Page 1

Gasoline Powered

Pressure Washer

Operating Instructions and Parts List PW2515

Carefully read and understand these instructions

before operating your pressure washer.

© 2006 Campbell Hausfeld/Scott Fetzer

IN467900AV 8/06

Getting To Know Your Pressure Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety and Warning Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Pre-Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 9

Maintenance and Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Replacement Parts Lists

• Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

• Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Contents Page

For parts, product & service information

visit www.chpower.com

Please record Model No. and Serial No. for use when contacting

the manufacturer:

Model No. ______________ Purchase date ____________________

Serial No. ______________ Purchase place ____________________

For Information About This Product, call 1-800-330-0712

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Model PW2515

Page 2

Pressure Washer

2

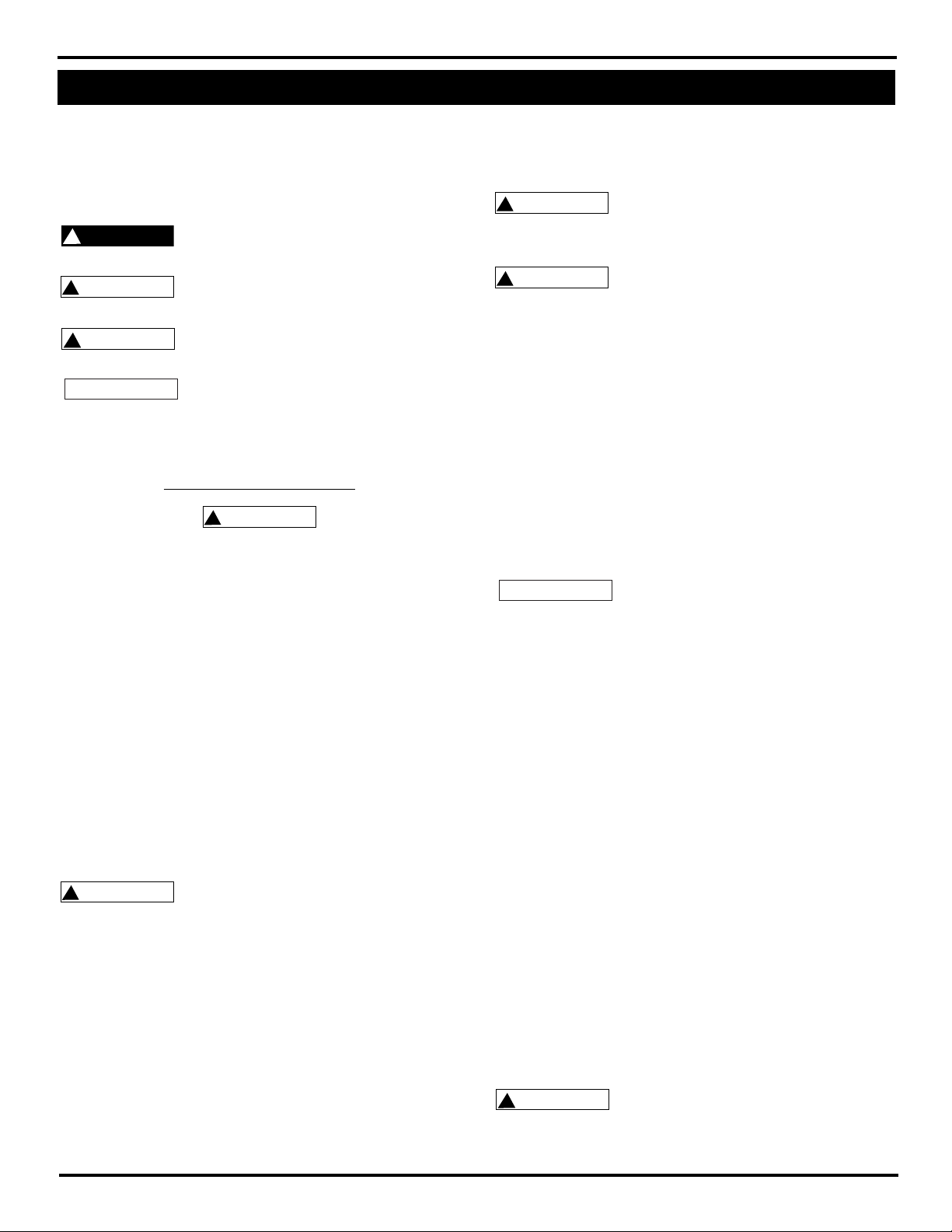

1 Detergent Tank

2 Muffler

3 Location of Serial Number/Product Decal

4 (Pump) Inlet Connection for Garden Hose

5 Lance with Quick Connect

6 Tip Holder with Spray Tips

7 Handle

8 Gun with trigger

9 Fuel Tank

10 Choke

11 Engine switch - On/Off

12 Fuel Valve - On/Off

13 (Pump) Outlet Connection for High Pressure

Hose

1

2

3

6

9

10

11

12

13

PW2515

www.chpower.com

Getting To Know Your Pressure Washer

5

4

7

8

Page 3

Pressure Washer

How do I start my pressure

washer?

1. Make sure you have gas and oil in the engine. The

engine DOES NOT COME FILLED WITH OIL.

2. Turn the water on, then trigger the gun to make sure the

water will flow smoothly out of the tip.

3. Open the fuel shutoff valve by turning the knob

counterclockwise until it stops.

4. Close the choke (if engine is cold) by moving the choke

ring fully to the right.

5. Set the shut off switch to “ON.”

6. Pull the trigger (to relieve any back pressure in the pump)

while pulling the starter cord.

What type of oil do I use?

ENGINE DOES NOT COME FILLED WITH OIL: See Page 10 for

engine oil types, quantities, and oil changing instructions.

Pump: The pump comes filled with the correct amount of

oil and should not need changing or filling.

Why don’t I have any water

pressure?

• Is the water hose attached to the pressure washer?

• Is the water turned on?

• Check for any kinks, leaks, or blockage in the hoses,

fittings, or the nozzle.

• Is the 15º (yellow) spray tip inserted into the end of the

lance (See Page 8)?

• Is the inlet filter screen free of debris? Check and remove

debris if needed.

How do I get high pressure?

• For high pressure, insert the 15º (yellow) spray tip into

the end of the lance (See Page 8).

How do I get the soap suction to

work?

1. Connect the clear plastic chemical suction tube to the

plastic hose barb on detergent tank.

2. Fill the detergent tank with detergent forumlated for use

with pressure washers.

3. To spray soap, insert the 65° (black) soap spray tip into

the end of the lance (see page 8).

3

Why doesn’t the pressure

washer apply detergents with

high pressure?

Detergents “bounce” off cleaning surfaces as fast as they are

applied. The pressure washer’s features allow for a detergent

to be drawn while in low pressure mode only. By applying

detergent at low pressure, the effect of “bouncing” is

reduced. Also, detergents are only effective when time is

allowed for them to work on the surface of whatever is

being cleaned. After applying the detergent, wait 1-3

minutes while it works, and then proceed to rinse the surface

with high pressure.

What maintenance do I need to

perform on my pressure washer?

1. After turning off the pressure washer and the water,

depressurize the hose by triggering the gun.

2. Remove the garden hose and high pressure hose from the

pump.

3. Pull the start rope slowly five times to purge water from

the pump. This will help protect the pump from damage.

4. Do not store your pressure washer in an area where the

temperature will drop below 32˚ F.

5. Follow proper storage and winterizing instructions found

on page 9.

What do I do if I’m missing a

part?

Call Campbell Hausfeld at 1-800-330-0712 and we will

promptly replace your missing parts. DO NOT RETURN THE

PRESSURE WASHER TO THE RETAILER!

Where can I buy accessories for

my pressure washer?

• If you can’t find accessories at the store where you

purchased your pressure washer, call Campbell Hausfeld

at 1-800-330-0712 or visit our website at

www.chpower.com.

Who do I call if I have questions

or problems?

Call Campbell Hausfeld at

1-800-330-0712 (U.S.A.)

www.chpower.com

Frequently Asked Questions

Page 4

www.chpower.com

• Always follow detergent manufacturer’s label

recommendations for proper use of detergents. Always

protect eyes, skin, and respiratory system from detergent

use.

Do not use pressure that exceeds the

operating pressure of any of the parts

(hoses, fittings, etc.) in the pressurized system. Ensure all

equipment and accessories are rated to withstand the

maximum working pressure of the unit.

Explosion hazard.

• NEVER spray flammable liquids or use pressure washer in

areas containing combustible dust, liquids, or vapors.

• Never operate this machine in a closed building or in or

near an explosive environment.

• Do not remove fuel tank cap or fill fuel tank while engine

is hot or running (allow engine to cool two minutes

before refueling). Always fill the tank slowly.

• Never disconnect the high pressure discharge hose from

the machine while the system is pressurized. To

depressurize machine, turn power and water supply off,

then press the gun trigger 2-3 times.

• Never permanently engage the trigger mechanism on the

gun.

• Never operate the machine without all components

properly connected to the machine (handle, gun/wand

assembly, nozzle, etc.).

Equipment damage.

• ALWAYS turn water supply “ON” before turning pressure

washer “ON.” Running pump dry causes serious damage.

• Do not operate the pressure washer with the inlet water

screen removed. Keep screen clear of debris and

sediment.

• NEVER operate pressure washer with broken or missing

parts. Check equipment regularly and repair or replace

worn or damaged parts immediately.

• Use only the nozzle supplied with this machine.

• Never leave the wand unattended while the machine is

running.

• Never tamper with the engine governor or attempt to

alter factory settings. Altering factory settings could

damage the unit and will void the warranty.

• Always hold gun and wand firmly when starting and

operating the machine.

• NEVER allow the unit to run with the trigger released

(off) for more than one minute. Resulting heat buildup

will damage the pump.

• NEVER store the pressure washer outdoors or where it

could freeze. Freezing temperatures can seriously damage

the pump.

• Release the trigger when changing from high to low

pressure modes. Failure to do so could result in damage

to the nozzle.

Keep hose away from sharp objects.

Bursting hoses may cause injury. Examine

hoses regularly and replace if damaged. Do not attempt to

mend a damaged hose.

Safety Guidelines

This manual contains information that is very important to

know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help

recognize this information, observe the following symbols.

Danger indicates an imminently

hazardous situation which, if not

avoided, WILL result in death or serious injury.

Warning indicates a potentially

hazardous situation which, if not

avoided, COULD result in death or serious injury.

Caution indicates a potentially hazardous

situation which, if not avoided, MAY

result in minor or moderate injury.

Notice indicates important information, that

if not followed, may cause damage to

equipment.

NOTE: Information that requires special attention.

Important Safety Instructions

SAVE THESE INSTRUCTIONS

When using this product, basic precautions should always be

followed, including the following:

1. Read all instructions before using the product.

2. To reduce the risk of injury, close supervision is necessary

when the product is used near children.

3. Follow all safety codes as well as the Occupational Safety

and Health Act (OSHA).

4. Ensure safety devices are operating properly before each

use. DO NOT remove or modify any part of the gun or unit.

5. Know how to stop this product and bleed pressure quickly.

Be thoroughly familiar with the controls.

6. Stay alert – watch what you are doing.

7. Do not operate the product when fatigued or under the

influence of alcohol or drugs.

8. Keep operation area clear of all persons.

9. Do not overreach or stand on unstable support. Keep good

footing and balance at all times.

10. Follow the maintenance instructions specified in the

manual.

