If the water pipe has a plain piece of copper

tubing, attach a ¼" O.D. compression union to the tubing and remove the nut.

4.

Connect the nut of the water supply hose to the tap, and connect the other end with the water inlet. Tighten

firmly by hand, then one-half turn with wrench.

8

Page 11

Drain

11/07/2017 PK

5.

Turn on the main water supply and tap. Check for water supply connection leaks. Tighten every connection

(including connection at the water inlet).

NOTE: When you connect the water supply hose and the drain hose, pay attention to the

indications of “Water inlet” and “Drain outlet” on the ice maker.

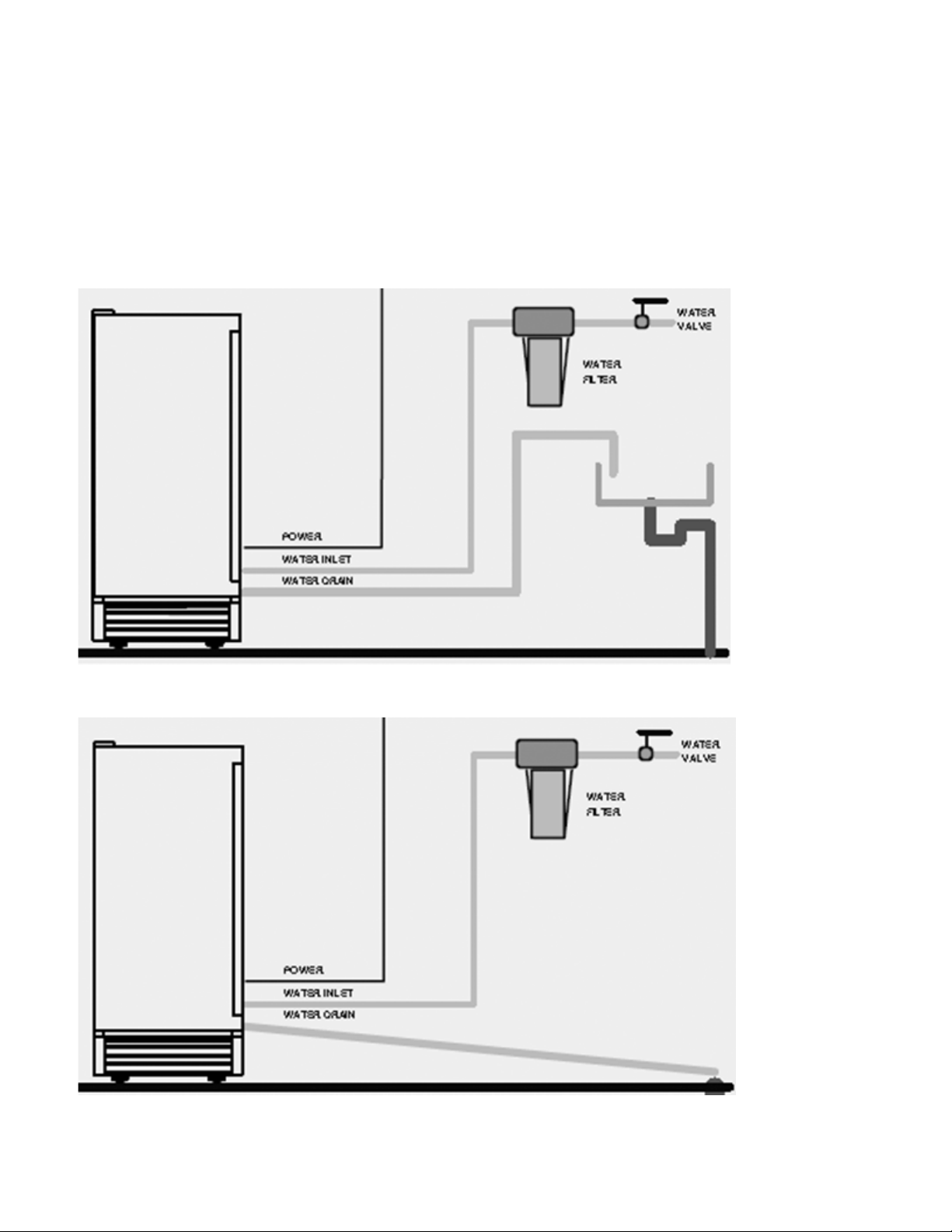

You must connect the drain line before using the ice maker. Follow the steps below.

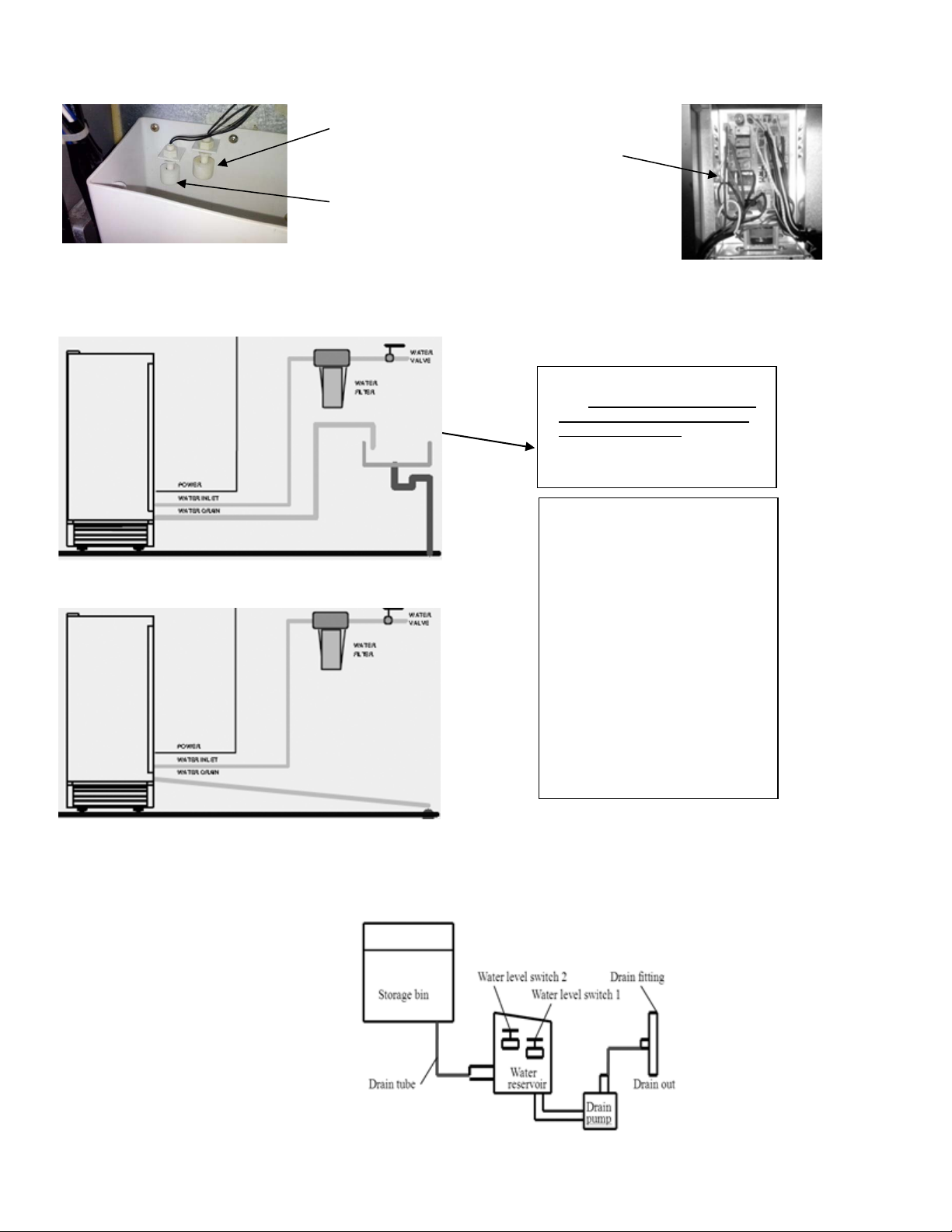

There are two types of ice machine modes, one that drains by gravity and one that has an internal drain pump.

