Page 1

VERTICAL WINDLASSES

6000 SERIES

Page 2

Copyright: Maxwell Marine Ltd

All rights reserved

Printed in New Zealand

P19137

12/12/07

Maxwell Marine International Ltd reserves the right

to make engineering changes to all products without

notice. Illustrations and specications not binding as to

detail.

Page 3

Contents

1.0 INTRODUCTION 4

1.1 PRE-INSTALLATION NOTES 4

1.2 PRODUCT VARIATIONS 5

1.3 SPECIFICATIONS 6

2.0 INSTALLATION 8

2.1 SELECTION OF POSITION FOR THE WINDLASS 8

2.2 PREPARATION OF MOUNTING AREA 9

2.3 PREPARATION OF THE WINDLASS 10

2.4 INSTALLING THE WINDLASS 11

2.5 SELECTION OF MOTOR STARTER 13

2.6 POWER CONNECTIONS TO AC MOTOR 14

2.7 POWER CONNECTIONS TO DC MOTOR 15

2.8 POWER CONNECTIONS TO HYDRAULIC MOTOR 15

2.9 INSTALLATION OF CONTROLS 16

2.10 NOTE TO BOAT BUILDER 17

3.0 USING THE WINDLASS 18

3.1 PERSONAL SAFETY WARNINGS 18

3.2 LOWERING THE ANCHOR UNDER POWER 19

3.3 RETRIEVING THE ANCHOR UNDER POWER 19

3.4 LOWERING THE ANCHOR UNDER MANUAL CONTROL 19

3.5 OPERATING THE WARPING DRUM INDEPENDENTLY 20

4.0 MAINTENANCE 21

4.1 WINDLASS MAINTENANCE 21

4.2 BAND BRAKE MAINTENANCE 22

4.3 RECOMMENDED LUBRICANTS 22

4.4 SPARE PARTS 23

4.5 TOOLS FOR MAINTENANCE 23

5.0 TROUBLESHOOTING 24

APPENDIX A - Dimensional drawings 26

APPENDIX B - Spare parts 29

APPENDIX C - Installation schematics 38

APPENDIX D - Network of Agents and Distributors 42

APPENDIX E - Warranty Form 47

Page 4

1.0 INTRODUCTION

1.1 PRE-INSTALLATION NOTES

• Read this manual thoroughly before installation

and using the windlass. Failure to adhere to

the correct procedures, recommendations and

guidelines described in this Owner’s Manual

may invalidate the warranty.

• Be mindful that the correct selection of

windlass for each application, together with

correct installation, normal care in use and

maintenance, are essential for long life and

reliable performance.

• Inspect your windlass carefully when unpacked.

Any damage or lack of components should be

reported immediately to your Maxwell distributor.

• The windlass is supplied with chainwheel, as

specied on purchase order. Make sure it is the

appropriate one for the chain being used on

board. Correct t of the chain to chainwheel is

essential for reliable and safe operation of the

windlass. This can be guaranteed only when

calibrated chain to a recognised international

standard is used and the chain is correctly

identied to Maxwell, or if a chain sample

is provided to Maxwell to develop a custom

chainwheel.

• The windlass is designed for use in conjunction

with chain stopper and tensioner of the

appropriate size. Their use is an important safety

feature.

• For side pocket anchors, a chain roller should

be installed above the hawse pipe to ensure

smooth and quiet travel of the chain from deck

to hawse pipe. The roller requires a central

groove to align chain and at faces (for longer

chains) to support and avoid bending the chain

links.

• The connection of the power lines and control

circuitry to the windlass must be done by

skilled technicians, to ensure reliable and safe

operation of the windlass.

4

Page 5

5

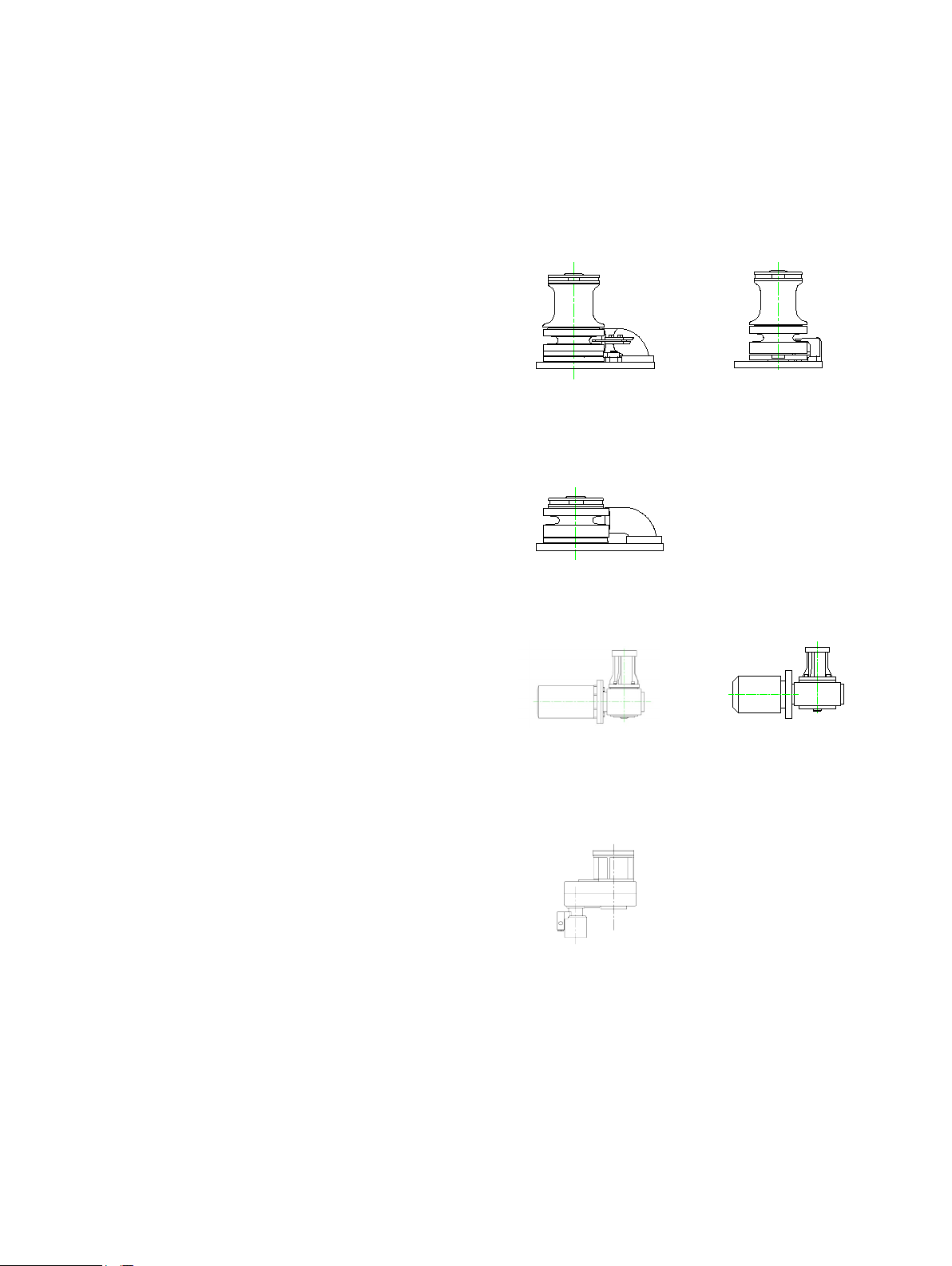

1.2 PRODUCT VARIATIONS

There are two options of above-deck arangements or

“topworks”, combined with four types of drives.

The types of topworks are:

VWC - vertical windlass with chainpipe

VWCLP - vertical windlass with chainpipe, low prole

Each of the above topworks is available as clockwise

or anticlockwise conguration (see description of

Denition of rotation in Section 2.1).

Beside friction clutch, which can be used for controlling

chain speed while free falling anchor, the windlasses

can also be equipped with an external band brake.

