Page 1

Tankless Electric Water Heater

MSxxxC2T_U &

SERIES

MSxxxC2TMU

Installation and Instructions Manual

Keep this Instructions Manual in a safe place once your unit is installed.

You may need to refer to it for general instructions or future maintenance.

Page 2

CONTENTS

Nomenclature … …………..........….…….........………..… 1

……………………………………………………

Product advantages ……………….................………………………………………………………………2

Product Features………………….....…………………………………………………………………………2

Warnings…………………………………………………………………………………………………………3

About Your Electric Tankless Water Heater…………….....…………………………………………………3

Before You Install Your Tankless Water Heater……………………...………………………………………4

Selecting Installation Location……………………………………….......……………………………………4

Mounting Your Electric Tankless Water Heater………………………………………………………………4

Dimensions……………………………………………....………………………………………………………5

Installation Guideline……………………...……………………………………………………………………6

Plumbing and Mechanical Installation…………...……………………………………………………………8

Heater Sizing Guide .......................…………...……………………………………………………………9

Temperature Rise Table & Graph……………………………………………………………………………10

Electrical Installation……………..……………………………………………………………………………11

Technical Data…………………………………………………………………………………………………15

Starting your Electric Tankless Water Heater………………………………………………………………16

Operation Instructions………………………………………………………………………………………16

Troubleshooting………………………………………………………………………………………………17

Normal Maintenance Recommendations………………………………....…………………………………17

Customer Service ................................................................................................................................. 18

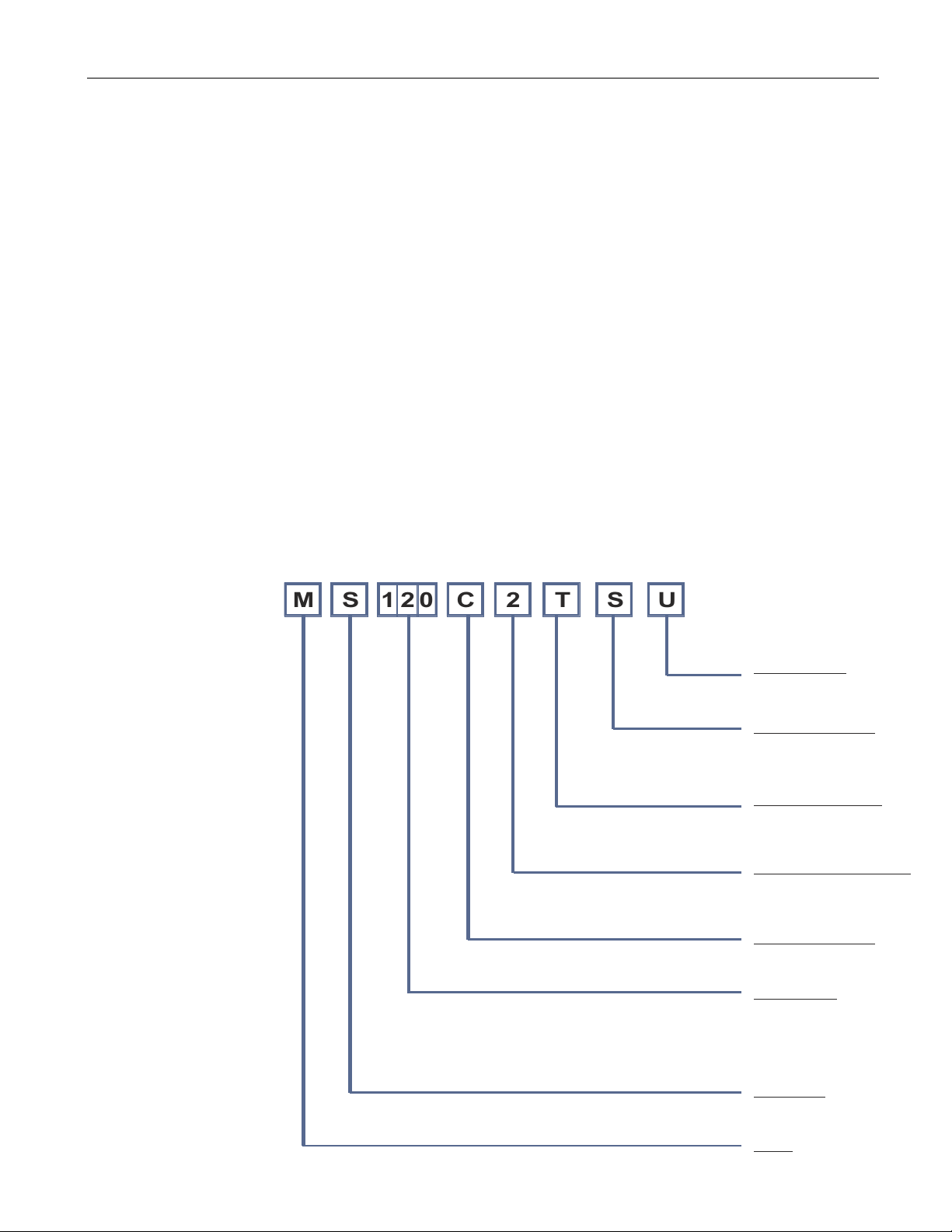

MODEL NUMBER

NOMENCLATURE

This Klimaire nomenclature supercedes

all previously issued (05/23/2013)

