Page 1

DiamondMax® Plus 40

54098U8, 53073U6, 52049U4,

51536U3, 51024U2

Part #1429/A

All material contained herein Copyright © 2000 Maxtor Corporation.

MaxFax™ is a trademark of Maxtor Corporation. DiamondMax®, Maxtor

and No Quibble® Service are registered trademarks of Maxtor Corporation.

Other brands or products are trademarks or registered trademarks of their

respective holders. Contents and specifications subject to change without

notice. All rights reserved.

®

Corporate Headquarters

510 Cottonwood Drive

Milpitas, California 95035

Tel: 408-432-1700

Fax: 408-432-4510

Research and Development Center

2190 Miller Drive

Longmont, Colorado 80501

Tel: 303-651-6000

Fax: 303-678-2165

Page 2

Before YBefore Y

Before Y

Before YBefore Y

Thank you for your interest in the Maxtor DiamondMax® Plus 40 AT hard disk drives. This manual provides

technical information for OEM engineers and systems integrators regarding the installation and use of DiamondMax

hard drives. Drive repair should be performed only at an authorized repair center. For repair information, contact

the Maxtor Customer Service Center at 800-2MAXTOR or 408-922-2085.

Before unpacking the hard drive, please review Sections 1 through 4.

ou Beginou Begin

ou Begin

ou Beginou Begin

CAUTION

Maxtor DiamondMax Plus 40 hard drives are precision products. Failure to

follow these precautions and guidelines outlined here may lead to

product failure, damage and invalidation of all warranties.

11

1

11

22

2

22

33

3 During handling,

33

44

4 Once a drive is removed from the Maxtor shipping container,

44

55

5

55

66

6

66

BEFORE unpacking or handling a drive, take all proper electro-static discharge (ESD)

precautions, including personnel and equipment grounding. Stand-alone drives are

sensitive to ESD damage.

BEFORE

temperature.

the drive through its mounting holes within a chassis. Otherwise, store the drive on a

padded, grounded, antistatic surface.

NEVER

into the drive's connector.

ELECTRICAL GROUNDING -

to a device bay that provides a suitable electrical ground to the drive baseplate.

removing drives from their packing material, allow them to reach room

NEVER

drop, jar, or bump a drive.

switch DC power onto the drive by plugging an electrically live DC source cable

NEVER

connect a live bus to the drive's interface connector.

For proper operation, the drive must be securely fastened

Please do not remove or cover up Maxtor factory-installed drive labels.

They contain information required should the drive ever need repair.

