Page 1

Tankless Electric Water Heater

MS-C2PSU Series

Installation and Instructions Manual

Keep this Instructions Manual in a safe place once your unit is installed.

You may need to refer to it for general instructions or future maintenance.

Page 2

Thank you for purchasing a quality Maxwell tank-less electric water heater.

To enjoy your new shower at its best, please take time to read this manual thoroughly

and having done so keep it handy for future reference.

CONTENTS

Important Safety Instructions -------------------------------------------------------------------------------- page 2

Electrical Diagram------------------------------------------------------------------------------------------------ page 3

Technical Data and Product Structure----------------------------------------------------------------------page 4

Installation Guideline---------------------------------------------------------------------------------------------page 6

Operation Instructions ------------------------------------------------------------------------------------------page 10

Trouble-shooting---------------------------------------------------------------------------------------------------page 11

Normal Maintenance----------------------------------------------------------------------------------------------page 11

Accessories--------------------------------------------------------------------------------------------------------page 12

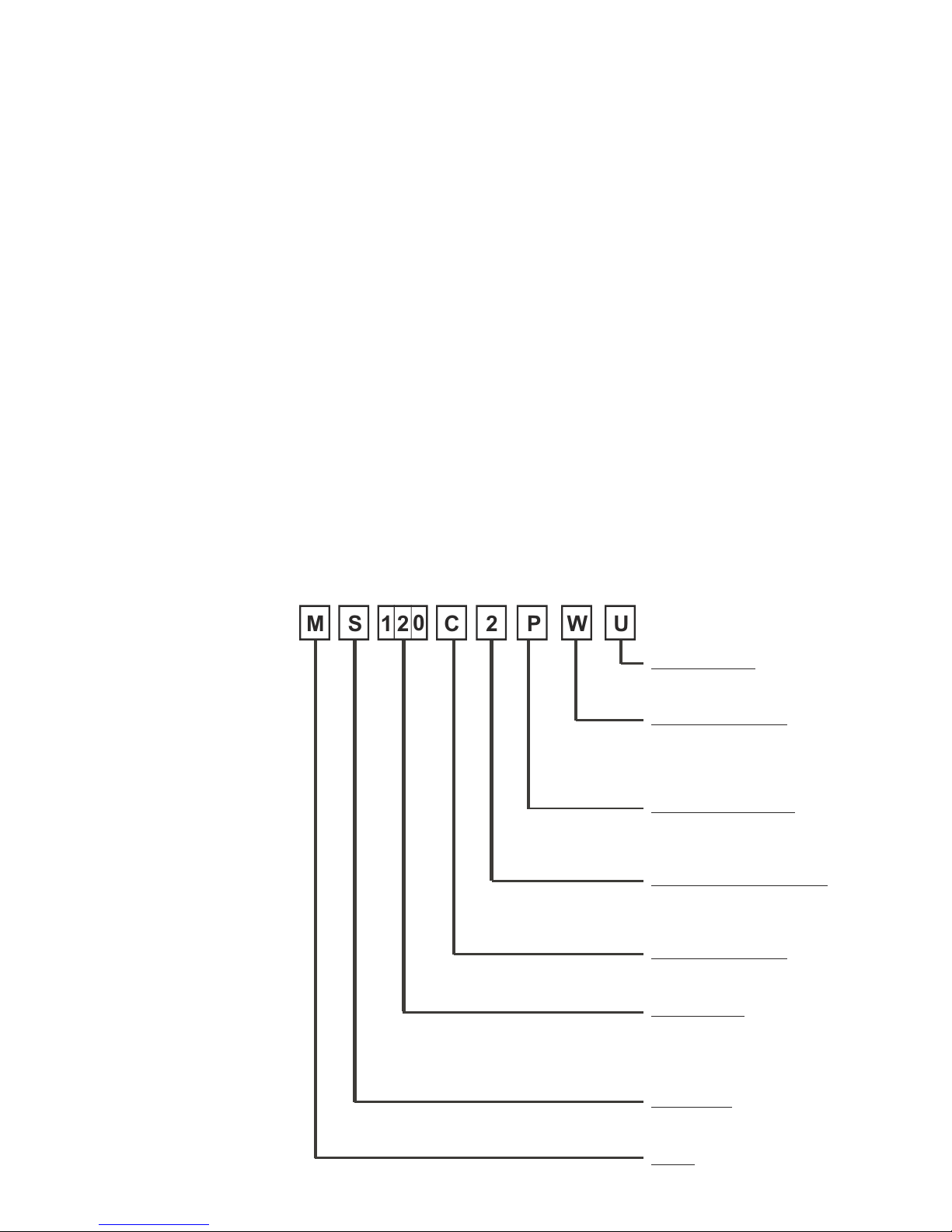

MODEL NUMBER

M

S

1 2

0

C

2

W P

U

NOMENCLATURE

Test Calification

U : UL/ETL

C : CSA

Casing Type & Color

B: Injection Molding – Black

D: Injection Molding – Silver w/Dots

S: Injection Molding – Silver

W:Injection Molding – White

M:Metal Casing – Silver

Minor Design Change

P : Plate Heater Exchanger

T : Tubular Stainless

Steel Heat Exchanger

This Klimaire nomenclature supercedes

all previously issued (06/07/2011)

Power Supply Code (V/ph)

1 – 120 / 1

2 – 240 / 1

5 – 240 / 3

Temperature Control

C : Automatic Constant

P : Power Level

Capacity (kW)

035 – 3.5

045 – 4.5

055 – 5.5

075 – 7.5

080 – 8.0

Heater Type

S : Tankless

H : Holding Tank

Brand:

M: Maxwell

100 – 10.0

120 – 12.0

150 – 15.0

180 – 18.0

210 – 21.0

11

Page 3