Risk of injection or severe injury. Keep

clear of nozzle. Do not discharge streams

at persons. This product is to be used only by trained

operators. Always remove lance from gun before cleaning

debris from tip.

• Keep clear of nozzle. NEVER direct high pressure spray at

a person, animal, or yourself.

• Always wear safety glasses or goggles and protective

equipment (hearing protection, gloves, rubber boots,

protective clothing) when operating or performing

maintenance.

• Never put hand or fingers over the spray tip while

operating the unit.

• Never try to stop or deflect leaks with any body part.

• Always engage the trigger safety latch in the safe

position when spraying is stopped even if only for a few

moments.

Safety and Warning Information

Pressure Washer

4

!

DANGER

!

WARNING

!

CAUTION

NOTICE

!

WARNING

!

WARNING

!

WARNING

!

WARNING

NOTICE

!

CAUTION

Page 5

UNPACKING

Remove the equipment and all parts from

the carton. The carton should contain the

following.

• One pressure washer (pump, engine,

cart base)

• One cart handle assembly

• One detergent tank

• One spray gun

• One lance

• One tip holder with 2 spray tips.

Additional tips available for purchase,

see Page 13

• One high pressure hose

• One pack of nuts, bolts, and manuals

• One bottle of engine oil

If any parts are missing, DO NOT RETURN THE UNIT TO THE

RETAILER. Know the unit’s model number (located on the

serial number tag on the pressure washer frame) and call 1800-330-0712 for replacement parts.

After unpacking the product, inspect it carefully for any

damage that may have occurred during transit. Make sure to

tighten fittings and bolts before using the pressure washer.

Do not operate the unit if it’s damaged

during shipping, handling, or use.

Damage could result in bursting and cause injury or property

damage.

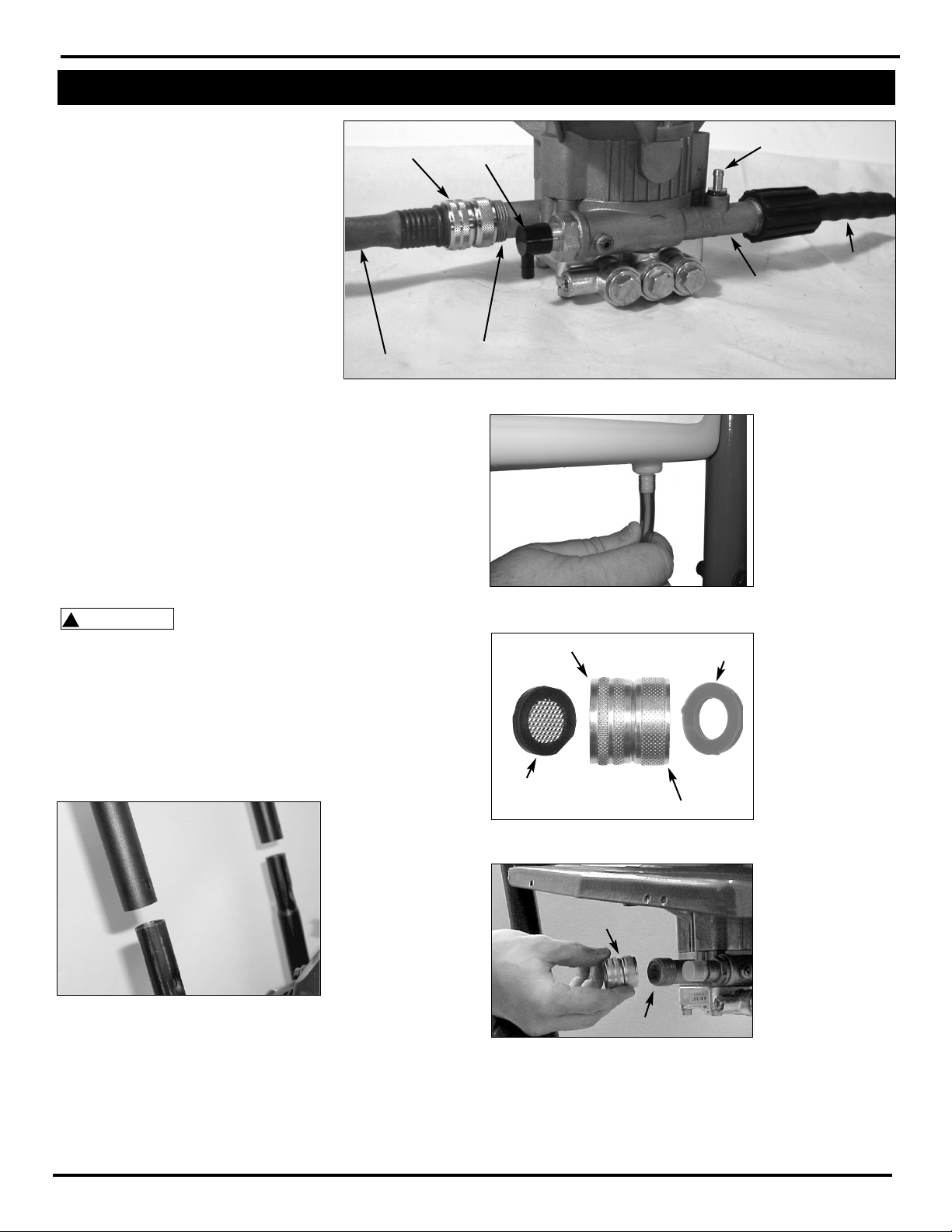

ASSEMBLY

Use two adjustable or 7/16” wrenches to assemble the

pressure washer.

1. Slide the handle assembly over the lower legs of the cart

base. Use the supplied nuts and bolts to secure the handle

to the legs. See Figure 1.

2. Attach detergent tank to backside of handle. Use the 4 hex

bolts with flat washer under hex head and 4 nuts provided.

3. Slide clear plastic hose attached to leg onto plastic hose barb

of detergent tank (see Figure 3).

4. Brass Swivel Adaptor (See Figure 2). If it’s not already

attached to the pump inlet, assemble the brass swivel adapter

and attach it to the pump inlet (See Figure 4 and Figure 5). Be

sure to connect the correct side of the brass swivel adapter to

the pump.

5. Secure garden hose (not included) to the inlet connection

on pump.

Pressure Washer

5

Pre-Operation

Figure 1 – Assemble Handle

Figure 3 – Attach suction tube to barb

fitting

Figure 4 - Brass swivel adapter

Connect this end to garden hose

Connect this end to pump

Washer

Washer

with filter

screen

Figure 5 - Connect the brass swivel to

the pump

Brass swivel adapter

Pump inlet

Figure 2 - Pump hook up

Brass swivel

adapter

Garden hose

Pump inlet

Pump

outlet

Chemical injector

hose barb

High

pressure

hose

Thermal

relief valve

www.chpower.com

!

WARNING

Page 6

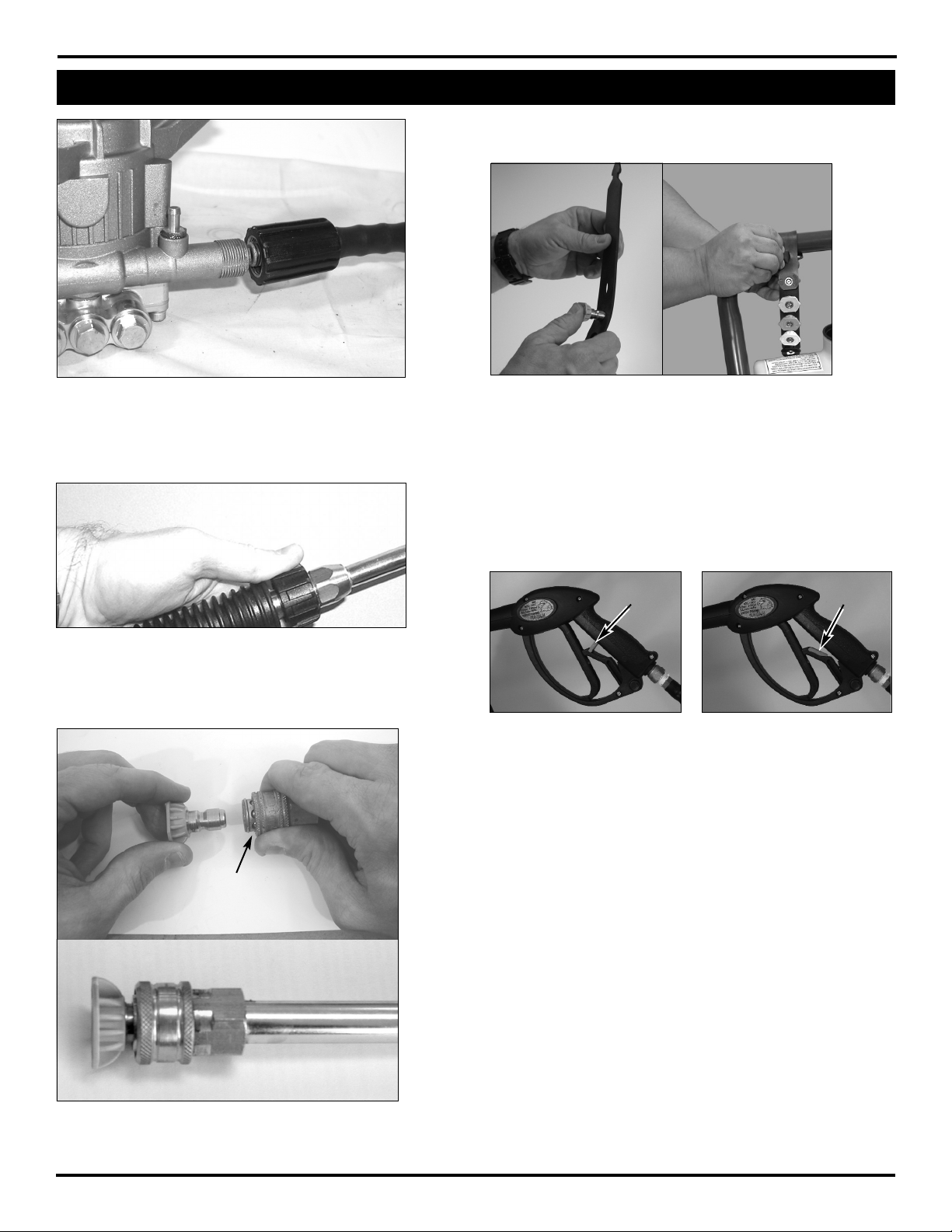

8. Install quick connect tip by pulling back on collar and pressing

in tip. Release collar, make sure it completely returns to its

forward position and tip is secure (see Figure 8).

Figure 10a - Trigger locked Figure 10b - Trigger unlocked

Engaged

6

Pre-Operation (Continued)

6. Connect the high pressure hose to the pump outlet (See Figures

2 and 6).

7. Attach the lance to the gun (see Figure 7).

Pressure Washer

Figure 6 – Connect high pressure hose to pump

www.chpower.com

Disengaged

Figure 7– Attach lance to gun

9. Install quick connect tips to tip holder and secure to the

pressure washer handle. See Figure 9.

TRIGGER SAFETY LATCH

In the engaged position, the trigger safety latch prevents the

gun from being triggered accidentally. Push the latch fully up to

engage it (See Figure 10).

Always engage the trigger safety latch when the unit is not in

use.

