Page 1

Electric Ta n k l e s s Water Heat e rs

Most Advanced Line of Residential & Commercial Instant Heaters

Endless Hot Water

Endless

Series

Savings

Page 2

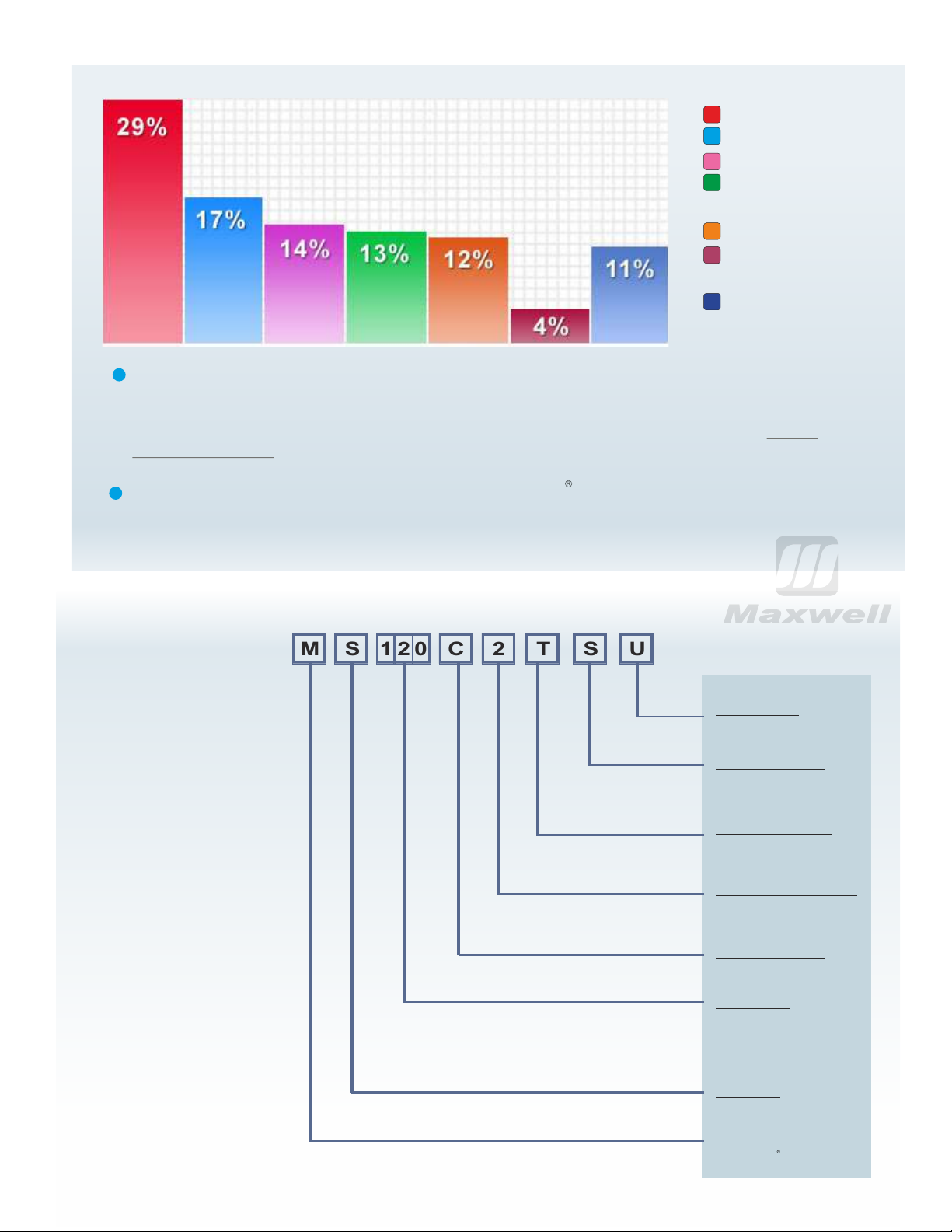

Heating

Cooling

Water Heating

Appliances

(includes refrigerator, dishwasher,

clothes washer and dryer)

Lighting

Electronics

(includes computer and monitor

and TV and DVD player)

Other*

(includes external power adapters,

telephony, set-top boxes, ceiling fans,

vent fans and home audio)

The US Department of Energy says that residential tank storage heaters are the highest energy

consuming home appliances only second to heating and air conditioning systems. It is consuming

more energy than your refrigerator, dish washer, washer and dryer combined. If you have a

traditional tank style water heater in your garage, attic, or basement and older than 9 years NOW is

the time to upgrade.

