Page 1

DiamondMax 2

0

B

A

6

0

40 - 300G

AT

November 200

PN: 10043521

Page 2

© 2006, Maxtor Corporation All rights reserved

Publication number: 100435210, Rev. A

November 2006

Maxtor and MaxFax are registered trademarks of Maxtor Corporation, registered in the

U.S.A. and other countr ies. Maxtor DiamondMax, AutoTransfer, AutoRead, AutoWrite, DisCache, DiskWare, Defect Free Interface, QuickView, and WriteCache are trademarks of

Maxtor Corporation . All o ther b rand nam es or trade marks a re the propert y of the ir ma nufac turers.

Maxtor reserves the rig ht to change, without notice, product offerings or specifications. No

part of this publica tion may be r eproduced in any form witho ut written p ermission of Maxtor

Corporation.

Page 3

DiamondMax 20 PATA Product Manual, Rev. A i

Page 4

ii DiamondMax 20 PATA Product Manual, Rev. A

Page 5

Contents

1.0 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Drive specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Specification summary tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Formatted capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.1 LBA mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Default logical geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Recording and interface technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Seek time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7 Start/stop times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.8 Power specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.8.1 Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.8.2 Conducted noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.8.3 Voltage tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.8.4 Power-management modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.9 Environmental specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.9.1 Ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.9.2 Temperature gradient. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.9.3 Humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.9.4 Altitude. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.9.5 Shock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.9.6 Vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.10 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.11 Electromagnetic immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.12 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.12.1 Annualized Failure Rate (AFR and Mean Time Between Failures (MTBF) . . . . 23

2.13 Agency certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.13.1 Safety certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.13.2 Electromagnetic compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.13.3 FCC verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.14 Environmental protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.14.1 European Union Restriction of Hazardous Substances (RoHS) . . . . . . . . . . . . 25

2.15 Corrosive environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.0 Configuring and mounting the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Handling and static discharge precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Breather filter hole precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3 Jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.1 Master/slave configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.2 Cable select option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.3 Ultra ATA/100 cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.0 ATA interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 ATA interface signals and connector pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1.1 Supported ATA commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.1.2 Identify Device command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.1.3 Set Features command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1.4 S.M.A.R.T. commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.0 Maxtor support services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

DiamondMax 20 PATA Product Manual, Rev. A iii

Page 6

iv DiamondMax 20 PATA Product Manual, Rev. A

Page 7

List of Figures

Figure 1. Typical 5V startup and operation current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2. Typical 12V startup and operation current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 3. Breather filter hole location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 4. Master/slave jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 5. Ultra ATA cable connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 6. Mounting dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 7. I/O pins and supported ATA signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DiamondMax 20 PATA Product Manual, Rev. A v

Page 8

vi DiamondMax 20 PATA Product Manual, Rev. A

Page 9

1.0 Introduction

This manual describes the functional, mechanical and interface specifications for the following Maxtor

DiamondMax® 20 PATA model drives:

STM3300622A STM3160212A

STM3250623A STM3160812A

STM3250624A STM3802110A

STM3200827A STM3402111A

These drives provide the following key features:

• 7,200-RPM spindle speed

• High instantaneous (burst) data transfer rates (up to 100 Mbytes per second) using Ultra DMA mode 5.

• Tunneling Giant magnetoresistive (TGMR) recording heads and EPRML technology, which provide the

drives with increased areal density.

• State-of-the-art cache and on-the-fly error-correction algorithms.

• Full-track multiple-sector transfer capability without local processor intervention.

• Quiet operation.

• Support for S.M.A.R.T. drive monitoring and reporting.

• Support for Read Multiple and Write Multiple commands.

• Support for autodetection of master/slave drives that use cable select (CSEL).

®

DiamondMax 20 PATA Product Manual, Rev. A 1

Page 10

2 DiamondMax 20 PATA Product Manual, Rev. A

Page 11

2.0 Drive specifications

Unless otherwise noted, all specifications are measured under ambient conditions, at 25°C, and nominal

power. For convenience, the phrases t he drive and this drive are used throughout th is manual to indi cate the

following drive models:

STM3300622A STM3160212A

STM3250623A STM3160812A

STM3250624A STM3802110A

STM3200827A STM3402111A

2.1 Specification summary tables

The specificatio ns l isted in the f ollowing tables i n thi s se ction are for q uick r efer ence. F or de tails on s pecif ication measurement or definition, see the appropriate section of this manual.