Figure 8 - Installing Quick Connect Tip

Pull collar back

Figure 9 - Insert spray tips into the rubber tip holder

Page 7

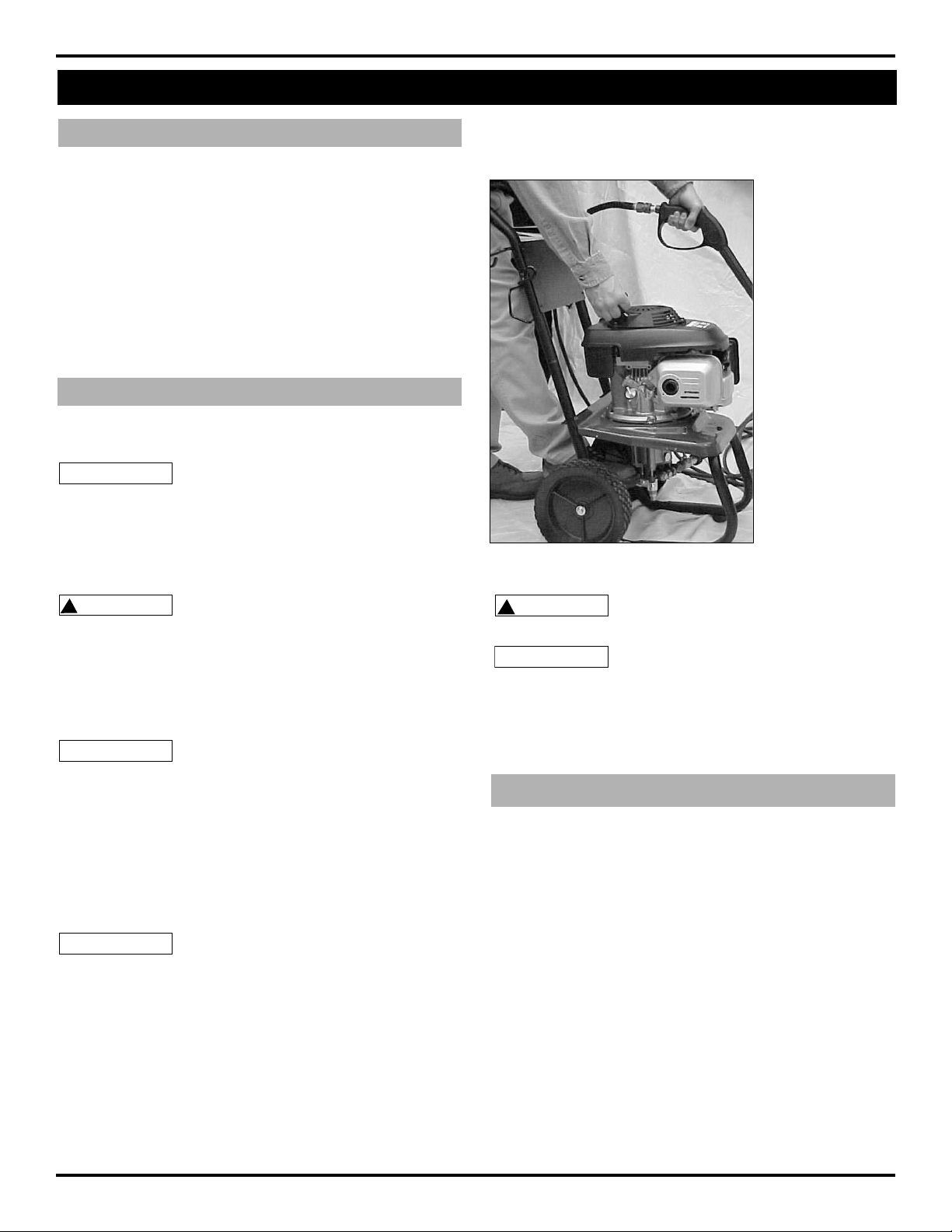

the trigger on the gun, pull the starter rope rapidly and firmly

(See Figure 11). Continue holding the rope as it returns. Repeat

these steps until the engine starts.

When pulling the starter rope, make

sure to keep your hand and arm clear of

the engine and cart components.

Never let the starter rope return by itself.

Doing so could jam the recoil system.

8. If the engine does not start after two or three pulls or if the

rope is hard to pull, squeeze the gun trigger to release the

pressure that has built up in the high pressure hose. Repeat

Steps 7 and 8 until the engine starts.

Spray the cleaning surface with water to clear off any dirt or

grime that may have collected on the surface. Doing so allows

the detergent to attack the deep down dirt that has worked its

way into the cleaning surface.

ANGLE TO THE CLEANING SURFACE

When spraying water against a surface, you can generate

maximum impact by striking the surface head on. However,

this type of impact can cause dirt particles to embed in the

surface and can prevent the desired cleaning action.

The optimum angle for spraying water against a cleaning

surface is 45 degrees (see Figure 12).

Spray water against a surface at a 45 degree angle to achieve

the most beneficial impact force and to efficiently remove

debris.

The following cleaning procedure will help you organize

your cleaning task and ensures that you will achieve the best

results in the shortest amount of time. Remember to use the

spraying / cleaning techniques mentioned in the following

section.

Before starting a pressure washer cleaning job, prepare the

surface you intend to clean. Clear furniture from the area

and make sure that all windows and doors are closed tightly.

Also, protect all plants and trees near the cleaning area with

a drop cloth. A covering ensures that your plants won’t be

sprayed by the detergents.

ALWAYS use the following start up procedure to ensure that the

unit is started safely and properly.

If water has frozen in the pressure

washer, thaw the pressure washer in a

warm room before starting. DO NOT pour hot water on or

into the pump; internal parts will be damaged.

1. Check engine oil levels. Add oil as necessary.

2. Check fuel level. Add unleaded gasoline (rated 86 octane or

higher) as required

DO NOT refuel a hot engine. Refueling

a hot engine could cause a fire. Use only

fresh, clean regular or unleaded gasoline. Close the fuel

shutoff valve during refueling.

3. Attach a garden hose to the inlet side of the pump and

connect it to the water supply. Use a hose with an internal

diameter (I.D.) of 5/8” (1.58 cm) and a length of 50 ft. (15 m) or

less.

Some local plumbing codes require

backflow prevention when connecting to

a fresh water supply. Install a backflow preventer upstream

from the pump if necessary.

a. If inlet water pressure is over 100 psi, install a regulating

water valve at the garden hose connection.

b. Do not exceed 100˚ F (38˚ C) inlet water temperature.

NOTE: The inlet water supply must have a minimum flow rate of

5 gpm (19 lpm).

4. Turn the water supply ON.

Never run the unit dry. Be sure the

water supply is completely turned on

before operating the unit.

5. Trigger the gun until water sprays smoothly from the tip

indicating that all air is purged from the system. Lock the

trigger safety latch.

6. Open the fuel valve by turning the knob counterclockwise

until it stops. Close the choke (if engine is cold) by moving

the choke ring fully to the right. Turn the ignition switch to

“ON”.

7. Start the engine (See Figure 10). Unlock the trigger safety

latch on the gun. Grasp the starter rope and brace one foot on

the chassis. Point the gun in a safe direction. While squeezing

Figure 11 - Start the engine

Operation

Pressure Washer

7

www.chpower.com

1. Surface Preparation

2. Start Up

3. Initial High Pressure Rinse

!

NOTICE

!

WARNING

!

NOTICE

!

NOTICE

!

CAUTION

!

NOTICE

Page 8

Pressure Washer

DISTANCE FROM CLEANING SURFACE

The distance between the spray tip and the cleaning surface is

another factor that affects the impact force of the water. The

impact force of the water increases as the spray tip is moved

closer to the surface.

HOW TO AVOID DAMAGING SURFACES

Damage to cleaning surfaces occurs because the impact force

of the water exceeds the durability of the surface. You can

vary the impact force by controlling the spray tip angle to

the cleaning surface and the distance from the cleaning

surface and by changing the spray tip. NEVER use a narrow

high impact stream on a surface that is susceptible to

damage. Avoid spraying windows with a narrow high impact

stream. Doing so may break the window. The most sure way

to avoid damaging surfaces is to follow these steps:

1. Before triggering the gun, make sure the quick connect

tip you are using is appropriate for the application.

2. Place the spray tip approximately 4-5 feet (1,22-1,52 m)

away from the cleaning surface. Then hold the lance and

spray tip at a 45 degree angle to the cleaning surface.

Trigger the gun.

3. Vary the fan pattern spray angle and the distance to the

cleaning surface until optimum cleaning efficiency is

achieved without damaging the surface.

NOTE: Use only detergents formulated for pressure washers.Test

detergent in an inconspicuous area before use.

DETERGENTS

The use of detergents can dramatically reduce cleaning time

and assist in the removal of difficult stains. Many detergents

are customized for pressure washer use on specific cleaning

tasks. Pressure washer detergents are as thick as water.

Using thicker detergents – like dish soap – will clog the

chemical injection system and prevent the application of the

detergent.

Once applied to a cleaning surface, detergents take time to

break down dirt and grime. Detergents work best when applied

at low pressure.

You can effectively clean surfaces by combining the chemical

action of detergents with high pressure rinses. On vertical

surfaces, apply the detergent starting at the bottom and work

your way upward. This method prevents the detergent from

sliding down and causing streaks. Begin high pressure rinsing at

the bottom and work your way upward. On particularly tough

stains, use a brush in combination with detergents and high

pressure rinsing.

1. Follow manufacturer’s label directions for mixing correct

concentrations of soap/detergents. The soap detergent to

water ratio through the pump is approximately 12% (1 to

8).

2. Pour detergent into the detergent tank. The tank capacity is

1.5 gallons.

3. Install 65º (Black) Low Pressure Detergent Tip in the quick

connect fitting on the end of the lance.

NEVER replace quick connect tip when gun

is triggered. Always engage trigger lock on

gun before removing or installing quick connect tips.

GENERAL CLEANING TIPS

1. Apply the detergent so that it thoroughly covers the

cleaning surface. Apply the detergent from bottom to top

to prevent the detergent from sliding down and streaking.

Wait a couple of minutes for the detergent to break down

the dirt and grime. Use a brush to lightly scrub heavily

soiled areas. Never allow the detergent to dry on the

cleaning surface.

2. Replace black 65º quick connect tip with the yellow 15º tip

and complete final rinse.

NEVER replace quick connect tip when gun

is triggered. Always engage trigger lock on

gun before removing or installing quick connect tips.

3. NOTE: After using detergents, flush the suction system by

rinsing out tank with clean water and running unit with

black 65º tip flushing clean water from tank through the

pump.

8

www.chpower.com

Operation (Continued)

4. Detergent Application

The color of the tip shows what spray angle it is:

Red – 0° – Maximum Duty*

Yellow – 15° – Heavy Duty

Green – 25° – General Duty*

White – 40° – Light Duty*

Black – 65° – Low Pressure Detergent

* = Not Included

Figure 12 - Optimum angle to cleaning

surface

!

WARNING

!

WARNING

Page 9

The easiest way to regulate the cleaning power of your

pressure washer is by changing the distance from the surface

you are cleaning. Begin spraying while standing several feet

from the surface. Slowly move closer to the object you are

cleaning until you find the most effective cleaning technique.

The final rinse should start at the bottom and work upward.

Make sure that you thoroughly rinse the surface and that you

remove all detergent.

To reduce the risk of bodily injury or property damage, always

follow this procedure whenever spraying is stopped, when work

is completed, and before checking or repairing any part of the

system.

1. Engage the trigger safety latch.

2. Turn the unit off.

3. Shut off the water supply.

4. Disengage the trigger safety latch and trigger the gun to

relieve pressure.