Tank-less Water Heating is the futurist solution — now Maxwell electric tank-less water heaters

available in 99% efficiency to save you up to 50% in energy consumption, enjoy endless hot water

without any recovery time, and significant space savings.

MODEL NUMBER

NOMENCLATURE

This Klimaire nomenclature supercedes

all previously issued (05/23/2013)

M

S

1 2

0

C

2

S T

U

Test Calification

U : UL/ETL

C : CSA

O : NLA

Casing Type & Color

B: Injection Molding – Black

S: Injection Molding – Silver

W:Injection Molding – White

M:Metal Casing – Silver

Minor Design Change

P : Plate Heater Exchanger

T : Tubular Stainless

Steel Heat Exchanger

Power Supply Code (V/ph)

1 – 120 / 1

2 – 240 / 1

5 – 240 / 3

Temperature Control

C : Automatic Constant

P : Power Level

Capacity (kW)

120 – 12.0

150 – 15.0

180 – 18.0

210 – 21.0

240 – 24.4

270 – 21.0

Heater Type

S : Tankless

H : Holding Tank

Brand:

M: Maxwell

Page 3

Tankless Water Heaters ApplicationsTankless Water Heaters Applications

Residential Electric Water Heating

Maxwell AquaFinity Series tankless water

heaters are perfect for single family homes,

townhouses, condos, manufactured housing,

apartments, cottages, cabins.

Applications include new installations, retrofits

replacements and in conjunction with your new or

existing heating appliance.

Commercial and Multi-Dwelling Electric

Water Heating

Applications for commercial properties including

hotels/motels, resorts, multi-family houses, businesses,

shopping centers, laboratories, hair salons, laundromats,

stadiums, restaurants, theme parks, medical facilities, car

washers.

Our compact units utilize a fraction of wall space and

zero floor space without any venting requirements

providing you the best solution for any application.

Supplemental/Auxiliary Electric Water Heating

Application as a booster for solar water heaters and

geothermal water heaters.

Maxwell electric water heater can work as a booster or an

auxiliary heating appliance and raise the temperature when

your system needs – perfect back up heater.

Point of Use

Applications are numerous – it is recommended in every wet zone

utilizing hot water to use tankless water heaters to receive warm

water immediately and avoid waiting long time while wasting water

unnecessarily.

Radiant Floor Heating

Maxwell water heaters are ideal to

provide heated water for a closed

loop system for uniform space

heating.

Recreational

Boat kitchens and bathrooms – RV kitchens and bathrooms

Page 4

AdvantagesAdvantagesAdvantages

Endless hot water supply on demand.

Saves up to 50% on water heating costs.

Space saving compact design.

99% plus energy efficientcy

No minimal stand by energy losses.

Sleek, lightweight & modern

design fits most applications.

Instant hot water at point of use

applications reducing waiting

time and water consumption.

Double the life expectancy

over conventional water heaters.

No hot water storage, thus reducing

mineral deposits and lime scaling to

prevent efficiency reduction over time.

Easy installation with provided accessories.

Environmentally friendly no venting required.

Compact design

(15 3/4 H x 10 1/4 W x 3 5/8 D)

wall mounting saves valuable floor space.

No corrosion

No enefficient mixing cold water

Series

Point of use

10"

15.2"

Recommended Optional AccessoriesRecommended Optional Accessories

Ball valve:

It is required to

isolate the heater

without affecting the water flow

to the rest of the house, and for

maintenance. The valve can also

be used to regulate the GPM

without restrictions.

Hex nipple:

to make easier

the connection

of the heater and

the water piping

WarrantyWarrantyWarranty

YEAR

ALL PARTS

1

1

GUARANTEE

3

3

Flexible tubes:

Ideal to readily connect

the heater to the water

inlet and to the point

of use.

YEAR

HEATING CHAMBER

GUARANTEE

Dimensions

Water filter:

Filters water at

the supply to help

reduce sediment,

sand and rust

to extend the life and performance of

the water heater, avoiding calcification

of the heating element, and the

internal water channel.

3

3

3.7"

YEAR

OPTIONAL REPLACEMENT

GUARANTEE

One year all parts

Three years

heating chamber

Three years optional

replacement warranty

Page 5

FeaturesFeatures

58

Models available in multiple colors

to match your interior design.

Black Silver Silver

IMD Injection Molding Models

12 kW - 24 kW

Case-unique glossy IMD front cover,

splash-proof, corrosion and age resistant

Attractive Metal Casing

15 kW - 27 kW

Patented heating technology – enclosed loop heating system for instant

hot water with less heating loss, nano insulation material totally separates

water from electricity

Reliability – Single piece cast aluminum with a stainless steel flow channel

that eliminates water and electric leakages in the heating chamber, therefore

the heating element will have an extended service life unaffected by the quality

of the water thus avoiding lime scaling.