The MIM50P and MIM50P-O models come with an internal drain pump that can pump out water up to a rise of 1.5m

(59”)

or over a horizontal length of 1.5m (59”).

9

Page 12

11/07/2017 PK

Connecting The Drain Line

NOTE: If there is a drain line near the ice maker, the best choice to drain water to the drain line, is through

the drain water hose provided with ice maker.

1. Locate the floor drain near the ice maker. The distance should be less than 5 feet since the length of the long

drain water hose provided with the ice maker is about 5 feet.

2. Find the drain outlet on the back of ice maker, take off the rear drainage plug. Connect the nut of the drain

outlet to the water draining hose, insert the other end of the hose into the drain line.

NOTE: Never allow the drain hose to hang or loop higher than the floor of the ice storage bin.

3. All horizontal runs of drain lines must have a fall of ¼" per foot. An air gap will likely be required between the ice

maker drain tube and the drain/waste receptacle. A stand pipe with a trap below it would be acceptable for the

drain/waste receptacle. A floor drain is also acceptable. If this is not possible, Maxx Ice recommends the use of

a condensate pump. Available at local hardware stores. (An internal pump comes standard on

the MIM50P

and MIM50P-O models.)

4. Pour 1 gallon of water into the ice storage bin to check for leaks at all drain connections and at the nut of the

drain water hole. Tighten any connections or nuts that leak.

NOTE: This ice maker is not a freezer. Hot temperatures will cause a high rate of melting in the ice

storage bin. Ice will drain over time. A drain is required.

INSTALLATION TYPES

This ice maker has been designed for Mobile (free-standing) installation. However, it can also be Enclosed (under a

cabinet) or Built-in (sealed to the floor). In every case, there must be adequate air space around the unit for ventilation.

Mobile Installation

A mobile installation will allow you to install the ice maker free-standing in any place you desire provided you have

access to a water supply, proper electrical, a drain and you’ve leveled the ice maker.

Enclosed Installation

An enclosed installation will allow you to install the ice maker under a cabinet provided the required clearance

space around the ice maker is respected, and you have access to a water supply, proper electrical, a drain and

you’ve leveled the ice maker.

Built-in installation

If this method of installation is chosen, it will still be necessary to allow adequate ventilation space around the unit.

The following additional items must be observed.

1.

Place ice maker in front of installation location. Remove the feet and place the unit flat on the floor or

on a platform depending on your installation requirements.

2.

The water supply line must be plumbed before connecting to the ice maker.

3.

The drain line must be connected. If you do not have a floor drain, you will require a condensation pump. Not

required for the MIM50P and MIM50p-O models they come with an internal drain pump

4.

Turn on main water supply and tap. Check for water supply connection

leaks. Tighten every connection (including connection at the water inlet).

5.

If the electrical outlet for the ice maker is behind the cabinet, plug in the ice maker.

6.

Push the ice maker into position.

7.

Seal all around the cabinet to the floor with an approved caulking compound.

.

10

NOTE: Be sure the drain hose is connected and fed into the drain line before the ice maker is

moved into its final position.

Page 13

11/07/2017 PK

OPERATION

Final Check List Prior To Operation

1.

Have all packing materials and tape been removed from the interior and exterior of the ice maker?

2.

Did you clean the ice storage bin?

3.

Have the installation instructions been followed, including connecting the ice maker to water, drain and

electricity?

4.

Has the ice maker been leveled?

5.

Is the ice maker in a site where the ambient temperature is between 50°F (10°C) and 99°F (37°C) and the water

temperature between 40°F (4°C) and 90°F (32°C) all year-round?

6.

Has the water supply pressure been checked to ensure a minimum of 15 psi (1 bar or 103 kPa) with a static pressure

not to exceed 75 psi (5.2 bar or 517 kPa)?

7.

Is there a clearance of at least 4" (102 mm) at the rear, and 1" (25 mm) at top and sides for proper air

circulation?

8.

Has the power supply voltage been checked or tested against the nameplate rating? And has proper grounding

been installed in the ice maker?

9.

Is the ice maker plugged in?

10.

Have you turned on the main water supply and tap?

11.

Have you checked for leaks at all water supply connections?

Operating Method

1. Turn on the water tap, let the water trough fill, then press the ON/OFF button on the front panel. The ice

maker will start working automatically.

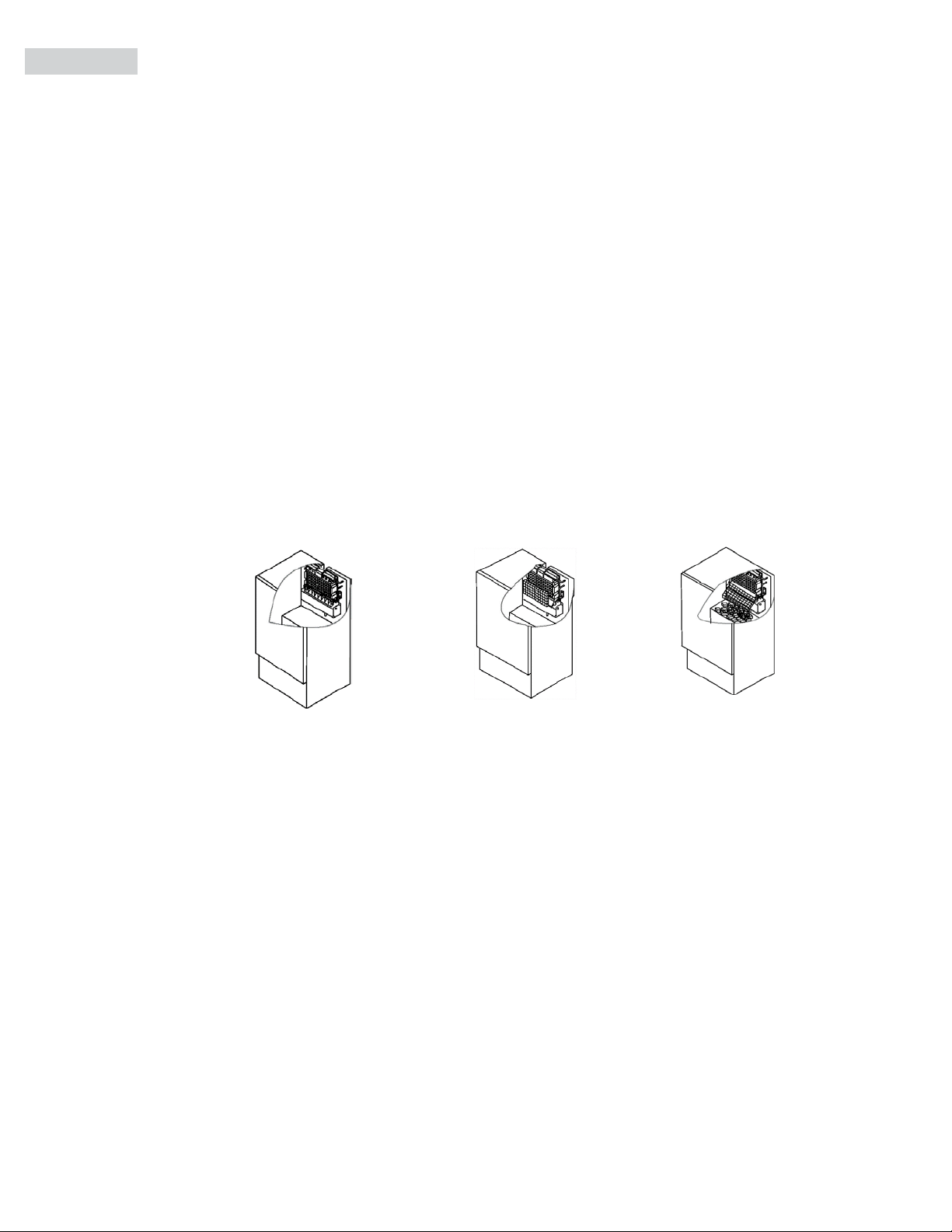

Ice Making Stage Ice Harvest Stage Bin Full Stage

2.