IMMEDIATELY

secure

Page 3

ContentsContents

Contents

ContentsContents

DIAMONDMAX PLUS 40 PRODUCT MANUAL

Section 1 Section 1

Section 1 —

Section 1 Section 1

Maxtor Corporation 1 - 1

Products 1 - 1

Support 1 - 1

Manual Organization 1 - 1

Abbreviations 1 - 1

Conventions 1 - 2

Key Words 1 - 2

Numbering 1 - 2

Signal Conventions 1 - 2

Section 2 Section 2

Section 2 —

Section 2 Section 2

The DiamondMax® Plus 40

Product Features 2 - 2

Functional/Interface 2 - 2

Cache Management 2 - 4

Buffer Segmentation 2 - 4

Read-Ahead Mode 2 - 4

Automatic Write Reallocation (AWR) 2 - 4

Write Cache Stacking 2 - 4

Major HDA Components 2 - 5

Drive Mechanism 2 - 5

Rotary Actuator 2 - 5

Read/Write Electronics 2 - 5

Read/Write Heads and Media 2 - 5

Air Filtration System 2 - 5

Microprocessor 2 - 5

Subsystem Configuration 2 - 6

Dual Drive Support 2 - 6

Cable Select Option 2 - 6

Jumper Location/Configuration 2 - 6

Cylinder Limitation 2 - 6

Introduction Introduction

Introduction

Introduction Introduction

Product Description Product Description

Product Description

Product Description Product Description

Zone Density Recording 2 - 2

Read/Write Multiple Mode 2 - 2

UltraDMA - Mode 4 2 - 2

Multi-word DMA (EISA Type B) - Mode 2 2 - 2

Sector Address Translation 2 - 2

Logical Block Addressing 2 - 3

Defect Management Zone 2 - 3

On-the-Fly Hardware Error Correction Code (ECC) 2 - 3

Software ECC Correction 2 - 3

Automatic Head Park and Lock Operation 2 - 3

i

Page 4

DIAMONDMAX PLUS 40 PRODUCT MANUAL

Section 3 Section 3

Section 3 —

Section 3 Section 3

Models and Capacities 3 - 1

Drive Configuration 3 - 1

Performance Specifications 3 - 1

Physical Dimensions 3 - 2

Power Requirements 3 - 3

Power Mode Definitions 3 - 3

Spin-up 3 - 3

Seek 3 - 3

Read/Write 3 - 3

Idle 3 - 3

Standby 3 - 3

Sleep 3 - 3

EPA Energy Star Compliance 3 - 3

Environmental Limits 3 - 3

Shock and Vibration 3 - 4

Reliability Specifications 3 - 4

Annual Return Rate 3 - 4

Quality Acceptance Rate 3 - 4

Start/Stop Cycles 3 - 4

Data Reliability 3 - 4

Component Design Life 3 - 4

EMC/EMI 3 - 5

EMC Compliance 3 - 5

Canadian Emissions Statement 3 - 5

Safety Regulatory Compliance 3 - 5

Product Specifications Product Specifications

Product Specifications

Product Specifications Product Specifications

Section 4 Section 4

Section 4 —

Section 4 Section 4

Hard Drive Handling Precautions 4 - 1

Electro-Static Discharge (ESD) 4 - 1

Unpacking and Inspection 4 - 2

Repacking 4 - 3

Physical Installation 4 - 3

Before You Begin 4 - 4

Please Read 4 - 4

Back up. Protect Your Existing Data 4 - 4

Tools for Installation 4 - 4

System Requirements 4 - 4

Operating System Requirements 4 - 4

Hook up 4 - 4

Boot the System with MaxBlast Plus Diskette 4 - 4

Configure the Drive Jumpers 4 - 4

Installaing 5.25-inch Mounting Brackets 4 - 4

Install Hard Drive in Device Bay 4 - 5

Attach Interface and Power Cables 4 - 5

Start up 4 - 5

Set up 4 - 5

Handling and Installation Handling and Installation

Handling and Installation

Handling and Installation Handling and Installation

ii

Page 5

DIAMONDMAX PLUS 40 PRODUCT MANUAL

Section 5 Section 5

Section 5 —

Section 5 Section 5

Interface Connector 5 - 1

Pin Description Summary 5 - 1

Pin Description Table 5 - 2

PIO Timing 5 - 3

DMA Timing 5 - 4

Ultra DMA Timing Parameters 5 - 5

Section 6 Section 6

Section 6 —

Section 6 Section 6

Task File Registers 6 - 1

Data Register 6 - 1

Error Register 6 - 1

Features Register 6 - 1

Sector Count Register 6 - 2

Sector Number Register 6 - 2

Cylinder Number Registers 6 - 2

Device/Head Register 6 - 2

Status Register 6 - 2

Command Register 6 - 3

Read Commands 6 - 3

Write Commands 6 - 3

Mode Set/Check Commands 6 - 3

Power Mode Commands 6 - 3

Initialization Commands 6 - 3

Seek, Format, and Diagnostic Commands 6 - 3

S.M.A.R.T. Commands 6 - 3

Summary 6 - 4

Control Diagnostic Registers 6 - 5

Alternate Status Register 6 - 5

Device Control Register 6 - 5

Digital Input Register 6 - 5

Reset and Interrupt Handling 6 - 6

AT Interface Description AT Interface Description

AT Interface Description

AT Interface Description AT Interface Description

Host Software Interface Host Software Interface

Host Software Interface

Host Software Interface Host Software Interface

Section 7 Section 7

Section 7 —

Section 7 Section 7

Command Summary 7 - 1

Read Commands 7 - 2

Write Commands 7 - 4

Interface Commands Interface Commands

Interface Commands

Interface Commands Interface Commands

Read Sector(s) 7 - 2

Read Verify Sector(s) 7 - 2

Read Sector Buffer 7 - 2

Read DMA 7 - 3

Read Multiple 7 - 3

Set Multiple 7 - 3

Write Sector(s) 7 - 4

iii

Page 6

DIAMONDMAX PLUS 40 PRODUCT MANUAL

Write Verify Sector(s) 7 - 4

Write Sector Buffer 7 - 4

Write DMA 7 - 5

Write Multiple 7 - 5

Ultra DMA 7 - 5

Set Feature Commands 7 - 5

Set Features Mode 7 - 5

Power Mode Commands 7 - 7

Standby Immediate 7 - 7

Idle Immediate 7 - 7

Standby 7 - 7

Idle 7 - 7

Check Power Mode 7 - 7

Set Sleep Mode 7 - 7

Default Power-on Condition 7 - 7

Initialization Commands 7 - 9

Identify Drive 7 - 9

Initialize Drive Parameters 7 - 12

Seek, Format, and Diagnostic Commands 7 - 13

S.M.A.R.T. Command Set 7 - 14

Section 8 Section 8

Section 8 —

Section 8 Section 8

Service Policy 8 - 1

No Quibble Service 8 - 1

Support 8 - 1

GlossaryGlossary

Glossary

GlossaryGlossary

Service and Support Service and Support

Service and Support

Service and Support Service and Support

iv

Page 7

FiguresFigures

Figures

FiguresFigures

Figure Title Page

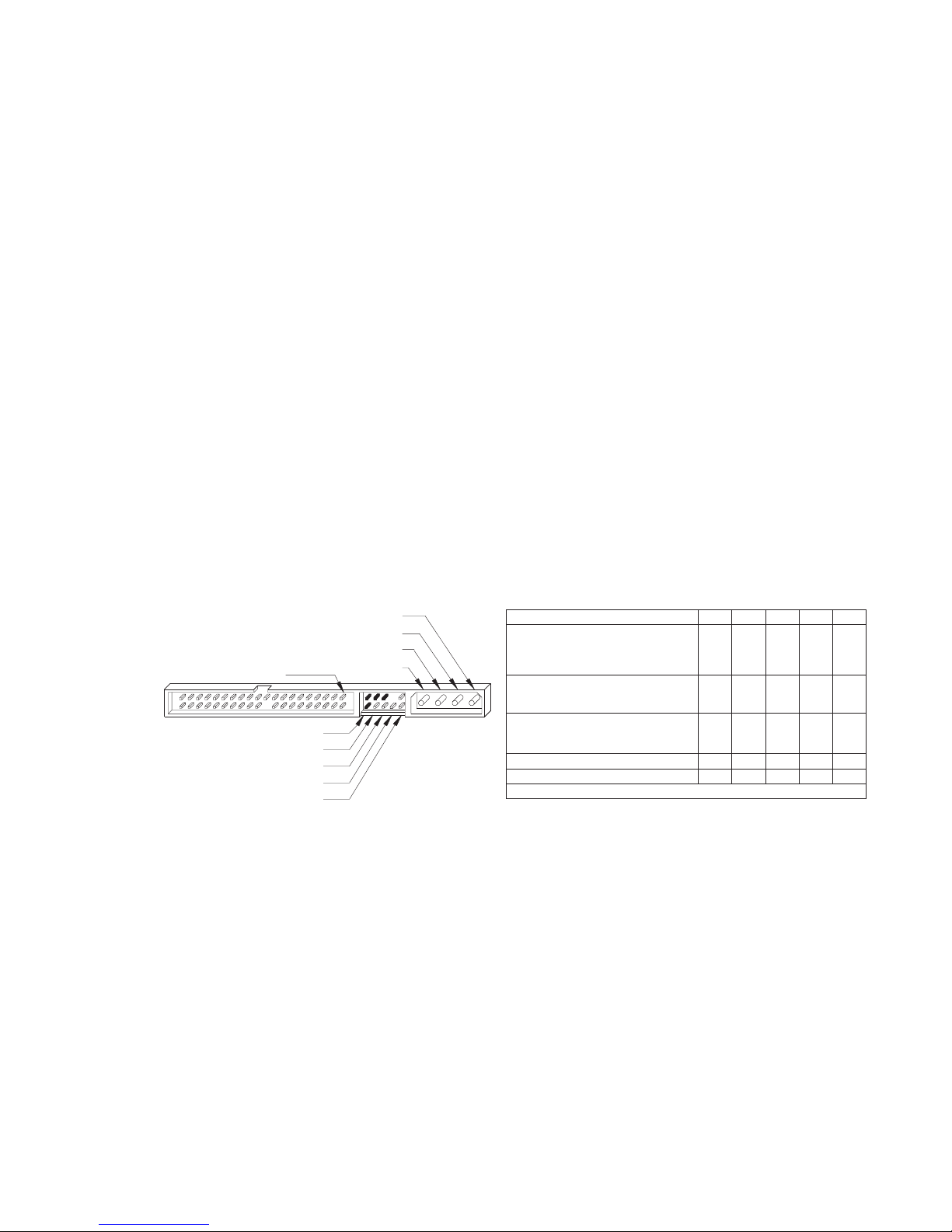

2 - 1 PCBA Jumper Location and Configuration 2 - 6

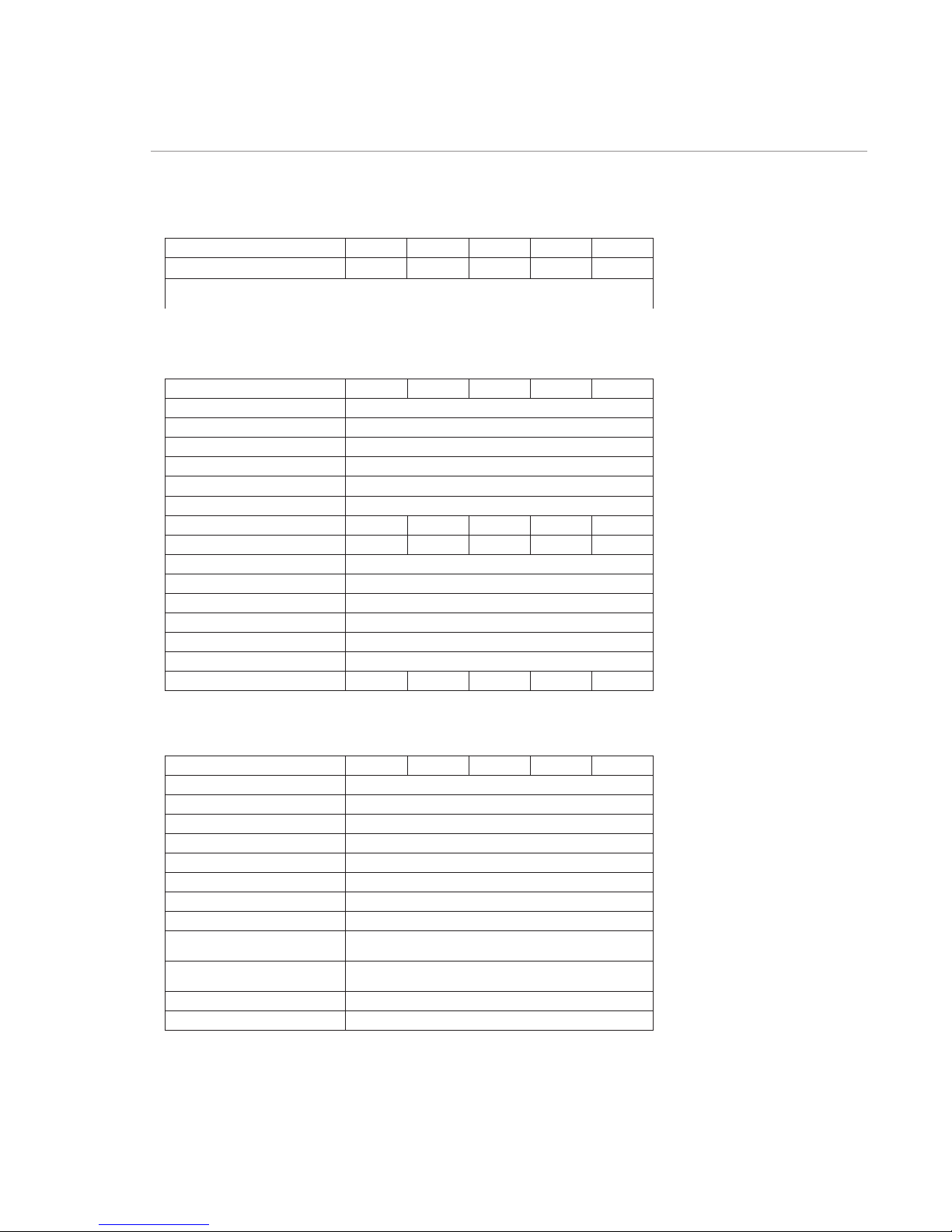

3 - 1 Outline and Mounting Dimensions 3 - 2

4 - 1 Multi-pack Shipping Container 4 - 2

4 - 2 Single-pack Shipping Container (Option A) 4 - 3

4 - 3 Single-pack Shipping Container (Option B) 4 - 3

4 - 4 Master, Slave and Cable Select Settings 4 - 5

4 - 5 5.25-inch Mounting Brackets and Rails 4 - 6

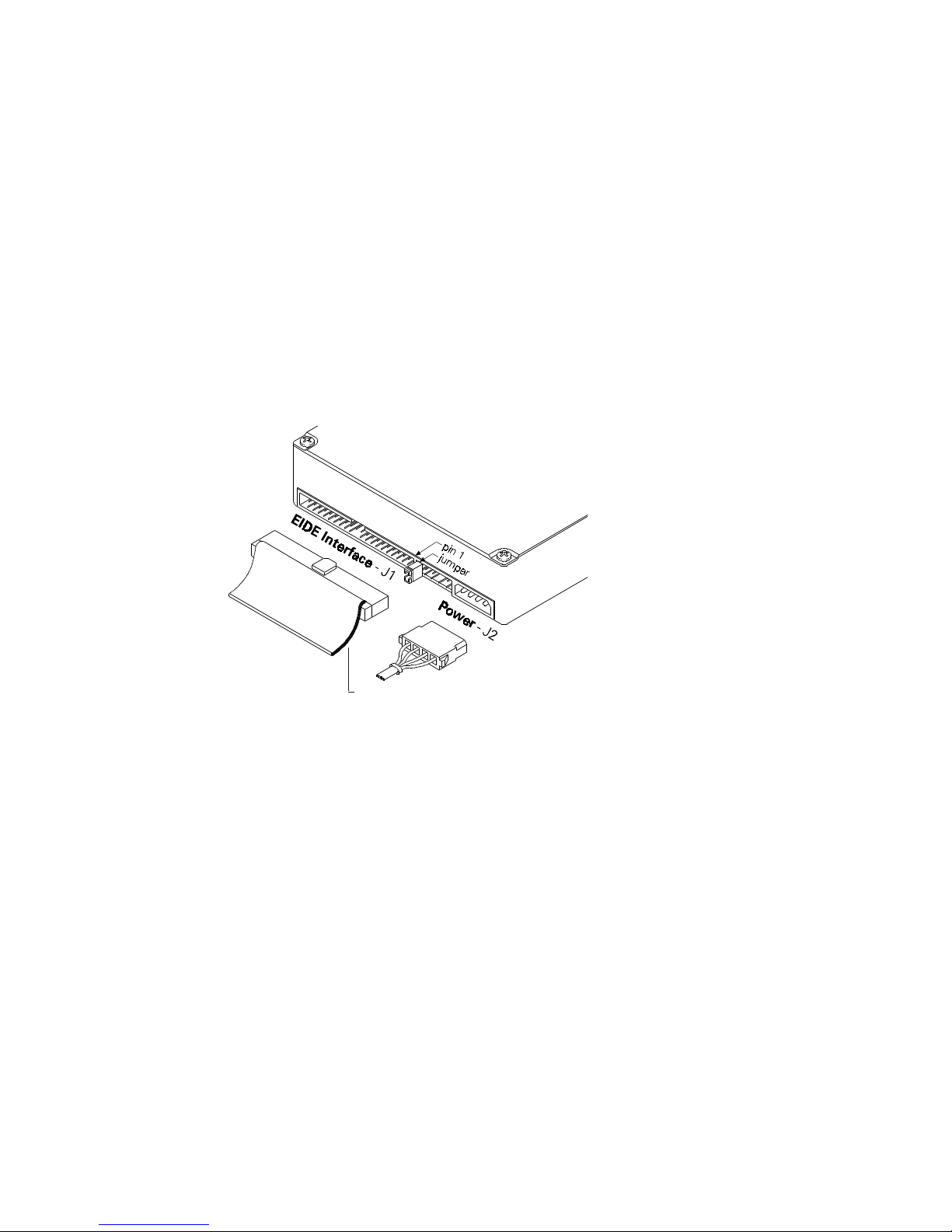

4 - 6 IDE Interface and Power Cabling Detail 4 - 7

4 - 7 Master, Slave and Cable Select Settings 4 - 10

5 - 1 Data Connector 5 - 1

5 - 2 PIO Data Transfer to/from Device 5 - 3

5 - 3 Multi-word DMA Data Transfer 5 - 4

5 - 4 Initiating an Ultra DMA Data In Burst 5 - 5

5 - 5 Sustained Ultra DMA Data In Burst 5 - 6

5 - 6 Host Pausing an Ultra DMA Data In Burst 5 - 6

5 - 7 Device Terminating an Ultra DMA Data In Burst 5 - 7

5 - 8 Host Terminating an Ultra DMA Data In Burst 5 - 7

5 - 9 Initiating an Ultra DMA Data Out Burst 5 - 8

5 - 10 Sustained Ultra DMA Data Out Burst 5 - 8

5 - 11 Device Pausing an Ultra DMA Data Out Burst 5 - 9

5 - 12 Host Terminating an Ultra DMA Data Out Burst 5 - 9

5 - 13 Device Terminating an Ultra DMA Data Out Burst 5 - 10

DIAMONDMAX PLUS 40 PRODUCT MANUAL

v

Page 8

DIAMONDMAX PLUS 40 – INTRODUCTION

SECTION 1

IntroductionIntroduction

Introduction

IntroductionIntroduction

Maxtor CorporationMaxtor Corporation

Maxtor Corporation

Maxtor CorporationMaxtor Corporation

Maxtor Corporation has been providing high-quality computer storage products since 1982. Along the way,

we’ve seen many changes in data storage needs. Not long ago, only a handful of specific users needed more than

a couple hundred megabytes of storage. Today, downloading from the Internet and CD-ROMs, multimedia,

networking and advanced office applications are driving storage needs even higher. Even home PC applications

need capacities measured in gigabytes, not megabytes.

ProductsProducts

Products

ProductsProducts

Maxtor’s products meet demanding storage capacity requirements with room to spare. They feature proven

compatibility and reliability. While DiamondMax

performance 7,200 RPM desktop and workstation hard drives, our DiamondMax

deliver industry-leading capacity, reliability and value for entry-level systems and consumer electronics

applications.

SupportSupport

Support

SupportSupport

No matter which capacity, all Maxtor hard drives are supported by our commitment to total customer

satisfaction and our No Quibble Service

®

guarantee. One call – or a visit to our home page on the Internet

(http://www.maxtor.com) – puts you in touch with either technical support or customer service. We’ll

provide you the information you need quickly, accurately and in the form you prefer – a fax, a downloaded

file or a conversation with a representative.

®

Plus 40 is the latest addition to our legacy of high

®

VL 20 series hard drives

Manual OrganizationManual Organization

Manual Organization

Manual OrganizationManual Organization

This hard disk drive reference manual is organized in the following method:

❏ Section 1 – Introduction

❏ Section 2 – Description

❏ Section 3 – Specifications

❏ Section 4 – Installation

❏ Section 5 – AT Interface

❏ Section 6 – Host Software Interface

❏ Section 7 – Interface Commands

❏ Section 8 – Service and Support

❏ Appendix – Glossary

AbbreviationsAbbreviations

Abbreviations

AbbreviationsAbbreviations

VRBBANOITPIRCSEDVRBBANOITPIRCSED

ATAtnemhcattaTABMetybagem

ipbhcnirepstibces/stibMdnocesrepstibagem

SHCrotces-daeh-rednilycces/BMdnocesrepsetybagem

bdslebicedzHMztrehagem

ABddethgiewA,slebicedsmdnocesillim

AMDsseccayromemtceridBSMtibtnacifingistsom

CCEedocnoitcerrocrorreVmstlovillim

icfhcnirepsegnahcxulfsnsdnocesonan

GnoitareleccaOIPtuptuo/tupnidemmargorp

BGetybagigMPRetunimrepsnoitulover

zHztrehipthcnirepskcart

BKetybolikAMDUsseccayromemtceridartlu

ABL)gni(sserddakcolblacigolcesµdnocesorcim

BSLtibtnacifingistsaelVstlov

AmserepmaillimWsttaw

1 – 1

Page 9

DIAMONDMAX PLUS 40 – INTRODUCTION

ConventionsConventions

Conventions

ConventionsConventions

If there is a conflict between text and tables, the table shall be accepted as being correct.

Key WordsKey Words

Key Words

Key WordsKey Words

The names of abbreviations, commands, fields and acronyms used as signal names are in all uppercase type

(e.g., IDENTIFY DRIVE). Fields containing only one bit are usually referred to as the “name” bit instead of

the “name” field.

Names of drive registers begin with a capital letter (e.g., Cylinder High register).

NumberingNumbering

Numbering

NumberingNumbering

Numbers that are not followed by a lowercase “b” or “h” are decimal values. Numbers that are followed by

a lowercase “b” (e.g., 01b) are binary values. Numbers that are followed by a lowercase “h” (e.g., 3Ah) are

hexadecimal values.

Signal ConventionsSignal Conventions

Signal Conventions

Signal ConventionsSignal Conventions

Signal names are shown in all uppercase type.

All signals are either high active or low active signals. A dash character (-) at the end of a signal name

indicates that the signal is low active. A low active signal is true when it is below ViL and is false when it is

above ViH. A signal without a dash at the end indicates that the signal is high active. A high active signal is

true when it is above ViH and is false when it is below ViL.

When a signal is asserted, it means the signal is driven by an active circuit to its true state.

When a signal is negated, it means the signal is driven by an active circuit to its false state.

When a signal is released, it means the signal is not actively driven to any state. Some signals have bias

circuitry that pull the signal to either a true or false state when no signal driver is actively asserting or negating

the signal. These instances are noted under the description of the signal.

1 – 2

Page 10

PRODUCT DESCRIPTION

SECTION 2

ProductProduct

Product

ProductProduct

Maxtor DiamondMax® Plus 40 AT disk drives are 1-inch high, 3.5-inch diameter random access storage devices

which incorporate an on-board ATA-5/Ultra DMA 66 controller. High capacity is achieved by a balanced

combination of high areal recording density and the latest data encoding and servo techniques.

