Page 1

Automatic Ice maker

Service manual

MIM452 MIM600 MIM1000

1

Page 2

Table of contents

Installation Guidelines ---------------------------------------------------------3

How the Ice Maker Works ----------------------------------------------------4

Water System --------------------------------------------------------------------7

Wiring Connections and Controller ------------------------------------------9

Exploding Drawing -------------------------------------------------------------12

TroubleShooting ----------------------------------------------------------------14

Before Maintenance ------------------------------------------------------------14

Basic Checking ------------------------------------------------------------------14

TroubleshootingGuide ----------------------------------------------------------15

Adjustment and Replacement -------------------------------------------------20

Advanced component troubleshooting techniques --------------------------21

Spare parts list ------------------------------------------------------------------- 28

2

Page 3

Installation Guidelines

Note: Installation should be performed by a trained Service Technician.

For proper operation of the ice machine, the following installation guidelines must be followed.

Failure to do so may result in loss of production capacity, premature part failures, and may void all

warranties.

Ambient Operating Temperatures

Minimum Operating Temperature: 50°F (10°C)

Maximum Operating Temperature 100°F (38°C).

Note: These products are not designed for outdoor installation.

Incoming Water Supply

Minimum incoming water temperature: 40°F (5°C)

Maximum incoming water temperature: 90°F (32°C)

Minimum incoming water pressure: 15 psig

Maximum incoming water pressure: 80 psig

Note: If water pressure exceeds 80 psig, a water pressure regulator must be installed.

Drains: Route bin drain, purge drain and water condenser drain individually to a floor drain. The

use of condensate pumps for draining water on equipment producing over 200 lbs./day is not

recommended by Manufactor. We assumes no responsibility for improperly installed equipment.

Water Filtration

A water filter system should be installed with the ice machine.

Clearance Requirements

Self contained air cooled ice machines must have a minimum of 6 inches (15cm) of clearance at the

rear, top, and sides of the ice machine for proper air circulation. Since undercounter machines

breathe from the front, top and side clearances are minimal.

Stacking

If the ice machines are to be stacked, refer to the instructions in the stacking kit. We does not

endorse stacking aircooled ice machines.

Dispenser Application

A thermostatic bin control kit must be installed if the ice machine is placed on a dispenser. A bin

top may or may not be required.

Ice Maker Maintenance

Maintenance Procedure

1. Clean the icemaking section per the instructions below. Cleaning should be performed a

minimum of every 6 months. Local water conditions may require that cleaning be performed more

often.

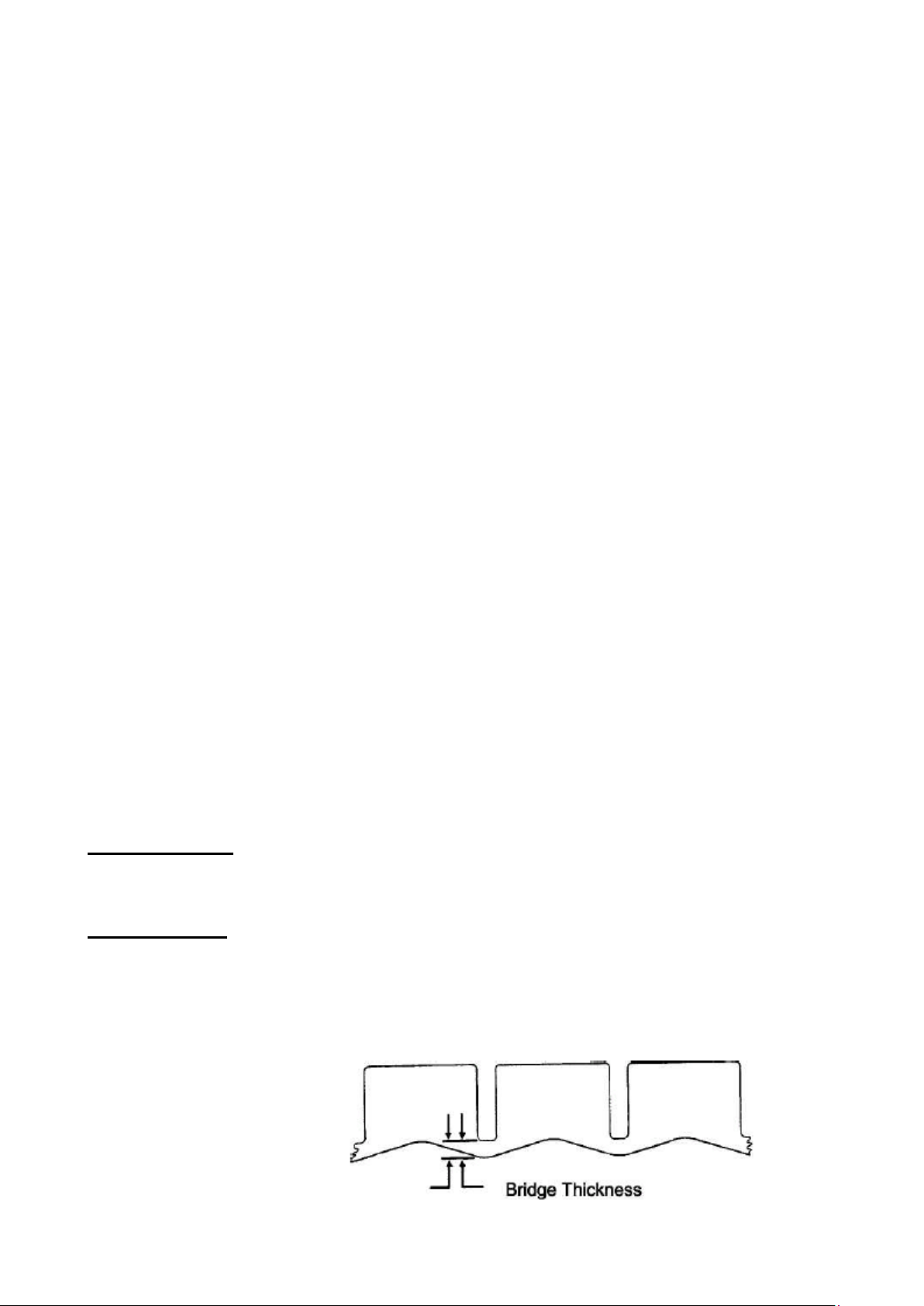

2. Check ice bridge thickness. Proper thickness should be 1/16-1/8’’.

3. Check water level in trough. See troubleshooting for proper water level and adjustment.

4. Clean the condenser to insure unobstructed air flow.

5. Check for leaks of any kind: Water, Refrigerant, Oil, Etc.

6. Check the bin switch for proper adjustment.

7. Check all electrical connections.

3

Page 4

8. Oil the fan motor if the motor has an oil fitting.

Cleaning and Sanitizing

Harvest problems may occur if the following procedures are not performed every 6 months.

1. Remove the ice machine front panel.

2. Make sure that all the ice is off of the evaporator. If ice is being made, wait for cycle completion,

then turn the machine “OFF” at the selector switch.

3. Remove or melt all ice in the storage bin.

4. Add recommended amount of approved ice machine cleaner to the water trough according to

label instructions on the container.

5. Initiate the clean cycle at the controller board switch by turning on the machine and activating the

switch marked as “CLEAN”. Note: This must be done within 3 minutes of turning the machine

“ON”. Allow the cleaner to circulate for approximately 15 minutes to remove mineral deposits.