5. Re-engage the trigger safety latch.

6. When checking or repairing unit, remove the ignition cable

from the spark plug.

7. Before overnight storage, long term storage, or transporting

unit, disconnect the water supply and turn off the fuel supply

valve.

1. Be sure all detergent is flushed from system.

2. Turn the engine OFF.

3 Turn the water supply OFF.

4. After the engine and water supply are turned off, trigger the

gun to depressurize the system.

NEVER turn the water supply off before

turning the engine/motor off. Serious

damage could occur to the pump and/or engine/motor.

NEVER disconnect the high pressure

discharge hose from the machine while the

system is pressurized. To depressurize, turn engine/motor off, turn

water supply off and squeeze gun trigger 2-3 times.

5. After each use, wipe all surfaces of the pressure washer with

a clean, damp cloth.

• Do not store the pressure washer outdoors.

• Do not store the pressure washer where it might freeze

unless it has been properly winterized.

5. Cleaning Power

7. Pressure Relief Procedure

8. Shutdown

9. Storage

6. Final Rinse

Operation (Continued)

Pressure Washer

www.chpower.com

9

LONG TERM STORAGE INSTRUCTIONS (MORE THAN 30 DAYS

IN STORAGE)

1. Remove fuel from the tank and run the pressure washer in a

normal operating mode until the engine stops from a lack of

fuel. Normal operating mode means actually spraying water

from the gun while the engine is running.

Alternate method – Add fuel stabilizer to gas in the tank and

run in normal operating mode for at least five minutes.

2. Stop the engine, turn off the water supply, and trigger the

gun to release pressure in the high-pressure hose.

3. Disconnect the water supply and high pressure hose from the

pump.

4. Allow the engine to cool.

5. Disconnect the spark plug wire and remove the spark plug.

6. Pour 1/2 oz. of engine oil into the spark plug hole.

Never pull the starter rope on the engine

when the spark plug is removed unless the

spark plug hole is covered. Fuel vapor from the hole can ignite by

a spark.

7. Place a rag over the spark plug hole and slowly pull the

starter rope several times to distribute the oil.

WINTERIZING INSTRUCTIONS

1. Follow and complete the Long Term Storage Instructions

above.

2. Disconnect the spark plug wire.

3. Disconnect the high pressure hose from the pump.

4. Insert a 12” to 14” piece of garden hose into the pump inlet.

5. Place a funnel in the other end of the garden hose.

Read the manufacturer’s instructions for

safe handling and disposal of RV

antifreeze.

6. Pour approximately 6 oz. of RV antifreeze into the funnel.

7. Pull the starter rope several times until the RV antifreeze

comes out of the pump outlet.

8. Disconnect the high pressure hose from the gun and drain

the hose. Hold the gun and lance in a vertical position and

squeeze the trigger to drain the water out.

TIPS FOR EXTENDING THE LIFE OF YOUR PRESSURE WASHER

1. Never operate the unit without water.

2. Your pressure washer is not meant to pump hot water. Never

connect your pressure washer to a hot water supply as it will

significantly reduce the life of the pump.

3. Running the unit for more than one minute without spraying

water causes heat to build up in the pump. Running the unit

without spraying water can damage pump components.

!

NOTICE

!

CAUTION

!

WARNING

NOTICE

Page 10

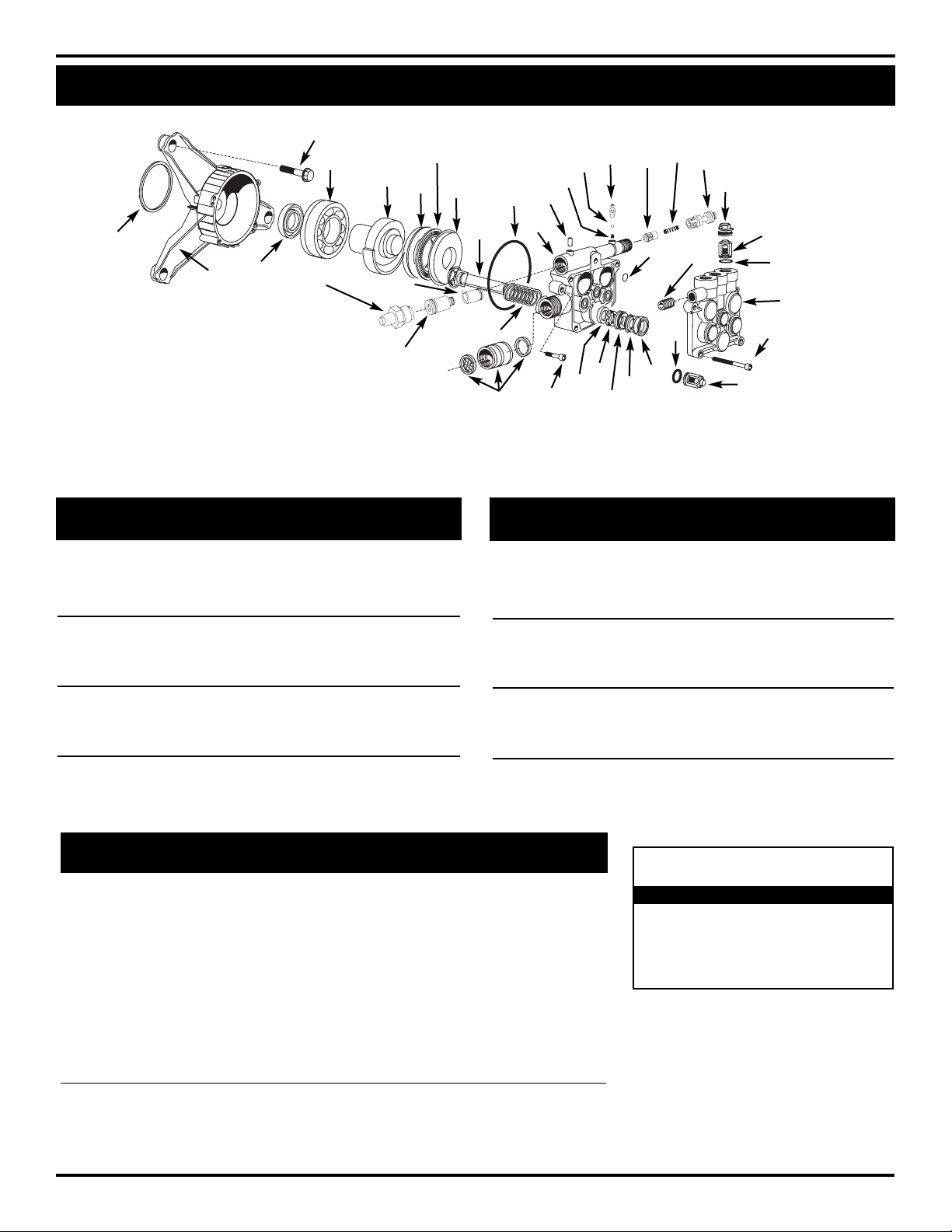

Engine Oil Type SAE 10W-30

SAE 30W (Above 60˚ F)

Engine Oil Capacity

Honda engines 18.5 fl. oz.

Engine Fuel Capacity

Honda engines 0.29 gal

Pump Oil Type

Wobble pumps SAE20W or SAE30W

non-detergent oil

Pump Oil Capacity

Vertical wobble pumps 4.0 fl. oz.

Pump Detergent Suction

Water to detergent ratio 8 to 1 (12% detergent)

Water Supply Requirements

Minimum inlet pressure 20 psi

Maximum inlet pressure 100 psi

Maximum inlet temperature 100˚ F

Minimum inlet flow rate 5 gpm

Inlet garden hose size 5/8” I.D.

Maximum inlet garden

hose length 50 ft

Daily

After first 5 hours of

operation

Every 25 hours of

operation

Every 50 hours of

operation

Each 100 hours of

operation or every 3

months

• Check water inlet screen and

filter.

• Check engine oil levels. Fill as

necessary.

• Check gasoline level. Fill as

necessary.

• Change engine break-in oil.

Use SAE30 or 10W-30

detergent oil.

• Change oil if operating under

heavy load or high ambient

temperature.

• Clean or replace paper air

cleaner cartridge. Tap gently

to remove dirt.

• Change oil.

• Replace spark plug.

• Replace paper air cleaner

cartridge.

• Change engine oil.

Maintenance Schedule Action needed

Maintenance Schedule

Vertical Oriented Pressure Washers

Technical and Consumer Information

Pressure Washer

10

Maintenance

Observe regular maintenance intervals to ensure maximum

performance and life from the pressure washer. Refer to the

schedule for recommended maintenance. If you operate the

pressure washer in dusty conditions, perform maintenance

checks more often.

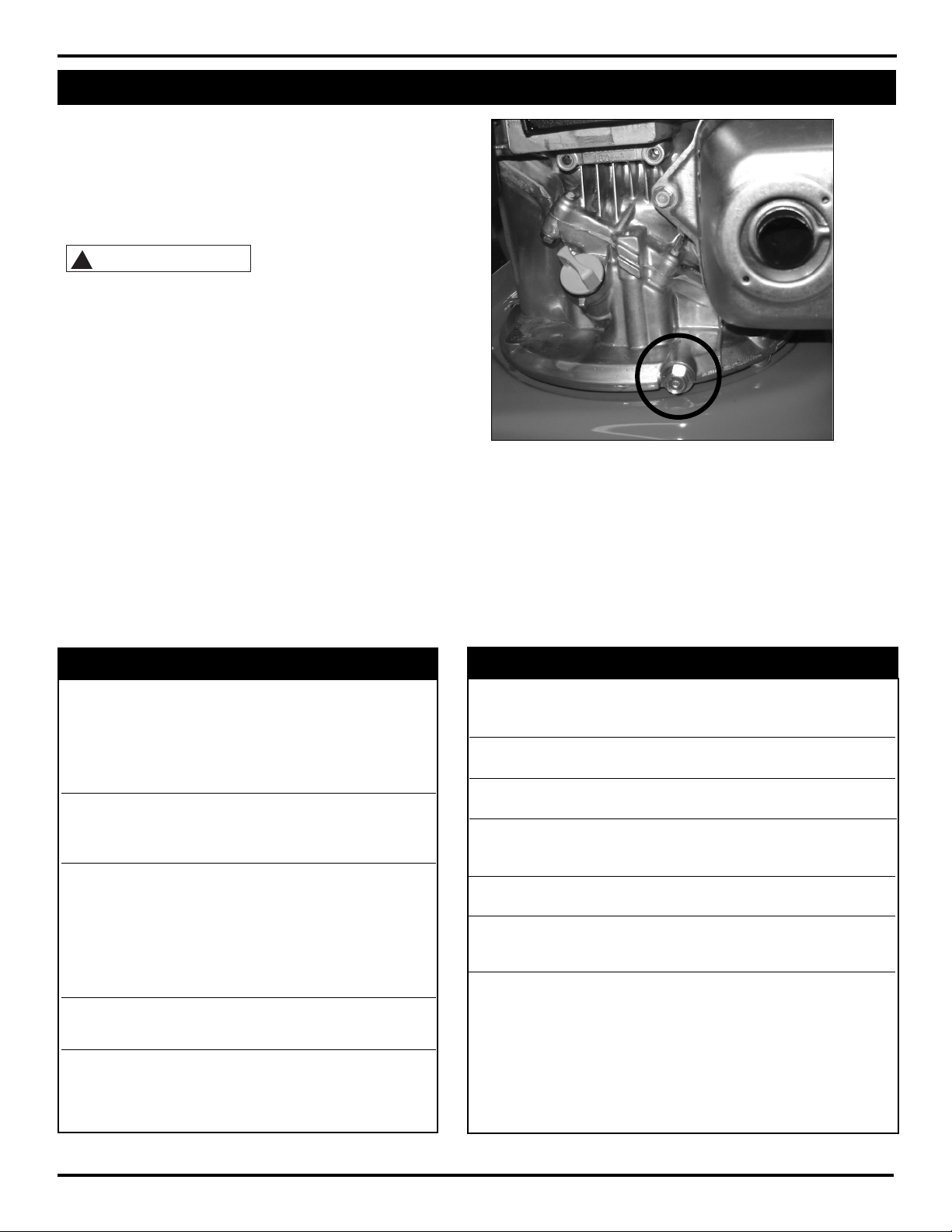

ENGINE OIL CHANGING INSTRUCTIONS

Before tipping the

engine or equipment to

drain oil, drain fuel from the fuel tank.