Multi-protection devices – anti-scalding, over-pressure, over-temperature,

and electricity isolation

Digital temperature control - Direct temperature setting, from 86º F -127º F,

allows you to get constant hot water at the precise temperature for maximum

comfort and suitable for different applications; memory function avoids

repeating settings.

Convenience - LED wide screen touch button displays the working

conditions, outlet temperature, working time, and power consumption.

Advanced micro-processor control - Self-diagnostic function automatically

monitors and displays working conditions, providing constant temperature

water flow by engaging heating elements in stages

Soft Start. – Power is regulated to avoid excessive startup surge.

Page 6

Top Reasons to Select Maxwell Tankless Water Heaters (TWH)

Unlike traditional tank water heaters wasting energy and heating water all day long with limited hot water

supply capability, lengthy recovery time with decaying efficiency and capacity over time, MAXWELL tankless

heaters offer you endless hot water supply consistent over life, comfortable water temperature, saving up to

50% in energy consumption, maintaining 99% efficiency throughout its service life with minimal standby loss.

By providing warm water immediately where it's used, tankless water heaters waste less water. Maxwell

tankless water heaters use the most advanced technology to produce the most eco-friendly water heating

appliance available in the market. Using Maxwell AquaFinity heaters you contribute to reduce the

environmental impact while conserving water and saving money. Maxwell AquaFinity Series electric water

heaters use state-of-the-art patented technology with several different layers of insulating ceramic avoiding

direct contact of water with heating elements to prevent corrosion and scaling.

11

23”

Space Saving Technology

16

51"

Traditional tank water heaters can take 16 sq. ft of valuable floor space. However, AquaFinity

Series are smaller than attaché case — sleek, lightweight and attractive, design allows you for

unconcealed installation applications with any decoration virtually on any wall inside your

house. Our compact design gives you limitless installation options. By strategically locating the

Aquafinity Series maximum performance, energy efficiency, and reduced water consumption

will be achieved for point of use application or whole house water heating.

Never-ending Hot Water On-Demand

Maxwell AquaFinity Series tankless water heaters supply hot water when needed. Since

there is not storage tank you enjoy hot water as long as needed. Even during the peak use

you don't have to concern running out of hot water or to wait for the tank to recover.

Average Annual Operating Costs Comparison

ElectricNatural Gas PropaneOil

Electric

Water

Heater

$775

$578

$320

E N ERG Y FA C TO R

0.99 0.575 0.9 0.55 0.575

F U EL CO S T

11.7 ¢ $1,63 11.7 ¢ $2,97 $2,59

Y E ARL Y C ON SUM P TI O N

2739 kW-h 269 Therm 5015 kWh 203 Gal 269 Therm

AV ERG A GE S E RV I CE L IFE

20 yrs. 10 yrs. 14 yrs. 9 yrs. 10 yrs.

$438

$603

Proven Energy Savings

Traditional tanks as well as conventional tankless water

heaters use immersed coils in the water directly heating it.

This kind of design causes heat spots and over time lime

scaling and mineral deposits that decrease the heating

capacity that lowers the efficiency of the heater. The newly

designed Maxwell unit heats water instantly as it flows thru

the heating channel. The flow rate and temperature of the

incoming water are monitored by the electronic control that

activates the number of heating elements

required to reach the set temperature,

and keep it constant for maximum

comfort.

Proven and Reliable Technology

Traditional tank and conventional tank-less water heaters heat the water directly using immersed coils. This type of design causes

heat spots, lime scaling, and mineral deposit build up that affect the heating capacity, and reduce the efficiency. Since there is not

water storage and traditional coil heating element in the Maxwell heaters their efficiency improves and the product life is doubled.

The Maxwell heaters are built with a stainless steel water flow channel inside single piece aluminum cast that further increase their

service life. Precise digital control provides an endless hot water supply at constant temperature.

Page 7

SpecificationsSpecifications

Injected Mold Model

Model

Phase

Voltage V

Wattage kW

Max. Amp. Load @ 240V A

No. of circuits n

Min. required double pole

circuit breaker

Min. wire size AWG cooper

Min. water flow to activate

Working pressure PSI/bar

Temperature range - ºF

Weight

Product Dimensions mm

Water connections NPT

Stainless Steel Model

Phase

Voltage V

Wattage kW

Max. amp. load A

No. of circuits

Min. required circuit breaker

GPM / L/min.