6. After 15 minutes (or 30 minutes automatically), stop the process and drain the sump. Refill with

clean water run another 5 minutes and drain again. Fill the trough with fresh incoming water.

7. Terminate the wash cycle at the switch by placing the switch in the “OFF” position. Remove the

splash curtain (if available) and inspect the evaporator and water spillway (the plastic top of the

evaporator) to assure all mineral residue has been removed.

8. If necessary, wipe the evaporator, spillway and other water transport surfaces with a clean soft

cloth to remove any remaining residue. If necessary, remove the water distribution tube,

disassemble and clean with a bottlebrush. Reassemble all components and repeat steps 4 through 7

as required to remove residue.

9. Turn OFF ice machine water supply and clean the water trough thoroughly to remove all scale or

slime buildup. If necessary, remove the water trough to reach all splash areas and float.

10. Prepare 1½ to 2 gallons (5.7 to 7.5 liters) of approved (EPA/FDA) sodium hypochloride food

equipment sanitizer to form a solution with 100 to 200 ppm free chlorine yield.

11. Add enough sanitizing solution to fill the water trough to overflowing and activate the switch to

the “CLEAN” position and allow circulation to occur for 10 minutes and inspect all disassembled

fittings for leaks. During this time, wipe down all other ice machine splash areas, plus the interior

surfaces of the bin, deflector and door with the remaining sanitizing solution. Inspect to insure that

all functional parts, fasteners, thermostat bulbs (if used), etc. are in place.

12. After 3 minutes, stop the process and drain the sump. Refill with clean water run another 5

minutes and drain again. Fill the trough with fresh incoming water.

13. Place the switch to the “ON” position and replace or close the panel. Discard the first two ice

harvests.

How the Ice Maker Works

Refer to the Operation section of the User’s Manual (pages 12 to 14) for a clear description of how

the ice maker makes ice and uses water.

There are 3 systems: the Cooling System, the Water System and the Electrical System.

4

Page 5

Cooling System

5

Page 6

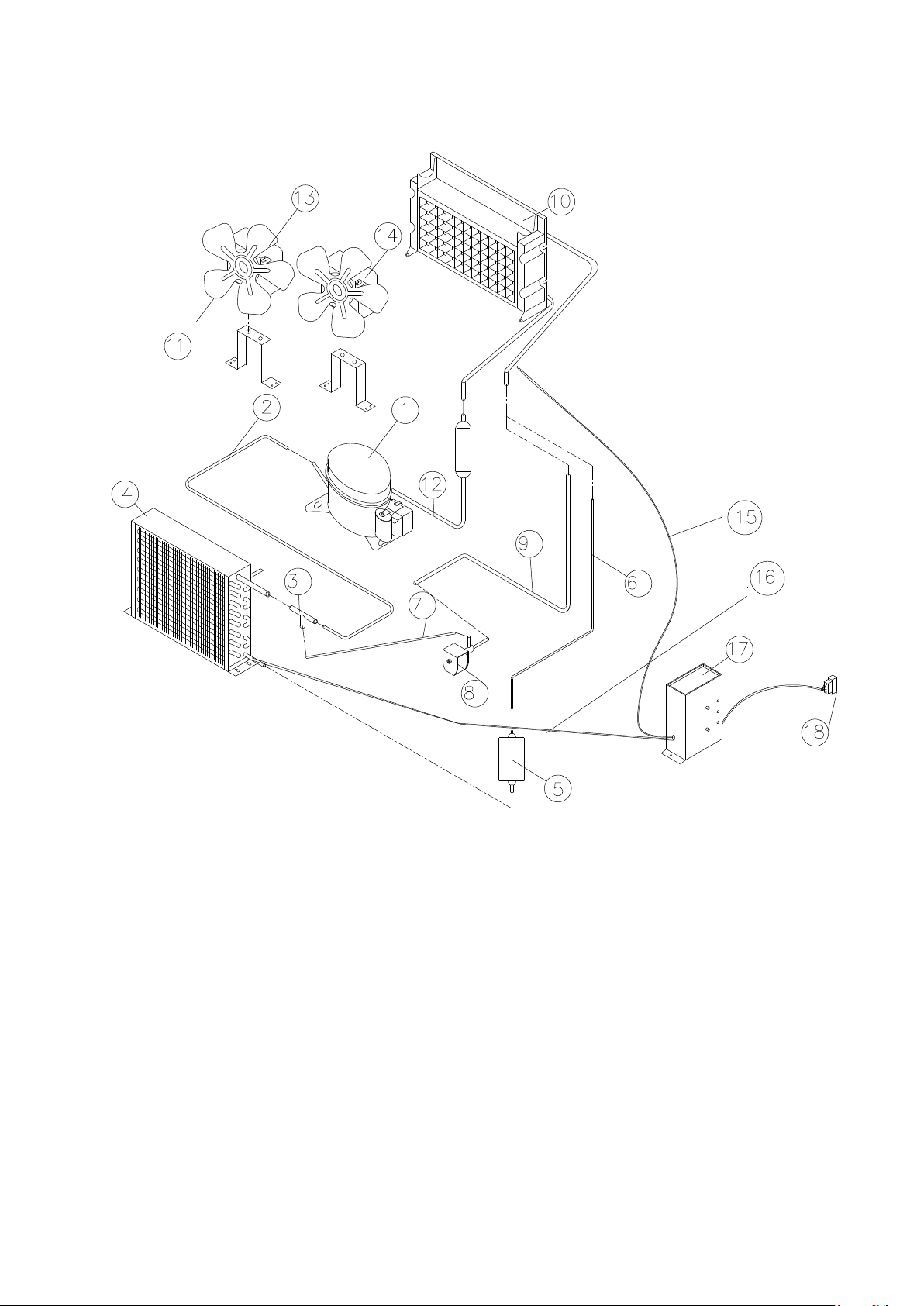

ITEM NO

DESCRIPTION

1

Compressor

2

Discharge tube

3

Cu three ways

4

Condenser

5

Drier and filter

6

Capillary tube

7

Connection tube

8

Hot gas valve

9

Hot gas tube

10

Evaporator (Ice Mold)

11

Fan blade(φ200X28°)

12

Suction pipe

13

Motor 5W

14

Motor 10W

15

Temperature sensor of the evaporator

16

Temperature sensor of the condenser

17

Controller

During the icemaking stage, the hot gas solenoid valve is closed. The hot refrigerant gas is

pumped out of the compressor to the condenser. The hot gas is cooled by fanforced air to cool the

liquid refrigerant after passing through the condenser. The drier and filter reduce possible dirt and

moisture in the refrigerant. The refrigerant expands in the evaporator cooling it so ice will form

while in the presence of water. Low pressure refrigerant gas returns to the compressor from the

evaporator where the cycle continues.

During the ice harvest stage, the solenoid valve is open. The hot refrigerant gas is pumped out of

the compressor to the evaporator through the hot gas valve. As the hot gas is not cooled by the

condenser, the refrigerant warms the evaporator. Ice in contact with the evaporator begins to melt

on the back side. The ice gradually ice slides off of the evaporator and drops to the storage bin.