Maxtor's latest advancements in electronic packaging and integration methods have lowered the drive's power

consumption and increased its reliability. Advanced giant magneto-resistive read/write heads and a state-of-the-art

head/disk assembly - using an integrated motor/spindle design - allow up to four disks in a 3.5-inch package.

Exceptionally high data transfer rates, 7,200 RPM spin speed and < 9.0 ms access times make these performance

series disk drives especially well-suited to high-end desktop and server applications.

DiamondMax Plus 40 Key FeaturesDiamondMax Plus 40 Key Features

DiamondMax Plus 40 Key Features

DiamondMax Plus 40 Key FeaturesDiamondMax Plus 40 Key Features

ANSI ATA-5 compliant PIO Mode 4 interface (Enhanced IDE)

Supports Ultra DMA Mode 4 for up to 66.7 MB/sec data transfers

2 MB buffer with multi-adaptive cache manager

7,200 RPM spin speed

< 9.0 ms seek time

DescriptionDescription

Description

DescriptionDescription

Zone density and I.D.-less recording

Outstanding shock resistance at 250 Gs

High durability with 50K contact start/stop cycles

Advanced multi-burst on-the-fly Error Correction Code (ECC)

Extended data integrity with ECC protected data and fault tolerant servo synchronization fields

Supports EPA Energy Star Standards (Green PC Friendly) with ATA powering savings commands

Auto park and lock actuator mechanism

Low power consumption

S.M.A.R.T. Capability

Note: Maxtor defines one megabyte as 106 or one million bytes and one gigabyte as 109 or one billion bytes.

2 – 1

Page 11

PRODUCT DESCRIPTION

ProductProduct

Product

ProductProduct

Functional / InterfaceFunctional / Interface

Functional / Interface

Functional / InterfaceFunctional / Interface

Maxtor DiamondMax Plus 40 hard drives contain all necessary mechanical and electronic parts to interpret control

signals and commands from an AT-compatible host computer. See Section 3 Product Specifications, for complete

drive specifications.

Zone Density RecordingZone Density Recording

Zone Density Recording

Zone Density RecordingZone Density Recording

Read / Write Multiple ModeRead / Write Multiple Mode

Read / Write Multiple Mode

Read / Write Multiple ModeRead / Write Multiple Mode

UltraDMA - Mode 4UltraDMA - Mode 4

UltraDMA - Mode 4

UltraDMA - Mode 4UltraDMA - Mode 4

Multi-word DMA (EISA Type B) - Mode 2Multi-word DMA (EISA Type B) - Mode 2

Multi-word DMA (EISA Type B) - Mode 2

Multi-word DMA (EISA Type B) - Mode 2Multi-word DMA (EISA Type B) - Mode 2

FeaturesFeatures

Features

FeaturesFeatures

The disk capacity is increased with bit density management – common with Zone Density Recording. Each

disk surface is divided into 16 circumferential zones. All tracks within a given zone contain a constant

number of data sectors. The number of data sectors per track varies in different zones; the outermost zone

contains the largest number of data sectors and the innermost contains the fewest.

This mode is implemented per ANSI ATA/ATAPI-5 specification. Read/Write Multiple allows the host to

transfer a set number of sectors without an interrupt request between them, reducing transfer process

overhead and improving host performance.

Maxtor DiamondMax Plus 40 hard drives fully comply with the new ANSI Ultra DMA protocol, which

greatly improves overall AT interface performance by significantly improving burst and sustained data

throughput.

Supports multi-word Direct Memory Access (DMA) EISA Type B mode transfers.

Sector Address TranslationSector Address Translation

Sector Address Translation

Sector Address TranslationSector Address Translation

All DiamondMax Plus 40 drives feature a universal translate mode. In an AT/EISA-class system, the drive may

be configured to any specified combination of cylinders, heads and sectors (within the range of the drive's

formatted capacity). DiamondMax Plus 40 drives power-up in a translate mode:

LEDOMLYCDHTPSenoZLmocPWABLXAMYTICAPAC

8U89045604,976136)*()*(842,140,08BM089,04

6U37035455,956136)*()*(234,030,06BM537,03

4U94025307,936136)*()*(426,020,04BM094,02

3U63515777,926136)*()*(612,510,03BM763,51

2U42015258,916136)*()*(618,010,02BM542,01

(*) The fields LZone (Landing Zone) and WPcom (Write Pre-comp) are not used by the Maxtor hard drive

and the values may be either 0 or the values set by the BIOS. All capacities listed in the above table are based

on 106 or one million bytes.

Logical Block AddressingLogical Block Addressing

Logical Block Addressing

Logical Block AddressingLogical Block Addressing

The Logical Block Address (LBA) mode can only be utilized in systems that support this form of translation. The

cylinder, head and sector geometry of the drive, as presented to the host, differs from the actual physical

geometry. The host AT computer may access a drive of set parameters: number of cylinders, heads and sectors

per track, plus cylinder, head and sector addresses. However, the drive can’t use these host parameters directly

because of zoned recording techniques. The drive translates the host parameters to a set of logical internal

addresses for data access.

The host drive geometry parameters are mapped into an LBA based on this formula:

LBA = (HSCA - 1) + HHDA x HSPT + HNHD x HSPT x HCYA (1)

where HSCA = Host Sector Address, HHDA = Host Head Address

= (HSCA - 1) + HSPT x (HHDA + HNHD x HCYA) (2)

HCYA = Host Cylinder Address, HNHD = Host Number of Heads

HSPT = Host Sectors per Track

2 – 2

Page 12

PRODUCT DESCRIPTION

The LBA is checked for violating the drive capacity. If it does not, the LBA is converted to physical drive

cylinder, head and sector values. The physical address is then used to access or store the data on the disk and

for other drive related operations.

Defect Management Zone (DMZ)Defect Management Zone (DMZ)

Defect Management Zone (DMZ)

Defect Management Zone (DMZ)Defect Management Zone (DMZ)

Each drive model has a fixed number of spare sectors per drive, all of which are located at the end of the

drive. Upon detection of a bad sector that has been reassigned, the next sequential sector is used.

For example, if sector 3 is flagged, data that would have been stored there is “pushed down” and recorded

in sector 4. Sector 4 then effectively becomes sector 3, as sequential sectors are “pushed down” across the

entire drive. The first spare sector makes up for the loss of sector 3, and so maintains the sequential order of

data. This push down method assures maximum performance.

On-the-Fly Hardware Error Correction Code (ECC)On-the-Fly Hardware Error Correction Code (ECC)

On-the-Fly Hardware Error Correction Code (ECC)

On-the-Fly Hardware Error Correction Code (ECC)On-the-Fly Hardware Error Correction Code (ECC)

5 symbols, single burst, guaranteed

Software ECC CorrectionSoftware ECC Correction

Software ECC Correction

Software ECC CorrectionSoftware ECC Correction

22 symbols, single burst, guaranteed

Automatic Park and Lock OperationAutomatic Park and Lock Operation

Automatic Park and Lock Operation

Automatic Park and Lock OperationAutomatic Park and Lock Operation

Immediately following power down, dynamic braking of the spinning disks delays momentarily allowing the

read/write heads to move to an inner mechanical stop. A small fixed magnet holds the rotary actuator in

place as the disk spins down. The rotary actuator is released only when power is again applied.

Cache ManagementCache Management

Cache Management

Cache ManagementCache Management

Buffer SegmentationBuffer Segmentation

Buffer Segmentation

Buffer SegmentationBuffer Segmentation

The data buffer is organized into two segments: the data buffer and the micro controller scratch pad.

The data buffer is dynamically allocated for read and write data depending on the commands received.

A variable number of read and write buffers may exist at the same time.

Read-Ahead ModeRead-Ahead Mode

Read-Ahead Mode

Read-Ahead ModeRead-Ahead Mode

Normally, this mode is active. Following a read request, disk read-ahead begins on the first sector and

continues sequentially until the allocated buffer is full. If a read request is received during the read-ahead

operation, the buffer is examined to determine if the request is in the cache. If a cache hit occurs, readahead mode continues without interruption and the host transfer begins immediately.

Automatic Write Reallocation (AWR)Automatic Write Reallocation (AWR)

Automatic Write Reallocation (AWR)

Automatic Write Reallocation (AWR)Automatic Write Reallocation (AWR)

This feature is part of the write cache and reduces the risk of data loss during deferred write operations. If a

disk error occurs during the disk write process, the disk task stops and the suspect sector is reallocated to a

pool of alternate sectors located at the end of the drive. Following reallocation, the disk write task continues

until it is complete.

Write Cache StackingWrite Cache Stacking

Write Cache Stacking

Write Cache StackingWrite Cache Stacking

Normally, this mode is active. Write cache mode accepts the host write data into the buffer until the buffer

is full or the host transfer is complete. A command complete interrupt is generated at the end of the transfer.

A disk write task begins to store the host data to disk. Host write commands continue to be accepted and

data transferred to the buffer until either the write command stack is full or the data buffer is full. The drive

may reorder write commands to optimize drive throughput.

2 – 3

Page 13

PRODUCT DESCRIPTION

Major HDA ComponentsMajor HDA Components

Major HDA Components

Major HDA ComponentsMajor HDA Components

Drive MechanismDrive Mechanism

Drive Mechanism

Drive MechanismDrive Mechanism

A brush-less DC direct drive motor rotates the spindle at 7,200 RPM (±0.1%). The dynamically balanced

motor/spindle assembly ensures minimal mechanical run-out to the disks. A dynamic brake provides a fast

stop to the spindle motor upon power removal. The speed tolerance includes motor performance and motor

circuit tolerances.

Rotary ActuatorRotary Actuator

Rotary Actuator

Rotary ActuatorRotary Actuator

All DiamondMax Plus 40 drives employ a rotary voice coil actuator which consists of a moving coil, an

actuator arm assembly and stationary magnets. The actuator moves on a low-mass, low-friction center shaft.

The low friction contributes to fast access times and low power consumption.

Read/Write ElectronicsRead/Write Electronics

Read/Write Electronics

Read/Write ElectronicsRead/Write Electronics

An integrated circuit mounted within the sealed head disk assembly (near the read/write heads) provides up

to eight head selection (depending on the model), read pre-amplification and write drive circuitry.

Read/Write Heads and MediaRead/Write Heads and Media

Read/Write Heads and Media

Read/Write Heads and MediaRead/Write Heads and Media

Low mass, low force giant magneto-resistive read/write heads record data on 3.5-inch diameter disks. Maxtor

uses a sputtered thin film medium on all disks for DiamondMax Plus 40 drives.

Air Filtration SystemAir Filtration System

Air Filtration System

Air Filtration SystemAir Filtration System

All DiamondMax Plus 40 drives are assembled in a Class 100 controlled environment. Over the life of the

drive, a 0.1 micron filter and breather filter located within the sealed head disk assembly (HDA) maintain a

clean environment to the heads and disks. DiamondMax 40 drives are designed to operate in a typical office

environment with minimum environmental control.

MicroprocessorMicroprocessor

Microprocessor

MicroprocessorMicroprocessor

The microprocessor controls the following functions for the drive electronics:

Command execution

Cache management

Data correction and error recovery

Diagnostic execution

Data sequencing

Head positioning (including error recovery)

Host interface

Index detection

Spin speed control

Seeks

Servo

S.M.A.R.T.