After 3 minutes, the ice maker will automatically go to the ice-making stage, and the sound of water flowing will

be heard.

3. When the batch of ice has been fully formed, ice will automatically be harvested to the ice storage bin.

4. When the ice storage bin is full, the sheet of cubes will not fall completely and will hold the bin-full probe

open. The ice maker stops making ice automatically.

5. The unit will start making ice again after the ice cubes are removed. Then the bin-full probe swings back to

operating position.

6. Bin light (if present) (standard on MIM50P and MIM50P-O): The bin light is controlled by a magnetic reed switch

that has been installed on the inner surface of the door. It is turned On or Off automatically with the opening or

closing of the door.

7. Pump Water Drain system (if used) (standard on MIM50P and MIM50P-O): As soon as the ice melt water or other

surplus overflow water in the water reservoir reaches the maximum level, the water level switch closes and

transmits a low-voltage current to the PC board. The PC board energizes the water drain pump for 20 seconds,

pumping out most of the excess water in the water reservoir.

NOTE:

• Although the unit has been tested and cleaned at the factory, due to long-term transit and

storage, the first batch of cubes must be discarded.

• Never turn the water supply tap off when the ice maker is working.

• Never touch evaporator when unit is running!

• Except to take ice from the unit, keep the door closed to reduce melting and insure

proper ice formation.

11

Page 14

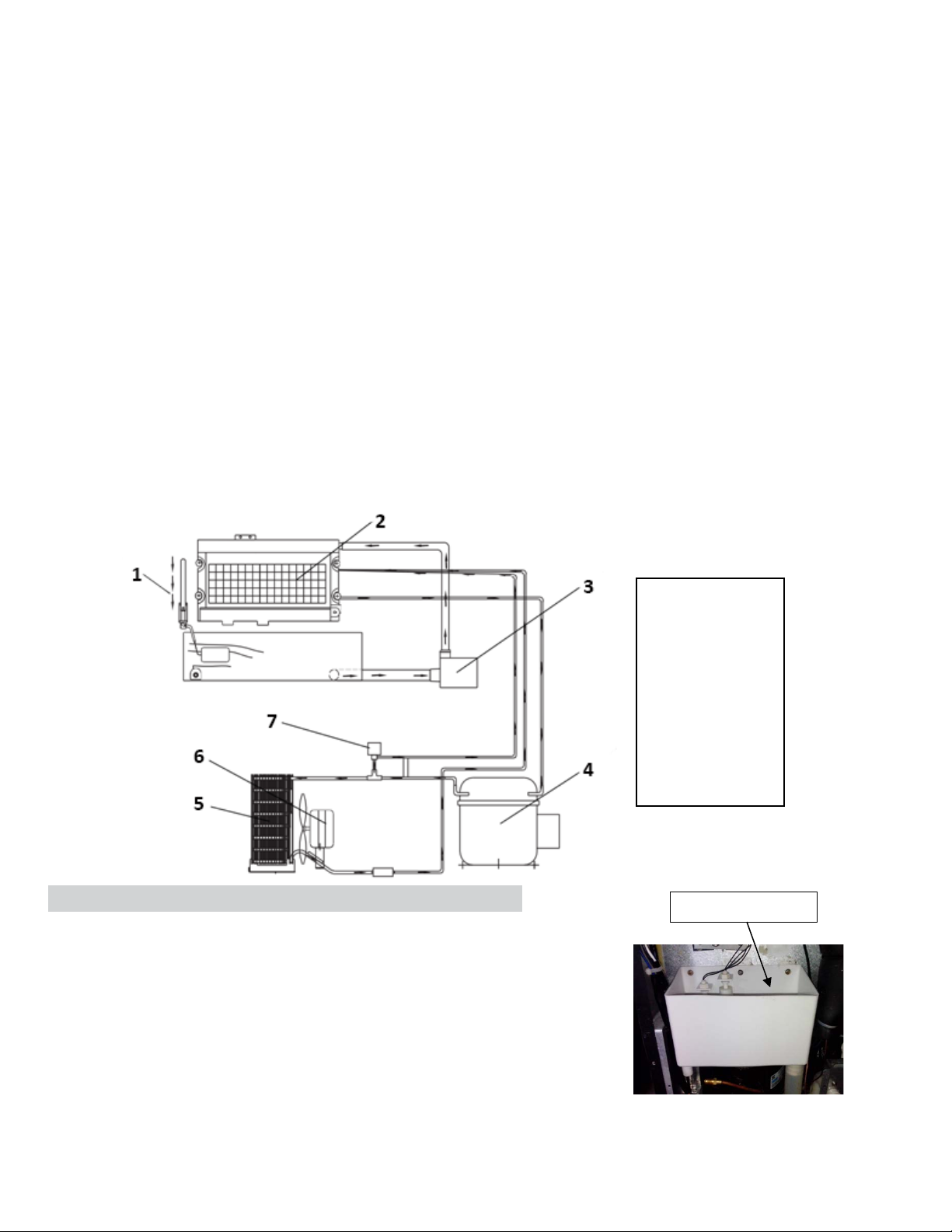

1- Water Inlet

Water Reservoir

11/07/2017 PK

How The Ice Maker Makes Ice

Set the ON/OFF button to the ON position. The ice maker will automatically go to the ice making stage.

There are two distinct cycles: ice freeze and harvest.

1. The freeze cycle happens when water flows to the evaporator surface.

2. The harvest cycle is when the ice is released and water enters the ice maker.

20 Minutes: A complete cycle takes about 20 minutes, but it depends on temperature and operating conditions.

Freeze: During the freeze cycle the compressor is pumping refrigerant, the fan motor is blowing air, and the water pump

is circulating water. When the batch of ice has been fully formed, the ice maker stops the freeze cycle and harvest cycle

begins.

Harvest: During the harvest cycle the compressor is still operating, but the water pump has stopped. The hot gas valve

opens, diverting hot refrigerant gas into the evaporator. The hot refrigerant gas warms the evaporator, causing the cubes

to slide as a unit off the evaporator and into the storage bin. The freeze cycle will restart when all the cubes have been

harvested.

How The Ice Maker Uses The Water

The ice maker begins with a fixed charge of water that is contained in the water trough. As the water flows to the freezing

evaporator surface, the portion of water that does not contain mineral impurities freezes and sticks to the ice cube molds.

The water containing impurities falls back into the water trough. During the ice making process, fresh water enters into the

water trough continuously as the water in trough freezes continuously in the evaporator

.