Installation of this product is restricted to indoor locations by licensed plumbing or electrical

contractors only. By installing this product you acknowledge the terms of manufacturer's warranty and

your authorized dealers return policy. Water heaters that have been installed cannot be returned.

If you plan to install your water heater on a second floor/above ground or in a heated attic space you must

follow all code requirements for installation in your area. It is highly recommended to install a drip pan

connected to a safe drain as per code requirements, below the water heater to avoid property damage in

case of eventual leaks, and / or install an active water leak detector and shut off valve to turn off your

water supply in the event that a leak is ever detected.

■ Important Safety Instructions

1. The installation must be in compliance with the National Electrical Code, your local electrical and

plumbing codes.

2. This appliance must be GROUNDED.

3. All wiring and installation jobs must be supervised by a qualified electrician.

4. CAUTION: This product has more than one power-supply connection point. Disconnect all power supplies

before servicing.

5. This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do

not play with the appliance.

6. This appliance MUST be permanently connected to a fixed circuit breaker and it must be installed vertically. DO

NOT install this appliance near flammable substances or near a strong magnetic field place.

7. It is forbidden to switch on this appliance if you think it may be frozen, as this could result in serious damage to

the unit. Wait until you are sure that it has completely thawed out before switching it on.

8. Please check the hot water temperature with your hand to make sure it is at a comfortable temperature before

taking a shower to avoid getting scalded.

9. Before connecting pipes to the water heater hoses, it is extremely important to FLUSH the pipes to wash away all

plumbing paste or residue in the pipes.

10. The heating chamber is treated with composite nano-insulation material; it is natural there might be a bit of smell

or green blue smoke when the unit is used for the first time.

11. If there is damage to the wire, you must contact a qua lified electrician to replace it with an approved wire.

12.