M

S

1 2

0

C

2

S T

U

Test Calification

U : UL/ETL

C : CSA

O : NLA

Casing Type & Color

B: Injection Molding – Black

S: Injection Molding – Silver

W:Injection Molding – White

M:Metal Casing – Silver

Minor Design Change

P : Plate Heater Exchanger

T : Tubular Stainless

Steel Heat Exchanger

Power Supply Code (V/ph)

1 – 120 / 1

2 – 240 / 1

5 – 240 / 3

Temperature Control

C : Automatic Constant

P : Power Level

Capacity (kW)

120 – 12.0

150 – 15.0

180 – 18.0

210 – 21.0

240 – 24.4

270 – 21.0

Heater Type

S : Tankless

H : Holding Tank

Brand:

M: Maxwell

1

Page 3

Congratulations! Now that you have purchased brand new Maxwell tankless water heater Aquafinity™ series and

will soon begin to enjoy the instant hot water supply as long as you need.

PRODUCT ADVANTAGES

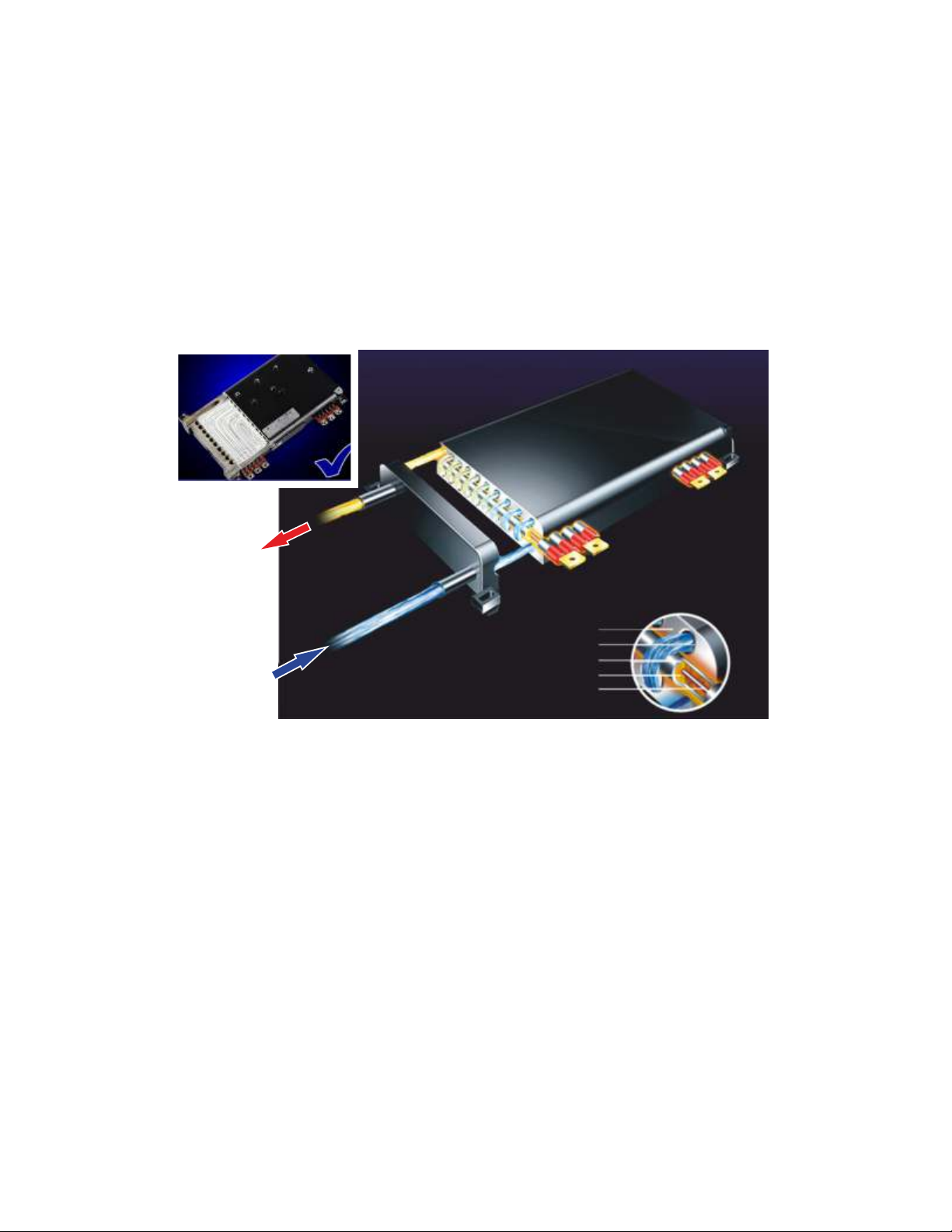

Your Maxwell heating appliance is an endless hot water on demand supply source. The heating chamber is made from

a single piece of cast aluminum with stainless steel water channels to have a longer and reliable life expectancy

despite the quality of the water entering the heater. The design of the enclosed nickel-chromium heating elements with

magnesium powder thermal conductivity insulation sets apart this heater.