2 – 4

Page 14

PRODUCT DESCRIPTION

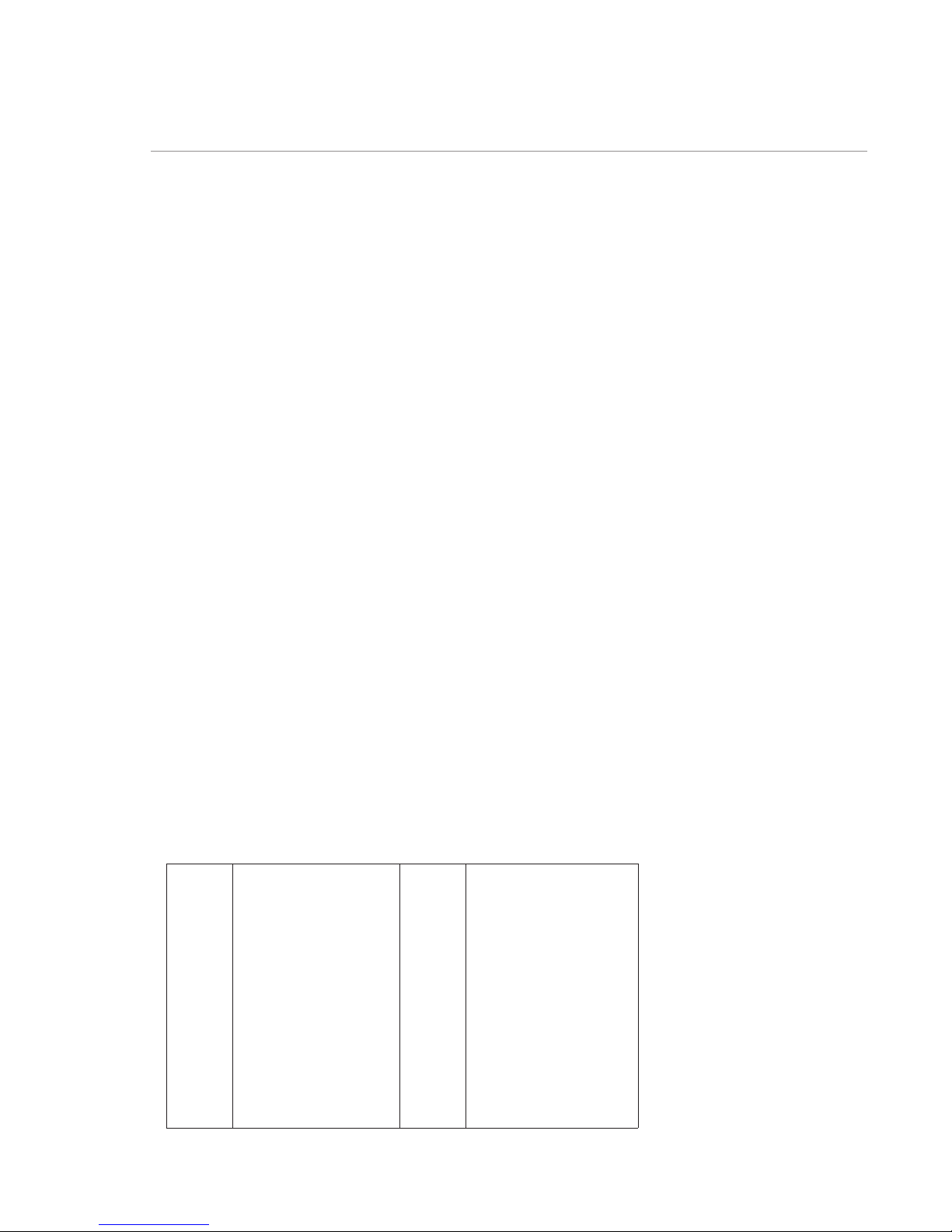

NOITARUGIFNOCREPMUJ05J84J64J44J24J

evalS/retsaM

*metsysevirdelgnisnievirdylnO

*metsysevirdlaudnievirdretsaM

metsysevirdlaudnievirdevalS

C

C

O

tceleSelbaC

*delbasiD

delbanE

O

C

noitatimiLrednilyC

*delbasiD

delbanE

O

C

devreseRyrotcaFO

devreseRyrotcaF O

desolC=CtluafeD=*yeK

)dellatsnirepmuj(

nepO=O

)dellatsnirepmujon(

Subsystem ConfigurationSubsystem Configuration

Subsystem Configuration

Subsystem ConfigurationSubsystem Configuration

Dual Drive SupportDual Drive Support

Dual Drive Support

Dual Drive SupportDual Drive Support

Two drives may be accessed via a common interface cable, using the same range of I/O addresses. The drives

are jumpered as device 0 or 1 (Master/Slave), and are selected by the drive select bit in the

Device/Head register of the task file.

All Task File registers are written in parallel to both drives. The interface processor on each drive decides

whether a command written to it should be executed; this depends on the type of command and which

drive is selected. Only the drive selected executes the command and activates the data bus in response to

host I/O reads; the drive not selected remains inactive.

A master/slave relationship exists between the two drives: device 0 is the master and device 1 the slave.

When J50 is closed (factory default, figure 2-1), the drive assumes the role of master; when open, the drive

acts as a slave. In single drive configurations, J50 must be closed.

Cable Select OptionCable Select Option

Cable Select Option

Cable Select OptionCable Select Option

CSEL (cable select) is an optional feature per ANSI ATA specification. Drives configured in a multiple drive

system are identified by CSEL’s value:

– If CSEL is grounded, then the drive address is 0.

– If CSEL is open, then the drive address is 1.

Jumper Location / ConfigurationJumper Location / Configuration

Jumper Location / Configuration

Jumper Location / ConfigurationJumper Location / Configuration

Darkened jumper pins indicate factory-installed (default) shunts.

+12 VDC

+12 V return

EIDE Interface Connector

J1 pin 1

J50 - Master/Slave

J48 - Cable Select

J46 - Cylinder Limitation

J44 - Factory Reserved

J42 - Factory Reserved

+5 V return

+5 VDC

Power Connector

J2

Figure 2-1

PCBA Jumper Location and Configuration

Cylinder Limitation Jumper DescriptionCylinder Limitation Jumper Description

Cylinder Limitation Jumper Description

Cylinder Limitation Jumper DescriptionCylinder Limitation Jumper Description

On some older BIOS', primarily those that auto-configure the disk drive, a hang may occur. The Cylinder

Limitation jumper reduces the capacity in the Identify Drive allowing large capacity drives to work with older

BIOS'. The capacity reported when J46 is closed will be as follows: drives less than or equal to 32GB will

report 2.1GB. Drives greater than 32GB will report 32GB.

2 – 5

Page 15

Product SpecificationsProduct Specifications

Product Specifications

Product SpecificationsProduct Specifications

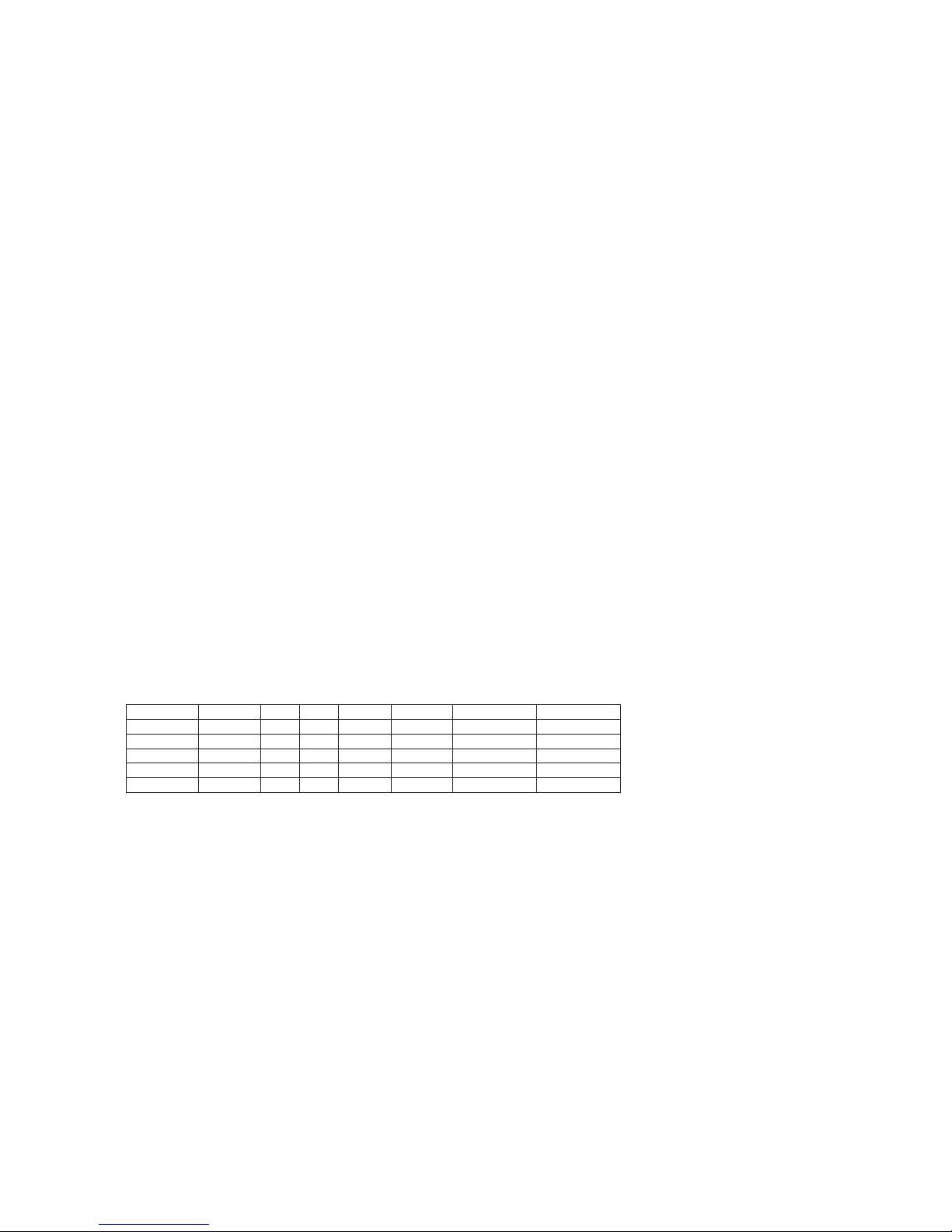

Models and CapacitiesModels and Capacities

Models and Capacities

Models and CapacitiesModels and Capacities

LEDOM

yticapaCdettamroF

.setybnoillib

Drive ConfigurationDrive Configuration

Drive Configuration

Drive ConfigurationDrive Configuration

LEDOM8U890456U370354U940253U635152U42015

dohteMgnidocnEE

evaelretnI1:1

metsySovreSdeddebmE

epyT/eziSreffuBMARDSBM2

ecafruSrepsenoZataD61

sdaeH/secafruSataD86432

sksiDforebmuN43221

ytisneDlaerA542.7ni/bG

ytisneDkcarT005,12ipt

ytisneDgnidroceR733-072ipbk

ytisneDxulFicfk853-682

kcolB/rotceSrepsetyB215

kcarTrepsrotceS065-523

evirDrepsrotceS

)edoMABLBM(

ecafretnI/rellortnoCdetargetnIAMDartlU/5-ATA

8U890456U370354U940253U635152U42015

089,04537,03094,02763,51542,01

6

01saetybagemenosenifedrotxaM

2

2

842,140,08234,030,06426,020,04612,510,03618,010,02

PRODUCT SPECIFICATIONS

SECTION 3

9

01saetybagigenodnasetybnoillimenoro

enoro

71/61LLR4RP

xam

Performance SpecificationsPerformance Specifications

Performance Specifications

Performance SpecificationsPerformance Specifications

LEDOM8U890456U370354U940253U635152U42015

semiTkeeS

kcarT-ot-kcarTsm0.1

egarevAsm0.9<

ekortSlluFsm0.02<

aideMmorF/oTces/BM2.34otpu

emiTtratS

)daerlacipyt(

ycnetaLegarevAsm71.4

deepSlanoitatoR

)%1.0±(

daehrevOrellortnoCsm3.0<

etaRrefsnarTataD

ecafretnImorF/oT

4M-AMDartlU(

)

ecafretnImorF/oT

4MAMDdrow-itluM/4OIP(

)