CAUTION: FOR HOUSEHOLD AND INDOOR USE ONLY

13. Combustible materials should be kept at least 2 ft away from your water heater and output water pipe.

14. AFTER TIGHTENING BOTH FITTINGS AT THE WATER HEATER OPEN SEVERAL HOT WATER FAUCETS

AND ALLOW WATER TO RUN THROUGH THE WATER HEATER FOR AT LEAST 3 MINUTES. THIS

PROCESS PURGES ALL AIR FROM THE WATER LINES AND HEATER.

HIS PROCESS MUST BE PERFORMED PRIOR TO TURNING ON THE POWER OF THE WATER HEATER.

FAILURE TO FOLLOW THIS STEP CAN CAUSE PERMANENT DAMAGE TO THE HEATING ELEMENT.

2

Page 4

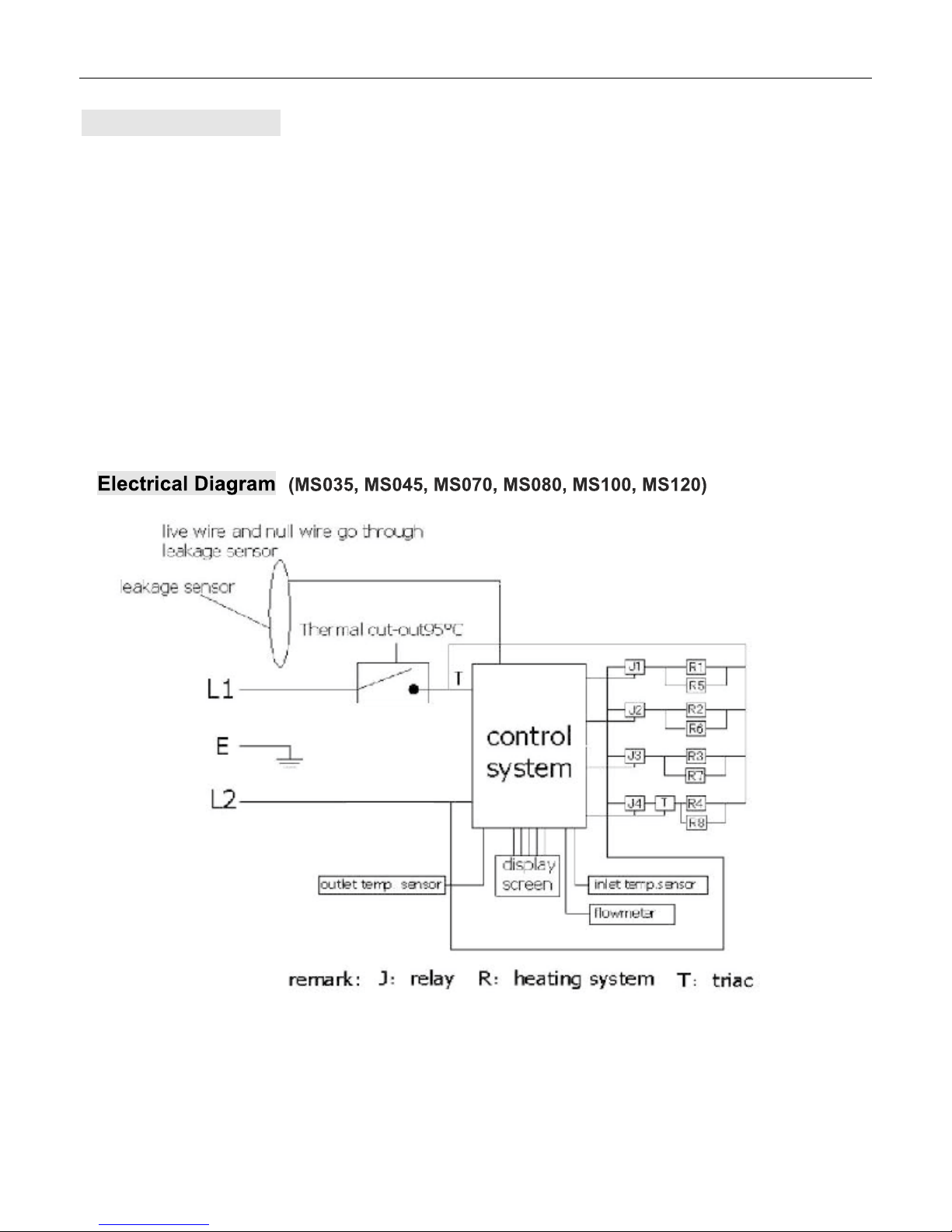

■ Product Features

The Maxwell tank-less electric water heaters are made with multi-safety devices patented technology

Additionally, the unit has the following features.

1. Tank-less, instantaneous heating on demand. No pr e-heating. No stand-by heating loss energy-saving.

2. Micro-computer control, adopting patented heating technology. Water is completely separated from

electricity by multi-layers of composite nano insulation material.

3. Over-heating thermal cut-off. When the outlet water temperature reaches over 140℉/60ºC, the electricity

will be cut off automatically to avoid getting scalded and the screen beeps and displays E1.

4. Creepage protection. If the unit detects electricity leakage, the electricity will be cut off within mil seconds

by the creepage protector and the screen displays E2.