Sheathed

Heating Plate

Hot Water

Cold Water

PRODUCT FEATURES

1. Energy efficient – Instantaneous heating on demand. Maxwell modern light weight and sleek

design compact tankless water heater does not require pre-heating and there are not standby heating losses.

2. Reliable and safe – water is completely separated from electricity by multi-layers of composite

nano insulation material.

3. Advance micro-processor control – self-diagnostic function automatically monitors and

displays working conditions with soft-start function providing constant temperature water flow

by engaging heating elements in stages for a precise temperature control for maximum

comfort.

4. Multi-protection devices – your heater has built-in protection features to prevent antiscalding, over-pressure, over-temperature and electricity isolation.

Aluminium magnesium cast body

Stainless steel water channel

Stainles steel

Magnesium powder thermal conductivity insulation

Nickel-chromium heating element

Picture 1

5. Convenience – LED wide screen touch button displays the working conditions, outlet

temperature, working time, and power consumption.

2

Page 4

MS-C2TMU

Stainless Steel Model

MS-C2T_U

Injected Mold Model

Stainless Steel

Rear Cover

Temp. Controller

Thermal cut-out

(Manual Reset)

Temp. Sensor

Water Outlet

Connection

Control Board

Triac

Terminal Block

Flowmeter

Temp. Sensor

Water Inlet

Connection

Rear Cover

Heating Chamber

Thermal cut-out

(Manual Reset)

Temp. Sensor

Water Outlet

Connection

Control Board

Triac

Terminal Block

Flowmeter

Temp. Sensor

Water Inlet

Connection

Picture 2 Picture 3

1. WARNINGS

This is not a do-it-yourself project. Failure to have this appliance installed by a licensed and certified electrician and

plumber will void all warranties.

Under no circumstances should you attempt to clean, install, inspect, repair, disassemble or service the Maxwell electric

tankless water heater without first shutting off all power to the unit directly at the circuit breaker box. SERIOUS BODILY

INJURY OR DEATH COUILD OCCUR IF THIS WARNING IS IGNORED.

INSTALLATION OF THIS PRODUCT IS RESTRICTED TO INDOOR LOCATIONS BY QUALIFIED PLUMBING,

HEATING, MECHANICAL, ELECTRICAL CONTRACTORS ONLY, IN ACCORDANCE WITH ALL NATIONAL,

STATE, PROVINCIAL, AND LOCAL ELECTRICAL AND PLUMBING CODES.

By installing this product you acknowledge the terms of manufacturer's warranty and your authorized dealers return

policy. Water heaters that have been installed cannot be returned. If you plan to install your water heater on a second

floor/above ground or in a heated attic space you must follow all code requirements for installation in your area. It is

highly recommended to install a drip pan connected to a safe drain as per code requirements below the water heater

to avoid property damage in case of eventual leaks, and / or install an active water leak detector and shut off valve to

turn off your water supply in the event that a leak is ever detected.

Installation of this product is restricted to indoor locations only.

2. ABOUT YOUR ELECTRIC TANKLESS WATER HEATER

Please read thoroughly and understand this safety and installation manual completely before beginning to enjoy your

new on demand electric Maxwell tankless water heater, as it contains important safety information and installation

instructions.

If you need assistance or have any questions please contact us at: (305) 593-8358

Please keep this manual for future reference and technical information.

3

Page 5

3. BEFORE YOU INSTALL YOUR TANKLESS WATER HEATER

By installing this product you acknowledge the terms of manufacturer's warranty and your authorized dealers

return policy. Water heaters that have been installed cannot be returned. If you have any questions regarding

the warranty or product return policies please consult your authorized dealer.

Please open your tankless water heater box and carefully unpacked it, and inspect all components.

4. SELECTING INSTALLATION LOCATION

Your tankless water heater is a compact design and it has to be wall mounted, however improper installation,

maintenance or service adjustments may cause property damage. This appliance is designed to be installed

vertically and indoors only. You may be able to install your appliance in outdoor location provided that it is

mounted in a suitable enclosure that protects it from rain and water splashing, direct sun light, debris, and

insects. This product should NOT be installed in locations where it may be subject to freezing temperatures. If

the water inside your tankless water heater unit freezes, it can cause severe and permanent damage that is not

covered under your warranty. If you suspect your Maxwell tankless water heater has frozen, do not turn on

your unit until it has completely thawed out, and you have inspected the unit for leaks.

It is recommended and you should give consideration to your existing plumbing configuration and location of

your main electrical panel, and future servicing. DO NOT locate the unit in a location that will be difficult to

access. Most of the times, it is better and easier to install your new appliance at the same location as your old

one.

Combustible materials should be kept at least 24 inches or 60 cm. from your unit and the output hot water pipe.

Your unit does not require any type of venting. You should avoid installing your unit in places subject to

excessive humidity, moisture or dust, and even splashing water or other liquids, like under water pipes, water

gutters, air conditioning drain or refrigerant lines that might leak or condense moisture that could drip onto the

unit. DO NOT install your unit above electrical boxes or junction boxes.