DiamondMax 20 PATA Product Manual, Rev. A 3

Page 12

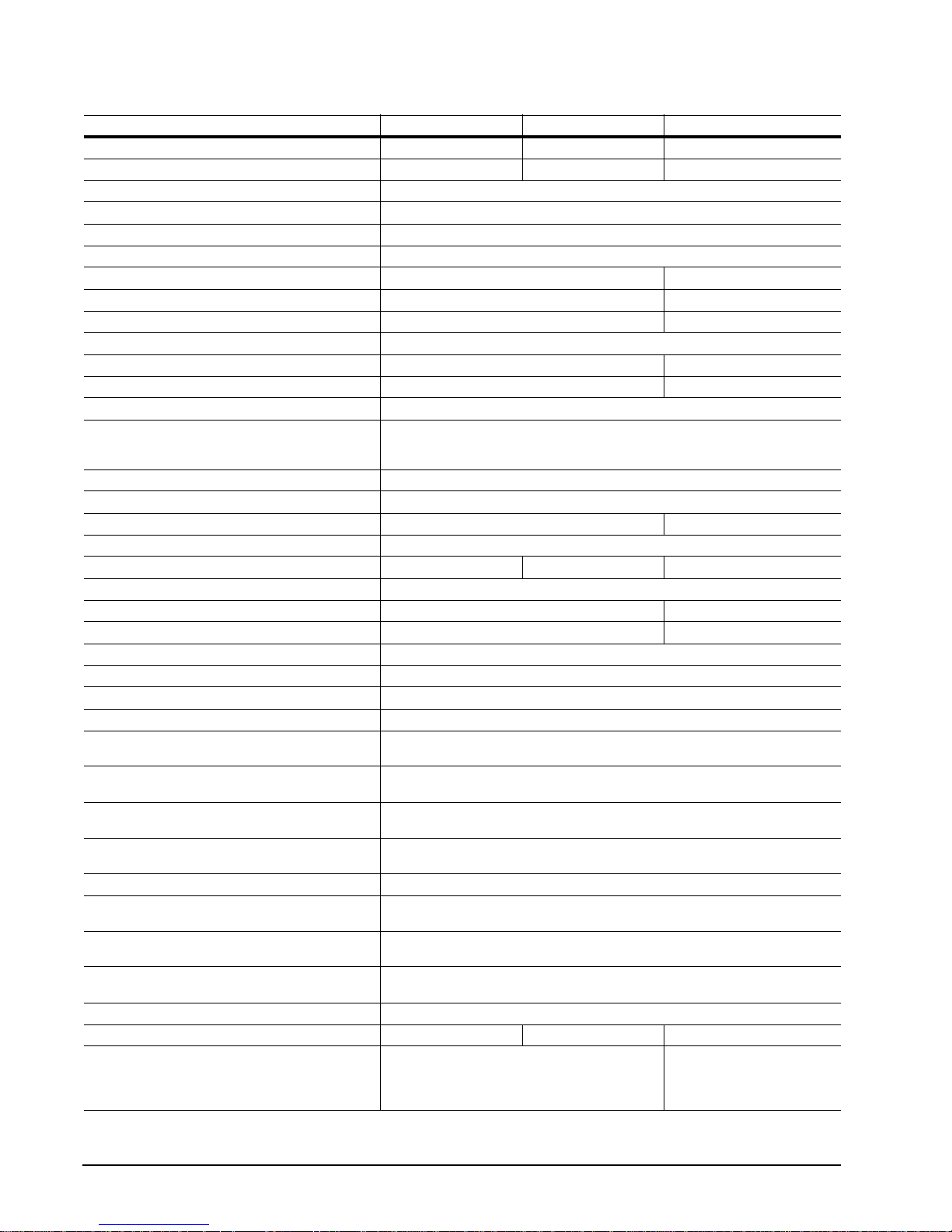

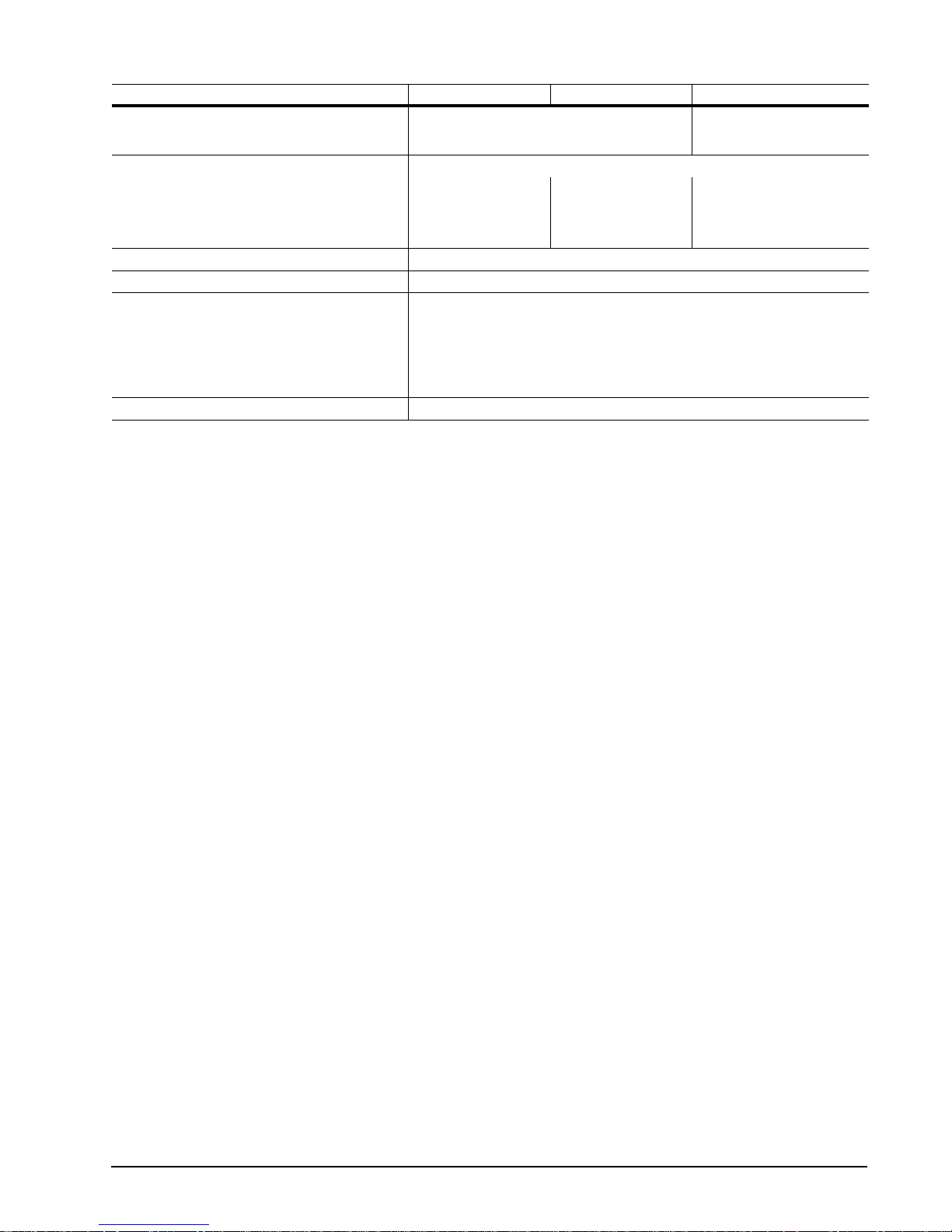

Table 1: Drive specifi cations summary for 300 and 250 Gbyte models

Drive specification STM3300622A STM3250624A STM3250623A

Formatted Gbytes (512 bytes/sector)* 300 250 250

Guaranteed sectors 586,072,368 488,397,168 488,397,168

Bytes per sector 512

Default sectors per track 63

Default read/write heads 16

Default cylinders 16,383

Recording density 790.1 kbits/in max 763 kbits/in max

Track density 124.5 ktracks/in avg 120 ktracks/in avg

Areal density 97.69 Gbits/in

Spindle speed 7,200 RPM

Internal data transfer rate 867.2 Mbits/sec max 760 Mbits/sec max

Sustained data transfer rate OD 76.6 Mbytes/sec max 65 Mbytes/sec max

I/O data-transfer rate 100 Mbytes/sec max

ATA data-transfer modes supported PIO modes 0–4

Cache buffer 16 Mbytes

Height (max) 26.11 mm (1.028 inches)

Width (max) 101.6 mm (4.000 inches) +/- 0.010 inches 101.85 mm (4.010 inches)

Length (max) 146.99 mm (5.787 inches)

Weight (max) 655 grams (1.44 lb.) 580 grams (1.28 lb.) 635 grams (1.39 lb.)

Average latency 4.16 msec

Power-on to ready (max) 11.0 sec 10.0 sec

Standby to ready (max) 11.0 sec 10.0 sec

Track-to-track seek time <0.8 msec typical (read), <1.0 msec typical (write)

Average seek, read <11.0 msec typical)

Average seek, write <12.0 msec typical)

Startup current (typical) 12V (peak) 2.8 amps

Voltage tolerance (including noise) 5V ± 5%

Ambient temperature 0° to 60°C (operating)

Temperature gradient 20°C per hour max (operating)

Relative humidity 5% to 90% (operating)

Relative humidity gradient 30% per hour max

Wet bulb temperature 37.7°C max (operating)

Altitude, operating –60.96 m to 3,048 m

Altitude, nonoperating

(below mean sea level, max)

Operational Shock 63 G max at 2 msec

Non-Operational Shock 300 G max at 2 msec 350 G max at 2 msec 300 G max at 2 msec

Vibration, operating 5–22 Hz: 0.25 G, Limited displacement

Multiword DMA modes 0–2

Ultra DMA modes 0–5

12V ± 10%

–40° to 70°C (nonoperating)

30°C per hour max (nonoperating)

5% to 95% (nonoperating)

40.0°C max (nonoperating)

(–200 ft. to 10,000+ ft.)

–60.96 m to 12,192 m

(–200 ft. to 40,000+ ft.)

22–350 Hz: 0.5 G

350–500 Hz: 0.25 G

2

avg 91.56 Gbits/in2 avg

5–22 Hz:

Limited displacement

23–350 Hz:

0.5 G acceleration

4 DiamondMax 20 PATA Product Manual, Rev. A

Page 13

Drive specification STM3300622A STM3250624A STM3250623A

Vibration, nonoperating 5–22 Hz: 0.25 G, Limited displacement

Drive acoustics, sound power (Bels)

Idle** 2.7 (typical)

Quiet seek 3.0 (typical)

Nonrecoverable read errors 1 per 10

Annualized Failure Rate (AFR) 0.34%

Warranty 3 years on distribution units.

Contact start-stop cycles 50,000 at 25°C, 50% rel. humidity

*One Gbyte equals one billion bytes when referring to hard drive capacity. Accessible capacity may vary depending on operating environment

and formatting.

**During periods of drive idle, some offline activity may occur according to the S.M.A.R.T. specification, which may increase acoustic and

power to operational levels.

22–350 Hz: 5.0 G

350–500 Hz: 1.0 G

2.9 (max)

3.2 (max)

14

bits read

To determine the warranty for a specific drive, use a web browser to access the

following web page:

www.seagate.com/support/service/

From this page, click on the “Verify Your Warranty” link. You will be asked to provide the drive serial number, model number (or part number) and country of purchase. The system will display the warranty information for your drive.

2.7 (typical)

2.9 (max)

3.0 (typical)

3.2 (max)

5–22 Hz:

Limited displacement

23–350 Hz: 5.0 G

2.8 (typical)

3.4 (max)

3.7 (typical)

3.9

DiamondMax 20 PATA Product Manual, Rev. A 5

Page 14

Table 2: Drive specifi cations summary for the 200 Gbyte model

Drive specification STM3200827A

Formatted Gbytes (512 bytes/sector)* 200

Guaranteed sectors 390,721,968

Bytes per sector 512

Default sectors per track 63

Default read/write heads 16

Default cylinders 16,383

Recording density 790.1 kbits/in max

Track density 124.5 ktracks/in avg

Areal density 97.69 Gbits/in

Spindle speed 7,200 RPM

Internal data transfer rate 867.2 Mbits/sec max

Sustained data transfer rate OD 76.6 Mbytes/sec max

I/O data-transfer rate 100 Mbytes/sec max

ATA data-transfer modes supported PIO modes 0–4

Cache buffer 8 Mbytes

Height (max) 26.1 mm (1.028 inches)

Width (max) 101.6 mm (4.000 inches) +/- 0.010 inches

Length (max) 146.99 mm (5.787 inches)

Weight (max) 580 grams

Average latency 4.16 msec

Power-on to ready (max) 11 sec

Standby to ready (max) 11 sec

Track-to-track seek time <0.8 msec typical (read), <1.0 msec typical (write)

Average seek, read (typical) <11.0 msec

Average seek, write (typical) <12.0 msec

Startup current (typical) 12V (peak) 2.8 amps

Voltage tolerance (including noise) 5V ± 5%

Ambient temperature 0° to 60°C (operating)

Temperature gradient 20°C per hour max (operating)

Relative humidity 5% to 90% (operating)

Relative humidity gradient 30% per hour max

Wet bulb temperature 37.7°C max (operating)

Altitude, operating –60.96 m to 3,048 m

Altitude, nonoperating

(below mean sea level, max)

Operational Shock 63 G max at 2 msec

Non-Operational Shock 350 G max at 2 msec

Vibration, operating 5–22 Hz: 0.25 G, Limited displacement

Multiword DMA modes 0–2

Ultra DMA modes 0–5

12V ± 10%

–40° to 70°C (nonoperating)

30°C per hour max (nonoperating)

5% to 95% (nonoperating)

40.0°C max (nonoperating)

(–200 ft. to 10,000+ ft.)

–60.96 m to 12,192 m

(–200 ft. to 40,000+ ft.)

22–350 Hz: 0.50 G

350–500 Hz:: 0.25 G

2

avg

6 DiamondMax 20 PATA Product Manual, Rev. A

Page 15

Drive specification STM3200827A

Vibration, nonoperating 5–22 Hz: 0.25 G, Limited displacement

Drive acoustics, sound power (Bels)

Idle** 2.7 (typical)

Quiet seek 3.0 (typical)

Nonrecoverable read errors 1 per 10

Annualized Failure Rate (AFR) 0.34%

Warranty 3 years on distribution units.

Contact start-stop cycles 50,000 at 25°C, 50% rel. humidity

*One Gbyte equals one billion bytes when referring to hard drive capacity. Accessible capacity may vary depending on operating environment

and formatting.

**During periods of drive idle, some offline activity may occur according to the S.M.A.R.T. specification, which may increase acoustic and

power to operational levels.

22–350 Hz: 5.0 G

350–500 Hz:: 1.0 G

2.9 (max)

3.2 (max)

14

bits read

To determine the warranty for a specific drive, use a web browser to

access the following web page:

www.seagate.com/support/service/

From this page, click on the “Verify Your Warranty” link. You will be asked

to provide the drive serial number, model number (or part number) and

country of purchase. The system will display the warranty information for

your drive.