2- Evaporator

3- Water Pump

4- Compressor

5- Condenser

6- Fan Motor

7- Hot Gas Value

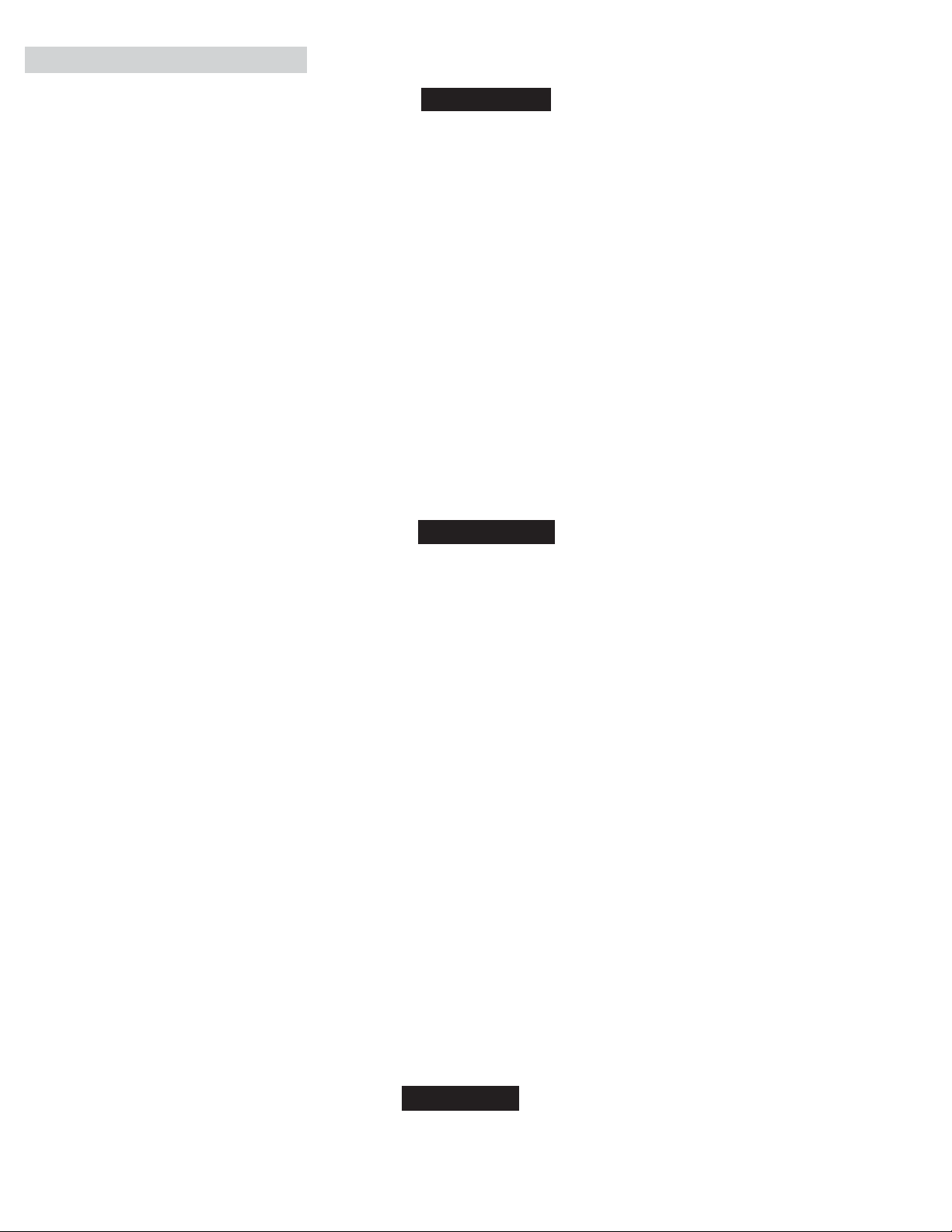

MIM50P and MIM50P-O DRAIN SYSTEM OPERATION

How the drain system operates when water is pumped out

The components of the Pump-Out Water Drain System are

• Water reservoir

• PC Board & Water level switch 1, 2

• Water Drain Pump

Drain Pump Operation

• All water coming from the overflow and the melted ice is

collected in the water reservoir.

• As soon as the water in the reservoir reaches the maximum level,

the water level switch 1 closes, transmitting a low voltage current

to the PC Board.

12

Page 15

NOTE:

reservoir.

WARNING!

Water Level Switch 1

Water Level Switch 2

PC Board

11/07/2017 PK

• The PC board activates the water drain pump for 20 seconds, pumping out

most of the water contained in the water reservoir.

• The water can be pumped out up a rise of 1.5m (59”) or

The outlet of the drain hose

must be raised higher than

the water surface to prevent

the drained water from

flowing back into the water

over a horizontal length of 1.5m (59”).

If alarm buzzer sounds, turn

off the ice maker and the

water supply, remove all ice

from storage bin, and wipe

up any water that may have

overflowed. Check if there is

any water in water trough at

back of unit; if no water,

drainage pump may not be

receiving the proper amount

of power. Check power

source. If the problem can be

corrected, turn on the unit

again. Also check that none

of the water lines are kinked.

If the problem remains,

contact Customer Service.

• If water level switch 2 closes, transmitting a low-voltage current to the PC board, the PC board

activates the buzzer alarm, informing you that the drain pump, water level switch or drain tube may

be malfunctioning.

Drain System Schematic Diagram

13

Page 16

11/07/2017 PK

Normal Sounds

Your new ice maker may make sounds that are not familiar to you. Most of the new sounds are normal. Hard surfaces like the

floor and walls can make the sounds louder than they actually are. The following list describes the sounds that might be new to

you and what may be causing them.

• Rattling noises may come from the flow of the refrigerant or the water line. Item stored

on top of the ice maker can also make noises.

• The high efficiency compressor may make a pulsating or high-pitched sound.

• Water running may make a splashing sound.

• You may hear air being forced over the condenser by the condenser fan.

• During the harvest cycle, you may hear the sound of ice cubes falling into the ice storage bin.

Preparing The Ice Maker For Long Storage

If the ice maker will not be used for a long time, or is to be moved to another place, it will be necessary to drain the system

of water.

1.

Shut off the water supply at the main water source.

2.

Disconnect the water supply line from the water inlet.

3.

Shut off the electric supply at the main electrical power source.

4.

Take out the ice storage bin to remove any remaining ice and water. Dry the bin.

5.

Pull off the drainage tube of the water trough to drain off all water.

6.

Leave the door open to allow for circulation and to prevent mold and mildew.

7.

Leave water supply line and power cord disconnected until ready to reuse.

NOTE: Do not touch the power plug when your hands are wet. Never unplug the unit by pulling on the cord.

Grasp the plug and pull out firmly.

14

Page 17

11/07/2017 PK

CLEANING AND MAINTENANCE

CAUTION

If the ice maker is left unused for a long time, before the next use it must be thoroughly cleaned.

Follow carefully any instructions provided for cleaning or use of sanitizing solutions.

Do not leave any solution inside the ice maker after cleaning.

Periodic cleaning and proper maintenance will ensure efficiency, top performance, and long life. The maintenance

intervals listed are based on normal conditions. You may want to shorten the intervals if you have pets, or if there are

other special considerations.

What Shouldn’t Be Done?

Never keep anything in the ice storage bin that is not ice: objects like wine and beer bottles are not only unsanitary,

but the labels may slip off and plug up the drain.

What Parts Should Be Kept Clean?

1. The exterior

2. The interior

3. The condenser

4. Water distribution tube

5. The ice-making system

Before proceeding with cleaning and maintenance operations, make sure

the power line of the unit is disconnected and the water line is shut off.