5. MOUNTING YOUR ELECTRIC TANKLESS WATER HEATER

Your appliance should be mounted on a solid and secure surface. Prior to installation ensure that the unit is

leveled before tightening the screws. We recommend that for ease of installation and service product should be

installed in upright position with the inlet and outlet water connections at the bottom of the unit.

Recommended clearances: Above and below unit 12” and front panel 6”.

CAUTION: Clearances to combustible materials should be at a minimum of 24” away from the unit, and the

water inlet and outlet connections.

4

Page 6

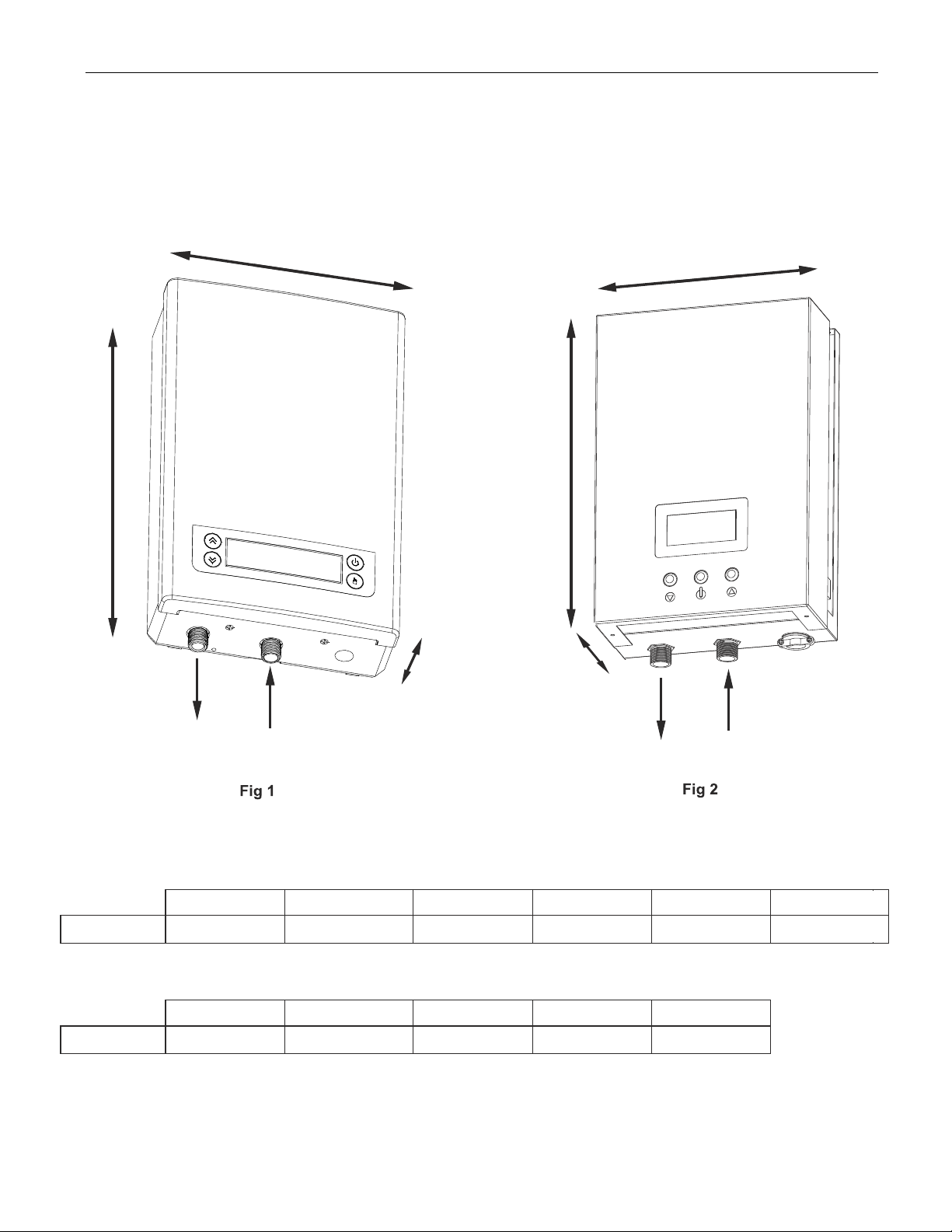

DIMENSIONS

B

MS-C2T_U

A

MS-C2TMU

D

E

WATER OUTLET

A x B x C

C

WATER INLET

Injected Mold Model Stainless Steel Model

MS120C2T_U

in. 15.1x10.2x3.7 15.1x10.2x3.7 15.1x10.2x3.7 15.1x10.2x3.7 15.1x10.2x3.7 15.1x10.2x3.7

MS150C2TMU

in.D x E x F

16.1 x 11 x 3.5 16.1 x 11 x 3.5 16.1 x 11 x 3.5 16.1 x 11 x 3.5 16.1 x 11 x 3.5

MS150C2T_U

MS180C2TMU

MS180C2T_U

MS210C2TMU MS240C2TMU

F

WATER OUTLET

MS210C2T_U MS240C2T_U

WATER INLET

MS270C2TMU

MS270C2T_U

5

Page 7

Installation Guideline

MS-C2T_U MS-C2TMU

Injected Mold Model

Stainless Steel Model

Front and back of the appliance(Typical)

Fig 4

Remove screw which fixes the bracket on back of the appilance (Typical).