DiamondMax 20 PATA Product Manual, Rev. A 7

Page 16

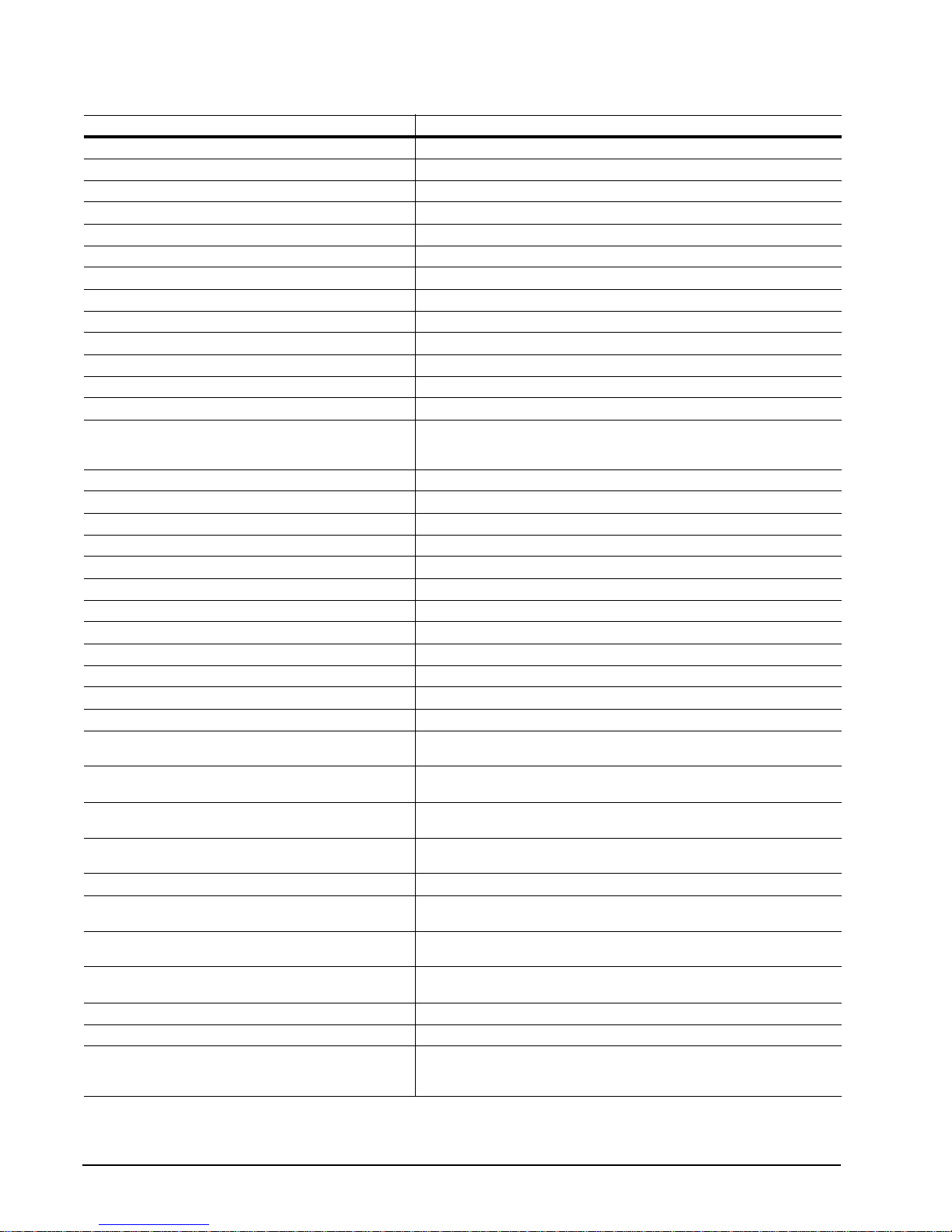

Table 3: Drive specifi cations summary for the 160 Gbyte models

Drive specification STM3160812A STM3160212A

Formatted Gbytes (512 bytes/sector)* 160

Guaranteed sectors 312,581,808

Bytes per sector 512

Default sectors per track 63

Default read/write heads 16

Default cylinders 16,383

Recording density 840.0 kbits/in max

Track density 141.5 ktracks/in avg

Areal density 119. 0 Gbit s/in

Spindle speed 7,200 RPM

Internal data transfer rate 867.2 Mbits/sec max

Sustained data transfer rate OD 83.0 Mbytes/sec max

I/O data-transfer rate 100 Mbytes/sec max

ATA data-transfer modes supported PIO modes 0–4

Cache buffer 8 Mbytes 2 Mbytes

Height (max) 26.1 mm (1.028 inches)

Width (max) 101.6 mm (4.000 inches) +/- 0.010 inches

Length (max) 146.99 mm (5.787 inches)

Weight (max) 580 grams (1.28 lb.)

Average latency 4.16 msec

Power-on to ready (max) <10.0 sec

Standby to ready (max) <10.0 sec

Track-to-track seek time <0.8 msec typical (read), <1.0 msec typical (write)

Average seek, read (typical) <11.0 msec

Average seek, write (typical) <12.0 msec

Startup current (typical) 12V (peak) 2.8 amps

Voltage tolerance (including noise) 5V ± 5%

Ambient temperature 0° to 60°C (operating)

Temperature gradient 20°C per hour max (operating)

Relative humidity 5% to 90% (operating)

Relative humidity gradient 30% per hour max

Wet bulb temperature 37.7°C max (operating)

Altitude, operating –60.96 m to 3,048 m

Altitude, nonoperating

(below mean sea level, max)

Operational Shock 63 G max at 2 msec

Non-Operational Shock 350 G max at 2 msec

Vibration, operating 5–22 Hz: 0.25 G, Limited displacement

Multiword DMA modes 0–2

Ultra DMA modes 0–5

12V ± 10%

–40° to 70°C (nonoperating)

30°C per hour max (nonoperating)

5% to 95% (nonoperating)

40.0°C max (nonoperating)

(–200 ft. to 10,000+ ft.)

–60.96 m to 12,192 m

(–200 ft. to 40,000+ ft.)

22–350 Hz: 0.50 G

350–500 Hz:: 0.25 G

2

avg

8 DiamondMax 20 PATA Product Manual, Rev. A

Page 17

Drive specification STM3160812A STM3160212A

Vibration, nonoperating 5–22 Hz: 0.25 G, Limited displacement

Drive acoustics, sound power (Bels)

Idle** 2.5 (typical)

Quiet seek 2.8 (typical)

Nonrecoverable read errors 1 per 10

Annualized Failure Rate (AFR) 0.34%

Warranty 3 years on distribution units.

Contact start-stop cycles 50,000 at 25°C, 50% rel. humidity

*One Gbyte equals one billion bytes when referring to hard drive capacity. Accessible capacity may vary depending on operating environment

and formatting.

**During periods of drive idle, some offline activity may occur according to the S.M.A.R.T. specification, which may increase acoustic and

power to operational levels.

22–350 Hz: 5.0 G

350–500 Hz:: 1.0 G

2.7 (max)

3.0 (max)

14

bits read

To determine the warranty for a specific drive, use a web browser to

access the following web page:

www.seagate.com/support/service/

From this page, click on the “Verify Your Warranty” link. You will be asked

to provide the drive serial number, model number (or part number) and

country of purchase. The system will display the warranty information for

your drive.

DiamondMax 20 PATA Product Manual, Rev. A 9

Page 18

Table 4: Drive specifi cations summary for the 80 and 40 Gbyte models

Drive specification STM3802110A STM3402111A

Formatted Gbytes (512 bytes/sector)* 80 40

Guaranteed sectors 156,301,488 78,165,360

Bytes per sector 512

Default sectors per track 63

Default read/write heads 16

Default cylinders 16,383

Recording density 840.0 kbits/in max 611.5 kbits/in max

Track density 141.5 ktracks/in avg 103.9 ktracks/in avg

Areal density 119. 0 Gbit s/in

Spindle speed 7,200 RPM

Internal data transfer rate 867.2 Mbits/sec max

Sustained data transfer rate OD 83.0 Mbytes/sec max 69.4 Mbytes/sec max

I/O data-transfer rate 100 Mbytes/sec max

ATA data-transfer modes supported PIO modes 0–4

Cache buffer 2 Mbytes

Height (max) 26.1 mm (1.028 inches)

Width (max) 101.6 mm (4.000 inches) +/- 0.010 inches

Length (max) 146.99 mm (5.787 inches)

Weight (max) 580 grams (1.28 lb.) 525 grams (1.16 lb.)

Average latency 4.16 msec

Power-on to ready (max) <10.0 sec

Standby to ready (max) <10.0 sec

Track-to-track seek time <0.8 msec typical (read), <1.0 msec typical (write)

Average seek, read (typical) <11.0 msec

Average seek, write (typical) <12.0 msec

Startup current (typical) 12V (peak) 2.8 amps

Voltage tolerance (including noise) 5V ± 5%

Ambient temperature 0° to 60°C (operating)

Temperature gradient 20°C per hour max (operating)

Relative humidity 5% to 90% (operating)

Relative humidity gradient 30% per hour max

Wet bulb temperature 37.7°C max (operating)

Altitude, operating –60.96 m to 3,048 m

Altitude, nonoperating

(below mean sea level, max)

Operational Shock 63 G max at 2 msec

Non-Operational Shock 350 G max at 2 msec

Vibration, operating 5–22 Hz: 0.25 G, Limited displacement

Multiword DMA modes 0–2

Ultra DMA modes 0–5

12V ± 10%

–40° to 70°C (nonoperating)

30°C per hour max (nonoperating)

5% to 95% (nonoperating)

40.0°C max (nonoperating)

(–200 ft. to 10,000+ ft.)

–60.96 m to 12,192 m

(–200 ft. to 40,000+ ft.)

22–350 Hz: 0.50 G

350–500 Hz:: 0.25 G

2

avg 63..53 Gbits/in2 avg

10 DiamondMax 20 PATA Product Manual, Rev. A

Page 19

Drive specification STM3802110A STM3402111A

Vibration, nonoperating 5–22 Hz: 0.25 G, Limited displacement

Drive acoustics, sound power (Bels)

Idle** 2.5 (typical)

Quiet seek 2.7 (typical)

Nonrecoverable read errors 1 per 10

Annualized Failure Rate (AFR) 0.34%

Warranty 3 years on distribution units.

Contact start-stop cycles 50,000 at 25°C, 50% rel. humidity

*One Gbyte equals one billion bytes when referring to hard drive capacity. Accessible capacity may vary depending on operating environment

and formatting.

**During periods of drive idle, some offline activity may occur according to the S.M.A.R.T. specification, which may increase acoustic and

power to operational levels.

22–350 Hz: 5.0 G

350–500 Hz:: 1.0 G

2.7 (max)

2.9 (max)

14

bits read

To determine the warranty for a specific drive, use a web browser to

access the following web page:

www.seagate.com/support/service/

From this page, click on the “Verify Your Warranty” link. You will be asked

to provide the drive serial number, model number (or part number) and

country of purchase. The system will display the warranty information for

your drive.

2.0 (typical)

2.3 (max)

2.4 (typical)

2.6 (max)

DiamondMax 20 PATA Product Manual, Rev. A 11

Page 20

2.2 Formatted capacity

Formatted

Model

STM3300622A 300 Gbytes 586,072,368 512

STM3250623A 250 Gbytes 488,397,168 512

STM3250624A 250 Gbytes 488,397,168 512

STM3200827A 200 Gbytes 390,721,968 512

STM3160212A 160 Gbytes 312,581,808 512

STM3160812A 160 Gbytes 312,581,808 512

STM3802110A 80 Gbytes 156,301,488 512

STM3402111A 40 Gbytes 78,165,360 512

*One Gbyte equals one billion bytes when referring to hard drive capacity. Accessible capacity may va ry depending on op erating environment and formatting.

capacity*

Guaranteed

sectors Bytes per sector

2.2.1 LBA mode

When addressing these d rives in LBA mode, all bl ocks (sectors) are cons ecutively numbered fr om 0 to n–1,

where n is the number of guaranteed sectors as defined above.

See Section 4.1.2, "Id enti fy Devic e co mma nd" (w ords 60 -6 1 a nd 1 00- 10 3) for a ddi tio nal in formation about 48bit addressing support of drives with capacities over 137 Gbytes.