WARNING

Exterior Cleaning

The door and cabinet may be cleaned with a mild detergent and warm water solution such as 1 oz. of dishwashing liquid

mixed with 2 gallons of warm water. Do not use solvent-based or abrasive cleaners. Use a soft sponge and rinse with

clean water. Wipe with a soft clean towel to prevent water spotting.

If the door panel is stainless steel, stainless steel can discolor when exposed to chlorine gas and moisture. Clean stainless

steel with a mild detergent and warm water solution and a damp cloth. Never use an abrasive cleaning agent.

Interior Cleaning

The ice storage bin should be sanitized occasionally. Clean the water trough before the ice maker is used first time and

reused after stopping for an extended period of time. It is usually convenient to sanitize the trough after the ice making

system has been cleaned, and the ice storage bin is empty.

1. Disconnect the power to the unit.

2. Open the door and take out the removable ice storage bin. With a clean cloth, wipe down the interior of unit

and ice bin with a sanitizing solution made of 1 ounce of household bleach or chlorine and 2 gallons of hot

(95˚F – 115˚F) water.

3. Rinse thoroughly with clear water.

4. Screw off the drainage nut to drain completely.

5. Put the ice storage bin inside the unit.

6. Reconnect power to the unit.

The ice scoop should be washed regularly. Wash it just like any other food container.

WARNING

DO NOT use solvent-based cleaning agents or abrasives on the interior.

These cleaners may transmit taste to the ice cubes and damage or discolor the interior.

15

Page 18

11/07/2017 PK

Condenser Cleaning

A dirty or clogged condenser prevents proper airflow, reduces ice making capacity, and causes higher than

recommended operating temperatures that may lead to component failure. Have the condenser cleaned at least

once every six months.

1. Unplug the ice maker or disconnect power.

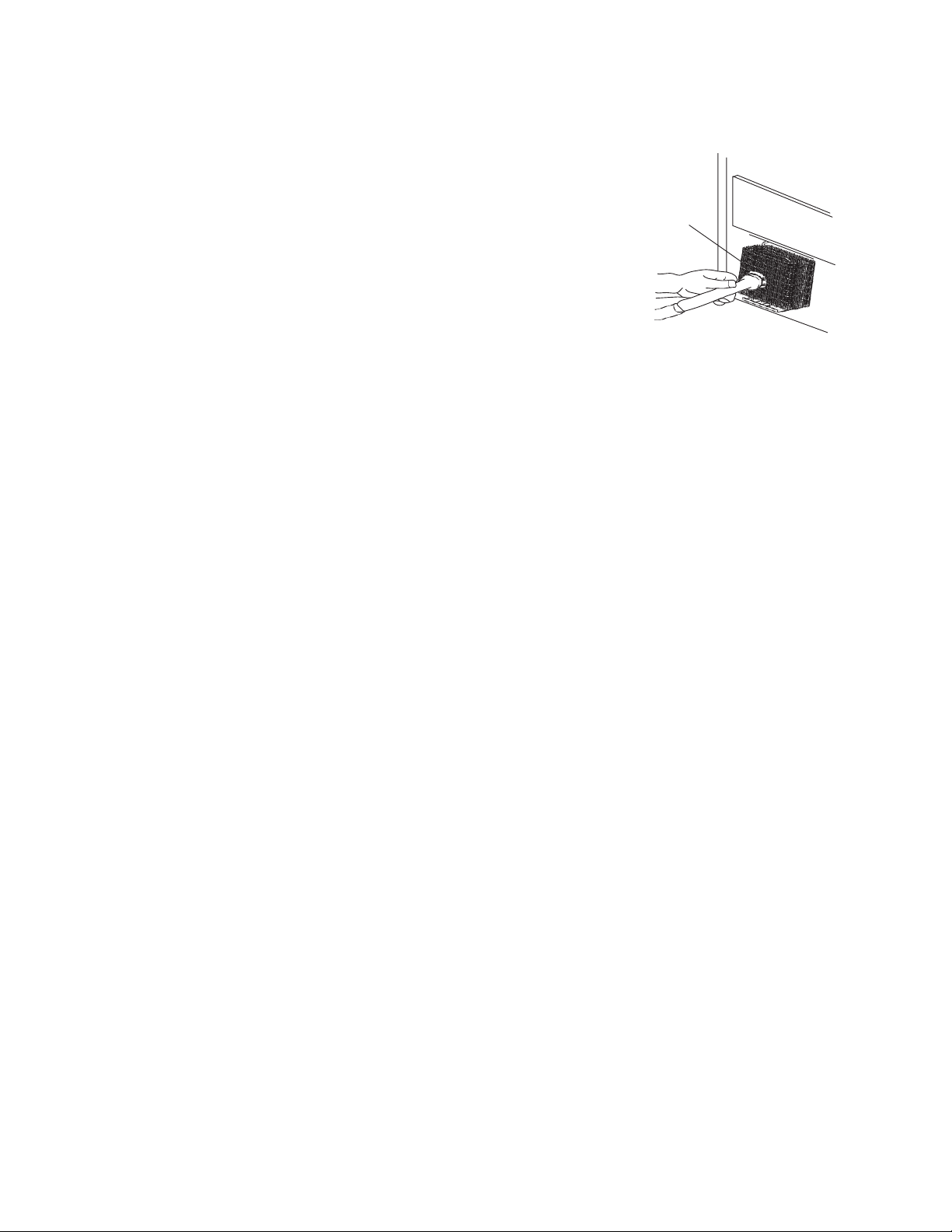

2. Gently pull off the lower front louver. (On MIM50-O only

Condenser

Surface

remove two screws securing front louver and then remove

louver.)

3. Remove dirt and lint from the condenser and the unit

compartment with the brush attachment of a vacuum cleaner.

4. Reassemble the lower front louver.

5. Plug in the ice maker or reconnect power.

Water Distribution Tube Cleaning

When you find the ice cubes are incompletely formed or the output is low, the water distribution tube may be blocked.

Turn off the power button, gently take out the water distribution tube, locate the holes in the distribution tube and use a

pointed object such as a toothpick to dredge the holes. Then put the water distribution tube back to its original position.

If the tube is badly blocked, clean it as follows:

1.

Shut off the water supply.

2.

Disconnect the water hose from the distribution tube.

3.

Gently take out the distribution tube.

4.

With a brush, clean the tube with a dilute solution of warm water and a mild detergent such as dishwashing

liquid. After removing the dirt and lint from the surface, rinse the tube with clean water.

5.

Replace the distribution tube.

6.

Reconnect the water supply.

Ice-Making System Cleaning and Sanitizing

Minerals that are removed from the water during the freezing cycle will eventually form a hard, scaly deposit in the

water system. Cleaning the system regularly helps remove the mineral scale buildup. How often to clean the system

depends upon how hard your water is or how effective your filtration may be. With hard water of 15 to 20 grains/gal.

(4 to 5 grains/liter), you may need to clean the system as often as once every 6 months.

1.

Make sure that all the ice is off the evaporator. If ice is being formed, wait until the cycle is completed, then

press the ice maker’s ON/OFF switch on the control panel.

2.

Remove all ice from the storage bin.

3.

Keep the ice maker connected to the water supply. Pour 8 oz. of Nickel-Safe Ice Machine Cleaner Solution into

the water trough. Then press the ON/OFF switch and the CLEAN button, initiating the wash cycle. The ice

maker will run in the Automatic Clean Mode.

16

Page 19

11/07/2017 PK

4.

5.

6.

7.

8.

9.