Fig 5

Remove the bracket from the appilance (Typical).

6

Page 8

100 mm

3”-15/16

100 mm

3”-15/16

100 mm

3”-15/16

Hold the back bracket hanger in position against the wall and mark the three mounting holes. Drill holes of

Fig 6

¼” inch (6.00mm) diameter; the distance between every two holes is 3”-15/16 (100mm). Insert plastic anchoring

in the hole, place the bracket on the wall and secure the hanger using the screws supplied or an appropiate

alternative method.

100 mm

3”-15/16

Fig 7

Remove (4) screws on appliance to remove the front cover. Carefully lift the cover a few inches of the unit.

Disengage the LCD panel plug connecting the front cover to the body of the unit. Remove the cover completely.

Warning: If LCD connection cable cannot be disengaged, simply set the front cover aside and keep

the cable connected.

7

Page 9

E L1 L2 L1 L2 L1 L2

Typical view (model MS210C2TMU)

Fig 8

Fix the appilance to the bracket which was screwed to the wall.

Make sure the unit is properly secured to the bracket.

6. PLUMBING AND MECHANICAL INSTALLATION

Please read these instructions truly and completely before installing your water heater.

Please follow all plumbing instructions carefully. This appliance must be installed by a licensed and qualified

plumber in accordance with all applicable national, state, provincial, and local plumbing codes. Failure to do so

could result in property damage and/or personal injury and void your warranty.

1. DO NOT SOLDER ANY PIPES WITH THE APPLIANCE CONNECTED TO. IF YOU DO, YOU COULD

DAMAGE THE FLOW SENSOR AND VOID THE WARRANTY.

2. A pressure valve and air purging fitting must be installed as shown in the cold water supply pipe, if the

pressure exceeds 150 psi (1 Mpa). Any threaded fittings should be installed using Teflon tape, or approved

liquid sealants, as code practices allow. The relief valve must be installed in accordance with applicable

codes. Use standard hydronic practices to eliminate air from the system.

3. Install air vent valves, expansion tanks, flow control valves, isolation valves, etc. as per code requirements.

4. The unit is designed to operate only when flow sensor senses water flow through it. Prior to powering up

(turning on your unit), PURGE ALL AIR FROM YOUR SYSTEM (see item 10 below), failure to do so might

cause an air-lock in your unit drying out the heat exchanger of your unit and cause permanent damage to the

heating element.

5. The unit should be connected directly to the water supply and it is extremely important to FLUSH the pipe

with water to remove any debris, or loose particles.

6. Check all the pipe connections and fittings for any leaks, and take corrective actions before proceeding.

7. Models MS120C2T_U require ½” NPT water connections.

8. Models MS150C2T_U, MS180C2T_U, MS210C2T_U, MS240C2T_U, MS270C2T_U require ¾” NPT water

connections.

9. Connect the cold water supply to the INLET threaded pipe, and the hot water to the OUTLET threaded pipe.

Important: A RUBBER WASHER MUST BE USED FOR PROPER SEAL.

8

Page 10

AFTER TIGHTENING BOTH FITTINGS AT THE WATER HEATER, PRIOR TO TURNING ON THE

10.

POWER OF THE WATER HEATER, OPEN SEVERAL HOT WATER FAUCETS AND ALLOW WATER

TO RUN THROUGH THE WATER HEATER FOR A MINIMUM OF 3 MINUTES. This process purges all

air from the water lines and the heater.

Fig 9

Connect the cable to the terminal blocks, please notice the guidance logo below the terminal blocks.

The unit will be connected to circuit breakers as per table 1

Average Water Consumpion

Application

Typical Shower

Typical Bath Tub Faucet

Bathroom Vanity Sink Faucet

Kitchen Sink Faucet

Clothes Washer

Heater Sizing Guide

Summer Winter

Inlet Water

Model Nº

Temp.

MS120C2T_U

MS150C2T_U

77º F 72º F 67º F 62º F 57º F 52º F 47º F 42º F 37º F

2.9 gpm 2.6 gpm 2.4 gpm 2.3 gpm 2.0 gpm 1.8 gpm 1.5 gpm 1.3 gpm 1.2 gpm

3.8 gpm 3.4 gpm 2.9 gpm 2.8 gpm 2.6 gpm 2.2 gpm 1.9 gpm 1.8 gpm 1.4 gpm

Flow Rate in

GPM at 60 PSI

1.5 to 2.0 GPM

2.0 to 3.0 GPM

0.5 to 1.5 GPM

1.0 to 2.2 GPM

1.5 to 3.0 GPM

Table 1

MS180C2T_U

MS210C2T_U

MS240C2T_U

MS270C2T_U

Shower (1.5 gpm) ― Sink Faucet (1.0 gpm) - All data above are based on water leaving temperature 105º F (40º C). 1.5 gpm showerhead flow rate;

1.0 gpm sink faucet flow rate, and adequate water pressure @ 60 psi. Actual performance may be altered by variations from these parameters.

For voltages less than 240 V the heating capacities will vary and it would be necessary to consider a higher capacity model.