6

Page 7

Water System

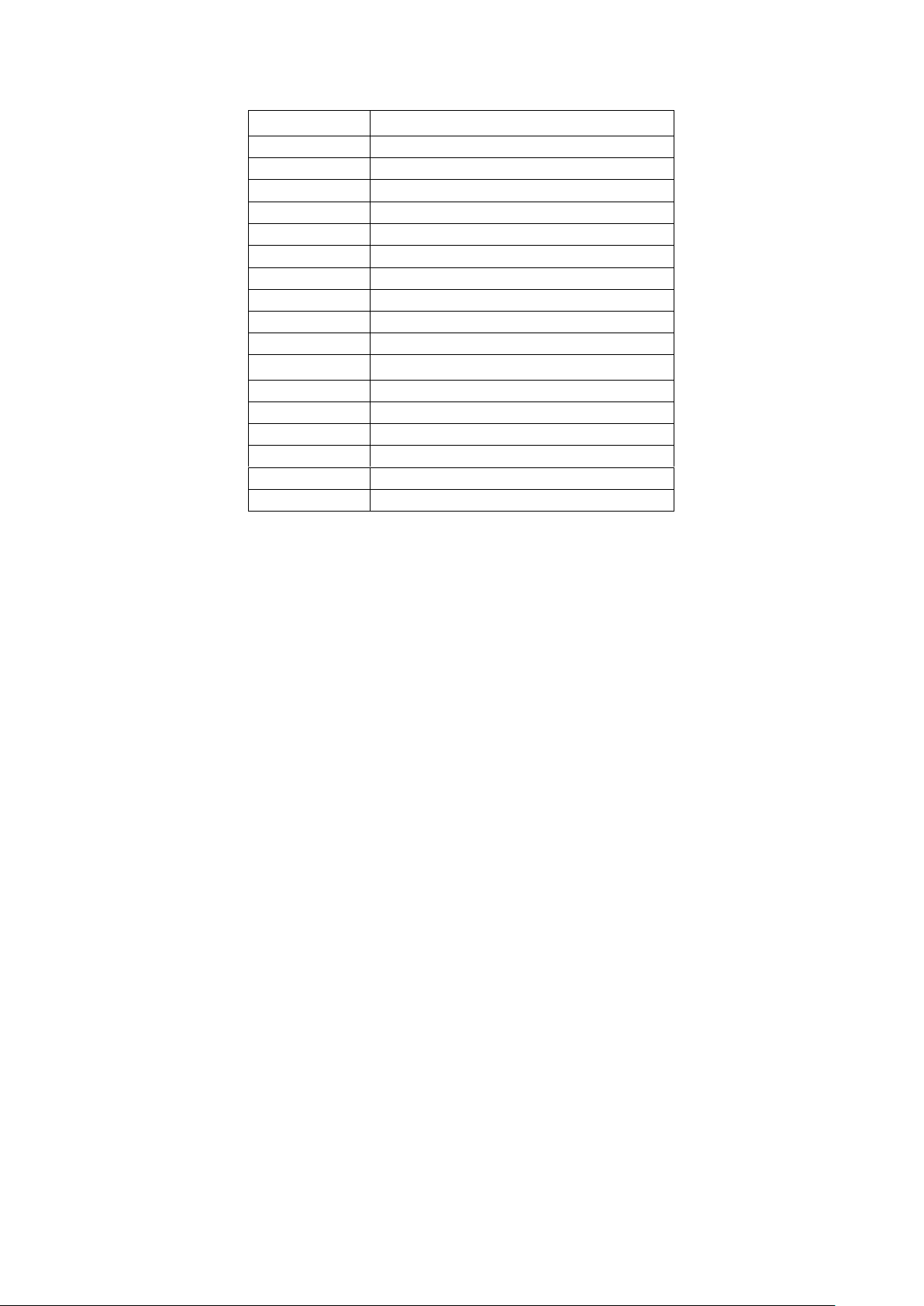

ITEM NO

DESCRIPTION

1

Water supply pipe

2

Water inlet connector

3

Nut of water inlet tube

4

Supporting tube

5

Water pump inlet tube

6

Nut of water inlet tube

7

Floater valve

8

Water trough

9

Water pump

10

Water pump outlet tube

11

Water distribution tube

12

Evaporator (Ice Mold)

13

Ice full sensor

14

Drain pipe connector

15

Drain pipe hex nut

16

Drain pipe

17

Drain pipe screw

18

Drain pipe stopple

19

Ice slideway

When the water inlet is connected with the main water supply, water will fill the trough through the

7

Page 8

float valve until the water level in the trough closes the valve. During the icemaking stage, water is

pumped from the water trough to the water distribution tube. The distributed water flows over the

surface of the cold evaporator where the purest water is converted to ice. The unfrozen water

returning to the trough. At the end of freeze cycle and during harvest, the water dump valve is

opened and the mineral laden remaining water is pumped down the drain.

8

Page 9

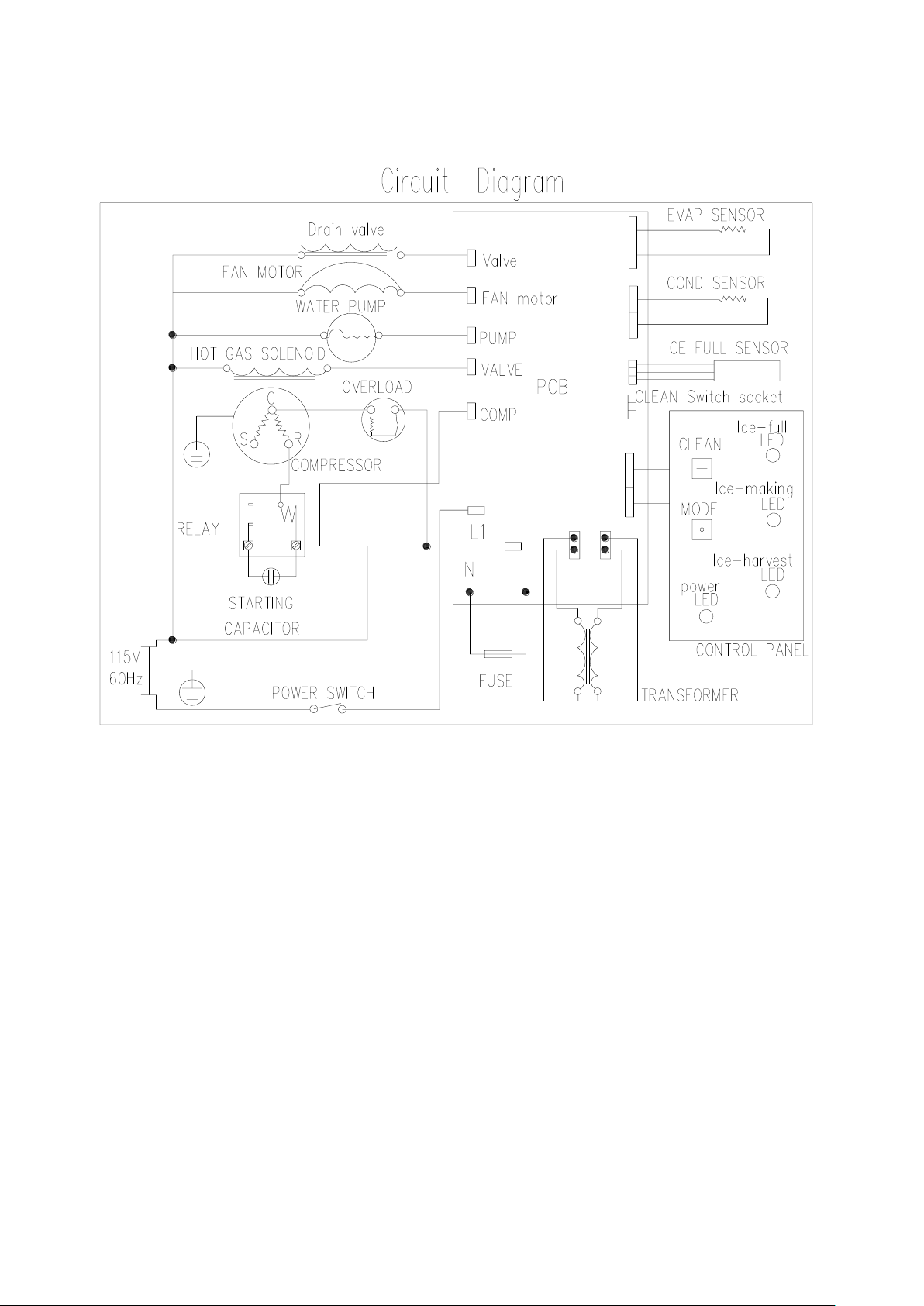

Wiring Connection :

9

Page 10

Circuit Description

1. Electrify Status For The First Time

As the icemaker is properly installed. switch on the water tap, let the water trough full (reach on the

level), then turn the Power switch to the ON position on the back panel. The icemaker will start

working automatically

In this status, the time is fixed about 3 minutes. This function is also helpful to protect the

compressor avoiding restart within 3 minutes.