A

Model MS150C2TMU MS180C2TMU MS210C2TMU MS240C2TMU MS270C2TMU

kg

@ 240V

Min. wire size AWG cooper

Min. water flow to activate

Temperature range - ºF

Working pressure PSI/bar

Weight lb

Product Dimensions in

Water connections NPT

Check your local electrical code requirements for different voltage application

GPM / L/min.

MS120C2T_U MS150C2T_U MS180C2T_U MS210C2T_U MS240C2T_U MS270C2T_U

1

240

12

50

1

60 2 x 40 2 x 50

8

0.84 / 3.2

0.84 / 3.2

86º - 122º

385x260x93

15.1x10.2x3.7

lb

in.

A

86º - 122º

3.6

7.9

385x260x93

15.1x10.2x3.7

1/2” 3/4” 3/4” 3/4” 3/4” 3/4”

1 1 1 1 1

240 V

15kw

63

2 2 3 3 3

2 X 40

2 X 8

0.84/ 3.2 0.84/ 3.2 0.84/ 3.2 0.84/ 3.2 0.84/ 3.2

86º - 122º 86º - 122º 86º - 122º 86º - 122º 86º - 122º

17.6

16.1 x 11 x 3.5

3/4” 3/4” 3/4” 3/4” 3/4”

1

240

15

63

2

2 x 8

5.3

11.7

240V

18kw

75

2 X 50

2 X 8

17.6 17.6 17.6 17.6

16.1 x 11 x 3.5 16.1 x 11 x 3.5 16.1 x 11 x 3.5 16.1 x 11 x 3.5

2 x 8

0.84 / 3.2

86º - 122º

11.7

385x260x93

15.1x10.2x3.7

1

240

18

75

2

Max.150/10

5.3

1 1 1

240 240 240

21 24 27

88 100 113

3 3 3

3 x 40 3 x 40 3 x 50

3 x 8 3 x 8 3 x 8

0.84 / 3.2 0.84 / 3.2 0.84 / 3.2

86º - 122º

5.5

12.1

385x260x93

15.1x10.2x3.7

86º - 122º

5.5

12.1

385x260x93

15.1x10.2x3.7

240 V 240 V 240 V

21kw 24kw 27kw

88 100 113

3X 40 3X 40 3X 50

3 X 8 3 X 8 3 X 8

Max.150/10

86º - 122º

5.5

12.1

385x260x93

15.1x10.2x3.7

W

W

MS_C2P_U MS_C2PMU

(Metal Case)(Injection Mold Case)

Average Household Water Usage

Point of Use GPM*

Shower 2.0

HH

DD

Tub 4.0

Lavatory sink 1.5

Dish washer 2.0

Kitchen sink 2.2

Washing machine 3.0

* Max

Page 8

MS-C2TMU

Stainless Steel Model

MS-C2T_U

Injected Mold Model

Stainless Steel

Rear Cover

Temp. Controller

Thermal cut-out

(Manual Reset)

Temp. Sensor

Water Outlet

Connection

Control Board

Triac

Terminal Block

Flowmeter

Temp. Sensor

Water Inlet

Connection

Picture 2

How Maxwell Tankless Water Heater Works

Undisputed twenty two years of heating

experience and engineering has applied

to develop the Maxwell tankless water

heaters delivering many years of reliable

water heating in your home or in

commercial applications. Below is the

explanation to help you to understand

and to familiarize with the operation of

Maxwell electric tankless water heaters.

1. Once you turn hot water faucet on,

cold water flows through the unit passing

thru a flow meter and inlet temperature

sensor that measure the precise flow rate

and temperature of the incoming water.

4. As the water flows out of the unit the

water is being heated in the patented

multilayer heating chamber and a

second sensor at the outlet makes any

necessary adjustments to ensure

Maxwell tankless water heater delivers

accurate and constant temperature hot

water.

5. System continues to operate and

remains on until no flow is detected then

Rear Cover

Heating Chamber

Thermal cut-out

(Manual Reset)

Temp. Sensor

Water Outlet

Connection

Picture 3

goes to stand-by mode until any hot

water faucet is turn on again.

6. Maxwell advanced micro-processor

has numerous features to monitor and

control with self-diagnostic functions and

displays the working conditions, the

outlet water temperature, working time

and the kW power consumption to

enable the homeowners to optimize the

usage of the heater and maximize

savings, and gain the most benefits from

their investment

Control Board

Triac

Terminal Block

Flowmeter

Temp. Sensor

Water Inlet

Connection

2. Advanced micro-processor control

monitors and senses all working

conditions of the heater and switches

devices to fully modulate the power of the

heating elements from 0-100% to provide

the most precise and consistent hot water

temperatures in the industry.