Allow 30 minutes for proper cleaning. After cleaning, press the ON/OFF switch again. Use a drain hose on the

front of the water trough to drain off the waste water to a convenient container. Don’t drain off the waste

water to the inside of the cabinet.

Repeat steps 3 and 4 (without Ice Machine Cleaning Solution) three times to rinse the ice making

system thoroughly.

Next, prepare a sanitizing solution made of 1 ounce of household bleach and 2 gallons of hot water (95˚ to 115˚F).

Fill a spray bottle with the sanitizing solution and spray all corners and edges, making sure to cover all surfaces

with the solution. Wipe the entire bin inside and outside, covering the entire surface of the walls. Allow the

solution to be in contact for at least 3 minutes, then dry.

Repeat steps 1 to 5 with the sanitizing solution of step 6 (bleach and water). Filling the water through to its

maximum level.

Repeat steps 3 and 4 to rinse the ice making system one more time.

Press the ON/OFF button again. The ice maker will return to the regular ice making mode. Discard the first

batch of ice.

DO NOT use or mix with any other solvent-based cleaner products. Use rubber gloves to protect hands.

Carefully read the material safety instructions on the container of the ice machine cleaner.

CONTROL PANEL

MIM50V / MIM50 / MIM50P

/ MIM50P-O

Front Inside Door

Description Of LEDs And Buttons

1. Bin Full (Red) LED: Bin full indicator light

When this is lit, the ice storage bin is full of ice or there is something blocking the bin-full probe. The unit will

stop working. When ice cubes are removed from the ice storage bin, freeing the bin-full probe, the red LED

will remain flashing for 3 minutes, then the unit will restart and return to the ice making mode.

2. Ice Making (Green) LED: Ice making indicator light

When this is lit, the unit is working in the ice making mode controlled by a temperature sensor.

3. Ice Harvest (Yellow) LED: Ice harvest indicator light

When this is lit, the unit is working in the ice harvest mode controlled by the ice-full probe.

4. Mode button: Mainly for service. When this is pressed, the ice making mode changes to the ice harvest mode

or vice versa. The mode can be judged from the status of the green and yellow LEDs.

5. Adjust button: To be used by an authorized service technician.

WARNING

The ice machine cleaner contains acids.

Discard the first batch of ice produced after cleaning.

MIM50-O

Front Inside Door Back

(Behind access panel)

17

Page 20

Problem

Possible Cause

Probable Correction

The ice maker is unplugged.

Plug the ice maker in.

Replace fuse. If it happens again, call for service to check

for a short circuit in the unit.

The ice maker power button is set at OFF.

Switch the ice maker power button to ON.

full probe is free

of ice.

The water doesn't feed

starts.

The air flow to the ice maker may be obstructed.

Check the installation.

are high, or unit is near some heat source.

Some water falls to the floor when you open the

door to remove ice from storage bin.

Normal condensation on the door or some water

together with ice. Take care when you take out ice.

Water supply connection is leaking.

Tighten fitting. See Connecting the water line.

Drain pipe higher than drain outlet.

MIM50V/50/50-O only. MIM50P/50P-O has drain pump)

formed or are white on

Check if the water supply pressure is below 15 psi (103

kPa).

Check water supply or filter may be restricted.

Check for a water leak at the water trough.

Level and lock the feet.

The electricity is off.

Reconnect the power supply line.

disconnected until the temperature returns to within the

stated range.

Remove some ice cubes; make sure the ice-full probe is

free of ice.

The body of the ice

maker is electrified

ice maker.

The drain hole below the ice storage bin is blocked.

Remove the ice storage bin and clean the drain hole.

The drain hose is kinked or improperly placed

higher than the floor of the ice storage bin.

Check the drain hose to be sure water can be drained

out unhindered.

Buzzer alarm.

MIM50P-O only)

Check for correct operation of drain water pump, water

11/07/2017 PK

MAJOR FUNCTIONS

1.

The operating procedure is completely automatic.

2.

When the ice storage bin is full of ice cubes, the ice maker stops making ice automatically. It starts making ice

again after ice cubes are removed.

3.

The different colors of the LED display indicate various work modes.

4.

A sensitive probe and accurate timer enhance the performance of the ice maker.

5.

A compressor protection system is built in.

TROUBLE SHOOTING

The ice maker doesn’t

operate.

in after the ice maker

Ice maker makes ice,

but bin does not fill up

with ice.

Water is leaking out of

the unit.

Cubes are partially

the bottom.

Noise during operation

The fuse is blown.

The ice storage bin is full of ice.

The water supply tap is turned off. Turn on the water supply tap.

The water supply pipe is not properly connected. Reconnect the water supply pipe.

The condenser may be dirty. Clean the condenser.

The ambient temperature and water temperature

(Applies to

Not enough water in the water trough.

The feet are not leveled and locked.

Certain sounds are normal. See Normal Sounds.

Remove some ice cubes. Be sure the ice-

Check the installation.

Lower drain pipe.

See Leveling the Ice Maker.

The ice maker stops

suddenly while making

ice.

Scaling occurs

frequently inside the

Water leaks from the

ice storage bin.

(Applies to MIM50P and

The room temperature is out of the stated range.

The ice storage bin is full of ice.

The ground line isn’t in the socket. Use a socket meeting the grounding requirements.

The hardness level of the water is too high.

Problem in pumping out water.

Cut off the electricity and leave the ice maker

Install a water-softening device in front of the water

inlet.

level switch and drain tube.

Page 21

11/07/2017 PK

Table des matières

SÉCURITÉ ET MACHINE À GLAÇONS ....................................................................................................................................... 20

MESURES DE PROTECTION IMPORTANTES ............................................................................................................................ 20

RENSEIGNEMENTS TECHNIQUES ............................................................................................................................................ 22

INTRODUCTION ...................................................................................................................................................................... 22

EMPLACEMENTS DES COMPOSANTS ..................................................................................................................................... 23

INSTALLATION DE LA MACHINE À GLAÇONS .......................................................................................................................... 24

Retirer le matériau d’emballage ................................................................................................................................... 24

Nettoyage avant l’utilisation ........................................................................................................................................ 24

Dégagements pour l’installation .................................................................................................................................. 24

Exigences en matière d’électricité ................................................................................................................................ 25

Méthode recommandée de mise à la terre.................................................................................................................. 25

Mise de niveau de la machine à glaçons ...................................................................................................................... 25

Inverser l’ouverture de porte pour MIM50-O et MIM50V ........................................................................................... 26

Inverser l’ouverture de porte pour MIM50, MIM50P et MIM50P-O ........................................................................... 27

Alimentation en eau ..................................................................................................................................................... 27

Outils requis .................................................................................................................................................................. 27

Évacuation .................................................................................................................................................................... 28

TYPES D’INSTALLATION .......................................................................................................................................................... 29

Installation mobile ........................................................................................................................................................ 29

Installation enfermée ................................................................................................................................................... 29

Installation intégrée ..................................................................................................................................................... 29

UTILISATION ........................................................................................................................................................................... 30

Liste de vérification finale avant l’utilisation ................................................................................................................ 30

Méthode d’utilisation ................................................................................................................................................... 30

Comment la machine à glaçons produit des glaçons ................................................................................................... 31

Comment la machine à glaçons utilise l’eau ................................................................................................................ 31

FONCTIONNEMENT DU SYSTÈME D’ÉVACUATION MIM50P et MIM50P-O ........................................................................... 31

Fonctionnement du système d’évacuation quand l’eau est pompée .......................................................................... 31

Fonctionnement de la pompe d’évacuation ................................................................................................................ 31

Sons normaux ............................................................................................................................................................... 33

Préparation de la machine à glaçons pour un entreposage à long terme ................................................................... 33

NETTOYAGE ET ENTRETIEN .................................................................................................................................................... 34

Ce qu’il ne faut pas faire. .............................................................................................................................................. 34

Les pièces qu’il faut garder propres. ............................................................................................................................ 34

Nettoyage de l’extérieur ............................................................................................................................................... 34

Nettoyage de l’intérieur ............................................................................................................................................... 34

Nettoyage du condenseur ............................................................................................................................................ 35

Nettoyage du tube de distribution d’eau ..................................................................................................................... 35

Nettoyage et assainissement du système de production des glaçons ......................................................................... 35

PANNEAU DE COMMANDE .................................................................................................................................................... 36

Description des voyants à DEL et des boutons ............................................................................................................. 36

FONCTIONS IMPORTANTES .................................................................................................................................................... 37

DÉPANNAGE ........................................................................................................................................................................... 37

The Legacy Companies se réserve le droit d’apporter des modifications aux caractéristiques et à la conception sans préavis.