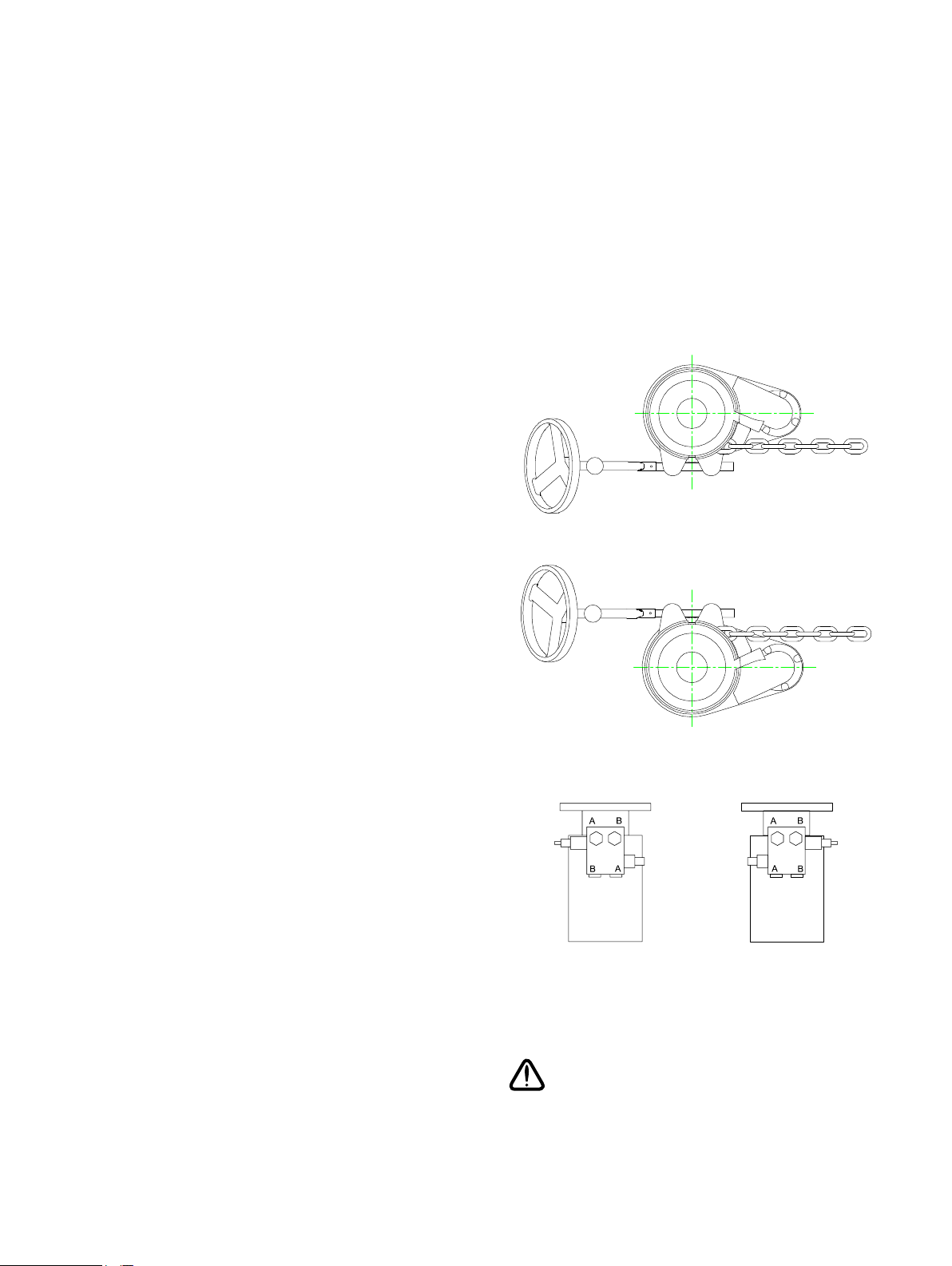

Picture 1.1

VWC topworks

Picture 1.2

VW topworks

The types of drives are:

Electric DC drive (24V)

Electric AC drive (horizontal motor)

Hydraulic drive

The above deck components of the windlass can come

in several different materials / nishes:

Chrome over polished bronze

Bare polished bronze

Stainless steel

Titanium nitride coated bronze or stainless steel

Picture 1.3

VWCLP topworks

Picture 1.4

Electric DC drive

Picture 1.6

Hydraulic drive

Picture 1.5

Electric AC drive

Page 6

6

1.3 SPECIFICATIONS

General

Maximum stud link chain size 16mm

Maximum short link chain size 19mm (3/4”)

Maximum pull capacity at chainwheel 2730kg (6006lb)

Electric DC Drive

Chain speed at 1000kg load 10m/min (33ft/min)

Continuous pull capacity at chainwheel 680kg (1496lb)

Current at 1000kg load 215A

Motor power 3.5kW (48HP)

Weight of windlass 195kg (429lb)

Electric AC Drive

Vertical motor Horizontal motor

Chain speed 15m/min (49ft/min) 13m/min (43ft/min)

Continuous pull capacity at chainwheel 1490kg (3278lb) 1286kg (2829lb)

Current at continuous pull rating (@ 400V) 8.7A 8.2A

Current at start-up (@ 400V DOL) 47A 55A

Motor power 4kW (5.5HP) 4kW (5.5HP)

Weight of windlass 285kg (627lb) 247kg (543lb)

Hydraulic Drive

Chain speed (at Recommended ow) 14m/min (47ft/min)

Recommended hydraulic oil ow 41l/min (11USgal/min)

Maximum hydraulic oil ow 76l/min (20USgal/min)

Continuous pull capacity at chainwheel 2730kg (6006lb)

Maximum hydraulic oil pressure 138bar (2000psi)

Motor port size (pressure and return) 7/8” x 14tpi UNF - SAE 10

Minimum size of oil supply/return lines 16mm (5/8”)

Weight of windlass 153kg (337lb)

*See Appendix C for other options of ow and pressure.

Rated capacity and chain speed is based

on the chainwheel for 16mm chain. The

performance may vary slightly when other

chainwheels are used.

Page 7

Hydraulic oil characteristics

Viscosity: ISO 32 - 68 (at 20ºC)

Suitable oils:

Shell Rimula X 15W-40

Shell Myrina M 15W-40

Penzoil SAE 10W-40

Texaco 2109 SAE 15W

Texaco 1814 SAE 10W-40

BP HLPHM 32-68

BP Autrans T0410

Castrol Hyspin AWS 32-68

Minimum 0.125% Zinc anti-wear additive.

7

Chainwheels

The chainwheel numbers consist of two parts: main

part number and sufx, for example 2514-001.

The main part number refers to the type of chainwheel

and the sufx refers to size and type of chain.

Types of chainwheels

2513 for windlasses without band brake

2514 for windlasses with band brake

Sufxes

Sufx Chain to t

001 16mm PWB, Campbel, EN818-3

002 14mm EN818-3; 13mm GR4

1/2” G40 (ISO) & G63 ACCO

003 16mm DIN 766; 5/8” G4 ACCO (ISO)

004 13mm PWB, Weissenfels

008 13mm DIN 766

010 14mm stud link

011 16mm stud link

012 12.5mm stud link

013 12mm EN818-3

There are other chainwheel models less commonly

used. Contact your Maxwell distributor for details.

Page 8

8

2.0 INSTALLATION

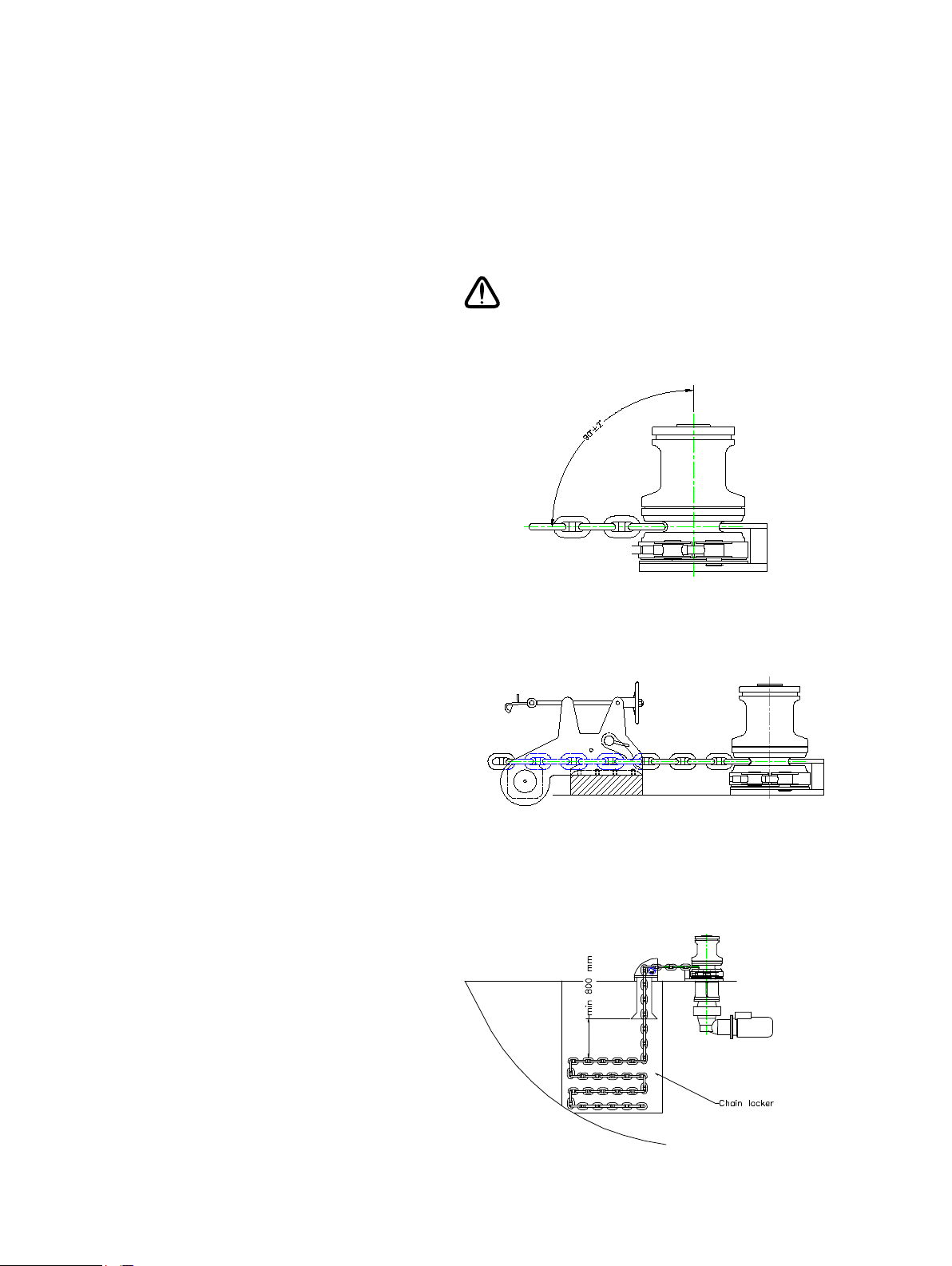

2.1 SELECTION OF POSITION FOR THE WINDLASS

Windlasses of this size will often be installed in

pairs, giving an emergency backup in the event of

mechanical or electrical failure. In this case one of the

windlasses will normally be retrieving anchor running

clockwise and the other anticlockwise.