ydaeRevirDot0(

)lacipytces01<

MPR002,7

ces/BM0.66otpu

ces/BM7.61otpu

3 – 1

Page 16

PRODUCT SPECIFICATIONS

x

m

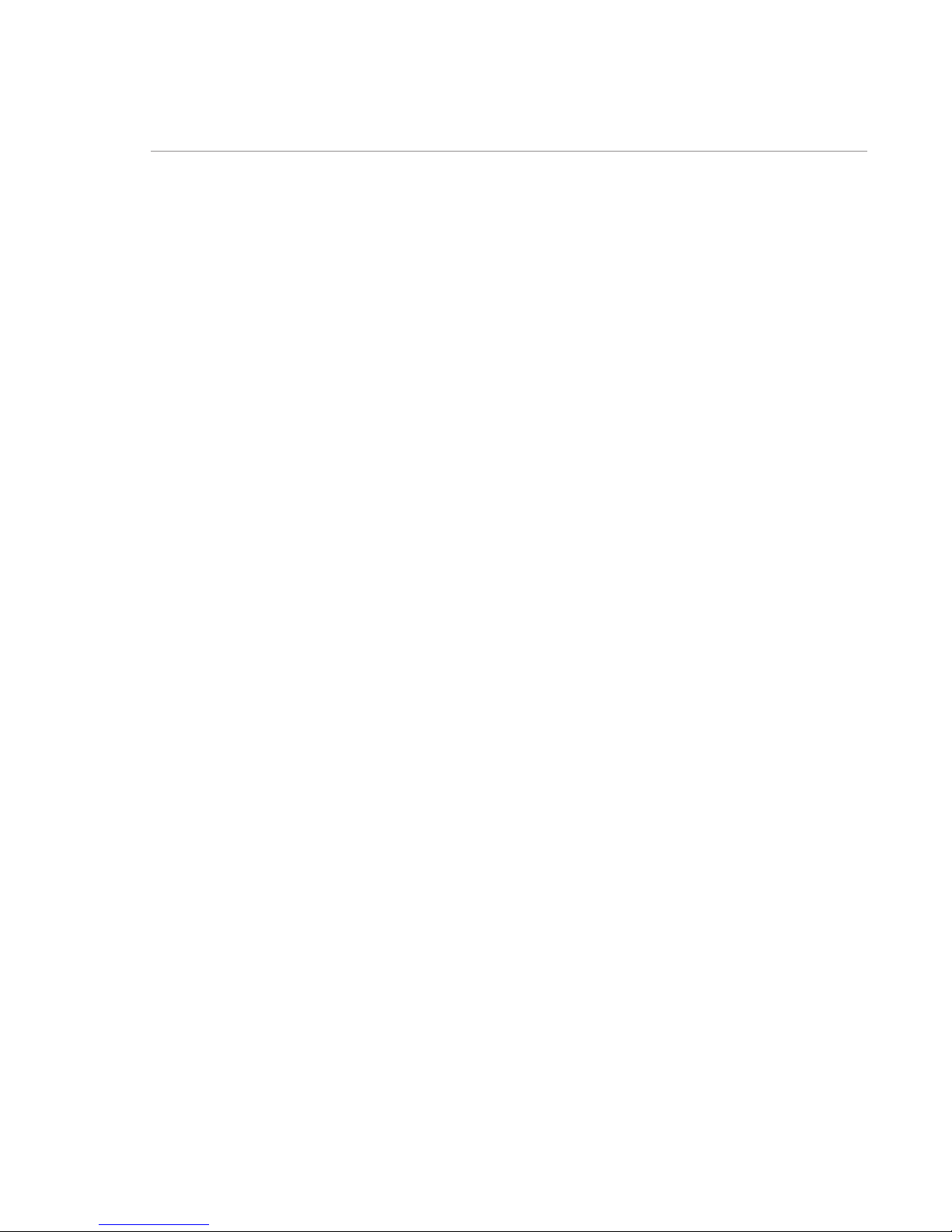

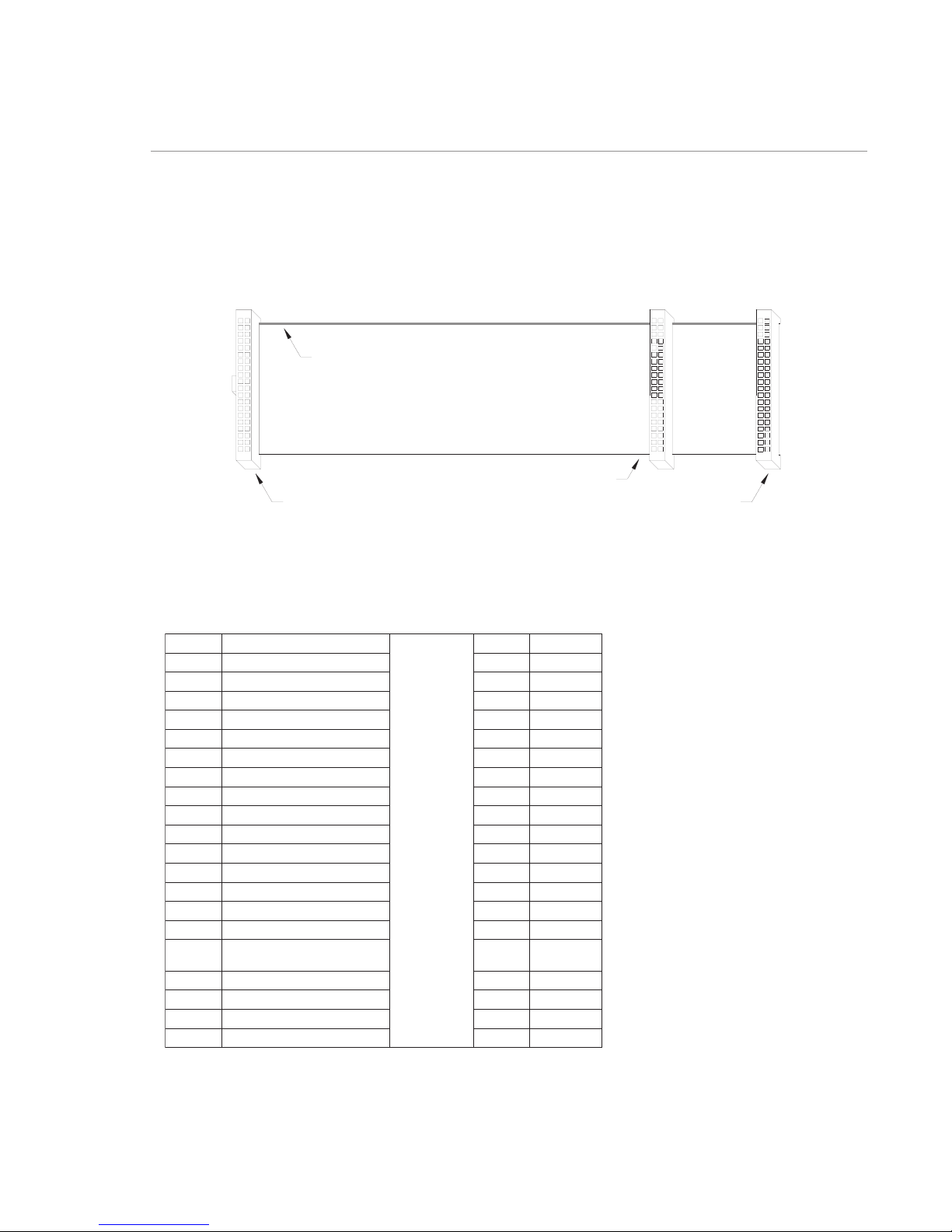

Physical Dimensions Physical Dimensions

Physical Dimensions (maximum)

Physical Dimensions Physical Dimensions

RETEMARAPDRADNATSCIRTEM

thgieHsehcni820.1sretemillim1.62

htgneLsehcni787.5sretemillim741

htdiWsehcni00.4sretemillim6.101

thgieWsdnuop3.1smargolik95.0

1.028 max

[26.1 mm ma

6 x 6-32

UNC -28

THREAD

4 x 6-32

UNC -28

THREAD

4.00 ± .01

[101.6 ± 0.5 mm]

5.787 max

[147 mm max]

1.75 ± .01

[44.95 ± 0.25 mm]

1.638 ± .010

[41.6 ± 0.25 mm]

1.122 ± .020

[28.5 ± 0.5 mm]

1.625 ± .02

[41.28 ± 0.5 mm]

.25 ± .01

[6.35 ± 0.25 m

4.00 ± .01

3.75 ± .01

[101.6 ± 0.25 mm]

[95.25 ± 0.25 mm]

3 – 2

Outline and Mounting Dimensions

Figure 3 - 1

.125 ± .010

[3.18 ± .025 mm]

Page 17

Power RequirementsPower Requirements

Power Requirements

Power RequirementsPower Requirements

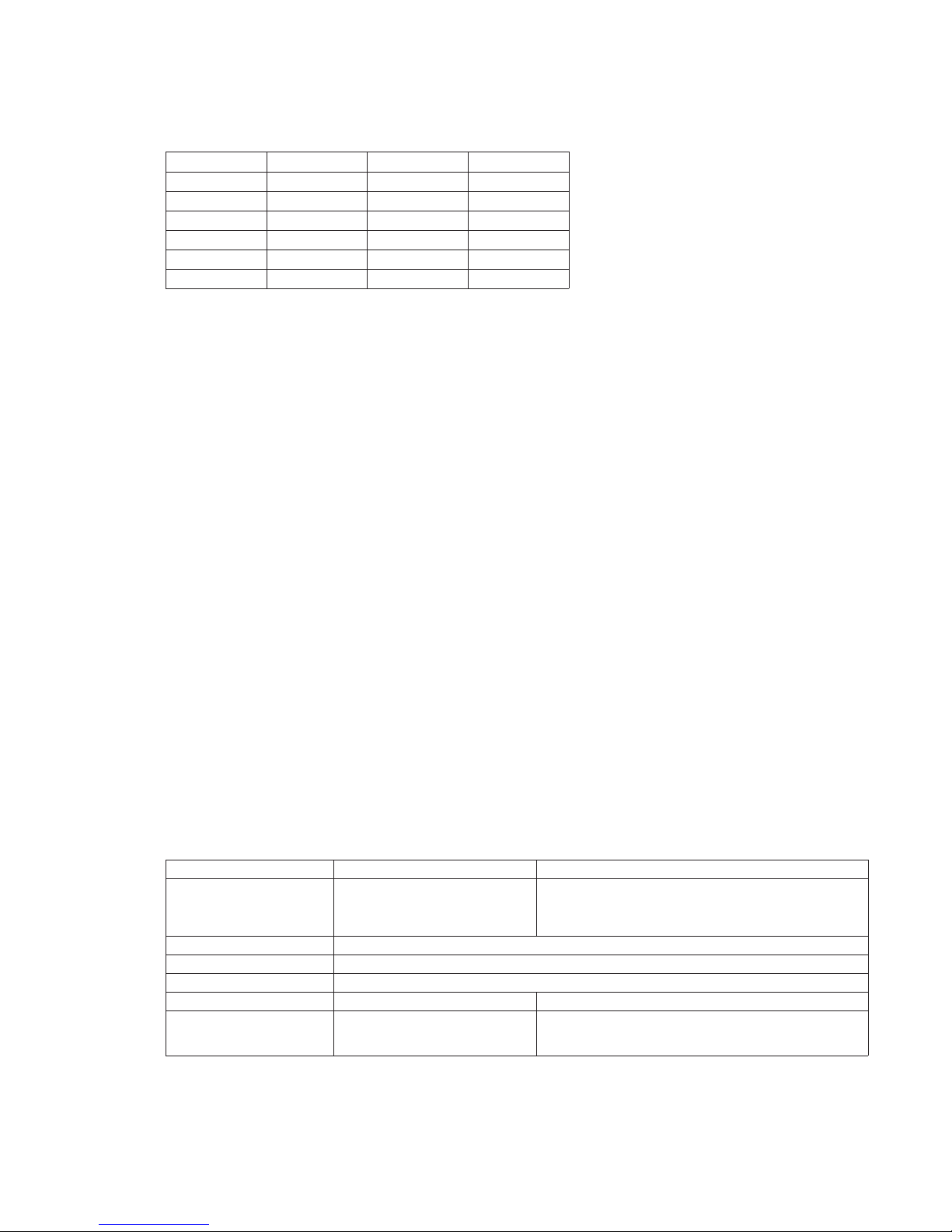

EDOM%01±V21%5±V5REWOP

pu-nipS )kaep( Am0052Am026

keeS )gva( Am008Am015W9.21

etirW/daeR )gva( Am053Am035W8.6

eldI )gva( Am053Am094W6.6

ybdnatS )gva( Am51Am532W4.1

peelS )gva( Am51Am071W0.1

Power Mode DefinitionsPower Mode Definitions

Power Mode Definitions

Power Mode DefinitionsPower Mode Definitions

Spin-upSpin-up

Spin-up

Spin-upSpin-up

The drive is spinning up following initial application of power and has not yet reached full speed.

SeekSeek

Seek

SeekSeek

A random access operation by the disk drive.

Read/WriteRead/Write

Read/Write

Read/WriteRead/Write

Data is being read from or written to the drive.

PRODUCT SPECIFICATIONS

IdleIdle

Idle

IdleIdle

The drive is spinning, the actuator is parked and powered off and all other circuitry is powered on.

The drive is capable of responding to read commands within 40 ms.

StandbyStandby

Standby

StandbyStandby

The spin motor is not spinning. The drive will leave this mode upon receipt of a command that requires

disk access. The time-out value for this mode is programmable. The buffer is active to accept write data.

SleepSleep

Sleep

SleepSleep

This is the lowest power state – with the interface set to inactive. A software or hardware reset is required

to return the drive to the Standby state.

EPA Energy Star ComplianceEPA Energy Star Compliance

EPA Energy Star Compliance

EPA Energy Star ComplianceEPA Energy Star Compliance

Maxtor Corporation supports the goals of the U.S. Environmental Protection Agency’s Energy Star program

to reduce the electrical power consumption of computer equipment.

Environmental LimitsEnvironmental Limits

Environmental Limits

Environmental LimitsEnvironmental Limits

RETEMARAPGNITAREPOEGAROTS/GNITAREPO-NON

erutarepmeTC°55otC°5 )C°04-(erutarepmetwol

.snoitidnocdecudni-toh;yrogetaccitamilc

tneidarGlamrehT (ruohrepC°52

ytidimuHevitaleR %59ot%5

bluBteW

edutitlAteef000,01ot002-teef000,04ot002-

edoMeldI-esioNcitsuocA

,enohporcim01,9777OSIrep(

rewopdnuosegareva)

leb6.3:sledomksid2dna1

leb7.3:sledomksid3

leb8.3:sledomksid4

03

° C

)mumixam

gnisnednoc-non(

)

)mumixam(

,3.105dohtem,E018-DTS-LIMrep)C°17(erutarepmethgih

3 – 3

Page 18

PRODUCT SPECIFICATIONS

Shock and VibrationShock and Vibration

Shock and Vibration

Shock and VibrationShock and Vibration

RETEMARAPGNITAREPOGNITAREPO-NON

zH003-01edutilpma)kaep-0(G0.1

Reliability SpecificationsReliability Specifications

Reliability Specifications

Reliability SpecificationsReliability Specifications

Annual Return RateAnnual Return Rate

Annual Return Rate

Annual Return RateAnnual Return Rate

< 1.0% Annual Return Rate (ARR) indicates the average against products shipped.

Quality Acceptance RateQuality Acceptance Rate

Quality Acceptance Rate

Quality Acceptance RateQuality Acceptance Rate

< 1,000 DPPM The quality acceptance rate indicates the percentage of Maxtor products

kcohSlacinahceMsrorreon,sm0.2,sG06 egamadon,sm0.2,sG052

kcohSlanoitatoR egamadon,sm0.1-5.0,ces/daR000,02

noitarbiVmodnaRG400.0tazH54-01

srorreon

noitarbiVeniStpewS

2

zH/

2

G800.0tazH26-84

zH/

2

G400.0tazH003-56

zH/

2

G6000.0tazH005-103

zH/

ARR includes all reasons for returns (failures, handling damage, NDF), but

does not include inventory credit returns.

successfully installed by our customers, and/or the number of defective parts

per million (DPPM) encountered during the entire installation process.

2

G50.0tazH01

zH/

2

G550.0tazH02

zH/

2

G50.0tazH003

zH/

2

G4100.0tazH103

zH/

2

G100.0tazH067-005

zH/

2

G300.0tazH778

zH/

2

G100.0tazH0751-0001

2

G100.0tazH0002

zH/

zH/

Start/Stop CyclesStart/Stop Cycles

Start/Stop Cycles

Start/Stop CyclesStart/Stop Cycles

50,000 This indicates the average minimum cycles for reliable start/stop function.

Data ReliabilityData Reliability

Data Reliability

Data ReliabilityData Reliability

< 10 per 1015 bits read Data errors (non-recoverable). Average data error rate allowed with all error

recovery features activated.