At this status, the White, Green, Yellow and Red LEDs are light together.

2. Ice-making Status

The compressor, motor fan and pump are powered on. The hot gas solenoid valve is powered off.

When this green LED is lit, the unit is working in the ice making mode controlled by a temperature

probe on the evaporator. When the green LED is flashing, the unit is working in the ice making

mode controlled by a fixed timer.

The fan motor is also controlled by a condenser sensor. When the ambient temperature is too lower,

the motor fan stop working for good condensation to refrigerant.

3. Ice Harvest Status

The pump is powered off. The hot gas solenoid valve, compressor and motor fan is powered on.

The fan motor is also controlled by a condenser sensor. When the ambient temperature is too lower,

the motor fan stop working for good condensation to refrigerant.

The Yellow LED indicates the ice harvest status.

4. Ice Full Status And Cold Preservation Stage

If the ice bin is fulfilled with ice, the machine stops making ice and turn to cold preservation stage

automatically.

In this status, the compressor works regularly to keep the lower temperature for lower ice melting.

The rest of the electric components are powered off. The WHITE LED indicates the ice full status

and the GREEN AND YELLOW LEDs together indicates the cold preservation status .

5. Cleaning Status

Turn the machine CLEAN SWITCH at the CLEAN in 3 minutes after the POWER SWITCH is

turned on, the machine turn to Cleaning Status. At this status, the pump is powered on. Compressor,

motor fan and are powered off. The GREEN and YOLLOW LEDs are flashing together. To stop the

cleaning mode, turn the machine “OFF” at the Power switch or it will turned off automatically after

30 minutes.

NOTE: In order to start the Clean Status the power switch must be on. The CLEAN switch must be

turned in 3 before the COMPRESSOR starts. To clean, it is no use turning the CLEAN switch when

machine is in ice-making status or ice-harvest status.

Controller box:

Instructions for LEDs and buttons:

1. White LED: Ice full indicator light.

When this LED is lit, the ice storage bin is full of ice or there is something between the ice-full

sensor and the evaporator. The unit will stop making ice. When ice cubes are taken out of the ice

storage bin making the ice-full probe free, the white LED will keep flashing for 3 minutes. Then the

unit will restart and return to the ice making mode.

2. Green LED: Ice making indicator light.

When this LED is lit, the unit is working in the ice making mode controlled by a temperature probe

on the evaporator. When the green LED is flashing, the unit is working in the ice making mode

controlled by a fixed timer.

3. Yellow LED: Ice harvest indicator light.

When this LED is lit, the unit is working in the ice harvest mode controlled by ice-full probe.

10

Page 11

When green LED and yellow LED is lit, it means the unit is working in the cold preservation

stage .

4.Red LED: power indicator light.

The power is on when the red LED is lit.

5. Mode button:

Mainly for service. When this button is pressed, it can change from ice making mode to ice harvest

mode, or from ice harvest mode to ice making mode. You can judge the mode from the status of the

green and yellow LEDs.

6. Ice size adjust:

1. Press and hold the “Clean” button and the “Mode” button together for at least 3 seconds. The

unit will enter the Ice Size Adjustment mode. The “ICE” LED (green) will be blinking

continuously during the ice size adjustment.

2. While in the Ice Size Adjustment mode, press the “Clean” button or the “Mode” button for the

desired ice size.

Smaller ice setting:

By pressing the “Clean” button, you can decrease the size of the ice cubes. The “FULL” LED (red)

will flash as you lower the ice size and will finally be blinking at the setting of smallest ice size.

Larger ice setting:

By pressing the “Mode” button, you can increase the size of the ice cubes. The “HARVEST” LED

(yellow) will flash as the larger size is set and will blink when the setting of largest ice size has been

reached.

After 10 seconds without any operation, the unit will automatically memorize the current state and

return to the previous mode.

NOTE: If during the ice size adjustment, the “BIN FULL”, “ICE” and “HARVEST” LEDS blink

all at once, this indicates that the unit is in the default factory setting of the ice size adjustment.