Position of the windlass should be selected together

Denition of rotation

The windlass is called a “clockwise windlass” if

it rotates clockwise, viewed from above, when

retrieving the ground tackle.

with positions of hawse pipe and spurling pipe.

The deckplate should be installed pointing with its

narrower end in the direction of the incoming chain.

That allows the chain to have maximum engagement

with the chainwheel.

Allow the chain a straight run from the bow roller to

the chainwheel with no more than a 2° deviation from

horizontal (Picture 2.1).

The bow roller should have a vertical groove to suit

the prole of the chain. Its centre line should be

tangentional to the chainwheel (Picture 2.2). This

will align the chain so that it enters the chainwheel

without twisting.

When positioning the windlass, make sure that there

Direction of chain entering the chainwheel

is room to swing the clutch lever, so that it will clear

the pulpit and life lines or bulwark.

The tting of a chain stopper is essential to take the

load off the windlass while the vessel is at anchor. It

must be correctly aligned with the direction of chain

and installed at appropriate height to avoid the chain

rubbing over chain stopper body or pawl. Make sure

the chain stopper clears the anchor stock.

A tensioner device to tension the anchor into its

pocket is recommended. If the anchor is not snug in

the pocket, it could cause damage to the pocket in a

heavy seaway.

Correct height of Chain Stopper

Ensure a minimum of 800mm (32") clearance

between the end of spurling pipe and the chain piled

up in the chain locker. This will assist kinks, which

may develop in outgoing chain, to shake free.

The chain must gravity feed into the locker. If the

chainpipe cannot be positioned directly over the

locker, a heavy wall pipe can be used to direct

the chain to the required area. It is important that

the chain slips through the pipe easily, completely

unaided, sharp corners should be avoided. It may

be necessary to provide the pipe with a bell mouth

or to bell mouth the entrance to the chainpipe from

the locker to assist the free ow of the chain from the

locker.

The chain locker must be of such a size and shape

that the chain will heap up and feed out naturally

without fouling.

Recommended free space in chain locker

Picture 2.1

Picture 2.2

Picture 2.3

Page 9

9

If it can be arranged, the chain locker bulkhead should

pass between the chainpipe outlet in the deckplate

and the gearbox. This will keep the gearbox, motor

and power lines dry and away from aying chain.

Access for servicing from inside the cabin area can

usually be arranged through a locker.

Note that the gearbox can be indexed through a

number of different angles in relation to the windlass

deckplate. Be sure to select the most convenient

arrangement at installation and ensure incoming

chain well clears the gearbox, motor and power

supply lines.

To ensure safe position of the operator while tailing

from the warping drum, footswitches should be

positioned at least 500mm (20”) away from the

windlass.

The below deck portion of the footswitch should not

be exposed to water or wet environment and the

breather holes must be kept clear. The arrows on

the footswitches should be arranged to indicate the

direction of operation.

The motor starter (solenoid valves for hydraulic

windlasses) should be located in a dry area in close

proximity to the windlass. It must not be located in the

wet environment of the chain locker.

The breaker/isolator panel (DC powered windlasses

only) is selected to provide limited overload protection

for the motor and full protection for the supply cables.

It also provides the means for isolating the electrical

system from the battery.

This should be mounted in a dry place within 1.8m

(72”) of cable length from battery.

This equipment or equivalent is mandatory to meet

U.S.C.G. requirements.

Picture 2.4

Positions of drive, relative to topwork

2.2 PREPARATION OF MOUNTING AREA

It is of paramount importance that the vessel has

sufcient deck reinforcing and total structural strength

to sustain the loads that can be transmitted to the

mounting area of the windlass and chain stopper.

This should be equal to the loading of the equipment

to beyond breaking strength of the chain.

The mounting area for the windlass must be perfectly

at and rigid. A structural grade ller can be used

to level this area if initial atness is inadequate.

Mounting area for the chain stopper should be

prepared at the same time. The chain stopper has to

be installed at an appropriate height to ensure that

chain lays horizontally when it comes out of the chain

Page 10

stopper and into windlass. Maximum allowed angle

deviation in vertical plane is ±2°.

If hawse pipe is angled outboard from deck to anchor

pocket, the chain stopper should also be angled by

half of the angle of the hawse pipe (Picture 2.5). That

will help to reduce twisting of the chain between the

chain stopper and the windlass and ensure good t of

the chain into the chainwheel. The chain stopper can

be installed vertically if the hawse pipe angle is less

than 4°.

A deck cutout detail drawing is enclosed with these

instructions to assist in marking out all the drilling and

cutting required for installing the windlass. Before

drilling and cutting, check the marked out area is

dimensionally correct and make any necessary

corrections.

The hole for mounting band brake guide (where

applicable) should be marked and drilled after

assembling the band brake on the windlass.

10

2.3 PREPARATION OF THE WINDLASS

Remove windlass from its packing case.

Disassemble it in the following order (refer to

drawing in Appendix B):

• Remove the Cap and O-Ring from the top of the

windlass, taking care not to damage the chromed

surface.

• Undo and remove the Retaining Screw and

Retaining Washer under the Cap, using a at

screwdriver.

• Undo and remove Clutch Nut, remove Drum and

Upper Clutch Cone .

• On VWC & VWCLP versions, undo Screws that

retain Chainpipe and remove it. On VW versions

undo Screws and remove Stripper.

• Remove Plungers, springs, upper spring holder,

Chainwheel, Lower Clutch Cone and Key. The

Lower Clutch Cone might be held by a Grub

Screw to the shaft. If that is the case, undo the

Grub Screw before removing the cone. Make sure

not to displace the two Retention Clips that were

supporting the Lower Clutch Cone.

• Carefully remove Deck Seal to avoid damage to

it.

• Undo Screws and remove the Deckplate.

• Refer to Appendix B of this Manual and identify

all parts. If any parts are damaged or missing,

contact your Maxwell distributor. Some smaller

parts might not be assembled on the windlass

by the factory, but supplied in a plastic bag in the

packing case.

Picture 2.5

Installation angle of chain stopper

Page 11

11

Maxwell strongly recommends generous application

of a high quality anti-corrosive paste or coating to

the mating sections of main shaft, drive key, anges,

screw threads, dowels and other surfaces that are

likely to seize after being in contact for a prolonged

period of time.

Also ensure anti-corrosive coating is liberally applied

to the inside wall of the Spacer Tube.

2.4 INSTALLING THE WINDLASS

Refer to the drawing in Appendix B for help with

identifying components and installing them correctly.

Extra care should be exercised when handling

polished parts to avoid any damage to polished

surfaces.

When assembling the parts, apply an anti-seize

compound generously over all screw threads, keys

and keyways, Mainshaft and inside the spacer tube.

Proceed with installation in the following order:

• After cutting holes for the windlass in the deck,

apply an appropriate bedding/sealing compound

to the clean surface, place Deck Gasket and

bolt the Deckplate to the deck using Mounting

Screws, and Insulating Bushes. Tighten them

evenly to 80 Nm (60 ft lb). Heel Block should

already be assembled to Deckplate.

• Offer up, from below deck, the drive assembly

sliding the Mainshaft through the Deckplate,

taking care not to damage the deck bearing.

• After aligning them correctly, bolt the Deckplate

and Spacer Tube together, from above deck,

using the Hex Head Screws and Spring Washers.

Tighten them evenly to 80 Nm (60 ft lb).

• Re-check that the position of the drive assembly

is satisfactory and convenient for connecting

power supply lines to the motor. Also, make sure

that the drive is not in the way of chain coming

into the locker.

• If a chain counter is used, its sensor should be

tted into the Ø15mm hole in the Deckplate,

currently covered with a Plastic Plug. Make sure

the deck is drilled below for the sensor cable.

See brochure supplied with Chain Counter for

detailed assembly instructions.