2.3 Default logical geometry

Cylinders Read/write heads Sectors per track

16,383 16 63

12 DiamondMax 20 PATA Product Manual, Rev. A

Page 21

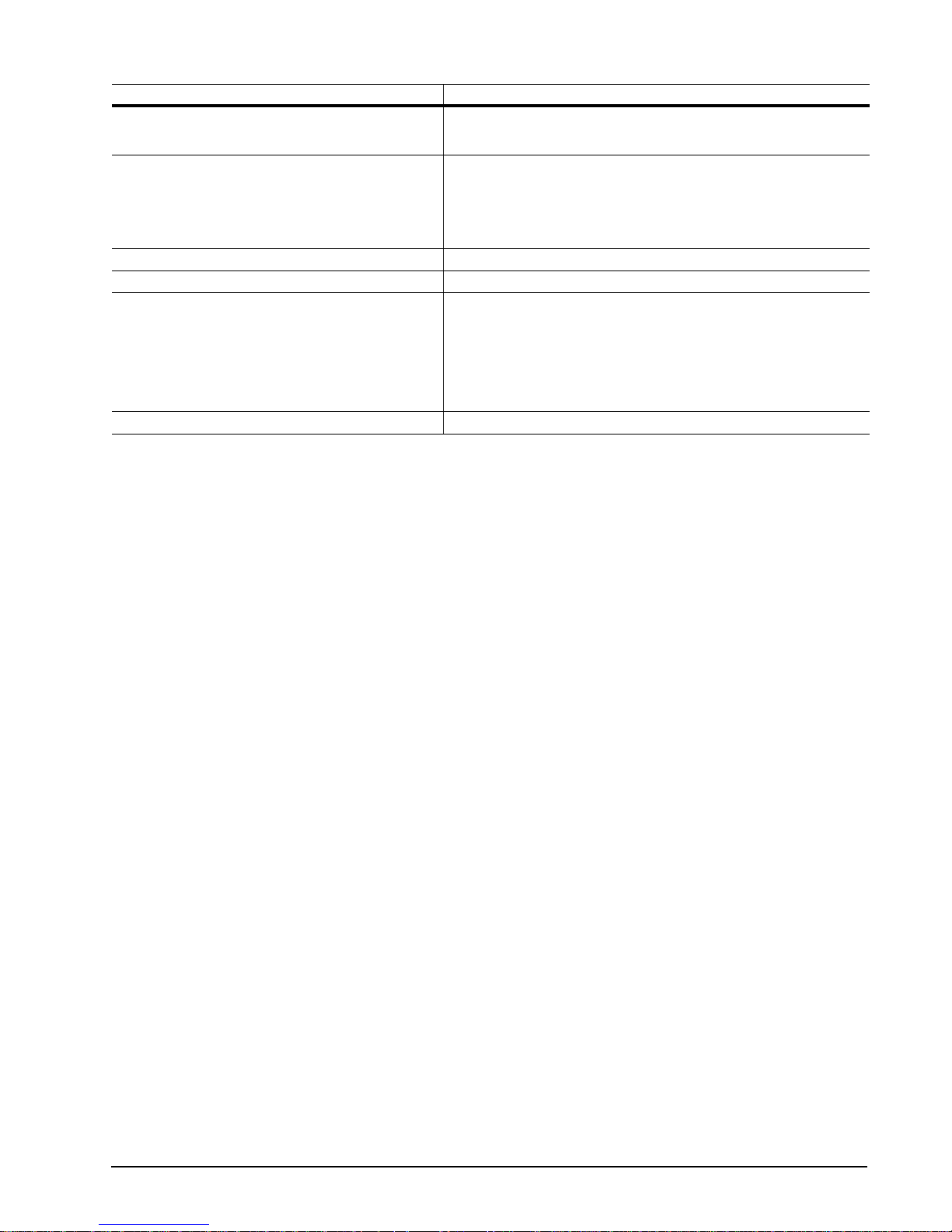

2.4 Recording and interface technology

STM3300622A

STM3250624A

STM3200827A STM3250623A

Interface ATA

Recording density, KBPI (kbits/inch max) 790.1 763 840.0 611.5

Track density, KTPI (ktracks/inch avg) 124.5 120 141.5 103.9

2

Areal density (Gbits/inch

Spindle speed (RPM) (± 0.2%) 7,200

Internal data transfer rate (Mbits/sec max) 867.2 760 867.2 867.2

Sustained data transfer rate

(Mbytes/sec max)

I/O data-transfer rate (Mbytes/sec max) 100 (Ultra DMA mode 5)

avg) 97.69 91.56 119.0 63.53

76.6 65.0 83.0 69.4

STM3160212A

STM3160812A

STM3802110A STM3402111A

2.5 Physical characteristics

Drive specification

Maximum height

(mm)

(inches)

Maximum width

(mm)

(inches)

26.11

1.028

101.6

4.000 +/- 0.010

Maximum lengt h

(mm)

(inches)

Max weight

STM3300622A

STM3250623A

STM3250624A

STM3200827A

STM3160812A

STM3160212A

STM3802110A

STM3402111A

Cache Size

STM3300622A

STM3250623A

STM3250624A

STM3200827A

STM3160812A

STM3160212A

STM3802110A

STM3402111A

146.99

5.787

655 grams (1.44 lbs)

635 grams (1.39 lbs)

580 grams (1.28 lbs)

580 grams (1.28 lbs)

580 grams (1.28 lbs)

580 grams (1.28 lbs)

580 grams (1.28 lbs)

525 grams (1.16 lbs)

16 Mbytes

16 Mbytes

16 Mbytes

8 Mbytes

8 Mbytes

2 Mbytes

2 Mbytes

2 Mbytes

2.6 Seek time

Seek measurements are taken with nominal power at 25°C ambient temperature. All times are measured using

drive diagnostics. The specifications in the table below are defined as follows:

DiamondMax 20 PATA Product Manual, Rev. A 13

Page 22

• Track-to-track seek time is an average of all possible single-track seeks in both directions.

• Average seek time is a true statistical random av erage of at least 5,000 measurements of seeks betwee n

random tracks, less overhead.

*Typical seek times (msec) Read Write

Track-to-track <0.8 <1.0

Average <11.0 <12.0

Average latency 4.16 4.16

*Measured in quiet mode

Note. These drives are designed to consistently meet the seek times represented in this manual. Physical seeks,

regardless of mode (such as track-to-track and average), are expected to meet or exceed the noted values.

However, due to the manner in which these drives are formatted, benchmark tests that include command

overhead or measure logical seeks may produce results that vary from these specifications.

2.7 Start/stop times

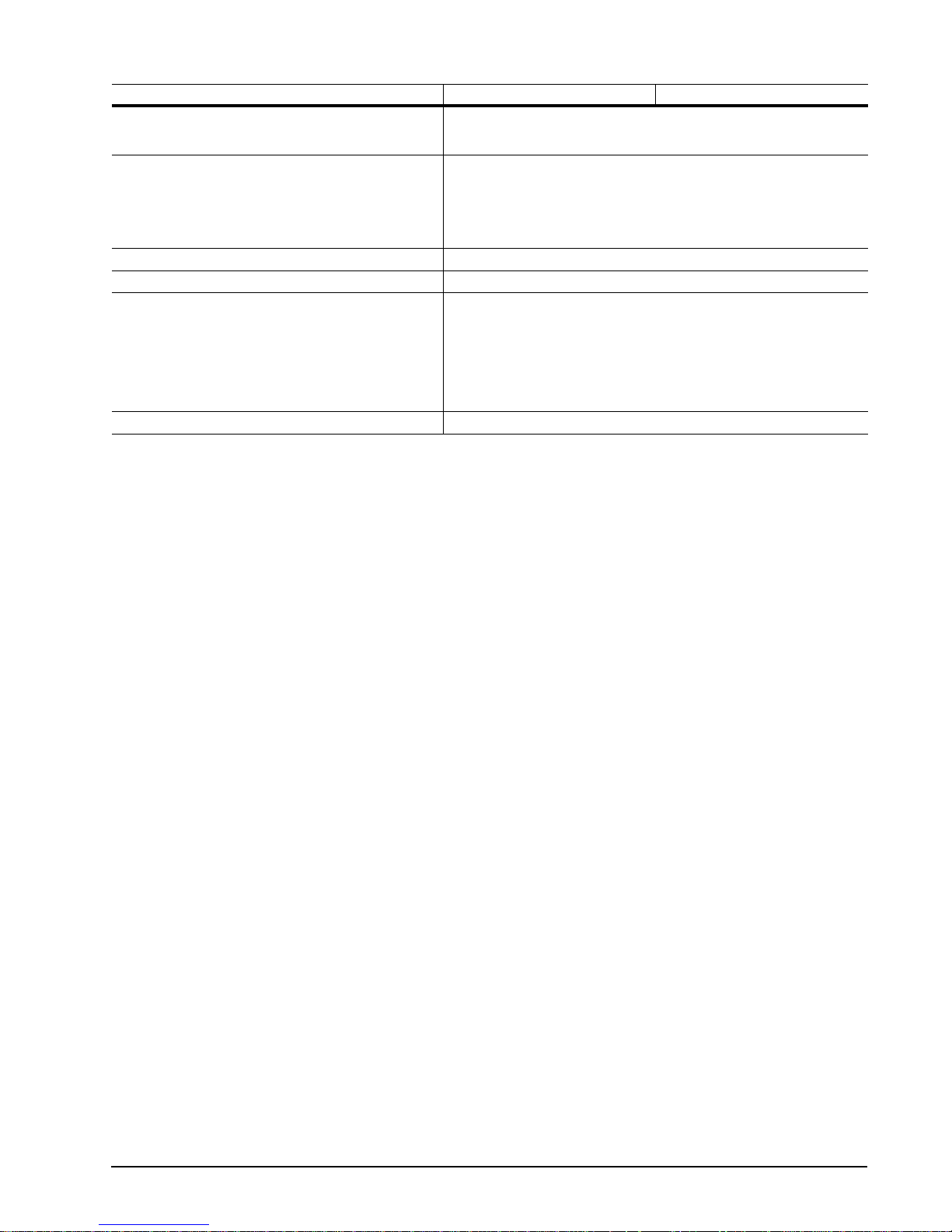

STM3300622A STM3250623A All other models

Power-on to Ready (sec) 11 (max) 10 (max) <10 (max)

Standby to Ready (sec) 11 (max) 10 (max) <10 (max)

Ready to spindle stop (sec) 12 (max) 12 (max) <11 (max)

14 DiamondMax 20 PATA Product Manual, Rev. A

Page 23

2.8 Power specifications

The drive receives DC power (+5V or +12V) through a four-pin standard drive power connector.

2.8.1 Power consumption

Power requirements for the dr i ves ar e lis ted i n th e table s beg inn in g o n page 15. Typical power meas ur em ents

are based on an av erage of driv es te sted, under nomin al co nditio ns, u sing +5.0V and + 12.0V input voltage a t

25°C ambient temperature.

• Spinup power

Spinup power is measured from the time of power-on to the time that the drive spindle reaches operating speed.

• Seek mode

During seek mode, the read/write actuator arm moves toward a specific position on the disc surface and does

not execute a read or write operatio n. Se rvo electr onics ar e active. S eek mode power repres ents the worstcase power consump tion, using only random se eks with read or write laten cy time. This mod e is not typic al

and is provided for worst-case information.