5. Malfunction sensor- when the temperature sensor malfunctions, the heater stops working and displays E3

6. Conversion between Fahrenheit degrees and Celsius degrees.

7. This product does not require venting.

AC 240V/60Hz

3

Page 5

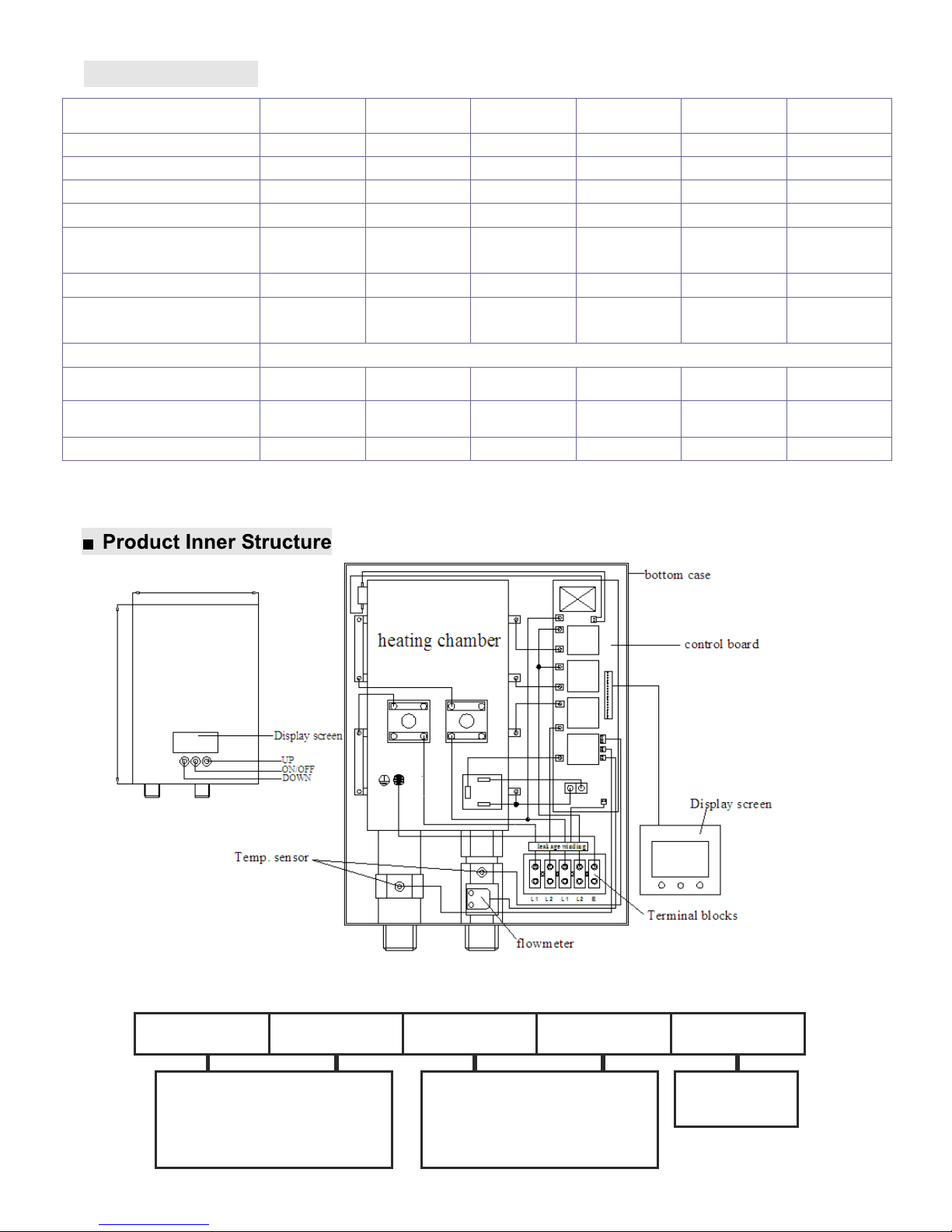

■ Technical Data

Model MS80C2P_U MS100C2P_U MS120C2P_U MS150C2P_U MS180C2P_U MS210C2P_U

Phase

Voltage/Freq V

Wattage kW

Max. amp.load A

Min. required circuit breaker*

A

Min. wire size AWG cooper

Min. water flow to activate

GPM / L/min.

Working pressure PSI/bar

Weight

Product Dimensions

Water connections NPT

Note: *suitable recognized strain relief means shall be provided when the product installed.

kg

mm

lb

in

1 1 1 1 1 1

240 V/60Hz 240 V/60Hz 240 V/60Hz 240 V/60Hz 240 V/60Hz 240 V/60Hz

8kw 10kw 12kw 15kw 18kw 21kw

34 42 50 63 75 88

45 60 60 2 X 40 2 X 50 2 X 60

8 6 6 2 X 8 2 X 8 2 X 8

0.53 / 2 0.53 / 2 0.53 / 2 0.85 / 3.2 0.85 / 3.2 0.85 / 3.2

Max.150/10

7.7 7.7 7.7 12.1 12.1 12.1