Component Design LifeComponent Design Life

Component Design Life

Component Design LifeComponent Design Life

5 years (minimum) Component design life is defined as a.) the time period before identified

wear-out mechanisms impact the failure rate, or b.) the time period up to the

wear-out point when useful component life expires.

3 – 4

Page 19

PRODUCT SPECIFICATIONS

EMC/EMIEMC/EMI

EMC/EMI

EMC/EMIEMC/EMI

Radiated Electromagnetic Field Emissions - EMC ComplianceRadiated Electromagnetic Field Emissions - EMC Compliance

Radiated Electromagnetic Field Emissions - EMC Compliance

Radiated Electromagnetic Field Emissions - EMC ComplianceRadiated Electromagnetic Field Emissions - EMC Compliance

The hard disk drive mechanism is designed as a subassembly for installation into a suitable enclosure and is

therefore not subject to Subpart J of Part 15 of FCC Rules (47CFR15) or the Canadian Department of

Communications Radio Interference Regulations. Although not required, the disk mechanism has been

tested within a suitable end-use product and found to comply with Class B limits of the FCC Rules and

Regulations of the Canadian Department of Communications.

The CE Marking indicates conformity with the European Union Low Voltage Directive (73/23/EEC) when

the disk mechanism is installed in a typical personal computer. Maxtor recommends that testing and analysis

for EMC compliance be performed with the disk mechanism installed within the user's end-use application.

Canadian Emissions StatementCanadian Emissions Statement

Canadian Emissions Statement

Canadian Emissions StatementCanadian Emissions Statement

This digital apparatus does not exceed the Class B limits for radio noise emissions from digital apparatus as set

out in the radio interference regulations of the Canadian department of communications.

Le present appareil numerique n'emet pas de bruit radioelectriques depassant les limites applicables aux

appareils numeriques de Class B prescrites dans le reglement sur le brouillage radioelectrique edicte par le

ministere des communications du Canada.

Safety Regulatory ComplianceSafety Regulatory Compliance

Safety Regulatory Compliance

Safety Regulatory ComplianceSafety Regulatory Compliance

All Maxtor hard drives comply with relevant product safety standards such as CE, CUL, TUV and UL rules and

regulations. As delivered, Maxtor hard drives are designed for system integration before they are used.

3 – 5

Page 20

SECTION 4

Handling and InstallationHandling and Installation

Handling and Installation

Handling and InstallationHandling and Installation

Hard Drive Handling PrecautionsHard Drive Handling Precautions

Hard Drive Handling Precautions

Hard Drive Handling PrecautionsHard Drive Handling Precautions

◆ If the handling precautions are not followed, damage to the hard drive may result - which may void the warranty.

◆ During handling, NEVER drop, jar, or bump a drive. Handle the drive by its sides and avoid touching the printed circuit board

assembly (PCBA).

◆ Hard drives are sensitive to electrostatic discharge (ESD) damage. Use proper ESD practices by grounding yourself and the

computer system the hard drive will be installed in.

◆ Allow the hard drive to reach room temperature BEFORE installing it in your computer system.

◆ NEVER switch DC power onto the drive by plugging an electrically live DC source cable into the drive's connector. NEVER

connect a live connector to the hard drive's IDE interface connector.

◆

ELECTRICAL GROUNDING - For proper operation, the drive must be securely fastened to a device bay

that provides a suitable electrical ground to the drive baseplate.

INSTALLATION

Electro-Static Discharge (ESD)Electro-Static Discharge (ESD)

Electro-Static Discharge (ESD)

Electro-Static Discharge (ESD)Electro-Static Discharge (ESD)

To avoid some of the problems associated with ESD, Maxtor advises that anyone handling a disk drive use a

wrist strap with an attached wire connected to an earth ground. Failure to observe these precautions voids the

product warranty.

Manufacturers frequently experience “unsolved” component/hardware malfunctions often caused by ESD. To

reduce the incidence of ESD-related problems, Maxtor recommends that any electronics manufacturing plans

include a comprehensive ESD program, the basic elements and functions of which are outlined here:

ESD Program Element ESD Program Function

Management Institute and maintain

Chief coordinator Organize and enforce

Multi-department committee Evaluate and improve

Employee training Educate and inform

ESD program supplies typically include: wrist- and foot-worn grounding straps; counter-top and floor antistatic

matting; wrist strap testers; ESD video and training materials. Sources for such supplies include:

Static Control Systems – 3M Charleswater

225-4S, 3M Center 93 Border St.

St. Paul, MN 55144 West Newton, MA 02165-9990

Maxtor also offers a complete video training package, “Care and Handling of Maxtor Disk Drives.”

Contact your Maxtor representative for details.

4 – 1

Page 21

INSTALLATION

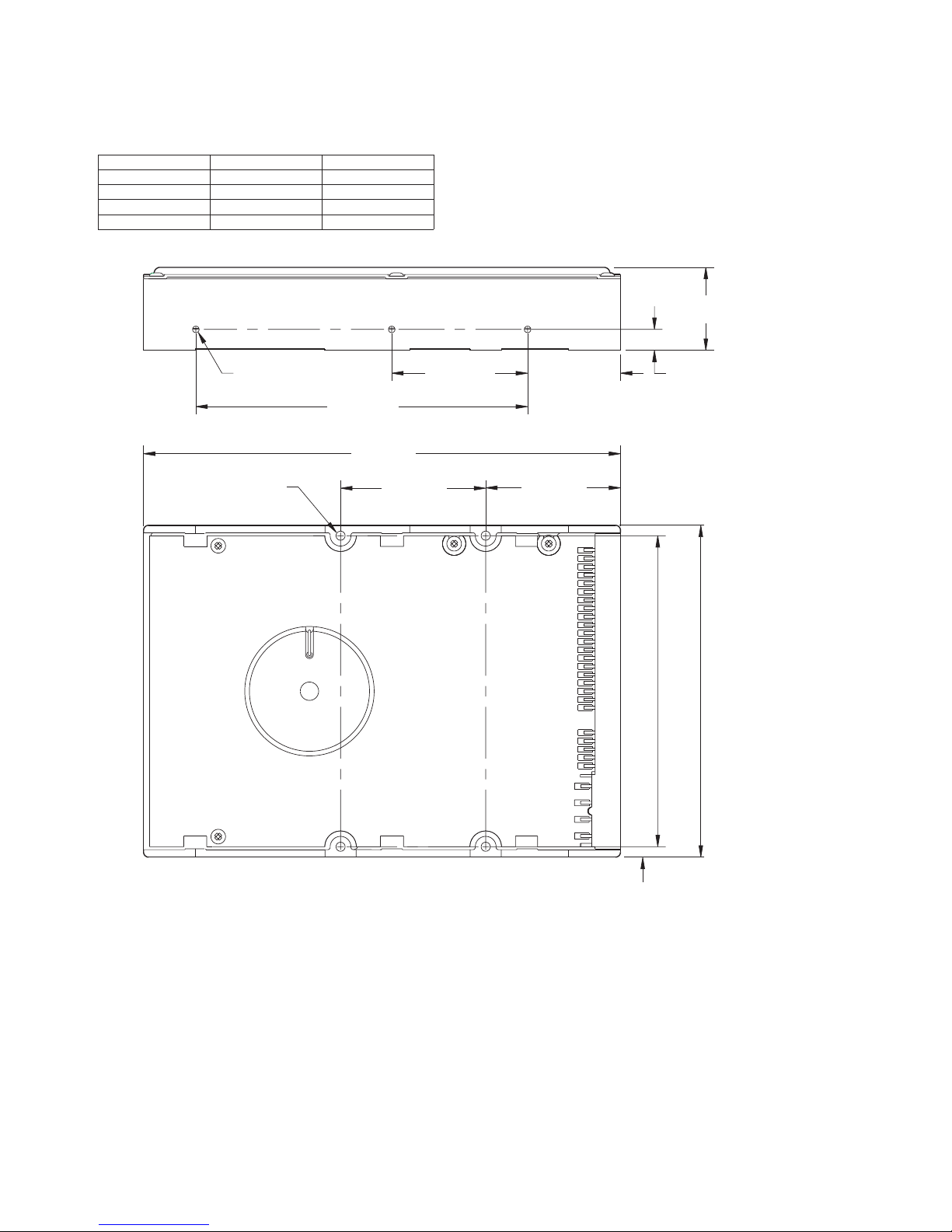

Unpacking and InspectionUnpacking and Inspection

Unpacking and Inspection

Unpacking and InspectionUnpacking and Inspection

Retain any packing material for reuse. Inspect the shipping container for evidence of damage in transit. Notify

the carrier immediately in case of damage to the shipping container.

As they are removed, inspect drives for evidence of shipping damage or loose hardware. If a drive is damaged

(and no container damage is evident), notify Maxtor immediately for drive disposition.

4 – 2

Multi-pack Shipping Container

Figure 4 - 1

Page 22

INSTALLATION

RepackingRepacking

Repacking

RepackingRepacking

Single Pack Shipping Container (Option A)

Figure 4 - 2

Single Pack Shipping Container (Option B)

Figure 4 - 3

If a Maxtor drive requires return, repack it using Maxtor packing materials, including the antistatic bag.

Physical InstallationPhysical Installation

Physical Installation

Physical InstallationPhysical Installation

Recommended Mounting ConfigurationRecommended Mounting Configuration

Recommended Mounting Configuration

Recommended Mounting ConfigurationRecommended Mounting Configuration

The DiamondMax® drive design allows greater shock tolerance than that afforded by larger, heavier drives.

The drive may be mounted in any attitude using four size 6-32 screws with 1/8-inch maximum penetration

and a maximum torque of 5-inch pounds. See Figure 3-1 for mounting dimensions. Allow adequate

ventilation to the drive to ensure reliable operation. See the following pages for specific installation steps.

4 – 3

Page 23

INSTALLATION

Before You BeginBefore You Begin

Before You Begin

Before You BeginBefore You Begin

Important – Please ReadImportant – Please Read

Important – Please Read

Important – Please ReadImportant – Please Read

Please read this installation section completely before installing the Maxtor hard drive. It gives general

information for installing a Maxtor hard drive in a typical computer system. If you don’t understand the

installation steps, have a qualified computer technician install the hard drive.

Back up. Protect your Existing DataBack up. Protect your Existing Data

Back up. Protect your Existing Data

Back up. Protect your Existing DataBack up. Protect your Existing Data

Periodic backup of important data is always a good idea. Whenever your computer is on, there is the

potential for losing data on your hard drive. This is especially true when running disk utilities or any software

that directly manipulates your files. Maxtor recommends that you make a backup copy of the files on any

existing hard drives prior to installing the new drive. If required, this data may then be copied to the Maxtor

hard drive after it has been installed in the computer. Refer to your computer user’s manual for detailed data

backup instructions.

Tools for InstallationTools for Installation

Tools for Installation

Tools for InstallationTools for Installation

The following tools are needed to install your new Maxtor hard drive:

• A small (#2) Phillips head screw driver

• Small needle-nose pliers or tweezers

• Your computer user’s manuals

• Operating system software

System RequirementsSystem Requirements

System Requirements

System RequirementsSystem Requirements

• IDE/AT interface

Maxtor recommends:

• Drives less than or equal to 8.4 GB – 486 DX 66 MHz

• Drives larger than 8.4 GB – Pentium-class processor

Operating System RequirementsOperating System Requirements

Operating System Requirements

Operating System RequirementsOperating System Requirements

• Drives less than or equal to 8.4 GB:

- DOS 5.0 or higher

• Drives larger than 8.4 GB:

- Installing as boot drive (Primary Master) requires full installation set of Windows 95/98 – not an update

from DOS or Windows 3.x.

- Installing as non-boot drive (Primary Slave, Secondary Master or Slave) requires Windows 95/98 on the

boot drive.

Hook upHook up

Hook up

Hook upHook up

Maxtor recommends that you use the MaxBlast™ Plus software to create a customized installation guide for your

system before physically installing your new hard drive. The information created by MaxBlast Plus relates to the

following illustrations.

Boot the System with the MaxBlast Plus DisketteBoot the System with the MaxBlast Plus Diskette

Boot the System with the MaxBlast Plus Diskette

Boot the System with the MaxBlast Plus DisketteBoot the System with the MaxBlast Plus Diskette

Before physically installing the Maxtor hard drive, boot your system with the MaxBlast Plus diskette. It will

assist you with the instructions in this section for a successful installation.

Configure the Drive JumpersConfigure the Drive Jumpers

Configure the Drive Jumpers

Configure the Drive JumpersConfigure the Drive Jumpers

The jumper configurations have three valid jumper settings – Master, Slave and Cable Select. Maxtor hard

drives are always shipped with the Master jumper setting enabled.

Install the 5.25-inch Mounting BracketsInstall the 5.25-inch Mounting Brackets

Install the 5.25-inch Mounting Brackets

Install the 5.25-inch Mounting BracketsInstall the 5.25-inch Mounting Brackets

If the Maxtor hard drive will be mounted in a 5.25-inch device bay, you will need to attach 5.25-inch

brackets to the hard drive. These brackets are not required if the drive is mounted in a 3.5-inch device bay.

4 – 4

Page 24

Install the Hard Drive in a Device BayInstall the Hard Drive in a Device Bay

Install the Hard Drive in a Device Bay

Install the Hard Drive in a Device BayInstall the Hard Drive in a Device Bay

Refer to your computer user’s manual for specific mounting information. Be sure to secure the drive to the

device bay with all four screws.

Attach the Interface and Power CablesAttach the Interface and Power Cables

Attach the Interface and Power Cables

Attach the Interface and Power CablesAttach the Interface and Power Cables

Do not force or rock the connectors into their sockets on the hard drive. Push them in straight until they

are seated.