• Read/write power and current

Read/write power is me asured with the he ads on track, b ased on a 16-sec tor write followed by a 32-msec

delay, then a 16-sector read followed by a 32-msec delay.

• Operating power and current

Operating power is mea sure d using 40 percent random s eek s, 40 p er cent r ead /write mo de ( 1 wri te fo r e ach

10 reads) and 20 percent drive idle mode.

• Idle mode power

Idle mode power is measur ed wi th th e driv e up to s pee d, wi th ser vo ele ctron ics act ive and with the heads in

a random track location.

• Standby mode

During Standby mode, the driv e accepts commands, but the drive is not spinning, and the ser vo and read/

write electronics are in power-down mode.

T a ble 5: STM3300622A DC power requirements

Power dissipation (watts) Avg (watts, 25° C) Avg 5V typ amps Avg 12V typ amps

Spinup — — 2.80 (peak)

Idle* 7.40 0.393 0.453

Idle* (with offline activity) 9.40 0.483 0.582

Operating (40% r/w, 40% seek, 20% inop.) 13.00 0.811 0.746

Seeking (random, 20% idle) 12.80 0.471 0.870

Standby 0.80 0.112 0.02

Sleep 0.80 0.112 0.02

*During periods of drive idle, some o ffline activity may occur according to th e S.M.A.R.T. specification, which may increase ac oustic and

power to operational levels.

DiamondMax 20 PATA Product Manual, Rev. A 15

Page 24

Table 6: STM3250623A DC power requirements

Power dissipation (watts) Avg (watts, 25° C) Avg 5V typ amps Avg 12V typ amps

Spinup — — 2.80 (peak)

Idle* 7.2 0.401 0.433

Idle* (with offline activity) 9.1 0.78 0.433

Operating (40% r/w, 40% seek, 20% inop.) 12.8 0.841 0.715

Seeking (random, 20% idle) 12.4 0.602 0.782

Standby 0.8 0.145 0.006

Sleep 0.8 0.145 0.006

*During periods of drive idle, some o ffline activity may occur according to the S. M.A.R.T. specification, which may increase acoust ic and

power to operational levels.

Table 7: STM3250624A and STM3200827A DC power requirements

Power dissipation (watts) Avg (watts, 25° C) Avg 5V typ amps Avg 12V typ amps

Spinup — — 2.80 (peak)

Idle* 7.20 0.382 0.441

Idle* (with offline activity) 9.10 0.491 0.554

Operating (40% r/w, 40% seek, 20% inop.) 12.80 0.687 0.781

Seeking (random, 20% idle) 12.40 0.446 0.848

Standby 0.80 0.113 0.020

Sleep 0.80 0.110 0.021

*During periods of drive idle, some o ffline activity may occur according to the S. M.A.R.T. specification, which may increase acoust ic and

power to operational levels.

Table 8: STM3160212A and STM3160812A DC power requirements

Power dissipation (watts) Avg (watts, 25° C) Avg 5V typ amps Avg 12V typ amps

Spinup — — 2.80 (peak)

Idle* 7.20 0.590 0.354

Idle* (with offline activity) 9.10 0.880 0.391

Operating (40% r/w, 40% seek, 20% inop.) 12.80 0.920 0.682

Seeking (random, 20% idle) 12.40 0.690 0.745

Standby 0.80 0.113 0.020

Sleep 0.80 0.113 0.020

*During periods of drive idle, some o ffline activity may occur according to the S. M.A.R.T. specification, which may increase acoust ic and

power to operational levels.

16 DiamondMax 20 PATA Product Manual, Rev. A

Page 25

T able 9: STM3802110A and STM3402111A DC power requirements

Power dissipation (watts) Avg (watts, 25° C) Avg 5V typ amps Avg 12V typ amps

Spinup — — 2.80 (peak)

Idle* 7.00 0.490 0.379

Idle* (with offline activity) 8.90 0.873 0.378

Operating (40% r/w, 40% seek, 20% inop.) 12.60 0.897 0.676

Seeking (random, 20% idle) 12.20 0.627 0.755

Standby 0.80 0.116 0.018

Sleep 0.80 0.116 0.018

*During periods of drive idle, some o ffline activity may occur according to th e S.M.A.R.T. specification, which may increase ac oustic and

power to operational levels.

2.8.1.1 Typical current profile

Figure 1 Typical 5V startup and operation current profile

Figure 2 Typical 12V startup and operation current profile

DiamondMax 20 PATA Product Manual, Rev. A 17

Page 26

2.8.2 Conducted noise

Input noise ripple is mea su red at the ho st system power supply acr o ss an equ iv al ent 80 -ohm r es isti ve load on

the +12 volt line or an equivalent 15-ohm resistive load on the +5 volt line.

• Using 12-volt power, the drive is expected to operate with a maximum of 120 mV peak-to-peak square-wave

injected noise at up to 10 MHz.

• Using 5-volt power, the drive is expect ed to ope rate wi th a max imum of 1 0 0 mV peak -to-peak squa re-wav e

injected noise at up to 10 MHz.

Note. Equival ent resistance is calcul ated by dividing the nomina l voltage by the typical RMS read/write

current.

2.8.3 Voltage tolerance

Voltage tolerance (including noise):

5V ± 5%

12V ± 10%

2.8.4 Power-management modes

The drive provides programmab le power mana gement to provide grea ter energy efficiency. In most systems,

you can control power management through the system setup program. The drive features the following

power-management modes :

Power mode Heads Spindle Buffer

Active Tracking Rotating Enabled

Idle Tracking Rotating Enabled

Standby Parked Stopped Enabled

Sleep Parked Stopped Disabled

• Active mode

The drive is in Active mode during the read/write and seek operations.

• Idle mode

The buffer remains en abled, and the drive a ccepts a ll comm ands and re turns to Ac tive mode any time disc

access is necessary.

• Standby mode

The drive enters Standby mode when the host sends a Standby Immediate command. If the host has set the

standby timer, the dri ve can also enter Stand by mode automaticall y after the drive has be en inactive for a

specifiable length of time. The standby timer delay is established using a Standby or Idle command. In Standby

mode, the drive buffer is enab led, the heads are parked and the spi ndle is at rest. The drive accepts all

commands and returns to Active mode any time disc access is necessary.

• Sleep mode

The drive enters Sleep mode after receiving a Sleep command from the host. In Sleep mode, the drive buffer

is disabled, the he ads are p arke d and the spind le is at rest. T he dr ive leav es Slee p mo de after it rece ives a

Hard Reset or Soft Reset from the host. After receiving a reset, the drive exits Sleep mode and enters Standby

mode with all current translation parameters intact.

• Idle and Standby timers

Each time the drive perfo rms an Active function (read, wr ite or seek), the standby time r is reinitialized and

begins counting down from its specified delay times to zero. If the standby timer reaches zero before any drive

18 DiamondMax 20 PATA Product Manual, Rev. A

Page 27

activity is required, the driv e makes a transi tion to Standb y mode. In both Idle and Standby mode, the d rive

accepts all commands and returns to Active mode when disc access is necessary.

2.9 Environmental specifications

2.9.1 Ambient temperature

Ambient temperature is defined as the temperature of the environment immediately surrounding the drive.

Actual drive case t emperatur e shoul d not excee d

ommended measurement locations are shown in See Figure 6 on page 31.

Above 1,000 feet (305 meters), the ma ximum temperature is derated linearly to 112°F (44°C) at 10,000 feet

(3,048 meters).

Operating: 5° to 60°C (41° to 140°F)

Nonoperating: –40° to 70°C (–40° to 158°F)

2.9.2 Temperature gradient

Operating: 20°C per hour (68°F per hour max), without condensation

Nonoperating: 30°C per hour (86°F per hour max)

2.9.3 Humidity

69°C (1 56°F) within the opera ting ambient conditio ns. Rec-

2.9.3.1 Relative humidity

Operating: 5% to 90% noncondensing (30% per hour max)

Nonoperating: 5% to 95% noncondensing (30% per hour max)

2.9.3.2 Wet bulb temperature

Operating: 37.7°C (99.9°F max)

Nonoperating: 40.0°C (104°F max)

2.9.4 Altitude

Operating: –60.96 m to 3,048 m (–200 ft. to 10,000+ ft.)

Nonoperating: –60.96 m to 12,192 m (–200 ft. to 40,000+ ft.)

DiamondMax 20 PATA Product Manual, Rev. A 19

Page 28

2.9.5 Shock

All shock specificat ions assume that the drive is mou nted securely with the input s hock applied at the drive

mounting screws. Shock may be applied in the X, Y or Z axis.

2.9.5.1 Operating shock

These drives compl y with the performance level s specified in this docu ment when subjected to a ma ximum

operating shock of 63 G based on half-sine shock pulses of 2 msec. Shocks should not be repeated more than

two times per second.

2.9.5.2 Nonoperating shock

The nonoperating s hock l evel that th e driv e can expe rience withou t incur ring ph ysic al d amage or degr adatio n

in performance when subsequently put into operation is 300 G (300GB models), 350 G (250 , 200, 160, 80 and

40GB models) based on a nonrepetitive half-sine shock pulse of 2 msec duration.

2.9.6 Vibration

All vibration spec ifications assume that the drive is mounted securely with the input vibration applied at the

drive mounting screws. Vibration may be applied in the X, Y or Z axis.

2.9.6.1 Operating vibration

The following table lists the maximum vibration lev els that the dri ve may expe rience while meet ing the perfor mance standards specified in this document.

5–22 Hz 0.25 G (limited dis placement)

22–350 Hz 0.50 G

350–500 Hz 0.25 G

2.9.6.2 Nonoperating vibration

The following table l ists the maximum no noperating vibr ation that the drive may expe rience without incurring

physical damage or degradation in performance when subsequently put into operation.

5–22 Hz 0.25 G (limited displacement)

22–350 Hz 5.0 G

350–500 Hz 1.0 G

20 DiamondMax 20 PATA Product Manual, Rev. A

Page 29

2.10 Acoustics

Drive acoustics a re measured as overall A -weighted acoustic soun d power levels (no pu re tones). All measurements are consistent with ISO document 77 79. Sound power measur ements are taken under essential ly

free-field conditions over a reflecting plane. For all tests, the drive is oriented with the cover facing upward.

Note. For seek mode tests, the drive is placed in seek mode only. The number of seeks per second is defined

by the following equation:

(Number of seeks per second = 0.4 / (average latency + average access time)

Table 10: Fluid Dynamic Bearing (FDB) motor acoustics

Acoustic mode

Idle* Quiet seek

STM3300622A 2.7 Bels (typ)

STM3250623A 2.8 Bels (typ)

STM3250624A

STM3200827A

STM3160212A

STM3160812A

STM3802110A 2.5 Bels (typ)

STM3402111A 2.0 Bels (typ)

*During periods of drive idle, some o ffline activity may occur according to th e S.M.A.R.T. specification, which may increase ac oustic and

power to operational levels.