3.5 3.5 3.5 5.5 5.5 5.5

385x260x93

15.2"x10.2"x3.7" 15.2"x10.2"x3.7" 15.2"x10.2"x3.7" 15.2"x10.2"x3.7" 15.2"x10.2"x3.7" 15.2"x10.2"x3.7"

385x260x93 385x260x93 385x260x93 385x260x93 385x260x93

1/2” 3/4” 3/4” 3/4” 1/2” 1/2”

(MS150, MS180, MS210)

11.02"

16.14"

WIRE CONNECTIONS TO BREAKERS (MS150, MS180, MS210)

L1 L2 L1 L2

DOUBLE POLE BREAKER

40 Amp MS150

50 Amp MS180

60 Amp MS210

DOUBLE POLE BREAKER

40 Amp MS150

50 Amp MS180

60 Amp MS210

E / G

EARTH/

GROUND

4

Page 6

PATENTED HEATING TECHNOLOGY

PATENT NO.: ZL2008 2 0081568.0

1. High temperature insulating ceramic layer.

2. Macromolecule heatconducting insulating layer.

3. High temperature heating plate.

4. Macromolecule heatconducting insulating layer.

5. High temperature insulating ceramic layer.

Hot Water

Cold Water

Sheathed Heating Plate

5

Page 7

■ Installation Guideline

The installation must be in compliance with the National Electrical Code, your local electrical and plumbing

codes.