Note: DiamondMax Hard Drive Kits that carry a “U” in the kit number are UltraDMA 66 compatible hard

drives. A standard IDE cable can be used for drive installation; however, an UltraDMA cable is required to

achieve UltraDMA 66 data transfers in UltraDMA 66 compatible systems. Follow the illustration below for

proper cable connections to the system and hard drive(s) when using this cable.

Attach an IDE interface connector to J1 on the Maxtor drive. Attach a power connector to J2 on the

Maxtor drive. This connector is keyed and will only fit one way. Check all other cable connections before

you power up. Striped/colored edge is pin 1

After attaching the IDE interface cable and the

power cable to the Maxtor hard drive, verify that

all other cables connected to other devices, the

mother board or interface card(s) are correctly

seated.

INSTALLATION

Striped/colored edge is pin

Start upStart up

Start up

Start upStart up

Turn your system ON. During the system start up sequence, run the SETUP (BIOS) program. Newer systems

usually display a message like “press DEL to enter Setup,” showing how to access the SETUP (BIOS) program.

Choose the device position where the Maxtor hard drive will be installed (Primary Master, Primary Slave,

Secondary Master, Secondary Slave or their equivalents) and select the “Auto Detect” option. Save and exit the

BIOS. The system will now boot. Boot to the MaxBlast™ Plus diskette.

Set upSet up

Set up

Set upSet up

MaxBlast™ Plus will guide you through the steps to prepare (partition and format) your new Maxtor hard drive.

Once you have completed this step, your new Maxtor hard drive will be ready to use.

Note: Do not discard the MaxBlast Plus diskette once the installation is complete. The diskette contains Maxdiag,

a diagnostic utility that is a separate program from the MaxBlast™ Plus installation software.

4 – 5

Page 25

AT INTERFACE DESCRIPTION

SECTION 5

AA

T Interface DescriptionT Interface Description

A

T Interface Description

AA

T Interface DescriptionT Interface Description

Interface ConnectorInterface Connector

Interface Connector

Interface ConnectorInterface Connector

All DiamondMax® Plus 40 AT drives have a 40-pin ATA interface connector mounted on the PCBA. The

drive may connect directly to the host; or it can also accommodate a cable connection (maximum cable

length: 18 inches).

Striped Edge (Pin 1)

Drive 1 - Slave (gray)

System Connector (blue) Drive 0 - Master (black)

Figure 5-1

Data Connector

Pin Description SummaryPin Description Summary

Pin Description Summary

Pin Description SummaryPin Description Summary

NIPLANGISNIPLANGIS

10-teseR20dnuorG

307DD408DD

506DD609DD

705DD8001DD

904DD0111DD

113DD2121DD

312DD4131DD

511DD6141DD

710DD8151DD

91dnuorG02)nipyek(

12QRAMD22dnuorG

32POTS:-WOID42dnuorG

52EBORTSH:YDRAMDH:-ROID62dnuorG

72EBORTSD:YDRAMDD:YDROI82LESC

92-KCAMD03dnuorG

13QRTNI23

331AD43-GAIDP

530AD632AD

73-0SC83-1SC

93-PSAD04dnuorG

61SCOI

etelosbO

5 – 1

Page 26

AT INTERFACE DESCRIPTION

Pin Description TablePin Description Table

Pin Description Table

Pin Description TablePin Description Table

EMANNIPNIPO/IEMANLANGISNOITPIRCSEDLANGIS

-TESER10I teseRtsoH .retfaevitcanidnapurewopgnirudevitcA.metsystsohehtmorflangisteseR

0DD71O/IsuBataDtsoH retsigerrofdesustib8rewoL.evirddnatsohneewtebsubatadlanoitcerid-ibtib61

1DD51O/I

2DD31O/I

3DD11O/I

4DD90O/I

5DD70O/I

6DD50O/I

7DD30O/I

8DD40O/I

9DD60O/I

01DD80O/I

11DD01O/I

21DD21O/I

31DD41O/I

41DD61O/I

51DD81O/I

QRAMD12O tseuqeRAMD eht,langissihtgnitressayB.srefsnartAMDrofKCAMDhtiwdesusilangissihT

-WOID

POTS

-ROID

YDRAMDH

EBORTSH

YDROI

YDRAMDD

EBORTSD

LESC82tceleSelbaC metsystsohnognilbaclaicepsseriuqeR.elbacaivnoitcelesevalS/retsaMrofdesU

-KCAMD92I egdelwonkcAAMD eht,langissihtgnitressayB.srefsnartAMDrofQRAMDhtiwdesusilangissihT

QRTNI13O tpurretnItsoH

61SCOI23O/Itib61eciveDetelosbO

-GAIDP43O/IcitsongaiDdessaP .edomretsaMninehwevirdottupnI;edomevalSninehwevirdybtuptuO

0AD53I suBsserddAtsoH .evirdehtniretsigeratcelesottsohehtmorfsserddayranibtib3

1AD33I

2AD63I

-0SC73I 0tceleSpihCtsoH .evirdehtnisretsigerkcolBdnammoCehtsseccaotdesutsohehtmorftcelespihC

-1SC83I 1tceleSpihCtsoH sihT.evirdehtnisretsigerlortnoCehtsseccaotdesutsohehtmorftcelespihC

-PSAD93O/I1evirD/evitcAevirD

DNG20A/NdnuorG.dnuorglangiS

YEK02A/NyeK.rotcennocecafretniehtgniyekrofdesuniP

32I etirWO/ItsoH ehtnoretsigeraotsubatadtsohehtmorfatadskcolcebortsetirWfoegdegnisiR

52I daeRO/ItsoH .subatadtsohehtotnoevirdehtnoretsigeramorfatadselbaneebortsdaeR

72O ydaeRlennahCO/I .selcycO/ItsohotnisetatstiawtresniotevirdehtybwolnevirdebyamlangissihT

tseuqeR

tneserP

91

22

42

62

03

04

.srefsnartatadrofdesustib61llA.srefsnartetybCCEdna

.tsohehtmorfdnaotderefsnartebotydaersiatadtahtsetacidnievird

.evird

.stsrubniatadAMDartlUgnirudydaerAMD

.stsrubtuoatadAMDartlUgnirudebortsataD

.stsrubtuoatadAMDartlUgnirudydaerAMD

.stsrubniatadAMDartlUgnirudebortsataD

.repmujtceleSelbaCfonoitallatsnidna

.elbaliavasiatadtahtgnitacidnisiroatadfotpiecerehtgnigdelwonkcasitsoh

.tsohehtmorfnoitnettaseriuqerevirdehtnehwdetressatsohehtottpurretnI

.xeh7F1-0F1sesserddaO/IfoedocedasilangissihT

.xeh7F3-6F3sesserddaO/Ifoedocedasilangis

.tneserpsi1ecived

tahtro,evitcasievirdatahtsetacidnihcihwtuptuorotcellocnepo,dexelpitlum-emiT

5 – 2

Page 27

AT INTERFACE DESCRIPTION

PIO TimingPIO Timing

PIO Timing

PIO TimingPIO Timing

SRETEMARAPGNIMIT0EDOM1EDOM2EDOM3EDOM4EDOM

0t)nim(emiTelcyCsn006sn383sn042sn081sn021

1t)nim(putes-WOID/-ROIDotdilavsserddAsn07sn05sn03sn03sn52

2t)nim(tib-61-WOID/-ROIDsn561sn521sn001sn08sn07

i2t)nim(emityrevocer-WOID/-ROID sn07sn52

3t)nim(putesatad-WOIDsn06sn54sn03sn03sn02

4t)nim(dlohatad-WOIDsn03sn02sn51sn01sn01

5t)nim(putesatad-ROIDsn05sn53sn02sn02sn02

6t)nim(dlohatad-WOIDsn5sn5sn5sn5sn5

Z6t)xam(etatsirtatad-ROIDsn03sn03sn03sn03sn03

9t)nim(dlohdilavsserddaot-WOID/-ROIDsn02sn51sn01sn01sn01

dRt)nim(evitcaYDROIotdilaVataDdaeR 00000

AtemiTputeSYDROIsn53sn53sn53sn53sn53

Bt)xam(htdiWesluPYDROIsn0521sn0521sn0521sn0521sn0521

Figure 5 - 2

PIO Data Transfer To/From Device

5 – 3

Page 28

AT INTERFACE DESCRIPTION

DMA TimingDMA Timing

DMA Timing

DMA TimingDMA Timing

0t)nim(emiTelcyCsn084sn051sn021

CtyaledQRAMDotKCAMD

Dt)nim(-WOID/-ROIDsn512sn08sn07

Et)nim(sseccaatad-ROIDsn051sn06

Ft)nim(dlohatad-ROIDsn5sn5sn5

Gt)nim(putesatad-WOID/-ROIDsn001sn03sn02

Ht)nim(dlohatad-WOIDsn02sn51sn01

It)nim(putes-WOID/-ROIDotKCAMD 000

Jt)nim(dlohKCAMDot-WOID/-ROIDsn02sn5sn5

rKt)nim(htdiweslupdetagen-ROIDsn05sn05sn52

wKt)nim(htdiweslupdetagen-WOIDsn512sn05sn52

rLt)xam(yaledQRAMDot-ROIDsn021sn04sn53

wLt)xam(yaledQRAMDot-WOIDsn04sn04sn53

Zt)xam(etatsirtot-KCAMDsn02sn52sn52

SRETEMARAPGNIMIT0EDOM1EDOM2EDOM

5 – 4

Multi-word DMA Data Transfer

Figure 5 - 3

Page 29

Ultra DMA TimingUltra DMA Timing

Ultra DMA Timing

Ultra DMA TimingUltra DMA Timing

SRETEMARAPGNIMIT )sdnocesonannisemitlla( 0EDOM1EDOM2EDOM3EDOM4EDOM

t

CYC

2t

CYC

t

SD

t

HD

t

SVD

t

HVD

t

SF

t

IL

t

ILM

t

IU

t

ZA

t

HAZ

t

DAZ

t

VNE

t

RS

t

SFR

t

PR

t

ZYDROI

t

YDROIZ

t

KCA

t

SS

emiTelcyC)egdeEBORTSotegdeEBORTSmorf(21137459352

emitelcycowTroegdegnisirtxenotegdegnisirmorf(

emitputesataD)tneipicerta(5101775

emitdlohataD)tneipicerta( 55555

EBORTStsriF)EBORTStsrifdnesotecivedrofemit(00320002007100310021

emitepolevnEehtnihtiwerasnoitisnartlangislortnoclla(

-KCAMD

NIMXAMNIMXAMNIMXAMNIMXAMNIMXAM

EBORTSfoegdegnillaftxenotegdegnillafmorf)

rednestaemitputesdilavataDgniebsubatadmorfemit(

)egdeEBORTSlitnudilav

rednestaemitdlohdilavataDegdeEBORTSmorfemit(

)dilavniogyamatadlitnu

emitkcolretnidetimiLybnoitcananeewtebdewollaemit(

)tnegarehtoehtyb

0324515116875

078403026

66666

noitcagniwollofehtdna,ecivedrotsohrehtie,tnegaeno

00510 051005100010001

muminimhtiwemitkcolretnI0202020202

emitkcolretnidetimilnU 00000

esaelerotstuptuorofdewollaemitmumixaM0101010101

0202020202

)etatsdesaelermorf(

)emithcumsihtybepolevneKCAMD

YDRAMDotEBORTSehterusneotemitesnopser(

emitEBORTS-lanif-ot-ydaeRyamsegdeEBORTSeromon(

emitesuap-ot-ydaeRemussayamtneipiceralitnuemit(

nogninrutsrevirdtuptuorofderiuqeremityaledmuminiM

00000

02070207020702550255

)gnisuapsitneipicerehtnehwesacesuapsuonorhcnys

)noitagen-YDRAMDgniviecerretfagnolsihttneseb

)-YDRAMDfonoitagenretfadesuapsahrednesehttaht

050302ANAN

5707060606

061521001001001

desaelerebotYDROIgniwollaerofebemitpu-lluP0202020202

YDROIgnivirderofebtiawllahsecivedemitmuminiM 00000

fonoitagendnanoitressaerofebsemitdlohdnaputeS

gnippotssirednes

ehtnehwnoitressaPOTSotegdeEBORTSmorfemiT

0202020202

0505050505

AT INTERFACE DESCRIPTION

DMARQ

(device)

DMACK-

(host)

STOP

(host)

HDMARDY-

(host)

DSTROBE

(device)

DD(15:0)

DA0, DA1, DA2,

CS0-, CS1-

t

UI

t

ACK

t

ACK

t

ZIORDY

t

t

ACK

t

ENV

t

ENV

t

AZ

Figure 5 - 4

Initiating an Ultra DMA Data In Burst

t

ZAD

ZAD

t

t

t

FS

FS

VDS

t

DVH

5 – 5

Page 30

AT INTERFACE DESCRIPTION

DSTROBE

at device

DD(15:0)

at device

DSTROBE

at host

t

2CYC

t

CYC

t

DVH

t

DVS

t

DVH

t

CYC

t

DVS

t

DVH

t

2CYC

DD(15:0)

at host

DMARQ

(device)

DMACK-

HDMARDY-

DSTROBE

DD(15:0)

(host)

STOP

(host)

(host)

(device)

(device)

t

DH

t

DS

t

DH

t

DS

t

DH

Figure 5 - 5

Sustained Ultra DMA Data In Burst

t

RP

t

SR

t

RFS

5 – 6

Host Pausing an Ultra DMA Data In Burst

Figure 5 - 6

Page 31

DMARQ

(

)

(

)