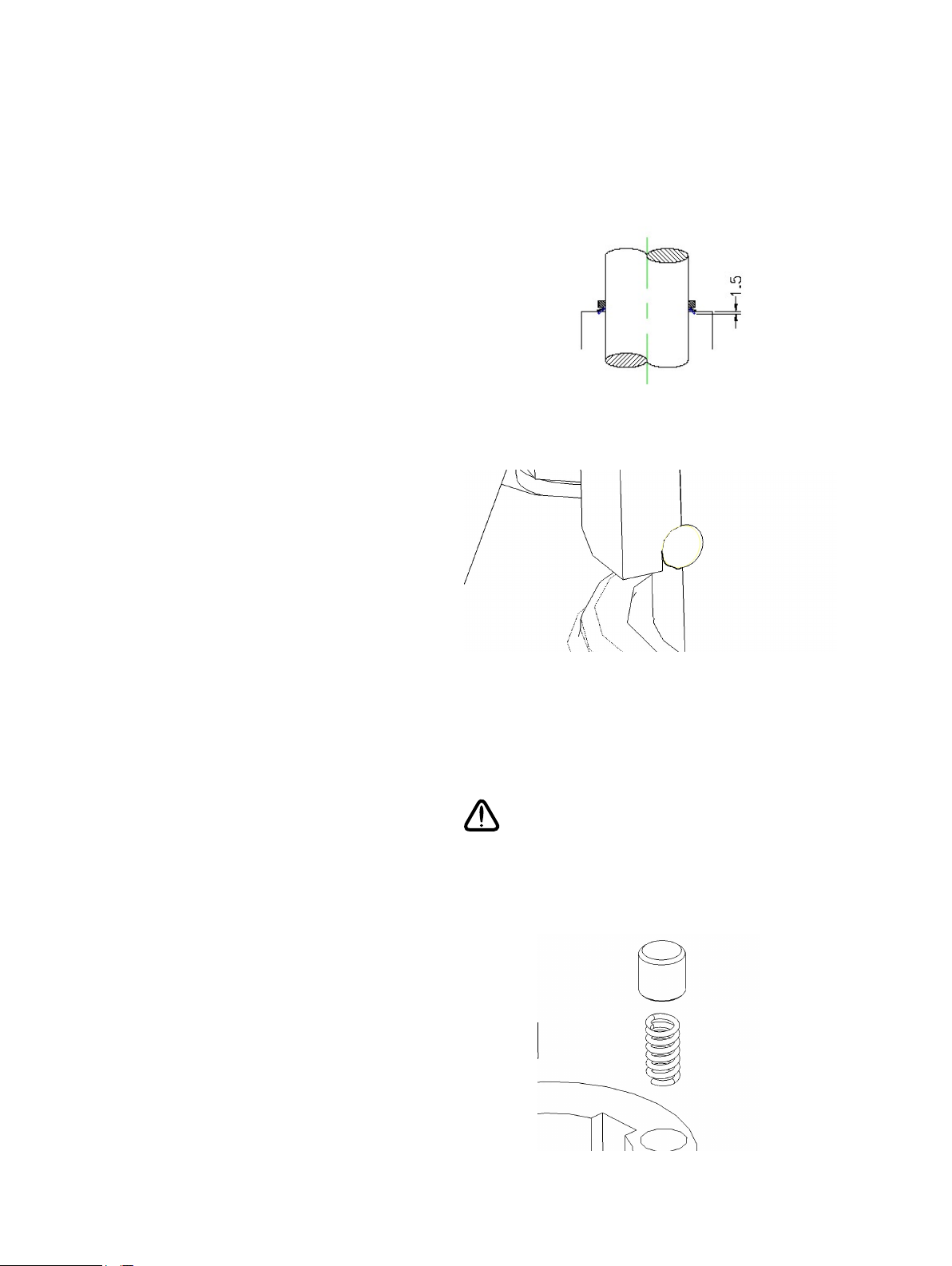

• Grease Deck Seal and carefully slide it down

the Mainshaft. Push it against the Deck Bearing

(28) by approx 1.5 mm after initial contact (see

Picture 2.8).

Picture 2.6

Clockwise topwork

Picture 2.7

Anticlockwise topwork

clockwise

windlass

Picture 2.8

Positions of valves on hydraulic motors

When assembling hydraulic drives, take

care not to swap over the drives (couple the

clockwise motor and gearbox to anticlockwise

topworks). See letters on Picture 2.8 for drive

identication.

anticlockwise

windlass

Page 12

• Insert the two Retention Clips into the groove in

the Mainshaft; apply some grease to help keep

them in position.

• Apply anti-seize compound generously over

the Mainshaft and keyway. Insert Key into the

keyway in the Mainshaft.

• Assemble the Lower Clutch Cone making sure it

sits nicely on the retention clips (see Picture 2.9).

Apply Lithium based marine grease generously

to the conical surface of the Lower Clutch Cone,

to assist with free falling the anchor.

• Install 6 springs and Plungers into holes in the

Lower Clutch Cone.

• Install Chainwheel, Upper Spring Holder and the

remaining 3 Plungers and springs.

• Install Band Brake (if applicable) on the

Chainwheel, putting its two stops one each side

of Heel Block. The Band Brake can be assembled

with its handle pointing either direction, choose

more convenient option.

• Make sure the band sits at on the shoulder at

the lower end of the Chainwheel and tighten the

brake by turning the Lead Screw. Slide shaft

guide (5 – Band brake) on Handle Shaft (6

– Band brake). Line up both parts of the Lead

Screw Assembly in one vertical plane and make

sure the bottom surface of the Shaft Guide sits

at on the deck.

• Mark up the position of the Shaft Guide on deck,

then remove the guide and drill Ø13mm clearance

hole in the deck for the retaining screw (not

supplied). The Shaft guide has a mounting hole

M12 x 25mm deep and should be retained from

under the deck with a M12 bolt of appropriate

length (depending on the deck thickness).

• Apply the same bedding/sealing compound as

used under the deck plate, replace the Shaft

guide and retain it from underneath.

• Slide the Retaining Nut (2 – Band brake) on

the Shaft (6 – Band brake) and insert the Pin (3

– Band brake) into the hole in the Shaft. Then put

on the Handwheel (1 – Band brake), making sure

the end of the Shaft comes into the square recess

in the Handwheel, and fasten it with the Retaining

Nut.

• Install Chainpipe and retain it with the 3 cap

screws. Note that there are three Spacers

supplied for the Stripper. They should be used

to adjust the position (height) of the Stripper.

The correct height is when the Stripper is in, or

as close as possible to the centre of the central

12

Picture 2.9

Installing Deck Seal

Picture 2.10

Lower Clutch Cone Assembly

For effective operation of the band brake,

the friction lining must remain free from

contamination by any lubricant. Lithium

complex base grease should, however, be

applied to the lead screw thread.

Picture 2.11

Plunger and Spring Assembly

Page 13

13

groove of the Chainwheel.

• Slide Upper Clutch Cone. Note that this cone has

friction lining, which SHOULD NOT be greased,

unlike the lower cone.

• Assemble Drum on top of the clutch cone (VWC

models only).

• Assemble Clutch Nut.

• Put Retaining Washer on top of the Mainshaft

and secure it with the Screw.

• Insert Cap into the Clutch Nut.

2.5 SELECTION OF MOTOR STARTER

Several AC motor starter options for windlasses are

available, each with characteristic current demands

and start load limitations. Maxwell recommends that

selection of the best motor start system be entrusted

to experienced persons familiar with anchoring

procedures and the vessels generating capacity.

"Direct On Line" starter is the simplest way of starting

an AC motor and it will allow the windlass to start

under full rated load. However, this method requires

relatively high momentary starting current, which the

generators may have adverse effect to the rest of

the electrical system on board. See specications

for current values at 400V in Section 1.3 and make

sure to recalculate it for the voltage used on board.

Start current may be limited to about half the above

amount by using a "Star-Delta" starter. However, start

torque is thereby limited to loads of about 25-30% of

the windlass rated capacity.

“Star-delta” and “soft starters” are not recommended

for starting windlass motors, as the motor torque is

severely limited during start up period. Since these

motors often have to start under load (when retrieving

the ground tackle), they might not be able to move

until they reach the full voltage and torque. The

benet of starting at lower current would therefore be

lost. Also, the motor brake would release immediately

on start-up, which could cause short movement of the

chain in opposite direction.

The Variable Frequency Drives (VFD) offer accurate

control of current during start up period while keeping

high motor torque. They also offer various other

benets like:

• innite speed control

• running the windlass over its nominal speed

• accurate current overload and thermal overload

control

The selection of the type of motor starter

should be done by a qualied electrical

engineer, taking into consideration the power

generating capacity on board.

Maxwell offers both advice and different types

of custom made starters to complement our

windlasses.

The “up” and “down” start contactors must

be mechanically or electrically interlocked

to safeguard the motor, in the event that an

accidental attempt is made to start the motor

in both directions simultaneously.

Page 14

14

Both “Direct On Line” starters and Variable Frequency

Drives are suitable and available from Maxwell,

customised to suit the anchor windlass and stern

capstan application.

2.6 POWER CONNECTIONS TO AC MOTOR

Remove the motor terminal box cover and take care

not to misplace the sealing gasket and screws.

Select a suitably sized, waterproof cable gland for

the armoured supply cable. The selected gland tting

must t the terminal box, be capable of anchoring the

armoured cable, and allow an effective waterproof

entry seal to be made.

Make the line connections to motor terminals. Make

also an effective earth connection.

Separately and similarly, enter the 2 thermistor cables

to the motor terminal box, and connect to the two

auxiliary terminal connectors of the thermistor circuit.

Check:

• Is the direction of rotation of the motor correct?

• Are cables satisfactorily xed?

• Are cable entry points to motor terminal box

satisfactorily waterproofed?

Spray the cable gland, cable entry points and motor

terminal box with anti-corrosive waterproof coating

"CRC 3013 Soft Seal" or equivalent.