11

Page 12

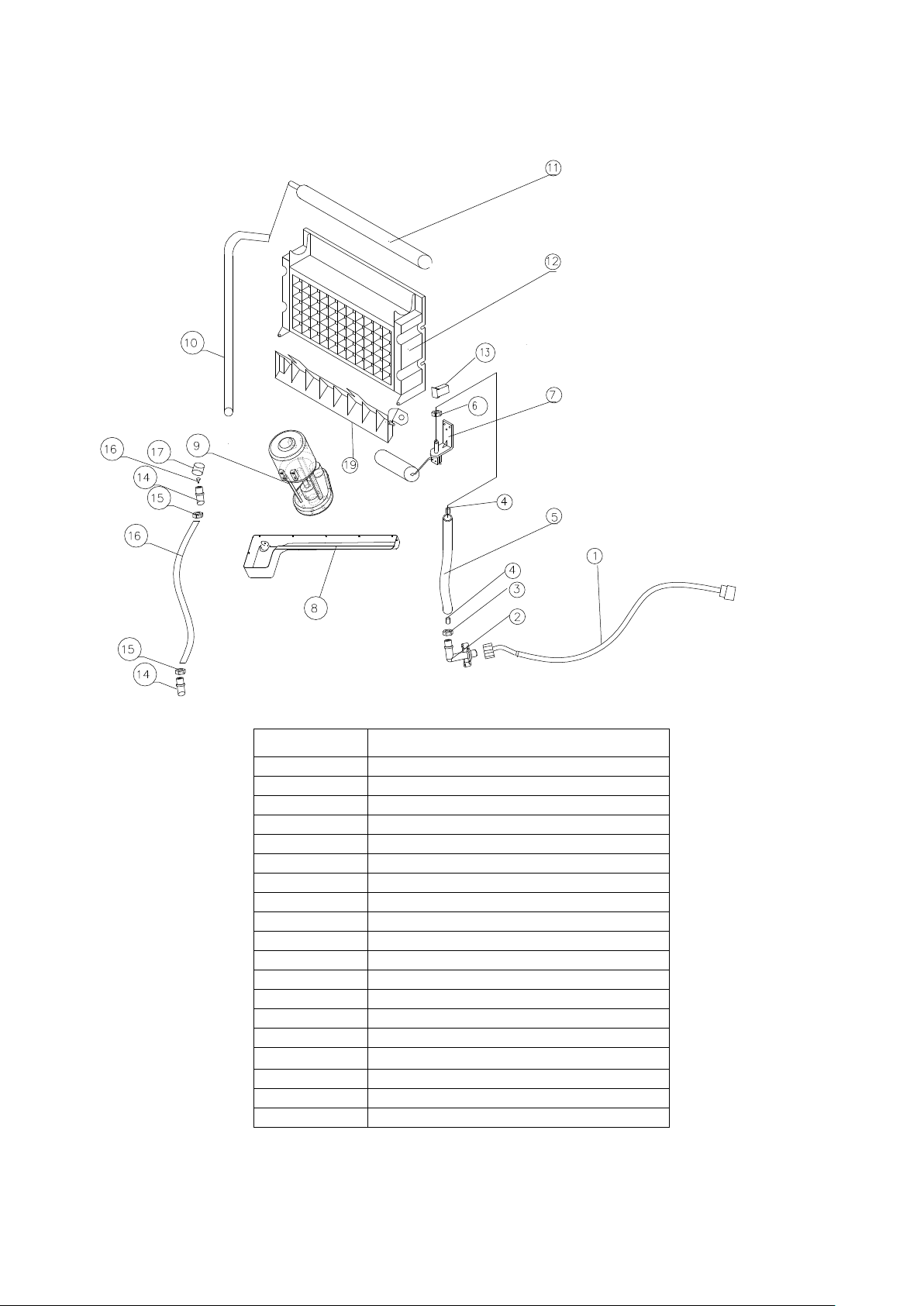

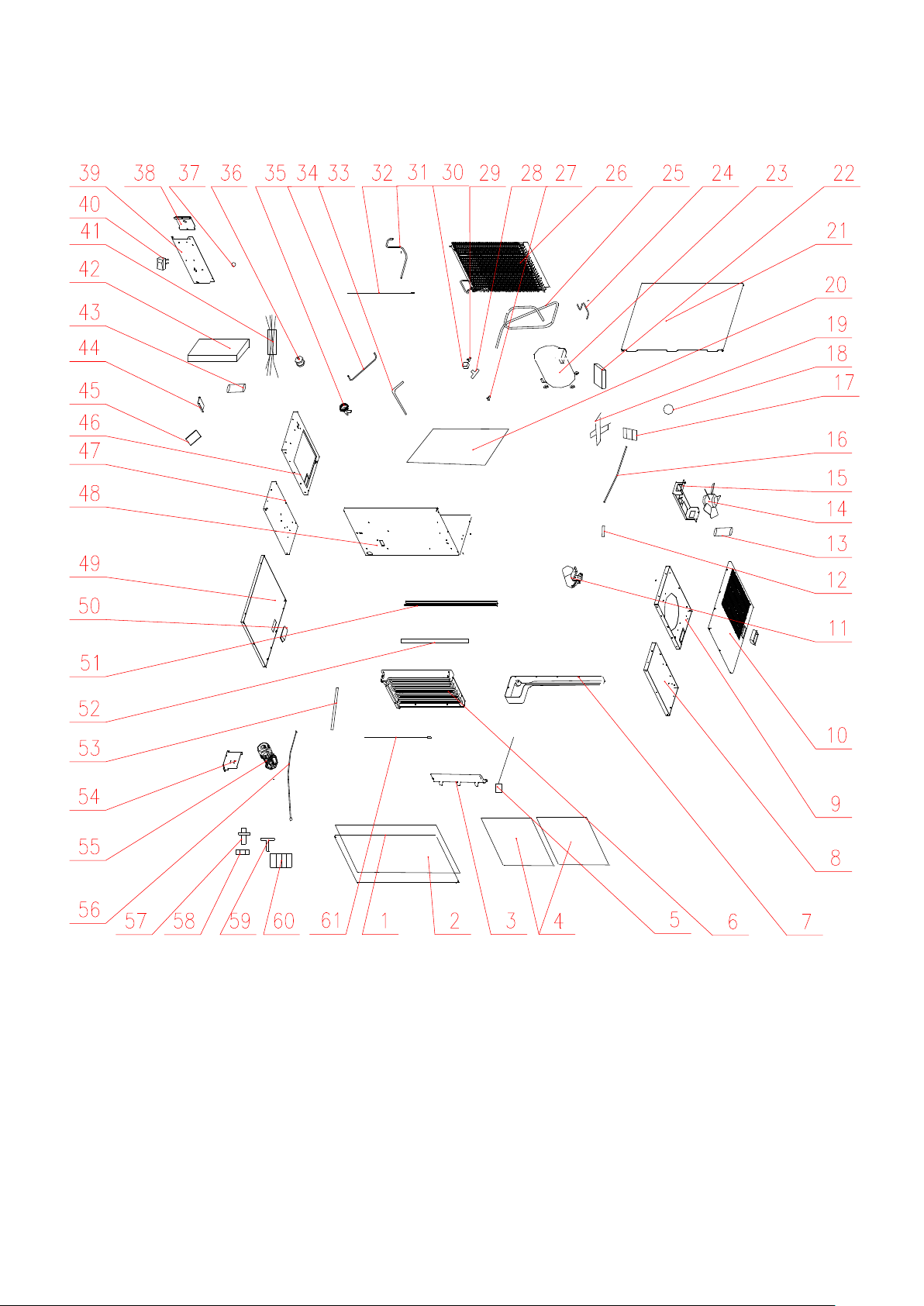

Exploding Drawing

12

Page 13

ITEM

NO.

DESCRIPTION

1

front panel

2

inner front panel

3

Ice full probe

4

inner foam front panel

5

Ice full sensor

6

evaporator

7

water trough

8

front inner right panel

9

back inner right panel

10

right panel

11

Floater valve

12

support

13

fan motor capacitor (6uf)

14

Condenser fan motor

15

fan motor support

16

Water inlet pipe

17

Water outlet pipe screw

18

water outlet pipe screw

19

Water inlet connector

20

foaming PE

21

top panel

22

compressor starting device

component

23

compressor

24

discharge pipe1

25

suction pipe

26

condenser and filtrate

27

T shape three ways

28

hot gas valve body

29

Cu Three ways

30

Has gas valve coil

31

hot gas pipe

32

Condenser sensor line

33

hot gas pipe

34

discharge pipe2

35

Expansive valve

36

drier

37

protect line cord

38

access cover

39

back panel

40

Power switch

41

Wiring harness

42

Control box

43

15A fuse

13

Page 14

44

Control box upper support

45

control box lower support

46

left back panel

47

left front panel

48

compressor base

49

left panel

50

knob

51

compressor base support

52

Water distributor tube

53

Water out of pump

54

water pump support

55

Water pump

56

Drain pipe

57

Drain pipe connector

58

Drain pipe hex nut

59

Drain pipe stopple

60

Drain pipe screw

61

Evaporator sensor line

14

Page 15

Troubleshooting

ELECTRICAL SHOCK HAZARD

Disconnect Electrical Power Before

Beginning Removal of Parts

Before Maintenance

1. Be sure the electrical supply is 115 VAC, 60Hz, 15A and is properly grounded to protect

maintenance personnel against electrical shock.

2. Are any electrical leads loose? Danger of short circuit? If so, disconnect power.

Basic Troubleshooting

Some problems can be pinpointed through the service technician’s senses of hearing, sight and

touch. Examples are listed below.

Listen

Listen to the user’s description of how the ice maker was operating, especially the depiction of

unusual phenomena. Ask how the unit was operating before the user called for service and try to

deduce the defect from the comments.

Does the machine sound normal when it is running (like a window air conditioner)?