NOTE: Change oil while the engine is cool.

1. Disconnect the spark plug wire from the spark plug.

2. Locate and remove the engine oil drain plug (See Figure

13).

3. Drain old oil.

4. Replace the drain plug and set the unit upright.

5. Refill the unit with new oil of a recommended type and

quantity. Fill the unit to the proper level shown on the dipstick.

PUMP OIL CHANGING INSTRUCTIONS

Changing or refilling the oil in the pump requires removal of

the pump from the engine and should not be required unless

oil has leaked out due to worn or damaged oil seals in the

pump. If oil has leaked out of the pump, bring the pressure

washer to a certified Campbell Hausfeld service center for

repair.

Figure 13 - Oil Drain Location

www.chpower.com

!

CAUTION

Page 11

www.chpower.com

11

Service Record

Pressure Washer

Date Maintenance performed Replacement components required

Page 12

5

6

7

8

1

2

3

4

39

11

12

16

17

18

19

13

14

15

20

21

22

23

28

29

24

25

26

10

9

27

30

31

32

37

33

34

35

36

38*

Ref.

Description

Part

Qty

.

No. Number

12

Pressure Washer

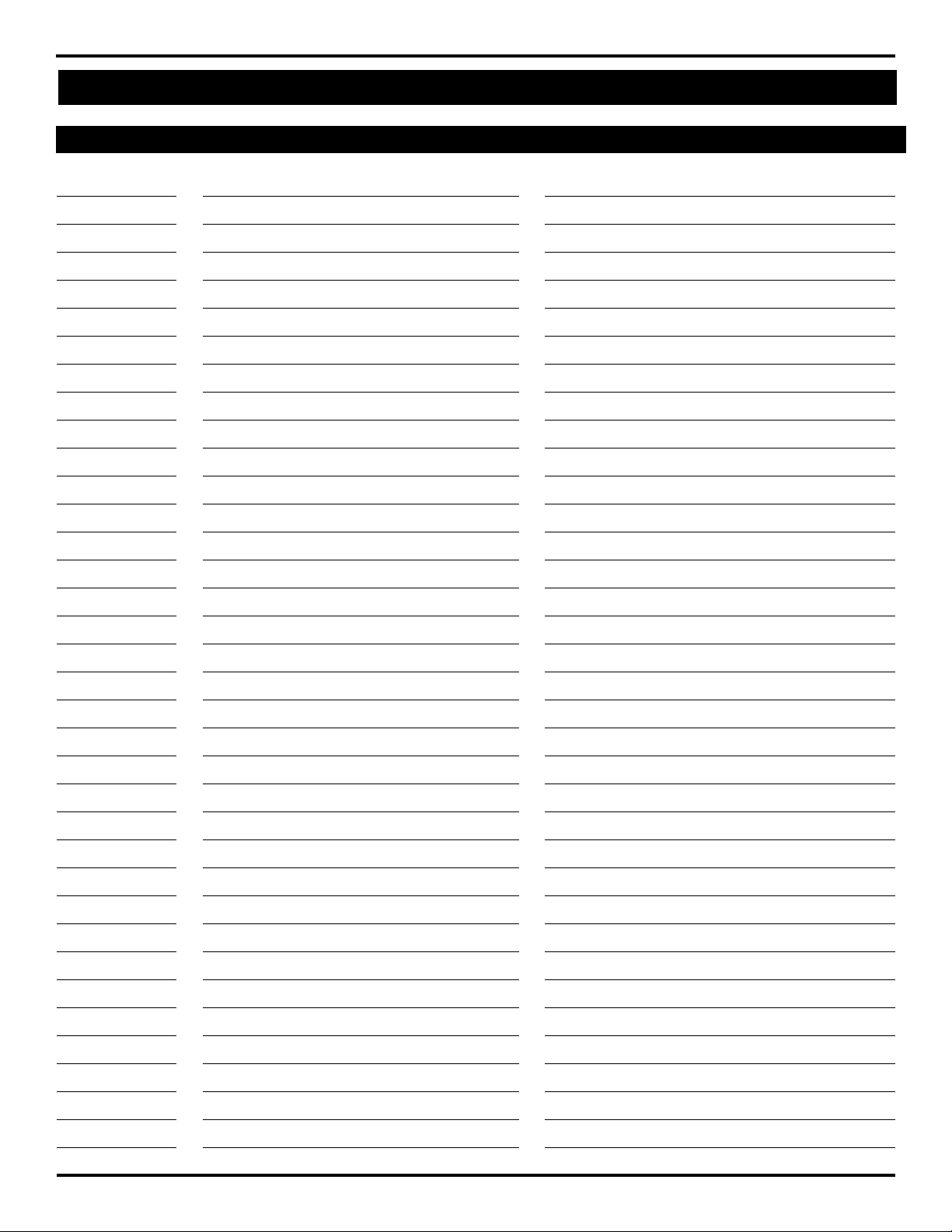

Replacement Parts List — Pump PM341000SJ

For Replacement Parts, Call 1-800-330-0712

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Campbell Hausfeld

Attn: Customer Service

100 Mundy Memorial Drive

Mt. Juliet, TN 37122

Housing assembly (Includes one each of items 1-5) PM255230SV 1

Unloader assembly (Includes one each of items 7-10 and 26) PM344900SV 1

Oil seal kit (Includes three each of item 12) PM256500SV 1

Piston guide kit (Includes three each of items 13-15) PM344905SV 1

Water seal kit (Includes three each of item 16) PM344910SV 1

Outlet valve kit (Includes three each of items 21 and 22) PM064304SV 1

Inlet valve kit (Includes three each of items 17 and 18) PM064740SV 1

Valve cap kit (Includes three each of item 23) PM064750SV 1

O-ring kit (Includes three each of items 17 and 21

and one each of items 25 and 33) PM058000SV 1

Detergent injector kit (Includes one each of items 27-29) PM064305SV 1

Piston kit (Includes three each of items 32 and 34) PM344920SV 1

Needle bearing kit (Includes one each of items 35-37) PM041840SV 1

Notes

* Available Separately

Oil capacity: 4 fl. oz.

OIl type: SAE 30W (non-detergent)

PAR T

SERVICE KITS NUMBER QTY.

TORQUE SPECIFICATIONS

(in-lbs)

Ref. No. Description Torque

6 Thermal relief valve 110

11 Screw 96

19 Head bolt 96

23 Valve cap 240

21 O-ring –

22 Outlet valve assembly –

23 Valve cap –

24 Plug PM064301SV 1

25 O-ring PM041870SV 1

26 Chemical injector assembly PM341015SV 1

27 Spring –

28 Ball –

29 O-ring and hose barb –

30 Screw PM064302SV 1

31 Piston body PM341020SV 1

32 Piston spring –

33 O-ring, 85 x 2.5 –

34 Piston –

35 Thrust shoe –

36 Needle bearing –

37 Bearing disk –

38* Bolt MJ101211AV 3

39 Brass swivel assembly PM041360SV 1

Ref.

Description

Part

Qty

.

No. Number

1 Dust ring –

2 Pump housing –

3 Oil seal ring –

4 Bearing –

5 Wobble plate –

6 Thermal relief valve PM005405SV 1

7 Unloader valve body assembly –

8 Body guide assembly –

9 Check valve body assembly –

10 Check valve spring 1

11 Screw PM007500SV 2

12 Oil seal –

13 Oil seal spacer –

14 Seat seal ring –

15 Anti-extrusion ring –

16 Water seal –

17 O-ring –

18 Suction valve –

19 Head bolt PM025100SV 4

20 Head, 12 mm PM255240SV 1

www.chpower.com

Page 13

Pressure Washer

13

Replacement Parts List — Vertical Shaft Pressure Washer

Ref

Description

Product

Qty

No. Number

1 Handle tube PM344830BH 1

2 * 1/4” - 20 Bolt (handle) PM001903AV 2

3 * Flat washer PM002000AV 18

4 * 1/4” - 20 Nylon lock nut ST073808AV 7

5 * 1/4” - 20 Bolt (base) PM001902AV 3

6 Left leg PM344828BH 1

7 Right leg PM345100BH 1

8 Rubber bumper AL062300AV 2

9 * 1/4” - 20 x 3/4 Self tapping

screw MJ102100AV 2

10 Wheel WA005600AV 2

11 Pushnut PM066300AV 2

12 * 1/4” - 20 Bolt (axle) PM001904AV 2

13 Axle PM344831BH 1

14 Baseplate PM345520AV 1

15 Detergent tank assembly PM252000SJ 1

16 1/4” - 20 Serrated nut (tank) PM031101AV 4

17 1/4” - 20 Bolt, (tank)" MJ101104AV 4

For Replacement Parts, Call 1-800-330-0712

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Campbell Hausfeld

Attn: Customer Service

100 Mundy Memorial Drive

Mt. Juliet, TN 37122

Ref

Description

Product

Qty

No. Number

18 Cap PM252450AV 1

19 Detergent tube PM013700SV 1

20 Gun PM005136AV 1

21 O-ring (gun) PM245800SV 1

22 Hose PM344302AV 1

23 Lance PM035120AV 1

24 Tip, 15° (yellow) PM039880AV 1

25 Tip, 65° (black) PM039820AV 1

26 Holder, QC Tip PM344304AV 1

* Item available at local hardware store

Tip Accessories Available for PW2515:

(Not supplied with unit)

Tip, 0° (Red) PM039870AV

Tip, 25° (Green) PM039890AV

Tip, 40° (White) PM039900AV

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

3

11

www.chpower.com

Page 14

Pressure Washer

Troubleshooting Chart - Gasoline Powered Pressure Washers Only

Symptom Possible Cause(s) Corrective Action(s)

Engine will not start or is hard

to start

Engine misses or lacks power

Low pressure and/or pump

runs rough

Water leakage from under

pump manifold

Water in pump crankcase

(milky oil)