(

)

device

DMACK-

(host)

STOP

(host)

HDMARDY-

(host)

DSTROBE

device

DD(15:0)

DA0, DA1, DA2,

CS0-, CS1-

AT INTERFACE DESCRIPTION

t

MLI

t

t

ACK

ACK

t

t

DVH

IORDYZ

t

LI

t

LI

t

SS

t

ZAH

t

AZ

t

LI

t

DVS

CRC

t

ACK

DMARQ

(device)

DMACK-

(host)

STOP

host

HDMARDY-

(host)

DSTROBE

(device)

DD(15:0)

Device Terminating an Ultra DMA Data In Burst

Figure 5 - 7

t

LI

t

t

RP

t

RFS

AZ

t

LI

t

ZAH

t

MLI

t

ACK

t

ACK

t

t

DVS

MLI

t

IORDYZ

t

DVH

CRC

DA0, DA1, DA2,

CS0-, CS1-

Host Terminating an Ultra DMA Data In Burst

Figure 5 - 8

t

ACK

5 – 7

Page 32

AT INTERFACE DESCRIPTION

(

)

DMARQ

(device)

DMACK-

host

t

UI

STOP

(host)

DDMARDY-

(device)

HSTROBE

(host)

DD(15:0)

(host)

DA0, DA1, DA2,

CS0-, CS1-

HSTROBE

at host

DD(15:0)

at host

t

DVH

t

ACK

t

ZIORDY

t

ACK

t

ACK

t

ENV

Figure 5 - 9

Initiating an Ultra DMA Data Out Burst

t

2CYC

t

CYC

t

t

DVS

DVH

t

CYC

t

LI

t

t

DVS

DVS

t

UI

t

DVH

t

2CYC

t

DVH

HSTROBE

at device

t

DH

DD(15:0)

at device

5 – 8

t

DS

t

DH

Figure 5 - 10

Sustained Ultra DMA Data Out Burst

t

DS

t

DH

Page 33

DMARQ

(device)

DMACK-

(host)

STOP

(host)

DDMARDY-

(device)

HSTROBE

(host)

DD(15:0)

(host)

AT INTERFACE DESCRIPTION

t

RP

t

SR

t

RFS

DMARQ

(device)

DMACK-

(host)

STOP

(host)

DDMARDY-

(device)

HSTROBE

(host)

DD(15:0)

(host)

DA0, DA1, DA2,

CS0-, CS1-

Device Pausing an Ultra DMA Data Out Burst

Figure 5 - 11

t

LI

t

MLI

t

t

SS

t

LI

LI

t

DVS

CRC

t

t

ACK

t

ACK

t

ACK

IORDYZ

t

DVH

Host Terminating an Ultra DMA Data Out Burst

Figure 5 - 12

5 – 9

Page 34

AT INTERFACE DESCRIPTION

(

)

(

)

,

DMARQ

(device)

DMACK-

(host)

STOP

host

DDMARDY-

device

HSTROBE

(host)

DD(15:0)

(host)

DA0, DA1, DA2,

CS0-

CS1-

t

MLI

t

MLI

t

RFS

t

LI

t

RP

t

LI

Figure 5 - 13

Device Terminating an Ultra DMA Data Out Burst

t

DVS

CRC

t

ACK

t

IORDYZ

t

ACK

t

DVH

t

ACK

5 – 10

Page 35

HOST SOFTWARE INTERFACE

SECTION 6

Host Software InterfaceHost Software Interface

Host Software Interface

Host Software InterfaceHost Software Interface

The host communicates with the drive through a set of controller registers accessed via the host’s I/O ports.

These registers divide into two groups: the Task File, used for passing commands and command parameters and

the Control/Diagnostic registers.

Task File RegistersTask File Registers

Task File Registers

Task File RegistersTask File Registers

The Task File consists of eight registers used to control fixed disk operations. The host accesses each register

by the I/O port address shown in this Task File register map:

TROPO/IDAERETIRW

h0F1retsigeRataDretsigeRataD

h1F1retsigeRrorrEretsigeRserutaeF

h2F1tnuoCrotceStnuoCrotceS

h3F1rebmuNrotceSrebmuNrotceS

h4F1woLrednilyCwoLrednilyC

h5F1hgiHrednilyChgiHrednilyC

h6F1)HDS(daeH/evirD)HDS(daeH/evirD

h7F1retsigeRsutatSretsigeRdnammoC

Data RegisterData Register

Data Register

Data RegisterData Register

Provides access to the drive’s sector buffer for read and write operations. With the exception of ECC byte

transfers (which, during Read long and Write long commands, are 8 bits wide), data transfers through the

Data register are all 16 bits wide.

Error RegisterError Register

Error Register

Error RegisterError Register

A read-only register containing specific information regarding the previous command. Data interpretation

differs depending on whether the controller is in operational or diagnostic mode. A power up, reset,

software reset, or receipt of a diagnostic command sets the controller into diagnostic mode. This mode

invalidates contents of the Status register. The contents of the Error register reflect a completion code.

Issuing any command (apart from a Diagnostic command) places the controller into operational mode.

In operational mode, the Error register is valid only when the Error bit in the Status register is set. The bit

definitions for operational mode follow:

765432 10

0CCE0 FNDI0TRBA0KTFNMA

ecafretnI

CRC

ataD

rorrECCE

toN

desU

DI

dnuoFtoN

toN

desU

detrobA

dnammoC

0kcarT

rorrE

sserddA

toNkraM

dnuoF

Interface CRC – An interface CRC error occurred during an Ultra DMA transfer.

Data ECC Error – An non-correctable ECC error occurred during a Read Sector command.

Firmware Problem – Indicates a firmware problem was detected, (e.g., invalid interrupt, divide overflow).

ID Not Found – Either a matching ID field not found, or a CRC error occurred.

Aborted Command – Invalid commands, write fault, no seek complete, or drive not ready.

Track 0 Error – Track 0 was not found during execution of a Restore command.

Address Mark Not Found – The Address Mark could not be found after an ID match.

Features RegisterFeatures Register

Features Register

Features RegisterFeatures Register

Enables or disables features through the Set Features command.

6 – 1

Page 36

HOST SOFTWARE INTERFACE

Sector Count RegisterSector Count Register

Sector Count Register

Sector Count RegisterSector Count Register

Holds the number of sectors to be sent during a Read or Write command, and the number of sectors per

track during a Format command. A value of zero in this register implies a transfer of 256 sectors. A multisector operation decrements the Sector Count register. If an error occurs during such an operation, this

register contains the remaining number of sectors to be transferred.

Sector Number RegisterSector Number Register

Sector Number Register

Sector Number RegisterSector Number Register

Holds the starting sector number for any disk operation. The register is updated as each sector is processed in

a multi-sector operation.

Cylinder Number RegistersCylinder Number Registers

Cylinder Number Registers

Cylinder Number RegistersCylinder Number Registers

Two 8-bit Cylinder Number registers (Low and High) specify the starting cylinder for disk operation.

Device/Head RegisterDevice/Head Register

Device/Head Register

Device/Head RegisterDevice/Head Register

Used to specify the drive and head number to be operated on during any disk operations. Within the

context of a Set Parameters command, this register specifies the maximum number of heads on the drive.

Bit definitions follow:

765432 10

1ABL1VRD3SH2SH1SH0SH

edoM

evirD

tceleStceleS

daeH

tceleS

daeH

tceleS

daeH

tceleS

Select LBA Mode

the Task File register contents are defined as follows for the Read/Write and translate command:

– Enabling this bit for commands not supported by LBA mode will abort the selected command. When set,

STNETNOCSTIBABL

rebmuNrotceS7-0

woLrednilyC51-8

hgiHrednilyC32-61

daeH/evirD72-42

Drive Select – Set to 0 to select the master drive; set to 1 to select the slave drive.

Head Select – Specifies the binary coded address of the head to be selected.

Status RegisterStatus Register

Status Register

Status RegisterStatus Register

Contains results of the last command executed, and the drive’s status. The other seven Task File registers may

be read only when bit 7 (BUSY) of the Status register is low. Reading any of the Task File registers when

BUSY is high returns the value of the Status register. Reading the Status register also clears any interrupt

request to the host. Bit definitions follow:

7654 3210

YSUBYDRDFDCSDQRD00 RRE

rellortnoC

ysuB

eciveD

ydaeR

eciveD

tluaF

keeSeciveD

etelpmoC

ataD

tseuqeR

rorrE

Controller Busy – Goes active when a command is written to the Command register, indicating controller

task execution. After a command, this bit resets.

Device Ready – Indicates that the drive is ready for commands. If drive ready is not present, all commands abort.

Device Fault – Indicates the drive’s detection of a write fault condition, causing all commands to abort.

Device Seek Complete – Signifies a seek completion, and that the drive is on track.

Data Request – Indicates that the drive’s sector buffer is ready for data transfer.

Error – The Error bit sets when the previous command has completed with a non-recoverable error.

6 – 2

Page 37

HOST SOFTWARE INTERFACE

Command RegisterCommand Register

Command Register

Command RegisterCommand Register

Contains code for the command to be performed. Additional command information should be written to the

task file before the Command register is loaded. When this register is written, the BUSY bit in the Status

register sets, and interrupt request to the host clears; invalid commands abort. (Detailed information on interface

commands is given in Section 7.) Hex values for valid command formats follow:

Read CommandsRead Commands

Read Commands

Read CommandsRead Commands

Read Sector(s) 20h Normal reads; retries enabled

21h Normal reads; retries disabled

22h Read Long; retries enabled

23h Read Long; retries disabled

Read Verify Sector(s) 40h Retries enabled

41h Retries disabled

Read Sector Buffer E4h

Read Multiple C4h

Read DMA C8h

C9h No retries

Write CommandsWrite Commands

Write Commands

Write CommandsWrite Commands

Write Sector(s) 30h Normal writes; retries enabled

31h Normal writes; retries disabled

32h Write Long; retries enabled

33h Write Long; retries disabled

Write Verify Sector(s) 3Ch

Write Sector Buffer E8h

Write Multiple C5h

Write DMA CAh

CBh No retries

Mode Set/Check CommandsMode Set/Check Commands

Mode Set/Check Commands

Mode Set/Check CommandsMode Set/Check Commands

Set Features EFh

Set Multiple Mode C6h

Power Mode CommandsPower Mode Commands

Power Mode Commands

Power Mode CommandsPower Mode Commands

Standby Immediate 94/E0h Stops drive spindle; do not change time-out value

Idle Immediate 95/E1h Starts spindle; do not change time-out value

Standby 96/E2h Stops spindle; change time-out value

Idle 97/E3h Starts spindle; change time-out value

Check Power Mode 98/E5h

Set Sleep Mode 99/E6h

Initialization CommandsInitialization Commands

Initialization Commands

Initialization CommandsInitialization Commands

Identify Drive ECh

Initialize Drive Parameters 91h

Re-calibrate 1xh

Seek, Format, and Diagnostic CommandsSeek, Format, and Diagnostic Commands

Seek, Format, and Diagnostic Commands

Seek, Format, and Diagnostic CommandsSeek, Format, and Diagnostic Commands

Seek 7xh

Format Track 50h

Execute Drive Diagnostic 90h

S.M.A.R.T. CommandsS.M.A.R.T. Commands

S.M.A.R.T. Commands

S.M.A.R.T. CommandsS.M.A.R.T. Commands

Execute S.M.A.R.T. B0h

6 – 3

Page 38

HOST SOFTWARE INTERFACE

SummarySummary

Summary

SummarySummary

etarbilaceR 0001xxxx NNNN D

)s(rotceSdaeR 001000Lx NYYY Y

AMDdaeR 1100 100x NYYY Y

AMDetirW 1100101x NYYY Y

kcarTtamroF 010 10000 NNNY Y

keeS 0111xxxx NNYY Y

evirDyfitnedI 11 10 1 1 0 0 NNNN D

serutaeFteS 1110 1111 YNNN D

elpitluMdaeR 11000 100 NYYY Y

elpitluMetirW 11000101 NYYY Y

DESUSRETEMARAPEDOCDNAMMOCEMANDNAMMOC

7b6b5b4b3b2b1b0bFCSNSC HDS

)s(rotceSetirW 00 1100Lx NYYY Y

)s(rotceSyfireVetirW 00111100 NYYY Y

)s(rotceSyfireVdaeR 0100000x NYYY Y

citsongaiDetucexE 100 10000 NNNN D

sretemaraPezilaitinI 100 10001 NYNN Y

reffuBrotceSdaeR 11 10 0 1 0 0 NNNN D

reffuBrotceSetirW 11 10 1 0 0 0 NNNN D

edoMelpitluMteS 11000110 NYNN D

EULAVREMITDOIREPTUO-EMIT

0delbasidtuo-emiT

042-1sdnoces)5*eulav(

152-142setunim)03*)042-eulav((

252setunim12

352sruoh01=doirepeuqinurodneV

452devreseR

552sdnoces51,setunim12

6 – 4

Page 39

HOST SOFTWARE INTERFACE

Control Diagnostic RegistersControl Diagnostic Registers

Control Diagnostic Registers

Control Diagnostic RegistersControl Diagnostic Registers

These I/O port addresses reference three Control/Diagnostic registers:

TROPO/IDAERETIRW

h6F3sutatSetanretlAlortnoCksiDdexiF

h7F3tupnIlatigiDdesutoN

Alternate Status RegisterAlternate Status Register

Alternate Status Register

Alternate Status RegisterAlternate Status Register

Contains the same information as the Status register in the Task File. However, this register may be read at

any time without clearing a pending interrupt.

Device Control RegisterDevice Control Register

Device Control Register