2.9 Bels (max)

3.4 Bels (max)

2.7 Bels (typ)

2.9 Bels (max)

2.5 Bels (typ)

2.7 Bels (max)

2.7 Bels (max)

2.3 Bels (max)

3.0 Bels (typ)

3.2 Bels (max)

3.7 Bels (typ)

3.9 Bels (max)

3.0 Bels (typ)

3.2 Bels (max)

2.8 Bels (typ)

3.0 Bels (max)

2.7 Bels (typ)

2.9 Bels (max)

2.4 Bels (typ)

2.6 Bels (max)

DiamondMax 20 PATA Product Manual, Rev. A 21

Page 30

2.11 Electromagnetic immunity

When properly installed in a representative host system, the drive operates without err ors or degradation in

performance when subjected to the radio frequency (RF) environments defined in the following table:

Table 11: Radio frequency environments

Test Description

Electrostatic discharg e Con t ac t, HCP, VCP: ± 4

± 8 kV

Radiated RF immunity 80 to 1,000 MHz, 3 V/m,

80% AM with 1 kHz sine

900 MHz, 3 V/m, 50% pulse

modulation @ 200 Hz

Electrical fast transient ± 1 kV on AC mains , ± 0.5 kV on

external I/O

Surge immunity ± 1 kV different ial, ± 2 kV com-

mon, AC mains

Conducted RF immunity 150 kHz to 80 MHz, 3 Vrms,

80% AM with 1 kHz sine

Voltage dips, interrupts 0% open, 5 seconds

0% short, 5 seconds

40%, 0.10 seconds

70%, 0.01 seconds

kV; Air:

Performance

level

B EN 61000-4-2: 95

A EN 61000-4-3: 96

B EN 61000-4-4: 95

B EN 61000-4-5: 95

A EN 61000-4-6: 97

C

C

C

B

Reference

standard

ENV 50204: 95

EN 61000-4-11: 94

22 DiamondMax 20 PATA Product Manual, Rev. A

Page 31

2.12 Reliability

2.12.1 Annualized Failure Rate (AFR and Mean Time Between Failures (MTBF)

The product shall achieve an Ann ual iz ed Fai lu re Rate ( AFR) of 0.3 4% (MT BF of 0.7 milli on ho urs) whe n operated in an environment of am bient air temp eratures of 25

tions in Section 2.9 ma y inc reas e the pr oduc t A FR (decr ea se MTBF ). AF R a nd MT B F ar e pop ula tio n sta tisti cs

that are not relevant to individual units.

AFR and MTBF specifications are based on the following assumptions for desktop personal computer environments:

• 2400 power-on-hours per year.

• 10,000 average motor start/stop cycles per year.

• Operations at nominal voltages.

• Temperatures outside the specifications in Section 2.9 may reduce the product reliability.

• Normal I/O duty cycle for de sktop pe rsonal compu ters. Oper ation at ex cessive I/O duty cyc le may degrad e

product reliability.

The desktop personal c omputer environment of oower-on-hours , temperature, and I/O duty cycle affect the

product AFR and MTBF. The AFR and MTBF will be degraded if used in a enterprise application.

Nonrecov erable read errors 1 per 1014 bits read, max

Annualized Failure Rate (AFR) 0.34% (nominal power, 25°C ambient temperature)

°C. Operation at temperat ures outside the s pecifica-

Contact start-stop cycles 50,000 cycles

Warranty 3 years on distributi on units.

Preventive maintenance None required.

(at nominal voltage and temperature, with 60 cycles per hour and a 50% duty cycle)

To determine the warranty for a specific drive, use a web browser to access the following web page:

www.seagate.com/support/service/

From this page, click on the “Verify Your Warranty” link. You will be asked to provide

the drive serial number, model number (or part number) and country of purchase.

The system will display the warranty information for your drive.

2.13 Agency certification

2.13.1 Safety certification

The drives are recogni ze d in ac co rd anc e with UL 1950 and CSA C22.2 (950) and meet all applicab le s ec ti ons

of IEC950 and EN 60950 as tested by TUV North America.

2.13.2 Electromagnetic compatibility

Hard drives that display the CE mark comply with the European Union (EU) requirements specified in the Electromagnetic Compatibili ty Directive (89/336/EE C). Testing is performed to the l evels specified by the product

standards for Information Technology Equipment (ITE). Emission levels are defined by EN 55022, Class B and

the immunity levels are defined by EN 55024.

Seagate uses an independent laboratory to confirm compliance with the EC directives specified in the previous

paragraph. Drives are tested in representative end-user systems. Although CE-marked Seagate drives comply

with the directives wh en used in the test systems, we cannot guarantee t hat all systems will comply wit h the

DiamondMax 20 PATA Product Manual, Rev. A 23

Page 32

directives. The drive is designed for operation inside a properly designed enclosure, with properly shielded I/O

cable (if necessary) and termi nators on all unu sed I/O ports. Compute r manufacture rs and system inte grators

should confirm EMC compliance and provide CE marking for their products.

Korean RRL

If these drives have the Korea M inistry of Information a nd Comm unication ( MIC) logo , they co mply with paragraph 1 of Article 11 of the Electromagnetic Compatibili ty control Regulation and meet the Electr omagnetic

Compatibility (EMC) Framework req ui remen ts of the Radio Res earc h Labo rator y (RRL) Minis try of Infor ma tio n

and Communication Republic of Korea.

These drives have been tested and comply with the Electromagnetic Interference/Electromagnetic Susceptibility (EMI/EMS) for Class B products. Drives are tested in a representative, end-user system by a Korean-recognized lab.

• Family name: DiamondMax

• Certificate number: Pending

Australian C-Tick (N176)

If these models h ave the C-Tick marki ng, th ey com ply wi th the Aus tralia/N ew Z ealand Standard AS/NZS 3548

1995 and meet the Electromagnetic Compatibility (EMC) Framework requirements of the Australian Communication Authority (ACA).

2.13.3 FCC verification

These drives are intended to be contained solely within a personal computer or similar enclosure (not attached

as an external device). As such, each drive is considered to be a subassembly even when it is individually marketed to the customer. As a subassembly, no Federal Communications Commission verificati on or certification

of the device is required.

Seagate Technology LLC has tested this device in enclosures as described above to ensure that the total

assembly (enclosure, dis c drive, motherboard, power supply, etc.) does comply with the limits for a Class B

computing device , pursuant to Subpa rt J, Part 15 of the FCC ru les. Opera tion with nonce rtified assem blies is

likely to result in interference to radio and television reception.

Radio and television interference. This equipment generates and uses radio frequency energy and if not

installed and used in strict accordance with th e manufacturer ’s instructions, may cause i nterference to radio

and television reception.

This equipment is designed to provide reasonable protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interfer ence to radio or te levision, whic h can be determi ned by turning t he equipment on and off,

you are encouraged to try one or more of the following corrective measures:

• Reorient the receiving antenna.

• Move the device to one side or the other of the radio or TV.

• Move the device farther away from the radio or TV.

• Plug the computer into a different outlet so that the receiver and computer are on different branch outlets.

If necessary, you should consult your dealer or an experienced radio/tel evision technician for additional sug-

gestions. You may find helpful the following booklet prepared by the Federa l Communications Commission:

How to Identify and Resolve Radio-Television Interference Problems. This booklet is available from the Superintendent of Documents, U.S. Gov ernment Printing Office, Washington, DC 20 402. Refer to public ation number 004-000-00345-4.

24 DiamondMax 20 PATA Product Manual, Rev. A

Page 33

2.14 Environmental protection

Seagate designs its prod ucts to meet environ mental protectio n requirem ents worldwide, in cluding regul ations

restricting certain chemical substances.

2.14.1 European Union Restriction of Hazardous Substances (RoHS)

The European Union Restriction of Hazardous Substances (RoHS) Directive restricts the presence of chemical

substances, including Lead (Pb), in electronic products effective July 2006. Although amendments to the

Euro-pean Union’s Restri ction of Hazardous Substances (Ro HS) Dire cti ve ha ve not bee n finalized, to the best

of our knowledge the disc drives documented in this publication will comply with the final RoHS Directive

require-ments.

A number of parts and materials in Seag ate products are procured from external suppl iers. We rely on the

rep-resentations of our suppliers regarding the presence of RoHS substances in these parts and materials. Our

supplier contracts r equire compliance with our chem ical substance restrictions, a nd our suppliers document

their compliance with our requirements by providing material content declarations for all parts and materials for

the disc drives documented in this publication. Current supplier declarations include disclosure of the inclusion

of any RoHS-regulated substance in such parts or materials.

Seagate also has internal systems in place to ensure ongoing compliance with the RoHS Directive and all laws

and regulations which restrict chemical content in electronic products. These systems include standard

operat-ing procedures that ensure that restricted su bstances are not utiliz ed in our manufacturi ng operations,

labora-tory analyti cal validatio n testing, and an internal auditing pr ocess to ens ure that all standar d operatin g

procedures are complied with.

2.15 Corrosive environment

Seagate electronic driv e components pass accelerated corr osion testing equivalent to 10 ye ars exposure to

light industrial envir onments containi ng sulfuro us gases, chlorine an d nitric oxide , classes G and H per ASTM

B845. However, this accelerated testing cannot duplicate every potential application environment. Users

should use caution exposing any electronic components to uncontrolled chemical pollutants and corrosive

chemicals as elec tronic drive componen t reliabi lity ca n be affected by th e installati on environm ent. The s ilver,

copper, nickel and gold films used in Seagate products are especially sensitive to the presence of sulfide, chloride, and nitrate contaminants. Sulfur is found to be the most damaging. In addition, electr onic components

should never be ex pose d to c ondensin g water on the surfac e of th e pri nted cir cuit bo ard a ssembly (PCBA ) or

exposed to an ambient relative humidity greater than 95%. Materials used in cabinet fabrication, such as vulcanized rubber, that can outgas corr osive compoun ds should be m inimized or e liminated. Th e useful life of any

electronic equipment may be extended by replacing materials near circuitry with sulfide-free alternatives.

DiamondMax 20 PATA Product Manual, Rev. A 25

Page 34

26 DiamondMax 20 PATA Product Manual, Rev. A

Page 35

3.0 Configuring and mounting the drive

This section contains the specifications and instructions for configuring and mounting the drive.

3.1 Handling and static discharge precautions

After unpacking, and before installation, the dr ive may be ex posed to pote ntial handli ng and electros tatic discharge (ESD) hazards. Observe the following standard handling and static-discharge precautions:

Caution:

• Before handling the drive, put on a grounded wrist strap, or ground yourself frequently by touching the metal

chassis of a com puter that is plugge d into a grounded outl et. Wear a grounded wris t strap throughout th e

entire installation procedure.

• Handle the drive by its edges or frame only.

• The drive is extremely fragile—handle it with care. Do not press down on the drive top cover.