Page 15

15

2.7 POWER CONNECTIONS TO DC MOTOR

The main power system is a two cable, ungrounded,

fully insulated, negative return system. The motor is

of the isolated earth type. This system is selected to

minimise electrolytic corrosion problems.

The DC motor has four power terminals, marked 1-4.

They should be connected to the starter box as per

schematic P101807 in Appendix C.

After connecting the cables, spray all terminals with

anti-corrosive waterproof coating, “CRC 3013 Soft

Seal” or equivalent.

2.8 POWER CONNECTIONS TO HYDRAULIC MOTOR

A basic hydraulic schematic is shown in Appendix C.

Port sizes on the hydraulic motor and minimum hose

sizes are specied in Section 1.3.

The motor is supplied with oil through two ports on

the Counterbalance Valve Block. They should be

connected to a bi-directional, solenoid controlled valve

(not supplied by Maxwell). The pressure line (when

retrieving the anchor) should be connected to the port B

and the return line to the port A (see Picture 2.8).

After connecting the power lines, spray all ports and

ttings with anti-corrosive waterproof coating, “CRC

3013 Soft Seal” or equivalent.

Page 16

2.9 INSTALLATION OF CONTROLS

The windlass can be operated using:

• Deck mounted footswitches

• Hand held pendant controller (single or dual

speed)

• Helm switch (single or dual speed)

• Chain counter

These control accessories are available from Maxwell

customised to suit your windlass.

It is the choice of the designer/builder to use one,

two or all three of these controls. They are wired

in parallel to the directional valve (for hydraulic

windlasses) or to the starter unit (for electric

windlasses). The controls can work on 12 or 24V

power supply.

If footswitches are used, then an isolator switch for

them must be installed in the wheelhouse, to prevent

operating the windlass by someone accidentally

stepping on the footswitch.

Hand held pendant controller is often the most

convenient way of operating the windlass. Maxwell

offers several variations of pendants, including single

speed, dual speed, single pendant for running a pair

of windlasses, pendants with auxiliary buttons which

can be used for starting chain wash system, hydraulic

pump etc. They are supplied with a plug on the other

end of cable and a matching waterproof socket,

which should be installed on a convenient location

on the deck.

All units are supplied with detailed wiring instructions

to assist installation.

Refer to wiring schematics in Appendix C for control

circuits. All control wiring should be done using no

smaller than 1.5mm² wire (AWG 16).

Where applicable, a manually resetable, ignition proof

3A breaker or fuse should be installed on the power

supply line for controls, within 1m (40”) from the main

breaker/isolator. These requirements are mandatory

to meet USCG, ABYC and NMMA rules.

After connecting the power lines, spray all ports and

ttings with anti-corrosive waterproof coating “CRC

3013 Soft Seal” or equivalent.

16

Picture 2.15

Pendant controller for operating two windlasses

Page 17

17

2.10 NOTE TO BOAT BUILDER

Experience has shown that, on long ocean

deliveries, sulphur from the ship's exhaust can settle

on polished surfaces, which can affect the quality of

the nish.

Please ensure that, upon completion of installation,

the windlass is treated with suitable corrosion

protective coating (“CRC 3097 Long Life”) and

wrapped in plastic lm. This ensures that your

customer receives the windlass from you in the

same top quality condition as you received it from

Maxwell.

Page 18

3.0 USING THE WINDLASS

3.1 PERSONAL SAFETY WARNINGS

• As with all load carrying equipment, the

consequences of heavy overload, neglect or

misuse may be unexpected failure and exposure

of crew and/or vessel to risk. Operate the

windlass with extreme care at all times.

• Before testing the windlass for the rst time,

check that all the wiring has been done correctly.

• When using the windlass, at all times practice

good seamanship and adhere to the following

rules in order to avoid any likelihood of injury or

accident.

• At all times keep hands, feet, loose clothing,

cordage and your hair WELL CLEAR.

• Never operate the windlass from a remote station

without maintaining a clear view of it and having

made sure that everyone is well clear of the

windlass, anchor and chain.

• Never use the windlass under power with

the clutch handle inserted into clutch nut or

emergency crank collar.

• When engaging the pawl while chain is running,

keep ngers away from the chain. Use clutch nut

lever, underneath and guarded by the chainpipe.

• Always motor up to the anchor position before

retrieving it from the bottom. Do not use the

windlass to pull the boat to the anchor.

• If the anchor is fouled, do not use the windlass

to break it out. With the chain stopper taking the

load, use the boat’s engine to break the anchor

loose.

• When lowering the anchor under manual control,

use the band brake or friction clutch (if tted) to

control the speed of the chain. Never lower the

anchor without maintaining safe chain speed.

• When the windlass is not in use, make sure the

power supply is isolated, making an accidental

operation thereby impossible.

• Do not use the windlass as an anchoring point

for the chain. Engage the chain stopper when the

windlass is not in operation.

• Never proceed at speed without rst ensuring

that the chain stopper is engaged. Also engage

the tensioner to keep the anchor snug in the

pocket.

• When using the windlass, do not switch

immediately from one direction of rotation to the

other, without waiting for windlass to stop. Abuse

is not covered by warranty.

Page 19

19

3.2 LOWERING THE ANCHOR UNDER POWER

• Ensure the clutch is fully engaged by inserting the

clutch nut lever in one of the slots on the clutch

nut, and turning clockwise rmly. The windlass

is equipped with a friction clutch, so it can be

engaged in any position (there is no need to

match the position of the opposite sides of the

clutch before engaging it).

• Remove clutch handle.

• Release band brake or pawl (whichever is

tted).

• Disengage chain stopper and chain tensioner (if

tted). To disengage the chain stopper pawl the

windlass may require momentary jogging in the

up direction.

• The windlass may now be lowered under power

by operating either the hand held pendant control,

helm switch or footswitch.

• When nished, turn off the isolator switch for the

controls.

3.3 RETRIEVING THE ANCHOR UNDER POWER

• Ensure the clutch is engaged, as described

above, and band brake or pawl is released.

• Remove clutch handle from the clutch nut.

• If a pawl type chain stopper is used, it can be left

ratchetting on the chain, so it will engage itself

automatically when the windlass stops.

• The windlass may now be operated to raise the

anchor.

• After retrieving the anchor make sure the chain

stopper and tensioner are engaged.

• Turn off the isolator switch for the controls.

As a safety feature all buttons on the controls

(pendant, toggle switch or footswitch) are

non-latching and the windlass will continue to

operate up or down only while they are held in

the engaged position.

Picture 3.1

Engaging the clutch

It is regarded as sound practice to motor

over the anchor position and so reduce chain

tension. This will also help the anchor to break

out, reduce the power consumption and reduce

load on the windlass and deck gear.

Care should be exercised when docking the

anchor to avoid damage to the anchor pocket.

Jog in the last meter (3-4’) of the chain

carefully seating the anchor home.

3.4 LOWERING THE ANCHOR UNDER MANUAL CONTROL

This method will normally be employed to lower

the anchor quickly, to lower it in "quiet ship" and in

emergencies (power loss or control failure).

Proceed as follows:

• Tighten the clutch and band brake (if tted).

• Release the chain stopper and chain tensioner.

If the anchor has to be lowered in case of power

loss and pawl on the chain stopper is engaged

and under tension (by chain), to release it, pull

the chain in slightly, using tensioner. Once the

pawl is disengaged, release the tensioner and

Page 20

20

disengage it. If there is too much slack in the

chain, it might be necessary to remove the domed

nut from the end of lead screw and release the

It is considered potentially dangerous to allow

the chain to free fall in an unrestricted manner

- always control the chain speed.

screw completely. If doing that, make sure the

band brake and clutch is still engaged, for safety

reasons.

• Fully disengage the clutch by turning the clutch

nut anticlockwise until it comes to a stop.

• Slowly release the band brake in a controlled

manner. The chain should now release, the

weight of self-launching anchor being sufcient to

draw out the chain. Regulate the chain speed by

gradually engaging/disengaging the band brake.

• When the required amount of chain is out, tighten

the band brake and engage the chain stopper.

• If the band brake is not tted, the speed of chain

can be controlled by the clutch. In that case, after

disengaging the chain stopper, slowly release the

clutch by inserting the lever into the clutch nut

and turning it anti-clockwise. Regulate the chain

speed by gradually engaging/disengaging the

clutch.

Chain Roller-Stopper-Tensioner

The chain slack between the tensioner and

the windlass should be kept to less than the

end travel of the tensioner. This allows for safe

disengagement of the tensioner and transfer of

load to the chainwheel.

3.5 OPERATING THE WARPING DRUM INDEPENDENTLY

This is applicable to VW and VWC models only.

The drum can be operated independently of the

chainwheel and can be used to manage docking

lines or a second anchor. To use in this way, proceed

as follows:

While handling docking lines with the capstan,

ensure everyone stays well clear of the lines

and the capstan.

• Engage the chain stopper, the pawl or the band

brake (whichever is tted).

• Fully disengage the clutch as described in

Section 3.4.

The drum may now be operated independently of

the chainwheel. Maxwell recommends all warping

operations be controlled by the footswitch. This

makes it a one-person operation and offers better

control of the capstan in case of emergency.