Look

Check the cooling system tubing, especially the welded joints. If some oil can be seen, the gas

may be leaking resulting in less than the normal amount of ice is being produced.

Is the cycle of the icemaking and ice harvesting normal (Does water run, is the fan running and

is the evaporator getting cold enough)?

Check the water system especially at the connections. Are there any water leaks?

Check the flow of water through the water filter and if not, replace the water filter.

Check if the ice maker was installed according to the user’s manual (level and air space).

Inspect the ice maker to see if it needs to be cleaned. Please note, cleaning a dirty ice maker is

not a warranty repair!

Feel

Touch the tubing at the evaporation weld, feeling the temperature. During the icemaking stage,

it should feel cold. During the ice harvest stage, it should feel hot.

If appropriate, touch the capillary tube or TXV tubing (near the drier). It should feel warm

during the ice making stage.

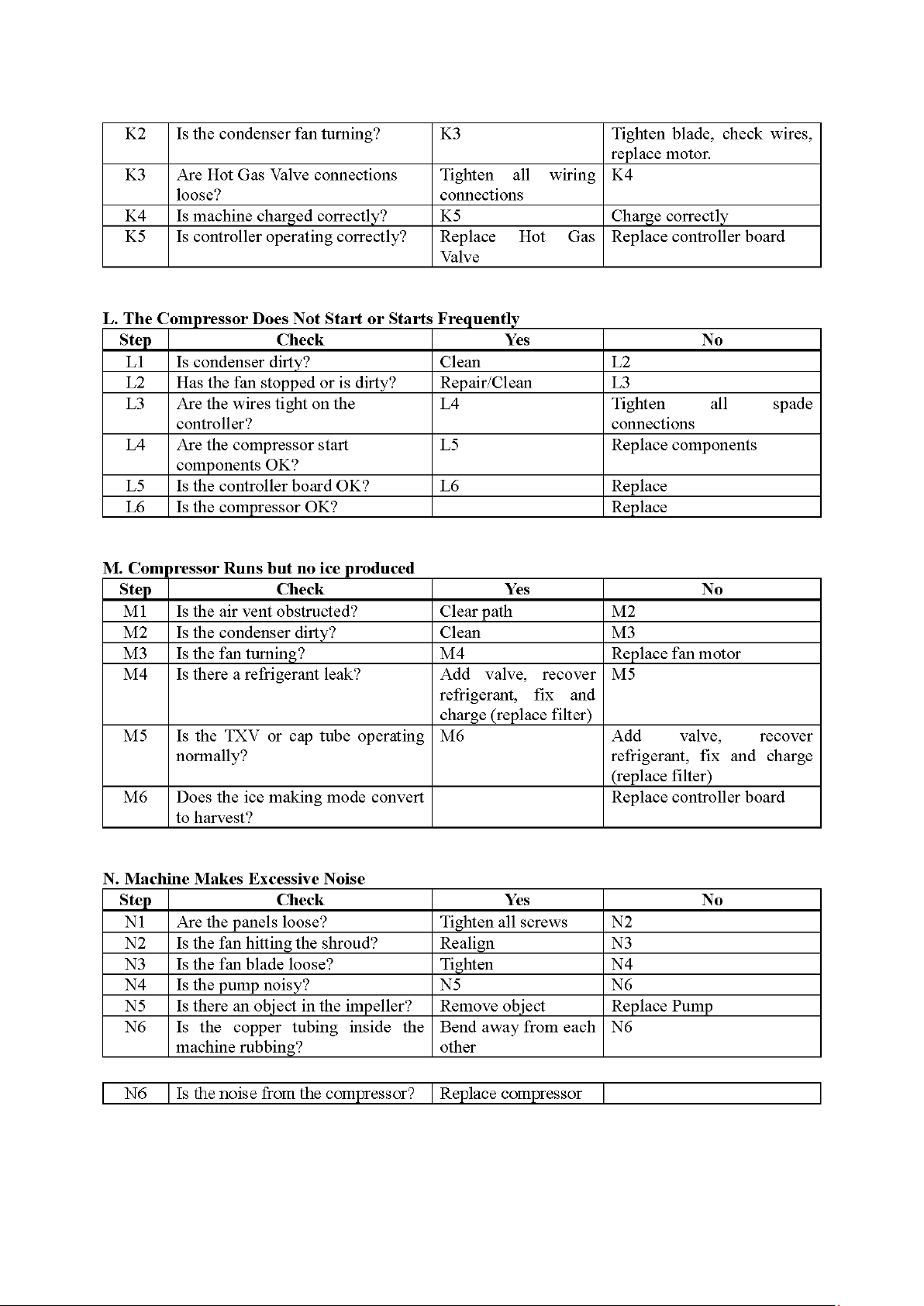

Troubleshooting Guide

This troubleshooting guide in the user manual should be read before this guide. Be sure only when

the trouble shooting in user manual can’t help you solve the problem, turn to this guide.

Troubleshooting Guide

15

Page 16

16 17

Page 17

Page 18

18 19 20

Page 19

Page 20

Page 21

Adjustment and Replacement

ELECTRICAL SHOCK HAZARD

Disconnect Electrical Power Before

Beginning Removal of Parts

Replace Control box, fuse and the sensor of temperature

Replacing Control Box Fuse and Temperature Sensor

Remove the rear cover and the louvered front panel or the side panel on a modular unit.

Locate the electronic control box in the unit.

Carefully pull out the temperature sensors (one at the evaporator, another at the condenser).

Loosen the screws holding the control box, replace with a new one. Reverse the foregoing steps

to reassemble.

If you need to replace the fuse, open the front panel of the control box and you will find this

figure:

If you need to replace a temperature sensor, pull out the sensor, open the panel of the control

box, pull out the other end of the sensor, replace with a new one. Reverse these steps to reassemble.

Replacing the water pump

Disconnect electrical power.

Remove the front cover.

Unplug the lines connected with the water pump, including the water outlet tube of the pump.

Loosen the screws. Replace the pump with a new one.

Reverse the above steps to reassemble.

Replacing the cooling system components

To replace the condensing components, see the Cooling System figure.

1. Replacing the compressor and the compressor kit (includes relay, thermal protect)

If only the compressor kit needs to be

replaced, remove the top panel and left

panel, locate the compressor, take off

the clip, replace the defective

components.

Reverse the above steps to reassemble.

ELECTRICAL SHOCK HAZARD

Disconnect electrical power before

beginning removal of parts.

If the compressor needs to be replaced, remove the top cover and locate the compressor.

Unplug lines and remove ground line, open the Process/Suction, evacuate refrigerant, take out

compressor, replace with a new one, join together, then recover refrigerant, weigh in the charge on

the nameplate.

Reverse the above steps to reassemble.

2. Replacing the fan motor and fan blade

Remove the top and right panels.

Locate the fan motor, unplug the lines connected with the fan motor, loosen the screws of the

holding bracket and fan motor bracket, remove the damaged unit and replace with a new one.

Reverse the above steps to reassemble.

21

Page 22

3. Replacing the hot gas valve, drier and evaporator

Remove the top panel.

Locate the drier and hot gas valve, open weld, replace the drier and hot gas valve, weld, recover

refrigerant, evacuate and weigh in the charge on the nameplate.

Reverse the above steps to reassemble.

If needed, replace the evaporator.

Remove the front and top panels, locate the evaporator, open the Process/Suction, open the two

welds, replace with a new evaporator. Recover refrigerant, evacuate and weigh in the charge on the

nameplate.

Reverse the above steps to reassemble.