• Always rest the drive on a padded, antistatic surface until you mount it in the computer.

• Do not touch the connector pins or the printed circuit board.

• Do not remove the factory-installed labels from the drive or cover them with additional labels. Removal voids

the warranty. Some factory-installed labels co ntain in for ma tio n nee ded to service the drive . O ther l abe ls ar e

used to seal out dirt and contamination.

DiamondMax 20 PATA Product Manual, Rev. A 27

Page 36

3.2 Breather filter hole precautions

This section contains information regarding the precautions which should be taken regarding the breather filter

hole in Seagate hard d isc drives. Prop er precautions should be taken to en sure full functio nality and preven t

possible damage to the drive.

Breather hole

Do not cover or seal

this hole.

Figure 3 Breather filter hole location

Caution: Do not cover, seal, or insert any object into this h ole.

This hole has two purposes:

• To allow condensation inside the hard disc to escape

• To allow air pressure inside the hard disc to equalize with ambient pressure

Note. If this hole is covered, sealed, or penetrated by any object, the drive reliability may be compromised

and could lead to permanent damage. Covering or sealing this hole voids the warranty.

28 DiamondMax 20 PATA Product Manual, Rev. A

Page 37

3.3 Jumper settings

Options jumper block

3.3.1 Master/slave configuration

The options jumper b lock shown in Figure 4 is used to configure the drive for operatio n. It is the 8-pin dual

header between the in terface connec tor and the power connector. Use the following settings to con figure the

drive as a master or a slave.

Master or single drive. The drive is configured at the factor y for a master or single-drive operation with a

jumper set on pins 7 and 8.

Drive as slave. Remove all jumpers.

Drive as master with a non-ATA-compatible slave.

Use this jumper setting only if the drive does not work as a master with no jumpers installed.

*Master or single drive

Drive is slave

Master with non ATA-

compatible slave

*Cable select

1753

684

2

Figure 4 Master/slave jumper settings

3.3.2 Cable select option

Computers that use cable select det ermine the master and slave drives by selecting or dese lecting pin 28,

CSEL, on the interface bus. Master and slav e dr ives are det ermi ned by their phys ical pos i tio n on the cab le. To

enable cable selec t, set a jumper on pins 5 and 6 as shown i n Figure 4. Refer to your computer manual to

determine whether your computer supports this option.

DiamondMax 20 PATA Product Manual, Rev. A 29

Page 38

3.3.3 Ultra ATA/100 cable

An 80-conductor 40 -pin cable is required to run Ultra DMA mode 3, mode 4, and mode 5. This cable uses

even-numbered conductors connected to the ground pins to improve signal integrity.

Note.

If you are using a 40-pin, 80-conductor

cable, attach the blue connector to the

motherboard, the black connector to the

master drive, and the gray connector

to the slave.

Master

Slave

Figure 5 Ultra ATA cable connectors

Pin 1

Computer

Motherboard

Note. The drive supports both host and drive cable detection. The host detects the 80-conductor cable by

sampling pin 34, CBLID–, on the interface bus . The drive detec ts the 80-conduc tor cable by sensing a capacitor at the host side thr ough the CBLID– signal. The result is repor ted in a Fast Rise

Detected bit (bit 13 of word 93 in the Identify drive parameter block).

3.4 Drive mounting

You can mount the driv e in any o rientation u sing four screws in the s ide-mountin g hole s or four screws i n the

bottom-mounting holes. See Figure 6 for drive mounting dimensions. Follow these important mounting precautions when mounting the drive:

• Allow a minimum clearance of 0.030 inches (0.76 mm) around the entire perimeter of the drive for cooling.

• Use only 6-32 UNC mounting screws.

• Do not overtighten the mounting screws (maximum torque: 6 inch-lb.).

• Do not use a drive interface cable that is more than 18 inches long.

30 DiamondMax 20 PATA Product Manual, Rev. A

Page 39

Notes:

1. Dimensions are shown in inches (mm).

R

c

m

er

2 Dimensions per SFF-8301 specification.

ecommended

ase temperature

easurement location

1.028 max

(26.11)

3 x 0.25 0.010

(6.35 0.037)

both sides

1.122 0.02

(28.5 0.51)

1.638 0.01

(41.61 0.25)

3 x 6-32 UNC-2B

0.150 (3.81) max. fastener

penetration both sides. 3 threads

minimum engagement.

2

5.787 max

(146.99)

4.0 0.01

(101.60 0.25)

0.228

(5.79)

2.23

(56.56)

2.83

(71.80)

3.71

(94.35)

0.125 0.01

(3.18 0.25)

3.750 0.01

(95.25 0.25)

4.0 0.01

(101.60 0.25)

0.178

(4.27)

1.625 0.020

(41.28 0.51)

1.75 0.01

(44.45 0.25)

4 x 6-32 UNC-2B

0.150 (3.81) max. fasten

penetration. 3 threads

minimum engagement.

Recommended

case temperature

measurement location

Figure 6 Mounting dimensions

DiamondMax 20 PATA Product Manual, Rev. A 31

Page 40

32 DiamondMax 20 PATA Product Manual, Rev. A

Page 41

r

Host pin # and signal description

Drive pin #

).

4.0 ATA interface

These drives use t he industry-standard ATA task file interface that s upports 16-bit data transfer s. It supports

ATA programmed input/output (PIO) modes 0–4; m ultiwor d DMA m odes 0– 2, and Ul tra DMA mod es 0–5. The

drive also supports the use of the IORDY signal to provide reliable high-speed data transfers.

You can use a daisy-chai n cabl e to co nnect two drive s to a single AT host bus. For detailed i nform ation about

the ATA interfa ce, refer to the draft of AT Attachment with Packet Interface Extensi on (ATA/ATAPI-7), NCITS

T13 1410D, subsequently referred to as the Draft ATA-7 Standard.

4.1 ATA interface signals and connector pins

Figure 7 on page 33 summarizes the signal s on the ATA interface connector that the drive supports. For a

detailed description of these signals, refer to the Draft A TA-7 Standard.

Signal name

–

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Pins 28, 34 and 39 are used for master-slave communication (details shown below

28

34

39

Reset

Ground

DD7

DD8

DD6

DD9

DD5

DD10

DD4

DD11

DD3

DD12

DD2

DD13

DD1

DD14

DD0

DD15

Ground

(removed)

DMARQ

Ground

DIOW–

STOP

Ground

DIOR

–

HDMARDY

DDMARDY–

HSTROBE

Ground

IORDY

DSTROBE

CSEL

DMACK

Ground

INTRQ

IOCS16

DA1

–

PDIAG

CBLID–

DA0

DA2

–

CS0

–

CS1

–

DASP

Ground

Drive 0 (master)Drive 1 (slave)

28

34

39

–

–

–

Figure 7 I/O pins and supported ATA signals

1

Hardware Reset

2

Ground

3

Host Data Bus Bit 7

4

Host Data Bus Bit 8

5

Host Data Bus Bit 6

6

Host Data Bus Bit 9

7

Host Data Bus Bit 5

8

Host Data Bus Bit 10

9

Host Data Bus Bit 4

10

Host Data Bus Bit 11

11

Host Data Bus Bit 3

12

Host Data Bus Bit 12

13

Host Data Bus Bit 2

14

Host Data Bus Bit 13

15

Host Data Bus Bit 1

16

Host Data Bus Bit 14

17

Host Data Bus Bit 0

18

Device Data (15:0)

19

Ground

(No Pin)

20

21

DMA Request

22

Ground

23

Device I/O Write:

Stop Ultra DMA Burst

24

Ground

25

Device I/O Read:

Host Ultra DMA Ready:

Host Ultra DMA Data Strobe

26

Ground

27

I/O Channel Ready

Device Ultra DMA Ready

Device Ulta DMA Data Strobe

28

Cable Select

29

DMA Acknowledge

30

Ground

31

Device Interrupt

32

Reserved

33

Host Address Bus Bit 1

34

Passed Diagnostics

Cable Assembly Type Identifie

Device Address (2:0)

35

Device Address (2:0)

36

Chip Select (1:0)

37

Chip Select (1:0)

38

Drive Active/Slave Present

39

Ground

40

CSEL

PDIAG

DASP–

Host

28

–

34

39

DiamondMax 20 PATA Product Manual, Rev. A 33

Page 42

4.1.1 Supported ATA commands

The following table lists ATA - standa rd commands that the drive supports. For a detaile d des cri pti on of the ATA

commands, refer to the Draft ATA-7 Standard. See “S.M.A.R.T. commands” on page 40 for details and sub-

commands used in the S.M.A.R.T. implementation.

Table 12: Supported ATA commands

Command name Command code (in hex)

Check Power Mode 98

or E5

H

Device Configuration Freeze Lock B1H / C1

Device Configuration Identify B1H / C2

Device Configuration Restore B1H / C0

Device Configuration Set B1H / C3

Device Reset 08

Download Microcode 92

Execute Device Diagnostics 90

Flush Cache E7

Flush Cache Extended EA

Format Track 50

Identify Device EC

H

H

H

H

H

H

H

Idle 97H or E3

Idle Immediate 95H or E1

Initialize Device Parameters 9 1

Read Buffer E4

Read DMA C8

Read DMA Extended 25

Read DMA Without Retries C9

Read Log Ext 2F

Read Multiple C4

Read Multiple Extended 29

Read Native Max Address F8

Read Native Max Address Extended 27

Read Sectors 20

Read Sectors Extended 24

Read Sectors Without Retries 21

Read Verify Sectors 40

Read Verify Sectors Extended 42

Read Verify Sectors Without Retries 41

Recalibrate 10

Security Disable Password F6

Security Erase Prepare F3

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

34 DiamondMax 20 PATA Product Manual, Rev. A

Page 43

Command name Command code (in hex)

Security Erase Unit F4

Security Freeze F5

Security Set Password F1

Security Unlock F2

Seek 70

Set Features EF

Set Max Address F9

H

H

H

H

H

H

H

Note: Individual Set Max Address

commands are identified by the value

placed in the Set Max Features register as defined to the right.