3. The micro-processor engages heating

elements in stages depending on the

demand requested by the amount of the

water flow and inlet water temperature

using solid state switching triac. Power is

always regulated to avoid excessive

startup surge.

Magnesium powder thermal conductivity insulation

Sheathed

Heating Plate

Hot Water

Cold Water

Aluminium magnesium cast body

Stainless steel water channel

Stainles steel

Nickel-chromium heating element

Page 9

ºF

77º

72º

Heater Sizing GuideHeater Sizing Guide

67º

62º

57º

52º

47º

42º

37º

Model Nº

MS120C2P_U

MS150C2P_U

MS180C2P_U

MS210C2P_U

There are many factors that go into selecting the right water heater: the number of people in the home, type

of showers and tubs, water pressure and geographic region. To make the process easier, we offer the map

and flow-rate table below.

1. On the map, determine the ground water temperature in your area.

2. In the corresponding column select the water heater based on how many fixtures you'll be running

at the same time.

3. The temperatures shown above are based on the average coldest ground temperature in your region.

Inlet Water

Temp.

Heater Sizing Guide

Summer Winter

77º F 72º F 67º F 62º F 57º F 52º F 47º F 42º F 37º F

2.7 gpm 2.4 gpm 2.2 gpm 2.1 gpm 1.8 gpm 1.5 gpm 1.3 gpm 1.2 gpm 1.1 gpm

3.5 gpm 3.2 gpm 2.6 gpm 2.5 gpm 2.3 gpm 2.0 gpm 1.7 gpm 1.5 gpm 1.3 gpm

4.0 gpm 3.6 gpm 3.2 gpm 3.0 gpm 2.7 gpm 2.5 gpm 2.3 gpm 2.1 gpm 1.8 gpm

5.0 gpm 4.5 gpm 3.8 gpm 3.5 gpm 3.2 gpm 2.7 gpm 2.4gpm 2.2 gpm 2.1 gpm

MS240C2P_U

MS270C2P_U

Shower (1.5 gpm) ― Sink Faucet (1.0 gpm)

All data above are based on water leaving temperature 105º F (40º C). 1.5 gpm showerhead flow rate; 1.0 gpm sink faucet

flow rate, and adequate water pressure @ 60 psi. Actual performance may be altered by variations from these parameters.

For voltages less than 240 V the heating capacities will vary and it would be necessary to consider a higher capacity model.

5.6 gpm 4.8 gpm 4.2 gpm 3.5 gpm 3.3 gpm 2.8 gpm 2.6gpm 2.4 gpm 2.2 gpm

6.4 gpm 5.3 gpm 4.7 gpm 4.0 gpm 3.6 gpm 3.3 gpm 3.0gpm 2.7 gpm 2.5 gpm

Shower Sink Faucet

Page 10

Temperature Rise (ºF)

Selection GuideSelection Guide

Model

Power

(kw)

Water

Flow(GPM)

MS120C2T MS150C2T MS180C2T MS210C2T MS240C2T MS270C2T

12 15 18 21 24

0,5 164 205 246 287 328 369

1,0 82 102 123 143 164 184

1,5 55 68 82 96 109 123

2,0 41 51 61 72 82 92

2,5 33 41 49 57 66 74

3,0 27 34 41 48 55 61

3,5 23 29 35 41 47 53

4,0 20 26 31 36 41 46

4,5 18 23 27 32 36 41

5,0 16 20 25 29 33 37

5,5 15 19 22 26 30 34

6,0 14 17 20 24 27 31

6,5 13 16 19 22 25 28

7,0 12 15 18 20 23 26

27

Temp Rise

120

110

100

90

80

70

60

50

40

30

20

10

0

o

F

Temperature Rise

o

F @ 240V vs. Flow Rate (GPM)

0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0 4,5 5,0 5,5 6,0 6,5 7,0

MS120C2T

MS150C2T

MS180C2T

MS210C2T

MS240C2T

MS270C2T

Flow Rate

GPM

Based upon DOE formula for calculating flow at rise

Flow Rate (gpm) =

Temp rise (ºF)

kW rating x 6.83

Page 11

Series

Made by

Mark of Superior Quality

2190 NW 89th Place, Doral, FL 33172

Tel: (305)594-4972 Fax (305) 499-4378

www.klimaire.com sales@klimaire.com

USC

4002422

Loading...

Loading...