19

Page 22

11/07/2017 PK

CONSERVEZ CES CONSIGNES

SÉCURITÉ ET MACHINE À GLAÇONS

Votre sécurité et celle des autres sont extrêmement importantes.

Nous avons fourni de nombreux messages de sécurité importants dans ce manuel et sur votre appareil.

Voici le symbole d’alerte à la sécurité. Ce symbole vous avertit de dangers potentiels qui pourraient vous blesser ou vous

tuer ainsi que d’autres personnes. Tous les messages de sécurité suivront le symbole d’alerte

DANGER

AVERTISSEMENT

ATTENTION

à la sécurité et l’un des mots suivants, « DANGER », « AVERTISSEMENT » OU « ATTENTION ».

DANGER signifie qu’un manque à respecter cette déclaration de sécurité peut entraîner des blessures

corporelles graves ou la mort.

AVERTISSEMENT signifie qu’un manque à respecter cette déclaration de sécurité peut entraîner des

dommages matériels considérables, des blessures corporelles graves ou la mort.

ATTENTION signifie qu’un manque à respecter cette déclaration de sécurité peut entraîner des

blessures plus ou moins graves ou des dommages aux biens ou à l’équipement.

Tous les messages de sécurité vous alerteront en quoi le danger potentiel consiste, vous indiqueront comment réduire

le risque de blessure et vous aviseront de ce qui pourrait se produire si vous ne suivez pas les instructions.

Lisez et respectez toujours tous les messages de sécurité.

AVERTISSEMENT

Pour réduire le risque d’incendie, de choc électrique ou de blessure lorsque vous utilisez votre machine à glaçons, veuillez respecter

ces précautions de base :

• Branchez dans une prise mise à la terre à 3 broches. • Coupez l’alimentation électrique avant le nettoyage.

• Ne retirez pas la broche de mise à la terre. • Coupez l’alimentation électrique avant l’entretien.

• N’utilisez pas d’adaptateur. • Remettez en place tous les panneaux avant l’utilisation.

• N’utilisez pas de rallonge. • Deux personnes ou davantage sont nécessaires pour

déplacer et installer la machine à glaçons.

MESURES DE PROTECTION IMPORTANTES

Avant d’utiliser la machine à glaçons, il faut la placer et l’installer correctement selon les instructions de ce manuel que

vous devez donc lire avec soin. Maxx Ice recommande fortement que vous fassiez appel à un professionnel pour

l’installation de votre nouvelle machine à glaçons. Une mauvaise installation pourrait nuire à la garantie ou l’annuler.

Pour réduire le risque d’incendie, de choc électrique ou de blessure lorsque vous utilisez votre machine à glaçons, veuillez

20

respecter les précautions de base, y compris les suivantes :

• Branchez dans une prise mise à la terre à 3 broches; ne retirez pas la broche de mise à la terre, n’utilisez pas d’adaptateur

et n’utilisez pas de rallonge.

• Il est recommandé de disposer d’un circuit séparé qui desserve uniquement votre machine à glaçons.

• Utilisez des prises qui ne peuvent pas être éteintes par un interrupteur ou chaîne (tirette).

• Ne branchez ou débranchez pas la fiche électrique lorsque vos mains sont mouillées.

• Ne débranchez jamais la machine à glaçons en tirant sur le cordon d’alimentation. Saisissez toujours la fiche fermement

et retirez-la tout droit de la prise.

• Ne nettoyez jamais les pièces de la machine à glaçons avec des fluides inflammables. N’entreposez ou n’utilisez aucune

essence ou autres vapeurs et liquides inflammables à proximité de cet appareil ou de tout autre appareil ménager.

Les vapeurs pourraient entraîner un risque d’incendie ou d’explosion.

• Avant d’entamer le nettoyage et l’entretien, assurez-vous que la ligne électrique de l’appareil est déconnectée et que

la conduite d’eau est fermée.

• Avant l’utilisation, remettez tous les panneaux en place.

• Ne laissez jamais les enfants utiliser, jouer avec ou grimper à l’intérieur de la machine à glaçons.

• Ne touchez pas l’évaporateur avec la main pendant que la machine à glaçons est en marche.

• Débranchez la machine à glaçons ou coupez l’alimentation électrique avant le nettoyage ou l’entretien. Un manque à le

faire peut entraîner un choc électrique ou la mort. Ne tentez pas de réparer ou remplacer une pièce quelconque de votre

machine à glaçons à moins que cela ne soit spécifiquement recommandé dans ce manuel. Vous devez faire appel à un

technicien qualifié pour effectuer tous les autres services.

Page 23

11/07/2017 PK

AVERTISSEMENT

• Deux personnes ou davantage sont nécessaires pour déplacer et installer la machine à glaçons. Ne pas respecter cette

consigne peut entraîner des blessures au dos ou autres blessures.

• N’installez ou n’utilisez jamais l’appareil derrière des portes fermées. Pour assurer une bonne ventilation de votre

machine à glaçons, vous devez absolument éviter toute obstruction devant l’appareil. Choisissez un emplacement bien

aéré dont la température ambiante varie entre 10 °C (50 °F) et 37 °C (99 °F). Cet appareil DOIT être installé dans un

emplacement protégé des éléments tels que le vent, la pluie, l’eau, les jets ou les égouttements d’eau.

• La machine à glaçons ne doit pas être située à côté de fours, de grils ou autres sources de chaleur élevée.

• La machine à glaçons doit être installée avec tous les raccordements électriques et d’eau effectués conformément aux

codes de l’état/la province et codes locaux. Une alimentation électrique standard correctement mise à la terre,

conformément au Code national de l’électricité et des codes et réglementations locaux est requise.

• N’entortillez ou pincez pas le cordon d’alimentation électrique entre la machine à glaçons et l’armoire.

• La taille du fusible (ou disjoncteur) correspond à une capacité de 15 ampères.

• Il est important que la machine à glaçons soit bien mise de niveau pour fonctionner correctement. Sinon, il se peut que

l’eau ne coule pas correctement dans l’évaporateur (moule à glaçons). La production de glaçons sera inférieure à la norme.

Il se peut que vous ayez à effectuer plusieurs réglages pour la mettre de niveau.

• Toutes les installations doivent être conformes aux exigences des codes de plomberie locaux.

• Assurez-vous que les tuyaux ne sont pas pincés, entortillés ou endommagés pendant l’installation.

• Vérifiez s’il y a des fuites après le raccordement de la conduite d’eau.

• Bien que l’appareil ait été testé et nettoyé en usine, il faut jeter le premier lot de glaçons en raison du transport et de

l’entreposage de longue durée.