Set Max Address Extended 37

Set Multiple Mode C6

H

H

Sleep 99H or E6

S.M.A.R.T. Disable Operations B0H / D9

S.M.A.R.T. Enable/Disable Autosave B0H / D2

S.M.A.R.T. Enable Operations B0H / D8

S.M.A.R.T. Execute Offline B0H / D4

S.M.A.R.T. Read Attribute Thresholds B0H / D1

S.M.A.R.T. Read Data B0H / D0

S.M.A.R.T. Read Log Sector B0H / D5

S.M.A.R.T. Return Status B0H / DA

S.M.A.R.T. Save Attribute Values B0H / D3

S.M.A.R.T. Write Log Sector B0H / D6

Standby 96H or E2

Sta ndb y Imm ed iate 94H or E0

Write Buffer E8

Write DMA CA

Write DMA Extended 35

Write DMA Without Retries CB

Write Log Extended 3F

Write Multiple C5

Write Multiple Extended 39

Write Sectors 30

Write Sectors Without Retries 31

Write Sectors Extended 34

H

H

H

H

H

H

H

H

H

H

Address:

Password:

Unlock:

Freeze Lock:

H

H

H

H

H

H

H

H

H

H

H

H

H

Lock:

00

01

02

03

04

H

H

H

H

H

DiamondMax 20 PATA Product Manual, Rev. A 35

Page 44

4.1.2 Identify Device command

The Identify Device command (command code EC

) transfers information about the drive to the host following

H

power up. The data is organized as a single 512-byte block of data, whose contents are shown in the Table 12

on page 34 . All reser v ed bits or word s shou ld be set to ze ro. Par am eters listed with an “x” are drive-specifi c or

vary with the state of the drive. See Section 2.0 on page 3 for default parameter settings.

The following commands contain drive-specific features that may not be included in the Draft ATA-7 Standard.

Word Description Value

Configuration information:

• Bit 15: 0 = ATA; 1 = ATAPI

0

• Bit 7: removable media

• Bit 6: removable controller

• Bit 0: reserved

1 Number of logical cylinders 16,383

2 ATA-reserved 0000

3 Number of logical heads 16

4 Retired 0000

5 Retired 0000

6 Number of logical sectors per logical track: 63 003F

7–9 Retired 0000

10–19 Serial number: (20 ASCII characters, 0000H = none) ASCII

0C5A

H

H

H

H

H

H

20 Retired 0000

21 Retired 0400

22 Obsolete 0000

23–26 Firmware revision (8 ASCII character string, padded with blanks to

x.xx

end of string)

27–46 Drive model number

MAXTOR STMxxxxxx

(40 ASCII characters, padded with blanks to end of string)

47 (Bits 7–0) Maximum sectors per interrupt on Read multiple and

8010

Write multiple (16)

48 R eserved 0000

49 Standard Standby timer, IORDY supported and may be disabled 2F00

50 ATA-reserved 0000

51 PIO data-transfer cycle timing mode 0200

52 Retired 0200

53 Words 54–58, 64–70 and 88 are valid 0007

54 Number of current logical cylinders xxxx

55 Number of current logical heads xxxx

56 Number of current logical sectors per logical track xxxx

57–58 Current capacity in sectors xxxx

59 Number of sectors transferred during a Read Multiple or Write Mul-

xxxx

tiple command

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

36 DiamondMax 20 PATA Product Manual, Rev. A

Page 45

Word Description Value

60–61 Total number of user-addressable LBA sectors available

(see Section 2.2 for related information)

*Note: The maximum value allowed in this field is: 0FFFFFFFh

(268,435,455 sectors, 13 7 Gby tes). Dr ives wit h cap aci ties o ver 137

Gbytes will have 0FFFFFFFh in this field and the actual number of

user-addressable LBAs s pecified in wo rds 100-103. Th is is required

for drives that support the 48-bit addressing feature.

STM3300622A = 0FFFFFFFh*

STM3250623A = 0FFFFFFFh*

STM3250624A = 0FFFFFFFh*

STM3200827A = 0FFFFFFFh*

STM3160212A = 0FFFFFFFh*

STM3160812A = 0FFFFFFFh*

STM3802110A = 156,301,488

STM3402111A = 78,165,360

62 Retired 0000

63 Multiword DMA active and modes supported

xx07

(see note following this table)

64 Advanced PIO modes supported (modes 3 and 4 supported) 0003

65 Minimum multiword DMA transfer cycle time per word (120 nsec) 0078

66 Recommended multiword DMA transfer cycle time per word (120

0078

nsec)

67 Minimum PIO cycle time without IORDY flow control (240 nsec) 00F0

68 Minimum PIO cycle time with IORDY flow control (120 nsec) 0078

69–74 ATA-reserved 0000

75 Queue depth 0000

76–79 SATA-specific xxxx

80 Major version number 007E

81 Minor version number 0000

82 Command sets supported 346B

83 Command sets supported 7D01

84 Command sets support extension 4003

85 C ommand sets enabled 34xx

86 C ommand sets enabled 3xxx

87 Command sets enable extension 4003

88 Ultra DMA support and current mode

xx3F

(see note following this table)

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

89 Security erase time 0000

90 Enhanced security erase time 0000

92 Master password revision code FFFE

93 Hardware reset value (see description following this table) xxxx

95–99 ATA-reserved 0000

100–103 Total number of user-addressable LBA sectors available (see Sec-

tion 2.2 for related information). These w ords are required for d rives

that support the 48-bit addressing feature. Maximum value:

0000FFFFFFFFFFFFh.

104–127 ATA-reserved 0000

128 Security status 0001

DiamondMax 20 PATA Product Manual, Rev. A 37

H

H

H

H

H

STM3300622A = 586,072,368

STM3250623A = 488,397,168

STM3250624A = 488,397,168

STM3200827A = 390,721,968

STM3160212A = 312,581,808

STM3160812A = 312,581,808

STM3802110A = 156,301,488

STM3402111A = 78,165,360

H

H

Page 46

Word Description Value

129–159 Seagate-reserved xxxx

160–254 ATA-reserved 0000

255 Integrity word xxA5

H

H

H

Note. Advanced Power Manag ement (APM) and Au tomati c Acoustic Mana gemen t (AAM) featu res are n ot supp orted

Note. See the bit descriptions below for words 63, 88, and 93 of the Identify Drive data:

Description (if bit is set to 1)

Bit Word 63

0 Multiword DMA mode 0 is supported.

1 Multiword DMA mode 1 is supported.

2 Multiword DMA mode 2 is supported.

8 Multiword DMA mode 0 is currently active.

9 Multiword DMA mode 1 is currently active.

10 Multiword DMA mode 2 is currently active.

Bit Word 88

0 Ultra DMA mode 0 is supported.

1 Ultra DMA mode 1 is supported.

2 Ultra DMA mode 2 is supported.

3 Ultra DMA mode 3 is supported.

4 Ultra DMA mode 4 is supported.

5 Ultra DMA mode 5 is supported.

8 Ultra DMA mode 0 is currently active.

9 Ultra DMA mode 1 is currently active.

10 Ultra DMA mode 2 is currently active.

11 Ultra DMA mode 3 is currently active.

12 Ultra DMA mode 4 is currently active.

13 Ultra DMA mode 5 is currently active.

Bit Word 93

13 1 = 80-conductor cable detected, CBLID above V

0 = 40-conductor cable detected, CBLID below VIL

IH

38 DiamondMax 20 PATA Product Manual, Rev. A

Page 47

4.1.3 Set Features command

This command controls the implementation of various features that the drive supports. When the drive receives

this command, it sets BSY, checks the contents of the Features register, clears BSY and generates an inter rupt. If the value in the register does not represent a feature that the driv e supports, the comman d is aborted .

Power-on default has the rea d look-ahe ad and wr ite cach ing featur es enabled . The ac ceptable va lues for the

Features register are defined as follows:

02

03

55

82

AA

F1

Enable write cache (default).

H

Set transfer mode (based on value in Sector Count register).

H

Sector Count register values:

00

01

08

09

Set PIO mode to default (PIO mode 2).

H

Set PIO mode to default and disable IORDY (PIO mode 2).

H

PIO mode 0

H

PIO mode 1

H

0AHPIO mode 2

0B

0C

20

21

22

40

41

42

43

44

45

Disable read look-ahead (read ca che) feature.

H

Disable write cache.

H

Enable read look-ahead (read cache) feature (default).

H

Report full capacity available

H

PIO mode 3

H

PIO mode 4 (default)

H

Multiword DMA mode 0

H

Multiword DMA mode 1

H

Multiword DMA mode 2

H

Ultra DMA mode 0

H

Ultra DMA mode 1

H

Ultra DMA mode 2

H

Ultra DMA mode 3

H

Ultra DMA mode 4

H

Ultra DMA mode 5

H

Note. At power-on, or after a hardwar e or software reset, the default v alues of the features are as indi-

cated above.

DiamondMax 20 PATA Product Manual, Rev. A 39

Page 48

4.1.4 S.M.A.R.T. commands

S.M.A.R.T. provides near-term failure pred iction for disc drives. When S.M .A.R.T. is enabled, the drive monitors predetermined driv e attr i bute s tha t are susceptible t o d egradation over time. If self-monitoring de ter mi nes

that a failure is likely, S.M.A.R.T. makes a status report a vailable to the host. Not a ll failures are predi ctable.

S.M.A.R.T. predictability is limite d to the attributes the dr ive can monitor. For more information on S.M.A.R.T.

commands and implementation, see the Draft ATA-7 Standard.

SeaTools diagnostic software a ctiva tes a b uilt-in driv e self- test (D ST S.M .A.R .T. command for D4

) that elimi-

H

nates unnecessary drive returns. The diagnostic software ships with all new drives and is also available at:

http://seatools.sea

gate.com.

This drive is shipped with S.M.A.R.T. features disabled. Y ou must have a recent BIOS or software package that

supports S.M.A.R.T. to enable this feature. The table below shows the S.M.A.R.T. command codes tha t the

drive uses.

Code in features

register S.M.A.R.T. command

D0

D2

D3

D4

D5

D6

D8

D9

DA

H

H

H

H

H

H

H

H

H

S.M.A.R.T. Read Data

S.M.A.R.T. Enable/Disable Attribute Autosave

S.M.A.R.T. Save Attribute Values

S.M.A.R.T. Execute Off-line Immediate (runs DST)

S.M.A.R.T. Read Log Sector

S.M.A.R.T. Write Log Sector

S.M.A.R.T. Enable Operations

S.M.A.R.T. Disable Operations

S.M.A.R.T. Return Statu s

Note. If an appropriate code is not writte n to the Features Register, the command is aborted and 0x04

(abort) is written to the Error register.

40 DiamondMax 20 PATA Product Manual, Rev. A

Page 49

5.0 Maxtor support services

Before contacting Maxtor Sup port, use th e Hard Disk Inf ormation featu re in MaxB last to vi ew the model n umber and serial number of y our drive. These numbers can be us ed to get help from Maxtor Support, r egister

your drive, and look up information on the Maxtor website.

Please visit www.maxtor.com to obtain comprehensive support information, such as:

• W arranty services

Drive returns, warranty status, and limited warranty statement.

• Product support

Installation tutorials, specifications, jumper settings, installation guides, and product manuals.

• Software downloads

Installation software, utilities, and diagnostics.

• Knowledge Base

Troubleshooting information, FAQs, and resolved problem database.

• Product Index

Current and legacy Maxtor products listing.

Click on Worldwide Suppo rt to access the Knowledge Base, download software upda tes, register your drive,

and get assistance via e-mail.

DiamondMax 20 PATA Product Manual, Rev. A 41

Page 50