1. Make sure the appliance is intact, and the fittings are complete.

2. Please make sure the main power supply, water pressure, grounding condition, ammeter and wires meet the

3. The appliance must be connected to properly ground dedicated branch circuits of proper voltage rating. Ground

4. This appliance MUST be permanently connected to the fixed circuit breaker. If you don’t use the heater, please

5. DO NOT install this appliance near to tinder or strong magnetic field places. The unit must only be mounted in

standard of installation requirements.

must be brought to the “ground” at the circuit breaker panel.

switch off the circuit breaker.

VERTICAL position near by the water fittings. Please electrify try the machine after getting through waterway.

■ Installation Method

Fixed installation on the wall

●

MS-PSU Series

Locate an appropriate place on a section of wall as above mentioned.

Fig 1 Front and back of the appliance

Fig 2 Remove screw which fixed the bracket on back of the appliance.

6

Page 8

Fig 3 Remove the bracket from the appliance

Fig 4 Hold the back bracket hanger in position against the wall and mark the three mounting holes. Drill

three holes of 6.00mm diameter, the distance between every two holes is 100mm. (Put plastic anchor in the hole, fix

the bracket on the wall. and secure the hanger using the screws supplied or an appropriate alternative method)

3.94"3.94"

.

3.94"3.94"

7

Page 9

Fig 5 Uninstall screws on appliance to remove the front cover. Please pull out carefully by hand the

screen row line plug before removing the front cover.

Fig 6 Fix the appliance to the bracket which was nailed to the wall, Make sure the unit fits onto the back

metal hanger correctly

8

Page 10

Fig 7 Connect the cable to the terminal blocks, please notice the guidance logo below the terminal

blocks. MS080C2PSU, MS100C2PSU, MS120C2PSU will be connected to one circuit breaker, MS150C2PSU,

MS180C2PSU, MS210C2PSU will be connected to two circuit breakers.

Fig 8 Fix the front cover on appliance, before that, please plug in the screen row line plug. Then nail the

screws to fix the cover.

Fig 9 Connect the water pipe to the water inlet and water outlet connections, please remember to

install the rubber seal ring.

10.24"

15.15"

9

Page 11

●

Water connections

1. All water pipe must comply with national and applicable state and local water pipe codes.

2. A pressure relief valve must be installed if the cold water supply pressure exceeds 150PSI (1Mpa)

3. The unit should be connected directly to the main water supply. Flush pipe with water to remove any debris or

loose particles

4. It is required to use 1/2”NPT water connections to fit the models MS080C2PSU, MS100C2PSU, MS120C2PSU;

use 3/4”NPT water connections to fit the models of MS150C2PSU, MS180C2PSU, MS210C2PSU, MS150C2PMU,

MS180C2PMU, MS210C2PMU.

5. Please remember to install the rubber seal o’ rings at the connections. When all water connections are completed,

check for leaks and take corrective action before proceeding.

● Electrical connection

1. All electrical work must comply with national and applicable state and local electrical codes.

2. All units must be connected to a properly grounded dedicated branch circuit of proper voltage rating.

3, MS080C2PSU, MS100C2PSU, MS120C2PSU can be connected to a single circuit, use a supply cable protected

by a double pole breaker. MS150C2PSU, MS180C2PSU, MS210C2PSU require two independent circuits. Use two

supply cables protected by two separate double pole breakers.

4. While connecting the cables to terminal the blocks, please make sure the metal wire ends and the terminal blocks

to touch completely. Then tighten the screws up to make sure the current can go through.

5. Before beginning any work on the electric installation, be sure that main panel breaker switch is OFF to avoid any

danger of electric shock, all mounting and plumbing must be completed before proceeding with electrical hook-up.

■ Operation Instructions

MS-PSU Series

1. Turn on the circuit breaker to bring electrical power to the unit.

2. Open water faucet for a few minutes until water flow is continuous and all air is purged from water pipes. The unit

must be operated after the breakers are turned on.