Frequent or premature failure

of the pump water seals

Strong surging at the inlet

and low pressure

Oil leakage between the

engine and the pump

Fluctuating pressure

Pressure drops after period of

normal use

Pump noisy / pump runs

rough

Pressure washer will not spray

detergent

1. No gasoline in fuel tank or carburetor

2. Low oil

3. Start/Stop switch in stop position

4. Water in gasoline or old fuel

5. Dirty air cleaner filter

6. Spark plug dirty, wrong gap or wrong type

7. Spray gun closed

8. Other causes

1. Partially plugged air cleaner filter

2. Spark plug dirty, wrong gap or wrong type

1. Worn or wrong size tip

2. Inlet filter on pump clogged

3. Worn water seals, abrasives in water, or natural wear

4. Fouled or dirty inlet or discharge valves

5. Restricted inlet

6. Worn inlet or discharge valves

7. Leaking high pressure hose

8. Pump drawing in air

9. Unloader valve seat faulty or worn

Worn water seals

1. Humid air condensing inside crankcase

2. Oil seals leaking

1. Scored damaged or worn plungers

2. Abrasive material in the fluid

3. Inlet water temperature too high

4. Overpressurizing pump

5. Excessive pressure due to partially plugged or

damaged tip

6. Pump running too long without spraying

7. Pump running dry

Foreign particles in the inlet or discharge valve or worn

inlet and/or discharge valves

Worn oil seals and/or o-ring

1. Valve worn, dirty or stuck

2. Pump drawing in air

3. Tip clogged

1. Worn pump water seals

2. Nozzle worn

3. Valve worn, dirty or stuck

4. Unloader valve seat worn or dirty

1. Pump drawing in air/low water supply

2. Valves dirty or worn

3. Worn bearings

4. Water too hot

1. Nozzle not pushed up far enough

2. Clog, kink, or hole in detergent suction hose

3. Hose length too long

4. Lance not functioning properly

1. Fill the tank with gasoline,open fuel shut off valve.

Check fuel line and carburetor

2. Check oil level. Fill if necessary

3. Move switch to start position

4. Drain fuel tank and carburetor. Use new fuel and dry

spark plug

5. Remove and clean or replace

6. Clean, adjust the gap, or replace

7. Trigger spray gun

8. See engine owner’s manual

1. Remove and clean or replace

2. Clean, adjust the gap, or replace

1. Replace with tip of proper size

2. Clean. Check more frequently

3. Check filter. Replace water seals. See service center

4. Clean inlet and discharge valve assemblies. Check filter

5. Check garden hose, may be collapsed or kinked. Check

inlet water flow

6. Replace worn valves

7. Replace high pressure hose

8. Ensure hoses and fittings are tight

9. Check and replace

Install new water seals. See service center

1. Change oil as specified in maintenance schedule

2. Install new oil seals. See service center

1. Install new plungers. See service center

2. Install proper filtration on pump inlet plumbing

3. Check water temperature; may not exceed 100

o

F.

4. Do not modify any factory set adjustments.

5. Clean or replace tip.

6. Never run pump more than 2 minutes without spraying

7. Do not run pump without water

Clean or replace valves. See service center

Replace oil seals and/or o-ring. See service center

1. Check and replace

2. Ensure hoses and fittings are tight. Purge air from garden hose

3. Check or replace

1. Check and replace

2. Check and replace

3. Check, clean or replace

4. Check, clean or replace

1. Ensure fittings are tight. Increase water pressure

2. Check, clean or replace

3. Check and replace

4. Reduce temperature below 100oF

1. Push nozzle forward as far as it will go.

2. If clean, unkink or replace hose.

3. Use only hose length provided with initial purchase of

pressure washer. Detergent suction will not function if

more than one section of hose is attached to unit.

4. Remove lance from gun. If detergent is dispensed

through gun, the lance must be replaced. If no detergent is dispensed through gun, remove 1” tapered

detergent barb from pump. Clean the barb, and make

sure that ball and spring are properly aligned with

tapered portion of the spring facing the ball. The ball

should be on top of the spring.

14

www.chpower.com

Page 15

www.chpower.com

Pressure Washer

15

Notes

Page 16

Pressure Washer

16

www.chpower.com

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: One Year

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Mundy Memorial Drive,

Mount Juliet, TN 37122, Telephone: (800) 330-0712

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld pressure washer.

4. WHAT PRODUCTS ARE COVERED UNDER THIS WARRANTY: Any Campbell Hausfeld Pressure Washer supplied or manufactured by the Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects on material and workmanship which occur within the duration of the warranty period with the exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE

DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this pressure washer is used for commercial, industrial or

rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States do not allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRESSURE WASHER. Some States do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from shipping damage, accident, purchaser’s abuse, neglect or failure to install and operate pres-

sure washer in accordance with instructions provided in the owner’s manual(s) supplied with product.

D. Pre-delivery service, i.e. assembly, oil or lubricants and adjustment.

E. Items or service normally required to maintain the pressure washer.

F. Gasoline engine and components are expressly excluded from coverage under this limited warranty. Such components

should be returned by the purchaser to the original manufacturer or to its authorized repair stations for service.

G. Additional items not covered under the warranty:

1. Normal wear items such as high pressure hoses, water and oil seals, o-rings, valves, lances and spray tips.

2. Motor brushes (Electric models only).

3. Cosmetic defects that do not interfere with functionality.

4. Rusted components.

5. Pump wear or valve damage caused by using improper oil, oil contamination or by failure to follow proper oil maintenance guidelines.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, pressure washer or

component which is defective, has malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld pressure washer or component to nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the pressure washer as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other

rights which vary from state to state or country to country.

Page 17

Nettoyeur haute

pression à essence

Instructions d’Utilisation et Manual de Pièces PW2515

Veuillez lire attentivement et bien comprendre ces instructions

avant de faire fonctionner votre nettoyeur haute pression.

© 2006 Campbell Hausfeld/Scott Fetzer

IN468000AV 8/06

Apprendre à connaître votre nettoyeur haute pression . . . . . . . . . . . . . . . . .2

Questions fréquemment posées . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Information de sécurité et avertissements . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Pré-opération . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 9

Information technique et entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Registre de service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Liste de pièces de rechange

• Pompe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

• Chariot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Tableau de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Contenu Page

Modèle PW2515

Veuillez inscrire le No de modèle et le No de série à utiliser pour

contacter le fabricant :

No modèle ______________ Date d’achat ____________________

No série ______________ Endroit d’achat ____________________

Pour de l’information sur le produit, composez le 1-800-330-0712

MÉMENTO : Gardez votre preuve datée d'achat à fin de la garantie !

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Page 18

Pulvérizateur Haute Pression

Fr 2

1 Réservoir de Détergent

2 Silencieux

3 Emplacement du numéro de série/décalque

du produit

4 (Pompe) Connexion d’aspiration du tuyau

d’arrosage

5 Lance à connexion rapide

6 Porte-buse et buses de pulvérisation

7 Manche

8 Pistolet et gâchette

9 Réservoir de carburant

10 Starter

11 Interrupteur On/Off (marche/arrêt) du

moteur

12 Valve de carburant On/Off (ouvert/fermé)

13 (Pompe) Connexion de sortie pour tuyau

haute pression

1

2

3

6

9

10

11

12

13

PW2515

Apprendre à connaître votre nettoyeur haute pression

5

4

7

8

Page 19

Pulvérizateur Haute Pression

Comment démarre mon

pulvérisateur haute pression ?

1. Assurez-vous d’avoir du carburant et de l’huile dans le

moteur. Le moteur est délivré SANS HUILE.

2. Ouvrir l’alimentation d’eau, puis tirer de la gâchette du

pistolet pour s’assurer que l’eau puisse sortir facilement

de la buse.

3. Ouvrir la soupape de contrôle du carburant en tournant

complètement le bouton dans le sens antihoraire jusqu’à

l’arrêt.

4. Fermer le starter (si le moteur est froid) en mouvant

l’anneau du starter complètement à droite.

5. Placer l’interrupteur de marche/arrêt sur « ON » (marche).

6. Tirer de la gâchette (pour soulager toute retro pression

de la pompe) tandis qu’on tire le cordon de marche.

Quel type d’huile devrais-je

utiliser ?

LE MOTEUR EST DÉLIVRÉ SANS HUILE. Voir page Fr 10 pour

les types d’huile, les quantités et les instructions pour

changer l’huile.

Pompe : La pompe est fournie remplie de la bonne quantité

d’huile et ne devrait pas avoir besoin d’être changée ou

remplie.

Pourquoi est-ce que je n’ai aucune

pression d’eau ?

• Est-ce que le tuyau d’eau est attaché au pulvérisateur ?

• L’eau est-elle en marche ?

• Vérifiez les tortillements, fuites, blocages de flexibles,

raccords ou gicleur.

• Est-ce que la buse de 15º (jaune) a été insérée dans

l’extrémité de la lance (voir page Fr 8)?

• Est-ce que l’écran du filtre d’aspiration est libre de débris ?

Vérifiez et retirez les débris au besoin.

Comment puis-je obtenir une

haute pression ?

• Pour haute pression, insérer la buse de 15º (jaune) dans

l’extrémité de la lance (voir page Fr 8).

Comment puis-je faire fonctionner

l’aspiration de savon ?

1. Connectez le tube d’aspiration de produits chimiques de

plastique transparent à la tétine de flexible de plastique

sur le réservoir du détergent.

2. Remplissez le réservoir du détergent avec un type à

formule spéciale pour les pulvérisateurs à haute pression.

Fr 3

3. Pour pulvériser le savon, insérer la buse de 65º (noire) pour

le savon dans l’extrémité de la lance (voir page Fr 8).

Pourquoi est-ce que le

pulvérisateur haute pression

n’applique pas de détergents avec

une haute pression ?

Les détergents « rebondissent » sur les surfaces de nettoyage à la

même vitesse qu’ils sont appliqués. Les fonctions du

pulvérisateur de lavage permettent à un détergent d’être tiré

seulement en mode de basse pression. En appliquant le

détergent à basse pression, l’effet de « rebondissement » est

réduit. Les détergents sont seulement efficaces lorsqu’on leur

donne le temps de travailler sur la surface à nettoyer. Après avoir

appliqué le détergent, attendre 1 à 3 minutes pendant qu’il

fonctionne, puis passer au rinçage de la surface avec une haute

pression.

Quel entretien dois-je effectuer

sur mon pulvérisateur haute

pression ?

1. Après avoir fermé le pulvérisateur haute pression et l’eau,

enlevez la pression du flexible en pressant la gâchette du

pistolet.

2. Retirez le tuyau d’arrosage et le flexible haute pression de la

pompe.

3. Tirez lentement la corde de lancement cinq fois pour purger

l’eau de la pompe. Ceci aidera à protéger la pompe de tout

dommage.

4. Ne rangez pas votre pulvérisateur haute pression dans un

endroit où la température tombera sous 0˚ C.

5. Suivre les instructions concernant le rangement et

préparation pour l’hiver appropriées, en page Fr 9.

Que faire s’il me manque une

pièce ?

Appelez Campbell Hausfeld au 1-800-330-0712 et nous

remplacerons rapidement toutes les pièces manquantes.

NE RETOURNEZ PAS LE PULVÉRISATEUR AU DÉTAILLANT !

Où puis-je acheter des accessoires

pour mon pulvérisateur

haute pression ?

• Si vous ne pouvez en trouver chez votre détaillant,

appelez Campbell Hausfeld au 1-800-330-0712.

Qui dois-je appeler si j’ai des

questions ou des problèmes ?

Appelez Campbell Hausfeld au

1-800-330-0712

www.chpower.com

Questions Fréquemment Posées

Page 20

• Suivez toujours les recommandations du fabricant de

détergents pour la bonne utilisation du produit. Protégez

toujours les yeux, la peau et le système respiratoire du

détergent.

N’utilisez pas de pression

qui dépasse la pression

d’exploitation de toute pièce (flexibles, raccords, etc.) du

système sous pression. Assurez-vous que tout équipement et

accessoires sont du calibre voulu pour résister à la pression

d’exploitation maximum de l’appareil.

Danger d’explosion.