ADVANCED COMPONENT TROUBLESHOOTING TECHNIQUES

Refrigeration System

Refrigerant Cycle and Components

Before diagnosing the refrigeration system, it is very important that the refrigeration charge be

correct. Whenever the refrigeration system has been opened, the filterdrier must be replaced and the

proper refrigerant charge must be weighed in.

Refrigerant Pressures

The suction pressure at the beginning of the freeze cycle can vary +/10 psi (.7 bar) depending on

operating conditions. Pressures less than this may indicate an undercharge. The discharge pressure

on air cooled units will vary with ambient conditions.

Refrigerant in a gas state is pumped throughout the refrigeration system by a hermetic compressor

to the condenser. Heat is removed from the refrigerant either by forced air movement through an

aircooled condenser or transferring heat from the refrigerant to water through a watercooled

condenser. The refrigerant changes to a liquid when cooled. The refrigerant in a liquid state passes

through a filter drier.

The filter drier traps small amounts of moisture and foreign particles from the system. The filter

drier must be replace whenever the refrigeration system is opened or if the refrigerant has been

completely lost.

Compressor

The compressor runs during the entire cycle. If the valves in the compressor are damaged, the

compressor will be unable to pump refrigerant efficiently. Damaged valves may be the result of

another problem in the refrigeration system such as liquid refrigerant returning to the compressor or

high head pressure. When a compressor is replaced it is important that the refrigeration charge be

weighed in and the system checked for proper operation to prevent a repeat failure.

An inefficient compressor will usually have a higher than normal suction pressure at the end of the

cycle. The freeze cycle will be longer than normal and/or the harvest cycle may be excessively long.

Check the compressor amperage draw 5 minutes into the freeze cycle. If the amp draw is less than

70% of rated full load amps, the compressor may be inefficient. These symptoms may also be

caused by other problems, therefore it is important to use the troubleshooting charts when

diagnosing a problem.

The air condenser is located in the back of the cabinet. Air is pulled through the condenser by a fan

motor and discharged through the right hand side panel. The Undercounter air intake and discharge

is through the front panel.

Do not block airflow as it will cause premature failure of the machine and will void the

warranty.

22

Page 23

Compressor Check

Compressor and Start Components

The compressor should run during the entire cycle. If the machine is in the ON position but the

compressor is not running, check the compressor contactor to see if it is engaged. If the contactor is

not engaged, the problem is not with the compressor or the compressor start components. If the

contactor is engaged and there is correct voltage through the contactor, there could be a problem

with one of the starting components or the compressor. It is recommended that the compressor

starting components be replaced when replacing a compressor.

DISCONNECT POWER BEFORE SERVICING!

If the compressor uses an internal overload, be certain that the compressor has cooled and the

overload has reset before diagnosing the compressor. If the compressor is cool and is still not

running, check the compressor motor windings by first removing the wires at the compressor

terminals. With an ohmmeter, check for continuity between all three terminals, if an open circuit

exists between any of the terminals, the compressor may need to be replaced. Check for continuity

from each terminal to the compressor body, if continuity is found from any terminal to the

compressor body, the compressor windings are shorted to ground and the compressor will need to

be replaced. If the compressor appears to be good at this point, it is advisable to use a compressor

analyzer to isolate the compressor from the start components while checking for a locked rotor. If

an analyzer is not available, the compressor starting components must be checked.

If all starting components are good, check the amperage draw from the common terminal of the

compressor, making sure proper voltage is supplied to the compressor and all wiring is properly

connected. If the compressor does not start and there is excessive amperage draw, (see locked rotor

amps on compressor tag) the compressor has a locked rotor and should be replaced.

Overload (External)

If there is no amperage draw check the compressor overload. The compressor overload can be

checked for continuity after removing it from the compressor and letting it cool to room

temperature. If there is no continuity between the two terminals, replace the overload. If the

overload is suspected of opening prematurely, it should be replaced with an overload, which is

known to be good.

Capacitors

The start capacitor is an electrical storage device used to provide starting torque to the compressor.

If a start capacitor is defective, the compressor will not start properly. The run capacitor is an

electrical storage device used to improve the running characteristics and efficiency of the

compressor. Before checking a capacitor, it should be discharged by shorting across the terminals.

If a run or start capacitor is cracked, leaking or bulging it should be replaced. If a capacitor is

suspected of being defective, it can easily be checked by replacing it with a capacitor of the correct

size, which is known to be good. If the compressor starts and runs properly, replace the original

capacitor. A capacitor tester can also be used.

Start Relay

The start relay breaks the electrical circuit to the start windings when the compressor motor speed

increases. If the relay is defective, the compressor will not start or it may start but will run for a very

short time.

A compressor relay can be checked by removing the relay and checking the relay contacts for

damage and check for continuity across the closed relay points. Check the relay coil with an

ohmmeter. If no continuity is read, replace the relay.

Other Components

23

Page 24

Thermostatic Expansion Valve (TXV)

The thermostatic expansion valve meters the flow of refrigerant into the evaporator changing its

state from a highpressure liquid to a lowpressure liquid. This drop in pressure causes the refrigerant

to cool. The cooled refrigerant absorbs heat from the water circulating over the evaporator. As the

evaporator fills with liquid refrigerant, the evaporator becomes colder.

The flow of refrigerant into the evaporator is controlled by the temperature at the outlet of the

evaporator. The expansion valve bulb, mounted to the top of the suction line, senses the evaporator

outlet temperature causing the expansion valve to open or close. As ice forms on the evaporator, the

temperature drops and the flow of refrigerant into the evaporator decreases, resulting in a drop in

suction pressure.

The evaporator should become completely flooded (filled with liquid refrigerant) during the freeze

cycle. A completely flooded evaporator will have a uniform freeze pattern (ice formation across the

evaporator).

A starved evaporator (not enough liquid refrigerant) will have poor or no ice formation at the top of

the evaporator, and the tube(s) exiting the evaporator will not frost. All tubes should be frosted

approximately 5 minutes from the start of the freeze cycle.

An expansion valve that is restricted or not opening properly will starve the evaporator resulting in

lower than normal suction pressure. A low refrigerant charge will also starve the evaporator and

cause low suction and discharge pressures. If not sure of the amount of charge in the system, the

refrigerant should be recovered and the correct charge be weighed in before a defective valve can be

diagnosed.

If the evaporator is starved but the suction pressure is higher than normal, the TXV is not the

problem, refer to the troubleshooting section. If the TXV sticks open or if the thermal bulb is not

making good contact with the suction line, the flow of refrigerant into the evaporator will be too

great and liquid refrigerant will flood the compressor. The suction pressure will remain higher than

normal and the machine will remain in an extended freeze cycle. Ice will build evenly but will be

very thick.

Hot Gas Valve

When the machine enters harvest the hot gas valve coil is energized opening the hot gas valve.

Discharge gas is pumped through the hot gas valve directly into the evaporator. The evaporator

temperature will reach approximately 40°F (4.5°C). The suction pressure during harvest should be a

minimum of 70 psi (4.8 bar) for R404a units or 50psi (3.4 bar) for R134a units. The discharge

pressure will drop during harvest.

If the hot gas valve does not completely open during harvest, there will not be enough hot gas in the

evaporator to defrost the ice. If there is not enough hot gas entering the evaporator, the suction

pressure will be lower than the above stated pressures. It is important when making this check that

the machine has the proper refrigerant charge, normal head pressure and the compressor is

24

Page 25

functioning properly. If the hot gas valve leaks during the freeze cycle, ice will not form on the top

of the evaporator and suction pressure will be higher than normal. To check if the hot gas valve is

leaking, let the machine run in the freeze cycle for approximately 5 minutes. Now feel the

temperature between the inlet and outlet of the valve. A definite temperature difference should be

felt. If the lines are the same temperature and the suction pressure is higher than normal; the valve is

leaking and should be replaced.