• Retirez le matériau d’emballage et nettoyez la machine à glaçons avant l’utilisation.

• Ouvrez le robinet d’alimentation en eau avant de mettre la machine à glaçons en marche. Ne fermez jamais le robinet

d’alimentation en eau pendant que la machine à glaçons est en marche.

• Sauf dans les cas où vous prenez des glaçons du bac de stockage, gardez la porte fermée afin d’éviter que les glaçons

fondent et de favoriser une bonne formation de glaçons.

• Si la machine à glaçons n’est pas utilisée pendant une longue période, il faut la nettoyer à fond avant l’utilisation suivante.

Suivez les instructions de nettoyage fournies avec soin. Ne laissez aucune solution désinfectante à l’intérieur de la machine

à glaçons après le nettoyage. N’utilisez PAS d’agents nettoyants à base de solvant ou abrasifs sur l’intérieur. Ces produits

de nettoyage peuvent donner un mauvais goût aux glaçons ou endommager ou décolorer l’intérieur. Le nettoyant pour

machine à glaçons contient des acides. Ne l’utilisez et ne le mélangez avec aucun autre produit de nettoyage à base de

solvant. Utilisez des gants en caoutchouc pour protéger vos mains. Lisez avec soin les consignes de sécurité stipulées sur

le conteneur du nettoyant pour machine à glaçons.

• N’utilisez pas cet appareil à des fins autres que celles pour lesquelles il est conçu.

• Ne touchez pas les ailettes du condensateur car elles sont pointues et peuvent être facilement endommagées.

Raccordement électrique

Ne coupez ou retirez en aucun cas la troisième broche (de mise à la terre) du cordon d’alimentation électrique. Pour votre sécurité

personnelle, cet appareil doit être correctement mis à la terre. Le cordon d’alimentation de cet appareil est doté d’une fiche de mise

à la terre à 3 broches qui se branche sur une prise murale de mise à la terre à 3 broches standard pour réduire le risque de choc

électrique dû à l’appareil.

Faites appel à un électricien qualifié pour inspecter la prise et le circuit muraux, pour vous assurer que la prise est correctement mise

à la terre. Lorsque vous rencontrez un prise murale à 2 broches standard, vous êtes responsable et obligé de la faire remplacer par

une prise murale correctement mise à la terre à 3 broches. La machine à glaçons doit toujours être branchée dans sa propre prise

électrique individuelle dont la tension nominale correspond à celle spécifiée sur l’étiquette de l’appareil. Ceci assure le meilleur

rendement possible et empêche également de surcharger les circuits de câblage résidentiel, ce qui pourrait poser un risque

d’incendie du fait de fils surchauffés. Ne débranchez jamais votre machine à glaçons en tirant sur le cordon d’alimentation. Saisissez

toujours la fiche fermement et retirez-la tout droit de la prise. Réparez ou remplacez immédiatement tous les cordons d’alimentation

qui sont effilochés ou autrement endommagés. N’utilisez pas un cordon qui présente des fissures ou abrasions sur sa longueur ou à

l’une de ses extrémités. Lorsque vous déplacez la machine à glaçons, veillez à ne pas endommager le cordon d’alimentation.

Rallonge

En raison des risques à la sécurité potentiels résultant de certaines conditions, il est fortement recommandé de ne pas utiliser une

rallonge avec cette machine à glaçons.

21

Page 24

Modèle :

MIM50 / MIM50V

MIM50-O

MIM50P

MIM50P-O

Machine à glaçons

d’intérieur de 22,7 kg

Machine à glaçons

d’extérieur de 22,7 kg

Machine à glaçons

d’intérieur de 22,7 kg

Machine à glaçons

d’extérieur de 22,7 kg

120 V/60 Hz/1 Ph,

220 V/50 Hz/1 Ph

120 V/60 Hz/1 Ph,

220 V/50 Hz/1 Ph

120 V/60 Hz/1 Ph,

220 V/50 Hz/1 Ph

120 V/60 Hz/1 Ph,

220 V/50 Hz/1 Ph

Ampères

(production/récolte de glaçons) :

Glaçon en forme

de plaque

Glaçon en forme

de plaque

Glaçon en forme

de plaque

Glaçon en forme

de plaque

cm

12,2 kWh / 45 kg de

glaçons

12,2 kWh / 45 kg de

glaçons

12,2 kWh / 45 kg de

glaçons

12,2 kWh / 45 kg de

glaçons

Stockage maximum de

glaçons :

Capacité de production de

glaçons :

37,1 cm x 60 cm x

83,8 cm

37,1 cm x 60 cm x

83,8 cm

37,1 cm x 60 cm x

83,8 cm

37,1 cm x 60 cm x

83,8 cm

Lumière à DEL bleue interne

quand la porte est ouverte.

11/07/2017 PK

RENSEIGNEMENTS TECHNIQUES

Description

Tension :

3,0 / 4,0 3,0 / 4,0 3,0 / 4,0 3,0 / 4,0

Type de glaçon :

Taille du glaçon : 2,2 cm x 2,2 cm x 2,2 cm 2,2 cm x 2,2 cm x 2,2

Consommation électrique :

Poids de l’appareil : 38 kg/84 lb 37,6 kg/83 lb 39 kg/86 lb 39 kg/86 liv.

11 kg 11 kg 11 kg 11 kg

22,7 kg par jour* 22,7 kg par jour* 22,7 kg par jour* 22,7 kg par jour*

Dimensions de l’appareil :

Non

Pompe d’évacuation Non

*La quantité réelle de glaçons produits chaque jour peut varier en fonctions des conditions de la pièce et de l’eau.

Les données techniques et les indices de rendement mentionnés ci-dessus peuvent faire l’objet de modifications et ne doivent être utilisés qu’à titre

de référence.

Non

Non

2,2 cm x 2,2 cm x 2,2 cm 2,2 cm x 2,2 cm x 2,2 cm

Oui

Oui

Oui

Oui

INTRODUCTION

La série de machines à glaçon MIM50 de Maxx Ice produit des glaçons durs de qualité supérieure et offre la commodité aux

propriétaires résidentiels, aux restaurants et aux clients d’hôtels. Un bac de stockage des glaçons isolé est intégré.

• Une alimentation en eau froide est nécessaire.

• Une vidange par gravité est nécessaire.

Ce manuel de l’utilisateur sert de ressource pour les individus chargés de l’installation, de l’utilisation et de l’entretien de la série MIM50.

Il contient des consignes de sécurité et d’entretien utiles. Maxx Ice recommande fortement que vous le conserviez dans

un emplacement facile d’accès au besoin.

La série MIM50 est conçue et fabriquée conformément aux normes de sécurité et de rendement les plus rigoureuses. Elle respecte

ou dépasse la norme de sécurité UL563 et la norme sanitaire NSF12.

Maxx Ice n’assume aucune responsabilité pour les produits fabriqués par Maxx Ice ayant été modifiés d’une manière quelconque,

y compris l’utilisation de toutes pièces et/ou autres composants non spécifiquement approuvés dans le cadre de Garantie et pièces

Maxx Ice. Maxx Ice se réserve le droit d’apporter des modifications et/ou améliorations à tout moment. Les caractéristiques et

conceptions sont susceptibles d’être modifiées sans préavis.

22

Page 25

MIM50V / MIM50 / MIM50P/MIM50P-O

MIM50-O

N°

D’ARTICLE

N°

D’ARTICLE

Water

Tube

Tubo de distribución de

Control Panel

panel)

Panneau de

le panneau d’accès)

Panel de control (detrás

Evaporator

(ice mold)

Évaporateur (moule à

glace)

Evaporador (molde de

hielo)

Water