• NE pulvisérez JAMAIS de liquides inflammables et

n’utilisez jamais le pulvérizateur haute pression dans des

endroits contenant de la poussière, des liquides ou des

vapeurs combustibles.

• Ne faites jamais fonctionner cet appareil dans un édifice

fermé ou dans ou près d’un environnement explosif.

• Ne retirez pas le bouchon du réservoir de combustible et ne

remplissez pas le réservoir tandis que le moteur est chaud ou

en marche (laissez le moteur refroidir deux minutes avant de

faire le plein). Remplissez toujours le réservoir lentement.

• Ne débranchez jamais le flexible de décharge de haute

pression de la machine tandis que le système est sous

pression. Pour décompresser, coupez le courant et l’eau,

puis pressez la gâchette du pistolet 2 ou 3 fois.

• N’engagez jamais en permanence le mécanisme de la

gâchette sur le pistolet.

• Ne faites jamais fonctionner la machine sans que tous les

composants soient bien raccordés à l’appareil (poignée,

pistolet/ rallonge, gicleur, etc.).

Dommage à l’equipement

• Mettez TOUJOURS l’eau à “ON” avant de mettre le

pulvérizateur haute pression en marche“ON”.

Faire fonctionner la pompe à sec cause de graves

dommages.

• Ne faites pas fonctionner le pulvérizateur haute pression

avec l’écran d’entrée d’eau retiré. Gardez l’écran libre de

tous débris et sédiments.

• NE faites JAMAIS fonctionner le pulvérizateur haute

pression avec des pièces brisées ou manquantes. Vérifiez

régulièrement l’équipement et réparez immédiatement

toutes pièces usées ou endommagées.

• Utilisez seulement le gicleur fourni avec l’appareil.

• Ne laissez jamais la rallonge sans surveillance tandis que

la machine est en marche.

• Ne modifiez jamais le régulateur du moteur et n’essayez

pas de modifier les réglages d’usine. Ceci pourrait

endommager l’appareil et annulera la garantie.

• Tenez toujours le pistolet et la rallonge bien fermement

en démarrant et en faisant fonctionner l’appareil.

• Ne laissez JAMAIS l’appareil fonctionner avec la gâchette

dégagée (arrêt) pendant plus d’une minute. L’accumulation

de chaleur pourrait endommager la pompe.

• NE rangez JAMAIS le pulvérizateur haute pression à

l’extérieur ou à des endroits où il pourrait geler. Le gel

peut endommager gravement la pompe.

• Dégagez la gâchette en changeant de haute à basse

pression sinon vous pourriez endommager le gicleur.

Gardez le flexible loin des objets

tranchants. Les flexibles qui

éclatent peuvent provoquer des blessures. Examinez régulièrement

les flexibles et remplacez ceux qui sont endommagés. N’essayez

pas de les réparer.

Directives de Sécurité

Ce manuel contient de l’information très important à

connaître et comprendre fournie pour votre SÉCURITÉ et

pour PRÉVENIR LES PROBLÈMES D’ÉQUIPEMENT. Pour aider à

reconnaître cette information, observez les symboles suivants.

Danger indique une situation

dangereuse imminente qui, si elle

n’est pas évitée, MÊNERA à la mort ou à une blessure grave.

Avertissement indique une

situation dangereuse possible

qui, si elle n’est pas évitée, POURRAIT mener à la mort ou à une

blessure grave.

Attention indique une situation

dangereuse possible qui, si elle

n’est pas évitée, POURRAIT mener à des blessures mineures ou

modérées.

Avis indique de l’information

importante qui, si elle n’est pas

respectée, pourrait provoquer des dommages à l’equipement.

NOTE: Information qui exige une attention spéciale.

Importantes Instructions de Sécurité

CONSERVEZ CES INSTRUCTIONS

En utilisant ce produit, ces précautions de base doivent être

respectées, dont:

1. Lire toutes les instructions avant d’utiliser ce produit.

2. Pour réduire les risques de blessures, il faut superviser

étroitment en présence d’enfants.

3. Suivez tous les codes de sécurité ainsi que l’Occupational

Safety and Health Act (OSHA).

4. Assurez-vous que tous les dispositifs de sécurité

fonctionnenet correctement avec chaque utilisation. NE

retirez PAS et ne modifiez pas toute pièce du pistolet ou

de l’appareil.

5. Sachez comment arrêter ce produit et dégager

rapidement la pression. Soyez bien au fait des contrôles.

6. Restez alerte – surveillez ce que vous faites.

7. N’utilisez pas l’appareil fatigué ou sous l’influence de

l’alcool ou drogues.

8. Gardez le secteur d’opération libre de toutes personnes.

9. Ne vous penchez pas trop et ne vous tenez pas sur un

support instable. Restez bien debout et en équilibre

en tous temps.

10. Suivez les instructions d’entretien spécifiées dans le manuel.

Risque d’injection ou de

blessures graves. Restez loin du

gicleur. Ne déchargez pas de jets vers les personnes. Ce

produit doit être utilisé seulement par un opérateur formé.

Retirez toujours la tige du pistolet avant de nettoyer les

débris de l’embout.

• Restez loin du gicleur. NE dirigez JAMAIS le jet haute

pression vers une personne, un animal, ou vous-même.

• Portez toujours des lunettes de sécurité et de

l’équipement de protection (protection auditive, gants,

bottes de caoutchouc, vêtements protecteurs) en faisant

fonctionner ou entretenant l’appareil.

• Ne mettez jamais la main ou les doigts sur l’embout de

pulvérisartion en opérant l’appareil.

• N’essayez jamais d’arrêter ou de dévier les fuites vers

toute partie du corps.

• Engagez toujours le verrou de sécurité de la gâchette en

position sûre à la fin de la pulvérisation même si ce n’est

que pour quelques instants.

Information de Sécurité et Avertissements

Pulvérizateur Haute Pression

Fr 4

!

DANGER

!

AVERTISSEMENT

!

ATTENTION

AVIS

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

AVIS

!

ATTENTION

Page 21

DÉBALLAGE

Retirer l’équipement et toute pièce de son

emballage. L’emballage doit contenir ce

qui suit.

• Un pulvérizateur haute pression

(pompe, moteur, base du chariot)

• Un assemblage de poignée du chariot

• Un réservoir de détergent

• Un pistolet de pulvérisation

• Una lance

• Un porte-buse avec 2 buses de

pulvérisation. De buses additionnelles

sont disponibles pour l’achat, voir

page Fr 13

• Un flexible haute pression

• Un paquet d’écrous, boulons et manuels

• Une bouteille d’huile à moteur

S’il manque des pièces, NE RETOURNEZ PAS L’APPAREIL AU

DÉTAILLANT. Notez le numéro de modèle de l’appareil

(situé sur l’étiquette du numéro de série du cadre du

pulvérizateur haute pression) et composez le 1-800-330-0712

pour les pièces de rechange.

Après le déballage, inspectez attentivement pour tout

dommage durant le transit. Assurez-vous de bien resserrer les

raccords et boulons avant d’utiliser le pulvérizateur haute

pression.

Ne faites pas fonctionner

l’appareil s’il a été endommagé

durant le transport, la manipulation ou l’utilisation car les

dommages pourraient provoquer l’éclatement et causer des

blessures ou des dommages à la propriété.

ASSEMBLAGE

Utilisez deux clés réglables ou de 7/16 po pour assembler le

pulvérisateur.

1. Glissez la poignée sur les pieds inférieurs de la base du

chariot. Utiliser les boulons and écrous fournis pour fixer

le manche aux pattes. Voir la Figure 1.

2. Fixer le réservoir de détergent à l’arrière de la poignée.

Utiliser les 4 boulons hexagonaux avec une rondelle plate

sous la tête hexagonale et 4 écrous fournis.

3. Glisser le tuyau de plastique transparent fixé au pied sur

la barbelure de tuyau de plastique du réservoir de

détergent (voir figure 3).

4. Adaptateur pivotant en laiton (voir la figure 2). Si ce

n’est pas déjà fait, assemblez l’adaptateur articulé de

laiton et fixez-le à l’entrée de la pompe (voir figures 4 et

5). Assurez-vous de raccorder le bon côté de l’adaptateur

articulé de laiton à la pompe.

Pulvérizateur Haute Pression

Fr 5

Pré-opération

Figure 1 – Assemblez la poignée

Figure 3 – Fixez le tube d’aspiration à la

tétine

Figure 4 - Adaptateur articulé de laiton

Connectez cette extrémité au tuyau d’arrosage

Connectez cette extrémité à

la pompe

Rondelle

Rondelle

avec écran

de filtre

Figure 5 - Connectez l’articulation

de laiton à la pompe

Adaptateur articulé

de laiton

Entrée de pompe

Figure 2 - Raccord de pompe

Adaptateur

pivotant

en laiton

Boyau d’arrosage

Entrée de la pompe

Sortie de

pompe

Barbelure de

tube d’injecteur

chimique

Tuyau

haute

pression

Soupape de

sûreté

thermique

!

AVERTISSEMENT

Page 22

7. Fixer la lance au pistolet (voir figure 7).

8. Installer la buse de connexion rapide en tirant vers l’arrière le

collier et en insérant la buse. Dégager le collier et s’assurer qu’il

revient complètement à sa position à l’avant et que la buse est

fixe (voir figure 8).

Figure 10a - Gâchette Figure 10b - Gâchette

verrouillée déverrouillée

Engagée

Fr 6

Pré-opération (Suite)

5. Fixez le tuyau d’arrosage (non inclus) au raccord d’entrée

de la pompe.

6. Connectez le flexible haute pression à la sortie de la

pompe (voir les figures 2 et 6).

Pulvérizateur Haute Pression

Figure 6 - Raccorder le tuyau haute pression à la

pompe

Désengagée

Figure 7 - Fixer la lance au pistolet

9. Mettre les buses de connexion rapide dans le support pour les

buses et le fixer sur le manche du nettoyeur haute pression.

Voir la figure 9.

VERROU DE SÉCURITÉ DE LA GÂCHETTE

En position engagée, le verrou de sécurité de la gâchette

empêche le déclenchement accidentel du pistolet.

Pousser

complètement le verrou de sécurité pour l’engager (voir

figure 10).

Engagez toujours le verrou de sécurité de la gâchette

lorsque vous n’utilisez pas l’appareil.

Figure 8 – Installation de la buse de connexion rapide

Tirer le collier

vers l’arrière

Figure 9 – Insérer les buses de pulvérisation dans le support

pour les buses.

Page 23

7. Démarrez le moteur (voir la figure 10). Déverrouillez le

verrou de sécurité de la gâchette sur le pistolet. Agrippez

la corde de lancement et appuyez un pied sur le châssis.

Pointer le pistolet dans une direction sans danger.

Tirez rapidement et fermement la corde de lancement

tout en pressant la gâchette du pistolet (voir la figure 11).

Continuez à tenir la corde quand elle revient. Répétez ces

étapes jusqu’à ce que le moteur démarre.

En tirant le lancement,

assurez-vous de garder la main

et le bras loin du moteur et des composants du chariot.

Ne laissez jamais la corde

de lancement revenir par elle-

même car cela pourrait bloquer le système de retour.

8. Si le moteur ne démarre pas après deux ou trois

enclenchements ou si la corde est difficile à tirer, pressez

la gâchette du pistolet pour dégager la pression

accumulée dans le flexible haute pression. Répétez les

étapes 7 et 8 jusqu’à ce que le moteur démarre.

Pulvérisez d’eau la surface à nettoyer pour enlever toute

poussière ou saleté accumulée sur la surface. Ceci permet au

détergent de s’attacher à la poussière en profondeur qui a

pénétré dans la surface à nettoyer.