Evaporator

As water is circulated over the front of the evaporator, liquid refrigerant is circulated through the

tubing attached to the back of the evaporator. As the liquid refrigerant in the tubing vaporizes, it

absorbs heat from the water causing the water to freeze. The evaporator should be completely

flooded throughout most of the freeze cycle. A flooded evaporator will build ice evenly across the

evaporator. A starved evaporator will have thick ice at the bottom and thin ice at the top. Most

problems with ice formation or harvesting are not related to a defective evaporator.

If the evaporator is flooded but not building ice evenly, it is possible the evaporator has coil

separation. Evaporator coil separation is the separation of the refrigerant tubing from the back of the

evaporator plate. This is very rare but occasionally occurs. The symptoms of coil separation are low

suction pressure, ice not releasing from the evaporator during harvest and hollow cubes or uneven

ice bridge on some areas of the evaporator.

If coil separation is suspected, let the machine run in freeze until the timer has energized. Check the

evaporator for areas where cubes are less developed than cubes in other areas. If the cubes are all

the same size, coil separation is not the problem. If there are areas other than the top row with less

developed cubes, check the refrigerant lines at the inlet(s) and outlet(s) of the evaporator, if both

lines are frosted the coil is separated. To confirm coil separation, remove and check the back of the

evaporator. If the coil is separated, the evaporator must be replaced. If the outlet(s) of the

evaporator is not frosted, the problem is not with coil separation (refer to Troubleshooting).

Note: Permanent discoloration of the evaporator plating is normal and will cause no problems with

harvesting the ice or sanitary conditions. Before condemning the evaporator for plating problems,

be certain it is not just discoloration. Good evaporators will not be covered under warranty. If the

spillway (plastic evaporator top) becomes damaged, it can be replaced. It is not necessary to replace

the entire evaporator.

As liquid refrigerant leaves the evaporator, it changes to a lowpressure gas before returning to the

compressor. Liquid refrigerant must not return to the compressor or damage will result. Frost on the

suction line at the inlet of the compressor indicates liquid returning to the compressor. Check for

frost at the end of the freeze cycle. If liquid is returning to the compressor, the problem must be

located and corrected. See Refrigerant Charge, Thermostatic Valve and Evaporator.

Refrigerant

Refrigerant in a highpressure liquid form is fed to an expansion valve where the refrigerant is

reduced to a lowpressure liquid. Under this low pressure, the liquid will absorb heat from the

evaporator causing the liquid to change to a vapor. This vapor is the drawn into the compressor

25

Page 26

where the temperature and pressure of the vapor are increased. The high temperature, high pressure

vapor flows to the condenser where the heat is removed, causing the vapor to return to the liquid

form, making the refrigerant ready to flow back to the evaporator to pick up more heat. ice machine

use R134a or R404a refrigerant. Always check the serial number data plate for the proper type of

refrigerant and the amount used in the machine you are servicing.

R404a and R134a are both HFC refrigerants, which result in no ozone depletion factor. R404a

cylinders are orange in color, R134a cylinders are light blue in color. Do not switch refrigerants in

the machine.

Important: When discharging refrigerant from an icemaker, recover as much of the

refrigerant as possible with a recovery device or some other means to prevent the refrigerant

from entering the atmosphere.

Electronics and Sensors

Control Board Checks

Timer Initiate

The timer initiate is a temperature sensor mounted on the liquid line to the evaporator. When the

sensor detects the correct low temperature the freeze timer is energized and the machine enters the

timed portion of the freeze cycle. When the freeze timer is energized, the machine is in the timed

portion of the freeze cycle. When the machine enters harvest, the temperature rises, but the amount

of time the machine is in harvest is predetermined and is controlled by the Controller Board. Once

the time has passed, the machine will enter the harvest cycle. The timer is not adjustable, but the

temperature at which the timer is initiated is adjustable as is outlined below.

Adjustments

Ice size adjust

1. Press and hold the “Clean” button and the “Mode” button together for at least 3 seconds. The

unit will enter the Ice Size Adjustment mode. The “ICE” LED (green) will be blinking continuously

during the ice size adjustment.

2. While in the Ice Size Adjustment mode, press the “Clean” button or the “Mode” button for the

desired ice size.

Smaller ice setting:

By pressing the “Clean” button, you can decrease the size of the ice cubes. The “FULL” LED (red)

will flash as you lower the ice size and will finally be blinking at the setting of smallest ice size.

Larger ice setting:

By pressing the “Mode” button, you can increase the size of the ice cubes. The “HARVEST” LED

(yellow) will flash as the larger size is set and will blink when the setting of largest ice size has been

reached.

After 10 seconds without any operation, the unit will automatically memorize the current state and

return to the previous mode.

26

Page 27

Bin Control Operation

The bin control is used to shut the machine off when the bin fills with ice. The bin control must be

checked upon installation or initial startup and when performing maintenance. Adjustments are

notcovered under warranty.

There is one bin switch for each evaporator. The actuator arm of the bin switch comes in contact

with the splash curtain. When the bin is full of ice, the splash curtain is held open when ice drops

off of the evaporator. This releases the pressure of the bin switch actuator arm allowing the switch

to open.

Undercounter and machines without curtains: An ice slide at the bottom of the evaporator is

used on all undercounter and some modular units. The slideway swivels up and down and has a

magnetic reed switch which detects its position. When ice is sitting on the control, the slideway

faces down indicating that ice is present (and disconnecting the circuit from the reed switch). When

the ice is removed, the slideway swivels up and the connection is completed allowing the machine

to begin producing ice again.

Bin Control Adjustment

All Models (except those without curtains): Check the bin switch for proper adjustment by

swinging the bottom of the curtain away from the evaporator. Slowly bring the curtain towards the

evaporator. The switch should close when the bottom edge of the curtain is even with the outer edge

of the water trough. Adjust the switch by loosening the screws the hold the switch in place. Move

the switch to the proper position and retighten the screws. Recheck the adjustment. Adjustments

are not ncovered under warranty.

Undercounter Models or Those Without Curtains

There are no adjustments needed for the bin (magnetic reed) switch.

27

Page 28

Spare parts list

Item No.

Material

Code

English Description

2

1864802401

Water trough

3

1880001701

Floater valve

4

1864600404

Water curtain

6

1858904400

Water pump

8

1880025700

Evaporator

9

1880002401

Water distributor tube

14

1854000600

Power switch

17

1854201200

Button control panel

19

1854202300

Main control panel

19.1

1854800300

Fuse

19.2

1851700700

Temperature sensor of condenser

19.3

1851700501

Temperature sensor of evaporator

20

1858442400

Transformer

24

1854700800

Drain valve

28

1854601900

Expansive valve

29.1

1854704410

Hot gas valve body

29.2

1854702700

Hot gas valve coil

30

1853107600

Wiring harness

31

1861530802

Water outlet connector

32

1864526600

Water inlet connector

36

1880014001

Condenser

38

1880008300

Drier

41.1

1858421200

Compressor

41.2

1858441400

Srarting device component

41.3

1858451300

Protector

45.1

1858203800

Condenser fan motor

45.2

1858441500

Fan motor capacitor(6uf)

49

1871018500

Microswitch

28

Loading...

Loading...