4.3 gpm 3.9 gpm 3.4 gpm 3.3 gpm 2.9 gpm 2.8 gpm 2.6 gpm 2.3 gpm 2.0 gpm

5.4 gpm 4.8 gpm 4.1 gpm 3.8 gpm 3.5 gpm 3.0 gpm 2.8gpm 2.5 gpm 2.4 gpm

6.0 gpm 5.2 gpm 4.5 gpm 3.8 gpm 3.7 gpm 3.2 gpm 3.0 gpm 2.7 gpm 2.5 gpm

6.8 gpm 5.7 gpm 5.1 gpm 4.4 gpm 3.9 gpm 3.6 gpm 3.3 gpm 3.0 gpm 2.7 gpm

9

Page 11

Temperature Rise

o

F

Table 2

Model

Power

(kw)

Water

Flow(GPM)

MS120C2T MS150C2T MS180C2T MS210C2T MS240C2T MS270C2T

12 15 18 21 24

0,5 164 205 246 287 328 369

1,0 82 102 123 143 164 184

1,5 55 68 82 96 109 123

2,0 41 51 61 72 82 92

2,5 33 41 49 57 66 74

3,0 27 34 41 48 55 61

3,5 23 29 35 41 47 53

4,0 20 26 31 36 41 46

4,5 18 23 27 32 36 41

5,0 16 20 25 29 33 37

5,5 15 19 22 26 30 34

6,0 14 17 20 24 27 31

6,5 13 16 19 22 25 28

7,0 12 15 18 20 23 26

27

Temperature Rise

Temp Rise

120

110

100

90

80

70

60

50

40

30

20

10

0

Based upon DOE formula for calculating flow at rise

o

F

1 2 3 4 5 6

0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0 4,5 5,0 5,5 6,0 6,5 7,0

o

F @ 240V vs. Flow Rate (GPM)

Flow Rate (gpm) =

Temp rise (ºF)

10

1

MS120C2T

2

MS150C2T

3

MS180C2T

4

MS210C2T

5

MS240C2T

6

MS270C2T

Flow Rate

GPM

kW rating x 6.83

Diagram 1

Page 12

7. ELECTRICAL INSTALLATION

Please follow all electrical instructions carefully. This appliance must be installed by a licensed and

qualified electrician in accordance with all applicable national, state, provincial, and local electrical codes.

All wiring (wire gages), circuit breakers (protector), must comply with the US National Electrical Code

(NEC), in the USA, or the Canadian Electrical Code (CEC). Failure to do so could result in property

damage and/or personal injury and void your warranty.

The Canadian electrical code generally requires all wires and corresponding circuit breakers used to install

tankless water heaters shall be sized to a minimum of 125% of the maximum current rating of the water

heater. (See model specifications and details below).

Before installing this appliance make sure the house has sufficient electrical power available to handle the

maximum amperage load of the applicable model of your heater.

Required Breaker Size to be installed in the main electrical panel

Table 3

Model No. MS120 MS150 MS 180 MS210 MS240 MS270

Breakers for

Main

Elecrical

Panel

Without the

Sub-panel

Amperage requirementes are based on 240 v

Check your local electrical code requirements for different voltage applications

Qty. 1

Double

Pole

60 A

Qty. 2

Double

Pole

50 A

Qty. 2

Double

Pole

50 A

Qty. 3

Double

Pole

40 A

Qty. 3

Double

Pole

40 A

Qty. 3

Double

Pole

50 A

A. Make sure all power sources to the unit are disconnected before doing any connection to the terminal box

and working with it. Follow the wiring diagrams based on the unit you have purchased. All mounting and

plumbing installation must be completed before proceeding with the electrical installation.

B-1. MS120C2T_U must be connected to a single double pole breaker. Read all name plates carefully and wire as

per instructions, and table 1.

11

Page 13

MODEL MS120C2T_U

Wiring Diagram

L1

L2

THERMAL CUT-OUT 194º F

E

CONTROL

SYSTEM

R1

T1

R2

T2

REMARK: J:RELAY R:HEATING SYSTEM T:TRIAC

10.2 in

11.22 in

DOWN

Fig 11

UP

Display screen

ON/OFF

Heating chamber

OUTLET TEMP.SENSOR

Bottom case

DISPLAY

SCREEN

INLET TEMP.SENSOR

FLOWMETER

Fig 10

Temp. sensor

WIRE CONNECTIONS TO BREAKERS

E / G L1 L2

Double Pole Breaker

60 A MS120

12

E L1 L2

Flowmeter

Control board

Display screen

Terminal blocks

Page 14

MS150C2T_U

MS180C2T_U

Wiring Diagram

L1

L2

L1'

L2'

E

THERMAL CUT-OUT 194º F

CONTROL

SYSTEM

R1

T1

R2

T2

OUTLET TEMP.SENSOR

DISPLAY

SCREEN

REMARK: J:RELAY R:HEATING SYSTEM T:TRIAC

B-2. MS150C2T_U & MS180C2T_U must be connected to two double pole breaker.

Read all name plates carefully and wire as per instructions, and tables 2 and 3.