3. After the unit is powered, a beep sound can be heard and a LED lights for 2 seconds, no other display, the

appliance keeps standby.

4. Press “

outlet. When the appliance stops working, the screen switches to the screen saver after 5 seconds. The display

screen light will be off. If the screen is touched, it will be lighted again.

5. Press and to adjust the outlet temperature. Temperature setting range is 30—53 ºC / 82-127 ℉.

z If the unit has been paused, you may initially get a short burst of very hot water while you turn it on again. Please

run the water through for a few seconds to let the temperature settle down. Please check water temperature with

your hand before taking a shower.

z If the unit will not be used in winter, drain out water completely so that the heater will not be frozen.

z Please periodically clean inlet strainer and the shower to keep a free water flow.

” to turn ON/OFF the appliance. When the unit is ON, LED displays actual water temperature of the

6. Press

7. There is an automatic memory function to avoid repetitive operation, while you turn on the appliance, the default

set temperature will be the same as set last time.

then press to convert the temperature display between Fahrenheit degree and Celsius degree.

10

Page 12

■ Trouble-shooting

Problems Possible Causes Corrective Actions

1. Inlet and outlet fittings leaking A. Fittings not tight

B. Rubber washer worn-out

2. LED no signal A. Power not connected.

B. LCD damaged.

3. Functional keys not working A. No water out from shower.

B. Water pressure too low.

C. Key or PCB damaged.

4. Water too hot A. Temperature set too high

B. Water flow too small.

5. Water too cold A. Low temperature set.

B. Too much water flow.

6. Outlet gets less and less water. Inlet strainer or shower clogged. Clean strainer and shower.

7. LED displays E1 Outlet temp. is over 60℃/140℉ A, Reduce the temperature

8. LED displays E2 There is electricity leakage Please contact your local dealer

9. LED displays E3 Temperature sensor failure Please contact your local dealer

10. Display overload Inlet water flow is too big. Reduce the inlet water flow

A. Tighten fittings.

B. Change rubber washer.

A. Connect power to the unit.

B. Change LCD.

A. Open valve to get water.

B. Open valve to get pressure.

C. Change key or PCB.

A. Set a lower temperature.

B. Increase valve opening.

A. Set a higher temperature.

B. Reduce water flow.

B, Increase the water flow

7, 8 and 9 should only be performed by a qualified electrician. The person who initially installed the unit is

the best one to contact for help.

■ Normal Maintenance

Note: Do not attempt to repair this water heater yourself. Call a service person for assistance. Always turn

off the power supply before servicing your unit.

It is not required any regular maintenance. However, to ensure consistent water flow, the following

maintenance is recommended.

1. Periodically remove scale and dirt that may build up at the aerator of the faucet or in the shower head.

2. There is a built in filter screen at the inlet connection which should be cleaned from time to time. Please turn off the

water flow before doing this.

11

Page 13

■ ACCESSORIES

½” and 3/4" water

connection Ball valve

For heaters with 1/2” inlet

water connections for models ranging 3.3kW-,

12kW (including)

For heaters with 3/4”inlet

water connections for models 15 kW and over

24 inch (60cm) stainless steel,

with ½” and 3/4" water connection

Flexible hose

For heaters with 3/4”

water connections

for models 15 kW and over

For heaters with 1/2”

water connections

for models ranging

3.3kW-,12kW (including)

12

Page 14

■ TABLES

Required Wire Gauge & Breaker Size @ 230 Volt

* Maximum power (Amp.) based on 230 V. For 240 V

application see specification table on page 4. ……

** All above breakers are of the double pole type.

**

Warning: It is recommended to use restrictors for showers and faucets to prevent excessive water consumption.

13

Page 15

Klimaire Products Inc.

2190 NW 89 Place Doral, FL 33172 - USA

Phone: 305 5938358 Fax: 305 5938 212

Loading...

Loading...