Take several turns of the warping line around the

drum and pull on the rope tail with sufcient manual

force to provide good grip of the line to the drum,

Take care not to allow “riding turns”. This is

caused by the loaded line climbing on top of

lower loaded coils on the drum. A riding turn

can only be removed by paying the line out to

the point where the riding turn is created.

whilst operating the footswitch. Make sure the drum is

operated in the same direction as the line is wrapped

around it.

Do not engage more turns on the drum than are

necessary to accomplish the task. Whilst docking,

wind and tide can impose sudden and excessive line

tension. It is recommended to allow slipping to occur

at the drum. This will protect the capstan, docking

lines and vessel from damage.

Picture 3.2

Page 21

4.0 MAINTENANCE

4.1 WINDLASS MAINTENANCE

21

Every six months disassemble the above deck

components of the windlass (up to the Deckplate) as

described in Section 2.3. Clean all components and

check for damage. Grease the components using

lithium complex base, water proof grease, especially

grease the conical surface on the Lower Clutch Cone,

Upper Clutch Cone has a friction lining and should

not be greased. Grease bearing in the Deckplate

through the Grease Nipple.

Clean chromed surfaces with a cloth, damp with

kerosene. After cleaning spray them with “CRC 3037

Long Life” or alternatively, with “CRC 6-66” or “WD40”. Regular use of “CRC3097 Long Life” will assist in

maintaining the bright chrome nish.

Re-assemble in the reversed order.

Inspect the components below deck for corrosion,

chipped paint etc, clean them, touch up the paint if

necessary. Spray them for protection with “CRC 3013

Soft Seal”.

The gearbox on electric windlasses is lubricated for

life and, as such, does not need periodical oil change.

Once installed correctly, it should give many years of

trouble free service without maintenance.

If, for any reason, the oil in the gearbox has to

be replaced, use Shell Tivela Oil SC320. If not

available, another synthetic oil of equivalent viscosity

characteristics can be used.

The gearbox on hydraulic windlasses is lled with

synthetic oil, which should be changed every three

years. When changing the oil, take the gearbox of

the windlass together with the motor because motor

ange acts as a seal to the lower end of the gearbox.

Turn the gearbox up side down and then take the

motor off. When the new oil is lled up, the oil level

should be up to the centre of the Sight Glass (refer

– Gearbox assembly – appendix B).

Before doing any maintenance work on electric

motor, starter units and wiring, make sure the

power supply is switched off.

Use synthetic oils only. Never mix two oils, even

if they are from the same manufacturer.

Page 22

4.2 BAND BRAKE MAINTENANCE

The frequency of brake lining renewal will depend

entirely on its usage. Should visual inspection reveal

that the lining thickness has worn to below 2mm or if

the ends of brake band can touch each other when

tight, renewal of brake lining is necessary.

Grease the band brake lead screw at least every

three months.

Avoid grease contamination of brake friction linings.

4.3 RECOMMENDED LUBRICANTS

Greases

- Lithium complex base NLG1 consistency No.

2

• CASTROL LMX

• DUCKHAMS Keenol

• FINA CERAN WR 2

• SHELL Retinex LX

• MOBIL Mobilgrease HP

22

Gearbox Oils

- ISO 3448 VG 320

• CASTROL Alpha MAX 320

• SHELL Tivela oil SC320

• MOBIL Mobilgear 632

• BP MACH GR XP 320

Anti-Corrosive Coatings

• CRC 3013 Soft Seal

• Boeshield T9

• Lanocote

Anti-Seize Coating

• International Paints Res-Q-Steel

Never mix greases, use only one type. If in doubt,

remove the previous lubricant and clean the parts

thoroughly before applying the new one.

Page 23

23

4.4 SPARE PARTS

Maxwell recommends a modest quantity of spare

parts to be ordered as familiarity with the windlass is

developed during installation. As small parts can be

lost during maintenance, keeping spares (and spare

tools) is recommended.

We recommend the following list of spare parts per

windlass to be carried on board:

Part No. Description Qty

3006 Retention clip 2

4809 Cap 1

SP2769 O-Ring 1

3566 Plunger 5

3567 Spring 5

Topworks key* 1

SP0718 Deck Seal 1

SP0840 External circlip** 1

*The part number will vary depending on the model,

see Appendix B.

**Hydraulic drives only.

If any other spare part is required, please refer to

Appendix B for the correct part number and contact

one of our distributors worldwide (Appendix D). When

ordering spare parts, please quote:

• Windlass model

• Serial number of the windlass

• Part number (see Appendix B)

• Part description

• Quantity required

4.5 TOOLS FOR MAINTENANCE

We recommend the following tools be kept on board

for disassembling and assembling the windlass:

• Set of metric hexagon keys (Allen keys) 5, 8, 10

and 14mm

• Ring/open end spanner 17, 19, 24mm

• Curved ring spanner (or socket spanner) 17mm

• Circlip pliers

Page 24

24

Check the fuse on power supply to controls

Check wiring for damage

If there is more than one type of control (pendant unit, footswitch,

helm switch), check them all in an effort to isolate the problem

Check isolator switch and fuse on Variable Frequency Motor

Control, if supplied

Check the power supply to controls from the source, step by step,

and identify the point where it stops

between 50 and 500 ohms. When doing that, do not use voltage

Incorrect or incomplete wiring Check wiring against the diagrams supplied

Damaged thermistors on the motor To conrm, check resistance across thermistors, it should be

Faulty thermistor relay To conrm, check resistance between terminals 21 and 22. If it is

above 500 ohms, contact Maxwell

Check main isolator switch

Check hydraulic pump (hydraulic windlasses only)

Check name plate on the motor. If conrmed, contact Maxwell

No power supply to the windlass Check power supply lines

Motor voltage does not match the power supply

on board

Make sure the bolts have spring washers, adjust bolt length

Hydraulic relief valve not set correctly Check valve setting

The mounting bolts of the motor are touching

persists, contact Maxwell

the motor winding

The clutch is not fully engaged Tighten the clutch up, as described in Section 3.2. If the problem

Band brake is engaged Release band brake

Electric AC motors: leave it to cool down and the thermistor relay

will reset itself automatically

Topworks key (26) not installed Install the key

The motor has been overloaded and has

reached its critical temperature

Problem Possible cause Solution

5.0 TROUBLESHOOTING

Windlass does not start No electric power to controls Make sure the isolator switch for windlass controls is on

Windlass is not able to pull the

specied load

DC motor draws high current but

struggles to pull the load

Windlass runs but the chainwheel

stays stationary

Electric motor stops after prolonged

heavy use

Page 25

25

Electric DC motors: leave it to cool down and reset the circuit

breaker

The clutch is not fully disengaged Disengage the clutch fully

The band brake is not disengaged Disengage the band brake fully

board

Plungers & springs (8,9) not tted Fit as described in Section 2.4

Check the installation. If the problem persists, some height

adjustments might have to be made

Chain twisted between windlass and bow roller Untwist the chain

Vertical angle of incoming chain bigger than 2

degrees (see Picture 2.1)

The anchor does not free fall Lower clutch cone is not greased Disassemble the cone (19), clean and grease the conical surface

Chain jumps / slips on the chainwheel The chainwheel not selected correctly Contact Maxwell with correct identication of the chain used on

Page 26

APPENDIX A - Dimensional drawings

26

Page 27

27

220

140

CUTOUT

90 Cutout

R

190

250

142.5

R

70

DO NOT USE AS A TEMPLATE

THIS IS FOR REFERENCE ONLY

(SEE NOTE 3)

on a 250 PCD.

8 holes

or tap M12 x 1.75 into deck adapter plate,

12.5 Through Deck

PORT AND STARBOARD FITTING

NOTES:

1. BEFORE CUTTING DECK, CHECK AL L

UNDERDECK CLEARANCES.

READ & UNDERSTAND INSTALLATIO N

INSTRUCTIONS CONTAINED WITHI N

THE MANUAL.

2. CHECK YOUR MARKED OUT DIMENSI ONS

CAREFULLY, BEFORE CUTTING & D RILLING.

DECK BOLT HOLES MUST BE DRIL LED PARALLEL

& SQUARE TO MOUNTING FACES.

3. MAXWELL MARINE IS NOT RESPON SIBLE FOR

ANY INACCURATE DATA, DUE TO R EPRODUCTION

ERRORS OF FAX MACHINES, PRINTE RS,

PHOTOCOPIERS ETC.

3815

3.00

Deck Cutout D etails - 6000 VW C

1

1:1

A2

Scale

0.5

of

Sheet

1

Description:

Material:

Revision No:

0.5

Tolerances if none specified

1 DECIMAL (X.X)

Drawing No:

ALL ANGLES

0.1

Sheet Size

2 DECIMAL (X.XX)

0.2

0 DECIMAL (X)

This drawing is protected by copyright and the design and or details

contained therein are the confidential property of

MAXWELL MARINE LTD.

This drawing must be returned upon demand and must not be copied,

loaned or have its contents communicated to any other persons,

including subcontractors, without the consent in writing from

Maxwell Marine Ltd. This drawing must not be used for any other

purpose other than that for which it was originally supplied.

R

e

v

.

C

h

a

n

g

e

M

a

d

e

o

n

D

e

s

/

D

r

a

w

n

2

.

0

0

I

s

s

u

e

d

i

n

C

A

D

3

/

8

/

0

4

A

N

3

.