11 in

MS150C2T_U MS180C2T_U

Heating chamber

16.14 in

Display screen

UP

ON/OFF

DOWN

INLET TEMP.SENSOR

FLOWMETER

Fig 12

Bottom case

Control board

Display screen

Fig 13

WIRE CONNECTIONS TO BREAKERS

E / G L1 L2 L1 L2

Double Pole Breaker

40 A MS150

50 A MS180

Double Pole Breaker

40 A MS150

50 A MS180

Temp.sensor

13

E L1 L2 L1 L2

Flowmeter

Terminal blocks

Page 15

MS210C2T_U

MS240C2T_U

THERMAL CUT-OUT 194º F

MS270C2T_U

Wiring Diagram

L1

L2

L1'

L2'

L1"

CONTROL

SYSTEM

T1

T2

T3

L2"

E

OUTLET TEMP.SENSOR

REMARK: J:RELAY R:HEATING SYSTEM T:TRIAC

B-3. MS210C2T_U, MS240C2T_U, & MS270C2T_U must be connected to two double pole breaker.

Read all name plates carefully and wire as per instructions, and tables 2 and 3.

DISPLAY

SCREEN

INLET TEMP.SENSOR

FLOWMETER

MS210C2T_U MS240C2T_U MS270C2T_U

11 in

Bottom case

R1

R2

R3

Fig 14

16.14 in

Display screen

UP

ON/OFF

DOWN

Fig 15

Temp.sensor

WIRE CONNECTIONS TO BREAKERS

E / G L1 L2 L1 L2 L1 L2

Double Pole Breaker

40 A MS210

40 A MS240

50 A MS270

Double Pole Breaker

40 A MS210

40 A MS240

50 A MS270

Heating chamber

Double Pole Breaker

40 A MS210

40 A MS240

50 A MS270

E L1 L2 L1 L2 L1 L2

Flowmeter

Control board

Display screen

Terminal blocks

14

Page 16

C. Using the required wire gage as per table 3 that meets all applicable electrical codes for the size of the

required breakers, run a ground wire and two pair of wires per breaker from the main breaker panel to the

tankless water heater unit. Refer to the corresponding wire connections to breakers chart above.

D. The ground wire must be connected to "ground" at the circuit breaker panel.

E. Double check the electrical connections to make sure they are correct and all the wire connections are tight

and secure, and the unit has been connected to a ground in accordance with applicable codes.

Injected Mold Model

Phase

Voltage V

Wattage kW

Max. Amp. Load @ 240V A

No. of circuits n

Min. required double pole

circuit breaker

Min. wire size AWG cooper

Min. water flow to activate

Working pressure PSI/bar

Weight

Model

A

kg

Product Dimensions mm

Water connections NPT

Stainless Steel Model

Model MS150C2TMU MS180C2TMU MS210C2TMU MS240C2TMU MS270C2TMU

Phase

Voltage V

Wattage kW

Max. amp. load A

No. of circuits

Min. required circuit breaker

Min. wire size AWG cooper

Min. water flow to activate

Working pressure PSI/bar

Weight lb

Product Dimensions in

Water connections NPT

GPM / L/min.

@ 240V

GPM / L/min.

MS120C2T_U MS150C2T_U MS180C2T_U MS210C2T_U MS240C2T_U MS270C2T_U

lb

385x260x93

in.

15.1x10.2x3.7

A

16.1 x 11 x 3.5

1

240

12

50

1

60

8

0.84 / 3.2

3.6

7.9

1/2” 3/4” 3/4” 3/4” 3/4” 3/4”

1 1 1 1 1

240 V

15kw

63

2 2 3 3 3

2 X 40

2 X 8

0.84/ 3.2

17.6

3/4”

1

240

15

63

2

2 x 40

2 x 8

0.84 / 3.2

385x260x93

15.1x10.2x3.7

5.3

11.7

385x260x93

15.1x10.2x3.7

240V

18kw

75

2 X 50

2 X 8

0.84/ 3.2

17.6 17.6 17.6 17.6

16.1 x 11 x 3.5 16.1 x 11 x 3.5 16.1 x 11 x 3.5 16.1 x 11 x 3.5

3/4”

1

240

18

75

2

Max.150/10

5.3

11.7

3 x 40

0.84 / 3.2

385x260x93

15.1x10.2x3.7

2 x 50

2 x 8

0.84 / 3.2

240 V 240 V 240 V

21kw

88

3X 40

3 X 8

0.84/ 3.2

Max.150/10

3/4”

1

240

21

88

3

3 x 8

5.5

12.1

24kw

3X 40

3 X 8

0.84/ 3.2

0.84 / 3.2

385x260x93

15.1x10.2x3.7

100

3/4”

1

240

24

100

3

3 x 40

3 x 8

5.5

12.1

3X 50

0.84/ 3.2

27kw

113

3 X 8

3/4”

Table 4

1

240

27

113

3

3 x 50

3 x 8

0.84 / 3.2

5.5

12.1

385x260x93

15.1x10.2x3.7

Table 5

Check your local electrical code requirements for different voltage application

15

Page 17

8. STARTING YOUR ELECTRIC TANKLESS WATER HEATER

Make sure to flush and clean the pipes prior to connect the pipes to the tankless water heater. Refer to section 6,

Plumbing and Mechanical Installation. Your heater must be cleaned, flushed, and purged. Any debris and foreign

material circulating through the system could cause harm to your tankless water heater and may lead to malfunction of

your appliance.