ANGLE À LA SURFACE DE NETTOYAGE

En pulvérisant l’eau contre une surface, vous pouvez obtenir

un impact maximum en frappant la surface directement. Ce

type d’impact peut toutefois faire pénétrer les particules

de poussières dans la surface et ainsi empêcher d’avoir

l’action recherchée.

L’angle optimum de pulvérisation d’eau contre une surface de

nettoyage est de 45 degrés.

Pulvérisez l’eau contre une surface à un angle de 45 degrés pour

atteindre le meilleur impact et retirer efficacement les débris.

La procédure de nettoyage suivante vous aide à vous

organiser pour la tâche de nettoyage et pour vous assurer

d’atteindre les meilleurs résultats dans le temps le plus court.

Rappelez-vous d’utiliser les techniques de pulvérisation/

nettoyage mentionnées dans les sections suivantes.

Avant de commencer un travail de nettoyage à haute

pression, préparez la surface à nettoyer. Enlevez les meubles

et assurez-vous que toutes les fenêtres et portes sont bien

fermées. Protégez aussi toutes vos plantes et arbres près du

secteur à nettoyer en couvrant d’une toile pour ne pas les

pulvériser de détergent.

Utilisez TOUJOURS cette procédure de démarrage pour

assurer un démarrage exact et sans danger.

Si l’eau a gelé dans le

pulvérizateur à haute pression,

laissez-la dégeler à température ambiante avant de

commencer. NE versez PAS d’eau chaude sur ou dans la

pompe; les pièces intérieures seraient endommagées.

1. Vérifiez les niveaux d’huile à moteur. Ajoutez de l’huile

au besoin.

2. Vérifiez le niveau d’huile.

NE remettez PAS de carburant

avec un moteur chaud car cela

pourrait causer un incendie. Utilisez seulement de l’essence

sans plomb ou régulière propre, fraîche. Fermez le robinet

d’arrêt de carburant durant le remplissage.

3. Fixez un tuyau d’arrosage côté entrée de la pompe et

raccordez-le à l’alimentation d’eau. Utilisez un flexible de

D.I. de 5/8 po et d’une longueur de 50 pi (15 m) ou moins.

Certains codes de plomberie

locaux exigent un dispositif de

prévention de retour d’eau en connectant à une source d’eau

fraîche. Installez un dispositif de prévention de retour en

amont de la pompe, au besoin.

a. Si la pression d’eau d’alimentation dépasse 690 kPa,

installez une soupape régulatrice d’eau au raccord du

tuyau d’arrosage.

b. Ne dépassez pas 38˚ C de température d’eau

d’alimentation.

NOTE : L’approvisionnement d’eau d’alimentation doit avoir

un débit minimum de 19 lpm.

4. Ouvrez l’alimentation d’eau.

Ne laissez jamais l’appareil

fonctionner à sec. Assurez-vous

que l’alimentation d’eau est en marche avant de faire

fonctionner l’appareil.

5. Tirer de la gâchette jusqu’à ce que de l’eau puisse se pulvériser

facilement de la buse, ce qu’indique que tout air a été purgé

du système. Engager le verrou de sécurité de la gâchette.

6. Ouvrir la soupape de carburant en tournant complètement

le bouton dans le sens antihoraire jusqu’à l’arrêt. Fermer le

starter (si le moteur est froid) en mouvant l’anneau du

starter complètement à droite. Placer l’interrupteur

d’allumage sur « ON ».

Figure 11 - Démarrez le moteur

Opération

Pulvérizateur Haute Pression

Fr 7

1. Préparation de la surface

2. Démarrage

3.

Rinçage initial à haute pression

AVIS

!

AVERTISSEMENT

AVIS

AVIS

!

ATTENTION

AVIS

Page 24

Pulvérizateur Haute Pression

DISTANCE DE LA SURFACE À NETTOYER

La distance entre le gicleur de pulvérisation et la surface de

nettoyage est un autre facteur qui affecte la force d’impact

de l’eau. Celle-ci augmente au fur et à mesure où vous

déplacez le gicleur plus près de la surface.

COMMENT ÉVITER D’ENDOMMAGER LES SURFACES

Les dommages aux surfaces à nettoyer se produisent à cause

de la force d’impact de l’eau qui dépasse la durabilité de la

surface. On peut varier la force d’impact en contrôlant

l’angle de la buse de pulvérisation avec la surface à nettoyer,

la distance de la surface à nettoyer et en changeant la buse

de pulvérisation. NE JAMAIS utiliser un jet étroit à fort

impact sur une surface susceptible d’être endommagée.

Éviter de pulvériser les fenêtres avec un jet étroit à fort

impact. Ceci pourrait casser la fenêtre. Le meilleur moyen

d’éviter d’endommager les surfaces est de suivre ces étapes :

1. Avant de tirer de la gâchette, s’assurer que la buse de

connexion rapide utilisée est appropriée pour le travail.

2. Placer la buse à environ 1,2 à 1,5 m (4 à 5 pieds) de la

surface à nettoyer. Ensuite, tenir la lance et la buse de

pulvérisation à un angle de 45º avec la surface à nettoyer.

Tirer de la gâchette du pistolet.

3. Variez l’angle du jet à eventail et la distance à la surface à

nettoyer jusqu’à ce que vous atteigniez l’efficacité optimale

de nettoyage sans endommager la surface.

NOTE : Utilisez seulement les détergents formulés pour les

pulvérizateurs haute pression. Testez le détergent dans un

endroit retiré avant de l’utiliser.

DÉTERGENTS

Utiliser des détergents peut réduire de beaucoup le temps de

nettoyage et aider à retirer les taches rebelles. De nombreux

détergents sont faits pour le pulvérizateur haute pression pour

des tâches de nettoyage précises. Les détergents de

pulvérizateur haute pression sont aussi épais que l’eau. Le fait

d’utiliser des détergents plus épais - comme le savon de vaisselle

- bloquera le système d’injection chimique et empêchera

l’application de détergent.

Appliqués sur la surface, les détergents prennent du temps

pour s’attaquer à la poussière et à la saleté. Les détergents

fonctionnent mieux appliqués à basse pression.

Vous pouvez nettoyer efficacement les surfaces en combinant

l’action chimique des détergents avec les rinçages à haute

pression. Pour les surfaces verticales, appliquez le détergent en

commençant au bas pour aller vers le haut. La méthode

empêche le détergent de glisser vers le bas et de faire des

coulisses. Commencez le rinçage haute pression au bas et allez

vers le haut. Pour les taches particulièrement rebelles, utilisez

une brosse en plus des détergents et du rinçage haute pression.

1. Suivez les directives du fabricant sur l’étiquette pour les

bonnes concentrations de mélange de savon/détergents. La

proportion de détergent savon à eau dans la pompe est

d’environ 12 % (1 à 8).

2. Versez le détergent dans le réservoir de détergent. La

capacité du réservoir est de 1,5 gallons (5,67 litres).

3. Installer la buse basse pression (noire) à 65º sur la

connexion rapide à l’extrémité de la lance.

NE JAMAIS changer la buse de

connexion rapide au même temps

qu’on tire de la gâchette. Engager toujours le verrou de la

gâchette avant de quitter ou installer une buse de connexion

rapide.

CONSEILS GÉNÉRAUX DE NETTOYAGE

1. Appliquez le détergent pour couvrir entièrement la surface

à nettoyer, de bas en haut pour éviter qu’il ne glisse vers le

bas et fasse des marques. Attendez quelques minutes pour

que le détergent s’attaque à la poussière et à la saleté.

Utilisez une brosse pour frotter un peu les endroits

rebelles. Ne laissez jamais le détergent sécher sur la surface

à nettoyer.

2. Remplacer la buse noire 65º de connexion rapide par la buse

jaune 15º et faire le rinçage final.

NE JAMAIS changer la buse de

connexion rapide au même temps

qu’on tire de la gâchette. Engager toujours le verrou de la gâchette

avant de quitter ou installer une buse de connexion rapide.

3. REMARQUE : Après l’utilisation de détergents, laver le

système d’aspiration en rinçant le réservoir à l’eau fraîche et

faire fonctionner l’appareil avec la buse noire 65º en rinçant

à l’eau fraîche le réservoir jusqu’à la pompe incluse.

Fr 8

Opération (Suite)

4.

Application de détergent

La couleur de la buse indique l’angle de

pulvérisation :

Rouge - 0° - Travail extrêmement lourd*

Jaune – 15° – Travail lourd

Vert -25° - Travail géneral*

Blanc -40° - Travail léger*

Noir – 65° – Détergeant basse pression

* = Non incluse

Figure 12 - Angle optimum par rapport

à la surface à nettoyer

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 25

La façon la plus facile de réguler la capacité de nettoyage de

votre nettoyeur haute pression est en variant la distance de

la surface à nettoyer. Commencer la pulvérisation à une

distance de quelques mètres de la surface. Doucement se

déplacer plus près de l’objet que vous voulez nettoyer

jusqu’à rencontrer la technique de nettoyage las plus

effective.

Le dernier rinçage devrait commencer du bas vers le haut.

Assurez-vous de bien rincer toute la surface et de retirer toute

trace de détergent.

Pour réduire les risques de blessures ou de dommages à la

propriété, suivez toujours cette procédure lorsque la

pulvérisation est arrêtée, à la fin du travail et avant de vérifier

ou réparer toute pièce du système.

1. Engagez le verrou de sécurité de la gâchette.

2. Fermez l’appareil.

3. Coupez l’alimentation d’eau.

4. Désengagez le verrou de sécurité de la gâchette et pressez

sur la gâchette pour décompresser.

5. Réengagez le verrou de sécurité de la gâchette.

6. Pour vérifier ou réparer l’appareil, quitter le câble d’allumage

de la bougie.

7. Avant de ranger pour la nuit, de ranger à long terme ou de

transporter l’appareil, déconnectez l’alimentation d’eau et

fermez la soupape d’alimentation de carburant.

1. Assurez-vous que tout le détergent est vidé du système.

2. Coupez le moteur.

3 Fermez l’alimentation d’eau.

4. Après avoir coupé le moteur et fermé l’alimentation

d’eau, pressez la gâchette pour décompresser le système.

NE fermez jamais l’alimentation

d’eau avant de couper le moteur.

Cela pourrait endommager la pompe et/ou moteur.

NE déconnectez jamais le

flexible de décharge de haute

pression de l’appareil tandis que le système est sous pression.

Décompressez en coupant le moteur, fermant l’alimentation d’eau

et pressant la gâchette 2 ou 3 fois.

5. Après chaque utilisation, essuyez les surfaces du pulvérizateur

haute pression avec un chiffon propre et humide.

• Ne rangez pas le pulvérizateur haute pression à l’extérieur.

• Ne rangez pas le pulvérizateur haute pression à un endroit

où il pourrait geler à moins de le préparer pour l’hiver.

5. Puissance de nettoyage

7. Procédure de décompression

8.

Arrêt

9.

Rangement

6.

Dernier Rinçage

Opération (Suite)

Pulvérizateur Haute Pression

Fr 9

INSTRUCTIONS DE RANGEMENT À LONG TERME (PLUS DE

30 JOURS)

1. Retirez le carburant du réservoir et faites fonctionner le

pulvérizateur haute pression en mode d’opération normal

jusqu’à ce que le moteur s’arrête faute de carburant. Ce

mode signifie que vous pulvérisez de l’eau du pistolet