0

0

T

e

m

p

l

a

t

e

n

o

t

e

a

d

d

e

d

.

N

o

t

e

s

r

e

v

i

s

e

d

2

9

/

3

/

0

6

R

P

Page 28

8 Holes drill

15

Equispaced on 310 PCD

This drawing is protected by copyright and the

design and or details contained therein

are the confidential property of

MAXWELL MARINE LTD.

This drawing must be returned upon demand

and must not be copied, loaned or have its

contents communicated to any other persons,

including subcontractors, without the consent

in writing from Maxwell Marine Ltd. This

drawing must not be used for any other purpose

other than that for which it was originally supplied.

Recommended line of

deck pad

Drawing No:

Revision No:

Description

Deck Cutout Details - 6000 8000 11000 VC - 6000 VW

3983 3.00

Date:

3/8/04

AH

Drawn:

Scale:

A2=1:1

NOTES:

1. BEFORE CUTTING DECK, CHECK ALL

UNDERDECK CLEARANCES.

READ & UNDERSTAND INSTALLATION

INSTRUCTIONS CONTAINED WITHIN

THE MANUAL.

2. CHECK YOUR MARKED OUT DIMENSIONS

CAREFULLY, BEFORE CUTTING & DRILLING.

DECK BOLT HOLES MUST BE DRILLED PARALLEL

& SQUARE TO MOUNTING FACES.

3. MAXWELL MARINE IS NOT RESPONSIBLE FOR

ANY INACCURATE DATA, DUE TO REPRODUCTION

ERRORS OF FAX MACHINES, PRINTERS,

PHOTOCOPIERS ETC.

DO NOT USE AS A TEMPLATE

THIS IS FOR REFERENCE ONLY

(SEE NOTE 3)

LINE OF DECK BEARING

PROFILE

Cutout for under deck spacertube

232

346

28

Page 29

APPENDIX B - Spare parts

293031

Page 30

Page 31

Page 32

32

Item Description Qty Part no.

1 Cap 1 4809

1.1 O-Ring 1 SP2769

2 Label 1 3740

3 Hex head bolt M10 x 25 1 SP0281

4 Retaining washer 1 1474

5 Clutch nut

VWC VW 1 3801C

VWC VW - S/S 1 5186

VWCLP 1 3839C

6 Drum

chromed bronze 1 2637C

stainless steel 1 5188

7 Upper clutch cone 1 P14180

8 Plunger 9 3566

9 Spring 9 3567

10 Upper spring holder 1 2640

11 Chainwheel*

Non band brake version 1 2513C

Band brake version 1 2514C

12 Socket head cap screw M12 x 40 12 6417

13 Heel block - chrome 1 3808C

Heel block - stainless steel 1 5193

14 Socket head cap screw M10 x 30 2 SP0169

15 Socket head cap screw M12 x 35 3 SP2481

16 Chainpipe

clockwise version 1 3755C

anticlockwise version 1 3756C

17 Spacer 3 3733

18 Stripper arm - VWC VWCLP 1 3732

Stripper arm - VW VWLP 1 6856

18.1 Cap Screw - M10 x 30 2 SP0169

18.2 Cap Screw - M10 x 50 2 SP2464

18.3 Stripper arm support - VW VWLP 1 6854

18.4 Dowel 2 6193

18.5 Stripper arm support spacer - VW VWLP 1-3 6855

19 Lower clutch cone 1 2641

20 Grub screw 1 SP0113

21 Retention clip 2 3006

22 Deck seal 1 SP0718

23 Plug 1 SP0875

23.1 Socket head grub screw 2 SP0111

24 Hex head bolt M12 x 60 8 SP0283

25 Spring washer M12 8 SP0475

Page 33

33

26 Topworks key

VWC VW 1 2638

VWCLP 1 3273

27 Insulating bush 8 3012

28 Deck bearing 1 3028

29

30 Deckplate

VWC VWCLP clockwise version 1 P14521

VWC VWCLP anticlockwise version 1 P14523

VWC VWCLP non- band brake version 1 P14167

VW VWLP clockwise and anticlockwise S/S 1 6852

30.1 VW VWLP Deckplate Lower 1 6853

31 Insulating gasket 1 3015

32 Main shaft (see table below for part numbers) 1

33 Threaded insert 8 SP0589

34 Spacer tube

DC & AC right angle drive 1 5262

AC vertical & hydraulic drive 1 2646

35 Gearbox key

DC & AC right angle drive 1 5265

AC vertical drive 1 3759

Hydraulic drive 1 3005

36 Socket head cap screw M12 x 35 8 SP2481

37 Socket head cap screw M10 x 35 8 SP2451

38 Nut M16 4 SP0327

39 Spring washer M16 4 SP0451

40 Flat washer M16 4 SP0421

41 Adaptor ange 1 4409

42 Hex head bolt M16 x 70 4 SP0297

43 Socket head cap screw M10 x 30 8 SP0169

44 Spring washer M10 8 SP0466

45 External circlip 2 SP0840

46 Gearbox

Electric DC drive 1 SP2999

Electric AC right angle drive 1 SP4117

47 Retaining washer 1 5201

48 Spring washer M10 1 SP0466

49 Socket head cap screw M10 x 25 1 SP0166

50 Socket head cap screw M12 x 50 4 SP0180

51 Spring washer M12 4 SP0475

52 Nut M12 4 SP0326

Page 34

34

53 Motor

Electric AC motor 208V - 60Hz two speed 1 SP3344

Electric AC motor 208V - 60Hz 1 SP3395

Electric AC motor 400V - 50Hz 1 SP3394

Electric AC motor 400V - 50Hz two speed 1 SP3335

Electric DC motor 24V 1 SP2993

54 Vertical AC drive

AC motor & gearbox 220V 50Hz 1 5317

AC motor & gearbox 208V 60Hz 1 5320

AC motor & gearbox 400V 50Hz 1 5321

AC motor & gearbox 400V 50Hz two speed 1 5322

55 Gearbox 1 P14153

56 Socket head cap screw M12 x 40 4 SP0160

57 Hydraulic motor **

26 l/mmin, 206 bar 1 SP0934

42 l/mmin, 138 bar 1 SP1064

57 l/mmin, 103 bar 1 SP1065

58 Counterbalance valve block 1 SP2226

User's Manual 1 P19137

Clutch nut lever (not shown) 1 3081

* see Section 1.3 for complete part number

** refer to gearbox drawing for motor pinion (item 16) and locking nut (item 17) part no.s

Main shaft part numbers

VWC VWCLP VW - S/S

Shaft Shaft Shaft Shaft Ext

DC & AC right angle drive 5263 5264

AC vertical drive 3757 5383

Hydraulic drive 2654 3378 6441 5370

Page 35

35

Band brake part numbers

Item Description Qty Part no.

1 Hand Wheel 1 6925

2 Dowel 1 6927

3 Bush 1 6926

4 Cap Screw 4 SP2459

5 Guide Bush 1 5545

6 Shaft Guide 1 5525

7 Band Brake 1

8 Threaded Boss 1 3654

9 Circlip 4 SP0846

10 Anchor Pin 1 3655

Lead Screw Assembly - Standard 1 P103819

11

12 Thrust Washer 1 3656

13 Locking Nut 1 3656

14 Roll Pin 1 SP0528

15 Stud - M12 1 4587

16 Flat washer - M12 1 SP0424

17 Spring washer - M12 1 SP0475

18 Hx Hd Nut - M12 1 SP0326

Lead Screw Assembly - Short Shaft 1 P103820

Lead Screw Assembly - Long Shaft 1 P103821

Page 36

36

8

1

2

3

4

7

8

9

12

13

14

15

16

17

18

19

7

4

20

3

2

1

14

13

14

5

6

7

11

9

9

8

10

Page 37

37

Item Description Qty Part no.

1 Oil seal 2 SP0715

2 Socket head capscrew M6 x 35 12 SP2483

3 Main shaft bearing 2 3043

4 Nut 3/8" 12 SP0322

5 Threaded insert 8 SP0587

6 Bolt - Hex Hd - 3-8 x 3in 304 SS 3 SP0267

7 Flat washer 12 SP0434

8 O-ring seal 4 SP0720

9 Oil plug 3 3263

10 Gear case upper 1 2686

11 Sight glass 1 3223

12 Thrust washer 1 SP0681

13 Thrust bearing 2 SP0639

14 Thrust washer 3 SP0640

15 Output gear 1 2664

16 Pinion 1 2674

17 Pinion nut 1 3039

18 Stud 3 3610

19 Gear case lower 1 2673

20 Threaded insert 4 SP0589

Page 38

38

APPENDIX C - Installation schematics

Page 39

39

Page 40

40

Page 41

Bridge or Wheel house

controls

LEGEND:

C1C2C3

S1

S2

Roving 2 button (up-down) hand held water proof controller

Bridge/Wheel House fixed windlass control UP/OFF/DOWN

Footswitch

Isolator switch for power supply to the controls

Manually resetable circut breaker 3A, recommended ETA

41-10-P10-G10-WT

Tinned multistrand conductors of at least 1.5mm2 must be used

for all control circuits

Directional valve

Power supply

to controls

24V DC

41

Page 42

42

APPENDIX D - Network of Agents and Distributors

EUROPE

Composite Works–authorized service agent

Croatia

Heli d.d. – authorized service agent

Sv. Polikarpa 8

52100 Pula

Tel. +385 52 37 55 00

Fax +385 52 37 55 10

Quai Francois Mitterrand 46

13600 La Ciotat

Tel. +33 4 42 83 83 00

Fax +33 4 42 83 83 04

mark.salman@compositeworks.com

Contact: Mark Salman

iurem@heliyachts.com

Contact: Ivan Urem

Italy

Denmark

Pro Marine

Nobilisvej 8

DK - 9320 Hjallerup

Denmark

Tel. +45 96 473 200

Fax +45 96 473 201

info@promarine.dk

Saim SpA

Via Donizetti 9-11

20090 Assago - MI

Italy

Tel. +39 02 4570 3394

Fax +39 02 4570 0663

marine@saim-group.com

Saim SpA

Lungomare della Salute 2

Germany

Sailtec GMBH

Hasselbinnen 28

D-22869 Schenefeld

Bei Hamburg

00054 Fiumicino (Rome)

Italy

Tel. +39 06 6502 9462

Fax +39 06 6502 9468

marine.roma@saim-group.com

Germany

Tel. +49 40 08229940

Fax. +49 40 08304279

Christian Gnass – cg@sailtec.de

Anja Czemper – ac@sailtec.de

Norway

Engbo AS

Ollebukta N-3110

Tonsberg

Norway

France

Saim France

Allee Francois Coli-Bat 13 F

Tel. +47 33 300 850

Fax +47 33 300 860

rmapost@engbo.no

06210 Mandelieu

France

Tel. +33 4 9390 2822

Fax +33 4 9390 3487

saimfrance@wanadoo.fr

Page 43

43

Spain

Pasch y Cia. S.A.

Campo Volantin, 24-3

48007 Bilbao

Spain

Tel. +34 94 413 2660

Fax +34 94 413 2662

iaxpe@bilbao.pasch.es

Ferdicold – authorized service agent

Muelle Viejo 13C

07012 Palma de Mallorca

Tel. +34 971 72 72 25

Fax +34 971 72 72 25

ferdicold@ferdicold.jazztel.es

Contact: Fernando Lesmes

Malta

Strand Marine – authorised service agent

Valdor Buildings

Trig Is-Sebh

Qormi QRM05

Malta

Tel. +356 21 4723366

Fax. +356 21 472338

info@strandmarinemalta.com

Fenerbahce

81030 Istanbul

Turkey

Tel. +90 216 338 1441

Fax +90 216 337 4492

deniz@marinadeniz.com.tr

United Kingdom

Golden Arrow Marine

Saxon Wharf

Lower York Street

Southampton

SO14 5QF

United Kingdom

Tel. +44 (0)23 8071 0371

Fax +44 (0)23 8071 0671

sales@goldenarrow.co.uk

NORTH AMERICA

USA

Maxwell America LLC.

5829 B Triangle Drive

Raleigh

North Carolina 27617

Tel. +1 919 791 3845

Fax +1 919 791 3844

infousa@maxwellmarine.com

The Netherlands

Ocean Yacht Systems

Nijverheidsstraat 10

Hardinxveld-Giessendam

The Netherlands 3371 XE

Tel. +31 184 676730

Fax. +31 184 621130

Contact. Mr Jan Blokland

Email. j.blokland@dbr-pumps-parts.nl

Turkey

Marina Deniz Araclari

Kalamisfener Cad. 75

Carribean Island Rigging

8186 Sub Base, Suite4

St Thomas US Virgin Islands

Tel. +1 809 774 6833

Fax +1 809 774 5024

Canada

Western Marine

1494 Powell Street

Vancouver,

BC V5L5B5

Tel. +1 604 253 3322

Fax. +1 604 253 8696

Page 44

SOUTH AMERICA

Argentina

Trimer SA

PO Box 206

1425 Buenos Aires

Argentina

Tel. +54 11 4777 4577

Fax +54 11 4777 4588

Brazil

Equanautic

Rua Emesto Paiva

139 Porto Alegre RS

Brazil CEP91900-200

Tel. +55 51 32686675

44

Malaysia

Explorer Marine Centre SDN BHD

Lot 593-A1, Off Jalan PBS

14/11

Taman Perindustrian Bukit

Serdang

43300 Seri Kembangan,

Selangor

Malaysia

Tel +603 8945 7258

Fax +603 8945 5326

Email: emcmarin@tm.net.my

Website: www.explorermarine.com.my

Territory: Recreational Marine for all of

East and West Malaysia.

ASIA - PACIFIC

Taiwan

Mercury Marine Supply Co Ltd

15 Chongshan Street

812, Kaohsiung

Taiwan, ROC

Tel +886 7 8133 2335

Fax +886 7 8133 236

mms46654@ms16.hinet.net

China

Ronsil Development Ltd.

Unit 2002, 20F, Kodak house II

39 Healthy Street East

Hong Kong

Tel +852 2834 1633

Fax +852 2834 1711

ronsil@netvigator.com

Semangat Lestari (M) SDN.

BHD.

2491A & 2491B, Pekan

Pumpong,

05250 Alor Setar

Kedah Darul Aman

MALAYSIA

Tel +604 733 3319

Fax +604 733 3375

Email: zilahs@pc.jaring.my

Contact: (Mr) Faizal Suleiman

Territory: East and West Malaysia

Singapore

Best Marine Electrical

61 Kaki Bukit Avenue 1 #03-17

Shun Li Industrial Park

Singapore 417943

Tel. +65 741 0317

Fax +65 744 0317

Page 45

Japan

Dives Trading Co Ltd

3-6-41 Liv. Bldg. 3f,

Marunouchi Kaka-ku, Nagoya, Aichi

460-0002, JAPAN

Tel. +81 52 971 5700

Fax +81 52 971 5708

dives@asahi-net.or.jp

Thailand

C/- Andaman Marine Consultants

90/5 M002 Chaofah Road West,

Vichit, Muang 83000

Thailand

Tel. +76 230031

Fax. +76 239032

45

New Zealand – Head ofce

Maxwell Marine International Ltd

16-18 William Pickering Drive

Albany, Auckland

PO Box 100-703 NSMC

New Zealand

Tel. + 64 9 9856600

Fax. +64 9 9856699

Call free 0800 MAXWELL (0800 6299355)

info@maxwellmarine.com

South Africa

Harken South Africa

48 Marine Drive

Paardenisland, 7405

Cape Town,

South Africa

Tel. +27 21 5113244

Fax. +27 21 5113249

Australia

Maxwell Marine International Ltd

PO Box 1292

Capalaba

Queensland 4157

Tel. +61 7 3245 4755

Call free 1800 816 957

Fax +61 7 3245 5906

infoaus@maxwellmarine.com

Page 46

46

Page 47

LIMITED WARRANTY

Warranty: Maxwell Marine International Ltd provides a three year limited warranty on all windlasses for pleasure boat usage, and a

one year limited warranty for those systems used on commercial or charter vessels. Warranty, service and parts are available around

the world. Contact your nearest Maxwell office for a complete list of service centres and distributors.

This warranty is subject to the following conditions and limitations:

1. This Warranty will be null and void if (a) there is any neglect or failure to properly maintain and service the products.

(b) the products are serviced, repaired or maintained improperly or by unauthorised

persons.

(c) loss or damage is attributed to any act, matter or omission beyond the

reasonable control of Maxwell or the purchaser.

2. Maxwell’s liability shall be limited to repair or replacement (as determined by Maxwell) of the goods or parts defective in

materials or workmanship.

3. Determination of the suitability of the product and the materials for the use contemplated by the buyer is the sole responsibility

of the buyer, and Maxwell shall have no responsibility in connection with such suitability.

4. Maxwell shall not be liable for any loss, damages, harm or claim attributed to:

(a) use of the products in applications for which the products are not intended.

(b) corrosion, wear and tear or improper installation.

(c) improper use of the product.

5. This Warranty applies to the original purchaser of the products only. The benefits of the Warranty are not transferable to

subsequent purchasers.

6. Maxwell shall not be responsible for shipping charges or installation labour associated with any warranty claims.

7. There are no warranties of merchantability, fitness for purpose, or any other kind, express or implied, and none shall be implied

by law. If any such warranties are nonetheless implied by law for the benefit of the customer they shall be limited to a period of

three years from the original purchase by the user.

8. Maxwell shall not be liable for consequential damages to any vessel, equipment, or other property or persons due to use or

installation of Maxwell equipment.

9. This Warranty sets out your specific legal rights allowed by Maxwell; these may be varied by the laws of different countries. In

addition, the purchaser may also have other legal rights which vary from country to country.

10. To make a claim under this Warranty, contact your nearest Maxwell Marine office or distributor. Proof of purchase and

authorisation from Maxwell will be required prior to any repairs being attempted.

To be eligible for warranty protection, please either complete

the form below at the time of purchase and return it to the

appropriate address above, or fill out the electronic Warranty

Form on our website, www.maxwellmarine.com

Purchaser

Name:

Telephone: Facsimile

Address:

Supplier / Dealer

Name:

Telephone: Facsimile

Address:

Windlass Model Serial Number

Date of Purchase

Boat Type

Name L.O.A.

Built by

Windlasses Supplied

With boat

Fitted by boat yard/dealer

Purchased from dealer/chandler

47

Page 48

Page 49

Loading...

Loading...