ALL AIR MUST BE REMOVED FROM THE SYSTEM AND YOUR ELECTRIC WATER HEATER BEFORE THE

ELECTRIC POWER IS ON.

When maintenance, repair, installation or disassembling is to be performed you must disconnect all power to the unit

directly at the breaker box. FAILURE TO DO SO CAN CAUSE SERIOUS BODILY INJURY OR DEATH.

9. OPERATION INSTRUCTIONS

1. Open water faucets for a few minutes until water flow is continuous and all air is purged from water pipes.

The unit must be operated after the breakers are turned on.

2. Check for and correct any leaking connections.

3. Turn on the circuit breaker to bring electrical power to the unit.

4. Press ON/OFF bottom to start up the unit.

If there is power to the unit, but no digital display, turn on the circuit breaker. Double check the cable to the

LCD panel on the front cover is connected tightly inside the unit, then turn the breaker back on.

After the unit is supplied with power, a beep sound can be heard and LED lights for 2 seconds, no other

display, the appliance keeps standby.

5. Press “ “ to turn ON/OFF the appliance. When the unit is ON, LED displays actual temperature

of the outlet water. After 5 seconds, the screen switches to the screen saver to conserve power.

The display screen light will be off. If you touch the screen it will light up again.

6. The outlet water temperature can be adjusted by changing the temperature settings on the control panel.

Press and to adjust the outlet temperature. Temperature setting range is 30--52°C/ 86-127℉.

WARNING: If the unit has been paused, you may initially get a short burst of very hot water from the unit.

Allow few seconds to run the water to cool down to the set point. Test the water before taking a shower.

If the unit will not be used in winter, drain out water completely so that the heater will not freeze.

Periodically clean inlet strainer and the shower head(s) to keep a free water flow.

7. Press to convert the temperature display between Fahrenheit degree and degree Celsius.

8. Your unit features an automatic memory function to avoid repetitive operation, when you turn on

the appliance, the default set temperature will be the same as previous setting.

Typical Installation

Fig 16

Wires from main service panel (3 circuit models typical)

BALL VALVE

WATER OUTLET

Note: *Check your local electrical code

requirements for different voltage applications

PRESSURE

RELIEF

VALVE

BREAKERS

FILTER

BALL VALVE

WATER INLET

16

Page 18

Trouble-shooting

Problems

1. Inlet and outlet fittings leaking A. Fittings not tight

B. Rubber washer worn-out

2. LED no signal

3. Functional keys not working

4. Water too hot

5. Water too cold

6. Outlet gets water smaller and

smaller.

7. LED displays E1

8. LED displays E3

9. Display overload

10. LED Displays E4

11. Pressure relief valve

releases water

7 and 8 should only be performed by a qualified electrician. The person who initially installed the unit is the best one to contact for help.

A. Power not connected.

B. LCD damaged.

A. No water out from shower.

B. Water pressure too low.

C. Key or PCB damaged.

A. Too high temperature set.

B. Water flow too small.

A. Low temperature set.

B. Water flow too much.

Inlet strainer or shower clogged.

Outlet temp. is over 67℃/153℉

Temperature sensor failure

Inlet water flow is too high Reduce the inlet water flow

Dry heating

A. Outlet blocked

B. Inlet pressure over 0.7 Mpa - 102 psi

Possible Causes

A. Tighten fittings.

B. Change rubber washer.

A. Connect power to the unit.

B. Change LCD.

A. Open valve to get water.

B. Open valve to get pressure.

C. Change key or PCB.

A. Set a lower temperature.

B. Open valve bigger.

A. Set a higher temperature.

B. Reduce water flow.

Clean strainer and shower.

A Reduce the temperature

B Turn up the water flow

Please contact with your local dealer

Shut off. Clean all outlets of any debris,

dirt, any particle or scale inside the pipe.

A. Clean shower set

B. Reduce water pressure

Corrective Actions

Normal Maintenance

Note: Do not attempt to repair this water heater yourself. Call a service person for assistance. Always turn off of

these operations the power supply needs to be shut off.

It is not required any regular maintenance. However, to ensure consistent water flow, it is recommended following

maintenance.

1. Periodically remove scale and dirt that may build up at the aerator of the faucet or in the shower head.

2. There is a built in filter screen at inlet connection which should be cleaned from time to time. Please turn off the

water flow before doing this.

17

Page 19

305-593-8358

Customer Service

We are dedicated and proud of the top quality of the customer service provided by our support technicians.

Please feel free to contact us at 305-593-8358 for any questions you might have, and warranty service, or if

your certified installer needs assistance when installing a unit.

Your valuable suggestions and comments are always welcome, it will help us to continuously improve our

service as part of our commitment to serve you better.

customerservice@klimaire.com

www.klimaire.com

18

Page 20

Klimaire Products Inc.

2190 NW 89 Place Doral, FL 33172 - USA

Phone: 305 593 8358 Fax: 305 499 4378

Certified by

Loading...

Loading...